Patents

Literature

34results about How to "High descaling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

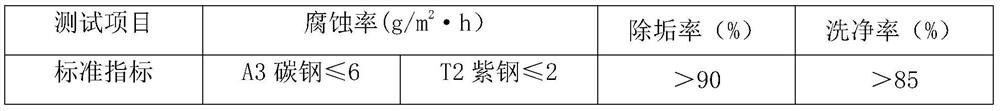

Fully-organic inhibition dirty-proof industrial water conditioning agent and method for making same

InactiveCN101117256AHigh descaling rateScale removal and water softeningIndustrial water treatmentBenzotriazole

The invention relates to a fully organic corrosion and deposit inhibitor for industry water treatment and a fabrication method to be concerned, which is fabricated by the weight percentage compositions of the following elements: 20 percent to 30 percent of acrylate-acrylate copolymer, 12 percent to 20 percent of sulfonic acid copolymer, 5 percent to 10 percent of polyepoxysuccinic acid, 0.6 percent to 0.9 percent of benzotriazole, 10 percent to 15 percent of hydroxy ethylidene diphosphoric acid, 2-butane phosphate 1,2,4, 15 percent to 25 of percent tricarboxylic acid, 2 percent to 4 percent of zinc salt and deionized water; the invention is the corrosion and deposit inhibitor for industry water, which is fabricated by acrylate-acrylate copolymer, sulfonic acid copolymer, polyepoxysuccinic acid, hydroxy ethylidene diphosphoric acid, 2-butane phosphate 1,2,4, tricarboxylic acid (PBTCA), benzotriazole and zinc salt, the invention solves the problems of complicated operation for site user and high cost; after testing, the scale removing rate of the invention is over 95 percent.

Owner:南京市第一精细化工公司精细化工厂(普通合伙)

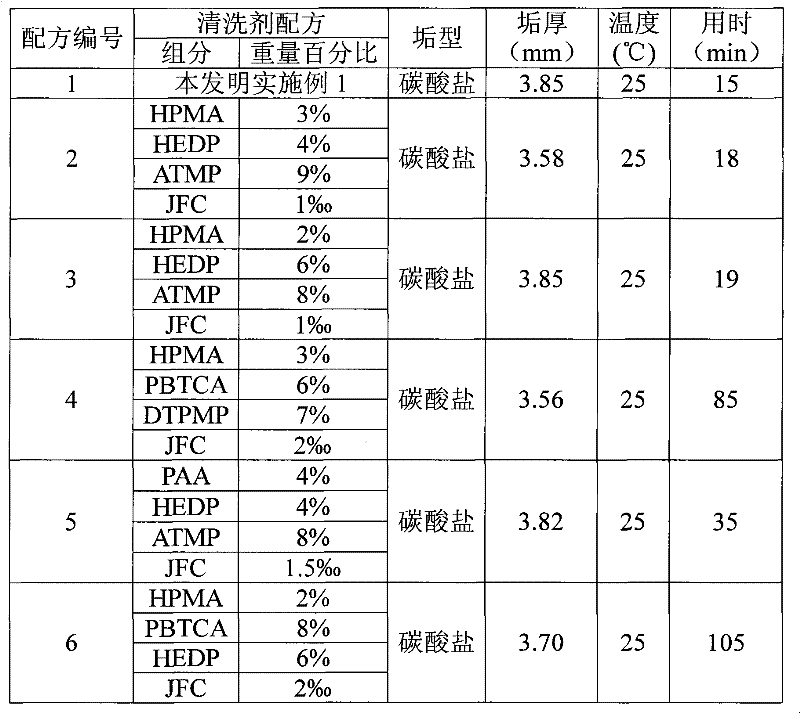

Organic descaling composition, preparation method and application thereof

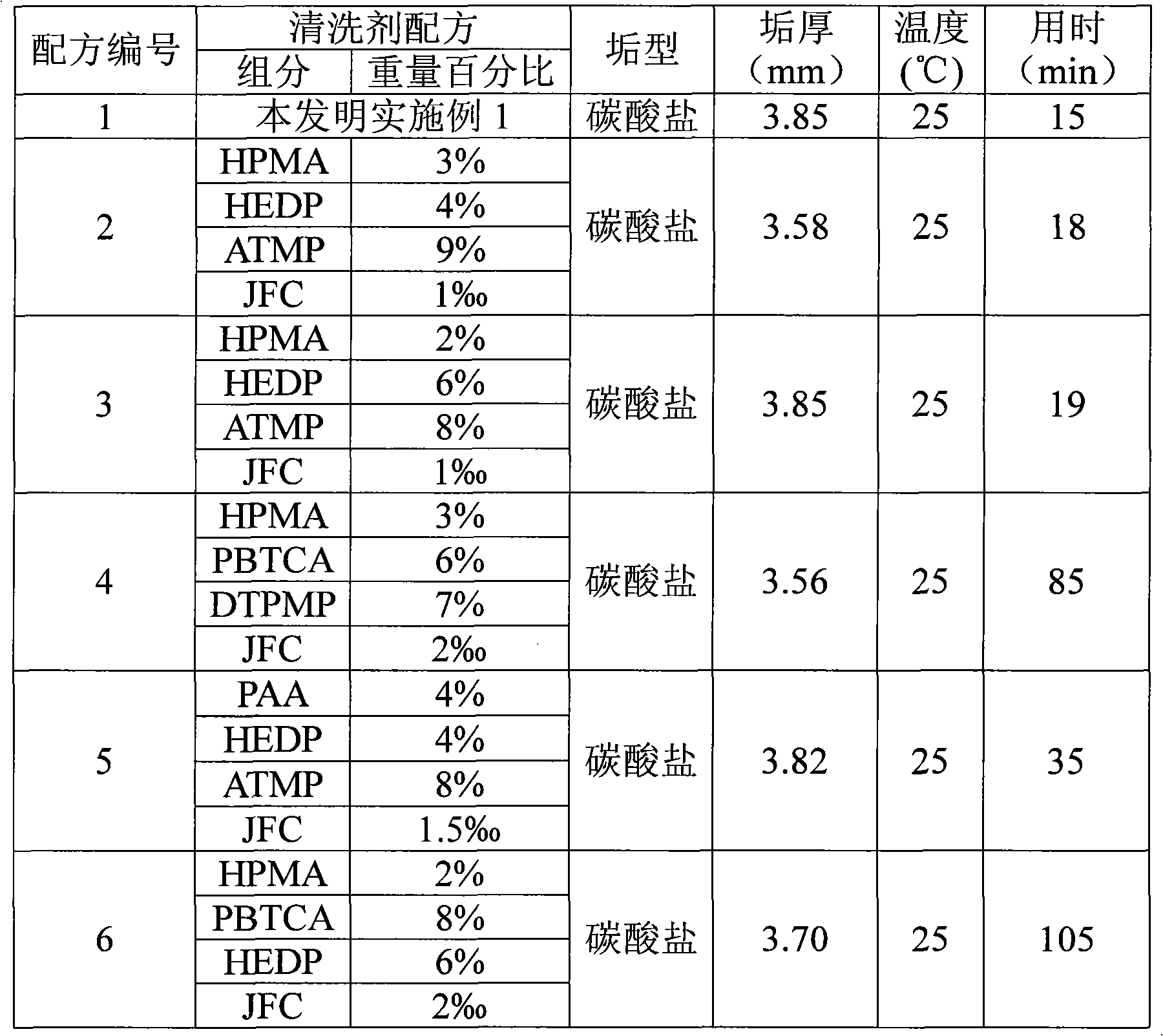

ActiveCN101565660AStrong chelationGood dispersionHollow article cleaningOrganic non-surface-active detergent compositionsReaction speedCleansing Agents

The invention provides an organic descaling composition, which includes an organic cleaning agent and a corrosion inhibitor CM-911, and the weight ratio of the organic cleaning agent and the corrosion inhibitor is 100:0.1-0.3. The organic cleaning agent includes the follow components by weight: 1%-15% of maleic acid-crylic acid copolymer (MA-AA), 1%-25% of 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP), 2%-30% of amino trimethylene phosphonic acid (ATMP), 0.03%-0.5% of penetrating agent JFC and balance of water. The organic descaling agent provided by the present invention has advantages of fast reaction speed, small corrosivity for material and high descaling efficiency.

Owner:河南伯淼水处理有限公司

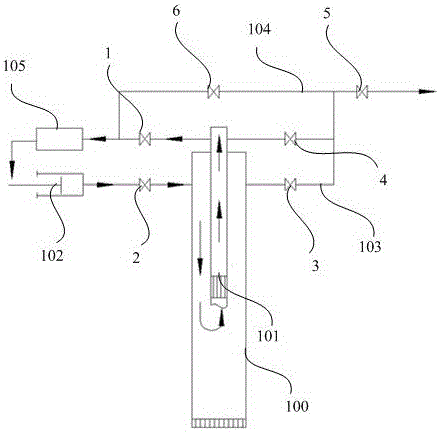

External cold water descaling device for direct-current converter valve cooling system and method

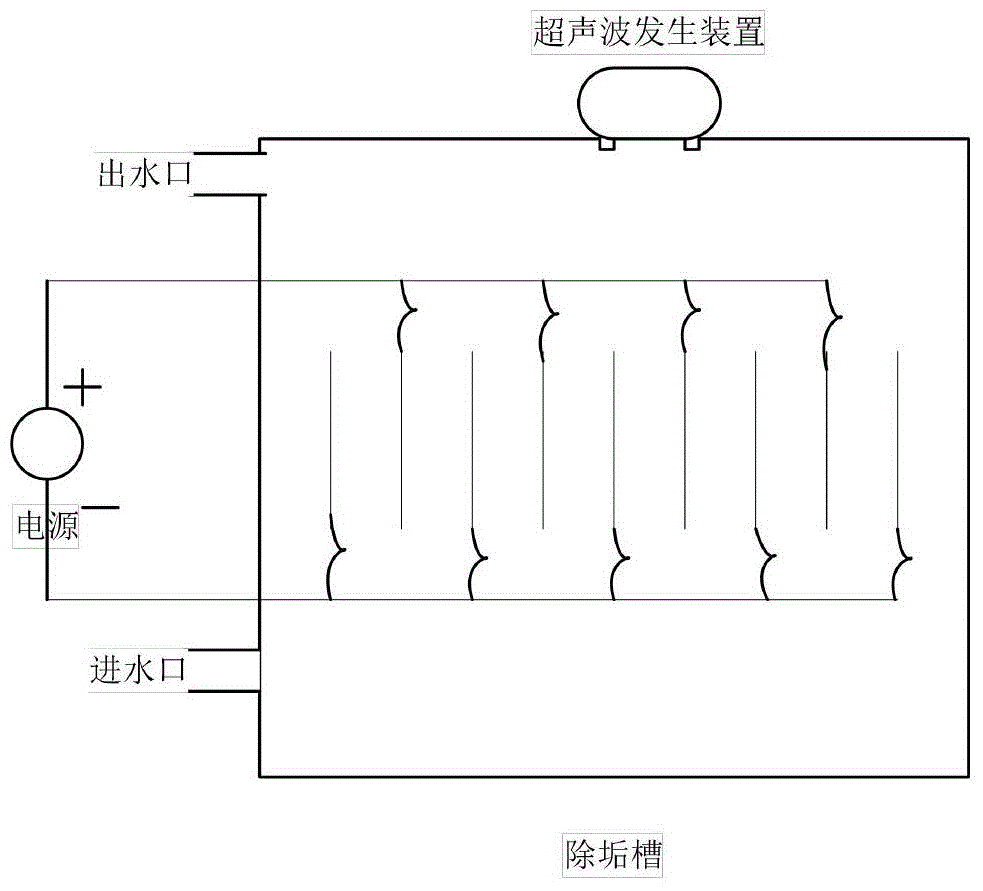

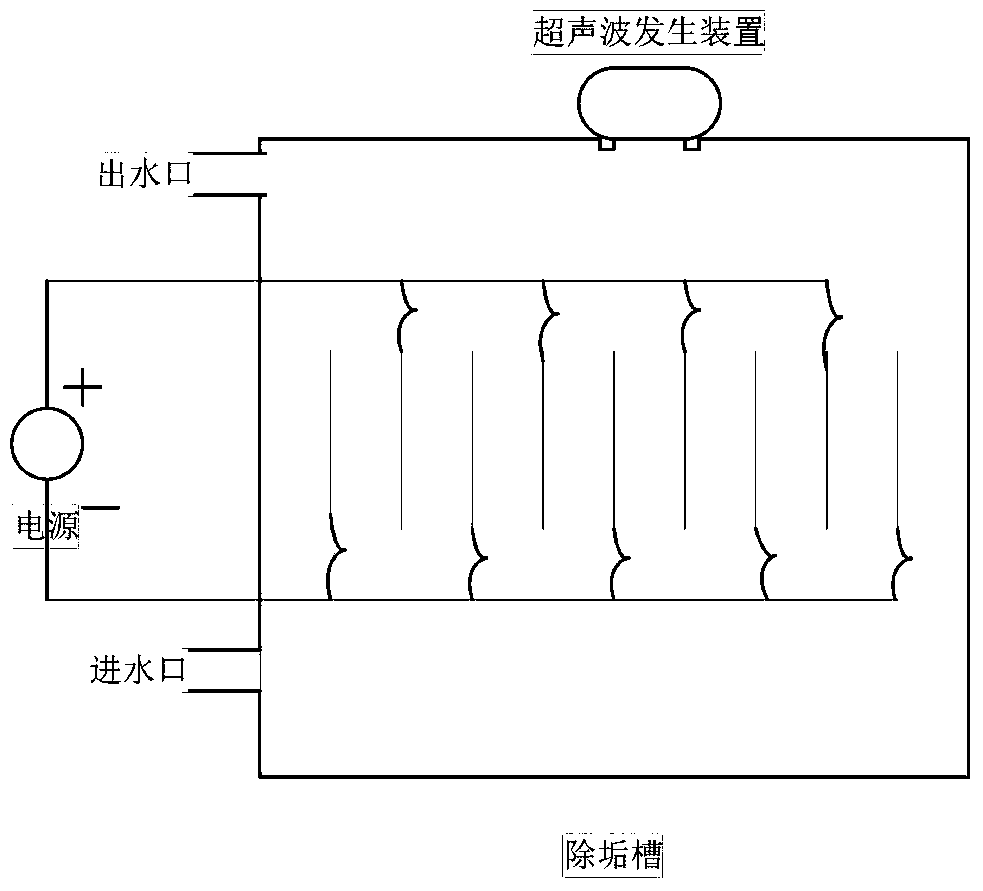

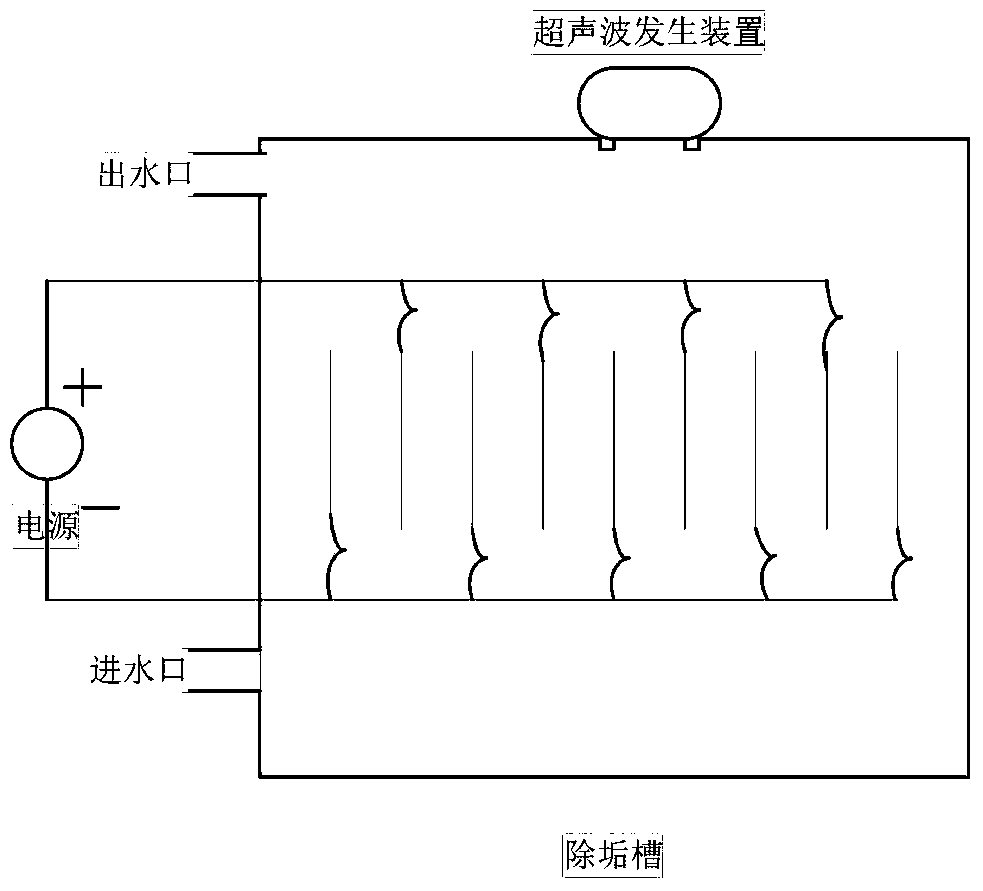

ActiveCN105712500AIncrease the number of precipitatesHigh descaling rateWater/sewage treatment with mechanical oscillationsWater/sewage treatment by electrochemical methodsCooling towerChemical reaction

