Patents

Literature

209results about How to "Good discoloration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chameleon fiber fabric processing technology

InactiveCN102304857BReduce consumptionSimple production processSynthetic resin layered productsTextiles and paperFiberColor changes

The invention relates to the field of production of chameleon fiber fabric, in particular to a chameleon fiber fabric processing technology based on graft polymerization. The processing technology comprises preparation of graft mixed liquid and coating and transferring of the graft mixed liquid, wherein the coating and transferring of the graft mixed liquid comprises the following steps of: step a, coating the graft mixed liquid on one side of release paper, baking the release paper at 110 DEG C-220 DEG C to dry the coated graft mixed liquid; and step b. coating an adhesive on the other side of the release paper, baking the release paper till the drying degree of the coated adhesive reaches 70%-80%, and adhering the side of the release paper, which is coated with the adhesive, on a fabricbase material. According to the invention, the graft mixed liquid is coated on the release paper, the release paper coated with a color-change layer is adhered on the fabric base material, and the graft mixed liquid prepared in one time can be used for different fabric base materials, thus the processing technology is convenient and quick and has low cost.

Owner:PENGCHENG IND

Weather-resistant multiple-layer alteration paint and preparation method thereof

InactiveCN101200605AGood discoloration effectColorfulInorganic pigment treatmentGlass/slag layered productsRefractive indexThin layer

The invention provides weather resistant discoloration pigment with a plurality of layers and a preparation method thereof, which relates to the pigment field. At present, the technical effects of the pigment with a plurality layers are various, but the weather resistant problem is not solved. The weather resistant discoloration pigment with a plurality of layers of the invention uses a natural mica thin section (including a synthetic mica thin section and a glass thin section) as substrate. A plurality of layers of metal oxides are alternatively coated on the surface of the substrate. The first layer is SiO2 thin layer. The refractive index of the metal oxides in the second layer and the fourth layer is bigger than 20. The refractive index of the oxide in the third layer is smaller than 1.8. The outer layer is a colorless transparent weather resistant protection layer which consists of four oxides. The weather resistant discoloration pigment with a plurality of layers has the advantages of obvious discoloration effects, bright color and good weather resistant performance. The preparation method is to use a wet chemical hydrolysis process to coat a plurality of oxides on the surface of the substrate. The method has the advantages of reasonable structure, advanced process, easy operation and stable product quality and is applied to the industrialized production.

Owner:河北欧克新型材料股份有限公司

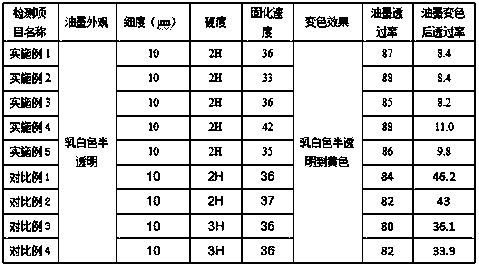

Special varnish for musical instruments and preparation method thereof

ActiveCN102070978AGood fullnessGood discolorationPolyurea/polyurethane coatingsPolyester coatingsSound boxVarnish

The invention discloses special varnish for musical instruments and a preparation method thereof. The special varnish for the musical instruments is a four-component coating; a PE (polyethylene) coating and a PU (polyurethane) coating are combined in the formula and give full play of respective advantages, and the defects of single use of the coatings are avoided, thus solving the defects in single use of the conventional products for musical instrument manufacturers. The special varnish has the advantages of high hardness up to over 2H, excellent fullness, good color change property, no greening property of PE, polishability and thickened viscosity for 5 seconds within 2 hours, thus solving the problem of use time of a single PE component. The special varnish for the musical instruments can be sprayed by an electrostatic machine, can be widely applied to the musical instruments such as a guitar, a loudspeaker box, a piano and the like, and has good comprehensive property and good constructability, thus being beneficial to large-scale popularization.

Owner:HUIZHOU CHANGRUNFA PAINT

Photochromic powder, photochromic glass and preparation method thereof

ActiveCN103627334AImproved discoloration performanceLow costNon-macromolecular adhesive additivesFilm/foil adhesivesFirst glassesPhotochromism

Owner:信义超薄玻璃(东莞)有限公司

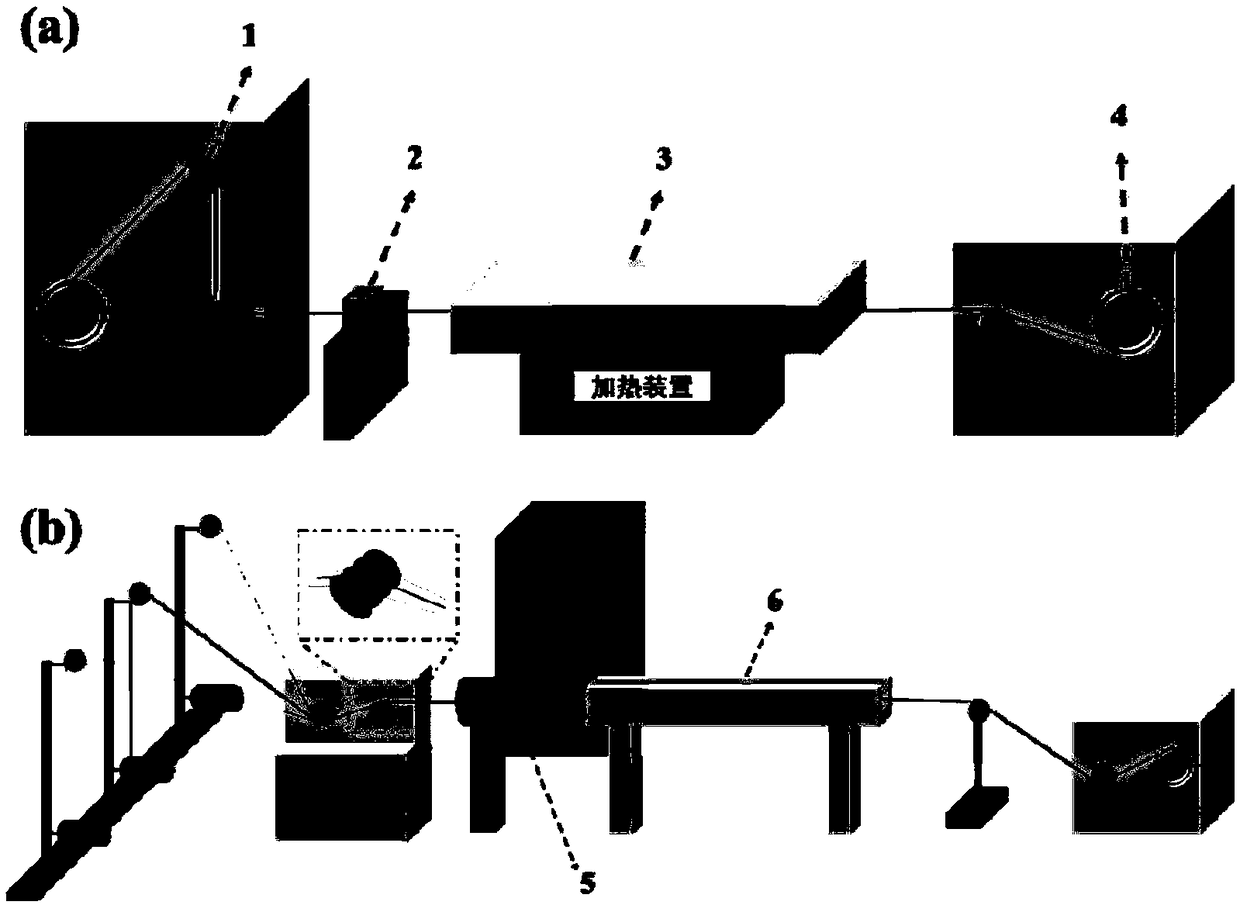

Electrochromic fiber and preparing method and application thereof

ActiveCN108873539ASimple structureRealize long-term constructionNon-linear opticsFiberElectrochromism

The invention relates to an electrochromic fiber and a preparing method and application thereof. The preparing method includes the steps that a metal wire is used as an electrode, the surface of the metal wire is coated with a viologen electrochromic electrolyte solution through fiber continuous construction equipment, heating solidifying is carried out, then external electrodes and a protection layer are prepared on the outer side, and the electrochromic fiber is obtained. The electrochromic fiber prepared with the method has good flexibility and discoloration performance, electrochromic fibers of 100 m or above can be continuously prepared, the problems that the electrochromic fiber is complex in structure, and cannot be continuously prepared are solved, and the electrochromic fiber hasgood application prospects in the field of intelligent garments.

Owner:DONGHUA UNIV

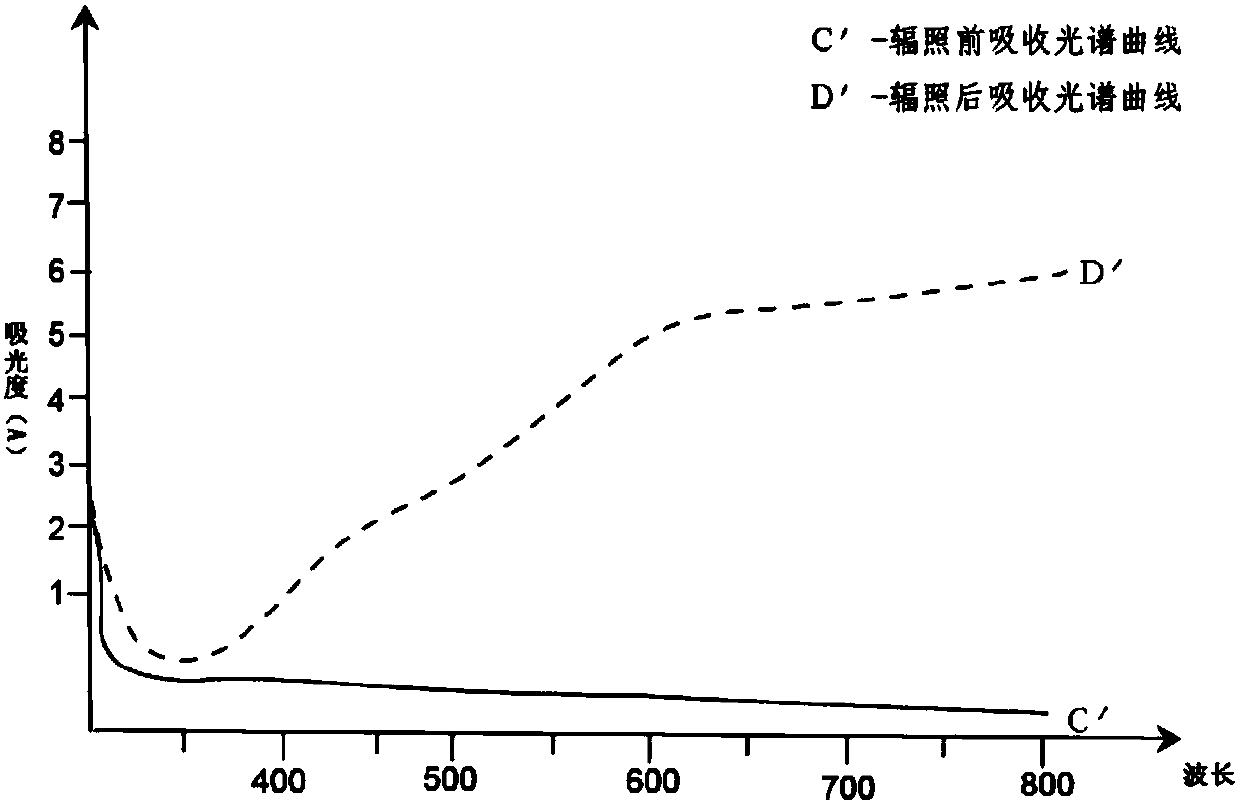

Spiropyrane photochromic optical material and preparation method thereof

ActiveCN107778510AFree from influenceIncrease space volumeOrganic chemistryCoatingsMicrosphereSulfate

The invention relates to a preparation method of a spiropyrane photochromic optical material. The surface of the optical material prepared by adopting the preparation method is coated with a photochromic coating, the coating contains a polyurethane / spiropyrane / zinc sulfide composite multilayer photochromic material, a core of the coating is zinc sulfide mesoporous nano microspheres, an intermediate layer is a photochromic layer composed of spiropyrane compounds, and a shell is polyurethane; and the outer diameter of the composite microspheres is 50-350nm, the diameter of the zinc sulfate mesoporous nano microspheres is 30-250nm, the thickness of the intermediate layer is 5-25nm, and the thickness of the shell is 5-25nm. The optical material prepared by adopting the preparation method can become colored from colorless under ultraviolet irradiation condition, can also be rapidly faded to be colorless after ultraviolet rays disappear and has the advantages of strong fatigue resistance, good stability and high color-changing speed.

Owner:南京米兰达视光科学研究院有限公司

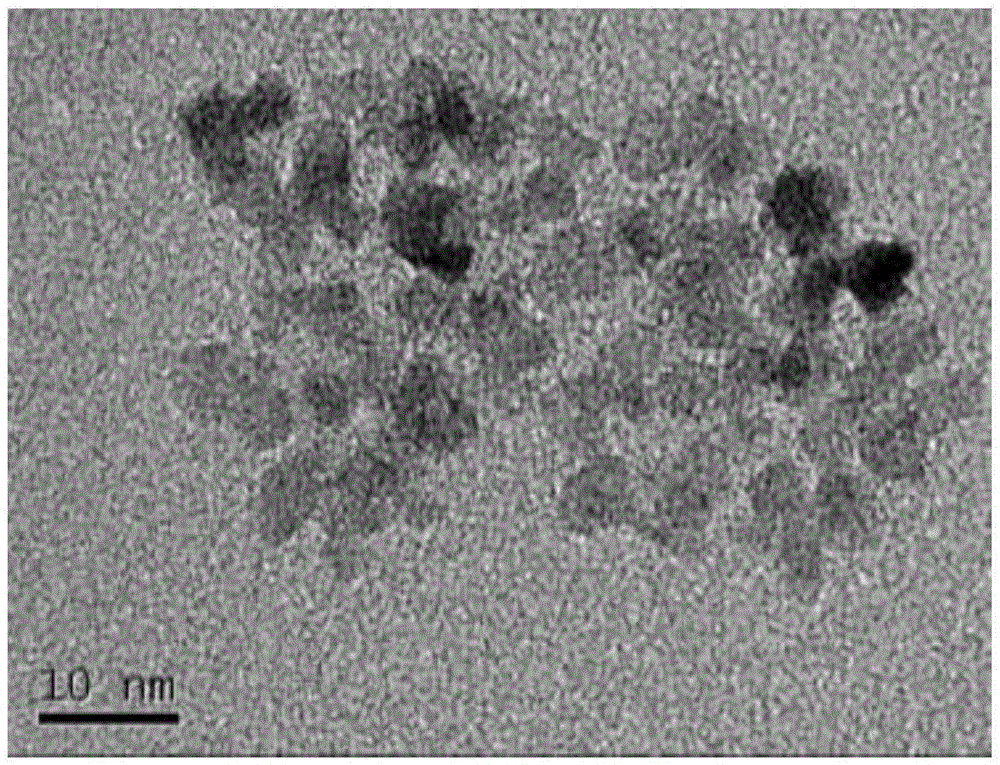

Photochromic nano composite microsphere and application thereof

ActiveCN107903889AThe van der Waals area growsIncrease space volumeTenebresent compositionsOptical partsMicrosphereUltraviolet

The invention discloses a photochromic nano composite microsphere and an application thereof. The photochromic composite microsphere has a three-layer composite core-shell structure, an inner core isa zinc sulfide mesoporous nano microsphere, a middle layer is a photochromic layer formed by a spiropyran compound, and an outer layer is polyurethane; and the outer diameter of the composite microsphere is 50-350nm, wherein the diameter of the zinc sulfide mesoporous nanosphere is 30-250nm, the thickness of the middle layer is 5-25nm, and the thickness of the outer shell is 5-25nm. The photochromic composite microsphere provided by the invention can be used to prepare a photochromic coating or doped into a resin optical material to prepare a photochromic material. The material can be changedfrom colorless to colored under the irradiation of ultraviolet rays, and after the ultraviolet rays disappear, the material can be quickly faded into colorless, and has the advantages of strong fatigue resistance, good stability, a fast color change speed and the like.

