LED material for filtering yellow light and preparation method thereof

A technology of yellow light and base material, applied in the field of LED materials for filtering yellow light and its preparation, can solve the problems of large difference in light transmittance and haze, easy generation of yellow light, different refractive index, etc., and achieve narrow particle size distribution. , The effect of fine control of particle micro-morphology and excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

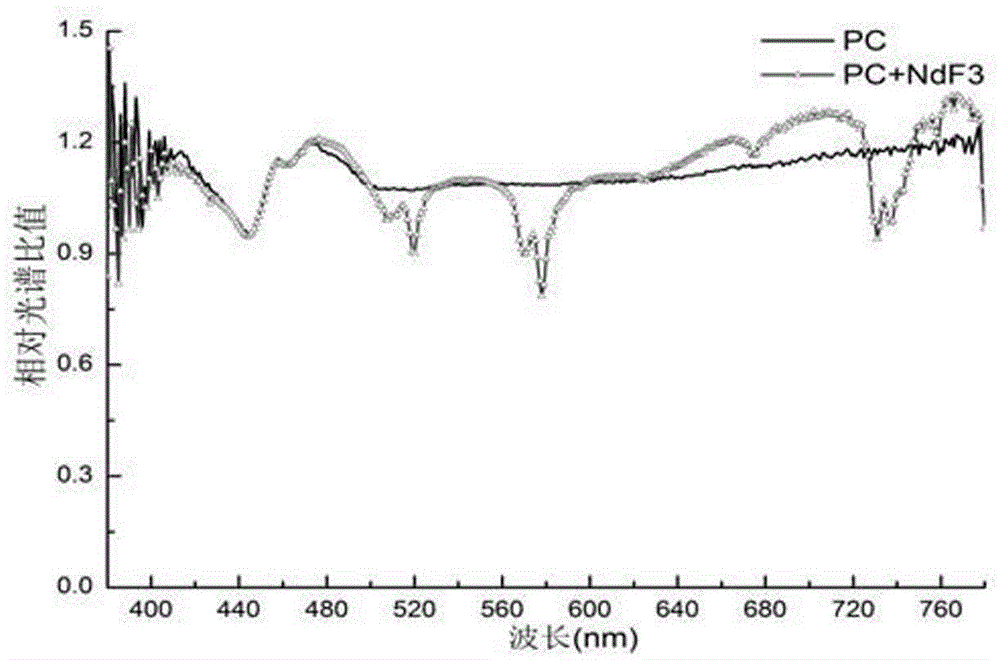

Embodiment 1

[0040] A kind of LED material that filters yellow light of the present embodiment, it comprises the raw material of following mass parts:

[0041] 60 parts of base material,

[0042] 1 part of yellow light filter aid,

[0043] 0.1 part of light diffusing agent,

[0044] Antioxidant 0.1 part,

[0045] DP310 0.2 parts,

[0046] 2 parts deionized water,

[0047] Wherein, the yellow light filtering additive is neodymium fluoride.

[0048] In this embodiment, the substrate is PC.

[0049] In this embodiment, the light diffusing agent is a silicone light diffusing agent.

[0050] In this example, the antioxidant is a mixture of 1076 and 168 in a mass ratio of 1:1.

[0051] A preparation method of an LED material for filtering yellow light in this embodiment comprises the following steps:

[0052] Step A. Disperse deionized water and filter yellow light additive in a large beaker by weight of the formula, and heat it to 80°C while stirring. After reaching the target temperature...

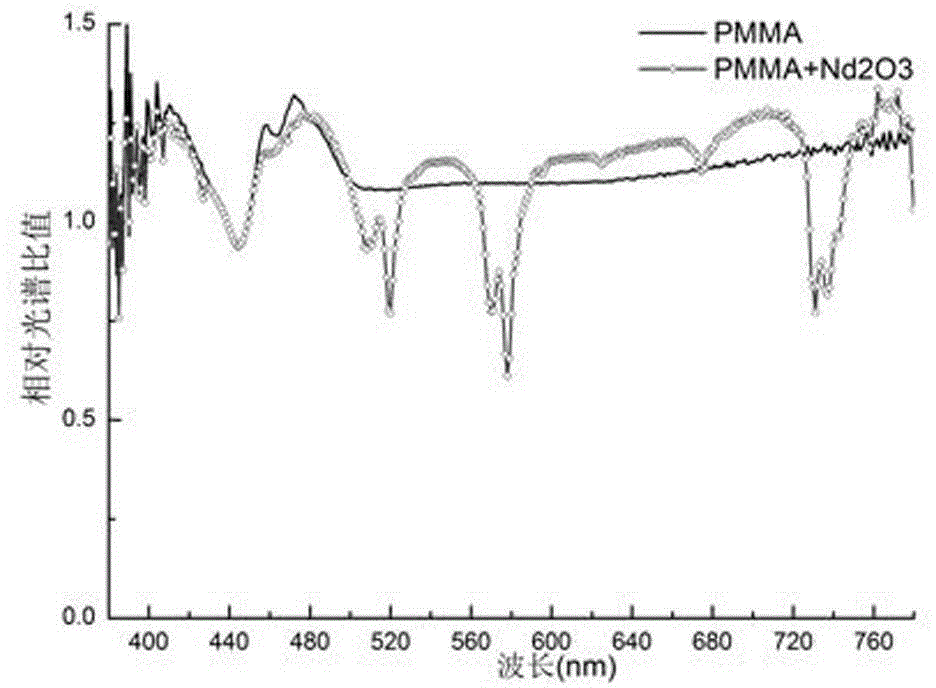

Embodiment 2

[0060] A kind of LED material that filters yellow light of the present embodiment, it comprises the raw material of following mass parts:

