Patents

Literature

262results about How to "The preparation process is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of novel three-dimensional nitrogen doped graphene composite material system

ActiveCN105000548AEfficient preparationThe preparation process is easy to controlHybrid capacitor electrodesCell electrodesNitrogen doped grapheneBiomedicine

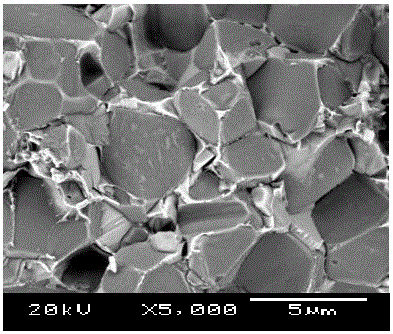

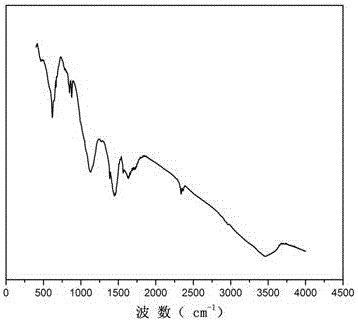

The invention discloses a preparation method of a novel three-dimensional nitrogen doped graphene composite material system. The method comprises the following steps: 1, uniformly dispersing graphene oxide in a solvent at room temperature, adding a selected material and a nitrogen-containing compound, and uniformly mixing to form a mixed solution; 2, reacting the mixed solution at a temperature from room temperature to 150DEG C for 0-8h; and 3, cooling the above obtained product to room temperature, centrifuging, collecting the obtained product, washing, and drying to obtain the nitrogen doped graphene composite material. The three-dimensional nitrogen doped graphene composite material system with the nitrogen content of 8-19% can be efficiently and controllably prepared through the method, and the nitrogen content of the system can be controlled by changing the kind and the amount of the added nitrogen-containing compound, the reaction temperature and the reaction time; and the method is simple, is easy to enforce, allows the yield to be greater than 98.9%, and can be widely used in fields of water treatment, biomedicines, energy generation, conversion and storage devices, electrostatic prevention, heat management, heat conduction and dissipation, sensors, electromagnetic shielding, wave absorption and catalysis.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

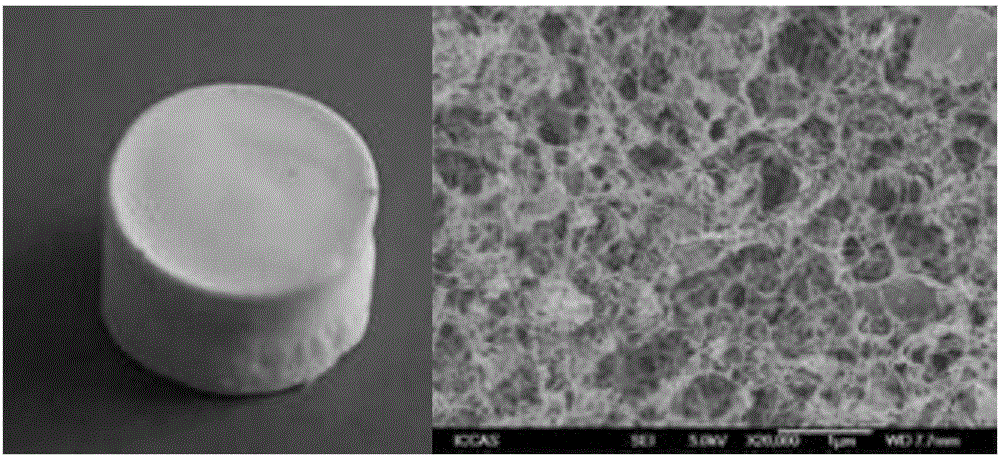

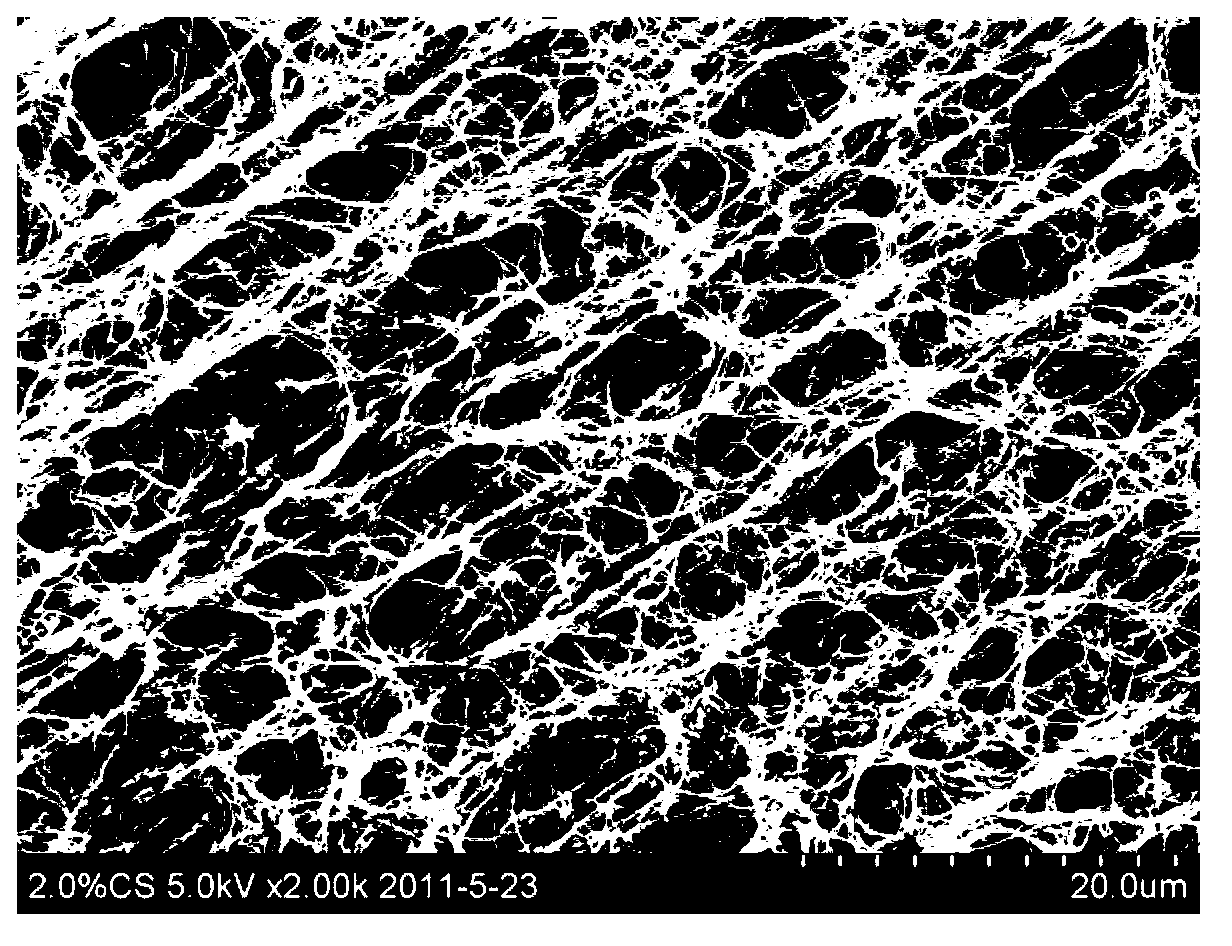

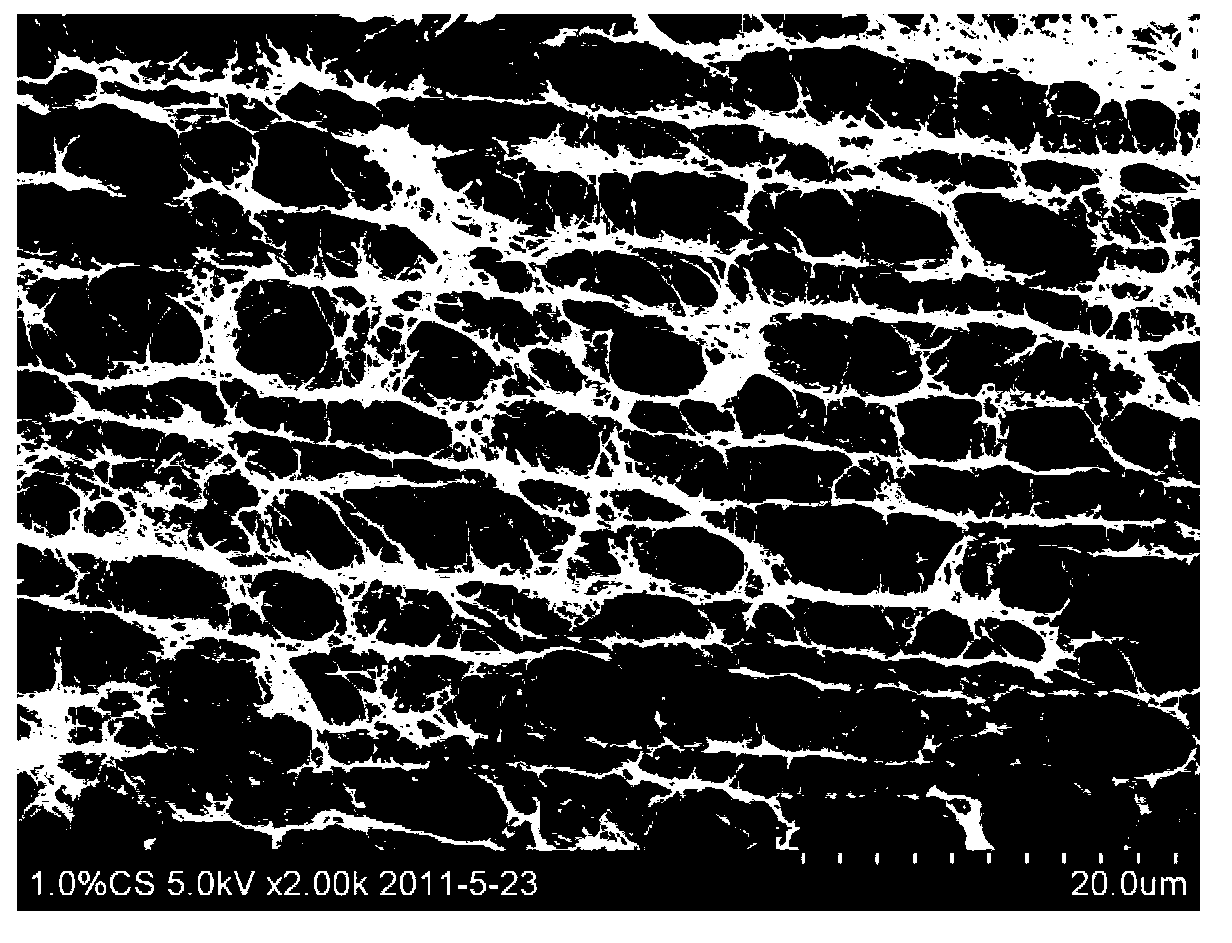

Cellulose aerogel and preparation method for hybrid aerogel thereof

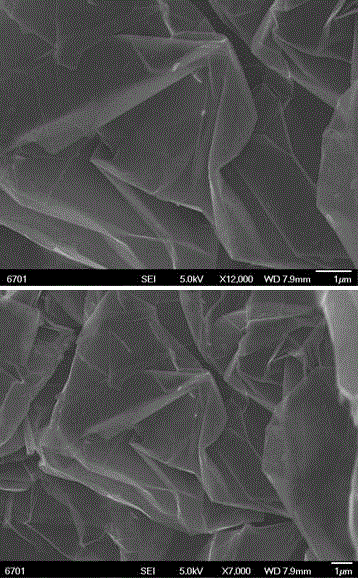

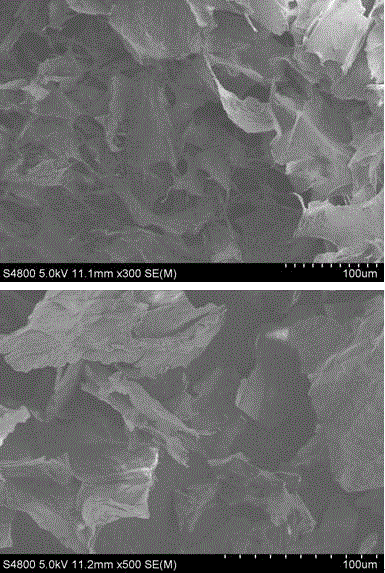

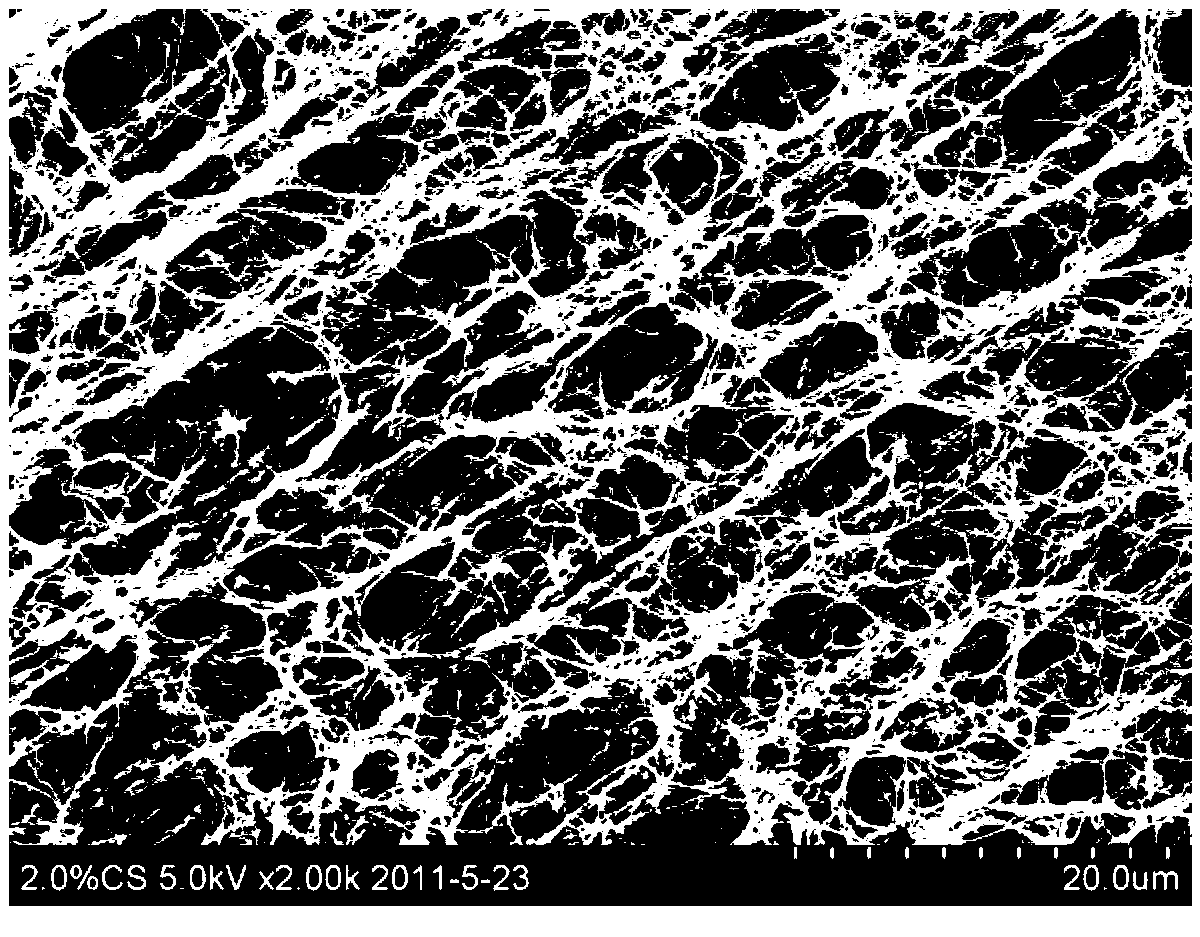

The invention discloses low-cost green cellulose aerogel and a preparation method for hybrid aerogel thereof. The preparation method for the hybrid aerogel of the cellulose aerogel comprises the following steps that cellulose is dissolved into a zinc chloride aqueous solution, centrifugal deaeration is performed, and a uniform and transparent cellulose solution is obtained; the cellulose solution is formed, then the formed cellulose solution is placed into a coagulating bath to be regenerated, in addition, the regenerated cellulose solution is fully washed by use of a solvent, and cellulose solvent gel is obtained; the solvent in the cellulose solvent gel is removed by use of supercritical carbon dioxide drying or freeze drying, and the cellulose aerogel is obtained. Functional filler can be added into the cellulose solution to obtain the hybrid aerogel. By the adoption of different solution forming methods, the cellulose aerogel and the hybrid aerogel thereof in the shapes of sheets, fibers, particles and the like can be prepared. The preparation method is low in cost and is environmentally friendly, and the prepared aerogel is provided with a uniform nano-grade net porous structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

