Patents

Literature

303results about How to "Improve surface hydrophilicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perovskite type electroluminescence device and preparation method thereof

ActiveCN104681731AIncrease brightnessEasy to filmSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionBlocking layer

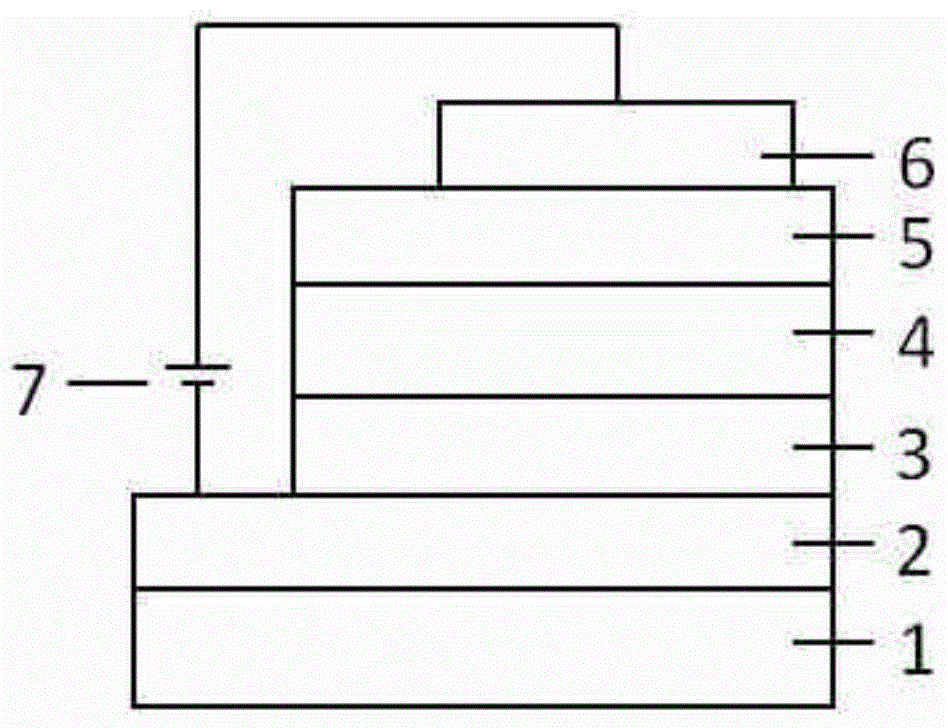

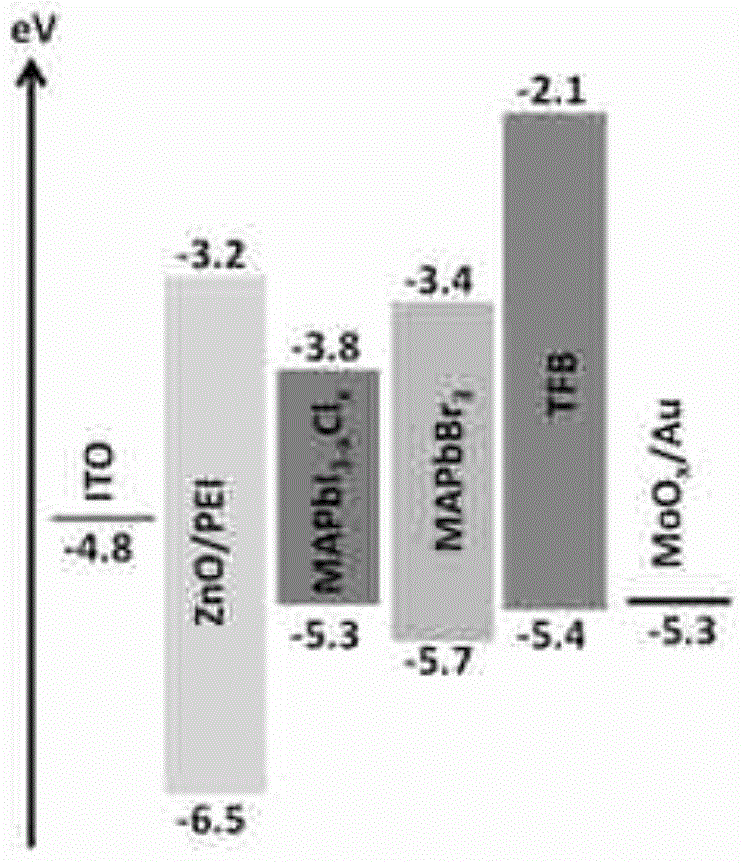

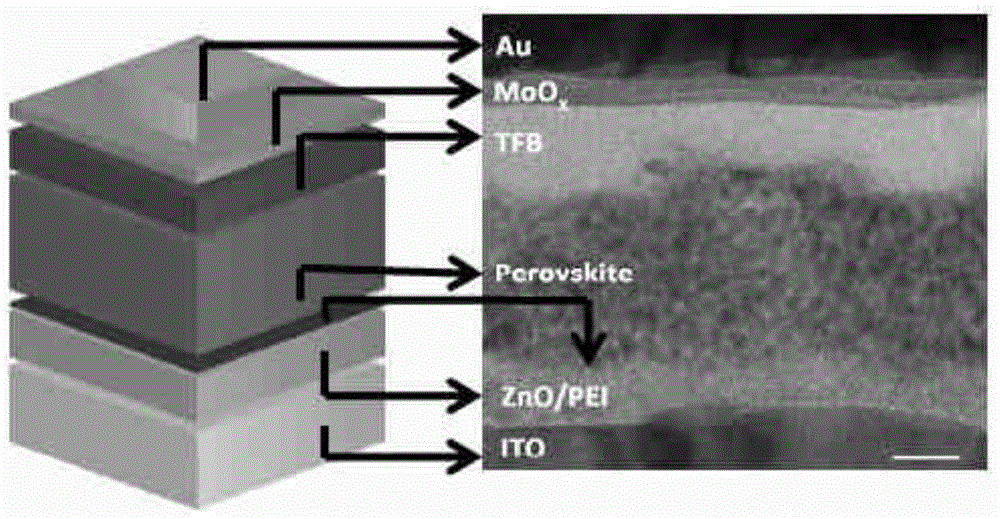

The invention discloses a perovskite type electroluminescence device. The device comprises a substrate, a cathode, an electronic transmission-hole blocking layer, a luminescent layer, a hole transmission-electron blocking layer and an anode, wherein the luminescent layer is made of a material of a perovskite structure; the structure of the device can effectively promote injection and transmission of the charge carriers, restrict the sufficient recombination luminescence of the charge carriers / excitons, and adjust the emission color from the near ultraviolet light band, the visible light band to the near-infrared band by means of changing the components of the luminescent material. The electroluminescence device provided by the invention is high in efficiency, low in turn-on voltage, excellent in color saturation and stable in spectrum changed along with the voltage, meanwhile, the perovskite type electroluminescence device is simple in process, low in cost and is suitable for being widely used in the products of the display and illumination field, in particular suitable for the large-sized industrial production of the high-performance electroluminescence devices with low cost and flexible substrate.