The invention relates to an external cold water descaling device for a direct-current converter valve cooling system and a method. The external cold water descaling device comprises a descaling tank, a direct-current power source, an electrode, an ultrasonic generator and a scale residue collection tank, a cathode and an anode of the electrode are corresponding connected with a cathode and an anode of the direct-current power source, the electrode is fixedly mounted in the descaling tank, the ultrasonic generator is mounted on the descaling tank, the scale residue collection tank is mounted at the bottom of the descaling tank, and the bottom of the descaling tank is open. The method includes: fixedly mounting the electrode with the descaling tank, and applying low voltage on the electrode; enabling calcium and magnesium ions of spraying water to be in chemical reaction at the cathode of the electrode to generate fouling; applying vibration of certain frequency on the electrode, and adjusting vibration frequency of the ultrasonic generator to vibration frequency identical when the fouling is adhered on the electrode to enable the fouling to shed into the scale residue collection tank. Through the descaling device and the method, scaling ions in spraying water can be removed, and the scaling problem of a cooling tower in a convertor station is solved.

Owner:STATE GRID CORP OF CHINA +2

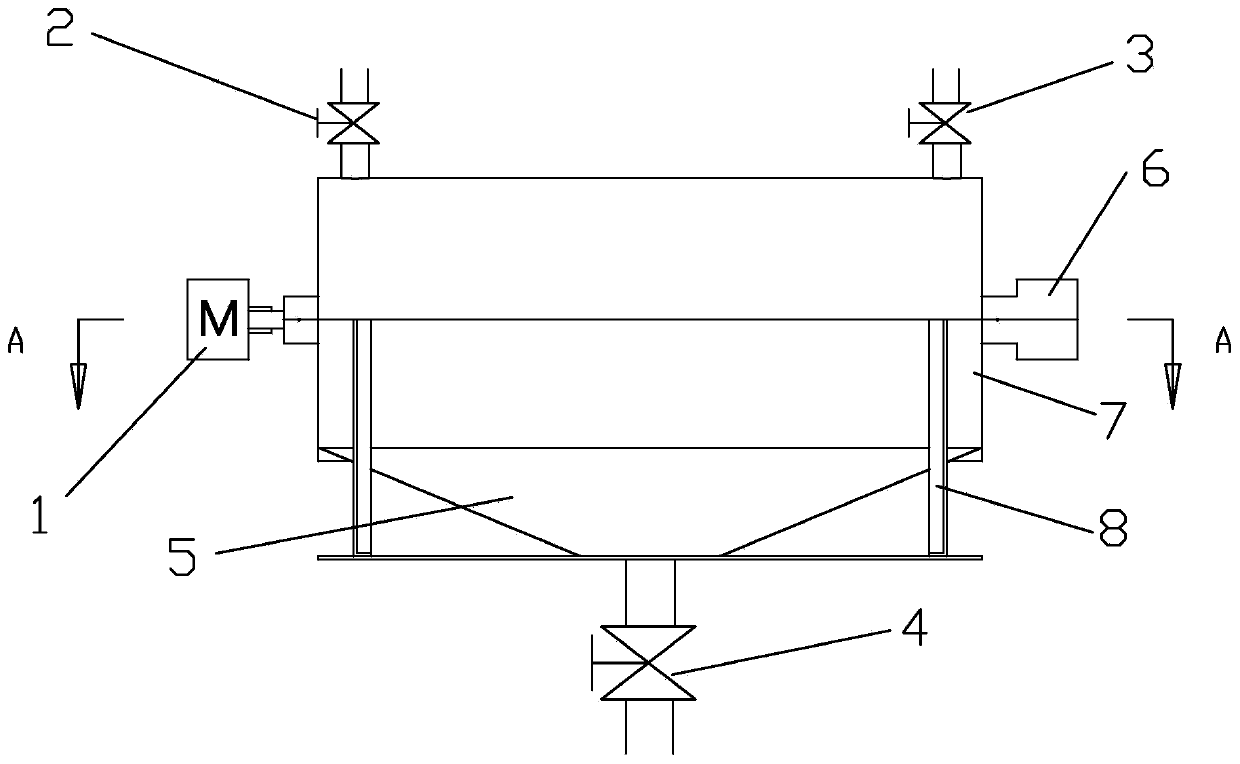

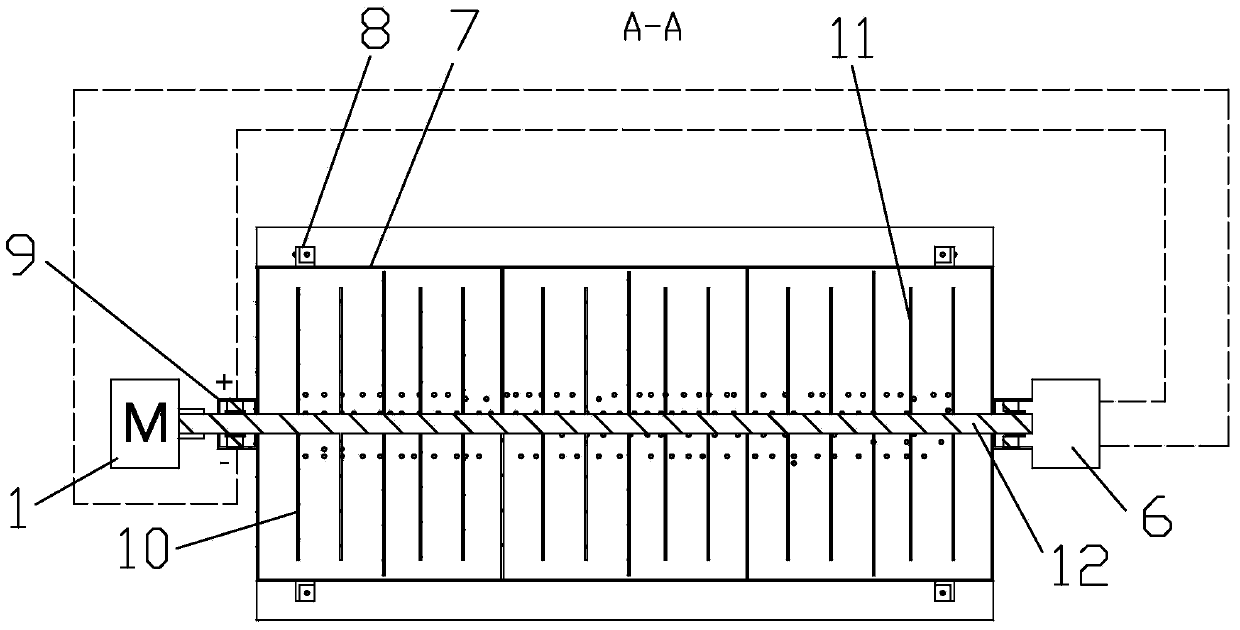

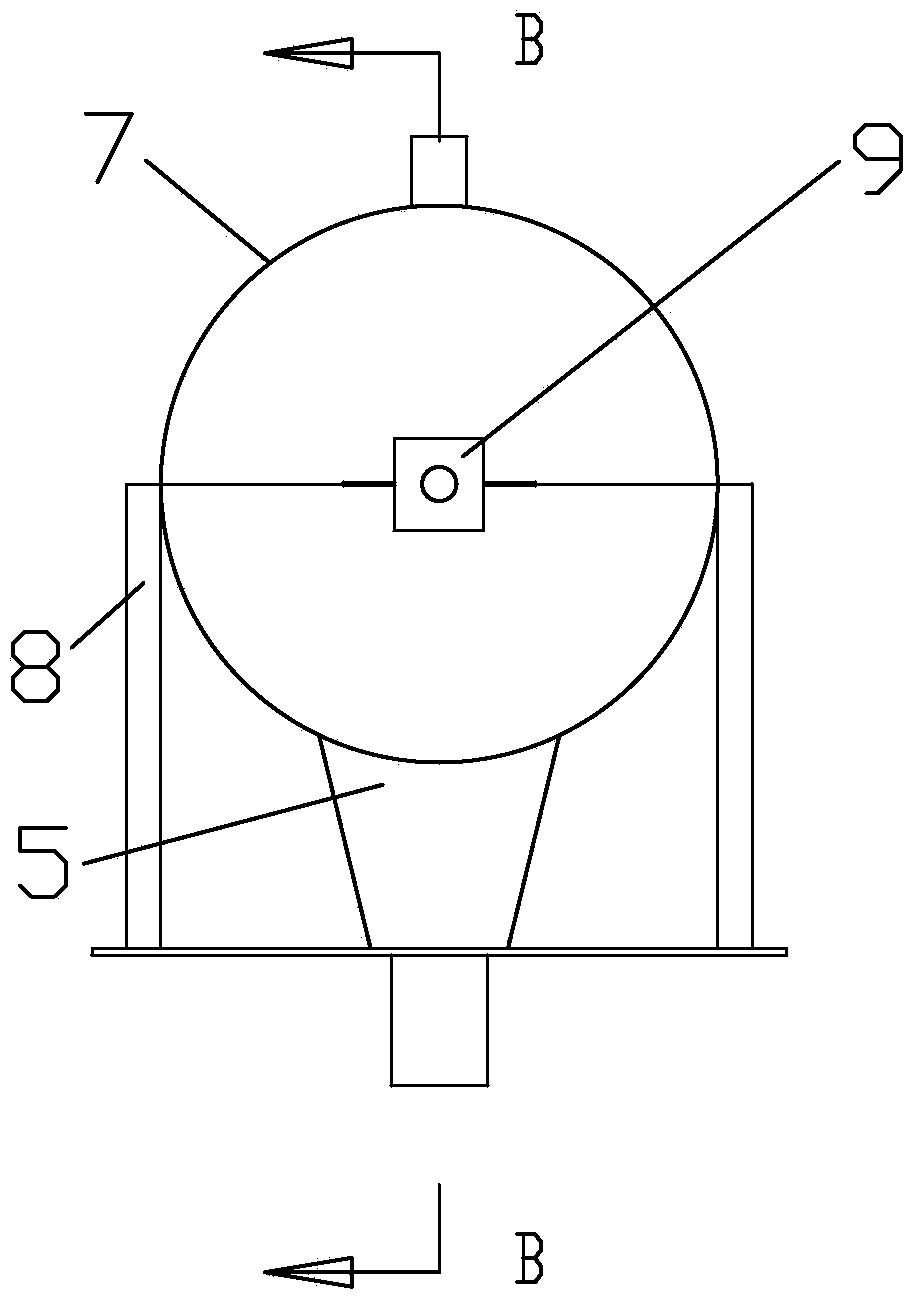

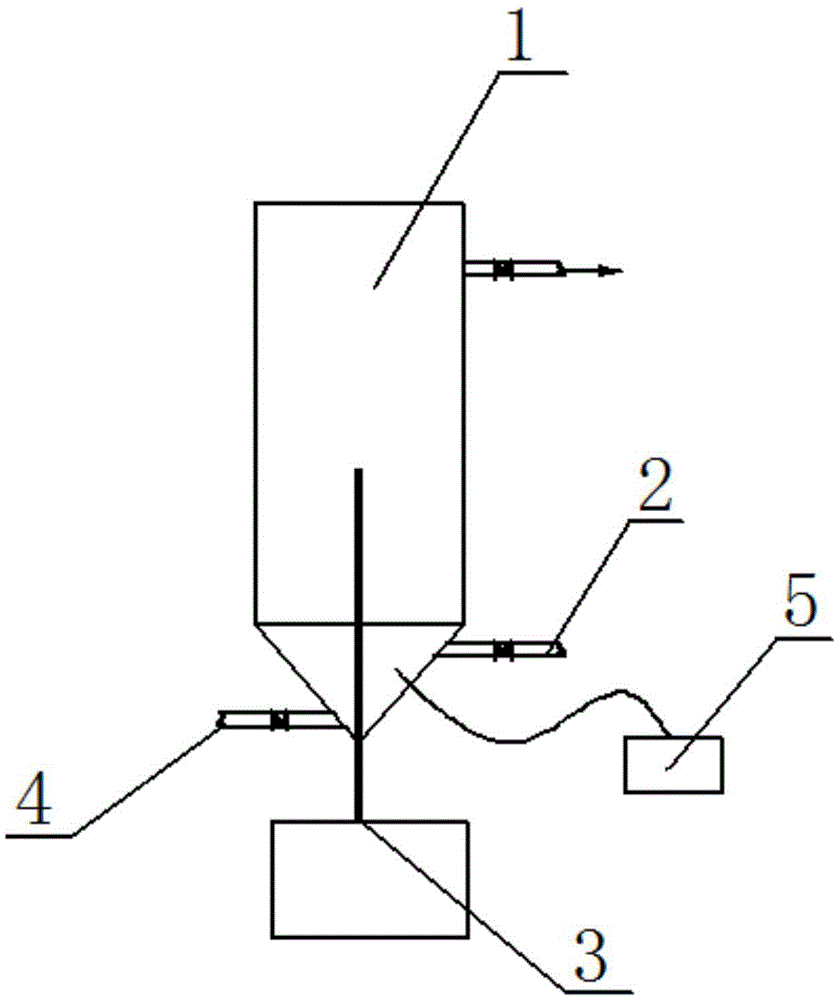

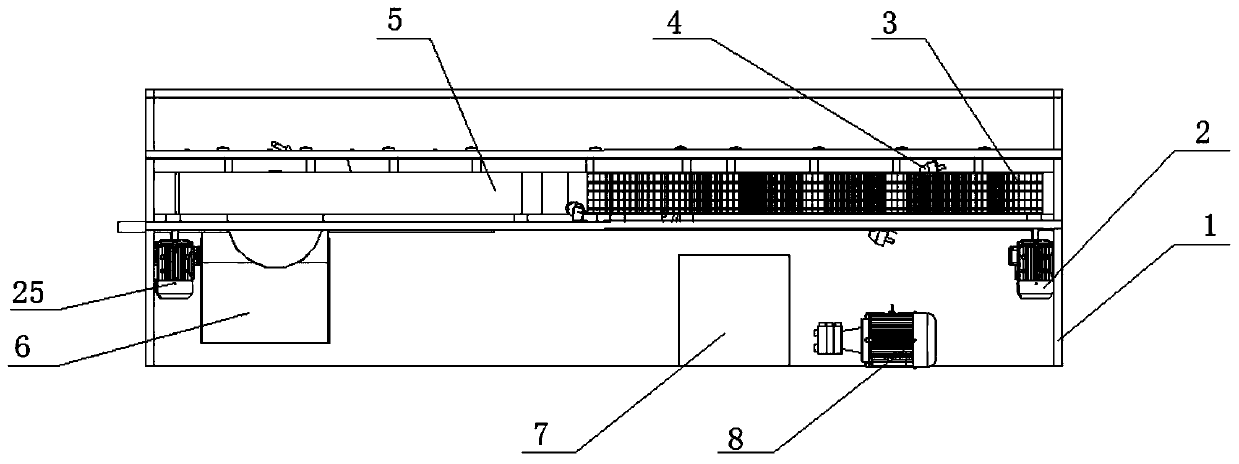

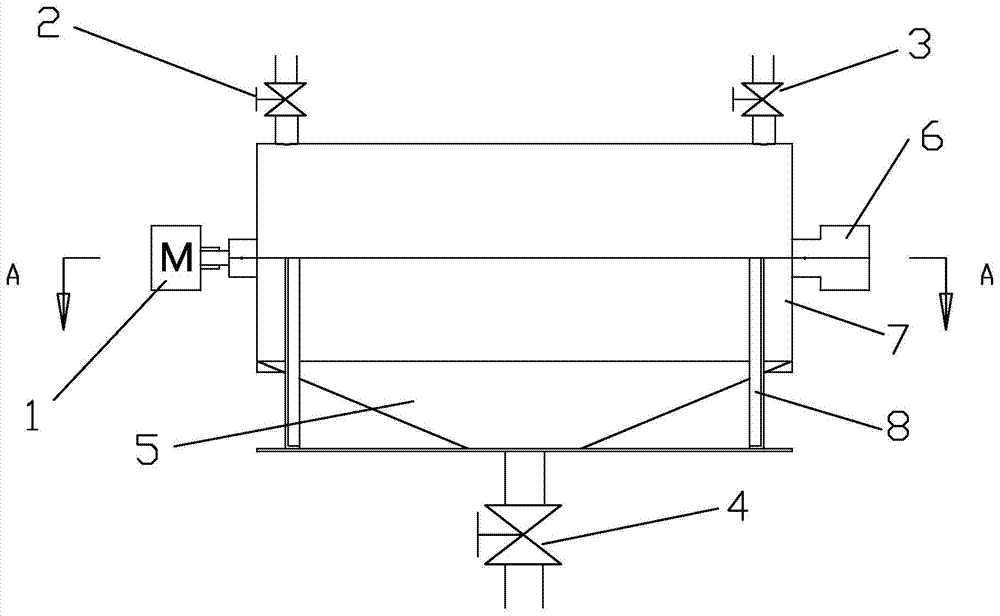

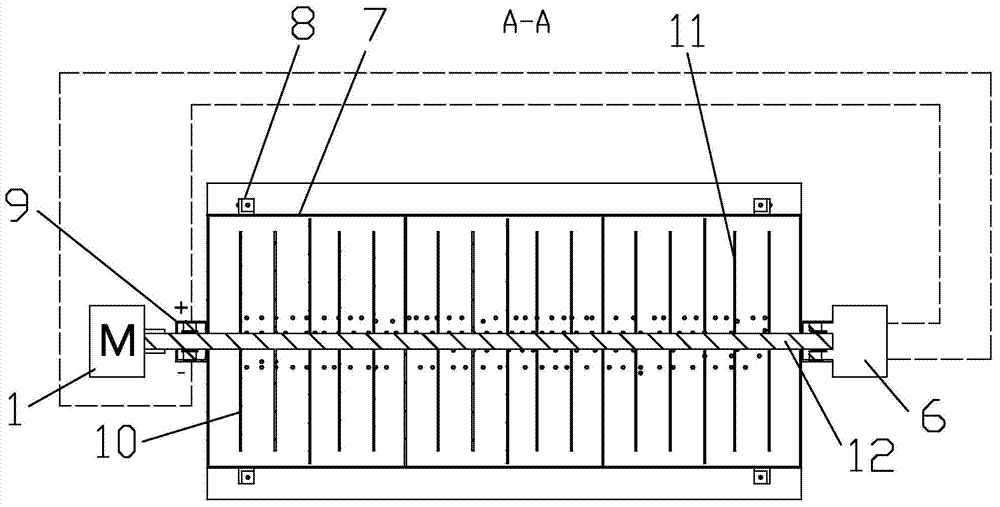

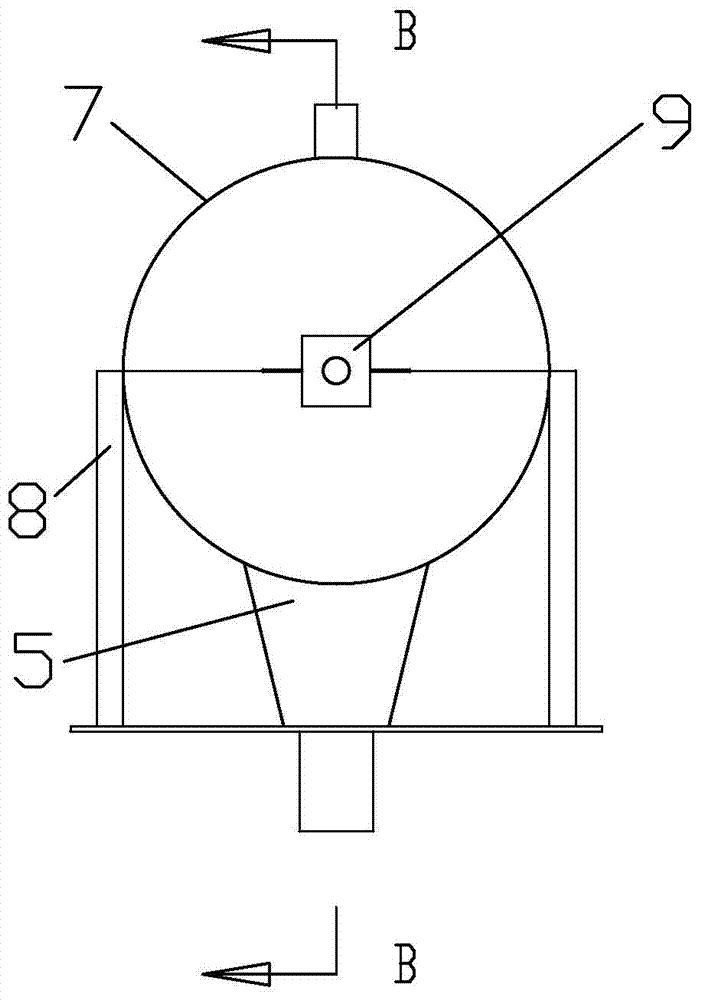

Electrolytic descaling device for circulating water treatment of ship boiler

InactiveCN103693761AElectrolytic reaction area is smallLow efficiencyScale removal and water softeningCircular discElectrochemical response

The invention discloses an electrolytic descaling device for circulating water treatment of a ship boiler. The device comprises a reducing motor, a water inlet valve, a water outlet valve, a drainage valve, a reverser, a scraper, circular disc plate electrodes, a precipitation tank, conductivity detection electrodes, a scale controller, a cylindrical barrel, a precipitation tank, a rotary shaft, a slide ring and a shaft sleeve, wherein six pairs of circular disc plate electrodes are sequentially fixed on the rotary shaft, respectively; the front five pairs of circular disc plate electrodes are connected with the reverser through leads to form a multi-stage serial treatment structure; the last pair of the circular disc plate electrodes is taken as the conductivity detection electrodes which are connected with the scale controller through leads. According to the device disclosed by the invention, the multi-stage serial plate electrodes are adopted, so that the contact area of electrochemical reaction can be effectively enhanced, the descaling rate in unit time is improved, and meanwhile, the size of the device is reduced, and the spatial utilization rate is improved. The device disclosed by the invention collects hardness of treated water to form closed-loop control to automatically feed back and adjust the decomposition voltage, so that the device is simple and convenient to operate, and the energy consumption of the whole device can be effectively reduced.

Owner:DALIAN MARITIME UNIVERSITY

Online supermolecular cleaning agent for oil well, preparation method and online cleaning using method

ActiveCN106085396ARealize safe online cleaningAdvanced online cleaning methodCleaning apparatusDrilling compositionALLYL SUCROSECleansing Agents

The invention discloses an online supermolecular cleaning agent for an oil well, a preparation method and an online cleaning using method. The online supermolecular cleaning agent for the oil well is prepared from the following components in percentage by weight: 10%-15% of acrylic acid, 11%-15% of 1-hydroxyethane 1,1-diphosphonic acid, 4.5%-7% of fatty alcohol polyoxyethylene ether, 2%-3% of dodecyl dimethyl benzyl ammonium chloride, 2%-3% of 1H-benzotriazole, 2%-3% of trisodium phosphate, 1.5%-2.5% of ethylenediamine triacetic acid, 2%-3% of polyacrylic acid, 2%-2.5% of sodium silicate and the balance of water. With the adoption of the online supermolecular cleaning agent for the oil well, the oil well is cleaned rapidly and conveniently, and the cleaning efficiency is improved.

