Patents

Literature

514 results about "Decanoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decanoic acid, also known as capric acid (C10:0) or decylic acid, is a saturated fatty acid. Its formula is CH₃(CH₂)₈COOH. Salts and esters of decanoic acid are called decanoates or caprates. The term capric acid is derived from the Latin "caper / capra" (goat) because the sweaty, unpleasant smell of the compound is reminiscent of goats.

Preparation method of grease with humanized structure

ActiveCN102776077AHuge market potentialHigh number of reusesMilk preparationFatty acid esterificationVegetable oilMolecular rearrangement

The invention discloses a preparation method of grease with a humanized structure. The preparation method comprises the following steps: carrying out intra-molecular rearrangement reaction to palm oil with palmitic acid content of higher than 50% under the action of catalyst to obtain Sn-2 locus triglyceride with palmitic acid content of higher than 50%; and carrying out ester exchange reaction to the Sn-2 locus triglyceride with palmitic acid content of higher than 50% with mixed fatty acid or non-glyceride under the action of 1,3 locus Specificity lipase, and then subjecting the reaction product to after treatment, so as to obtain the grease with humanized structure, wherein the mixed fatty acid is mixture of at least two selected from the group consisting of decanoic acid, lauric acid,myristic acid, palmitoleic acid, stearic acid, oleic acid, linoleic acid and linolenic acid. The vegetable oils are used as the raw material according to the method, so the safety is high; the preparation process is simple, the reaction time is short, the enzyme dosage is low, and the cost is low; and the prepared grease with the humanized structure is very similar to the beast milk fat in the composition of fatty acid and the structural distribution of triglyceride, so the grease can be added in infant formula or formula foods and used as breast milk fat substitute.

Owner:ZANYU TECH GRP CO LTD

D1369 d radiation curable secondary coating for optical fiber

A new radiation curable Secondary Coating for optical fibers is described and claimed wherein said composition comprises a Secondary Coating Oligomer Blend, which is mixed with a first diluent monomer; a second diluent monomer; optionally, a third diluent monomer; an antioxidant; a first photoinitiator; a second photoinitiator; and optionally a slip additive or a blend of slip additives; wherein said Secondary Coating Oligomer Blend comprises:α) an Omega Oligomer; andβ) an Upsilon Oligomer;wherein said Omega Oligomer is synthesized by the reaction ofα1) a hydroxyl-containing (meth)acrylate;α2) an isocyanate;α3) a polyether polyol; andα4) tripropylene glycol; in the presence ofα5) a polymerization inhibitor; andα6) a catalyst;to yield the Omega Oligomer;wherein said catalyst is selected from the group consisting of dibutyl tin dilaurate; metal carboxylates, including, but not limited to: organobismuth catalysts such as bismuth neodecanoate; zinc neodecanoate; zirconium neodecanoate; zinc 2-ethylhexanoate; sulfonic acids, including but not limited to dodecylbenzene sulfonic acid, methane sulfonic acid; amino or organo-base catalysts, including, but not limited to: 1,2-dimethylimidazole and diazabicyclooctane; triphenyl phosphine; alkoxides of zirconium and titanium, including, but not limited to Zirconium butoxide and Titanium butoxide; and Ionic liquid phosphonium salts; and tetradecyl(trihexyl)phosphonium chloride; andwherein said Upsilon Oligomer is an epoxy diacrylate.

Owner:DSM IP ASSETS BV

Pesticidal compositions and methods of use thereof

ActiveUS20100227010A1Enhances insecticidal/pesticidal activityImprove insect repellent effectBiocideOrganic active ingredientsVegetable oilGnat

A pest-combating composition including sodium lauryl sulfate and one or more of C6-12 fatty acids, preferably lauric and / or capric and / or caprylic acid, soy methyl ester, and 2-undecanone, and methods of combating pests utilizing same, are disclosed. The compositions can include a carrier oil such as silicon oil, soy methyl ester, or a vegetable oil, and can be in the form of an emulsion. The composition may be constituted as a spray composition, an aerosol, a lotion, a paste, or another compositional form. Pests that may be usefully combated with such composition include flying insects, including flies, mosquitoes, and wasps, ants, including arthropods such as fire ants, ticks, fleas, cockroaches, silver fish, thrips, gnats, aphids, Japanese beetles, and agricultural and horticultural arthropods and insects including beetles (potato and bean), flea beetles, fleahoppers, squash bugs, slugs, leaf hoppers, harlequin bugs, milk weed bugs, spiders, mites, lice, rodents, and deer.

Owner:HOMS

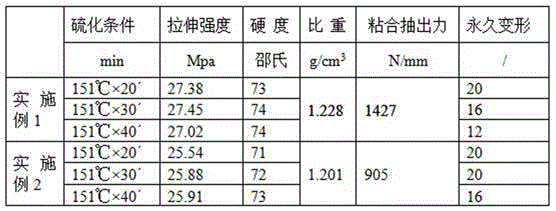

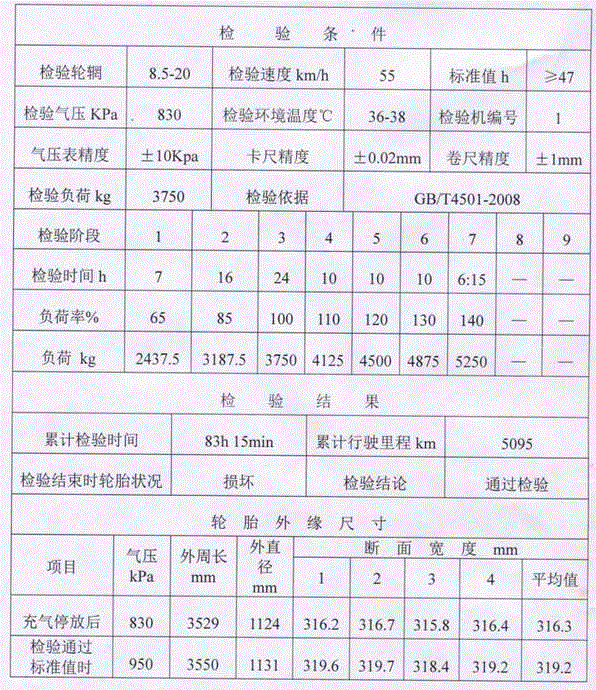

Tire apex composition for improving bond system and its preparation method and application

The invention relates to the tire manufacture field, especially to a tire apex composition for improving a bond system and its preparation method and application. The tire apex composition for improving the bond system is formed by the mixing of the following ingredients of: by weight, 70-100 parts of natural rubber, 0-30 parts of styrene-butadiene rubber, 55-75 parts of carbon black, 1.0-4.0 parts of resorcinol, 0.2-3.0 parts of cobalt decanoate, 3-8 parts of a methylene donator adhesive, 0-20 parts of white carbon black, 3-8 parts of a vulcanizing agent and a sulfuration promoter and other processing auxiliary agents. The tire apex composition for improving a bond system obviously raises modulus and binding property, decreases heat generation, minimizes modulus loss at high temperature,and simultaneously reduces formula cost. By employing BTR tires under the precondition of unchanged structure, the hard apex strength and hardness can be guaranteed not to be decreased, the modulus is substantially increased, the bond performance between the apex and steel wires / steel wire cords is remarkably improved, and the anti-destroy performance of tire bead positions is raised.

Owner:ZHONGCE RUBBER GRP CO LTD

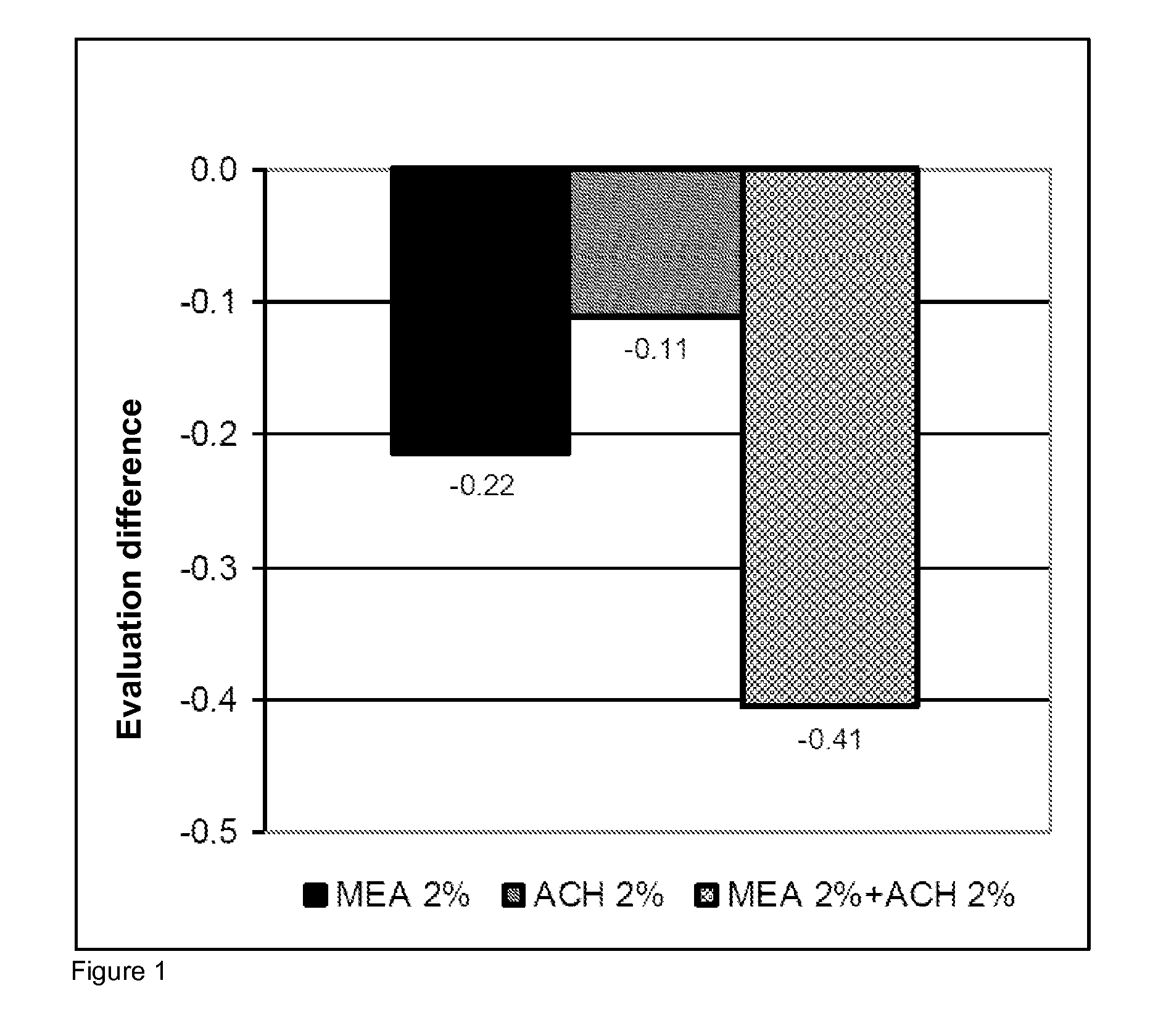

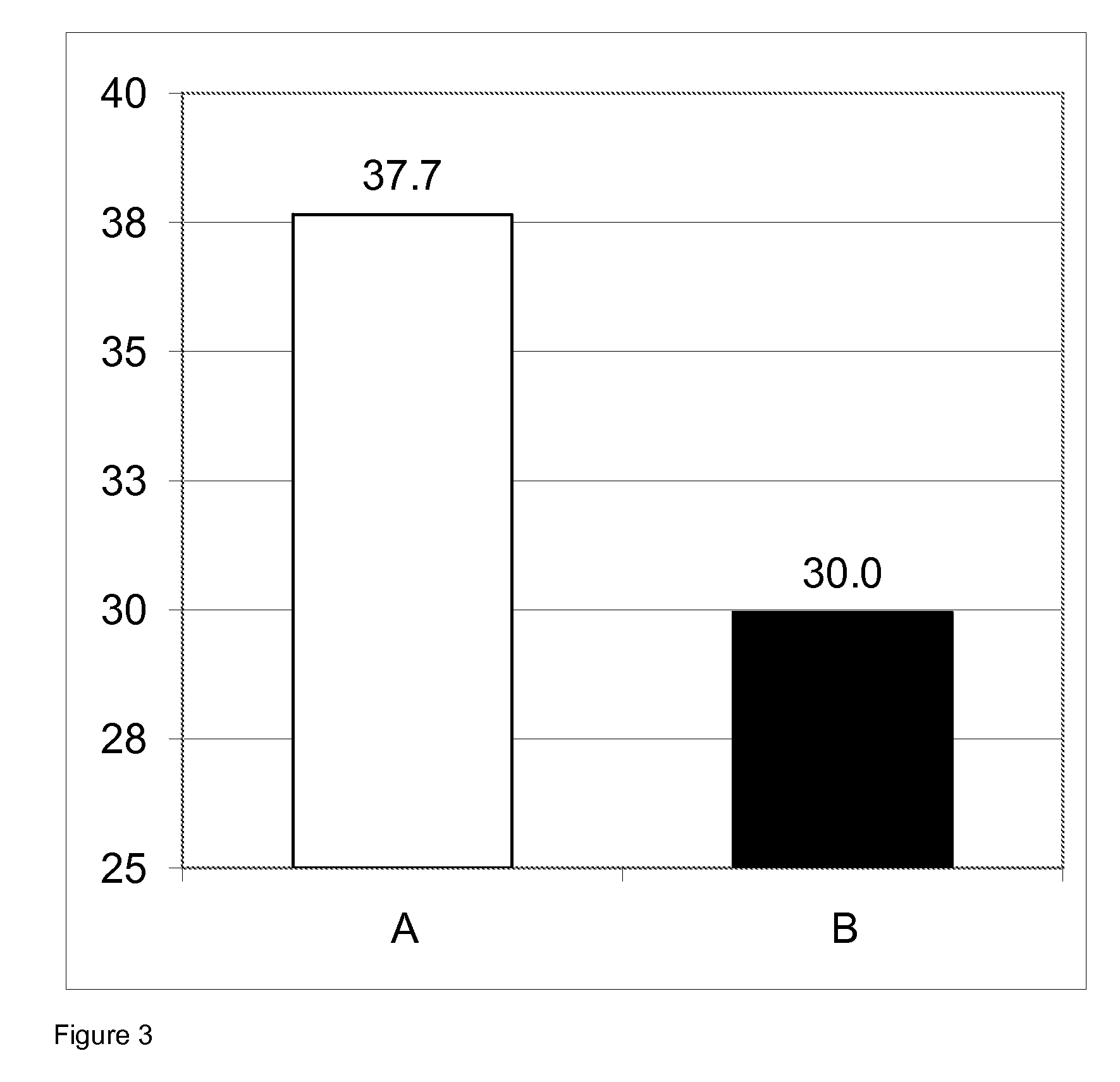

Formulation comprising caprylic acid ethanolamide and/or capric acid ethanolamide in combination with an aluminium salt and its use

InactiveUS20150118173A1Largely constantGood skin compatibilityBiocideCosmetic preparationsAluminium saltsMedicine

The invention relates to a formulation comprising caprylic acid ethanolamide and / or capric acid ethanolamide in combination with an aluminium salt and to its use.