Owner:NANJING UNIV OF TECH

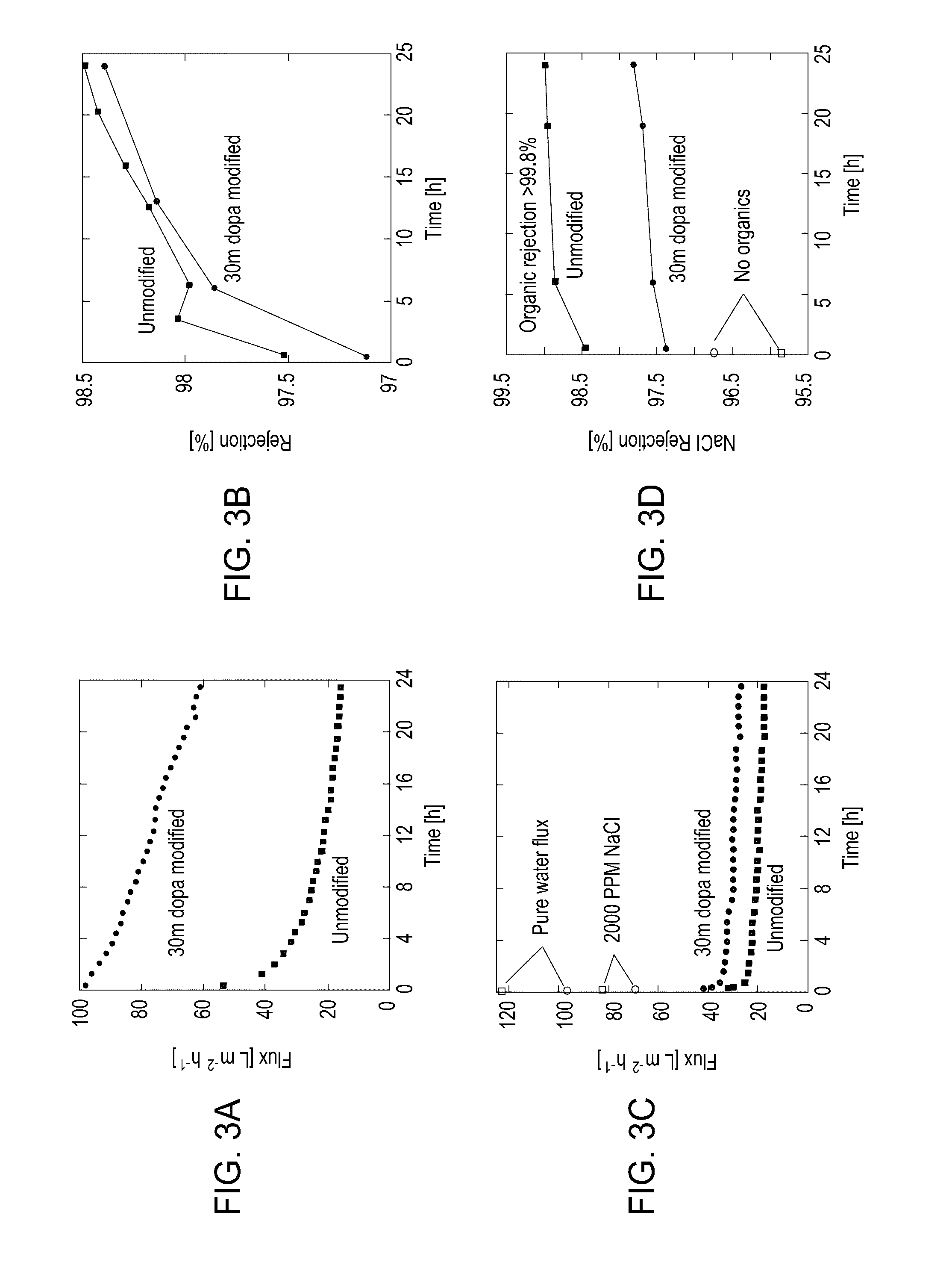

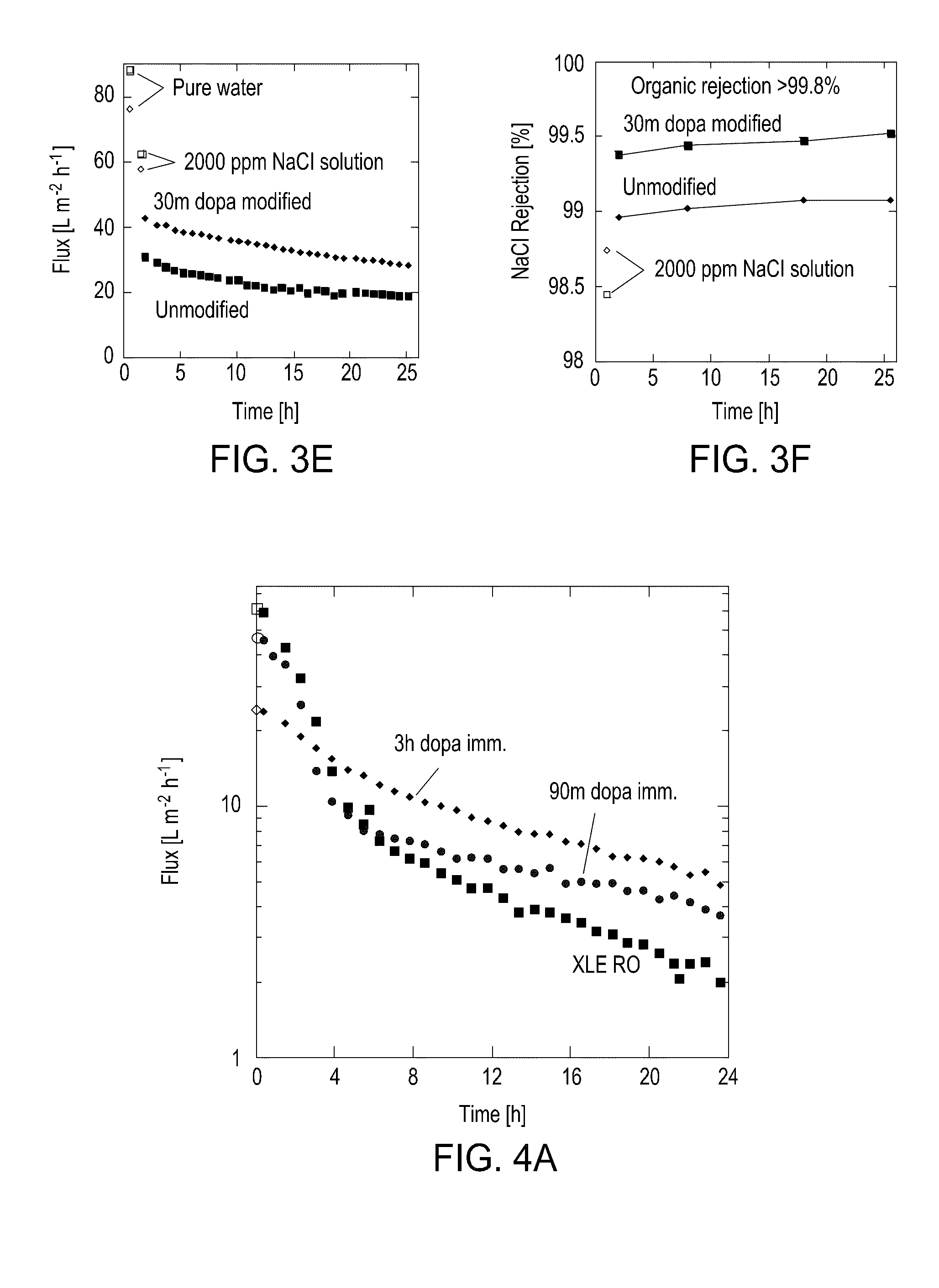

Water purification membranes with improved fouling resistance

ActiveUS20100051538A1Increase membrane hydrophilicityMitigation of membrane foulingMembranesSemi-permeable membranesCoated membraneAir purification