Owner:QINGDAO JIENENG ENVIRONMENTAL PROTECTION CO LTD

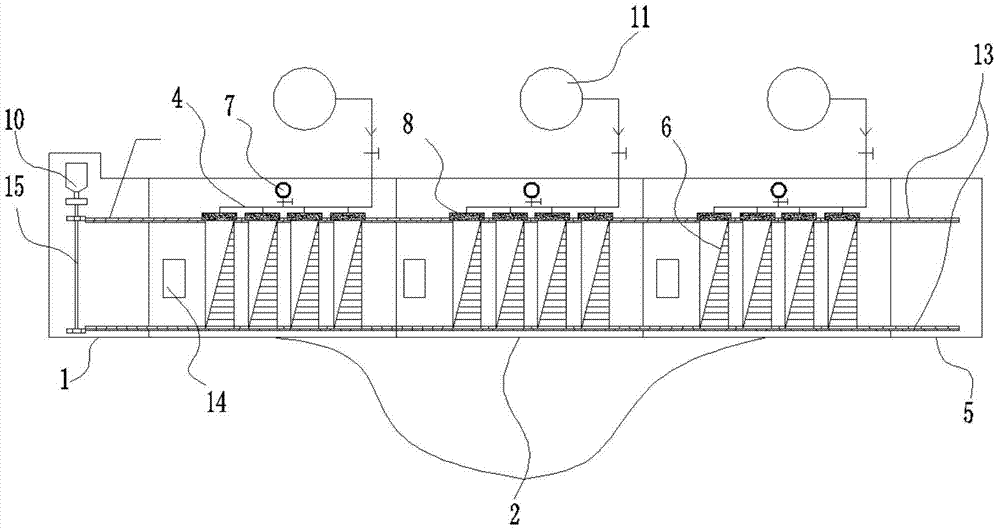

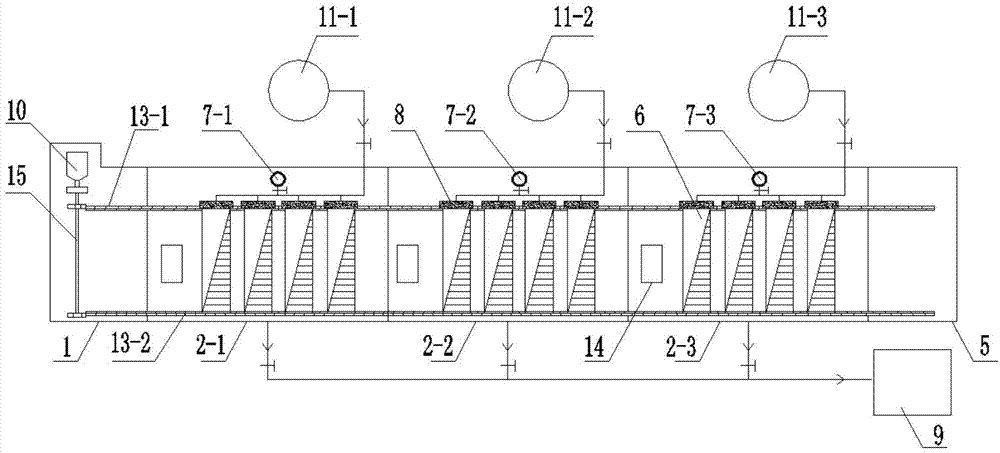

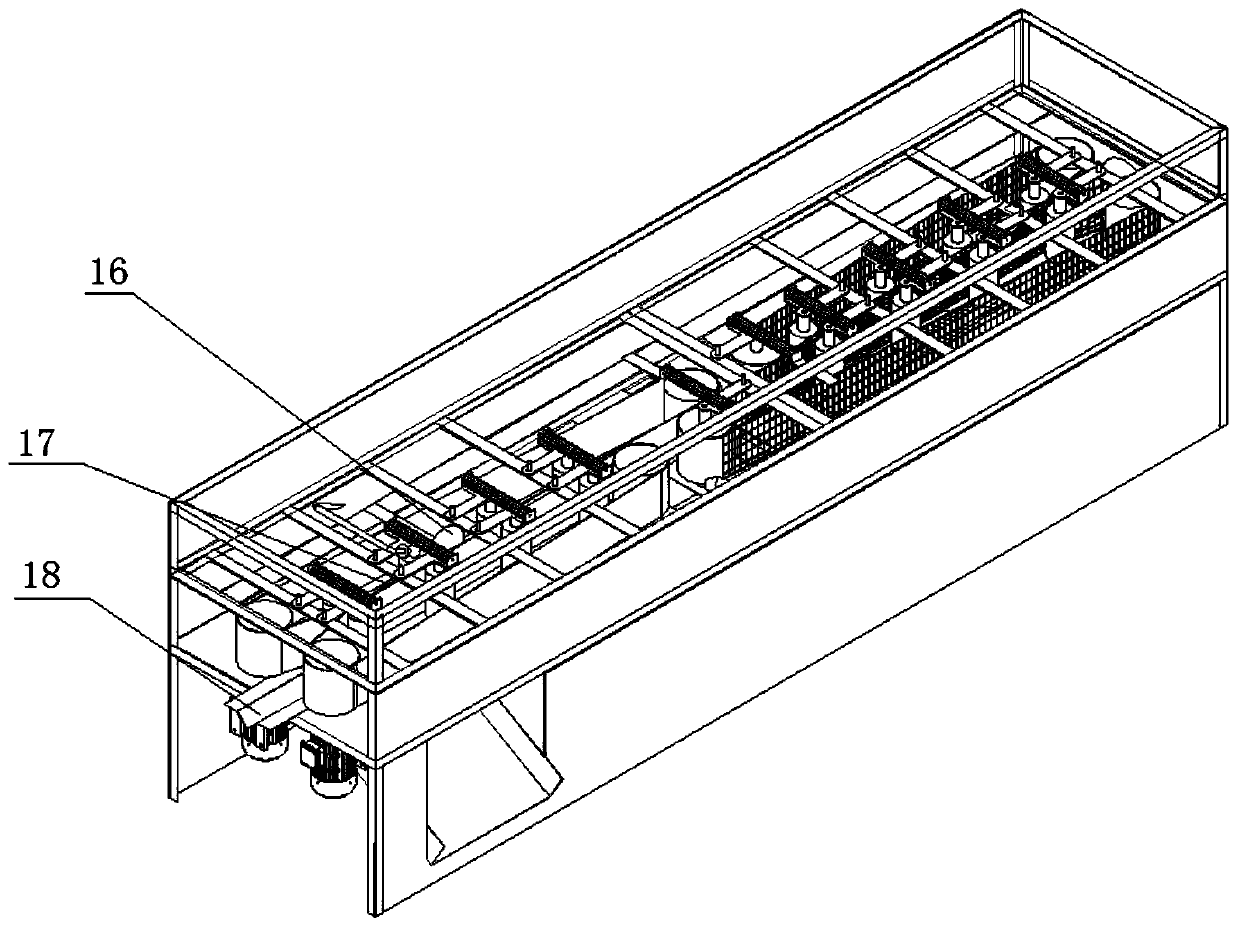

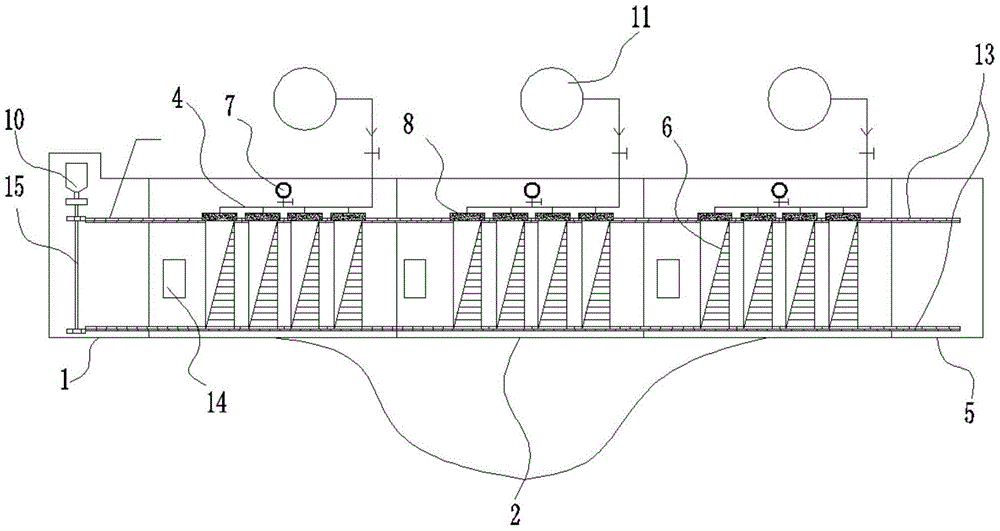

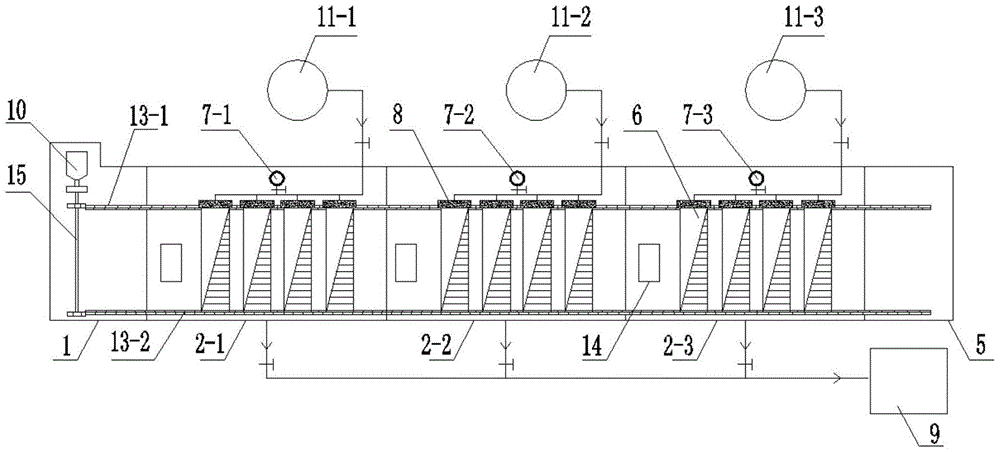

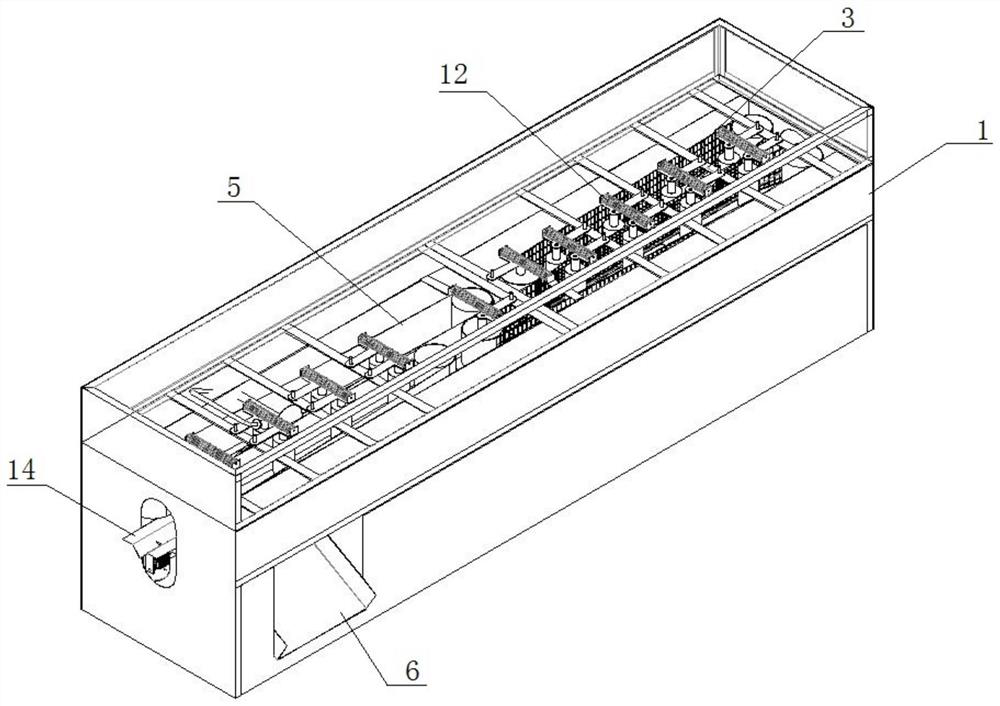

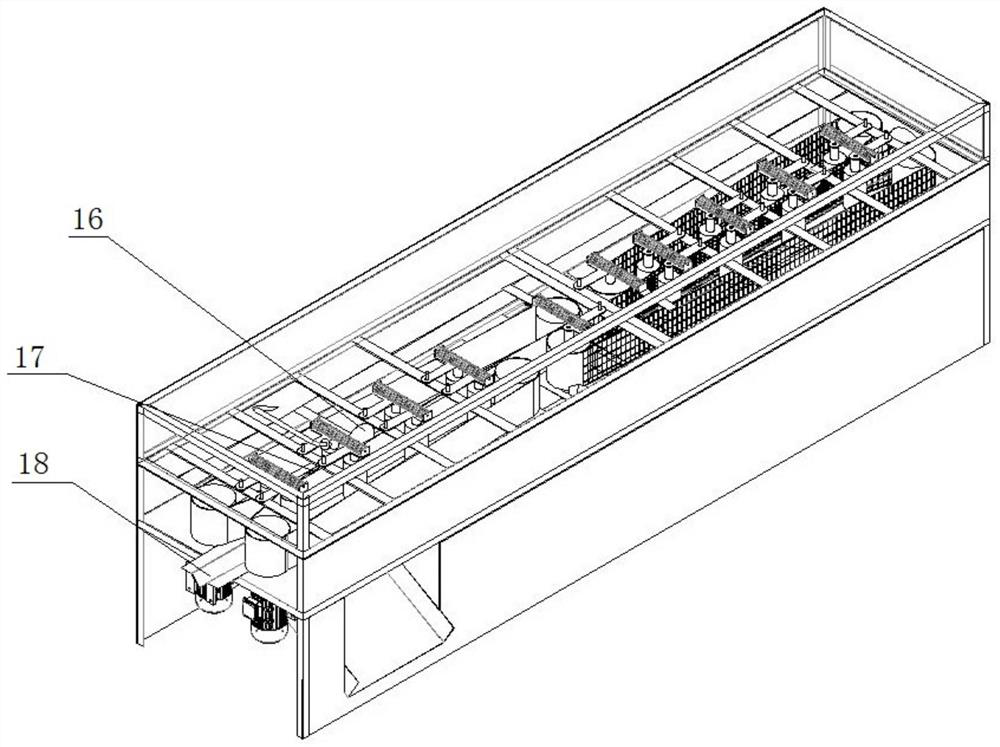

Reverse osmosis membrane assembly continuous cleaning device, and method utilizing device for reverse osmosis membrane assembly cleaning

ActiveCN104707484AEasy to installEliminate complicated disassembly processReverse osmosisAssembly disassemblyBiochemical engineering

The invention relates to a reverse osmosis membrane assembly continuous offline cleaning device. The device comprises a plurality of cleaning tanks, and a driving and conveying device, wherein the cleaning tanks are used for soaking and cleaning reverse osmosis membrane assemblies, and are independent from one another; the driving and conveying device is used for driving the reverse osmosis membrane assemblies to be continuously cleaned in the cleaning tanks which are independent from one another. The offline cleaning method is adopted; the polluted membrane assemblies are soaked in the cleaning solution tanks, and parallel connection is adopted by the equipment for simultaneous and separate cleaning of the multiple membrane assemblies; a cleaning solution inlet end cover and one end of each membrane assembly are fixed on a double-chain through clamps, and the other end of each membrane assembly is fixed on the other side of the double-chain, so that the assemblies can be conveniently mounted, the complex assembly disassembly process is avoided, and labor conservation is achieved; an identical number of the membrane assemblies are mounted in each cleaning solution tank, the equipment automation level is improved through the chain transmission method, and the membrane assemblies in the different cleaning solution tanks are operated at the same time, so that the whole assembly line is continuous, the cleaning time is reduced, and the cleaning efficiency is improved.

