Patents

Literature

539 results about "NEODYMIUM OXIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neodymium(III) oxide or neodymium sesquioxide is the chemical compound composed of neodymium and oxygen with the formula Nd2O3. It forms very light grayish-blue hexagonal crystals. The rare-earth mixture didymium, previously believed to be an element, partially consists of neodymium(III) oxide.

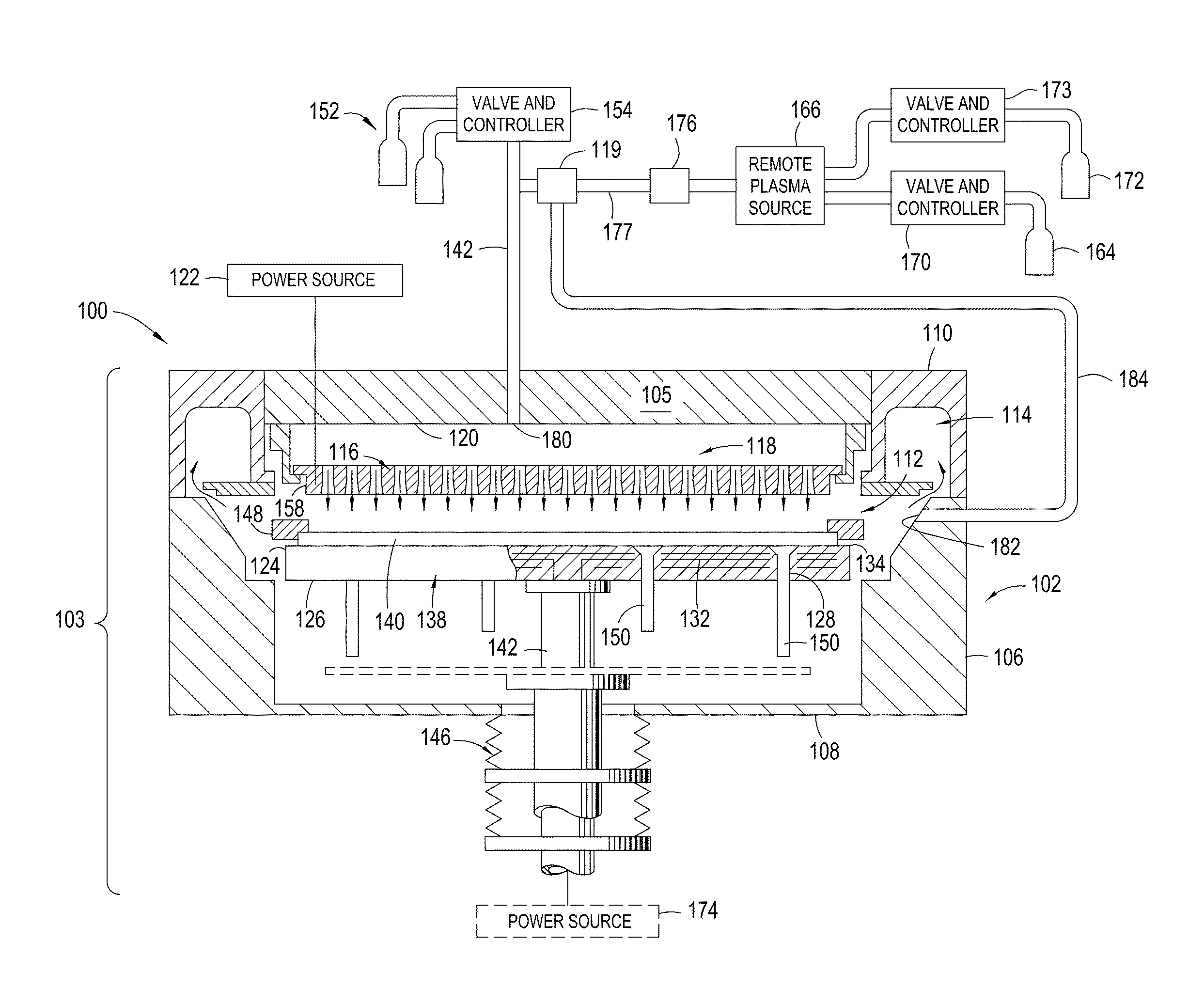

Yttria-based material coated chemical vapor deposition chamber heater

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

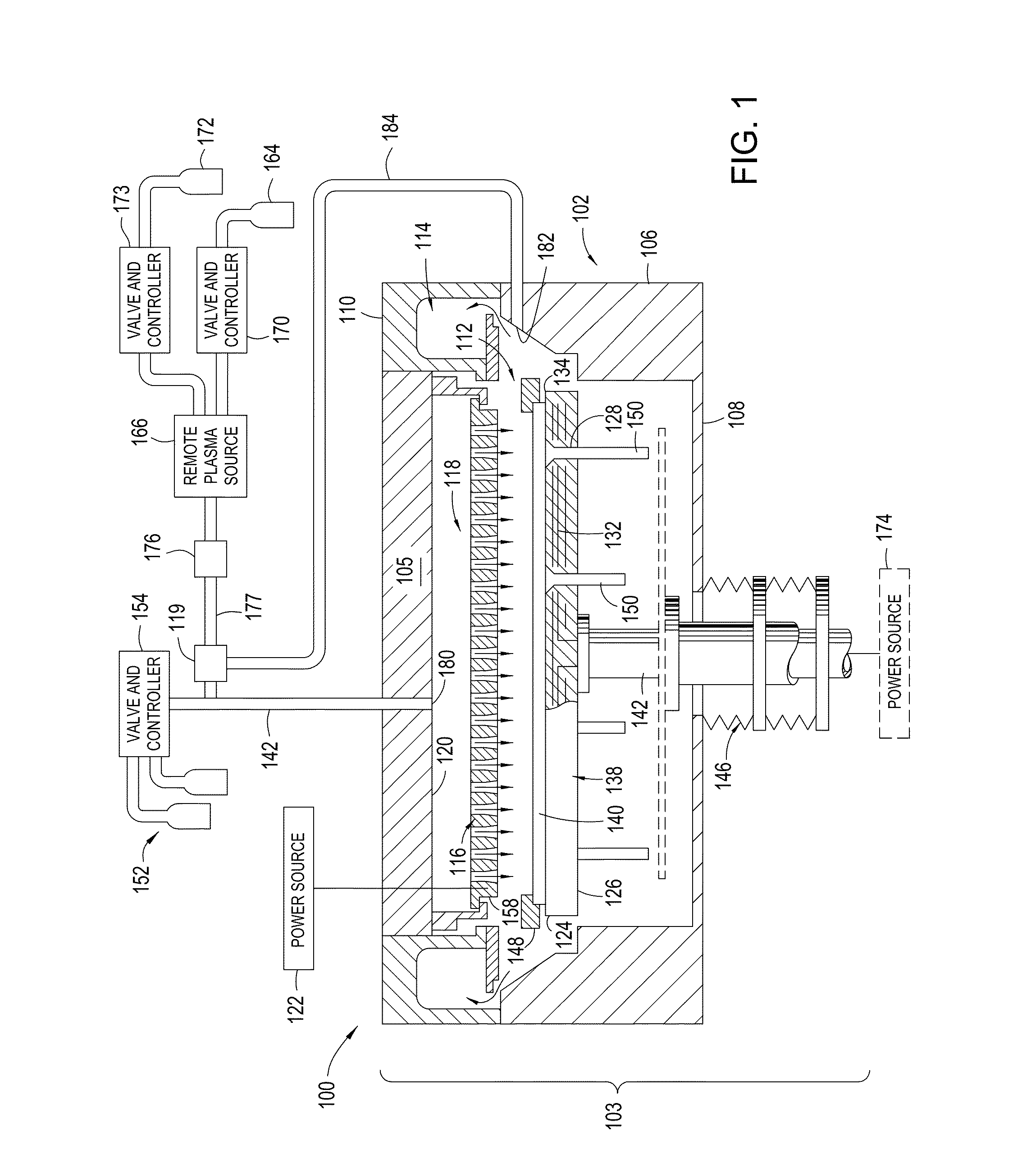

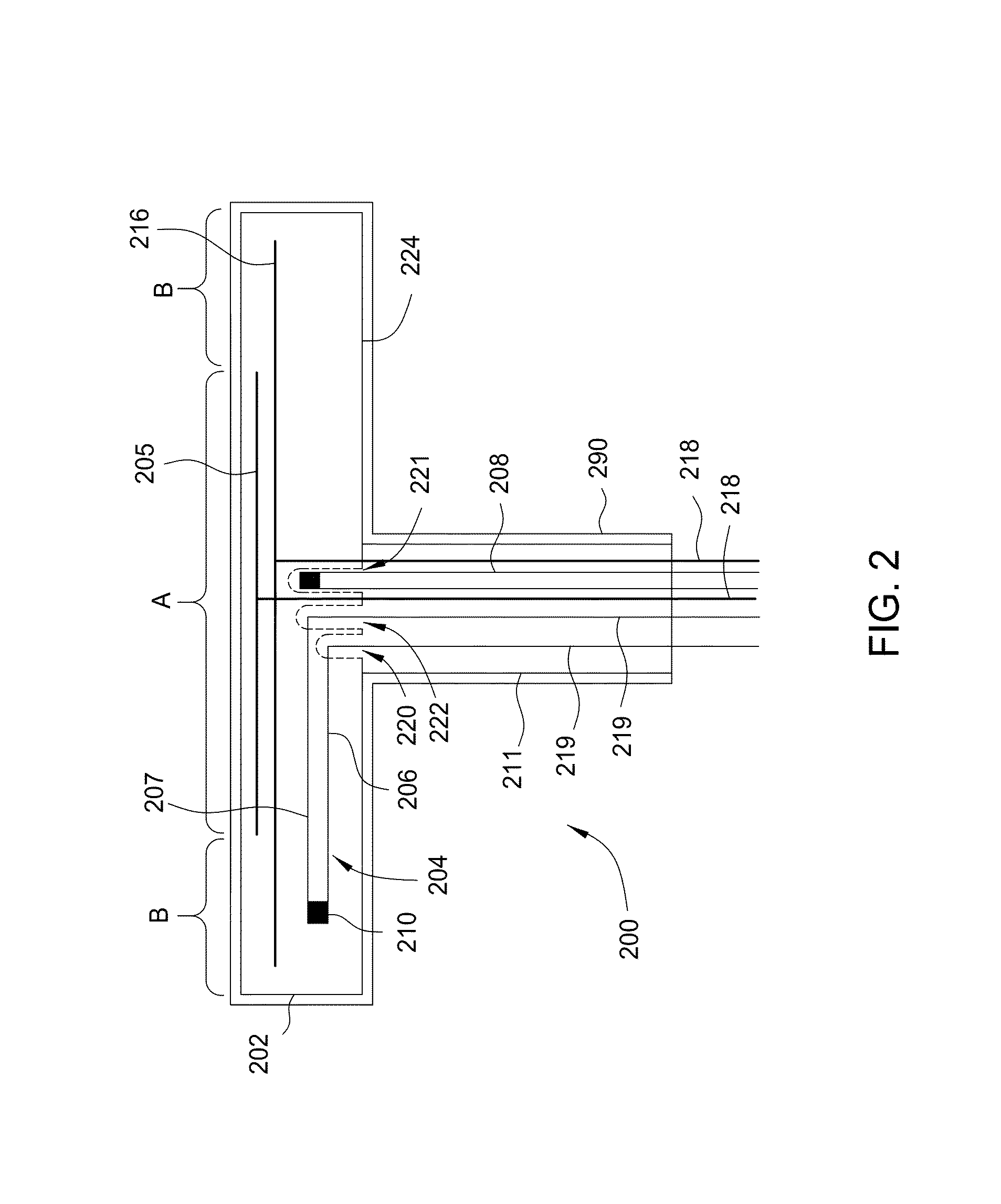

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS20080264565A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingYTTERBIUM OXIDEErosion rate

