Preparation method and application of thermochromic microcapsules with high sensitivity

A thermochromic and high-sensitivity technology, which is applied in the field of preparation of thermochromic microcapsules, can solve the problems such as the decreased sensitivity of thermochromic materials to discoloration, prolong storage and effective use time, arrange neatly, and improve heat transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

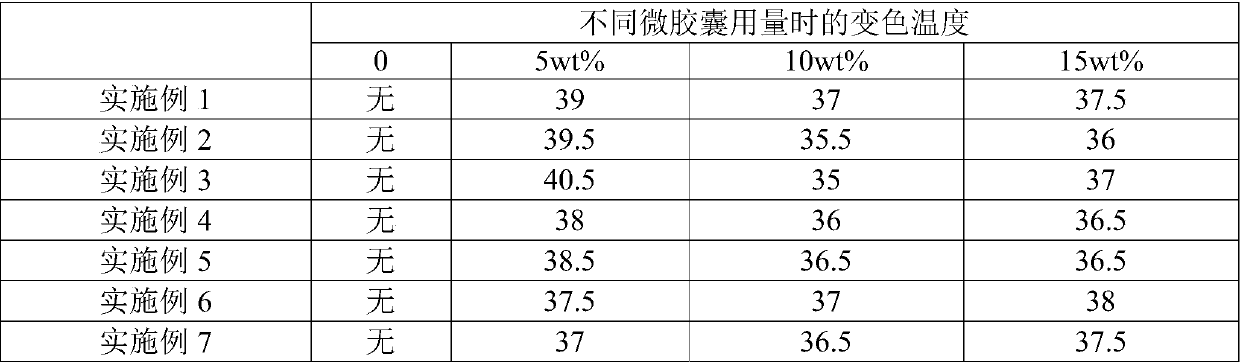

Examples

Embodiment 1

[0033] A preparation method for graphene-modified melamine resin thermochromic microcapsules, comprising the following steps:

[0034] 1) Weigh 10g and 14g of melamine and 37% formaldehyde aqueous solution, add 0.040g of graphene oxide and 50mL of distilled water, use triethanolamine to adjust the pH to 8-9, at 90°C with magnetic stirring After reacting for 1 hour, a modified melamine resin prepolymer with a solid mass concentration of 25.8% was obtained as a microcapsule wall material.

[0035] 2) Weigh crystal violet lactone, bisphenol A and lauryl alcohol according to a mass ratio of 1:4:60, keep warm at 90° C. and stir and mix for 1 hour to obtain a molten mixture as a microcapsule core material.

[0036] 3) Take the core material and the wall material according to the ratio of the mass ratio of the core wall to 1:1, add lauryl ammonium chloride and an appropriate amount of deionized water accounting for 7% of the core material mass fraction in the core material, and use h...

Embodiment 2

[0040] A preparation method for graphene-modified melamine resin thermochromic microcapsules, comprising the following steps:

[0041] 1) Weigh 10g and 16g of melamine and 37% formaldehyde aqueous solution, add 0.052g of aminographene and 50mL of distilled water, adjust the pH to 8-9 with triethanolamine, and place it at 80°C with magnetic stirring After reacting for 0.5 h, a modified melamine resin prepolymer with a mass concentration of 26.5% was obtained as a microcapsule wall material.

[0042]2) Weigh crystal violet lactone, bisphenol A and myristyl alcohol according to the mass ratio of 1:4:65, keep warm at 90° C. and stir and mix for 1 hour to obtain a molten mixture as a microcapsule core material.

[0043] 3) Take the core material and the wall material according to the ratio of the mass ratio of the core material to 1:1.5, add cetyltrimethylammonium bromide and an appropriate amount of deionized water accounting for 8% of the core material mass fraction in the core m...

Embodiment 3

[0047] A preparation method for graphene-modified melamine resin thermochromic microcapsules, comprising the following steps:

[0048] 1) Weigh 10g and 18g of melamine and 37% formaldehyde aqueous solution, add 0.060g of graphene oxide and 50mL of distilled water, use triethanolamine to adjust the pH to 8-9, at 100°C with magnetic stirring After reacting for 0.5 h, a modified melamine resin prepolymer with a mass concentration of 31.2% was obtained as a microcapsule wall material.

[0049] 2) Weigh crystal violet lactone, bisphenol A and myristyl alcohol according to the mass ratio of 1:6:70, keep warm at 90° C. and stir and mix for 1 hour to obtain a molten mixture as a microcapsule core material.

[0050] 3) Take the core material and the wall material according to the ratio of the core-wall mass ratio of 1:1.5, add cetylpyridinium bromide and appropriate amount of deionized water accounting for 10% of the core material mass fraction in the core material, and use high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com