Patents

Literature

742 results about "Capric Acid" patented technology

Efficacy Topic

Property

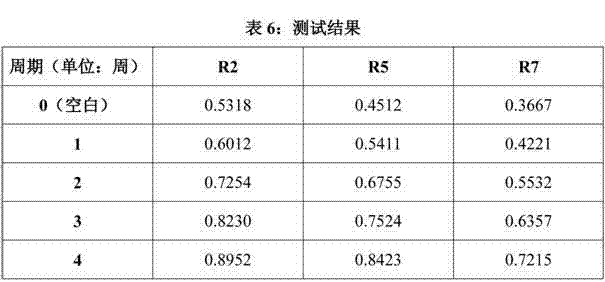

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A saturated medium-chain fatty acid with a 10-carbon backbone. Capric acid is found naturally in the coconut and palm kernel oils as well as the milk of various mammals.

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20050065214A1Stimulate bone healing processLower potentialBiocidePowder deliveryBarium saltTG - Triglyceride

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

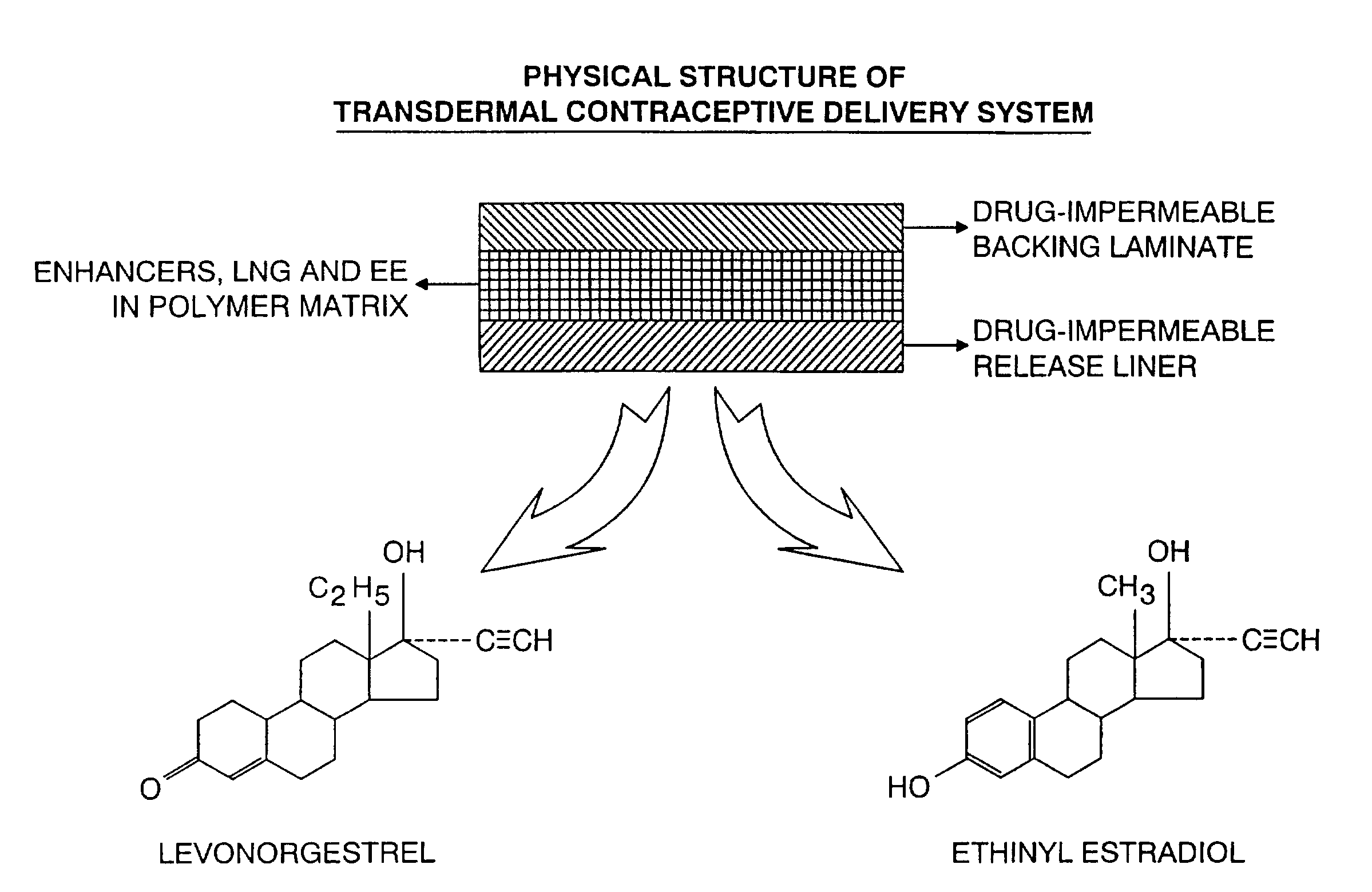

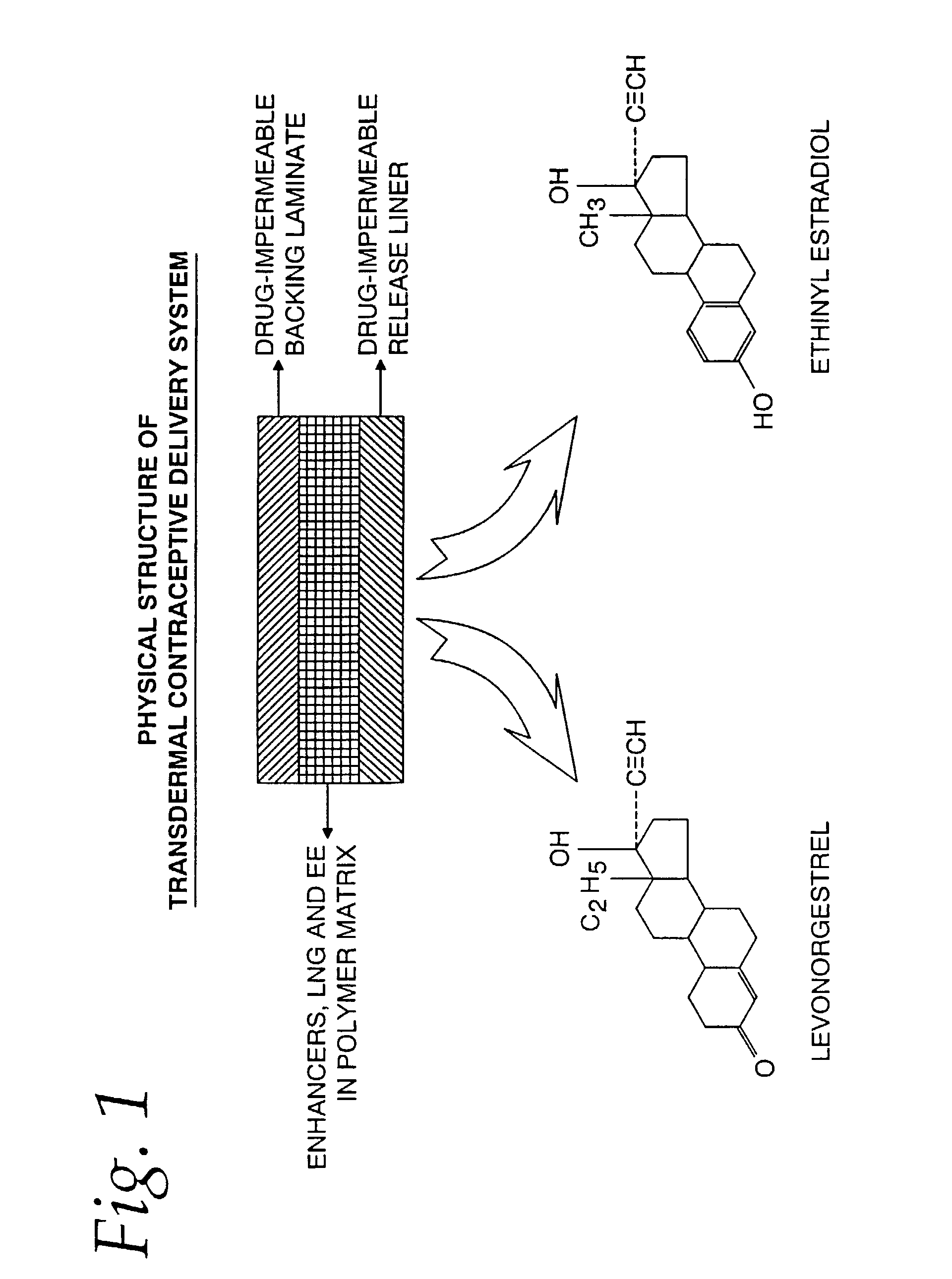

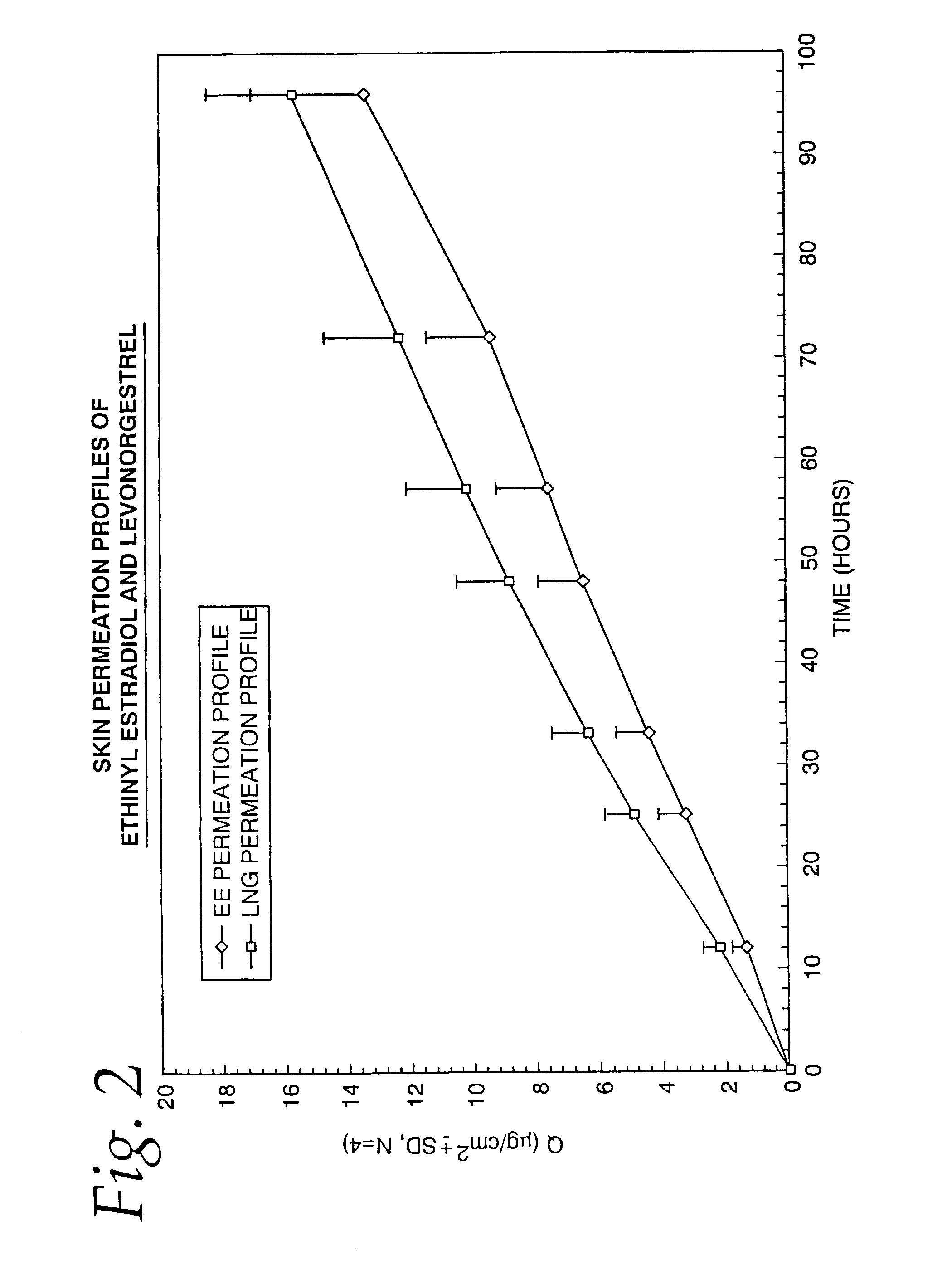

Transdermal contraceptive delivery system and process

InactiveUS7045145B1Cut skinReduce concentrationOrganic active ingredientsAdhesive dressingsObstetricsAdhesive

A transdermal contraceptive delivery system (TCDS) for fertility control in women is described. It comprises a backing layer, an adjoining layer of a solid absorption adhesive polymer matrix in which effective daily doses of an estrogen and a progestin are dispersed and released for transdermal absorption. Presently preferred is the use of the synthetic estrogen, ethinyl estradiol, and the synthetic progestin, levonorgestrel. Along with these two steroidal contraceptive agents, a combination of several chemical skin permeation enhancing agents, including capric acid, blended at specific weight ratios, ranging from 2:1:1:0.8 to 6:1:1:0.8, are homogeneously dispersed in the adhesive polymer matrix. The invention also provides a method of fertility control utilizing the transdermal contraceptive delivery system.