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

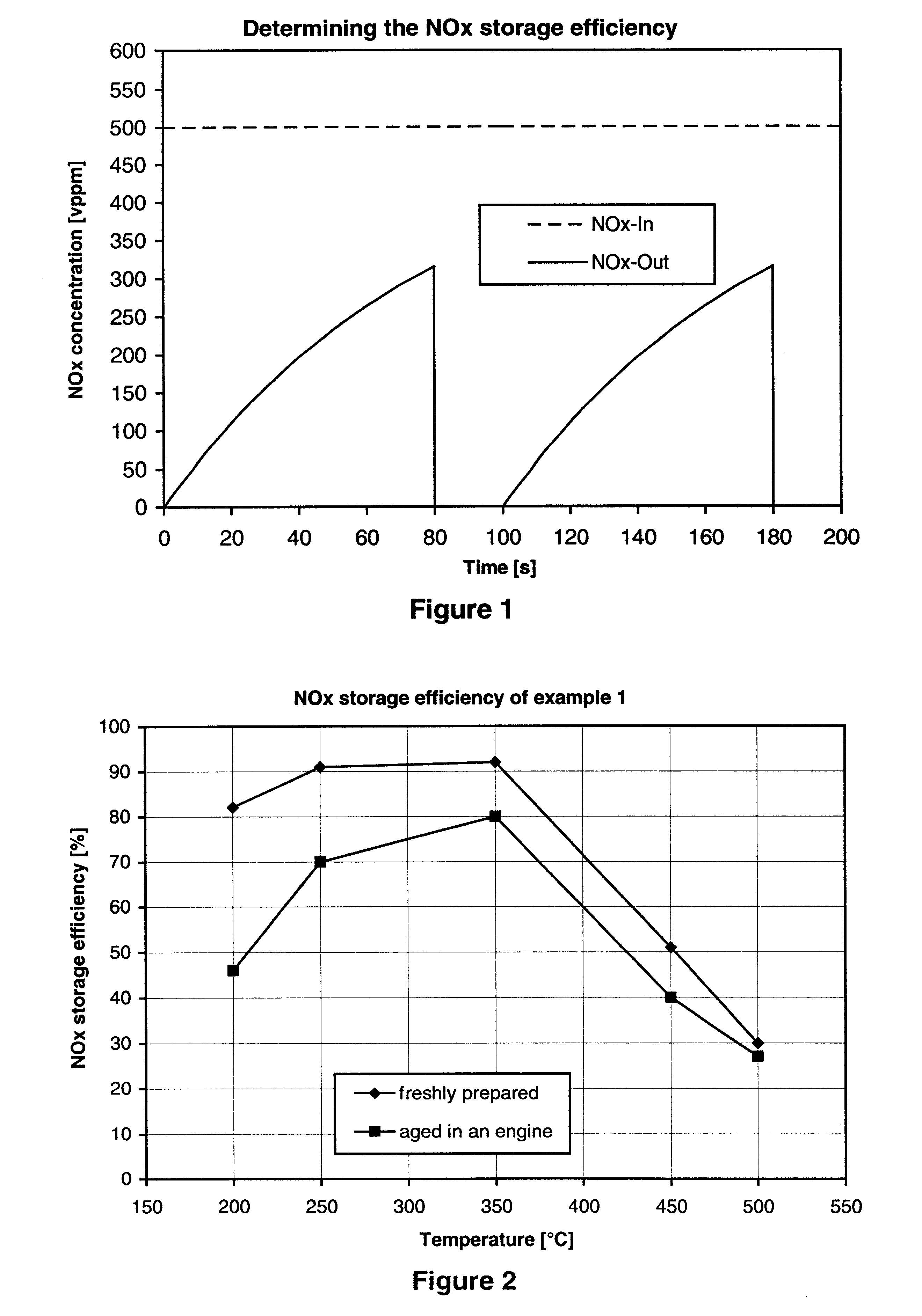

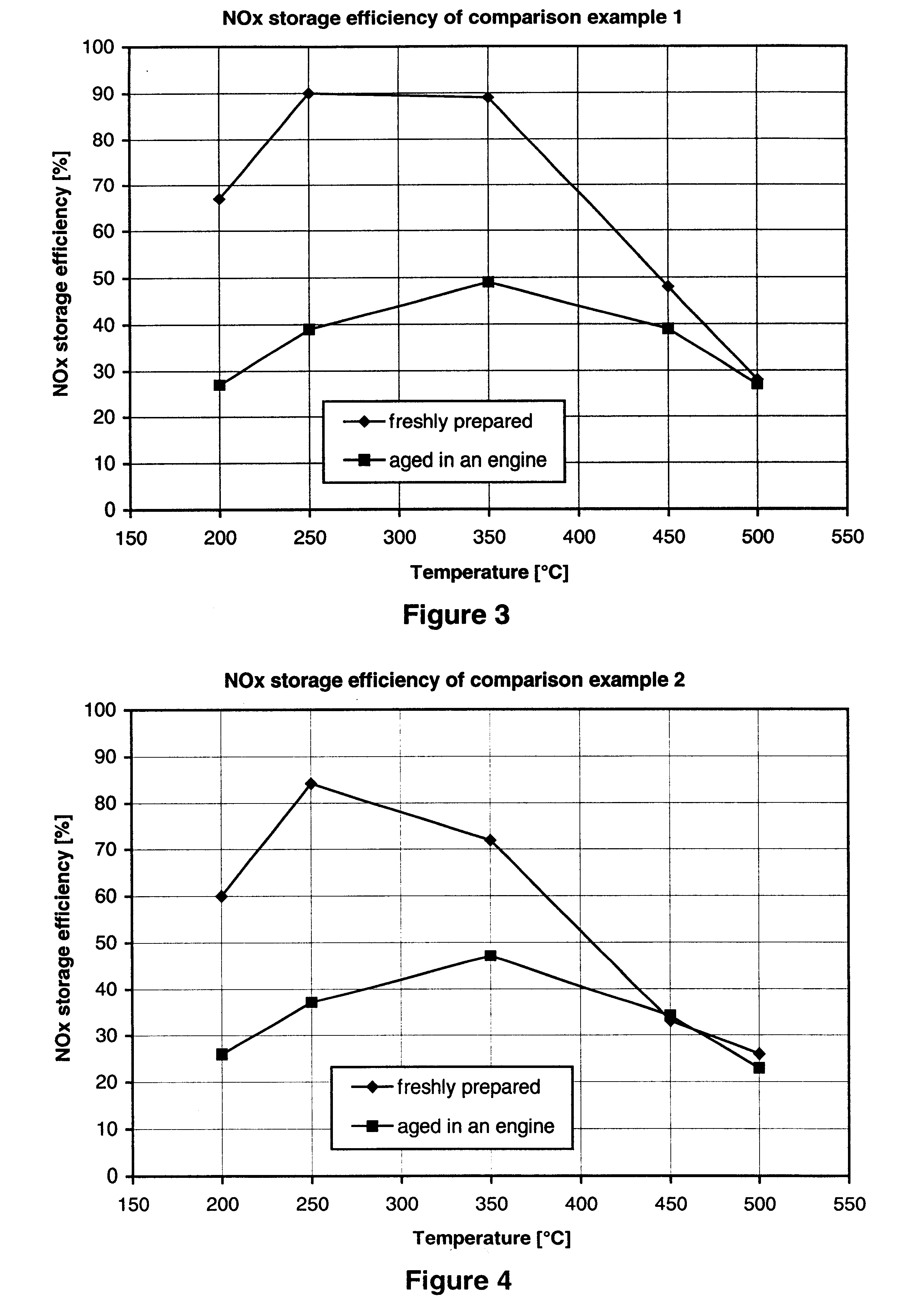

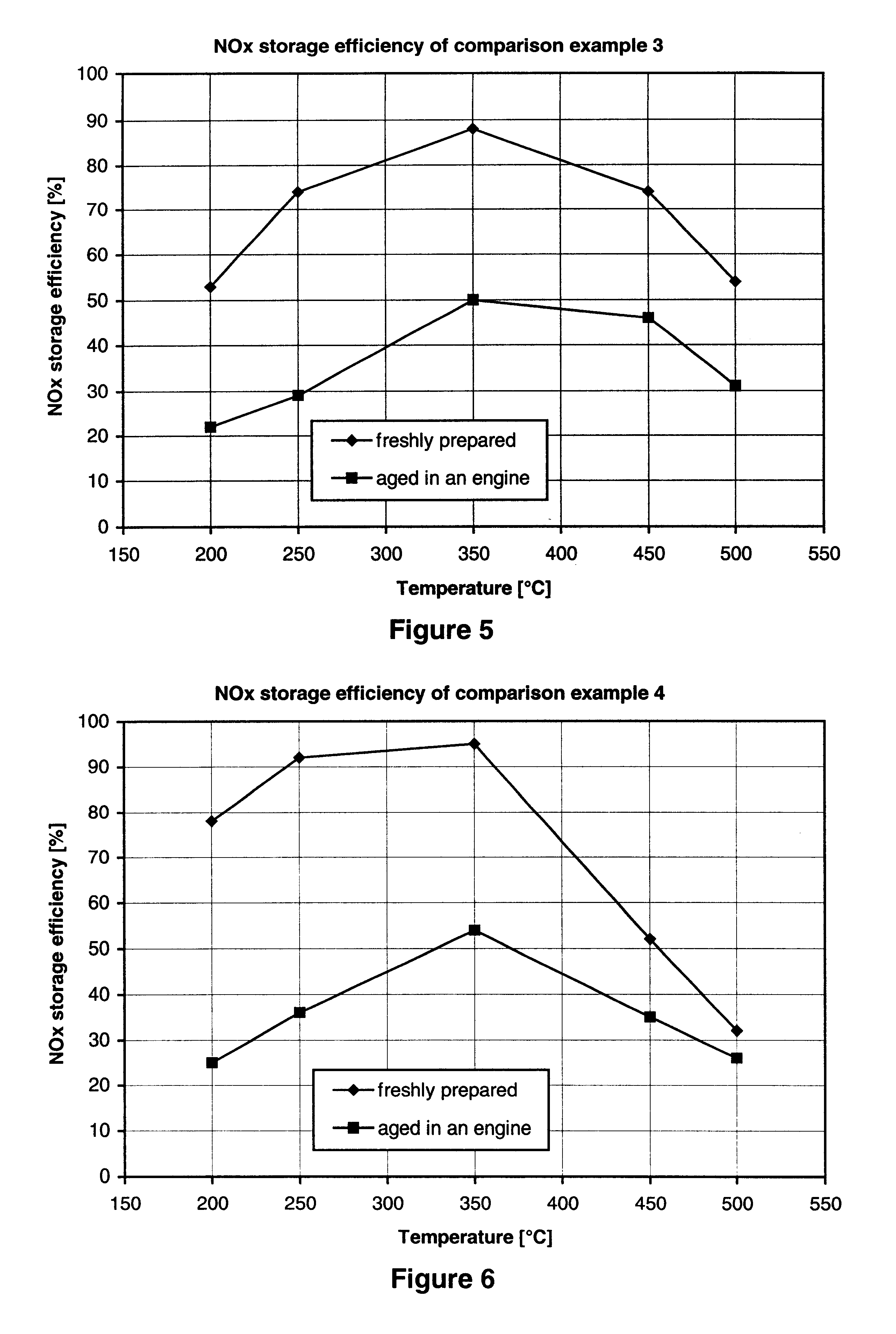

Nitrogen oxide storage material and nitrogen oxide storing catalyst prepared therefrom

InactiveUS6350421B1Determine efficiencyNitrogen compoundsExhaust apparatusAlkaline earth metalCuprate

A nitrogen oxide storage material is disclosed which contains at least one storage component for nitrogen oxides in the form of an oxide, mixed oxide, carbonate or hydroxide of the alkaline earth metals magnesium, calcium, strontium and barium and the alkali metals potassium and caesium on a high surface area support material. The support material can be doped cerium oxide, cerium / zirconium mixed oxide, calcium titanate, strontium titanate, barium titanate, barium stannate, barium zirconate, magnesium oxide, lanthanum oxide, praseodymium oxide, samarium oxide, neodymium oxide, yttrium oxide, zirconium silicate, yttrium barium cuprate, lead titanate, tin titanate, bismuth titanate, lanthanum cobaltate, lanthanum manganate and barium cuprate or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