Owner:QINGDAO AGRI UNIV

Cleaning fluid for removing rust, preparation method and application thereof

The invention discloses a cleaning fluid for removing rust, a preparation method and application thereof, and belongs to the technical field of chemical rust removal. The cleaning fluid comprises 2%-10% of an organic acid, 0.5%-4.5% of an organic acid salt, 10%-25% of a chelating agent, 2%-6% of a permeation aiding solvent, 0.15%-0.25% of a corrosion inhibitor and the balance of water, wherein theorganic acid is 2-hydroxy propane-1,2,3-tricarboxylic acid and / or 2,3-dihydroxy succinic acid, the organic acid salt is 8-hydroxyquinoline citrate or 2,3-sodium tartrate, and the chelating agent is tetrasodium glutamate diacetate. The cleaning fluid is high in scale dissolving rate, high in descaling rate, low in corrosion rate, good in biodegradability is good and particularly suitable for removing the rust in the oil field.

Owner:PETROCHINA CO LTD

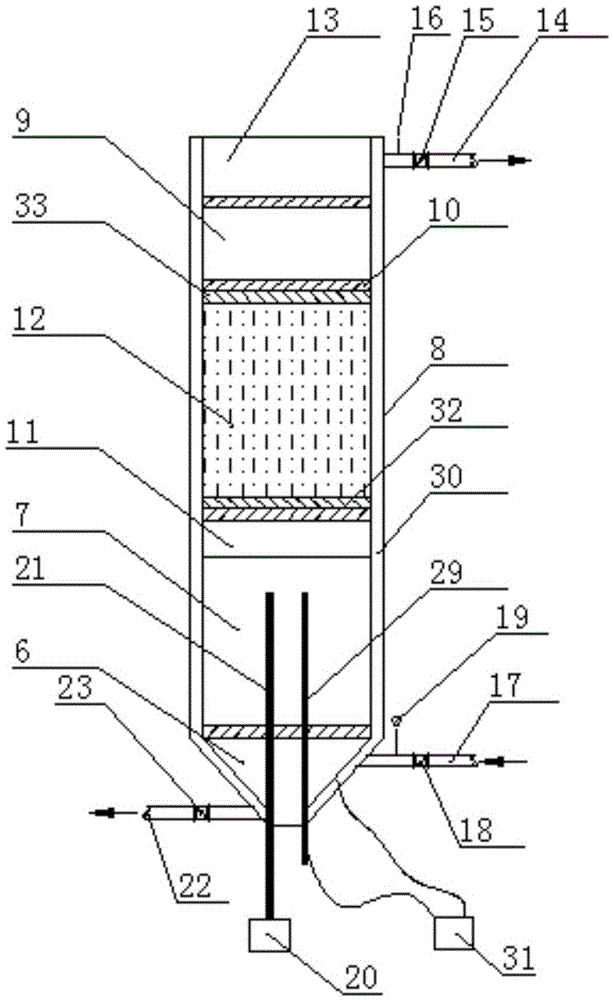

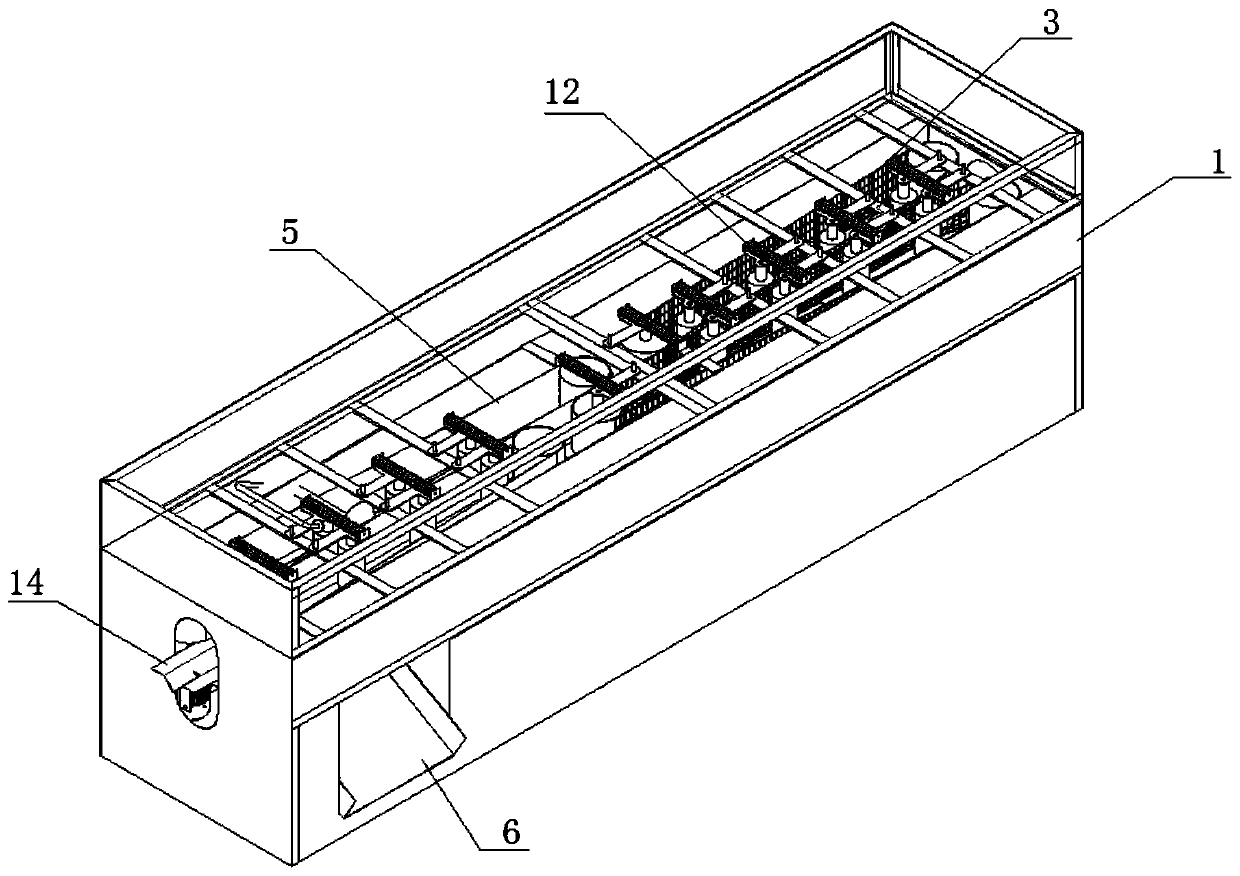

Electrochemical descaling device

ActiveCN105540955AGuaranteed uniformityFull play of pollution interception abilityTreatment involving filtrationMultistage water/sewage treatmentAutomatic controlMegasonic cleaning

The invention relates to an electrochemical descaling device. The electrochemical descaling device aims at solving the problems of non-thorough descaling, high descaling cost and large descaling difficulty of a traditional electrochemical descaling device and comprises a descaling body, a raw water inlet pipeline system, an ultrasonic cleaning system, a waste residue discharging system and an automatic control system, wherein the raw water inlet pipeline system, the ultrasonic cleaning system and the waste residue discharging system are respectively connected with the descaling body, and the automatic control system is connected with the descaling body, the raw water inlet pipeline system, the ultrasonic cleaning system and the waste residue discharging system respectively.