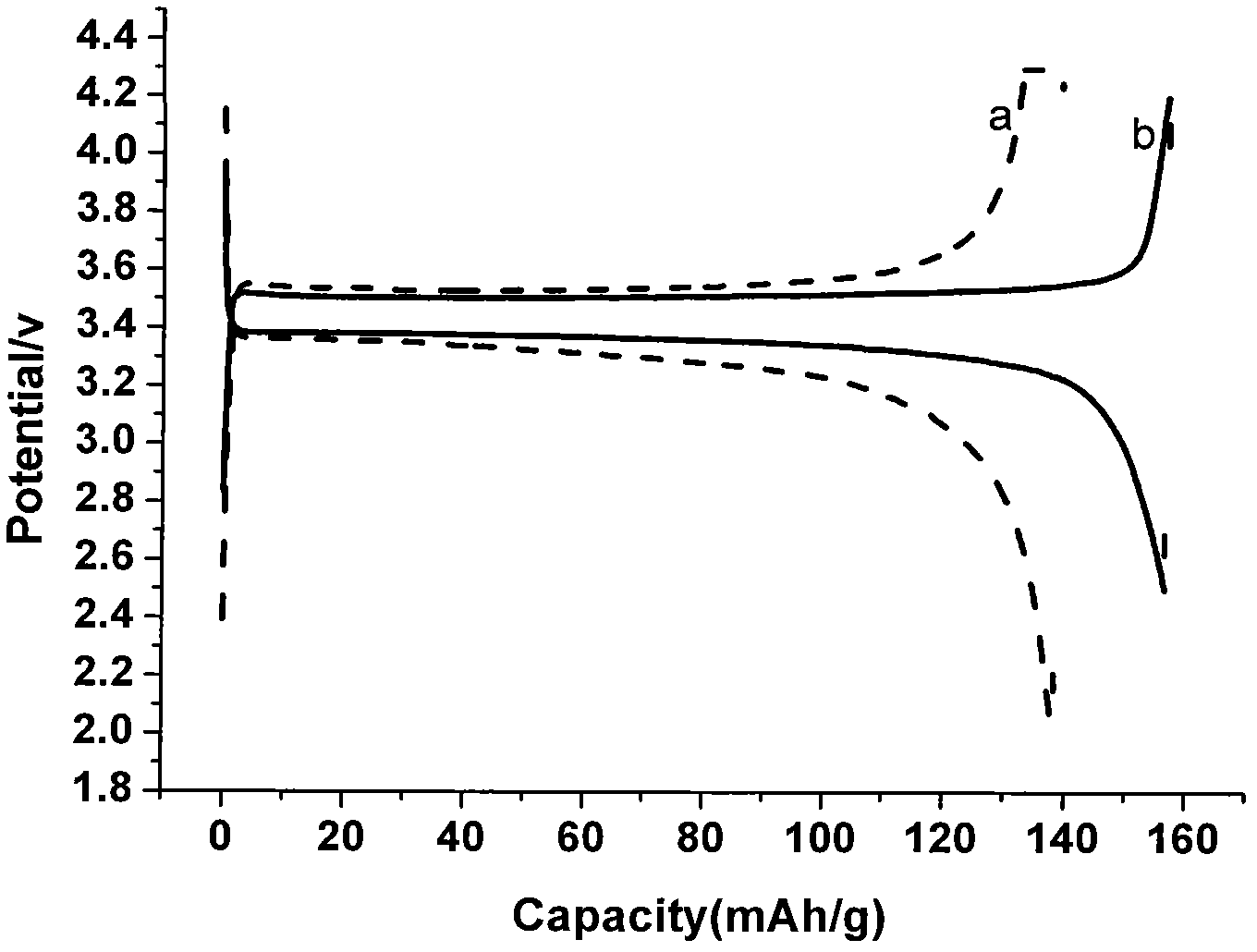

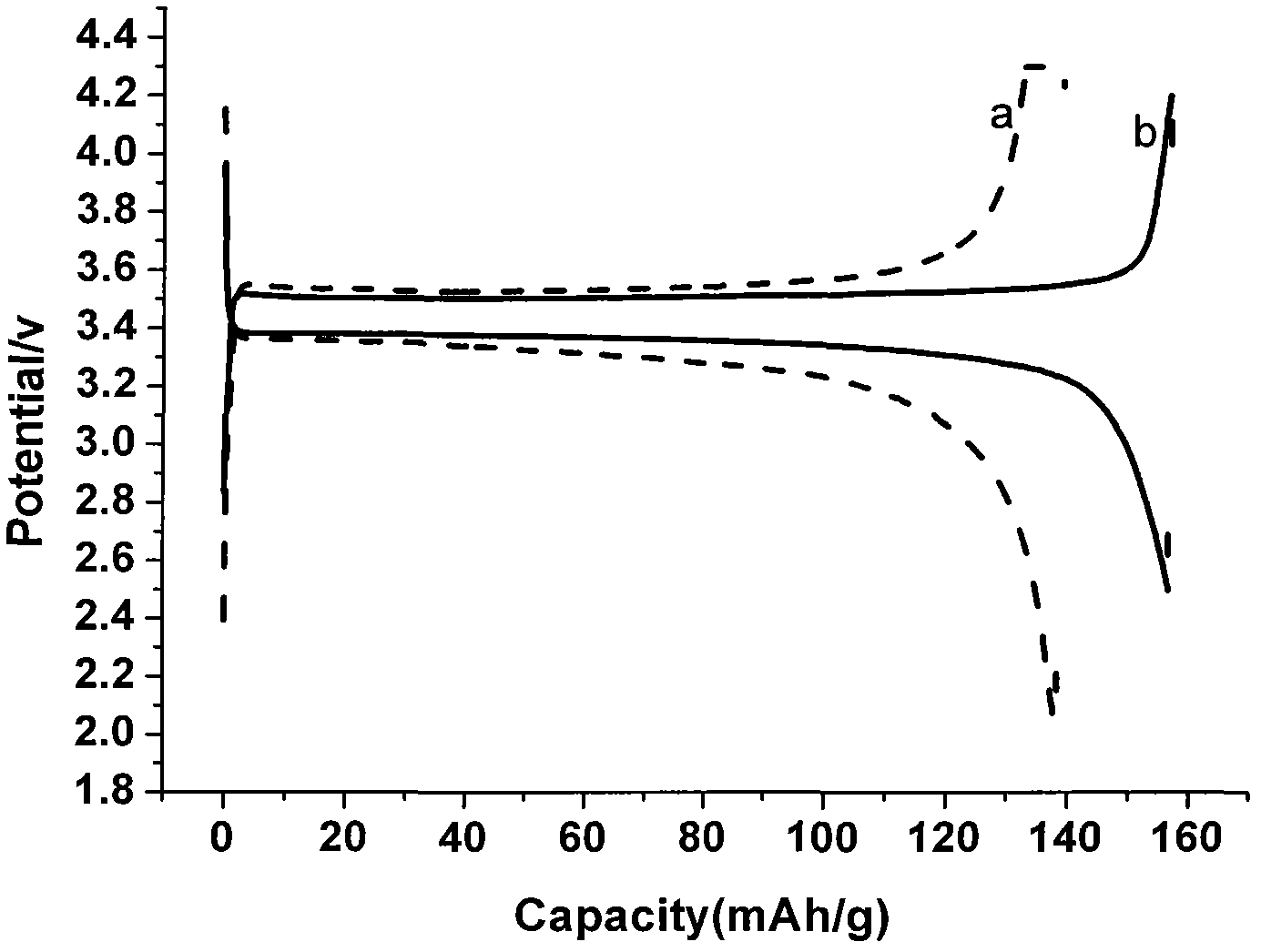

A kind of preparation method of the lithium-ion battery of conductive polymer coating positive electrode

InactiveCN102280656AImprove adhesionImprove conductivityCell electrodesSecondary cellsConductive polymerSlurry

The invention discloses a preparation method of a lithium-ion battery with a conductive polymer coated positive electrode. The positive electrode sheet is a positive electrode slurry made of a positive electrode material, a conductive agent, a positive electrode binder, a conductive polymer or a conductive polymer monomer, and a solvent. The negative electrode sheet is composed of negative electrode material, thickener, negative electrode binder, and solvent mixed into negative electrode slurry and negative electrode current collector. The specific capacity of the battery is increased by 10-20% by adding a conductive polymer or a conductive polymer monomer to the slurry for coating. The invention effectively improves the performance of the prepared positive electrode material, and because the method is simple, the product cost is reduced, the process is simplified, and the method is suitable for large-scale production.

Owner:WUHU HUAXINNUO ELECTROCHEM TECH

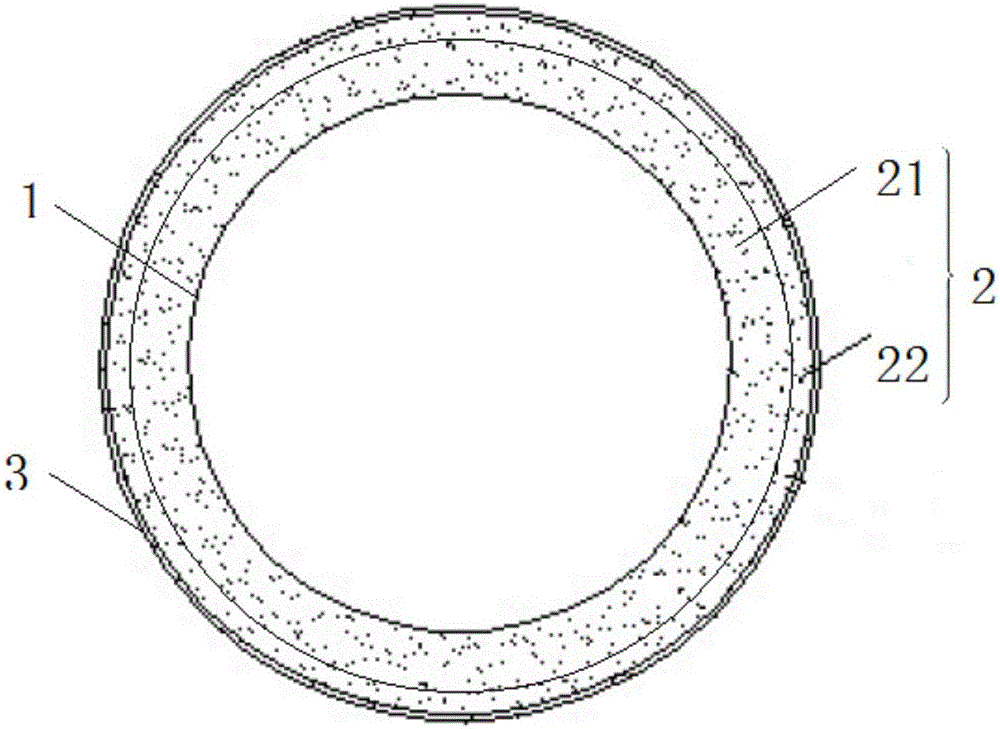

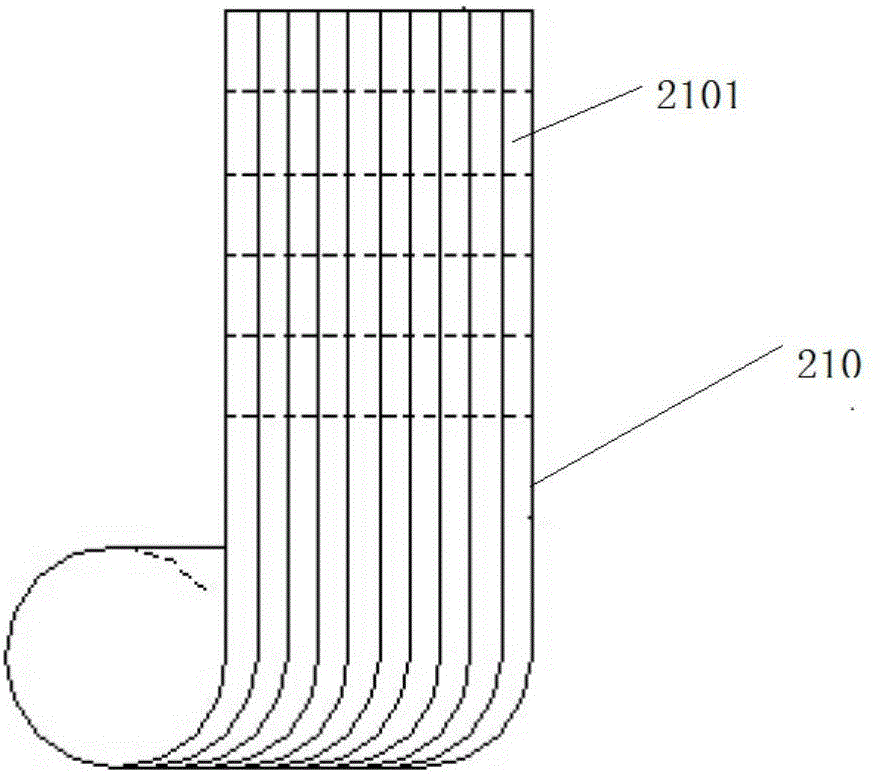

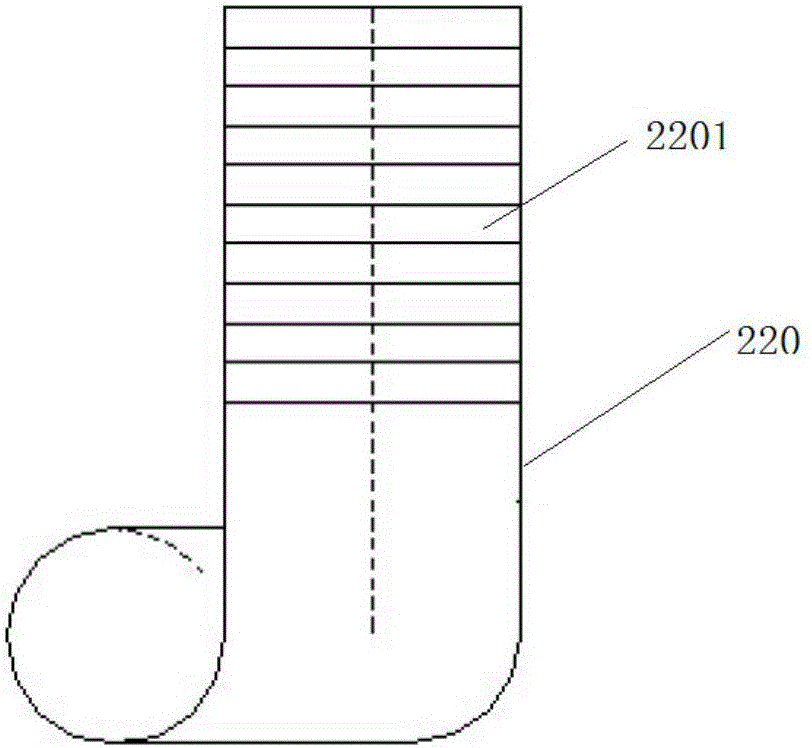

Ultra-large-diameter bamboo winding composite tube and manufacturing method thereof

ActiveCN105715881AImprove axial strengthEnhanced bending and impact resistanceRigid pipesTubular articlesStress distributionFiber

The invention belongs to the related field of composite tubes, and discloses an ultra-large-diameter bamboo winding composite tube. The bamboo winding composite tube comprises a lining layer, a composite strengthening layer and an outer protection layer from inside to outside, and the lining layer is made of fiber blankets or non-woven fabrics with anticorrosive resin in an adhesion manner; the composite strengthening layer is formed in a manner that two different types of bamboo skin curtains are wound outside the lining layer in a layer-by-layer manner according to the proper layer number and the thickness proportion wholly in the ring direction, the bamboo skin curtains are sprayed with the resin in a liquid-leaching manner while winding is carried out, and then bonding curing is carried out; and the outer protection layer is cured on the outer surface of the strengthening layer in a coating manner, and the effects of water prevention, corrosion prevention, radiation prevention and the like are achieved. The invention further discloses a corresponding manufacturing method. Through the ultra-large-diameter bamboo winding composite tube and the manufacturing method, even under the tube diameter obvious expanding condition, the characteristic that the whole structure of the bamboo winding composite tube is free of stress distribution defect can be well kept, and meanwhile comprehensive properties of pressure resistance, ring stiffness, long-term use quality stability and the like can be obviously improved.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

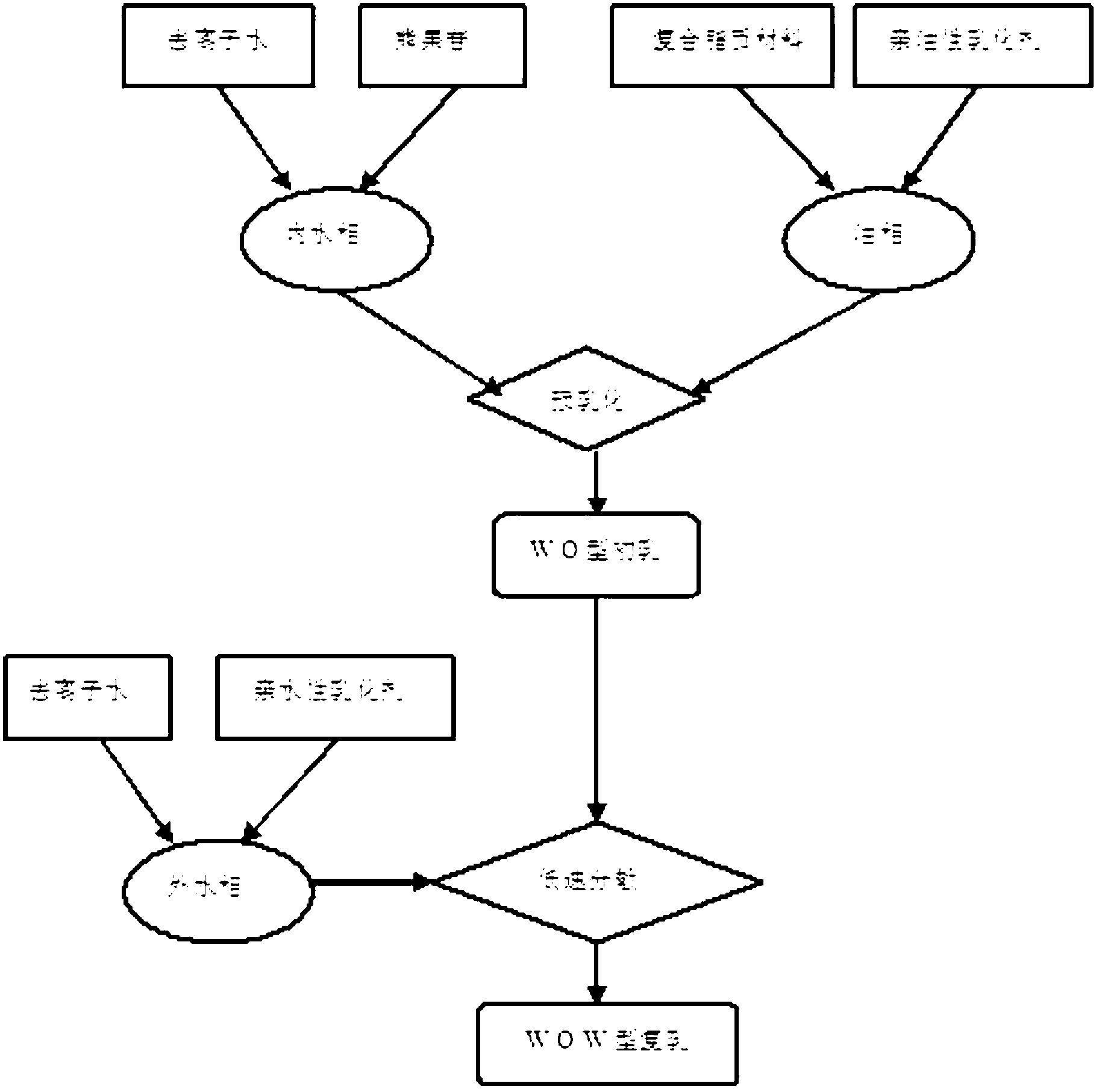

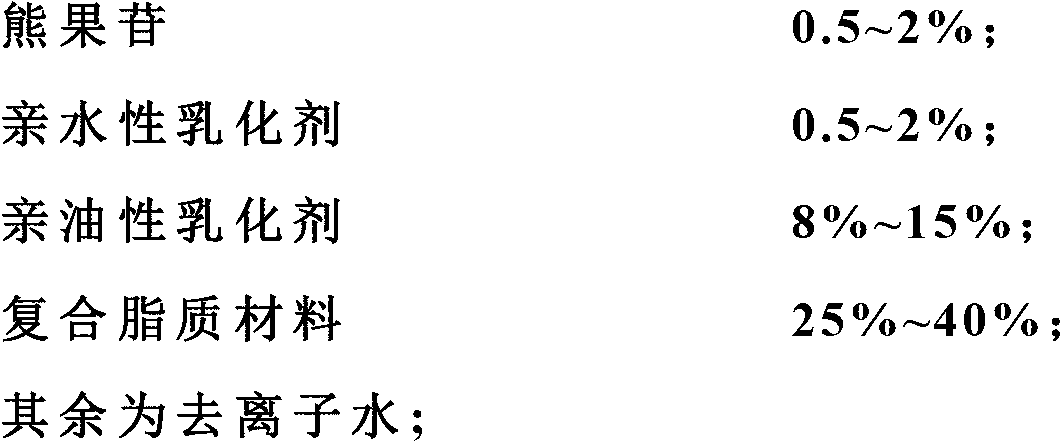

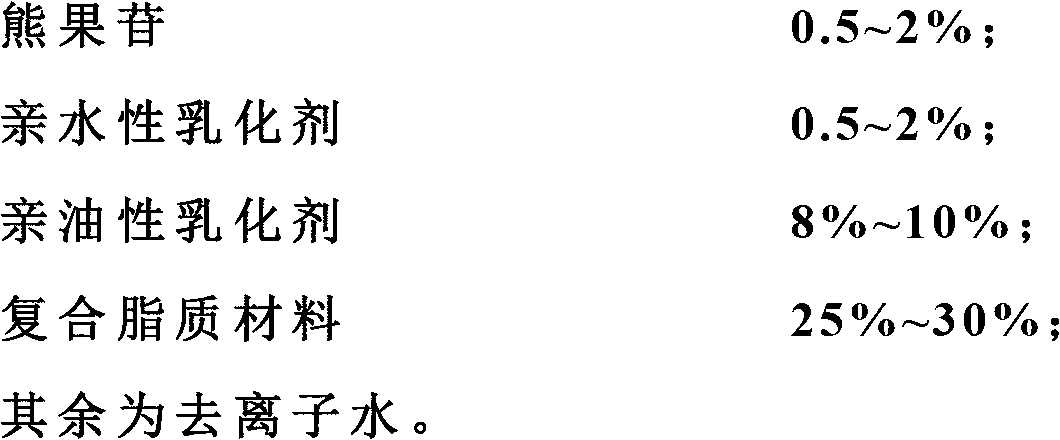

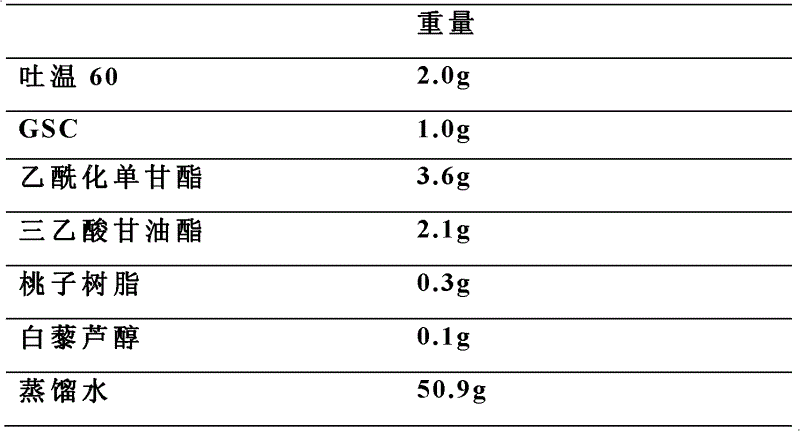

Multiple emulsion of arbutin and preparation method thereof

InactiveCN102697672AThe preparation process is easy to controlGood water solubilityCosmetic preparationsToilet preparationsSolubilityACETYLATED MONOGLYCERIDE

The invention discloses multiple emulsion of arbutin. The carrier is loaded with active components of the arbutin. The multiple emulsion is characterized by comprising the following components in percent by weight: 0.5-2% of arbutin, 0.5-2% of hydrophilic emulsifier, 8-15% of lipophilic emulsifier, 25-40% of composite lipid material and the balance of deionized water, wherein the composite lipid material is mixture of a solid lipid material and a liquid lipid material; the lipid material is at least one of the compounds: glycerin monostearate, oil-tea camellia seed oil, aloe oil, macadamia nut oil, avocado oil, acetylated monoglyceride, caprylic capric triglyceride, canola oil, sunflower seed oil and soybean oil. The multiple emulsion disclosed by the invention has good stability and water solubility; and the preparation method is simple and controllable, is good in repeatability and can be applied to preparation of cosmetics containing the arbutin.

