Photochromic/thermochromic material based on iodine cuprate hybrid and preparation of photochromic/thermochromic material

A color-changing material, photochromic technology, applied in the direction of color-changing fluorescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of restricting the development of color-changing materials, no activity performance, single response factors, etc., to achieve rich varieties and colors, Fast photochromic and achromatic effects with extended application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add CuI (190mg, 1mmol), nicotinic acid niacin (68mg, 0.2mmol), NaI (750mg, 5mmol) and 45% hydroiodic acid (0.2mL, 1.05mmol) into 3mL of methanol solution, after stirring for 40 minutes, The bright yellow turbid liquid was obtained, which was transferred to a 15mL polytetrafluoroethylene-lined hydrothermal reaction kettle, placed in a 70°C oven for 4 days, and slowly cooled at room temperature to obtain brownish yellow rod-shaped crystals, which were filtered and washed with ethanol After drying. Yield: 26.2% (based on Cu).

Embodiment 2

[0031] Add CuI (380mg, 2mmol), nicotinic acid niacin (136mg, 0.4mmol), NaI (750mg, 5mmol) and 45% hydroiodic acid (0.4mL, 2.1mmol) into 5mL methanol solution, after stirring for 40 minutes, The bright yellow turbid liquid was obtained, which was transferred to a 15mL polytetrafluoroethylene-lined hydrothermal reaction kettle, placed in an oven at 80°C for 3 days, and slowly cooled at room temperature to obtain brownish-yellow rod-shaped crystals, which were filtered and washed with ethanol After drying. Yield: 29.5% (based on Cu).

Embodiment 3

[0033] Add CuI (190mg, 1mmol), nicotinic acid niacin (68mg, 0.2mmol), NaI (750mg, 5mmol) and 45% hydroiodic acid (0.5mL, 2.64mmol) into 5mL of methanol solution, after stirring for 40 minutes, The bright yellow turbid liquid was obtained, which was transferred to a 15mL polytetrafluoroethylene-lined hydrothermal reaction kettle, placed in a 70°C oven for 4 days, and slowly cooled at room temperature to obtain brownish yellow rod-shaped crystals, which were filtered and washed with ethanol After drying. Yield: 24.6% (based on Cu).