Owner:烟台和盛康洁环保科技有限公司

Multifunctional dirty removing agent for boiler

InactiveCN102863089ANo pollution in the processNo damageScale removal and water softeningSolubilityPropanoic acid

The invention relates to a dirty removing agent, in particular to the dirty removing agent for a boiler. The dirty removing agent is non-toxic and free of pollution, and has descaling and rust removal functions. The dirty removing agent is prepared by the following raw materials in parts by weight: N,N-dimethyldodecylamine-N-oxide sol, triethanolamine, sodium hexametaphosphate, propionic acid, butyric acid, polyacrylic acid, formic acid and water in a ratio of 6-20:3-12:1-10:0.5-5:2-10: 20-30:0.1-0.5:80-100. The dirty removing agent is safe and free of corrosion, low in metal corrosion rate in a washing process, almost free of any corrosion damage on the boiler and high in descaling ratio, is capable of effectively dissolving scales in various types, is strong in water dissolubility capability, and has double functions of descaling and rust removal. Waste liquid has no pollution, the dirty removing agent is non-toxic and free of damage; the washing waste liquid has no damage to animals and plants; and direct discharge of the washing waste liquid cannot pollute the environment.

Owner:刘生力

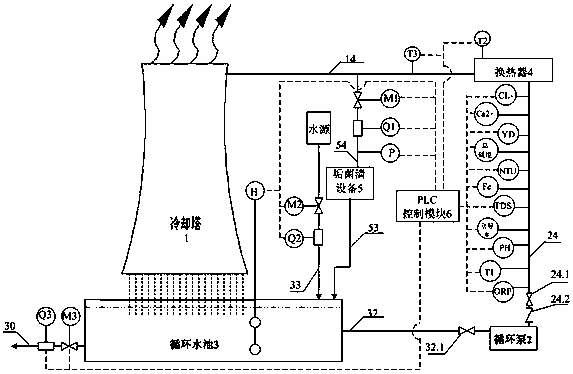

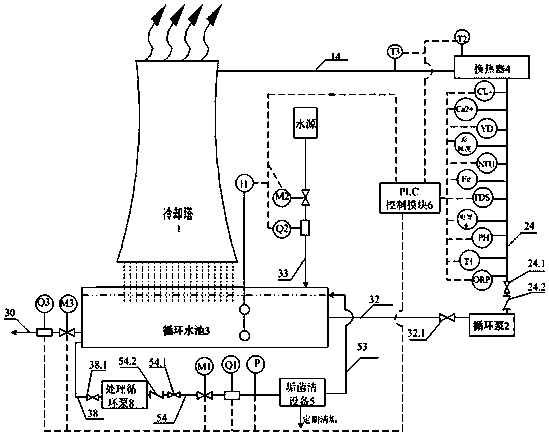

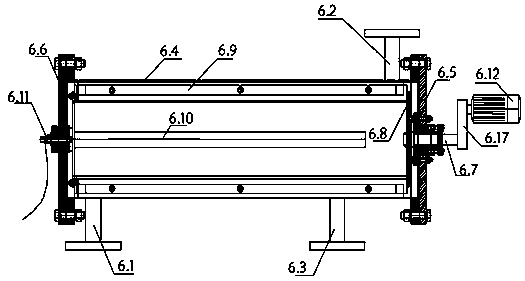

Circulating water quality stability control system and control method

PendingCN108585225AHigh descaling rateImprove the bactericidal effectWater treatment parameter controlWater treatment compoundsEngineeringWater tanks

The invention provides a circulating water quality stability control system and control method. The system comprises a circulating water tank, a circulating pump, a heat exchanger and a cooling tower.The cooling tower is arranged above the circulating water tank, and the circulating water tank, the circulating pump, the heat exchanger and the cooling tower are sequentially connected through pipelines. The circulating water tank is further connected with scale and bacterium eliminating equipment which is used for descaling, sterilization and alga eliminating treatment of circulating water. Thesystem further comprises a detection module, a PLC control module and regulating valves, the regulating valves are arranged on the pipelines respectively, and the scale and bacterium eliminating equipment, the detection module and the regulating valves are all connected with the PLC control module.

Owner:SHANDONG HAINENG ENVIRONMENT TECH CO LTD

Composition for removing scale, preparation method and applications thereof

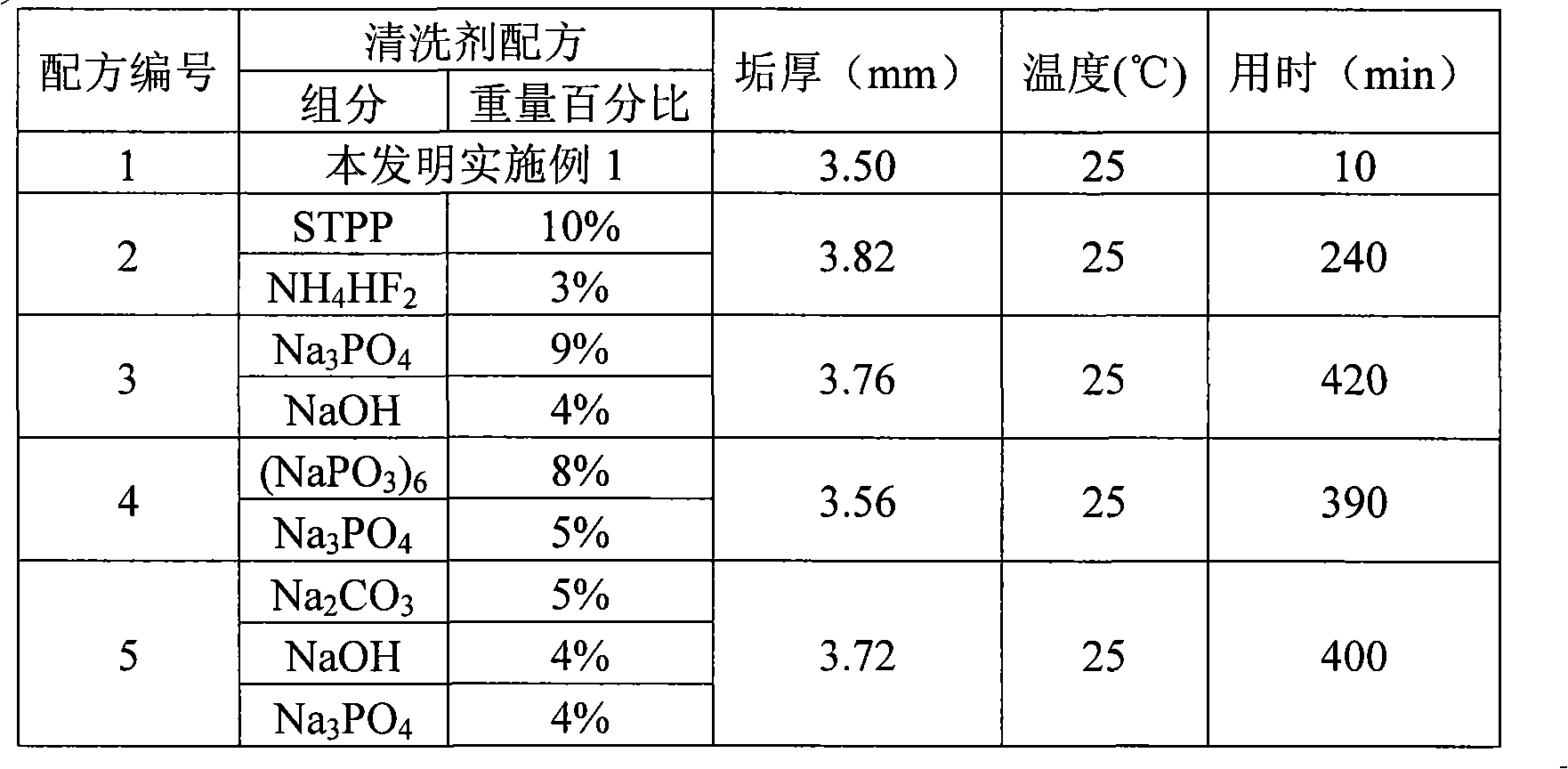

InactiveCN101555075AImprove solubilityViolent reactionTreatment using complexing/solubilising chemicalsCleaning processes and apparatusSodium phosphatesPhysical chemistry

The invention provides a composition for removing scale. The composition comprises the following ingredients by weight: 2 to 50 percent of aminosulfonic acid (NH2SO3H), 1 to 10 percent of sodium tripolyphosphate (STPP) and 0.5 to 5 per thousand of penetrating agent (JFC). The invention also provides a preparation method and applications of the composition. The composition has fast reaction velocity for removing scale, little corrosion to the material and high scale-removing rate.

Owner:董宇新

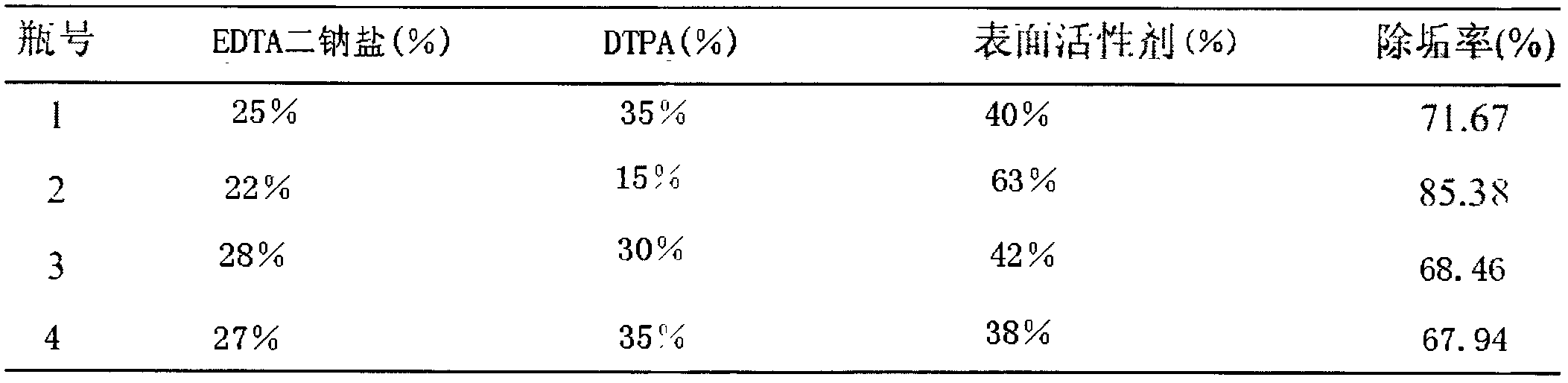

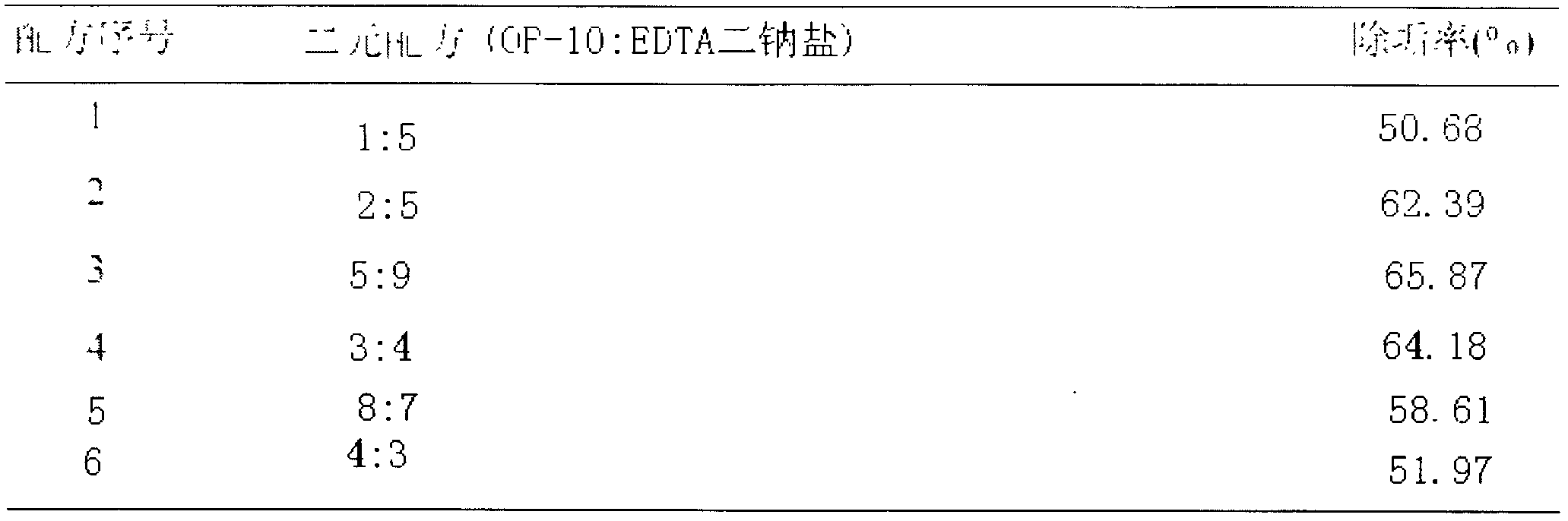

Surfactant and chelating agent ternary compound descaling agent

InactiveCN103805357AGood descaling effectHigh descaling rateOrganic detergent compounding agentsSurface-active detergent compositionsEthylene diamineSurface-active agents

The invention discloses a surfactant and chelating agent ternary compound descaling agent prepared by mixing the following components in percentage by mass: 20-30% of EDTA (Ethylene Diamine Tetraacetic Acid) disodium salt, 10-40% of DTPA (Diethylenetriaminepentaacetic Acid) and the balance of OP-10. The surfactant and chelating agent ternary compound descaling agent is prepared by mixing OP-10, EDTA disodium salt and DTPA and is favorable in descaling performance; when the surfactant and chelating agent ternary compound descaling agent is used for descaling, the descaling rate is greatly increased, and the manufacturing cost is low, so that the descaling cost is greatly reduced.