Owner:SOUTHEAST UNIV

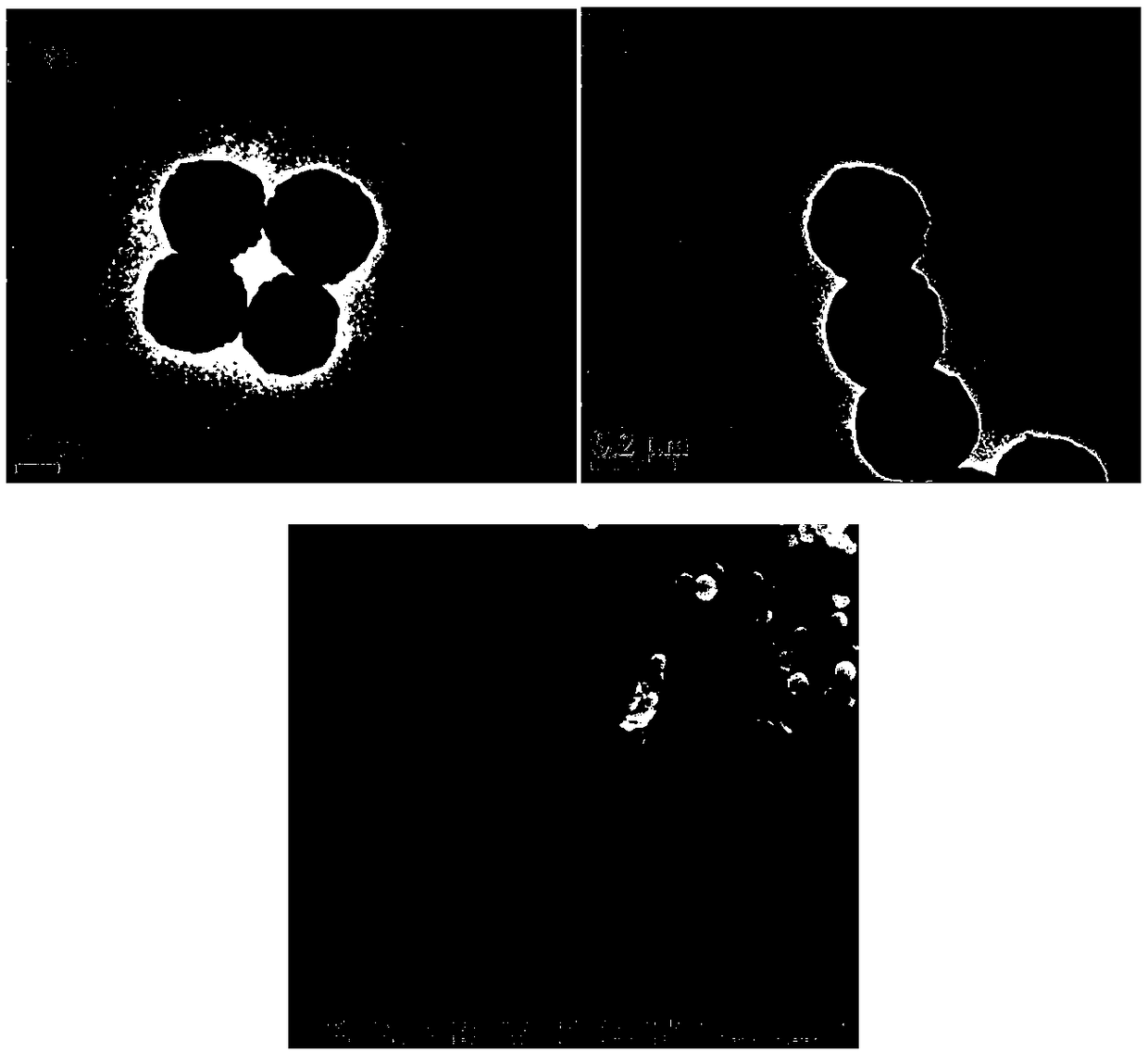

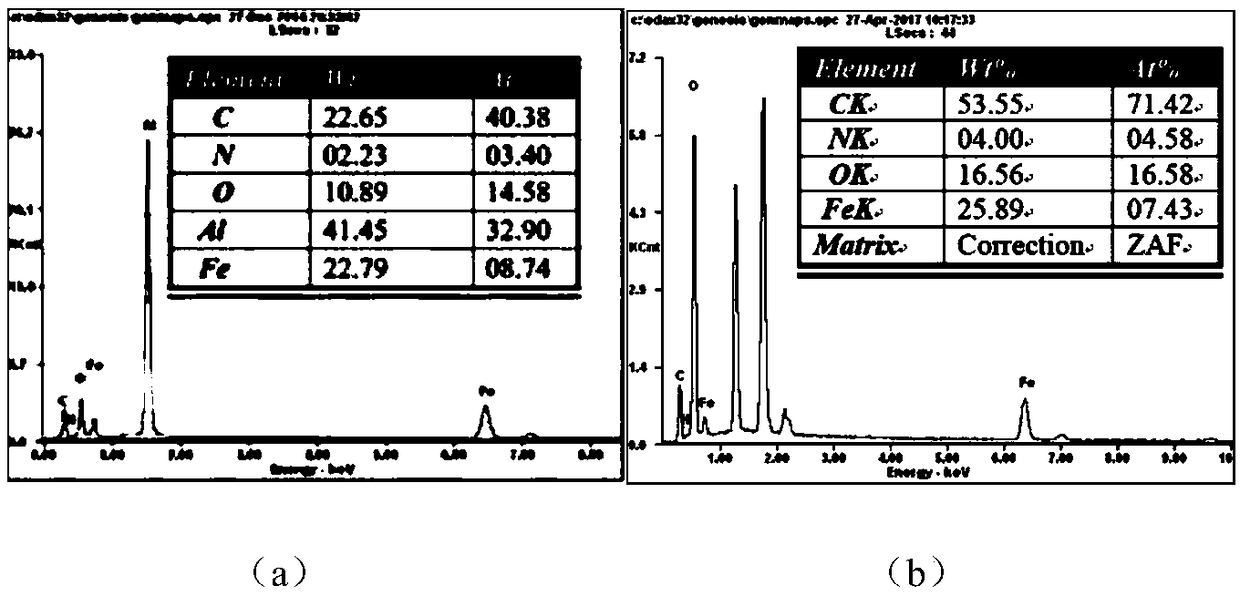

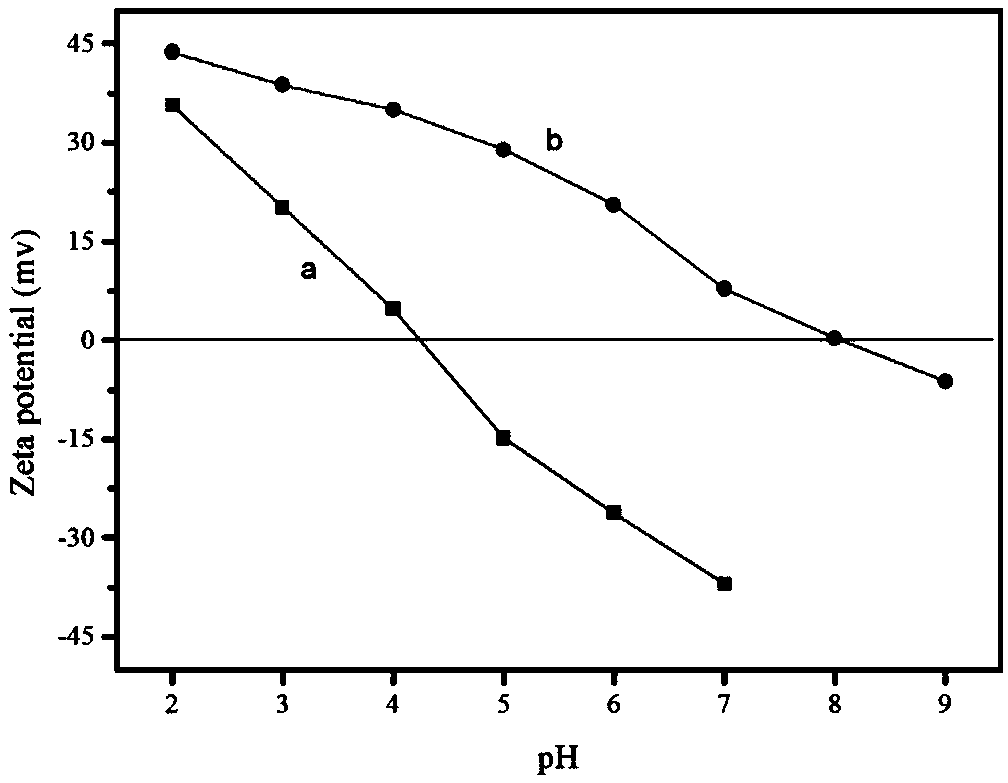

Preparation method and application of polyethylenimine-modifed magnetic microspheres

InactiveCN108620048AGood size controlSimple manufacturing methodOther chemical processesComponent separationWater bathsMicrosphere

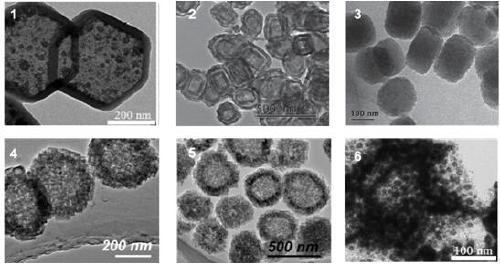

The invention discloses a preparation method and application of polyethylenimine-modifed magnetic microspheres. The preparation method comprises the following steps: firstly synthesizing ferroferric oxide magnetic microspheres, then performing ultrasonic dispersion on the prepared Fe3O4 nanoparticles in a Tris-HCI solution and then dropwise adding a dopamine-dissolved Tris-HCl solution; reacting under the action of mechanical stirring and drying to obtain dry Fe3O4@PEI magnetic microspheres; finally dispersing the prepared Fe3O4@PEI nanoparticles in the Tris-HCI solution, slowly adding a PEI aqueous solution, reacting under water bath conditions and drying to obtain the dry Fe3O4@PDA@PEI magnetic microspheres. The preparation method disclosed by the invention is simple, effective and goodin reproducibility; the prepared magnetic microspheres are uniform in particle size, larger in specific area, controllable in size, quick in response to an external magnetic field, good in selectivity, capable of producing an electrostatic effect with a negatively-charged sulfonic acid group in a pigment, easy for pigment absorption, good in stability, renewable and reusable.