Owner:AGILE THERAPEUTICS

Pesticidal compositions and methods of use thereof

ActiveUS20100227010A1Enhances insecticidal/pesticidal activityImprove insect repellent effectBiocideOrganic active ingredientsVegetable oilGnat

A pest-combating composition including sodium lauryl sulfate and one or more of C6-12 fatty acids, preferably lauric and / or capric and / or caprylic acid, soy methyl ester, and 2-undecanone, and methods of combating pests utilizing same, are disclosed. The compositions can include a carrier oil such as silicon oil, soy methyl ester, or a vegetable oil, and can be in the form of an emulsion. The composition may be constituted as a spray composition, an aerosol, a lotion, a paste, or another compositional form. Pests that may be usefully combated with such composition include flying insects, including flies, mosquitoes, and wasps, ants, including arthropods such as fire ants, ticks, fleas, cockroaches, silver fish, thrips, gnats, aphids, Japanese beetles, and agricultural and horticultural arthropods and insects including beetles (potato and bean), flea beetles, fleahoppers, squash bugs, slugs, leaf hoppers, harlequin bugs, milk weed bugs, spiders, mites, lice, rodents, and deer.

Owner:HOMS

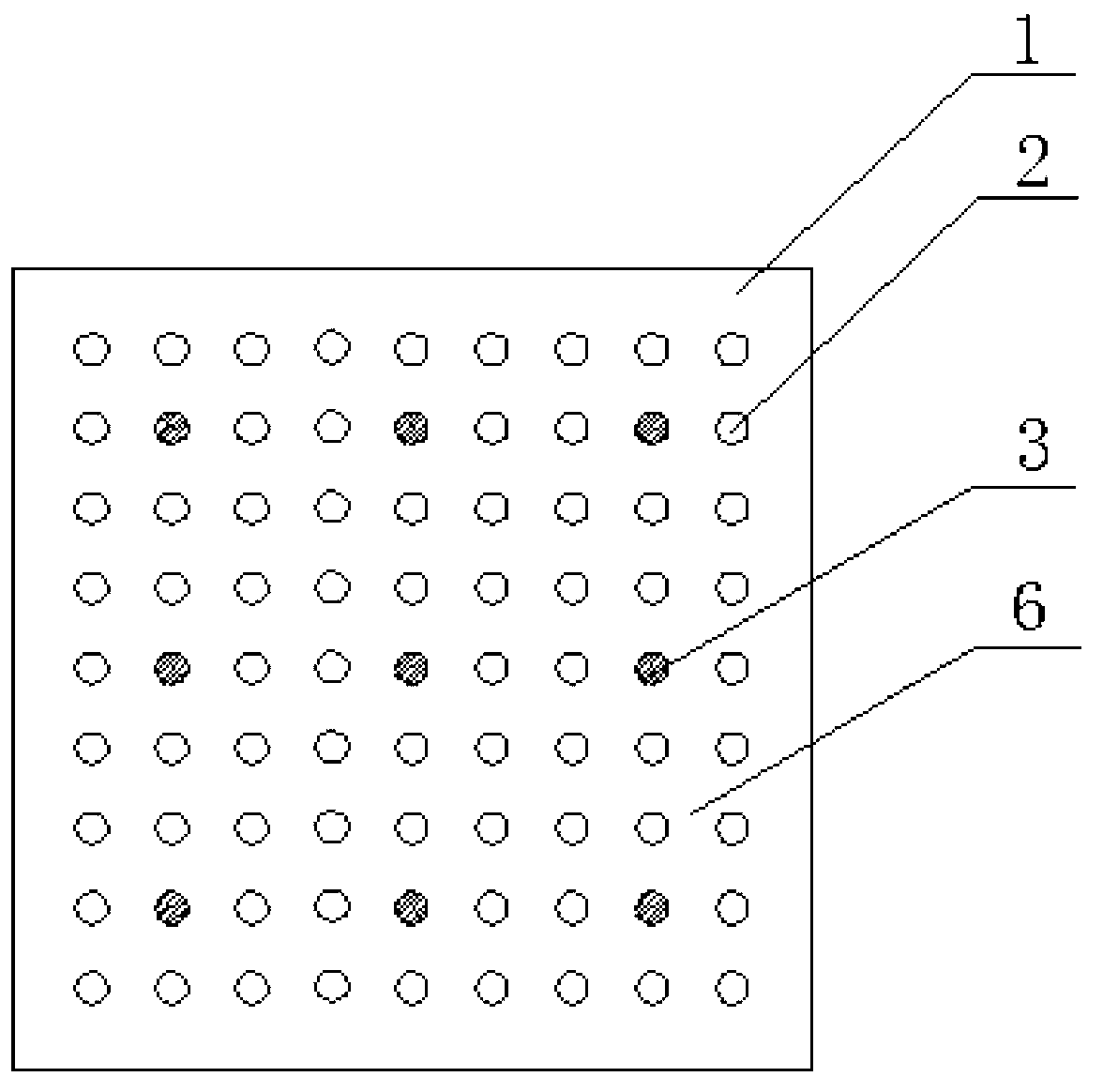

Constructional phase change energy storage plate and manufacturing method thereof

InactiveCN103015540APrevent leakageNo overflowLaminationLamination apparatusEnvironmental resistanceAlcohol

The invention discloses a constructional phase change energy storage plate, consisting of an upper cover plate, a lower bottom plate and a phase change material, wherein the phase change material is a mixture of fatty acid and high carbon alcohols; the fatty acid is n-decylic acid, lauric acid, myristic acid, palmitic acid and stearic acid; the alcohols are dodecanol, tetradecanol, hexadecanol and octadecanol; and the mass percent of the fatty acid to the mass percent of the high carbon alcohols is 46.4%: 53.6% to 97.5%: 2.5%. With the adoption of the constructional phase change energy storage plate and a manufacturing method thereof, the problems such as damages to mechanical performances, environmental protection, safety and the like are fundamentally solved, and meanwhile, the risks existing in actual application are prevented; the constructional phase change energy storage plate is stable in structure; the phase change material is not easy to leak; no irritant gas overflows; the appearance is attractive; and therefore, besides application onto constructed walls, the constructional phase change energy storage plate also can be used as an interior decoration, a suspended ceiling and a laid floor board.

Owner:TIANJIN UNIV

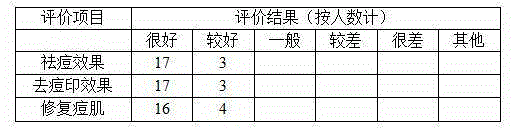

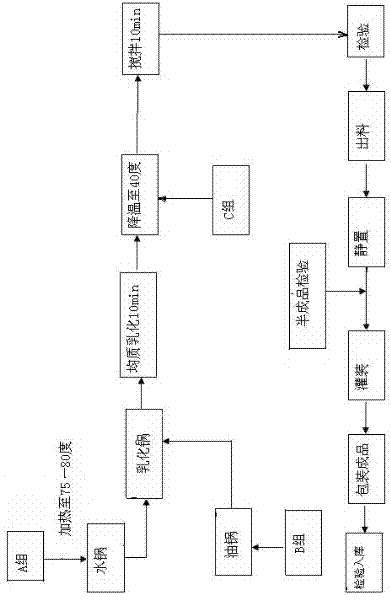

Acne treatment composition and application thereof and acne treatment cream containing acne treatment composition

ActiveCN105012479ASoothe rednessRelieve discomfort such as inflammationCosmetic preparationsToilet preparationsCentella asiatica extractEthylhexyl palmitate

The invention discloses an acne treatment composition and application thereof and an acne treatment cream containing the acne treatment composition. The acne treatment composition comprises shea butter, Chinese corktree bark extract, salix nigra bark extract, herba portulacae extract, purple perilla extract, asiatic pennywort herb extract and mung bean extract, effectively conditions acne skins and inhibits reproduction of acne, smoothens acne and removes acne marks, and can be applied to skin directly or added into acne treatment products. The acne treatment cream comprises the acne treatment composition, cetearyl alcohol, ethylhexyl palmitate, polydimethylsiloxane, glyceryl stearate, PEG-100 stearate, caprylic / capric triglyceride, propylene glycol, polyacrylamide, polysorbate-60, sorbitan stearate, laurocapram, PEG-20 methl glucse sesquistearate, menthol, borneol, edta disodium, methylparaben, propyl hydroxybenzoate and water. The acne treatment cream prepared by a hypo-allergenic formula is mild and non-irritating, easy to absorb, non-greasy, safe and effective.

Owner:广州科玛生物科技股份有限公司

Prinsepia utilis Royle oil-containing functional skin care product and preparation method thereof

ActiveCN102406576AMild textureImprove securityCosmetic preparationsToilet preparationsAllergic dermatitisDisease

The invention discloses a Prinsepia utilis Royle oil-containing functional skin care product and a preparation method thereof. The Prinsepia utilis Royle oil-containing functional skin care product is prepared from the following raw materials in part by weight: 1 to 2 parts of Prinsepia utilis Royle oil, 10 to 25 parts of purslane extracting solution, 5 parts of glycerol, 2 to 3 parts of 1,2-pentanediol, 5 to 7 parts of caprylic / caprictriglycerides, 2 parts of synthetic squalane, 1 to 5 parts of tocopheryl acetate, 1 to 3 parts of cetearyl alcohol, 0.1 to 0.2 part of allantoin, 0.6 to 0.9 part of coconut oil-base glucoside, 0.5 to 1 part of coconut oil alcohol, 0.5 to 2 parts of glyceryl stearate, 0.1 to 1 part of sodium hyaluronate and the balance of water. The functional skin care product has mild property and high safety without toxic or side reaction and anaphylactic reaction, can repair the destructed skin barrier, resists inflammation and skin ageing, and has a good effect and high safety of assisting in treating skin diseases related with skin barrier destruction, such as facial dermatitis (hormone dependence dermatitis, allergic dermatitis and acne), atopic dermatitis and the like.

Owner:YUNNAN BOTANEE BIO TECH GRP CO LTD

Non-additivated antisenescence cosmetic

ActiveCN103156786AImprove anti-aging effectCosmetic preparationsToilet preparationsGlycerolDimethyl siloxane

The invention discloses a non-additivated antisenescence cosmetic, which comprises the following components by weight: a component A composed of glycerin, propylene glycol, hydroxyethyl urea, allantoin, sodium hyaluronate and water; a component B composed of MONTANOV68, dipalmitoyl hydroxyproline, caprylic / capric triglyceride, shea butter, jojoba oil, tocopheryl acetate, polydimethylsiloxane, wheat germ oil and COSMOFERMMI XIII; a component C composed of hydroxyethyl acrylate / acryloyl dimethyltaurate crosspolymer; a component D composed of nicotinamide, panthenol, beta-glucan, mycose and water; a component E composed of acetyl Hexapeptide-8 and water; and a component F composed of SYMDIOL68T and SYMTRIOL. The antisenescence cosmetic has good antisenescence effect, simultaneously, no harmful antiseptic is added in the cosmetic.

Owner:广州市美驰化妆品有限公司

Anti-wrinkle face cream and preparation method thereof

ActiveCN105147591AAnti agingImprove youthCosmetic preparationsToilet preparationsEthylhexyl palmitateApple extract

The invention belongs to the technical field of cosmetics, and in particular relates to an anti-wrinkle face cream and a preparation method thereof. The anti-wrinkle face cream comprises butanediol, ethylhexyl palmitate, caprylic / capric triglyceride, glycerol, polyglycerol-10, ethylhexyl isononanoate, polymethyl methacrylate, polydimethylsiloxane, ceteareth-21, cetostearyl alcohol, ceteareth-2, acrylic acid (ester) type / acrylamide copolymer, betaine, avocado fruit butter, a lactic acid bacillus / balausta fermentation product extract, an arctic rock chlamydomonas essence, a starfish essence, a ginseng extract, a lucid ganoderma extract, an apple extract, tocopheryl acetate and the like. The anti-wrinkle face cream provided by the invention is good in penetrability and easy to absorb, can effectively replenish water and preserve moisture, and can repair skin wrinkles and inhibit generation of the winkles, thereby delaying skin aging.

