Organic descaling composition, preparation method and application thereof

A composition and organic technology, applied in the directions of organic non-surface-active cleaning compositions, cleaning methods and utensils, detergent compositions, etc., can solve the problems of slow scale removal speed and insufficient scale removal rate of scale removers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

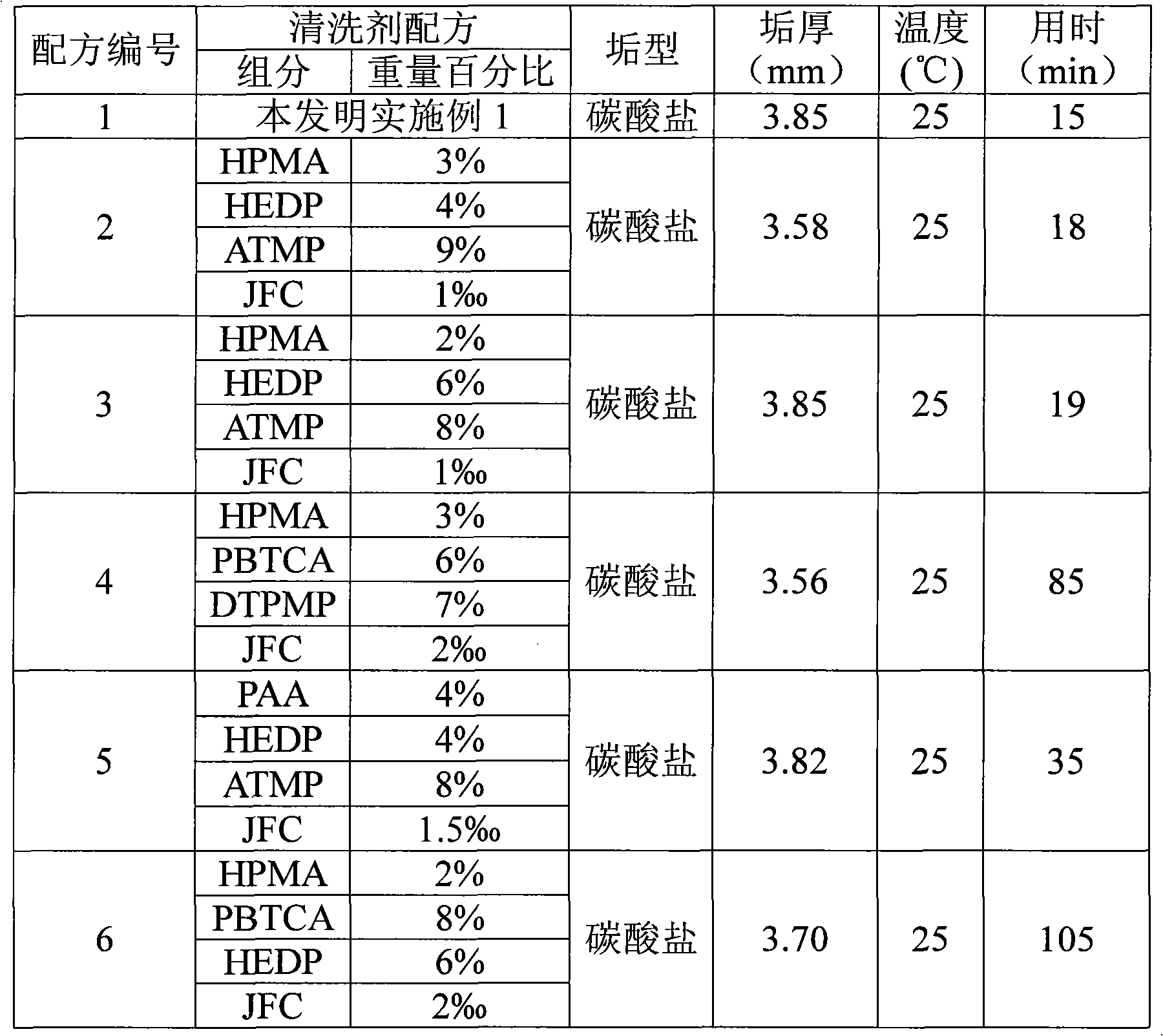

Examples

Embodiment 1

[0030] Recipe (by weight):

[0031] Detergent: MA-AA 2%

[0032] HEDP 6%

[0033] ATMP 8%

[0034] JFC 1‰

[0035] Water 84%

[0036] Corrosion inhibitor: 1‰ of the weight of CM-911 cleaning agent

[0037] preparation:

[0038] 1. First add the stated ratio of water into the cleaning agent preparation container, and then add the stated ratio of corrosion inhibitor (CM-911) and penetrant (JFC), and stir evenly.

[0039] 2. Add the proportion of MA-AA into the container in step 1 and stir evenly.

[0040] 3. Add the HEDP in the stated proportion, stir again, and finally add the ATMP in the stated proportion, stir well, and the obtained product A is a light yellow transparent liquid, odorless.

[0041] Descaling test:

[0042] The carbonate scale used in the test, the scale thickness is 3.85mm, the temperature is 25°C, it is completely dissolved in 15 minutes, and the corrosion rate is 0.032g / m 2 .h.

[0043] Descaling application:

[00...

Embodiment 2

[0046] Recipe (by weight):

[0047] Detergent: MA-AA 10%

[0048] HEDP 15%

[0049] ATMP 25%

[0050] JFC 1‰

[0051] water 50%

[0052] Corrosion inhibitor: 2‰ of the weight of CM-911 cleaning agent

[0053] Preparation: The method and steps are the same as in Example 1 to obtain product B.

[0054] Descaling test:

[0055] Carbonate scale is used for the test, the scale thickness is 3.85mm, the temperature is 20°C, it is completely dissolved in 18 minutes, and the corrosion rate is 0.033g / m 2 .h.

[0056] Descaling application:

[0057] The prepared product B can be used to remove silicate scale on the surface of carbon steel, and the cleaning temperature is 50°C.

Embodiment 3

[0059] Recipe (by weight):

[0060] Detergent: MA-AA 15%

[0061] HEDP 20%

[0062] ATMP 30%

[0063] JFC 5‰

[0064] Water 34.5%

[0065] Corrosion inhibitor: 1‰ of the weight of CM-911 cleaning agent

[0066] Preparation: The method and steps are the same as in Example 1 to obtain product C.

[0067] Descaling test:

[0068] The carbonate scale used in the test, the scale thickness is 3.58mm, the temperature is 25°C, it is completely dissolved in 13 minutes, and the corrosion rate is 0.033g / m 2 .h.

[0069] Descaling application:

[0070] The prepared product C can be used to remove silicate scale on the surface of carbon steel, and the cleaning temperature is 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com