Patents

Literature

70 results about "Cuprate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cuprate loosely refers to a material that can be viewed as containing anionic copper complexes. Examples include tetrachloridocuprate ([CuCl₄]²⁻), the superconductor YBa₂Cu₃O₇, and the organocuprates (e.g., dimethylcuprate [Cu(CH₃)₂]⁻). The term cuprates derives from the Latin word for copper, cuprum. The term is mainly used in three contexts - oxide materials, anionic coordination complexes, and anionic organocopper compounds.

Nitrogen oxide storage material and nitrogen oxide storing catalyst prepared therefrom

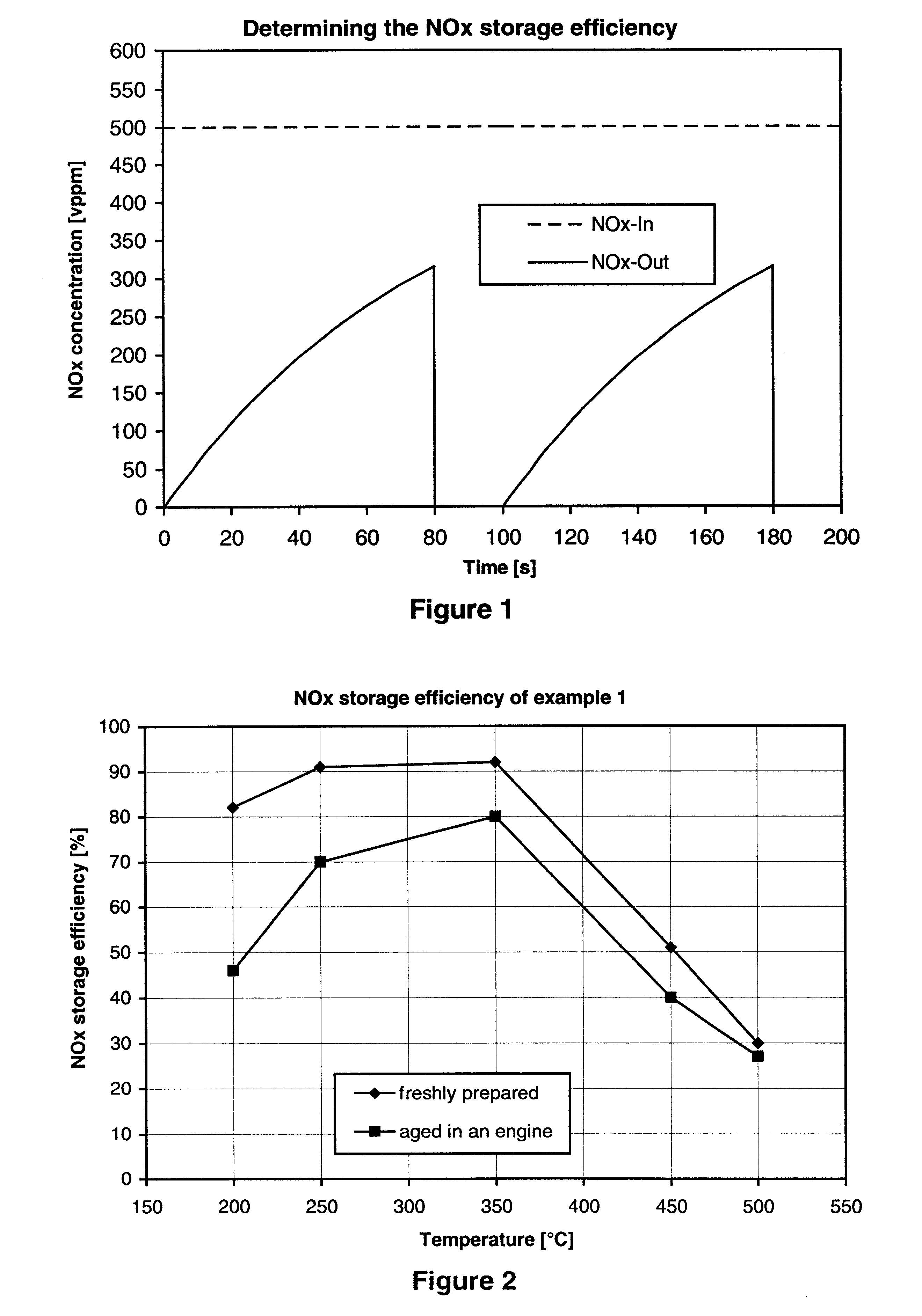

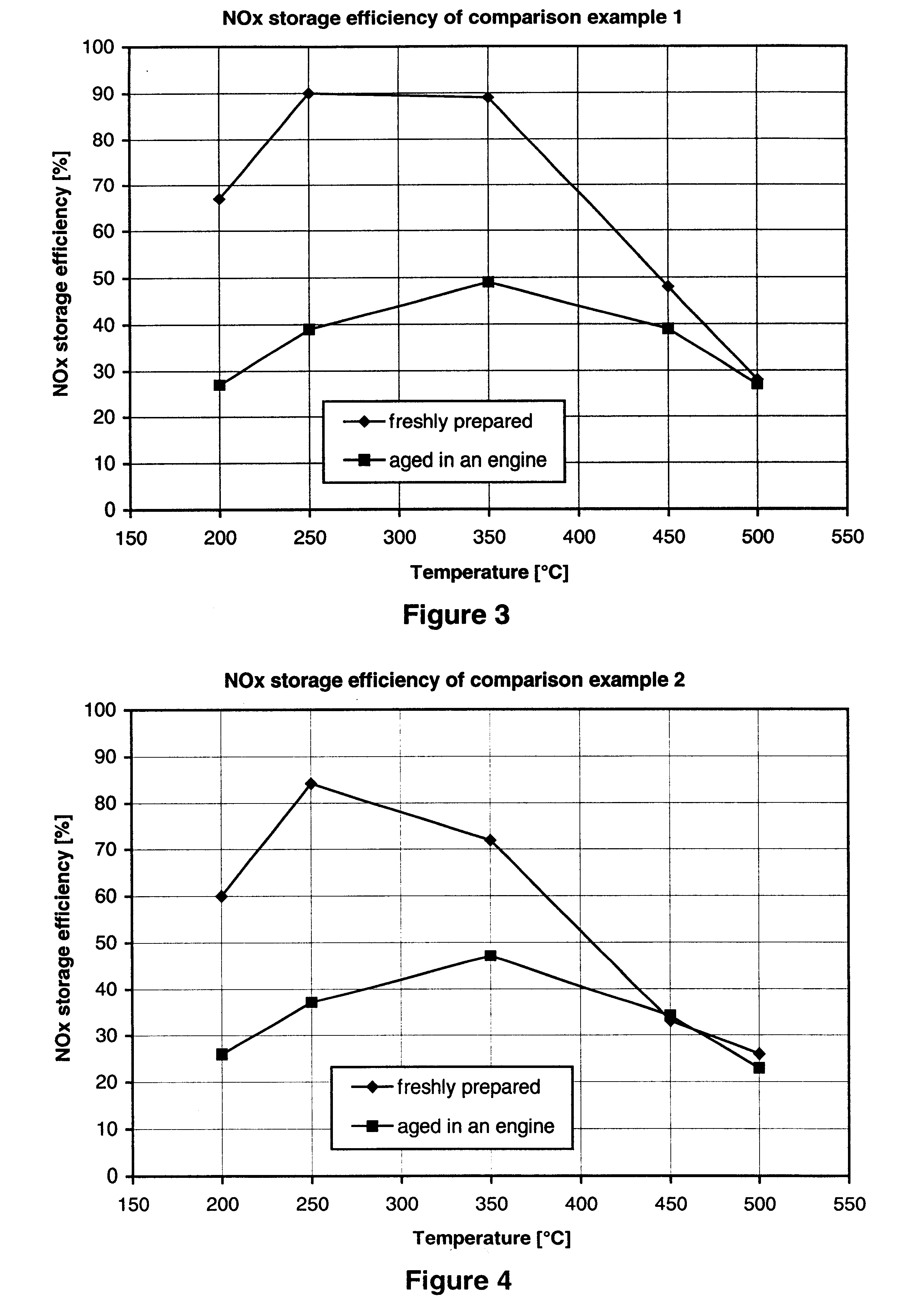

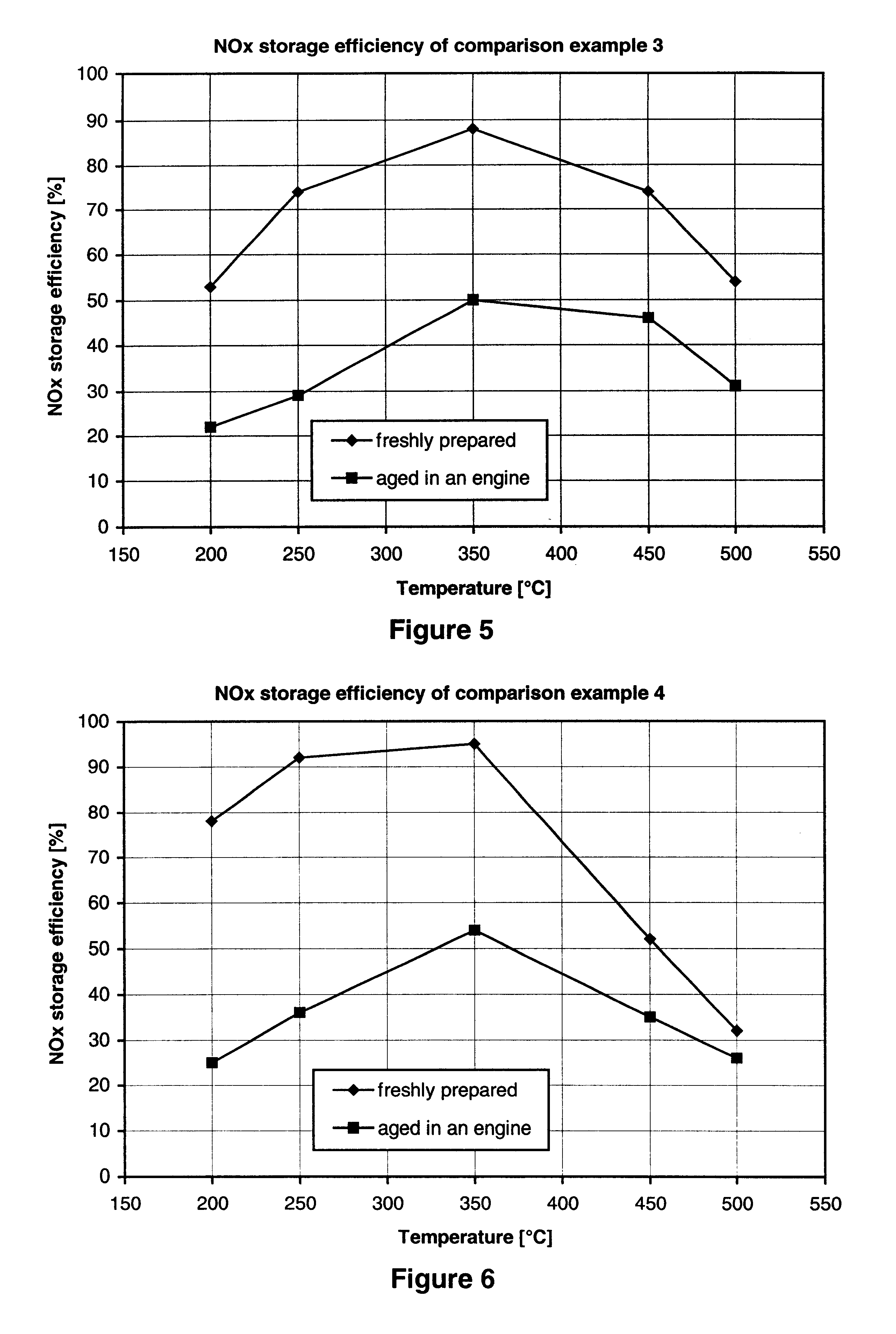

InactiveUS6350421B1Determine efficiencyNitrogen compoundsExhaust apparatusAlkaline earth metalCuprate

A nitrogen oxide storage material is disclosed which contains at least one storage component for nitrogen oxides in the form of an oxide, mixed oxide, carbonate or hydroxide of the alkaline earth metals magnesium, calcium, strontium and barium and the alkali metals potassium and caesium on a high surface area support material. The support material can be doped cerium oxide, cerium / zirconium mixed oxide, calcium titanate, strontium titanate, barium titanate, barium stannate, barium zirconate, magnesium oxide, lanthanum oxide, praseodymium oxide, samarium oxide, neodymium oxide, yttrium oxide, zirconium silicate, yttrium barium cuprate, lead titanate, tin titanate, bismuth titanate, lanthanum cobaltate, lanthanum manganate and barium cuprate or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

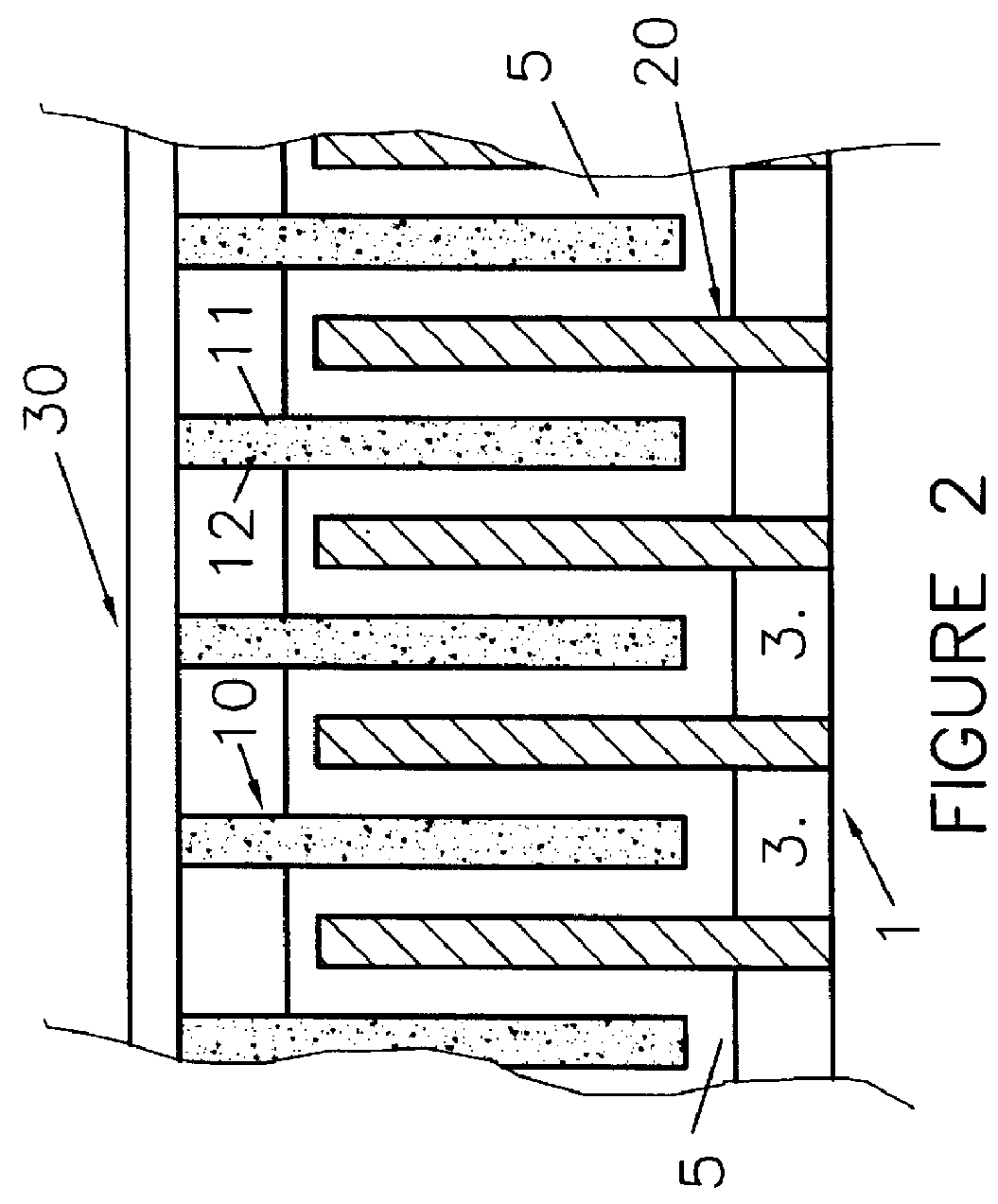

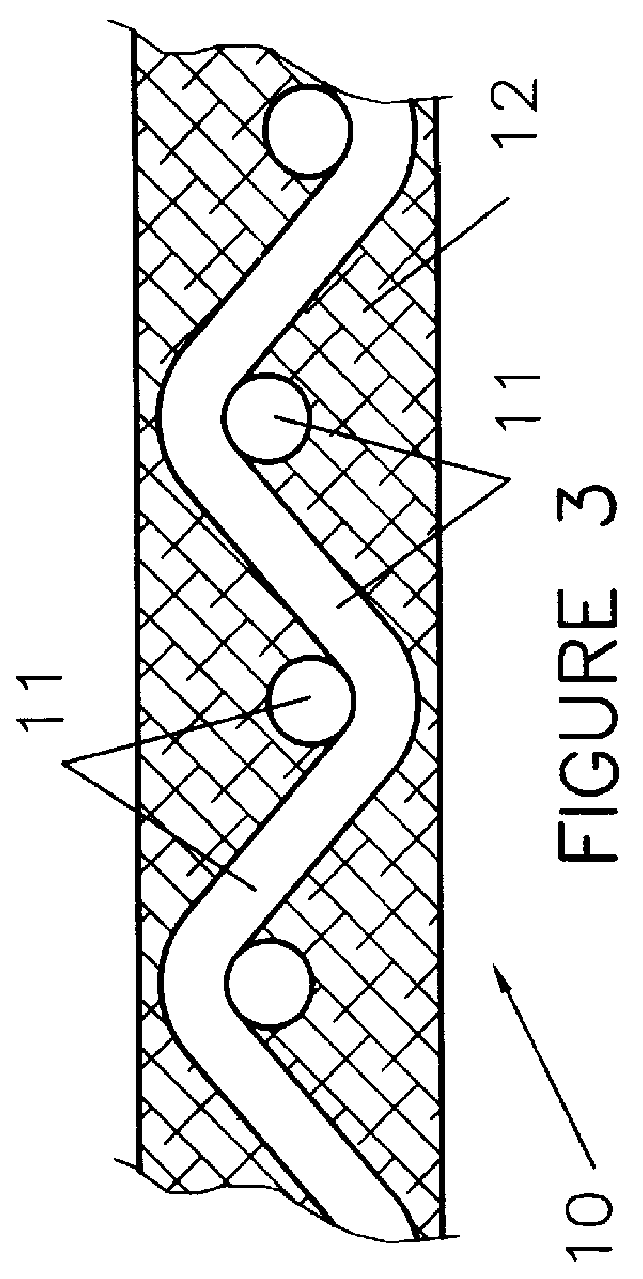

Porous non-carbon metal-based anodes for aluminium production cells

InactiveUS6113758AEliminate carbon-generated pollutionReduces high cell operating costMachining electrodesElectrical-based machining electrodesFiberCuprate

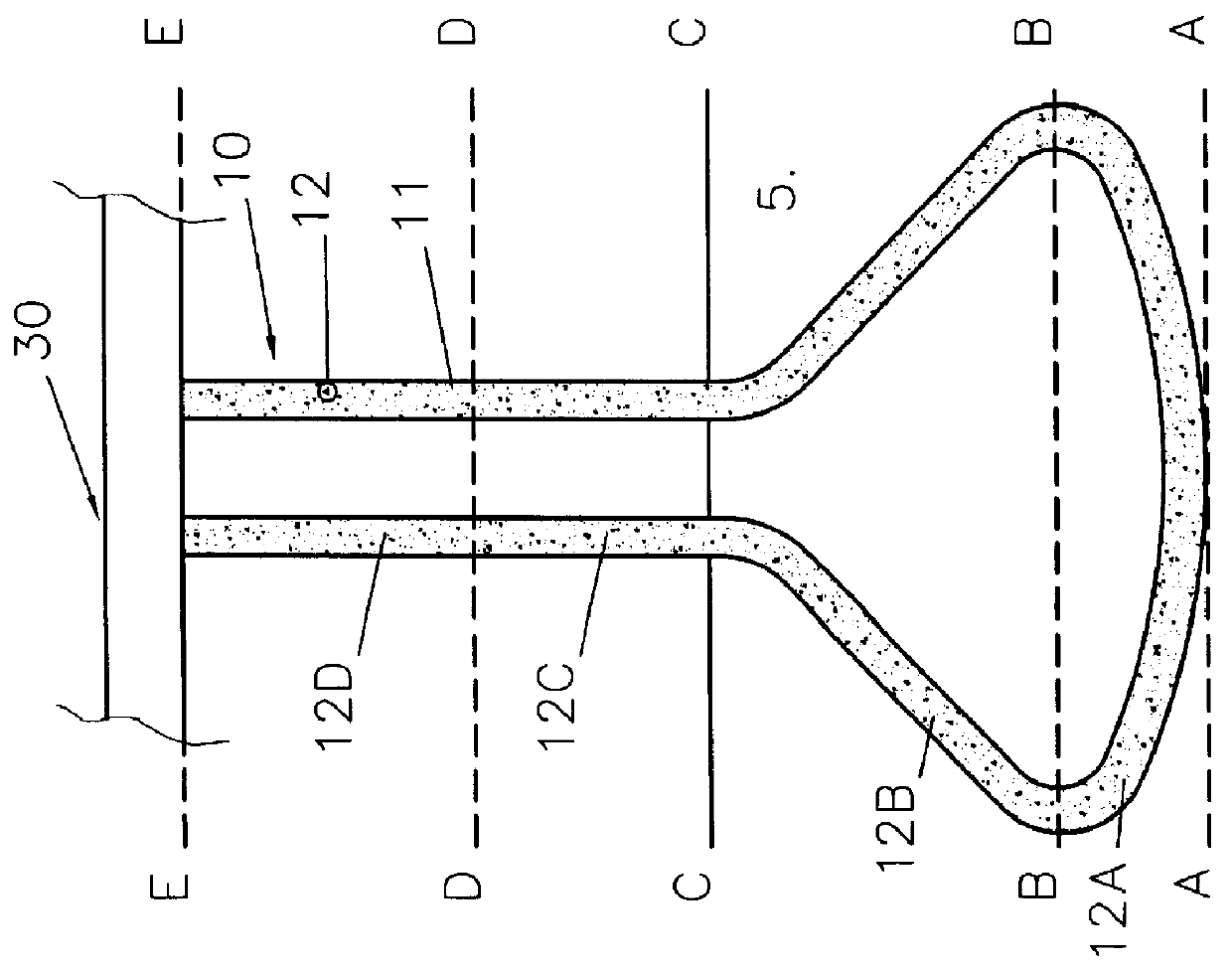

A non-carbon, metal-based anode (10) of a cell for the electrowinning of aluminium, comprising an electrically conductive, high temperature resistant and oxidation resistant metal structure (11) in the form of a wire mesh or net, a foraminate sheet, a fibrous network, a reticulated skeletal structure, or a porous structure having voids, recesses and / or pores which are filled or partly filled with an electrochemically active filling (12), such as oxides, oxyfluorides, phosphides, carbides, cobaltites and cuprates making the surface of the anode (10) conductive and electrochemically active for the oxidation of oxygen ions present at the anode surface / electrolyte (5) interface.