Owner:广州科玛生物科技股份有限公司

Skin care oil containing peony oil and preparation method thereof

ActiveCN103271860AImprove circulationAnti agingCosmetic preparationsToilet preparationsBiotechnologyMeadowfoam seed oil

The invention belongs to the technical field of skin care oil medicine, in particular to skin care oil medicine containing peony oil and a preparation method thereof. The skin care oil medicine provided by the invention comprises the following components in parts by weight: main ingredients: peony seed oil, caprylic / capric triglyceride, cyclopentasiloxane and 1, 2 - butyl glycol 1-12, wherein the peony oil is peony seed oil or peony essence oil or the mixture of peony seed oil and peony essence oil; auxiliary ingredients: isostearic acid, butylated hydroxytoluene, avocado oil, simmondsia chinensis seed oil, meadowfoam seed oil and macadamia ternifolia seed oil; the skin care oil medicine containing peony oil prepared by the method provided by the invention can remarkably improve of the skin epidermis cell cycle function, promote the microcirculation of the blood capillary of the dermal skin effect, inhibit lipid peroxidation, improve metabolism, delay skin aging process, is provided with anti-wrinkle, moisturizing and whiting effect, people feels smooth and comfortable after the skin care oil medicine is used on the skin, and the skin care oil medicine containing peony oil is provided with better effect to chloasma, aging skin wrinkles, skin cutin hardening peeling and skin chap.

Owner:HEZE YAO & SHUN PEONY BIOTECH

Water-glycol fire-resistant hydraulic fluid

InactiveCN102086422AEnhanced high-pressure anti-wear propertiesImprove the lubrication effectLubricant compositionBenzoic acidCapric Acid

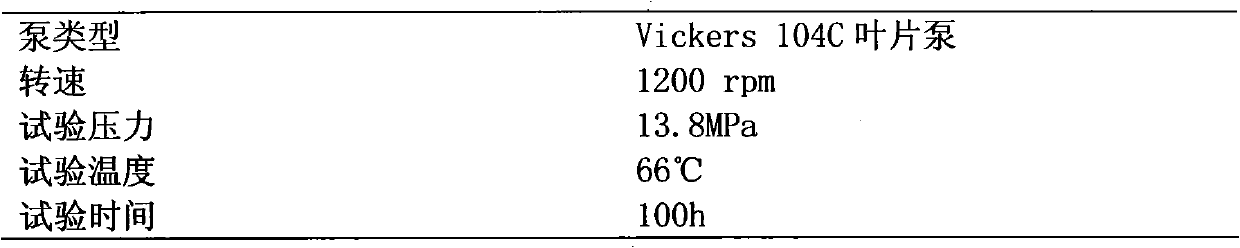

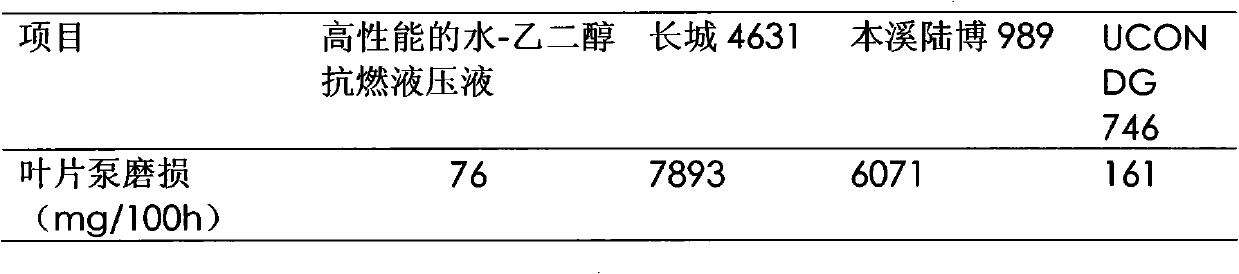

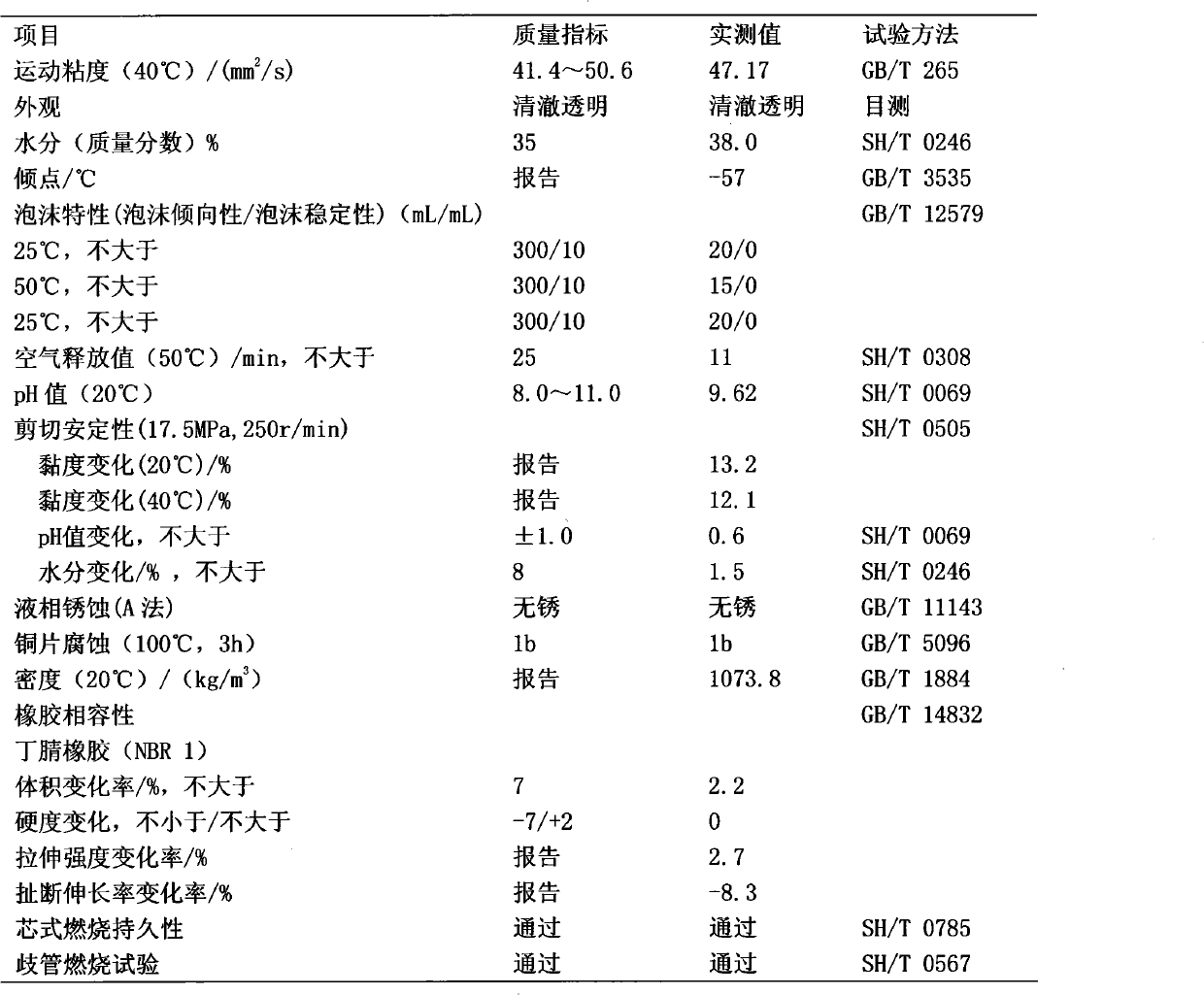

The invention relates to a water-glycol fire-resistant hydraulic fluid. The water-glycol fire-resistant hydraulic fluid comprises the following components in percentage by weight: 37 to 42 percent of water, 12 to 15 percent of the balance of glycol or diethylene glycol and water-soluble polyether tackifier, 0.1 to 0.2 percent of sulfur-containing extreme pressure antiwear additive, 1.0 to 3.0 percent of antiwear additive formed by capric acid or the compounding of the capric acid and caprylic acid, 1.5 to 3.0 percent of at least one amine type antirust agent, 0.1 to 0.3 percent of metal passivator, 0.01 to 0.02 percent of ethylenediaminetetraacetic acid disodium, 0.005 to 0.02 percent of benzoic acid, and 0.002 to 0.005 percent of defoaming agent. The water-glycol fire-resistant hydraulic fluid has the characteristics that: the product has strong high-pressure abrasion resistance, and still has good lubricating property under high-pressure working conditions; and a Vickers 104C vane pump bench test (ASTM D7043) with test pressure of 14MPa prove that the abrasion of a vane pump is less than 100mg.