Owner:刘治民

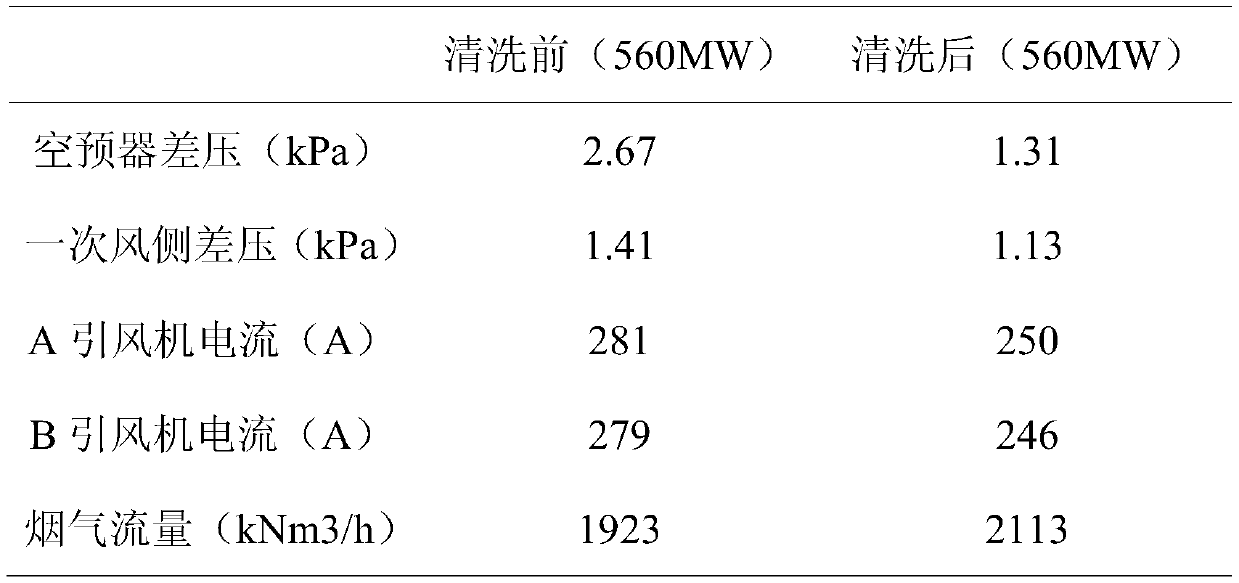

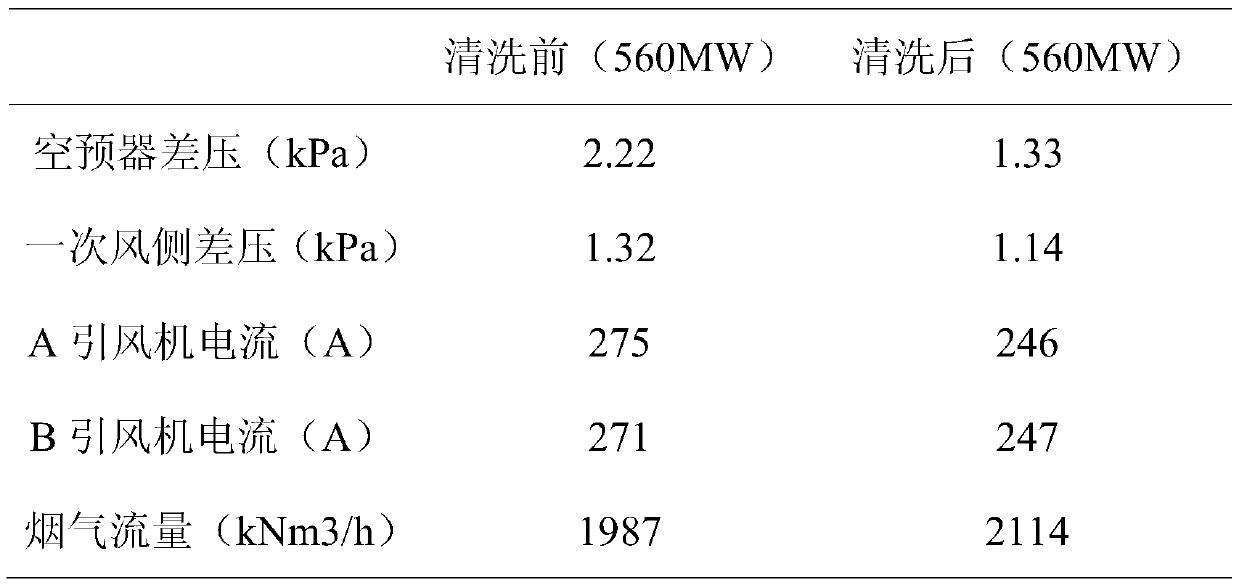

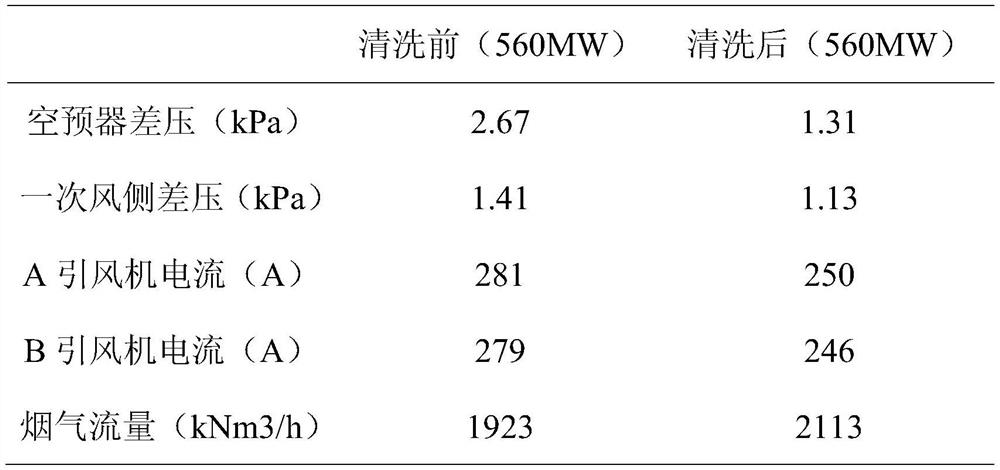

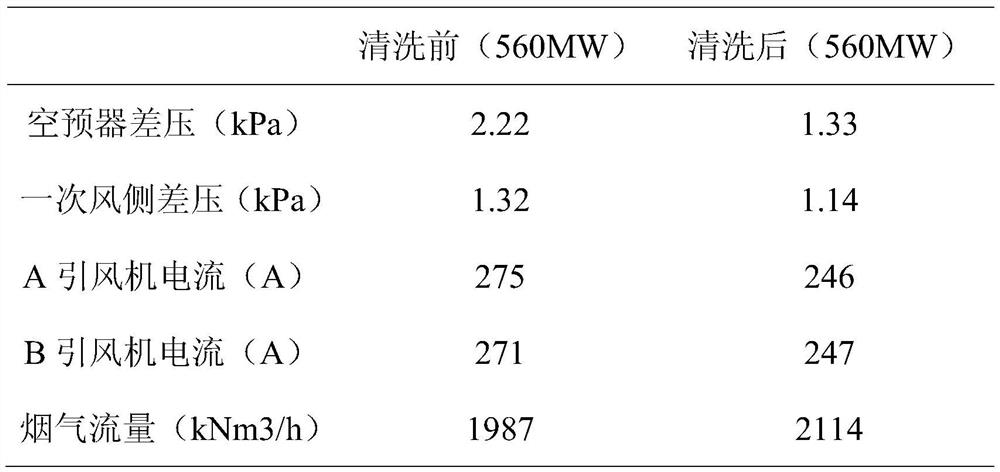

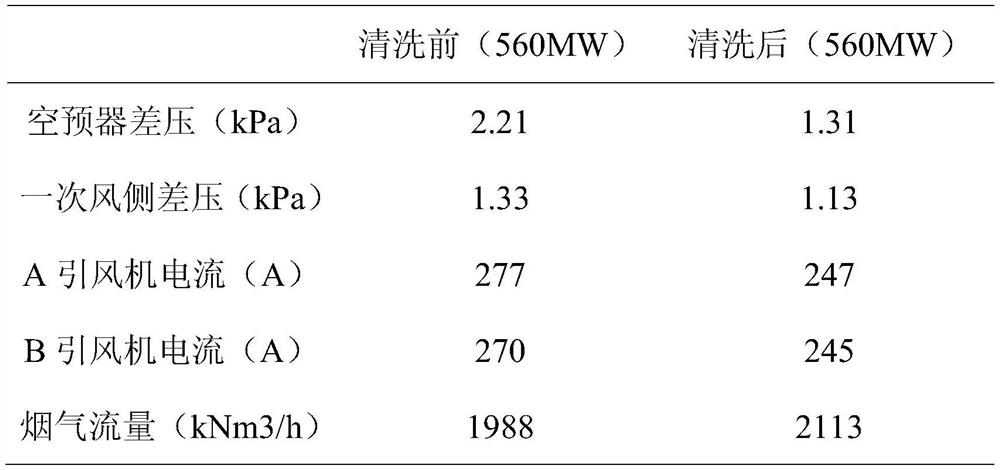

Air preheater chemical cleaning agent

ActiveCN110343579ADoes not affect operationNo pollution in the processInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAir preheaterPolyamide

The invention provides an air preheater chemical cleaning agent, which comprises sodium dodecylbenzenesulfonate, sodium alkyl succinate sulfonate, polyoxyethylene alkyl ether, alkylbenzene sulfonate,polyamide, organosilicone, trisodium phosphate, and sodium hydroxide. The air preheater chemical cleaning agent is a cleaning agent specially designed for cleaning air preheaters and can clean the airpreheater online without affecting the operation of the air preheater,the cleaning effect is good, the descaling rate is high, and the air preheater chemical cleaning agent is very practical.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +2

A device and method for descaling cold water outside the cooling system of a DC converter valve

ActiveCN105712500BIncrease the number of precipitatesHigh descaling rateWater/sewage treatment with mechanical oscillationsWater/sewage treatment by electrochemical methodsChemical reactionCooling tower

The invention relates to an external cold water descaling device for a direct-current converter valve cooling system and a method. The external cold water descaling device comprises a descaling tank, a direct-current power source, an electrode, an ultrasonic generator and a scale residue collection tank, a cathode and an anode of the electrode are corresponding connected with a cathode and an anode of the direct-current power source, the electrode is fixedly mounted in the descaling tank, the ultrasonic generator is mounted on the descaling tank, the scale residue collection tank is mounted at the bottom of the descaling tank, and the bottom of the descaling tank is open. The method includes: fixedly mounting the electrode with the descaling tank, and applying low voltage on the electrode; enabling calcium and magnesium ions of spraying water to be in chemical reaction at the cathode of the electrode to generate fouling; applying vibration of certain frequency on the electrode, and adjusting vibration frequency of the ultrasonic generator to vibration frequency identical when the fouling is adhered on the electrode to enable the fouling to shed into the scale residue collection tank. Through the descaling device and the method, scaling ions in spraying water can be removed, and the scaling problem of a cooling tower in a convertor station is solved.