Owner:MOLTECH INVENT

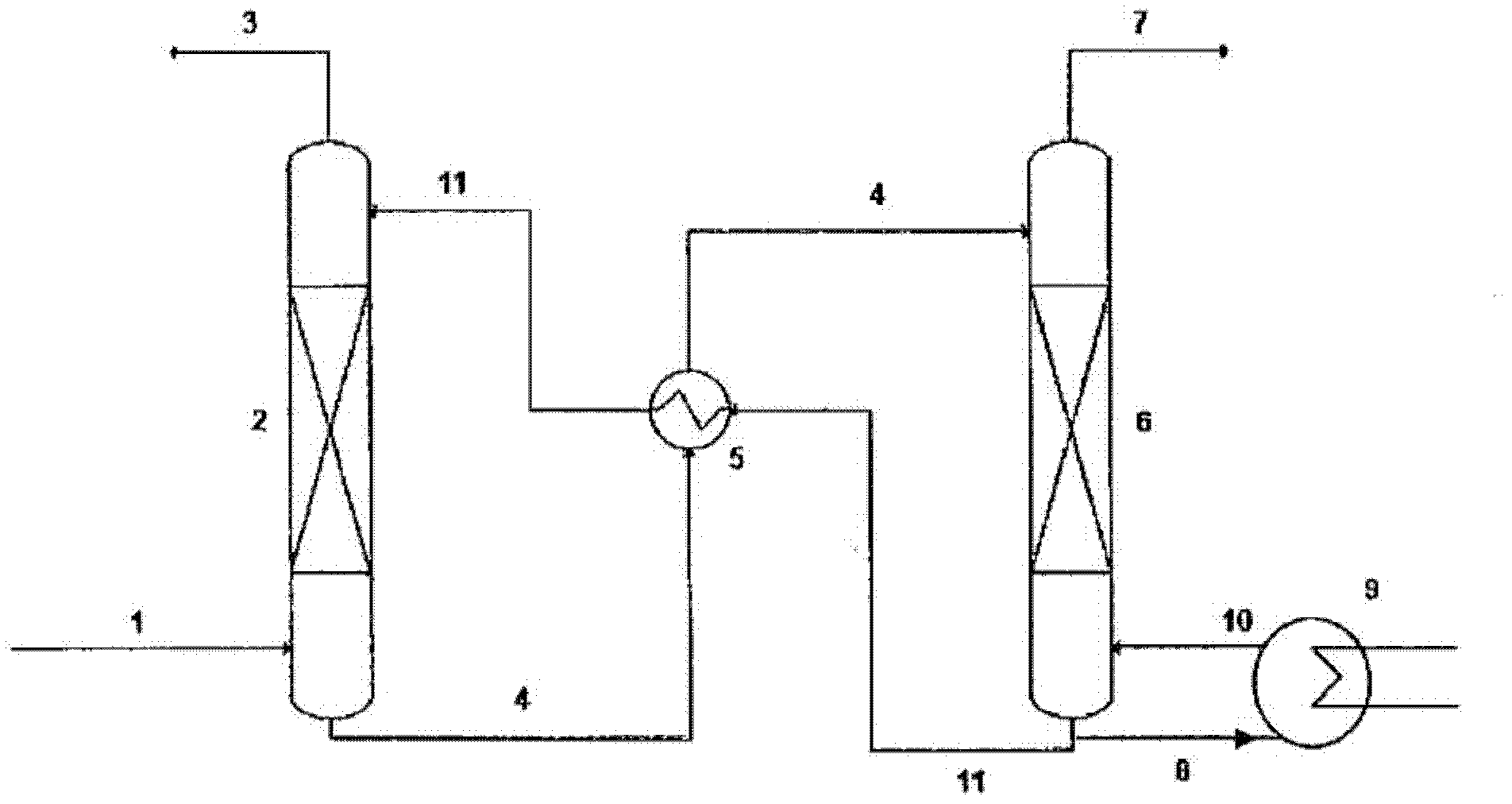

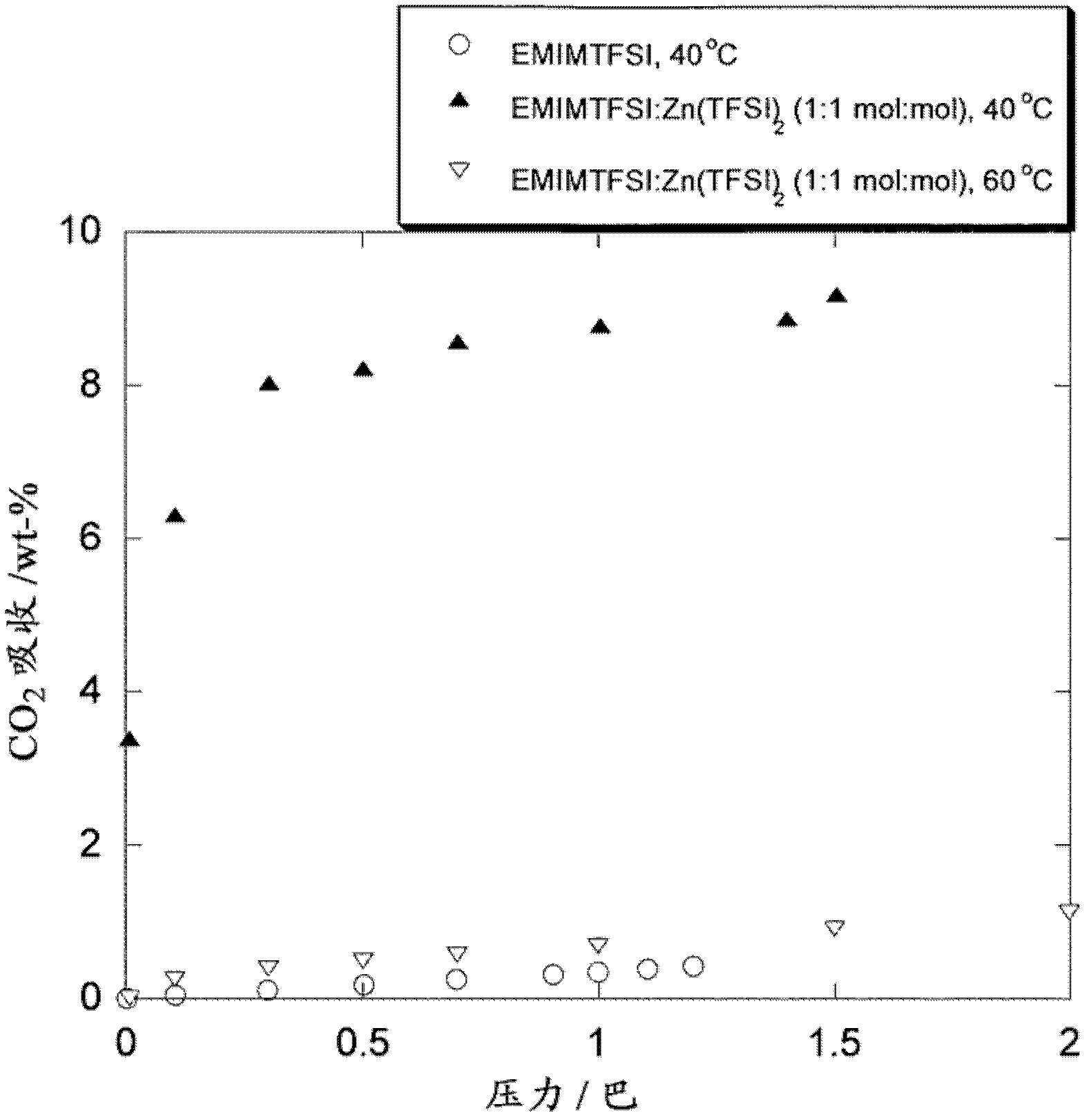

Ionic liquids

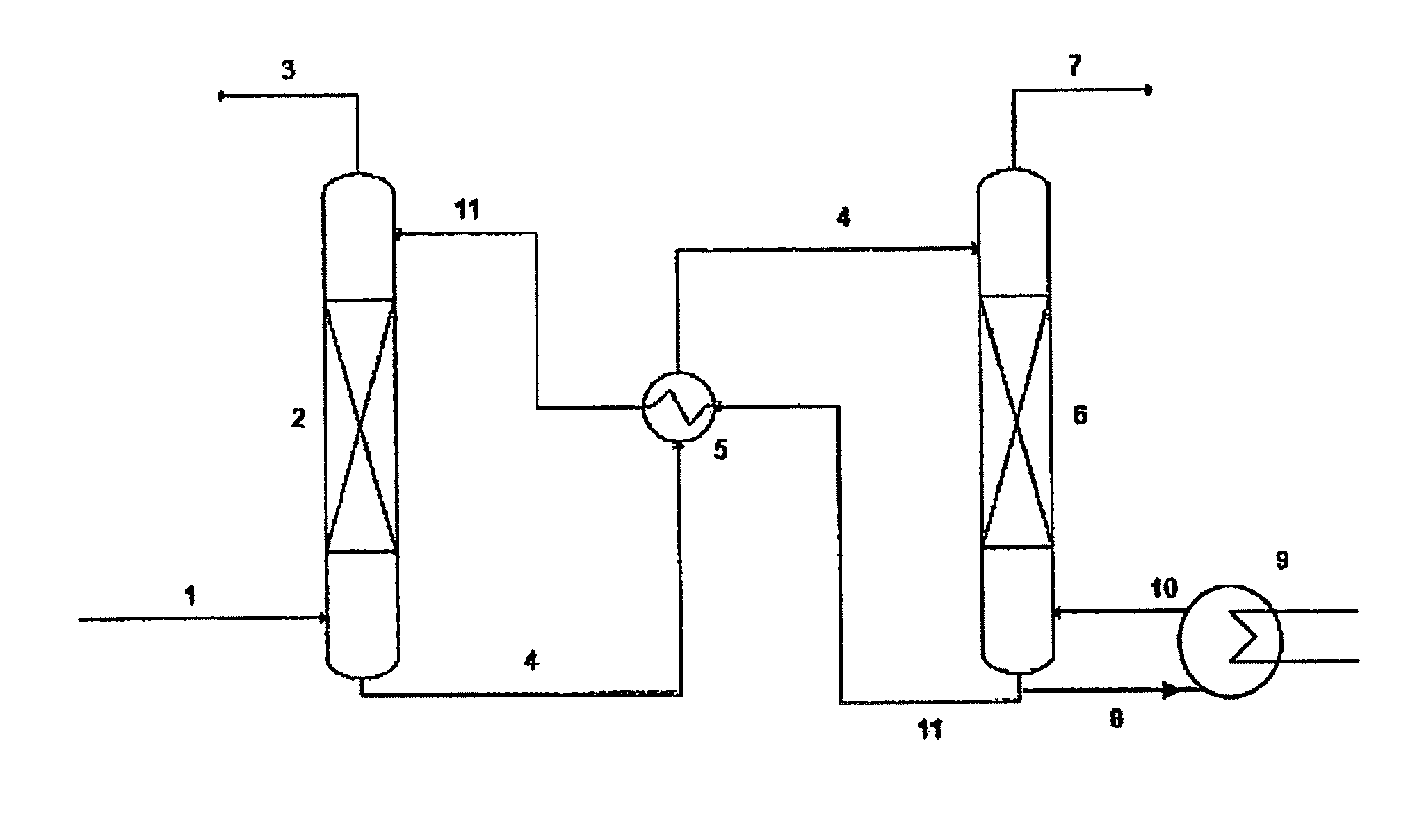

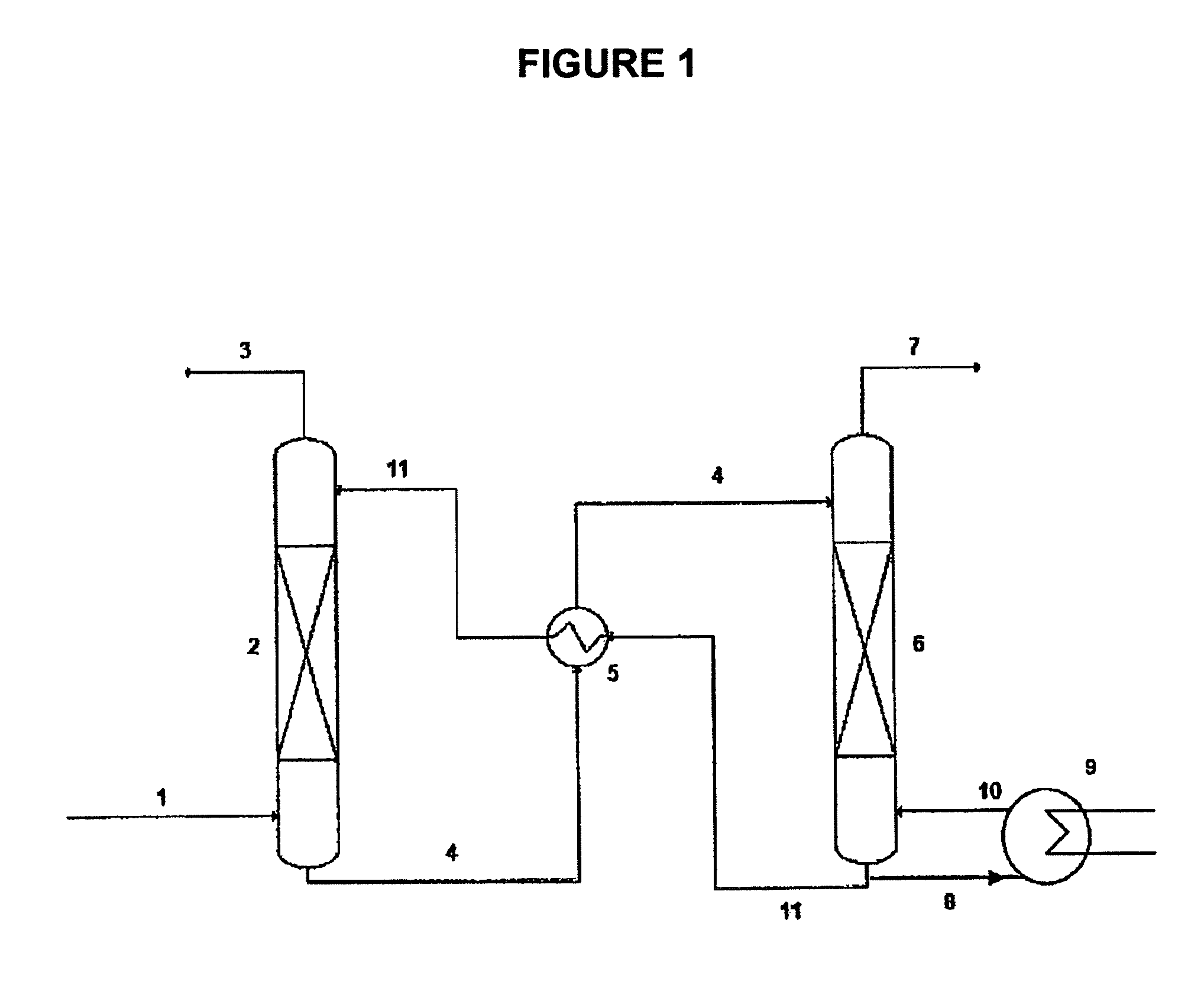

A process for the absorption of one or more gas(es) selected from the group consisting of carbon dioxide, hydrogen sulfide, sulfur oxides, nitrogen oxides and carbon monoxide from a fluid, the process including: providing a fluid containing the selected gas(es); and an ionic liquid absorbent, the absorbent including the components: one or more anions; one or more metal species; and optionally one or more organic cations; and optionally one or more ligands; the absorbent components being selected such that the absorbent is in a liquid state at the operating temperature and pressure of the process; with the provisos that: when the anion contains in the same molecular entity: both an amine functional group and a sulfonate functional group; both an amine functional group and a carboxylate functional group; both a phosphine functional group and a sulfonate functional group; or both a phosphine functional group and a carboxylate functional group, the metal species is not an alkali metal or alkaline earth metal; the anion and / or metal species do not form a cuprate; and when the anion and / or metal species form a metal halide, the ionic liquid absorbent includes one or more ligands; contacting the fluid with the ionic liquid absorbent such that the selected gas(es) interact with the metal species; and collecting an ionic liquid in which at least a portion of the selected gas(es) is absorbed.

Owner:COMMONWEALTH SCI & IND RES ORG

Ionic liquids

InactiveUS20120186993A1Nitrous oxide capturePolycrystalline material growthAlkaline earth metalCuprate

A process for the absorption of one or more gas(es) selected from the group consisting of carbon dioxide, hydrogen sulfide, sulfur oxides, nitrogen oxides and carbon monoxide from a fluid, the process including: providing a fluid containing the selected gas(es); and an ionic liquid absorbent, the absorbent including the components: one or more anions; one or more metal species; and optionally one or more organic cations; and optionally one or more ligands; the absorbent components being selected such that the absorbent is in a liquid state at the operating temperature and pressure of the process; with the provisos that: when the anion contains in the same molecular entity: both an amine functional group and a sulfonate functional group; both an amine functional group and a carboxylate functional group; both a phosphine functional group and a sulfonate functional group; or both a phosphine functional group and a carboxylate functional group, the metal species is not an alkali metal or alkaline earth metal; the anion and / or metal species do not form a cuprate; and when the anion and / or metal species form a metal halide, the ionic liquid absorbent includes one or more ligands; contacting the fluid with the ionic liquid absorbent such that the selected gas(es) interact with the metal species; and collecting an ionic liquid in which at least a portion of the selected gas(es) is absorbed.

Owner:COMMONWEALTH SCI & IND RES ORG

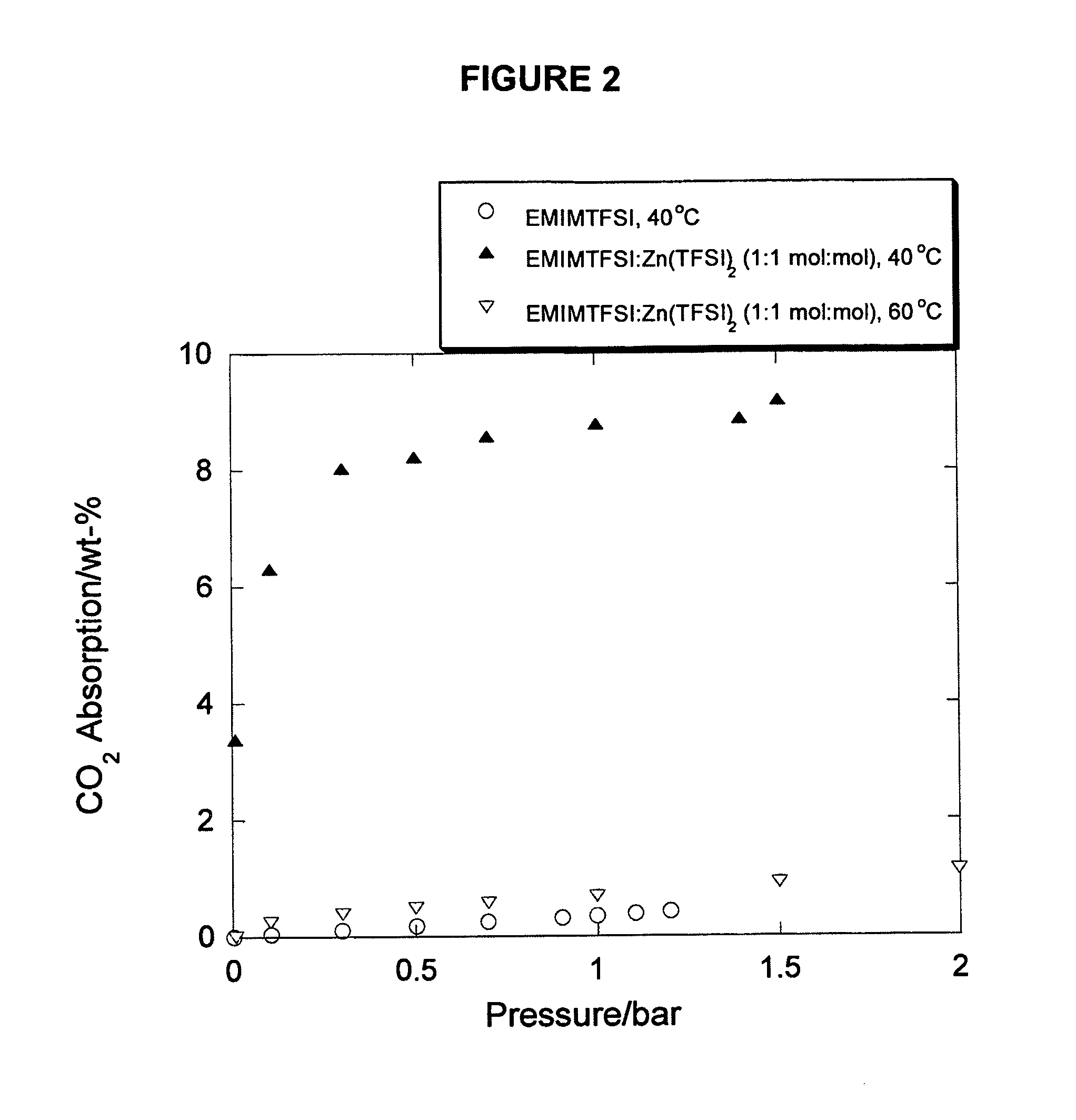

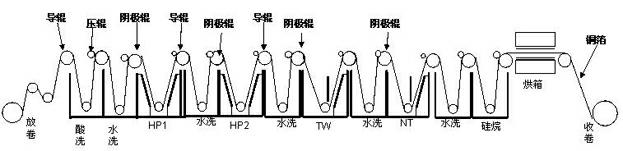

Additive for electrolytic copper foil and surface treatment process of very low profile electrolytic copper foil

ActiveCN102560584AEnhanced depth capabilitiesMicrocrystalline effectInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentElectrolysisMolybdate

The invention belongs to the technical field of electronic materials, particularly relates to a surface treatment process of a very low profile electrolytic copper foil, in particular to an additive used during the surface treatment of the very low profile electrolytic copper foil. The additive is composed of three components: titanous sulfate, titanium sulfate and molybdate, wherein the contents of the three components in the electroplate liquid are respectively 50-150mg / L, 150-250mg / L and 70-118mg / L (molybdate radical). The additive is used to be added into a microcrystalline coarsening slot; and the three components are used cooperatively, so that the treated copper foil coarse layer crystalline grains are small and dense, achieving a microcrystalline effect. In the invention, the addition amount of each additive and proper electroplating process conditions such as content of cuprate, temperature and current density are found out in the coarsening slot for the surface treatment, so that the treated 18-micron very-low profile electrolytic copper foil can meet the following technical indicators: the anti-stripping strength is equal to or greater than 1.0kg / cm and the value of surface roughness Rz is smaller than or equal to 5.1 microns.

Owner:惠州联合铜箔电子材料有限公司

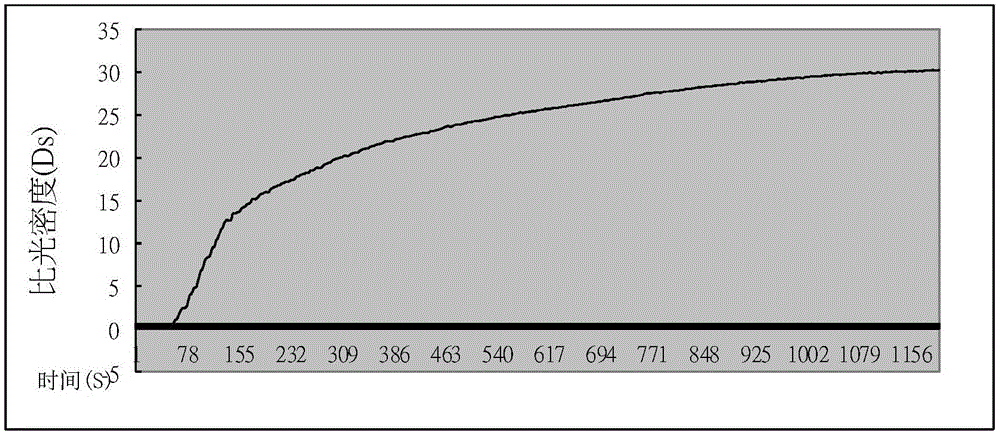

Intercalated layered double hydroxide smoke inhibitor and preparation method thereof

The invention discloses an intercalated layered double hydroxide smoke inhibitor and a preparation method thereof. The smoke inhibitor is a layered structural material formed by assembling a laminated sheet consisting of metal cations and interlayer anions, wherein a specific composition general formula of the smoke inhibitor is M<2+>1-xM<3+>x(OH)2(A<n->)n / 2.mH2O. According to the preparation method disclosed by the invention, the intercalated layered double hydroxide smoke inhibitor is prepared by adopting a one-step coprecipitation method or a clean hydrothermal reaction at one step; the preparation method is simple and practical; according to the obtained intercalated layered double hydroxide smoke inhibitor, smoke inhibiting groups such as molybdate anions, an octamolybdate radical, a cuprate radical and a stannate radical are arranged at an interlayer, and smoke inhibiting elements such as iron and copper are introduced into the laminated sheet, so that a good carbon forming effect is realized, the smoke generating amount can be reduced, and the smoke inhibiting effect is synergically enhanced; meanwhile, a layered double hydroxide laminated sheet forms an alkaline porous substance at high temperature; the alkaline porous substance has greater specific surface area and can effectively adsorb smog; the prepared intercalated layered double hydroxide smoke inhibitor is applied to an ordinary rubber-plastic product and a high-temperature rubber-plastic product; the maximum density (Ds, max) at low additive amount (1phr) can be reduced by 87.3 percent; the intercalated layered double hydroxide smoke inhibitor is remarkable in smoke inhibiting effect and is a smoke inhibitor material with excellent performance.

Owner:BEIJING UNIV OF CHEM TECH

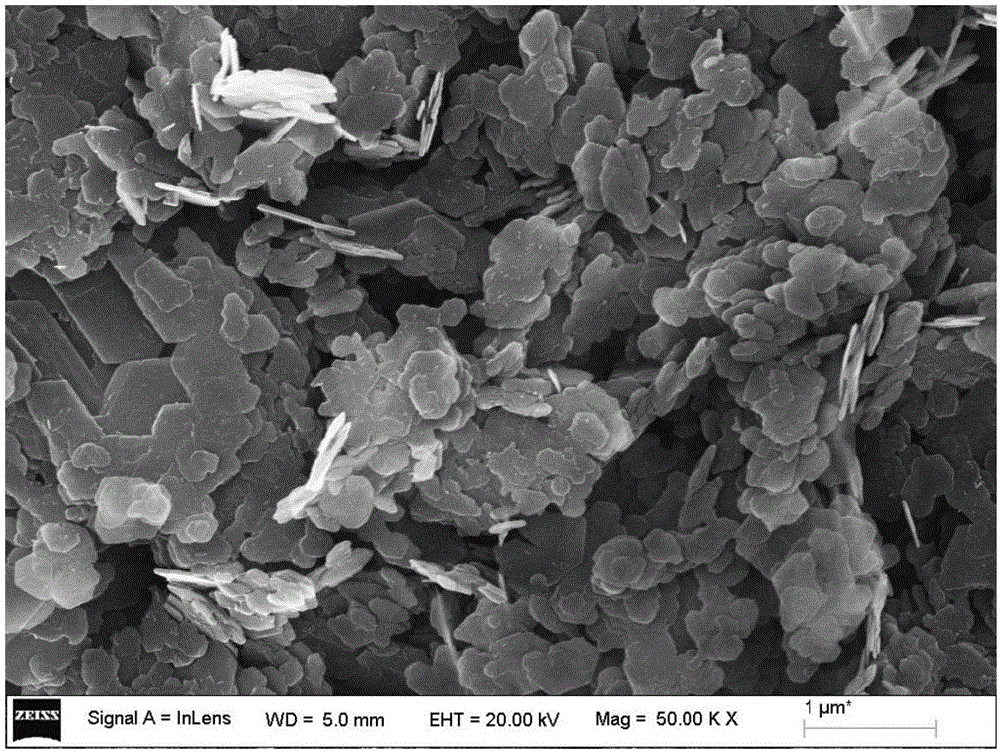

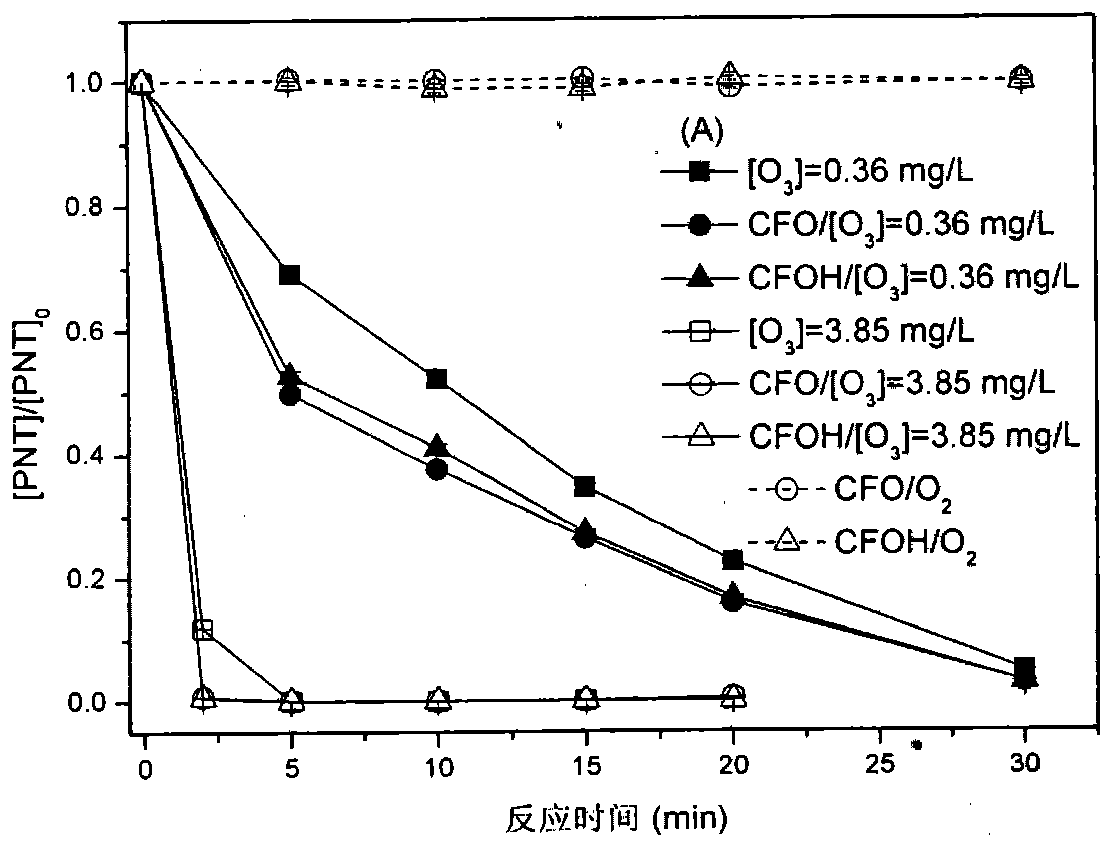

Preparation of magnetic nano copper-iron oxyhydroxide and application thereof to pollution removal by catalytic ozonation

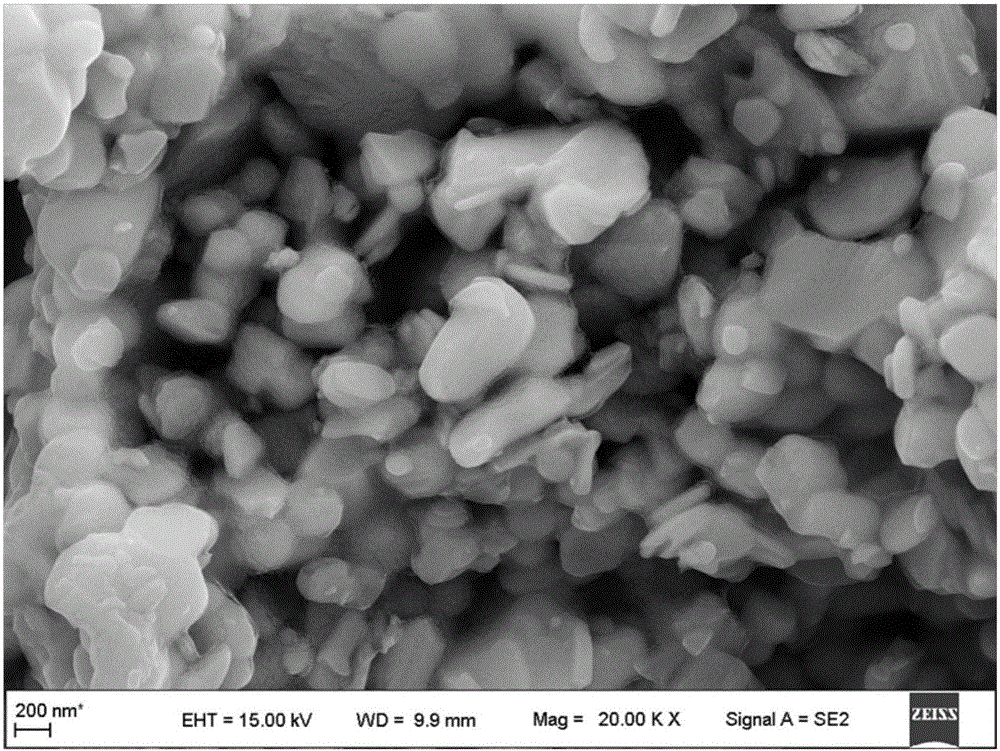

ActiveCN104069860ARich reservesEasy to getWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsIron saltsCuprate

The invention provides a preparation method for a catalyst which is used for purifying a water body containing pharmaceutical and personal care products (PPCPs) including phenacetin and the like, aiming at the disadvantages and the defects of an existing water treatment technology for removing trace phenacetin in water. A magnetic nano copper-iron oxyhydroxide catalyst takes an iron salt and cuprate as key active components to integrate the surface characteristics of binary metal oxyhydroxides including Fex(OH)y and Cux(OH)y; the catalyst has a large specific surface area; meanwhile, the high surface hydroxyl density is the other important factor for providing the catalytic activity. More importantly, the magnetic nano copper-iron oxyhydroxide has the magnetism and the powdery catalyst is separated from a water phase by adopting a magnetic field. The catalyst can be applied to a catalytic ozonation technology so as to effectively improve the removing effects of the PPCPs including the phenacetin and the like in the water body; the phenacetin pollution removing effect is realized so as to obtain high-quality and stable output water; the catalyst has a wide application prospect.