Owner:PETROCHINA CO LTD

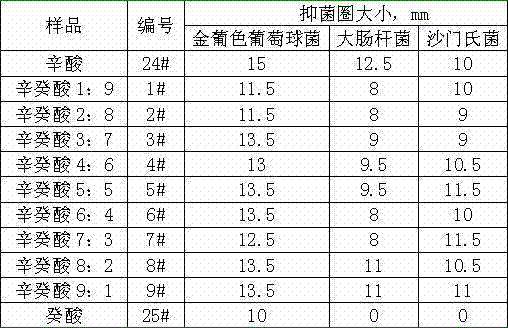

Medium Chain Fatty Acids Applicable as Anti-Microbial Agents

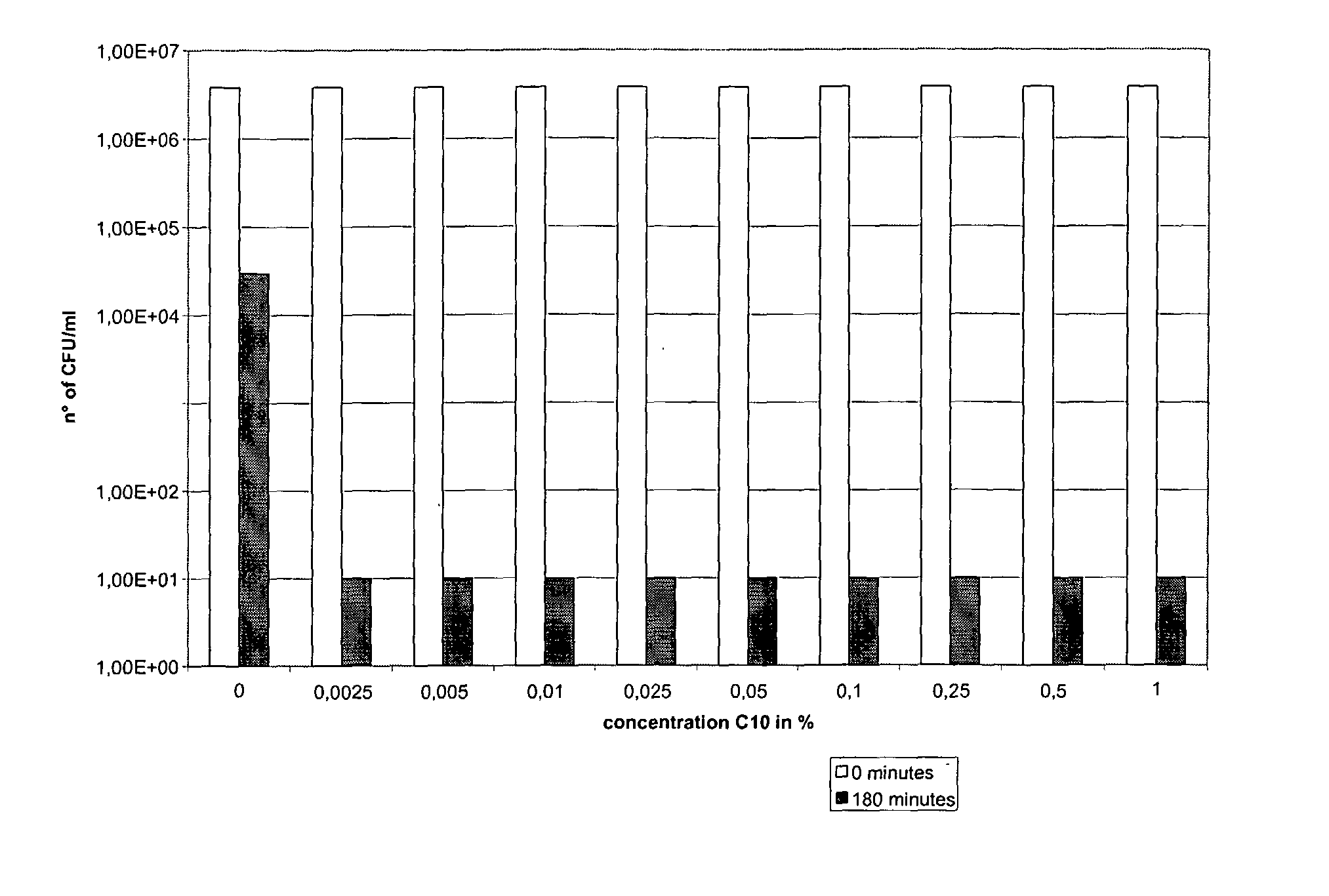

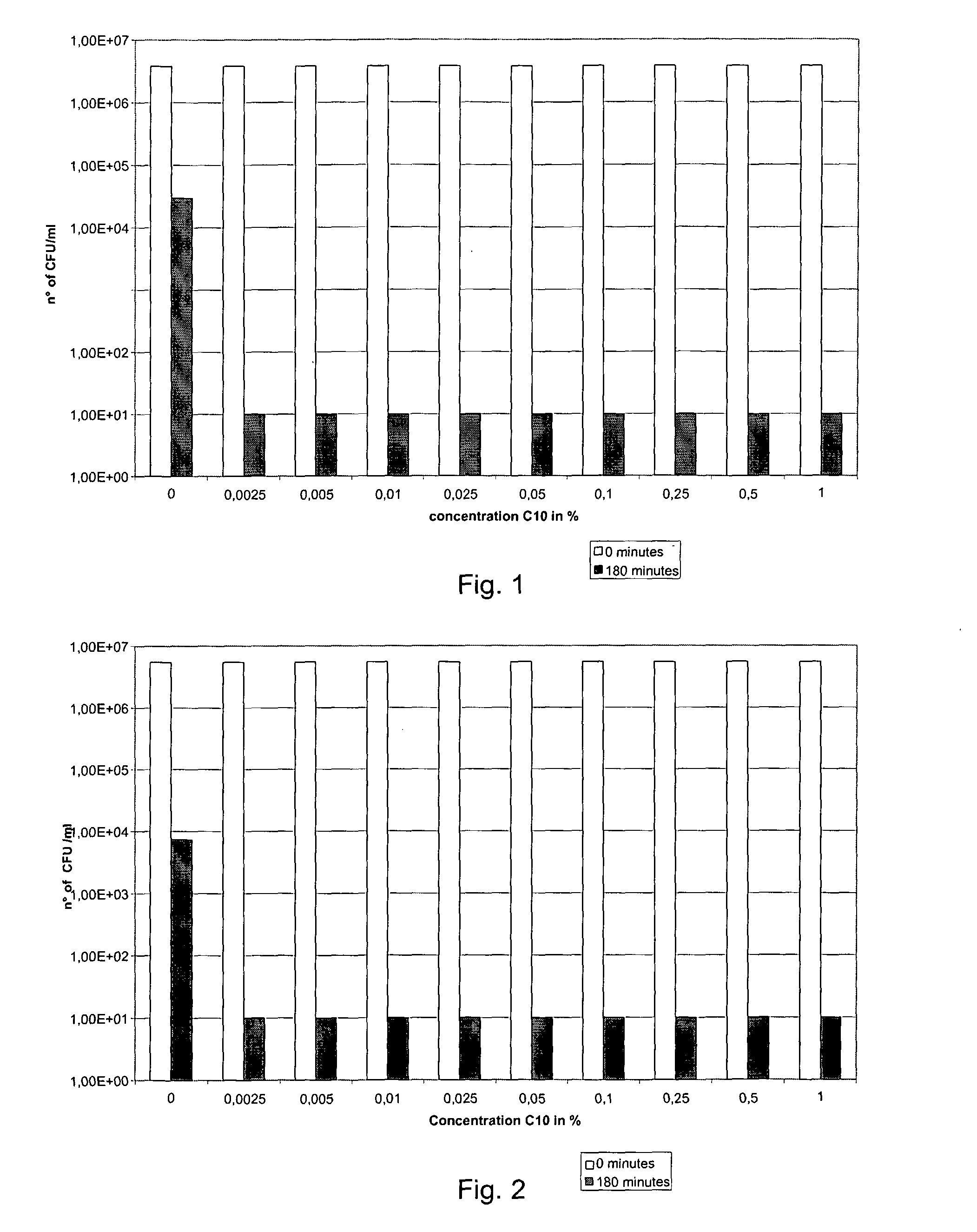

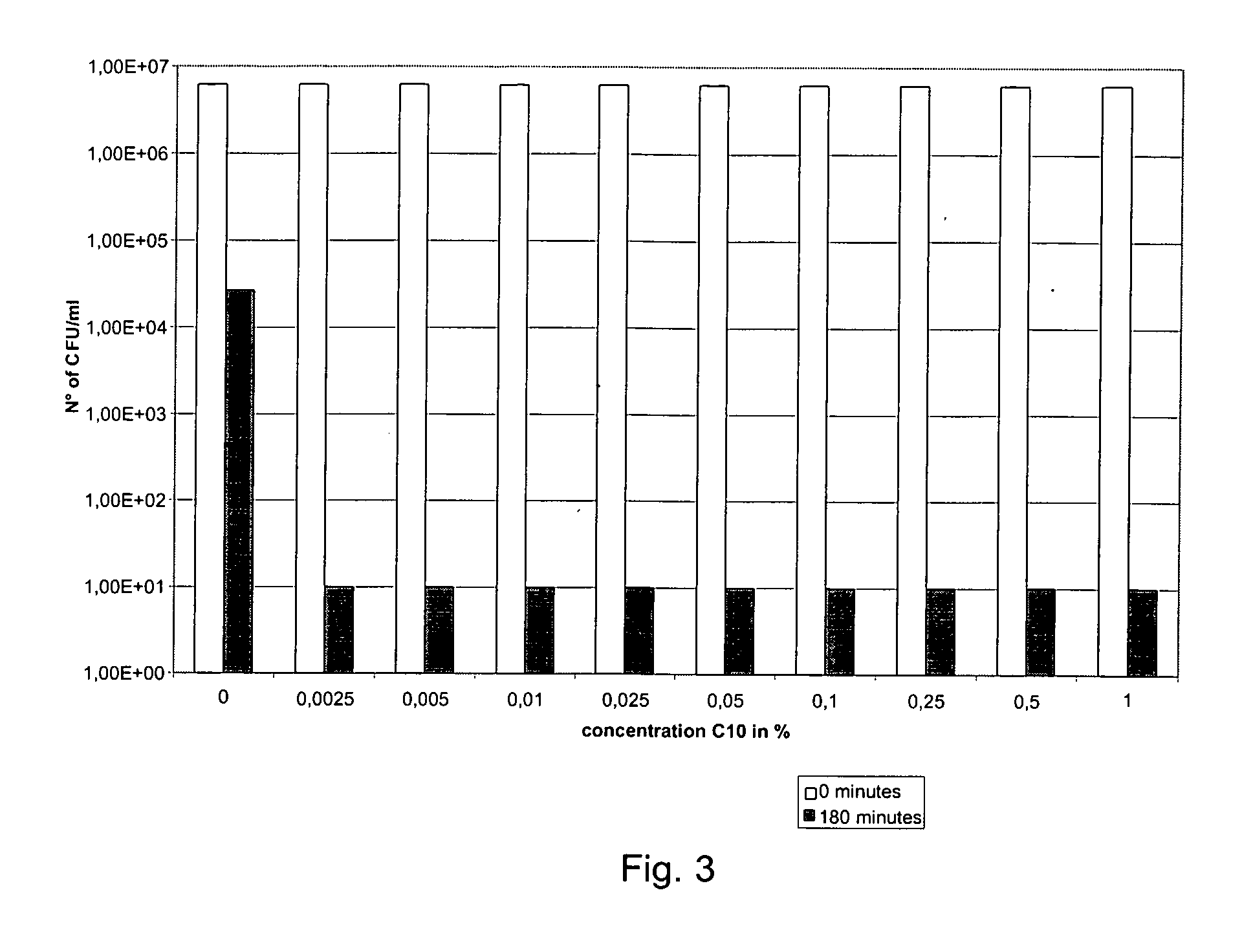

InactiveUS20070219270A1Good effectGrowth inhibitionAntibacterial agentsBiocideCapric AcidMicrobial agent

The present invention relates to the use of medium chain fatty acids (MCFA), chosen from the group consisting of caproic acid (C6), caprylic acid (C8) and capric acid (C10), salts, derivatives or mixtures thereof, in a total amount by weight comprised between 0.01% and 5% for inhibiting the growth of microbial pathogens.

Owner:NUTRITION SCI N V

Dutasteride soft capsule preparation and preparation process thereof

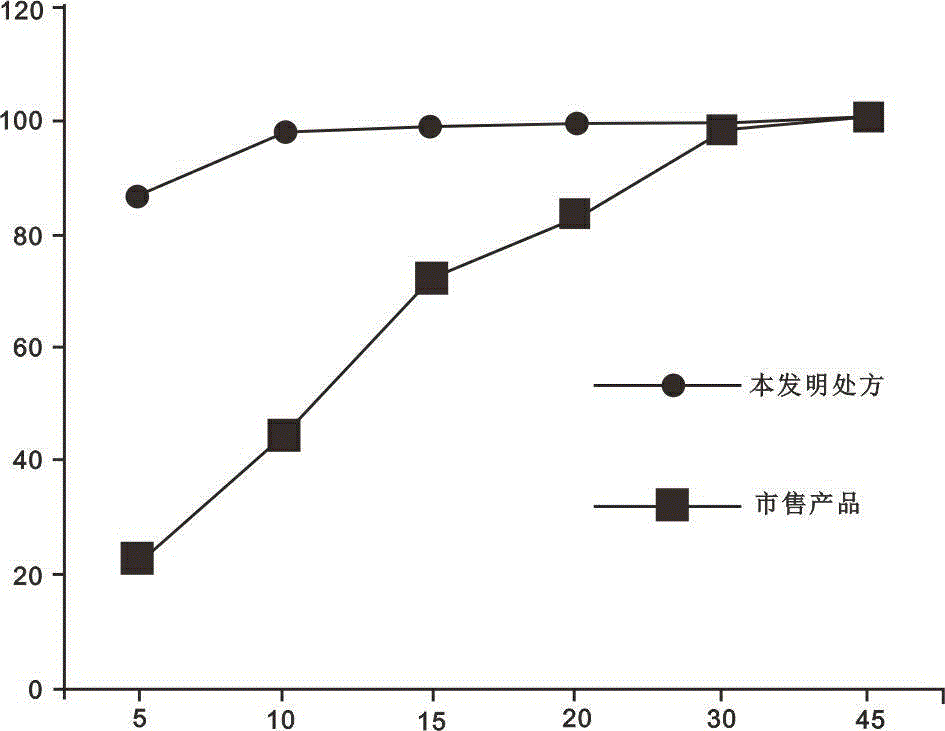

ActiveCN105395517AImprove dissolution efficiencyImprove stabilityOrganic active ingredientsPharmaceutical non-active ingredientsCresolPolyethylene glycol

The invention discloses a dutasteride soft capsule preparation, comprising a soft capsule and contents. A prescription for the contents comprises 0.5 g of a dutasteride raw material, 200 to 250 g of labrasol, 30 to 60 g of polyglycerol oleate, 50 to 100 g of medium-chain triglyceride and 0.02 to 0.05 g of 2,6-di-t-butyl p-cresol. The dutasteride soft capsule prepared in the invention is substantially improved in accumulated dissolution in 5 minutes of dissolving-out and enhanced in the dissolving-out efficiency of a main drug in a preceding time period and has good stability and good appearance quality.

