Compound vitamin lipid nanoparticle and preparation method thereof

A lipid nanoparticle and multivitamin technology, which is applied in the field of carrier systems, can solve the problems of poor stability and low bioavailability, and achieve the effects of good stability, simple preparation method, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of complex vitamin lipid nanoparticles

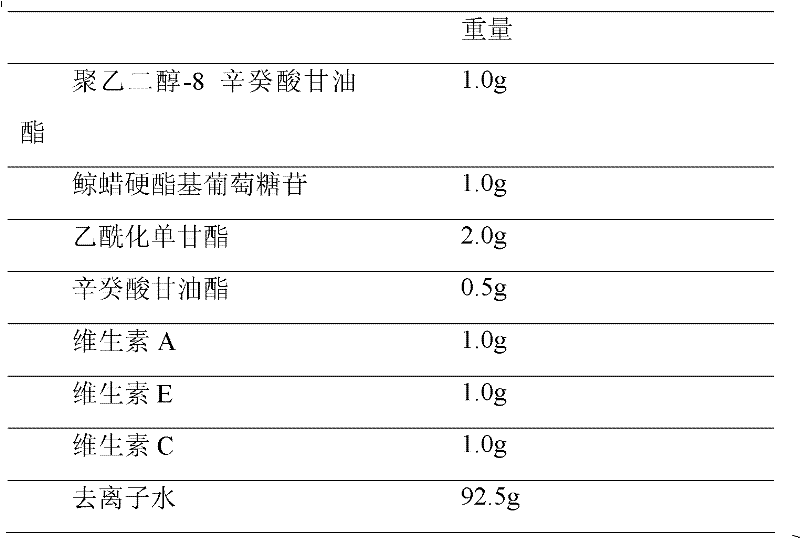

[0034] Composition formula

[0035]

[0036] The preparation steps of this embodiment are as follows:

[0037] 1. Weigh 1.0 g of polyethylene glycol-8 caprylic capric acid glyceride, 1.0 g of cetearyl glucoside, and 92.5 g of deionized water into a beaker, and heat it in a water bath at 60°C to a homogeneous solution.

[0038] 2. Weigh 2.0 g of acetylated monoglyceride and 0.5 g of caprylic capric acid glyceride and heat in a water bath at 60°C.

[0039] 3. After the lipid in the beaker is completely melted, add 1.0 g of vitamin A and 1.0 g of vitamin E, heat and mix well.

[0040] 4. Add the water phase to the above system, stir evenly, add 1.0 g of vitamin C, and shear. At the same time, turn on the high-pressure homogenizer and preheat it to 60°C with 70°C deionized water.

[0041] 5. Inject the high-temperature emulsion system after uniform shearing into the high-pressure homogenizer, adjust th...

Embodiment 2

[0044] weight Polyethylene Glycol-8 Caprylic Glycerides 4.0g cetearyl glucoside 1.5g Acetylated Monoglycerides 1.5g Glyceryl Caprylate 0.5g Soybean Powder Phospholipids 0.5g Vitamin A 1.5g Vitamin E 3.0g Vitamin C 2.5g Deionized water 85.0g

[0045] Preparation steps:

[0046] 1. Weigh 4.0 g of polyethylene glycol-8 caprylic capric acid glyceride, 1.5 g of cetearyl glucoside, 0.5 g of soybean powder phospholipid, and 85.0 g of deionized water into a beaker, and heat in a water bath at 55°C until homogeneous solution.

[0047] 2. Weigh 1.5 grams of acetylated monoglycerides and 0.5 grams of caprylic capric acid glycerides and heat them in a water bath at 55°C.

[0048] 3. After the lipid in the beaker is completely melted, add 1.5 grams of vitamin A and 3.0 grams of vitamin E, heat and mix well.

[0049] 4. Add the water phase to the above system, stir evenly, add 2.5 grams of vitamin C, and shear. At the ...

Embodiment 3

[0053] weight Cetostearyl Alcohol / Polyethylene Glycol-20 Cetostearyl Alcohol 1.0g Macrogol-100 Stearate 2.0g Glyceryl monostearate 2.0g Acetylated monoglyceride 4.0g olive oil 0.5g Corn oil 0.5g Vitamin A 2.0g Vitamin E 5.0g Vitamin C 4.0g Deionized water 79.0g

[0054] Preparation steps:

[0055] 1. Weigh 1.0 grams of cetostearyl alcohol / polyethylene glycol-20 cetostearyl alcohol, 2.0 grams of polyethylene glycol-100 stearate, and 79.0 grams of deionized water into a beaker for 70 ° C Heat in a water bath until a homogeneous solution is obtained.

[0056] 2. Weigh 2.0 grams of glyceryl monostearate, 4.0 grams of acetylated monoglycerides, 0.5 grams of olive oil, and 0.5 grams of corn oil and heat them in a water bath at 70°C.

[0057] 3. After the lipid in the beaker is completely melted, add 2.0 grams of vitamin A and 5.0 grams of vitamin E, heat and mix well.

[0058] 4. Add the water phase to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com