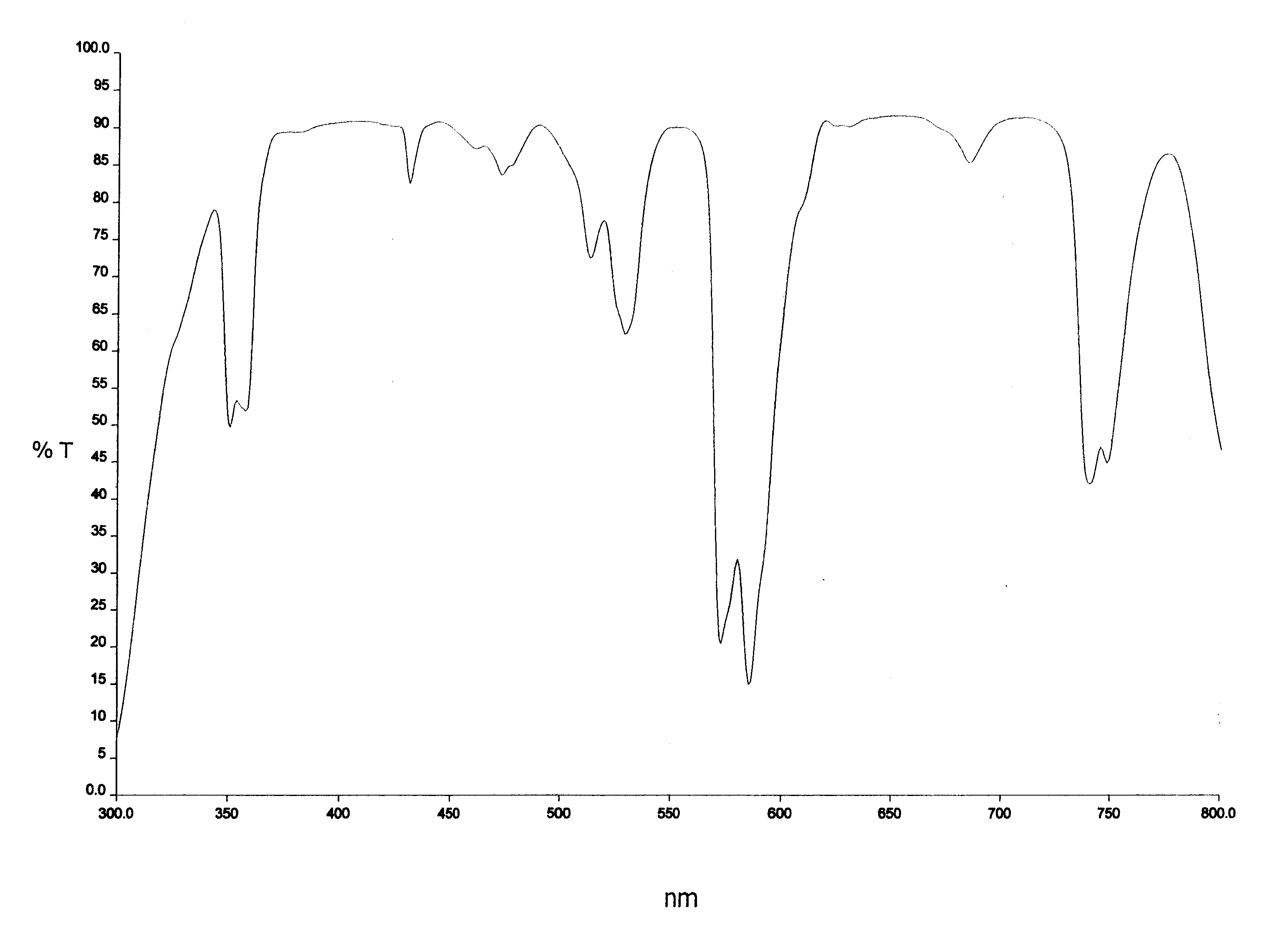

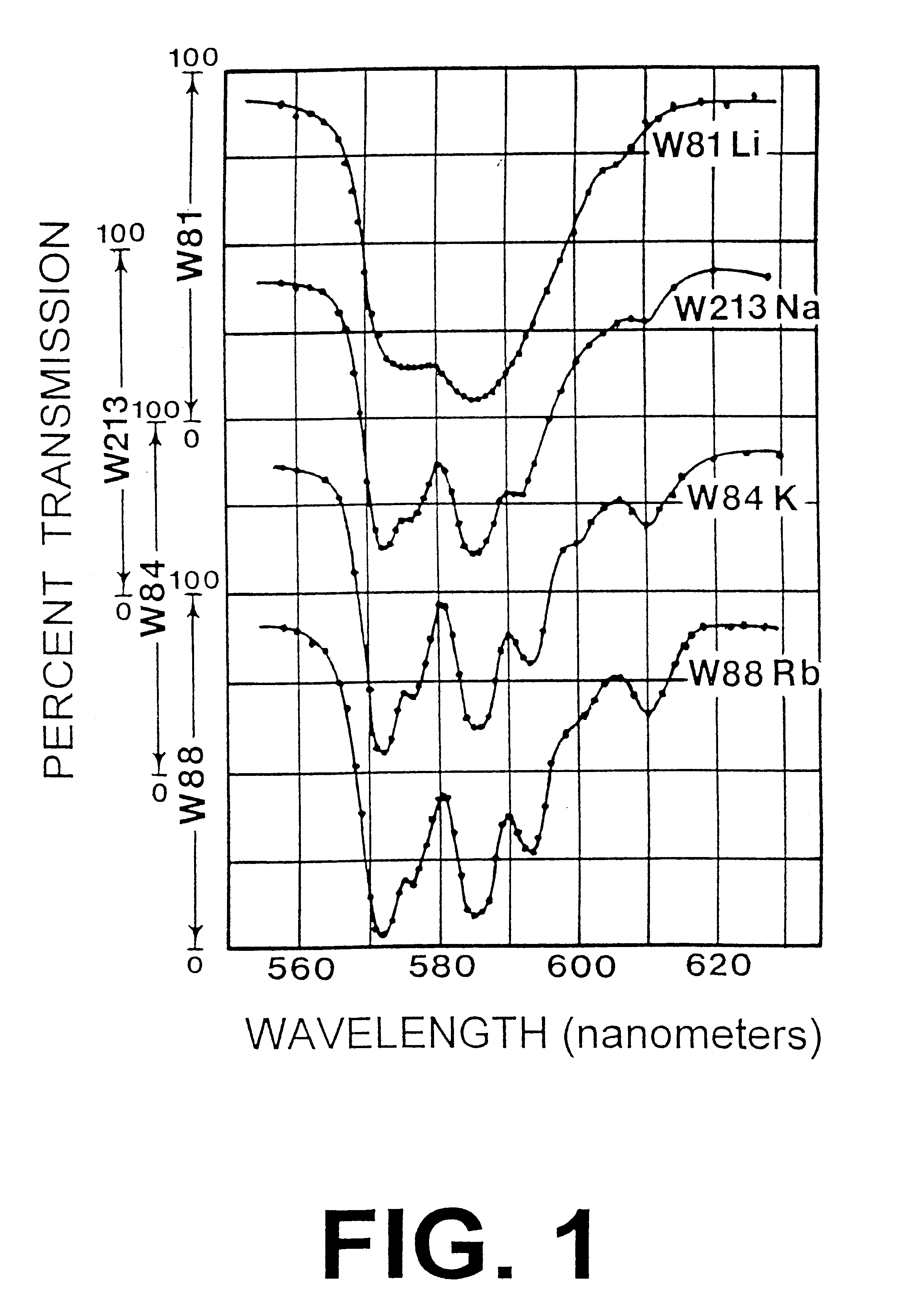

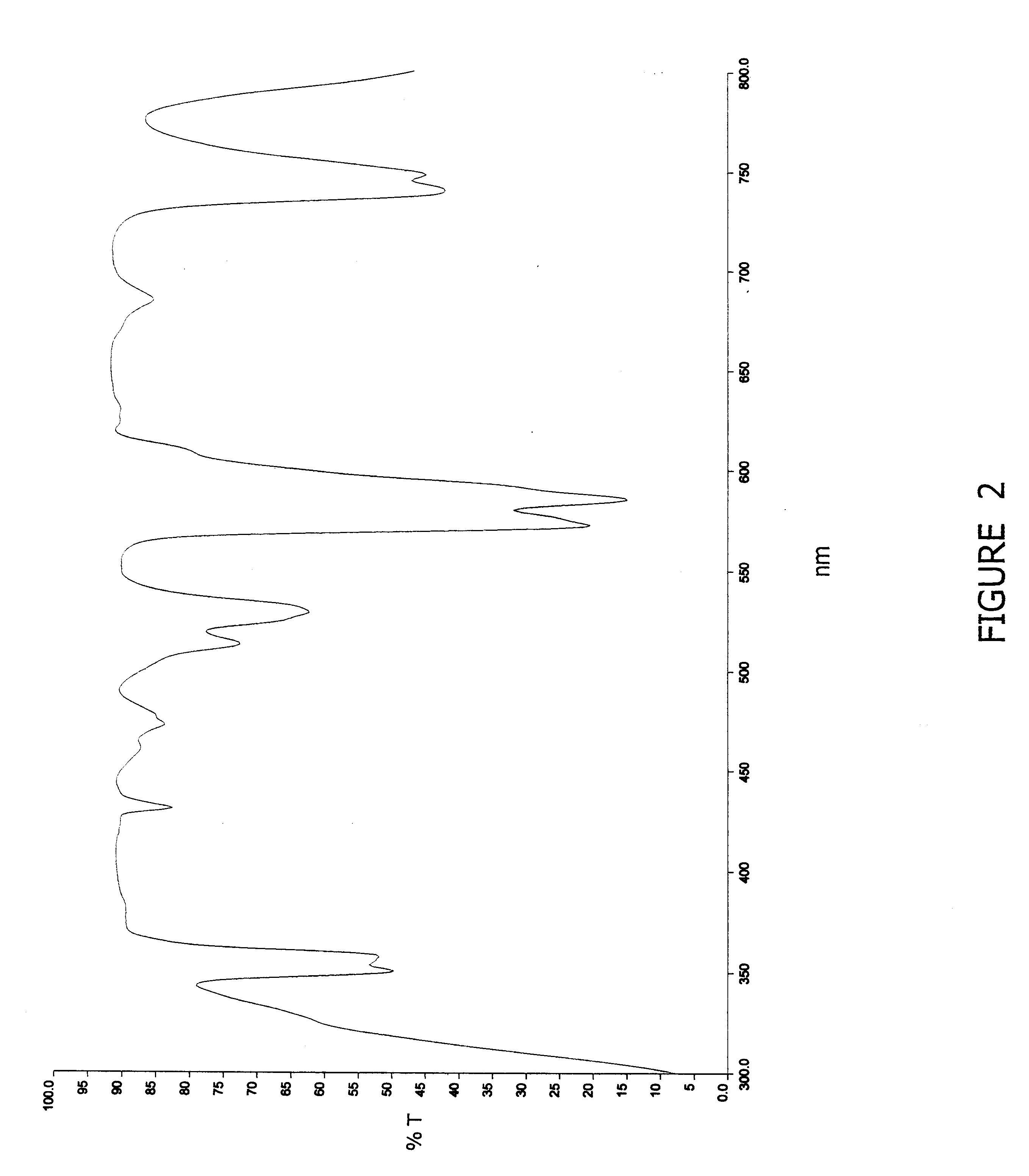

Neodymium oxide doped motor vehicle windshield and safety glazing material

Motor vehicle windshields and safety glazing material, suitable for use as motor vehicle windshields and safety glazing material for automobiles, trucks, buses, motorcycles, locomotives. sport utility vehicles, all terrain vehicles, and vans. The motor vehicle windshields and safety glazing material contains Neodymium Oxide, a rare earth compound. The Neodymium Oxide filters out the yellow portion of the spectrum, reducing glare. Incorporation of yellow light in the spectrum desaturates colors and reduces contrast. Improvement in contrast and a reduction in glare permits, for example, a motor vehicle driver to better discriminate the contrast of objects when there is no daylight and the only illumination is artificial. For drivers, in particular, elimination of the yellow light lessens eye strain currently resulting from light emitted by the conventional headlights of oncoming vehicles during hours of darkness. Neodymium Oxide can also be added to safety glazing materials for use in bullet resistant shields.

Owner:KARPEN DANIEL NATHAN

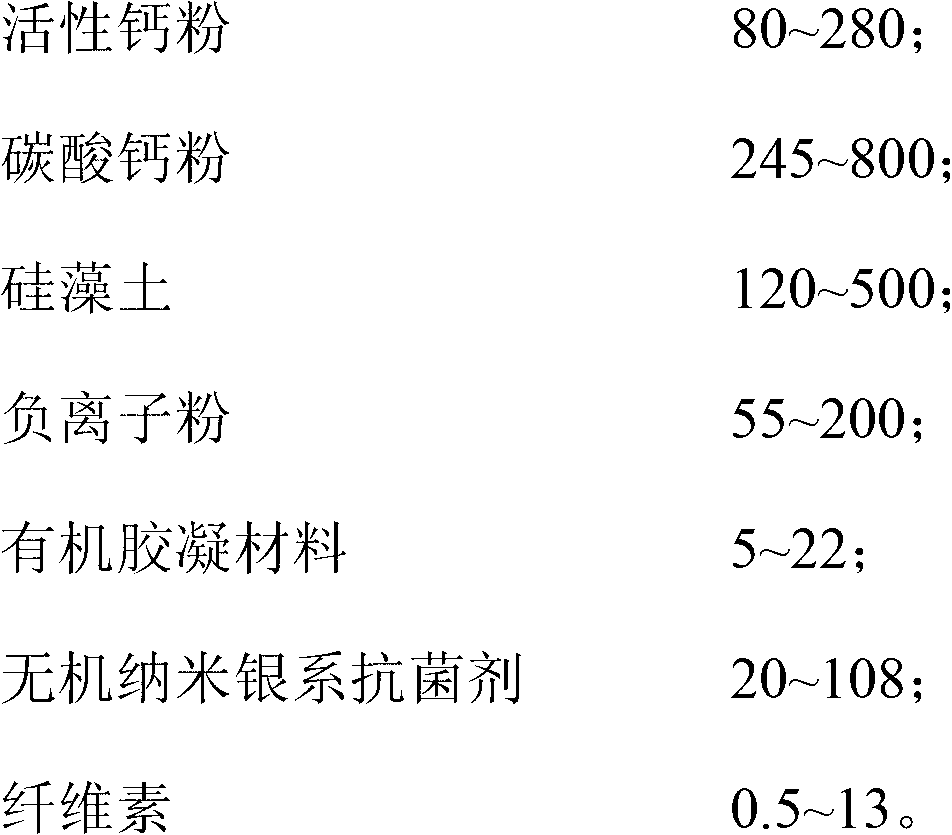

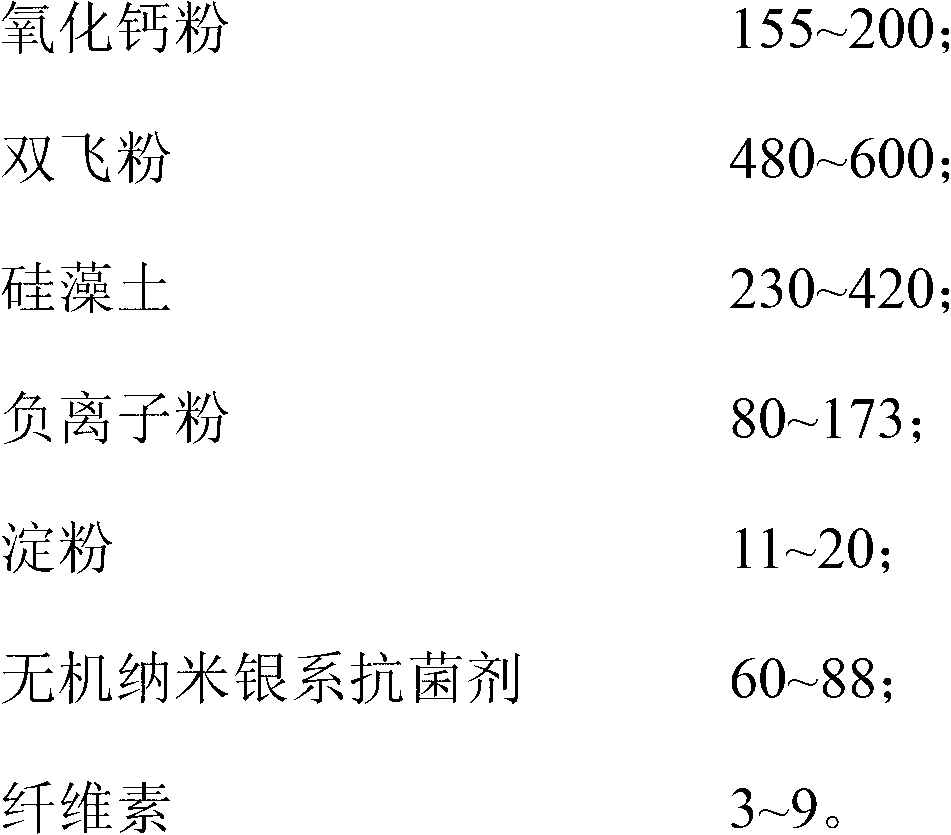

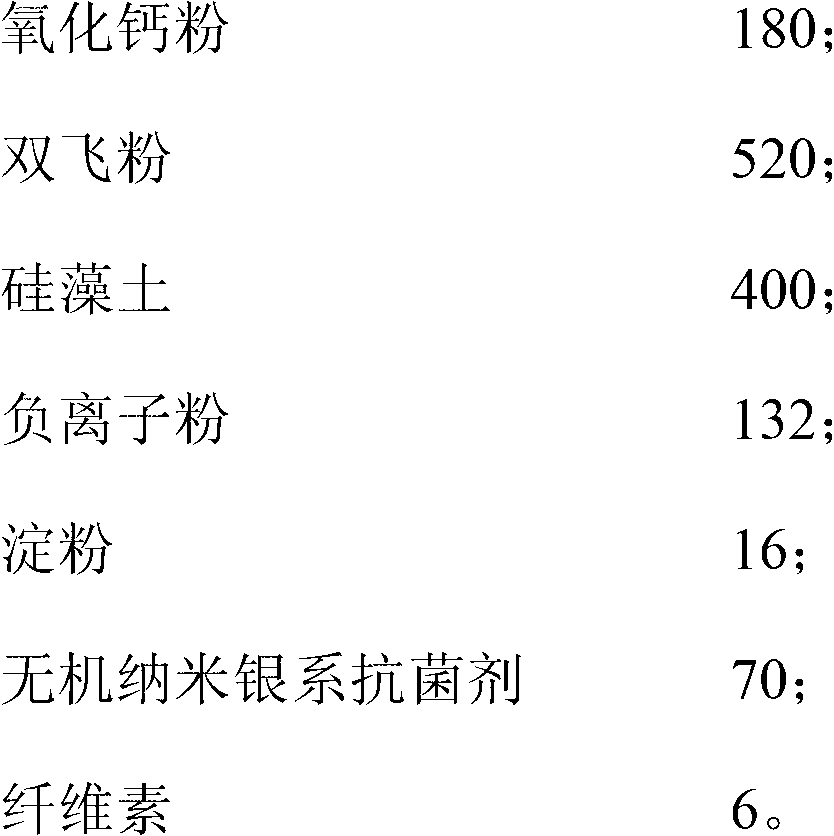

Antibacterial negative ion putty powder

The invention relates to antibacterial negative ion putty powder. The putty powder mainly comprises the following components: active calcium powder, calcium carbonate powder, kieselguhr, negative ion powder, an organic binding material, an inorganic nano-silver germicide and cellulose. The negative ion powder, provided by the invention, comprises the following components: tourmaline powder, cerium oxide, yttrium oxide, neodymium oxide and titanium dioxide. The antibacterial negative ion putty powder, provided by the invention, has an effect of purifying the air, and is mainly manifested in absorbing and neutralizing the positive ions in the air, eliminating toxic and harmful gas such as formaldehyde, ammonium, benzene and the like, which is released in indoor decoration and decoration materials, inhibiting growth of bacterium and mildew, and enhancing antibacterial performance of the putty powder.

Owner:TIANCHANG JULONG TRAVEL PAINT

Clear glass composition

Glass is provided so as to have high visible transmission and / or fairly clear or neutral color. In certain example embodiments of making glass according to examples of the invention, the glass batch may include a base glass (e.g., soda lime silica base glass) and, in addition, by weight percentage:total iron (expressed as Fe2O3): 0.01 to 0.30%erbium oxide (e.g., Er2O3): 0.01 to 0.30%cerium oxide (e.g., CeO2):0.005 to 0.30%.Optionally, neodymium oxide (e.g., Nd2O3) may also be provided in the glass in certain example embodiments. In other embodiments, the cerium oxide may be replaced with or supplemented by NaNO3 or some other nitrate(s) as an oxidizer.

Owner:GUARDIAN GLASS LLC

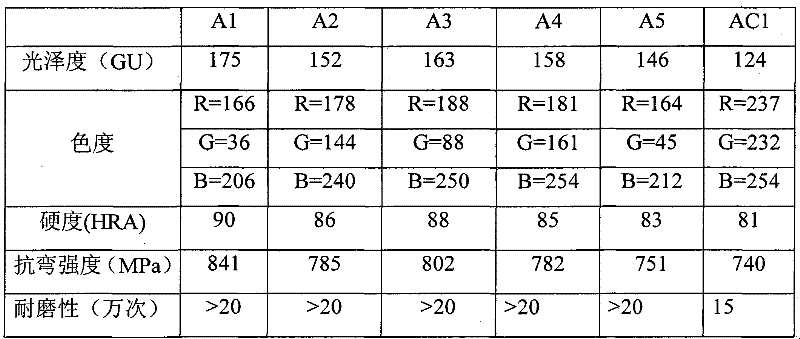

A kind of zirconia ceramic and its preparation method

The invention, belonging to the technical field of zirconia ceramic, discloses a zirconia ceramic and a preparation method thereof. The ceramic comprises matrix, sintering aid, neodymium oxide and additive, wherein, the matrix is yttria stabilized zirconia, the additive is selected from one or more of zinc oxide, barium carbonate and calcium fluoride, and the diffraction peak of the XRD appears when the 2 theta is 34.8-36.2 degrees. The zirconia ceramic has stable and beautiful purple. The preparation method comprises the following steps: adding neodymium oxide particles in a diethanolamine solution for soaking, then carrying out solid-liquid separation; carrying out ball mill mixing of the matrix, processed neodymium oxide particles, sintering aid and additive, then carrying out die forming and high temperature sintering. The preparation method provided by the present invention is simple and easy, and is suitable for large-scale industrial production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

A nanometer antibacterial tile and a preparing method thereof

InactiveCN106242525AReduce clusteringActivate the antibacterial effectClaywaresRare earthAntibacterial agent

A nanometer antibacterial tile is disclosed and comprises ceramic raw materials and an antibacterial agent. The weight of the antibacterial agent is 1-5% of the total weight of the ceramic raw materials. The antibacterial agent is prepared from, by weight, 20-30 parts of nanometer silica sol, 2-3 parts of nano-silver, 1-2 parts of nanometer titanium oxide, 17-22 parts of a silane coupling agent, 2-3 parts of neodymium oxide and 1-2 parts of cerium oxide. The antibacterial agent comprising the nanometer silica sol, the nano-silver, the nanometer titanium oxide, the silane coupling agent, the neodymium oxide and the cerium oxide is added, wherein a cluster phenomenon between the nano-silver and the nanometer titanium oxide is effectively reduced through adopting the hydrosol of the nanometer silica as a carrier and adopting the silane coupling agent as a medium, the neodymium oxide and the cerium oxide which are rare earth oxides are introduced to activate antibacterial functions of the nano-silver and the nanometer titanium oxide, and the antibacterial functions of the nano-silver and the nanometer titanium oxide are effectively combined to achieve an excellent sterilization effect.

