Foaming glaze and glaze foaming ceramic manufactured by using the same

A glaze foaming and foaming glaze technology, applied in the field of ceramics, can solve the problems of long firing time, less raw material formula, slow heating rate, etc., and achieve the effect of bright color, simple process and various colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

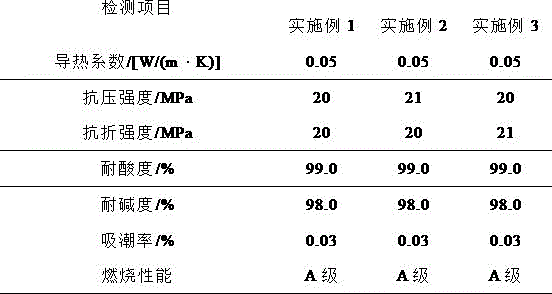

Embodiment 1

[0026] A foaming glaze comprising the following components in parts by mass: 38 parts of potassium feldspar, 13 parts of kaolin, 5 parts of zirconium silicate, 8 parts of barium carbonate, 7 parts of quartz, 7 parts of calcium carbonate, 2 parts of zinc oxide 5 parts of talc, 0.8 parts of magnesium carbonate, 1 part of silicon carbide, 2 parts of neodymium oxide, 8 parts of clay, 16 parts of borax, 0.2 parts of manganese oxide, 0.2 parts of iron oxide, 18 parts of glass powder, 15 parts of low-temperature frit, Wherein, the low-temperature frit includes the following components in parts by mass: 47 parts of borax, 38 parts of potassium feldspar, 11 parts of calcium carbonate, and 6 parts of kaolin.

[0027] The method for making glazed foamed ceramics with the described foaming glaze comprises the following steps:

[0028] Step 1, Grinding:

[0029] According to the mass ratio, after mixing the raw material components, add water with 70% of the total mass of raw materials for...

Embodiment 2

[0037] A foaming glaze comprising the following components in parts by mass: 40 parts of potassium feldspar, 15 parts of kaolin, 7 parts of zirconium silicate, 10 parts of barium carbonate, 9 parts of quartz, 8 parts of calcium carbonate, and 2 parts of zinc oxide 8 parts of talc, 1 part of magnesium carbonate, 1.6 parts of silicon carbide, 3 parts of neodymium oxide, 9 parts of clay, 19 parts of borax, 0.2 parts of manganese oxide, 0.2 parts of iron oxide, 20 parts of glass powder, and 19 parts of low-temperature frit. Wherein, the low-temperature frit includes the following components in terms of mass fractions: 48 parts of borax, 29 parts of potassium feldspar, 12 parts of calcium carbonate, and 8 parts of kaolin.

[0038] The method for making glazed foamed ceramics with the described foaming glaze comprises the following steps:

[0039] Step 1, Grinding:

[0040] According to the mass ratio, after mixing the raw material components, add water with 80% of the total mass o...

Embodiment 3

[0048] A foaming glaze comprising the following components in parts by mass: 40 parts of potassium feldspar, 15 parts of kaolin, 7 parts of zirconium silicate, 10 parts of barium carbonate, 9 parts of quartz, 8 parts of calcium carbonate, and 2 parts of zinc oxide 8 parts of talc, 1 part of magnesium carbonate, 1.6 parts of silicon carbide, 3 parts of neodymium oxide, 9 parts of clay, 19 parts of borax, 0.2 parts of manganese oxide, 0.2 parts of iron oxide, 20 parts of glass powder, and 19 parts of low-temperature frit. Wherein, the low-temperature frit includes the following components in terms of mass fractions: 48 parts of borax, 29 parts of potassium feldspar, 12 parts of calcium carbonate, and 8 parts of kaolin.

[0049] The method for making glazed foamed ceramics with the described foaming glaze comprises the following steps:

[0050] Step 1, Grinding:

[0051] According to the mass ratio, after mixing the raw material components, add water with 80% of the total mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com