Decanoic acid microcapsules and preparation method thereof

A technology of microcapsules and capric acid, which is applied in the field of melamine-modified capric acid microcapsules and its preparation, can solve the problems of difficult large-scale application, expensive core material, and low effect, and achieve good phase change performance, equipment and raw material requirements Low, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

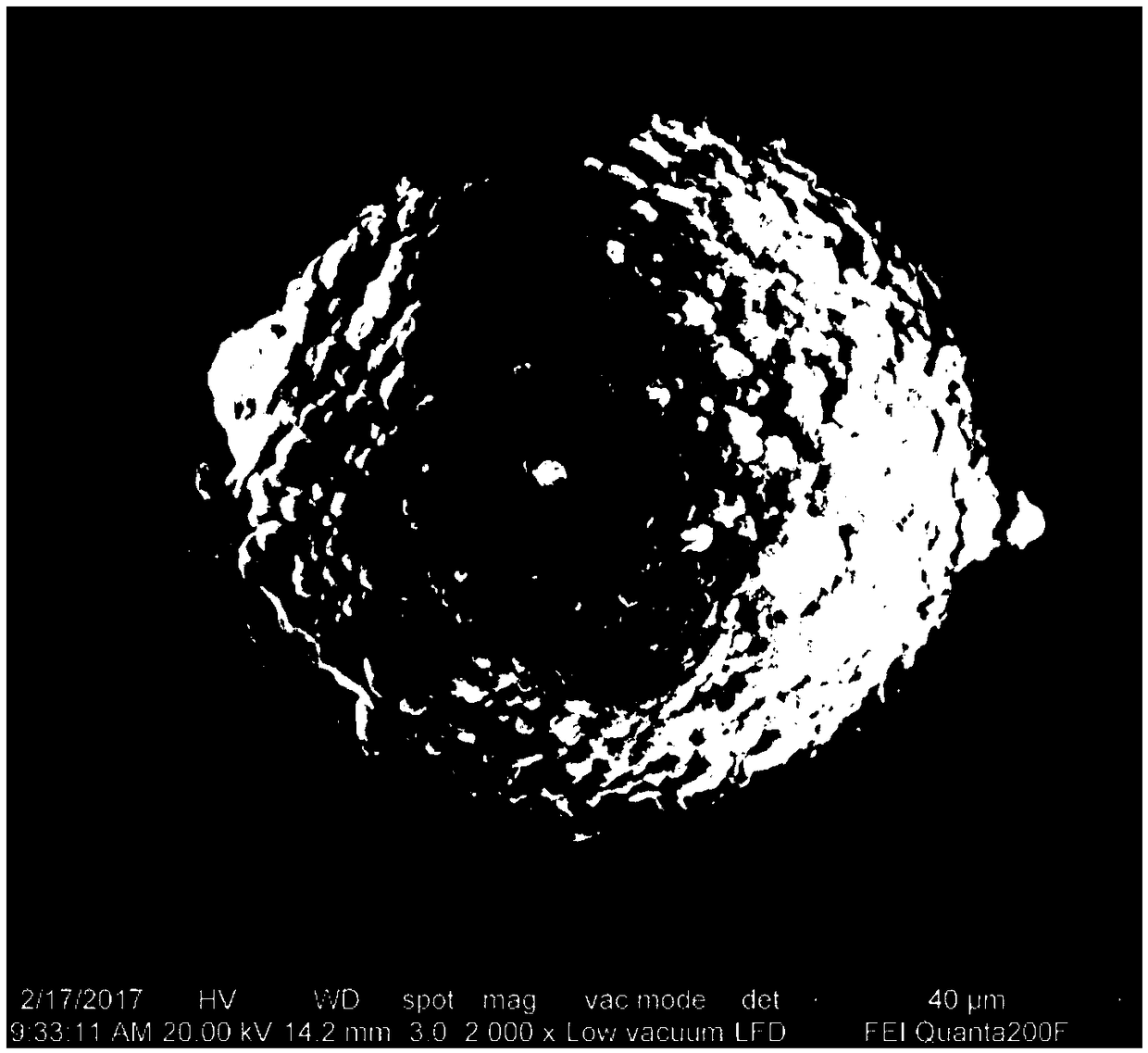

Image

Examples

preparation example Construction

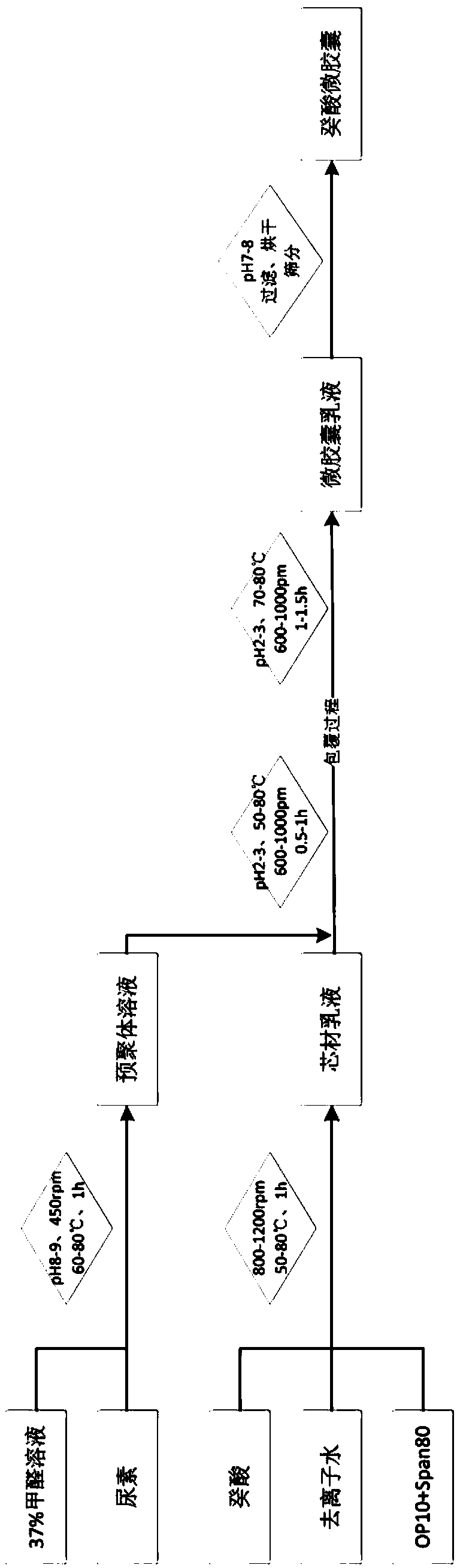

[0025] A preparation method of capric acid microcapsules, the method comprising the following steps:

[0026] In the first step, mix 4.4-4.9 parts by mass of urea and 9.8-10.8 parts by mass of 37% formaldehyde solution, adjust the pH value of the system to 8-9, and react at a constant temperature of 60-80°C. After the solution is clarified, add 0.22 -0.25 parts by mass of melamine to obtain a prepolymer solution;

[0027] In the second step, add 9.8-10.9 parts by mass of capric acid and 0.49-0.55 parts by mass of emulsifier to 70-75 parts by mass of deionized water, and react at a constant temperature of 50-80°C for 0.5-1h, with a stirring rate of 800 -1200rpm obtains capric acid emulsion;

[0028] In the third step, pour the prepolymer solution obtained in the first step into the capric acid emulsion obtained in the second step, adjust the pH value of the reaction system to 2-3, and react at a constant temperature of 50-80°C for 0.5-1h, and the stirring rate 600-1000rpm;

...

Embodiment 1

[0039] Mix 44.5g of urea and 91.6g of 37% formaldehyde solution, adjust the pH of the system to 8-9, and react at a constant temperature of 70°C. After the solution is clarified, add a total of 1.8g of melamine in two times at a stirring rate of 450rpm to obtain a prepolymer solution. spare;