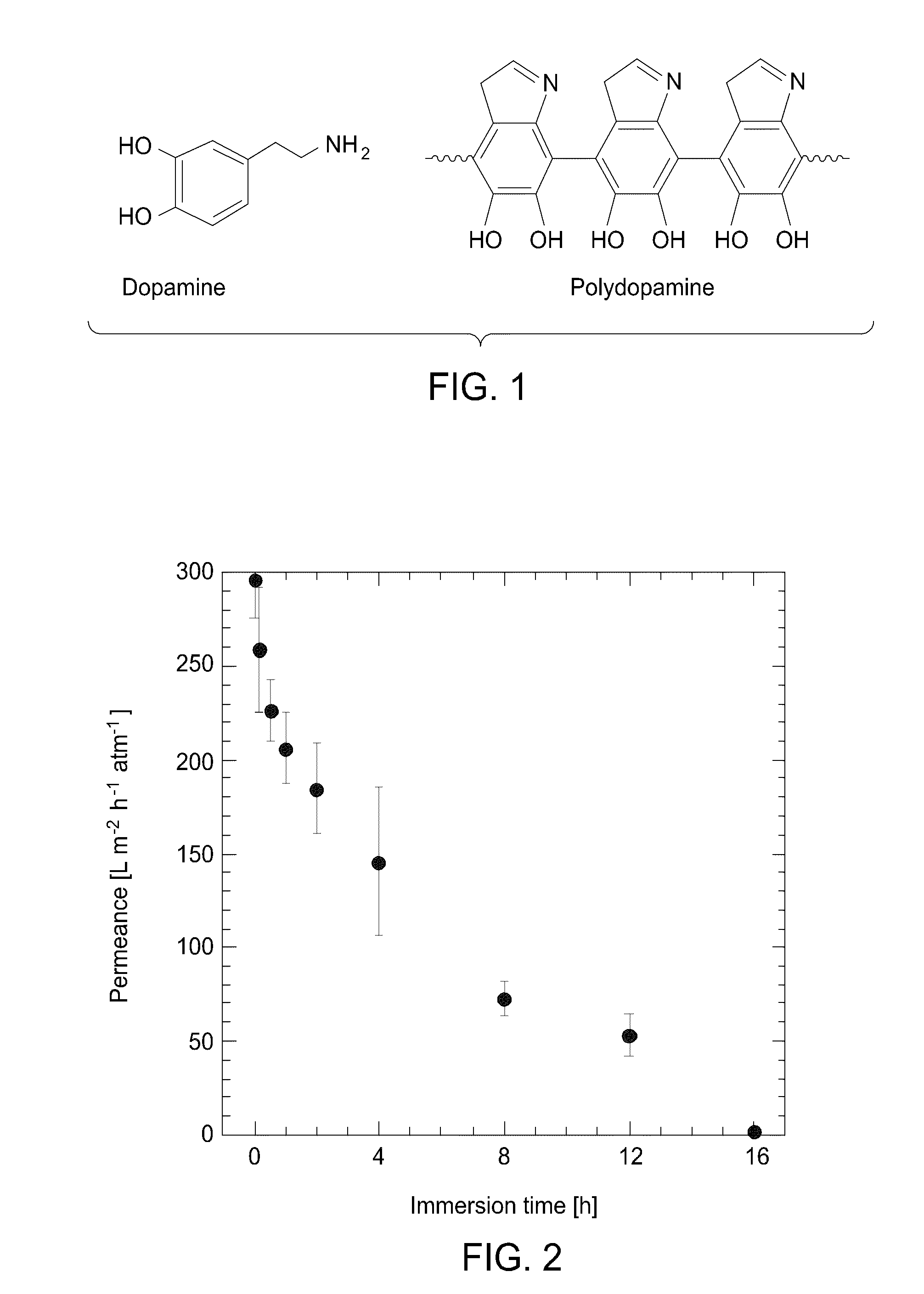

The present invention includes methods and compositions for liquid separation and water purification. The present invention includes a purification membrane having a polymer matrix purification membrane that has been treated with dopamine to form a polydopamine coated membrane with a high water flux and a high hydrophilicity.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Hydrogel contact lens and preparation method thereof

InactiveCN103467652AEnhanced ability to bind waterGood surface hydrophilicity, wettability and dehydration resistanceOptical partsComposite materialInitiation

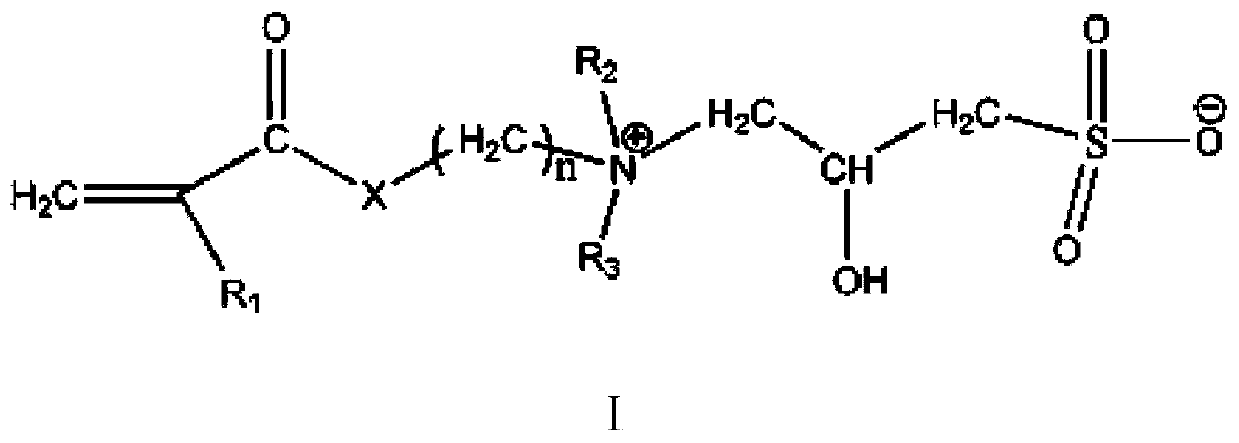

The invention provides a hydrogel contact lens and a preparation method thereof. The hydrogel contact lens comprises a reacting product of a polymerizable composition, wherein the polymerizable composition contains a hydroxysulfo zwitterionic monomer, at least one or more polymerizable monomers, a crosslinking agent of at least one or more monomers and at least one radical initiator. The hydrogel contact lens is prepared by performing ultraviolet initiation or thermal-initiation polymerization on the hydroxysulfo zwitterionic monomer, the polymerizable monomer, the crosslinking agent and the radical initiator and further hydrating. The contact lens has the characteristics of high water content, high hydrophily, dehydration resistance and protein deposition resistance.