Owner:成都华宇制药有限公司

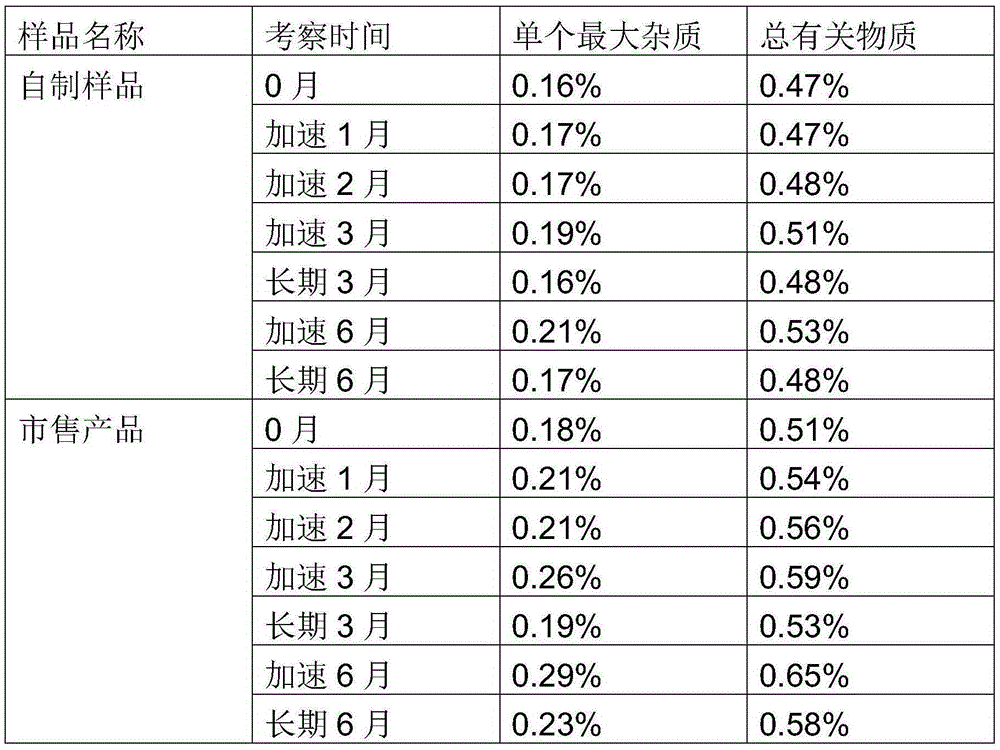

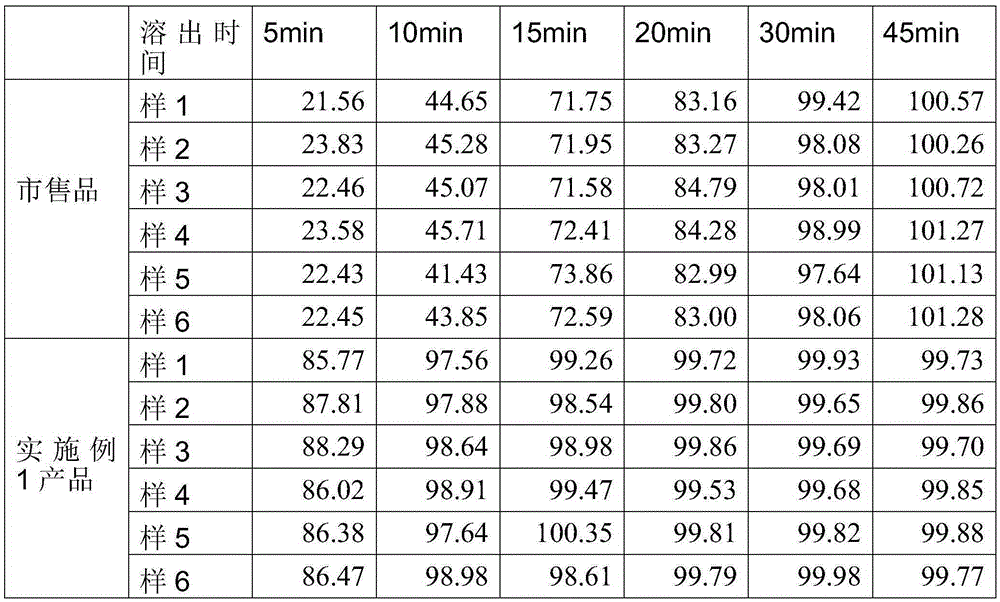

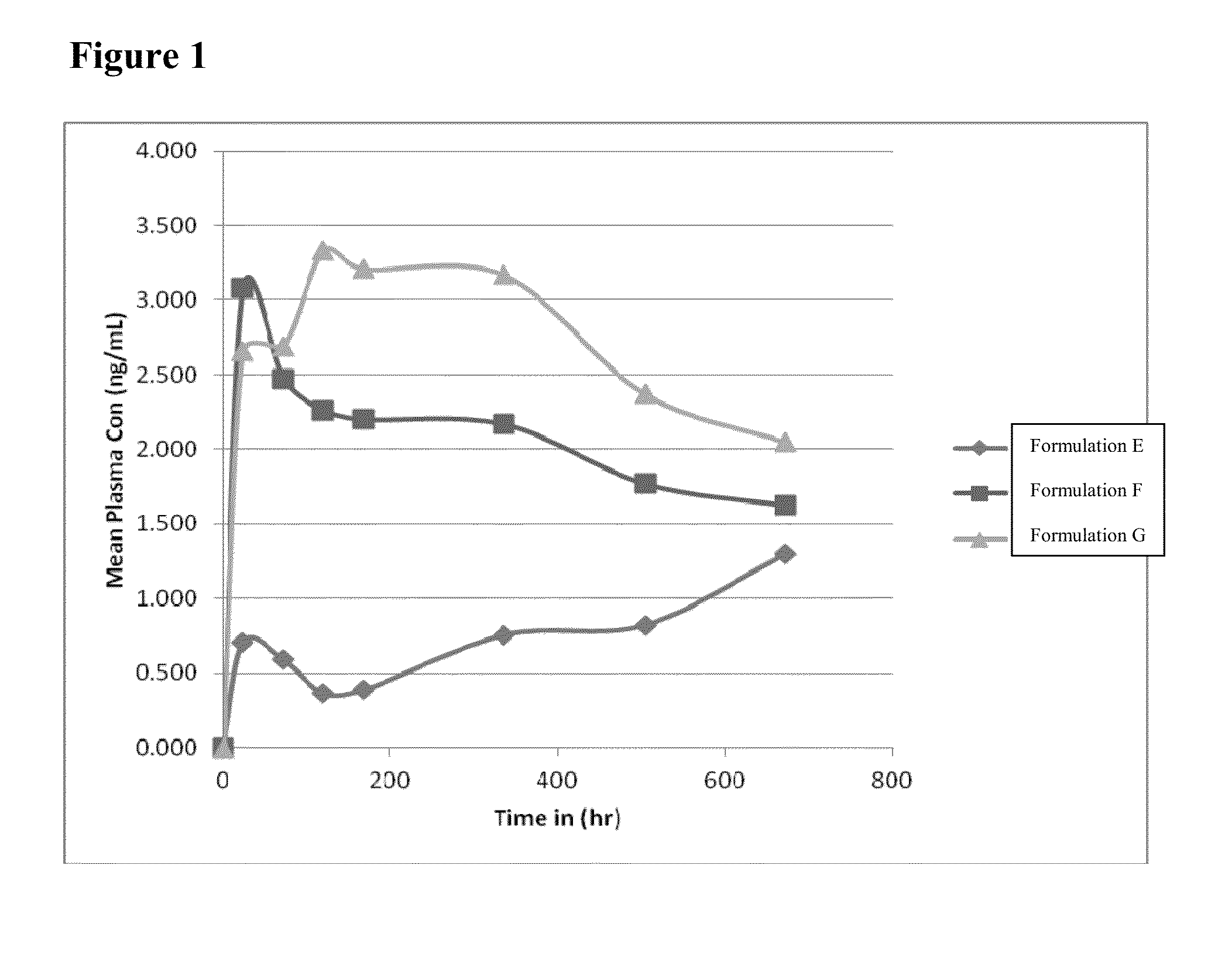

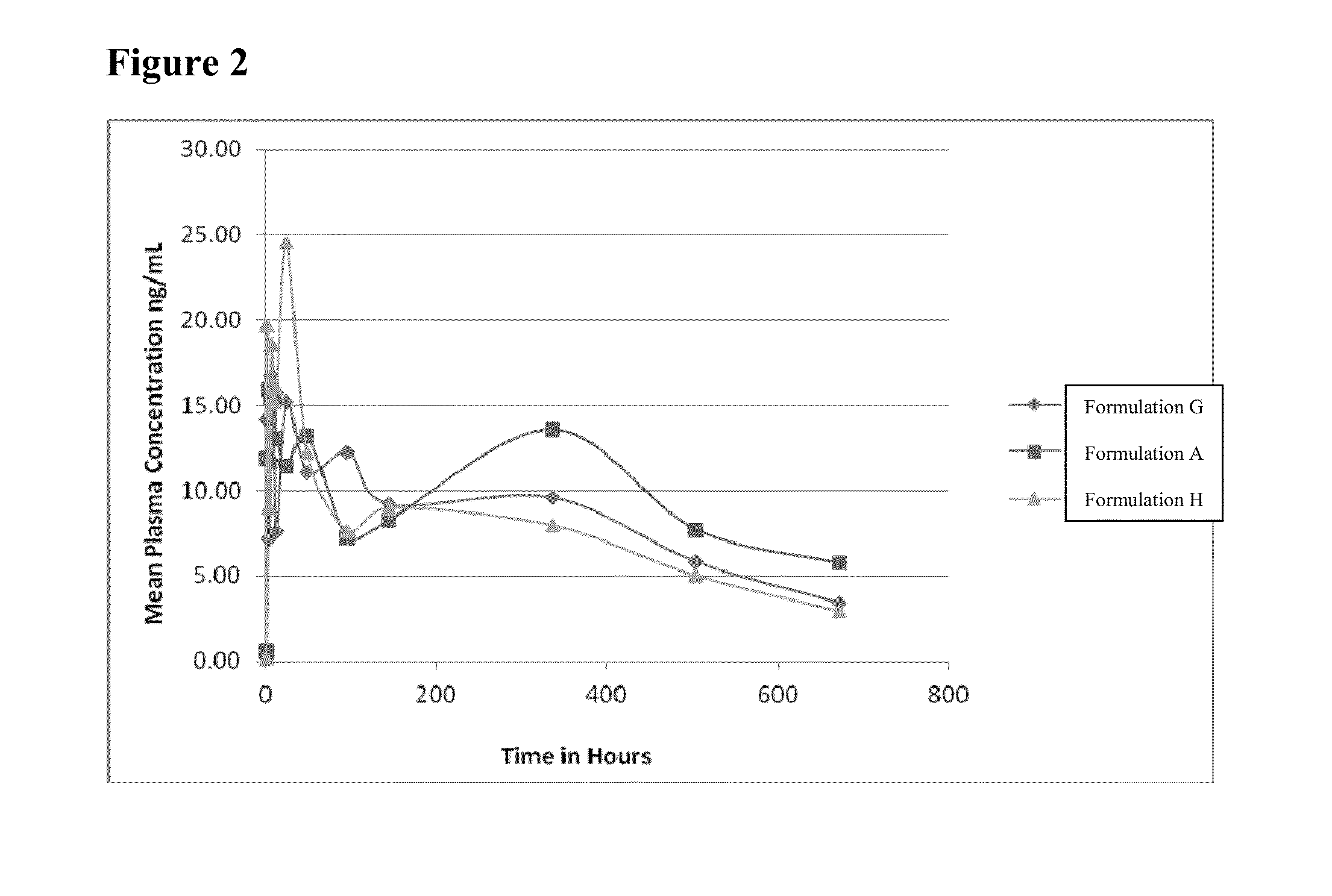

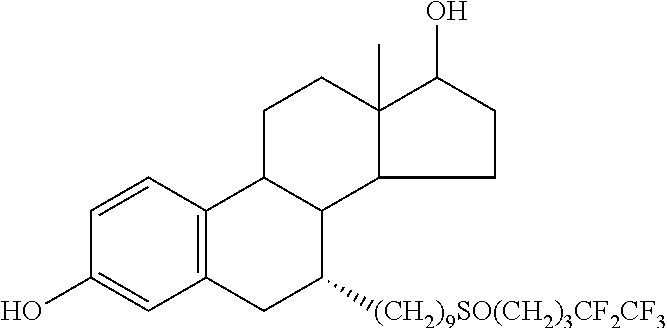

Fulvestrant formulations

ActiveUS20130267489A1Improve long-term stabilityOrganic active ingredientsPharmaceutical delivery mechanismCAPRYLIC TRIGLYCERIDETG - Triglyceride

Long term storage stable fulvestrant-containing compositions are disclosed. The compositions can include fulvestrant; a solvent selected from dimethyl sulfoxide (DMSO), glycofurol, N-methyl pyrrolidone, and mixtures thereof; an oil mixture selected from a mixture of caprylic and capric triglycerides, a mixture of caprylic, capric and linoleic triglycerides, a mixture of caprylic, capric and succinic triglycerides, and a mixture of propylene glycol dicaprylate and propylene glycol dicaprate; and a sustained release member selected from benzyl benzoate, dihydrolipoic acid, benzyl alcohol and lipoic acid. The fulvestrant-containing compositions have less than about 5% total impurities, on a normalized peak area response (“PAR”) basis as determined by high performance liquid chromatography (“HPLC”) at a wavelength of 223 nm, after at least about 24 months of storage at a temperature of from about 5° C. to about 25° C.

Owner:EAGLE PHARMACEUTICALS INC

Condensed milk essence

The invention relates to a condensed milk essence, which is composed of the following components in parts by weight: 0.1-100 parts of incense base, 0-99.9 parts of solvent, 0-20 parts of surfactant, 0-20 parts of cosurfactant, and 0-99.9 parts of carrier; wherein, the incense base is composed of the following components in parts by weight: 10-40 parts of ethyl maltol, 10-40 parts of capric acid, 5-20 parts of 5-decanolide, and 10-30 parts of delta-dodecalactone. The essence provided by the invention has natural condensed milk aroma and low cost, and beverages and other foods added with the condensed milk essence have aroma and taste of natural condensed milk.

