A kind of photochromic organic pigment and preparation method thereof

A technology of photochromic materials and organic pigments, applied in the field of organic pigments, can solve the problems of poor stability of photochromic materials, poor fatigue resistance, narrow chromatographic range, etc., and achieve rich color layering and diverse needs, stability Strong, extended chromatographic range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

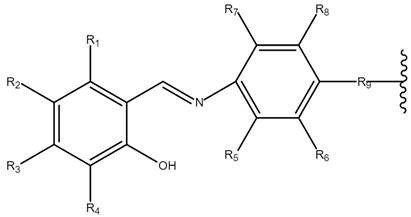

Method used

Image

Examples

Embodiment 1

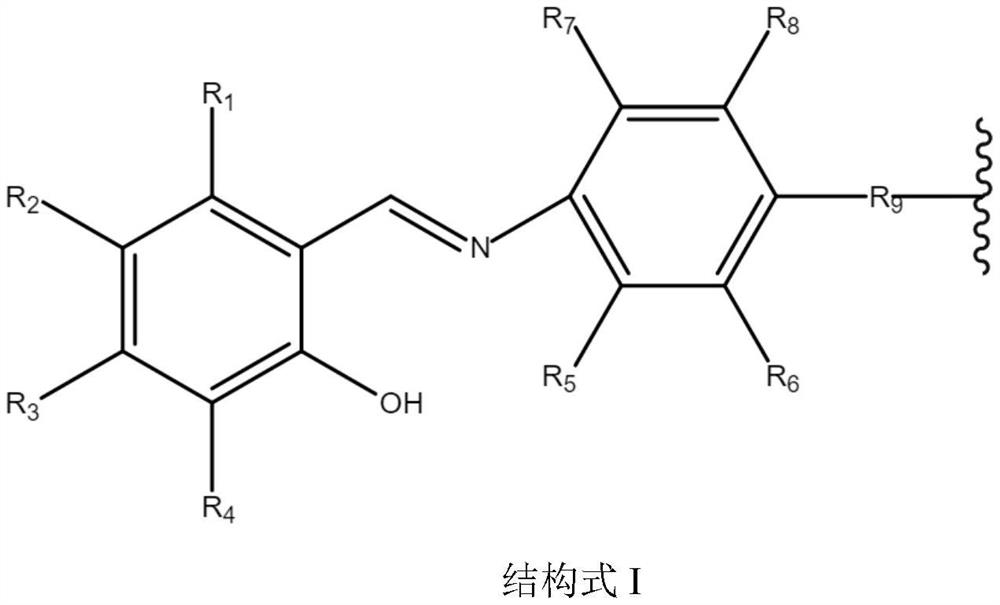

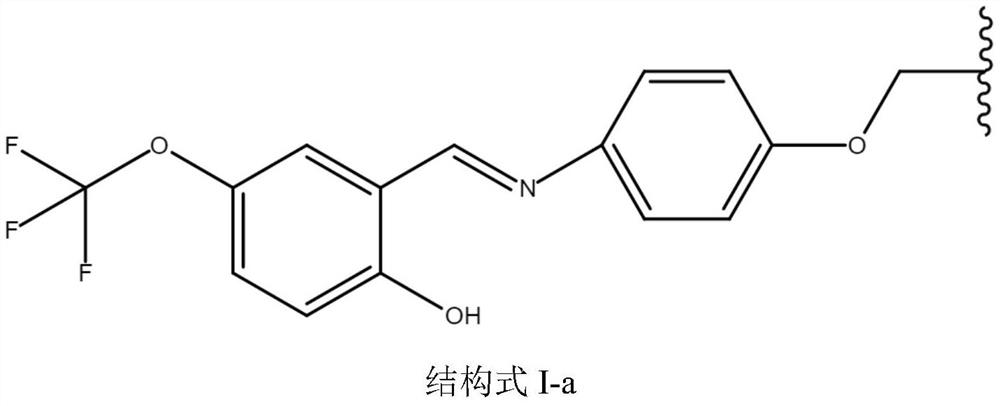

[0027] In the photochromic organic pigment of this embodiment, the organic pigment includes the photochromic material represented by the structural formula I-a:

[0028]

[0029] In the formula, It is a polymer reacted with trimethyl-1,6-hexamethylene diisocyanate and 3-(allyloxy)-1,2-propanediol as raw materials.

[0030] The preparation method of the photochromic organic pigment of the present embodiment comprises the following steps:

[0031] S1: add trimethyl-1,6-hexamethylene diisocyanate and 3-(allyloxy)-1,2-propanediol in a molar ratio of 1:1.1 into the reaction kettle, introduce nitrogen protection, heat up to 120°C, and react 2h to obtain a branched polyurethane polymer rich in olefinic double bonds;

[0032] S2: adding the branched olefinic double bond-rich polyurethane polymer obtained in step S1 into a composite solvent composed of deionized water and toluene, stirring and mixing evenly, then adding 4-(vinyloxy)-aniline and an initiator Di-tert-butyl peroxid...

Embodiment 2

[0036] In the photochromic organic pigment of this embodiment, the organic pigment includes the photochromic material represented by the structural formula I-b:

[0037]

[0038] In the formula, It is a polymer reacted with 2,2,4-trimethylhexan-1,6-diyl diisocyanate and (R)-5-hexene-1,2-diol as raw materials.

[0039] The preparation method of the photochromic organic pigment of the present embodiment comprises the following steps:

[0040] S1: 2,2,4-trimethylhexan-1,6-diyldiisocyanate and (R)-5-hexene-1,2-diol in a molar ratio of 1:1.05 were added to the reaction kettle, and the Under nitrogen protection, the temperature was raised to 130 °C, and the reaction was carried out for 3 h to obtain a branched polyurethane polymer rich in olefinic double bonds;

[0041] S2: adding the branched olefinic double bond-rich polyurethane polymer obtained in step S1 into a composite solvent composed of deionized water and toluene, stirring and mixing evenly, then adding 4-(allyloxy)a...

Embodiment 3

[0045]In the photochromic organic pigment of this embodiment, the organic pigment includes the photochromic material represented by the structural formula I-c:

[0046]

[0047] In the formula, It is a polymer reacted with trimethylhexamethylene diisocyanate and 3-butene-1,2-diol as raw materials.

[0048] The preparation method of the photochromic organic pigment of the present embodiment comprises the following steps:

[0049] S1: add trimethylhexamethylene diisocyanate and 3-butene-1,2-diol in a molar ratio of 1:1.02 to the reaction kettle, introduce nitrogen protection, heat up to 120°C, and react for 3h to obtain a branched chain Polyurethane polymers rich in olefinic double bonds;

[0050] S2: adding the branched olefinic double bond-rich polyurethane polymer obtained in step S1 into a composite solvent composed of deionized water and toluene, stirring and mixing evenly, then adding 2-isopropyl-4-vinylaniline and triggering Potassium persulfate, the molar ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com