Edible blend oil and preparation method thereof

A technology for blending oil and pine nut oil, which is applied in the field of edible oil to achieve the effects of inhibiting activity, reducing oxidative catalysis, and inhibiting lipid peroxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

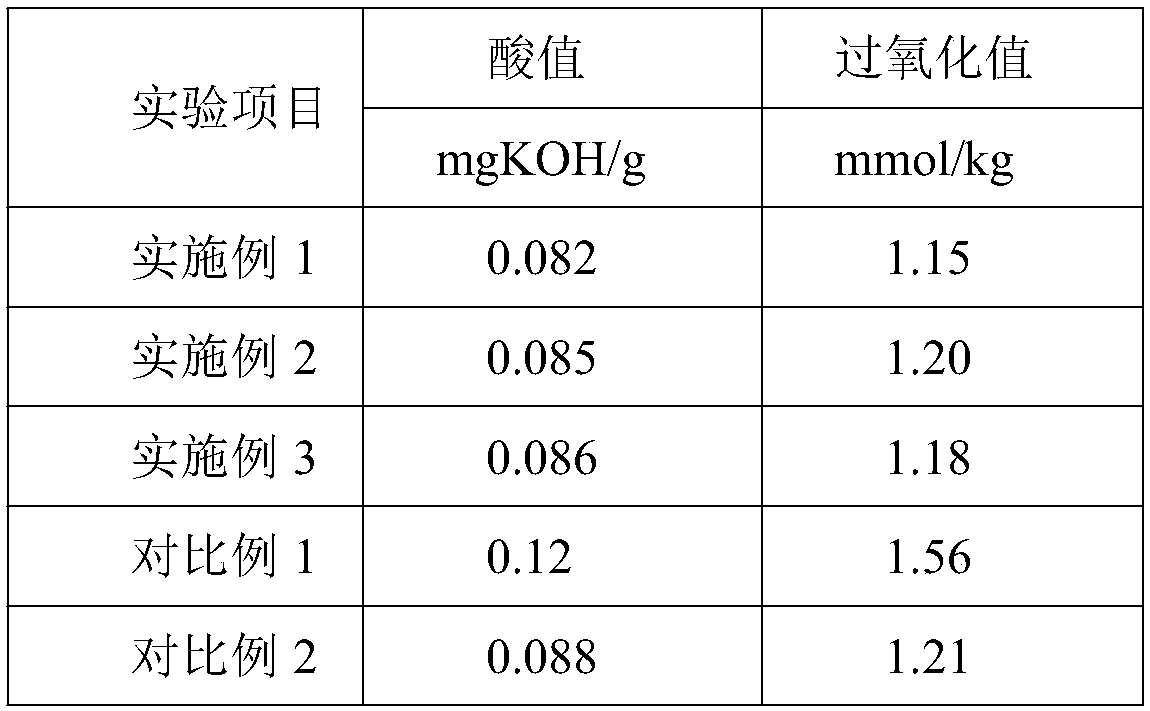

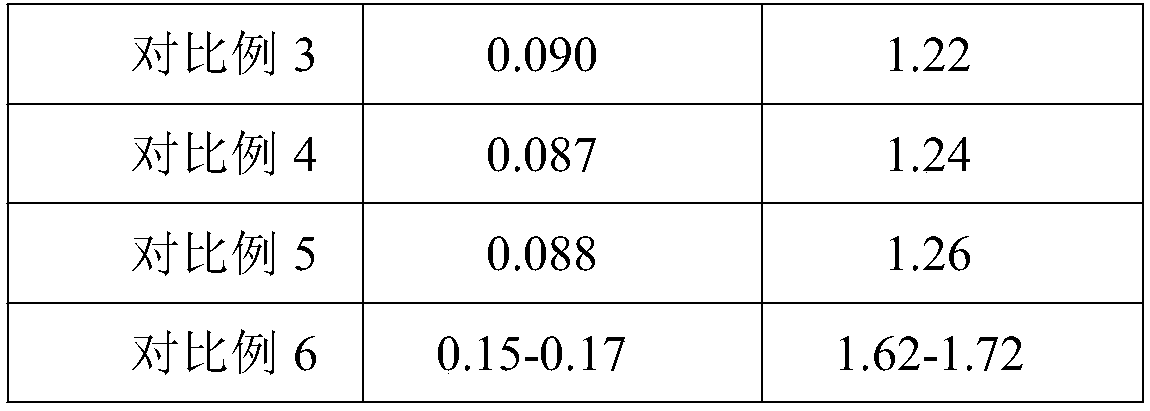

Examples

preparation example Construction

[0029] The preparation method of described edible blending oil comprises the following steps:

[0030] S1: Take refined palm oil by weight, using CO 2 Palmitoleic acid is separated by supercritical extraction; the CO 2 The temperature of supercritical extraction is 160-170°C, the extraction pressure is 5-10MPa, CO 2 The flow rate is 20-40kg / h, and the extraction time is 2-5h;

[0031] S2: Dissolve allicin in ethanol according to the weight ratio, then ultrasonically oscillate for 5-10min at a temperature of 40-60°C and then stand still for 2-5h. The power of the ultrasonic wave is 500-550W and the frequency is 360-400KHz;

[0032] S3: Mix palmitoleic acid and allicin, adjust the pH to 5.6-6.8, then distill at a vacuum of 1.2-2.3KPa and a temperature of 150-180°C, filter 2-3 times, and take the filtrate is an admixture;

[0033] S4: Take pine nut oil, peony seed oil, wheat germ oil, sunflower oil, and sesame oil according to the weight ratio, mix them all, then pump them in...

Embodiment 1

[0036] An edible blending oil in parts by weight, comprising the following raw materials: 12 parts of pine nut oil, 11 parts of peony seed oil, 5 parts of wheat germ oil, 9 parts of sunflower oil, 7 parts of sesame oil, 1.2 parts of lycopene, diced 0.2 parts of hydroxyanisole, 3 parts of tocopherol, 3 parts of sodium citrate, 1 part of cyclohexyl phosphate, and 2 parts of admixture.