Owner:EVONIK DEGUSSA GMBH

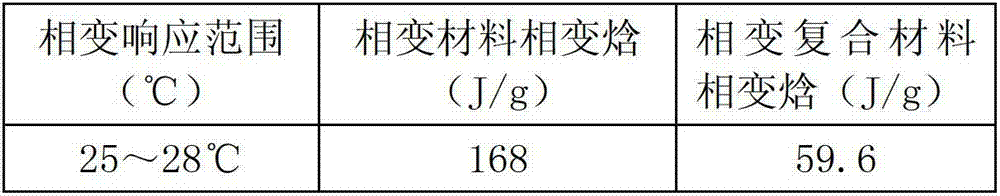

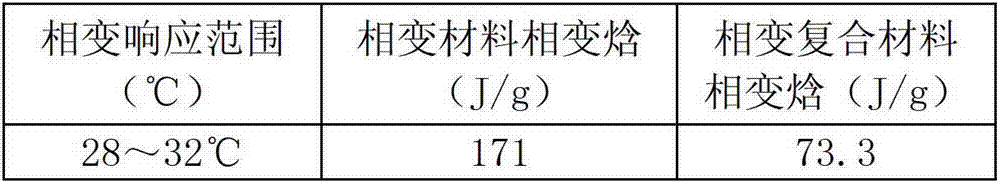

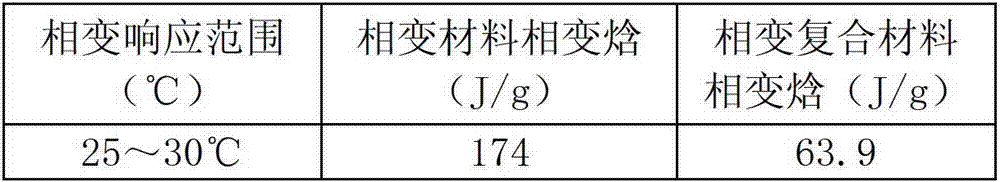

Phase change composite material and preparation method thereof

InactiveCN102827583AHigh phase change enthalpyCrystal stableHeat-exchange elementsThermal insulationStearic acid

The invention relates to a phase change composite material and a preparation method thereof. The phase change composite material is composed of a phase change material, expanded perlite particles and polymer emulsion in a weight ratio of (0.55-0.75): 1: (0.5-2.0), wherein the polymer emulsion is coated over the surface of the expanded perlite particles which have adsorbed the phase change material, and the phase change material is a blend of three or four selected from the group consisting of decanoic acid, lauric acid, tetradecanoic acid, palmitic acid and stearic acid. The preparation method comprises a step of combining the phase change material and the expanded perlite particles together by using a vacuum adsorption process and a step of coating a compound of the phase change material and the expanded perlite particles with the polymer emulsion. The phase change composite material provided by the invention has the advantages of great phase change energy storage capacity, good sealing capacity, wide material sources and low cost, can be used to substitute or partially substitute thermal insulation aggregate in conventional inorganic thermal insulation mortar for indoor and outdoor insulation of a building and can be mixed with inorganic cementing materials like cement and gypsum to prepare a sheet material product.

Owner:上海英硕聚合材料股份有限公司

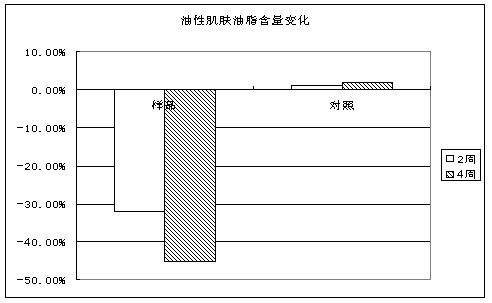

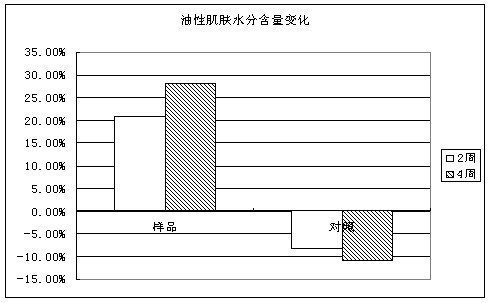

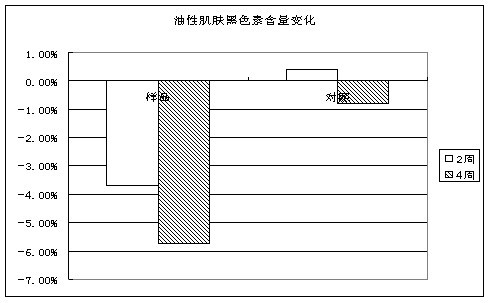

Acne removing cosmetic and preparation method thereof

ActiveCN102670469AGood moisturizing effectRegulate oil balanceCosmetic preparationsToilet preparationsJojoba oilButanediol

The invention discloses an acne removing cosmetic and a preparation method thereof. The cosmetic comprises, by weight, A components, B components, C components and D components, wherein the A components include, by weight, 64%-78% of deionized water, 0.01%-0.2% of sodium hyaluronate, 2%-10% of 1,3-butanediol, 0.5%-1% of acryloyl dimethyl taurine ammonium / pyrrolidone (VP) copolymer, 0.15%-0.5% of acrylics (esters) / vinyl alcohol isodecyl acid ester cross-linked polymer sodium and 0.15%-0.5% of triethanolamine; the B components include, by weight, 0.5%-5% of honey extract, 1%-3% of LS9088, 0.5%-2.0% of phellodendron extract, 1%-3% of hydrolysis opuntia ficus-indica flowers, 0.5%-1.5% of vitex agnus-castus extract, and 2%-6% of caprylic acid propyl heptyl ester; C components include, by weight, 2%-10% of jojoba oil and 2%-5% of polydimethylsiloxane; and D components include, by weight, 0.2%-1% of preservative and 0.1%-0.3% of essence.