Owner:佛山市寰田陶瓷有限公司

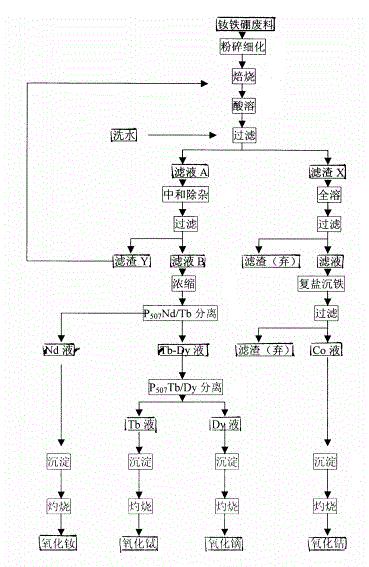

Recovery method of valuable element in neodymium iron boron waste material

ActiveCN1693493ANo emissionsNo pollution in the processProcess efficiency improvementAmmonium salt fertilisersRecovery methodRare earth

A process for recovering the valuable elements from the rejected NdFeB material includes such steps as RE extracting-separating to recover neodymium oxide, dysprosium oxide and terbium oxide, cobalt oxide separating to recover cobalt oxide, iron oxide separating to recover iron oxide, and reclaiming the discharged liquid to recover hydrochloric acid and distilled water.

Owner:西安西骏新材料有限公司

Clear glass composition

Glass is provided so as to have high visible transmission and / or fairly clear or neutral color. In certain example embodiments of making glass according to examples of the invention, the glass batch may include a base glass (e.g., soda lime silica base glass) and, in addition, by weight percentage:total iron (expressed as Fe2O3):0.01 to 0.30%erbium oxide (e.g., Er2O3):0.01 to 0.30%cerium oxide (e.g., CeO2): 0.005 to 0.30%. Optionally, neodymium oxide (e.g., Nd2O3) may also be provided in the glass in certain example embodiments. In other embodiments, the cerium oxide may be replaced with or supplemented by NaNO3 or some other nitrate(s) as an oxidizer.

Owner:GUARDIAN GLASS LLC

High-performance cerium zirconium oxide and production method of high-performance cerium zirconium oxide

ActiveCN104190438AOvercome doping defectsImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCeriumCopper oxide

The invention relates to a solid liquid supported catalyst and in particular relates to high-performance cerium zirconium oxide. The high-performance cerium zirconium oxide is prepared from the following chemical ingredients in parts by weight: cerium oxide, zirconium oxide, aluminum oxide, praseodymium oxide, lanthanum oxide, neodymium oxide, yttrium oxide, samarium oxide, vanadium oxide, chromic oxide, manganese oxide, iron oxide, cobalt oxide, copper oxide, manganese oxide, nickel oxide and the like. The invention also provides a preparation method of the high-performance cerium zirconium oxide. The preparation method comprises the steps of mixing all raw materials, adding surface active agents, regulating pH value to be 8-10 to obtain gelatinous precipitates, and calcinating to obtain the cerium zirconium oxide. The solid liquid supported catalyst can overcome the doping defect caused by doping in the cerium zirconium carrier and can improve the thermal stability, the aged specific surface area and the oxygen storage capacity of the supported catalyst; and the preparation method is simple, the technological process is simple and the method facilitates large-scale industrial production.

Owner:淄博加华新材料有限公司

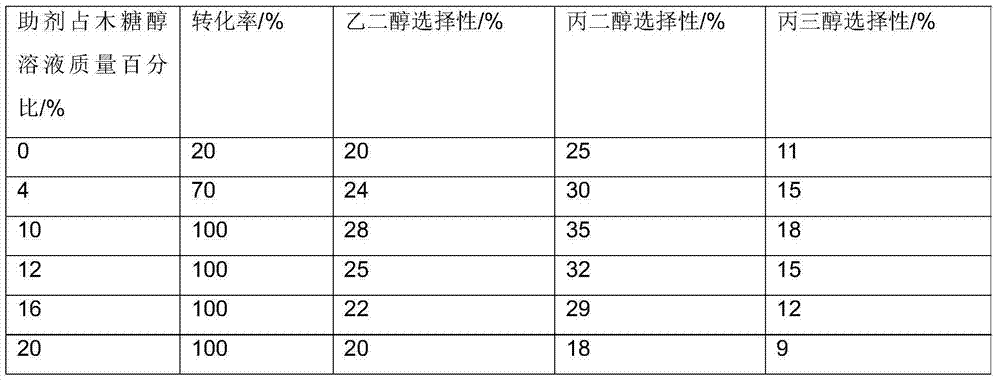

Method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol

InactiveCN104710277AEasy to achieve separationOrganic compound preparationPreparation by OH group eliminationGadolinium oxideGlycerol

The invention relates to a method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol. The method adopts sugar and sugar alcohol as the raw materials, takes one or more than two of iron, cobalt, nickel, copper, zinc, tin, platinum, ruthenium, palladium, iridium and other transition metals as the catalyst active component, and employs a rare earth oxide like promethium oxide, gadolinium oxide, terbium oxide, holmium oxide, erbium oxide, thulium oxide, cerium oxide, lanthanum oxide, praseodymium oxide, neodymium oxide, scandium oxide, yttrium oxide, dysprosium oxide, europium oxide, samarium oxide, ytterbium oxide, lutecium oxide and the like as the assistant. Under a temperature of 150-320DEG C and an H2 pressure of 1-20MPa, catalytic hydrocracking is carried out in a water solution to obtain ethylene glycol, propylene glycol, glycerol and other low carbon alcohols. The method provided by the invention has the advantages that: the rare earth oxide is added as the assistant to realize hydrocracking of sugar and sugar alcohol, rare earth oxides are insoluble in water and easy to separate, and at the end of reaction, the reaction system has no need for additional acid to neutralize.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ytterbium-phosphate glass

Owner:L3HARRIS KIGRE INC

High negative ion tourmaline powder and preparation method thereof

The invention relates to high anion tourmaline powder and a preparation method thereof. The high anion tourmaline powder is prepared from the following compositions by weight percentage: 60 to 80 percent of tourmaline, 5 to 10 percent of cerium oxide, 2 to 5 percent of yttrium oxide, 5 to 10 percent of neodymium oxide and 5 to 15 percent of titania, wherein the D50 of the high anion tourmaline powder is less than or equal to 2 micrometers. Compared with the prior art, the high anion tourmaline powder can obviously improve the anion-generating capacity, is safe and reliable, contributes to adjust the physiological function of human body, eliminate fatigue and improve cardiovascular and cerebrovascular disease symptoms and the immunity of the human body, has obvious health-care effect, can be widely used in building materials such as a coating, an emulsion paint, lacquer putty, ceiling and a furniture coating, and can also be used in the fields of plastic, fiber and so on. Simultaneously, the method for preparing the high anion tourmaline powder has simple technique and low cost, and prepared products have stable performance.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Multifunctional air cleaning agent

InactiveCN102989308ABactericidalGood absorption and decomposition effectBiocideDispersed particle separationAir cleaningRare earth

The invention provides a multifunctional air cleaning agent which comprises the following components in parts by weight: 35-80 parts of kieselguhr, 0.5-10 parts of nano titanium dioxide, 0.5-5 parts of dispersing agent, 0.1-1 part of rare earth activating agent, 50-100 parts of inorganic mineral powder and 30-60 parts of water, wherein the dispersing agent is sodium hexametaphosphate, sodium polyphosphate or ptassium triphosphate; the rare earth activating agent is gallium oxide, cerium oxide or neodymium oxide; and the inorganic mineral powder is gypsum powder or sepiolite clay powder. The multifunctional air cleaning agent is capable of efficiently absorbing and degrading harmful gases for a long time, and has the effects of deodorization, sterilization and anion release.

Owner:欧阳杰

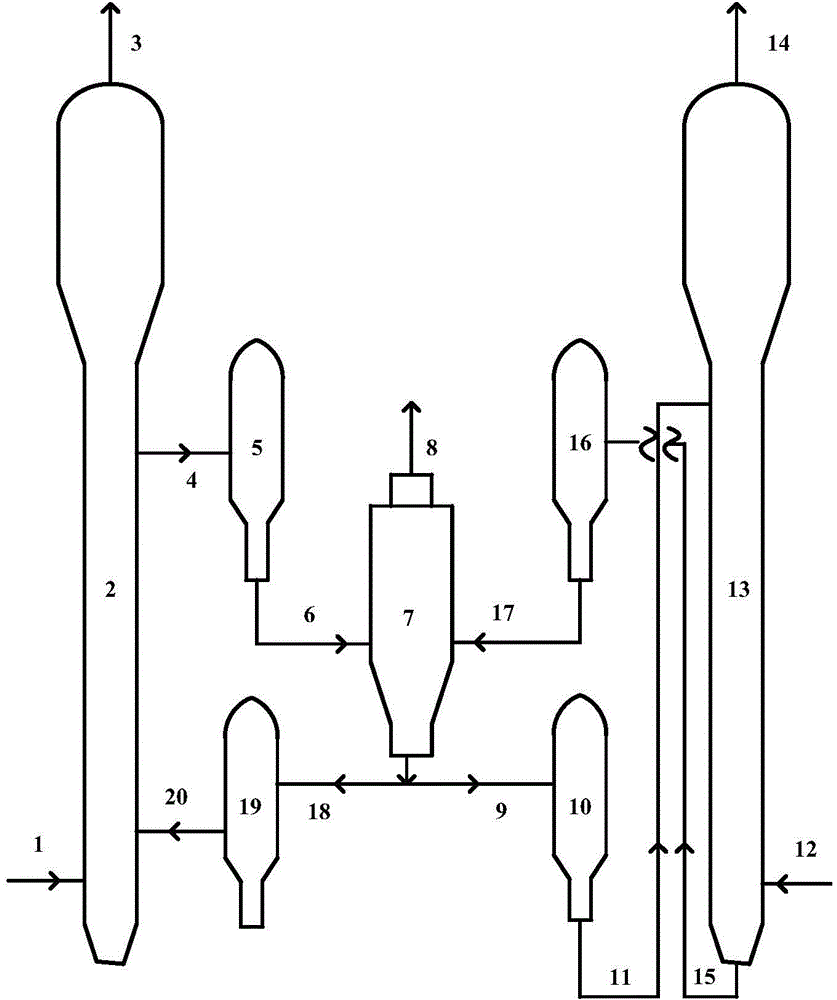

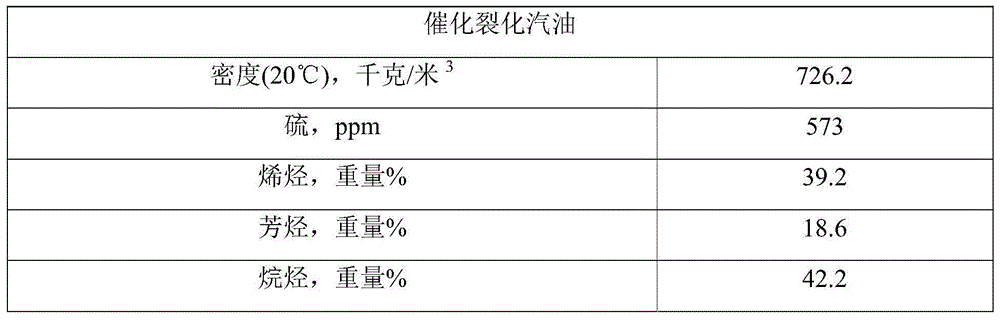

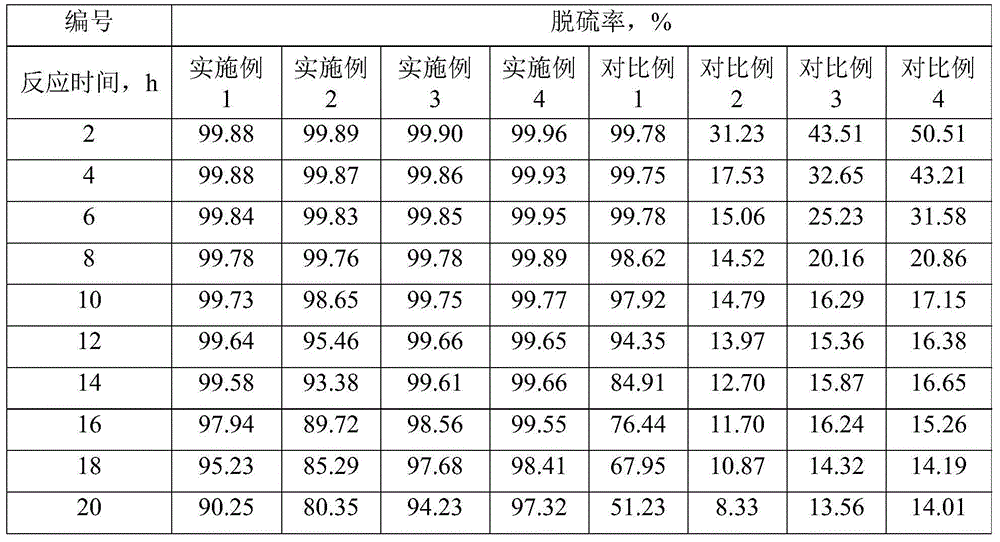

Adsorption desulfurization additive, as well as preparation method and desulfurization system thereof

InactiveCN104549131AImprove the stability of desulfurization activityImprove utilization efficiencyOther chemical processesHydrocarbon oils refiningSilicon oxideCopper oxide

The invention provides an adsorption desulfurization additive, a preparation method of the adsorption desulfurization additive, the adsorption desulfurization additive prepared by the method and a desulfurization system. The adsorption desulfurization additive comprises a an adsorption desulfurization additive carrier and a metal oxide ingredient loaded on the adsorption desulfurization additive carrier, wherein the adsorption desulfurization additive carrier is a mixture of aluminum oxide and silicon oxide; and the metal oxide ingredient is one or more of sodium oxide, potassium oxide, magnesium oxide, calcium oxide, titanium oxide, vanadium oxide, chromium oxide, manganese oxide, ferric oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide, cerium oxide, praseodymium oxide and neodymium oxide. The desulfurization system provided by the invention has an excellent desulfurization effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

LCD sheet glass

The invention discloses a base plate glass with rare-earth element to dope liquid crystal display device (TFT-LCD), which is characterized by the following: comprising glass basic oxide, lanthanum oxide, cerium oxide, neodymium oxide and or yttrium oxide; setting the mass ratio at (60. 5-195):(0. 003-28) of the glass basic oxide and all rare-earth oxide; adding at least three rare-earth oxide; improving the fusion of the glass; accelerating clarification and equalization in the course of formation; preventing glass crystallizer; decreasing the liquid phase temperature; delaying devitrification speed of the glass; fitting for productive technology of float glass; improving chemical stability of the glass; decreasing the expansion coefficient; fitting for large scale float glass procession.