Owner:SHANGHAI BAIRUN INVESTMENT HLDG GRP CO LTD

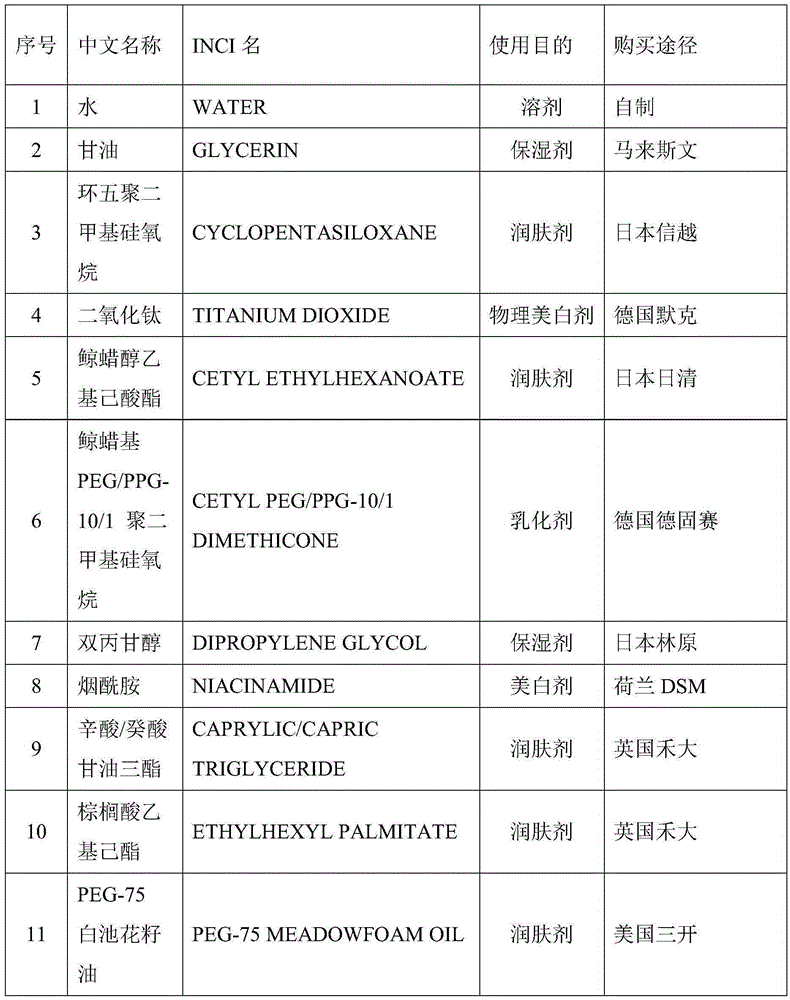

BB cream having whitening, moisturizing and makeup-dizziness preventing functions

InactiveCN105342884ASilky skinAdjust skin toneCosmetic preparationsToilet preparationsSodium hyaluronateEthyl hexanoate

The invention discloses a BB cream having whitening, moisturizing and makeup-dizziness preventing functions. The BB cream consists of the following components: glycerol, cyclopentasiloxane, titanium dioxide, cetyl ethyl hexanoate, cetyl PEG / PPG-10 / 1 polydimethylsiloxane, dipropylene glycol, nicotinamide, caprylic / capric triglyceride, ethylhexyl palmitate, PEG-75 meadowfoam seed oil, hydrogenated polydecene, sodium chloride, quaternary ammonium salt-18 bentonite, white beeswax, argania spinosa kernel oil, tocopherol, CI 77492, panthenol, CI 77491, CI 77499, phenoxyethanol, allantoin, methylparaben, propyl hydroxybenzoate, sodium hyaluronate, essence, EDTA disodium, butylated hydroxytoluene, adenosine and water. By virtue of the meadowfoam seed oil, the adenosine, the argania spinosa kernel oil, the panthenol and the nicotinamide, the functions of the finished BB cream are effectively expanded, so that the BB cream is better in moisturizing performance, makeup-dizziness preventing performance and whitening performance.

Owner:HANGZHOU BAOZIDA BIOLOGICAL TECH CO LTD

Gas-phase anti-corrosion paint

InactiveCN101245218ADry fastHigh hardnessAnti-corrosive paintsPolyester coatingsBenzoic acidOctanoic Acids

The invention relates to a gas phase antirust coating, the components of the combination account according to parts by weight, and the scope is as follows: 8 to 25 parts of acrylate modified alkyd resin, 5 to 20 parts of 2402 phenolic resin, 0 to 15 parts of petroleum sulfonate barium, 0 to 25 parts of oxidized malthenes magnesium soap, 0 to 5 parts of dodecatylene base succinic acid imidazoline, 0 to 6 parts of sebacic acid morpholine, 0 to 6 parts of octanoic acid two cyclohexylamines, 0 to 6 parts of octanoic acid tributyl amine, 0 to 6 parts of capric acid tributyl amine, 0 to 15 parts of benzoic acid monoethanolamine, 0.1 to 1.0 part of drier, 0 to 5 parts of thixotropic agent, 1 to 5 parts of dibutyl phthalate, 0 to 5 parts of black paste, and the rest of xylene / 200 model solvent (1:1). The gas phase antirust coating of the invention has the advantages of fast table-drying speed, long antirust time, high rigidity, high brightness, good temperature resistance, etc., and can satisfy the requirements of the automatic pipeline production and long time open storage antirust need of oil steel pipes and other large pipes or profiles.

Owner:DALIAN YATAI SCI & TECH NEW MATERIAL

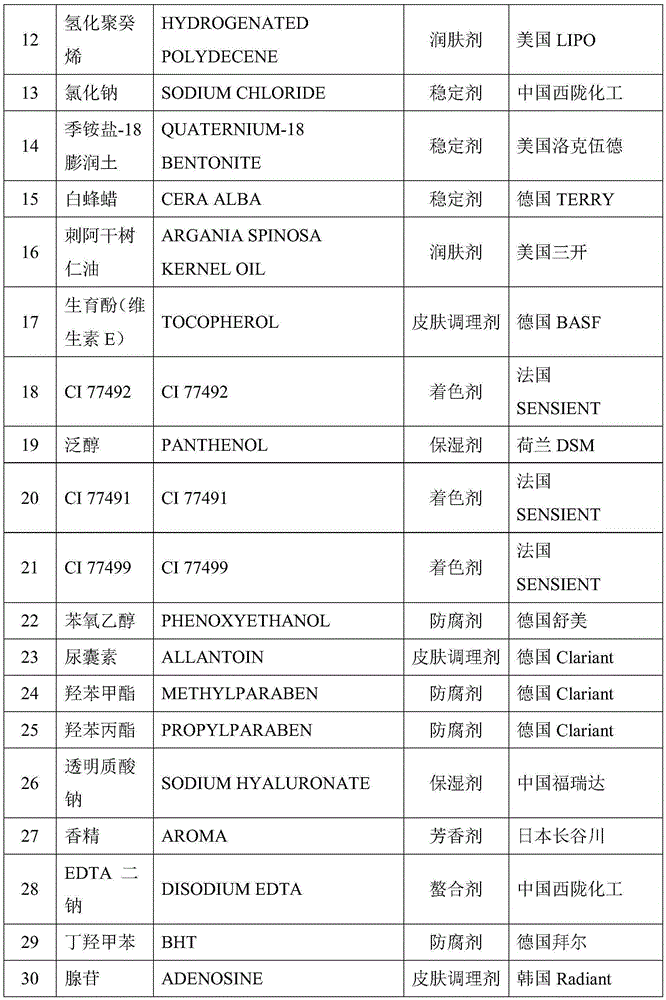

Compound vitamin lipid nanoparticle and preparation method thereof

InactiveCN102552058AEasy to prepareGood repeatabilityCosmetic preparationsToilet preparationsMonoglycerideVitamin C

The invention discloses a compound vitamin lipid nanoparticle. The lipid nanoparticle is loaded with three active ingredients, i.e. vitamin A, vitamin C, vitamin E and is characterized by comprising the following ingredients in percentage by weight: 1-2% of vitamin A, 1-4% of vitamin C, 1-5% of vitamin E, 2-10% of emulsifying agent, 1-12% of compound lipid material and the rest of water, wherein the compound lipid material is a mixture of a solid lipid material and a liquid lipid material; and the lipid materials are selected from at least one or several of glycerol monolaurate, caprylic capric triglyceride, olive oil, soybean oil, corn oil, sunflower seed oil, acetylation monoglyceride, glycerin monostearate and stearic acid. The lipid nanoparticle has good stability, water solubility and repeatability and can be applied to the preparation of daily chemical products and health care foods containing the vitamin A, vitamin C and vitamin E; and a preparation method is simple and controlled.

Owner:SOUTHEAST UNIV

Antioxidant network efficacy nanoemulsion externally used for skin and preparation method thereof

ActiveCN101664372AFormulated ingredients streamlinedFormulated with fine ingredientsCosmetic preparationsToilet preparationsAdditive ingredientPolyethylene glycol

The invention relates to an antioxidant network efficacy nanoemulsion externally used for skin and a preparation method thereof. The nanoemulsion consists of the following raw materials according to weight mixture ratio: 1.0-1.5 of vitamin E, 2.0-3.0 of glutathione, 2.0-2.5 of L-ascorbic acid-2-heteroside, 1.0-1.8 of seabuckthorn oil, 1.0-1.6 of coenzyme Q10, 0.5-0.6 of alpha-lipoic acid, 8.0-10 of isopropyl myristate, 20-25 of caprylic acid capric acid polyethylene glycol glyceride, 7.0-9.0 of polyglyceryl fatty acid ester, 0.5-1.0 of azone, 46-50 of triple distilled water, 0.05-0.25 of citric acid and 1.0-1.6 of sodium citrate. The functional ingredients in the formula can form an antioxidant network system with cooperative interaction, synergy and regeneration, and the penetrating function of a nanoemulsion carrier system greatly enhances the antioxidant function and effect of the functional ingredients. The preparation method can enhance the stability and effectiveness of antioxidant, is simple in preparation technology and easy for scale production, needs no extra energy, saves time, energy and raw materials and is beneficial to environment protection.

Owner:董萍 +1

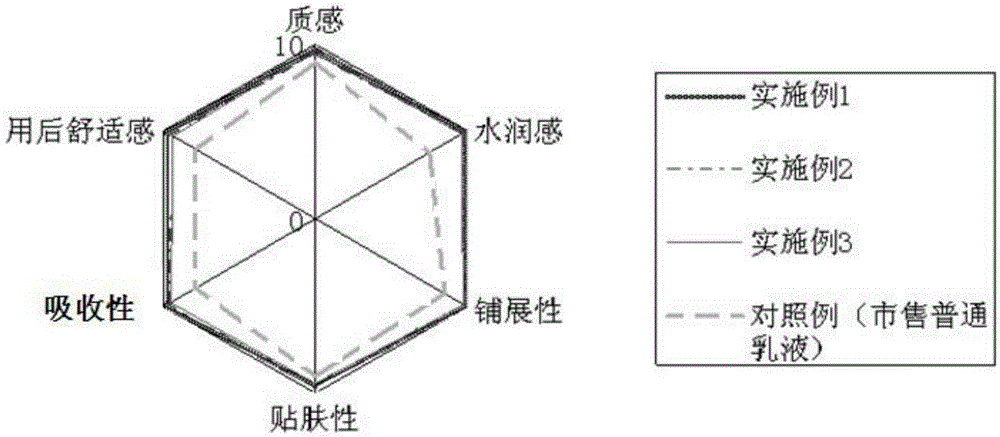

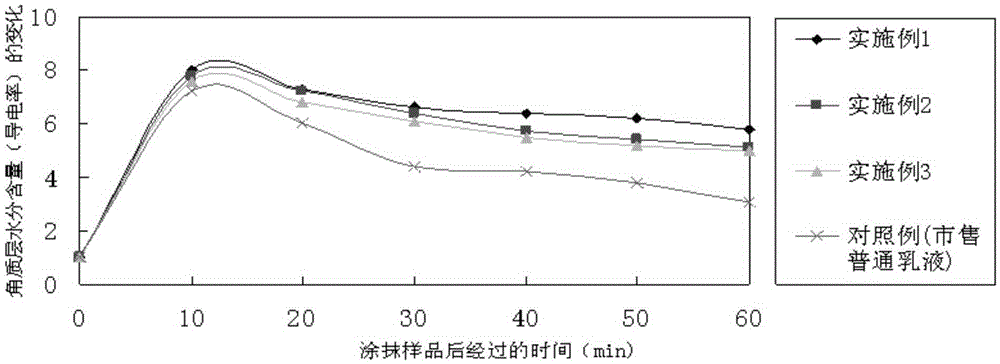

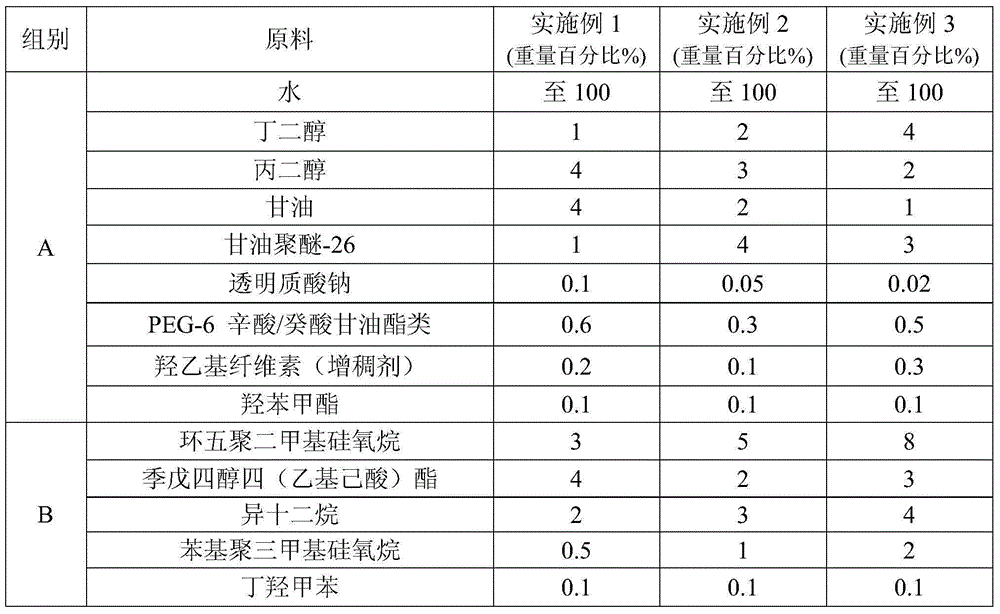

Water-milk bilayer essence emulsion and preparation method thereof

InactiveCN105147528AClear dividing lineNew and beautiful appearanceCosmetic preparationsToilet preparationsPEG-6 Caprylic/capric glyceridesCaprylyl Glycol

The invention provides a water-milk bilayer essence emulsion. The water-milk bilayer essence emulsion is composed of decamethyl cyclopentasiloxane, lubrajel, isododecane, pentaerythritol tetraester (ethylhexoic acid), butanediol, propanediol, glycerin polyether-26, glycerin, oat beta-glucosan, hamamalis water, phenyl trimethicone, phenoxyethanol, PEG-6 octanoic acid / capric acid glyceride, thickener, caprylyl glycol / ethylhexylglycerin, methylparaben, butylated hydroxytoluene, sodium hyaluronate, pigment and water. The water-milk bilayer essence emulsion is novel and beautiful in appearance, capable of realizing quick layering, stable in property and high in moisture retention performance.