Owner:SOUTHEAST UNIV

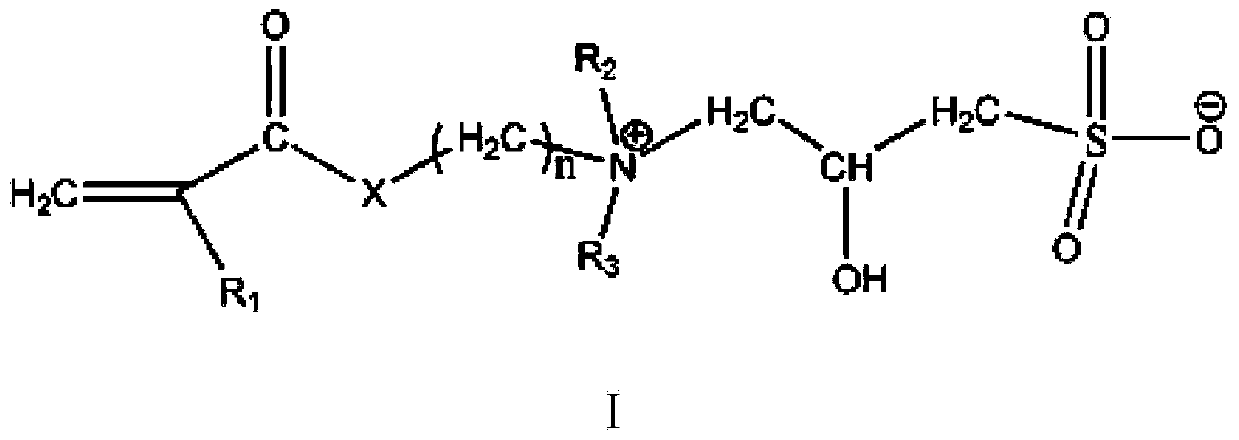

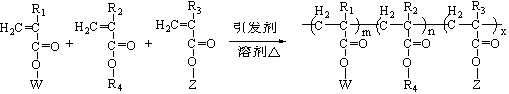

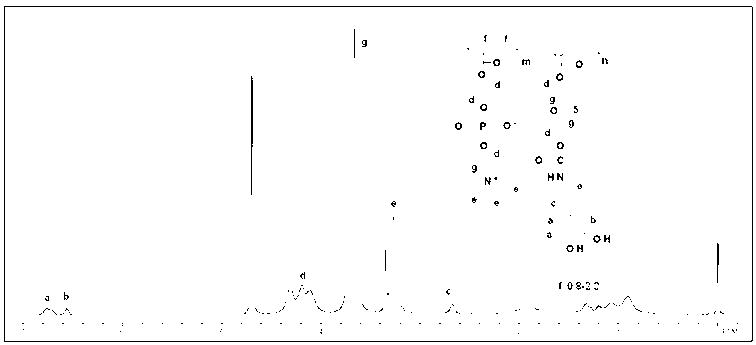

Imitation mussel attachment protein and cell membrane structure copolymer and preparation method and application thereof

The invention discloses an imitation mussel attachment protein and cell membrane structure double-bionic copolymer shown by the structural formula (I), wherein m is an integer from 10 to 1,000, n is an integer from 0 to 500, and x is an integer from 5 to 500; in the m, n and x, the molar percentage of m is 30-90%, the molar percentage of n is 0-50%, and the molar percentage of x is 10-70%; R1, R2 and R3 are H or CH3; R4 is an alkyl with 4-18 carbon atoms; V is a catechol group with 2-300 carbon atoms in chain connection; W is a hydrophilic group with 2-8 carbon atoms in chain connection; and the hydrophilic group is a quaternary ammonium group, phosphorylcholine group, pyridinium, sulfonic acid group, phosphate group, carboxylic acid group or sulfuric acid group. According to the invention, the coating is in firm combination, the copolymer is almost suitable for an establishment method of a surface imitation cellulosa membrane structure of any material, and the surface hydrophilic performance and biocompatibility of artificial organ and related materials, medicine controlled-release systems, separation materials and other materials can be improved.