Owner:广州泰润合投资有限公司

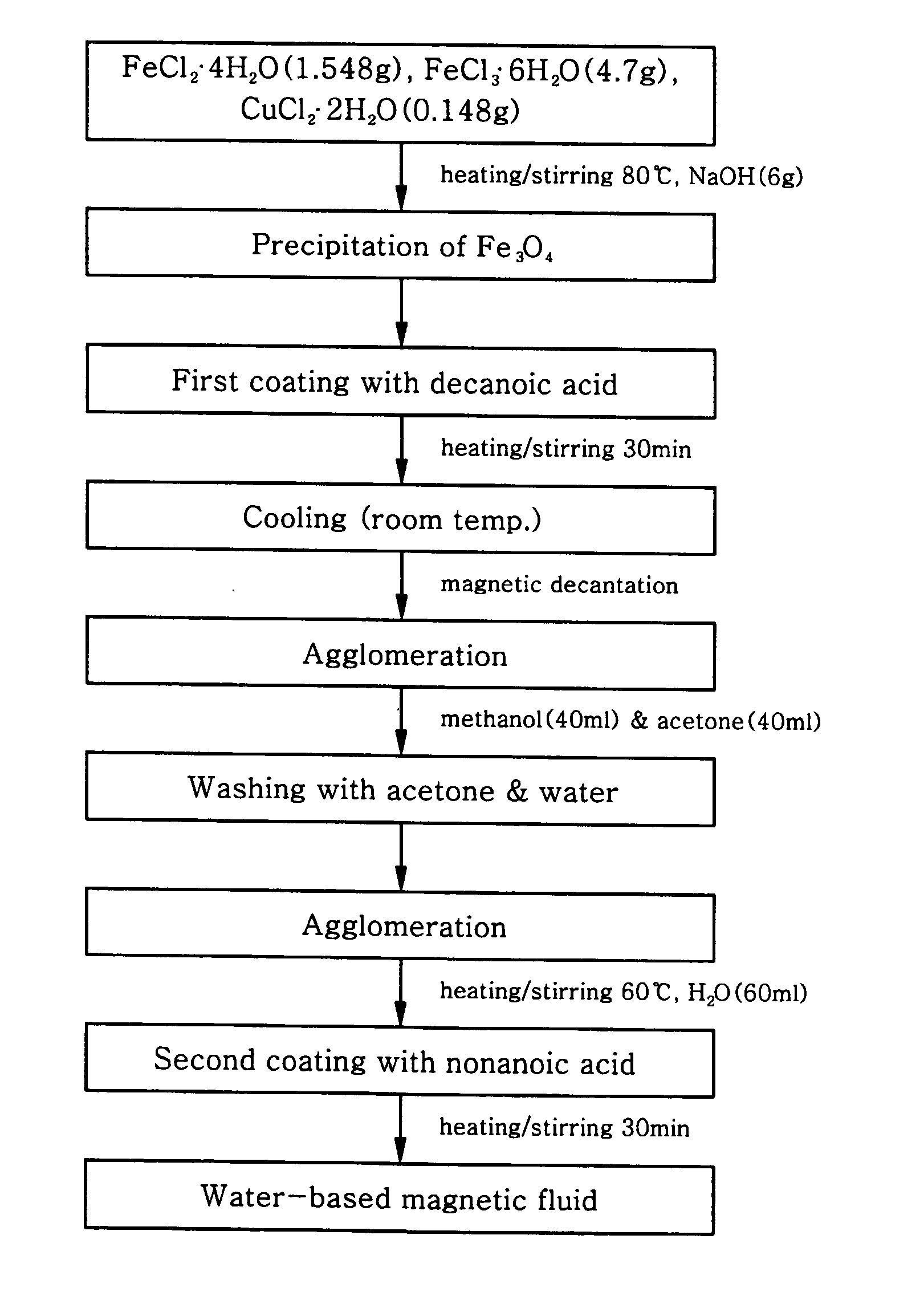

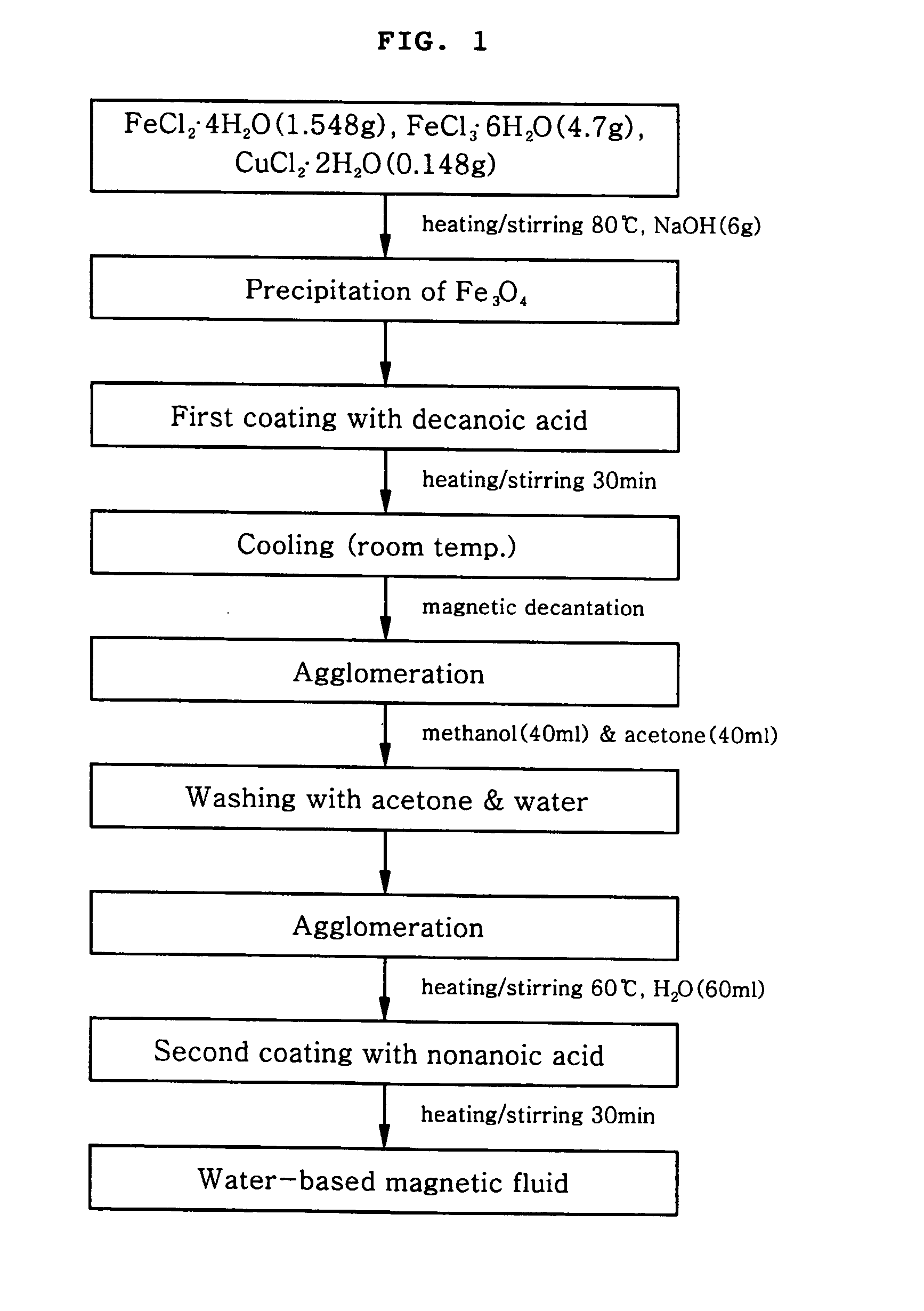

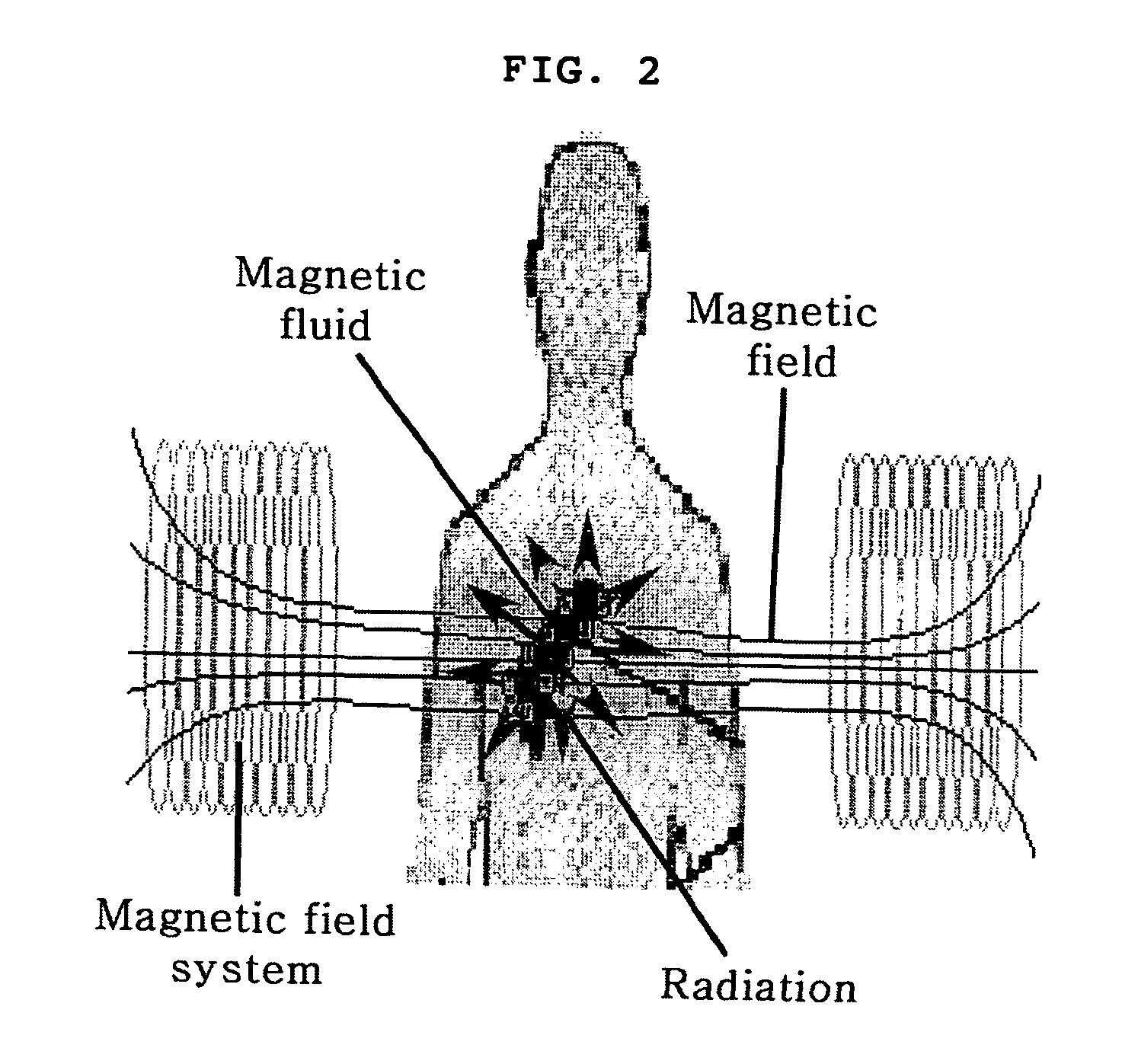

Radioactive magnetic fluids for treatment or diagnosis of cancer, process for preparing them and use thereof

The present invention relates to radioactive magnetic fluids, process for preparing them and use thereof. Particularly, the present invention relates to the radioactive magnetic fluids for treatment or diagnosis of cancer, process for preparing them and use thereof. The radioactive magnetic fluids of the present invention include the component of Cu2+ which radiates a β-ray and γ-ray. The β radiation can effectively kill the tumor cells. Since the γ radiation are easily imaged with γ-camera, the magnetic fluids can be gathered to the treatment site with the radiograph under external magnetic field. Therefore, the radioactive magnetic fluids of the present invention can be used for treatment of cancer with minimal side effects. Also, the tightly bonded decanoic acid and nonanoic acid layer of the present invention not only increase particle-particle repulsion but also take hydrophilicity, to disperse homogeneously and stably the magnetic nanoparticles in water. Also, carboxylic acid of the surfactant is exposed to outside, to prevent the magnetic nanoparticles from being oxidized by air. Therefore, the radioactive magnetic fluids can be used as therapeutic drug or diagnostic reagent for cancer.

Owner:KIM CHONG OH

Child care pig compound feed without tensile body and preparation method thereof

InactiveCN102919573AIncrease feed intakeImprove immunityFood processingAnimal feeding stuffFeed conversion ratioPhytase

The invention relates to child care pig compound feed without a tensile body, and the child care pig compound feed is prepared from the following components: corn, peeled soybean meal, puffed soybean meal, fermented soybean meal, steam white fish meal, flour, soybean oil, mountain flour, calcium hydrogen phosphate, edible salt, child car pig compound premix, coated slow-release acidifier, L-lysine hydrochloride, DL methionine, L-thronine, tryptophan, octanoic / decanoic acid glyceride, yeast nucleic acid, xylo-oligosaccharides, sodium glutamate, sodium butyrate, the root of Chinese pulsatilla, coptis chinensis, golden cypress, ash bark, choline chloride and phytase. The child care pig compound feed without the tensile body provided by the invention starts from the physiological characteristics of a child care pig, adopts multiple combinations of raw materials, is complementary in nutrition, designs amino-acid-balanced, calcium-phosphate-balanced and electrolyte-balanced daily ration, adds no antibiotic, adopts medium-chain fatty acid and natural Chinese herbal medicine additive for health protection, and can be used for improving food consumption of the child care pig, reducing the feed conversion ratio, improving intestinal health of the child care pig, improving immunity and drawing a skeleton of the child care pig, so that a good foundation is laid for later-stage growth.

Owner:HUAIAN ZHENGCHANG FEED

Esterification method of pentaerythritol

ActiveCN104086417AIncrease in positive chargePromote esterification reactionOrganic compound preparationCarboxylic acid esters preparationOctanoic AcidsAfter treatment

The invention provides an esterification method of pentaerythritol, which comprises the following step: under the action of a tin catalyst, carrying out esterification reaction on pentaerythritol and saturated fatty acid to obtain pentaerythritol ester, wherein the saturated fatty acid is one or more of butyric acid, valeric acid, hexanoic acid, heptylic acid, octanoic acid, pelargonic acid and capric acid. The esterification method provided by the invention has the advantages of higher product yield, higher product quality, simple esterification after-treatment and low pollution. The experimental result indicates that the conversion rate of the esterification reaction is greater than 99.5%, and the hydroxyl value in the reaction product is lower than 1mg KOH / g.

Owner:CHINA PETROLEUM & CHEM CORP

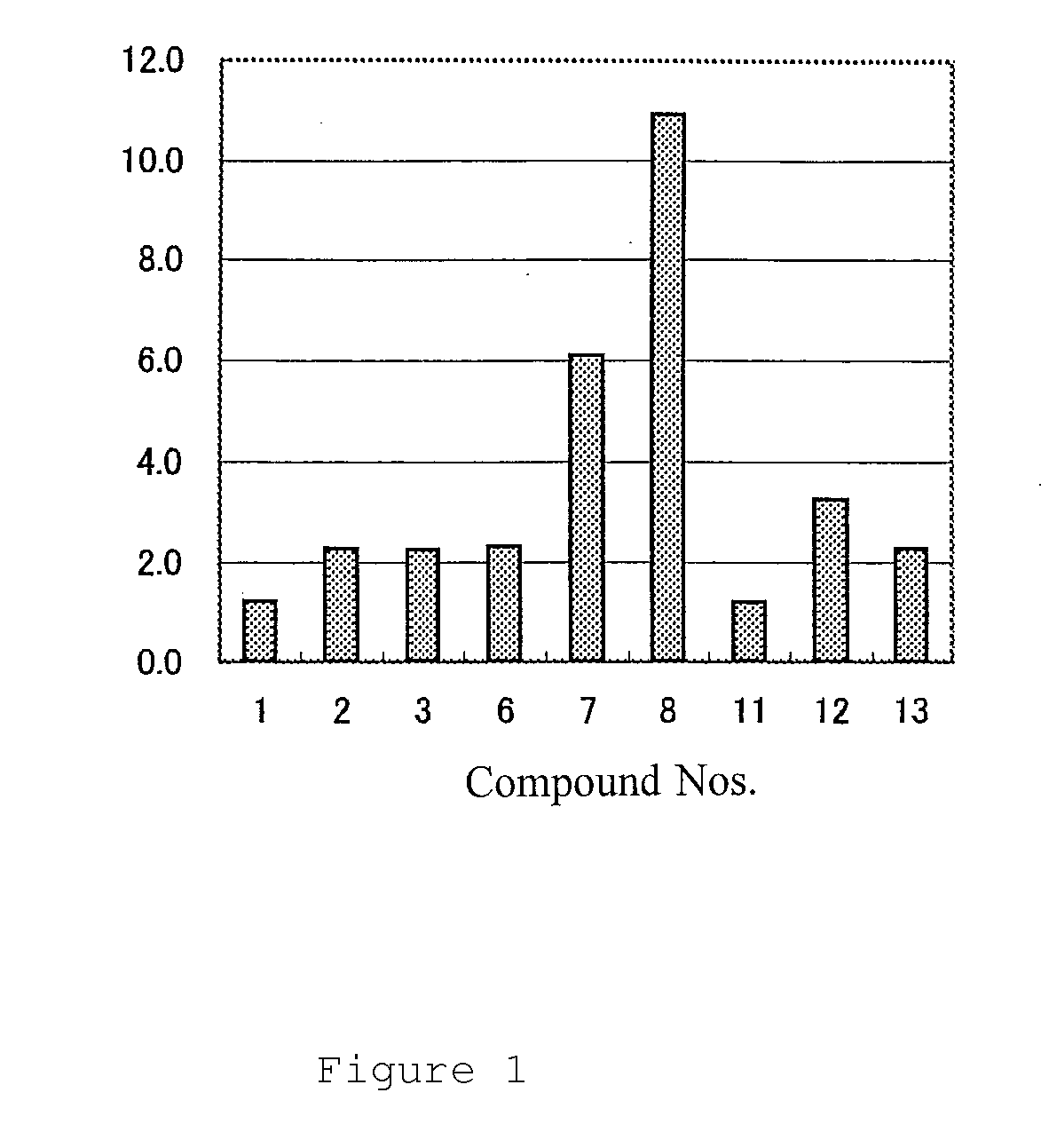

Agent having neurotrophic factor-like activity

InactiveUS20100204498A1Improve securityPrevention and improvementNervous disorderOrganic chemistryFactor iiEthyl ester