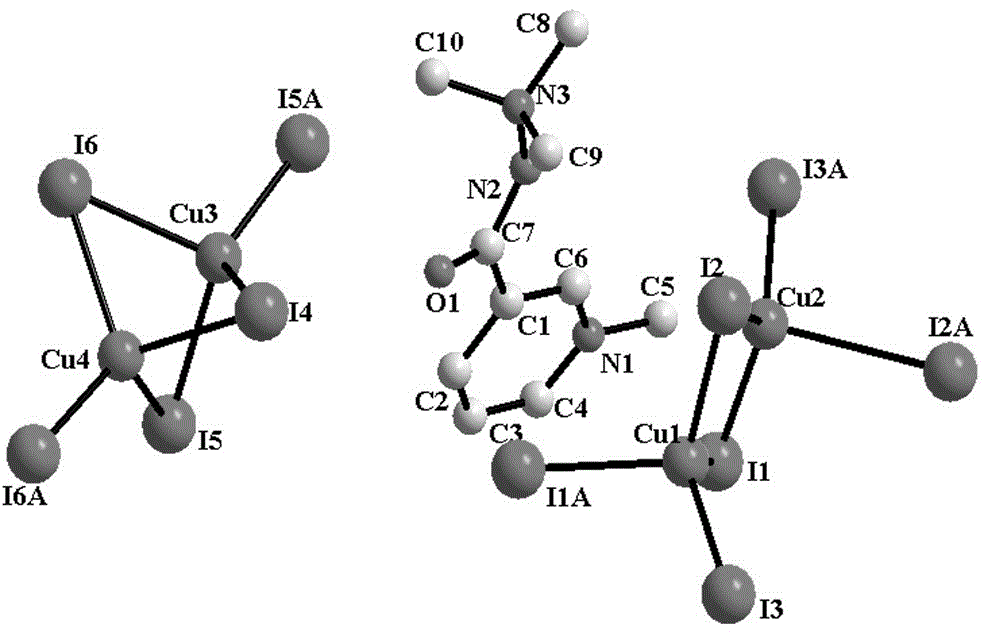

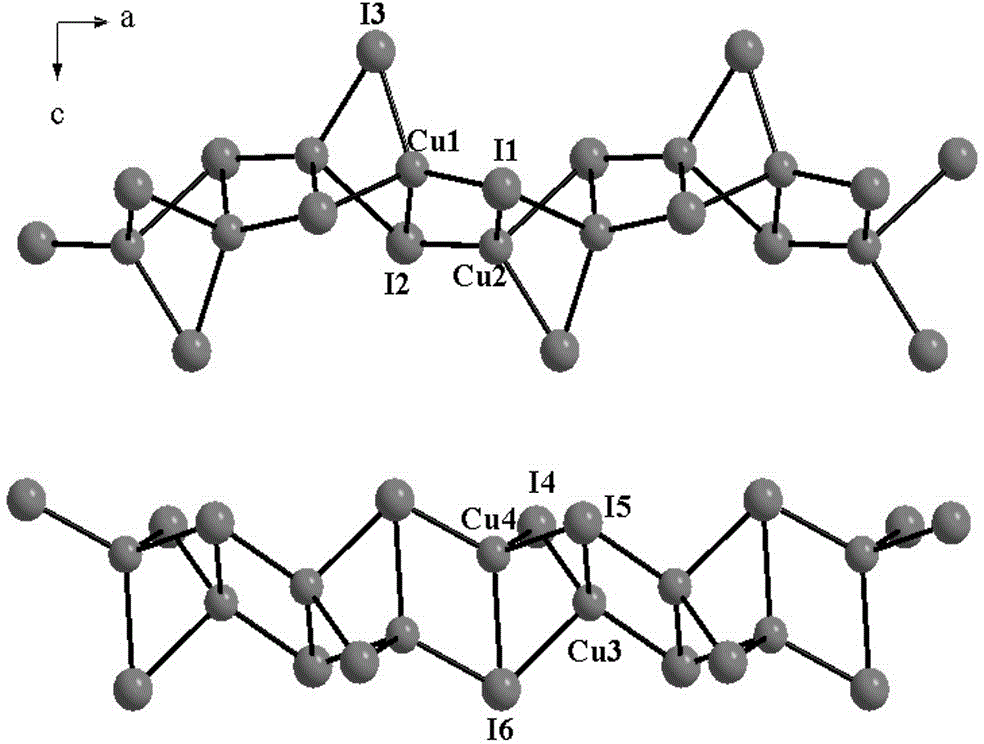

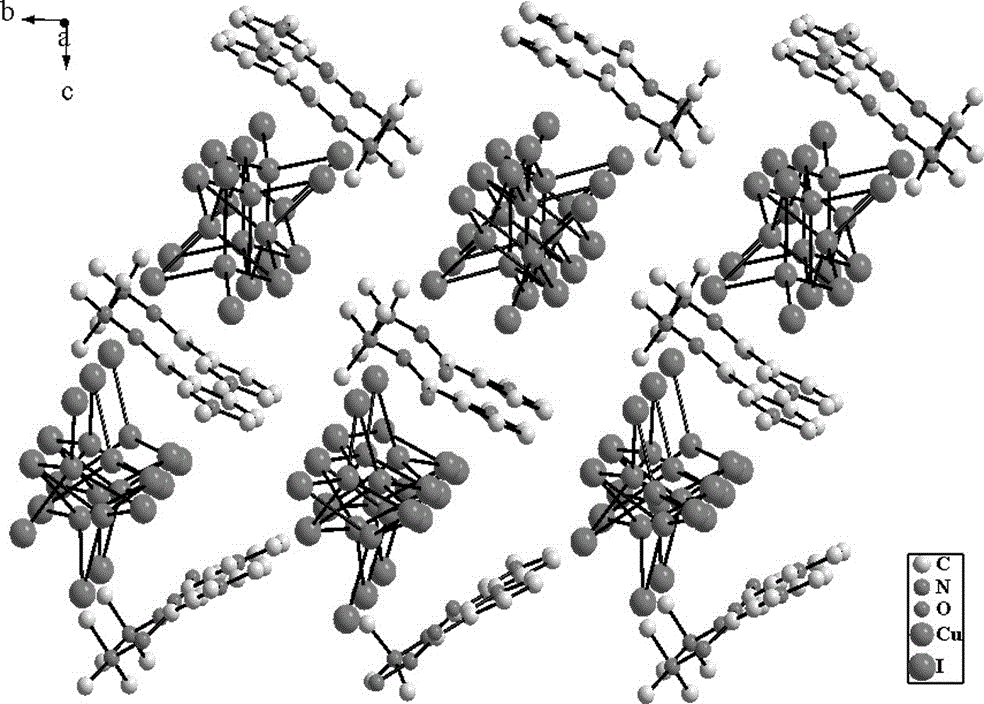

[0034] The determination of the crystal structure of the methyl nicotinic acid hydrazide iodocuprate hybrid obtained in Examples 1 to 3 is as follows: a single crystal with a suitable size is selected under a microscope for X-ray single crystal structure analysis. The X-ray diffraction data of the crystals were measured by a SMART APEXCCD single crystal diffractometer and irradiated with a graphite monochromator Mo-Kα Data were collected in ome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com