Owner:TIANJIN UNIV

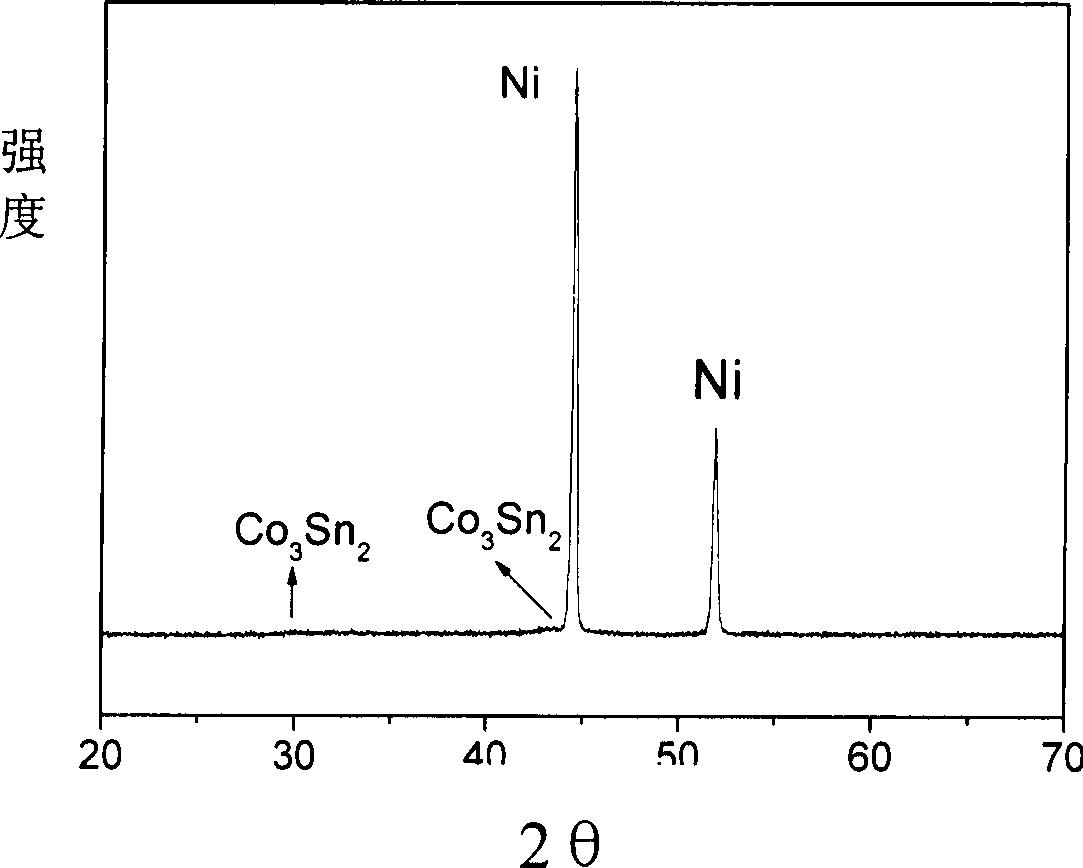

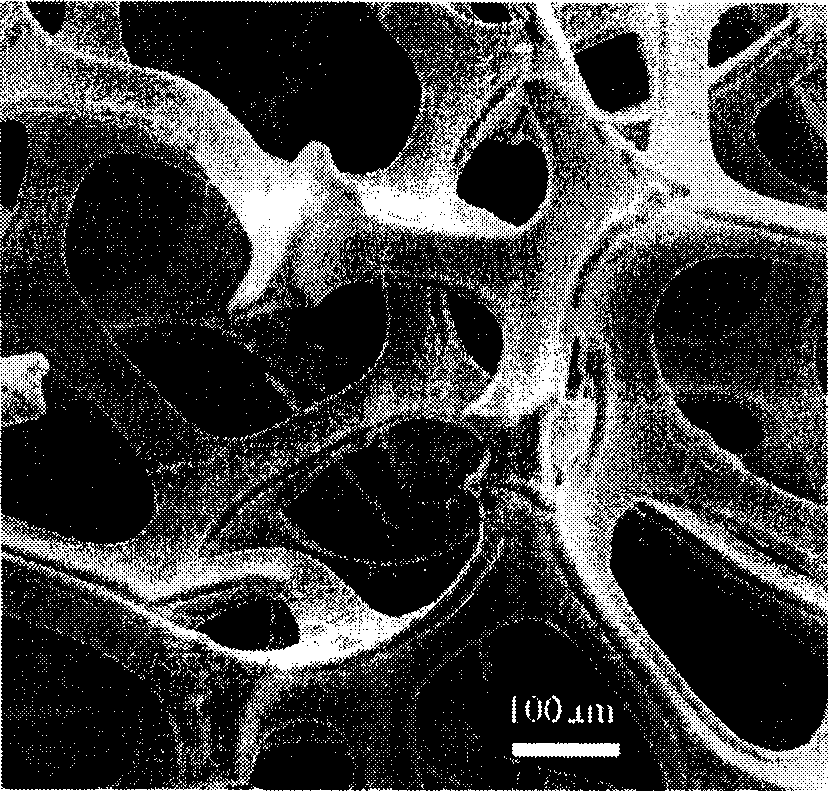

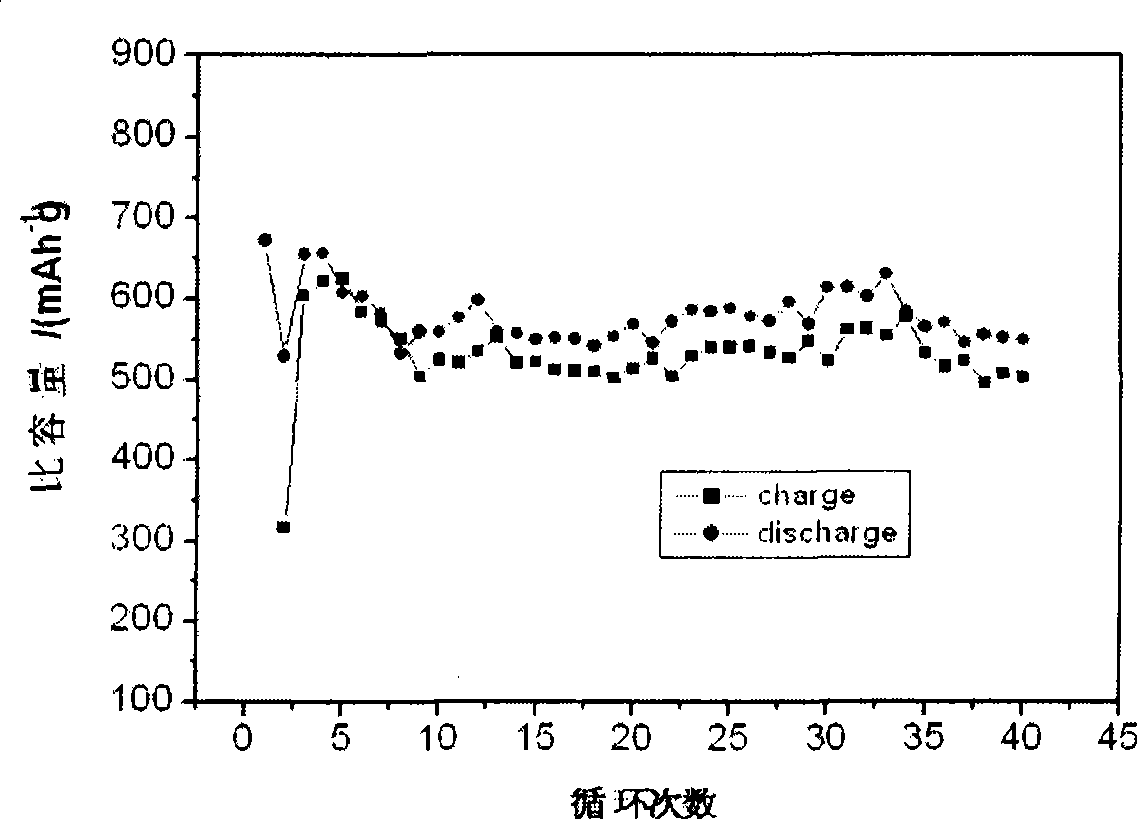

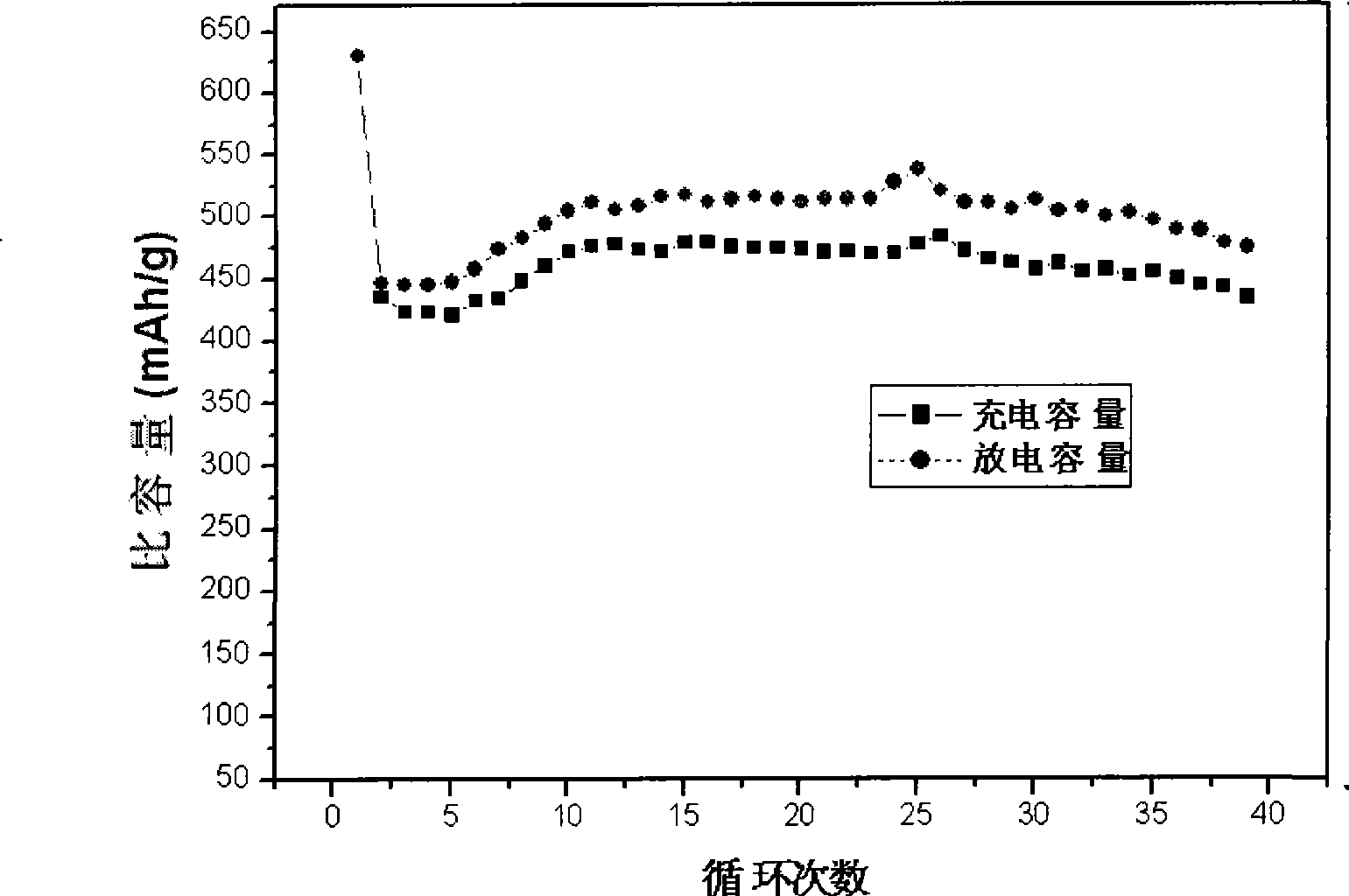

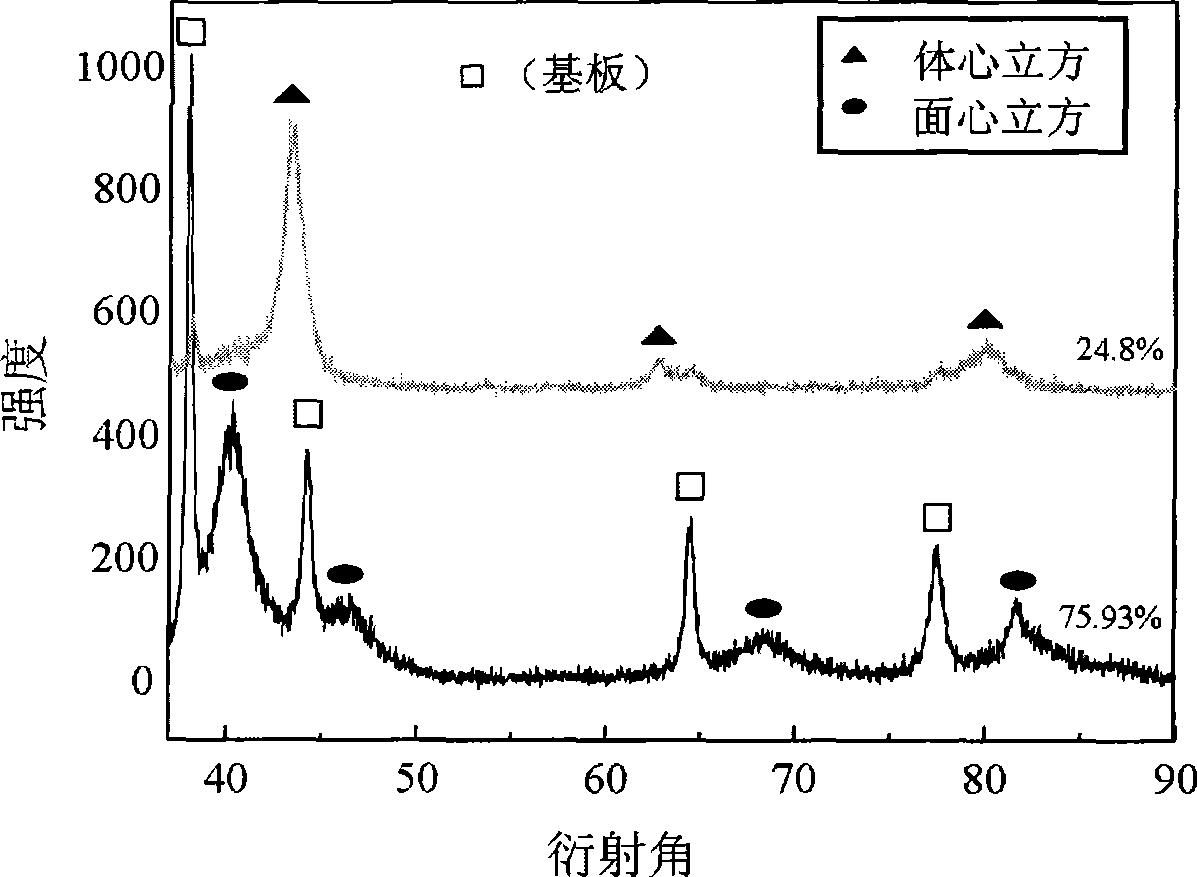

Electrochemical deposition preparation for lithium ionic cell tin-cobalt alloy film electrode

InactiveCN101476139AThe preparation process is easy to controlSimple processAlkaline accumulator electrodesThin film electrodeLyonium ion

The invention provides an electrical chemical depositing method for preparing lithium battery tin-cobalt alloy thin film electrode which has characteristics that foam nickel with a plurality of holes is used as basic body, the tin-cobalt alloy thin film is obtained by electrical chemical depositing on the foam nickel basic body for manufacturing lithium battery tin-cobalt alloy thin film electrode. The method has advantages of simple practical and low cost, and the tin-cobalt alloy thin film electrode is distributed on the foam nickel basic body that can ease electrode expansion in charge / discharge cycle process for improving cycle performance of battery. The method has latent application prospect in the lithium battery electrode material field.

Owner:HEFEI UNIV OF TECH

Graphene film and preparation method thereof

The invention relates to a preparation method of a graphene film, which comprises the following steps: (1) dispersing graphene oxide in a solvent to obtain a mixture; (2) pouring the mixture into a knifing machine, carrying out continuous knifing on a substrate at a speed V, and sending the film and substrate into a blast drying tunnel at the speed V to perform drying, thereby obtaining a substrate-bearing graphene oxide film; (3) continuously sending the substrate-bearing graphene oxide film into a pipe furnace at the speed V, and carrying out graphitizing in an inert atmosphere to reduce the graphene oxide and repair the structure defects on the surface, thereby obtaining a substrate-bearing graphene film; and (4) rolling the substrate-bearing graphene film from the pipe furnace, and peeling the substrate to obtain the graphene film. The invention also relates to a graphene film.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

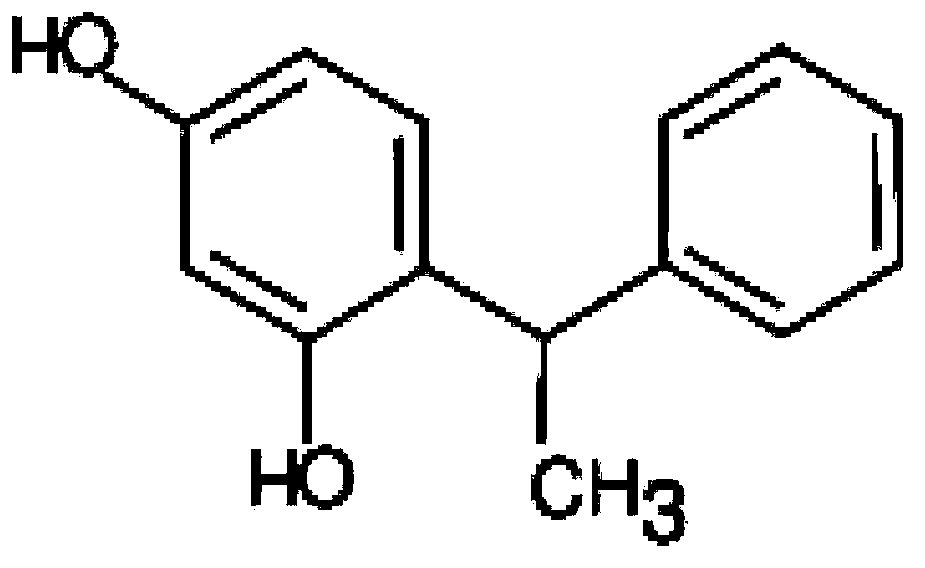

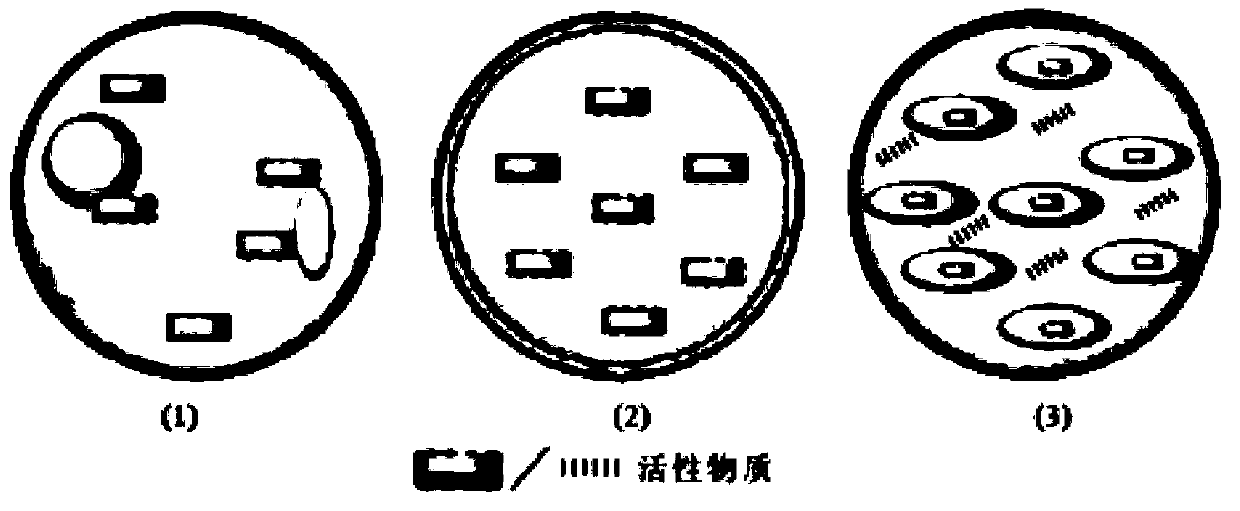

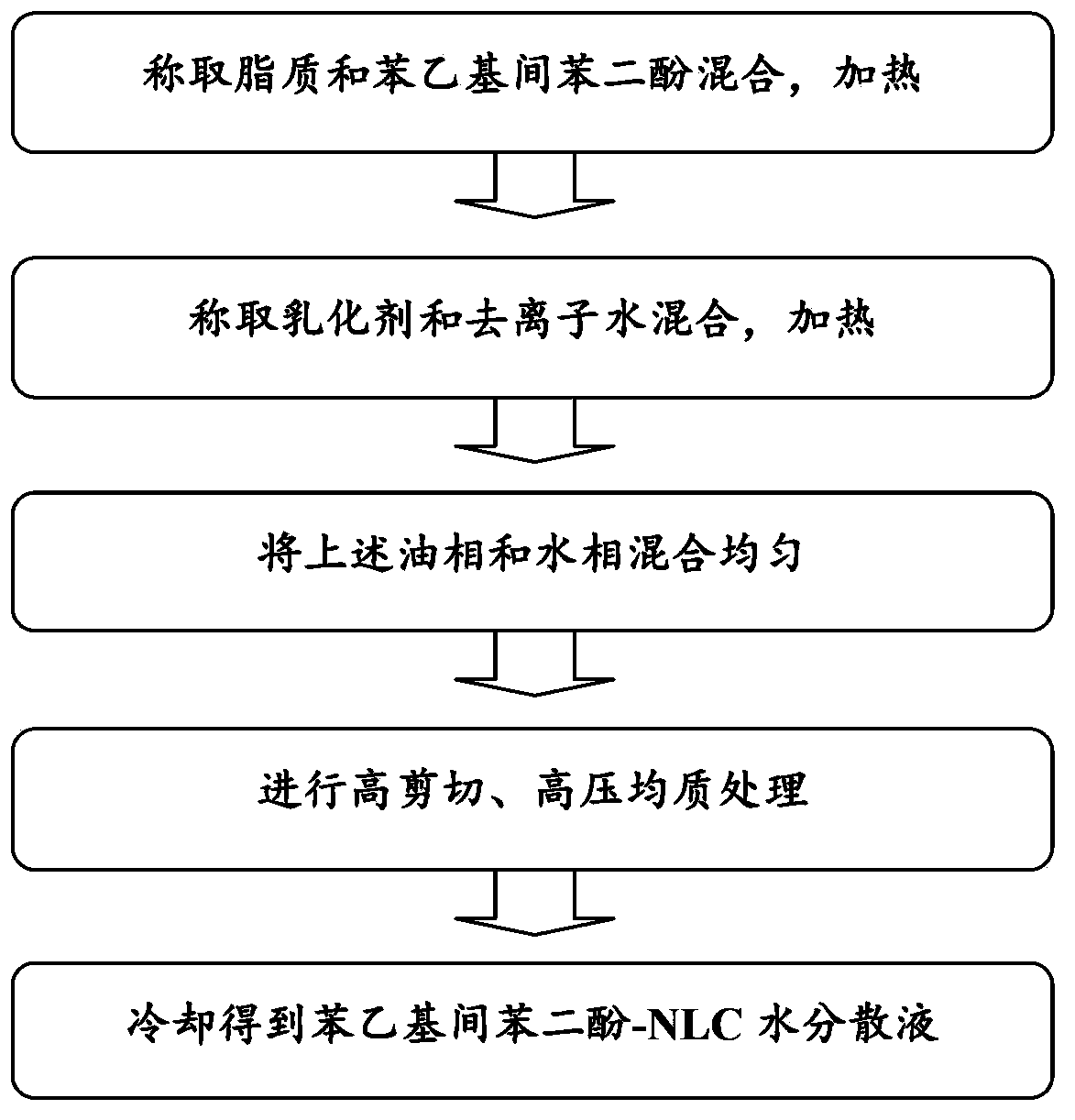

Nanostructured lipid carrier loaded with phenylethyl resorcinol, preparation method thereof and cosmetic containing same

InactiveCN103860389AImprove stabilityReduce leakageCosmetic preparationsToilet preparationsSolubilityActive component

The invention relates to nanostructured lipid carrier loaded with phenylethyl resorcinol. The carrier is loaded with the active component phenylethyl resorcinol (SymWhite 377) and is characterized in that the nanostructured lipid carrier comprises the following compositions in percent by weight: 0.5%-2% of phenylethyl resorcinol, 2%-5% of a nemulsifier, 5%-10% of a composite lipid material and 83%-92.5% of deionized water. The invention also relates to a preparation method of the nanostructured lipid carrier. The invention also relates to a skin-care product or a cosmetic containing the nanostructured lipid carrier. The nonostructured lipid carrier has excellent stability and water solubility, the preparation method is simple and controllable and good in repeatability, and is applicable to preparation of cosmetic containing phenylethyl resorcinol.

Owner:BEINONG BIOCHEM SUZHOU INDAL PARK +1

Composite degradable antibacterial artificial cerebral dura mater and preparation method thereof

The invention provides a composite degradable antibacterial artificial cerebral dura mater, comprising a vancomycin or ofloxacin hydrochloride injection, chitosan and sodium beta-glycerophosphate. The invention is characterized in that a spongy collagen biomembrane stent is prepared from a decellularized membrane-like derivative material, a chitosan solution with a concentration of 2% (w / v) and a sodium beta-glycerophosphate solution with a concentration of 56% (w / v) are used and mixed, and since a hydrogel formed by a compound of the chitosan solution and the sodium beta-glycerophosphate solution at a temperature of 37 DEG C has the characteristic of temperature sensitivity, the vancomycin or ofloxacin hydrochloride injection is added into the compound to form a solution which is used for soaking of the prepared spongy collagen biomembrane stent to prepare a suture-free cerebral dura mater, and the hydrogel compound uniformly infiltrates into the spongy collagen biomembrane stent after disposition in an incubator with a temperature of 37 DEG C for 10 min so as to form the absorbable artificial cerebral dura mater with antibacterial activity. The invention further provides a preparation method. The preparation method has the characteristics of convenience in preparation, easy film formation, low cost, convenient operation, etc.