The present invention provides a pharmaceutical agent having high safety and a neurotrophic factor-like activity, which contains, as an active ingredient, any one compound included in fatty acids each having 8 carbon atoms (C8) or having 10 carbon atoms (C10) to 12 carbon atoms (C12) or fatty acid esters thereof, such as 3,7-dimethyloctanoic acid ethyl ester, geranic acid ethyl ester, and the like, each of which has 8 carbon atoms (C8), decanoic acid methyl ester, trans-2-decenoic acid, trans-2-decenoic acid methyl ester, trans-2-decenoic acid ethyl ester, trans-2-decenoic acid-2-decenyl ester, trans-2-decenoic acid cyclohexyl ester, trans-2-decenoic acid isopropyl ester, trans-3-decenoic acid methyl ester, trans-9-decenoic acid methyl ester, and the like, each of which has 10 carbon atoms (C10), trans-10-undecenoic acid methyl ester, trans-10-undecenoic acid ethyl ester, and the like, each of which has 11 carbon atoms (C11), and dodecanoic acid, and the like, each of which has 12 carbon atoms (C12), or salts thereof or prodrugs thereof.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST

Fatty acid composition

ActiveCN101233852AImprove stabilityImprove the bactericidal effectBiocideSurface-active detergent compositionsAlkaneForm solution

The invention relates to a fatty acid composition, which is diluted at normal temperature and in cold water to form solution used for cleaning of sterilization, fungicide and antivirus. The fatty acid composition comprises at least the following components: component A: food fatty acid comprising at least octyl decanoic acid and nonanoic acid; component B: surfactant comprising alkane sulfonate; component C: acid. The fatty acid composition has the advantages that the fatty acid composition or the diluted solution thereof has good stability, bactericidal and antiviral activity under the water temperature of 4-20 DEG C, no phase separation or crystallization, thus having safer use performance, and active components are low in cost, having more broad-spectrum bactericidal activity which can kill various bacteria, epiphytes and viruses. The fatty acid composition or the diluted solution thereof can be used for sterilization, fungicide and antivirus, which has high-efficient and quick killing effect; the sterilizing rate can reach more than 99.999 percent with contact time less than 1 minute; The fatty acid composition or the diluted solution thereof also has strong cleaning ability, and can keep effective even in hard water; the killing ratio for poliovirus reaches 99.9999 percent and the poliovirus can be killed immediately.

Owner:SICHUAN LOMON BIO TECH CO LTD +1

Nursing agent for skin moisturizing and repairing and preparation method thereof

PendingCN110192985APromotes long-lasting hydrationGood compatibilityCosmetic preparationsToilet preparationsCentella asiatica extractAcetophenone

The invention discloses a nursing agent for skin moisturizing and repairing. The nursing agent for skin moisturizing and repairing comprises the following components by mass percentage: 0.05 0.15% ofdisodium EDTA, 0.5-3.0% of nicotinamide, 2.0-5.5% of glycerin, 2.5-5.5% of propylene glycol, 0.05-0.35% of xanthan gum, 0.05-0.5% of sodium hyaluronate, 0.15-0.5% of p-hydroxyl acetophenone, 1.0-5.0%of caprylic / capric triglyceride, 1.0-3.0% of polydimethylsiloxane, 1.0-5.0% of isononyl isononanoate, 0.5-5.0% of jojoba seed oil, 0.5-2.5% of avocado tree fruit oil, 1.75-10.5% of repair essential oil, 0.05-0.5% of fullerenes, 0.35-2% of repairing essence, 0.2-3.5% of cetostearyl alcohol, 1.0-2.5% of cetearyl olivate, 1.0-2.5% of sorbitan olivate, 0.1-1.0% of lecithin, 0.5-5.0% of oligopeptide-1, 0.1-0.5% of D-panthenol, 0.5-2.5% of a Centella asiatica extract, 0.5-2.5% of 1,2-hexanediol, and the balance of deionized water. The product of the invention can quickly improve the moisture retention of the skin, obviously improves the dryness of the skin, increases the moisture content in the skin, and makes the skin appear young. .

Owner:广州市百爱神生物科技有限公司

Antifreeze Concentrate and Coolant Compositions and Preparation Thereof

InactiveUS20090001313A1Improve thermal stabilityOther chemical processesHeat-exchange elementsBenzoic acidOctanoic Acids

A toxicological friendly antifreeze composition having improved thermal stability is provided. In one embodiment, the antifreeze composition comprises from 5 to 80 wt. % of an aqueous freezing point depressant selected from alkali metal salts of acetates, formates, proprionates, adipiates, and succinates, and mixtures thereof; 0.1 to 10 wt. % of at least one of a 2-ethylhexanoic acid, isononanoic acid and 3,5,5-trimethylhexanoic acid; and 0.1 to 10 wt. % of at least one of octanoic acid, nonanoic acid, decanoic acid, undecanoic acid, dodecanoic acid, neodecanoic acid, benzoic acid, 2-hydroxybenzoic acid, p-terbutylbenzoic acid, and mixtures thereof. In one embodiment, the composition is employed as a concentrate in admixture with 10 to 90 wt. % water.

Owner:CHEVROU USA INC

Preparation method of gypsum and clay composite phase-change energy storing material

ActiveCN104152114AHigh strengthImprove thermal performanceHeat-exchange elementsSodium BentoniteCalcite

The invention discloses a preparation method of a gypsum and clay composite phase-change energy storing material. The composite phase-change energy storing material is characterized by being prepared from a composite phase-change precursor and a gypsum cementing material, wherein the composite phase-change precursor is prepared through the steps of adsorbing an organic phase-change agent by using an inorganic porous clay material through a solution intercalation method, then, binding by using a binder, granulating and drying; and then, the product is mixed with hemi-hydrated gypsum, and the mixture is molded to prepare the gypsum and clay composite phase-change energy storing material. The phase-change agent is selected from decanoic acid, lauric acid, myristic acid, palmitic acid, stearic acid, dodecanol, tridecanol, tetradecanol, pentadecanol, methyl palmitate, methyl heptadecanoate, ethyl heptadecanoate, methyl octadecanoate and paraffin. The inorganic porous clay material is selected from attapulgite, sepiolite, montmorillonite, bentonite, diatomite, zeolite, silica, dolomite, calcite and illite. The molding binder is selected from water glass, hydroxymethyl cellulose, silica sol and aluminum sol. The prepared composite phase-change energy storing material is wide in phase change temperature range, high phase-change latent heat, favorable in mechanical property and high in thermal stability.

Owner:BEIJING UNIV OF CHEM TECH +1

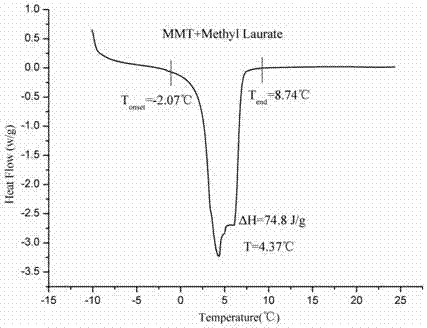

Preparation method of clay-based composite phase-change energy storage deicing (snow melting) material

The invention discloses a preparation method of a clay-based composite phase-change energy storage deicing (snow melting) material. The preparation method is characterized in that a composite phase-change energy storage material is prepared from a low-temperature organic phase-change material and a clay material, wherein the low-temperature organic phase-change material is prepared by single-element or multi-element mixing of various organic phase-change materials and is then physically compounded with the treated clay to prepare the clay-based composite phase-change energy storage deicing (snow melting) material. The low-temperature organic phase-change material is selected from polyethylene glycol-300, polyethylene glycol-400, polyethylene glycol-500, polyethylene glycol-600, decyl alcohol, undecanol, dodecanol, heptylic acid, octanoic acid, nonanoic acid, capric acid, methyl laurate, methyl myristate, methyl palmitate, tetradecane, pentadecane, hexadecane, heptadecane, octodecane, nonadecane and the like. The clay material is selected from kaolinite, montmorillonite, bentonite, vermiculite, halloysite, sepiolite, attapulgite, perlite, diatomite, rectorite, zeolite, silicon dioxide, dolomite, calcite and illite. The prepared composite phase-change energy storage deicing (snow melting) material is proper in phase-change temperature (0-5 DEG C), high in phase-change latent heat and high in heat stability.

Owner:CENT SOUTH UNIV

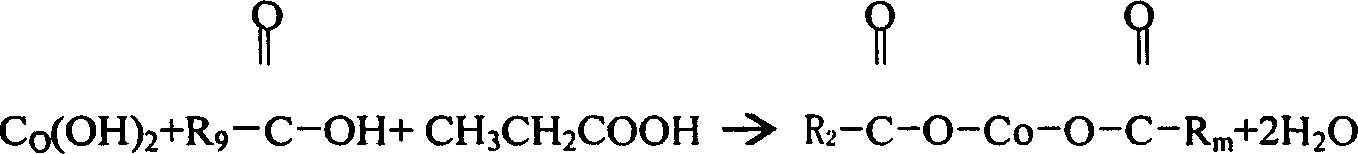

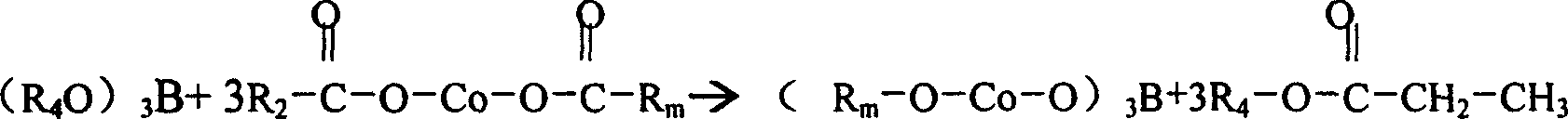

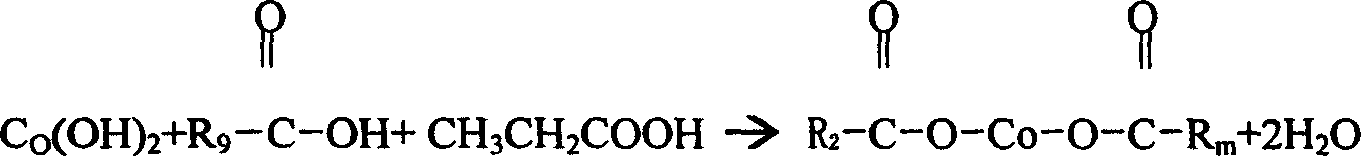

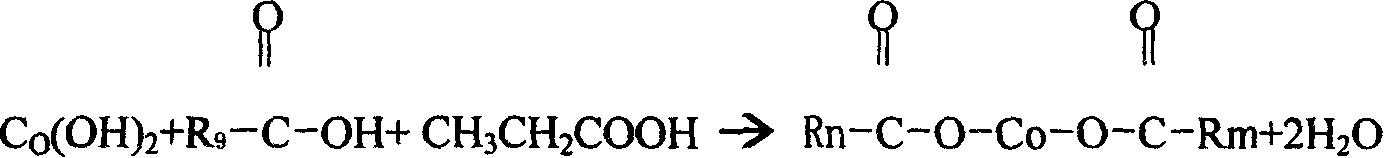

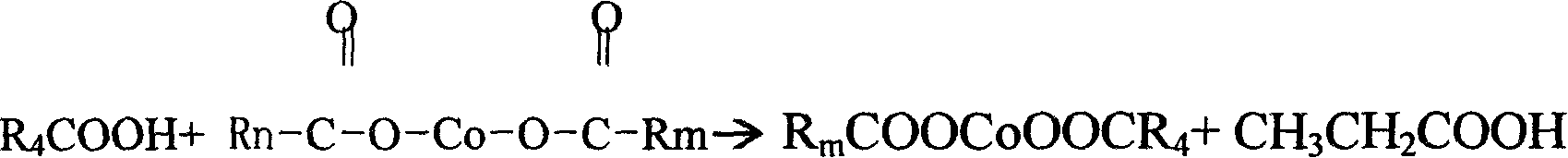

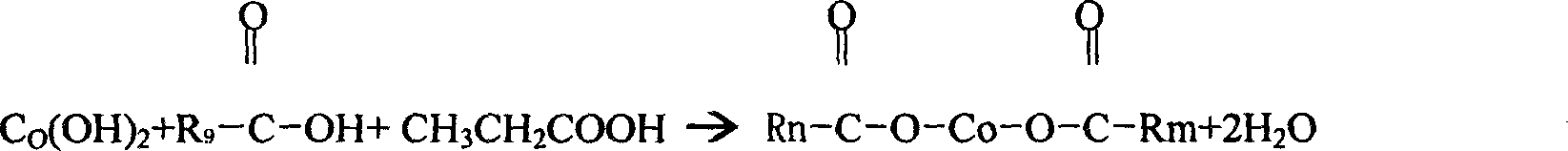

Method for preparing finished products of salt mixture of organic cobalt class of giving priority to cobalt boroacidate

InactiveCN101003544AHigh reactivityBalance pHNon-macromolecular adhesive additivesCobalt organic compoundsPropionatePropanoic acid

This invention relates to a method for preparing organic cobalt mixed salt product mainly composed of cobalt boroacylate. The method comprises: (1) reacting cobalt hydroxide and mixed acids of propionic acid and octocapric acid in a normal pressure sealed container at 150-190 deg.C for more than 2 h; (2) adding butyl borate, and reacting at 190-200 deg.C for more than 1 h to form cobalt boroacylate and butyl propionate byproduct; (3) adding calcium metaborate at 180-190 deg.C to obtain the organic cobalt mixed salt product. The raw materials comprise: cobalt hydroxide 31-22 parts, octocapric acid 60-62 parts, propionic acid 25-27 parts, butyl borate 26-28 parts, and calcium metaborate 7-8 parts. The method has such advantages as high cobalt content, high reaction activity, and appropriate melting point.