Owner:JIANGSU SHIKEXINCAI CO LTD

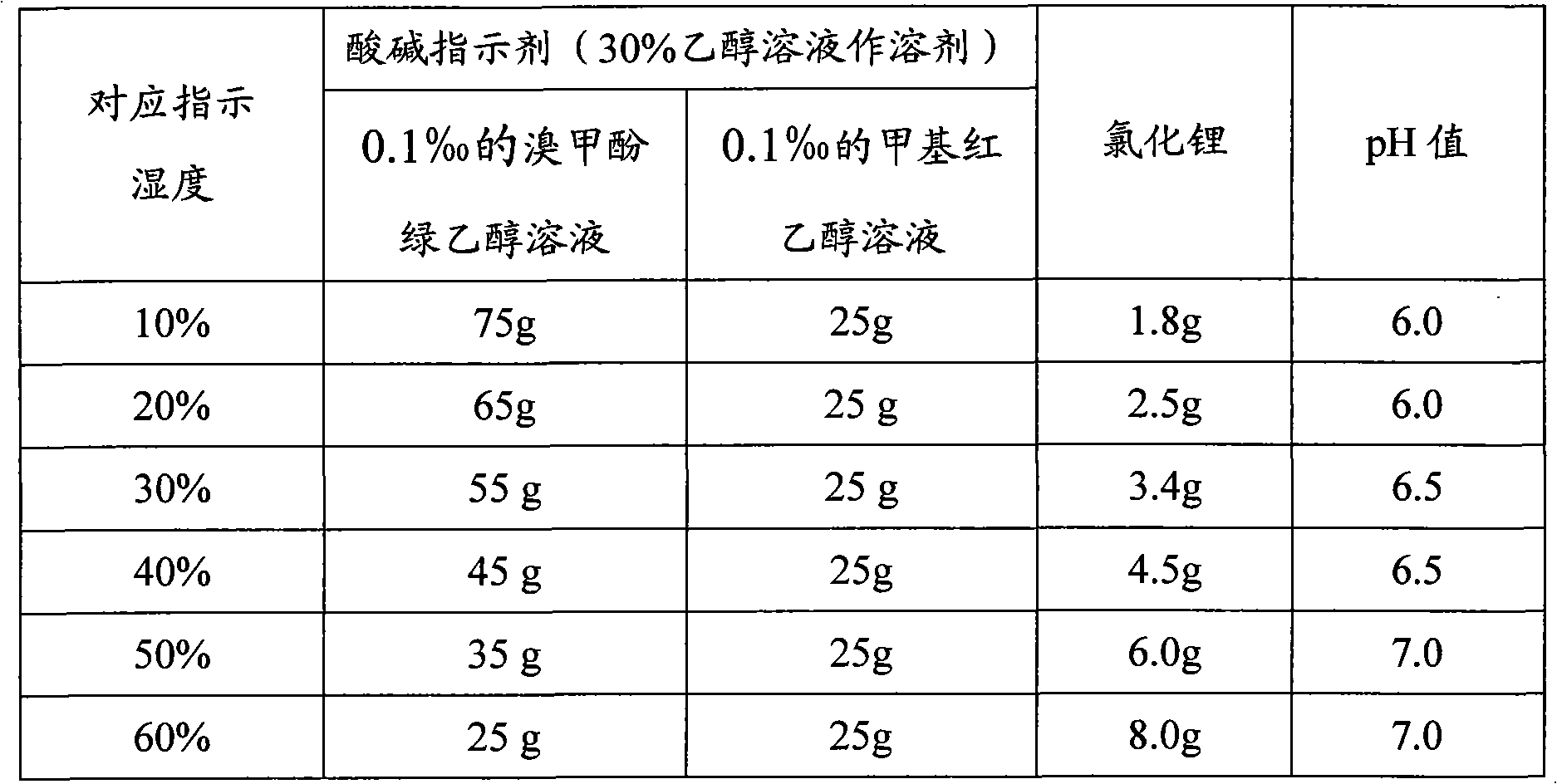

Humidity indicator and manufacturing method thereof

InactiveCN101556265AIndicates a wide rangeHigh sensitivityAnalysis using chemical indicatorsAlkaline earth metalBromothymol blue

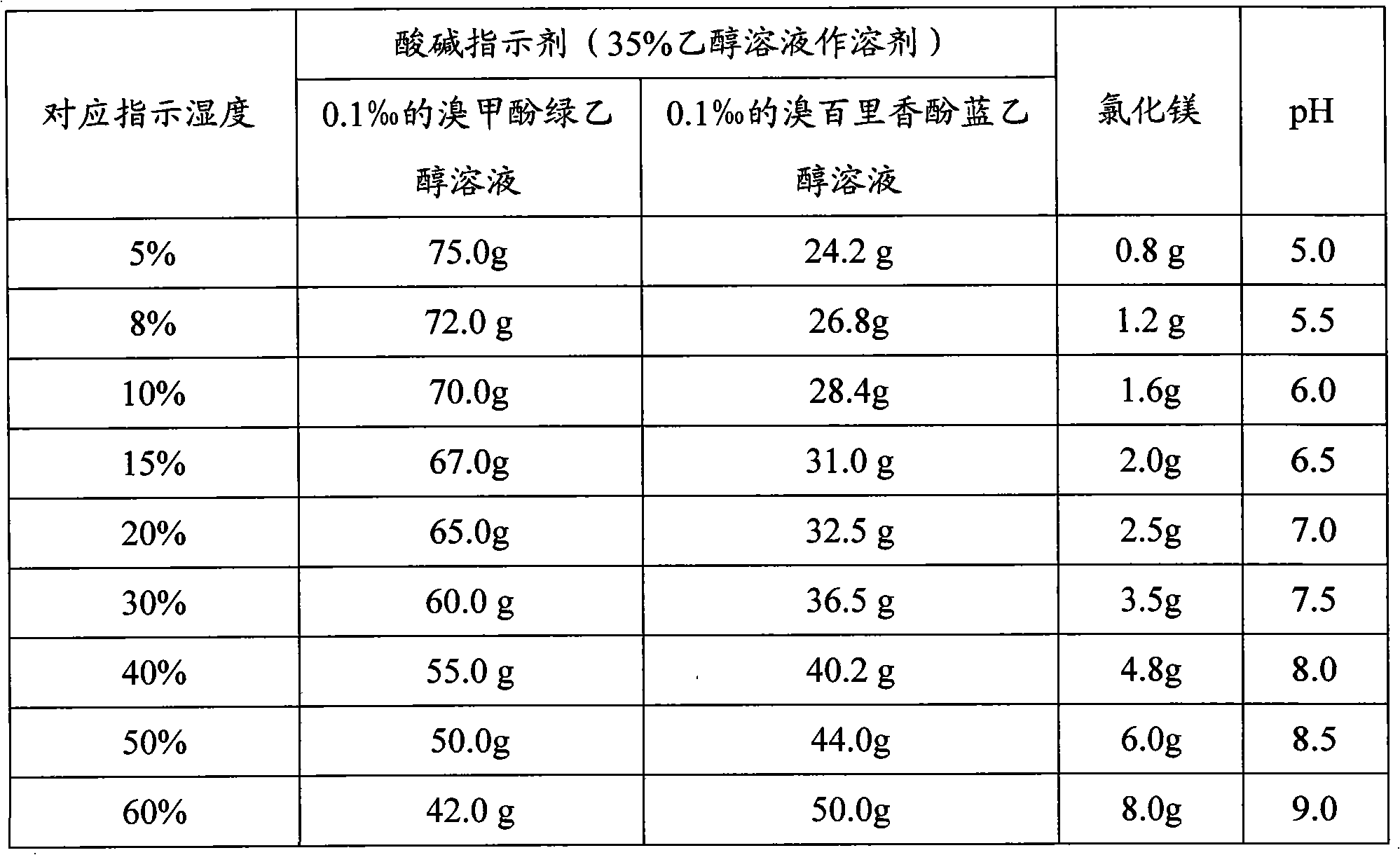

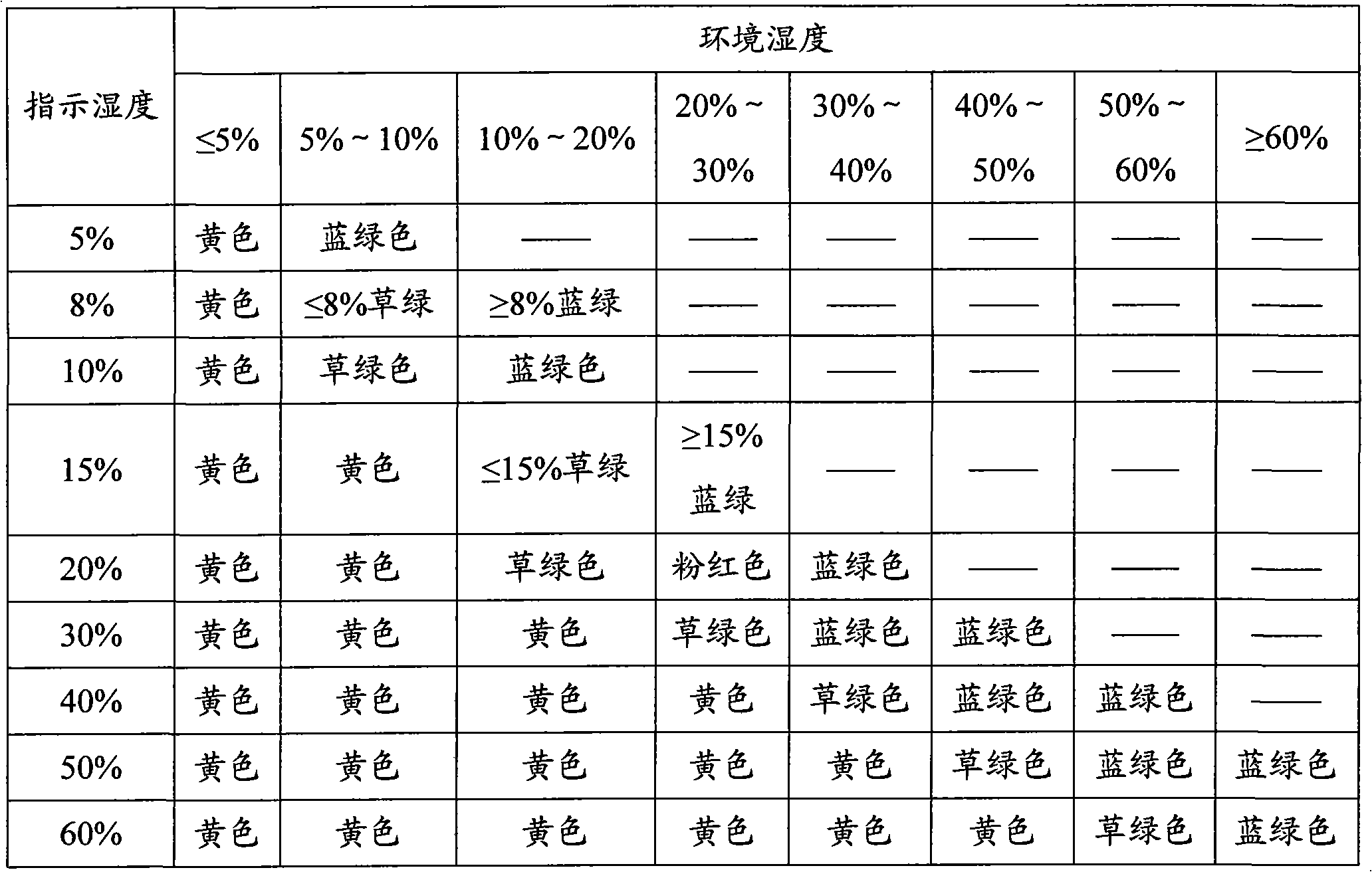

The invention provides a humidity indicator which is really effective in environmental protection and comprises a carrier and solution used for soaking the carrier; wherein, the solution takes 30-80% of ethanol as a solvent and contains 0.00862-0.00992% of acid-base indicator and 0.8-13.8% of hygroscopic salt. The acid-base indicator is one of bromocresol green, bromothymol blue, thymol blue, thymolphthalein, bromophenol blue, methyl red, methyl orange, methyl yellow , neutral red and phenol red or the mixture thereof. The hygroscopic salt is alkali halide or alkali-earth metal halide. The humidity indicator of the invention has wide indicating range (capable of indicating 5-90% of ambient humidity) and high sensitivity. Diverse humidity indicators different in discoloration can be manufactured by adjusting the components. The humidity indicator of the invention has evident discoloration effect, simple use, reutilization, good suitability and extensive application.

