Patents

Literature

186 results about "Palmitoleic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

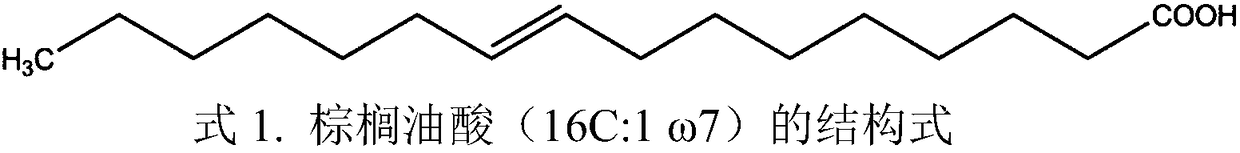

Palmitoleic acid, or (9Z)-hexadec-9-enoic acid, is an omega-7 monounsaturated fatty acid with the formula CH₃(CH₂)₅CH=CH(CH₂)₇COOH that is a common constituent of the glycerides of human adipose tissue. It is present in all tissues but, in general, found in higher concentrations in the liver. It is biosynthesized from palmitic acid by the action of the enzyme Stearoyl-CoA desaturase-1.

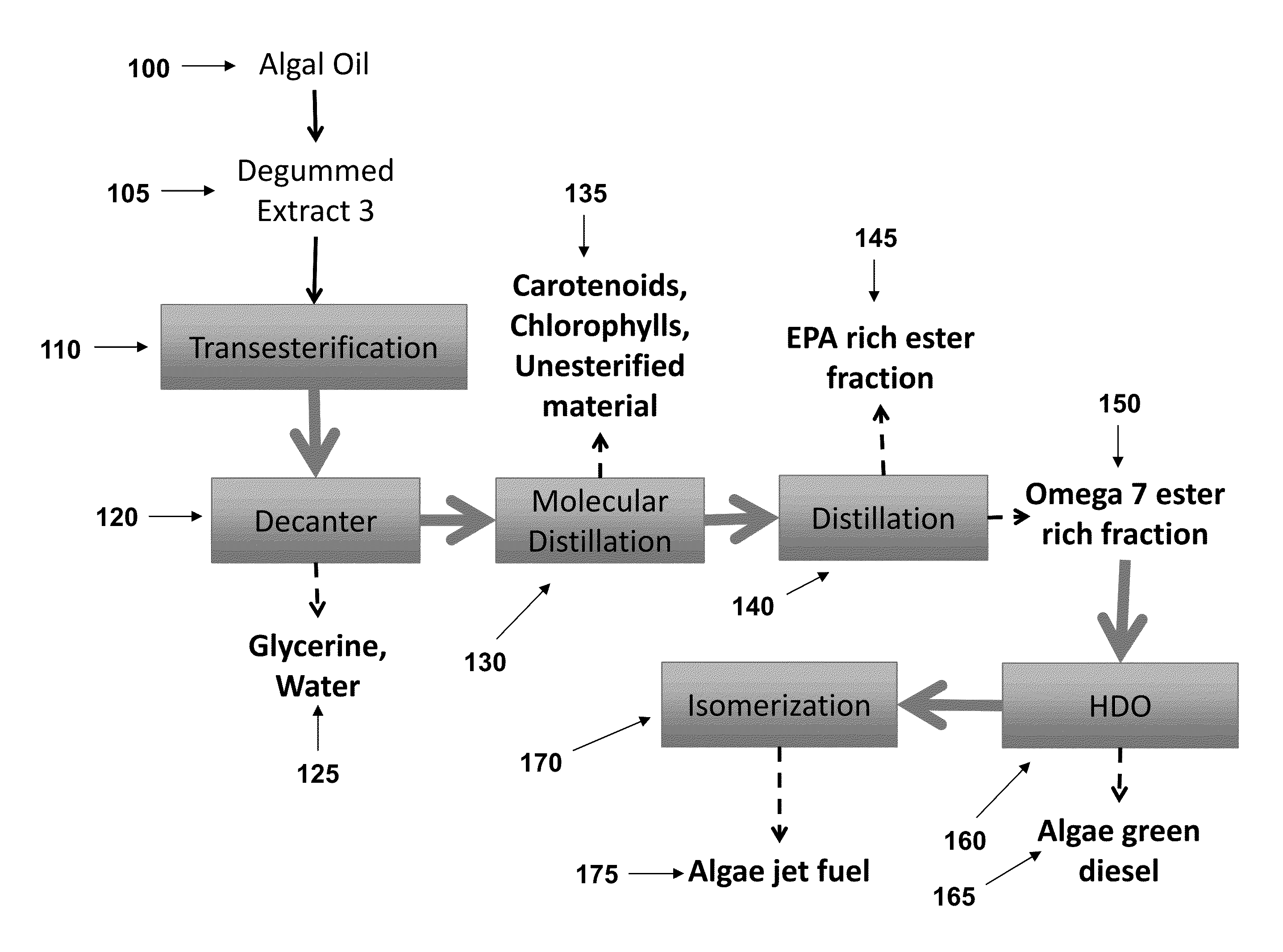

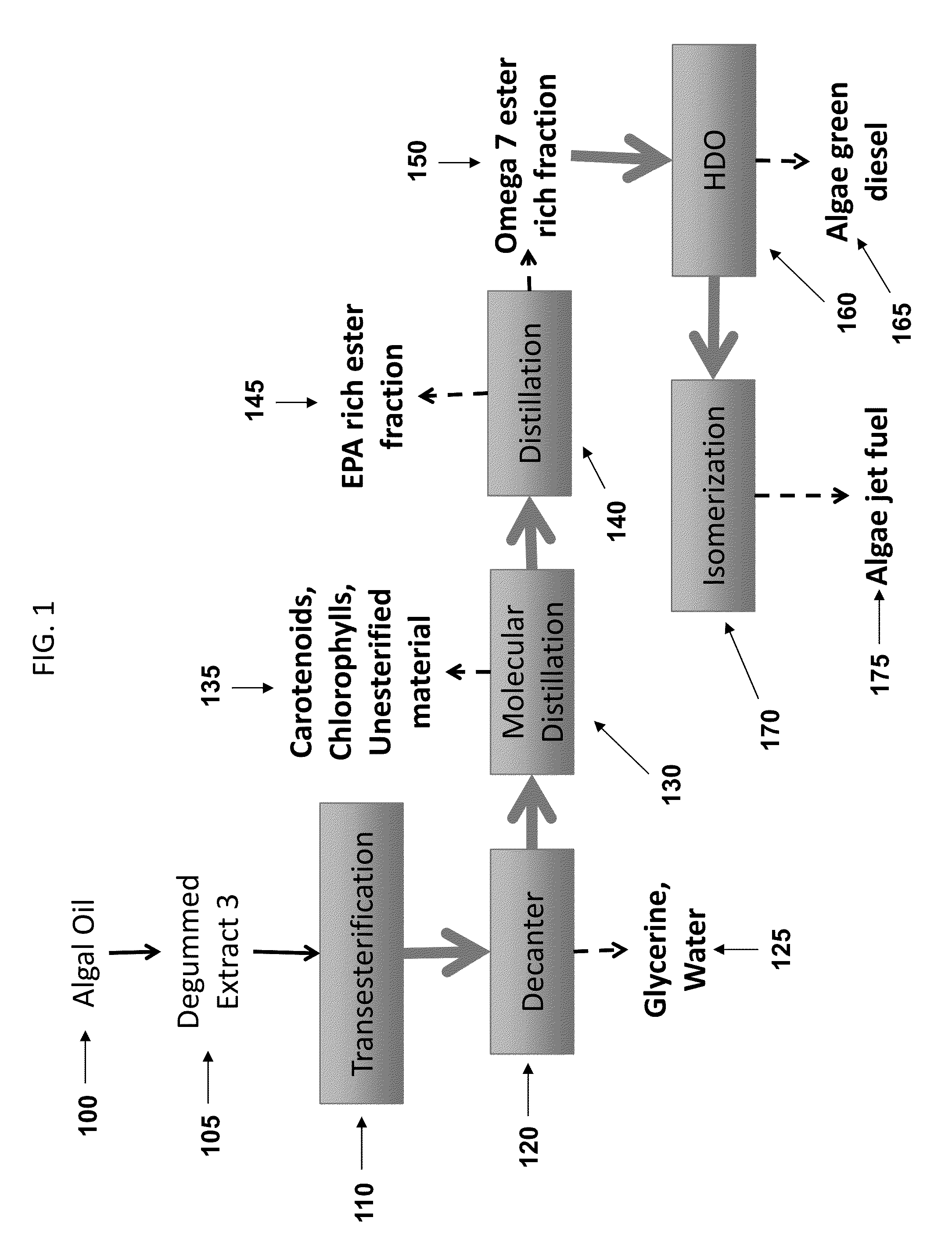

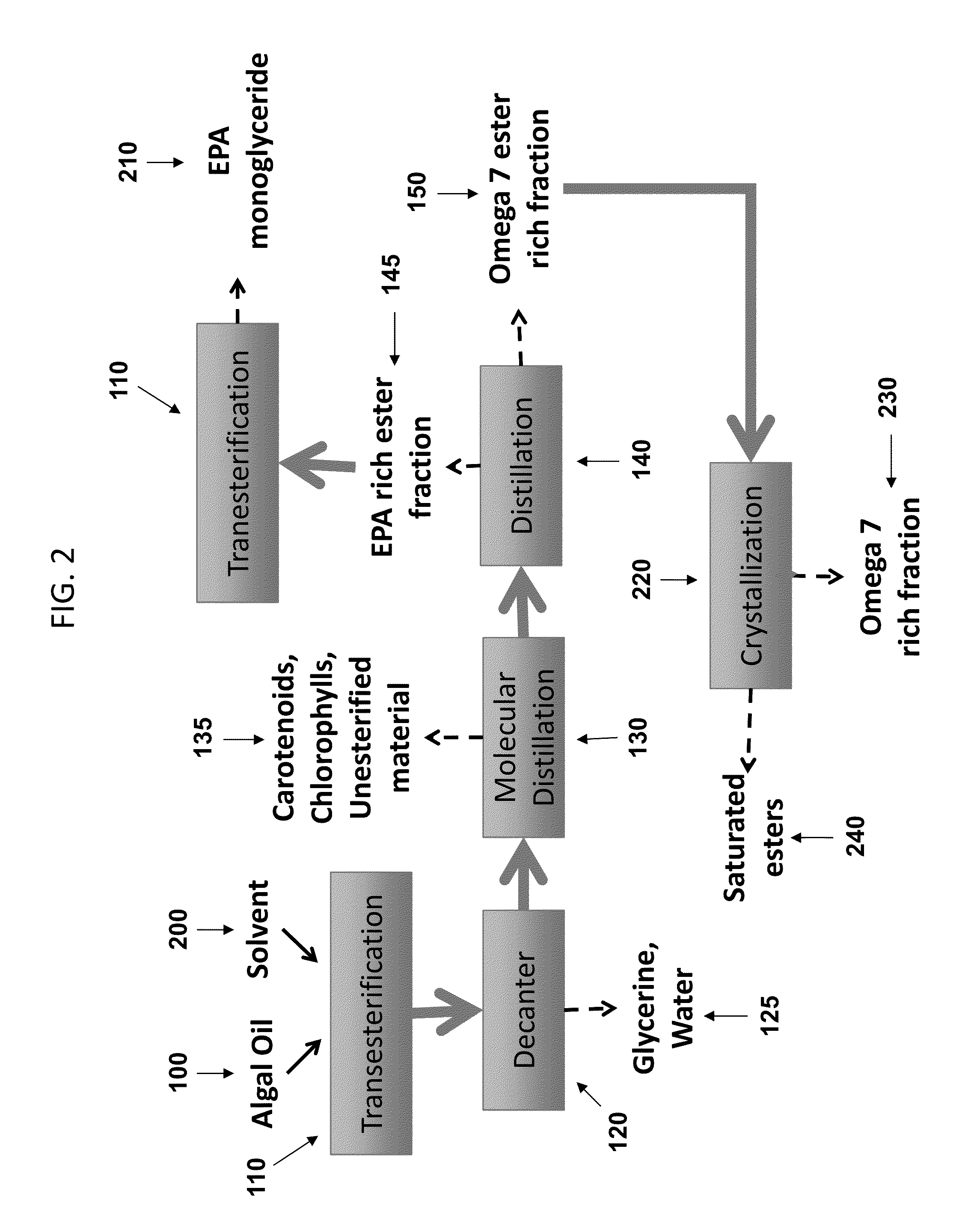

Omega 7 rich compositions and methods of isolating omega 7 fatty acids

ActiveUS20130129775A1Fatty oils/acids recovery from wasteCosmetic preparationsAdditive ingredientPalmitoleic acid

Disclosed here are compositions rich in omega-7 fatty acids, including palmitoleic acid, and products rich in omega-7 fatty acids derived from algal biomass. The algae and / or compositions rich in omega-7 fatty acids may be used in products or as ingredients of products. Methods and systems for increasing the production or concentration of omega-7 fatty acids, and isolating omega-7 fatty acids from algal biomass are also disclosed herein.

Owner:HELIAE DEVMENT

Preparation method of grease with humanized structure

ActiveCN102776077AHuge market potentialHigh number of reusesMilk preparationFatty acid esterificationVegetable oilMolecular rearrangement

The invention discloses a preparation method of grease with a humanized structure. The preparation method comprises the following steps: carrying out intra-molecular rearrangement reaction to palm oil with palmitic acid content of higher than 50% under the action of catalyst to obtain Sn-2 locus triglyceride with palmitic acid content of higher than 50%; and carrying out ester exchange reaction to the Sn-2 locus triglyceride with palmitic acid content of higher than 50% with mixed fatty acid or non-glyceride under the action of 1,3 locus Specificity lipase, and then subjecting the reaction product to after treatment, so as to obtain the grease with humanized structure, wherein the mixed fatty acid is mixture of at least two selected from the group consisting of decanoic acid, lauric acid,myristic acid, palmitoleic acid, stearic acid, oleic acid, linoleic acid and linolenic acid. The vegetable oils are used as the raw material according to the method, so the safety is high; the preparation process is simple, the reaction time is short, the enzyme dosage is low, and the cost is low; and the prepared grease with the humanized structure is very similar to the beast milk fat in the composition of fatty acid and the structural distribution of triglyceride, so the grease can be added in infant formula or formula foods and used as breast milk fat substitute.

Owner:ZANYU TECH GRP CO LTD

Compositions and methods for hair growth

A composition that promotes hair growth includes a lipophilic compound, such as a fatty acid, an allantoin, and a therapeutically effective amount of a biologically active substance. The fatty acid can be a palmitic, palmitoleic, stearic, oleic, linoleic, linolenic, arachidic, eicosenoic, behenic, erucic, myristic acid, and lignoderic fatty acid. The composition also includes jojoba oil, tea tree oil and wild carrot seed oil. A method for promoting hair growth using such composition.