Owner:GUANGZHOU SHEENCOLOR COSMETICS CO LTD

Gas-phase rust-preventing aerosol and preparation process thereof

ActiveCN103232883AExtended service lifeImprove rust resistanceLubricant compositionGas phaseMethyl oleate

The invention discloses a gas-phase rust-preventing aerosol and a preparation process thereof. The formula of the gas-phase rust-preventing aerosol comprises the following components in parts by mass: 0.5-1.5 parts of caprylic acid tributylamine, 1-3 parts of benzotriazole tributylamine, 2.5-3.5 parts of oleic acid, 1-3 parts of laurinol, 0.2-0.8 part of amino silicon oil, 2.5-3.5 parts of methyl oleate, 0.2-0.8 part of sodium petroleum sulfonate, 0.2-0.8 part of barium petroleum sulfonate, 0.5-1.5 parts of capric acid tributylamine, 51.5-61.5 parts of 20# machine oil and 27-33 parts of liquefied petroleum gas. The process comprises the following steps: mixing and stirring the raw materials; filling the obtained liquid into a spray can; inserting a capillary valve; filling the liquefied petroleum gas; performing leak detection, and blowing-dry; and boxing, and warehousing. The invention has the characteristics of small aerosol particle diameter and high aerosol particle uniformity DR, and can effectively enhance the corrosion inhibition effect of a metal component.

Owner:ZHEJIANG LUDAO TECH CO LTD

Energy-saving environmentally-friendly phase change energy storage material and preparation method thereof

ActiveCN102492227AGood coating effectReduce manufacturing costHeat-exchange elementsGrain treatmentsCapric AcidThermosetting polymer

The invention provides an energy-saving environmentally-friendly phase change energy storage material which is prepared by the following steps of: adding capric acid and lauric acid to a sealed mixer to prepare a ternary composite phase change material; internally mixing ethylene-propylene diene copolymer and the ternary composite phase change material; discharging the material after internal mixing into an extruder, and extruding to obtain sheets; carrying out irradiation cross-linking on the extruded sheets; and crushing the cross-linked thermosetting polymer sheets by an ultralow-temperature crusher to obtain the energy-saving environmentally-friendly phase change energy storage material. The obtained material has a better coating effect than microcapsules, is low in production cost and easy in process control, can be prepared into a filling power material, and can be added to multiple materials. The product has phase change temperature about 23 DEG C, can be cycled for a long term, is nontoxic in use and is harmless to a human body. The material can be added to a polymer-based composite material, and can be prepared into phase change automobile internal decoration materials, automobile mattress, heat storage temperature-adjusting floors, building phase change wall interlayers, inner wall phase change heat-insulating materials, phase change wallpaper, bedclothes, phase change coatings and the like.

Owner:HANCHUAN RUIFU PLASTIC PRODS

Acne cream capable of effectively removing acne and lightening acne mark and preparation method thereof

InactiveCN107753379AReduce the burden onAvoid stayingCosmetic preparationsToilet preparationsOctanoic AcidsMeadowfoam seed oil

The invention relates to acne cream capable of effectively removing acnes and lightening acne marks. The acne cream comprises water, glycerinum, butanediol, a hamamelis virginiana extract, an aloe vera extract, neopentyl glycol diheptanoate, octanoic acid / capric acid triglyceride, meadowfoam seed oil, squalane, macadimia nut oil, butyrospermum parkii kotschy grease, nicotinamide polydimethylsiloxane, cetostearyl alcohol, cetearyl glucoside, sorbitan olivate, cetearyl olivate, sodium hyaluronate, dipotassium glycyrrhizinate, oligopeptides-1, arbutin, L-ascorbyl dipalmitate, a calendula extract,a lavender extract, an acroloyl-dimethyl taurine amino / VP copolymer, a sodium acrylate / acroloyl-dimethyl taurine sodium copolymer, isohexadecane, polysorbate-80, fullerene, an angelica sinensis extract, p-hydroxyacetophenone, 1,2-hexanediol, sweet orange flower oil and EDTA (Ethylene Diamine Tetraacetic Acid). The acne cream is prepared through a series of procedures and has the characteristics of good acne treatment effect, no acne mark, no side effect, and the like.

Owner:达威控股有限公司

Fatty acid-based herbicidal composition

Disclosed is a herbicidal composition which combines two known active ingredients at concentrations of the individual active ingredients below the level generally necessary for the individual ingredients to exhibit herbicidal activity. The herbicidal activity of the disclosed composition is greater than that of either of the individual active ingredients used alone. One of the active ingredients is a fatty acid based composition selected from caprylic acid, pelargonic acid, capric acid, undecanoic acid, 10-undecanoic acid, lauric acid, oleic acid, salts thereof and mixtures thereof. In addition, other fatty acid or fatty acid salt mixtures may be used, such as soybean fatty acid or coconut fatty acid. This component is present at a concentration range of about 0.1 to 3.0 percent by weight. The other active ingredient is a glyphosate-based herbicidal active ingredient, e.g., the isopropyl amine salt of N-(phosphonomethyl) glycine, present at about 0.08 to 1.0 percent by weight.

Owner:MONSANTO TECH LLC

Vitamin E urea cream for protecting skin and preventing chap

InactiveCN102370588AGood curative effectCosmetic preparationsToilet preparationsMonoglycerideWhite petrolatum

The invention discloses a vitamin E urea cream for protecting skin and preventing chap. The vitamin E urea cream consists of squalane, caprylic / capric triglyceride, white oil, dimethyl silicone oil, monoglyceride, octadecanol, stearic acid, span-60, white petroleum jelly, vitamin E, methylparaben, propylparaben, glycerol, tween-60, urea, essence and purified water. The urea in the urea cream has extremely good effects of moisturizing, preventing chap and softening cutin; and 8 percent urea is added into a product of the urea cream, so that the functions of moisturizing and preventing chap are achieved, and light chap of hands and feet is also cured. The skin protection ingredients such as the vitamin E, the white petroleum jelly, the glycerol and the like are added into the product, so that the product has the skin protection function under the condition of moisturizing and preventing chap, can be used for long time, and is low in cost.

Owner:吴克

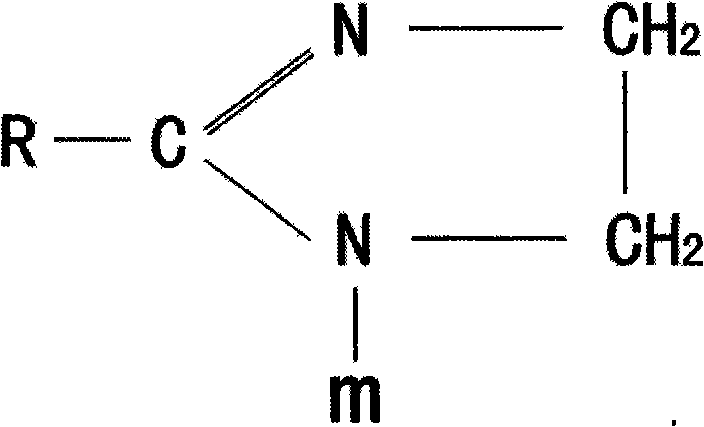

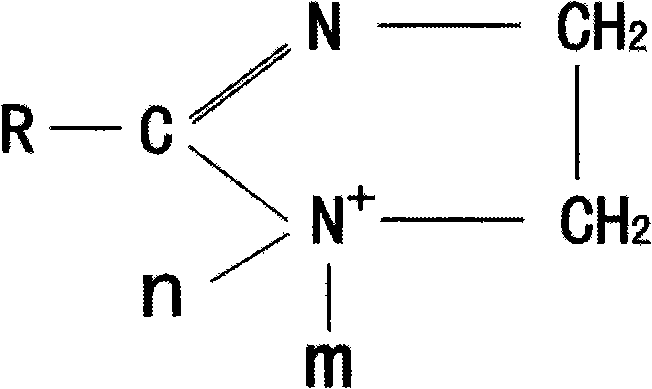

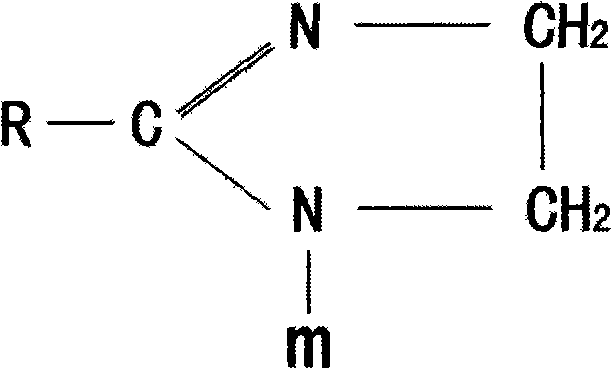

Method for synthesizing imidazoline intermediate and cationic derivative thereof

The invention relates to a method for synthesizing an imidazoline intermediate and a cationic derivative thereof. The method comprises the following process steps of: putting fatty acid, polyamine and water into a reaction kettle in a mole ratio of 1:1.1-2:1-5, heating to the temperature of between 100 and 180 DEG C to distill over the water added before and the water generated in the reaction, removing redundant polyamine and water under a pressure of between -0.04 and -0.1MPa and performing a reaction at a temperature of between 180 and 240 DEG C for 3 to 8 hours to synthesize the imidazoline intermediate; and reducing the temperature of the imidazoline intermediate to be below 80 DEG C, adding a solvent of which the mass is 30 to 100 percent of the imidazoline intermediate into the imidazoline intermediate, then adding 1 to 2mol of sulfate into the mixture and performing heat preservation reaction at the temperature of between 50 and 80 DEG C for 2 to 4 hours to synthesize cationic imidazoline. The fatty acid is oleic acid, linoleic acid, stearic acid, palmitic acid, lauric acid, coconut oil acid, capric acid and octanoic acid; the polyamine is ethylenediamine, diethylenetriamine, triethylene tetramine and tetraethylene pentamine; the solvent is isopropanol, absolute ethyl alcohol or 95 percent ethanol; and the sulfate is dithyl sulfate and dimethyl sulfate.