Owner:杨德成 +1

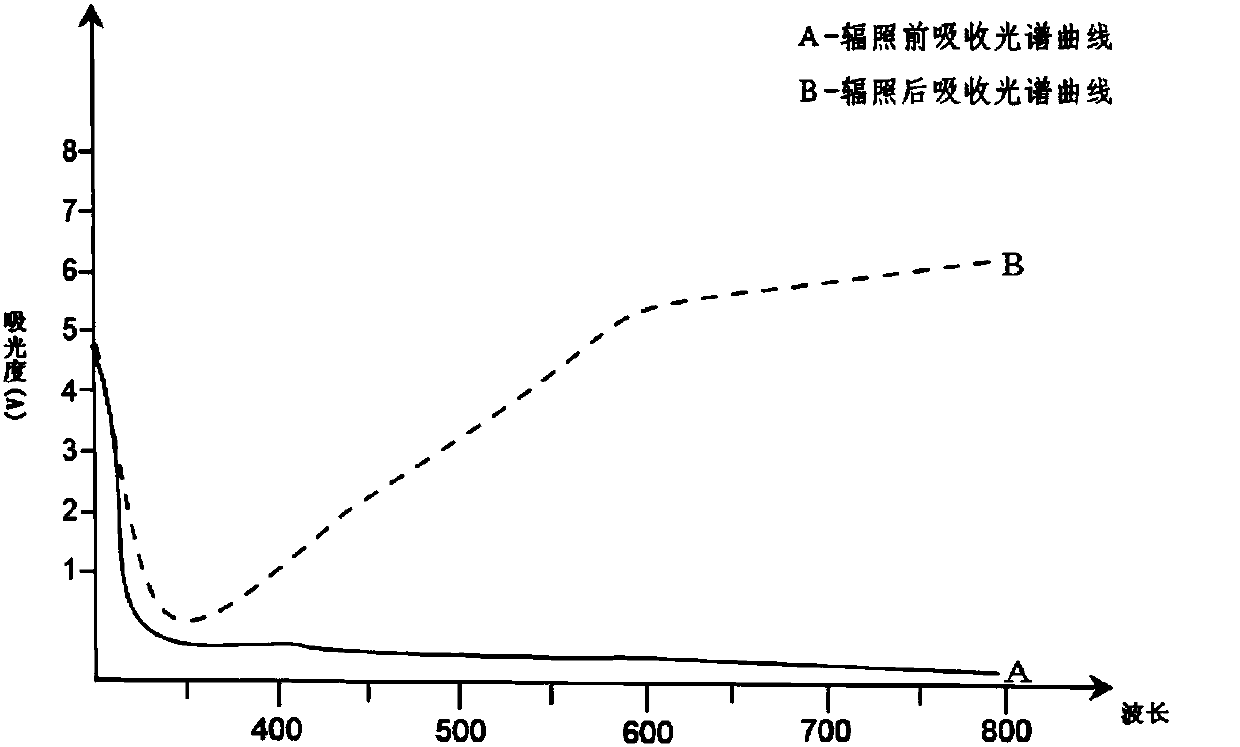

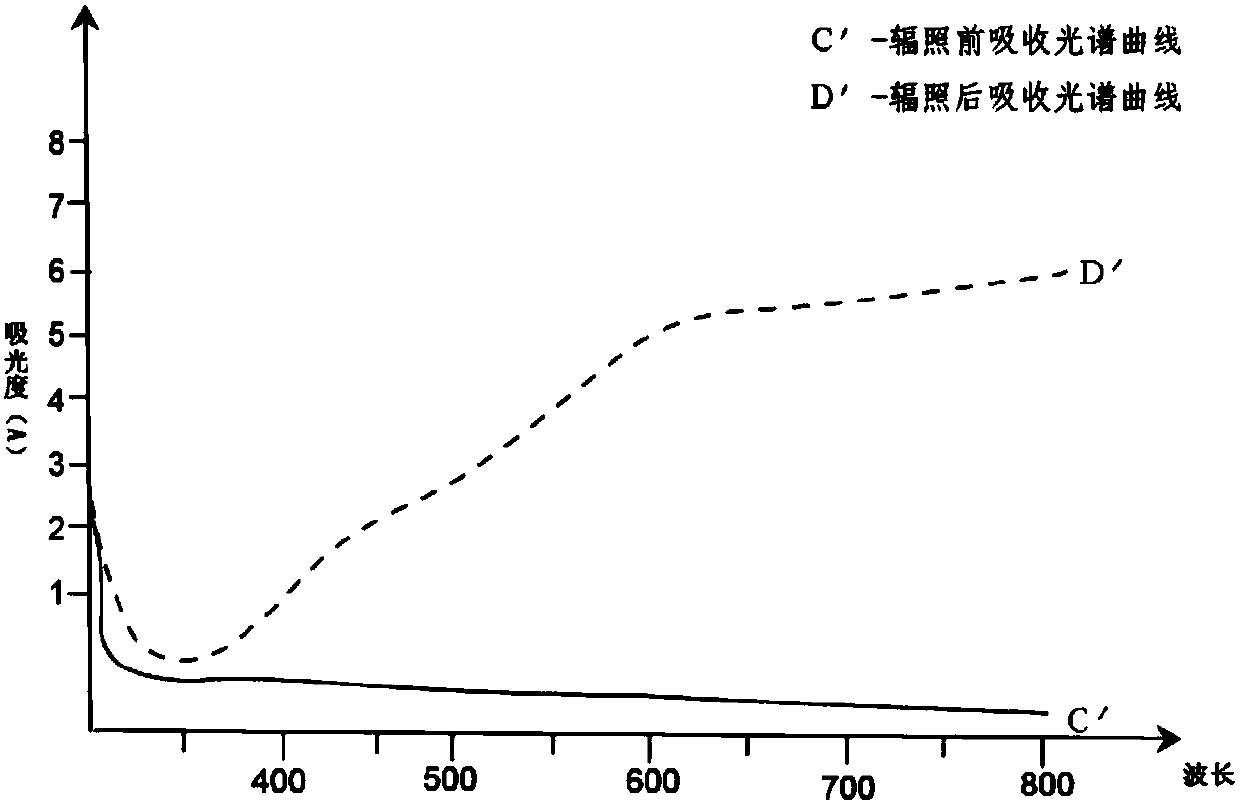

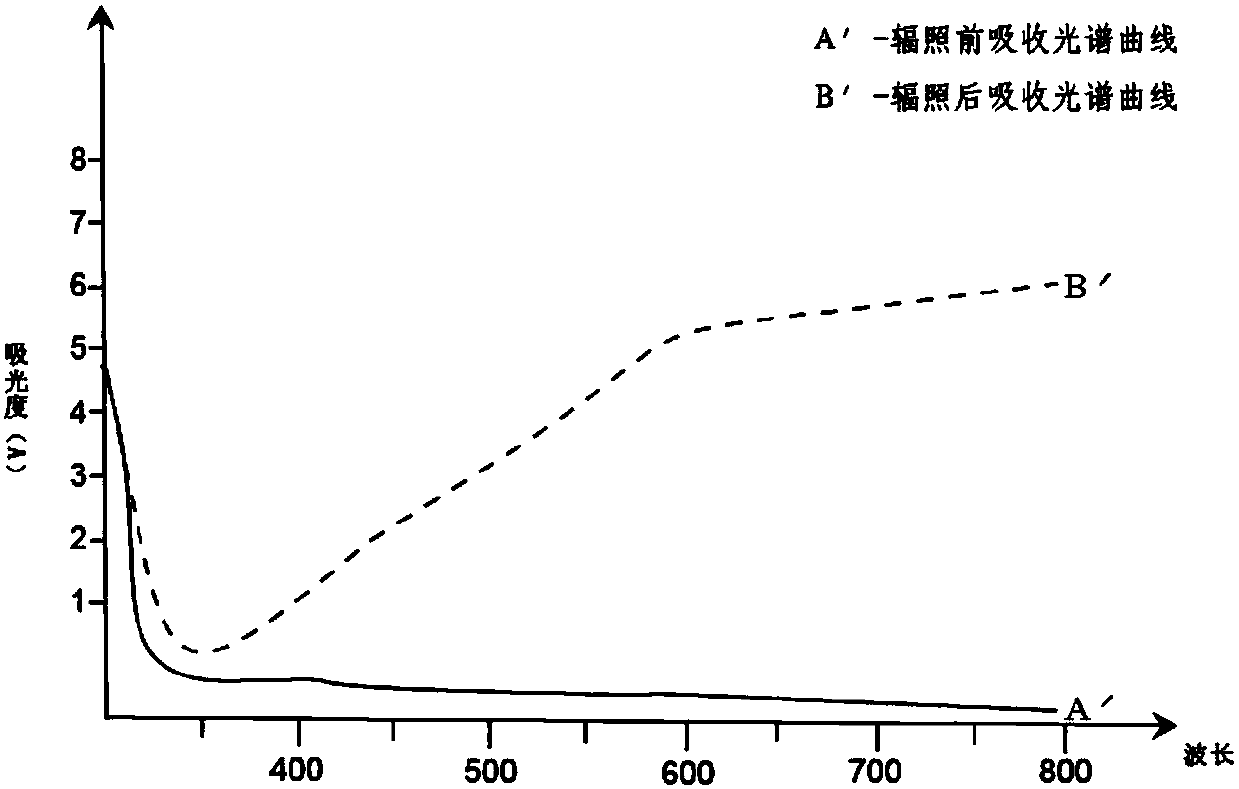

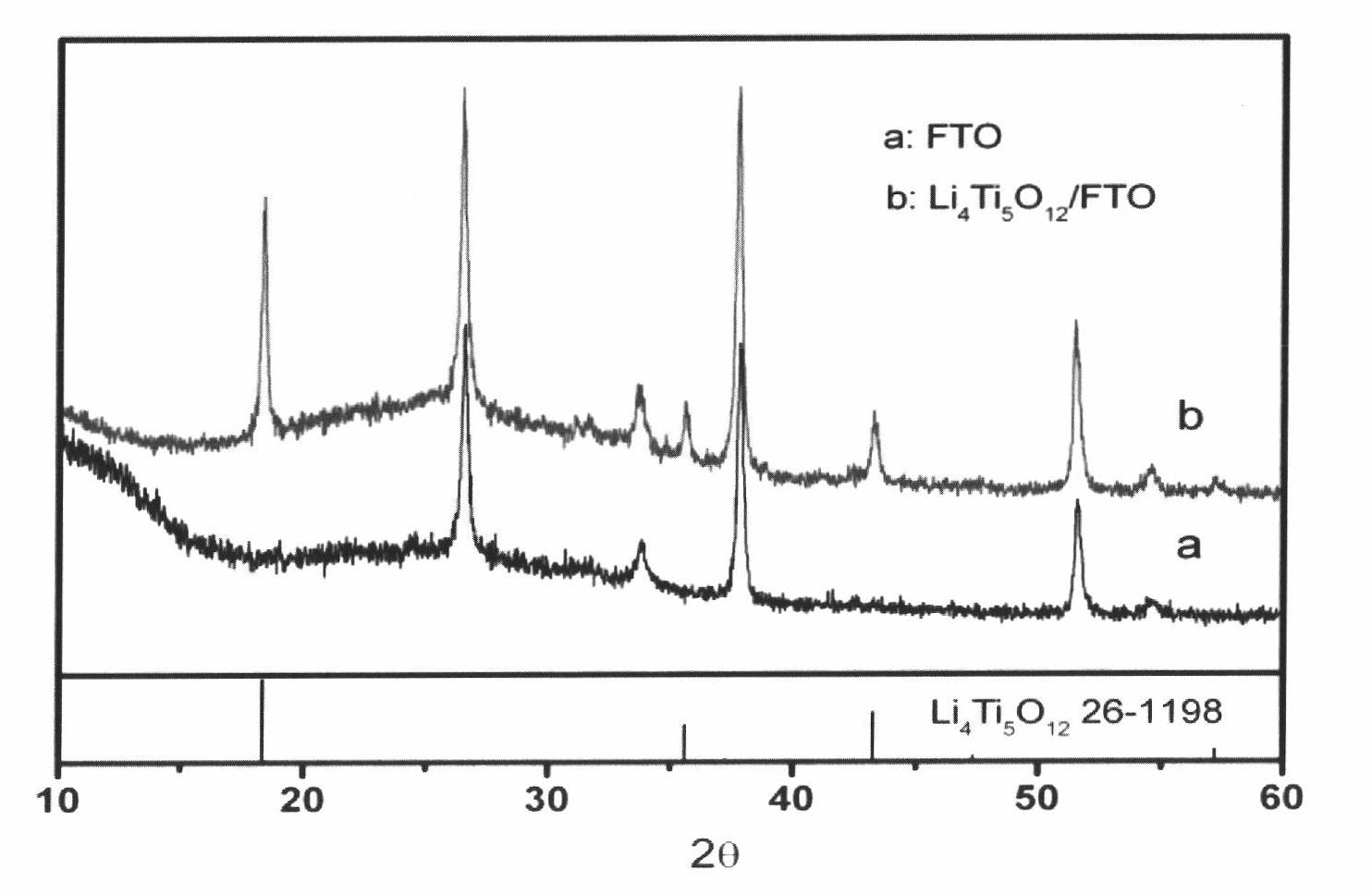

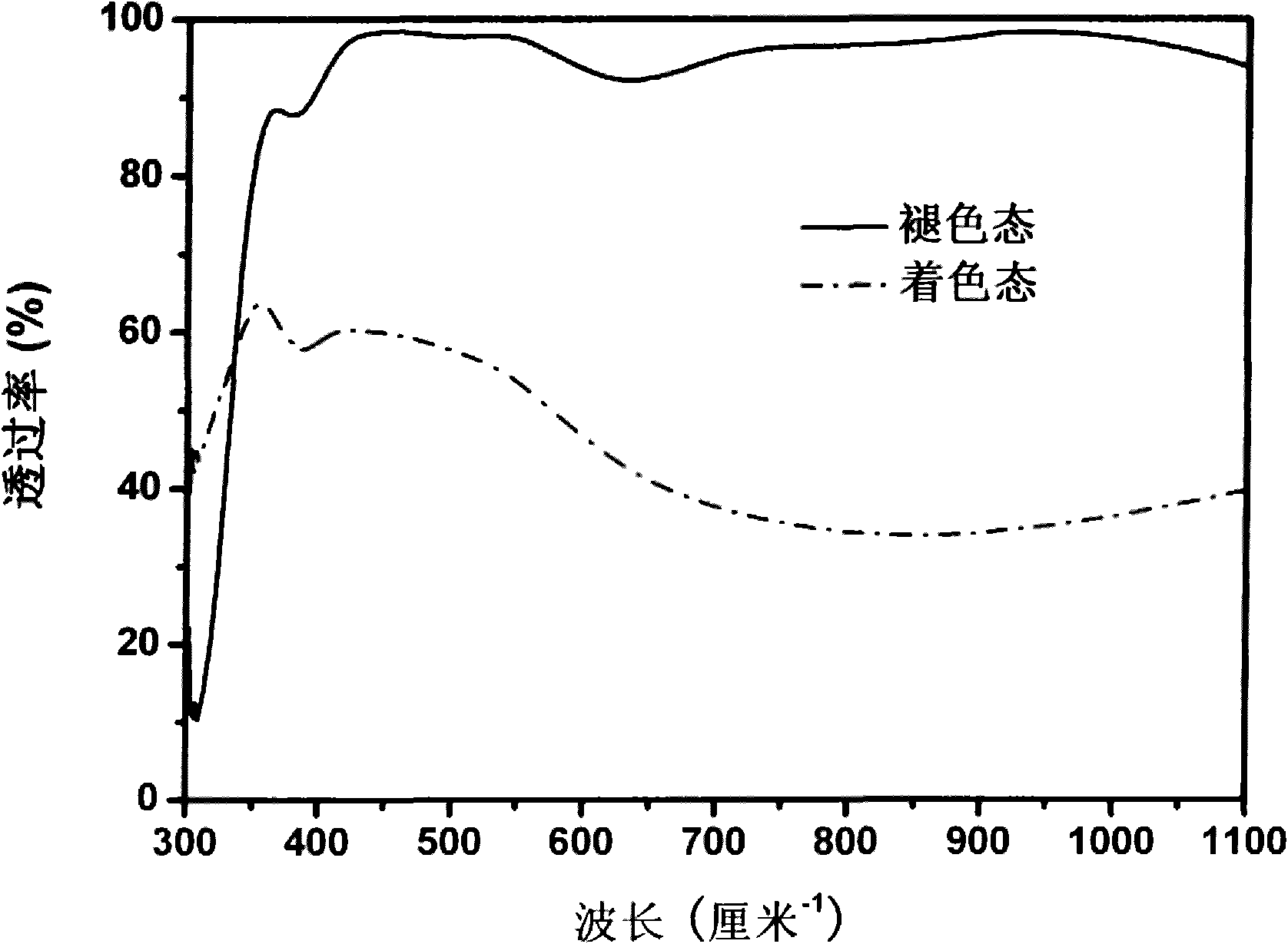

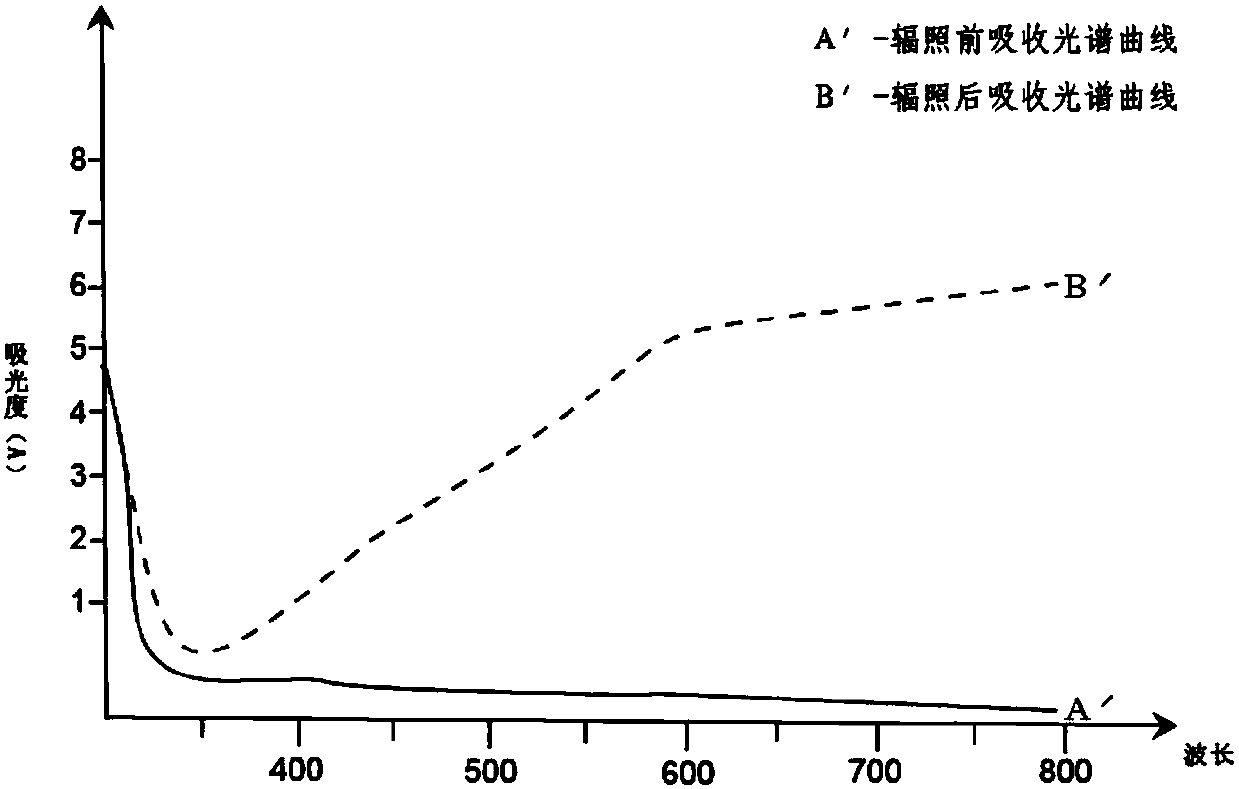

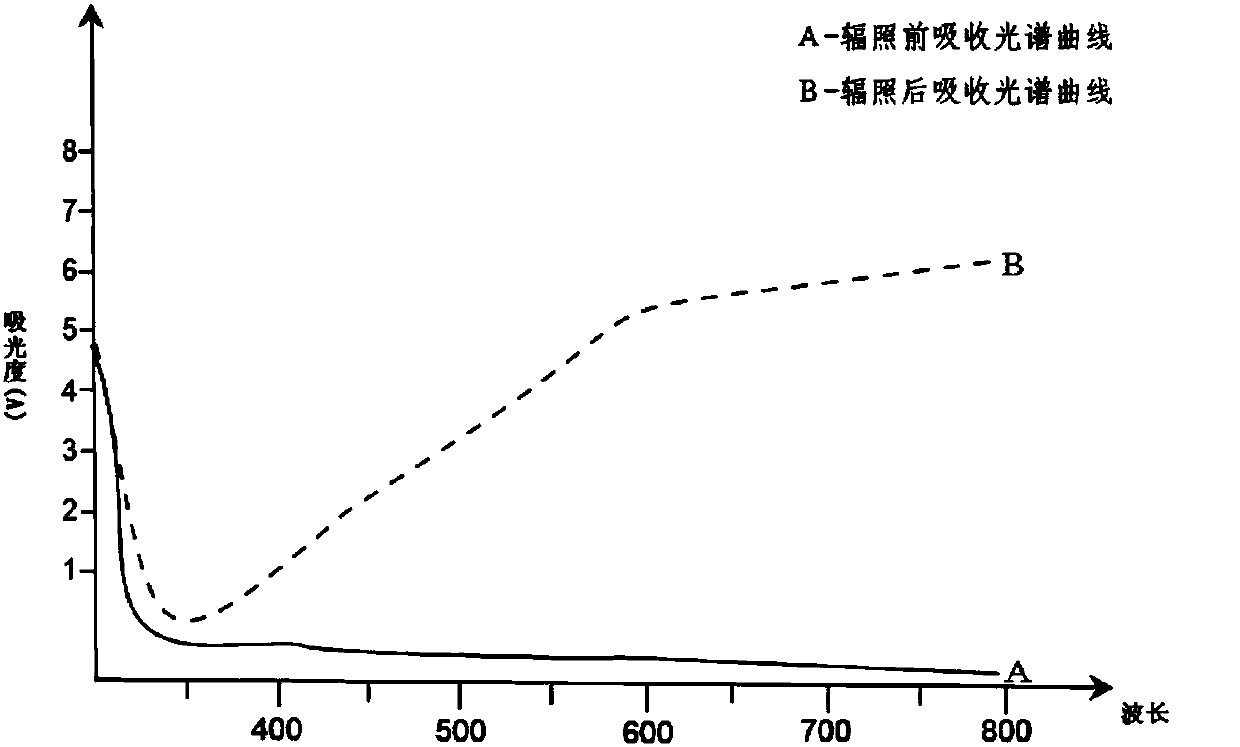

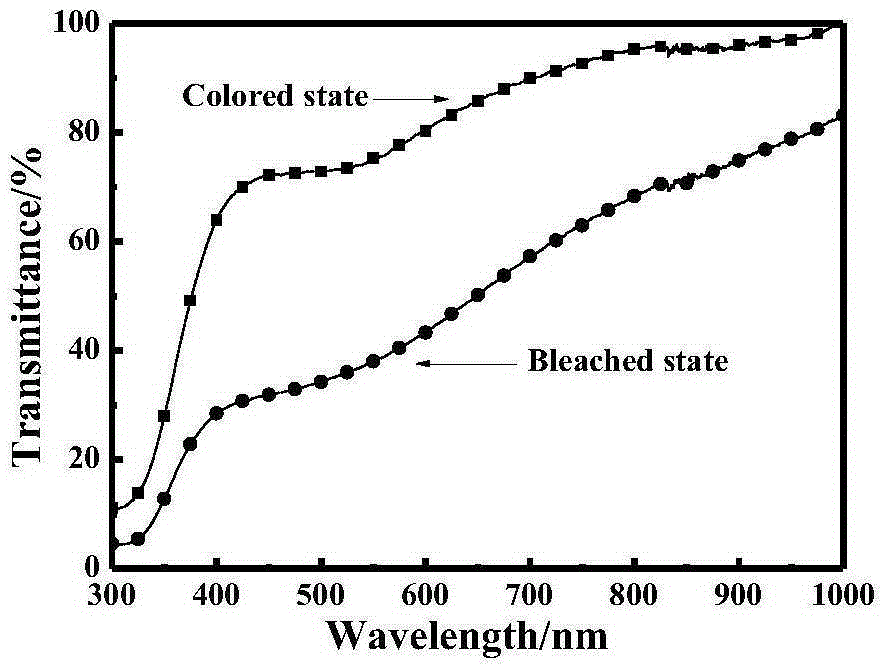

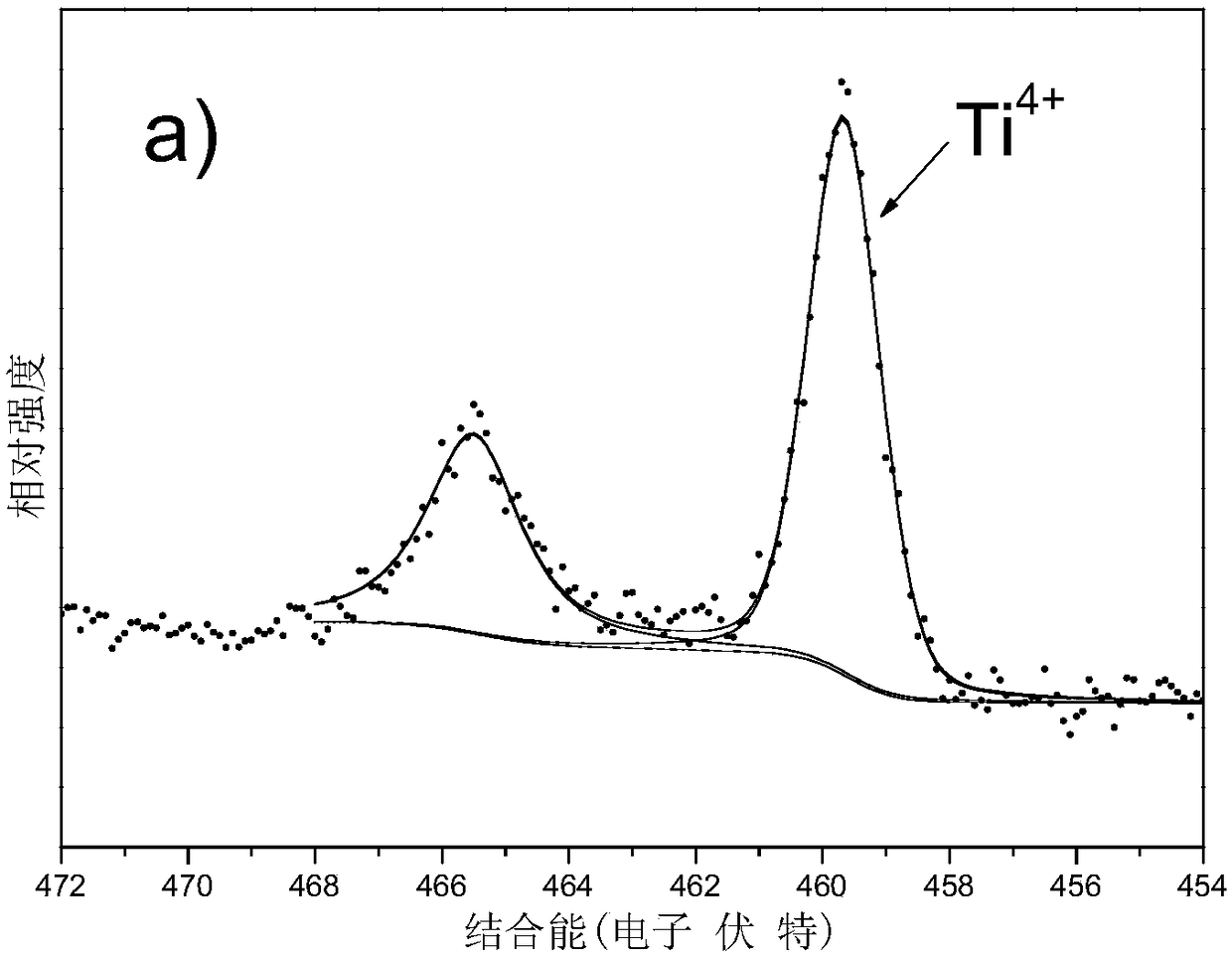

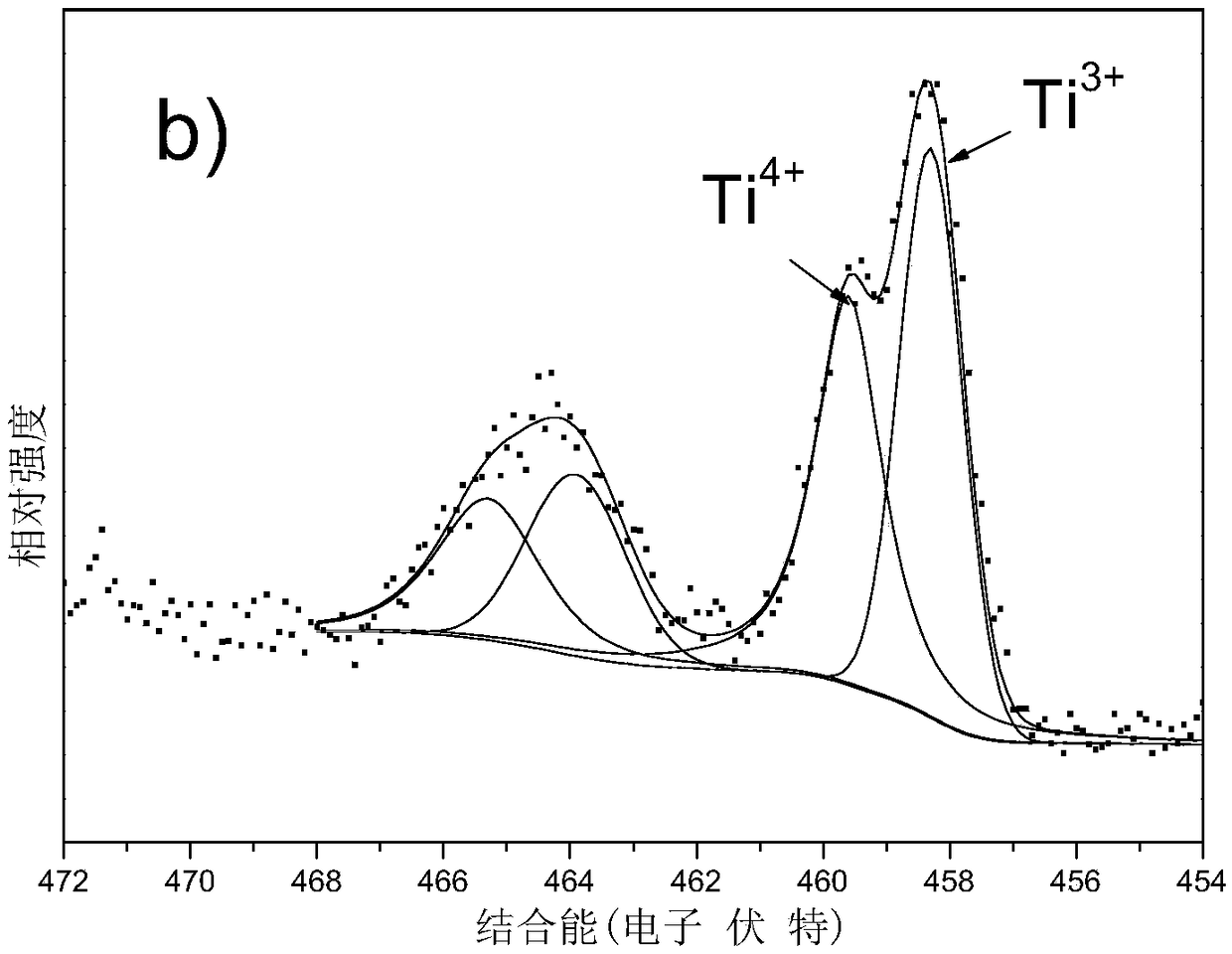

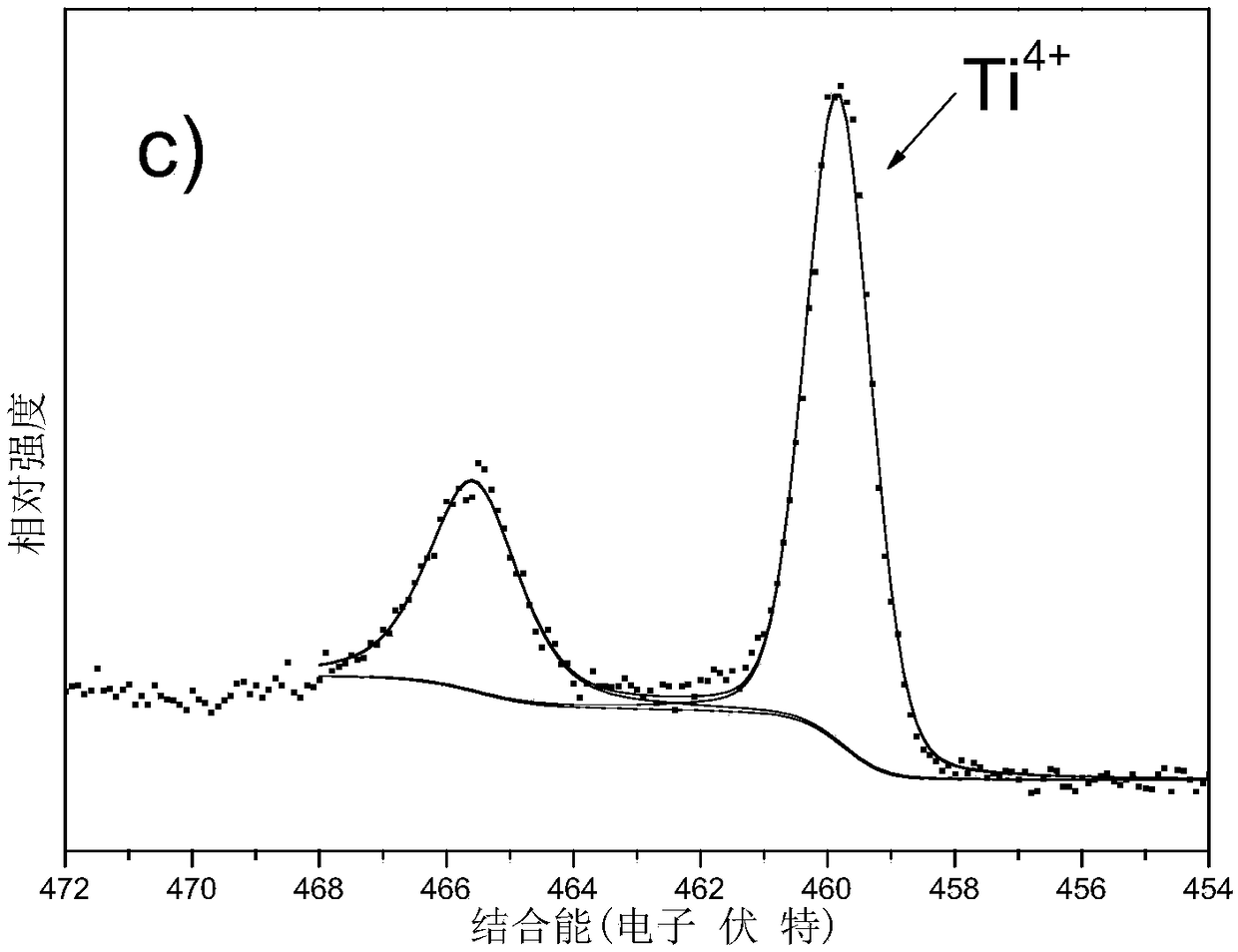

Photoelectric device including lithium titanate membrane electrode and application thereof

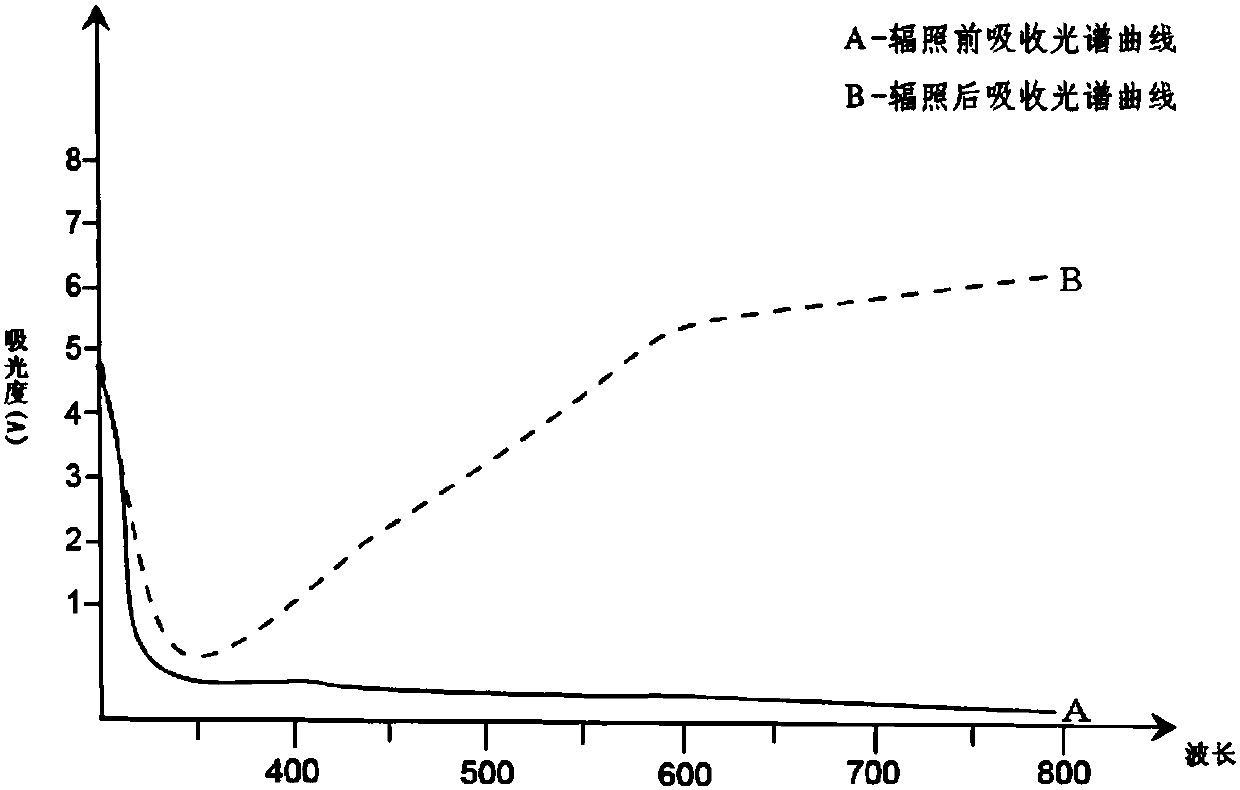

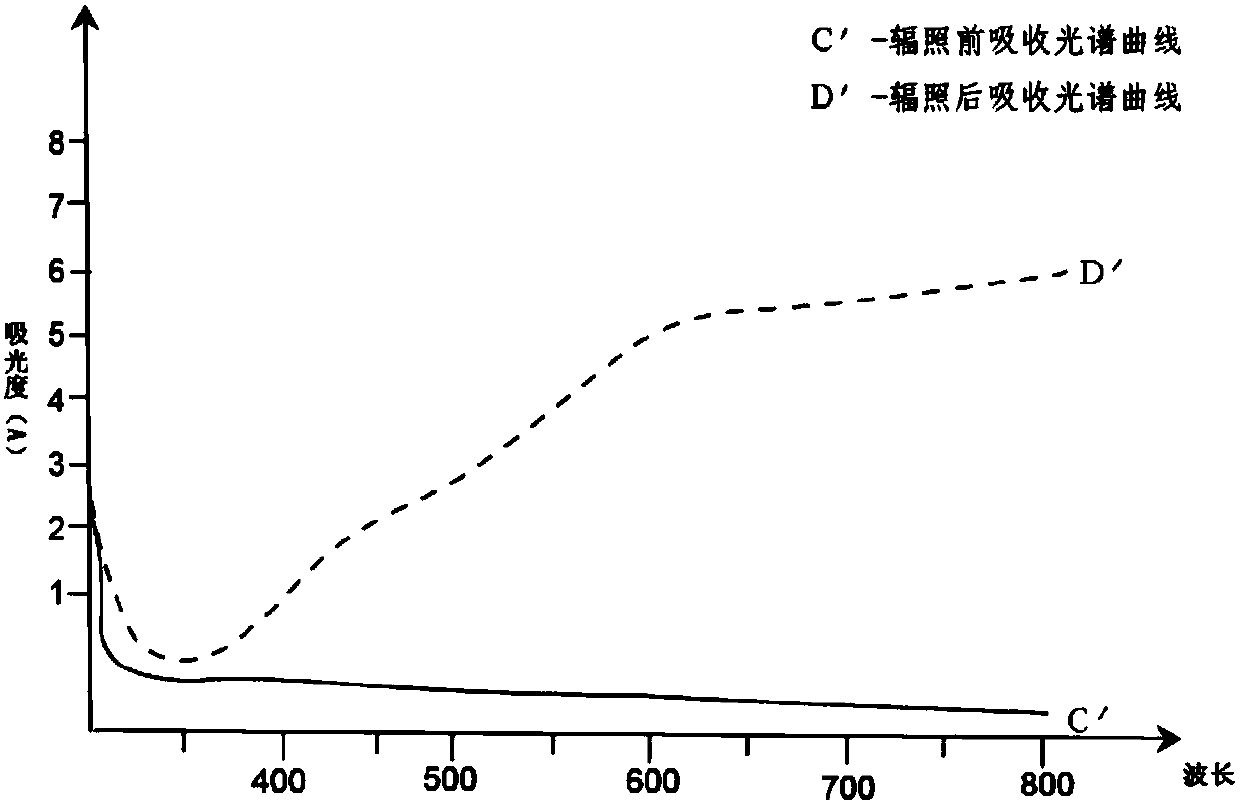

The invention provides a photoelectric device including a lithium titanate membrane electrode, which at least comprises a lithium titanate membrane electrode, electrolyte and a counter electrode, wherein a lithium titanate membrane grows on a transparent conductive substrate, and the thickness of the membrane is 1nm-100mum. The lithium titanate membrane comprises a substance with a chemical composition of Li4+xAaTi5-yO12-zBb, wherein A is selected from at least one of H, Na, K, Mg, Ca, Sr, Ba, B, Al, Ga, In, Si, Ge, Sn, Pb, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Zr, Nb, Mo, Ru, Rh, Pd, Ag, Cd,La, Ce, Pr, Nd, Sm, Eu, Gd, Er, Tm, Yb, Lu, W, Pt, Au or Bi; B is selected from at least one of N, P, S, Se, F, Cl, Br or I; x, a, y, z and b represent molar percent; and x is larger than or equal to-4 and smaller than or equal to 4, a is larger than or equal to 0 and smaller than or equal to 4, y is larger than or equal to 0 and smaller than or equal to 4, z is larger than or equal to 0 and smaller than or equal to 3 and b is larger than or equal to 0 and smaller than or equal to 4.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Photochromic double-shell microcapsule and preparation method and application thereof

ActiveCN104624125AImprove heat resistanceGood chemical stabilityInksMicroballoon preparationPolymer scienceOrganosolv

The invention discloses a photochromic double-shell microcapsule and a preparation method and an application thereof. The photochromic double-shell microcapsule comprises an internal shell formed by a photochromic material and a shell body coating the internal shell, the shell body comprises an internal layer shell body formed by one or more of a polymer, long-chain saturated hydrocarbon and long chain saturated aliphatic acid, the shell body also comprises an external shell body covering external part of the internal layer shell body, the external shell body is a compact layer formed by one or more of a nonmetallic oxide, a metal oxide or salt of the metal oxide; the preparation method of the photochromic double-shell microcapsule is characterized in that the prepared single-shell microcapsule dispersion liquid is mixed and reacted to a prepared dispersion liquid of alcoxyl nonmetal, alcoxyl metal or a predecessor of metal salt, and the photochromic double-shell microcapsule is prepared by further processing. The photochromic double-shell microcapsule has hear resistance and chemical stability, and especially has stability to acid, alkali and an organic solvent.