Owner:CHINA BUILDING MATERIALS ACAD

Foaming glaze and glaze foaming ceramic manufactured by using the same

The invention relates to a foaming glaze and a glaze foaming ceramic manufactured by using the same, and belongs to the technical field of ceramics. The foaming glaze comprises 38-42 parts by mass of potassium feldspar, 13-16 parts by mass of kaolin, 5-8 parts by mass of zirconium silicate, 8-11 parts by mass of barium carbonate, 7-12 parts by mass of quartz, 7-9 parts by mass of calcium carbonate, 2-5 parts by mass of zinc oxide, 5-10 parts by mass of talcum, 0.8-1.3 parts by mass of magnesium carbonate, 1-5 parts by mass of silicon carbide, 2-4 parts by mass of neodymium oxide, 8-11 parts by mass of clay, 16-20 parts by mass of borax, 0.2-0.5 part by mass of manganese oxide, 0.2-0.4 part by mass of iron oxide, 18-24 parts by mass of glass powder and 15-21 parts by mass of a low-temperature frit, wherein the low-temperature frit comprises 47-51 parts by mass of borax, 38-41 parts by mass of potassium feldspar, 11-13 parts by mass of calcium carbonate, and 6-9 parts by mass of kaolin. The method includes steps of grinding, adjusting a glaze concentration, glazing, firing, puffing and cooling to obtain the glaze foaming ceramic. The glaze foaming ceramic having color changing effects, and having high acid and alkali resistance, compression resistance and fracture resistance is provided.

Owner:德化县太阳鸟工艺品有限公司

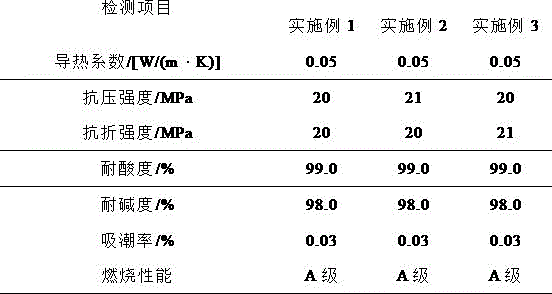

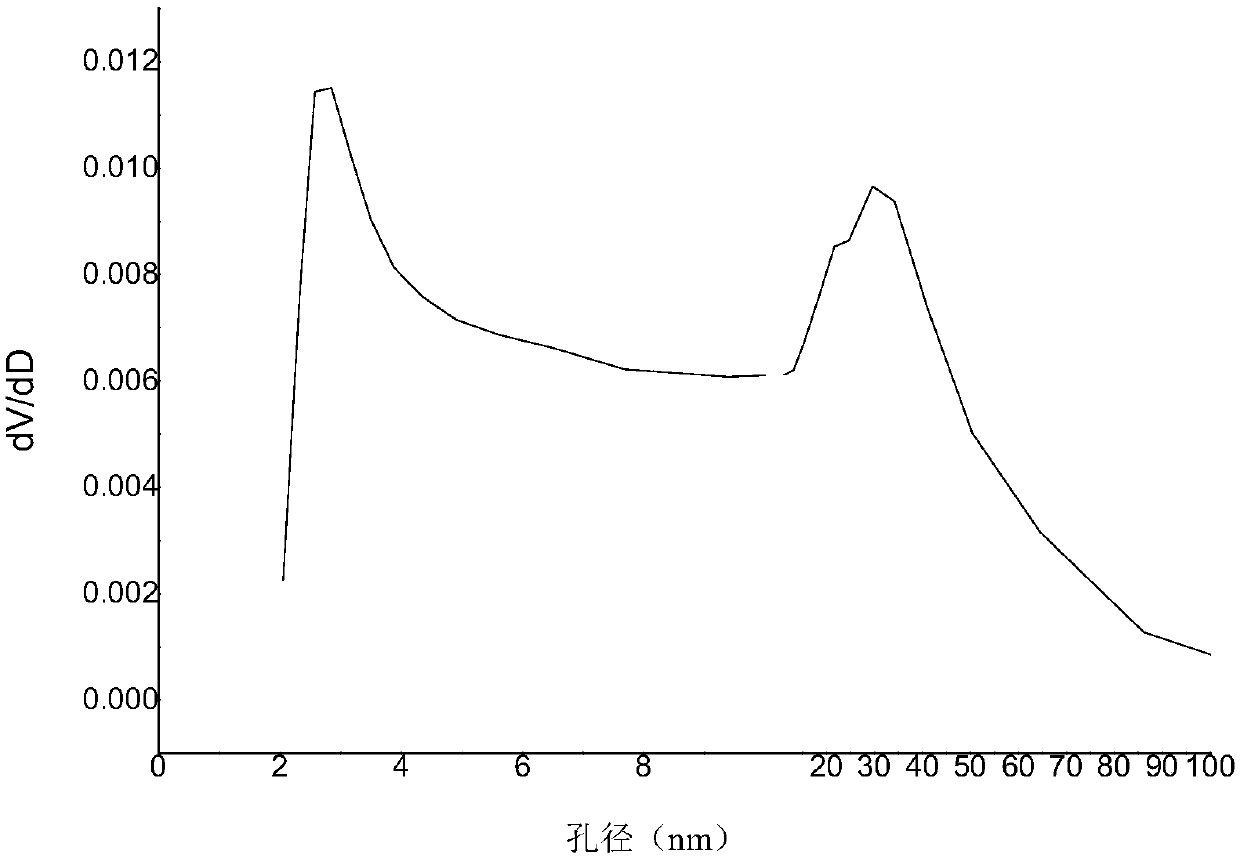

Controllable dual-porous Ce/Zr composite oxide, and preparation method and application thereof

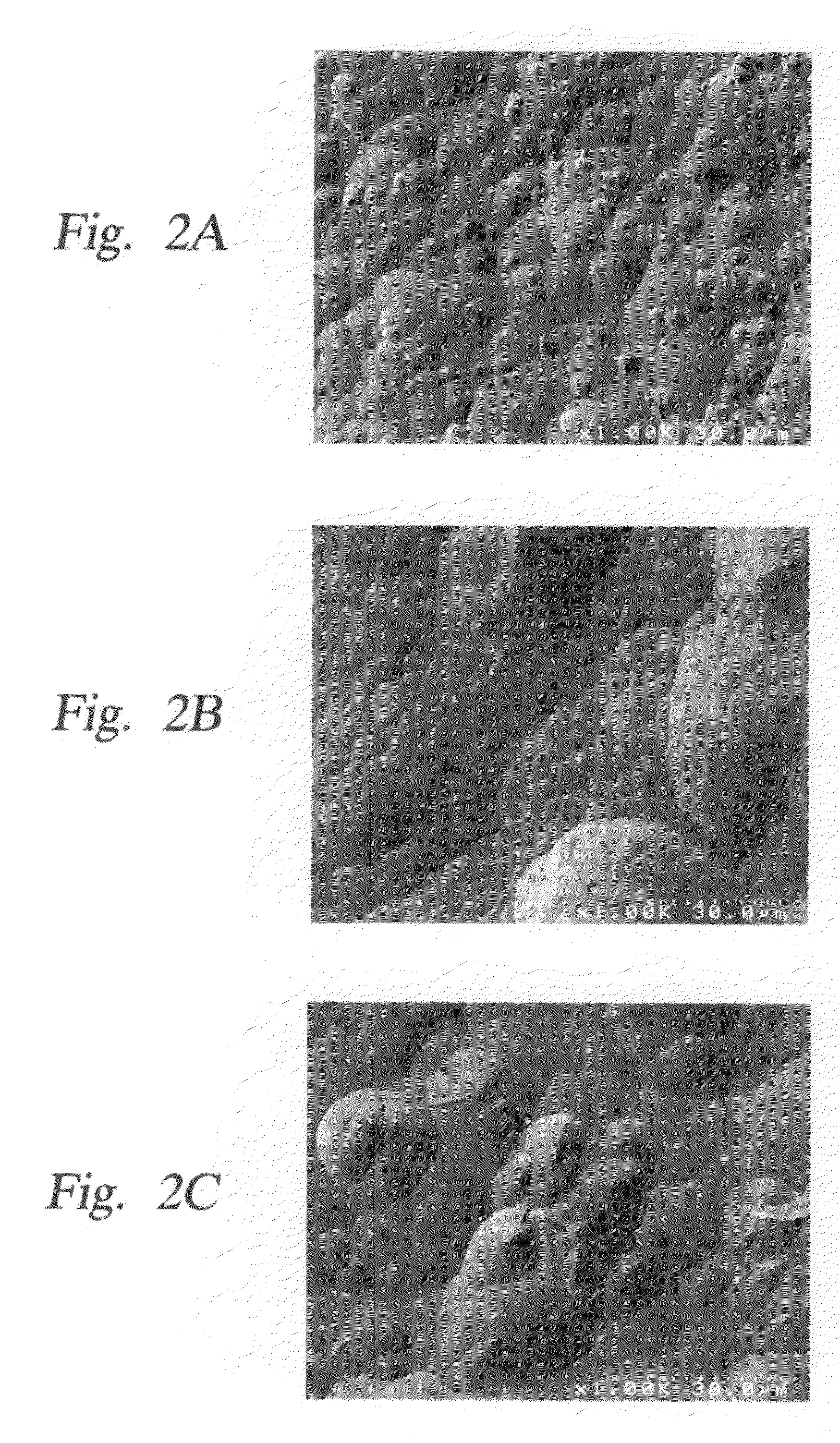

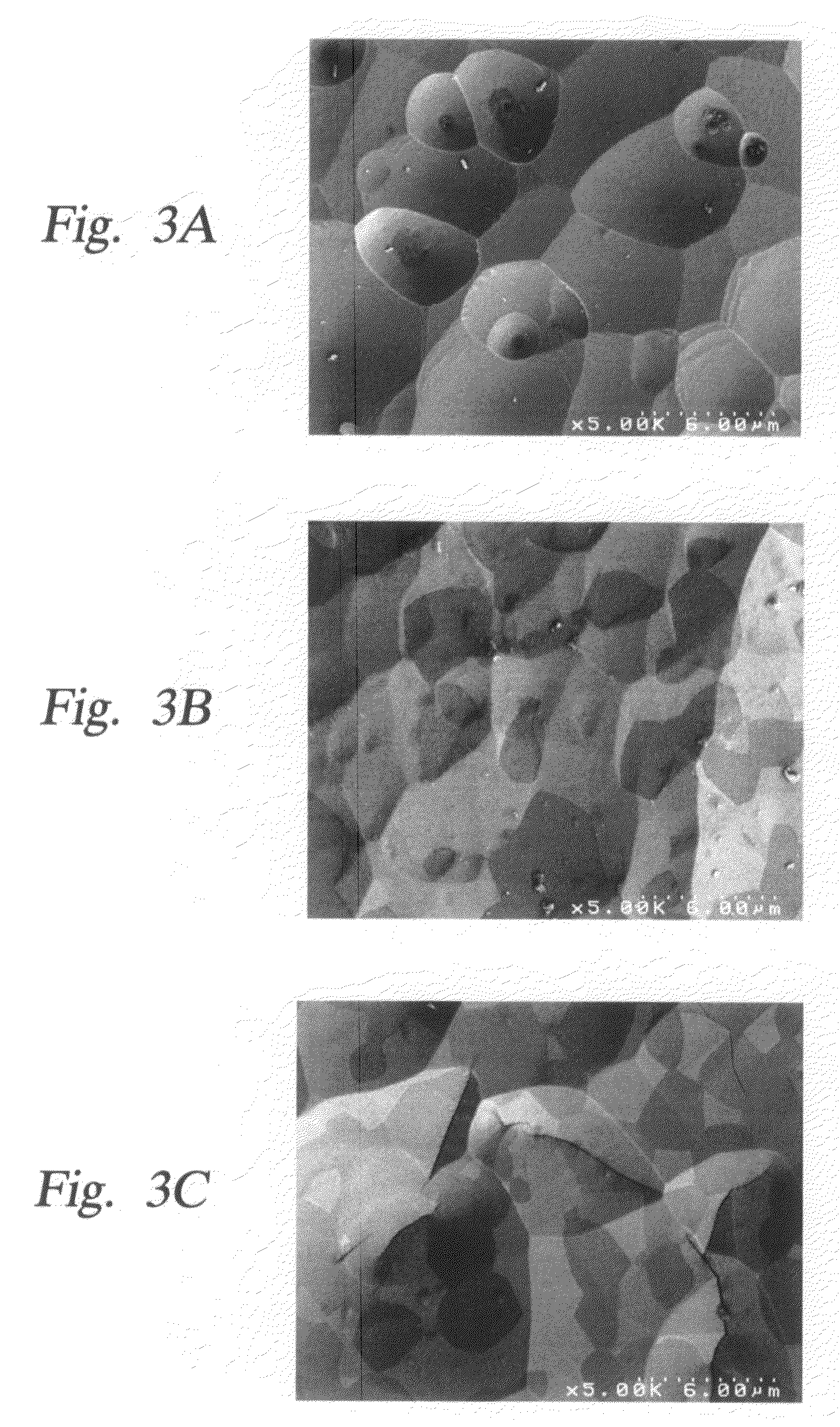

ActiveCN109529801ARough surfaceDeveloped surface voidsHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsComposite oxideCerium oxide

The invention relates to the field of inorganic nano materials and particularly relates to a controllable dual-porous Ce / Zr composite oxide, and a preparation method and an application thereof. The Ce / Zr composite oxide comprises, by weight, 25-60% of cerium oxide, 35-60% of zirconium oxide, and 5-15% of one or more of lanthanum oxide, praseodymium oxide, neodymium oxide, yttrium oxide or samariumoxide. The dual-porous Ce / Zr composite oxide has a spherical or spheroid approximated core / shell structure and includes an inner core and an outer shell. The pore diameter of an inner near-core structure is 0-10 nm while the pore diameter of an outer near-shell structure is 10-100 nm. The method employs accessible and low-cost raw materials and a simple and controllable synthesis approach and issuitable for large-scale production.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