Owner:徐美华

Novel adhesion promoting system tire belt ply and preparation method thereof

ActiveCN104479181AExtended service lifeImprove working environmentTyresSpecial tyresVulcanizationSulfur

The invention provides a novel adhesion promoting system tire belt ply and a preparation method thereof. The belt ply comprises, in parts by weight, 100 parts of natural rubber, 40-50 parts of carbon black, 8-15 parts of white carbon black, 5-10 parts of zinc oxide, 1-3 parts of cobalt neocaprate, 1-3 parts of a novel adhesion promoter, 2-4 parts of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine, 3-6 parts of sulfur, 1.0-1.5 parts of a vulcanization accelerator, 3-5 parts of a methylene donor and 0.1-0.3 parts of a scorch retarder. The preparation method comprises preparation of plasticated rubber, preparation of three-section master batch and final mixing. With the adoption of the belt ply, the using performance of a tire can be improved, the service life of the tire can be prolonged, resources are effectively saved, the cost is reduced, resource waste is reduced, the pollution can be reduced, and the performance can be improved.

Owner:WEIFANG YUELONG RUBBER

Mild and moist cleansing water and preparation method thereof

InactiveCN104490680AReduce stimulationAvoid dryness and peelingCosmetic preparationsMake-upBenzoic acidButanediol

The invention provides mild and moist cleansing water and a preparation method thereof. The mild and moist cleansing water is prepared from the following components in certain percentage by mass: 8%-20% of butanediol, 1%-10% of PEG-6 caprylic acid / caprin, 1%-5% of trimethylglycine (glycine betaine), 1%-5% of purslane, 0.05%-0.5% of tocopheryl acetate, 0.01%-1% of dipotassium glycyrrhizinate, 0.001%-0.1% of hydroxyphenyl propionamide benzoic acid, 0.01%-0.1% of polyglutamic acid, 0.05%-2% of 1,2-pentanediol and the balance being deionized water. The mild and moist cleansing water is capable of dissolving grease and cleaning various cosmetics; and meanwhile, moist and anti-allergic components are added, so that the mild and moist cleansing water has the characteristics of being mild, free of damage to skin, high in cleanness and low in thrill.

Owner:GUANGDONG YALGET FINE CHEM

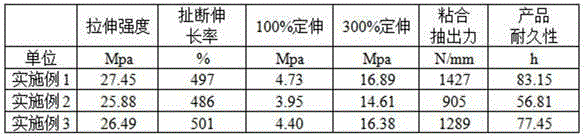

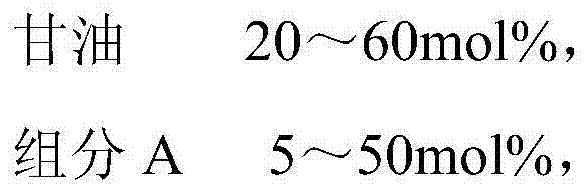

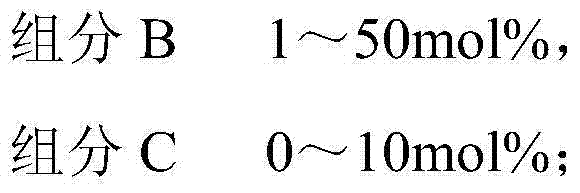

Fatty glyceride as well as preparation method and application thereof

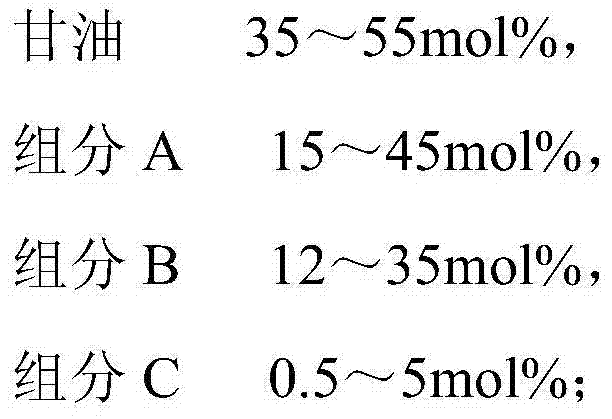

ActiveCN103772196AEasy to useEasy to operateCosmetic preparationsHair cosmeticsOctanoic AcidsGlycerol

The invention belongs to the technical field of fine chemical engineering, and discloses fatty glyceride as well as a preparation method and an application thereof. The fatty glyceride is prepared from the following components by mole percent: 20-60mol% of glycerinum, 5-50mol% of component A, 1-50mol% of component B and 0-10mol% of component C, wherein the component A is octanoic acid, methyl caprylate or ethyl caprylate, the component B is decanoic acid, methyl decanoate or ethyl decanoate and the component C is saturated fatty acid, fatty acid methyl ester or fatty acid ethyl ester with 12-16 carbon atoms. The preparation method comprises the following steps: carrying out a reaction on the components and a catalyst at a normal pressure at 130-180 DEG C for 1-6 hours in nitrogen; then, carrying out a decompression reaction at 130-210 DEG C for 1-6 hours and dehydrating to obtain the fatty glyceride. The fatty glyceride obtained has an extremely good synergic tackifying effect and good foaming characteristic and foaming behavior and can be used as a thickener for synthesis of daily detergent products and cosmetics.

Owner:广州星业科技股份有限公司

Process for preparing organic cobalts mixed salt finished product with cobalt neodecanoate as main raw material

The invention relates to a method for preparation of finished goods of organic cobalt composite salts, of which the cobalt neocaprate is the main substance. The method is characterized in that it selects cobalt hydroxide and organic acid as raw materials and performs acid-base salt reaction and acid replacement reaction to obtain the product. The method includes: selecting cobalt hydroxide, ethylformic acid and neocaprate as raw materials and reacting to prepare composite salts of cobalt propionate and cobalt neocaprate at a temperature of 150 DEG C-190 DEG C for more than 2 hours in an atmosphere airtight container; adding neopentanoic acid to react for replacement of propanoic acid at a temperature of 190 DEG C-200 DEG C for more than one hour; controlling the temperature between 180 DEG C and 190 DEG C; then adding calcium metaborate to prepare finished goods of organic cobalt composite salts, of which the cobalt neocaprate is the main substance. The product obtained by this invention has a higher cobalt content and fusing point.

Owner:JIANGYIN SANLIANG CHEM

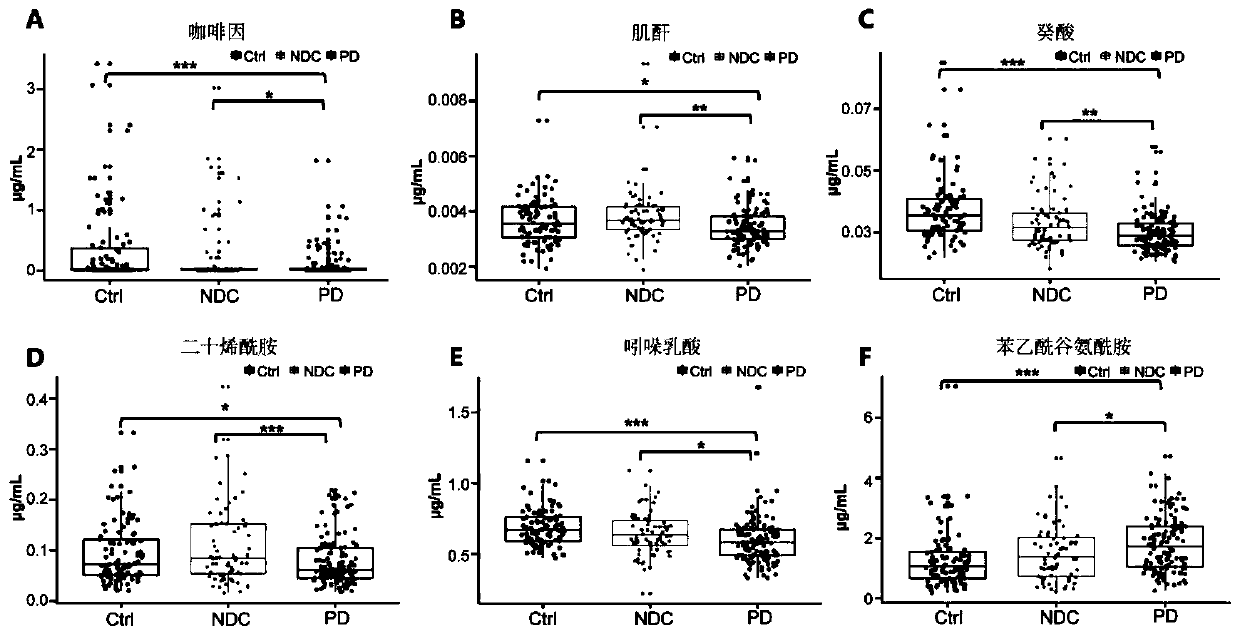

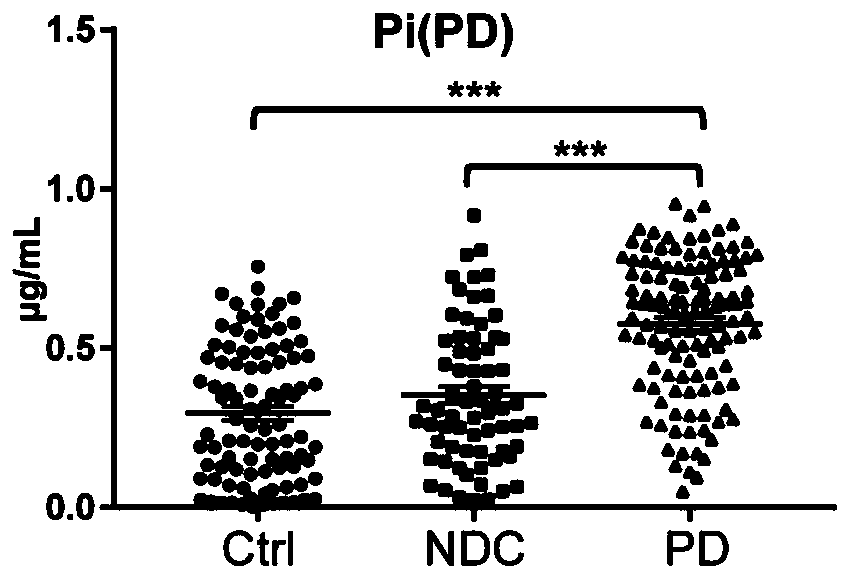

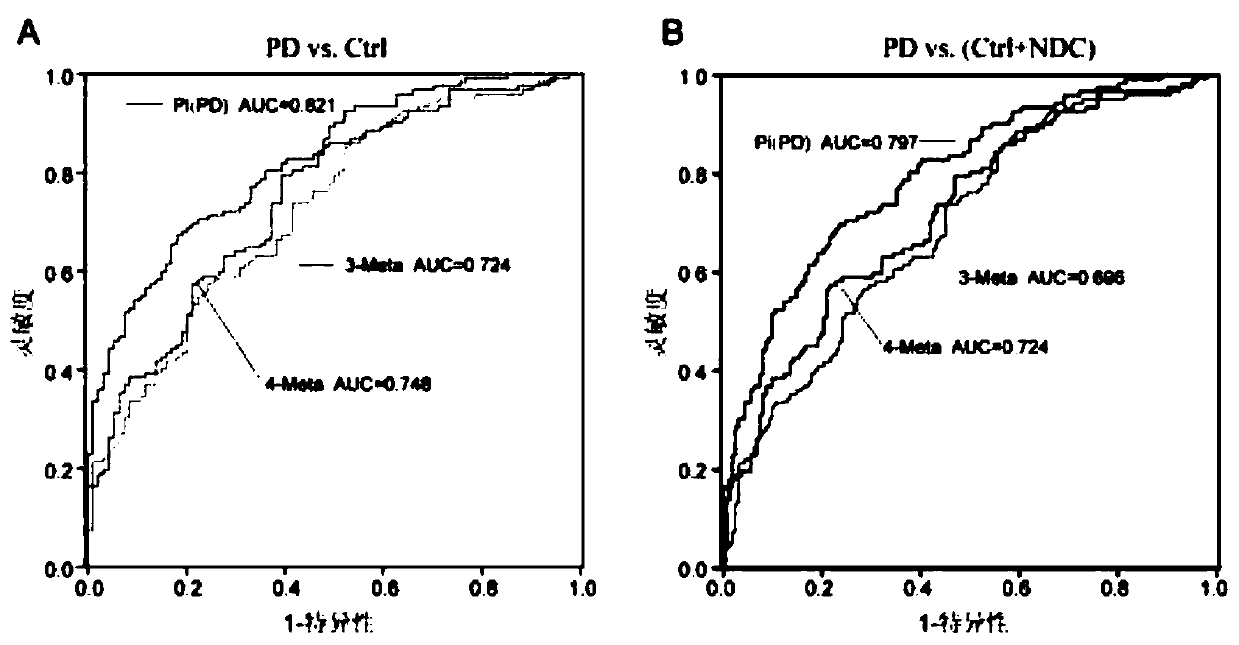

Combined marker and detection kit for diagnosing Parkinson's disease

The invention relates to new application of small molecular metabolites caffeine, creatinine, eicosamide, phenylacetylglutamine, decanoic acid and indolelactic acid in a plasma sample as combined markers in preparation of a kit for diagnosing Parkinson's disease patients in subjects. The invention also relates to the kit for detecting the Parkinson's disease patients in the subjects, and the kit is used for calculating the variables of the combined markers based on a binary logistic regression equation by detecting the respective relative concentrations of the combined markers in the plasma from the subjects, and judging whether the subjects suffer from Parkinson's disease or not based on determined intercept values. The kit can realize high-sensitivity detection of several metabolites involved in the invention, and has the characteristics of low detection cost and good repeatability. The combined use of the small molecule metabolites can be used for assisting the clinical diagnosis ofthe Parkinson's disease, and has higher development and application values.