Owner:DAVIS ROSE

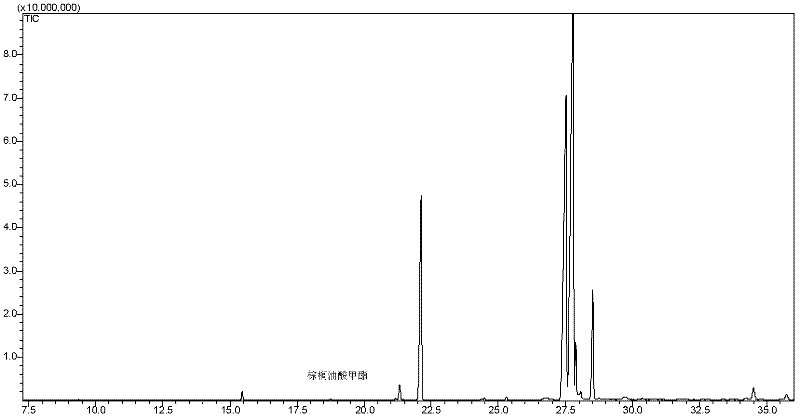

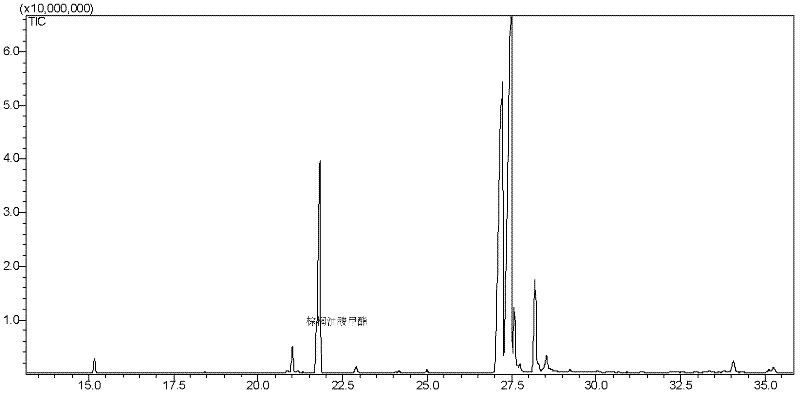

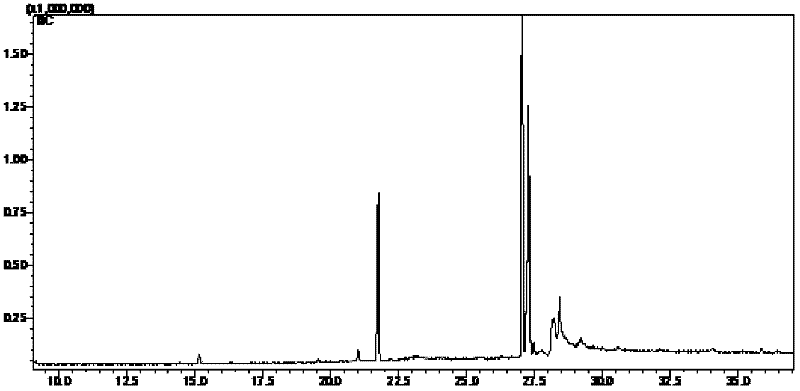

Identification method for illegal cooking oil

InactiveCN102393426ASuitable for rapid detectionFair priceComponent separationMass spectrometryPalmitoleic acid

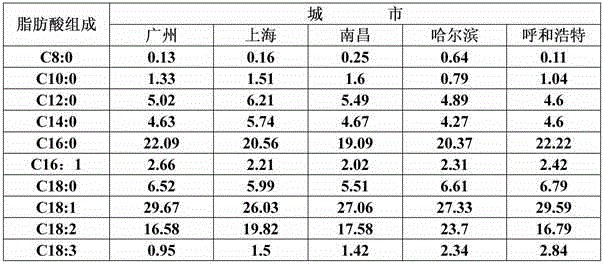

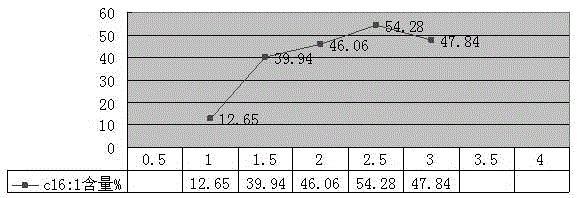

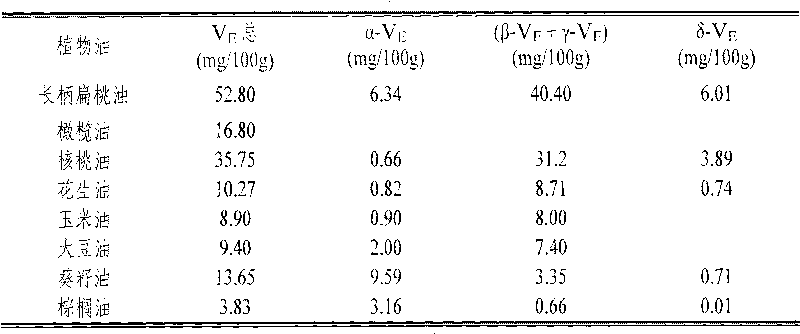

The invention provides an identification method for illegal cooking oil, and mainly solves the problems in the present identification method for illegal cooking oil. The identification method disclosed by the invention is mainly that: the mass fraction for palmitoleic acid occupying the total amount of fatty acid in grease is detected to identify whether the oil is illegal cooking oil or not; and in the practical detection, a sample is detected by adopting a gas chromatograph-mass spectrometer or a gas chromatography after being saponated and performed with methyl esterification, so as to identify whether the oil is illegal cooking oil or not after adopting peak area or peak height normalization quantitation. The method has the characteristics of definite target spot, strong feature, simplicity in operation, strong repeatability, application in quick detection and the like.

Owner:李涛 +1

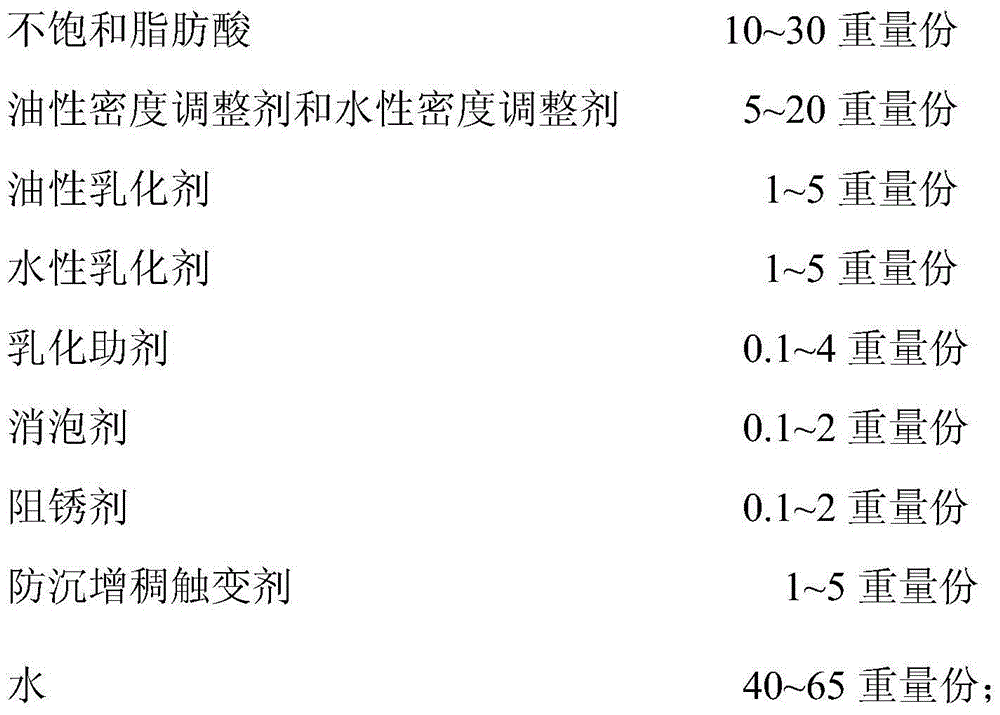

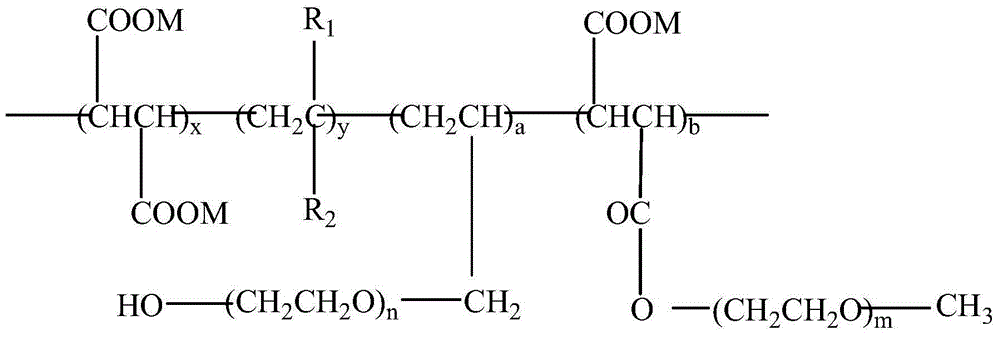

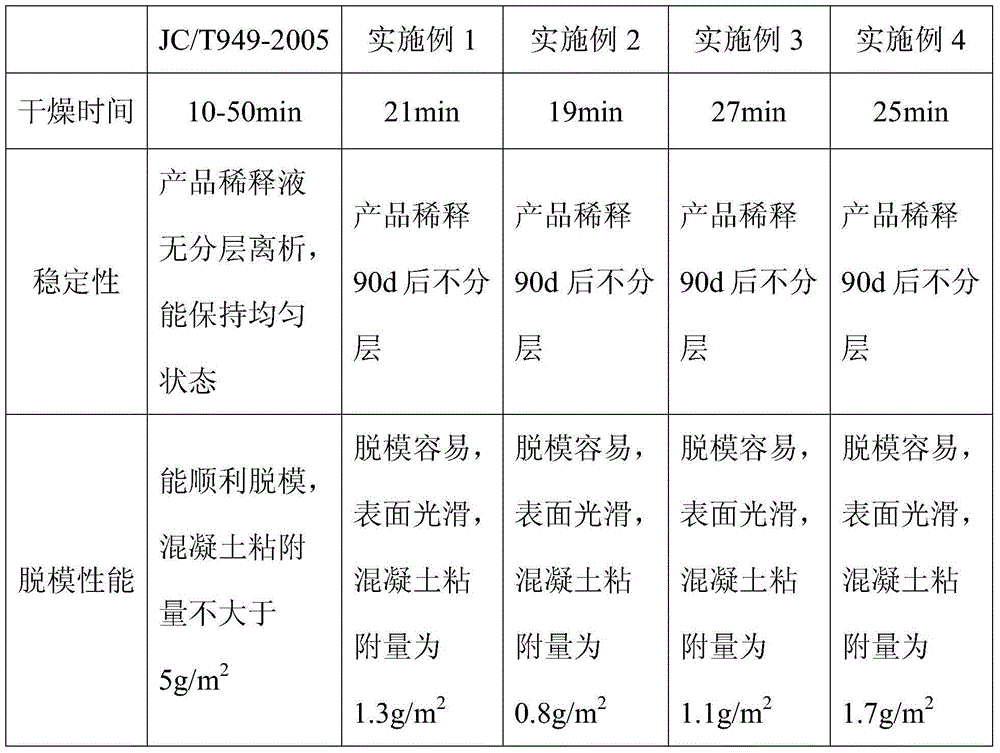

Demoulding agent used for precast concrete component and preparation method thereof

ActiveCN104403768AExtended storage timeDoes not affect the surfaceLubricant compositionPalmitoleic acidPrecast concrete

The invention discloses a demoulding agent used for precast concrete components. The demoulding agent includes following raw materials, by weight, 10-30 parts of an unsaturated fatty acid, 5-20 parts of an oily density adjusting agent and an aqueous density adjusting agent, 1-5 parts of an oily emulsifier, 1-5 parts of an aqueous emulsifier, 0.1-4 parts of an emulsification additive, 0.1-2 parts of a defoaming agent, 0.1-2 parts of an anti-rust agent, 1-5 parts of a settling-resistant and thickening thixotropic agent and 40-65 parts of water. The unsaturated fatty acid is oleinic acid, palmitoleic acid or ricinoleic acid. The emulsification additive has a structure formula represented as follows, wherein R1 is H or CH3, R2 is CONH2, CH2SO3Na or COOM, the x, the y, the a and the b are linking numbers of a copolymer repetitive unit and are ranged from 1 to 10, the m and the n are addition mole average numbers and are ranged from 10-50, wherein M is a hydrogen atom, a monovalent metal ion, an amino group or an organic ammonium group. The demoulding agent is low in cost, is free of generation of oil contamination, is long in storage time, is not liable to decay, deteriorate and layer, and is free of influence on surface and internal quality of concrete.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Biodiesel based fuel oil and preparation thereof

The invention provides biodiesel based fuel oil which comprises the following components by weight: 50-80 percent of crude biodiesel, 4-35 percent of compound emulsifying agent, and one or two mixture of water and methanol, wherein the compound emulsifying agent is the mixture of the two types of materials, the first-type material is one or the mixture of a plurality of oleic acid, palmitoleic acid, naphthenic acid, aliphatic amine polyethenoxy ether with C atomicity being 40-100, dehydration sorbitan fatty acid ester with C atomicity being 40-100, polyoxyethylenec dehydration sorbitan fatty acid ester with C atomicity being 40-100; the second-type material is one or the mixture of a plurality of monoethanol amine, diethanolameine, trolamine, diglycol amine, 1-octanol and tertiary butyl alcohol. The preparation method is as follows: the mixtures are mixed according to the percent by weight and are mixed uniformly so as to obtain transparent solution. The fuel oil has good stability, non layering for a long time, no discolor and no turbidity, and is directly prepared by adopting the crude biodiesel. Methanol or water or the mixture of the water and the methanol is added, thus the consumption of the biodiesel is saved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