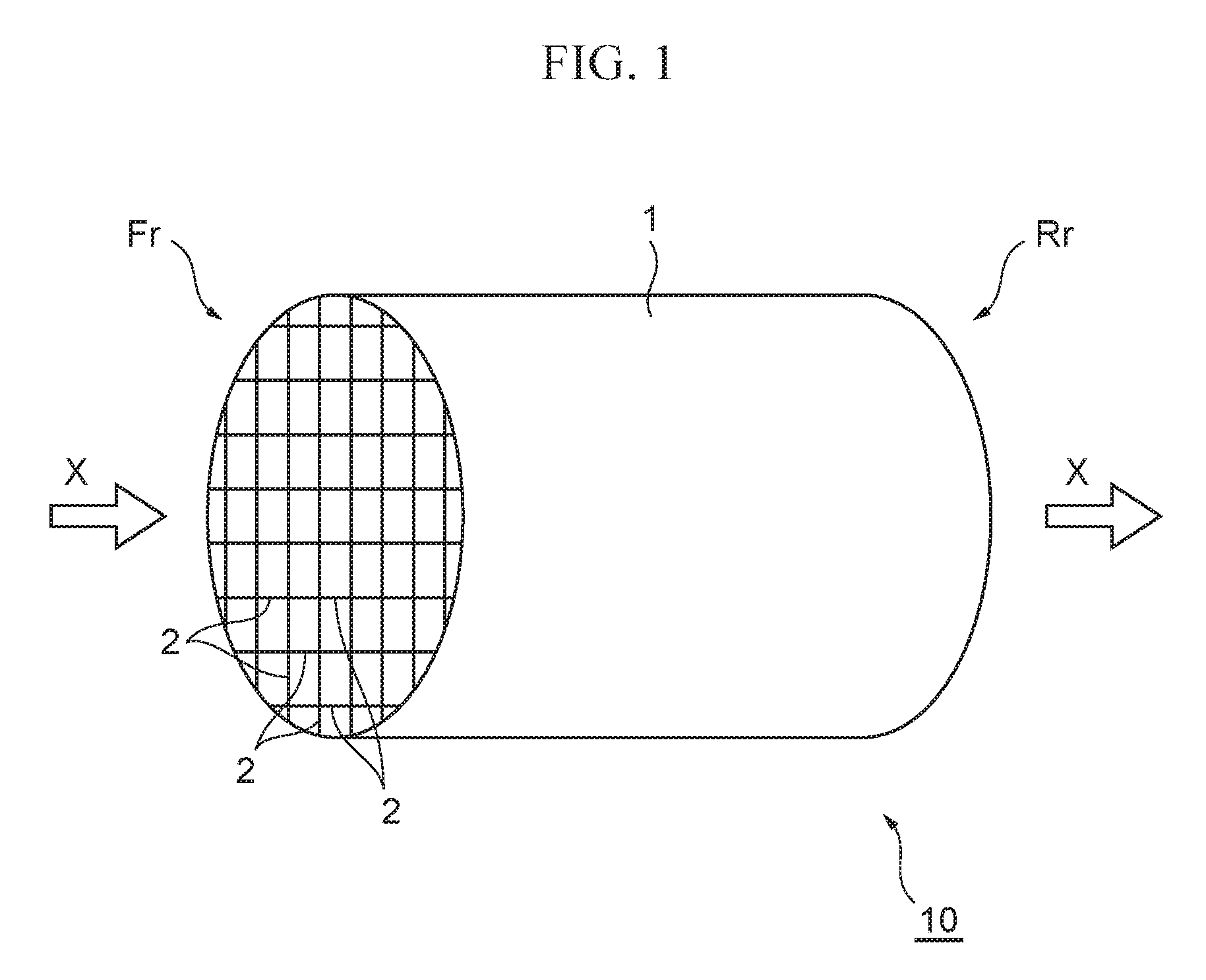

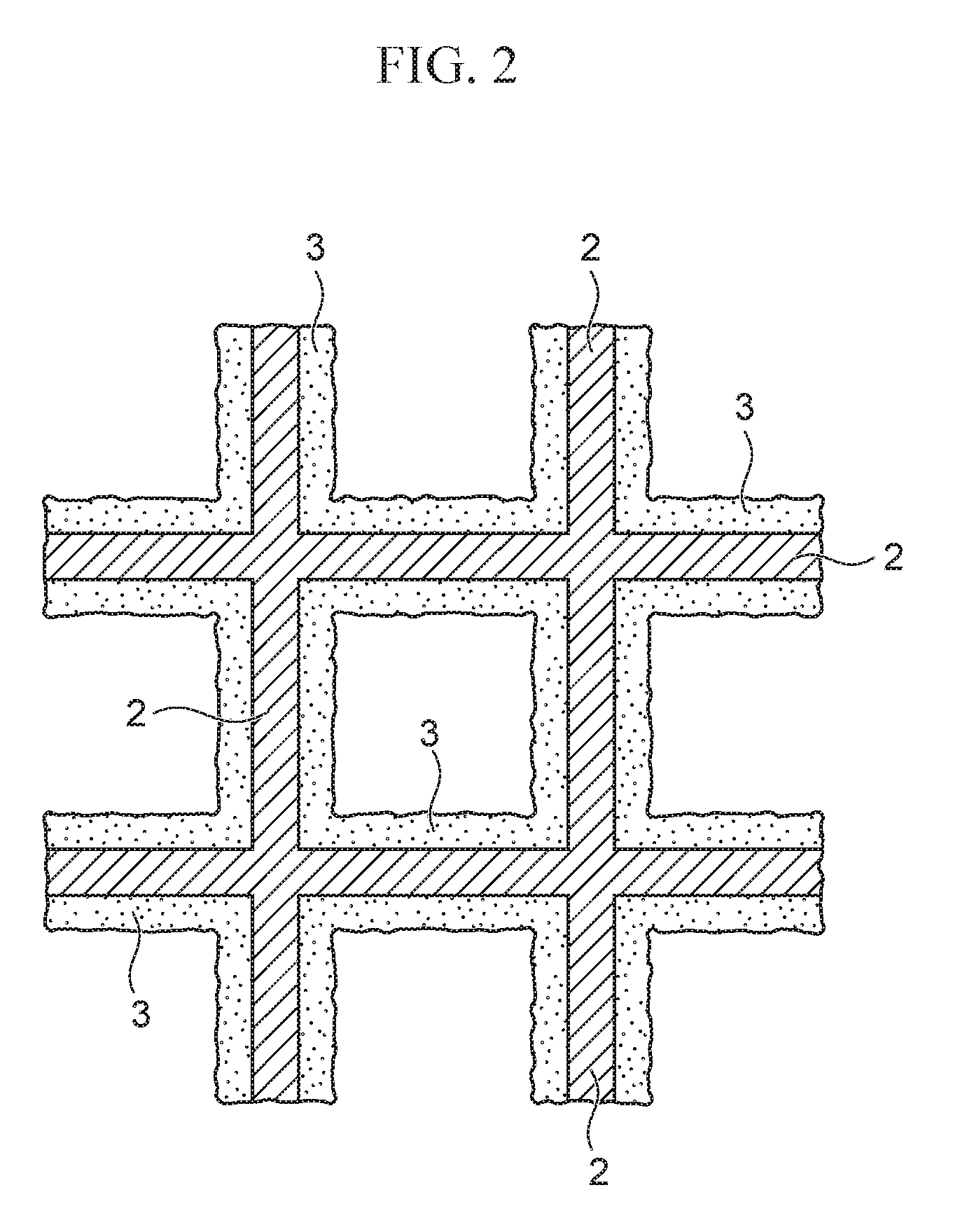

Catalytic converter

ActiveUS9579633B2Improve performanceNO purification performanceInternal combustion piston enginesExhaust apparatusCerium(IV) oxidePt element

A catalytic converter with excellent OSC performance and NOx purification performance. The catalytic converter includes a substrate with a cell structure and catalyst layer. The catalyst layer includes lower and upper catalyst layers. The upper catalyst layer includes a zirconia compound support with rhodium carried thereon that contains zirconia, lanthanum oxide, and yttrium oxide; an alumina compound without rhodium carried thereon that contains alumina and lanthanum oxide; and a ceria-zirconia-based composite oxide containing ceria, zirconia, lanthanum oxide, and neodymium oxide. The lower catalyst layer includes an alumina compound support with platinum carried thereon that contains alumina and lanthanum oxide that are the same materials as those of the alumina compound of the upper catalyst layer; and a ceria-zirconia-based composite oxide without platinum carried thereon that contains ceria, zirconia, lanthanum oxide, and neodymium oxide that are the same materials as those of the ceria-zirconia-based composite oxide of the upper catalyst layer.

Owner:TOYOTA JIDOSHA KK

Method for preparing large-particle and flaky praseodymium neodymium oxide

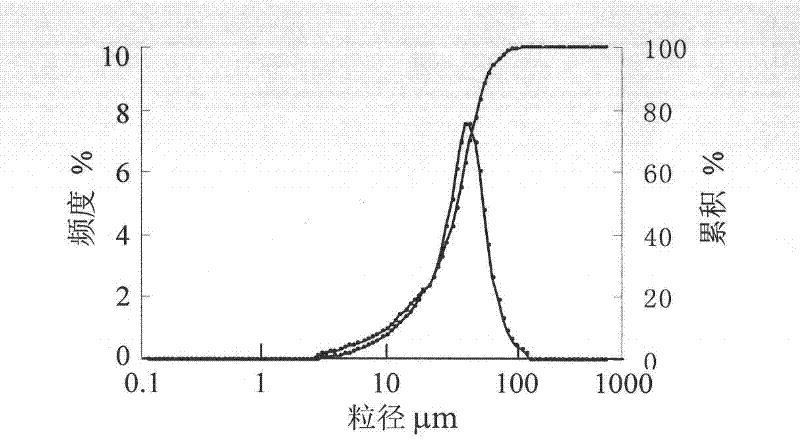

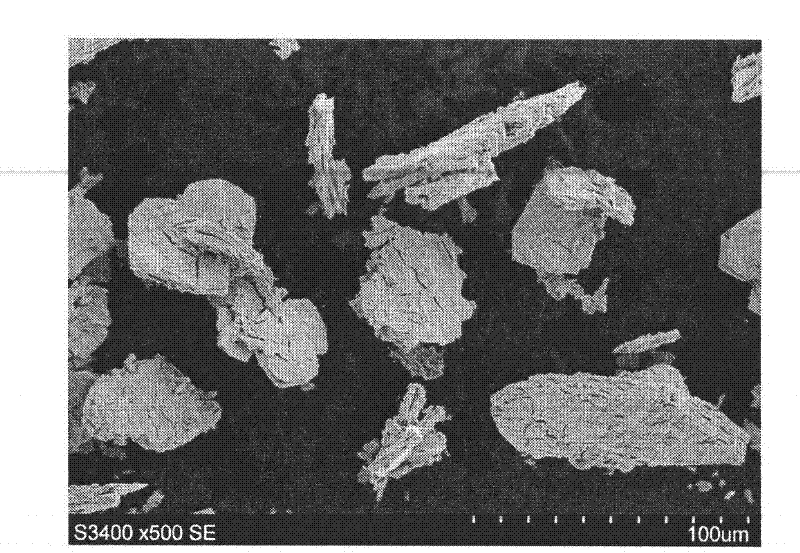

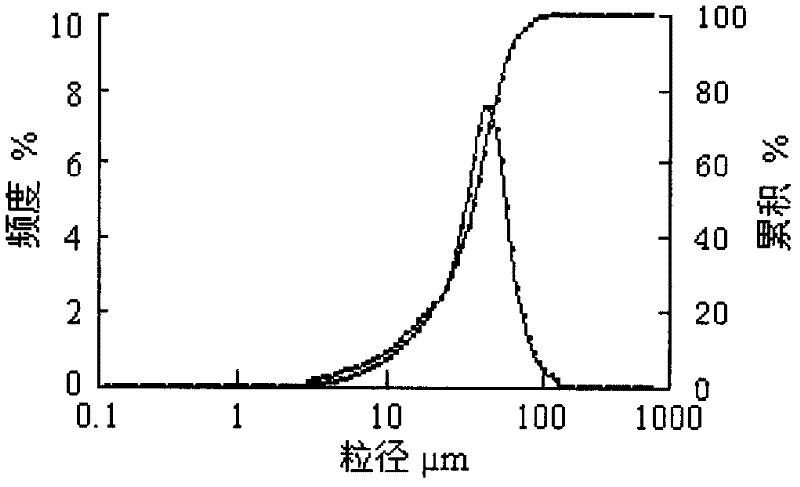

InactiveCN102502760AEvenly distributedGood dispersionNanotechnologyRare earth metal compoundsMaterials preparationNeodymium chloride

The invention relates to a method for preparing large-particle and flaky praseodymium neodymium oxide, and belongs to a material preparation technology. The method comprises the following steps of: preparing praseodymium neodymium carbonate by using a praseodymium neodymium chloride solution as a raw material and using ammonium hydrogen carbonate as a precipitating agent, washing, filtering, centrifugally drying and firing the praseodymium neodymium carbonate sediment, and thus obtaining the flaky praseodymium neodymium oxide product with the central particle size of 25 to 45 microns. The precipitation temperature and the concentration of the praseodymium neodymium carbonate are the key, the precipitation temperature is controlled to be 60 DEG C, and the concentration of the praseodymium neodymium chloride solution is controlled to be 0.15-0.5mol / L; the large-particle praseodymium neodymium oxide product of which the central particle size is 25 to 45 microns, is produced by using a conventional praseodymium neodymium carbonate precipitating procedure in a factory; and the product is uniform in particle distribution, good in dispersibility and flaky.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Neodymium, iron and boron waste recycling process with approximately zero wastewater discharge

InactiveCN102912134ANo pollution in the processEasy extractionProcess efficiency improvementDissolutionDouble salt

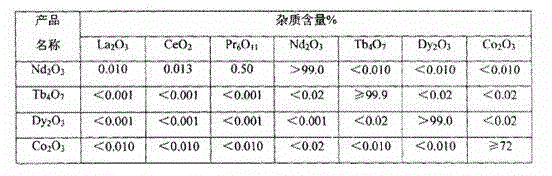

The invention discloses a neodymium, iron and boron waste recycling process with approximately zero wastewater discharge. The method is characterized in that recycling and separating for neodymium, terbium, dysprosium and cobalt in neodymium, iron and boron waste are researched, means such as fine grinding and crushing for the waste, oxidizing roasting, prior dissolution in hydrochloric acid, neutralization and impurity removal, double-salt iron settling and extraction separation are selected according to chemical properties of elements contained in the waste, valuable elements in the neodymium, iron and boron waste are successfully extracted, and neodymium oxide, terbium oxide, dysprosium oxide and cobalt oxide which are high in purity are obtained. The neodymium, iron and boron waste recycling process is simple, the production cost is low, an obvious economical benefit is realized, environmental pollution is prevented, and the process is applicable to industrial continuous production. Besides, the extraction rates of manufactured neodymium oxide, terbium oxide, dysprosium oxide and cobalt oxide products are maximized, and quality indexes of the manufactured neodymium oxide, terbium oxide, dysprosium oxide and cobalt oxide products meet industrial standards or customer standards.

Owner:XINFENG BAOGANG XINLI RARE EARTH

Preparation method of nano neodymium oxide with large specific surface area

InactiveCN106277021AImprove surface activityGood dispersionMaterial nanotechnologyRare earth metal compoundsInorganic saltsRare earth

The invention belongs to the technical field of preparation of rare earth oxide and particularly relates to a preparation method of nano neodymium oxide with large specific surface area. The method comprises the following steps: adding a surfactant into a neodymium-containing inorganic salt solution; dropwise adding a precipitant into the solution, and stirring for sufficient reaction of the two solutions; aging to obtain a precipitate; and washing the precipitate with deionized water, and performing vacuum drying and ignition to obtain nano neodymium oxide with large specific surface area. In the invention, through the application of the surfactant and control of the precipitant concentration and dropwise adding speed, according to TEM detection, the primary particle size of the prepared nano neodymium oxide is 20-60nm, and the specific surface area is 60-100m<2> / g. The method provided by the invention has the advantages of simple technology, relatively low cost and high controllability, remarkably improves the product purity and yield, and is environment-friendly and suitable for industrial production.