Owner:STATE GRID CORP OF CHINA +2

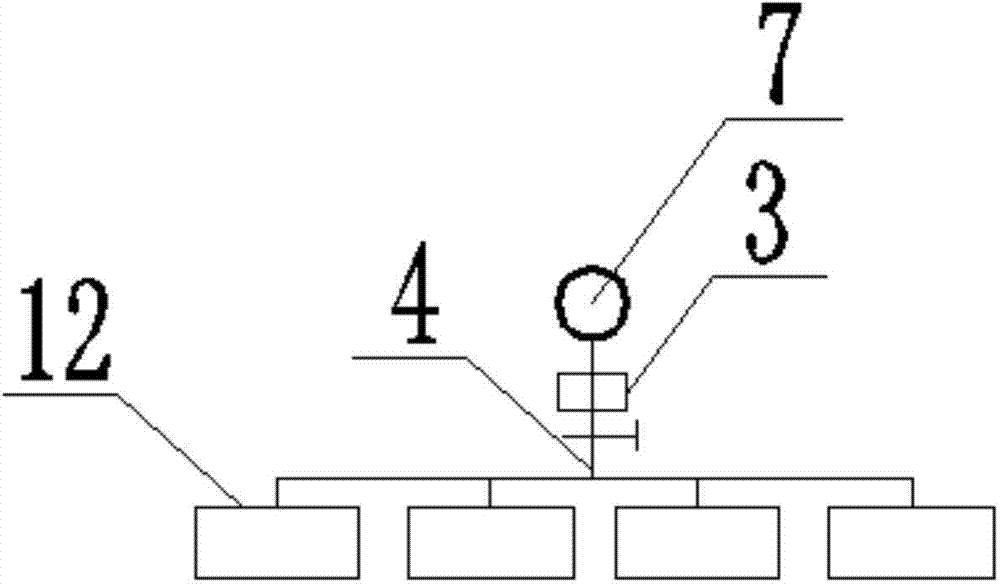

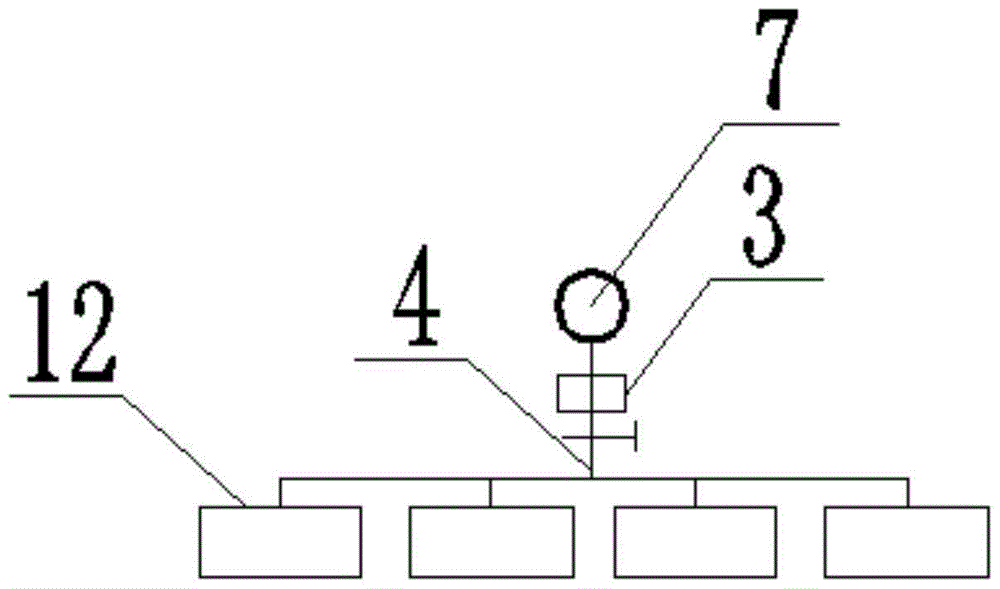

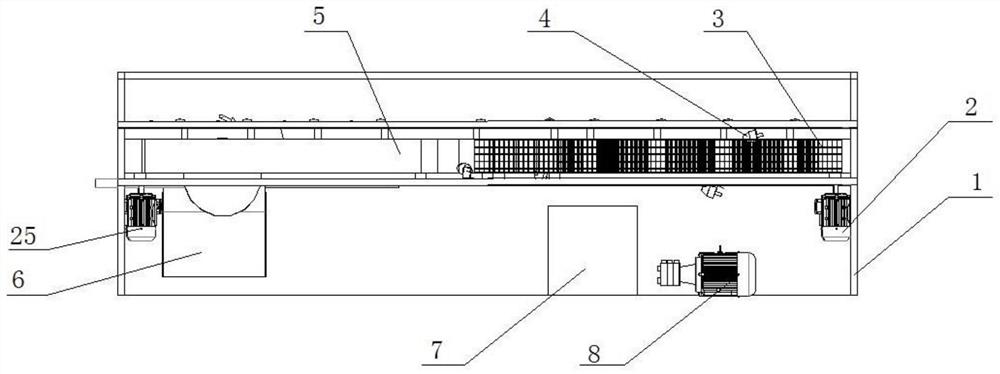

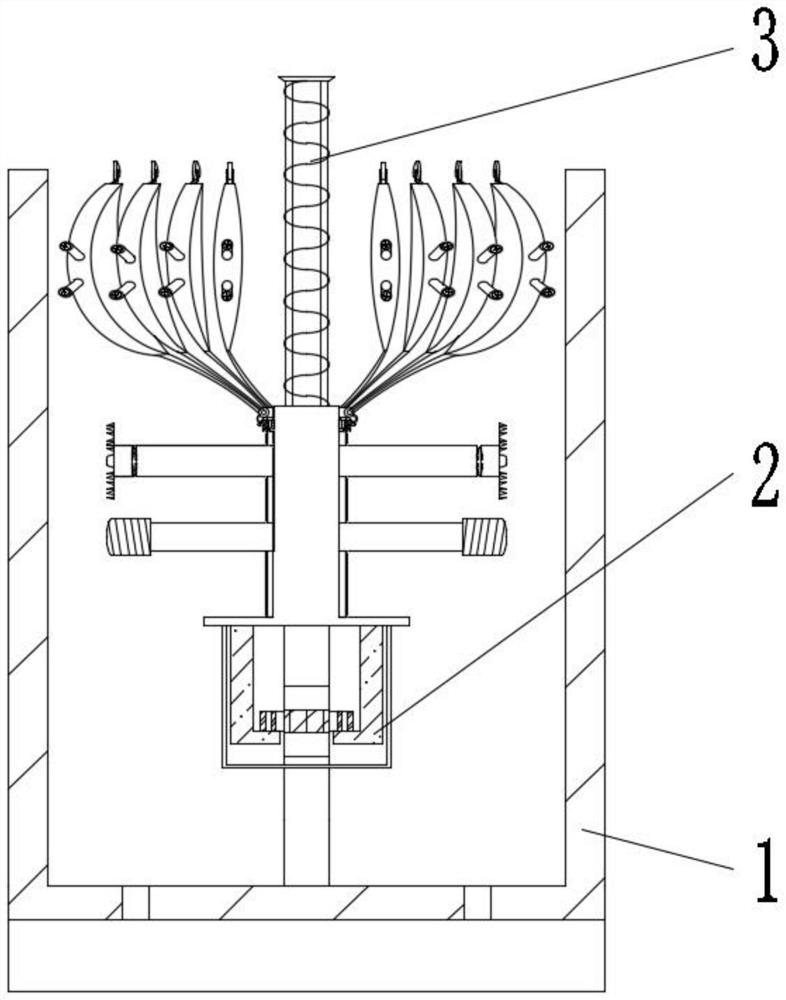

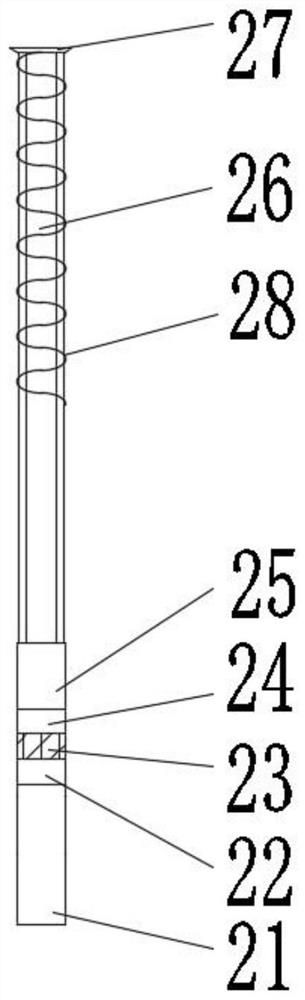

Fish scaling and slicing all-in-one machine

ActiveCN110915871AHigh descaling rateNo damageFish washing/descalingFish filletingWater flowEngineering

The invention discloses a fish scaling and slicing all-in-one machine which solves the problems that in the prior art, fish shakes under the pressure effect of a water gun, so that a slicing cutter cannot be accurately aligned, slicing is not uniform, and the operation assisting time is long, and has the effects of being high in scaling rate, free of damage and high in production efficiency. According to the technical scheme, the device comprises a rack, a scaling conveying mechanism and a slicing conveying mechanism, wherein the scaling conveying mechanism and the slicing conveying mechanismare sequentially installed in the rack, and the scaling conveying mechanism and the slicing conveying mechanism form a double-transmission space staggered connection structure; guide grooves used forguiding fish bodies are formed below the scaling conveying mechanism and the slicing conveying mechanism, a water gun arranged in a profiling structure is installed on the side face of the scaling conveying mechanism, and the water gun can enable water flow to be sprayed out in a spiral shape.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Descaling agent for leachate anaerobic system and preparation method of descaling agent

InactiveCN113415876AEasy to cleanGood removal effectSpecific water treatment objectivesScale removal and water softeningSodium phosphatesDodecylsulfonic acid

The invention relates to the technical field of landfill leachate treatment, and in particular, relates to a descaling agent for a leachate anaerobic system and a preparation method of the descaling agent, wherein the descaling agent comprises the following raw materials in parts by weight: 5-15 parts of hydrochloric acid, 1-5 parts of citric acid, 1-6 parts of EDTA, 0.4-3.5 parts of amino trimethylene phosphonic acid, 0.5-3.5 parts of a corrosion inhibitor, 0.3-0.6 part of sodium dodecyl sulfate, 0.9-1.8 parts of sodium hexametaphosphate and 45-180 parts of water. The hydrochloric acid, the citric acid, the EDTA and the amino trimethylene phosphonic acid are used in cooperation, cleaning of a pipe network and the interior of a UASB pool can be accelerated, removal of water scales is facilitated, the descaling time is shortened, and the descaling rate is effectively increased; by using the corrosion inhibitor formed by combining hydroxyethylidene-1,1-diphosphonic acid and polymaleic acid, the corrosion of the acidic descaling agent to the surface of equipment in the descaling process is effectively prevented; and by using a dispersing agent formed by combining sodium dodecyl sulfate and sodium hexametaphosphate, the water scales after stripping can be effectively prevented from being agglomerated and precipitated, so that the water scales after stripping is prevented from blocking the pipe network, and potential safety hazards are avoided.

Owner:江苏云尚环保装备有限公司

Organic descaling composition, preparation method and application thereof

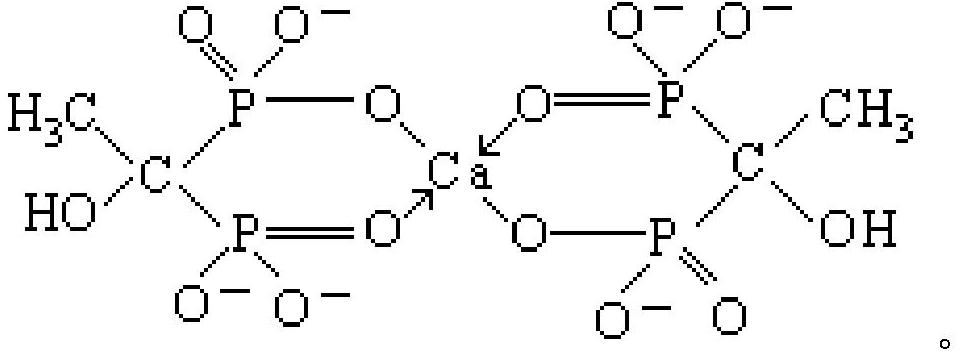

ActiveCN101565660BFast descalingDescaling speed comparisonHollow article cleaningOrganic non-surface-active detergent compositionsMeth-Diphosphenes

The invention provides an organic descaling composition, which includes an organic cleaning agent and a corrosion inhibitor CM-911, and the weight ratio of the organic cleaning agent and the corrosioninhibitor is 100:0.1-0.3. The organic cleaning agent includes the follow components by weight: 1%-15% of maleic acid-crylic acid copolymer (MA-AA), 1%-25% of 1-hydroxyethylidene-1,1-diphosphonic acid(HEDP), 2%-30% of amino trimethylene phosphonic acid (ATMP), 0.03%-0.5% of penetrating agent JFC and balance of water. The organic descaling agent provided by the present invention has advantages offast reaction speed, small corrosivity for material and high descaling efficiency.

Owner:河南伯淼水处理有限公司

A continuous cleaning device for reverse osmosis membrane components and a method for cleaning reverse osmosis membrane components using the device

ActiveCN104707484BEasy to installEliminate complicated disassembly processReverse osmosisBiochemical engineeringAssembly disassembly

The invention relates to a reverse osmosis membrane assembly continuous offline cleaning device. The device comprises a plurality of cleaning tanks, and a driving and conveying device, wherein the cleaning tanks are used for soaking and cleaning reverse osmosis membrane assemblies, and are independent from one another; the driving and conveying device is used for driving the reverse osmosis membrane assemblies to be continuously cleaned in the cleaning tanks which are independent from one another. The offline cleaning method is adopted; the polluted membrane assemblies are soaked in the cleaning solution tanks, and parallel connection is adopted by the equipment for simultaneous and separate cleaning of the multiple membrane assemblies; a cleaning solution inlet end cover and one end of each membrane assembly are fixed on a double-chain through clamps, and the other end of each membrane assembly is fixed on the other side of the double-chain, so that the assemblies can be conveniently mounted, the complex assembly disassembly process is avoided, and labor conservation is achieved; an identical number of the membrane assemblies are mounted in each cleaning solution tank, the equipment automation level is improved through the chain transmission method, and the membrane assemblies in the different cleaning solution tanks are operated at the same time, so that the whole assembly line is continuous, the cleaning time is reduced, and the cleaning efficiency is improved.

Owner:QINGDAO AGRI UNIV

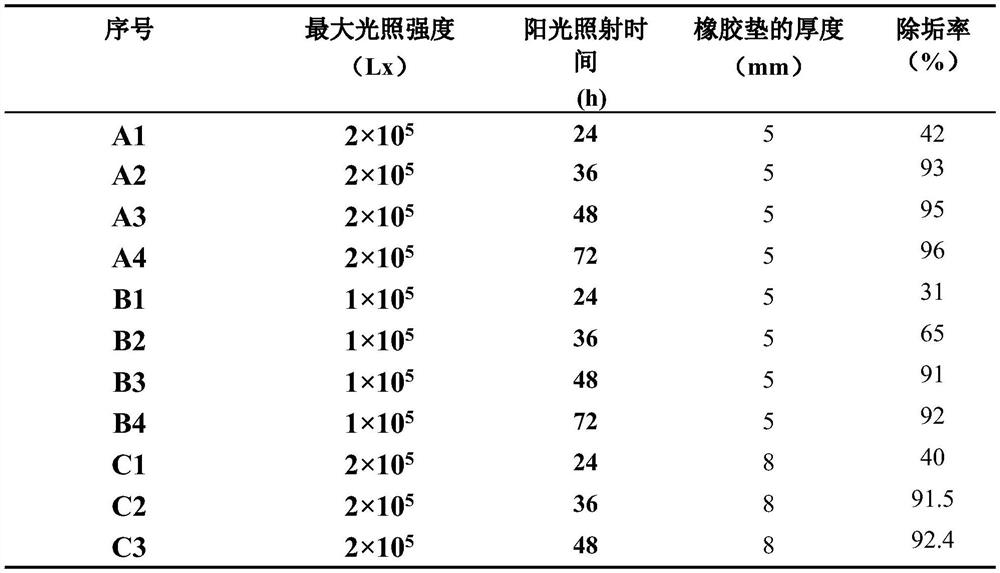

Method for cleaning scale on fins of plate type heat exchanger

PendingCN112393531AEffectively removes foulingHigh descaling rateDrying solid materials with heatVibration cleaningThermodynamicsEngineering

The invention relates to a method for cleaning scale on fins of a plate type heat exchanger. The method comprises the following steps: a) placing the sides, with scale, of the fins of the plate type heat exchanger on the ground with sufficient sunlight for sunlight irradiation; and b) when dry cracks occur in the scale on the fins, lifting and beating the fins on a rubber pad till the scale automatically falls off, and washing with clear water, so that the fins can be reused. According to the method, the scale on the fins of the plate type heat exchanger is removed in a sunlight exposure and fin beating mode, so that the descaling rate can reach 90%, workers and the working environment cannot be hurt, materials of the fins of the plate type heat exchanger cannot be corroded or damaged, theservice life of the plate type heat exchanger can be prolonged, and the heat efficiency of the plate type heat exchanger can be improved.

Owner:蓝孚医疗科技(山东)有限公司

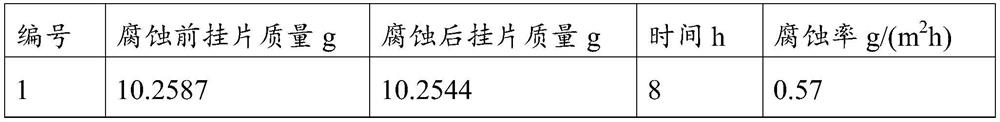

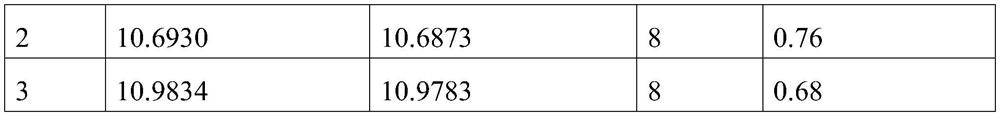

Fully-organic corrosion-inhibiting antiscaling industrial water conditioning agent and method for making same

The invention relates to a fully organic corrosion and deposit inhibitor for industry water treatment and a fabrication method to be concerned, which is fabricated by the weight percentage compositions of the following elements: 20 percent to 30 percent of acrylate-acrylate copolymer, 12 percent to 20 percent of sulfonic acid copolymer, 5 percent to 10 percent of polyepoxysuccinic acid, 0.6 percent to 0.9 percent of benzotriazole, 10 percent to 15 percent of hydroxy ethylidene diphosphoric acid, 2-butane phosphate 1,2,4, 15 percent to 25 of percent tricarboxylic acid, 2 percent to 4 percent of zinc salt and deionized water; the invention is the corrosion and deposit inhibitor for industry water, which is fabricated by acrylate-acrylate copolymer, sulfonic acid copolymer, polyepoxysuccinic acid, hydroxy ethylidene diphosphoric acid, 2-butane phosphate 1,2,4, tricarboxylic acid (PBTCA), benzotriazole and zinc salt, the invention solves the problems of complicated operation for site user and high cost; after testing, the scale removing rate of the invention is over 95 percent.

Owner:南京市第一精细化工公司精细化工厂(普通合伙)

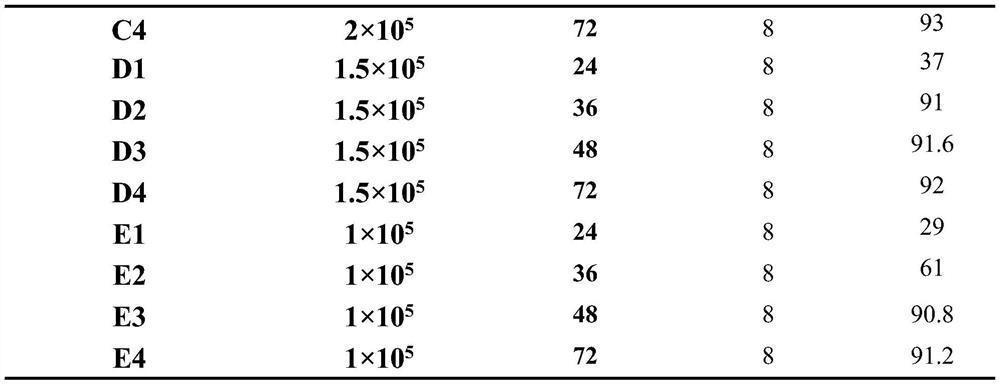

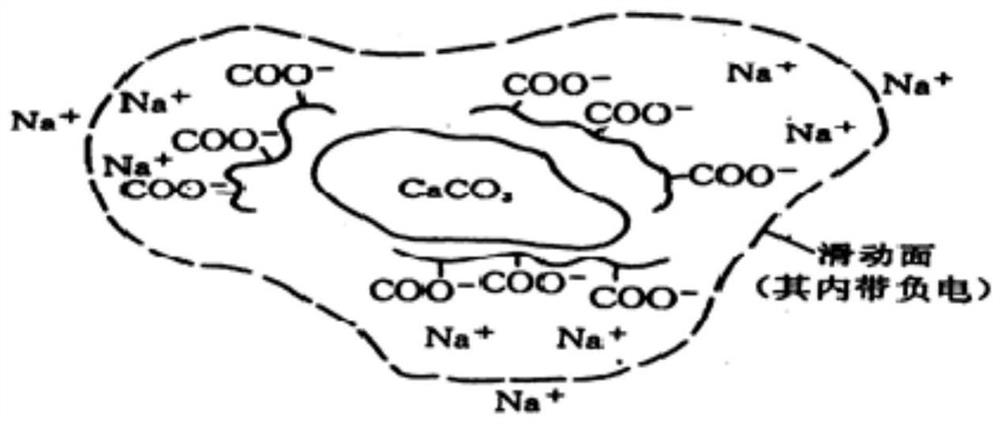

Binary compound surfactant

InactiveCN103805361AGood descaling performanceHigh descaling rateSurface-active detergent compositionsBinary compoundOrganic chemistry

The invention discloses a binary compound surfactant. The binary compound surfactant is formed by mixing OP-10 (polyoxyethyleneoctylphenyl-10) with Span 80, wherein a weight ratio of the OP-10 to the Span 80 ranges from (1:4) to (4:1). The binary compound surfactant provided by the invention is formed by mixing the OP-10 with the Span 80, and has the good descaling property; the descaling rate is greatly improved when the binary compound surfactant is applied to descaling; and furthermore, the manufacturing cost is low and the descaling cost is greatly reduced.