Owner:CHINA BANKNOTE SECURITY PRINTING TECH RES INST CO LTD

Photochromic fiber making method

InactiveCN104047069AExtended drying timeTo achieve slice drying effectFilament forming substance formingMelt spinning methodsMasterbatchYarn

The invention discloses a photochromic fiber making method which is realized by the following steps: (1) under vacuum conditions, drying light nylon slices with a low melting point, cooling to the room temperature, and excluding vacuum to discharge; (2) taking a certain quality of the dried nylon slices obtained by the step (1), adding a photochromic agent, a dispersing agent, a coupling agent, a heat stabilizer and an antioxidant, melting at 165 to 180 DEG C to prepare masterbatch; (3) taking the following raw materials by mass to mix: 70-90% of the nylon slices obtained by the step (1) and 10-20% of the masterbatch obtained by the step (2), and preparing photochromic POY (pre-oriented yarn) by melt spinning; and (4) drawing the photochromic POY to obtain the photochromic FDY (fully drawn yarn). The photochromic fiber is good in color changing effect, good in comprehensive application performance and low in production cost.

Owner:YIXING ZHENGTAI CHEM FIBER +1

Ink composition for plasma treatment detection, and plasma treatment detection indicator

ActiveUS20170101548A1Change propertiesAccurate completionElectric discharge tubesInksPlasma treatmentOrganic dye

Provided is a plasma treatment detection indicator that enables the completion of plasma treatment to be confirmed from the color change of a color-changing layer by controlling the color change rate, regardless of whether the type of plasma is reduced-pressure plasma or atmospheric-pressure plasma, and regardless of the degree of plasma intensity; also provided is an ink composition for detecting plasma treatment for forming the color-changing layer.The ink composition for detecting plasma treatment comprises an organic dye and at least one member selected from the group consisting of a photopolymerization initiator, silica, and hydrophobic alumina.

Owner:SAKURA COLOR PRODUCTS CORPORATION

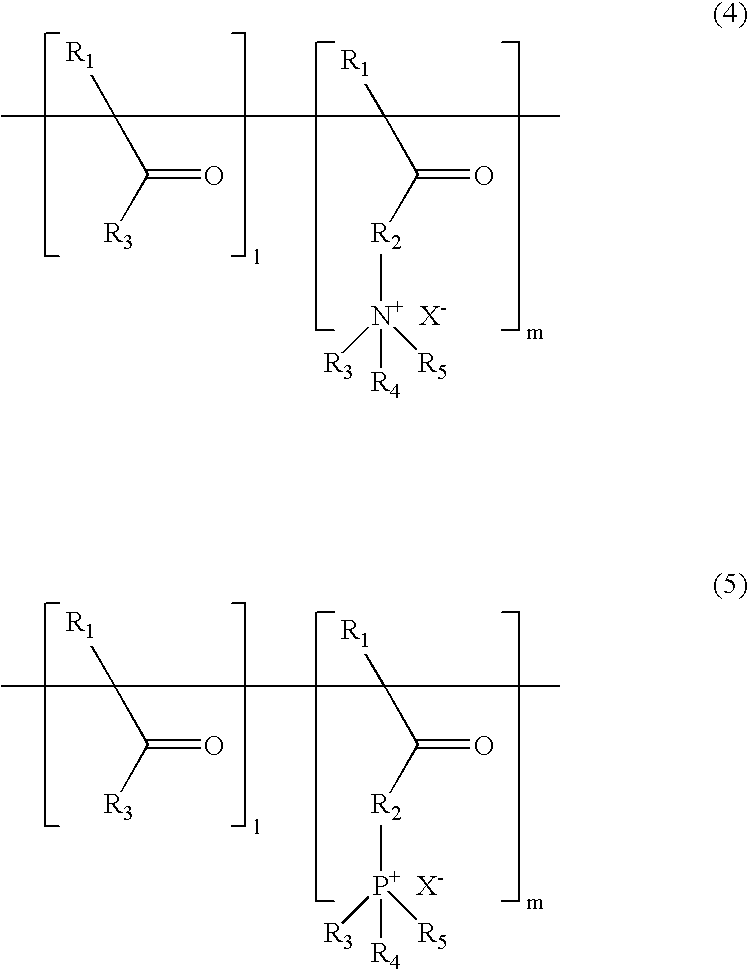

Polymer for a photochromic compound matrix, and a matrix comprising the said polymer

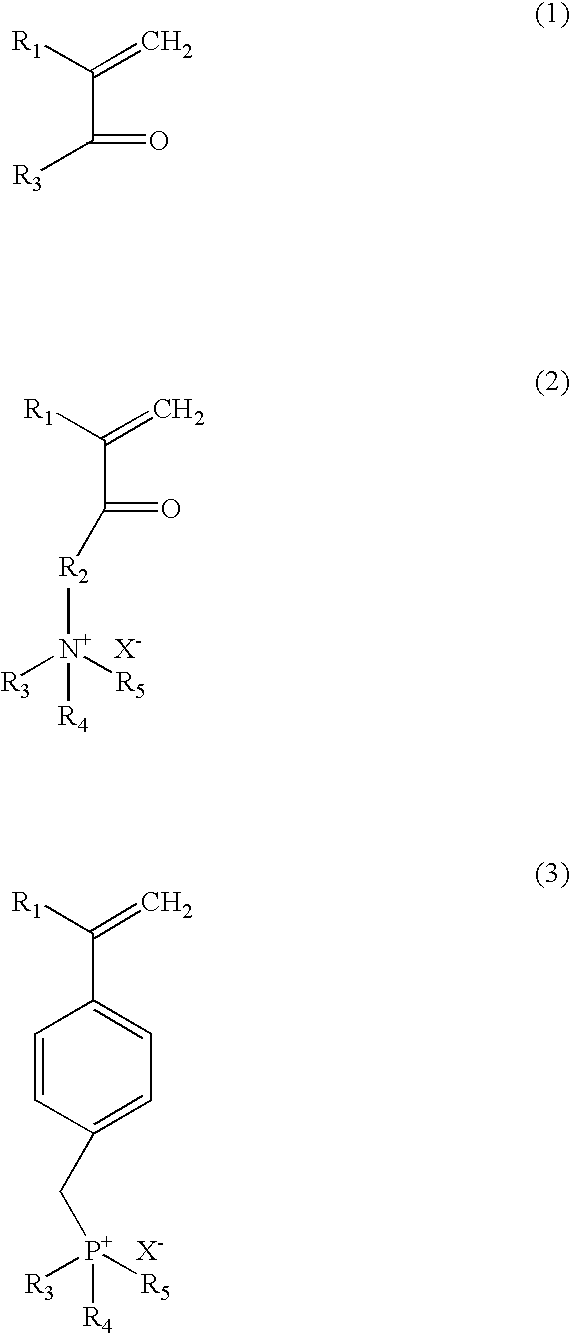

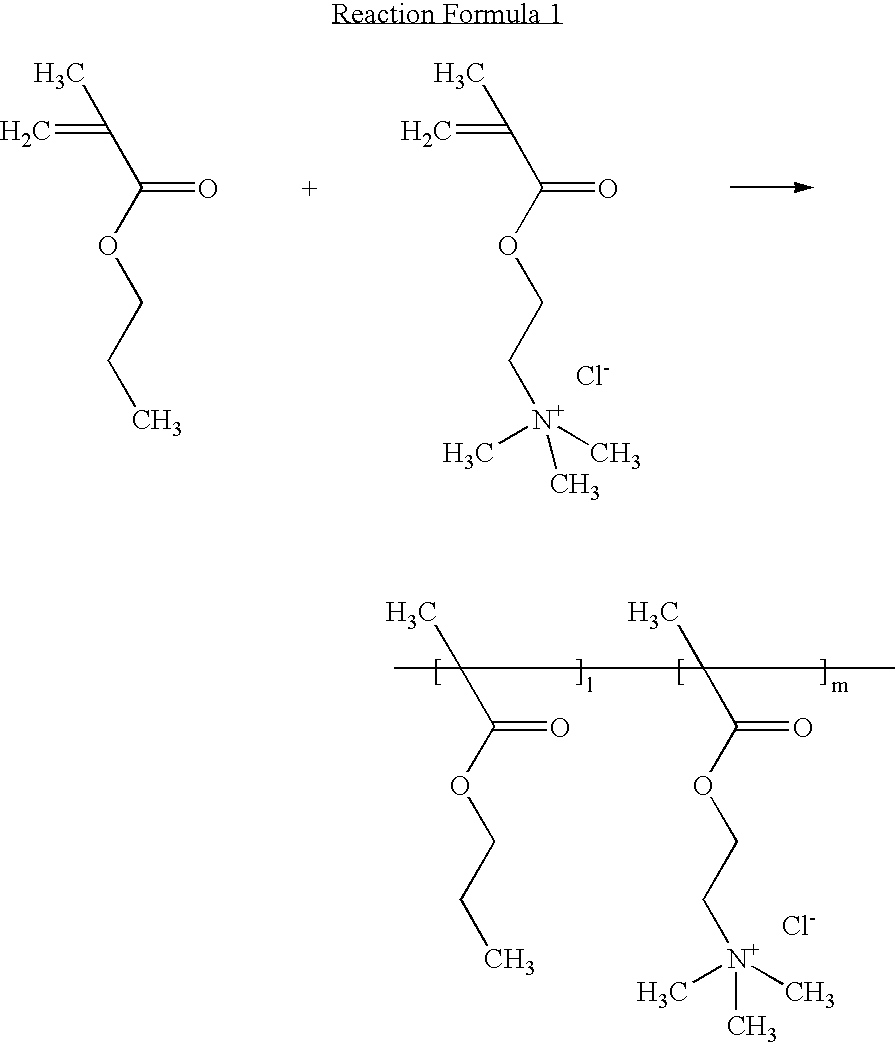

InactiveUS20060033088A1Excellent color changing propertyExcellent restoring rateGlass/slag layered productsOptical elementsPolymer sciencePhosphonium salt

The present invention provides a polymer of Formula (4) or (5) as manufactured by polymerizing alkylmethacrylate of the formula (1) or its salt with 2-metacroxyethyl triammonium chloride of Formula (2) or vinyl monomer of phosphonium salt of the formula (3), and further provides a photochromic polymer matrix manufactured by blending the said polymer as the supporter with a known photochromic organic compound. Further, the present invention enables a glass or a mirror, of which the transmittance and / or the reflectance can be adjusted, to be manufactured by coating it with the said photochromic polymer matrix in a given thickness. In the case of the glass manufactured by using the matrix of the present invention, it can be used in the field requiring adjustment the transmittance of light depending upon a weather condition, including a building or a car glass, a sunroof and the like. In the case of the mirror manufactured so, it can be applied to a rear-view mirror and a side view mirror for a vehicle and the like.

Owner:GYONGTAE KIM

Spiropyrane photochromic coating and preparation method thereof

ActiveCN107828268AImprove antioxidant capacityImprove fatigue resistanceLuminescent paintsPolyurea/polyurethane coatingsMicrosphereUltraviolet lights

The invention provides a spiropyrane photochromic coating and a preparation method thereof. The coating contains a polyurethane / spiropyrane / zinc sulfide composite multilayer photochromic material; aninner core of the coating is a zinc sulfide mesoporous nano-microsphere; an intermediate layer of the coating is a photochromic layer formed by a spiropyrane compound; a shell of the coating is polyurethane; the outer diameter of the composite microsphere is 50-350nm; the diameter of the zinc sulfide mesoporous nano-microsphere is 30-250nm; the thickness of the intermediate layer is 2-25nm; the thickness of the shell is 5-25nm. The photochromic coating prepared by the method can be used as a photochromic material or a surface color-changing layer of an optical lens; the coating is capable of changing from colorless to colored under irradiation of ultraviolet light, is also capable of rapidly fading to colorless after the ultraviolet light disappears, and has the advantages of high fatigueresistance, high stability, rapid color-changing speed and the like.

Owner:南京米兰达视光科学研究院有限公司

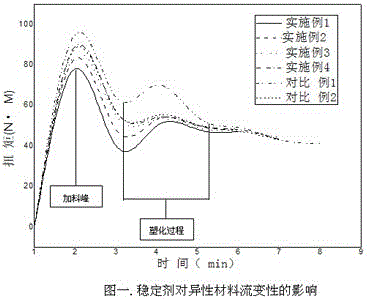

Novel lanthanum cyanurate composite PVC (polyvinyl chloride) heat stabilizer

The invention discloses a novel lanthanum cyanurate composite PVC (polyvinyl chloride) heat stabilizer. A preparation method of lanthanum cyanurate comprises the following steps of: mixing lanthanum carbonate with nitric acid; stirring the mixture so that lanthanum carbonate is completely dissolved; boiling; filtering; and adjusting pH value to obtain lanthanum nitrate; adding lanthanum nitrate to cyanuric acid, heating and stirring to be uniform; then adding sodium hydroxide with appropriate solubility and continuing stirring for a certain time; and filtering, washing, dehydrating and drying to finally obtain lanthanum cyanurate. Lanthanum cyanurate serving as a heat stabilizer has good synergic effect with calcium stearate, zinc stearate and pentaerythritol and the heat stability of PVC can be improved by combined use of lanthanum cyanurate, calcium stearate, zinc stearate and pentaerythritol.

Owner:TIANJIN DAOJUN PACKAGING PROD SALES

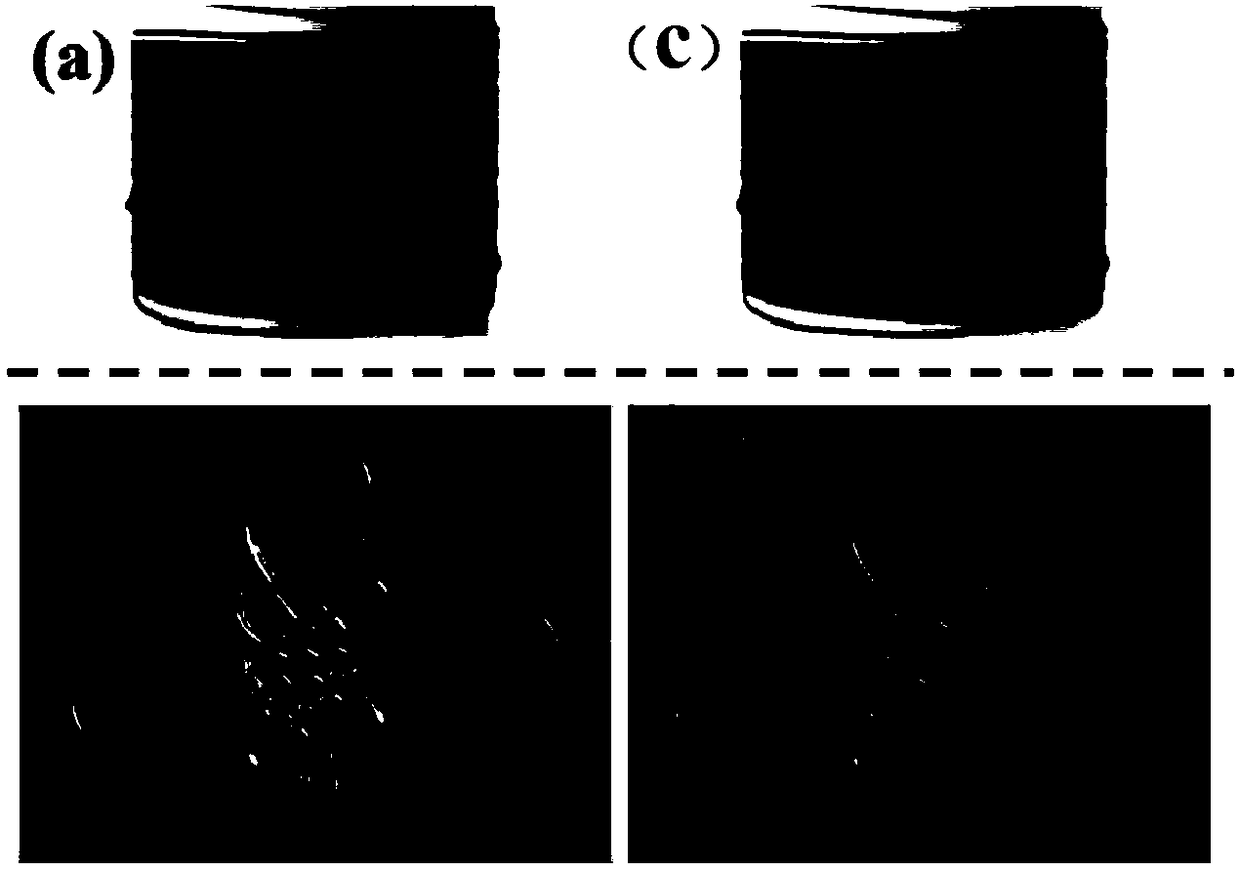

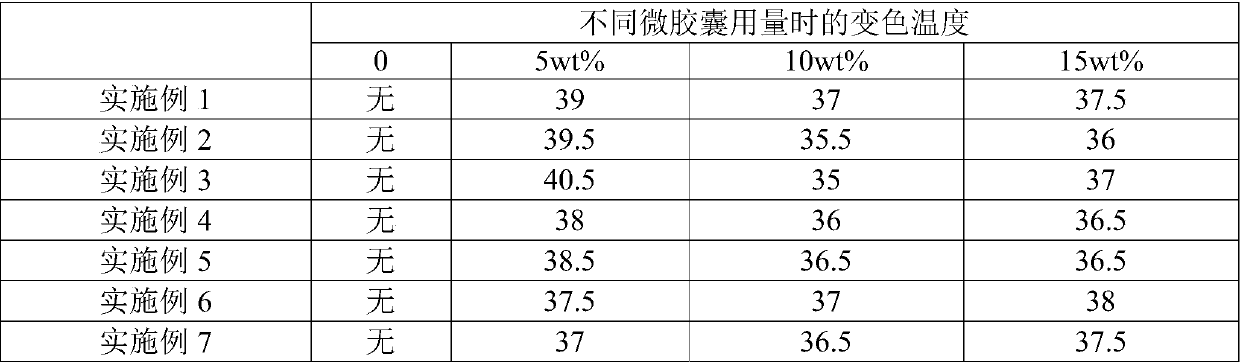

Preparation method and application of thermochromic microcapsules with high sensitivity

InactiveCN109758990AFast response to discolorationImprove mechanical propertiesTenebresent compositionsMicroballoon preparationEmulsionLeuco dye