Owner:BEIHUA UNIV

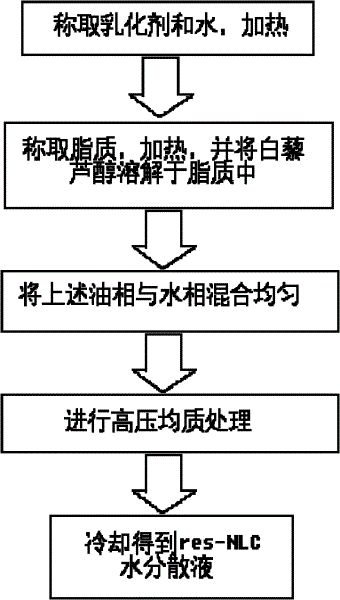

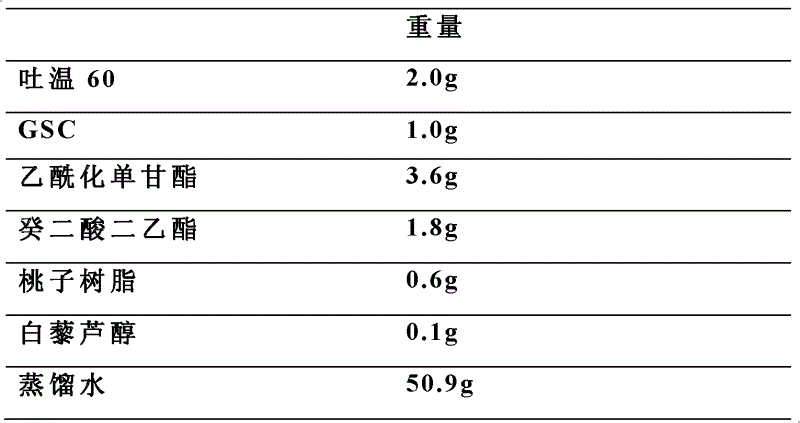

Resveratrol nanostructured lipid carrier and preparation method thereof

InactiveCN102614091AStructural disorderImprove stabilityCosmetic preparationsToilet preparationsLipid formationSolubility

The invention discloses a resveratrol nanostructured lipid carrier. The resveratrol nanostructured lipid carrier is loaded with active pharmaceutical ingredients of resveratrol and is characterized by comprising 0.1 to 1wt% of resveratrol, 2 to 20wt% of at least one emulsifier, 2 to 30wt% of a composite lipid material and the balance water, wherein the composite lipid material is a mixture of at least one solid lipid material and at least one liquid lipid material. The at least one solid lipid material and the at least one liquid lipid material are selected from glyceryl triacetate, acetylated monoglyceride, diethyl sebacate, diisopropyl adipate, diisopropyl sebacate, glycerol monolaurate, peach resin and an octadecyl alcohol. The resveratrol nanostructured lipid carrier has good stability and water-solubility. The preparation method of the resveratrol nanostructured lipid carrier is simple and controllable and has good repeatability. The resveratrol nanostructured lipid carrier can be utilized in preparation of resveratrol-containing cosmetics.

Owner:夏强 +1

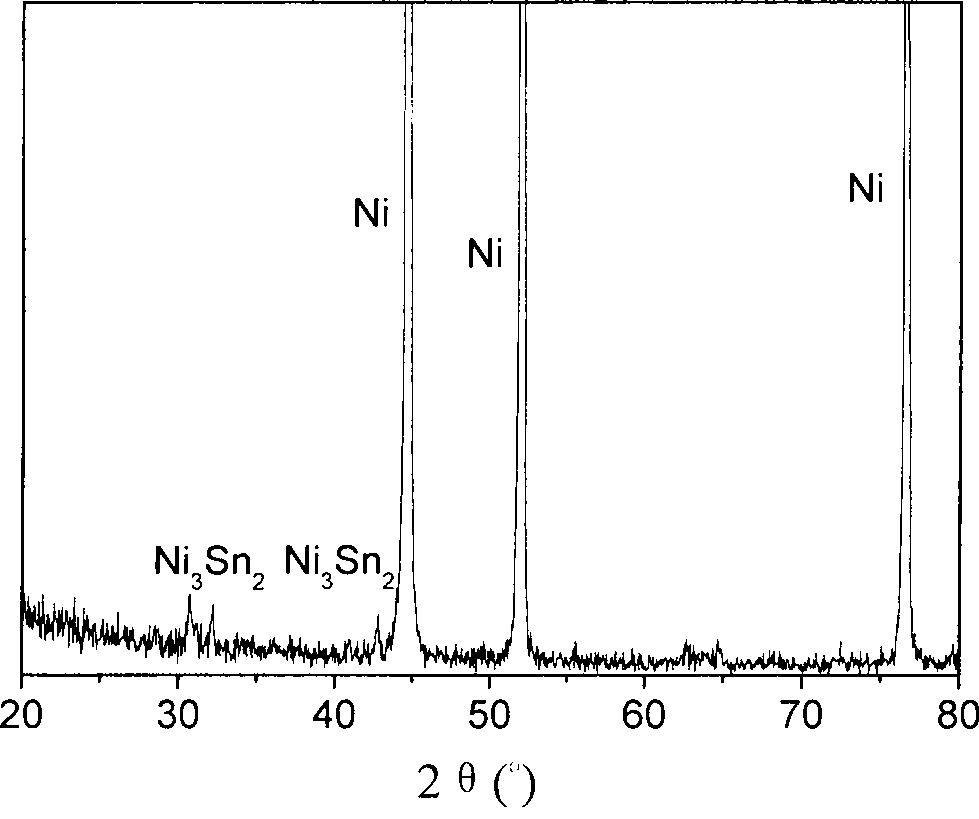

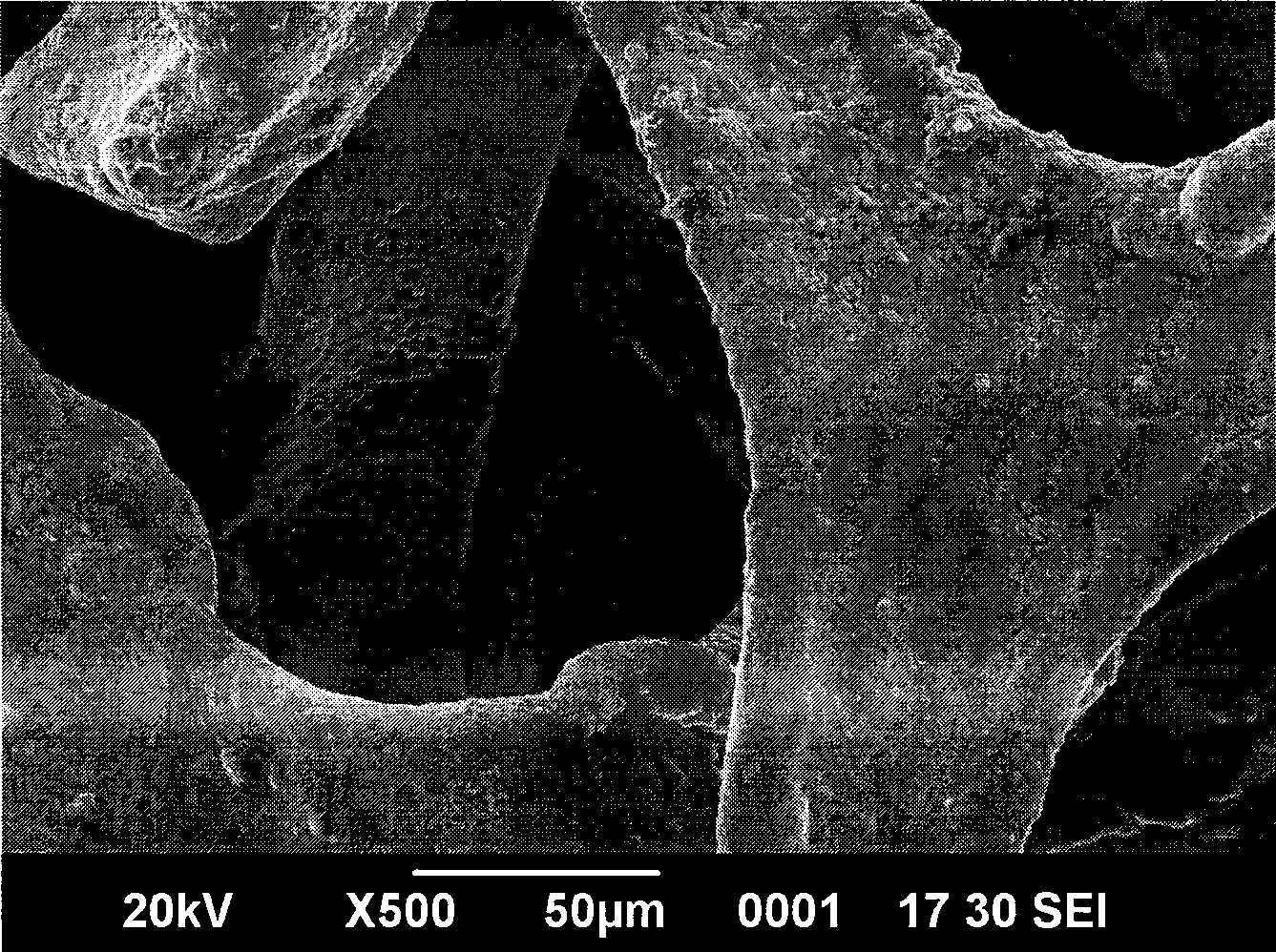

Method for preparing nickeltin thin film electrode for lithium ion battery through electrochemical deposition

InactiveCN101447567AThe preparation process is easy to controlSimple processElectrode manufacturing processesCyclic processThin film electrode

The invention relates to a method for producing lithium ion battery nickeltin thin-film electrode through electrochemical deposition. The method is characterized in that porous foamed nickel is adopts as the matrix, a nickeltin thin-film is obtained from the foamed nickel matrix through electrochemical deposition, and the lithium ion battery nickeltin thin-film electrode taking the foamed nickel as the matrix is produced. The method is simple, convenient and feasible, the cost is low, the nickeltin thin-film electrodes are distributed on the foamed nickel matrix, the expansion of the electrodes in the charging and discharging cyclic process can be eased, therefore, the cycle performance of the battery is improved, and the invention has potential application prospect on the application aspect of the electrode material of the lithium ion battery.

Owner:HEFEI UNIV OF TECH

Bacterial cellulose membrane with gradient structure and preparation method thereof

ActiveCN103233050AThe preparation process is easy to controlWide variety of sourcesMicroorganism based processesFermentationWound dressingFermentation

The invention discloses a bacterial cellulose membrane in a gradient structure and a preparation method of the bacterial cellulose membrane. The bacterial cellulose membrane is prepared by the steps of adding crop starch in a fermentation culture solution, heating for gelatinizing the mixture, adding a thickening agent into the gelatinized mixture, and carrying out static culture; and the bacterial cellulose membrane has a gradient structure with continuous transition from a compact upper surface downwards to a loose lower surface. The in-site fast controllable preparation of the gradient structure of the bacterial cellulose membrane can be realized by adjusting the proportion of the crop starch to the thickening agent. The preparation method of the bacterial cellulose membrane disclosed by the invention has the advantages that the resources of raw materials are wide, biosynthesis process is mild and pollution-free, and the product is environment-friendly, safe, low in production cost, controllable in process and designable and has a bright large-scale production prospect. The bacterial cellulose membrane with the gradient structure is suitable for the fields of cosmetics and biomedical materials including a facial mask, a cooling paste, a wound dressing, an artificial skin and the like.

Owner:DONGHUA UNIV

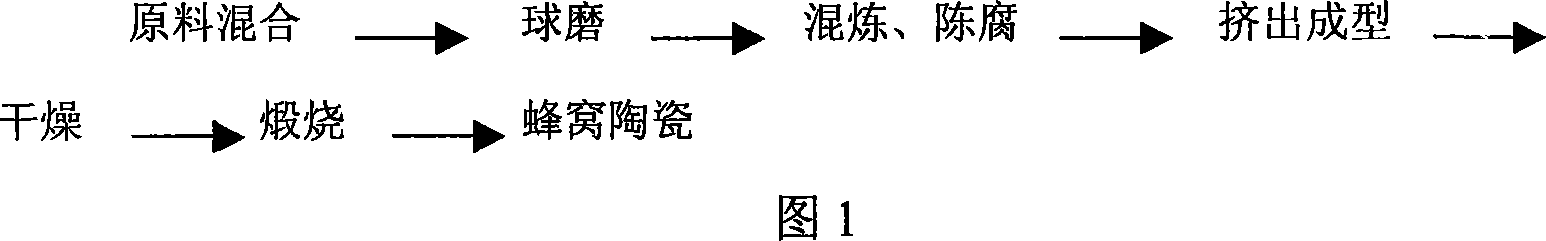

Multi-phase functional ceramic honeycomb support and preparation method thereof

ActiveCN101062868AThe preparation method is simple and controllableLow costCatalyst carriersCeramicwareRare earthSilicon dioxide

The invention discloses a preparing method of polyphase functionality honeycomb ceramic supporting body, which comprises the following steps: choosing titanium white, silica dioxide and aluminum oxide as main raw material; doping rare earth; adding right amount magnesium oxide accelerating burnt agent and additive; mixed-refining; squeezing; forming; drying; calcining for 2-3 h under 1200-1500 deg. c; generating the product with aluminium titanate and red schorl as principal crystalline phase. This product possesses shockproof, corrosion resistant, high intensity and good association with coated carrier, which can be used to the carrier of car exhaust gas cleansing activator and carrier reactor of photocatalyzer.