Owner:BEIJING FORESTRY UNIVERSITY

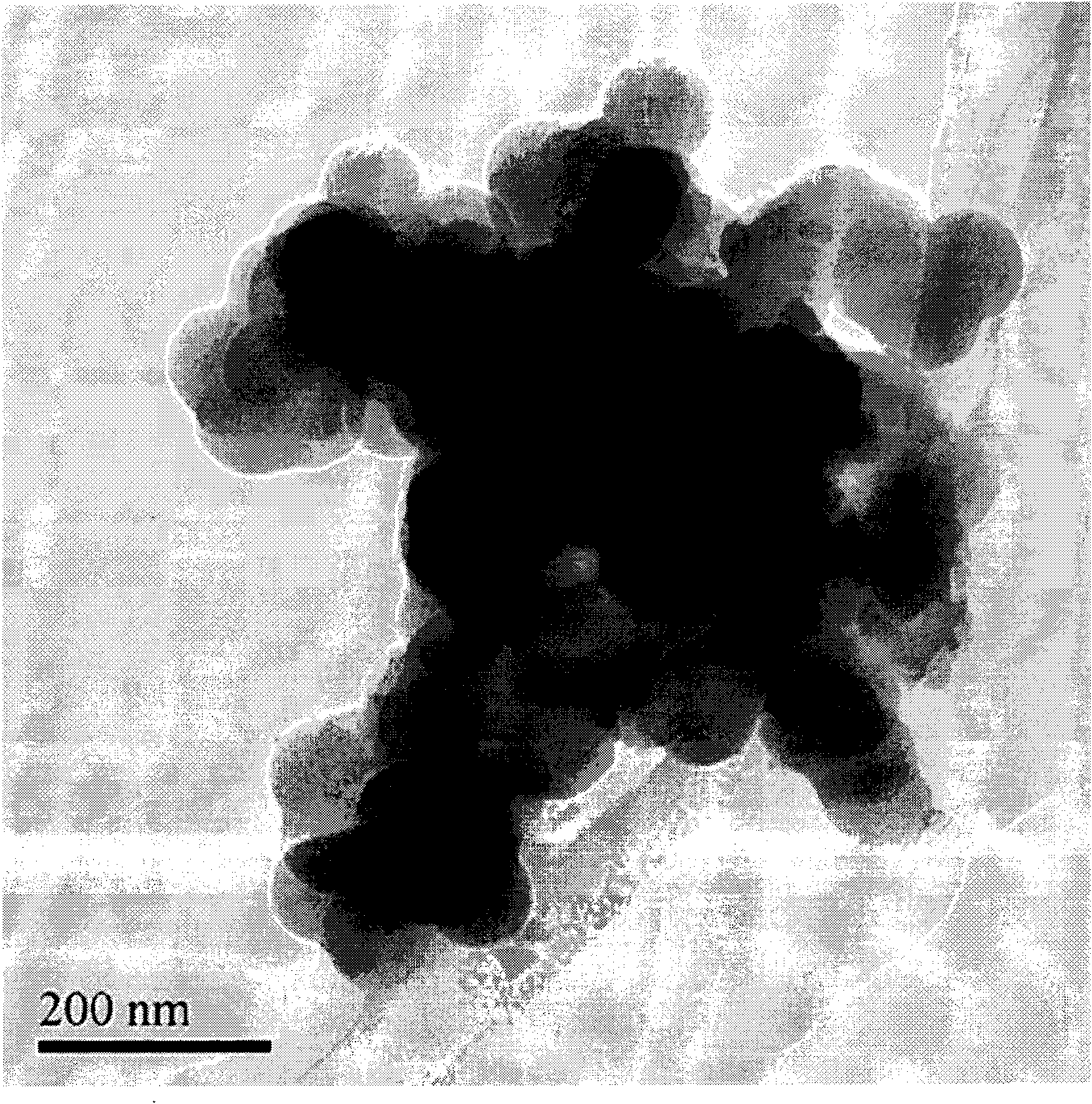

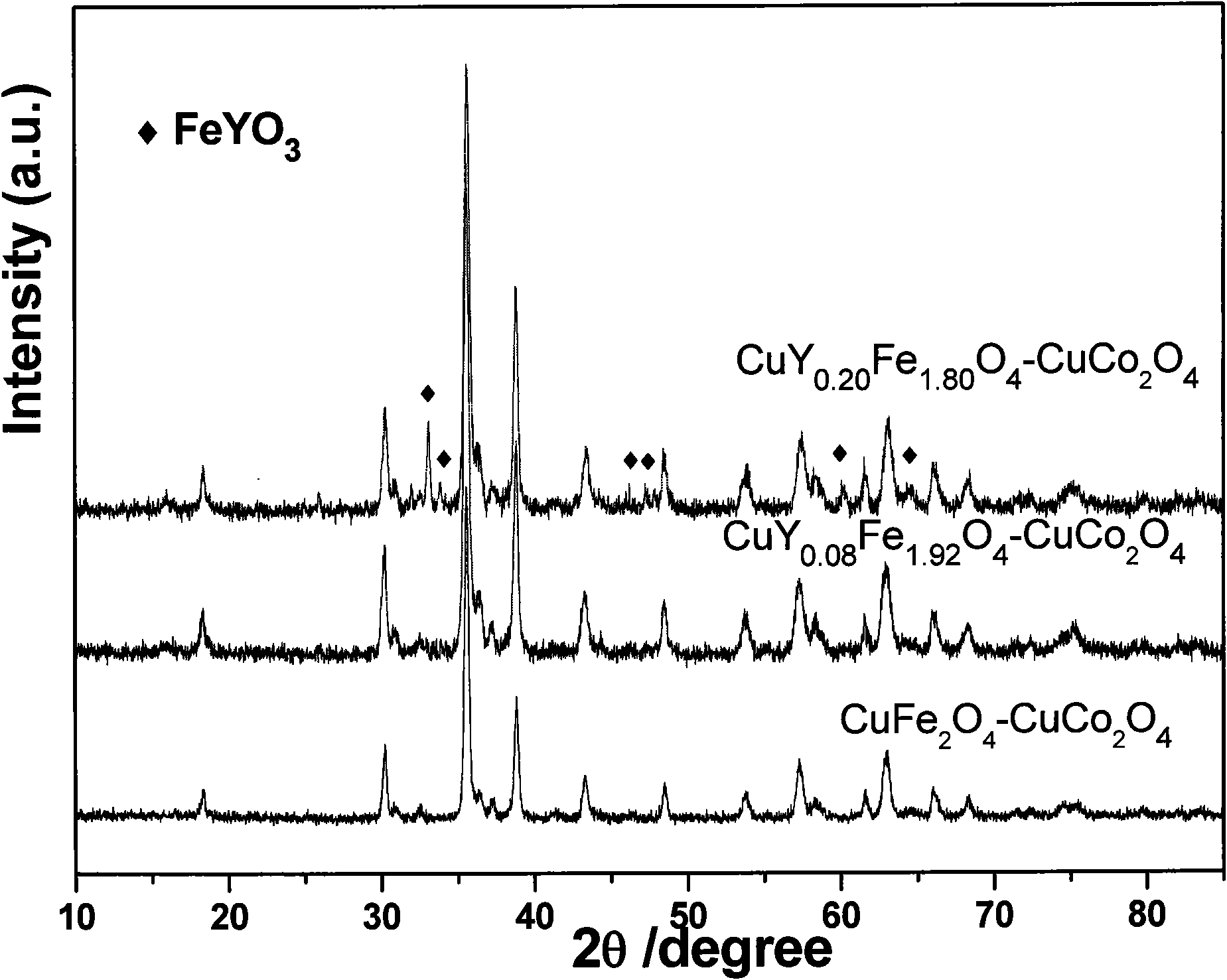

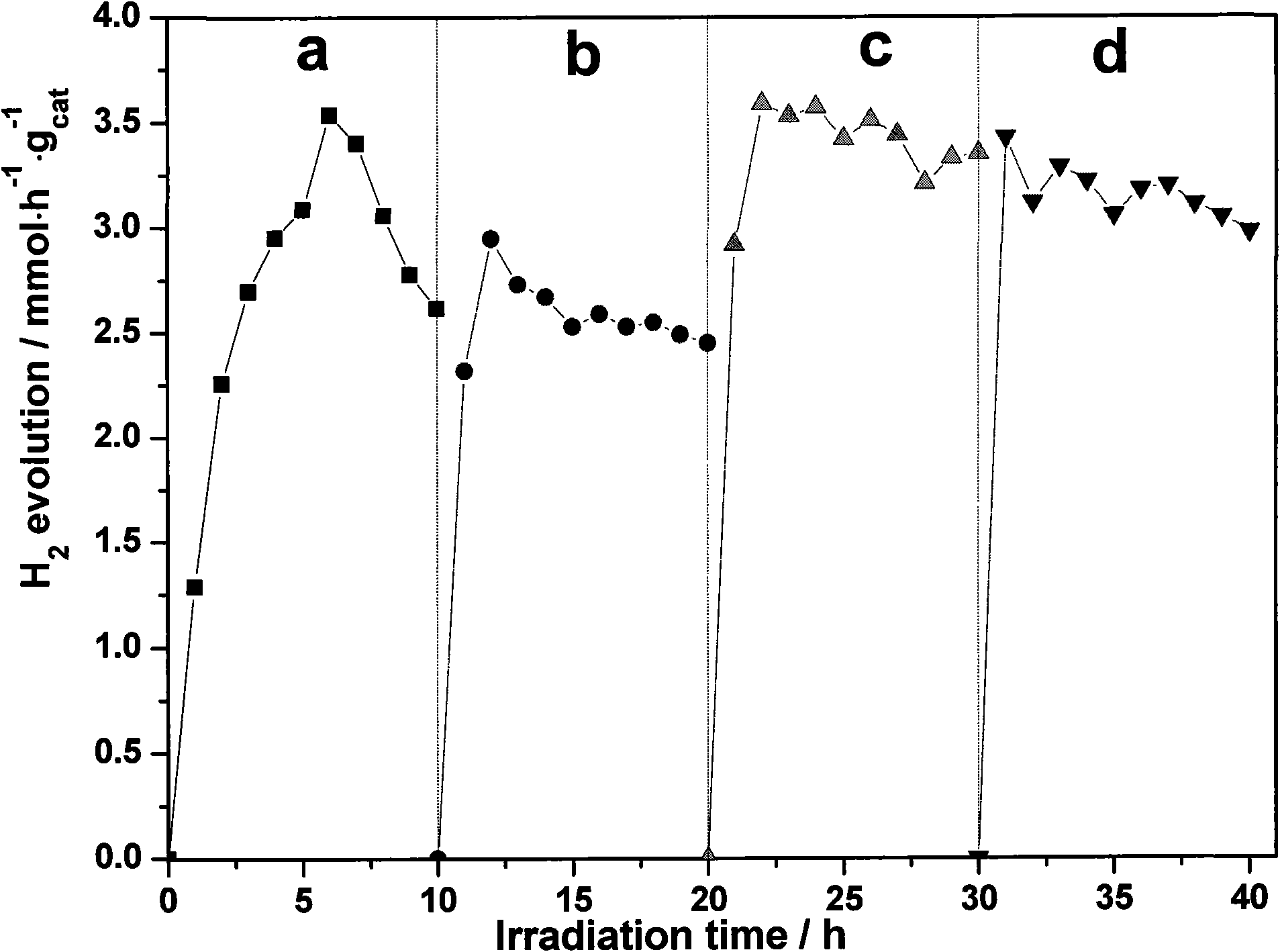

Preparation of visible light response composite cuprate photocatalysis material and application thereof

InactiveCN101623638AStable in natureExtended service lifeHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsWater bathsCuprate

The invention relates to a method for preparing yttrium-doped copper ferrite- copper cobalt composite photocatalyst, comprising: adding ferric nitrate, cobalt nitrate and yttrium nitrate into copper nitrate solution, and obtaining a mixed cuprate solution; under the agitation in water bath, dripping citric acid solution into the newly prepared mixed cuprate solution to obtain transparent colloidal sol; continuously heating the transparent colloidal sol in the water bath to obtain gel; transferring the gel into a drying oven and drying at a certain temperature to obtain precursor, and obtaining the yttrium-doped copper ferrite- copper cobalt composite photocatalyst by calcination. The photocatalyst has the best mole ratio of 1: 1 between Fe and Co and the best yttrium-doped quantity being 4% (mole percentage) of Fe, and is good in photocatalysis hydrogen production activity under visible light. The photocatalyst has good application prospect in the aspect of hydrogen production of visible light catalytic material, simple technique, convenient operation, lower cost and long service life.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

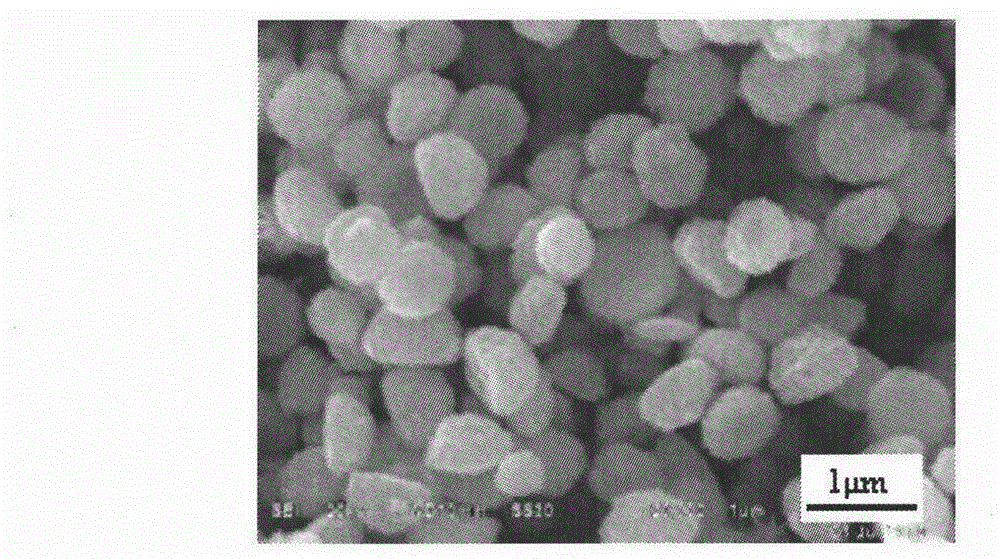

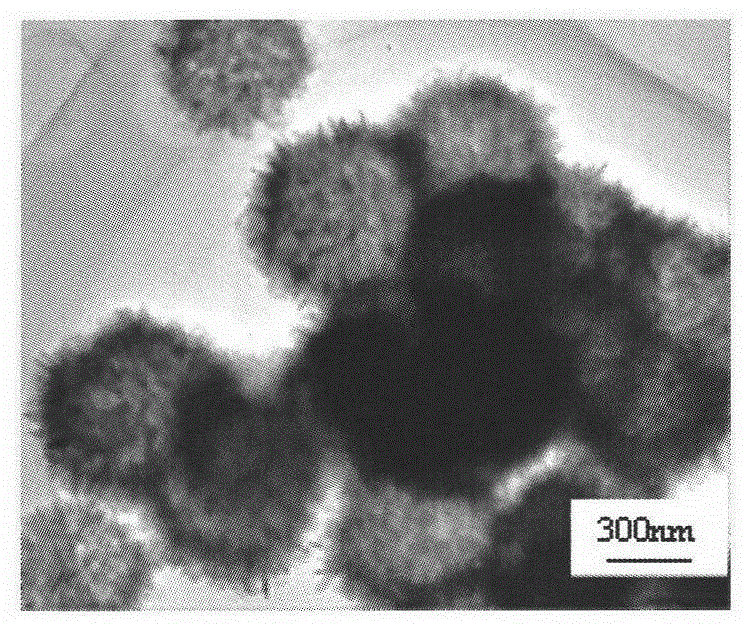

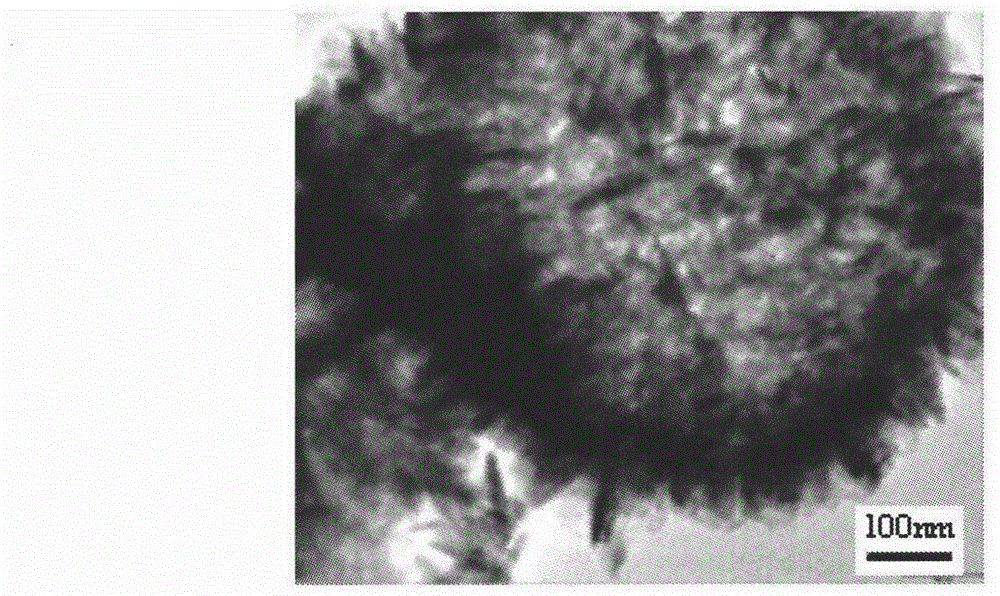

Preparation method for chestnut-shaped copper sulphide hollow micron sphere composed of nanosheets

The invention provides a preparation method for a chestnut-shaped copper sulphide hollow micron spheres composed of nanosheets. The method comprises the steps of dissolving soluble cuprate through deionized water, adding ethaidene diamine (en), obtaining a [Cu(en)2]2+ solution, mixing a surface active agent, cosurfactant and an oil phase with the [Cu(en)2]2+ solution, heating and stirring the mixed solution, obtaining reversed-phase microemulsion containing the [Cu(en)2]2+, adding CS2 into the reversed-phase microemulsion containing the [Cu(en)2]2+, after stirring and hydro-thermal treatment, cooling and centrifugally separating the microemulsion, obtaining black precipitation, washing and drying the precipitation, and obtaining the hexagonal-phase chestnut-shaped copper sulphide hollow micron spheres with the diameter of 0.5 to 0.9 micron. Each chestnut-shaped copper sulphide hollow micron sphere is composed of single crystal nanosheets with the length of 50 to 190nm, the width of 10 to 20nm and the thickness of 2 to 4nm. Products manufactured by the method are controllable in particle size and shape, good in dispersity and free of agglomeration. The method has the advantages that production technology is simple, reaction parameters are easy to control, implementation cost is low, and large-scale industrial production is prone to achievement. The method can be widely used for preparation of metal sulfide nanostructure materials with special shapes.