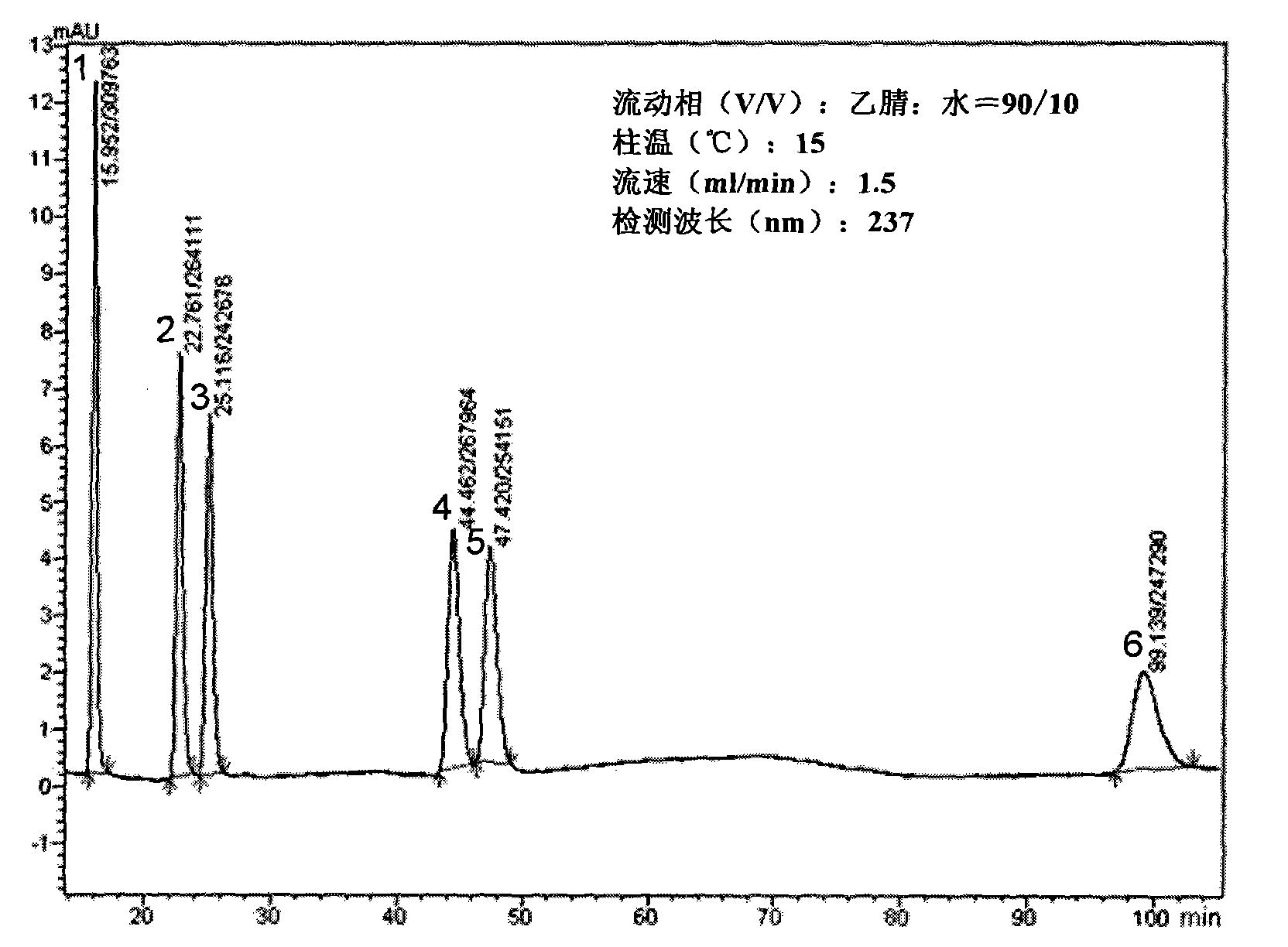

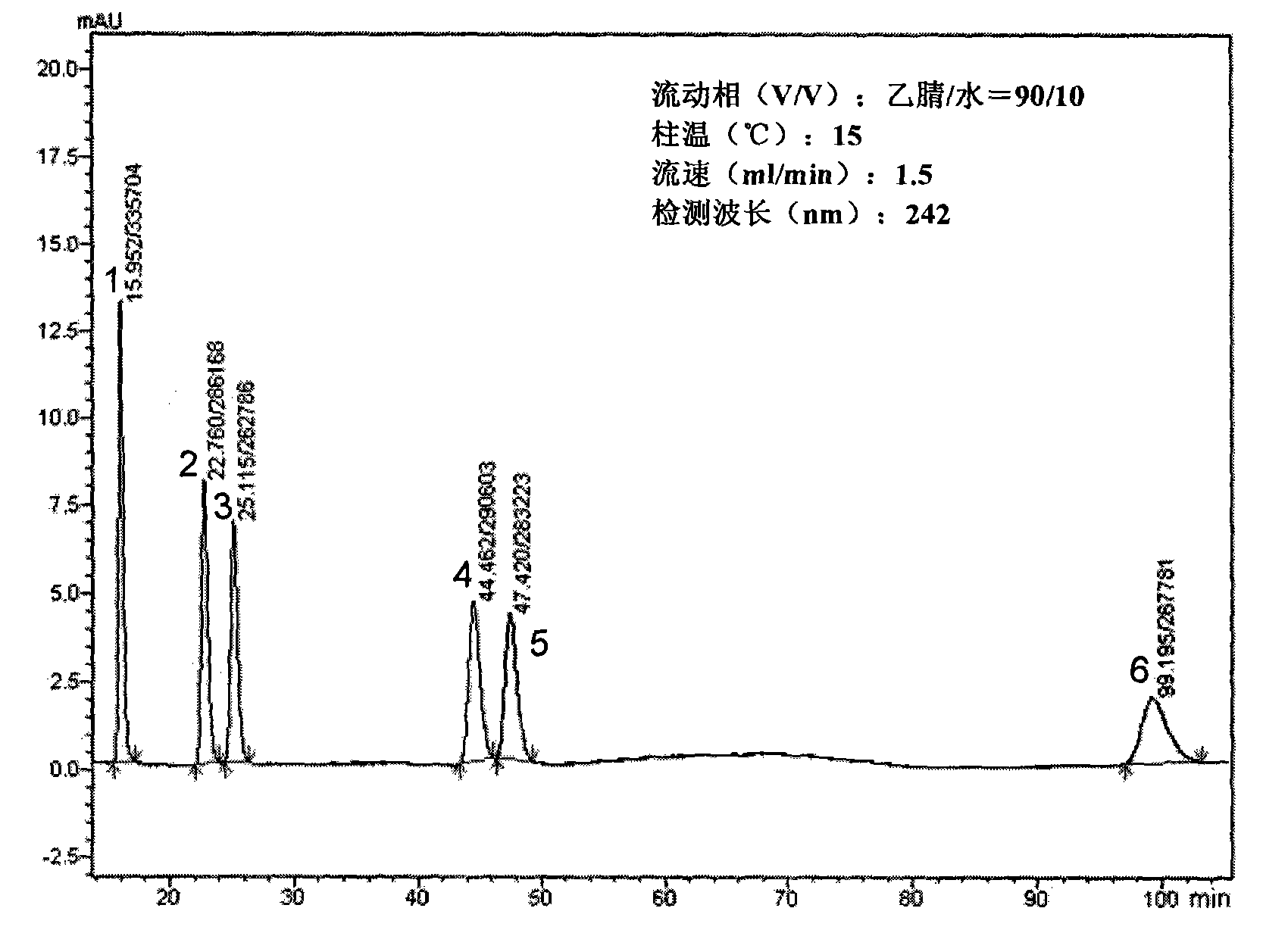

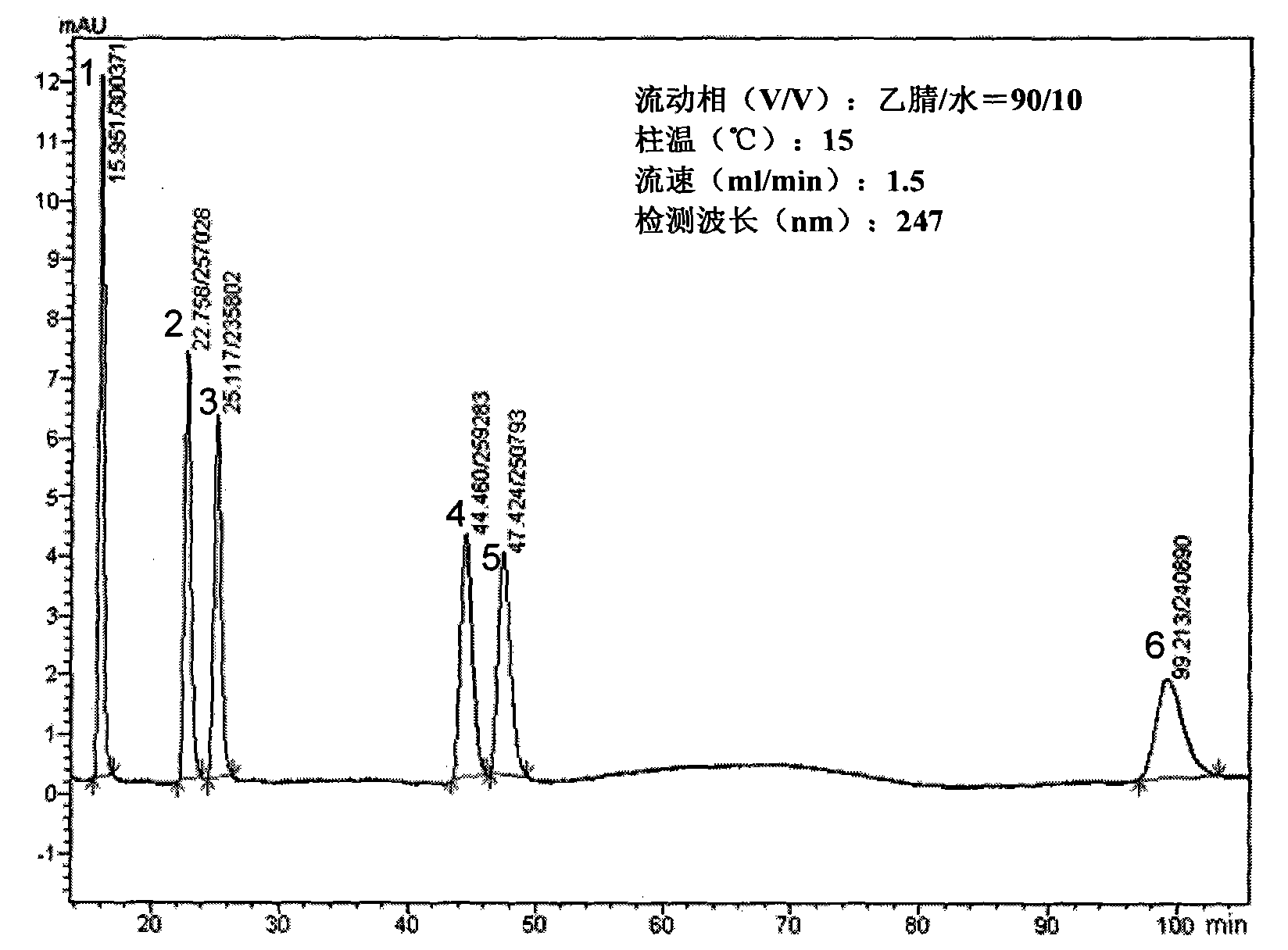

Mixed fatty acid high performance liquid phase chromatography method and application

InactiveCN101776666AImprove efficiencyShort separation timeComponent separationStearic acidPalmitoleic acid

The invention discloses a mixed fatty acid high performance liquid phase chromatography method and application thereof. In order to solve the problems that the prior art has single method in separating linolenic acid, palmitic acid, linoleic acid and other three fatty acid mixtures with very similar chemical and physical properties with HPLC, and defects in elution method, mobile phase composition selection and the like, the invention provides a method for simultaneously separating six fatty acid mixtures, i.e. linolenic acid, palmitic acid, linoleic acid, oleic acid, palmitic acid and stearic acid with HPLC. The method esterifies fatty acid solution to be tested with the acetone solution of omega-bromoacetophenone and the acetone solution of triethanolamine, and separates the solution with HPLC. The HPLC adopts an isocratic elution method, and the mixture of acetonitrile and CTAB solution or acetonitrile-water solution is selected to serve as the mobile phase. Compared with the priorart, the invention has the advantages of simple and feasible operation, good separation effect, high detection sensitivity, accurate and reliable results, and simultaneous separation of 6 fatty acids.

Owner:SICHUAN AGRI UNIV

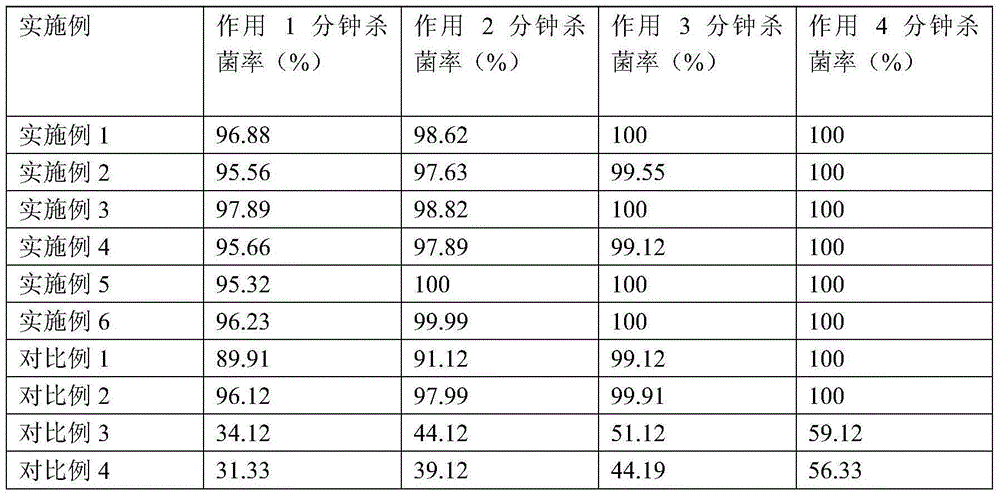

Antimicrobial nano-silver transparent soap and preparation method thereof

InactiveCN102978034APure textureMild in natureSoap detergents with organic compounding agentsAlkali/ammonium soap compositionsCelluloseGlycerol

The invention relates to a skin-care and washing product, and specifically relates to an antimicrobial nano-silver transparent soap and a preparation method thereof. The antimicrobial nano-silver transparent soap comprises a modified nano-silver solution, a surfactant and a cellulose thickening amendment and is prepared according to the following weight parts: 5-15 parts of glycerol, 5-10 parts of propylene glycol, 10-25 parts of sodium palmitoleate, 8-12 parts of sodium cocoate, 5-12 parts of sodium stearate, 10-20 parts of sodium myristate, 8-15 parts of stearic acid, 2-6 parts of EDTA-4Na, 10.5-26.5 parts of a mixed soluble surfactant, 4-12 parts of the modified nano-silver solution, 6-18 parts of the cellulose thickening amendment and 1-5 parts of essence. The soap has pure quality, mild property, rich and meticulous foam and strong decontamination capability, has the function of antisepsis and anti-inflammation, and has very good moistening and protecting effects for human skins.

Owner:YANCHENG CITY HUZHENG NANO MATERIAL SCI & TECH

Biomarker combination for early diagnosis and prediction for Alzheimer's disease or mild cognitive impairement for the old, and application and measuring method thereof