Owner:SHANDONG GEMSKY ENVIRONMENTAL PROTECTION TECH CO LTD

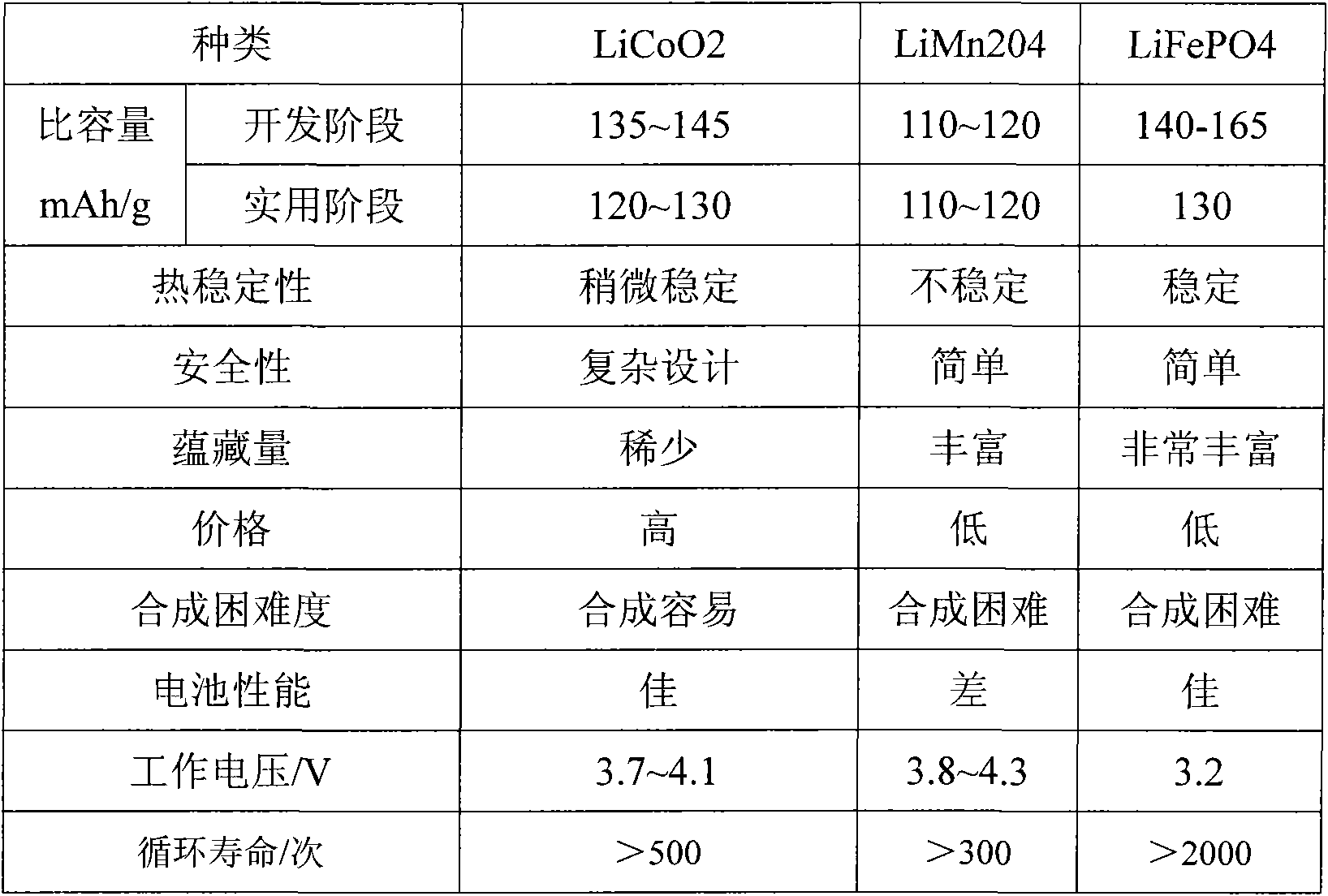

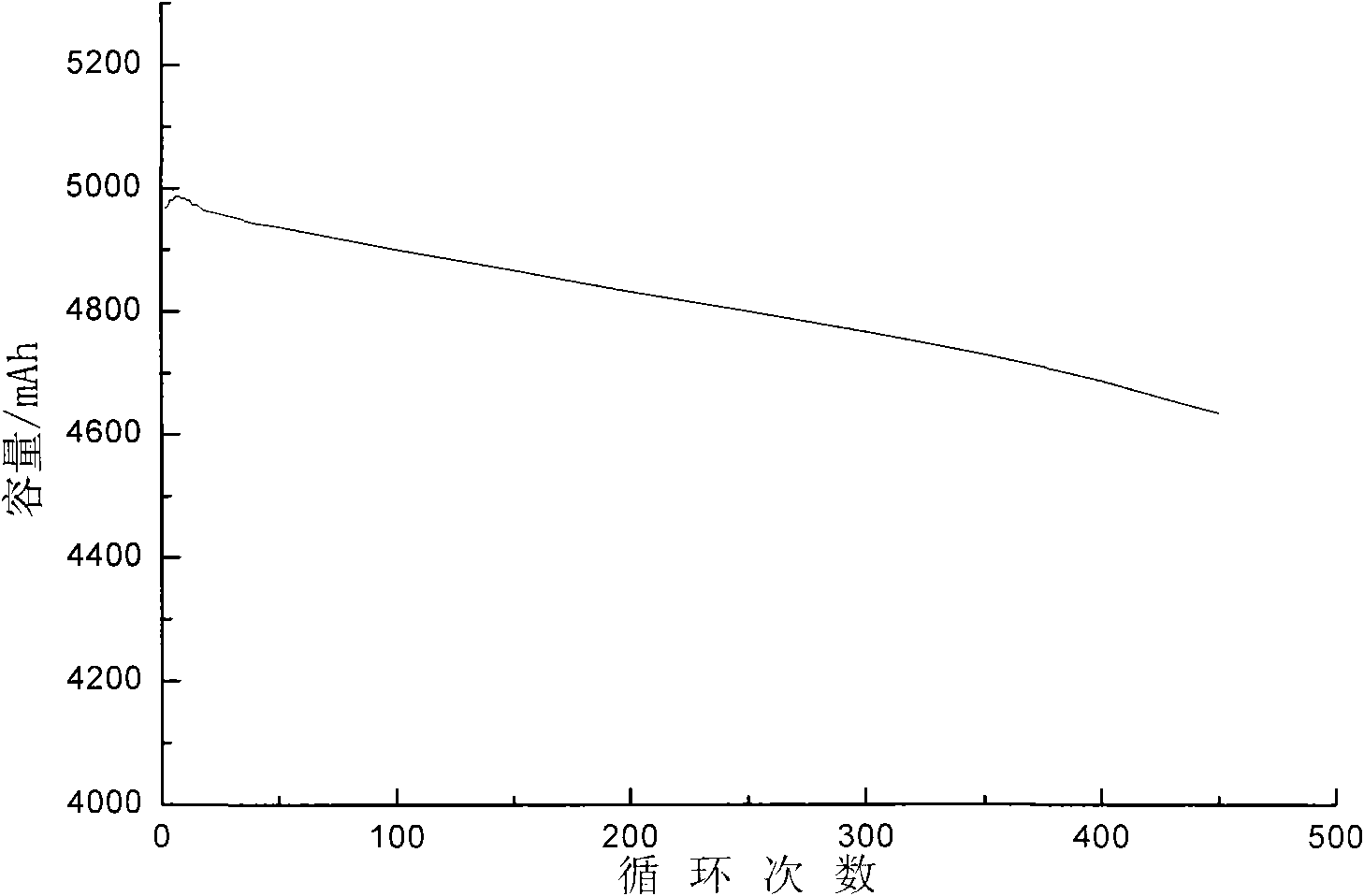

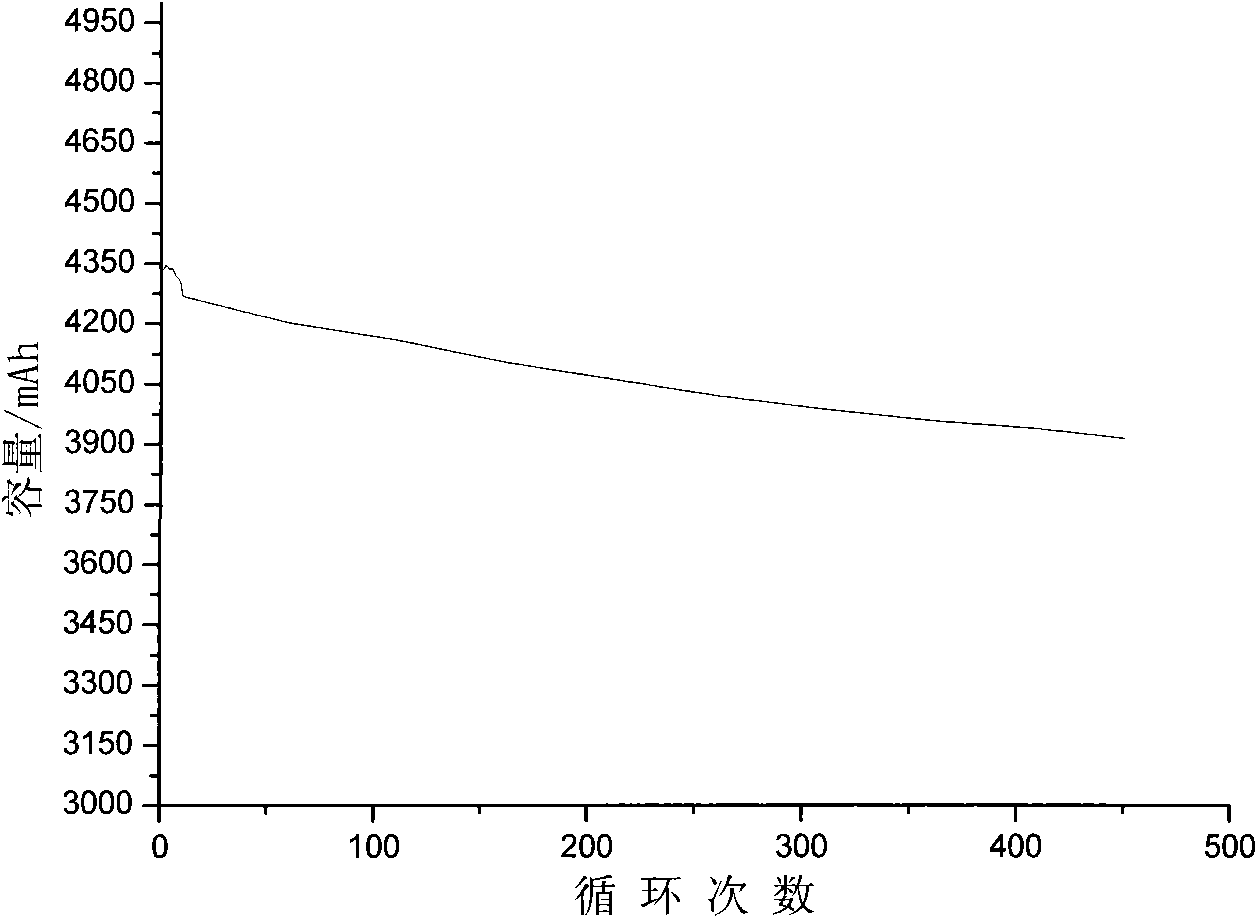

Power polymer lithium ion battery and fabricating process thereof

InactiveCN101567469AImprove electronic conductivityImprove high-magnification performanceElectrode manufacturing processesElectrode carriers/collectorsHigh ratePositive current

The invention discloses a power polymer lithium ion battery and a fabricating process thereof. A positive plate comprises modified lithium iron phosphate, conductive agent, positive adhering agent, dispersant and positive current collector. A negative plate comprises graphite, conductive agent, negative adhering agent and negative current collector. The fabricating process comprises the following steps: firstly, dispersing the conductive agent; secondly, dispersing the modified lithium iron phosphate; thirdly, adding the efficient organic adhering agent so as to increase the adhering property among grains of the conductive agent, between the conductive agent and the positive material, and between the conductive agent and the positive material and the current collector, and to increase the electrode contact conductivity and electron conductivity, thereby greatly improving the battery high-rate charge and discharge property. The invention has the advantages of simple process, easy control, good product safety and long circulation service life.

Owner:ZHEJIANG ZHENLONG BATTERY

Rotary writing method of multi-core fiber grating

InactiveCN101825740ASimple methodGreat tunabilityOptical fibre with multilayer core/claddingGratingEngineering

The invention provides a rotary writing method of a multi-core fiber grating, which comprises the following steps of stripping one section of coating on a multi-core fiber; fixing the multi-core fiber on a fiber fixture after cleaning treatment; arranging the fiber fixture on a rotary optical device; tightly attaching the multi-core fiber to a mask; regulating the rotary optical device so that one fiber core aligns with a writing optical source; starting an excimer laser, and conducting exposure after the optical source becomes parallel light through collimating and beam expanding; connecting one end of the multi-core fiber to a broadband optical source, and connecting the other end to a spectrograph; monitoring grating formation through the spectrograph, and stopping exposure after achieving the required reflectivity; regulating the rotary optical device to a proper angle so that the next fiber core of the multi-core fiber rightly aligns with the writing source for writing fiber by fiber; and packaging. The invention has the advantages of simple implementation and easy control, and can improve the writing quality of the grating; a plurality of manufactured multi-core fiber gratings are integrated in one fiber, which improves the integration of optical devices in the fiber and can be used for simultaneously measuring a plurality of physical quantities and multi-dimension information.

Owner:HARBIN ENG UNIV

Preparation method of DHA lipid nano-particles

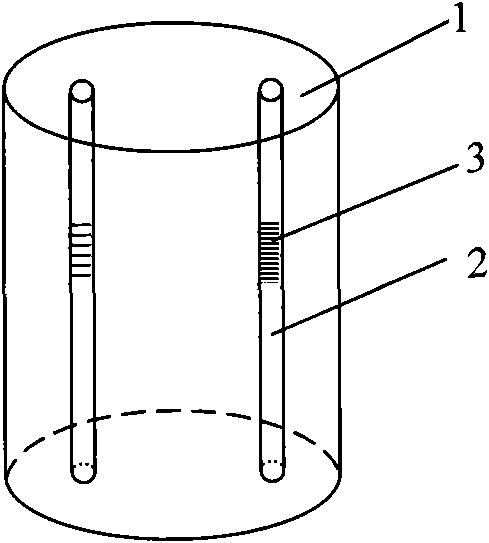

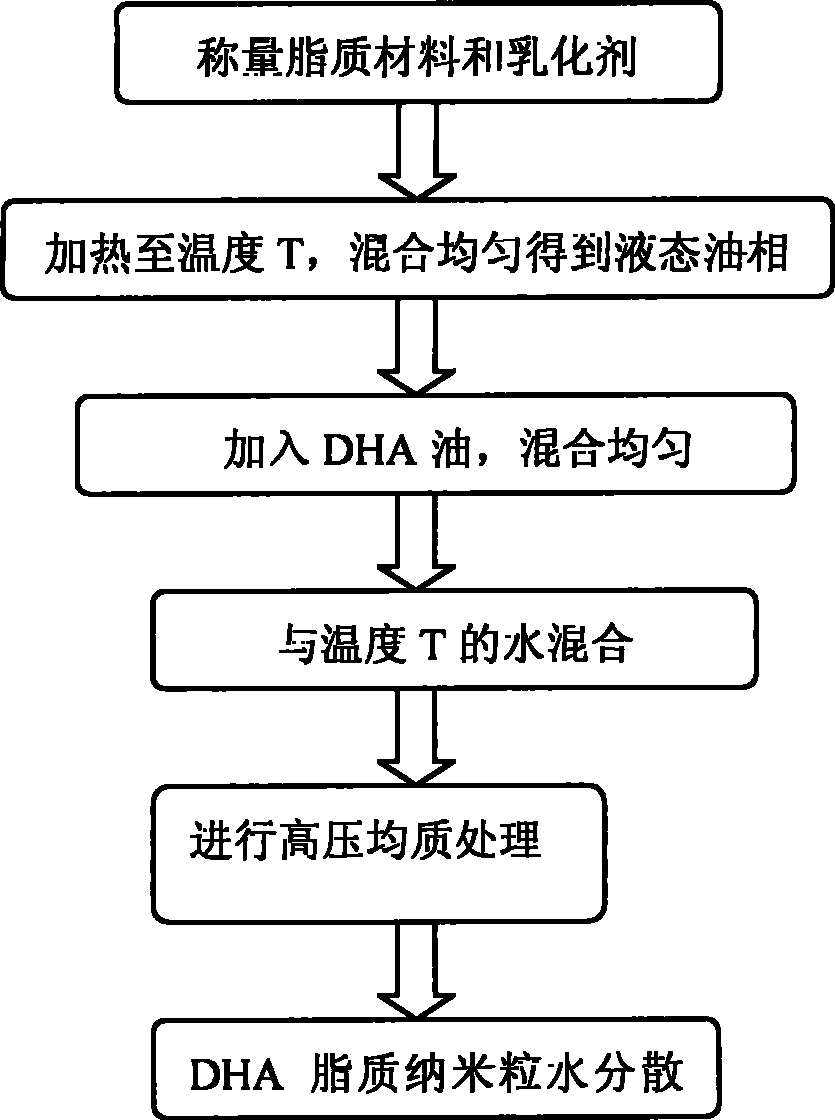

ActiveCN101385714AThe preparation process is easy to controlImprove stabilityOrganic active ingredientsMetabolism disorderLipid formationUniform system

The invention discloses a preparation method of DHA lipid nanoparticles, the preparation method comprises the following steps: step one: an emulsifying agent and lipid material are respectively weighed, the emulsifying agent and the lipid material are heated to the set temperature after the mixing, a liquid oil phase is obtained after the melting; step two: DHA is weighed, the DHA is added in the liquid oil phase, a uniform system is obtained by stirring; step three: water with the temperature which is the same with the set temperature T is added in the system, then the system enters a high pressure homogenizer which is preheated to the set temperature T and at the set pressure of 80MPa after the even mixing and stirring; step four: the obtained high temperature micro-emulsion is cooled to the room temperature, and aqueous dispersion of DHA-NLC is obtained; the preparation method adopts the lipid nanoparticles to load DHA, thereby protecting the DHA from being oxidized and covering up the stinking smell of DHA oil; furthermore, the prepared DHA aqueous dispersion can be conveniently added in foods, thereby expanding the using range thereof.

Owner:PROYA COSMETICS

Skin moisturizer containing ginkgo enzyme, as well as preparation method and application of skin moisturizer

ActiveCN103690469AGuard cellsPromote blood circulationCosmetic preparationsToilet preparationsWrinkleBlood circulation

The invention provides a skin moisturizer containing ginkgo enzyme, as well as a preparation method and application of the skin moisturizer. The skin moisturizer comprises the ginkgo enzyme and skin matrix. The preparation method comprises the following steps: inoculating raw materials of ginkgo kernels, fruits and vegetables, Chinese herbal medicine accessories and the like with compound strains, stirring the mixture evenly, sealing the mixture, fermenting the mixture away from light, stewing, filtering and removing fermentation residue to obtain the ginkgo enzyme, and adding the skin matrix to the ginkgo enzyme so as to obtain the skin moisturizer containing the ginkgo enzyme. The skin moisturizer containing the ginkgo enzyme does not contain any preservative component; therefore, the skin moisturizer which does not irritate skin can protect dermis cells, improve blood circulation, and prevent the cells from oxidation to wrinkle; at the same time, the skin moisturizer can hinder pigments from formation and pigmentation in dermis, and play the role of whitening the skin and preventing and treating hyperpigmented macule. The invention further discloses the application of the skin moisturizer to beauty masks.

Owner:SHENZHEN INST OF ADVANCED TECH

Multilayer stable black phosphorene and preparation method

InactiveCN106348263AStable crystal structureStabilizers stabilize the crystal structureMaterial nanotechnologyPhosphorus preparationSulfurSuperoxide

The invention belongs to the field of novel two-dimensional materials, and in particular relates to multilayer stable black phosphorene and a preparation method. The reaction of the black phosphorene and oxygen is hindered by chelating of a chelating agent and stable modification of a stabilizer, so that superoxide anions are more difficult to generate, thereby greatly reducing the degradation of black phosphorus in an environment. Further, the multilayer stable black phosphorene is obtained by encapsulating elemental sulfur. According to the method, a stable crystal structure of the black phosphorus is guaranteed; meanwhile, service requirements are met; the thickness of the obtained black phosphorene is between 10nm and 20nm. The multilayer stable phosphorene and the preparation method have a wide important application prospect in the fields such as transistors, sensors, solar cells, switches, battery electrodes and the like.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Method for preparing size-controlled graphene oxide by clean oxidation technology

The invention discloses a method for preparing size-controlled graphene oxide by a clean oxidation technology. The method comprises the following steps: performing pre-oxidization on natural flake graphite serving as a raw material to increase a gap between graphite layers and add an oxidization functional group on the edge, enabling ammonium hydroxide and hydrogen peroxide to act jointly under a hydrothermal condition to protect a flake graphite layer from being sheared too small, and performing deep oxidization by a hydroxyl radical produced by hydrogen peroxide excitation to prepare a graphite oxide product; cleaning the prepared graphite oxide, and performing ultrasonic treatment in a solvent to prepare a graphene oxide dispersing solution; drying the graphene oxide dispersing solution to obtain graphene oxide powder. In the preparation process, no strong acid and no heavy metal oxidant are needed; the post-treatment process is simple and environment-friendly; the raw materials are low in cost; furthermore, the preparation process is simple, and the method is a method expected to be used for preparing the graphene oxide in a large scale.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for preparing aromatic hydrocarbons through directed conversion of CO2 and preparation method of catalyst

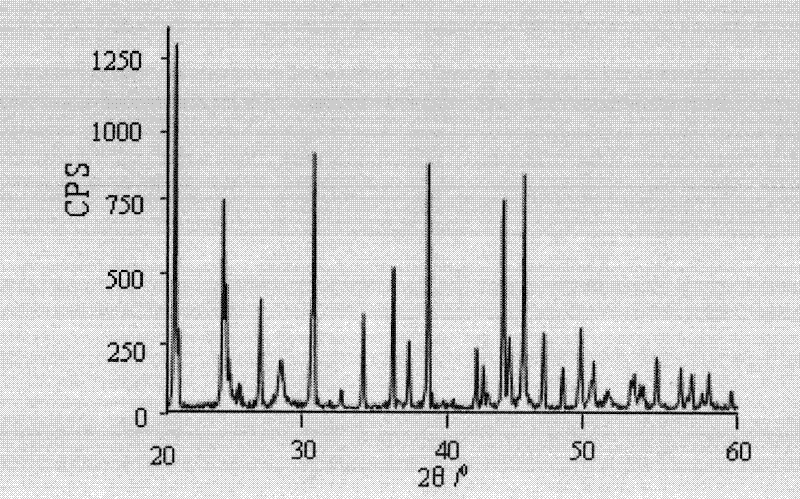

ActiveCN109985659AUniform compositionUniform structureHydrocarbon from carbon oxidesMolecular sieve catalystsSimple Organic CompoundsCore shell

The invention discloses a catalyst for preparing aromatic hydrocarbons through directed conversion of CO2, and relates to the technical field of catalytic hydrogenation. Metal oxide is adopted as a core, and a a molecular sieve is adopted as a shell so as to obtain the core-shell structure catalyst, wherein the metal ion center of the metal organic compound is one or more of Zn<2+>, Zr<2+>, Fe<3+>, Co<2+>, Ni<2+>, Cu<2+>, Cr<3+> and Mn<2+>, and the molecular sieve is one or more of ZSM-5, MCM-41, SAPO, MCM-22, USY and SBA-15. The catalyst for preparing aromatic hydrocarbons through directed conversion of CO2 has the characteristics of a uniform structure, uniform properties and precise regulation, the preparation process has simple procedures and high repeatability, and the prepared catalyst has the advantages of high conversion rate of CO2, high selectivity to aromatic hydrocarbons, a long service life, a wide application range and the like; and the prepared catalyst can be directly applied to preparation of aromatic hydrocarbons through directed conversion of CO2, and has an industrial value.