Owner:XIANGTAN UNIV

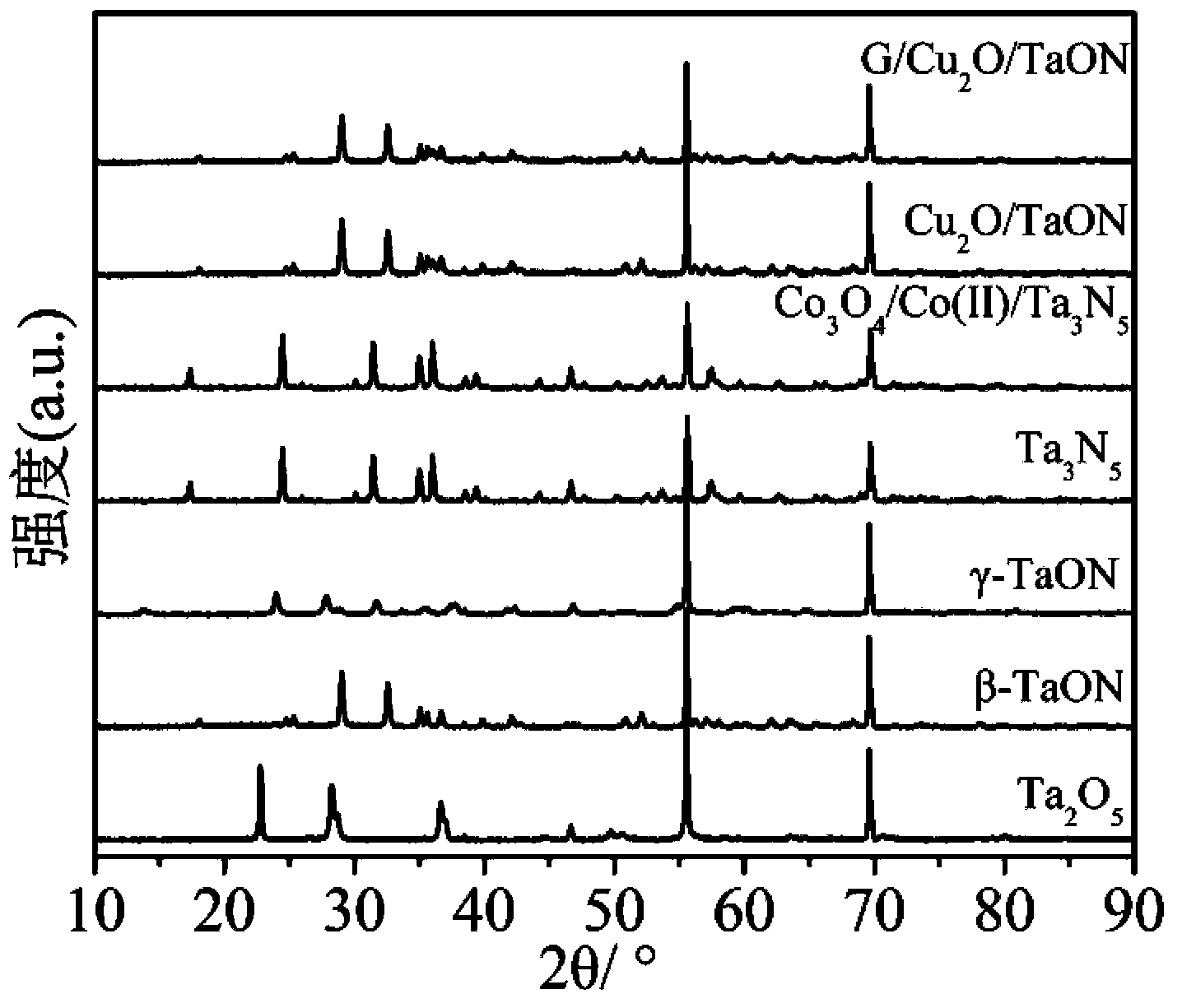

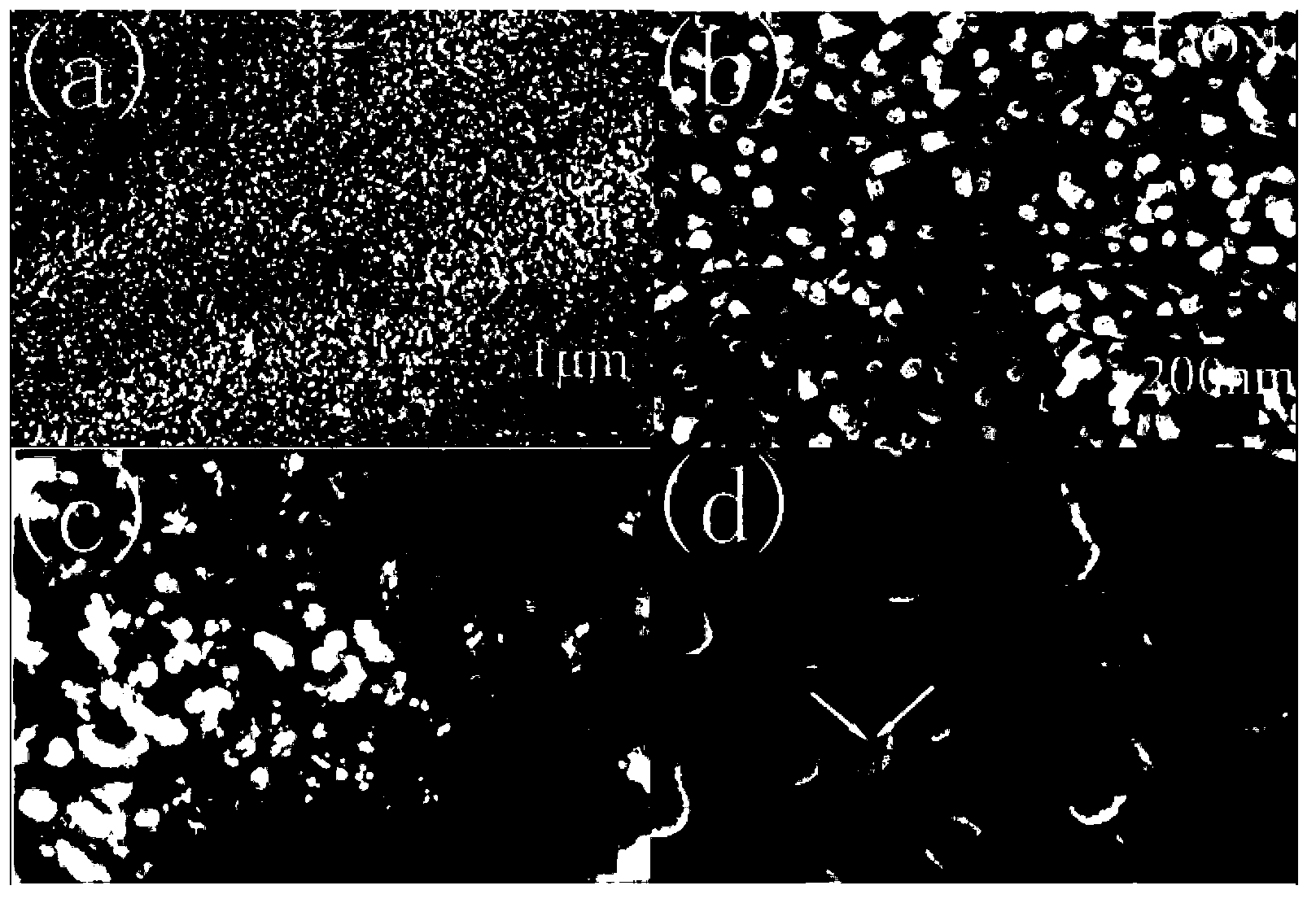

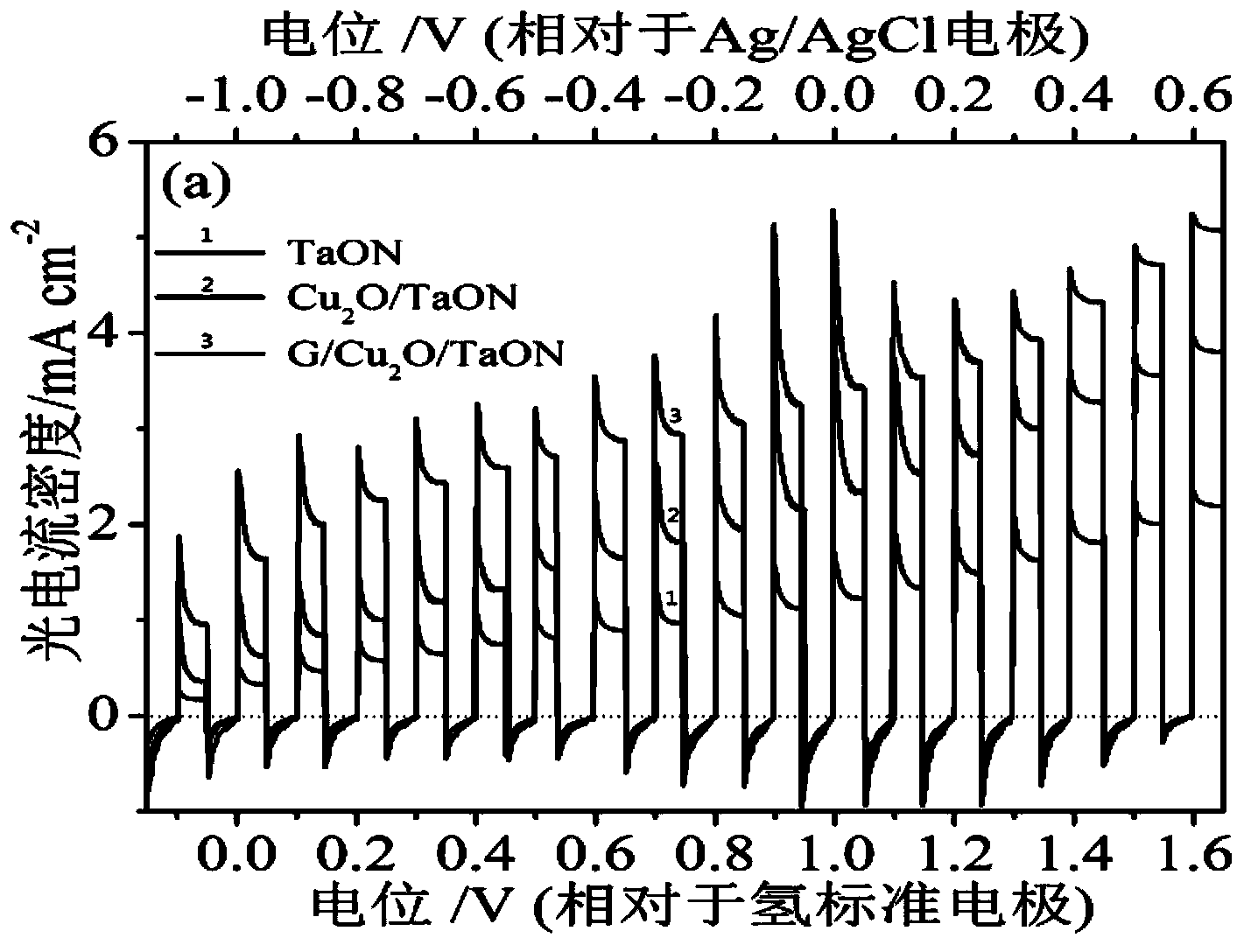

Preparation method of low-dimensional tantalum-based nano-array photo-electrode

InactiveCN103352211AHigh Oxygen Quantum EfficiencyElectrical apparatusEnergy inputWater vaporCuprate

The invention relates to a preparation method of a low-dimensional tantalum-based nano-array photo-electrode. The invention belongs to the field of solar energy, photo-catalyzing, and photochemical material. A metal tantalum foil is adopted as an initial raw material, and is mixed with hydrofluoric acid, hydrogen peroxide, cobaltate, cuprate, and the like; a constant-temperature reaction is carried out in an autoclave, such that a metal-oxide-loaded photo-electrode with the tantalum foil as a substrate and with a low-dimensional tantalum-based nano-array uniformly grown on the surface is obtained; the photo-electrode is washed by using ethanol and water, and is dried; the photo-electrode is further delivered into a heat treatment furnace, such that nitriding heat treatment is carried out; through the controlling over the ratio and flow rates of ammonia and water vapor, and through different periods of time, oxynitride and nitride array photo-electrodes with different nitrogen contents can be obtained; with a spin-coating method, graphene or nitrogen-doped graphene is uniformly covered on the surface of the nano-array. The photoelectric conversion efficiency of the tantalum-based composite nano-array photo-electrode is substantially improved. The visible-light-response tantalum-based composite nano-array photo-electrode provided by the invention has high Light-quantum conversion efficiency, and can be used in solar energy conversion and utilization.