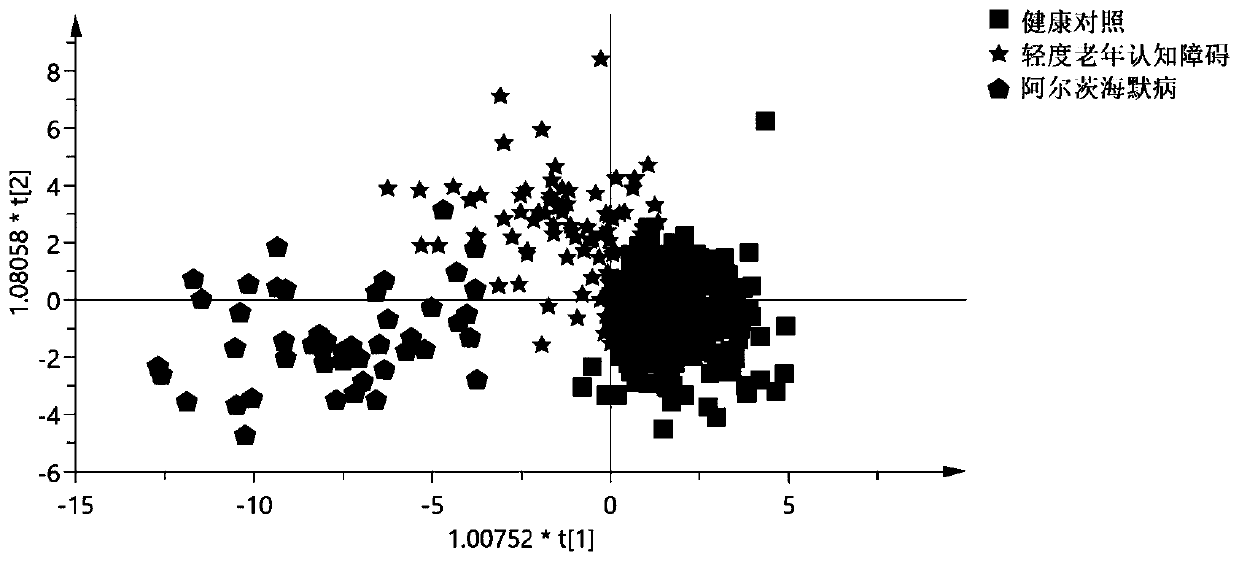

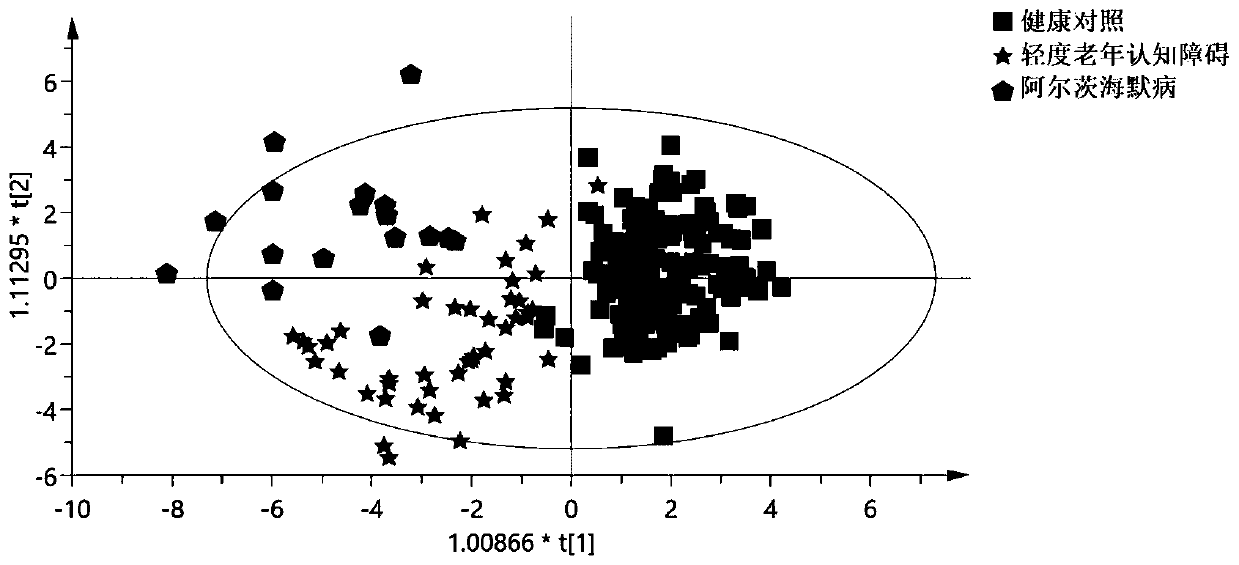

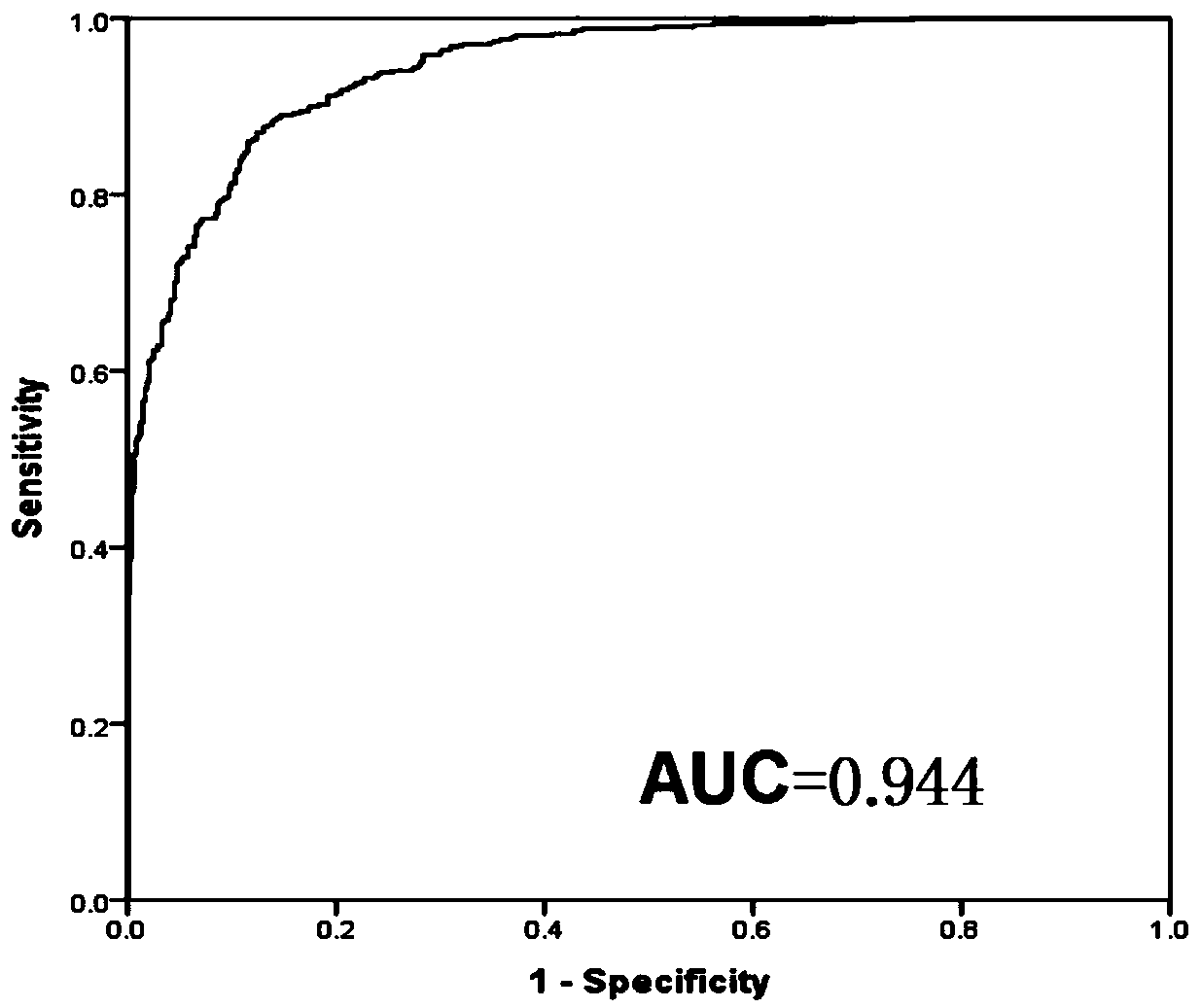

InactiveCN109709235AEffective access to treatmentImprove clinical efficacyComponent separationBiological testingDiseaseOld patients

The invention discloses a biomarker combination for early diagnosis and prediction for Alzheimer's disease or mild cognitive impairement for the old, and application and measuring method thereof. Thebiomarker combination comprises one or combination of arachidonic acid, thymine, linoleic acid, palmitic acid, palmitoleic acid, myristic acid, petroselinic acid, GLCA, CA, and DCA and the like. According to the invention, the serum or plasma of an old patient with the Alzheimer's disease or mild cognitive impairement is processed by a liquid / gas chromatography mass spectrometry analysis method. The diagnosis marker can be used for preparing a kit; the detection method has characteristics of high sensitivity and high specificity and has the high sensitivity and specificity in mild cognitive impairement diagnosis for the old.

Owner:马红华

Method for extracting palmitoleic acid from sea buckthorn fruit oil

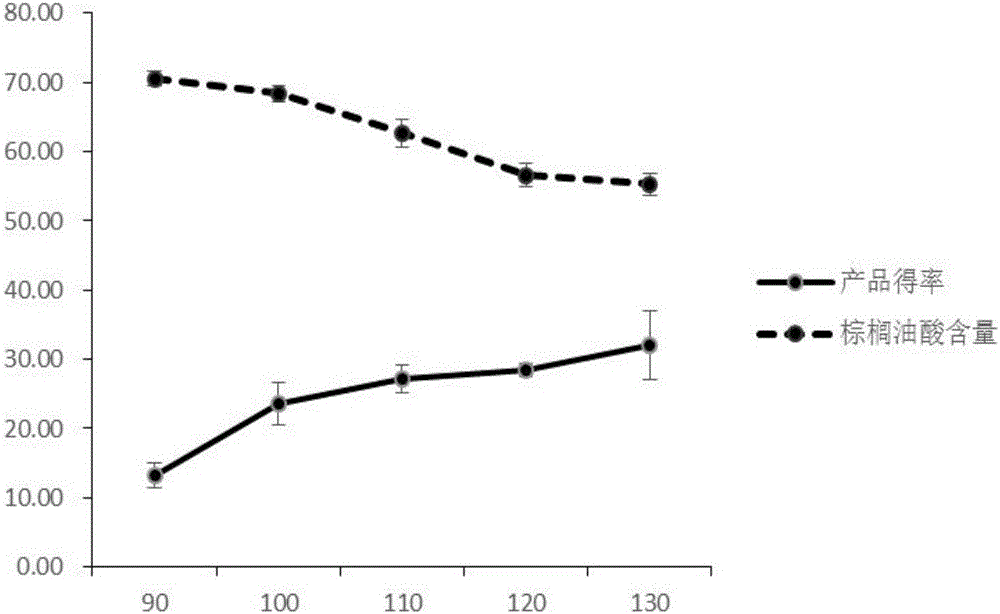

InactiveCN106010798AFill vacancySimple methodFatty acid chemical modificationFatty acids production/refiningDistillationFiltration

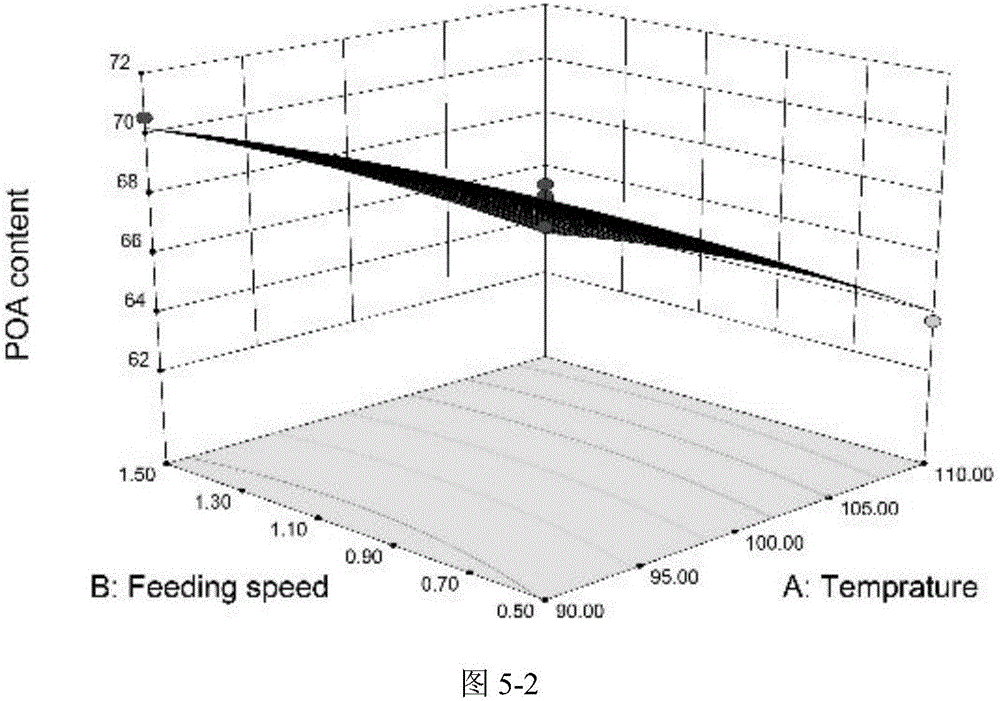

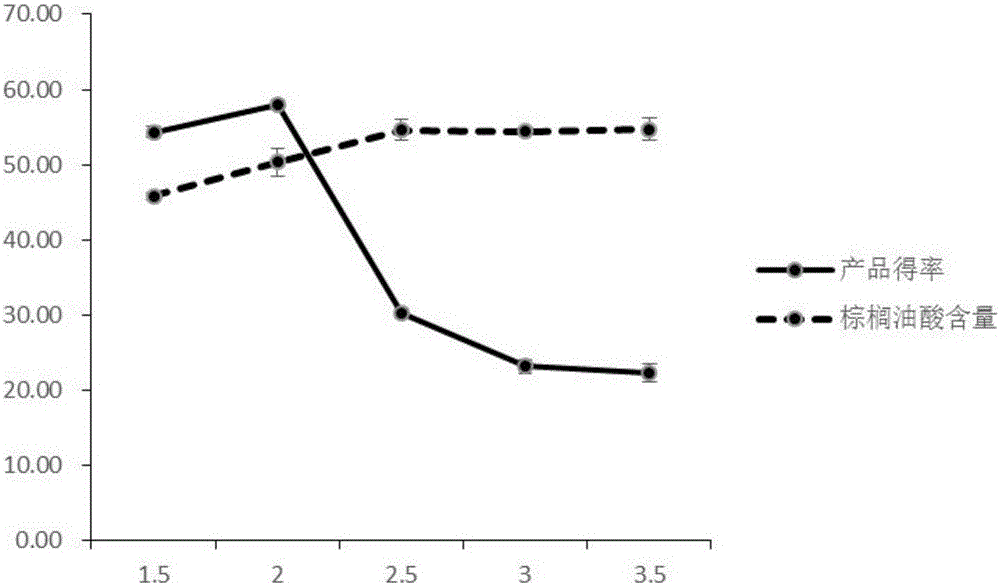

The invention relates to a method for extracting palmitoleic acid from sea buckthorn fruit oil. The method comprises the following steps that saponification treatment is conducted on a sea buckthorn fruit oil sample, and saponified sea buckthorn fruit oil mixed fatty acid is obtained; urea and a commonly-used organic solvent are mixed and subjected to stirring refluxing to enable urea to be completely dissolved, then the sea buckthorn fruit oil mixed fatty acid is added, refluxing extraction is conducted for 30 min to 120 min, and cooling is conducted to room temperature; suction filtration is conducted rapidly after embedding crystallization is conducted, the commonly-used organic solvent in filtrate is removed, urea in the filtrate is destroyed, and a fatty acid sample is obtained; the fatty acid sample obtained after urea embedding is conducted is treated, a light component with the average free path length is separated on the conditions that the pressure ranges from 0.1 Pa to 0.2 Pa, the distillation temperature ranges from 70 DEG C to 140 DEG C, and the feeding speed and the film scraping rotating speed are guaranteed to form homogeneous films, and palmitoleic acid is obtained. According to the method for extracting palmitoleic acid from the sea buckthorn fruit oil, the method is simple and convenient to operate, the content of obtained palmitoleic acid exceeds 80% of the total mass of the product, the yield of palmitoleic acid can be greatly increased, and the vacancy of domestic palmitoleic acid products is filled up.

