A kind of hot-melt thermally conductive adhesive for refrigerator or freezer evaporator and its preparation and application

An evaporator and hot-melt technology, which is applied in the field of hot-melt thermally conductive adhesive and its preparation, can solve the problems of uneven cooling of the evaporator, decreased cooling effect, poor thermal conductivity, etc., and achieves good thermal conductivity, less heat loss, Good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

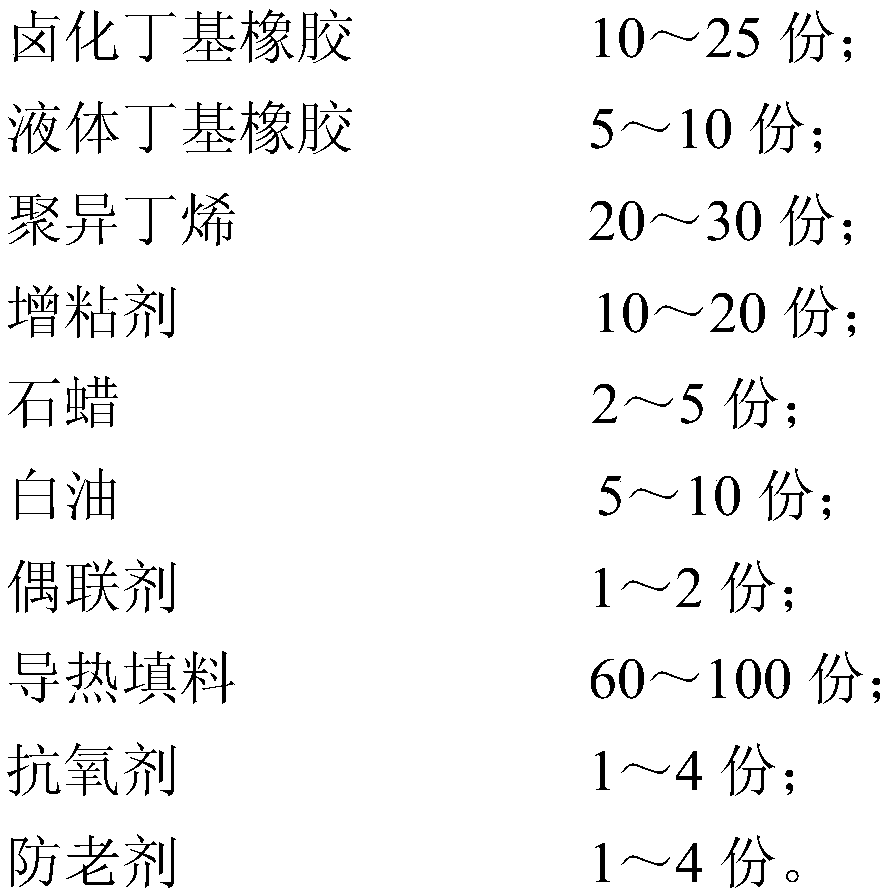

[0041] Hot-melt heat-conducting adhesive for refrigerator or freezer evaporator, containing the following components by weight:

[0042]

[0043]

[0044] The chlorinated butyl rubber is masticated on the open mill, the antioxidant 264 is added during the masticating process, and then the masticated rubber is put into the kneader; the liquid butyl rubber, polyisobutylene, terpene resin, paraffin wax Put the white oil into the kneader; raise the temperature to 130°C, keep it warm for 20 minutes, turn on the kneader, and knead for 1 hour; add graphite, titanate coupling agent NDZ-105, anti-aging agent DFC-34, knead for 30 minutes, and vacuum; When the vacuum degree reaches 0.075MPa, continue kneading for 1 hour to obtain a uniformly dispersed hot-melt heat-conducting adhesive for refrigerator or freezer evaporator.

Embodiment 2

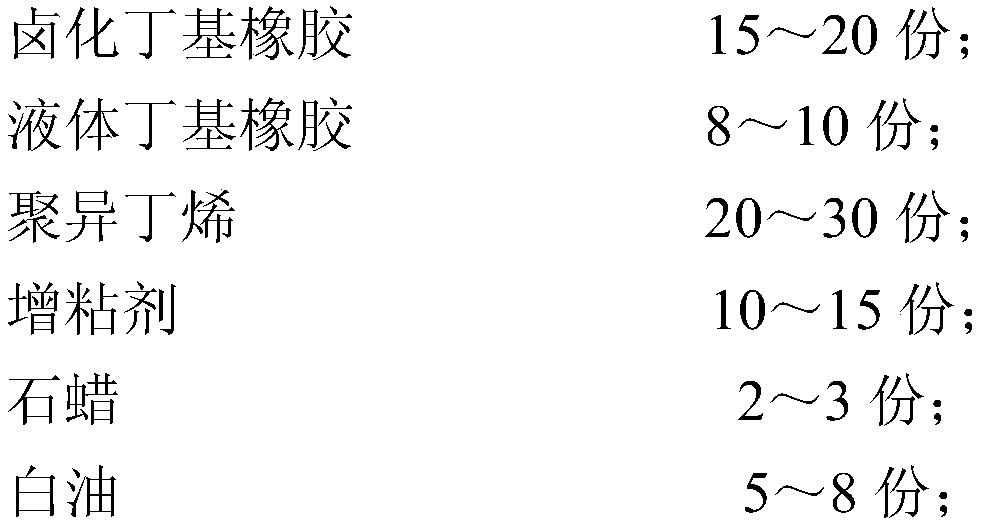

[0046] Hot-melt heat-conducting adhesive for refrigerator or freezer evaporator, containing the following components by weight:

[0047]

[0048]The chlorinated butyl rubber is masticated on an open mill, and antioxidant 1010 and antioxidant 168 are added during the masticating process, and then the masticated rubber is put into the kneader; liquid butyl rubber, polyisobutylene, Put hydrogenated rosin glyceride, paraffin, and white oil into the kneader; raise the temperature to 150°C, keep warm for 15 minutes, turn on the kneader, and knead for 1-2 hours; add graphite, titanate coupling agent NDZ-130, anti-aging agent 2246, Knead for 30 minutes and vacuumize; when the vacuum degree reaches 0.075MPa, continue to knead for 1.5 hours to prepare a uniformly dispersed hot-melt heat-conducting adhesive for refrigerator or freezer evaporator.

Embodiment 3

[0050] Hot-melt heat-conducting adhesive for refrigerator or freezer evaporator, containing the following components by weight:

[0051]

[0052] The chlorinated butyl rubber is masticated on an open mill, and antioxidant 264 and antioxidant 168 are added during the masticating process, and then the masticated rubber is put into the kneader; liquid butyl rubber, polyisobutylene, Put rosin resin, paraffin, white oil, etc. into the kneader; heat up to 140°C, keep warm for 20 minutes, turn on the kneader, and knead for 1.5 hours; add graphite, titanate coupling agent NDZ-105, antioxidant RD, and knead for 30 minutes , vacuum; when the vacuum reaches 0.075MPa, continue kneading for 1.5h to obtain a uniformly dispersed hot-melt heat-conducting adhesive for refrigerator or freezer evaporators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com