Owner:UNIV OF SCI & TECH BEIJING

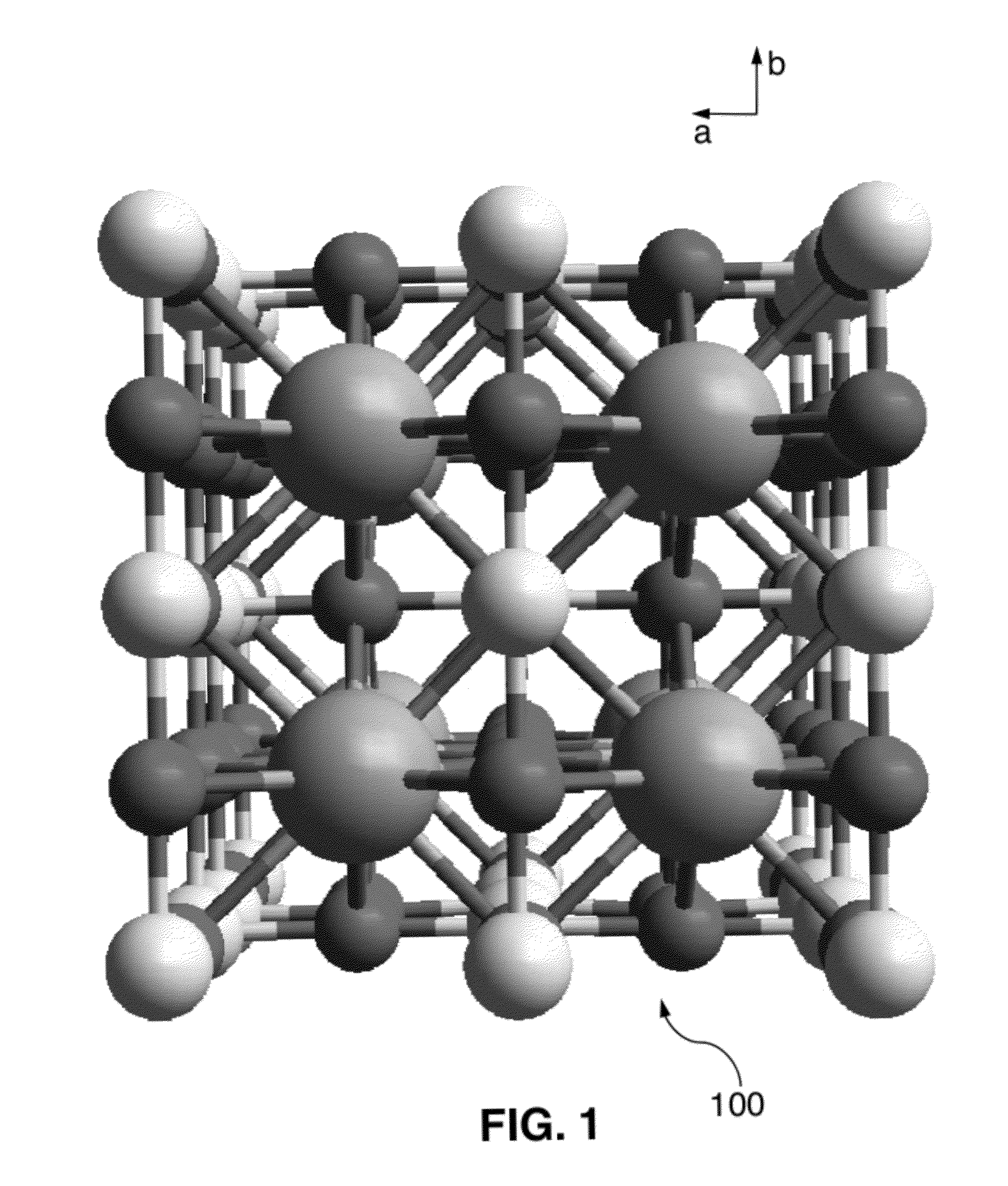

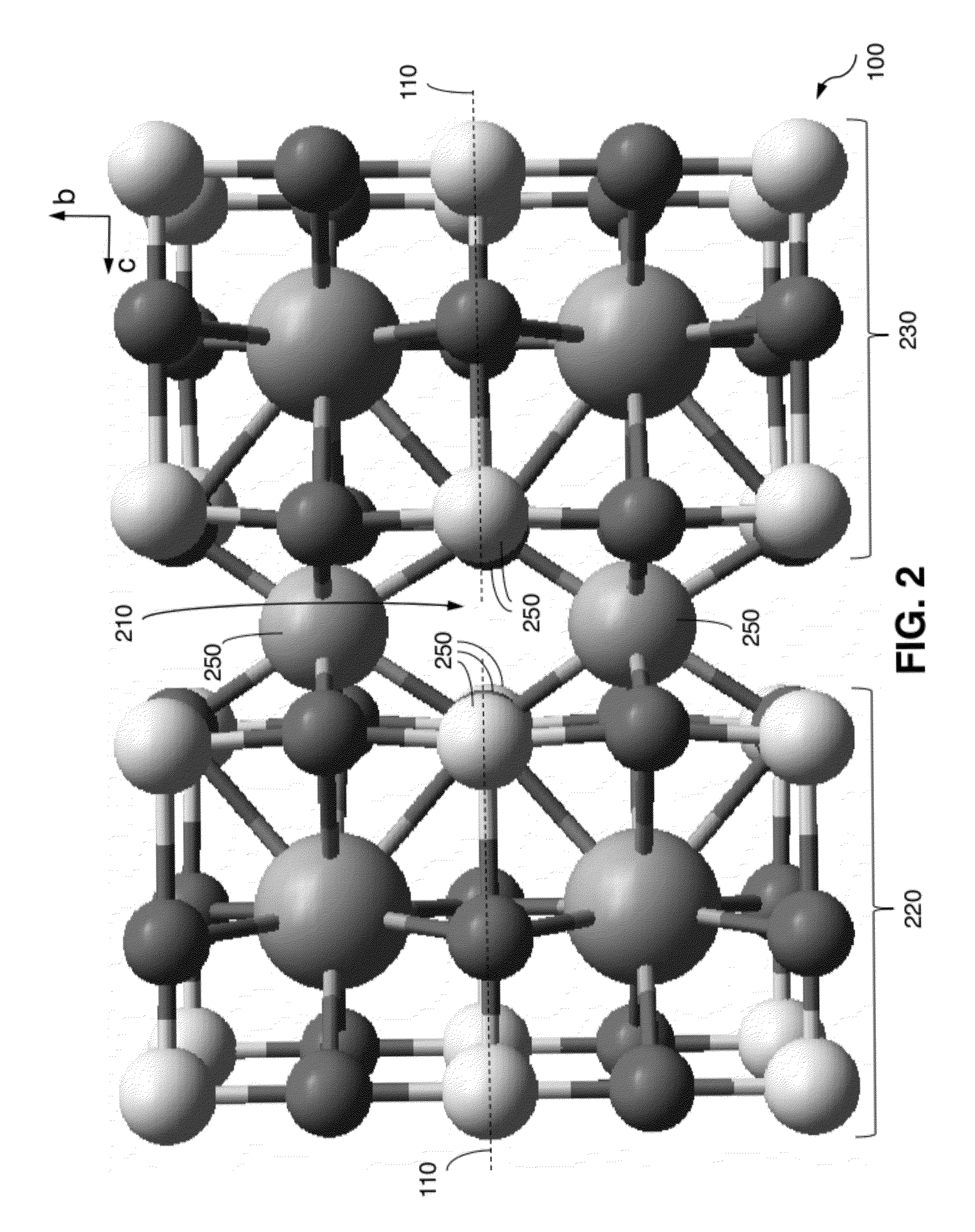

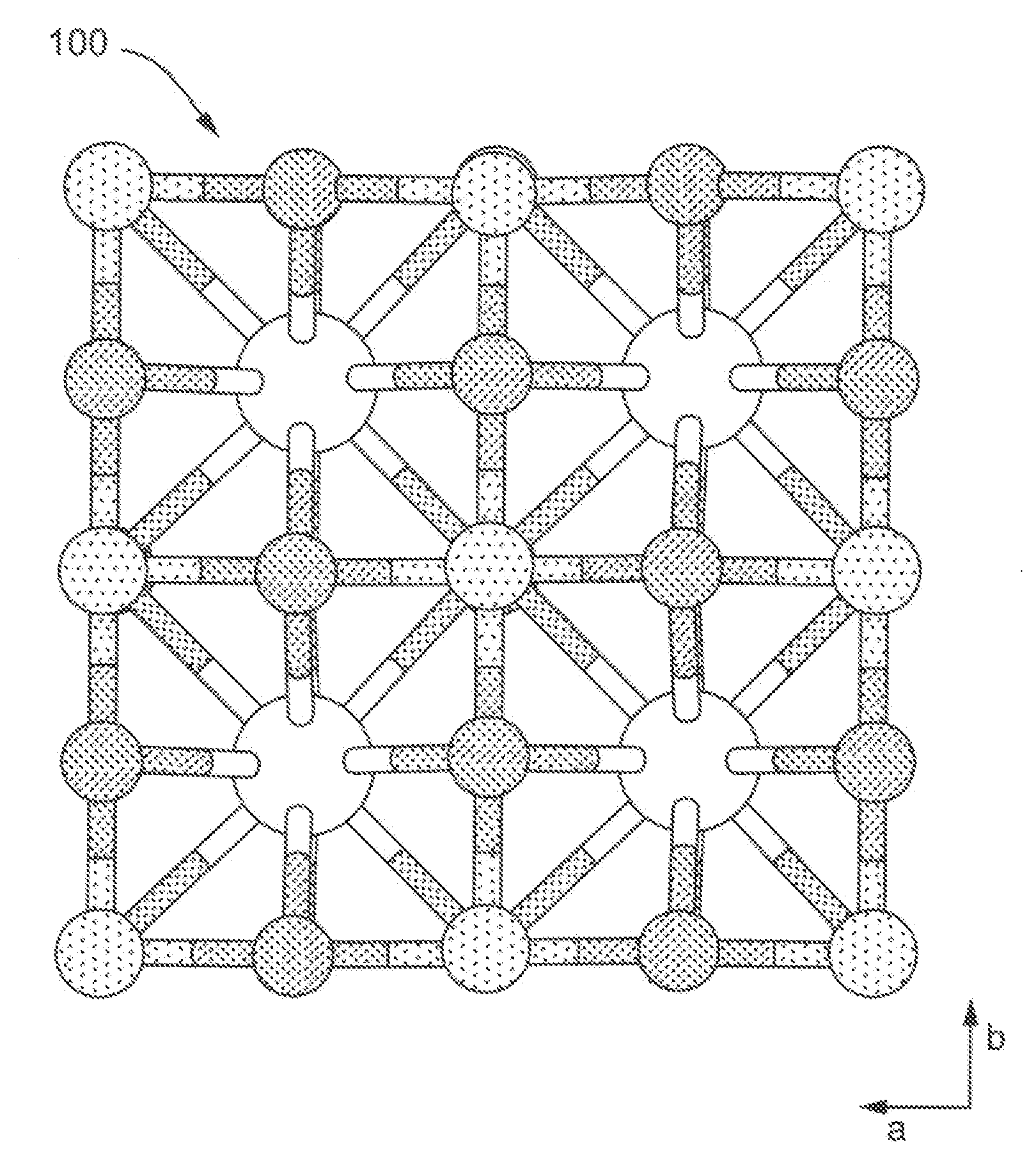

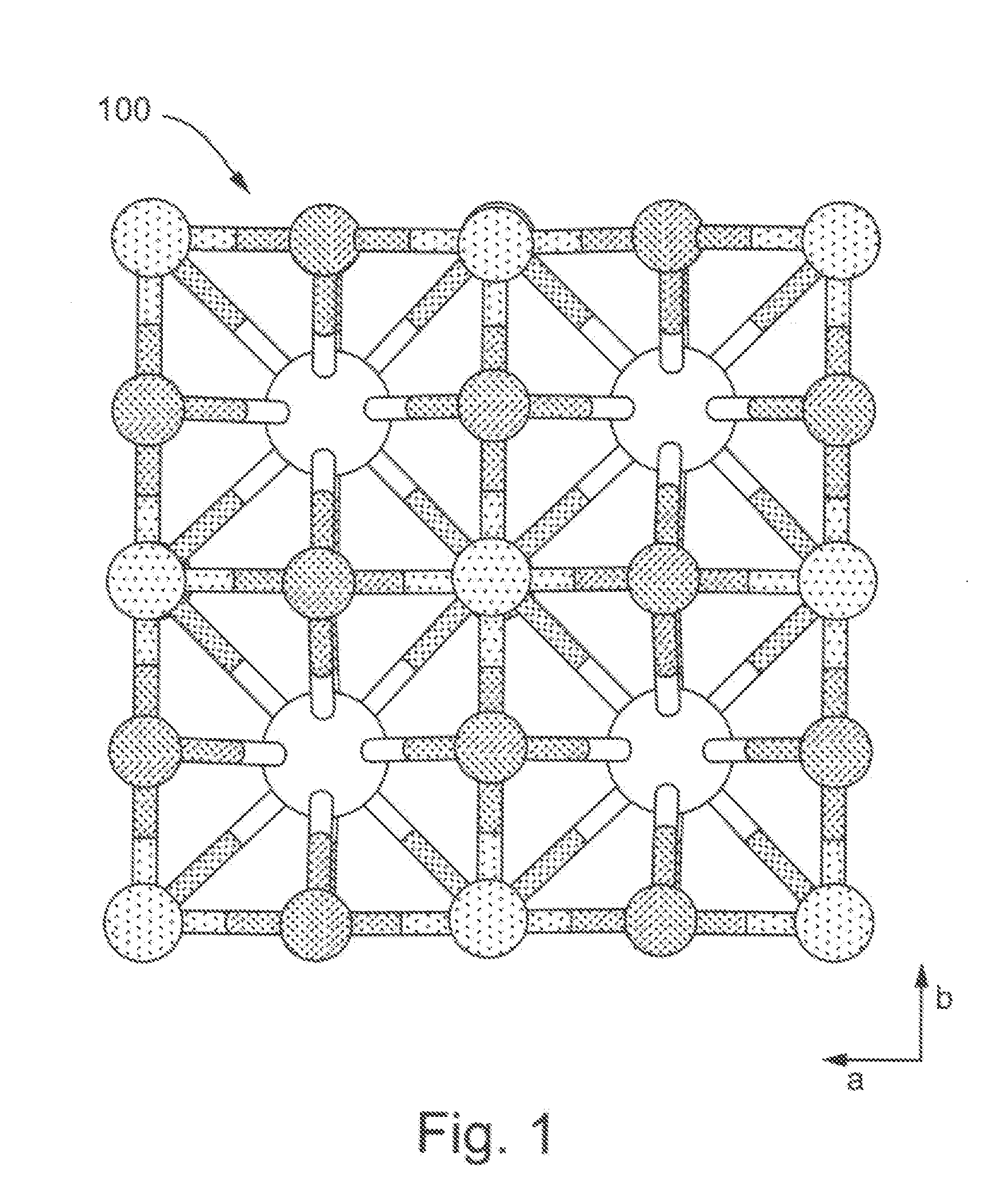

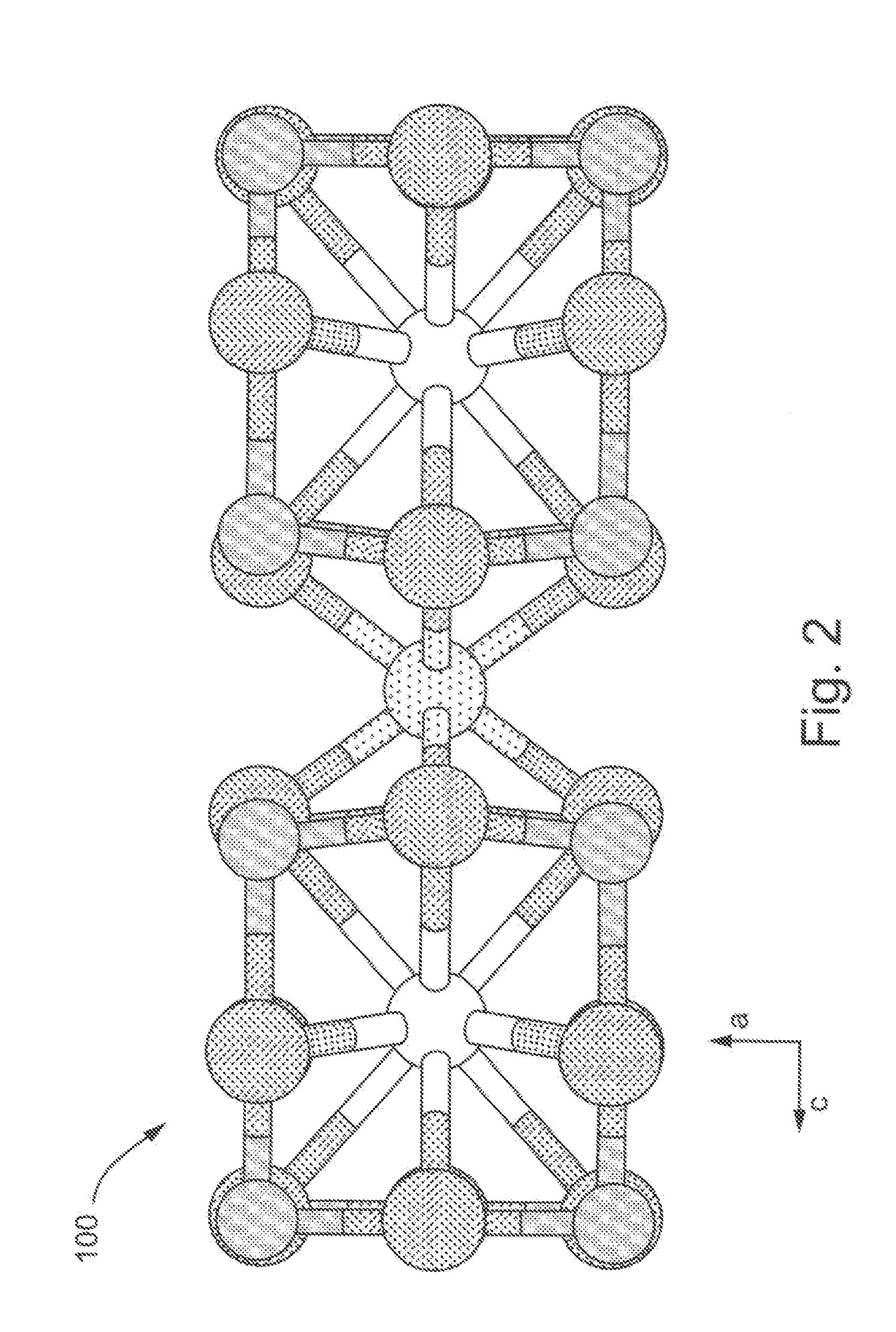

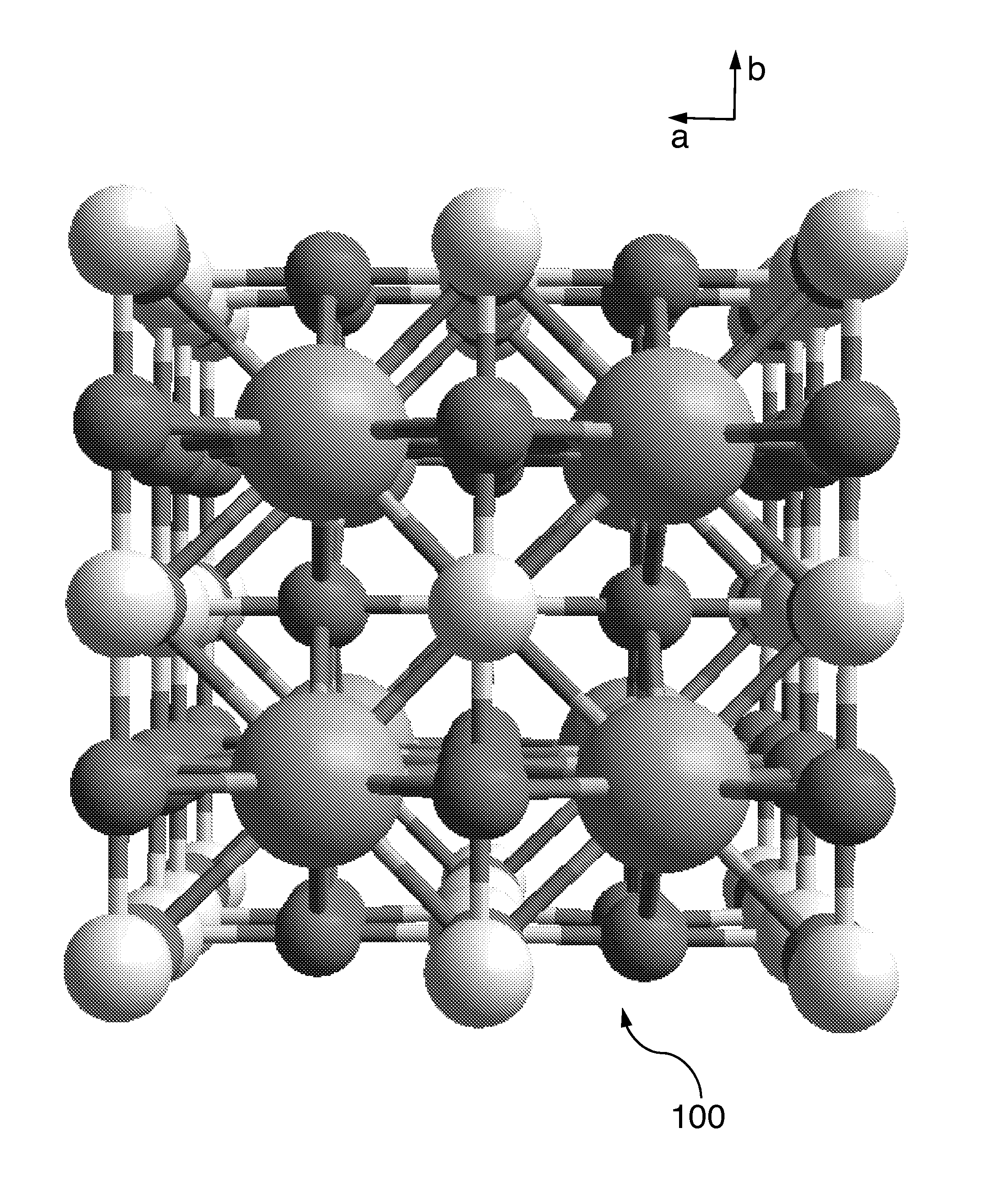

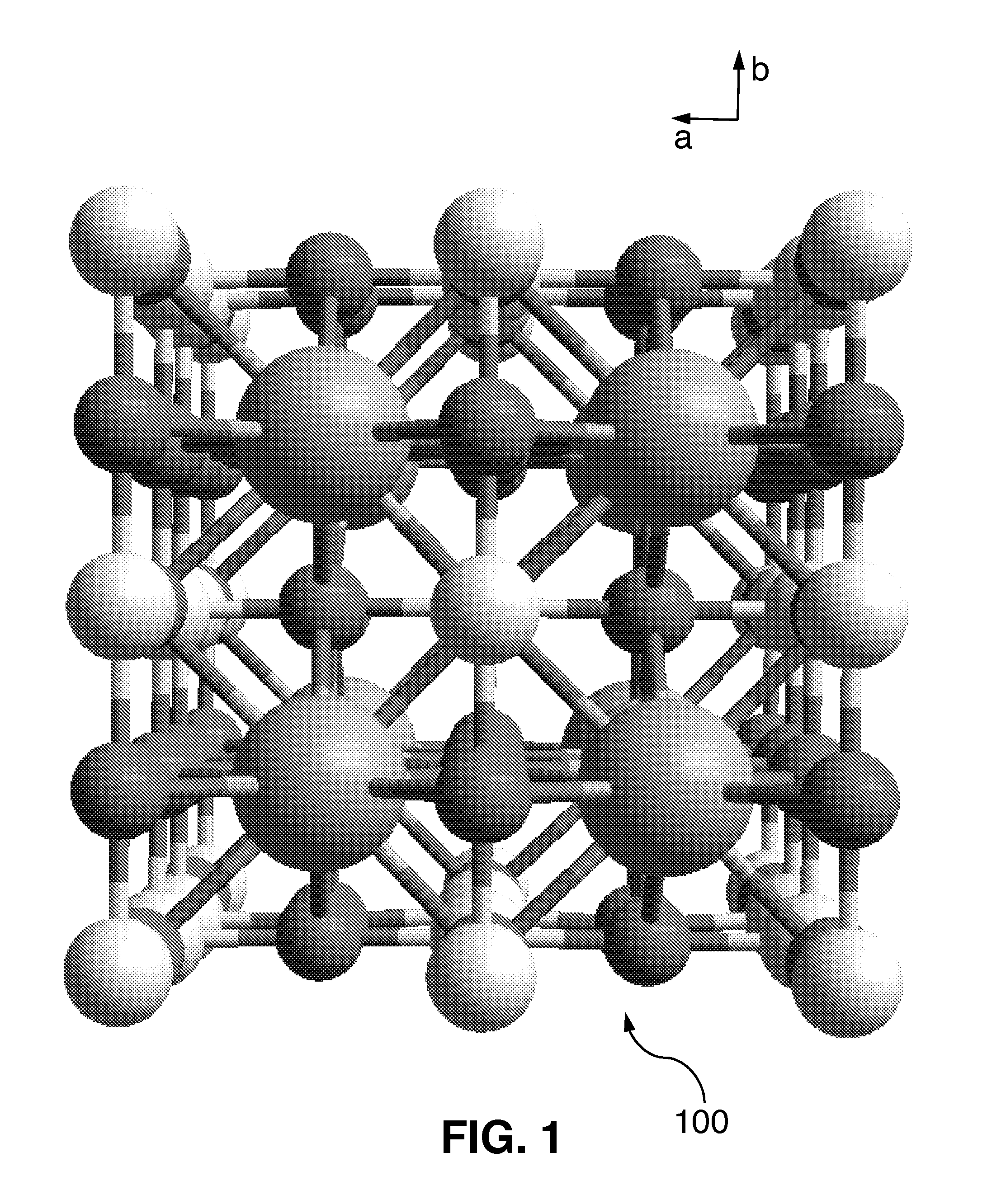

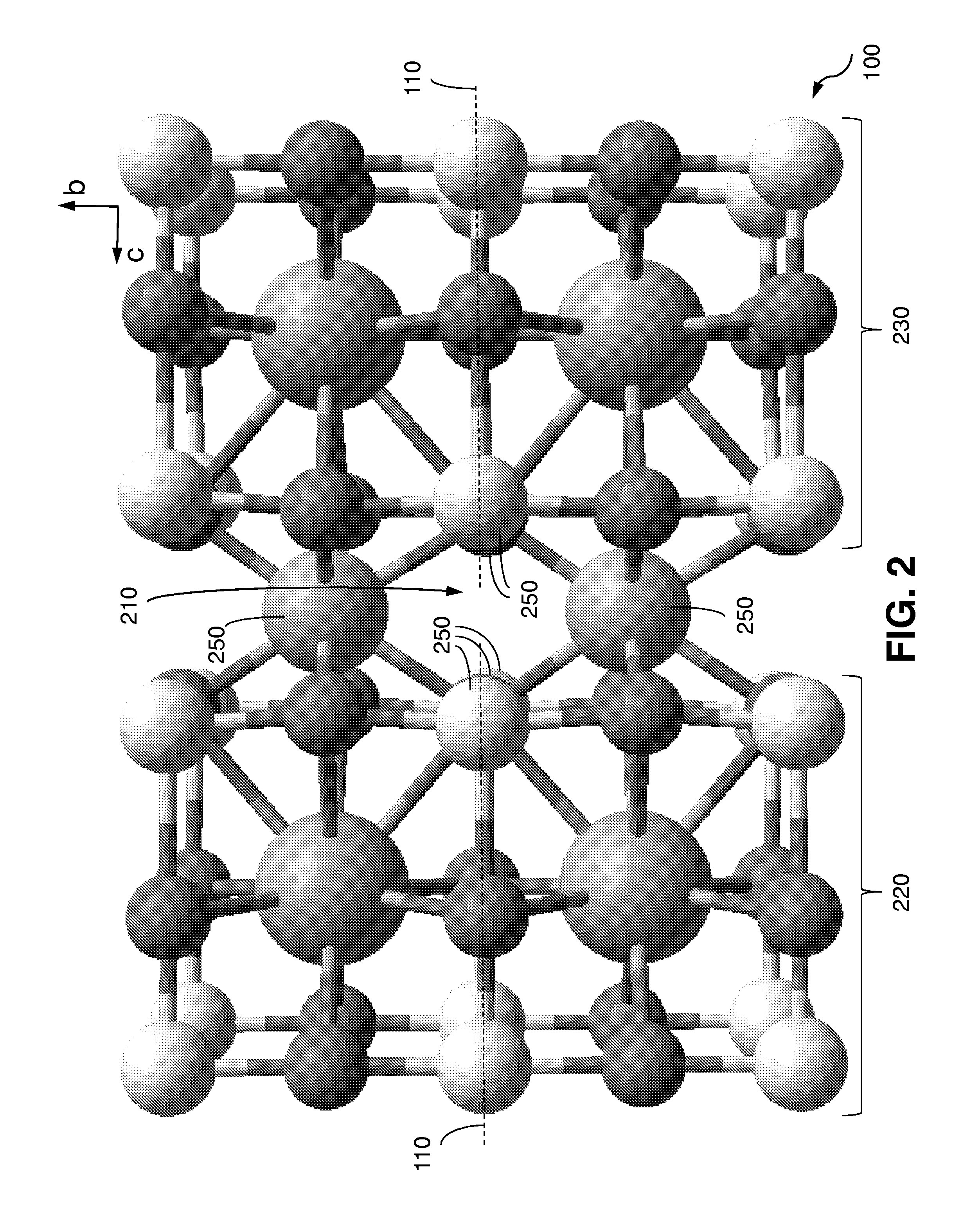

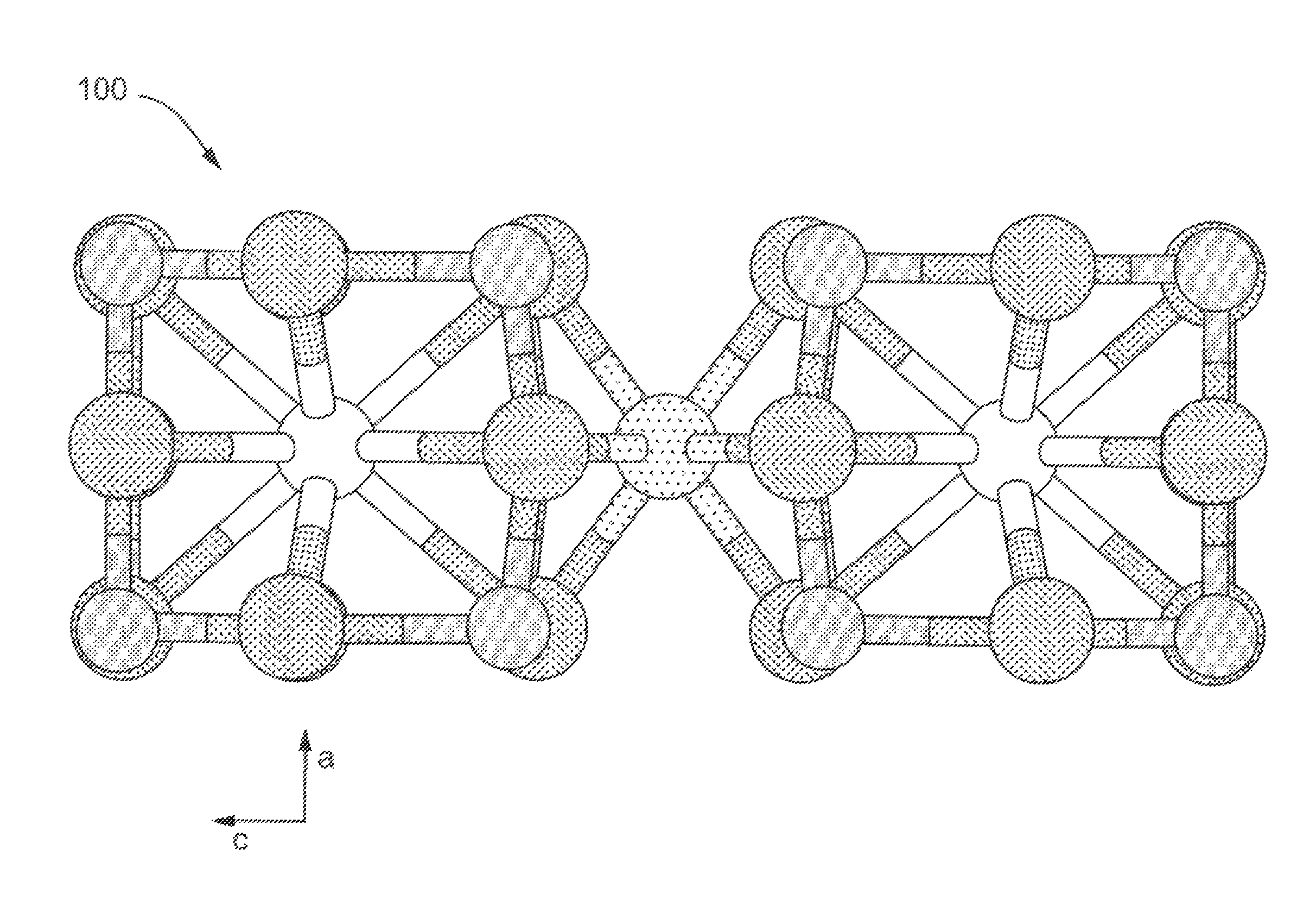

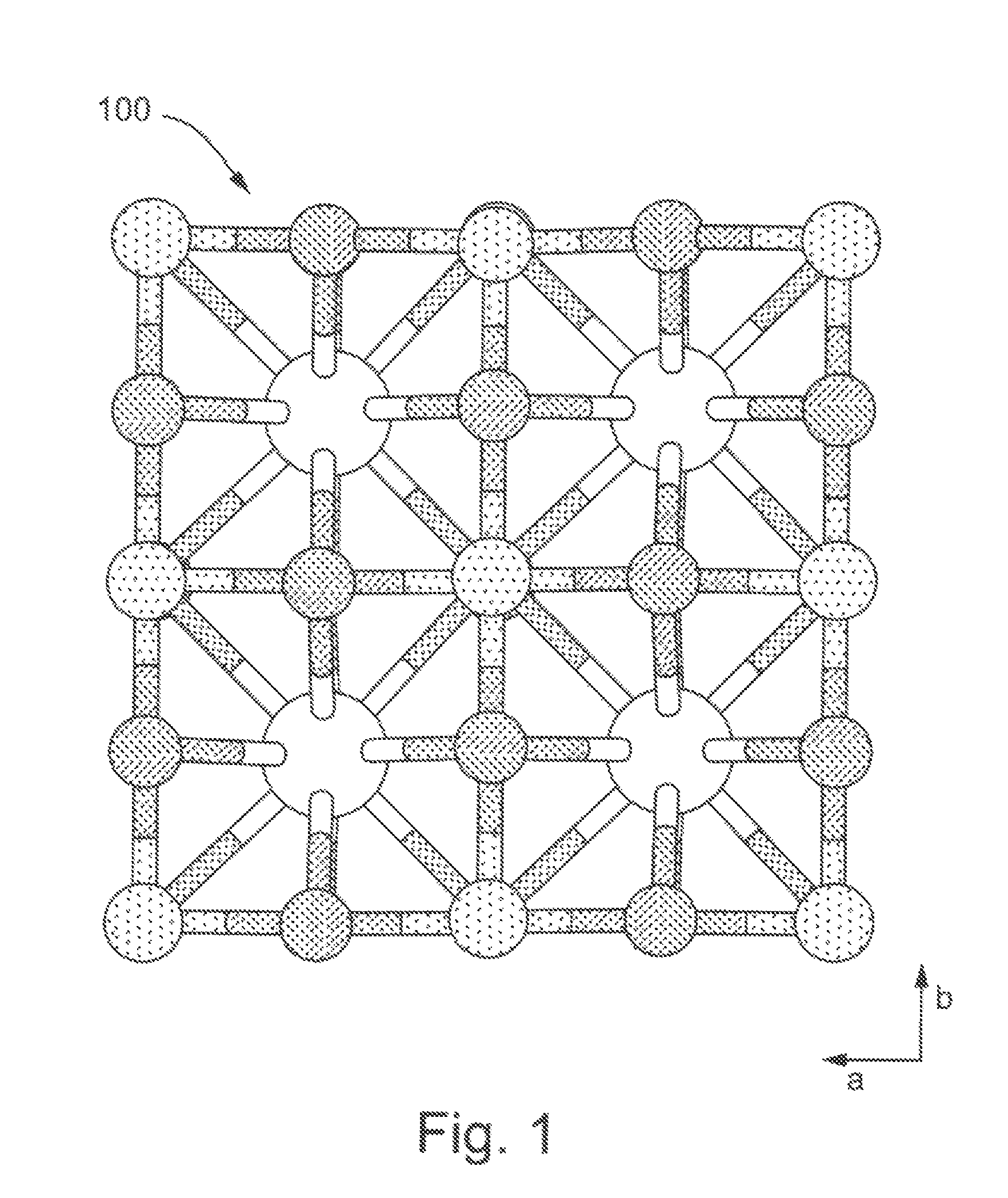

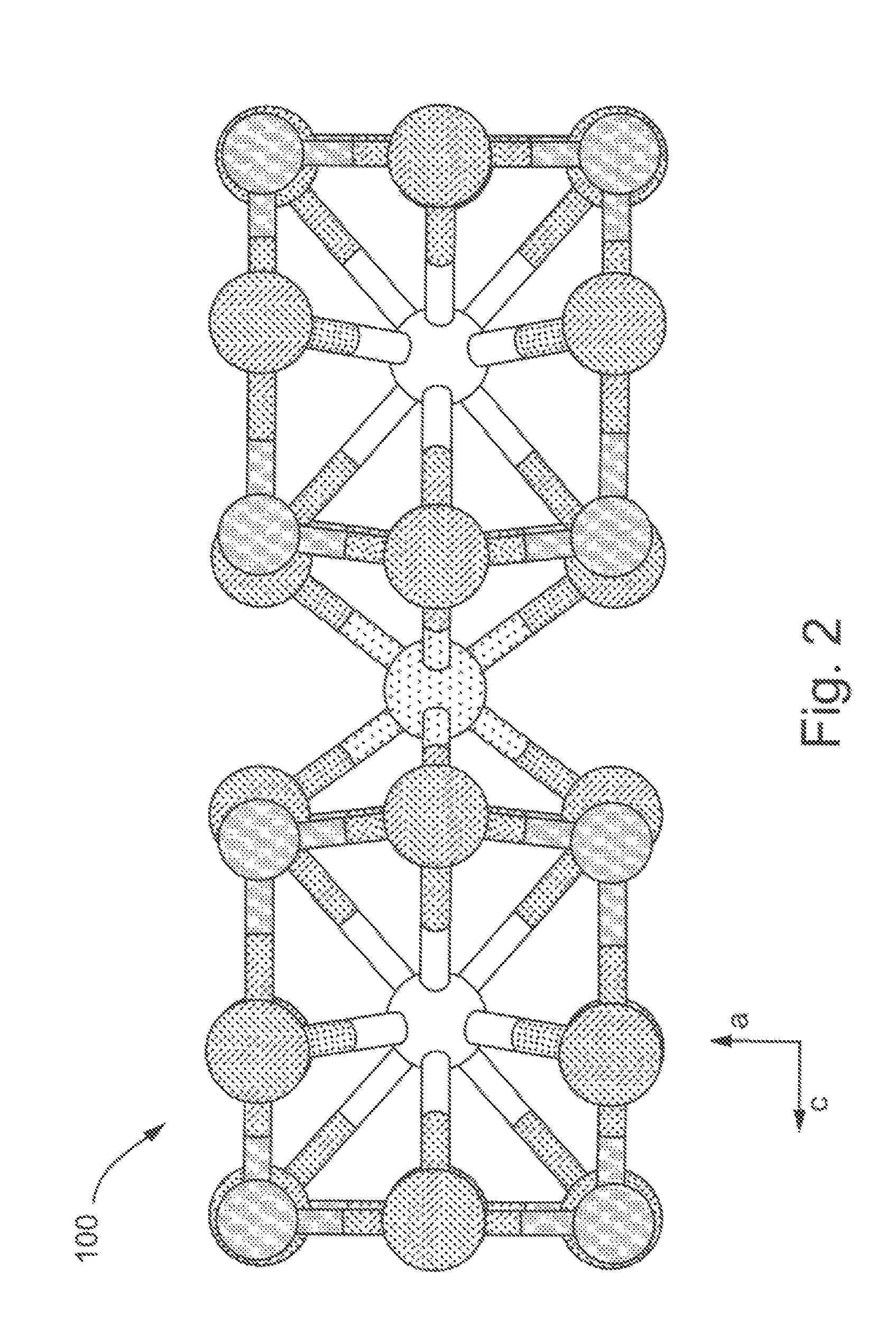

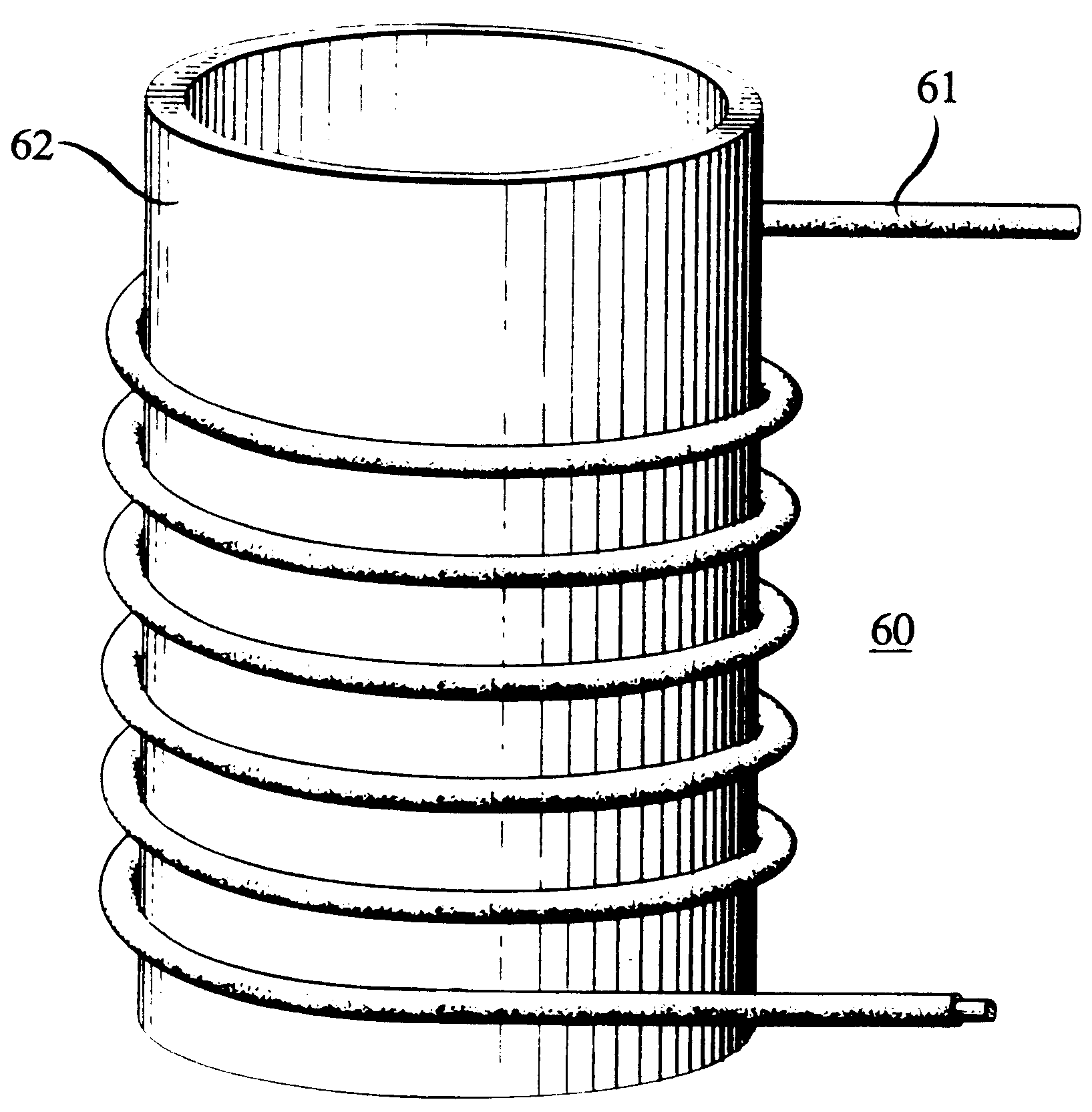

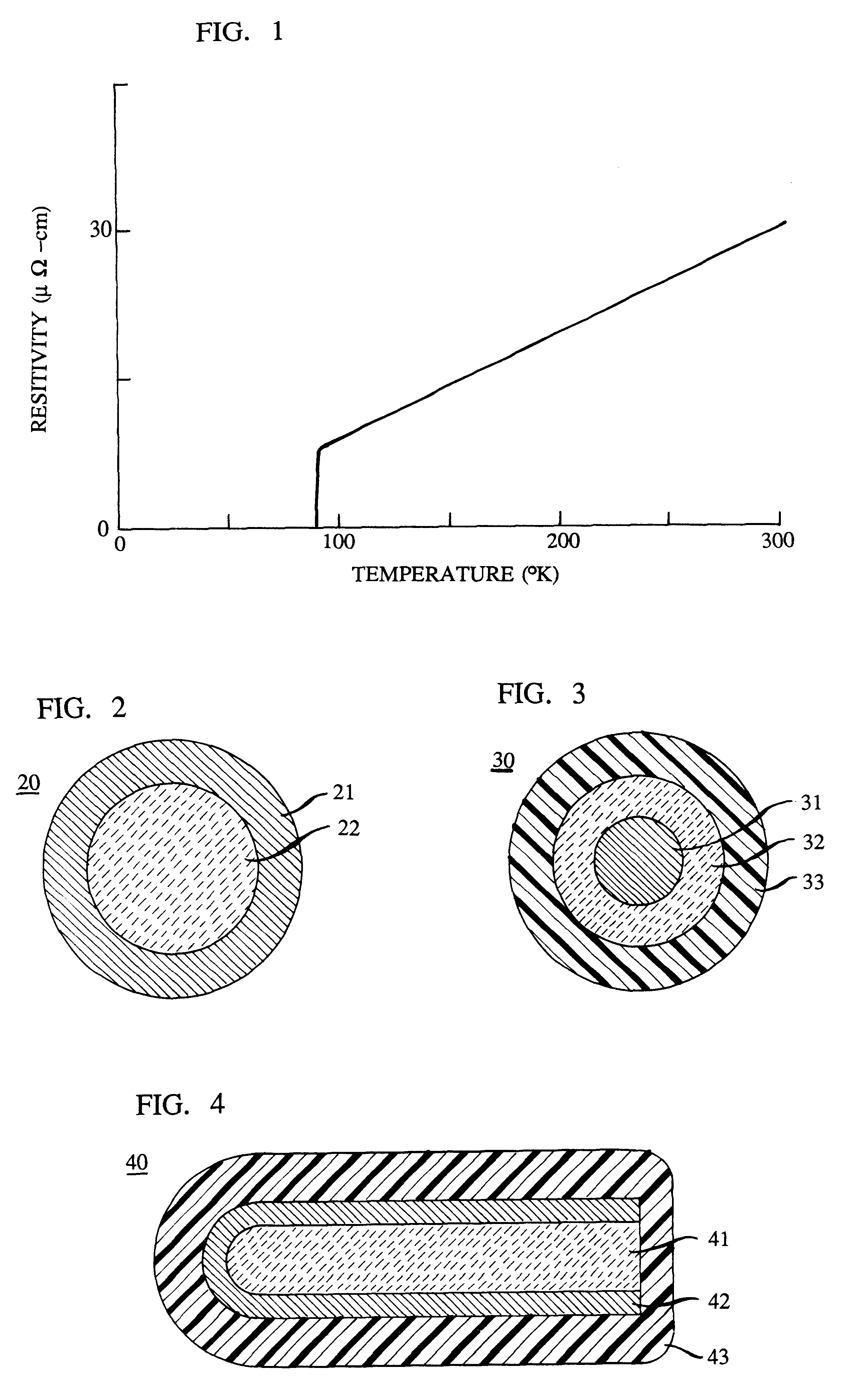

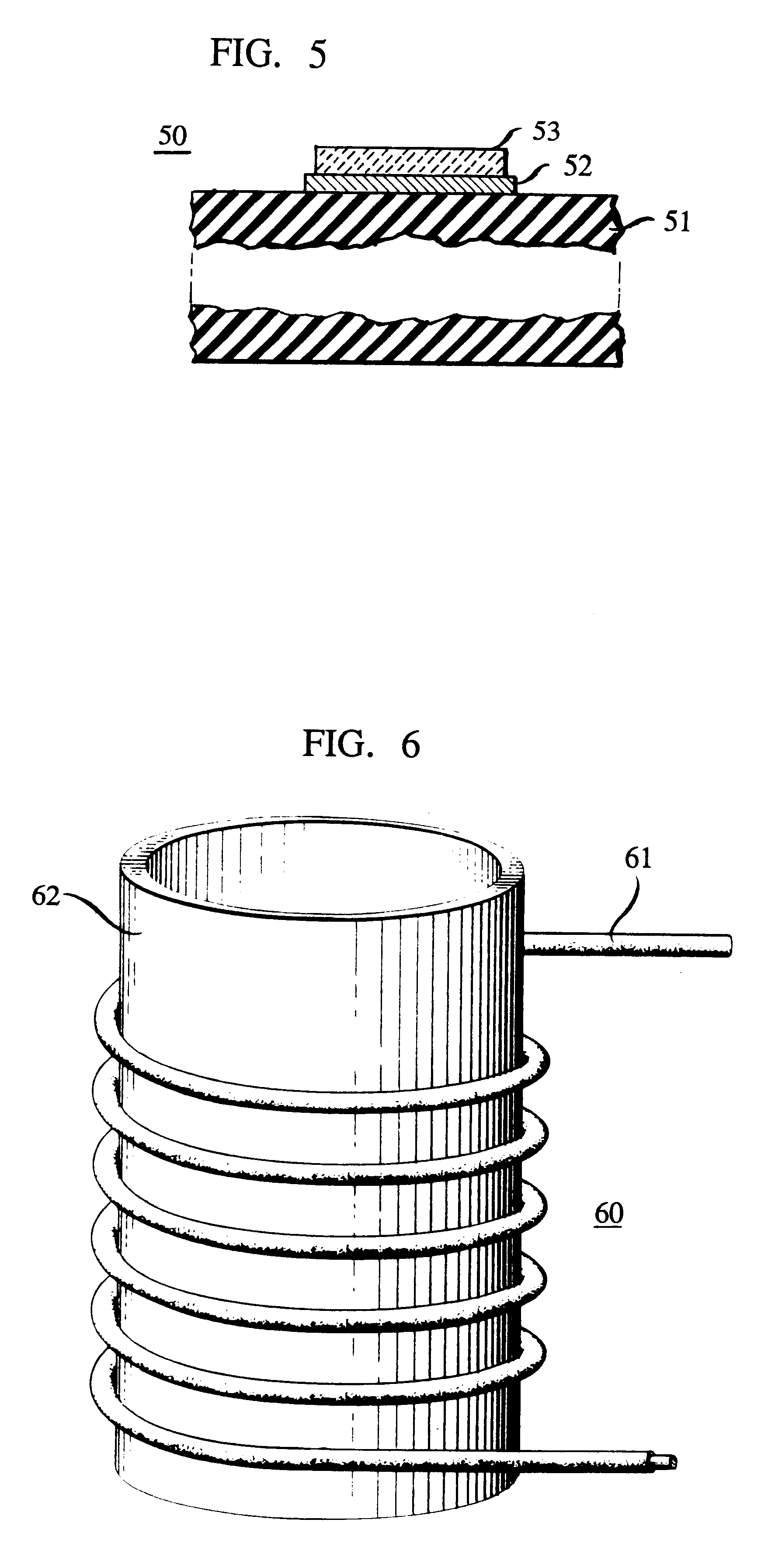

Extremely low resistance compositions and methods for creating same

ActiveUS8404620B2Superconductor devicesThin material handlingElectrical resistance and conductanceHigh-temperature superconductivity

The invention pertains to creating new extremely low resistance (“ELR”) materials, which may include high temperature superconducting (“HTS”) materials. In some implementations of the invention, an ELR material may be modified by depositing a layer of modifying material unto the ELR material to form a modified ELR material. The modified ELR material has improved operational characteristics over the ELR material alone. Such operational characteristics may include operating at increased temperatures or carrying additional electrical charge or other operational characteristics. In some implementations of the invention, the ELR material is a cuprate-perovskite, such as, but not limited to BSSCO. In some implementations of the invention, the modifying material is a conductive material that bonds easily to oxygen, such as, but not limited to, chromium.

Owner:AMBATURE

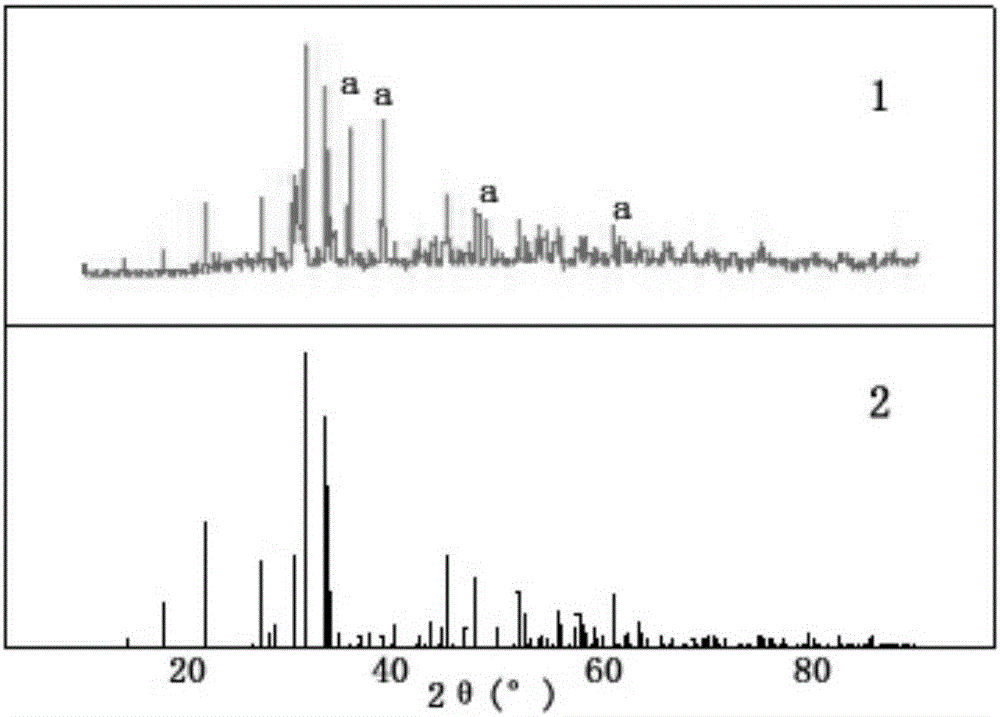

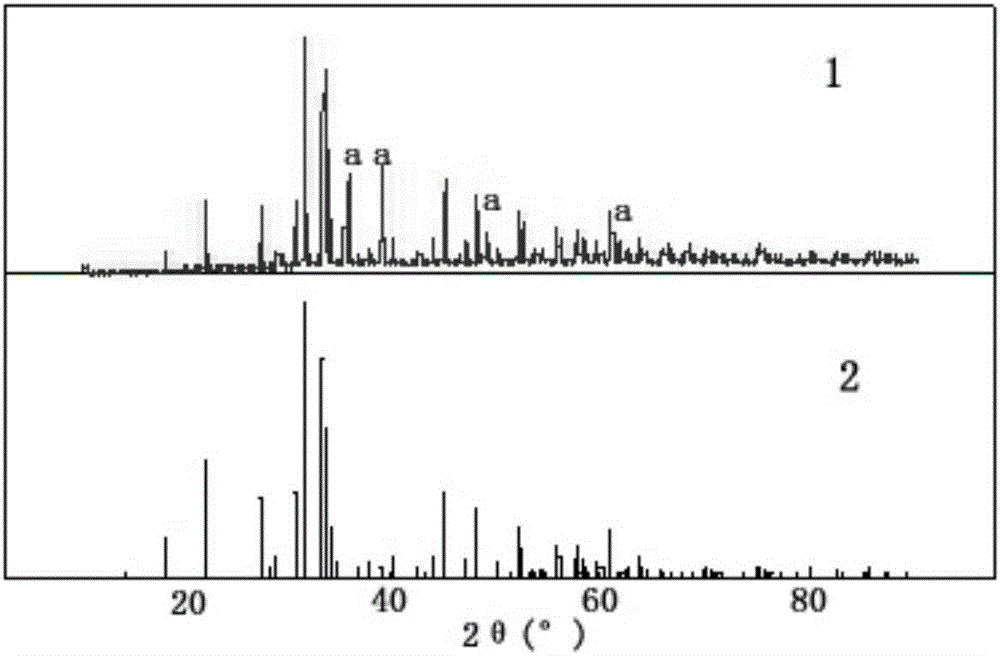

Preparation method of holmium cuprate nano powder

The invention discloses a preparation method of holmium cuprate nano powder. The preparation method comprises the following steps: weighing a Cu soluble salt and a Ho soluble salt according to the Cu / Ho stoichiometric proportion in the holmium cuprate Ho2Cu2O5, dissolving the Cu soluble salt and Ho soluble salt in deionized water, and uniformly mixing to prepare a solution A; weighing pyridine carboxylic acid, dissolving the pyridine carboxylic acid in alcohol, and adding an alkali to prepare a solution B; mixing the solution A and solution B, and stirring to prepare a solution C; slowly heating the solution C to precipitate a precursor D; sintering the precursor D in a reducing gas atmosphere, cooling to room temperature, and calcining in an air atmosphere to obtain a calcined product; and pulverizing the calcined product, grinding, screening, washing and drying. The preparation method disclosed by the invention can be used for preparing high-purity uniform-component Ho2Cu2O5 nano powder. The preparation method has the advantages of simple and accessible raw materials, low cost, mild conditions and high controllability, and is simple to operate.

Owner:NORTHEASTERN UNIV

Extremely low resistance composition and methods for creating same

The invention pertains to creating new extremely low resistance (“ELR”) materials, which may include high temperature superconducting (“HTS”) materials. In some implementations of the invention, an ELR material may be modified by depositing a layer of modifying material unto the ELR material to form a modified ELR material. The modified ELR material has improved operational characteristics over the ELR material alone. Such operational characteristics may include operating at increased temperatures or carrying additional electrical charge or other operational characteristics. In some implementations of the invention, the ELR material is a cuprate-perovskite, such as, but not limited to YBCO. In some implementations of the invention, the modifying material is a conductive material that bonds easily to oxygen, such as, but not limited to, chromium.

