Iridium oxide electrode and its manufacturing method

A technology of iridium oxide electrode and iridium oxide, which is applied in the field of electrochemistry, can solve the problems of not mentioning the temperature range and poor reproducibility of iridium oxide electrode performance, and achieve the effects of high-efficiency, high-quality manufacturing, high sensitivity, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

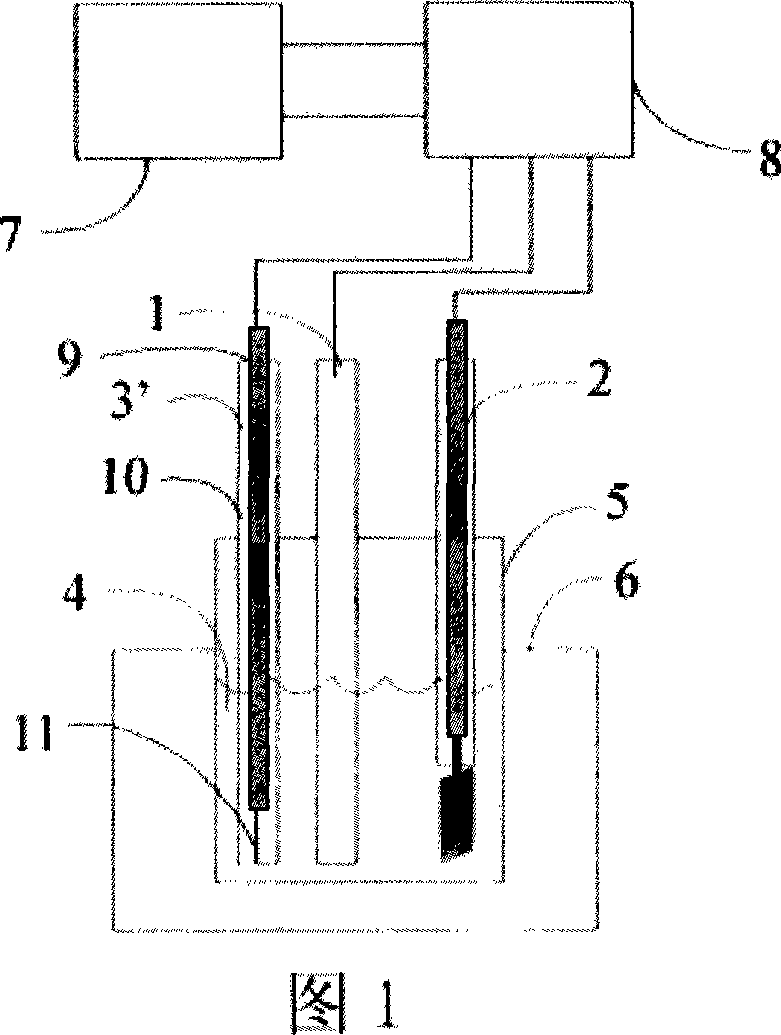

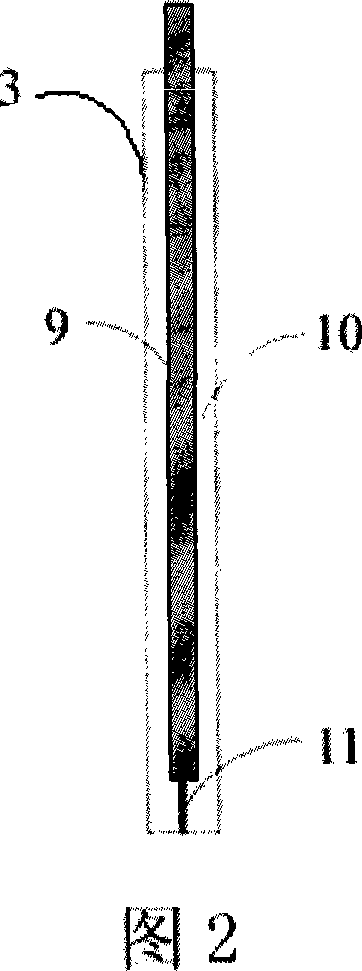

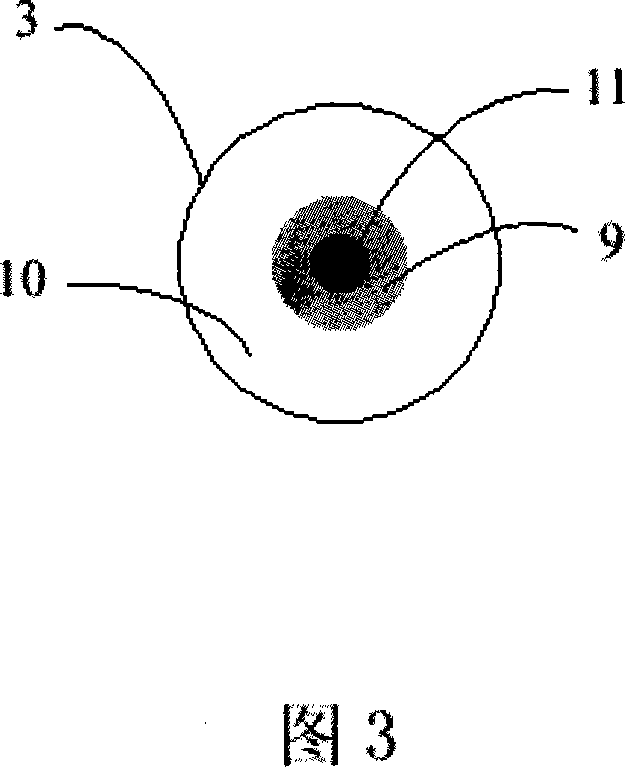

[0043]Embodiment 1: As shown in FIGS. 2 and 3 , it is an embodiment of the unipolar iridium oxide electrode with one electrode core 11 of the present invention. Described iridium oxide electrode, it has an insulating layer 10, wherein encapsulates an electrode core 11; Described electrode core 11 is a conductor that one end is in metal iridium, and its one end is connected with wire 9, and the surface layer of iridium oxide is exposed on the insulating layer 10 outside. The electrode core 11 is a conductor that is activated to generate an iridium oxide surface layer on the outer surface (or the outer surface) of one end of the metal iridium wire (a metal iridium sheet is another embodiment). The material of the insulating layer 10 is glass, and can also be selected as silicon rubber, or epoxy resin, or silicon dioxide, or ceramics.

Embodiment 2

[0044] Embodiment 2: As shown in FIGS. 4 and 5 , the difference from the above embodiments is an array type iridium oxide electrode with four electrode cores 11 .

Embodiment 3

[0045] Embodiment 3: Different from the above-mentioned embodiment, the electrode core 11 is a conductor whose one end is deposited on the outer surface of the non-iridium metal and then activated to generate the surface layer of iridium oxide on the bottom layer of metal iridium, and the non-iridium metal is preferably From titanium, platinum, or gold, or nickel, or silver, or copper, or iron, or alloys thereof may also be selected.

[0046] 2, the embodiment of the manufacture method of a kind of iridium oxide electrode of the present invention:

[0047] As shown in Figure 1, a kind of manufacture method of iridium oxide electrode of the present invention, it comprises the following steps:

[0048] A, the electrode core 11 that is not activated to generate the iridium oxide surface layer is connected to the wire 9, and is encapsulated in the insulating layer 10, and one end of the electrode core 11 is exposed outside the insulating layer 10, and becomes the electrode 3 ' to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com