The application discloses a preparation method and application of thermochromic microcapsules with high sensitivity, and belongs to the technical field of thermochromic materials. The preparation method comprises the following steps: using a graphene-modified melamine resin prepolymer as a wall material of a microcapsule material; mixing and melting leuco-dye, a colour-developing agent and a solvent to obtain a core material of the microcapsule material; adding a graphene dispersion solution into the core material, and performing emulsification to obtain uniform emulsion; adding the uniform emulsion into the wall material, and performing reaction crosslinking and posttreatment to obtain graphene-modified thermochromic microcapsules. By adopting the preparation method, the electron transferspeed between the colour-developing agent and the leuco-dye and the mechanical performance of the wall material are improved by graphene, so that the thermochromic response speed of the prepared graphene-modified microcapsules is improved, and the integral structure and thermal stability are improved.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

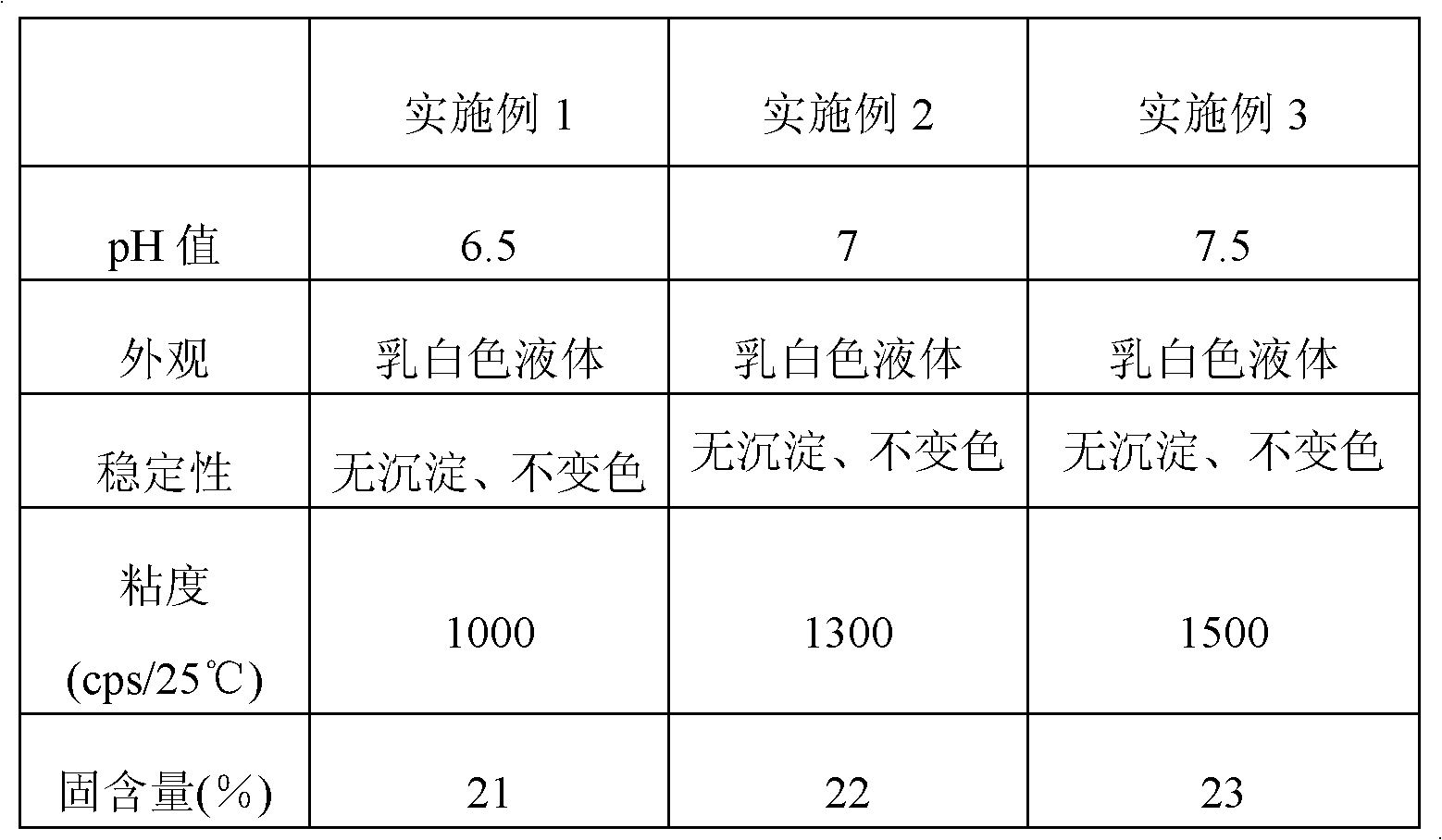

Leather finishing agent with color changing function and strong downy feeling and preparation method thereof

The invention discloses a leather finishing agent with color changing function and strong downy feeling and a preparation method thereof, relating to a surface treating agent for synthetic leather. The preparation method comprises the following steps: a, adding a solvent, adding cellulose acetate with stirring, after completely dissolving, adding wax powder to uniformly disperse, then filtering with a 200 mesh sieve, and then putting in a vat; and b, adding the rest materials in order, then stirring to uniformly disperse, wherein the order of adding the materials is a dispersant, a levelling agent, resin, thickening powder, and fluff powder, the stirring speed is 800-1500 rpm, and the temperature is controlled within 50 DEG C; c, after stirring, grinding one to three times by a three-roller machine, and packaging after passing the product inspection to obtain a finished product. According to the invention, the problem of bad dispersibility of fluff powder and wax powder in a high viscosity system is solved, and the prepared finished product has the advantages of good downy feeling, good suede effect, good resilience, good color-change property, high temperature resistance, and strong leather feeling.

Owner:HANGZHOU COLORICH CHEM MATERIALS

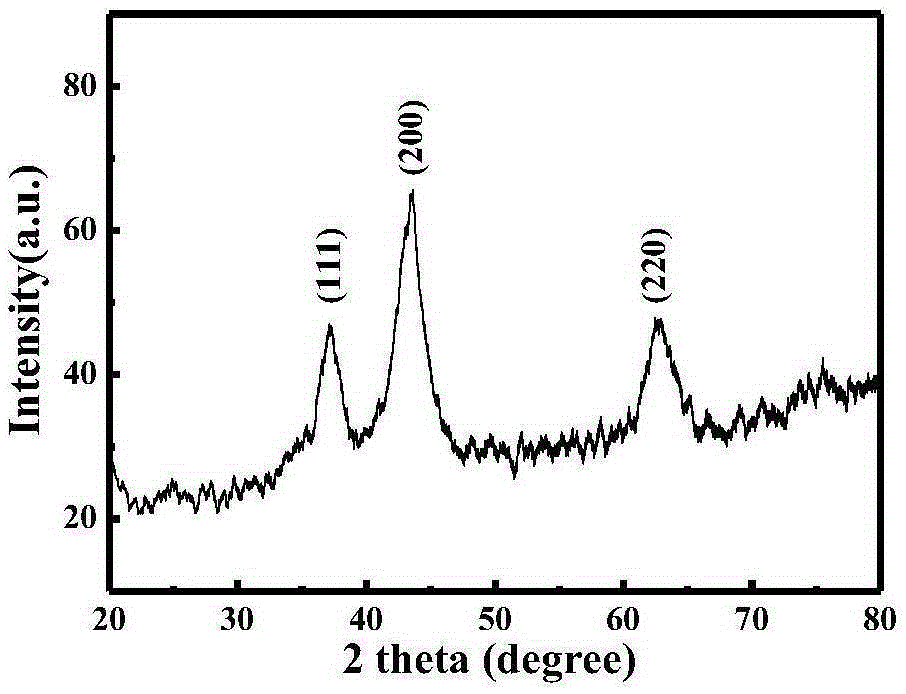

Making method of NiO nano-crystalline electrochromic film

The invention relates to a making method of a NiO nano-crystalline electrochromic film, and belongs to the technical field of functional materials. The method comprises the following steps: preparing NiO nano-crystals through an injection technology, adding a proper amount of n-hexane, carrying out ultrasonic dispersion, and fully stirring to obtain stable ink; and making the NiO nano-crystalline electrochromic film through a Czochralski technology. The ink prepared in the invention is stable, can be used in large-area production of the NiO electrochromic film, provides a new idea for development of green and environmentally-friendly low-cost and high-chromic performance NiO electrochromic film technology, and can promote industrial rapid development of NiO electrochromic film materials and intelligent windows.

Owner:BEIJING UNIV OF TECH

Cobaltless blue color-changing indicator and production method thereof

InactiveCN103091321AHigh sensitivityGood discoloration effectMaterial analysis by observing effect on chemical indicatorCobalt blueSilica gel

The invention discloses a cobaltless blue color-changing indicator, which comprises 0.01-0.1wt% of color indicator and a granular compound or mixture with a nano-sized microporous structure or adsorptive property, and is free of cobalt. The production method of the cobaltless blue color-changing indicator comprises the following steps of: (a) preparing the solution of a soaking carrier according to claim 3, and (b) enabling the carrier to contact the solution, and drying the carrier. The cobaltless blue color-changing indicator and the production method of the cobaltless blue color-changing indicator have the advantages that the cobaltless blue color-changing indicator can indicate humidity at a relative humidity of 5-90%, is high in sensitivity, and does not contain cobalt, copper, iron and other metal salts, so that the pollution to environment and the harm to human bodies can be eliminated from source; furthermore, the cobaltless blue color-changing indicator is accordant with conventional blue silica gel in appearance and color display and high in commercial value; and the humidity indicator provided by the invention is obvious in color changing effect, simple to use, capable of being repeatedly used for many times, and good in applicability, and has a very wide application range.

Owner:山东辛化硅胶有限公司

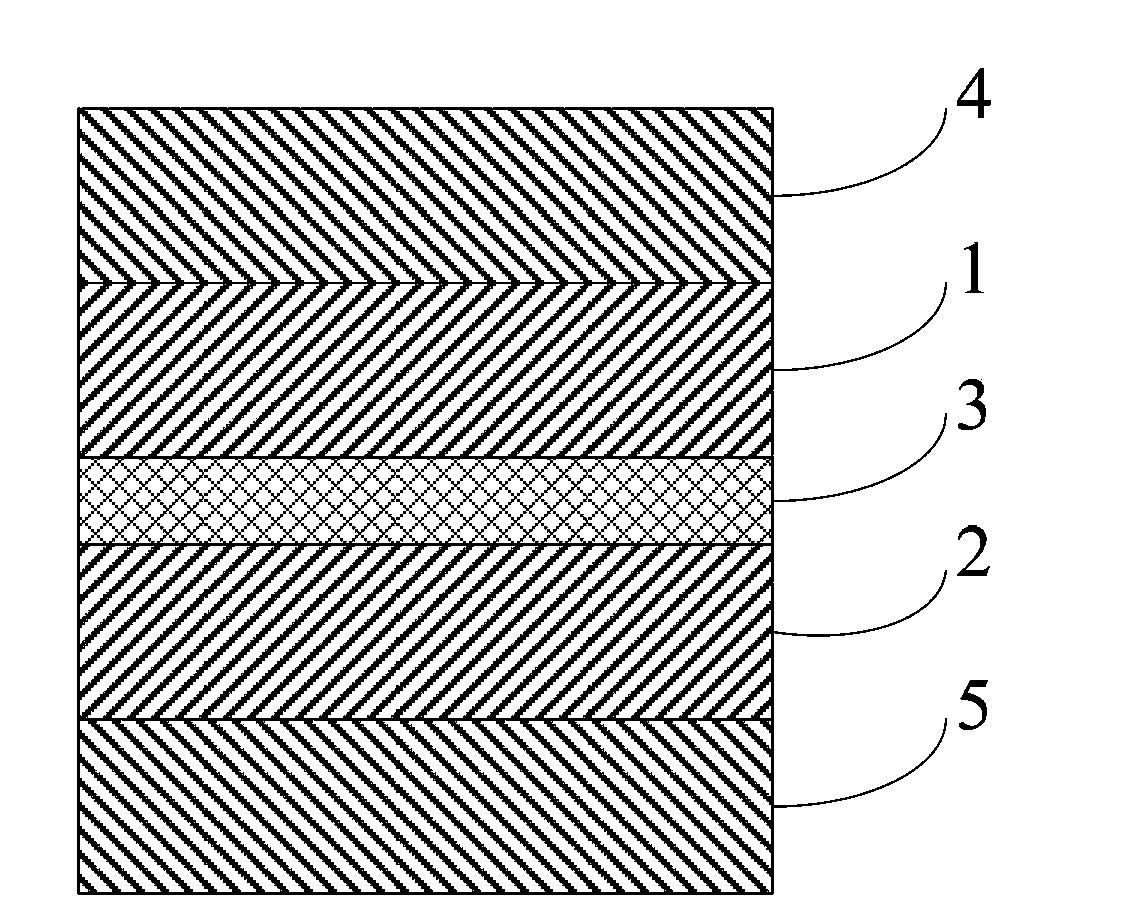

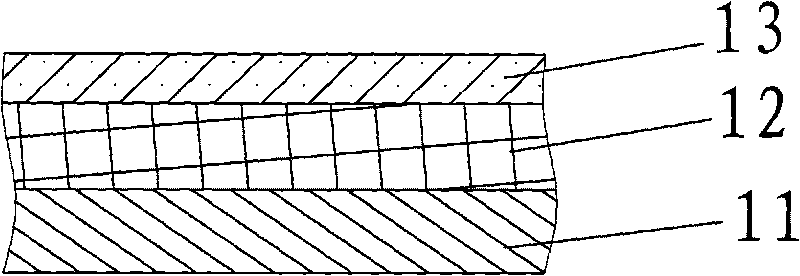

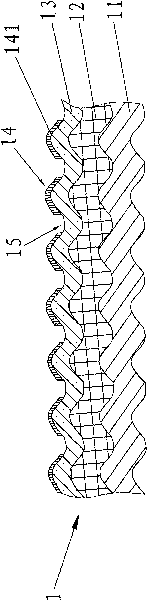

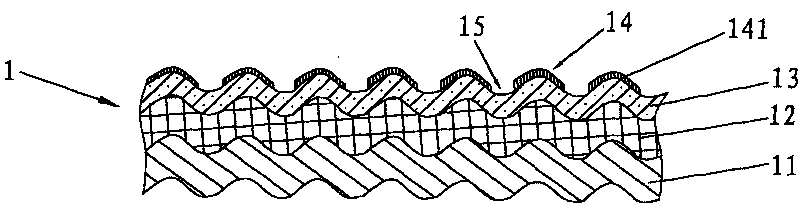

Embossing bicolor leather

InactiveCN101736600AImprove the color change effectGood discoloration effectTextiles and paperState of artEngineering

The invention discloses an embossing bicolor leather comprising a base cloth layer, a polyurethane foam layer coated on the base cloth layer and a crazy horse resin discoloration layer coated on the polyurethane foam layer. The upper surface of the bicolor leather is rough, and a plurality of crown parts and a plurality of groove parts are formed on the upper surface of the bicolor leather; and the surfaces of the crown parts are coated with a roller coating layer. Compared with the prior art, the bicolor leather is highly stereoscopic, and has double color and higher discoloration effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