Owner:苗俊良

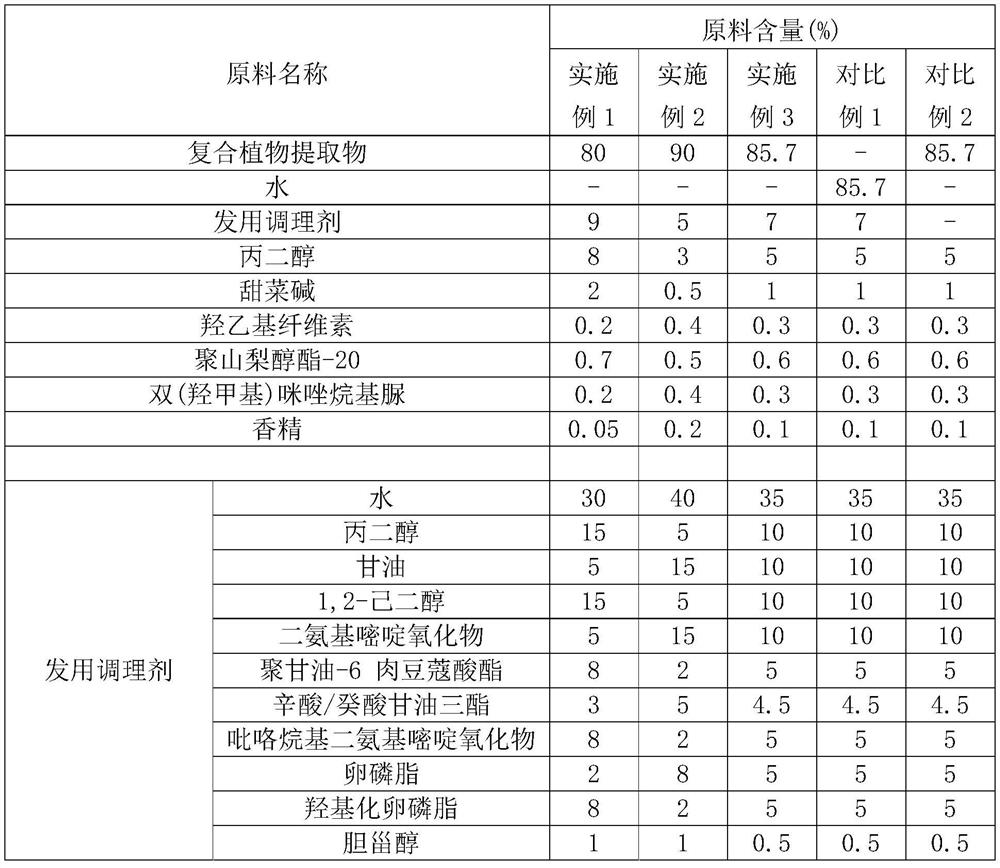

Anti-hair loss and hair-strengthening nutrient solution and preparation method thereof

PendingCN111803426AInhibit growthHair growth prevention as well as promotion ofCosmetic preparationsHair cosmeticsBiotechnologyTG - Triglyceride

The invention relates to an anti-hair loss and hair-strengthening nutrient solution and a preparation method thereof. The anti-hair loss and hair-strengthening nutrient solution is prepared from the following raw material components in parts by weight: 80 to 90 parts of compound plant extract, 5 to 9 parts of a hair conditioner, 3.5 to 10 parts of a humectant and 0.2 to 0.4 part of a thickening agent, wherein the composite plant extract is a mixture of water, a cacumen biotae extract, a radix polygoni multiflori extract, a ginger root extract, a folium mori extract, a black mulberry fruit extract, a sesame seed extract and a ginseng root extract, and the hair conditioner is a mixture of water, propylene glycol, glycerol, 1, 2-hexanediol, diaminopyrimidine oxide, polyglycerol-6 myristate, caprylic / capric triglyceride, pyrrolidinyl diaminopyrimidine oxide, lecithin, hydroxylated lecithin and cholesterin. The anti-hair loss and hair-strengthening nutrient solution has good effects of strengthening and toughening hair roots, preventing hair loss and promoting hair growth.

Owner:广州市逸轩精细化工有限公司

Plant anti-oil anti-acne face cream

InactiveCN104000769AEasy accessEasy to prepareCosmetic preparationsToilet preparationsPurslane extractCetearyl glucoside

Plant anti-oil anti-acne face cream is prepared from the following raw materials in parts by weight: deionized water, Alps alpine glacier water, caprylic / capric acid triglyceride, isopropyl myristate, cetearyl alcohol, hydrogenated lecithin, squalane, hamamelis virginiana, centella asiatica, monkey bread tree extract, butylene glycol, cetearyl glucoside, sodium shale oil sulfonate, glyceryl stearate, purslane extract liquid, chamomile, roe sauce extract, rose extract liquid, orchid extract liquid, brown alga cell extract, asparagopsis armata extract, collagen peptide, methyl glucose sesquistearate, polydimethylsiloxane, xanthan gum, allantoin, sodium hyaluronate, bisabolol, squalane and dunaliella salina extract, azone, vitamin E acetate, date palm extract, methylparaben, tourmaline, 2-methyl-4-isothiazoline-3-one / ethyl hexyl glycerin.

Owner:王赫

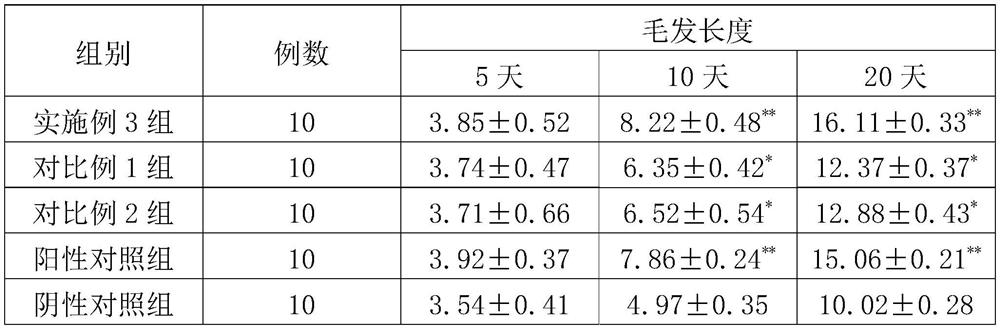

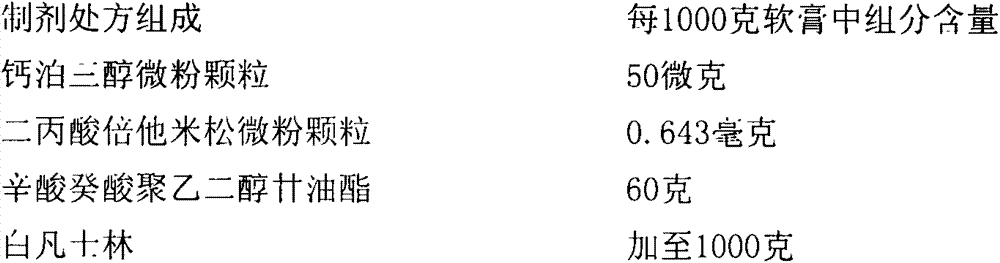

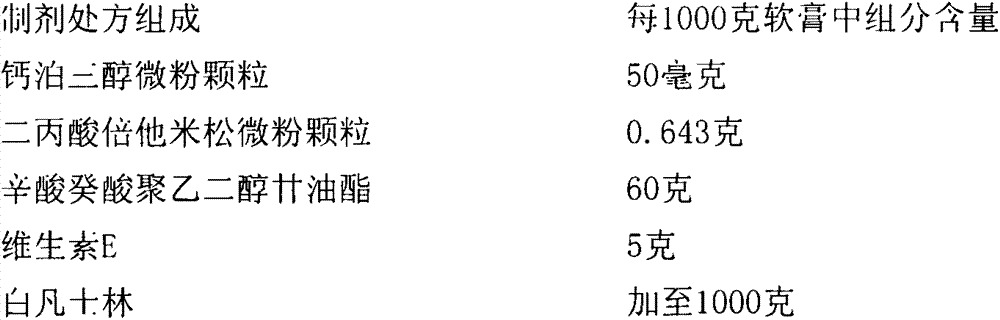

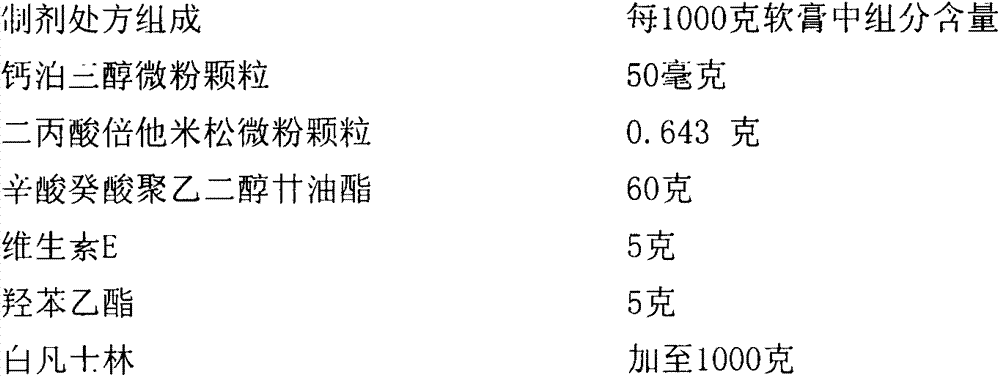

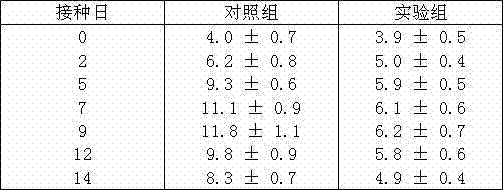

Calcipotriol betamethasone ointment and preparation method thereof

InactiveCN103110648AOrganic active ingredientsAerosol deliveryBetamethasone propionatePropanoic acid

The invention a calcipotriol betamethasone ointment prepared from caprylocaproyl macrogolglycerides. Under the conditions of high speed cutting and a homogeneous state, calcipotriol micronized particles with particle size range being 5-110 microns and the micronized particles of betamethasone dipropionate are uniformly dispersed to caprylocaproyl macrogolglycerides, affinities of caprylocaproyl macrogolglycerides and a commonly used ointment matrix are utilized to obtain the uniform ointment with uniformly distributed particle size. Furthermore, the stability of resisting high temperature (50 DEG C) is better, and is beneficial to improving the quality and the stability of a medicine.

Owner:JIANGSU SEMPOLL PHARMA

Medium-chain fatty glyceride and application thereof in microcapsules

InactiveCN102488088ANot easy to formNo antibacterial effectAnimal feeding stuffOctanoic AcidsCapric Acid

The invention discloses a medium-chain fatty glyceride, wherein the mass ratio of octanoic acid to capric acid is (10-90) to (90-10). In an application of the medium-chain fatty glyceride in microcapsules, the weight of the medium-chain fatty glyceride is 50-70% of the weight of the microcapsule grains. After the medium-chain fatty glyceride is used for feeding animals, the production performance is increased and the healthy degree is improved.

Owner:LONGYAN XINAO BIOTECH

Preparation method of clay-based composite phase-change energy storage deicing (snow melting) material

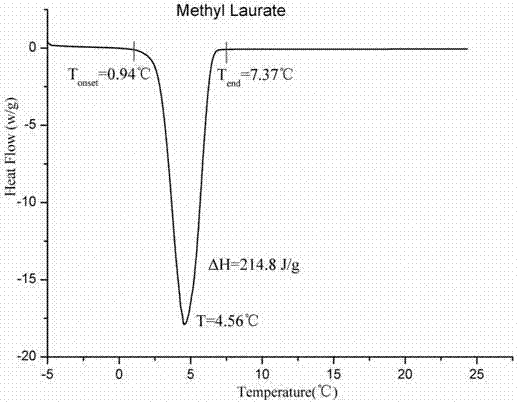

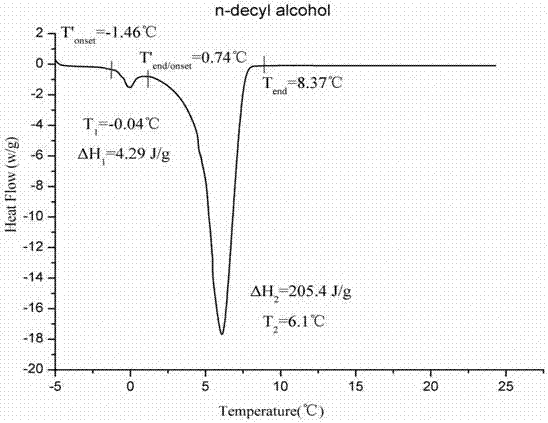

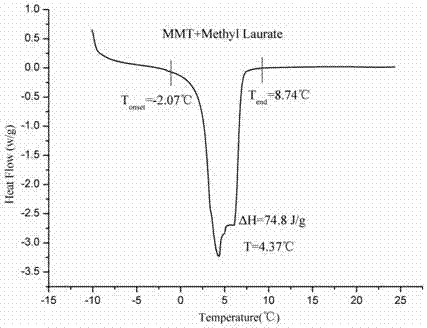

The invention discloses a preparation method of a clay-based composite phase-change energy storage deicing (snow melting) material. The preparation method is characterized in that a composite phase-change energy storage material is prepared from a low-temperature organic phase-change material and a clay material, wherein the low-temperature organic phase-change material is prepared by single-element or multi-element mixing of various organic phase-change materials and is then physically compounded with the treated clay to prepare the clay-based composite phase-change energy storage deicing (snow melting) material. The low-temperature organic phase-change material is selected from polyethylene glycol-300, polyethylene glycol-400, polyethylene glycol-500, polyethylene glycol-600, decyl alcohol, undecanol, dodecanol, heptylic acid, octanoic acid, nonanoic acid, capric acid, methyl laurate, methyl myristate, methyl palmitate, tetradecane, pentadecane, hexadecane, heptadecane, octodecane, nonadecane and the like. The clay material is selected from kaolinite, montmorillonite, bentonite, vermiculite, halloysite, sepiolite, attapulgite, perlite, diatomite, rectorite, zeolite, silicon dioxide, dolomite, calcite and illite. The prepared composite phase-change energy storage deicing (snow melting) material is proper in phase-change temperature (0-5 DEG C), high in phase-change latent heat and high in heat stability.

Owner:CENT SOUTH UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com