Owner:AMBATURE

Selenium-rich multi-element biological nutrient solution and preparation method

InactiveCN104860764AReduce diseaseImprove anti-pollution and disease resistanceFertilizer mixturesDiseaseNormal growth

The invention discloses a selenium-rich multi-element biological nutrient solution and a preparation method, and belongs to the field of fertilizers. The nutrient solution consists of the following raw materials in parts by weight: 14 to 42 parts of sodium selenite, 18 to 52 parts of active solid-state bacillus subtilis, 7 to 25 parts of zinc sulfate, 7 to 25 parts of ammonium cuprate, 7 to 25 parts of manganese sulfate, 7 to 25 parts of composite rare earth, 4 to 12 parts of boric acid, 1 to 5 parts of chlorophyll, 1 to 3 parts of a stabilizer and 786 to 934 parts of water. After the selenium-rich multi-element biological nutrient solution is applied, the pollution resistance and disease resistance of crops per se are improved, nutrients and trace elements required by the normal growth of the crops are provided, and the crops are favorably prevented from pollution; the quality and yield of the crops are improved; the effect of removing toxicity can be achieved for various crops polluted by heavy metals particularly in a heavy industrial area; the content of various nutrient substances and trace elements in crops and agricultural products is increased, and the nutrient substance and trace element intake of a human body is enriched.

Owner:YUNNAN YIXI GONGBAO BIOLOGICAL ENG TECH CO LTD

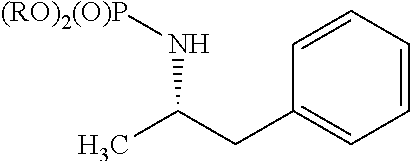

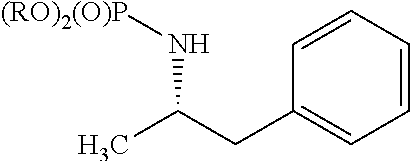

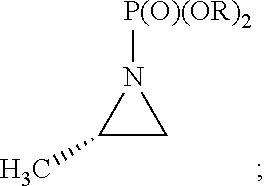

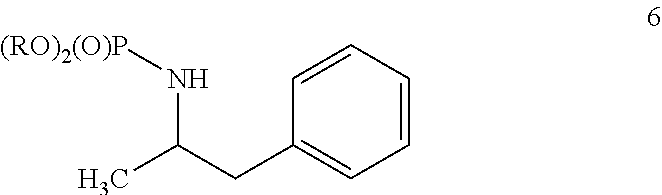

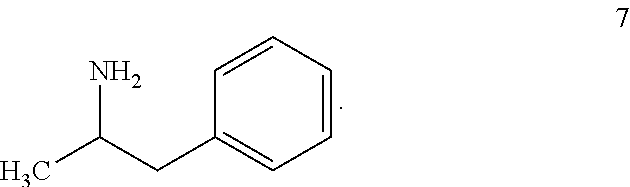

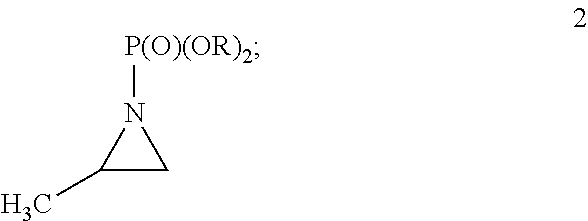

Synthesis of Chiral Amphetamine Derivatives by Stereospecific, Regioselective Cuprate Addition Reaction with Aziridine Phosphoramidate Compounds

Owner:CHEMAPOTHECA

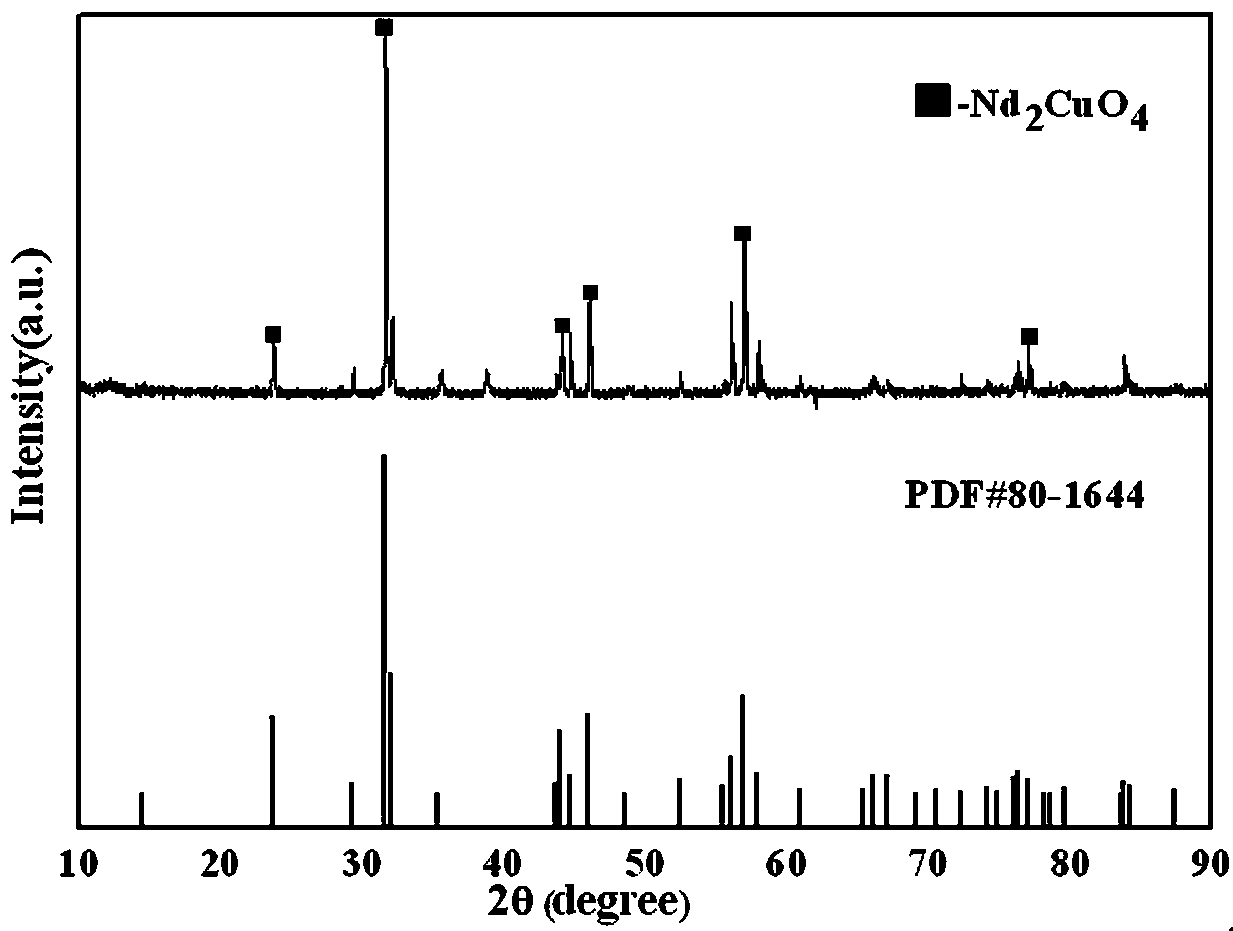

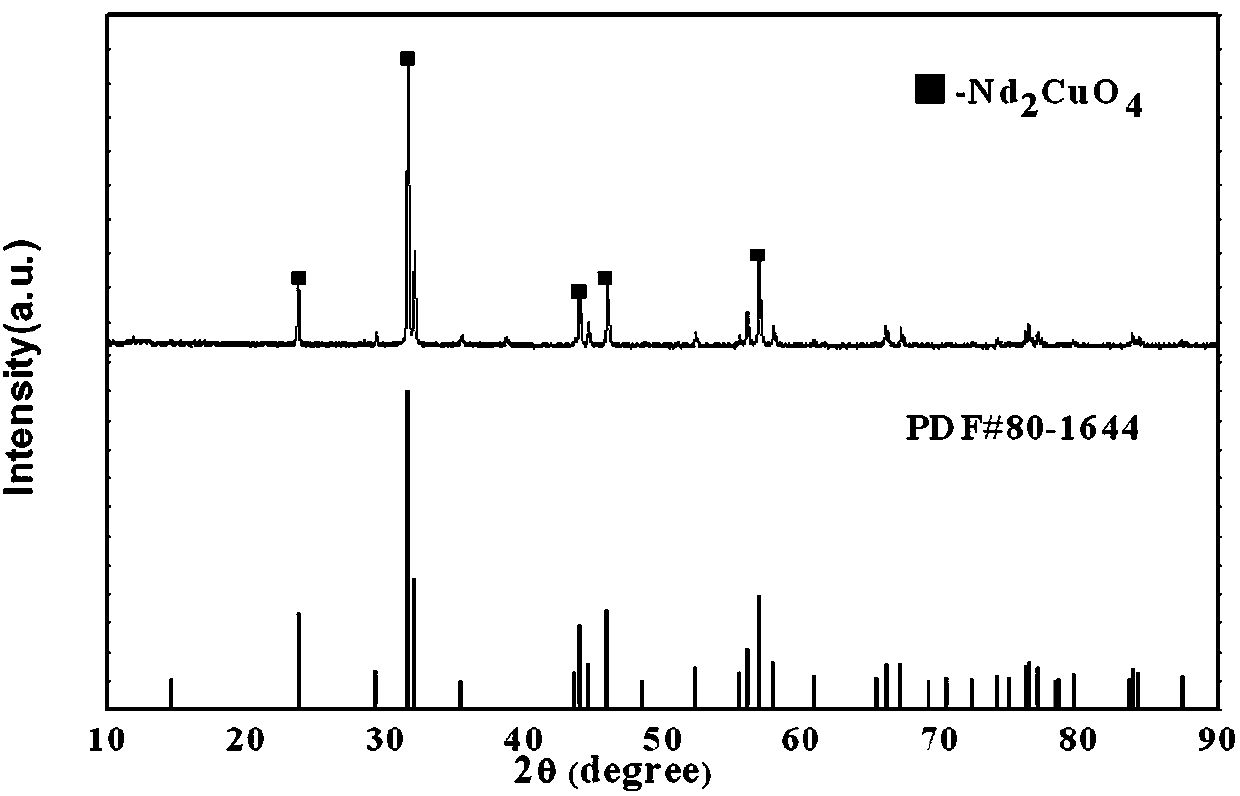

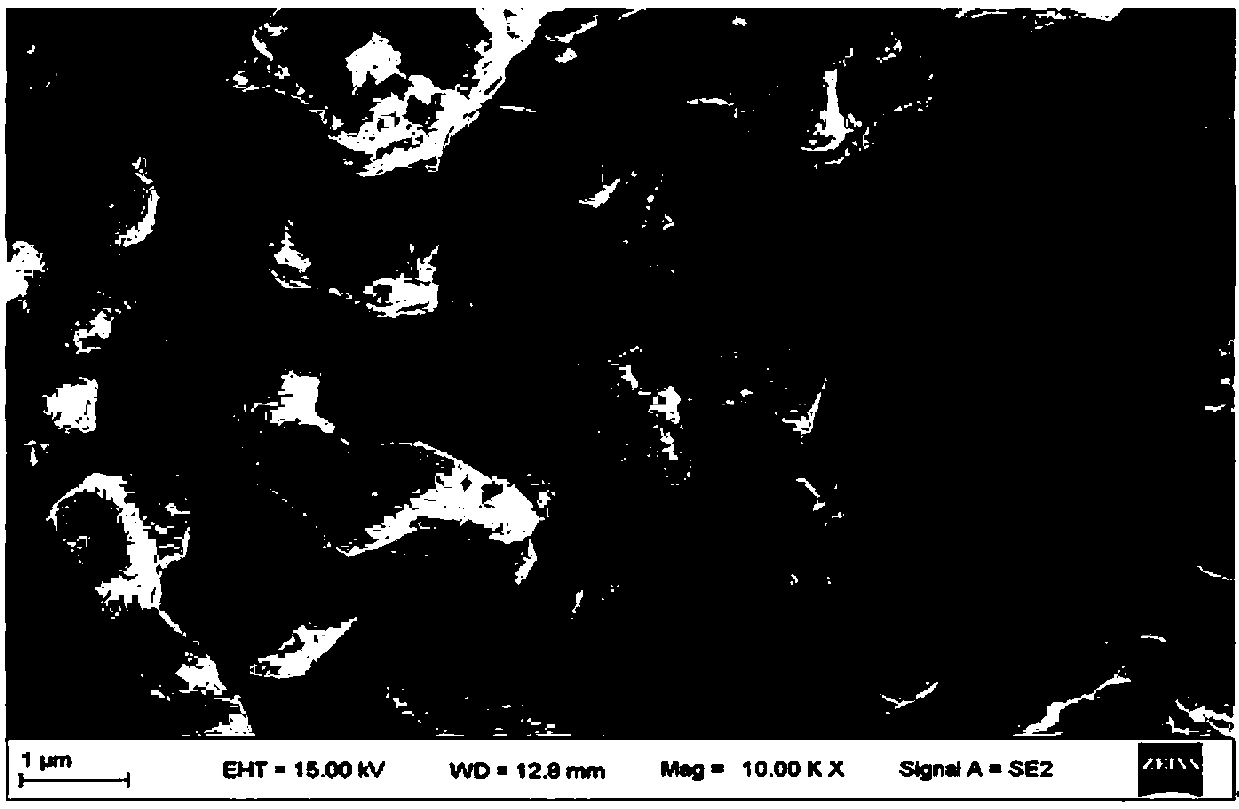

Preparation method and application of neodymium cuprate nano-powder

ActiveCN107673392AImprove performanceImprove the coordination effectMaterial nanotechnologyCopper compoundsMalachite greenMalachite green stain

The invention relates to the technical field of photocatalysis of nano-materials and in particular relates to a preparation method and application of neodymium cuprate nano-powder. The preparation method comprises the following steps: weighing soluble salt of copper and neodymium according to the mol ratio of Cu to Nd in Nd2CuO4; dissolving the soluble salt into de-ionized water and stirring untilthe soluble salt is dissolved to obtain a solution A; weighing dimethylglyoxime and putting the dimethylglyoxime into a beaker; adding de-ionized water and stirring until the dimethylglyoxime is dissolved to obtain a solution B; slowly pouring the solution B into the solution A and stirring until the solution A and the solution B are uniformly mixed to obtain a solution C; heating the solution Cunder the condition that the temperature is 60 DEG C to 80 DEG C; stirring until the solution is viscous and drying to obtain a substance D; taking out the substance D and putting the substance D intoa crucible; calcining in a low-temperature furnace; then putting the substance D into a high-temperature nitrogen furnace and calcining to obtain a calcined product; crushing and grinding to obtain the neodymium cuprate Nd2CuO4 nano-powder. The preparation method provided by the invention has the advantages that a preparation technology is simple and feasible and the obtained Nd2CuO4 nano-powderhas excellent performance and has an obvious photocatalytic effect on malachite green; the photocatalytic effect is not reported at present.