Owner:常州卓煜新材料科技有限公司

LED material for filtering yellow light and preparation method thereof

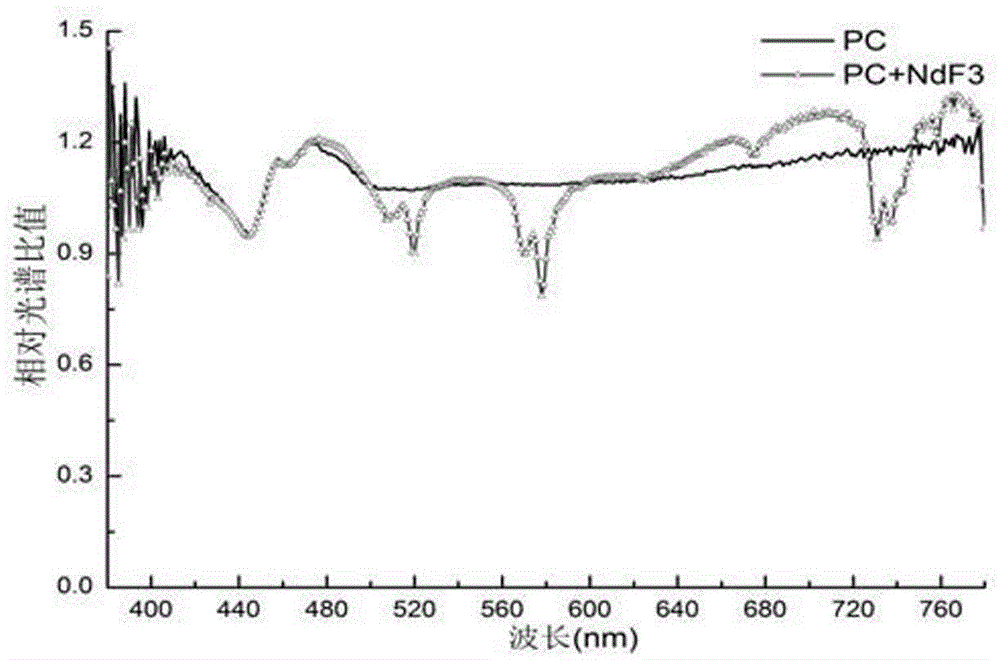

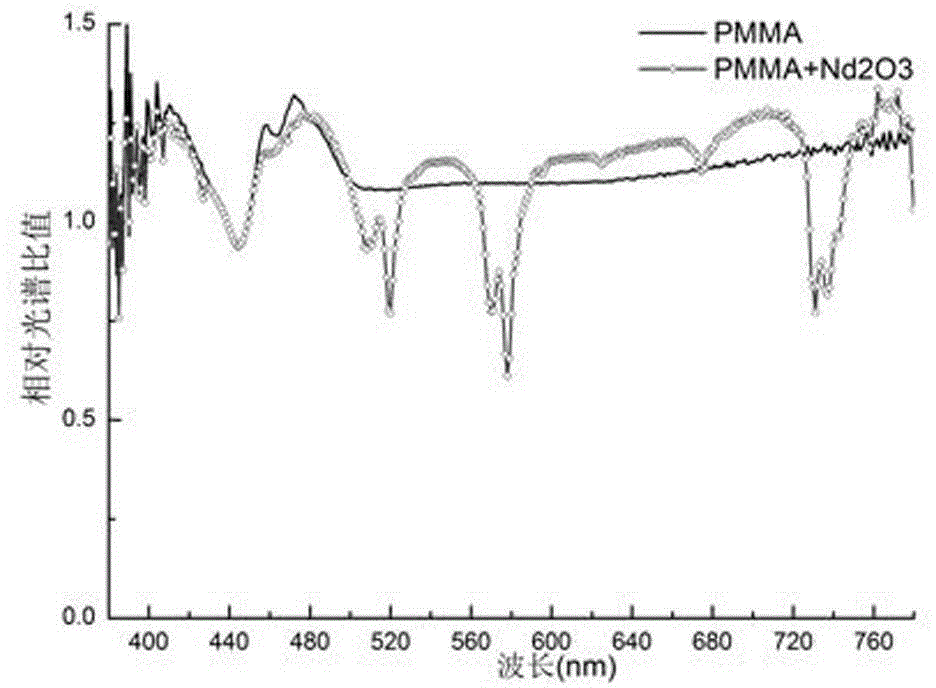

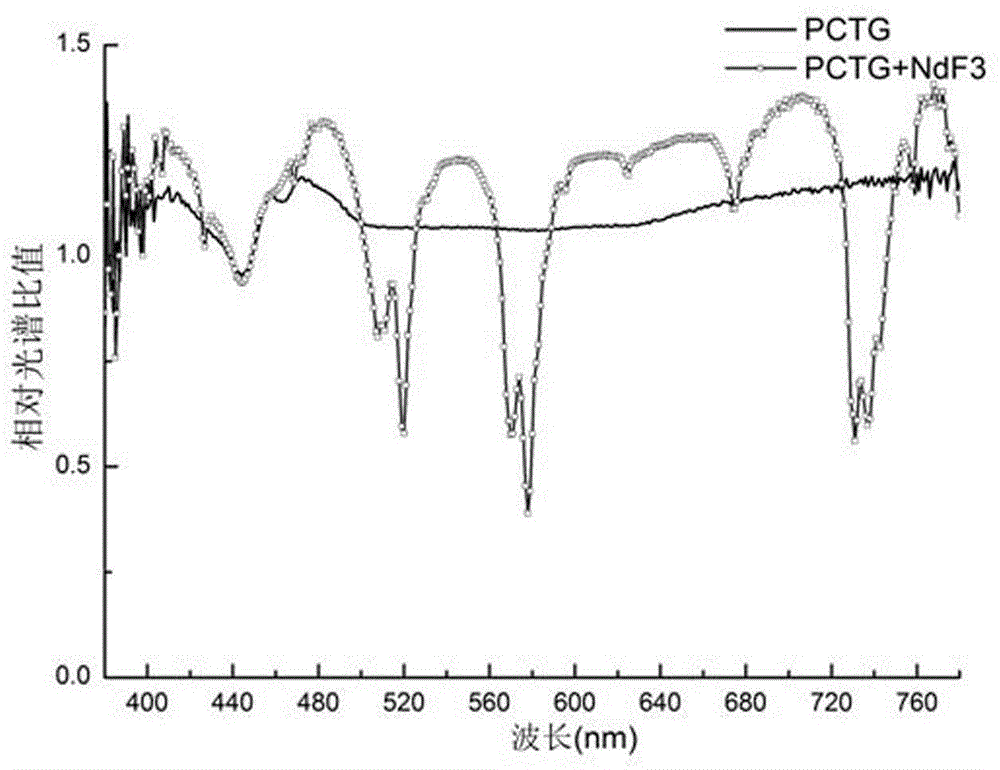

ActiveCN104650568AHigh light transmittanceExcellent optical properties such as hazePhysical chemistryOptical transmittance

The invention relates to the technical field of high-molecular materials and particularly relates to an LED material for filtering yellow light and a preparation method thereof. The LED material for filtering yellow light is prepared from the following raw materials in parts by mass: 60-100 parts of a base material, 1-13 parts of a yellow light filtration aid, 0.1-1.0 part of a light diffusing agent, 0.1-0.8 part of an antioxidant, 0.2-0.4 part of a dispersant DP310 and 2-26 parts of deionized water, wherein the yellow light filtration aid is one or more than one of neodymium fluoride, neodymium oxide, neodymium chloride and neodymium nitrate. The LED material for filtering yellow light, prepared by the method disclosed by the invention, is excellent in optical performances such as yellow light filtration property, light transmittance and haze and can be used for effectively filtering and eliminating yellow light generated by an LED lamp so as to relieve the fatigue of eyes and preventing the eyes from damages of yellow light. The preparation method of the LED material is simple in process, convenient to operate and control, stable in quality, high in yield, high in production efficiency and low in production cost.

Owner:DONGGUAN ZOYO ELECTRONICS TECH CO LTD

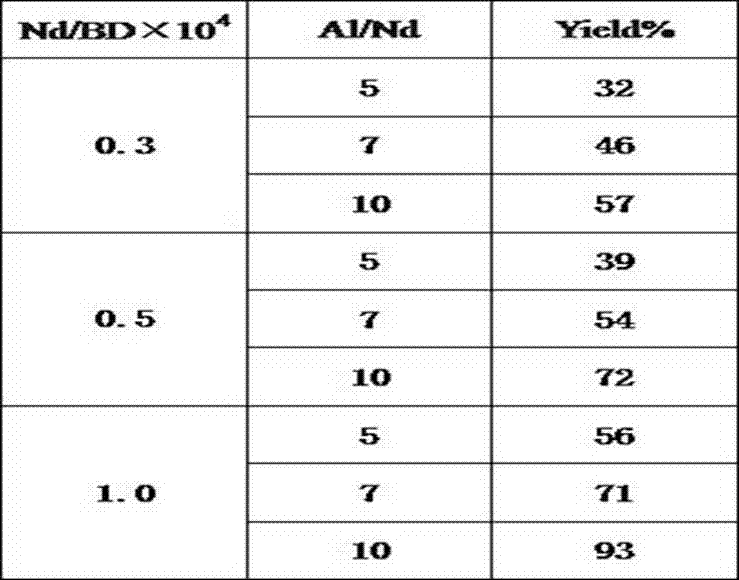

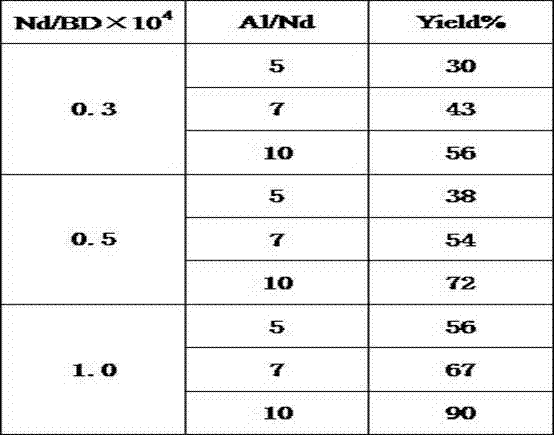

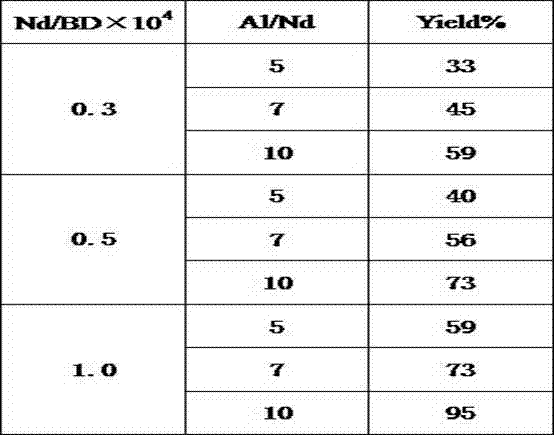

Method for synthesizing solution-type rare-earth rubber catalyst

The invention relates to a method for synthesizing a solution-type rare-earth rubber catalyst. The method comprises the following steps: preparing a neodymium trichloride water solution by using neodymium oxide and hydrochloric acid; mixing an organic phosphoric acid with an organic solvent to obtain an organic phosphoric acid solution; adding an alkaline solution to obtain saponification liquid; adjusting the viscosity of the solution by using a viscosity adjuster after completely dissolving; respectively carrying out binary ageing and ternary ageing, so as to obtain a rare-earth catalytic system which is directly applied to rubber production. The technology for preparing the rare-earth rubber catalyst provided by the invention is simple in process and low in cost, and the viscosity of organic phosphate neodymium can be freely adjusted according to the requirements. In addition, saturated alkane hexane is adopted in the preparation process, so that an organic solvent of polluting the environment is avoided; the waste water generated in the washing process comprises a main ingredient of sodium chloride, and can be safely discharged after being processed; a step of rectification dehydration is introduced to the technology, so that the moisture content in the catalyst can be strictly controlled.

Owner:华宇橡胶有限责任公司

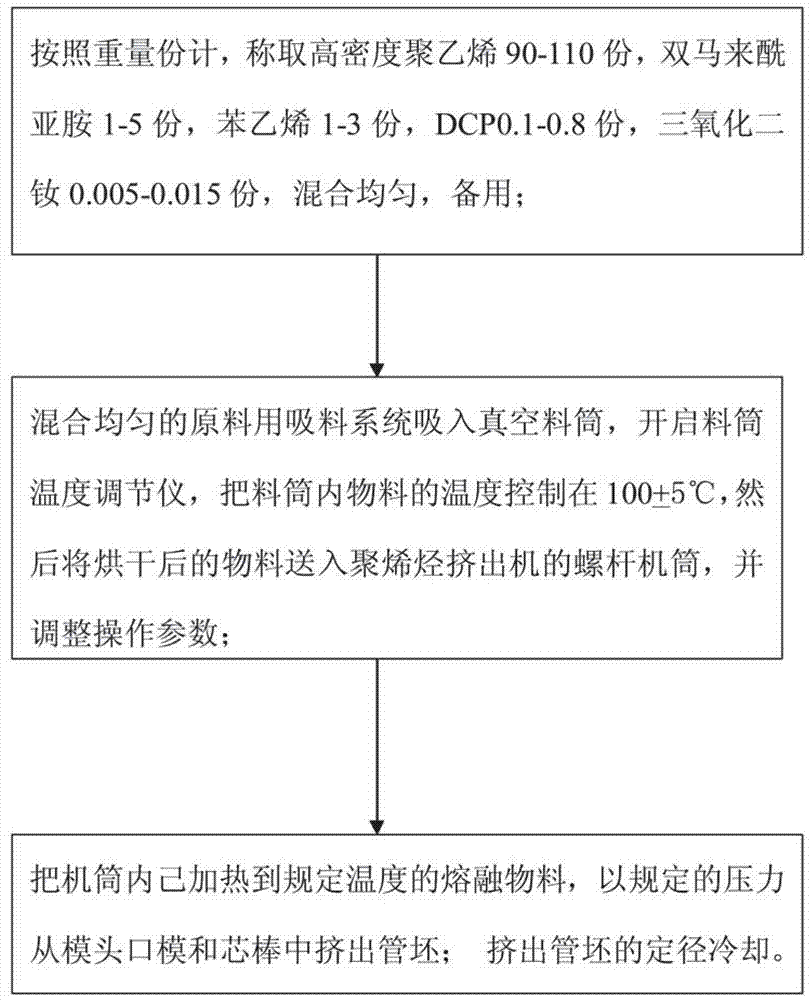

Anticorrosive, wax-proof and high-temperature-resistant polyethylene tube for oil extraction and preparation method of polyethylene tube

The invention relates to a polyethylene liner tube, particularly to an anticorrosive, wax-proof and high-temperature-resistant polyethylene tube for oil extraction and a preparation method of the polyethylene tube. The anticorrosive, wax-proof and high-temperature-resistant polyethylene tube comprises the following components in parts by weight: 90-110 parts of high-density polyethylene, 1-5 parts of bismaleimide, 1-3 parts of styrene, 0.1-0.8 part of DCP (Dicumyl Peroxide) cross-linking agent, and 0.005-0.015 part of neodymium oxide; and the polyethylene tube is manufactured by a screw cylinder of a polyolefin extruder. The vicat softening point of the prepared polyethylene tube is at 135 DEG C; the polyethylene tube with the use temperature capable of reaching 130 DEG C is applicable to an oil extraction pipe in an oil well which is 2000-3000m deep; and compared with a modified nylon oil extraction pipe applied to the oil extraction pipe below 2000m, the polyethylene tube provided by the invention is characterized in that the cost is low and the acid resistance is good.