Owner:FIRST AFFILIATED HOSPITAL OF DALIAN MEDICAL UNIV

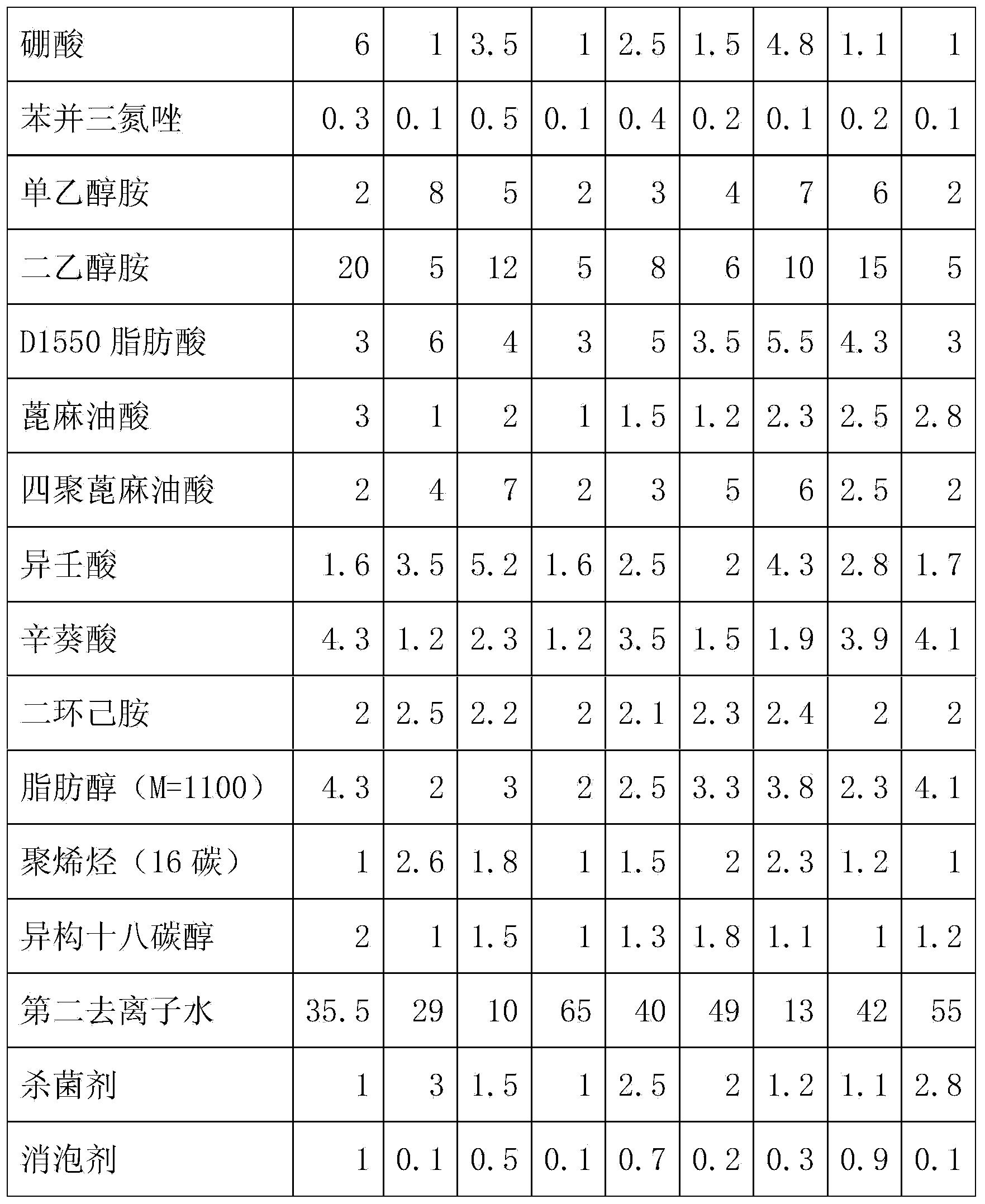

Chloride-free extreme pressure microemulsion cutting fluid and preparation method therefor

InactiveCN103710121AImprove the lubrication effectOvercoming perishable and smellyLubricant compositionHazardous substanceKerosene

Provided is a chloride-free extreme pressure microemulsion cutting fluid. The cutting fluid is prepared from the following raw materials, by weight, 4-5 parts of boric acid, 1-2 benzotriazole, 1-2 parts of octyl decanoic acid, 1-2 parts of lauryl sodium sulfate, 3-4 parts of polyacrylamide, 2-3 parts of urea, 0.8-1.2 parts of span 40, 0.5-1 part of lanthanum nitrate, 12-15 parts of kerosene, 6-8 parts of auxiliary agents and 200 parts of water. The cutting fluid contains no harmful substances of sodium nitrite, phenol, chlorine, mercury and the like, and is safe and environmentally friendly. Through application of boric acid and lanthanum nitrate, the cutting fluid has excellent extreme pressure performances, and workpieces are not easy to damage. The cutting fluid is advantaged by stable emulsification, no delamination, no coacervation, long service time and low cost. The cutting fluid is suitable for processing of a plurality of materials such as cast iron, steel, aluminum, copper, magnesium alloy and the like, and can meet a plurality of processing technology requirements of turning, drilling, grinding, center processing and the like.

Owner:MAANSHAN HENGYI MACHINERY MFG

Metal paste and film formation method using the same

InactiveUS20050127332A1Increasing the thicknessLower resistanceConductive materialNon-conductive material with dispersed conductive material2-Ethylhexanoic acidColloidal particle

Owner:TANAKA PRECIOUS METAL IND

High-stability moisture preservation sun-screen cream

InactiveCN107737027AImprove stabilityReasonable formulaCosmetic preparationsToilet preparationsSucroseIrritation

The invention provides high-stability moisture preservation sun-screen cream, which is prepared from cyclopentasiloxane, cyclohexasiloxane, titanium dioxide, caprylic / capric triglyceride, C12-15 alcohol benzoate, CI 77891, PEG-30 dihydroxy stearate, polydimethyl siloxane crosslinked polymers, ethylhexyl methoxycinnamate, disteardimonium hectorite, propylene garbonate, cetyl dimethicone, stearoyl inulin, tocopheryl acetate, bis-PEG / PPG-14 / 14 polydimethylsiloxane, cetyl PEG / PPG-10 / 1 polydimethylsiloxane, cyclopentasiloxane, PEG / PPG-18 / 18 polydimethylsiloxane, sucrose polyoleate, butanediol, propanediol, sodium chloride, 1,2-hexanediol, 1,2-pentanediol, allantoin, EDTA-disodium, butanol polyether-3, azimino-benzene butyl sodium phenolsulfonate, tributyl citrate, lycine, sodium hyaluronate, niacinamide, creatin, methyl hydroxybenzoate, peony root extracts, rice fermentation product filter liquid and phenoxyethanol. The formula design is reasonable; the irritation is small; the stability ishigher than that of a conventional sun-screen cream; the sun-screen and moisture preservation effects are ensured; the formation of free radicals is reduced; the anti-aging function is achieved.

Owner:NOX BELLCOW COSMETICS CO LTD

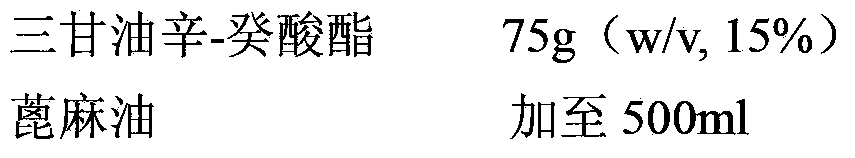

Fully synthetic cutting fluid for metal processing and preparation method thereof

InactiveCN104232283AGood adsorption and anti-rust effectImprove the lubrication effectLubricant compositionPolyolefinFatty acid

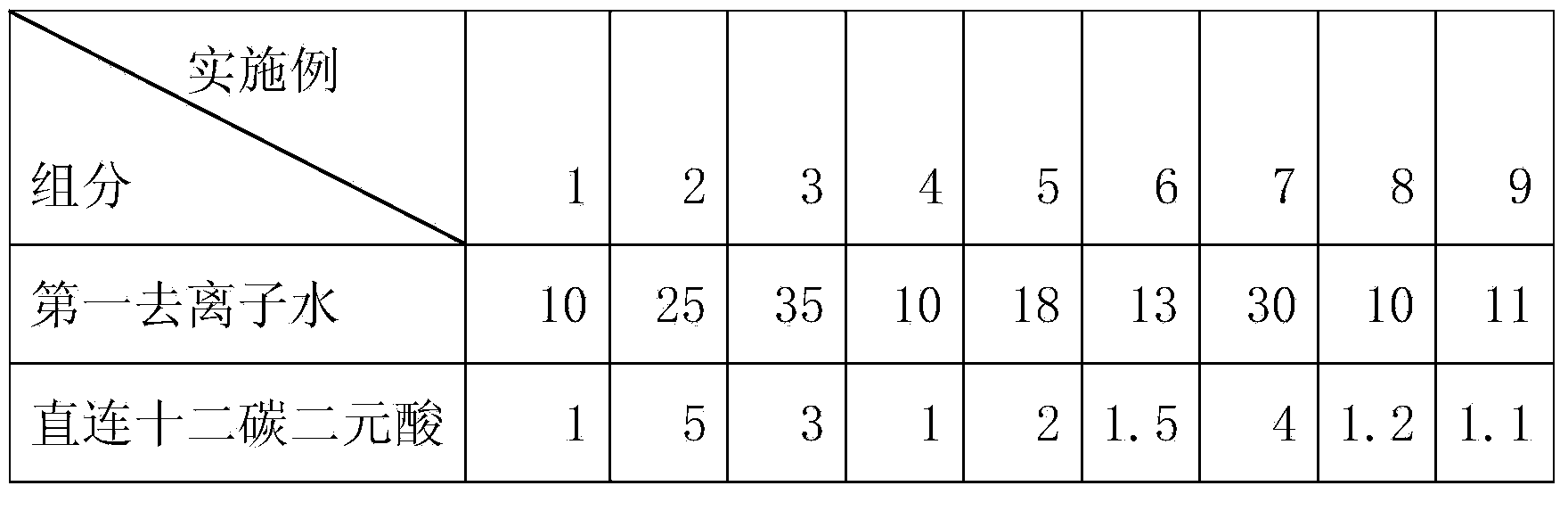

The invention discloses fully synthetic cutting fluid for metal processing. The cutting fluid is prepared from deionized water, linear chain dodecanedioic acid, boric acid, benzotriazole, monoethanolamine, diethanol amine, D1550 fatty acid, ricinoleic acid, tetraricinoleic acid, isononanoic acid, octanoic / decanoic acid, dicyclohexylamine, fatty alcohol, polyolefin, isooctadecanol, a sterilizing agent and an antifoaming agent according to a certain ratio. The fully synthetic cutting fluid for metal processing overcomes the defects that the using cost of the product is high, a diluent easily goes bad to generate foreign odor, lubrication is insufficient and the service time and cycle are short and the like existing in products in the market and also has excellent cooling and cleaning anti-rust performances, so that the metal processing and lubricating products are improved in the machining and lubricating aspects to a certain degree. The fully synthetic cutting fluid product for metal processing has the greatest characteristic that the lubricating property requirements of heavy processing modes of some materials which are difficult to machine in the machining process can be met, the fully synthetic cutting fluid does not contain base oil, and the service time can be greatly prolonged.