Owner:NORTHWEST UNIV

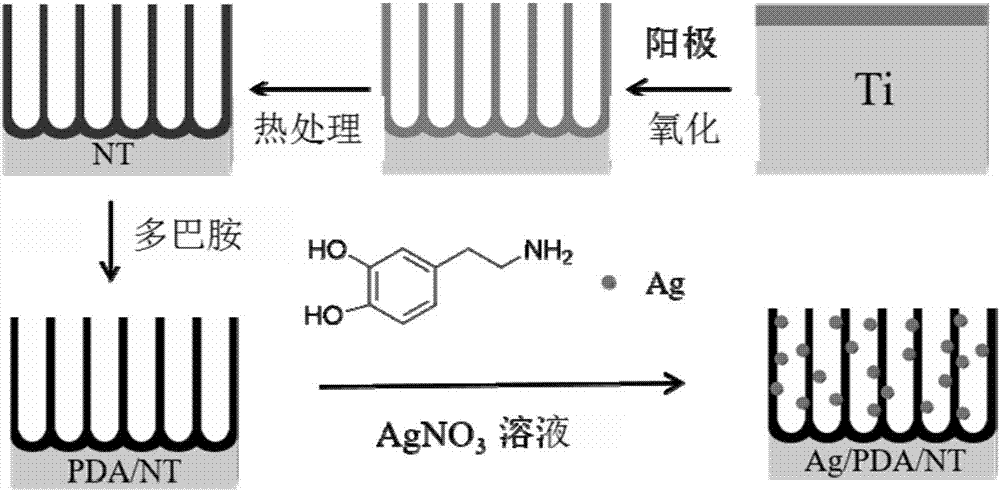

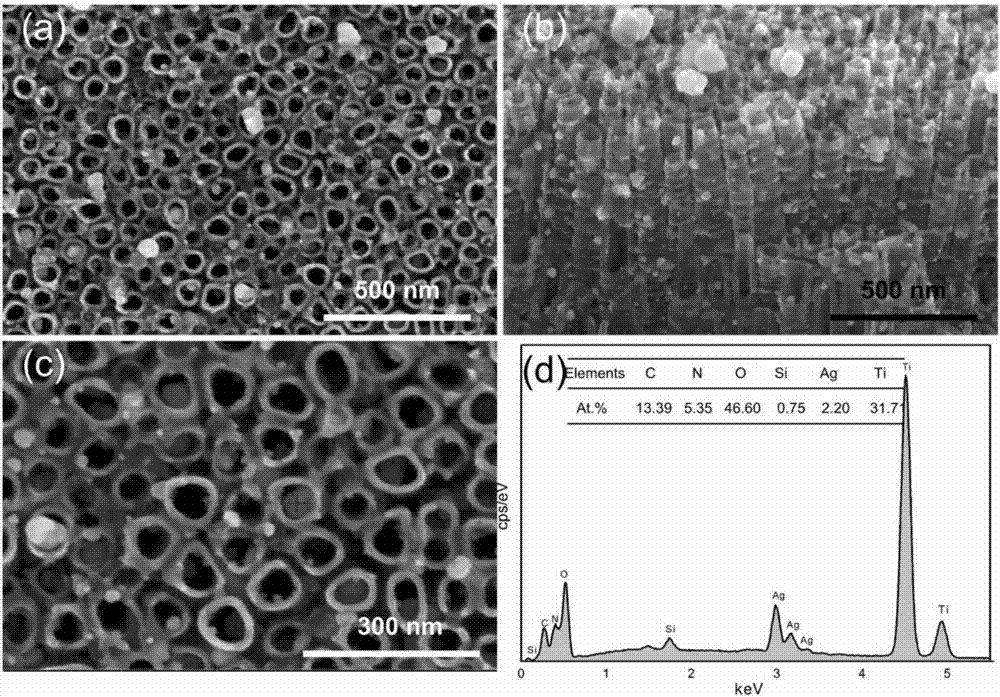