Owner:TIANJIN UNIV OF SCI & TECH

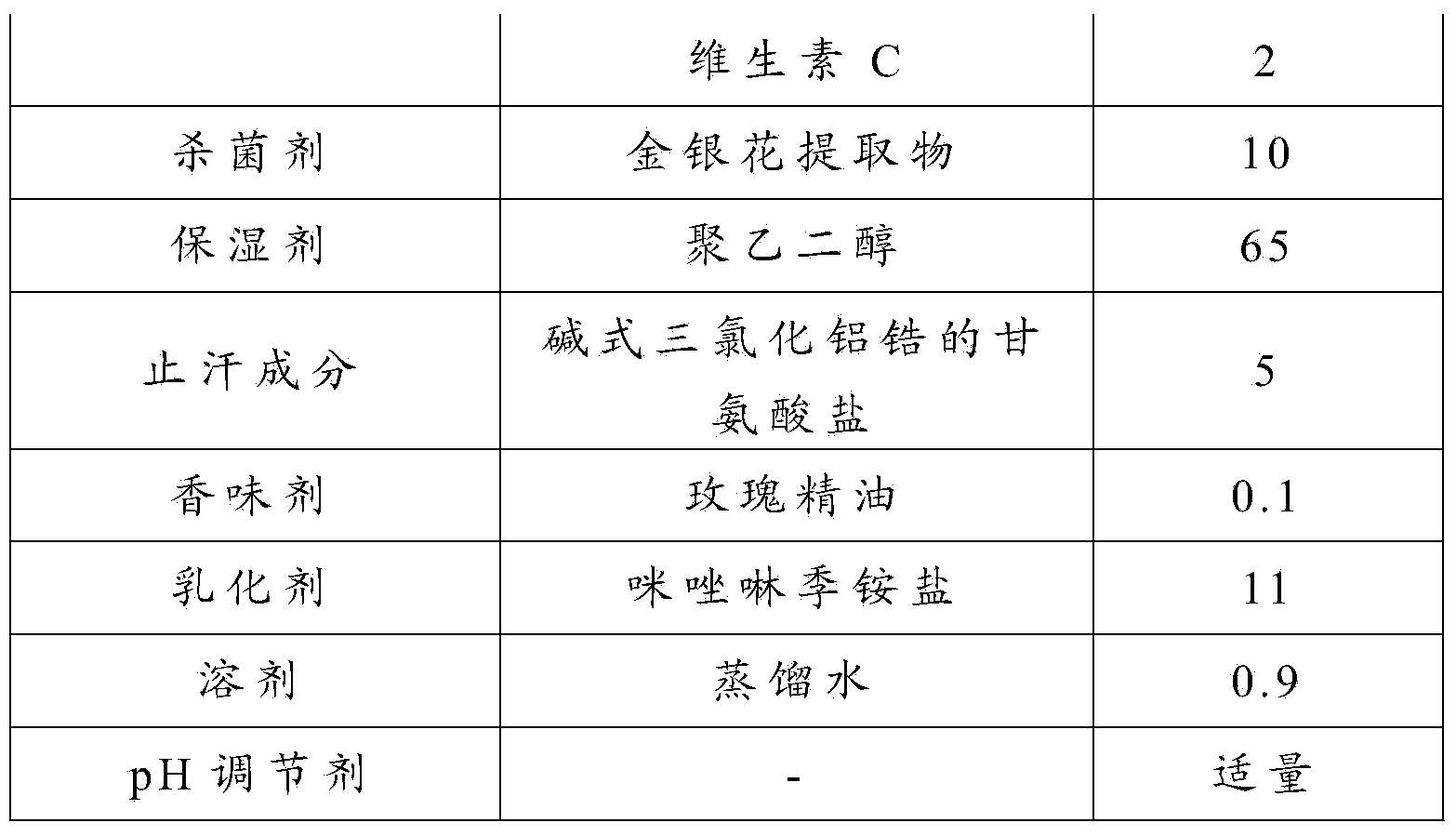

Composition for inhibiting body odor and tissue applying composition

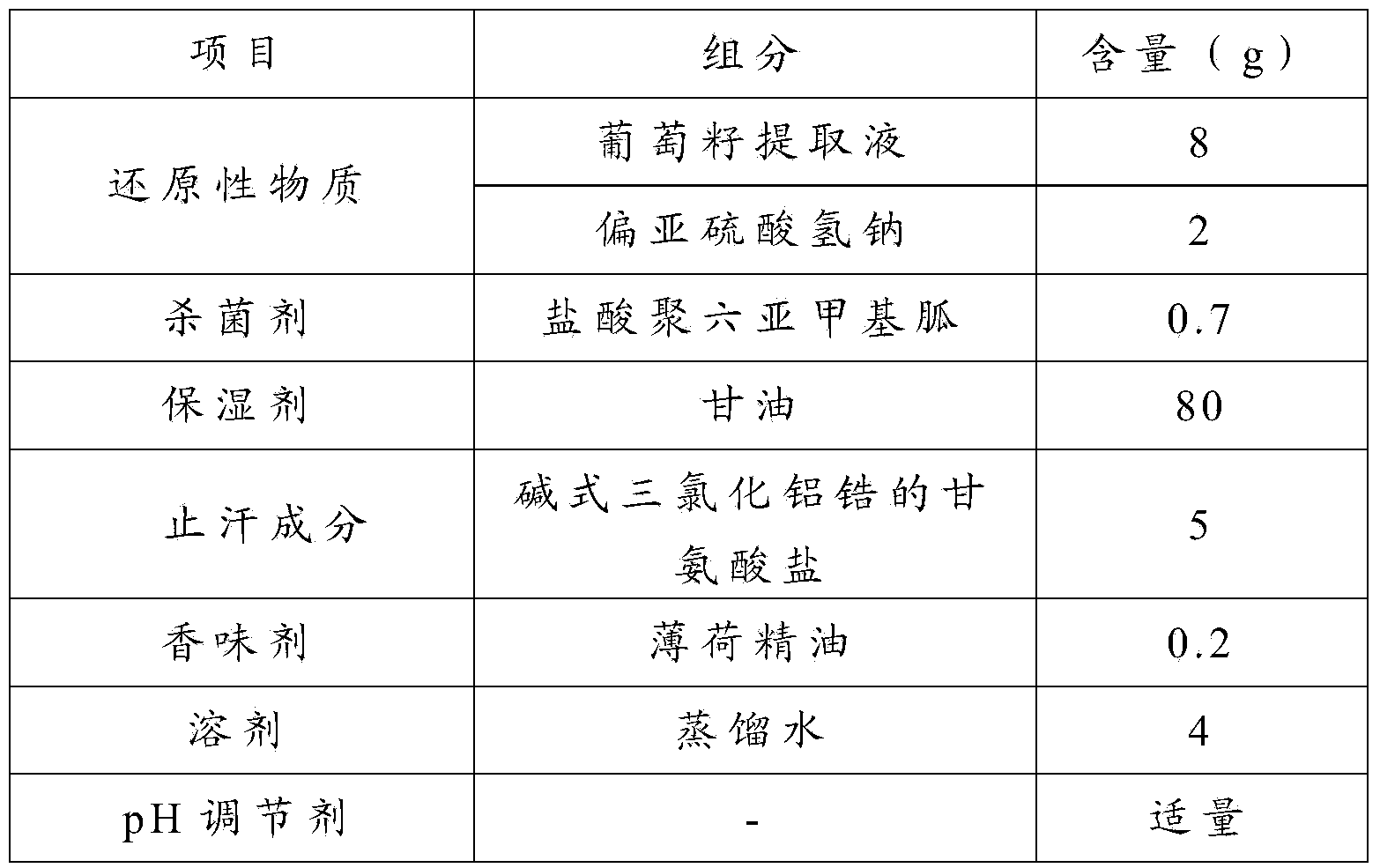

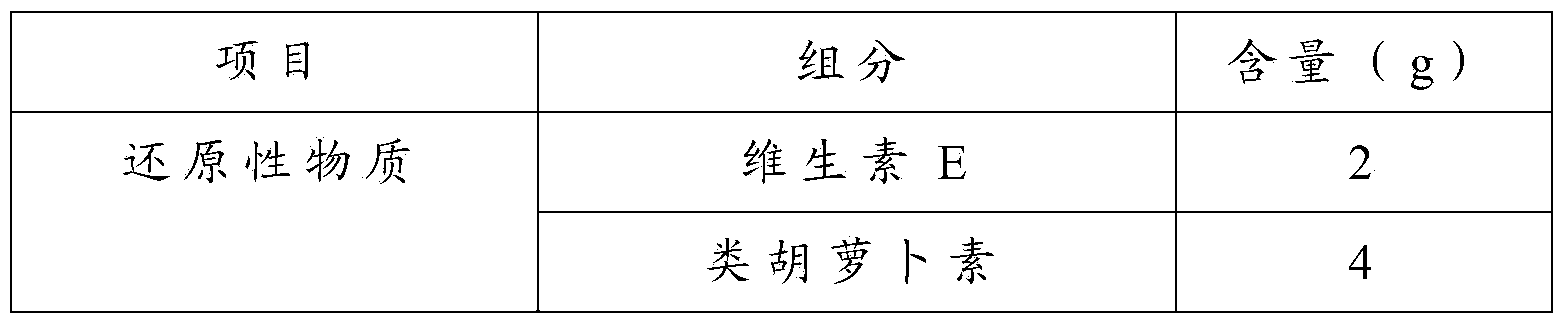

InactiveCN103585072AImprove water retentionCurb body odorCosmetic preparationsToilet preparationsPhysiologySkin surface

A composition for inhibiting body odor comprises a reducing substance, a sterilizing agent, a moisturizing agent and an anhidrotic ingredient, wherein the mass ratio of the reducing substance to the sterilizing agent to the moisturizing agent to the anhidrotic ingredient is (0.1-20):(0.05-10):(30-99):(0.1-20). The invention further provides a tissue containing the composition for inhibiting body odor. The composition for inhibiting body odor (body odor increased with aging) increases the amount of water kept in the surface of the skin, meanwhile, the rate of sebum secretion of palmitoleic acid is inhibited, an oxidative product of palmitoleic acid, 2-nonenoic acid, is decomposed, and the probability of occurrence of the body odor increased with aging is reduced. The tissue is carried along with a person, the composition for inhibiting the body odor on the tissue can be rapidly transferred to the surface of the skin while a consumer uses the tissue to wipe sweat or dirty marks, so that the body odor is effectively inhibited.

Owner:GOLD HONG YE PAPER

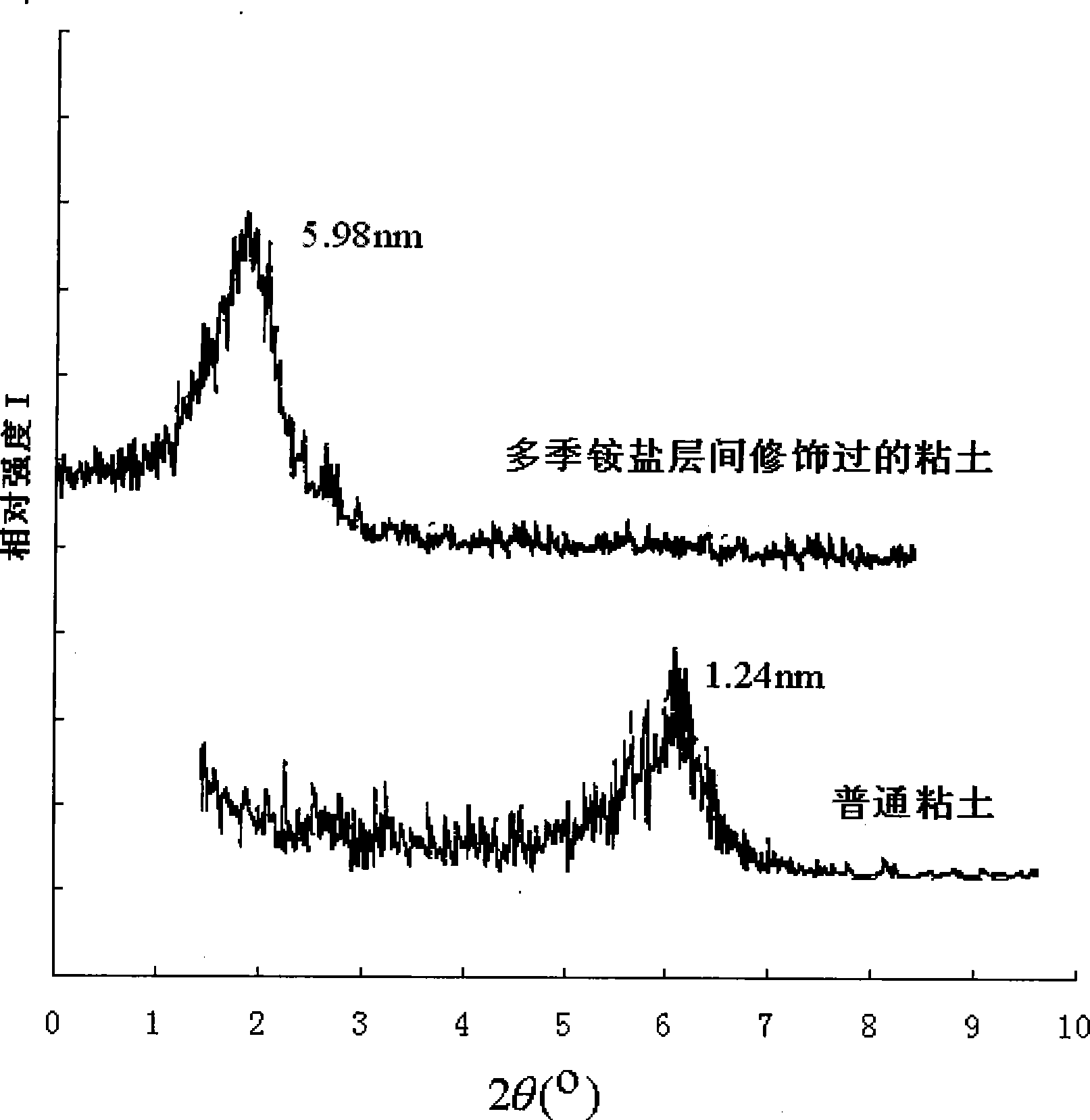

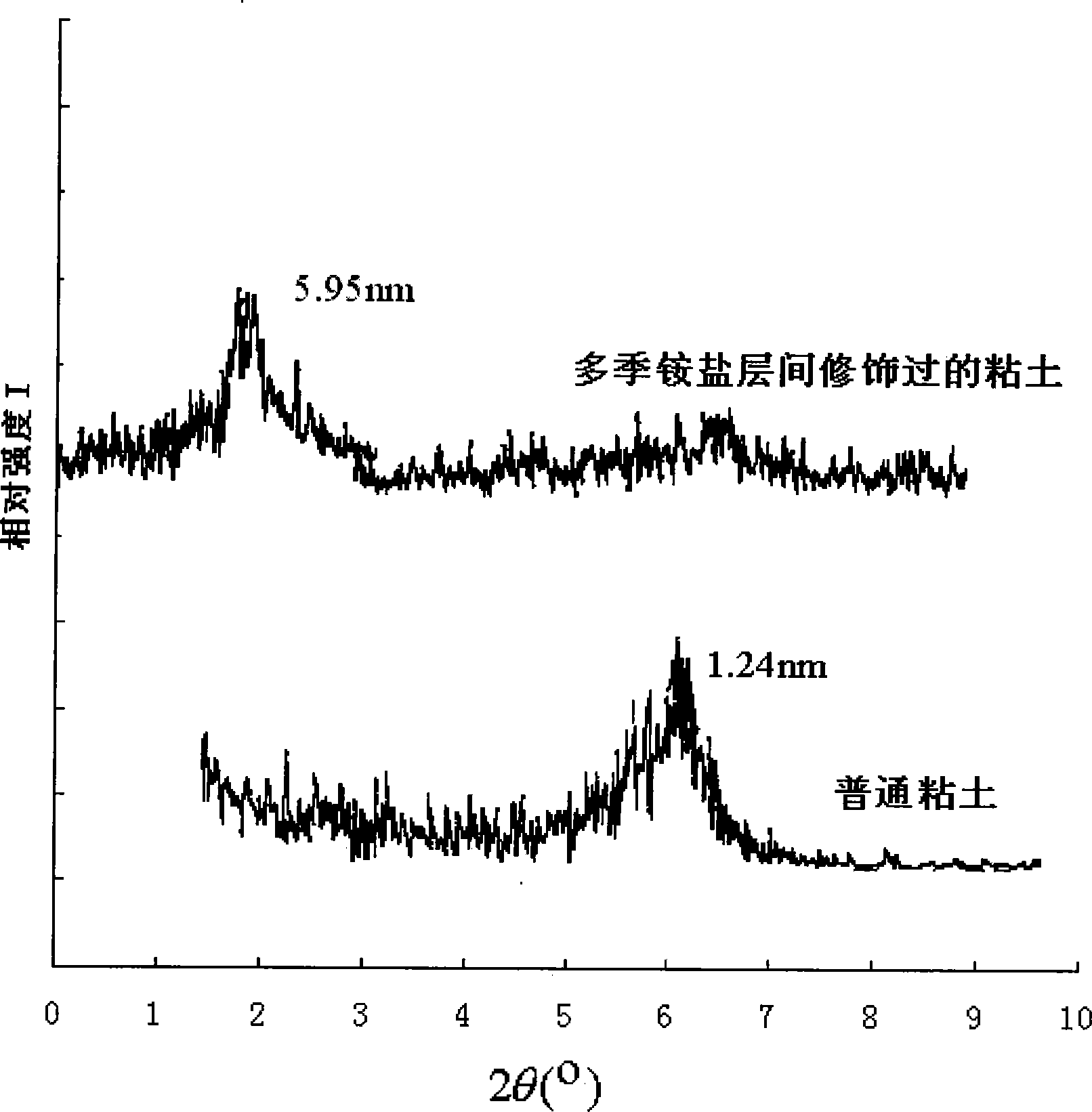

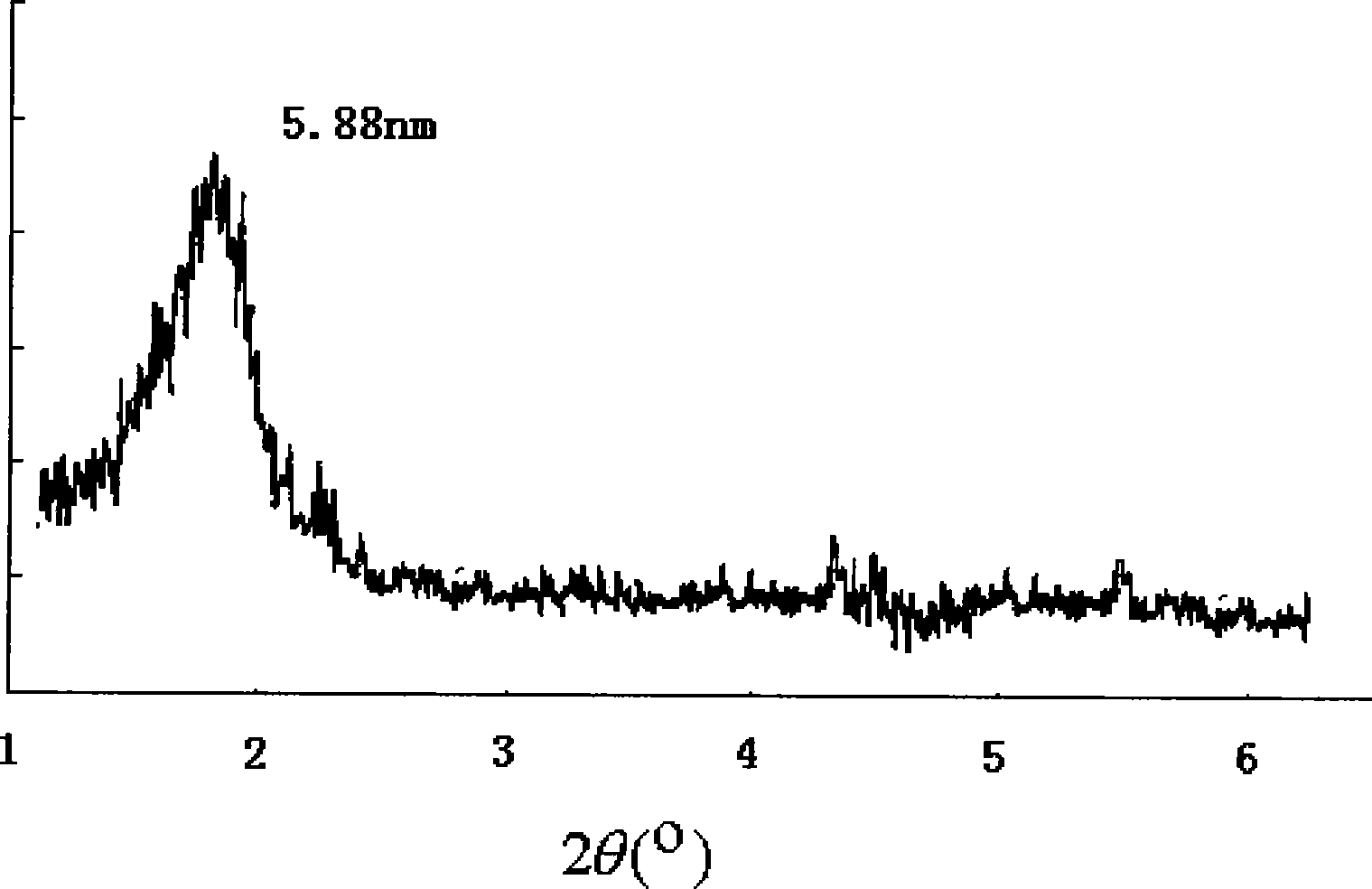

Multiple quaternary ammonium salts clay interlaminar modifier and preparation method thereof

The invention discloses multiple quaternary ammoniums salts type clay-intercalated modification agent and a process for preparation. The steps of the process for preparation comprise 1) dissolving unsaturated fatty acid into dimethylbenzene and mixing with catalyst, heating up to 180-220 DEG C, then adding with diethylenetriamine to react and obtaining bisamide, 2), mixing the bisamide with ethanol, heating up to 30-40 DEG C, adding with polyethylene polyamine and reacting at the temperature of 70-80 DEG C, wherein the unsaturated fatty acid is nutmeg oleic acid, kittul oleic acid, oleic acid, castor-oil plant oleic acid or erucic acid, the polyethylene polyamine is quadrol, triethylene tetramine, tetraethylene pentamine or 3-chlorine-2-hydroxypropyl trimethylammonium, the mol ratio of the unsaturated fatty acid, diethylenetriamine and polyethylene polyamine is 1.5-2:0.8-1:0.8-1. The multiple quaternary ammoniums salts type clay-intercalated modification agent provided by the invention increases solubility and suspension property of clay in water, and can enlarge the distance of the clay-intercalated from 1.24nm to 5.98nm.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Topical regulation of triglyceride metabolism

InactiveUS20050244359A1Elevated triglyceride levelImprove skin conditionCosmetic preparationsHair removalLipid formationTriglyceride metabolism

The present invention relates to methods of topically applying compositions useful in enhancing triglyceride concentration in the lipid barrier of the skin comprising an effective amount of palmitoleic acid, or derivatives thereof, as the sole fatty acid component in combination with a pharmaceutically or cosmetically acceptable carrier. Such compositions are useful in the treatment or prevention of dry skin and conditions in which the skin's lipid barrier is defective or damaged.