[0040] Add 100g of capric acid and 5g of OP-10 into 600g of deionized water, react at a constant temperature of 60°C for 0.75h, and stir at 1000rpm to obtain a capric acid emulsion;

[0041] Pour the prepolymer solution obtained in step (1) into the solution obtained in step (2), adjust the pH of the reaction system to 2-3 with 10% citric acid, react at a constant temperature of 60°C for 0.5h, and stir at a rate of 1000rpm;

[0042] Heat up to 80°C, add 4.5g of resorcinol to the mixture obtained in step (3), react at constant temperature for 1.5h, and stir at 800rpm;

[0043] The product obtained in step (4) is filtered, washed, dried and sieved to obtain the capric acid microcapsules. ...

Embodiment 2

[0045] Mix 44.5g of urea and 91.6g of 37% formaldehyde solution, adjust the pH of the system to 8-9, and react at a constant temperature of 70°C. After the solution is clarified, add a total of 2.25g of melamine in two times, with a stirring rate of 450rpm, to obtain a prepolymer solution. spare;

[0046] Add 100g of capric acid, 4g of OP-10 and 1g of Span-80 into 600g of deionized water, react at a constant temperature of 60°C for 0.5h, and stir at 1000rpm to obtain a capric acid emulsion;

[0047] Pour the prepolymer solution obtained in step (1) into the solution obtained in step (2), adjust the pH of the reaction system to 2-3 with 10% citric acid, react at a constant temperature of 60°C for 0.5h, and stir at a rate of 1000rpm;

[0048] Heat up to 80°C, add 4.5g of resorcinol to the mixture obtained in step (3), react at constant temperature for 1.5h, and stir at 800rpm;

[0049] The product obtained in step (4) is filtered, washed, dried and sieved to obtain the capric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com