Owner:济南赛辰高分子材料有限公司

Security inks containing infrared absorbing metal compounds

ActiveUS8157905B2Easy to detectNot easy to detectNon-fibrous pulp additionLayered productsNeodymium chlorideLanthanum hexaboride

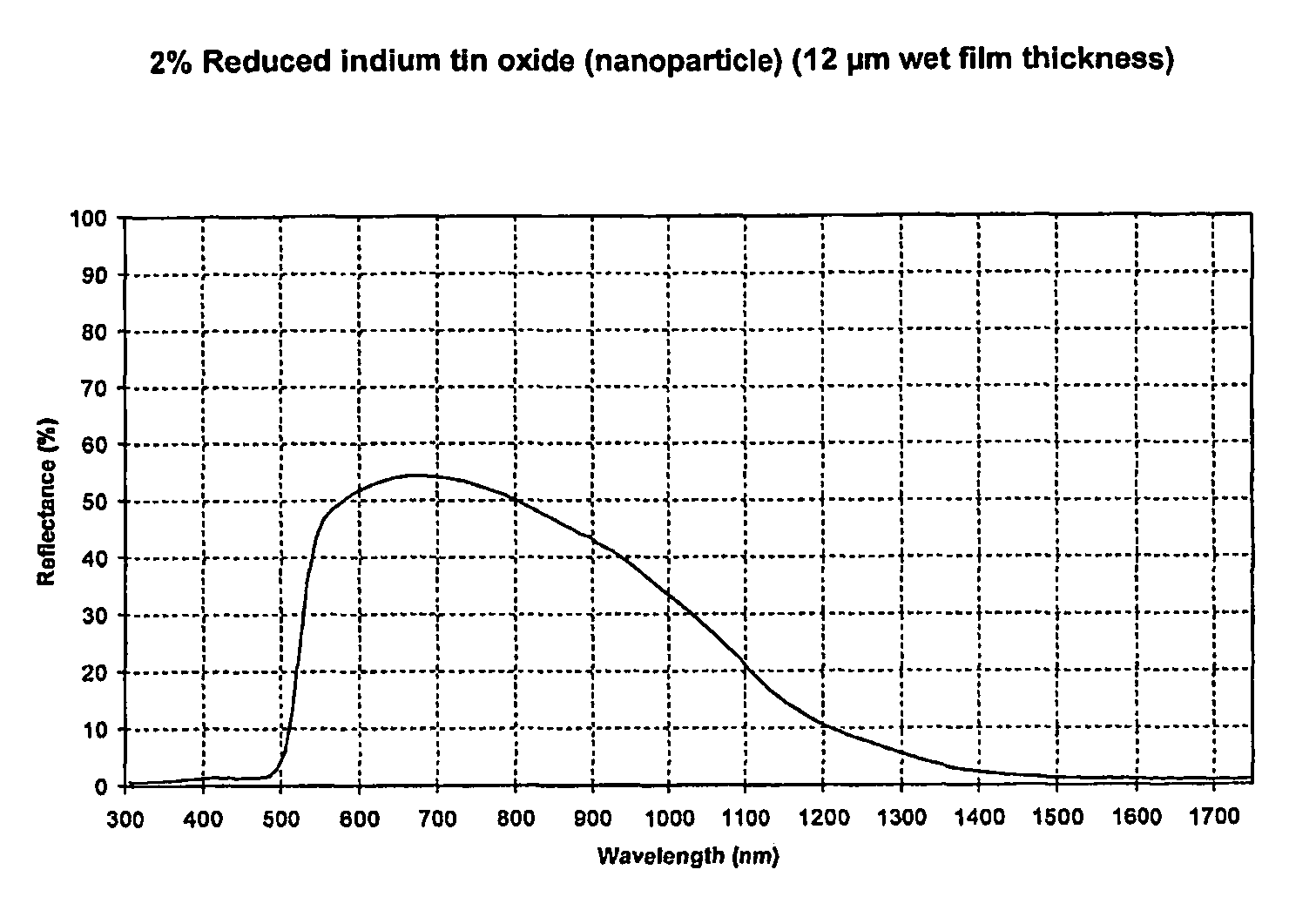

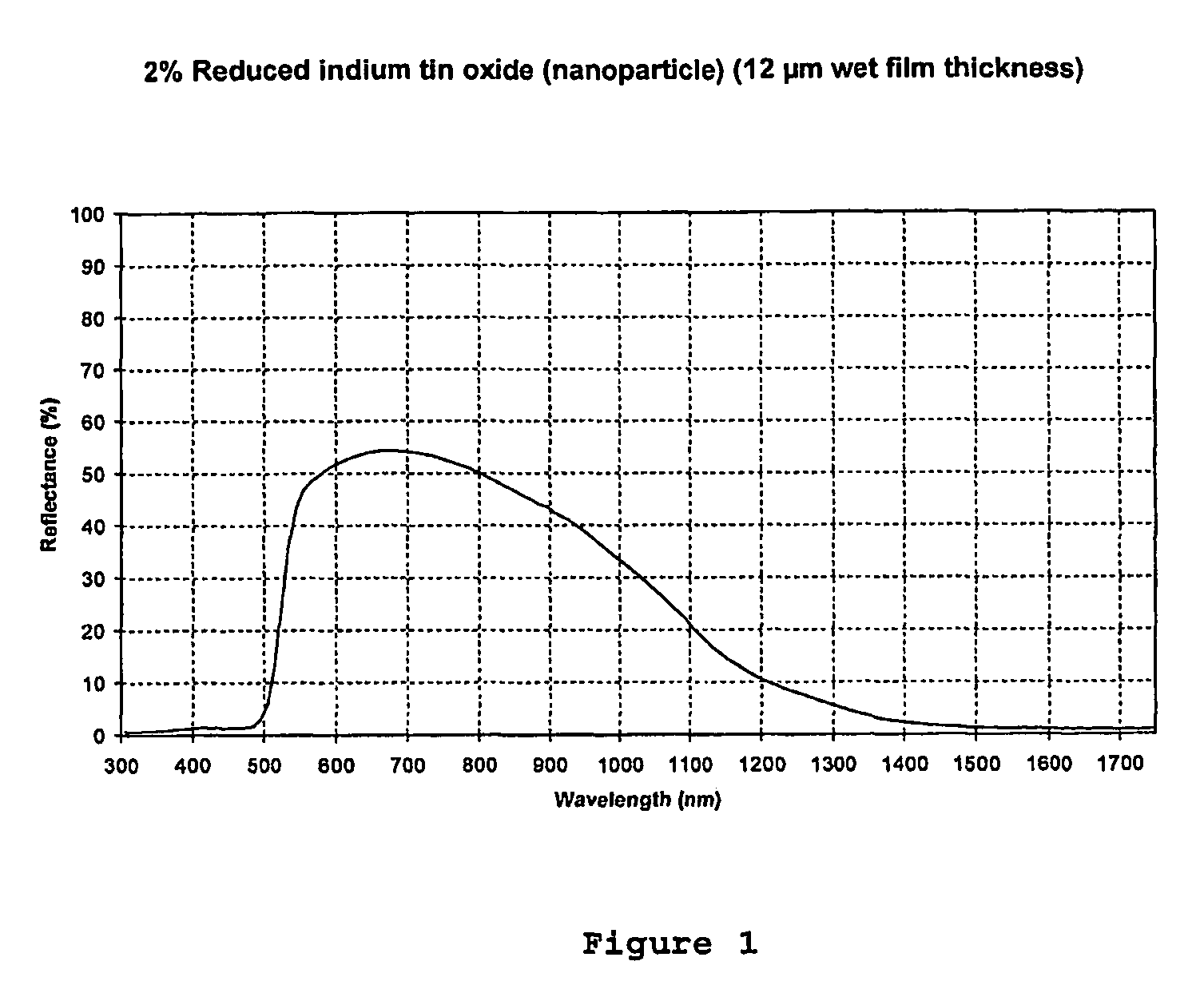

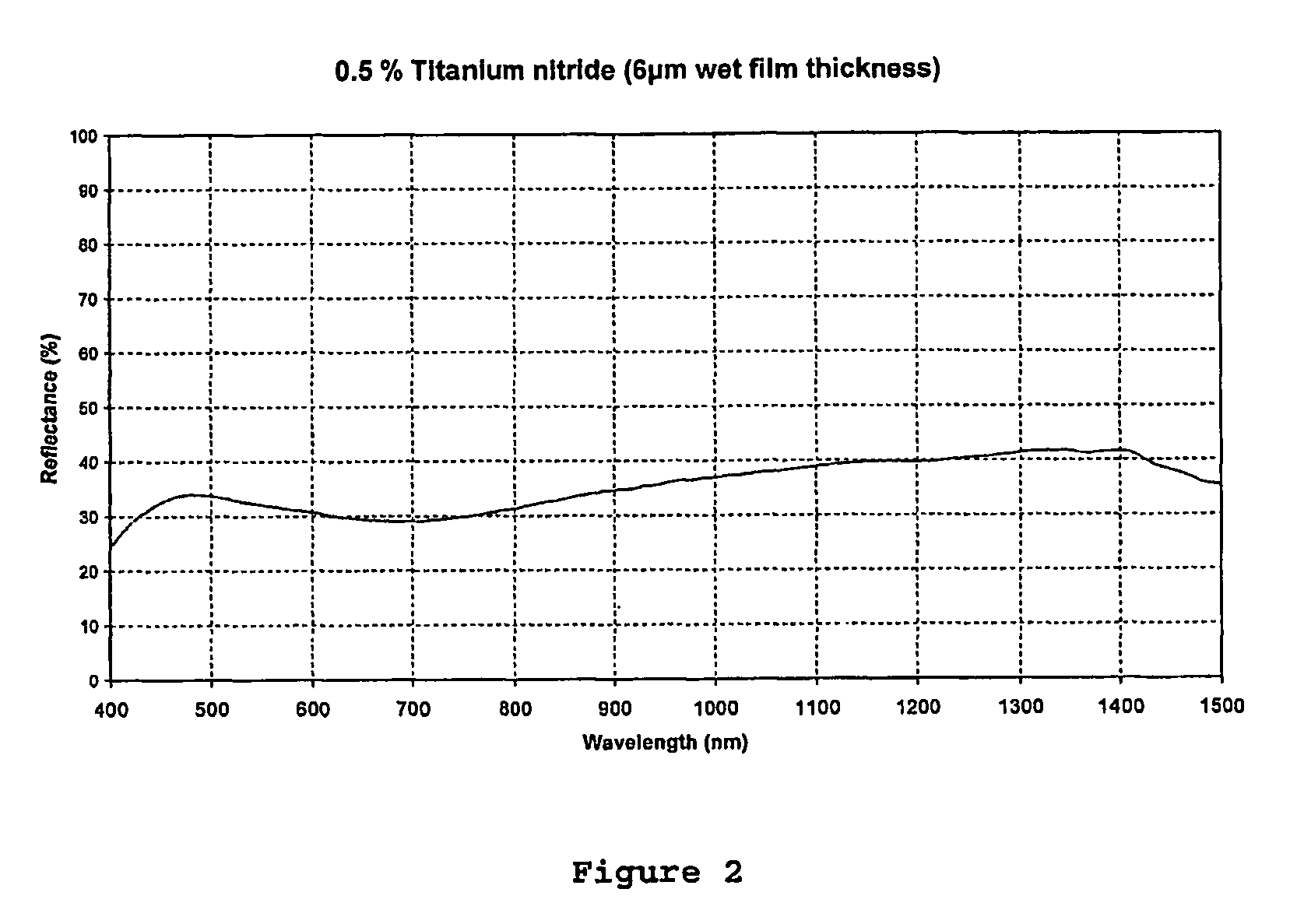

Composition including an oleophilic base ink composition having dispersed therein particles of an infrared-absorbing material wherein the infrared-absorbing material is selected from reduced indium tin oxide, titanium nitride, zirconium nitride, molybdenum metal, copper chromate, lanthanum hexaboride, neodymium oxide, neodymium chloride, dysprosium oxide and praseodymium oxide.

Owner:INOVINK

Hot pressed sintering high-purity zirconia composite ceramic and preparation method thereof

The invention provides a zirconia composite tough material with adjustable toughness and low price. The tough ceramic is prepared by complex powder of high-purity zirconia doped with at least one of hafnium oxide, yttrium oxide, cerium oxide, calcium oxide, magnesium oxide, aluminum oxide, titanium oxide, silicon oxide, cobalt oxide, iron oxide, scandium oxide, vanadium oxide, manganese oxide, nickel oxide, copper oxide, zinc oxide, niobium oxide, molybdenum oxide, indium oxide, stannic oxide, barium oxide, tantalum oxide, tungsten oxide, lanthanum oxide, praseodymium oxide, neodymium oxide, tellurium oxide, terbium oxide, europium oxide and erbium oxide. The preparation method comprises the following steps: dispersing the zirconia composite powder by using a high energy ball milling method, and adding the dispersed powder into a graphite mold for performing hot pressed sintering treatment, thereby obtaining the high-purity zirconia composite ceramic.

Owner:南京金鲤新材料有限公司

Aluminum-based composite radiating material for LED (light-emitting diode) doped neodymium oxide

The invention relates to a lamp radiating material and specifically relates to an aluminum-based composite radiating material for LED (light-emitting diode) doped neodymium oxide and a production method thereof. The radiating material is prepared from the following materials in parts by weight: 73-75 parts of aluminum, 10-12 parts of aluminum nitride, 4-5 parts of iron oxide black, 2-3 parts of neodymium oxide, 6-8 parts of steel slag, 10-12 parts of metakaolin, 6-8 parts of sodium silicate, 2-3 parts of ferrous sulfate, 2-5 parts of sucrose fatty acid ester and 4-5 parts of auxiliaries. The radiating material disclosed by the invention has integrated advantages of components such as aluminum, aluminum nitride, metakaolin, and the like, has good heat conduction and insulating performances; all materials are mixed and ground in sodium silicate aqueous liquor to increase compatibility of materials, so that the materials are easier to form; the doped neodymium oxide can improve radiating and temperature-resisting performances of the material; and the radiating material prepared in the invention is compact in structure, bright in color and luster, light and firm, good in thermal stability, durable, and efficient and lasting in radiating capacity, so that the LED lamp is effectively protected, and service life of the lamp is greatly prolonged.

Owner:YANYANG LAMP SET TIANCHANG CITY

High-performance energy-saving rare earth deashing and delayed action activator for boiler, and its manufacturing method

InactiveCN1730630APromote sheddingAvoid generatingLighting and heating apparatusFuel additivesCongruent meltingNitrate

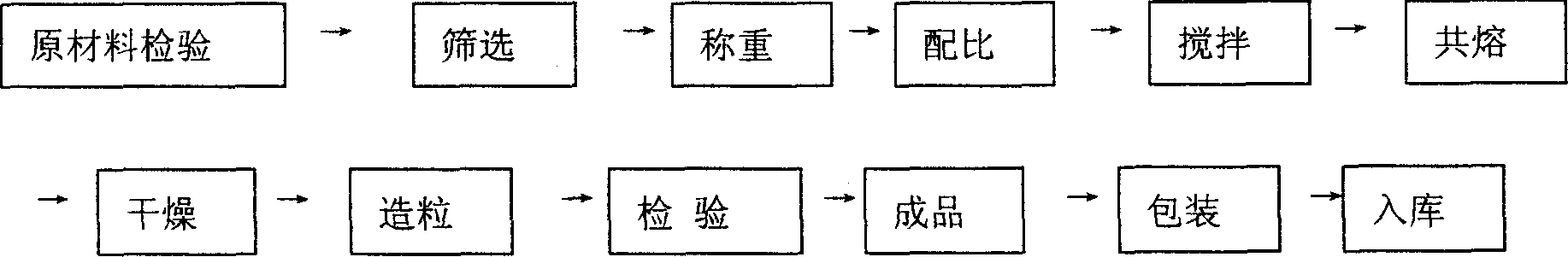

The invention provides a rare earth high-performance energy-saving boiler deashing and decoking agent and its manufacture process, which comprises selecting and weighing nitrates, cerium oxide, neodymium oxide, tinkalite, sodium carbonate, sodium chloride, calcium carbonate, magnesium oxide, agitating and mixing, congruent melting, drying, granulating and inspecting.

Owner:金余兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com