Owner:NANJING INST OF TECH

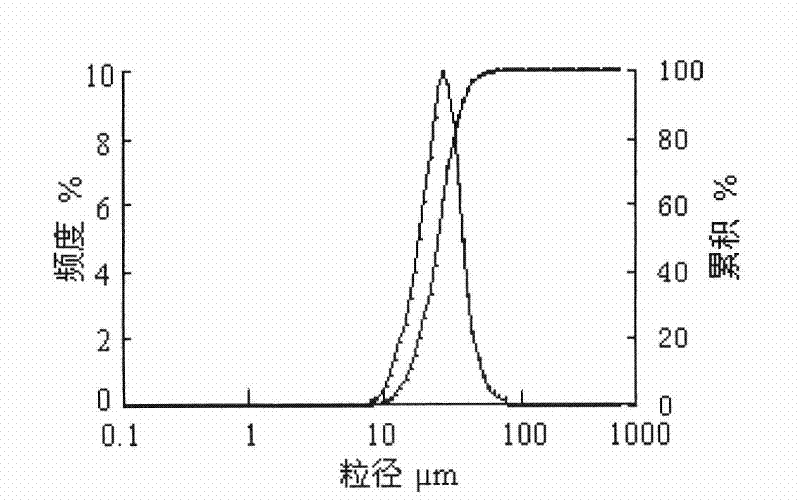

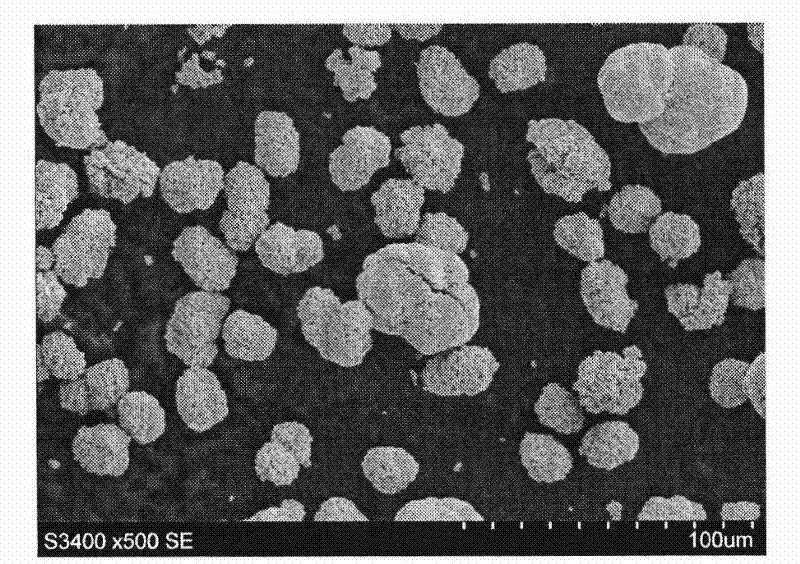

Method for preparing large-particle cerium oxide

InactiveCN102502758AThe preparation process is easy to controlUniform particle distributionNanotechnologyRare earth metal compoundsChemistryCerium oxide

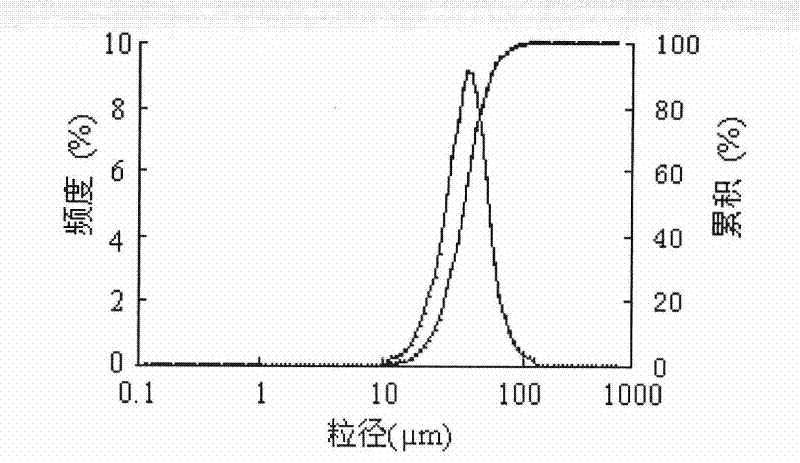

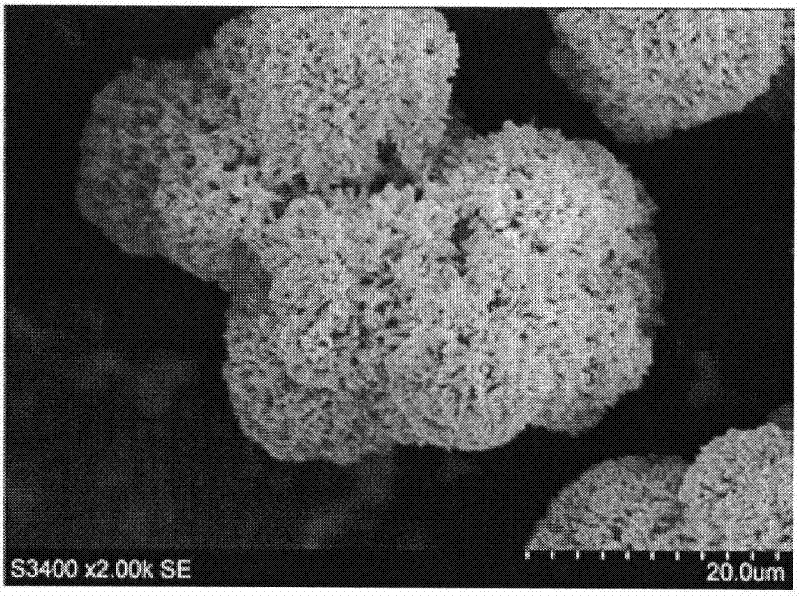

The invention relates to a method for preparing large-particle cerium oxide, belonging to a preparation process for material. The method for preparing large-particle cerium oxide disclosed by the invention comprises the following steps of: preparing cerium oxycarbonate by using cerium chloride solution as a raw material and using ammonium bicarbonate as a precipitant, and then washing, filtering, centrifugally spin-drying and burning the cerium oxycarbonate precipitate, so as to obtain a cerium oxide product having a medium particle size of 35 to 45 microns. In the method for preparing large-particle cerium oxide disclosed by the invention, the precipitation temperature and concentration of the cerium oxycarbonate are the key, and cerium carbonate instead of cerium oxycarbonate is obtained when the precipitation temperature is lower than 85 DEG C; moreover, the preparation process is easy to control, and a large-particle cerium oxide product having a medium particle size of 35 to 45 microns is produced by the traditional cerium carbonate precipitation procedure of factory; and the large-particle cerium oxide product is uniform in particle distribution, good in dispersibility and spherical in shape.

Owner:BAOTOU JINGRUI NEW MATERIAL

Acne-removing, oil control and skin beautifying cream

InactiveCN106176556AHas a health effectPromote repairCosmetic preparationsToilet preparationsSkin repairBud

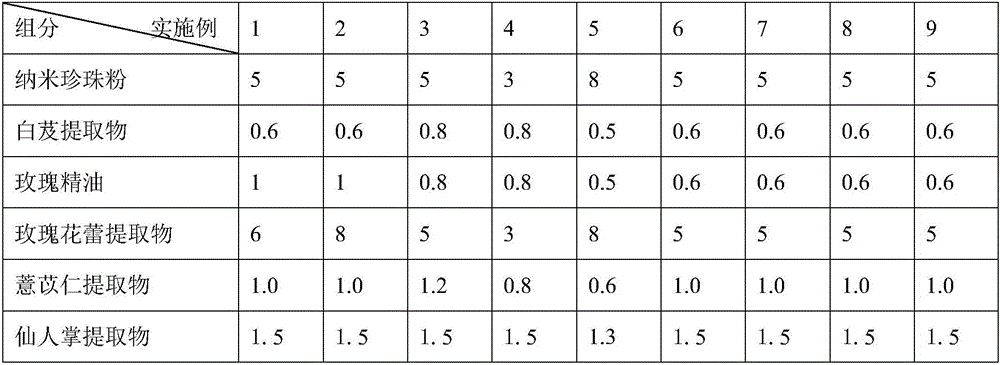

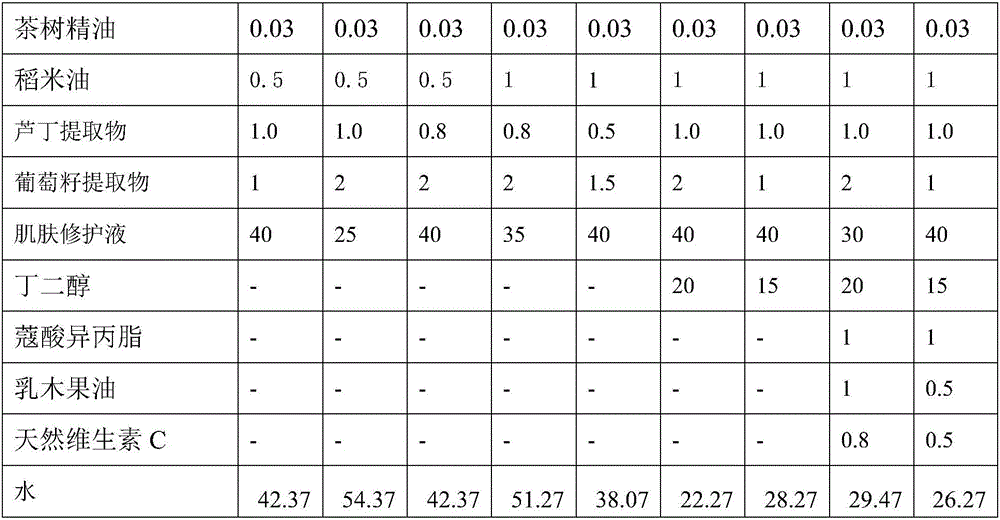

The invention relates to acne-removing, oil control and skin beautifying cream and belongs to the technical field of cosmetics. The acne-removing, oil control and skin beautifying cream is prepared from, by weight, nano pearl powder 3-8%, bletilla extract 0.5-0.8%, rose essential oil 0.5-1%, rose bud extract 3-8%, coix seed extract 0.6-1.2%, cactus extract 1.3-1.5%, tea tree oil 0.01-0.03%, rice oil 0.5-1.0%, cactus extract 0.5-1.0%, grape seed extract 1-2%, skin repair liquid 25-40% and the balance water. The acne-removing, oil control and skin beautifying cream is prepared by compounding a variety of natural plant extracts and the skin repair liquid, can produce a remarkable acne-removing effect, can achieve swelling subsidence and promote skin inflammation subsidence, improve, fade and remove acne marks and meanwhile plays the effects of whitening skin and prevention and control of pigment plaques.

Owner:张进

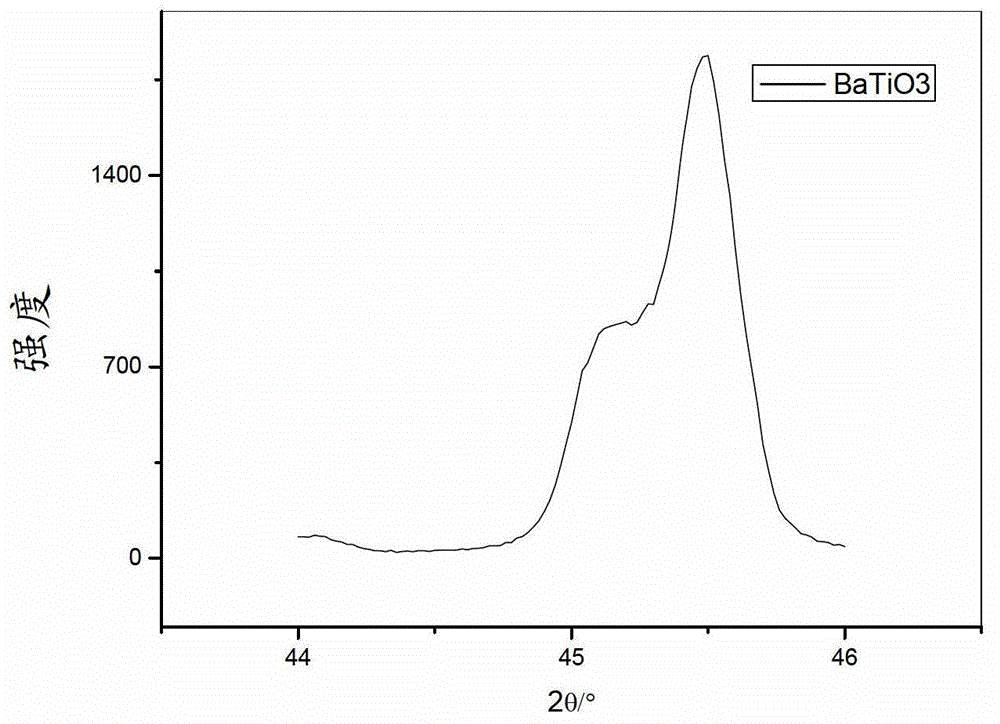

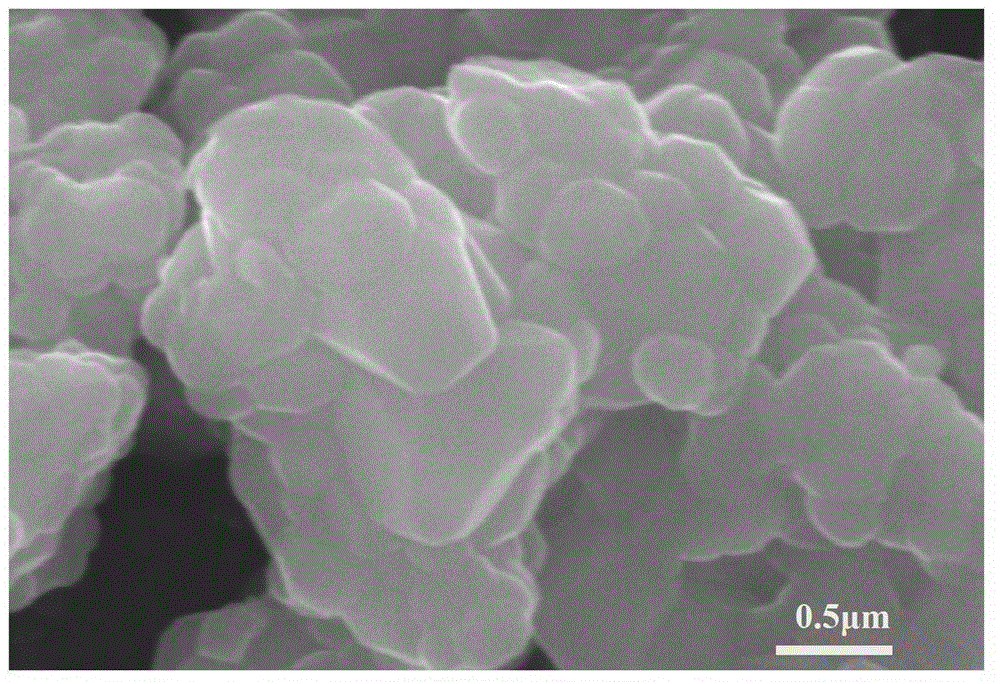

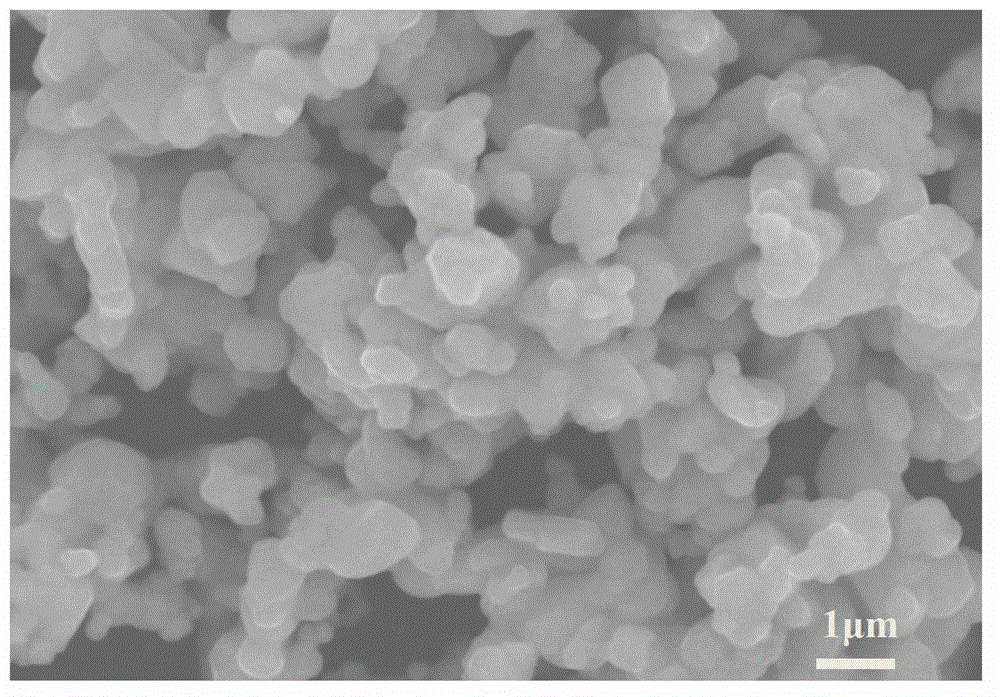

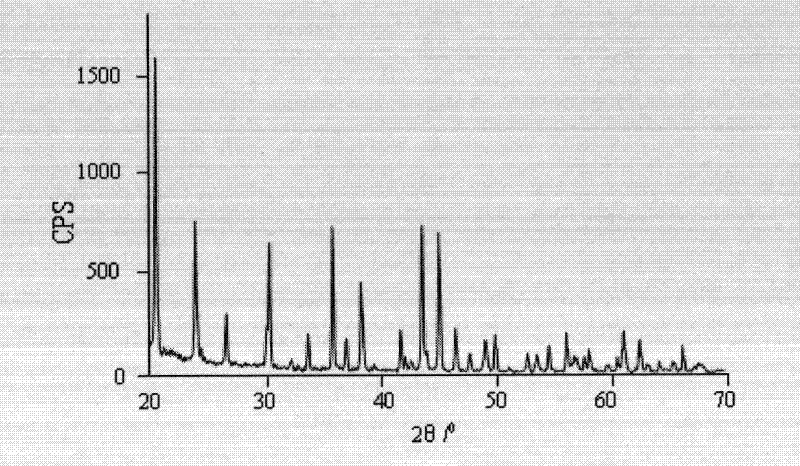

Preparation method for tetragonal phase nano barium titanate

InactiveCN102976400ASmall average particle sizeNarrow particle size distributionMaterial nanotechnologyTitanium compoundsComplex ionsOxalate precipitation

The invention provides a preparation method for tetragonal phase nano barium titanate. The preparation method comprises the steps as follows: i), preparing water solutions of barium chloride and oxalic acid respectively, and mixing alcoholic solution of butyl titanate and oxalic acid solution uniformly to obtain titanium oxyoxalate complex ion solution; ii), adding titanium oxyoxalate complex ion solution obtained in the step i) into a supergravity reactor as a circulating flowing phase to control the supergravity level; and meanwhile, dropping barium chloride solution to obtain white barium titanyl oxalate precipitation suspension as a precursor of barium titanate, and keeping the pH value of the whole system at 2.5-3.5 during reaction; and iii),ageing the precipitation suspension obtained in the step ii), leaching, washing and drying to obtain white barium titanyl oxalate power. The preparation method provided by the invention has the advantages that tetragonal phase nano barium titanate can be prepared; and the particle size of the prepared power can be controlled to be within the range of 30-90 nm; the average particle size is small, and the particle size is narrow in distribution; and the degree of crystallinity is high, and the crystal formation is intact.

