A nanofiltration membrane for water purification and its preparation method and application

A nanofiltration membrane and water purification technology, applied in general water supply conservation, chemical instruments and methods, membranes, etc., can solve the problem that the removal rate of high-valent salt and heavy metal ions cannot meet the requirements, the bonding force between porous base membrane and desalination layer is weak, performance degradation and other problems, to achieve excellent light transmittance, excellent pollution resistance, and reduce the effect of internal concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

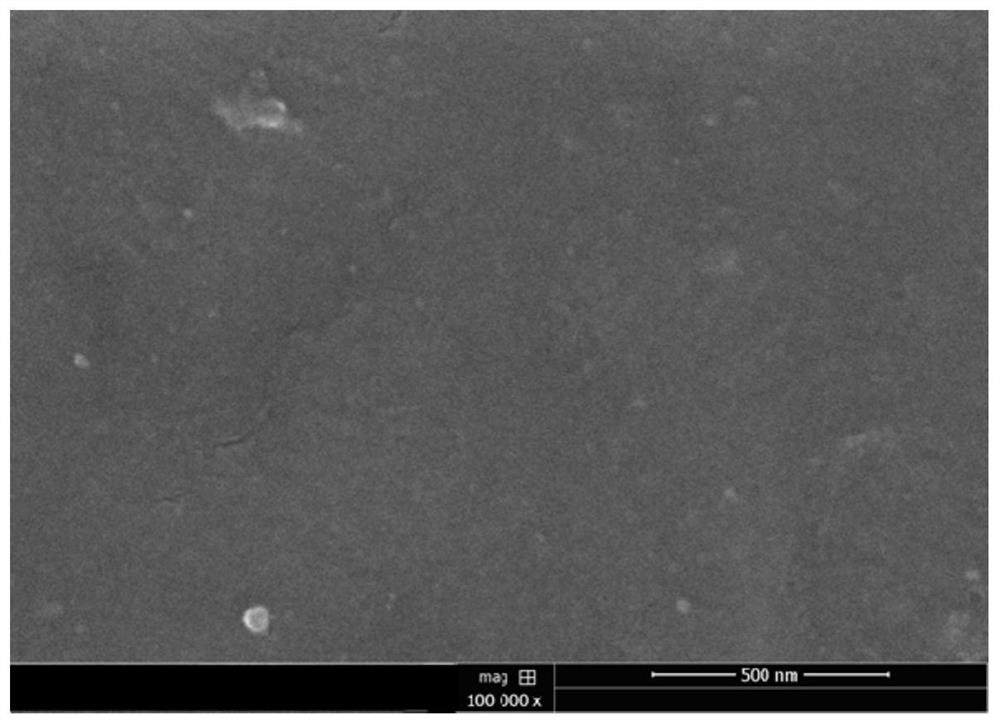

[0050] This embodiment is a nanofiltration membrane used for water purification, including a modified PVB porous base membrane and an ultra-thin polyamide desalination layer formed by reaction on one side of the PVB porous base membrane.

[0051] As a preferred embodiment, the molecular weight of the PVB, that is, polyvinyl butyral, is between 25,000 and 200,000, wherein the content of butyral is 65-88%, and the content of alcoholic hydroxyl groups is 11-27%. More preferably, the molecular weight of PVB is between 100,000 and 150,000, and the alcoholic hydroxyl content is 24-27%.

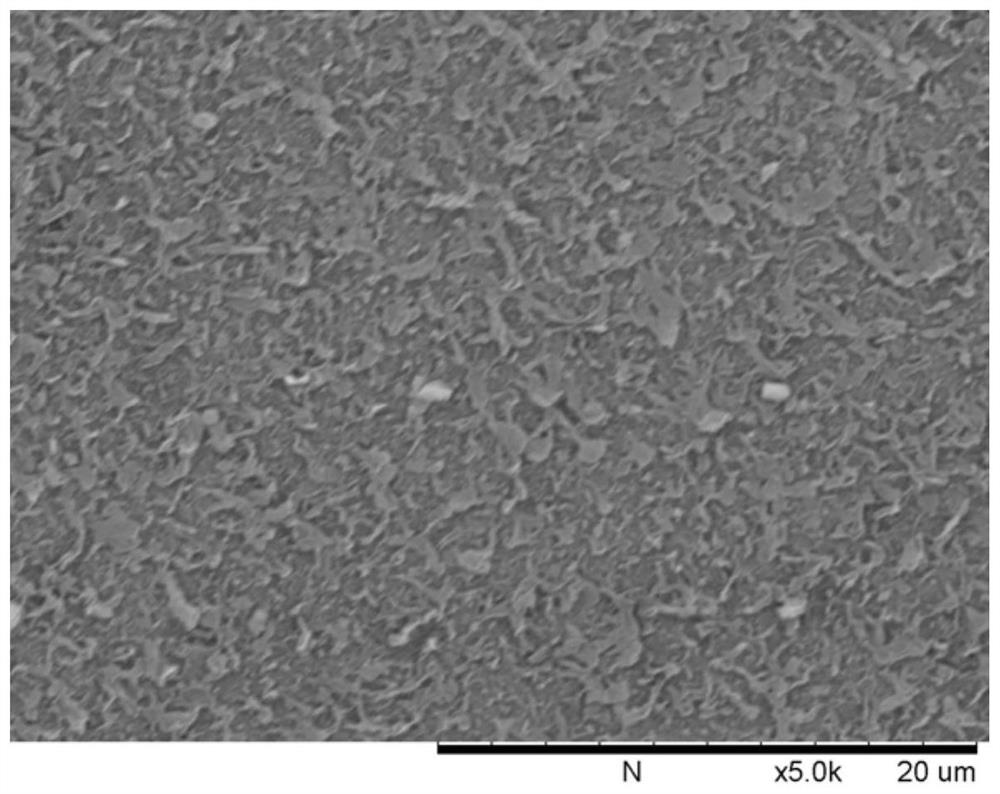

[0052] As another preferred embodiment, the modified PVB porous base membrane is an aminated PVB porous base membrane. More preferably, the aminated PVB porous base film is obtained by acyl chlorination of the PVB porous base film, and then through an amination reaction; wherein the PVB porous base film is The sponge pore structure with high porosity has an average pore diameter of 0.01-0.65 μm, an...

Embodiment 2

[0055] This embodiment is a method for preparing a nanofiltration membrane for water purification, comprising the following steps:

[0056] S1, configure polyvinyl butyral casting solution: configure PVB casting solution according to PVB 5-40wt%, solvent 50-85wt%, porogen 1-20wt%, at first the porogen is completely dissolved in the solvent, Then add PVB, stir and heat to dissolve to form a completely dissolved casting solution, let it stand for degassing for later use, and obtain the prepared PVB casting solution;

[0057] S2. Preparation of PVB porous base membrane: Extrude the prepared PVB casting solution to spin the hollow fiber nascent membrane filament, control the phase transformation of the nascent membrane filament, solidify the membrane filament from the liquid phase, and then wind the membrane filament on the On the film machine;

[0058] Put the PVB membrane in water to further dissolve the solvent and porogen in the membrane completely, and then freeze-dry the PV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com