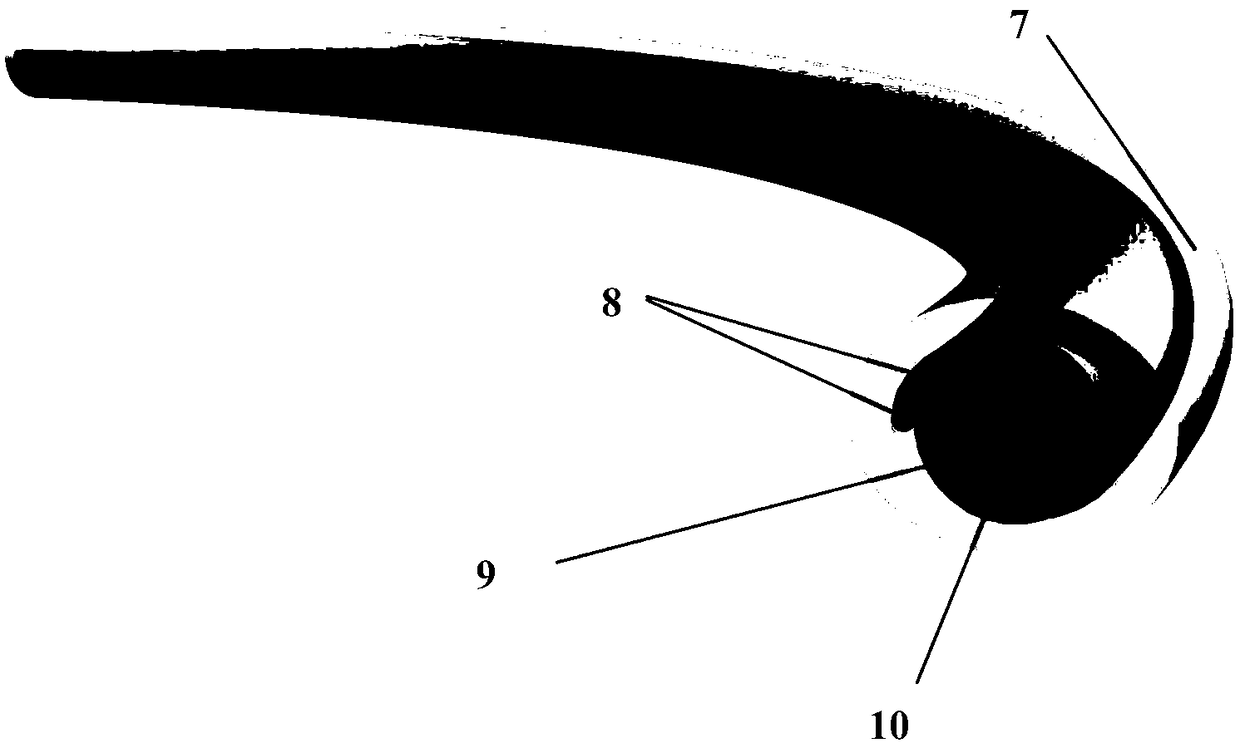

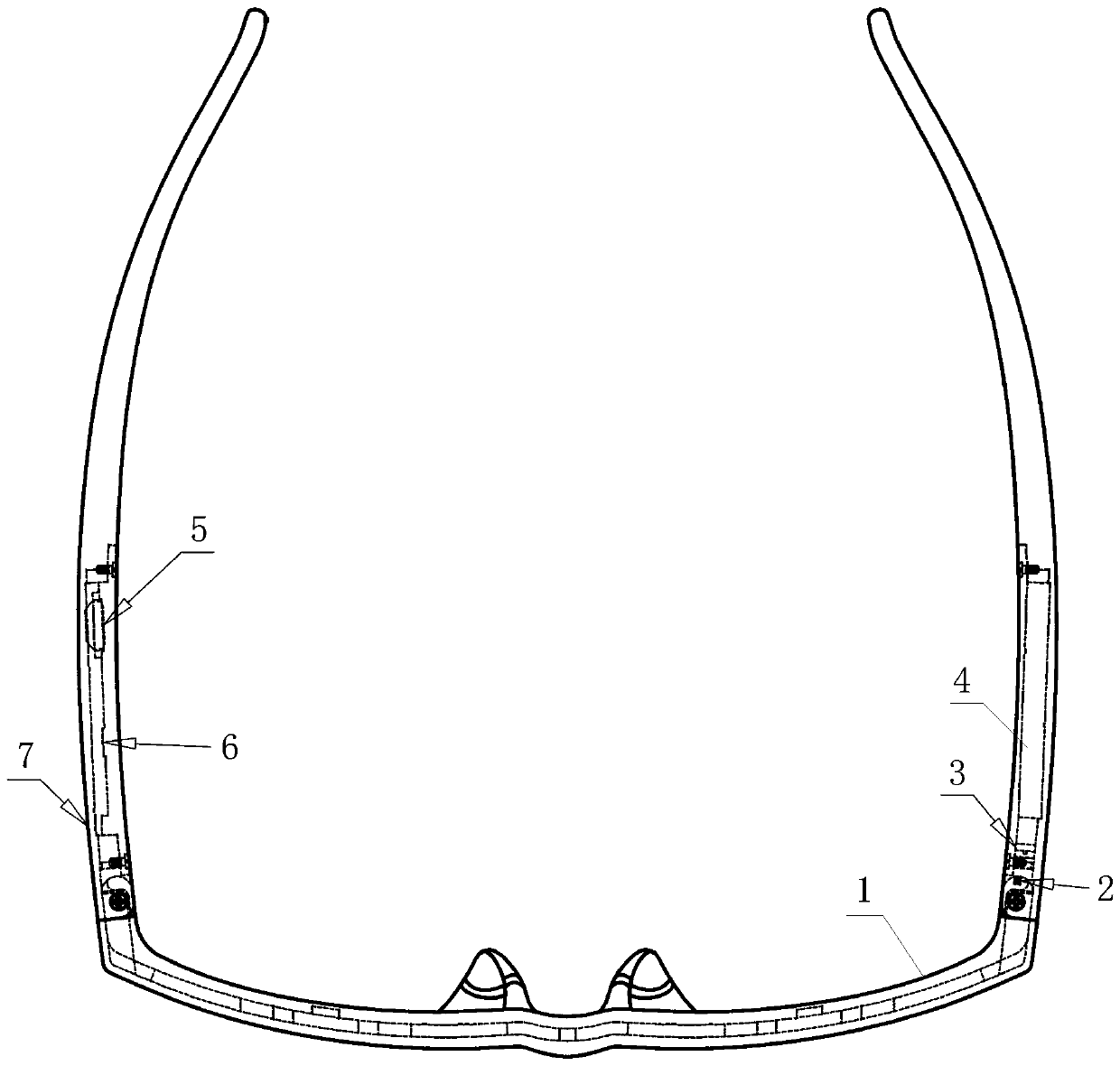

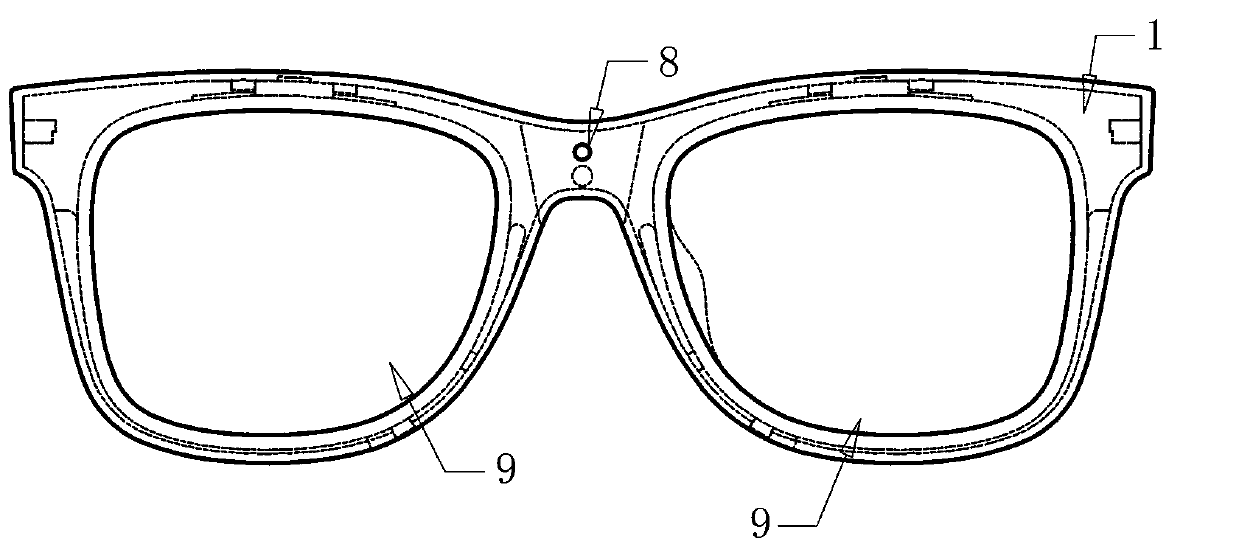

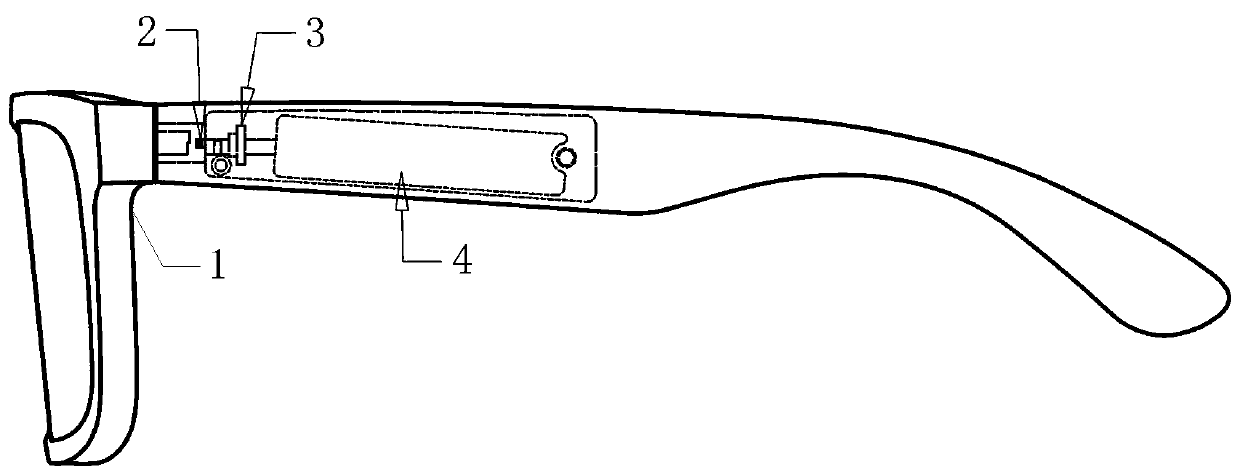

Intelligent color-changeable sunglasses capable of switching mode and sunglasses intelligent discoloration method

PendingCN108681103AQuick conversionSolve usabilityStatic indicating devicesNon-linear opticsPhotochromic sunglassesIn vehicle

The invention discloses intelligent color-changeable sunglasses capable of switching mode and a sunglasses intelligent discoloration method. The sunglasses comprise a glasses frame, two glasses legs,two liquid crystal glasses lenses, a battery, a photosensitive interface, a power switch controller, a touch control interface, a USB interface and an integration control circuit board; and the photosensitive interface is provided with a photosensitive electronic element. The sunglasses intelligent discoloration method comprises the following steps of a step of switching a working mode by touchingthe touch control interface with a human hand and a step of calling a control regulation scheme of a corresponding working mode to regulate the blackness of the two liquid crystal glasses lenses. Inthe sunglasses intelligent discoloration method, switching between two working modes of an in-vehicle mode and an outdoor mode is realized through touch control, and different control and regulation schemes are adopted to perform control and regulation on the blackness of the two liquid crystal glasses lenses under different working modes, so that the contradiction of incompatibility of in-vehicleuse and outdoor use of the intelligent color-changeable sunglasses is solved, and a person, wearing the intelligent color-changeable sunglasses, can get the best color changing effect whether in thein-vehicle environment or in the outdoor environment.

Owner:HANDAN FUYA ELECTRONICS TECH

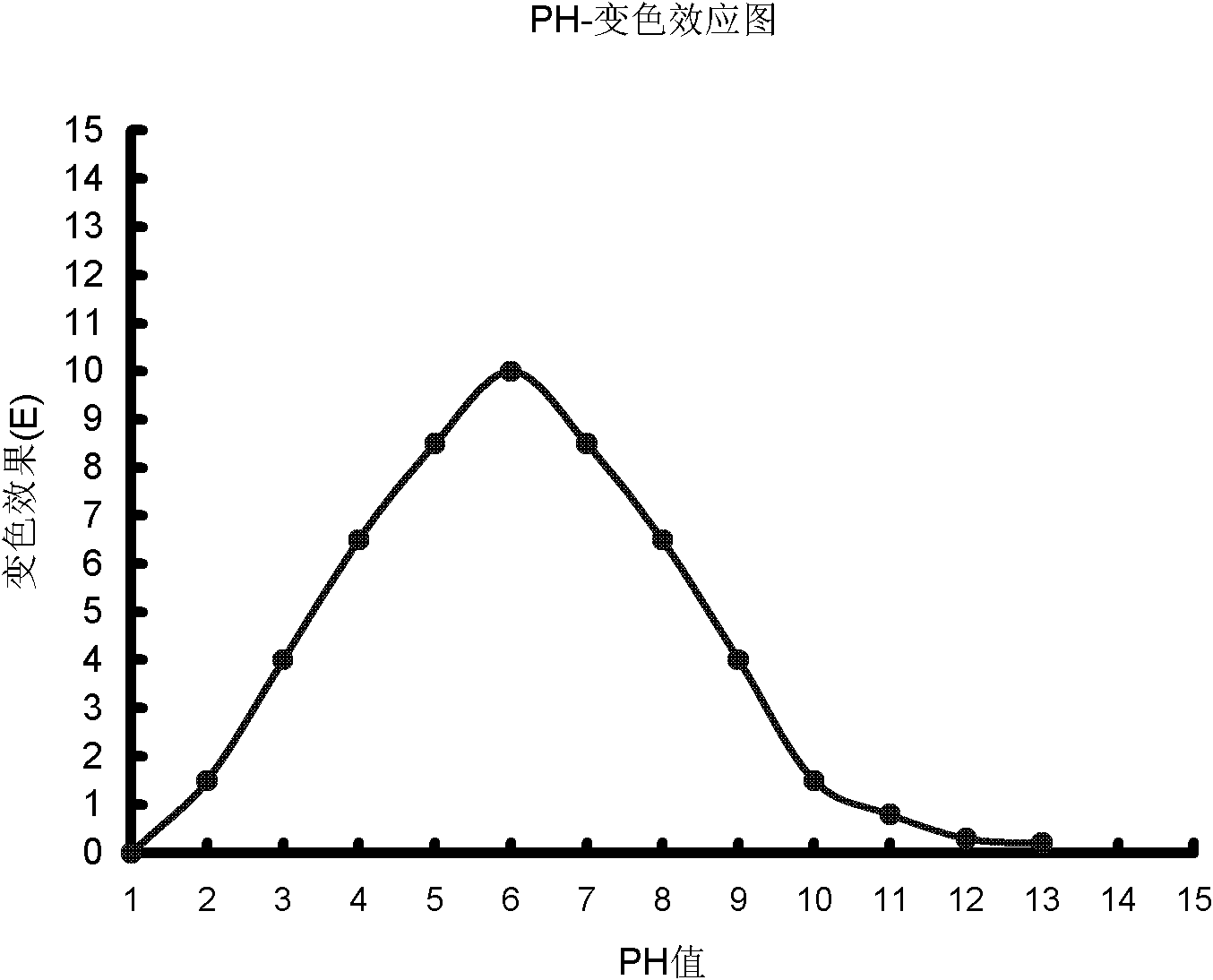

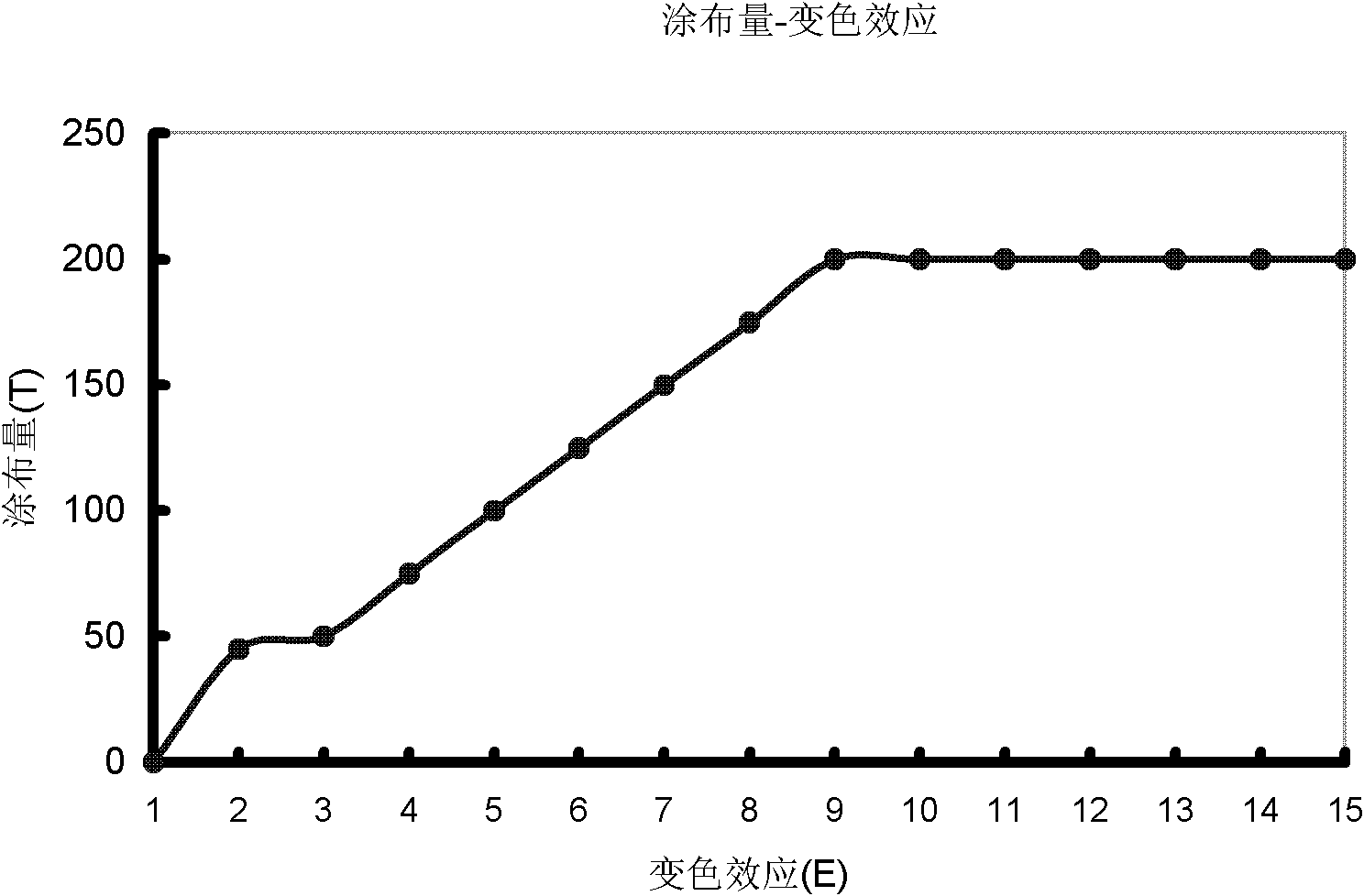

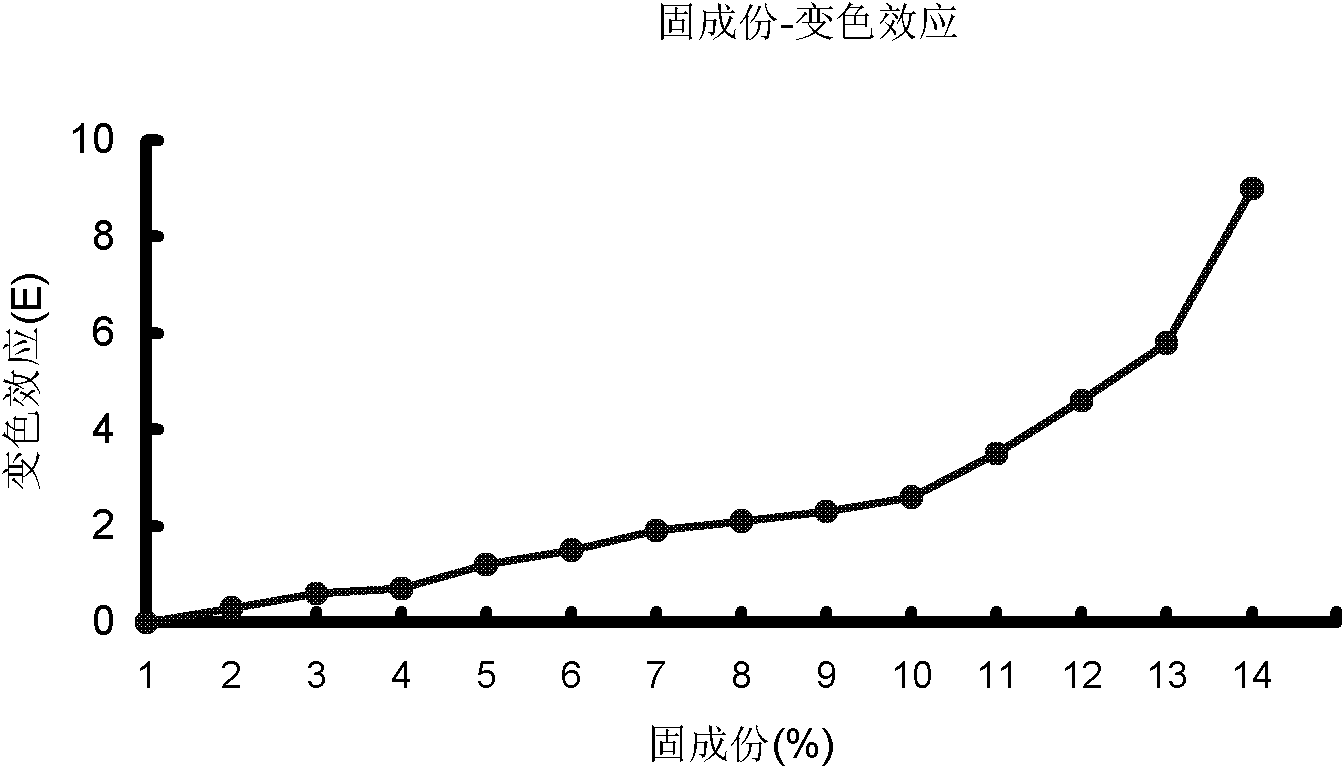

PH-sensitive allochroic inorganic material and preparation method thereof

The invention discloses a pH-sensitive allochroic inorganic material and a preparation method thereof. The preparation method includes compounding Li2CO3, ammonium polyphosphate, Al2O3, TiO2 and MnCO3to obtain LATP and LiMnPO4 ceramic powder, adding ethyl alcohol after mixing the LATP ceramic powder with 10-40% of LiMnPO4 ceramic powder, and performing ball grinding, drying and sieving to obtainmixed powder; adding binders into the mixed powder for pelleting, conducting preforming to prepare a blank, and calcinating the blank in an air atmosphere to prepare pH-sensitive allochroic ceramic; after direct calcination of the mixed powder in the atmosphere, subjecting the mixed powder to crushing, ball grinding and sieving to obtain pH-sensitive allochroic powder, mixing the allochroic powderwith other resin solutions or emulsion to obtain a pH-sensitive allochroic paint or film material. The prepared pH-sensitive allochroic inorganic material has the advantages of safety, reliability, simplicity in preparation process, economy and environment protection, and accordingly, industrial production can be realized.

