A smart color-changing glass with plasmonic wide-spectrum control

A color-changing glass and plasmon technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as poor stability, complex manufacturing process, and inability to dynamically tune the spectrum, achieving poor stability, good stability, and fast response slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

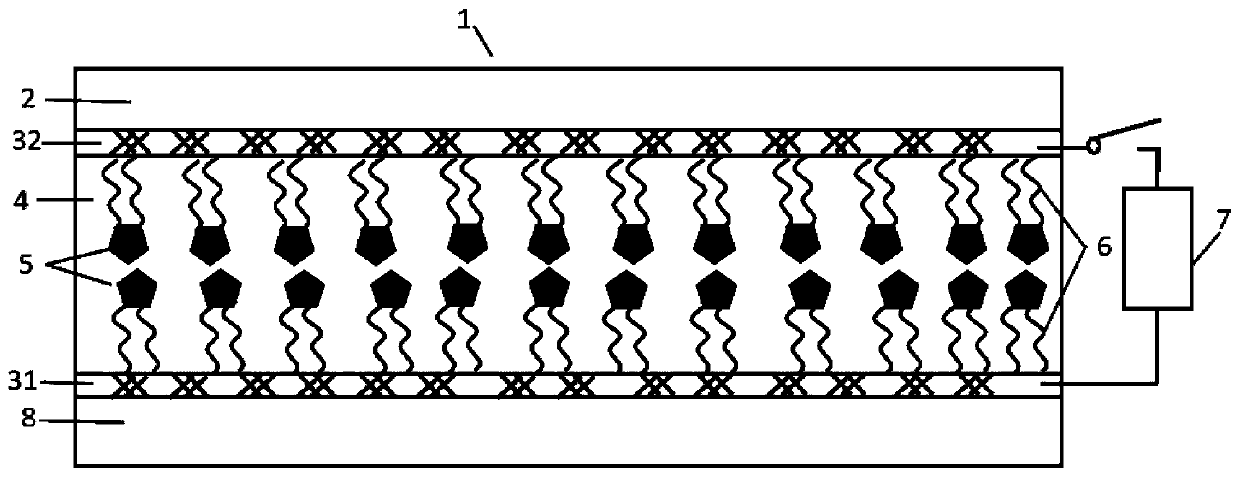

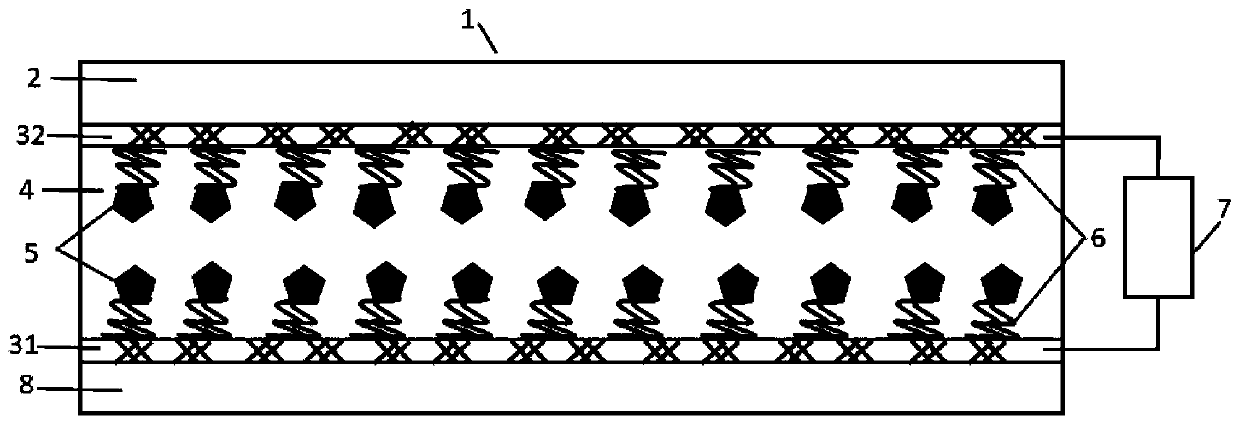

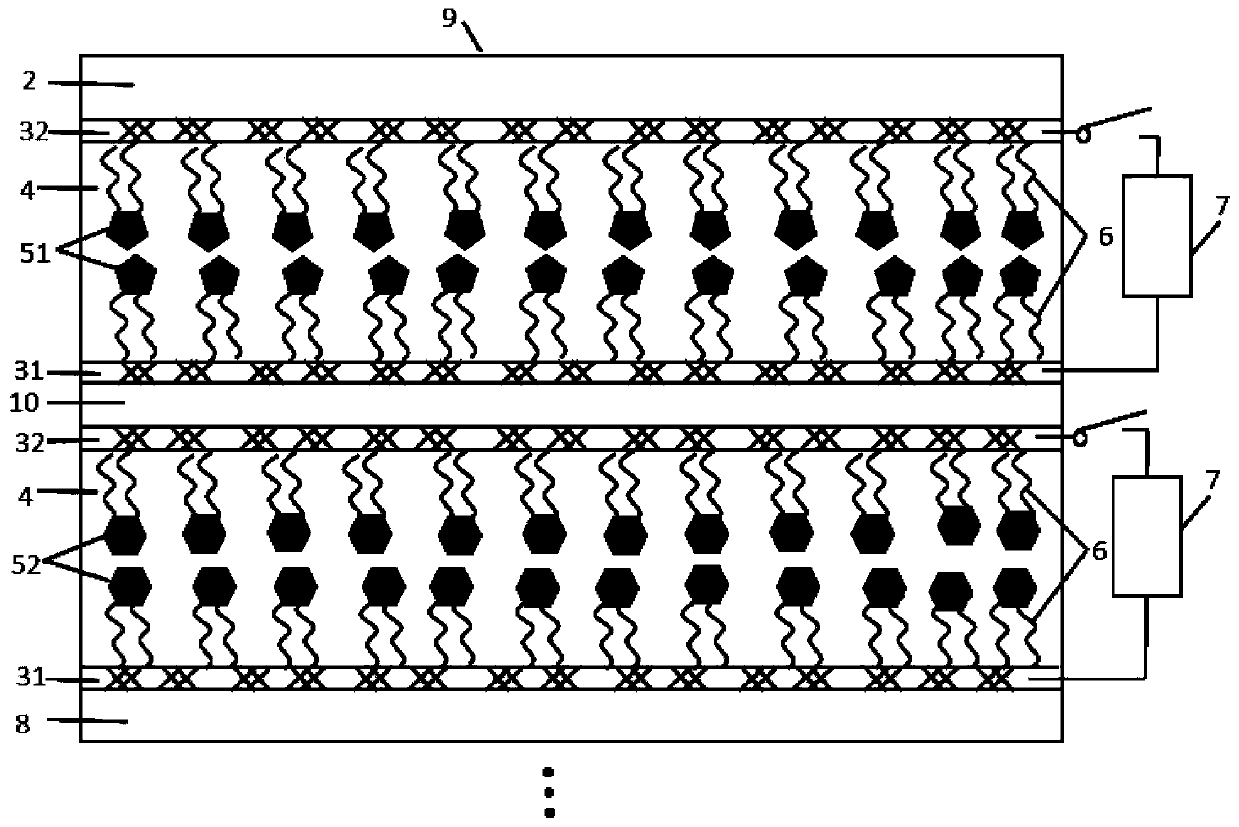

[0031] The smart color-changing glass regulated by plasmon wide spectrum of the present invention is based on the plasmon enhancement mechanism, and includes single-layer and multi-layer structures. The single-layer smart color-changing glass 1 includes an upper glass layer 2, a lower silver nanowire electrode 31, An upper silver nanowire electrode 32 , a transparent liquid 4 , a plasmonic nanoparticle 5 , a polymer molecular brush material layer 6 , a peripheral driving circuit 7 and a lower glass layer 8 . The positional relationship from bottom to top is the lower glass layer 8, the lower silver nanowire electrode 31, the polymer molecular brush material layer 6, the plasmonic nanoparticle 5, the upper silver nanowire electrode 32, and the upper glass layer 2; The polymer molecular brush material layer 6 between the silver nanowire electrode 31 and the upper silver nanowire electrode 32 has upper and lower parts. Meta-nanoparticles 5; the lower part of the polymer molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com