Owner:上海加美实业有限公司

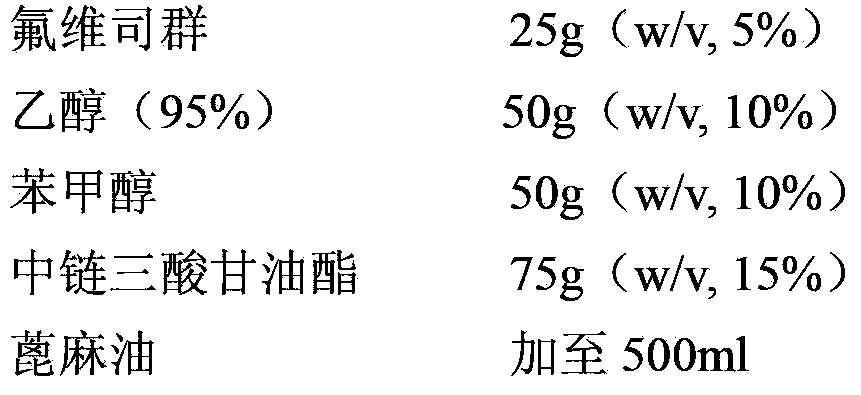

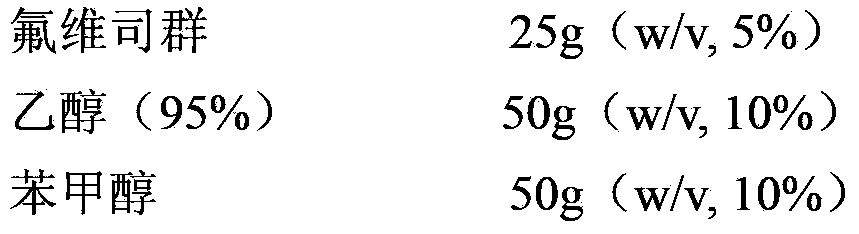

Fulvestrant pharmaceutical composition

ActiveCN104337761AImprove stabilityImprove bioavailabilityOrganic active ingredientsPharmaceutical delivery mechanismGlycerolPharmaceutical medicine

The invention relates to a fulvestrant pharmaceutical composition. Specifically, the invention relates to the fulvestrant-containing pharmaceutical composition for intramuscular injection, wherein the pharmaceutical composition comprises 1) fulvestrant, 2) a castor oil matrix; 3) at least one pharmaceutically acceptable alcohol, and 4) one or any mixture selected from the group consisting of medium-chain triglyceride, triglycerol caprylate-caprate, glyceryl triacetate, ethyl acetate and isopropyl myristate. The pharmaceutical composition is excellent in pharmaceutical safety and stability performance, and better in bioavailability.