Owner:COLOR ACCESS

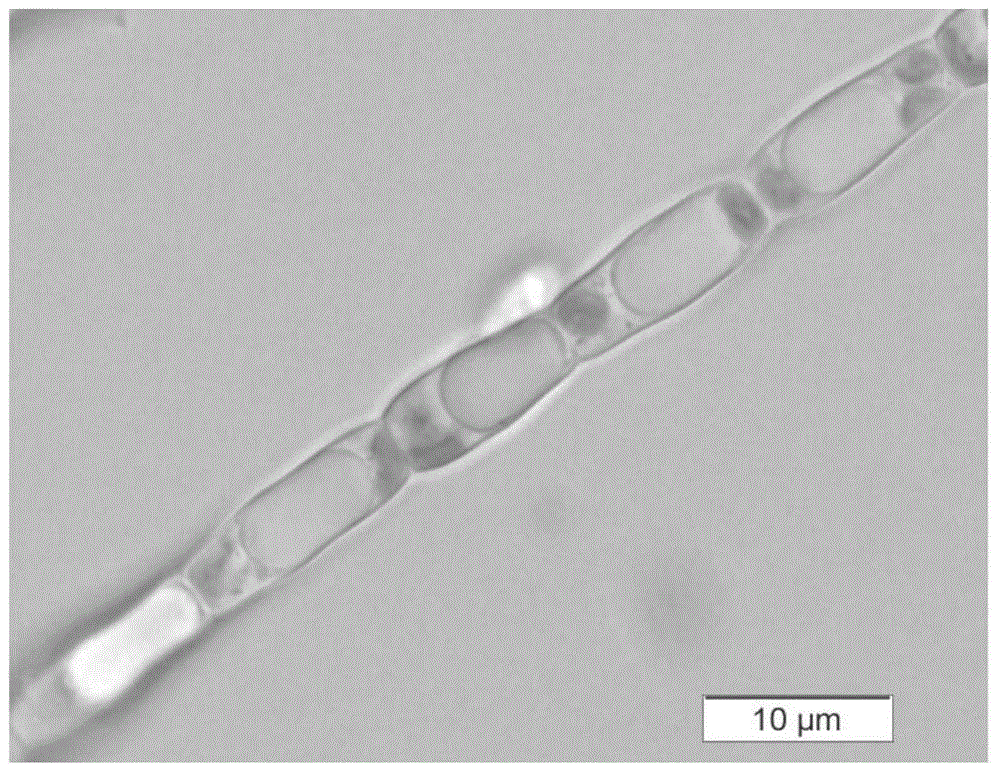

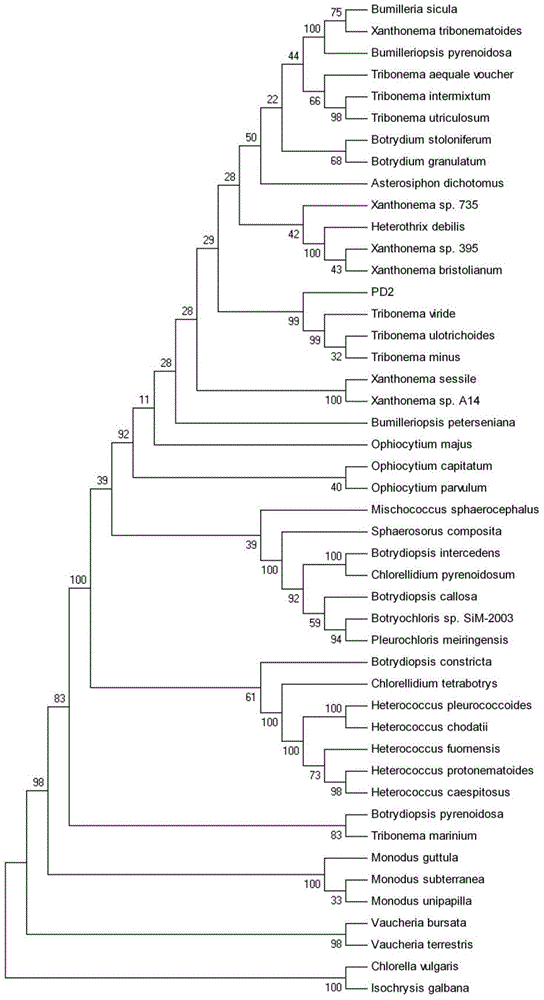

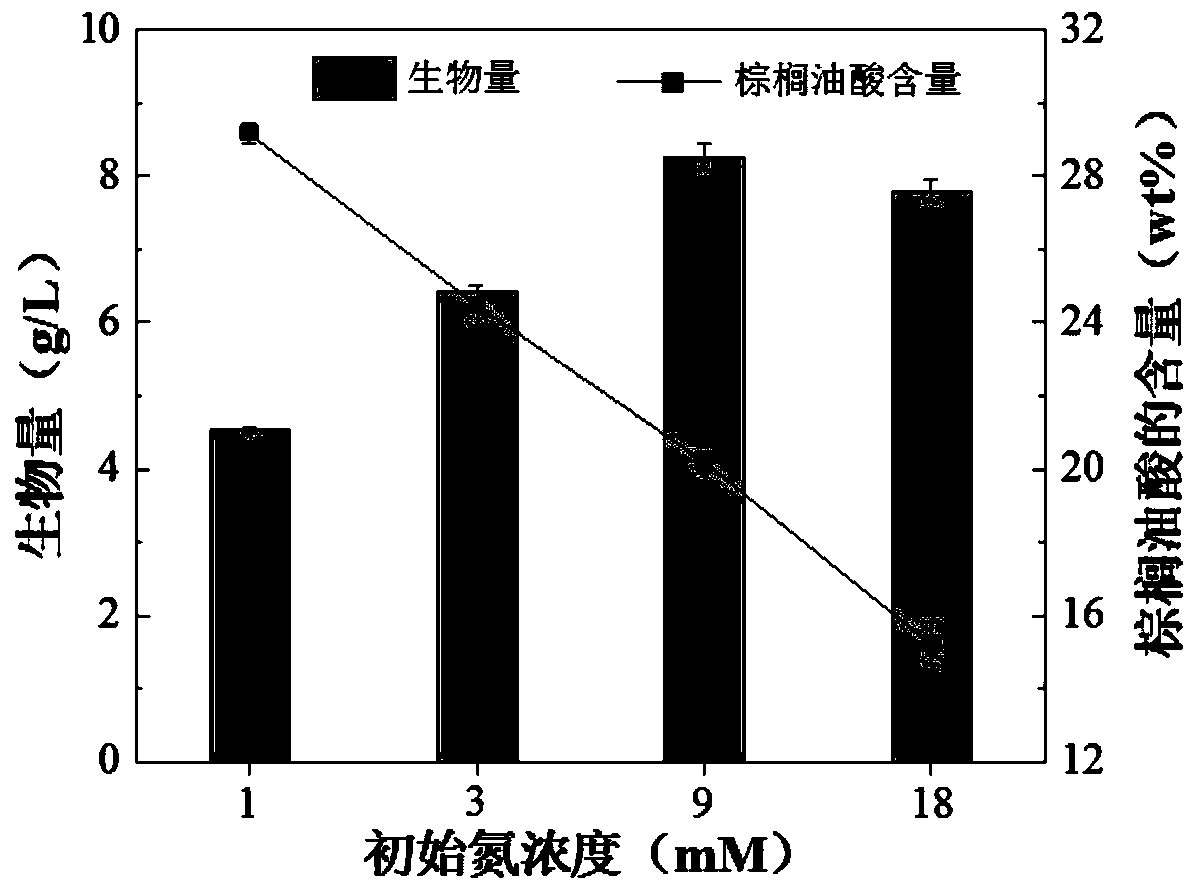

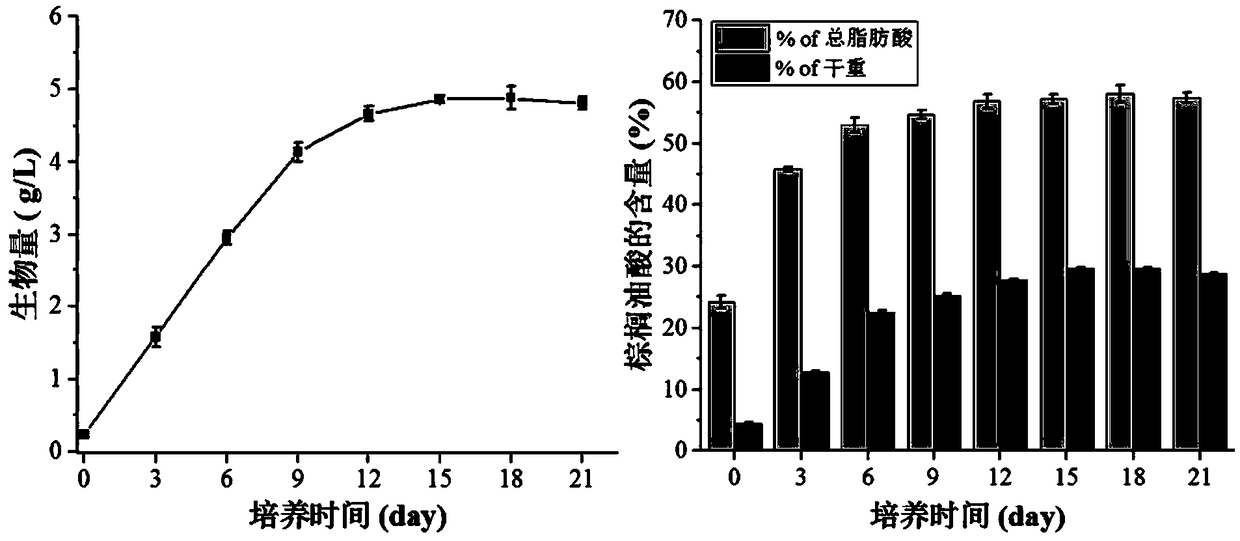

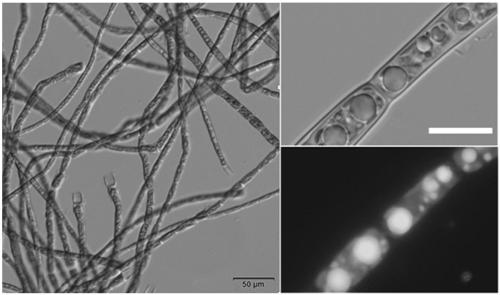

Novel-type tribonema and cultivation and application thereof

The invention discloses a Tribonema sp. PD2 strain with a preservation number of CGMCC No.10488, and application thereof in the production of biodiesel, palmitoleic acid, feed, food, skin care products, and therapeutic drugs for cardiovascular and cerebrovascular diseases, and in the carbon dioxide emission reduction, and waste gas treatment and / or wastewater treatment. The Tribonema sp. PD2 strain has the advantages of fast growth, high biomass and easiness in harvesting, and is suitable for industrial application. The oil content of the Tribonema sp. PD2 strain is as much as 60% or more of the dry biomass, wherein the content of C16-C18 is as much as 85% of the total fatty acids, the content of the palmitoleic acid (C16:1omega7) is no less than 45% of the total fatty acids, and the content of the total unsaturated fatty acids is as much as 65% of the total fatty acids. Therefore the Tribonema sp. PD2 strain is especially suitable for the production of biodiesel and the development of health care products and foods.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Oxidixable fatty acid composition delivery form

The present invention provides a chewable oral delivery vehicle comprising a chewable matrix and at least one soft gelatin capsule encapsulating an oxidizable fatty acid composition, wherein the at least one soft gelatin capsule is incorporated into the chewable matrix. The chewable matrix may be a gummy candy or jelly sweet. The oxidizable fatty acid composition may be a free fatty acid composition, fatty acid ester composition, glyceride composition, phospholipid composition or combinations thereof, and preferably comprise one or more fatty acids or residues thereof selected from the group consisting of eicosapentaenoic-, docosahexaenoic-, docosapentaenoic-, conjugated linoleic-, palmitoleic-, trans palmitoleic-, alpha linolenic-, gamma linolenic-, and stearidonic acid and combinations thereof.

Owner:INNOLIPID

Ferment compound soap and manufacturing method thereof

InactiveCN105087188AUnique mildnessImprove hard water resistanceSkin careAlkali/ammonium soap compositionsAntioxidantSkin surface

The invention discloses a ferment compound soap and a manufacturing method thereof. The ferment compound soap is composed of the following raw materials in percentage by weight: 72.5-98.05% of sodium palmitoleate-sodium palm kernelate compound soap base, 0.1-20.0% of amino acid surfactant, 0.01-2.0% of titanium dioxide, 0.05-0.5% of metal ion chelator, 0.01-0.5% of antioxidant, 0.5-2.5% of essence and 0.5-5.0% of ferment. The compound soap has the advantages of hard water resistance and high skin moistening effect, and can bring a pleasant use sense to the consumer. After the compound soap is used, the skin surface is moist and smooth, and is not tight and dry.

Owner:古吉生物科技(大连)有限公司

Collecting agent improving filtering effect for phosphorite floatation and preparing method of collecting agent

The invention relates to a collecting agent improving the filtering effect for phosphorite floatation and a preparing method of the collecting agent. The collecting agent is prepared from, by weight, 10-30 parts of coconut oil, 40-60 parts of palmitoleic acid and 30-50 parts of colza oil oleic acid. The mixture obtained after saponification of the coconut oil, the palmitoleic acid and the colza oil oleic acid is taken as 100 parts, and then 5-8 parts of penetrating type surface active agent is added. The preparing method includes the following steps that 10-30 parts of coconut oil, 40-60 parts of palmitoleic acid and 30-50 parts of colza oil oleic acid are mixed, and the mixture is heated to the temperature of 100-120 DEG C so that the mixture can be sufficiently dissolved and mixed; 150-170 parts of sodium hydroxide is added, and saponification is conducted for 50-70 minutes under the condition of the temperature of 70-90 DEG C; and then the mixture obtained after saponification is taken as 100 parts, 5-8 parts of infiltration type surface active agent is added to be evenly mixed, and therefore the collecting agent improving the filtering effect for phosphorite floatation is prepared. According to the collecting agent, qualified floatation indexes can be ensured, subsequent filtering efficiency of concentrate and tailings can be better improved, it is ensured that the water content of the filtered concentrate and tailings is smaller than 10%, and meanwhile production efficiency is greatly improved.