[0061] 70 parts of base material,

[0062] 5 parts of yellow light filter aid,

[0063] 0.2 parts of light diffusing agent,

[0064] Antioxidant 0.3 parts,

[0065] DP310 0.2 parts,

[0066] 10 parts deionized water,

[0067] Wherein, the yellow light filtering additive is neodymium oxide.

[0068] In this embodiment, the base material is PMMA.

[0069] In this embodiment, the light diffusing agent is a silicone light diffusing agent.

[0070] In this embodiment, the antioxidant is a mixture of 1076 and 168 in a mass ratio of 1:2.

[0071] A preparation method of an LED material for filtering yellow light in this embodiment comprises the following steps:

[0072] Step A. Disperse deionized water and filter yellow light additive in a large beaker by weight of the formula, and heat it to 85°C while stirring. After reaching the target...

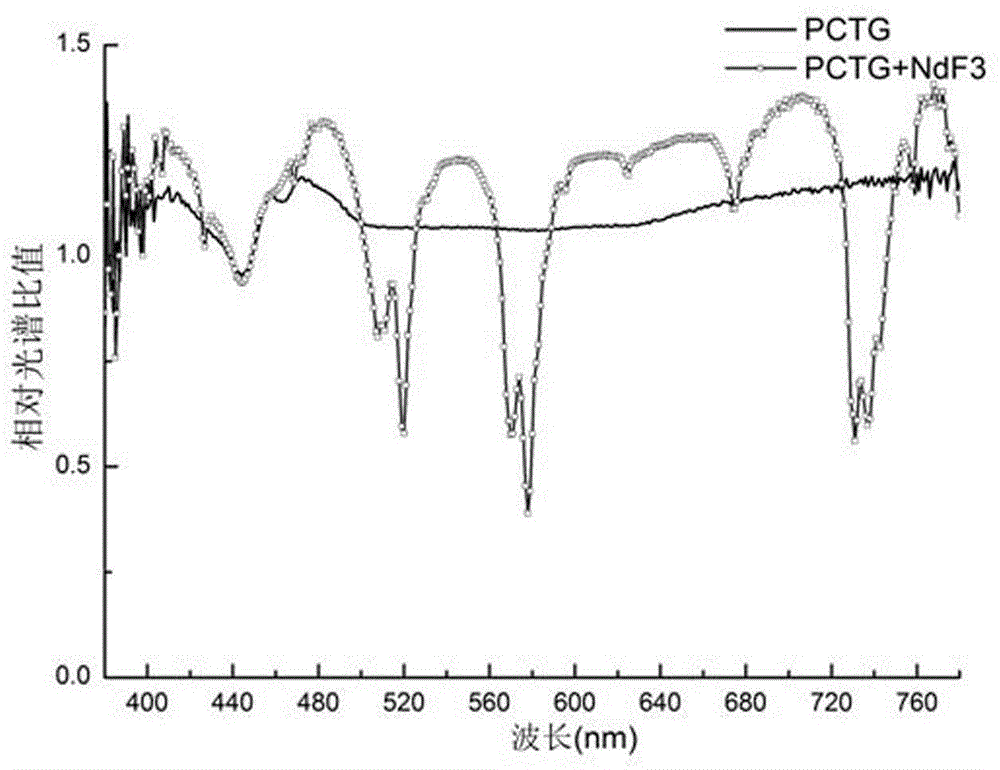

Embodiment 3

[0080] A kind of LED material that filters yellow light of the present embodiment, it comprises the raw material of following mass parts:

[0081] Base material 80 parts,

[0082] 7 parts of yellow light filter aid,

[0083] 0.4 parts of light diffusing agent,

[0084] Antioxidant 0.4 parts,

[0085] DP310 0.3 parts,

[0086] 15 parts of deionized water,

[0087] Wherein, the yellow light filtering additive is neodymium fluoride.

[0088] In this embodiment, the substrate is PCTG.

[0089] In this embodiment, the light diffusing agent is a silicone light diffusing agent.

[0090] In this embodiment, the antioxidant is a mixture of 1076 and 168 with a mass ratio of 2:1.

[0091] A preparation method of an LED material for filtering yellow light in this embodiment comprises the following steps:

[0092] Step A. Disperse deionized water and filter yellow light additive in a large beaker by weight of the formula, and heat it to 85°C while stirring. After reaching the targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com