Owner:东北大学秦皇岛分校

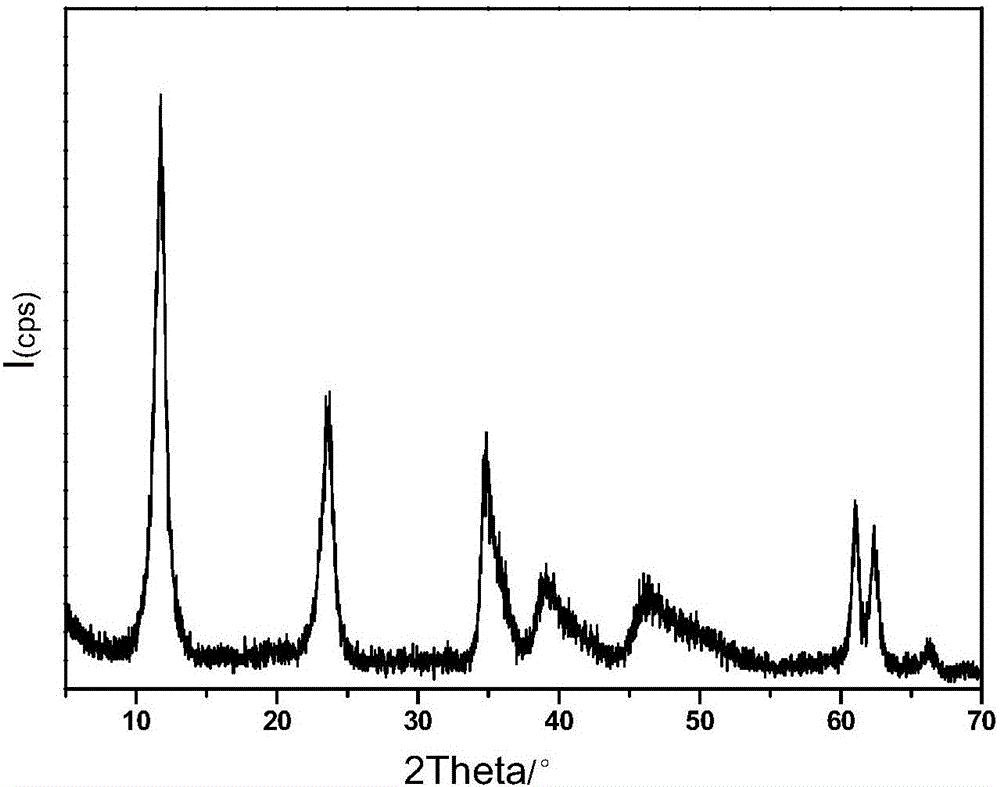

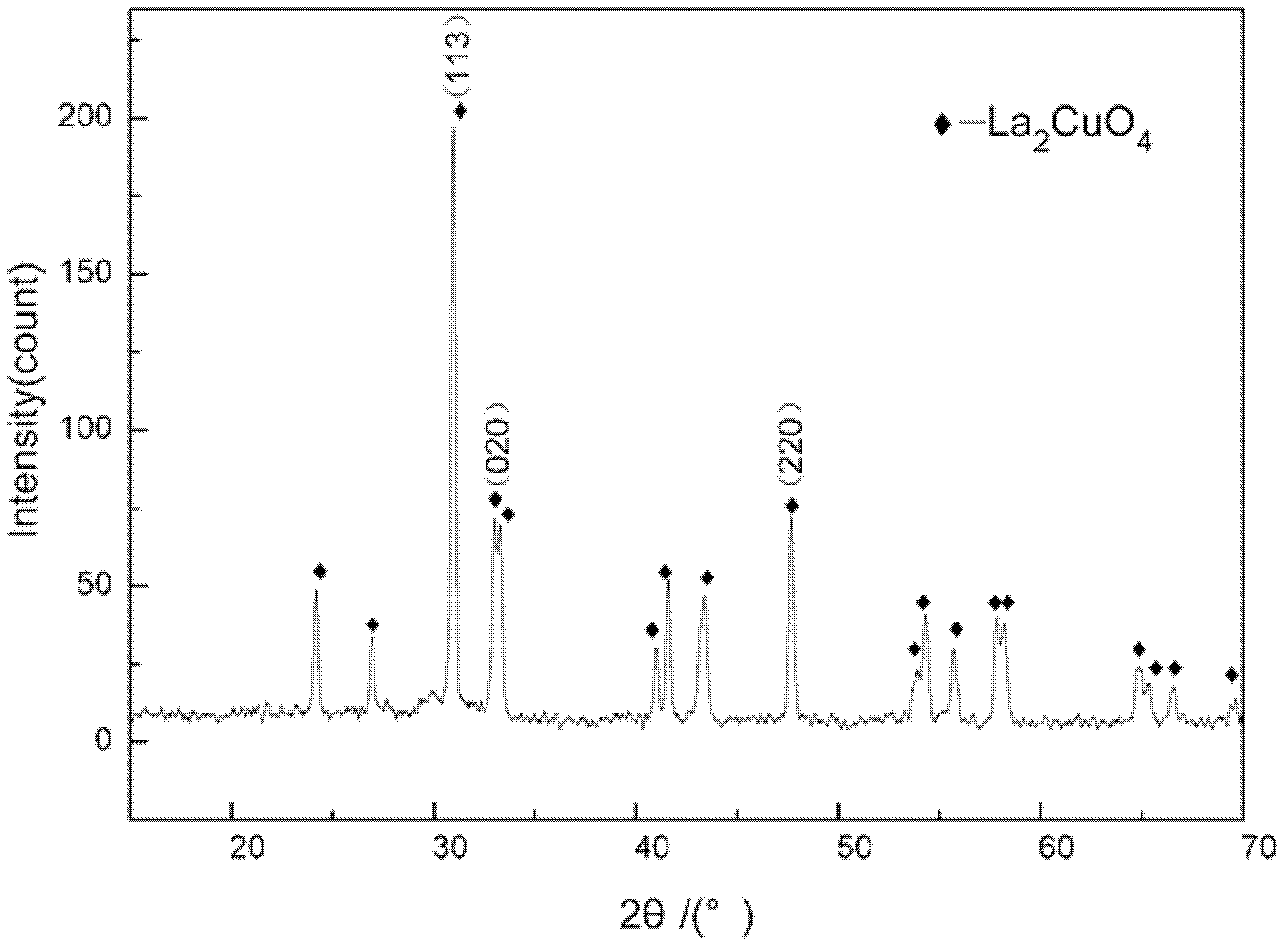

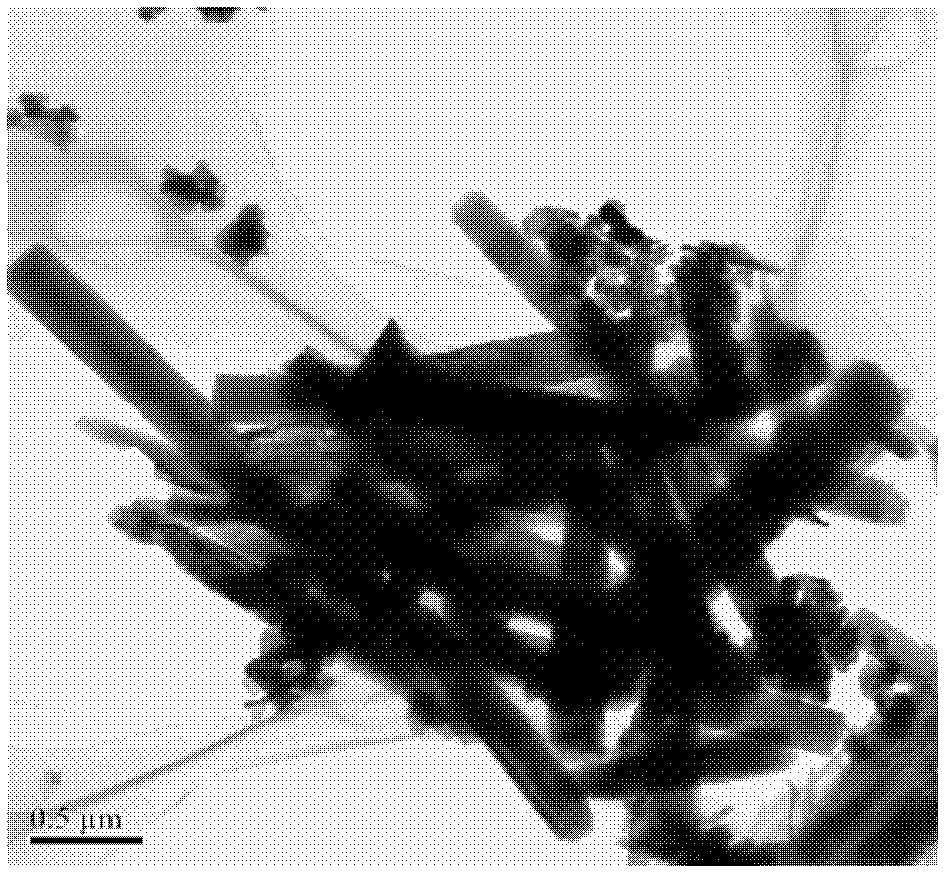

Method for preparing special-shaped lanthanum cuprate (La2CuO4) powder bodies by sol-gel method

ActiveCN102502768AFine particleShape is easy to controlCopper compoundsMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureCopper nitrate

The invention relates to a method for preparing special-shaped lanthanum cuprate (La2CuO4) powder bodies by a sol-gel method. The method comprises the steps of: dissolving lanthanum nitrate and copper nitrate by de-ionized water to obtain a solution A; sequentially adding glycine and dispersants into the solution A, and adjusting the pH to be 1.5 to 4.5 with urea to obtain a solution B; standing, aging and drying the solution B to obtain dry gel; and grinding the dry gel into powders by a mortar, placing into a muffle furnace for calcining and grinding into powder to obtain the special-shaped La2CuO4 powder bodies. According to the method, the special-shaped La2CuO4 powder bodies are prepared by using the sol-gel method; EDTA (Ethylene Diamine Tetraacetic Acid), stearic acid and oxalic acid are used as dispersants respectively, so that the needle-like, rod-like and spindle-like La2CuO4 powder bodies can be obtained; the prepared La2CuO4 has the advantages of good crystallization, complete shape, good repeatability and low reaction temperature, so that the energy consumption is greatly reduced, the cost is saved; and the method is simple to operate and is suitable for large scale production.

Owner:山东格新精工有限公司

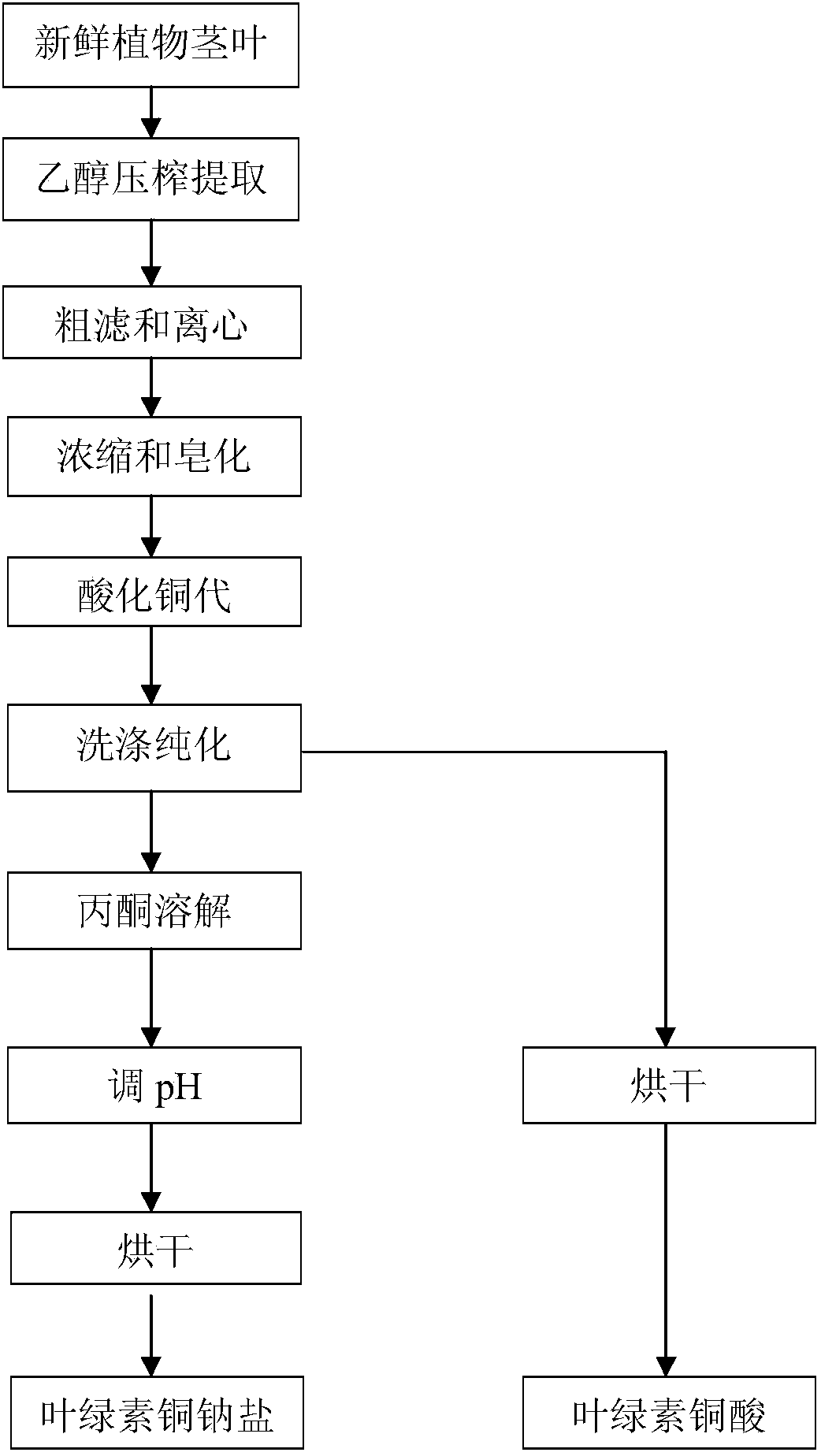

Method for preparing chlorophyll cuprate and sodium copper chlorophyll

ActiveCN103509028AReduce decompositionMinimize extraction stepsOrganic chemistryNatural dyesWarm waterFiltration

The invention discloses a method for preparing chlorophyll cuprate and sodium copper chlorophyll. The method comprises the following steps: taking fresh plant stem leaves, adding 90-95% of ethanol, pulping and extracting, and pressing and juicing; roughly filtering the juice by using a gauze of 180-300 meshes, and subsequently carrying out high-speed centrifugation with the speed of 4,000-6,000rpm; adding 5% of a NaOH solution and adjusting the pH value to be 11-12, saponifying, carrying out vacuum concentration and recycling the ethanol; adjusting the pH value to be 2-3, adding 10% of CuSO4 solution for copper substitution; subsequently sequentially washing sediment obtained from suction filtration in warm water for three times and washing the sediment in a low-degree ethanol solution for three times; directly drying the obtained sediment so as to obtain chlorophyll cuprate solid powder; dissolving the washed sediment by using acetone; adding 5% of a NaOH ethanol solution to adjust the pH value to be 10-12, washing the sediment, and drying the sediment after suction filtration so as to obtain sodium copper chlorophyll solid powder. The recycling rate of the method is 0.7-1.0%, and the prepared sodium copper chlorophyll meets various requirements of the GB36406-2011 standard. According to the method, as two time-consumption steps of concentration and saponification are combined together, the time is greatly shortened, the step of organic solvent extraction is eliminated, the process is simplified, and the cost is lowered.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Extremely Low Resistance Compositions and Methods for Creating Same

ActiveUS20120252676A1Lower resistanceResistance materialSuperconductor detailsSuperconductor device manufacture/treatmentHigh temperature superconductingCuprate

The invention pertains to creating new extremely low resistance (“ELR”) materials, which may include high temperature superconducting (“HTS”) materials. In some implementations of the invention, an ELR material may be modified by depositing a layer of modifying material unto the ELR material to form a modified ELR material. The modified ELR material has improved operational characteristics over the ELR material alone. Such operational characteristics may include operating at increased temperatures or carrying additional electrical charge or other operational characteristics. In some implementations of the invention, the ELR material is a cuprate-perovskite, such as, but not limited to BSSCO. In some implementations of the invention, the modifying material is a conductive material that bonds easily to oxygen, such as, but not limited to, chromium.

Owner:AMBATURE

Extremely low resistance composition and methods for creating same

ActiveUS8211833B2Superconductors/hyperconductorsSemiconductor/solid-state device detailsElectrical resistance and conductanceHigh-temperature superconductivity

The invention pertains to creating new extremely low resistance (“ELR”) materials, which may include high temperature superconducting (“HTS”) materials. In some implementations of the invention, an ELR material may be modified by depositing a layer of modifying material unto the ELR material to form a modified ELR material. The modified ELR material has improved operational characteristics over the ELR material alone. Such operational characteristics may include operating at increased temperatures or carrying additional electrical charge or other operational characteristics. In some implementations of the invention, the ELR material is a cuprate-perovskite, such as, but not limited to YBCO. In some implementations of the invention, the modifying material is a conductive material that bonds easily to oxygen, such as, but not limited to, chromium.

Owner:AMBATURE

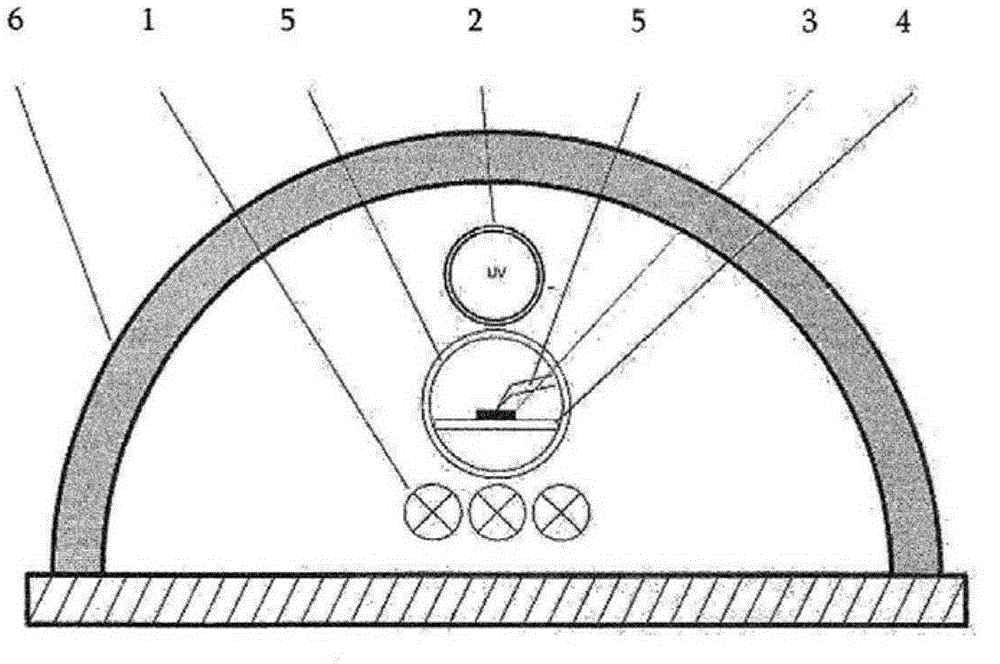

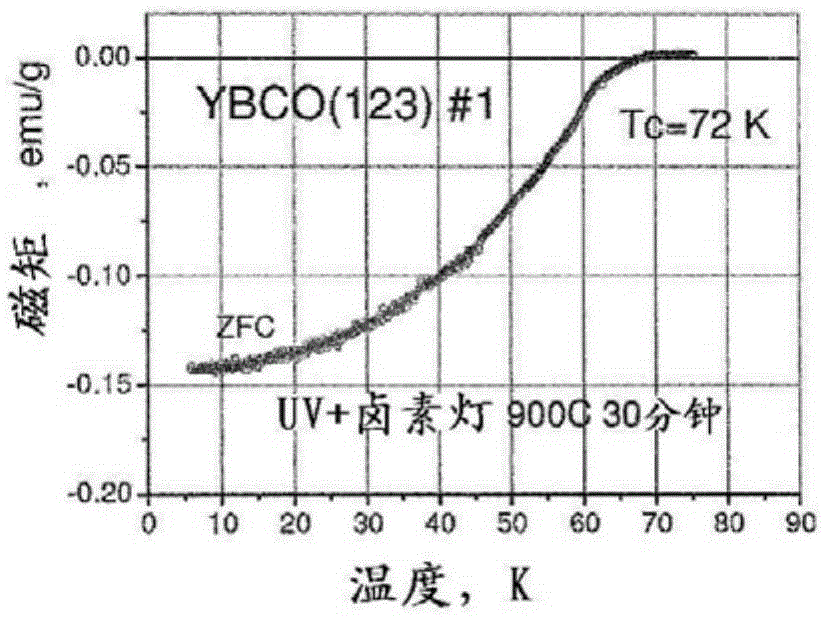

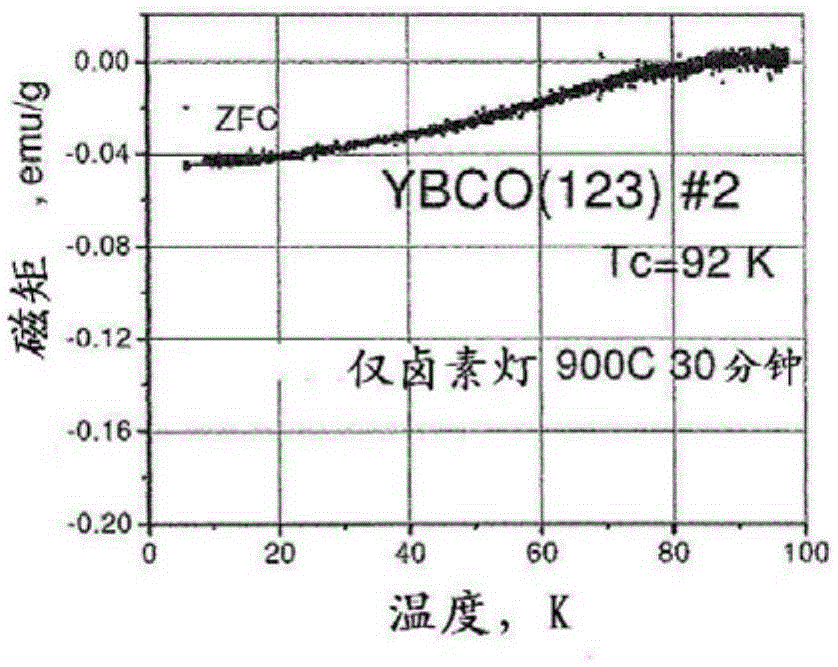

Rapid solid-state reaction of oxides with ultraviolet radiation

Owner:卡尔·亚历克斯·穆勒 +1

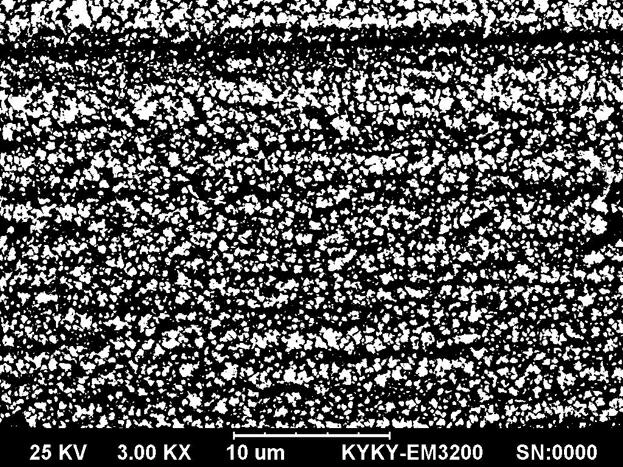

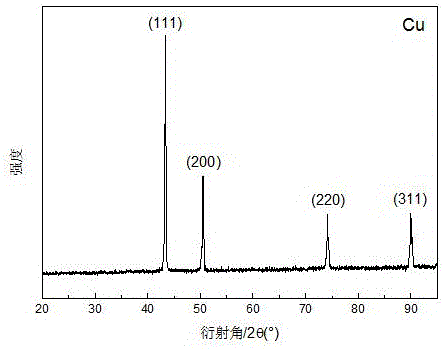

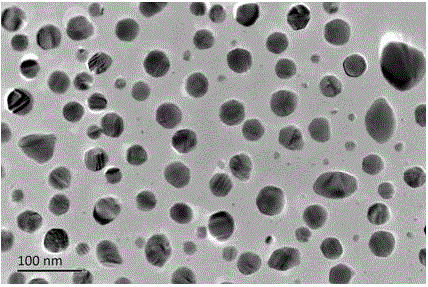

Preparation method of nano copper powder

InactiveCN106424751AUniform particle sizeGood dispersionTransportation and packagingMetal-working apparatusDispersityHydrogen atmosphere

The invention discloses a preparation method of nano copper powder. Copper oxide and calcium oxide powder are made into calcium cuprate powder by mechanical mixing and calcination technologies, then the calcium cuprate powder is reduced in a hydrogen atmosphere, then cleaning with a dilute hydrochloric acid solution is carried out, and the nano copper powder is obtained. The preparation method is simple in technology, the used raw materials are low-cost and are easy to obtain, no special equipment is required in a mixing stage, a calcination stage or a reduction stage, and rapid continuous mass production can be realized. The prepared nano copper powder is uniform in particle size, good in dispersity and low in oxygen content, and the mean particle size of primary particles is around 20 nanometers.