Owner:HUBEI FORBON TECH

Grease composition and preparation method thereof

InactiveCN105779141ALower requirementExpand sourceFatty acid esterificationEdible oils/fatsPalmitoleic acidOleic Acid Triglyceride

The invention relates to a grease composition and a preparation method thereof. The preparation method for the grease composition comprises a step of random ester interchange, i.e., a step of subjecting grease to random ester interchange, wherein the content of oleic acid in the grease is 40 wt% or above, and / or the content of palmitic acid in the grease is 25 wt% or above. In the grease composition, Sn-2 palmitic acid accounts for 30 to 80 wt% of the total palmitic acid content and / or Sn-2 palmitoleic acid accounts for 20 to 60 wt% of total palmitoleic acid content. The method provided by the invention greatly reduces requirements on raw materials; and compared with the prior art, the method has the advantage that the content of Sn-2 in raw grease needs no control, so the scope of sources of raw grease is greatly broadened. The proportion of palmitoleic acid in the grease composition and the proportion of Sn-2 palmitoleic acid in the total palmitoleic acid are similar to those in fat of breast milk.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Preparation method for extracting palmitoleic acid from fish oil

InactiveCN105461539ANo obvious fishy smellHigh purityPreparation from carboxylic acid esters/lactonesDistillationFish oil

A preparation method for extracting palmitoleic acid from fish oil comprises the steps of acid removal, decoloring, deodorization, ethyl esterification, multistage molecular distillation treatment, urea inclusion, redistilling and the like; the prepared palmitoleic acid is a yellow or faint yellow transparent liquid, and has the advantages of no obvious fishy smell, high purity, and high yield and quality.

Owner:ZHOUSHAN OCEAN FISH OIL

Linolenic acid health edible oil and prickly ash seed dregs and its preparing method

InactiveCN1943372AHigh economic valueEffective separation and removal of impuritiesEdible oils/fatsFood preparationAcid valueEdible oil

A method for the preparation of edible oil rich in linolenic acid and the cake of zanthoxy lum seed, includes the steps: (1)preparing crude oil, includes choosing fresh zanthoxy lum seed, rolling seed kernel, leaching out oil; (2)refining, includes hydration degumming, deacidifing by adding alkali, washing away impurity, dehydrating, decolouring and deodouring. Said oil comprises: palmic acid 8-15%, palmitoleic acid 5-15%, oleic acid 30-40%, linolic acid 20-35%, alpha-linolenic acid 10-18%. The cake of zanthoxy lum seed is produced at the same time. Said method can control oil acid value and peroxide value and said oil has health-care function.

Owner:保靖土司王花椒科技开发有限公司

Fatty acid composition and plant extract and pharmaceutical preparation and application thereof

ActiveUS20140287076A1No side effectsNo irritationCosmetic preparationsBiocideArachidic acidActive component

A fatty acid composition containing linoleic acid, linolenic acid and oleic acid is provided. Also provided is a fatty acid composition containing linoleic acid, linolenic acid and oleic acid, and at least one selected from palmitinic acid, palmitoleic acid, stearic acid, arachidic acid and docosanoic acid. A plant extract and a pharmaceutical preparation are provided, wherein the pharmaceutical preparation contains an active component including at least one of the fatty acid composition, the plant extract and modified products thereof. Also provided is an application of the fatty acid composition, the plant extract and the pharmaceutical preparation in multiple fields. The pharmaceutical preparation may function to repair various wounds and traumas in skin, mucosa, lumina and muscular tissues.

Owner:XING JUNWU +2

Metal cutting lubricant

InactiveCN102899146AImprove cooling effectEasy to cleanLubricant compositionPolyethylene glycolDiethylene glycol

The invention relates to a lubricant, in particular to a metal cutting lubricant for use during cutting in machinery industry. The lubricant consists of 75 to 85% of mixture of boric acid, polyethylene glycol, fatty acid, diethylene glycol, triethylene glycol and palmitoleic acid, 0.5 to 1.8% of metal deactivator, 1 to 5% of antirust agent, 0.3 to 1% of antioxygen, 0.2 to 1.5% of extreme pressure additive and the balance of deionized water. The components are mixed according to weight percentage. The lubricant is highly efficient, environment-friendly and pollution-free and has no damage to metal surface, good cleaning, antirust and lubricating effects, no toxic effect, no odor and no corrosive effect on equipment.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

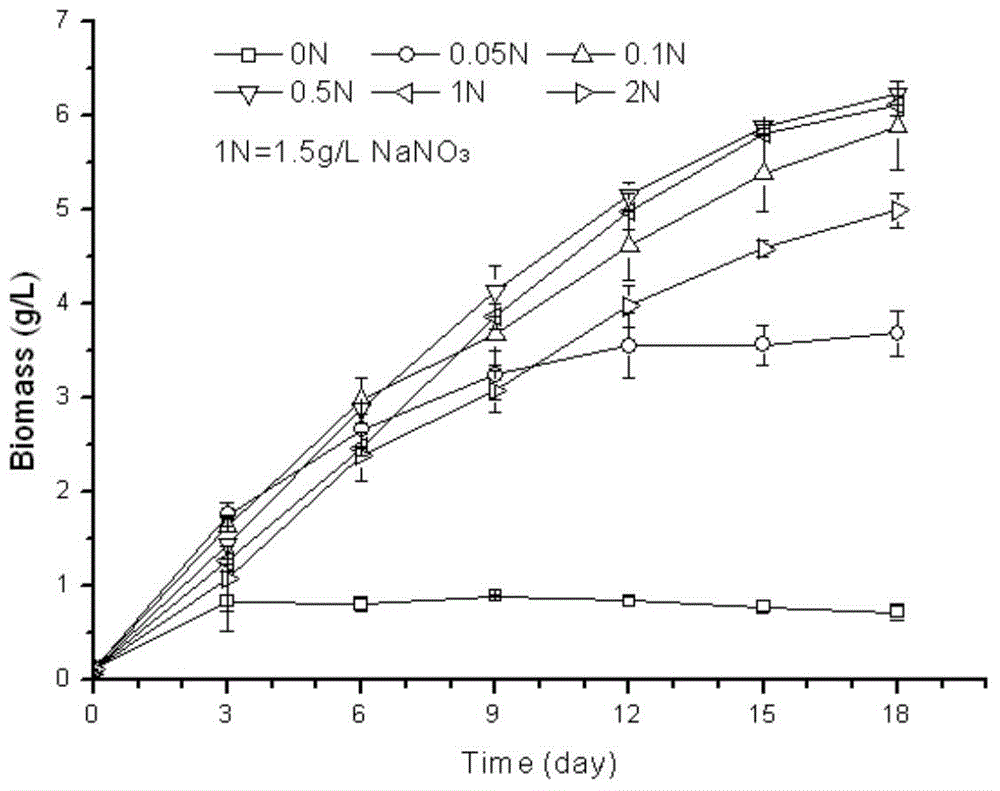

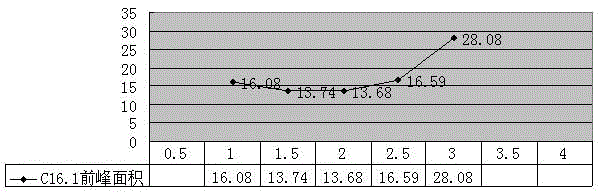

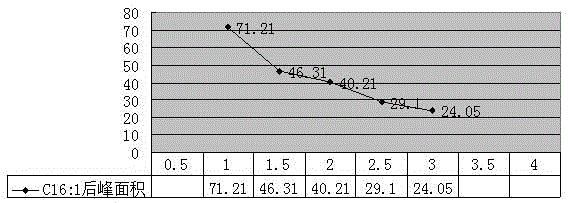

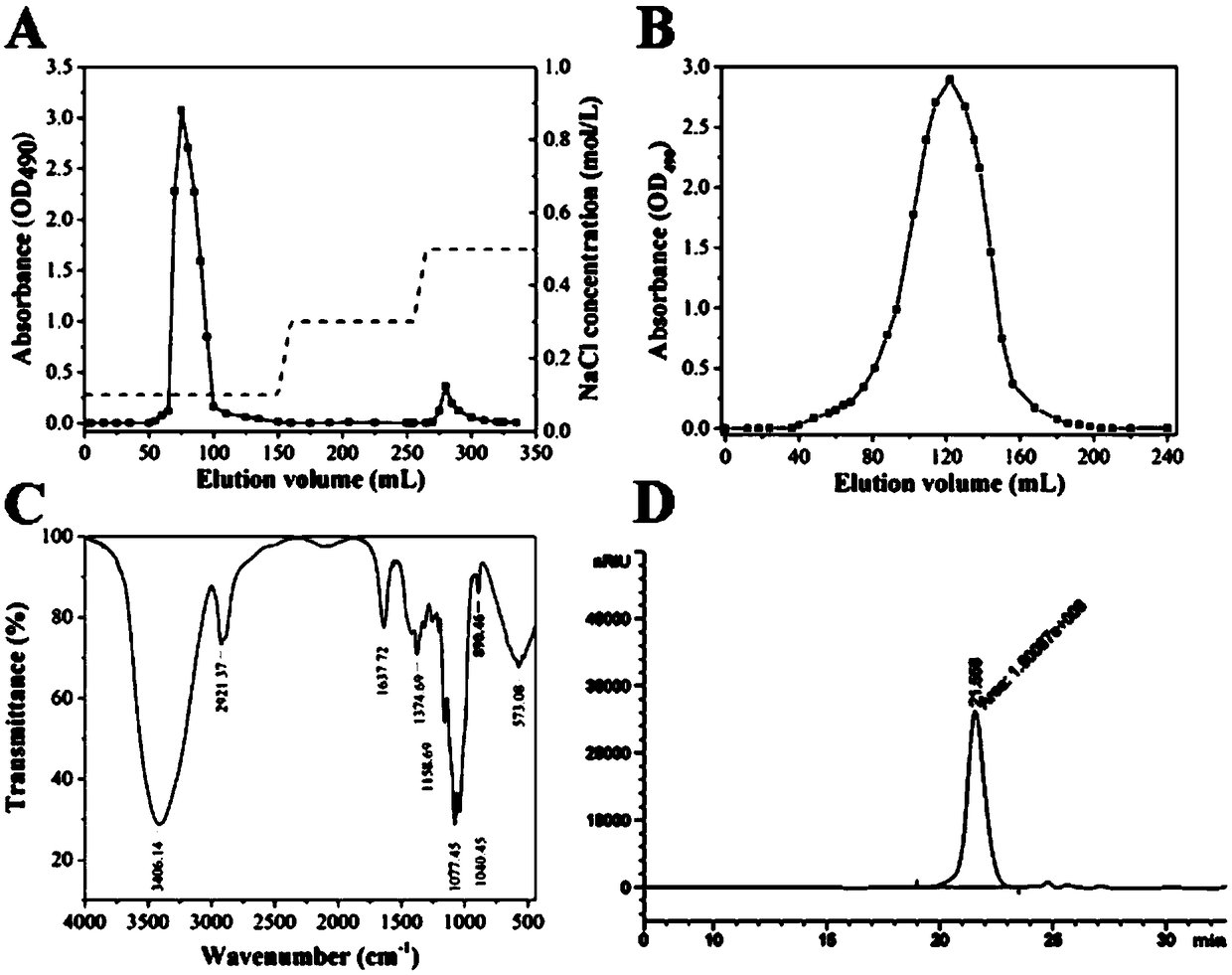

Method for producing palmitoleic acid from Eustigmatophyceae microalgae

ActiveCN109022508AHigh Palmitoleic Acid ContentAppropriate Induced Nitrogen ConcentrationMicroorganism based processesFermentationBiotechnologyPalmitoleic acid

The invention discloses a method for producing palmitoleic acid from Eustigmatophyceae microalgae, and relates to thel fields of microalga biological resources and the biotechnology. The preparation method comprises the following steps: total fat extraction, and concentrating of palmitoleic acid. The method for producing palmitoleic acid from E.cf. polyphem is green and safe, and the source of theraw material s not restricted by the geography or season, can be continuously harvested all through the year, and can meet a huge raw material gap. The preparation method for efficiently concentrating the palmitoleic acid, provided by the invention, has the advantages of simplicity in operation, high efficiency, low cost and high palmitoleic acid purity, is suitable for large-scale production, and lays a foundation for the commercial development of microalga-derived palmitoleic acid products.

Owner:JINAN UNIVERSITY

Adjuvant immunotherapy for the treatment cancer, of clinical manifestations associated with the diseases like cachexia and correction of adverse effects of drugs such as immunosuppression, secundary cachexia, neutropenia and lymphopenia, comprising the association or combination of a biological response modifier specially selected and other substances with antineoplastic action and/or other treatments

InactiveUS20160166683A1Maximize the effect of treatmentMinimize of functionalityHeavy metal active ingredientsRadioactive preparation carriersAnticarcinogenGranulocytopenias

A compound for use in a method of treatment of cancer, including precancerous lesions, and adverse events caused by the disease or anti-cancer agents and treatments, such as cancer cachexia, lymphopenia, neutropenia, febrile neutropenia includes in combination an immunomodulatory and at least one anti-cancer agent or treatment suitable for treating the disease. The immunomodulator is a proteic aggregate of ammonium and magnesium phospholinoleate-palmitoleate anhydride. The anti-cancer agent or treatment suitable for treating the disease provides synergistic effects without additional toxicity when used with the immunomodulatory. The anti-cancer treatment is selected from the following group: surgical procedures, transplantation of bone marrow cells, systemic and localized radiotherapy, and combinations thereof.

Owner:NUNES LSEU SILVA

Poult fat powder and preparation method thereof

ActiveCN105029096APromote digestion and absorptionMeet energy intakeAnimal feeding stuffBiotechnologyVitamin C

The invention belongs to the technical field of feeds, and particularly discloses poult fat powder and a preparation method thereof. The poult fat powder mainly comprises the following components in parts by weight: 10-20 parts of palmitic acid, 1-3 parts of palmitoleic acid, 3-8 parts of stearic acid, 15-20 parts of oleic acid, 5-10 parts of linoleic acid, 0.1-0.5 part of alpha-linolenic acid, 0.5-1.5 parts of arachidonic acid, 0.1-0.5 part of DHA, 0.1-0.5 part of EPA and 0.5-1.5 parts of vitamin C. The poult fat powder simulates fatty acid constitutes and proportions of fat in poultry eggs, meets the demand of poults for various fatty acids, and can be used for solving the problems that the poults have diarrhea, are high in death rate and the like due to insufficient energy intake after the brood time are solved. The poult fat powder is prepared into a special solid powder fat product for the poults, is small in particle size and high in fluidity and is easily digested and absorbed by the poults.