Owner:XIANGTAN UNIV

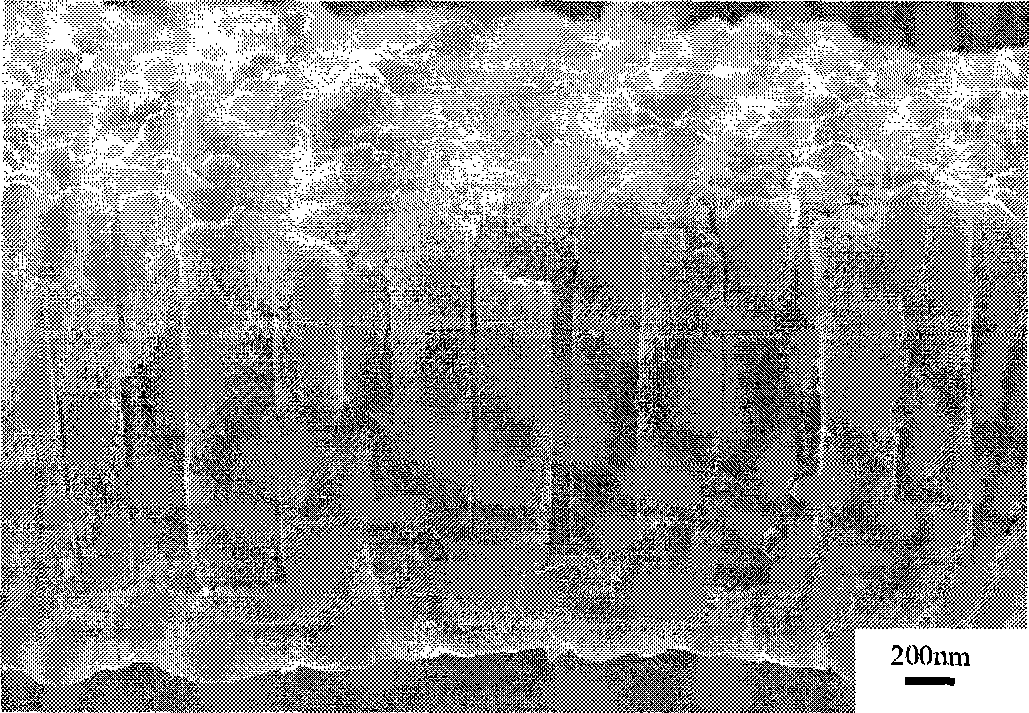

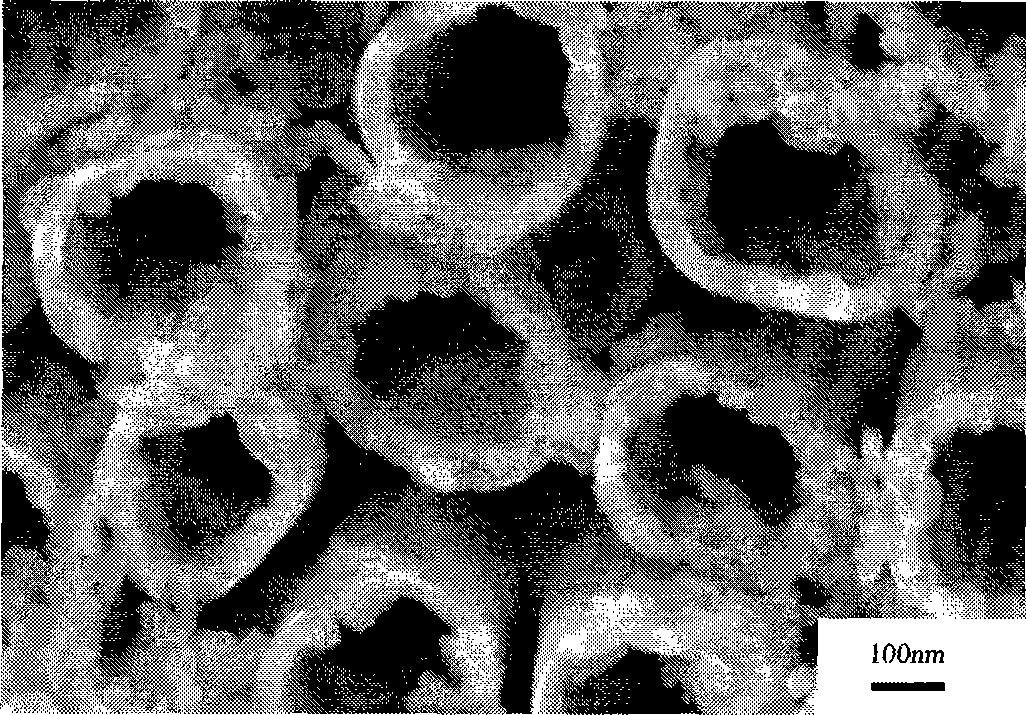

Alloy nanotube and manufacturing method thereof

InactiveCN101469453AEasy to manufactureThe preparation process is easy to controlPolycrystalline material growthSingle crystal growth detailsNanoholeNanotube

The invention discloses an alloy nano-tube and a preparation method thereof, which belong to the field of nanometer material. The alloy nano-tube is a solid solution, a metal compound or an amorphous state formed by two transition metal elements, namely A and B, wherein the A accounts for 15.3 to 86.4 percent of the total amount, and the B accounts for 13.6 to 84.7 percent of the total amount. The preparation method comprises the following steps: a formwork with a layer of gold or platinum film introduced into the back side is soaked in an electrolysis bath containing metal ion A and B, and is electrodeposited under certain voltage and current conditions to obtain a binary alloy nano-tube. Binary alloy nano-tubes with different diameters, different lengths and different components can be obtained by adopting formworks with nanochannels with different inner diameters, controlling the electrodeposition time and adjusting cathode current density. The binary alloy nano-tube has simple preparation process, mild reaction conditions, strong controllability and good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Bacterial cellulose facial mask with gradient structure and preparation method of facial mask

InactiveCN103211715AThe preparation process is easy to controlWide variety of sourcesCosmetic preparationsToilet preparationsCulture fluidFermentation

The invention relates to a bacterial cellulose facial mask with a gradient structure and a preparation method of the facial mask. The preparation method comprises the following steps of: adding a thickening agent and crop starch in fermentation culture liquid, heating to dissolve and paste the thickening agent and the crop starch, uniformly dispersing the thickening agent and the crop starch in the culture liquid, carrying out static culture on the thickening agent and the crop starch, so as to prepare the bacterial cellulose facial mask similar to the skin of a human body and having the loose structure in which the compactness of the upper surface gradually transits to the lower surface. The bacterial cellulose facial mask has good water binding capacity and dragging resistance and an extremely high veneering degree, is biodegradable, ecologic and environment-friendly, is low in preparation cost and is simple and convenient to use and carry.

Owner:DONGHUA UNIV

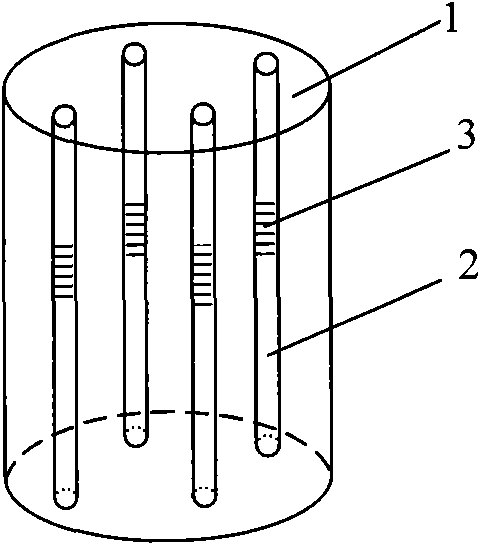

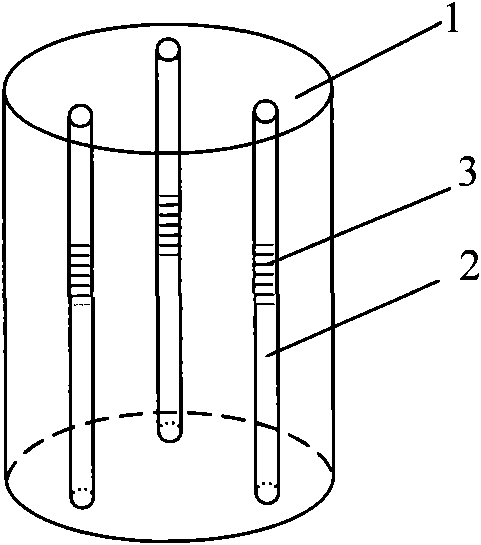

Iridium oxide electrode and its manufacturing method

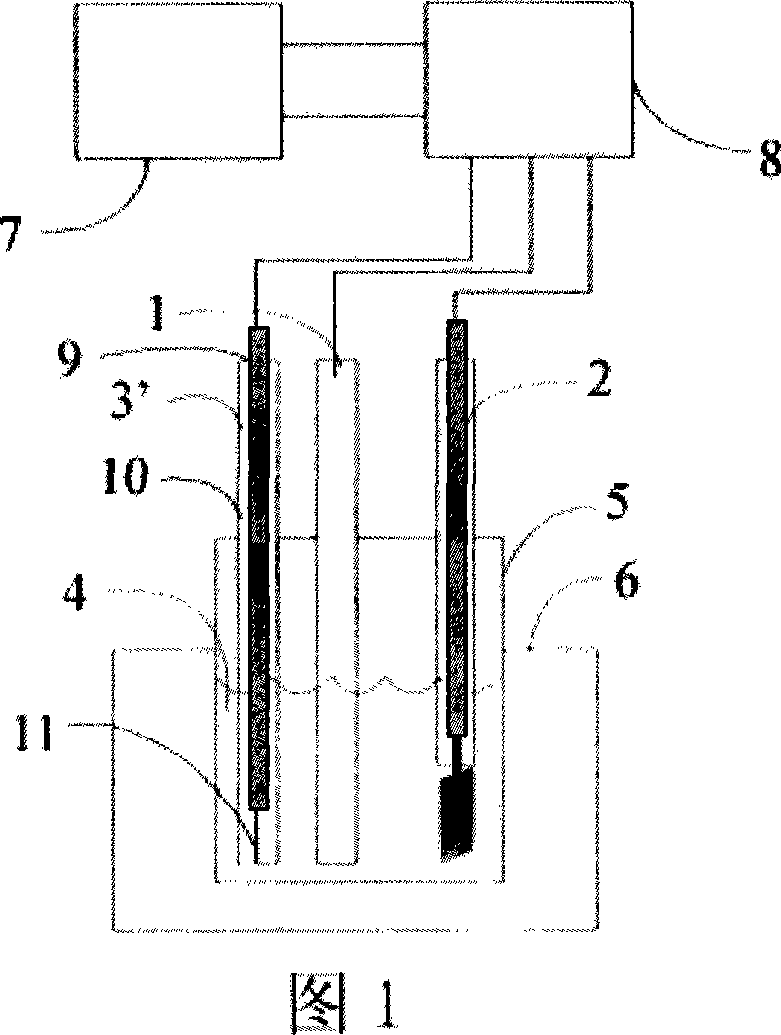

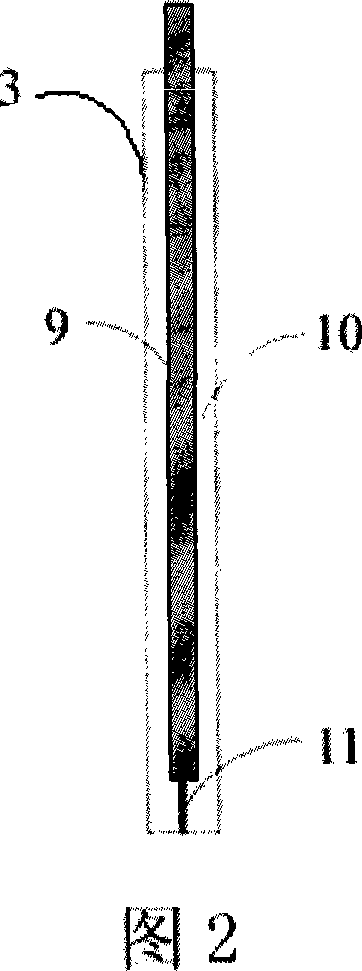

InactiveCN101057780AImprove mechanical stabilityImprove electrochemical stabilityDiagnostic recording/measuringSensorsElectricityAuxiliary electrode

The invention relates to an iridium oxide electrode and the method for preparing the same, belonging to the field of electrochemical technique. Said electrode is especially suitable for nerve electrographic recording and nerve electric stimulation and pH sensor. There is one insulating layer in the iridium oxide electrode, at least one electrode core is packed inside; at least one end of said electrode core is on the electric conductor, the outer surface of metallic iridium or non-iridium is deposited, and the electric conductor surface is regenerative iridium oxide. One end is connected with wire and the iridium oxide surface is out of insulating layer. The process of electrochemical activation to generate iridium oxide surface comprises following steps: a. pre-treating electrode; b. putting electrode into activating solution for treatment; c. depolarizing activation electrode through reference electrode and auxiliary electrode. The iridium oxide electrode is characterized by safety, reliability, high sensitivity, practical, wide application, fast, controllable and high efficient production method.

Owner:WUHAN UNIV

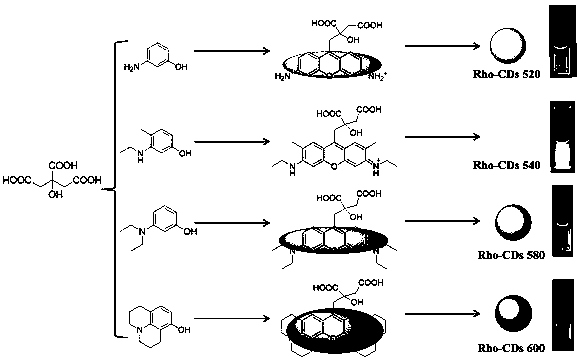

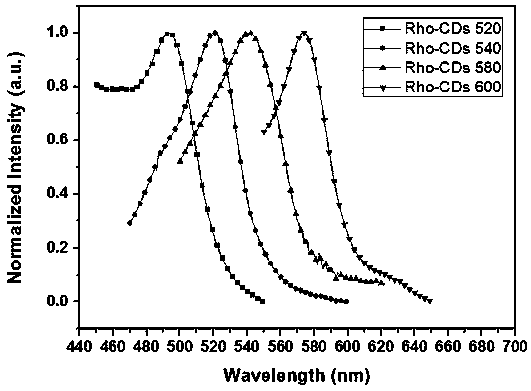

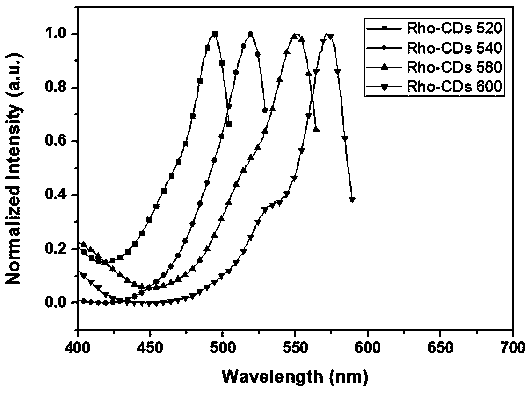

Preparation method of rhodamine hybridized carbon dots and application of rhodamine hybridized carbon dots in mitochondrion target recognition

ActiveCN108504349AThe preparation process is easy to controlPredictable preparationMaterial nanotechnologyNanoopticsLength waveCitric acid

The invention relates to a preparation method rhodamine hybridized carbon dots and application of the rhodamine hybridized carbon dots in mitochondrion target recognition. The preparation method disclosed by the invention has the beneficial effects that a microwave assisted method is utilized, citric acid and an m-amino phenol compound are used as raw materials, fluorescence emission wavelength can be regulated and controlled through a way of changing an amino group in a meta position of phenol, rhodamine molecular fluorogen hybridized carbon dots are generated, and preparation of controllableand divinable fluorescence emission wavelength carbon dots is realized. The preparation method disclosed by the invention is simple in operation, can easily obtain the raw materials and is green andenvironment-friendly, and a new strategy for synthesizing molecular fluorogen hybridized carbon dots is created. The rhodamine hybridized carbon dots prepared by the invention can be used for the mitochondrion target recognition in cells, and has potential application value in the fields of biology, medical treatment and the like.

Owner:ZHENGZHOU UNIV

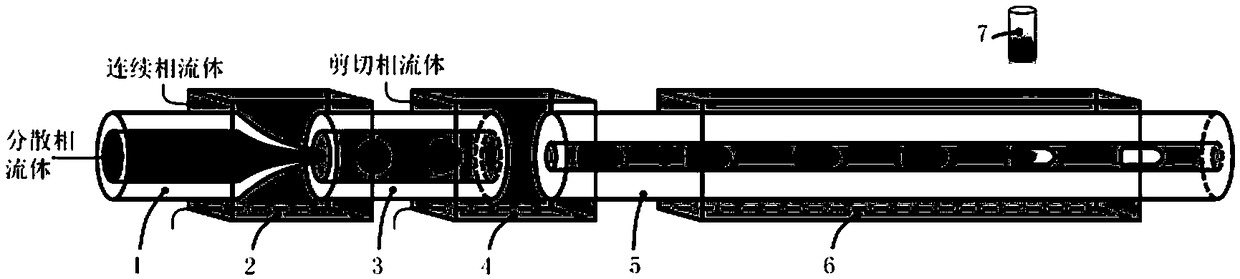

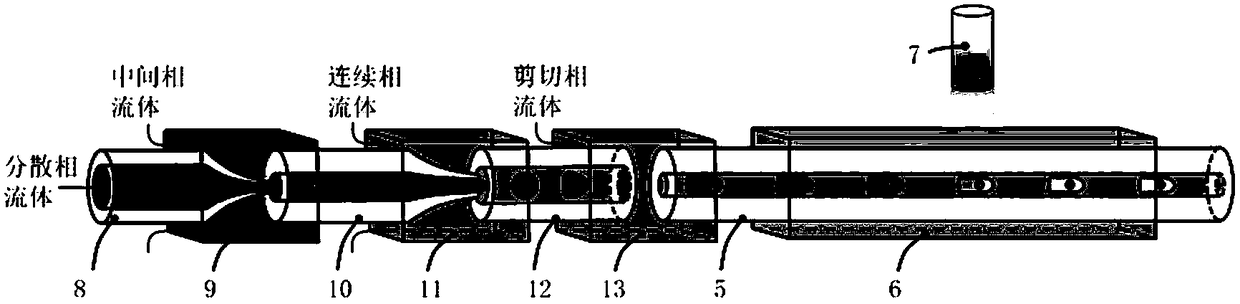

Bullet-shaped non-spherical micro-particle and microcapsule, and preparation method thereof

ActiveCN109482111AReduced shape resistanceImprove flow characteristicsPharmaceutical product form changePharmaceutical non-active ingredientsMicrofluidicsAgricultural engineering

The invention provides a bullet-shaped non-spherical micro-particle and microcapsule. A matrix of the micro-particle and micro-capsule is a polymerized photopolymerizable macromolecule, and the micro-particle and microcapsule is of an integrated bullet shape and consists of a similarly cone-shaped head portion and a cylindrical tail portion which are smoothly connected with each other; the microcapsule has at least one mutually independent chamber; and an oil phase solution is contained in the chamber. The invention further provides a method for continuously preparing the above bullet-shaped non-spherical micro-particle and microcapsule by using a microfluidic technique. The technical scheme provided by the invention can improve the flow characteristics and the movement rate of the microparticle and microcapsule in a channel, and improve the embedding effect of the microparticle and microcapsule. The microcapsule provided by the invention can realize entrapment and transport of activeingredients such as a drug.

Owner:四川大川合颐生物科技有限公司

Method for preparing large-grain spherical praseodymium neodymium oxide

InactiveCN102531024AThe preparation process is easy to controlUniform particle distributionNanotechnologyRare earth metal compoundsPrecipitationPraseodymium

The invention relates to a method for preparing large-grain spherical praseodymium neodymium oxide, belonging to a preparation technology of material. The method comprises the following steps of: taking praseodymium neodymium chloride solution as raw material, taking ammonium bicarbonate as precipitator, preparing basic praseodymium neodymium carbonate, and washing, filtering, centrifugally dripping and firing basic praseodymium neodymium carbonate precipitate, to obtain the spherical praseodymium neodymium oxide product with the centre grain diameter being from 25 to 30 mu m. The precipitation temperature and concentration of the basic praseodymium neodymium carbonate in the method are key factors, the precipitation temperature is less than 85 DEG C to obtain the praseodymium neodymium carbonate rather than the basic praseodymium neodymium carbonate, the preparation technology is easy to control, the large-grain praseodymium neodymium oxide product with the centre grain diameter being from 25 to 30 mu m is produced by a factory conventional praseodymium neodymium carbonate preparation working procedure, and the praseodymium neodymium oxide is even in grain distribution, good in dispersity and spherical in appearance.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com