Owner:NANCHANG UNIV

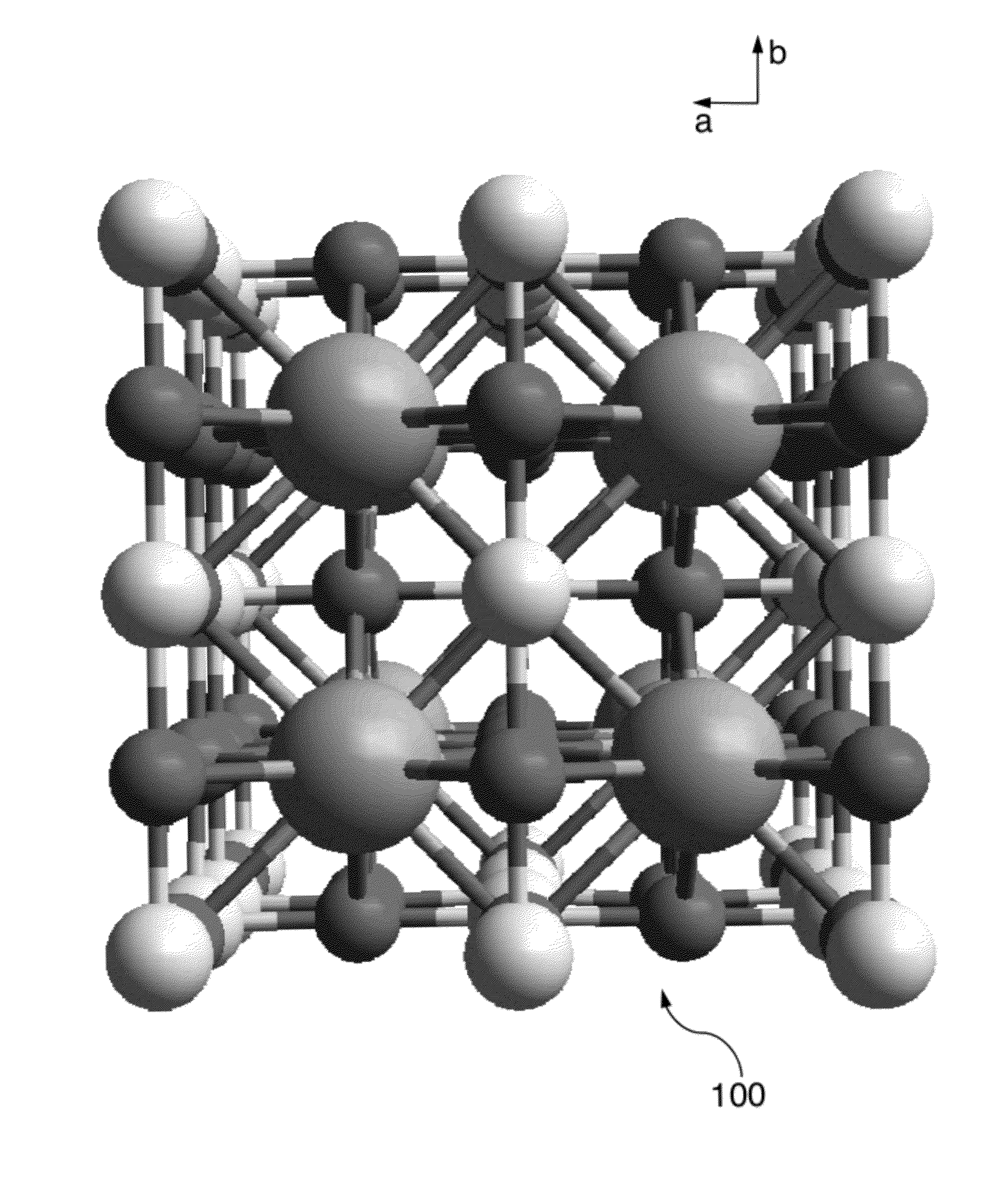

Super conducting cable conductor with rebco-coated conductor elements

ActiveUS7231239B2Thinner cableSufficient superconducting propertySuperconductors/hyperconductorsNon-conductive material with dispersed conductive materialElectrical conductorCuprate

The present invention relates to a superconducting cable conductor which contains a carrying element, on which is wound at least one layer comprising two or more superconducting conductor elements, the individual conductor elements of each layer being arranged next to one another, and the superconducting conducting elements are formed from a tape-type substrate coated with a superconducting material based on rare earth barium cuprate, preferably based on yttrium barium cuprates.

Owner:NEXANS SUPERCONDUCTORS

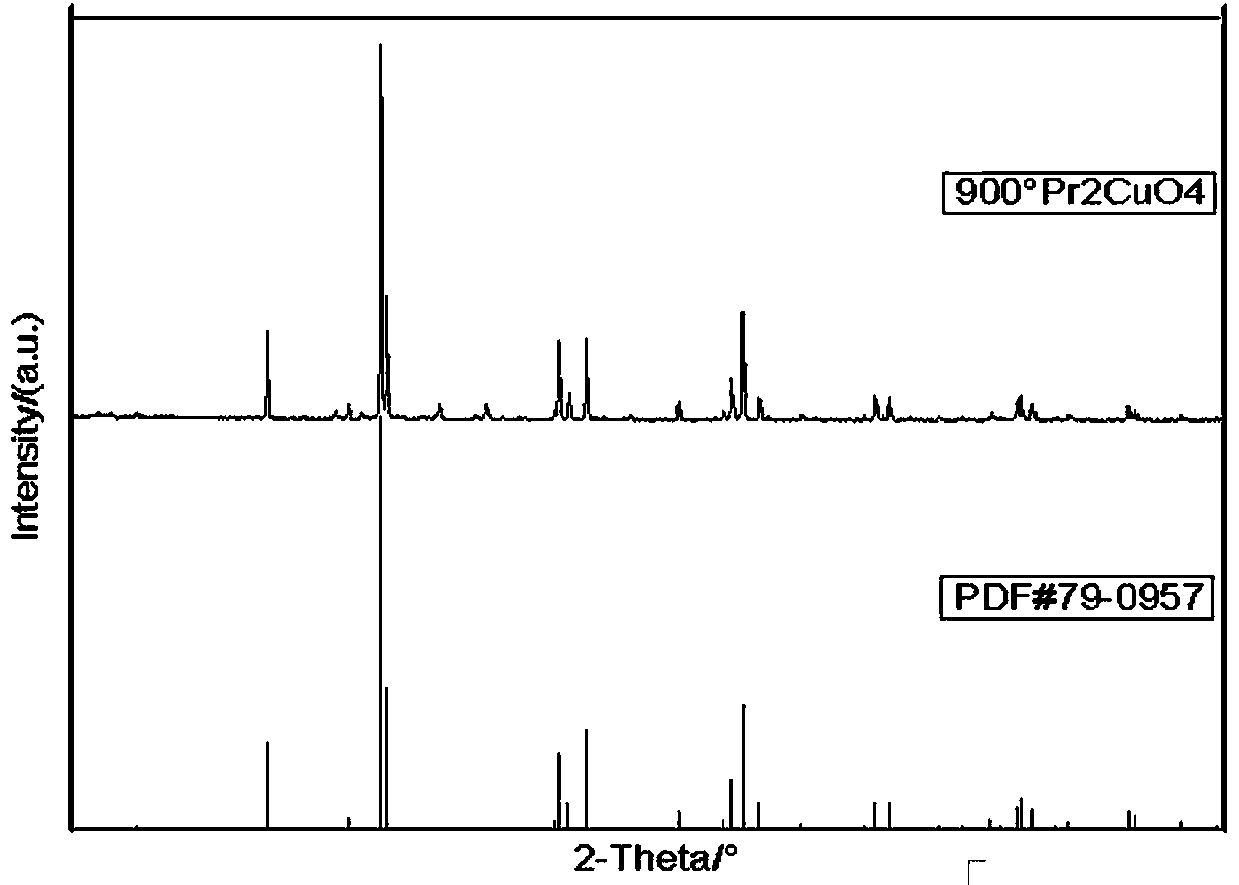

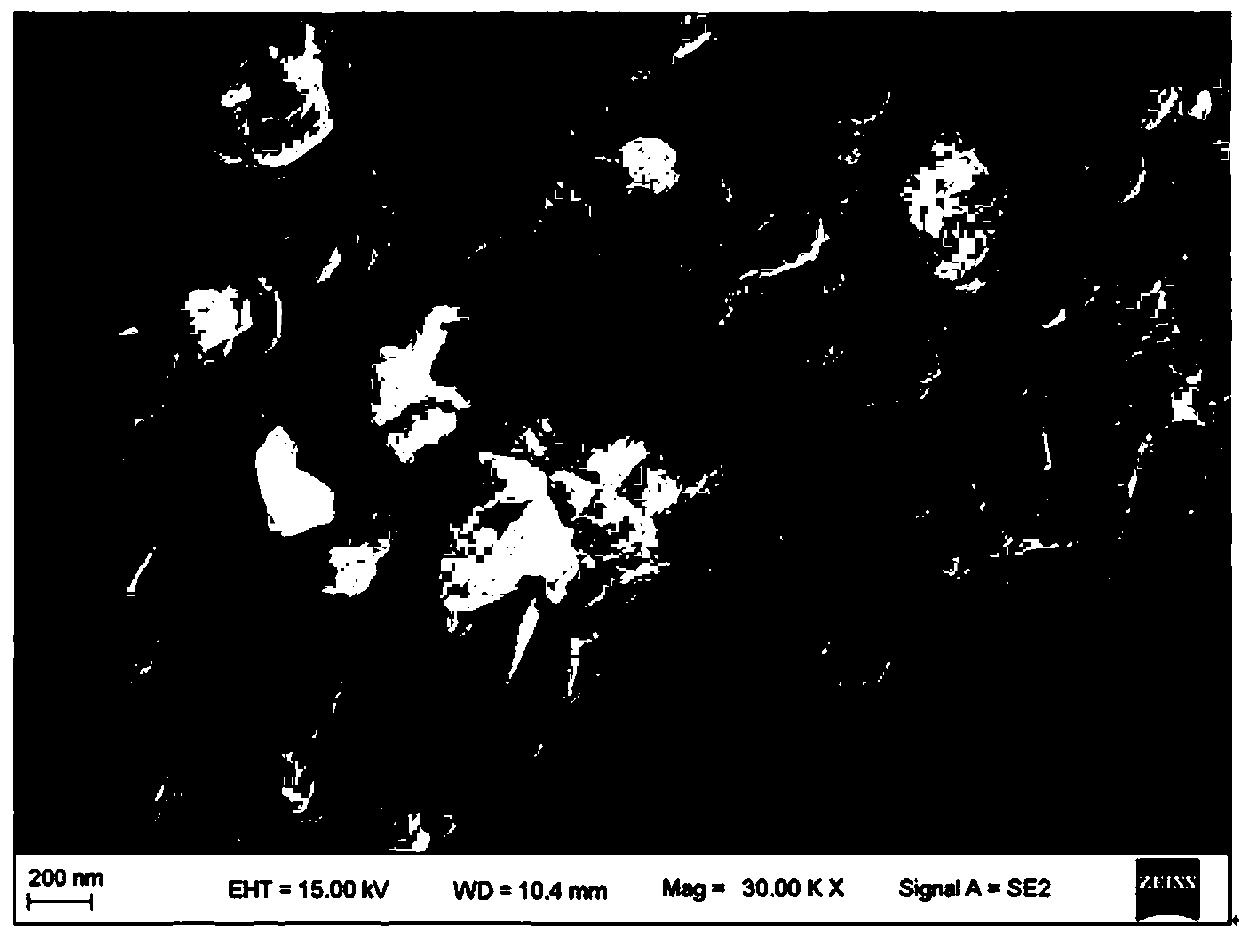

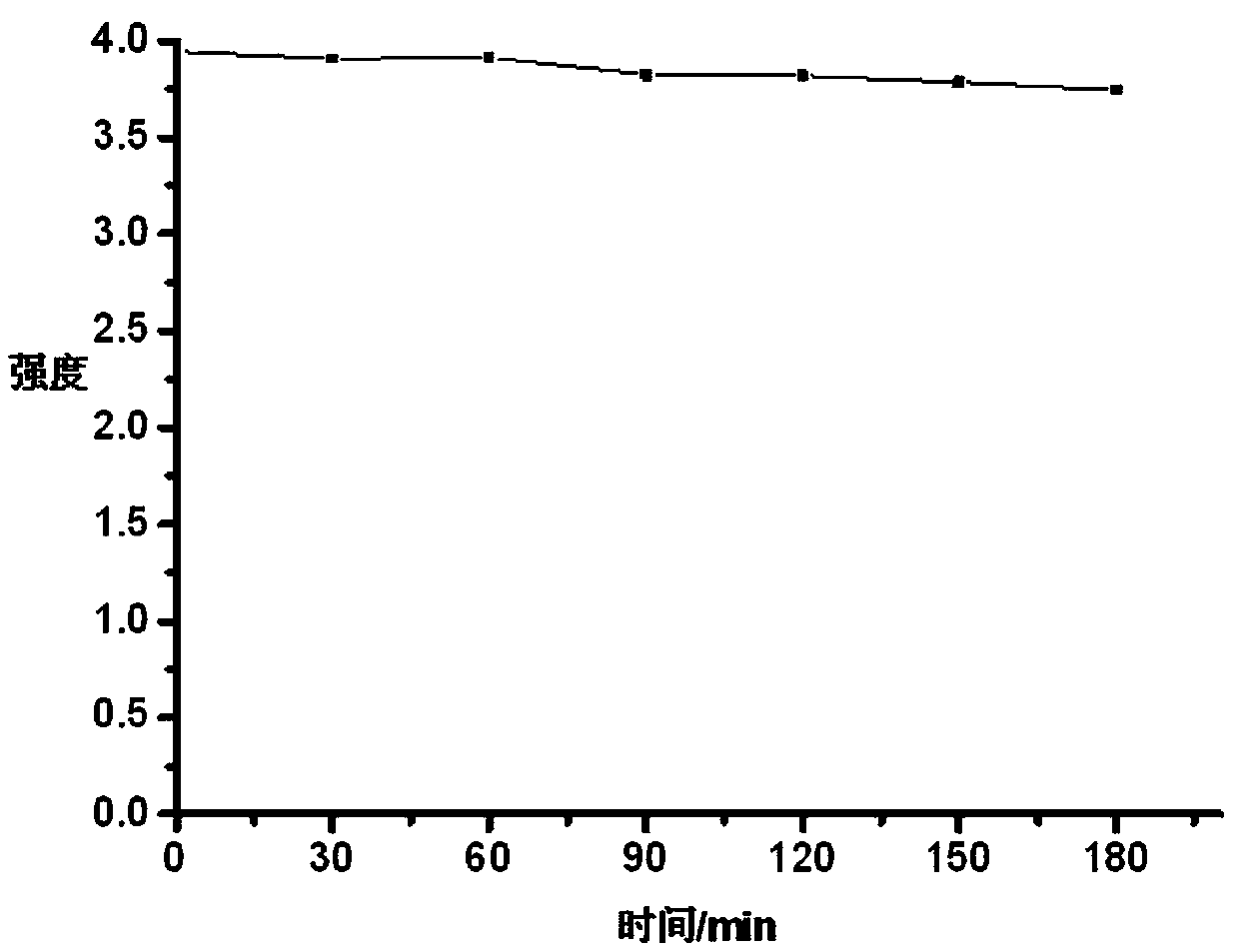

Preparation method and application of praseodymium cuprate nano absorbing material

ActiveCN107777719APromote NanoizationUniform particlesMaterial nanotechnologyOther chemical processesCuprateControllability

The invention belongs to the technical field of nano absorbing materials and particularly relates to a preparation method and application of a praseodymium cuprate nano absorbing material. The preparation method is implemented through impressed voltage, and through control over an applied electric field, can change morphology and related characters of prepared PrCuO4 nano powder, thereby achievinghigh controllability. The preparation method of the praseodymium cuprate nano absorbing material improves common electric field operation, combines the electric field with solution, and control overthe added amount of dispersing agent of dimethylglyoxime with change in the pH of the solution to prepare the nano powder with a large specific surface area and uniform particles; the nano powder hassingle absorbing effects, provides a new material and a new idea for existing water pollution treatment and develops new properties.

Owner:东北大学秦皇岛分校

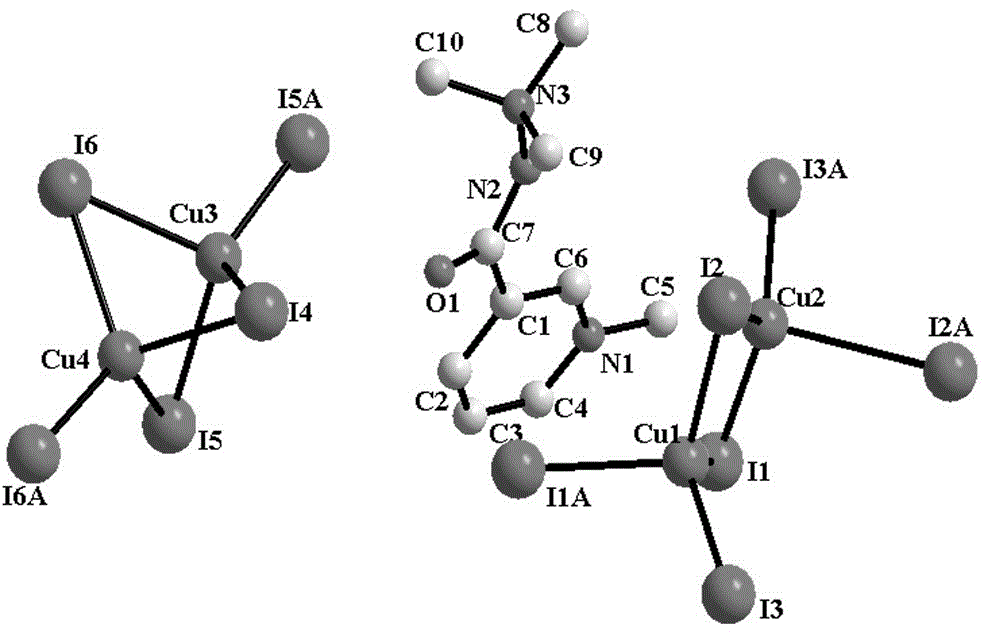

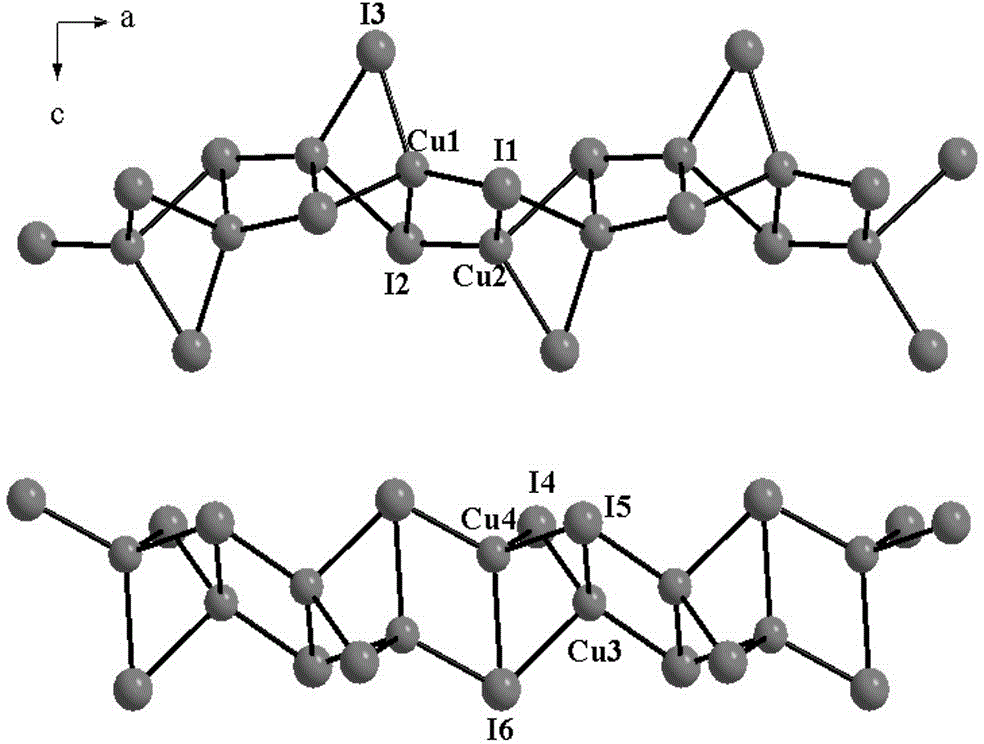

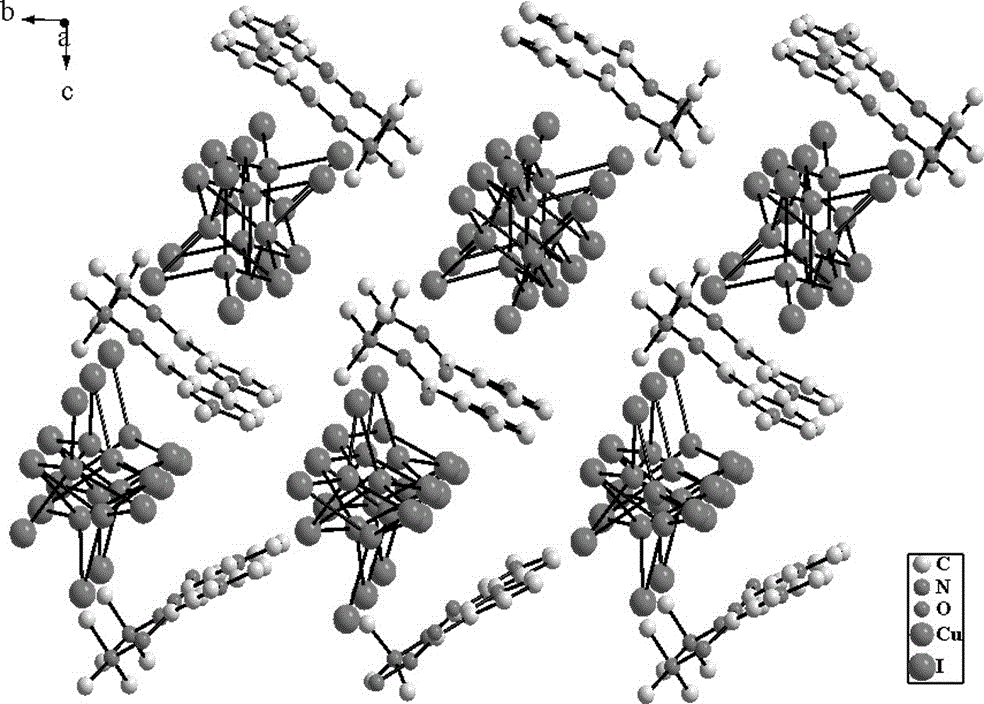

Photochromic/thermochromic material based on iodine cuprate hybrid and preparation of photochromic/thermochromic material

ActiveCN105950131ARich varietyRich in colorOrganic chemistryTenebresent compositionsThermochromismUltraviolet lights

The invention relates to the field of synthesis of organic-inorganic hybrid chromogenic materials, in particular to a photochromic / thermochromic material based on a methyl nicotinic hydrazide-iodine cuprate hybrid and preparation of the photochromic / thermochromic material. An in-situ generated methyl nicotinic hydrazide cation is taken as a structure-directing agent for guiding synthesis of the iodine cuprate hybrid with photochromic and thermochromic properties. According to the invention, the methyl nicotinic hydrazide cation and an iodine cuprate anionic framework are taken an electron acceptor and donor respectively, one photochromic / thermochromic difunctional material based on the methyl nicotinic hydrazide-iodine cuprate hybrid is provided, so that variety and color of a conventional chromogenic material are enriched, and the blank in the technical field is filled up. The photochromic / thermochromic material can respond to ultraviolet light and visible light besides response to low temperature to produce reversible thermochromism, photochromism and achromatism speeds are high, the photoresponse range is wide, the chromogenic contrast is high, the chromogenic performance of the conventional material is greatly improved, and the application range of the chromogenic material is broadened.

Owner:山西师范大学

Modified lithium nickel cobalt manganate material

InactiveCN106129398AAdvanced technologyImprove discharge capacityCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a modified lithium nickel cobalt manganate material. The modified lithium nickel cobalt manganate material comprises the following raw materials: 800-1,000 parts of lithium nickel cobalt manganate, 10-18 parts of nano graphene, 3-5 parts of microcrystalline silicon powder, 5-8 parts of nanocarbon particles, 5-6 parts of carbon fibers, 2-5 parts of iron boride, 4-5 parts of antimony pentoxide, 3-5 parts of silver hexafluorophosphate, 2-4 parts of tetrahydroxy sodium cuprate, 2-4 parts of maleic anhydride grafted compatilizer, 5-6 parts of ethylene diamine tetraacetic acid, 4-5 parts of titanate coupling agent, 5-6 parts of modified copper powder, 4-5 parts of conductive copper powder, 5-8 parts of nanometer aluminum powder and 10-25 parts of deionized water. The modified lithium nickel cobalt manganate material has the advantages of advanced technology, wide raw material resource, low cost, high discharge capacity, long service life and the like; meanwhile, the material has no toxins and environmental pollution; and therefore, the consistency of the industrialization and the cruising power of the power batteries are ensured.

Owner:陈新堂

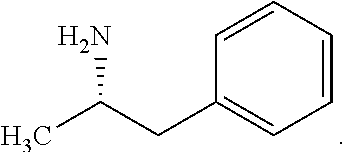

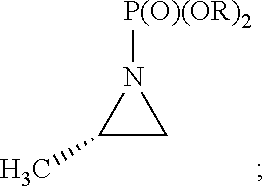

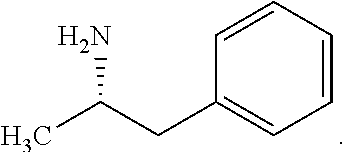

Synthesis of chiral amphetamine derivatives by stereospecific, regioselective cuprate addition reaction with aziridine phosphoramidate compounds

The invention includes processes for the synthesis of amphetamine, dexamphetamine, methamphetamine, derivatives of these, including their salts, and novel precursors and intermediates obtained thereby, by synthesizing aziridine phosphoramidate compounds in specified solvents at specified temperatures, and then converting to a novel aryl or aryl-alkyl phosphoramidate precursors using an organometallic compound such as a copper salt, where the novel aryl or aryl-alkyl phosphoramidate precursor is then easily converted to the target compounds using known reactions.

Owner:CHEMAPOTHECA

Synthesis of racemic amphetamine derivatives by cuprate addition reaction with aziridine phosphoramidate compounds

The invention includes processes for the synthesis of amphetamine, dexamphetamine, methamphetamine, derivatives of these, including their salts, and novel precursors and intermediates obtained thereby, by synthesizing aziridine phosphoramidate compounds in specified solvents at specified temperatures, and then converting to a novel aryl or aryl-alkyl phosphoramidate precursors using an organometallic compound such as a copper salt, where the novel aryl or aryl-alkyl phosphoramidate precursor is then easily converted to the target compounds using known reactions.

Owner:CHEMAPOTHECA

Method of making a superconductive oxide body

InactiveUS6291402B1High fracture loadImprove toughnessSuperconductors/hyperconductorsSuperconductor detailsElectrical conductorCuprate

Some mechanical, electrical, and thermal properties of high Tc superconductors such as (Ba, Y) cuprates can be substantially improved by the dispersal of an appropriate metal in the superconductive body. For instance, mixing Ag particles with superconductive powder of nominal composition Ba2YCu3O7 and processing the mixture in the conventional manner can produce superconductive bodies having Tc of about 93 K and substantially greater fracture strength and normal state electrical and thermal conductivity than otherwise identical bodies that do not contain Ag particles.

Owner:WSOU INVESTMENTS LLC

Normal-temperature corrosion-resistant phosphating solution and preparation method thereof

InactiveCN106498380APrevent rustSimplify the phosphating processMetallic material coating processesPhosphateNitrobenzene

The invention discloses a normal-temperature corrosion-resistant phosphating solution and a preparation method thereof. The normal-temperature corrosion-resistant phosphating solution is prepared from the following raw materials in parts by weight: 35-56 parts of deionized water, 6-8 parts of sodium molybdate dehydrate, 2-7 parts of chromic acid, 5-8 parts of hydroxylamine sulphate, 4-8 parts of methyl methacrylate, 4-5 parts of sodium fluoroborate, 4-9 parts of tartaric acid, 22-24 parts of citric acid, 2-6 parts of cyclohexanehexol hexaphosphate ester, 1-8 parts of ammonium cuprate, 2-6 parts of m-nitrobenzene, 3-6 parts of sodium silicate and 6-10 parts of manganese dihydrogen phosphate. Compared with a conventional phosphating solution and a conventional phosphating process, the normal-temperature corrosion-resistant phosphating solution disclosed by the invention has the advantages that when a workpiece is subjected to phosphating by adopting the normal-temperature corrosion-resistant phosphating solution, the phosphating process is simplified, the phosphating efficiency is improved, and the phosphating cost is reduced; meanwhile, a phosphating film formed by adopting the normal-temperature corrosion-resistant phosphating solution not only is denser and more uniform, but also can be used for effectively protecting the workpiece from corrosion; and the preparation method is simple and low in cost.

Owner:JIANGSU JINGWEI TECH INNOVATION CONSULTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com