Owner:GUANGZHOU YOUBAITE FEED SCI & TECH

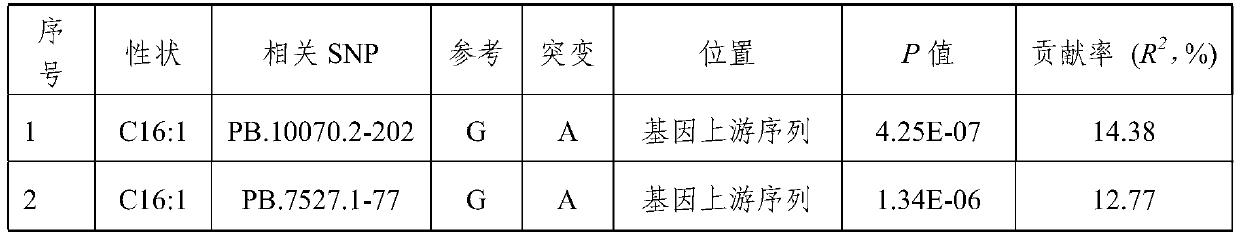

SNP molecular marker related to palmitoleic acid content in camellia oleifera seed grease and application thereof

ActiveCN111500763AImprove selection efficiencyImprove efficiencyFood processingMicrobiological testing/measurementBiotechnologyCamellia oleifera

The invention relates to the technical field of molecular markers, in particular to an SNP molecular marker related to palmitoleic acid content in camellia oleifera seed grease and application thereof. The invention provides two SNP molecular markers PB.10070.2-202 and PB.7527.1-77 related to palmitoleic acid content in camellia oleifera seed grease. The PB.10070.2-202 contains a nucleotide sequence with polymorphism of G / A at the 202nd site of the sequence shown as SEQ ID NO.1; the PB.7527.1-77 contains a nucleotide sequence with polymorphism of G / A at the 77th site of the sequence shown as SEQ ID NO.2. The two markers are used for identifying the palmitoleic acid content phenotype of camellia oleifera, seedling stage identification and auxiliary screening can be achieved, the selection efficiency of camellia oleifera breeding is effectively improved, and the breeding process is accelerated.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Light alkyd resin for interior decoration and furniture coating and preparation method thereof

The invention discloses light alkyd resin for interior decoration and furniture coating, which is formed by the following raw materials: glycerol, palmitoleic acid, benzoic acid, hexanedioic acid, neopentyl glycol, phthalic anhydride, tetramethylolmethane and dimethylbenzene; the preparation method comprises the following steps: a. the palmitoleic acid, the benzoic acid, the hexanedioic acid, the glycerin, the neopentyl glycol, the phthalic anhydride, the tetramethylolmethane and the dimethylbenzene are thrown in a reactor one time, are heated and are stirred; b. carbon dioxide gas flows in the reactor to protect temperature rise, when the temperature is raised to 130-180 DEG C and kept for 1-3 hours, at the moment, the dimethylbenzene flows back, and then the temperature is raised to 200 plus / minus 5 DEG C at the temperature raising speed with 8-12 DEG C per hour, and then the temperature is kept for 4-8 hours; c. a sample is taken out in the step b for measuring viscosity, when the viscosity reaches desired value, the temperature is cooled to 130-180 DEG C, so as to obtain the modified alkyd resin; d. the alkyd resin in the step c is transferred to another reactor, and then 2.5-8.5 percent of dimethylbenzene is added, the mixture is mixed uniformly to obtain the water-white alkyd resin liquid.

Owner:四川巴德士新材料有限公司

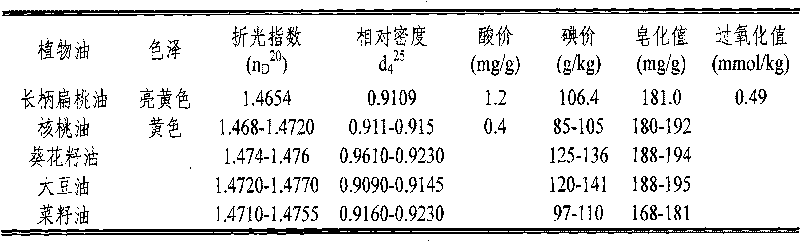

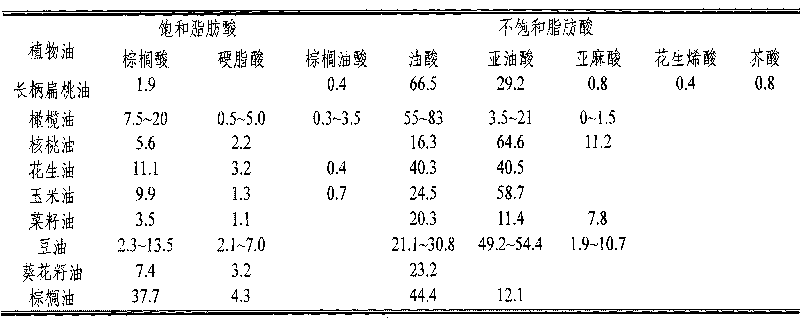

Application of amygdalus pedunculata pall oil as edible oil

InactiveCN101731367AExcellent physical and chemical indicatorsRich in nutrientsEdible oils/fatsAdditive ingredientColneleic acid

The invention discloses amygdalus pedunculata pall oil as well as an extracting preparation method thereof and application as edible oil. The amygdalus pedunculata pall oil comprises the following components according by weight percent: 1.9% of palmitic acid, 0.4% of palmitoleic acid, 66.5% of oleic acid, 29.2% of linoleic acid, 0.8% of linolenic acid, 0.4% of peanut olefine acid and 0.8% of erucic acid. The extracting method of the amygdalus pedunculata pall oil comprises the following steps of: (1) drying amygdalus pedunculata pall seeds to remove seed coats at 40-100 DEG C; (2) adding bran accounting for 1-3% of the mass of seeds after removing the seed coats, squeezing for several times (twice to four times) by a hydraulic oil mill at low temperature, combining and then filtering the oil squeezed for several times to obtain the amygdalus pedunculata pall oil. In the invention, the amygdalus pedunculata pall oil has excellent tupical properties and abundant nutrient elements and can be developed to be high-quality edible oil.

Owner:NORTHWEST UNIV(CN)

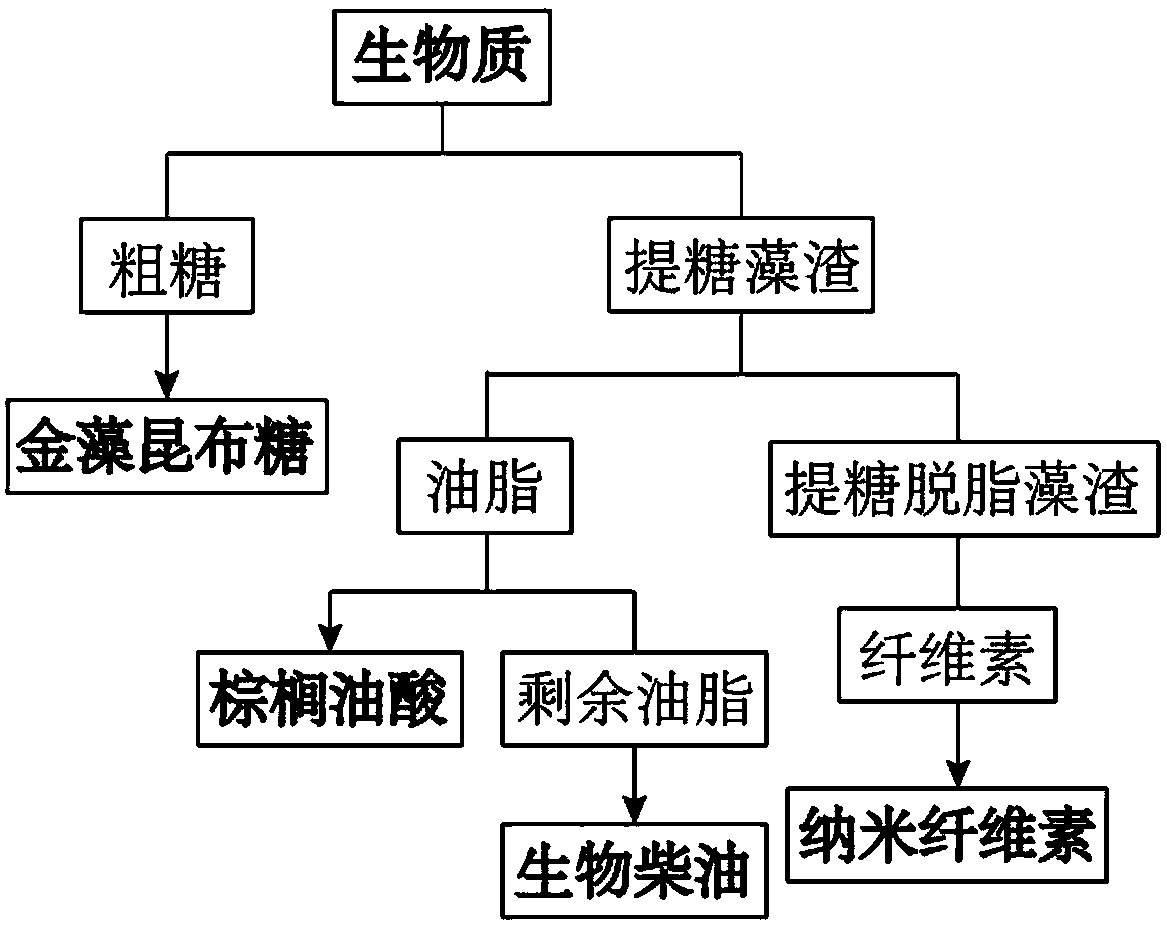

Method of utilizing tribonema to comprehensively refine biological product, biological diesel and biological material

ActiveCN109112168AEnhanced couplingImprove economyBiofuelsMicroorganism based processesBiodieselCompensation effect

The invention discloses a method of utilizing tribonema to comprehensively refine a biological product, biological diesel and a biological material. According to the method disclosed by the invention,the same biomass raw material of filiform microalgae-tribonema is utilized to jointly produce palmitoleic acid, chrysolaminaran, biological diesel and nano cellulose. The microalgae biomass resourceis comprehensively utilized, so that the biological product, biological energy and a biological nanomaterial in the microalgae industry can be better coupled, and economic effects are effectively improved. According to the method disclosed by the invention, a biological refining technical route of a high-efficiency and reasonable tribonema biomass resource is established for the first time; namely, diluted acid is utilized to treat microalgae biomass at first to extract intercellular polysaccharide; furthermore, cell wall structures can be loosened, the next step of grease extraction is more facilitated, and finally residual algae dregs can be fully utilized. The technical route obviously reduces production cost, improves microalgae biomass utilization efficiency and has an obvious compensation effect.

Owner:JINAN UNIVERSITY

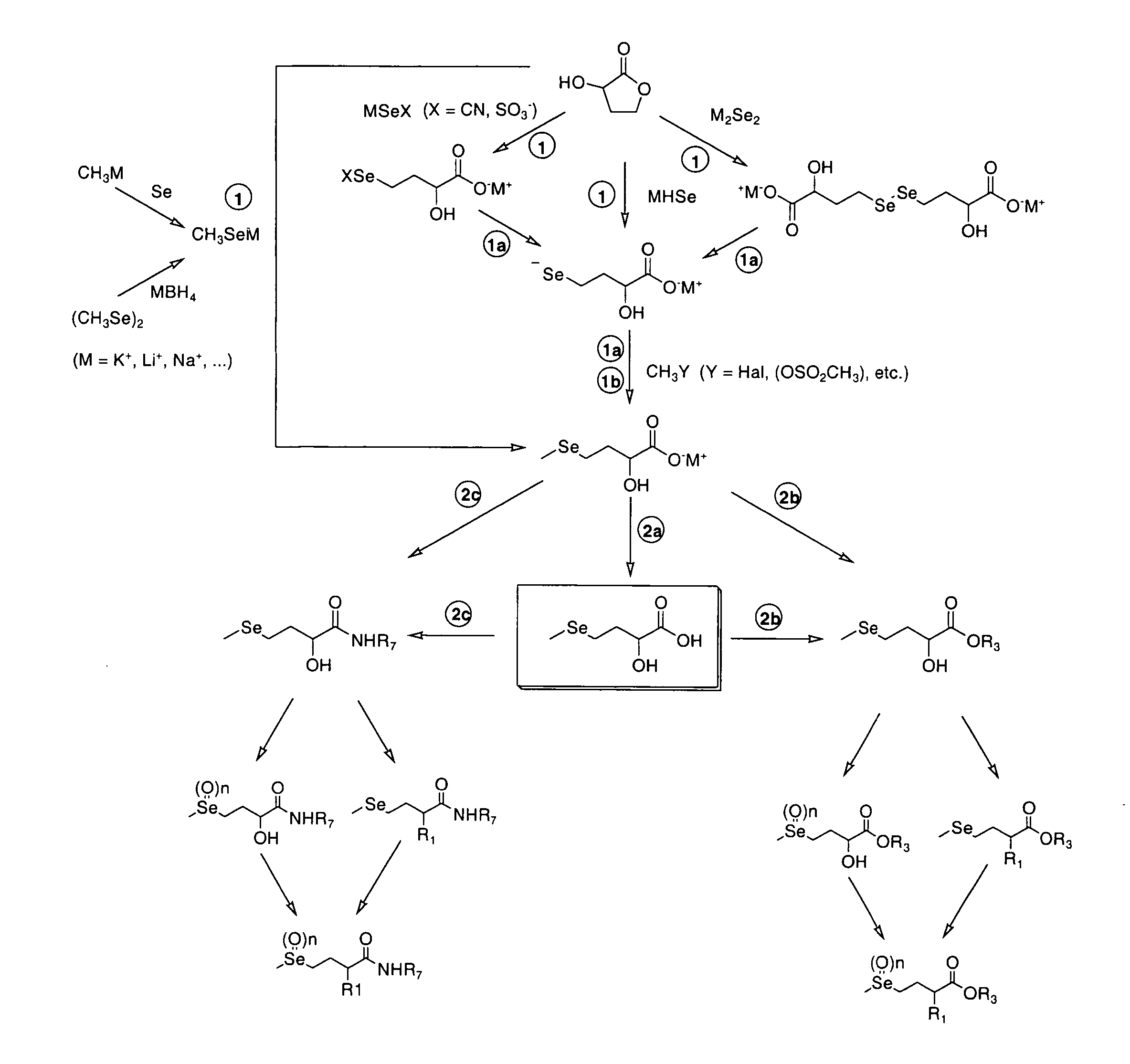

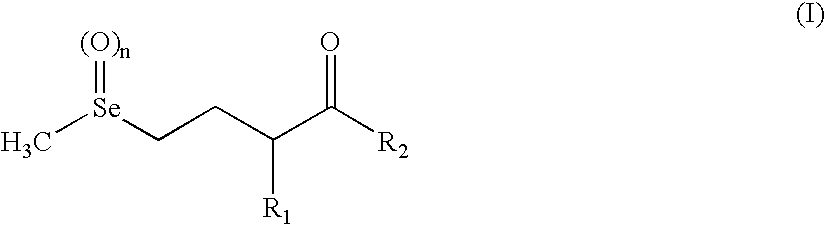

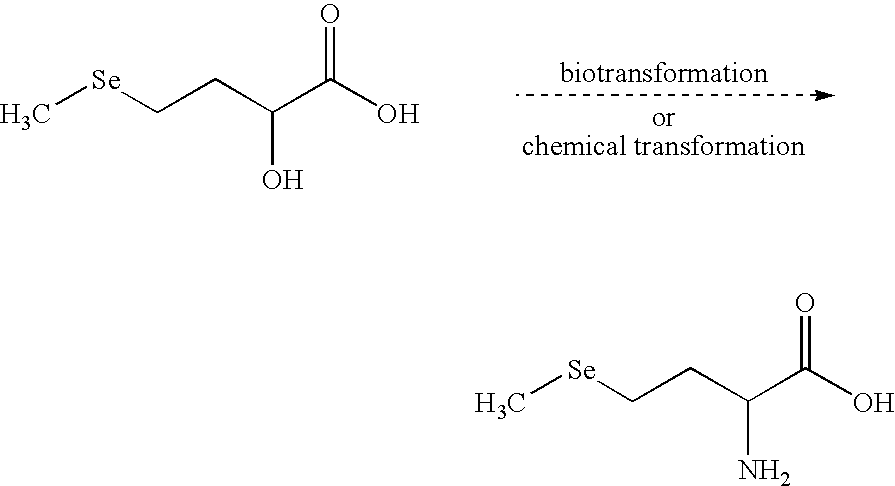

New selenohydroxy acids and their derivatives, applications in nutrition, cosmetics and pharmaceutics

ActiveUS20060105960A1Organic active ingredientsCosmetic preparationsLipid formationCis-Retinoic Acid

The purpose of this invention is: new selenohydroxy acid compounds and their derivatives; their process for the preparation; use of the said new compounds as precursors of L(+)-selenomethionine and / or source of selenium in human or animal nutrition, in cosmetics and pharmaceutics; and nutritional, cosmetic and pharmaceutical compositions containing them. The new compounds that are the subject of this invention satisfy the general formula (I): in which n=0, 1 or 2, R1=OH, OCOR3, OPO3H2, OPO(OR4)(OR5), or OR6, R2=OH, R3, or NHR7, R3=particularly alkoxyl (C1-C26), ceramide 1, ceramide 2, ceramide 3, ceramide 4, ceramide 5, ceramide 6a and 6b, S-cysteinyl, S-glutathionyl, carnitoyl, lipids, polyols, OR4=OR5=particularly alkoxyl (C1-C26), ceramide 1, ceramide 2, ceramide 3, ceramide 4, ceramide 5, ceramide 6a and 6b, S-cysteinyl, S-glutathionyl, carnitoyl, lipids, polyols, OR6=pyruvate, lactate, citrate, fumarate, maleate, myristate, palmitate, stearate, palmitoleate, oleate, linoleate, natural fatty acids, or 13-cis retinoate R7=H, alkyl, natural amino acids, or natural amines.

Owner:TETRAHEDRON SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com