Scale inhibitor for reverse osmosis membrane and preparation method thereof

A technology of reverse osmosis membrane and antiscalant, which is applied in the field of antiscalant, can solve the problems such as white flocculent precipitation, achieve good dispersion of light transmission performance, and improve the effect of scale removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

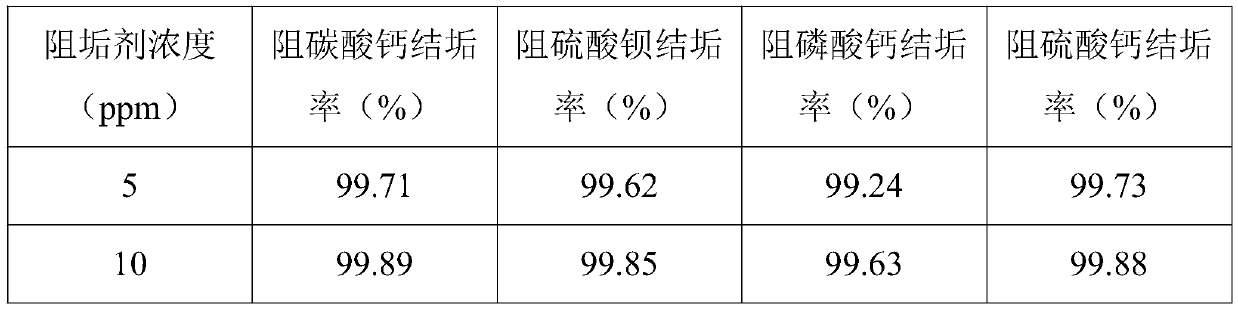

Embodiment 1

[0022] A scale inhibitor for reverse osmosis membranes, calculated in parts by weight, comprising the following components:

[0023] 14 parts of modified polyepoxysuccinic acid, 6 parts of hydrolyzed maleic anhydride, 4 parts of adipic acid / hexanediol methyl ester copolymer, 6 parts of malonic acid / amino-terminated polyether / diethylenetriamine copolymer, 1 part of pentasodium ethylene triamine pentaacetic acid, 0.03 part of phenylpropanisothiazolinone, and 60 parts of deionized water. The modified polyepoxysuccinic acid is prepared from maleic anhydride and 2-propenylamine-2-methylpropenesulfonic acid.

[0024] Preparation:

[0025] 1) First mix modified polyepoxysuccinic acid, adipic acid / hexanediol methyl ester copolymer, malonic acid / amino-terminated polyether / diethylenetriamine copolymer and part of deionized water before ultrasonic vibration, Obtain mixed solution A;

[0026] 2) Mix the hydrolyzed maleic anhydride, pentasodium diethylenetriaminepentaacetic acid and the...

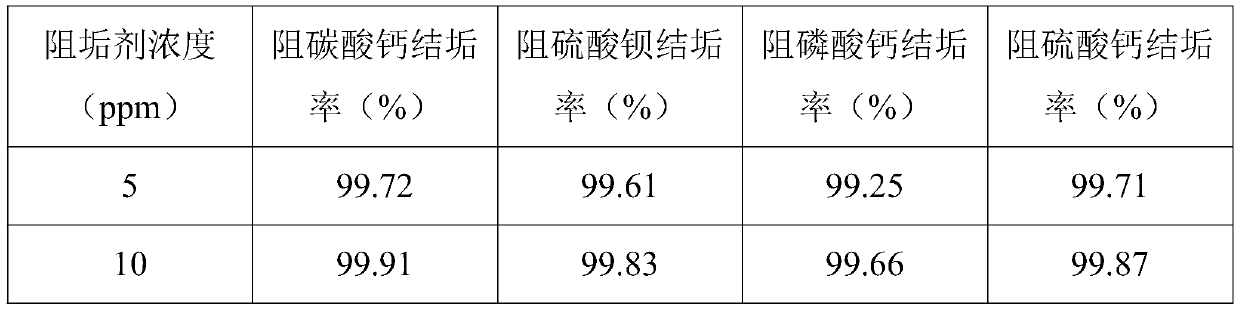

Embodiment 2

[0031] A scale inhibitor for reverse osmosis membranes, calculated in parts by weight, comprising the following components:

[0032] 12 parts of modified polyepoxysuccinic acid, 4 parts of hydrolyzed maleic anhydride, 6 parts of adipic acid / hexanediol methyl ester copolymer, 4 parts of malonic acid / amino-terminated polyether / diethylenetriamine copolymer, 2 parts of pentammonium ethylene triamine pentaacetic acid, 0.01 part of phenylpropanisothiazolinone, and 50 parts of deionized water. The modified polyepoxysuccinic acid is prepared from maleic anhydride and 2-propenylamine-2-methylpropenesulfonic acid.

[0033] Preparation:

[0034] 1) First mix modified polyepoxysuccinic acid, adipic acid / hexanediol methyl ester copolymer, malonic acid / amino-terminated polyether / diethylenetriamine copolymer and part of deionized water before ultrasonic vibration, Obtain mixed solution A;

[0035] 2) Mix and stir the hydrolyzed maleic anhydride, pentaammonium diethylenetriaminepentaacetat...

Embodiment 3

[0040] A scale inhibitor for reverse osmosis membranes, calculated in parts by weight, comprising the following components:

[0041] 16 parts of modified polyepoxysuccinic acid, 8 parts of hydrolyzed maleic anhydride, 3 parts of adipic acid / hexanediol methyl ester copolymer, 8 parts of malonic acid / amino-terminated polyether / diethylenetriamine copolymer, two 1 part of pentasodium ethylene triamine pentaacetic acid, 00.06 parts of bactericide, and 70 parts of deionized water. The modified polyepoxysuccinic acid is prepared from maleic anhydride and 2-propenylamine-2-methylpropenesulfonic acid.

[0042] Preparation:

[0043] 1) First mix modified polyepoxysuccinic acid, adipic acid / hexanediol methyl ester copolymer, malonic acid / amino-terminated polyether / diethylenetriamine copolymer and part of deionized water before ultrasonic vibration, Obtain mixed solution A;

[0044] 2) Mix the hydrolyzed maleic anhydride, pentasodium diethylenetriaminepentaacetic acid and the rest of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com