[0037] The additive is a mixture of palm oleic acid and allicin obtained by refining and extracting palm oil with a weight ratio of 2:3.

[0038] The preparation method of described edible blending oil comprises the following steps:

[0039] S1: Take refined palm oil by weight, using CO 2 Palmitoleic acid is separated by supercritical extraction; the CO 2 The temperature of supercritical extraction is 160°C, the extraction pressure is 10MPa, CO 2 The flow rate is 40kg / h, and the extraction time is 2h;

[0040] S2: Dissolve allicin in ethanol according to the weight ratio, then oscillate ultraso...

Embodiment 2

[0045] An edible blending oil in parts by weight, comprising the following raw materials: 15 parts of pine nut oil, 10 parts of peony seed oil, 8 parts of wheat germ oil, 6 parts of sunflower oil, 5 parts of sesame oil, 0.8 parts of lycopene, diced 0.6 parts of hydroxyanisole, 1 part of tocopherol, 2 parts of sodium citrate, 0.5 parts of cyclohexyl phosphate, and 1.3 parts of additives.

[0046] The additive is a mixture of palm oleic acid and allicin obtained by refining and extracting palm oil with a weight ratio of 1:5.

[0047] The preparation method of described edible blending oil comprises the following steps:

[0048] S1: Take refined palm oil by weight, using CO 2 Palmitoleic acid is separated by supercritical extraction; the CO 2 The temperature of supercritical extraction is 170°C, the extraction pressure is 8MPa, CO 2 The flow rate is 30kg / h, and the extraction time is 5h;

[0049] S2: Allicin was dissolved in ethanol according to the weight ratio, and then ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com