Owner:JIANGSU HANSOH PHARMA CO LTD

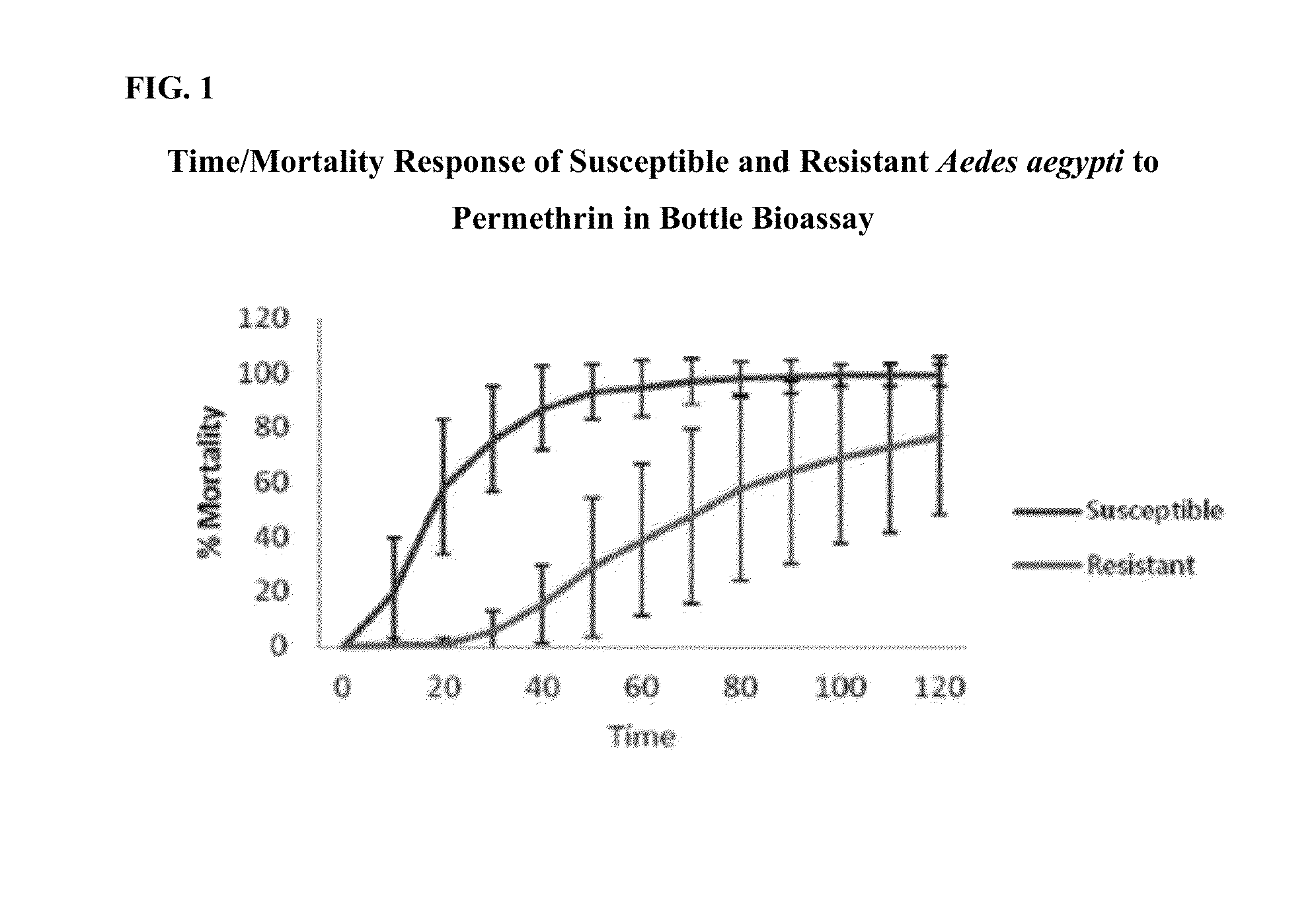

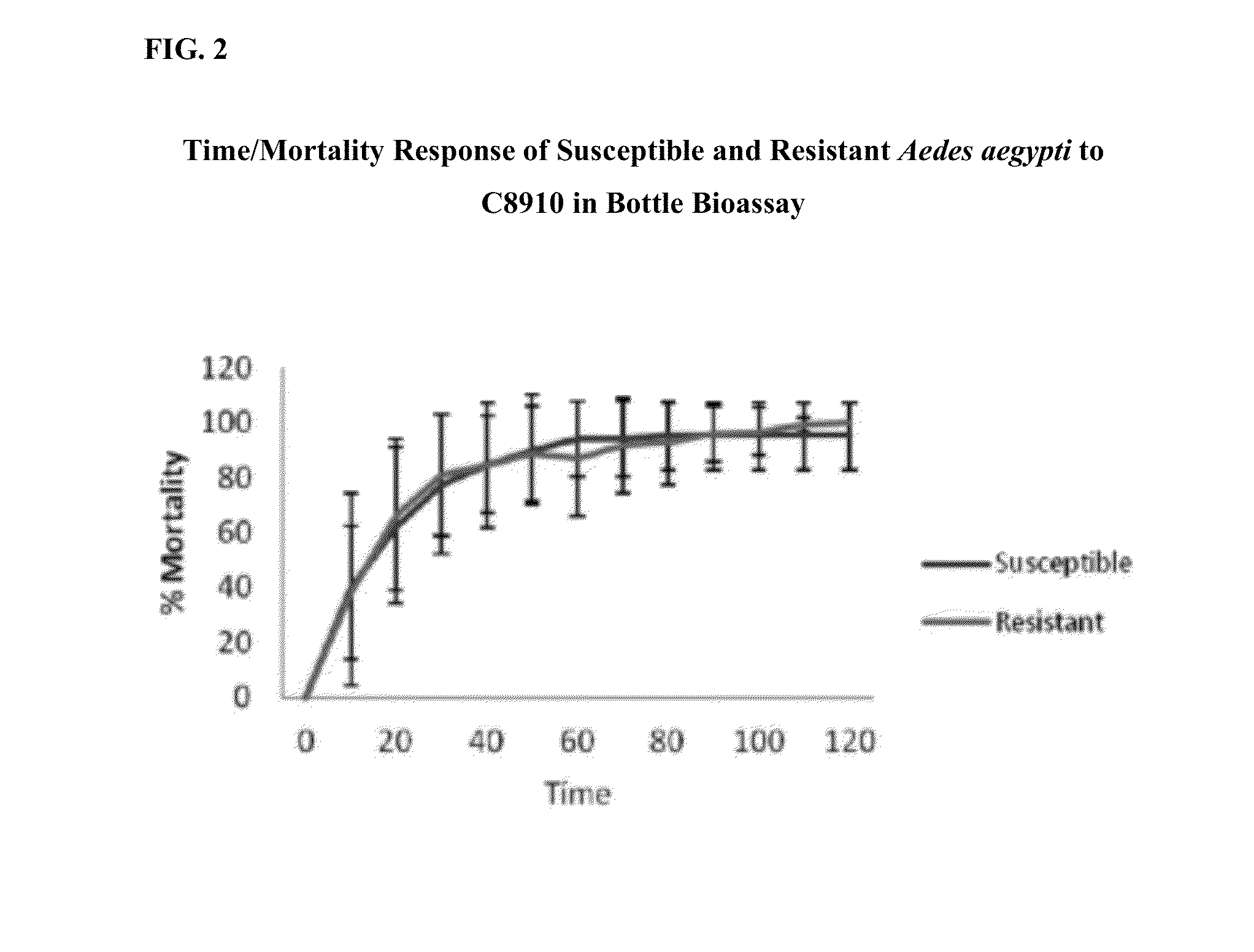

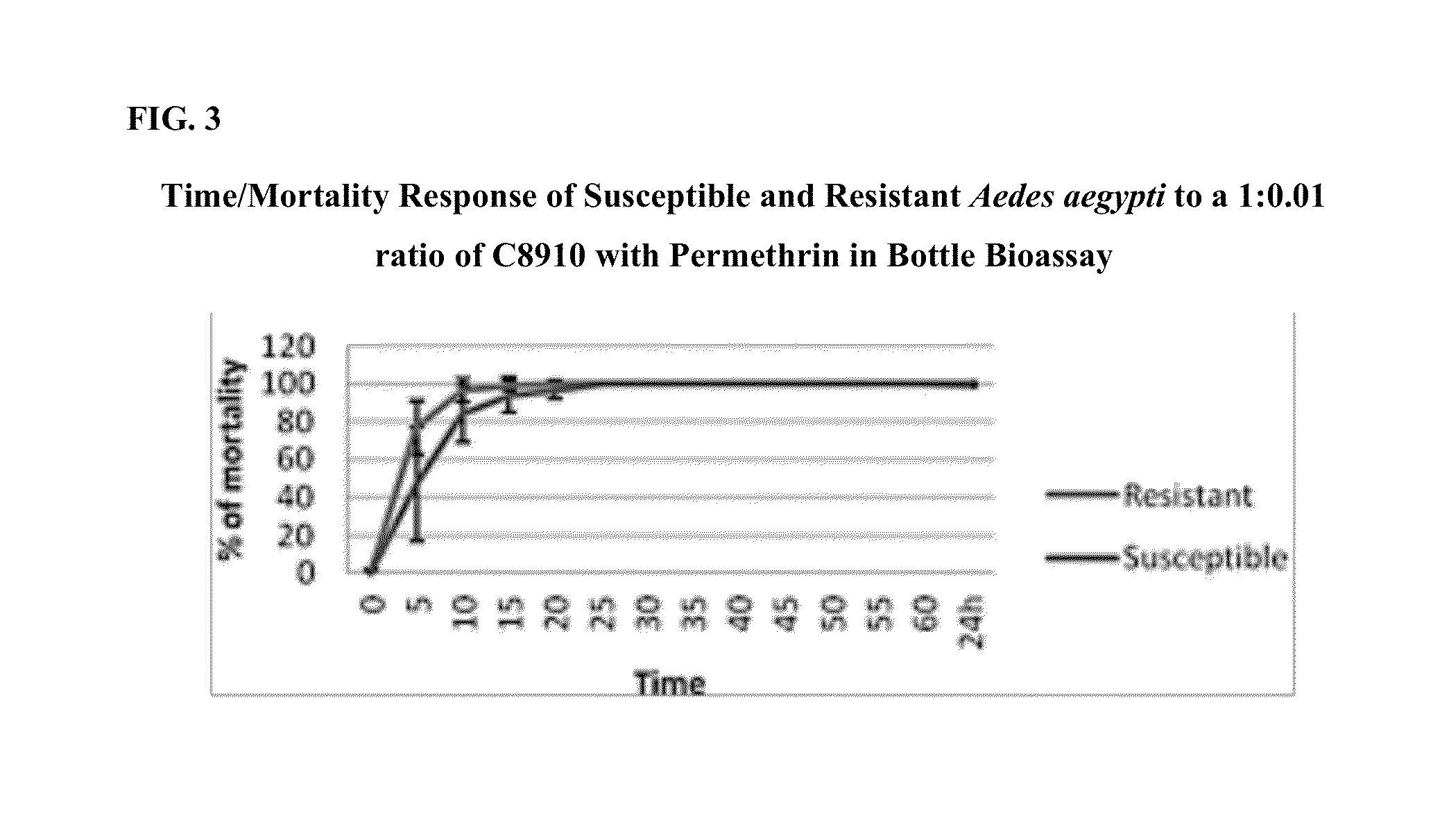

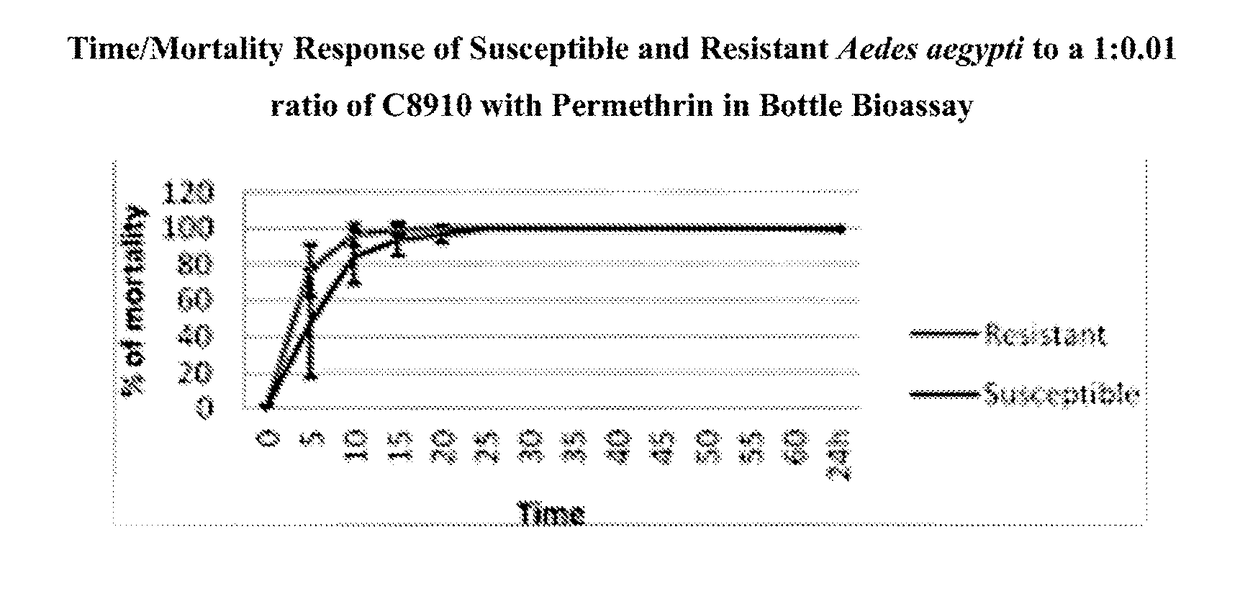

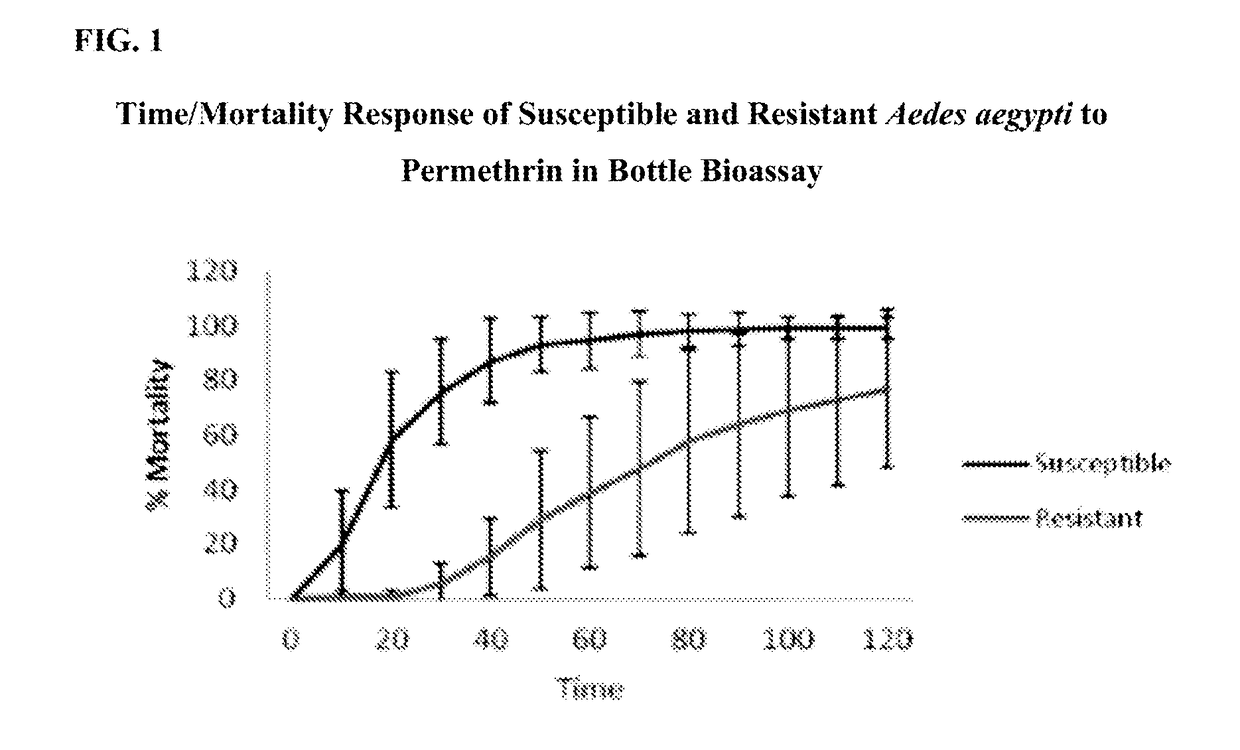

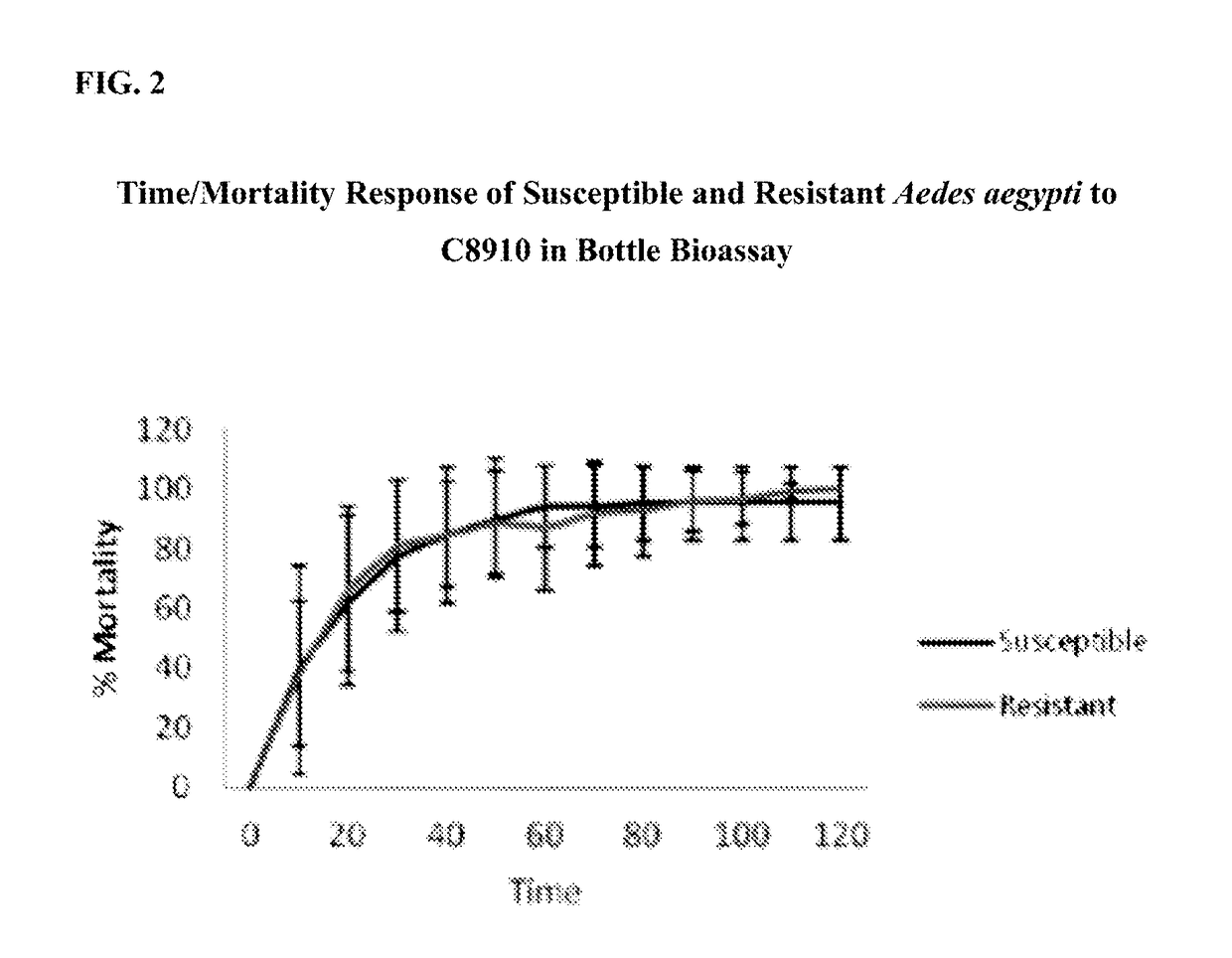

Octanoic, nonanoic and decanoic fatty acids with a pyrethroid adulticide

The invention relates to an octanoic, nonanoic and decanoic (C8, 9, 10) fatty acids mixture with a pyrethroid. The invention also relates to methods of using the octanoic, nonanoic and decanoic (C8, 9, 10) fatty acids and pyrethroid mixture to achieve superior arthropod control.

Owner:VALENT BIOSCIENCES CORP

Octanoic, nonanoic and decanoic fatty acids with pyrethroid adulticides

The invention relates to an octanoic, nonanoic and decanoic (C8, 9, 10) fatty acids mixture with a pyrethroid. The invention also relates to methods of using the octanoic, nonanoic and decanoic (C8, 9, 10) fatty acids and pyrethroid mixture to achieve superior arthropod control.

Owner:VALENT BIOSCIENCES CORP

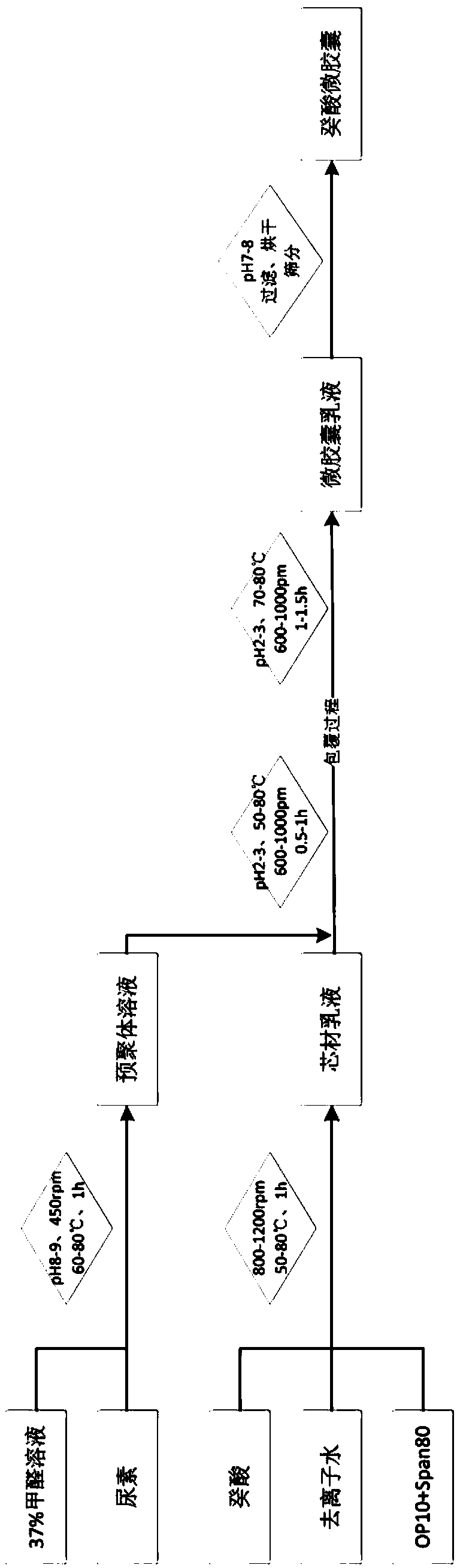

Decanoic acid microcapsules and preparation method thereof

ActiveCN108854878AGood lookingUniform particle size distributionHeat-exchange elementsMicroballoon preparationEmulsionMelamine

The invention discloses decanoic acid microcapsules and a preparation method thereof. The method comprises the following steps: 1, mixing urea with a formaldehyde solution, adjusting the pH value of asystem to 8-9, and adding melamine in batches when the solution is clear so as to obtain a prepolymer solution; 2, adding decanoic acid and an emulsifying agent into deionized water to obtain a decanoic acid emulsion; 3, pouring the prepolymer solution obtained in the first step into the decanoic acid emulsion obtained in the second step, adjusting the pH value of the reaction system to 2-3, andcarrying out a thermostatic reaction for 0.5-1h at 50-80 DEG C, wherein the stirring speed is 600-1000 rpm; 4, heating up to 70-80 DEG C, adding 0.44-0.5 part by mass of a curing agent into the mixture obtained in the third step, and carrying out a thermostatic reaction for 1-2h, wherein the stirring speed is 600-1000 rpm; 5, filtering, washing, drying and screening the product obtained in the fourth step to obtain the decanoic acid microcapsules. The decanoic acid microcapsules obtained by method is low in cost, simple in operation, high in repeatability and lower in requirements for equipment and raw materials, thus being suitable for industrial production.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com