Owner:SOUTH CHINA UNIV OF TECH

UV curable offset color changing ink as well as preparation method and application thereof

The invention relates to a UV curable offset color changing ink as well as a preparation method and application thereof. The UV curable offset color changing ink comprises the following components bymass percentage: 1-3% of photochromic powder, 4-17% of light variable microcapsule toner, 10-30% of an epoxy acrylate oligomer, 20-60% of a polyester acrylate oligomer, 1-4% of flexible resin, 3-20% of a reactive diluent, 5-10% of a photoinitiator, 3-8% of an amine co-initiator, 2-8% of a filler, 0.5-2% of wax powder, 0.5-2% of spherical fine powder, 1-6% of a dispersant, 0.01-0.3% of an antifoaming agent and 0.2-0.6% of a leveling agent. The UV curable offset color changing ink provided by the invention has no solvent evaporation, is environmentally-friendly, pollution-free, fast in curing and high in efficiency, and has a reversible photochromic function after natural light and UV illumination and an excellent discoloration effect.

Owner:广州市科涵实业有限责任公司

Variable color transparent lip balm and preparation method thereof

InactiveUS20160143837A1Pleasant feelHigh transparencyCosmetic preparationsMake-upEthylenediamineLanosterol

The present invention provides a variable color transparent lip balm, consisting of following components by weight percent: 4.0 to 5.0% by weight of dibutyl lauroyl glutamide, 2.0 to 3.0% by weight of polyamide-3, 15.0 to 20.0% by weight of bis-stearyl ethylenediamine / neopentyl glycol / stearyl hydrogenated dimer dilinoleate copolymer, 46.65 to 49.60% by weight of C12-15 alkyl benzoate, 1.0 to 3.0% by weight of heptyl undecylenate, 9.0 to 11.0% by weight of C10-30 cholesterol / lanosterol esters, 10.0 to 15.0% by weight of hydrogenated C6-20 polyolefin, 1.5 to 2.5% by weight of dextrin isostearate, 0.05 to 0.1% by weight of eosin yellowish and 0 to 0.8% by weight of excipient. The transparent lip balm of the present invention has good transparency, and excellent variable color effect.

Owner:GUANGZHOU SHEENCOLOR COSMETICS CO LTD

Matte discoloring long-wool printing treatment agent for synthetic leather and preparation method thereof

InactiveCN103103776AComply with environmental standardsGood discoloration effectFibre treatmentWaxNanofiber

The invention relates to a matte discoloring long-wool printing treatment agent for synthetic leather. The matte discoloring long-wool printing treatment agent is composed of the following components: modified polyurethane resin, toluene, butyl ester, acetone, silica extinction powder, modified siloxane, amino silicone oil, methoxy silicone oil, polyurethane nanofiber and polytetrafluoroethylene wax powder. The invention further relates to a preparation method of the matte discoloring long-wool printing treatment agent. Compared with the traditional matte long-wool leather surface treatment agent, the matte discoloring long-wool printing treatment agent for the synthetic leather is used to process the surface of the synthetic leather to ensure that the surface of the synthetic leather achieves oily and delicate hand feel, excellent waxy feel, unique downy feel and strong discoloring effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

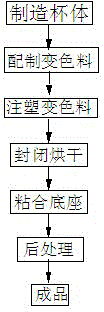

Preparation method of color-changing plastic cup

The invention discloses a preparation method of a color-changing plastic cup. The preparation method comprises the following steps: (a) manufacturing a cup body; (b) preparing a color-changing material; (c) carrying out injection molding on the color-changing material; (d) sealing and drying; (e) bonding a base; and (f) performing post treatment. According to the preparation method of the color-changing plastic cup, procedures are reasonably arranged, the preparation process is simple and convenient, the cost is moderate, a manufactured cup body is in a multi-layer structure design, a middle layer between an inner layer and an outer layer is a thermosensitive color-changing layer which can change with different colors according to the water temperature in the cup body, and the appearance performance and the interestingness of the plastic cup are effectively enriched; the plastic cup has the reasonable design and material selection, has the stable safety performance during use, and has the durable and remarkable color-changing effect.

Owner:SUZHOU YIQUN MOLD

Preparation process of photochromic polypropylene fiber yarn fabric

InactiveCN110578258AImprove thermal stabilityStrong sun and heat resistanceTextiles and paperYarnAdhesive

The invention discloses a preparation process of a photochromic polypropylene fiber yarn fabric. The preparation process comprises the steps of preparation of photochromic microcapsules, wherein firstly, an in-batch prepolymerization method is adopted for preparing a melamine resin prepolymer, then paraffin is utilized for preparing a stable O / W-type emulsion, finally the O / W-type emulsion is poured in a three-necked flask, and the melamine resin prepolymer is dropwise added slowly; citric acid is used for adjusting the pH of the system, after a heat preservation reaction is completed, a suitable amount of urea is added for after-treatment, and finally through washing, suction filtration and drying, the photochromic microcapsules are obtained; preparation of a photochromic coating fabric,wherein a coating adhesive is prepared through waterborne polyurethane, the photochromic capsules and a thickening agent; a polypropylene fiber yarn fabric is uniformly coated with the coating adhesive; and through pre-drying and baking, the photochromic polypropylene fiber yarn fabric is prepared. According to the formaldehyde content of the prepared photochromic polypropylene fiber yarn fabric,the content of free formaldehyde is reduced, and the fabric can be used for manufacturing various garments directly making contact with the skin, is good in heat stability at 24 DEG C, and has an obvious color changing effect in the sun.

Owner:绍兴墨织韵纺织科技有限公司

Temperature-resistant variable-color short hair printing treatment agent for synthetic leather and preparation method thereof

The invention relates to a temperature-resistant variable-color short hair printing treatment agent for synthetic leather. The temperature-resistant variable-color short hair printing treatment agent comprises the following components: modified high temperature-resistant polyurethane resin, dimethylbenzene, butyl ester, acetone, silicon dioxide matting powder, modified organic silicon, polyurethane nano-fiber and modified high temperature-resistant polytetrafluoroethylene variable-color wax powder. The invention further relates to a preparation method of the temperature-resistant variable-color short hair printing treatment agent for synthetic leather. Compared with the existing treatment agent for ordinary synthetic leather, the leather surface treated by using the temperature-resistant variable-color short hair printing treatment agent for synthetic leather, disclosed by the invention, has unique fluffy sense, the tactile sensation is fine and comfortable, the temperature resistance is great, and the leather treated by using the treatment agent disclosed by the invention has the advantages of unique tactile sensation, good variable-color effect, obvious fluffy effect, strong true leather effect and excellent comprehensive effects.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Preparation and application of novel environmental-friendly cyanuric acid compound stabilizer special for PVC profile

InactiveCN106366514AImprove thermal stabilityGood discoloration effectSodium stearateMaterials processing

The invention relates to the technical field of chemical stabilizers and in particular to preparation and application of a novel environmental-friendly cyanuric acid compound stabilizer special for a PVC profile. The preparation comprises the following steps: forming a basic catalyst by adopting caustic soda (sodium hydroxide), taking zinc oxide as a raw material, and directly reacting to produce cyanuric acid; neutralizing the basic catalyst by utilizing industrial stearic acid, taking the produced sodium stearate as a surfactant of zinc cyanurate; compounding an auxiliary stabilizer, a lubricating agent, an antioxidant, zinc stearate, calcium stearate and zinc cyanurate according to a set formula. Compared with the traditional heat stabilizer, the cyanuric acid is capable of improving the plasticizing quality of the PVC profile; due to the added lubricating agent, a phenomenon of flow velocity disorder occurring in material processing and production is avoided, so that production and processing can be normally performed, and the inherent quality and appearance quality are improved. Moreover, the stabilizer is environmental-friendly and non-toxic, has high heat stability and processability as well as wide application prospects in the PVC profile industry.

Owner:SHENZHEN AIMSEA IND

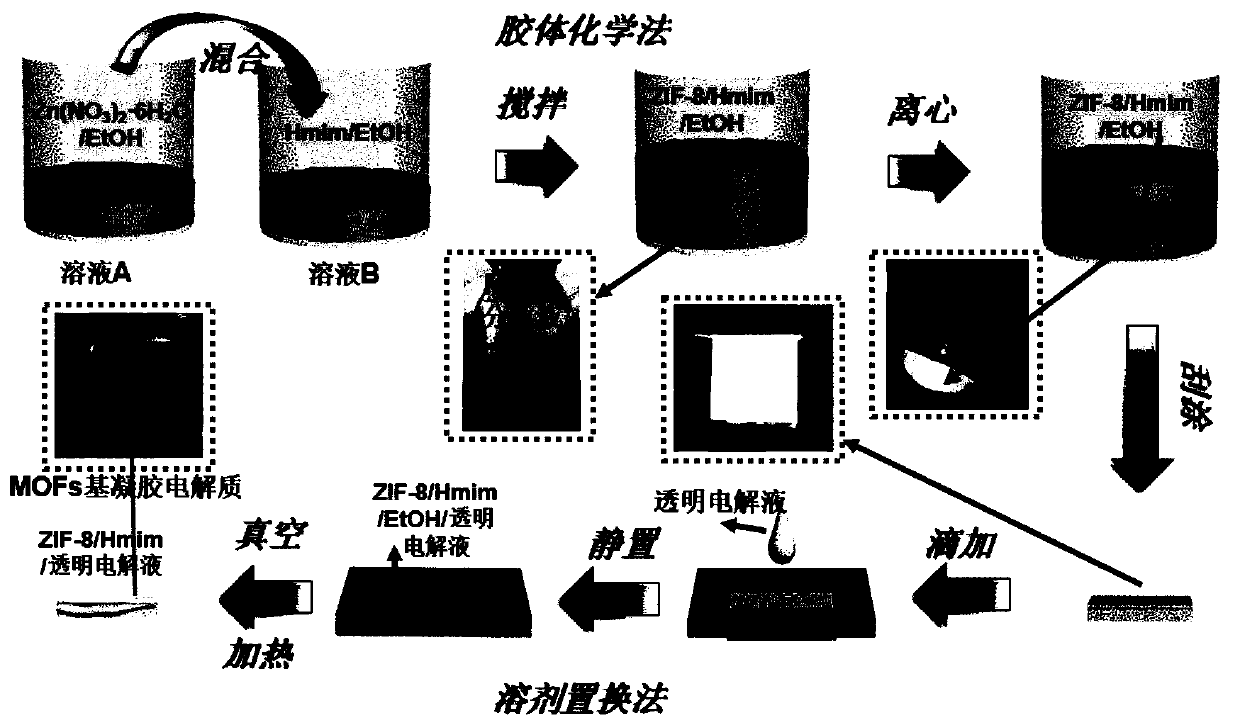

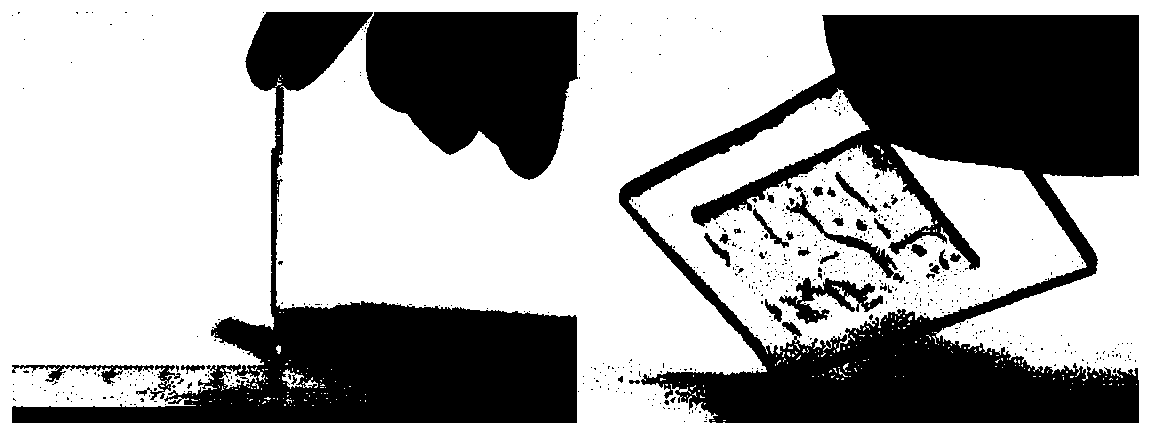

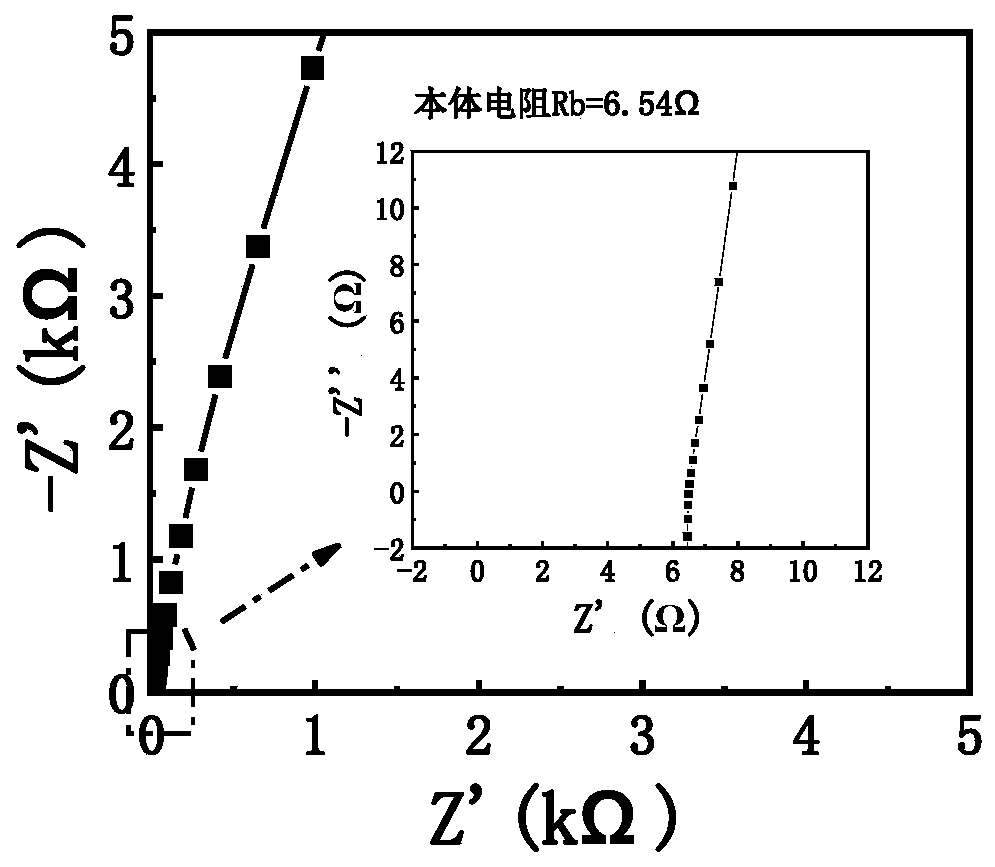

MOFs (Metal Organic Frameworks)-based gel electrolyte and preparation and application thereof

ActiveCN111443544AOvercoming the problem of low room temperature ionic conductivityHigh transparencyNon-linear opticsSolid state electrolyteElectrolytic agent

The invention relates to an MOFs (Metal Organic Frameworks)-based gel electrolyte and a preparation method and application thereof. The electrolyte comprises the following components: an MOFs materialand a transparent electrolyte. The preparation method comprises the following steps of preparing the transparent electrolyte; preparing MOFs pre-gel and preparing the MOFs-based gel electrolyte. Theelectrolyte overcomes the self defects of liquid and solid electrolytes, and has high transparency and ionic conductivity and good interface adhesion; an electrochromic device, especially a flexible device, assembled by the electrolyte is good in discoloration performance, excellent in mechanical property, resistant to bending, capable of being sheared and drilled, and even capable of stably working during bending-discoloration synchronous operation, and has extremely high practical application value.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com