Owner:李兰

Scale inhibitor and descaling agent and preparation method thereof

Owner:PETROCHINA CO LTD

Electrolytic descaling device for circulating water treatment of ship boiler

InactiveCN103693761BElectrolytic reaction area is smallLow efficiencyScale removal and water softeningCircular discElectrochemical response

The invention discloses an electrolytic descaling device for circulating water treatment of a ship boiler. The device comprises a reducing motor, a water inlet valve, a water outlet valve, a drainage valve, a reverser, a scraper, circular disc plate electrodes, a precipitation tank, conductivity detection electrodes, a scale controller, a cylindrical barrel, a precipitation tank, a rotary shaft, a slide ring and a shaft sleeve, wherein six pairs of circular disc plate electrodes are sequentially fixed on the rotary shaft, respectively; the front five pairs of circular disc plate electrodes are connected with the reverser through leads to form a multi-stage serial treatment structure; the last pair of the circular disc plate electrodes is taken as the conductivity detection electrodes which are connected with the scale controller through leads. According to the device disclosed by the invention, the multi-stage serial plate electrodes are adopted, so that the contact area of electrochemical reaction can be effectively enhanced, the descaling rate in unit time is improved, and meanwhile, the size of the device is reduced, and the spatial utilization rate is improved. The device disclosed by the invention collects hardness of treated water to form closed-loop control to automatically feed back and adjust the decomposition voltage, so that the device is simple and convenient to operate, and the energy consumption of the whole device can be effectively reduced.

Owner:DALIAN MARITIME UNIVERSITY

EDTA (Ethylene Diamine Tetraacetic Acid) disodium salt compound surfactant

InactiveCN103805362AGood descaling effectHigh descaling rateNon-ionic surface-active compoundsEthylene diamineInorganic chemistry

The invention discloses an EDTA (Ethylene Diamine Tetraacetic Acid) disodium salt compound surfactant prepared by mixing OP-10 and EDTA disodium salt, wherein the ratio of OP-10 to EDTA disodium salt is 2:5 to 4:3 according to the mass. The EDTA disodium salt compound surfactant is prepared by mixing OP-10 and EDTA disodium salt and is favorable in descaling performance; when EDTA disodium salt compound surfactant is used for descaling, the descaling rate is greatly increased, and the manufacturing cost is low, so that the descaling cost is greatly reduced.

Owner:刘治民

A kind of air preheater chemical cleaning agent

ActiveCN110343579BDoes not affect operationNo pollution in the processInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAir preheaterPolyamide

The invention provides a chemical cleaning agent for an air preheater, which comprises sodium dodecylbenzenesulfonate, sodium alkylsulfonate succinate, polyoxyethylene alkyl ether, alkylbenzenesulfonate, polyamide, Organic silicon, trisodium phosphate, and sodium hydroxide are special cleaning agents for cleaning the air preheater. They can clean the air preheater online without affecting the operation of the air preheater. The cleaning effect is good and the scale removal rate is high. practical.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +2

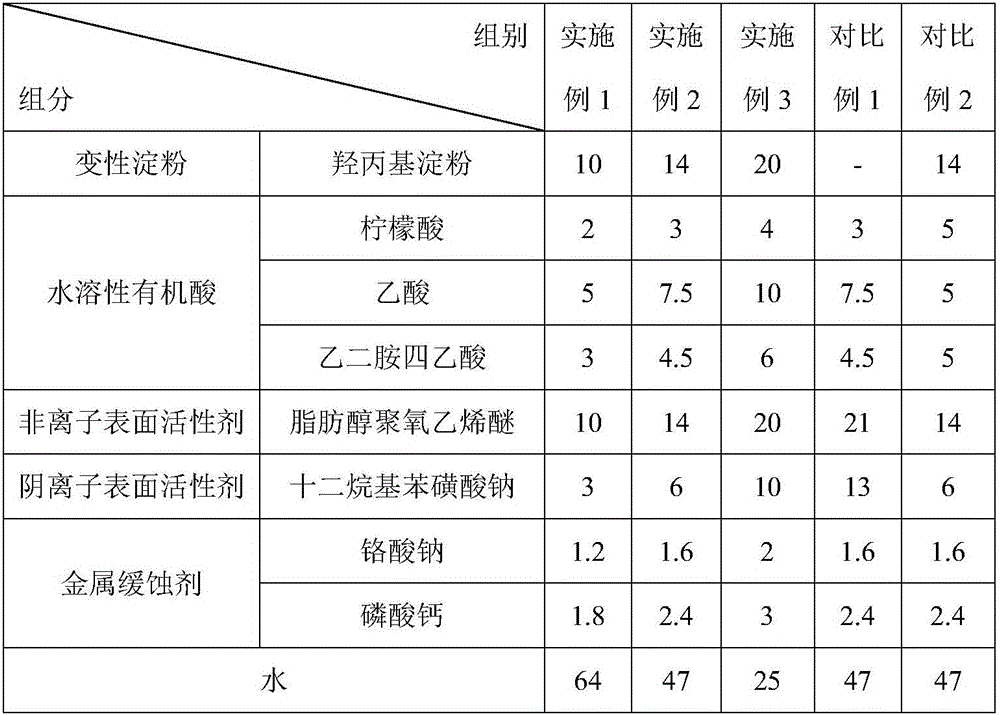

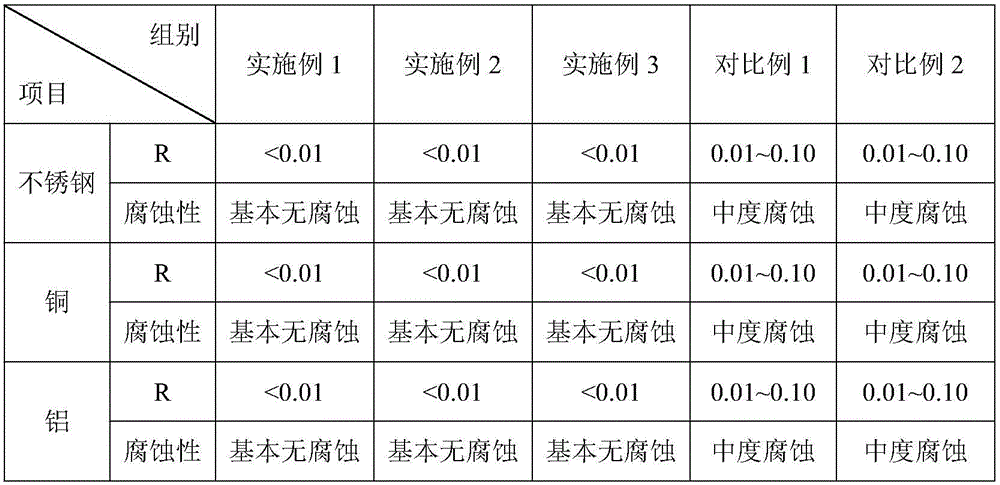

Scale scavenging agent and preparation method thereof

The invention belongs to the technical field of daily chemical products and particularly relates to a scale scavenging agent and a preparation method thereof. The scale scavenging agent provided by the invention comprises the following components in percentages by mass: 10-20% of modified starch, 10-20% of organic acid, 10-20% of a nonionic surfactant, 3-10% of an anionic surfactant, 3-5% of a metal corrosion inhibitor and 25-64% of water. The scale scavenging agent provided by the invention is fast in scale removal speed, high in scale removal rate and small in metal corrosion.

Owner:叶宗瑞

An all-in-one machine for fish descaling and flaking

ActiveCN110915871BHigh descaling rateNo damageFish washing/descalingFish filletingWater flowEngineering

The invention discloses a fish scaling and slicing all-in-one machine which solves the problems that in the prior art, fish shakes under the pressure effect of a water gun, so that a slicing cutter cannot be accurately aligned, slicing is not uniform, and the operation assisting time is long, and has the effects of being high in scaling rate, free of damage and high in production efficiency. According to the technical scheme, the device comprises a rack, a scaling conveying mechanism and a slicing conveying mechanism, wherein the scaling conveying mechanism and the slicing conveying mechanismare sequentially installed in the rack, and the scaling conveying mechanism and the slicing conveying mechanism form a double-transmission space staggered connection structure; guide grooves used forguiding fish bodies are formed below the scaling conveying mechanism and the slicing conveying mechanism, a water gun arranged in a profiling structure is installed on the side face of the scaling conveying mechanism, and the water gun can enable water flow to be sprayed out in a spiral shape.

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES

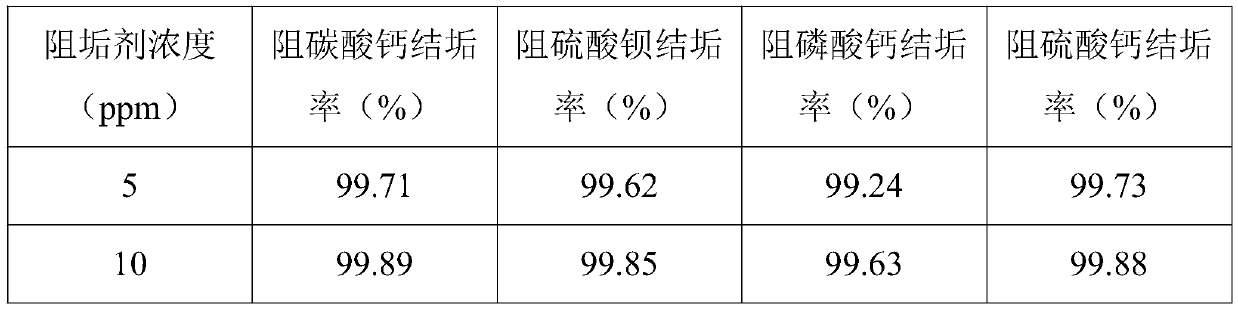

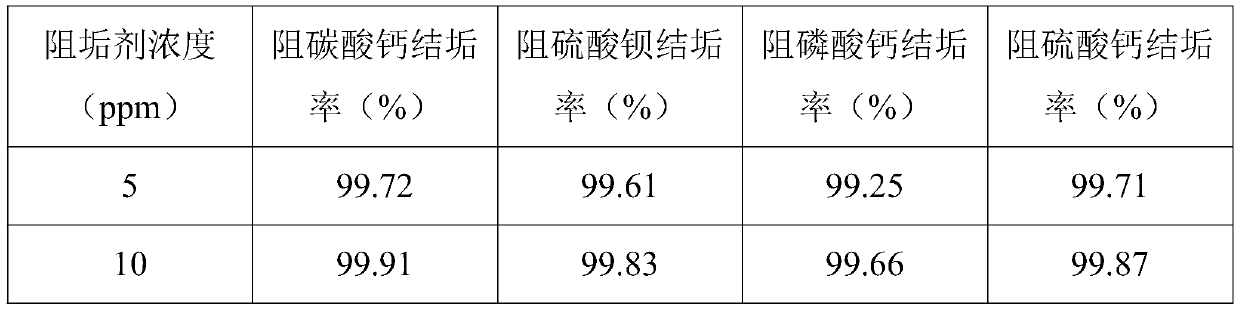

Scale inhibitor for reverse osmosis membrane and preparation method thereof

ActiveCN108295664BEfficient removalHigh descaling rateSemi-permeable membranesAcetic acidCalcium biphosphate

The invention provides an antisludging agent for a reverse osmosis membrane and a preparation method of the antisludging agent. The antisludging agent comprises the following components: 12-16 parts of modified polyepoxysuccinic acid, 4-8 parts of hydrolyzed maleic anhydride, 3-6 parts of adipic acid / hexanediol methyl ester copolymer, 4-8 parts of malonic acid / amine-terminated polyether / diethylenetriamine copolymer, 1-2 parts of diethylenetriamine pentaacetate, 0.01-0.06 part of bactericide, and 50-70 parts of deionized water. The preparation method is as follows: 1) mixing the modified polyepoxysuccinic acid, the adipic acid / hexanediol methyl ester copolymer, the malonic acid / amine-terminated polyether / diethylenetriamine copolymer and part of deionized water, carrying out ultrasonic concussion to obtain a mixed solution A; 2) mixing hydrolyzed maleic anhydride, diethylenetriamine pentaacetate and the rest of the deionized water, adding the mixed solution A and the bactericide, and stirring evenly. The antisludging agent not only effectively eliminates the deposition of CaSO4 and CaCO3, but also removes scales of calcium phosphate and silicon dioxide, and no white flocculent precipitate is produced.

Owner:NETWO XIAMEN ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of descaling device for cup wall and cup bottom

ActiveCN112790695BWon't fallAchieve dynamic balanceTableware washing/rinsing machine detailsEngineeringBrush device

The invention provides a cup wall and cup bottom descaling device, which includes a base mechanism for supporting the equipment, a transmission mechanism for transmitting the power of the equipment, and a cleaning mechanism for cleaning the scale on the cup wall and bottom of the cup , the bottom of the inner wall of the base mechanism is fixedly connected with a transmission mechanism, and the surface of the transmission mechanism is sleeved with a cleaning mechanism, which relates to the technical field of daily necessities. According to the situation that the existing cup brush does not clean the water cup and cannot completely remove the scale on the cup wall and bottom of the cup, this device is designed to manually clean the inner wall of the attached water cup and clean the bottom and bottom of the cup. The special structure at the junction of the cup wall and the bottom of the cup can absorb the remaining pigment and odor in the inner cavity of the cup, thus effectively solving the problem that it is difficult for the general cup brush device to completely clean the scale and odor in the inner cavity of the water cup, and even affect people's drinking for a long time. The quality of the water will cause people to have symptoms of stones and harm their health.

Owner:永康市蓝柚工贸股份有限公司

A compound acid descaling and derusting cleaning agent

This application designs the technical field of descaling and descaling, and specifically discloses a composite acidic descaling and descaling cleaning agent. In terms of mass percentage, the composite acidic descaling and descaling cleaning agent includes 10%-50% of acid, complexing agent 5‑10%, 0.5‑2% corrosion inhibitor, 3‑10% wetting agent, 0.05‑2% color code indicator, and deionized water as the balance. The composite acidic descaling and descaling cleaning agent provided by the application has the advantage of quickly indicating whether the cleaning end point is reached, so that metal cleaning is complete.

Owner:浙江康星科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com