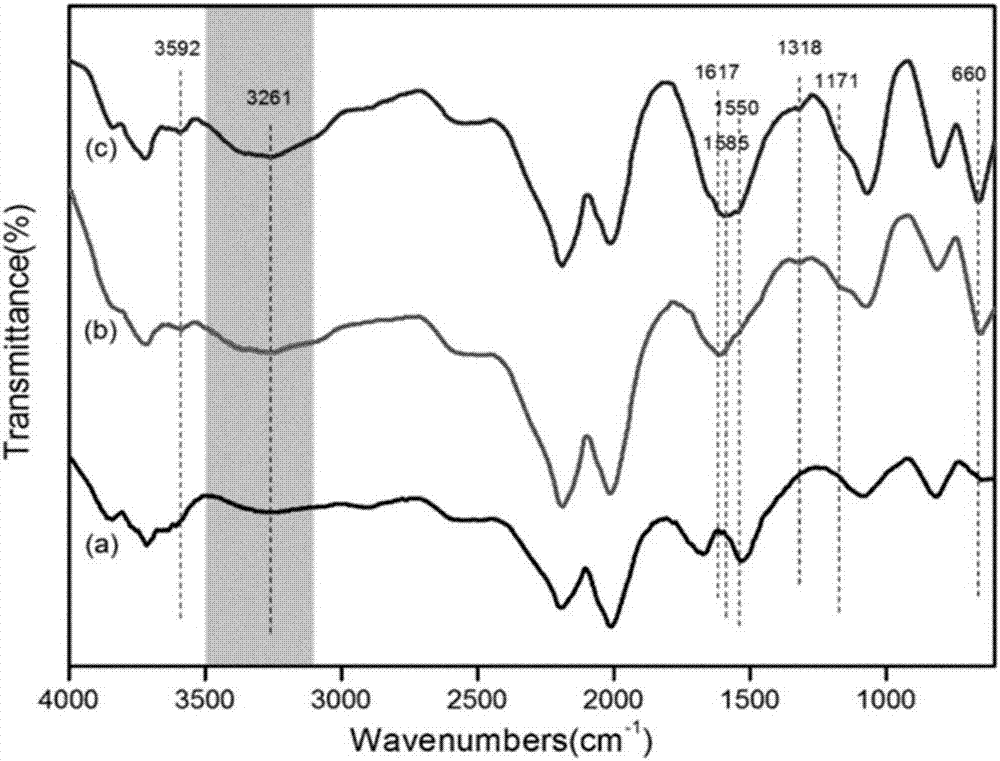

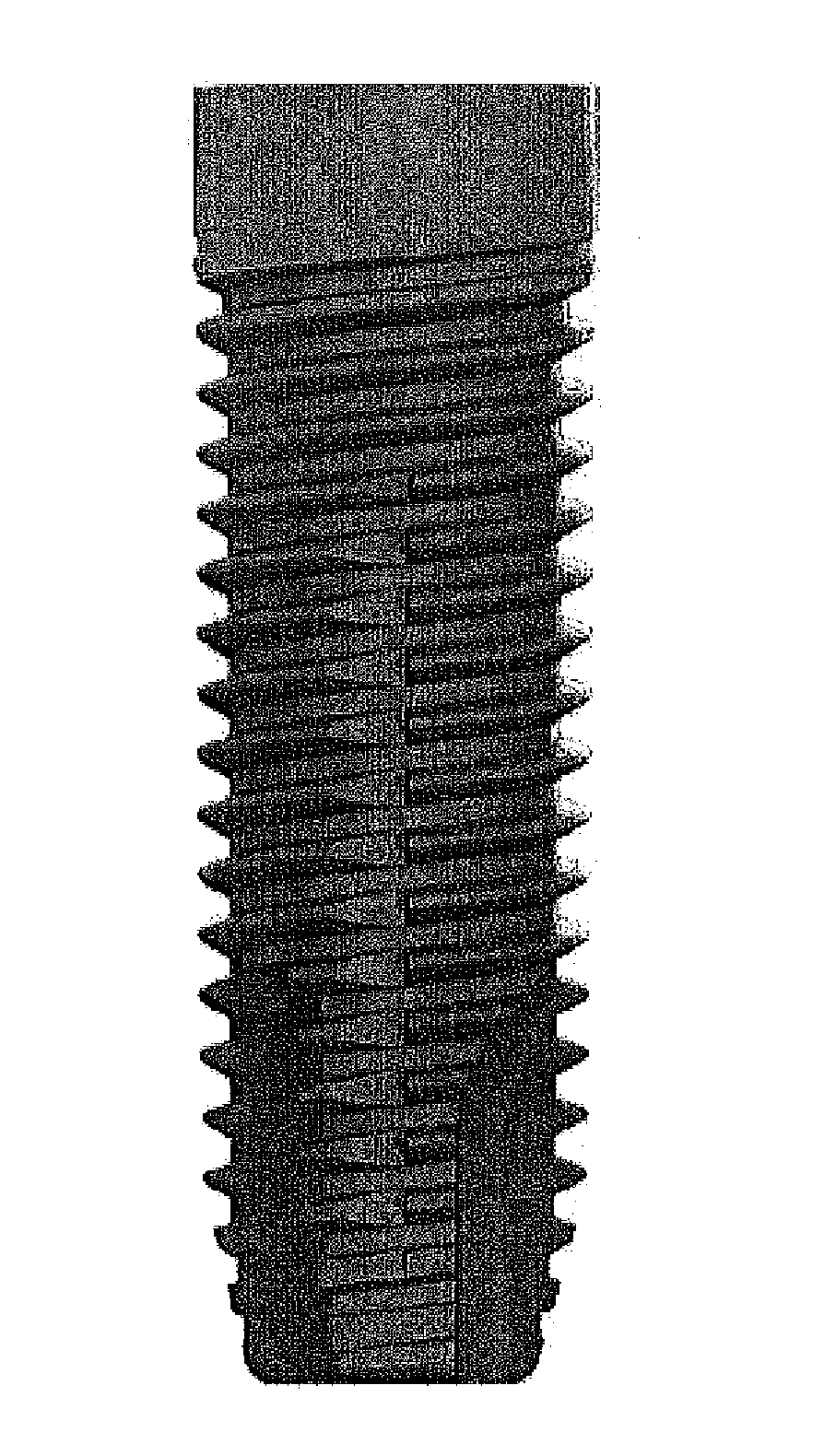

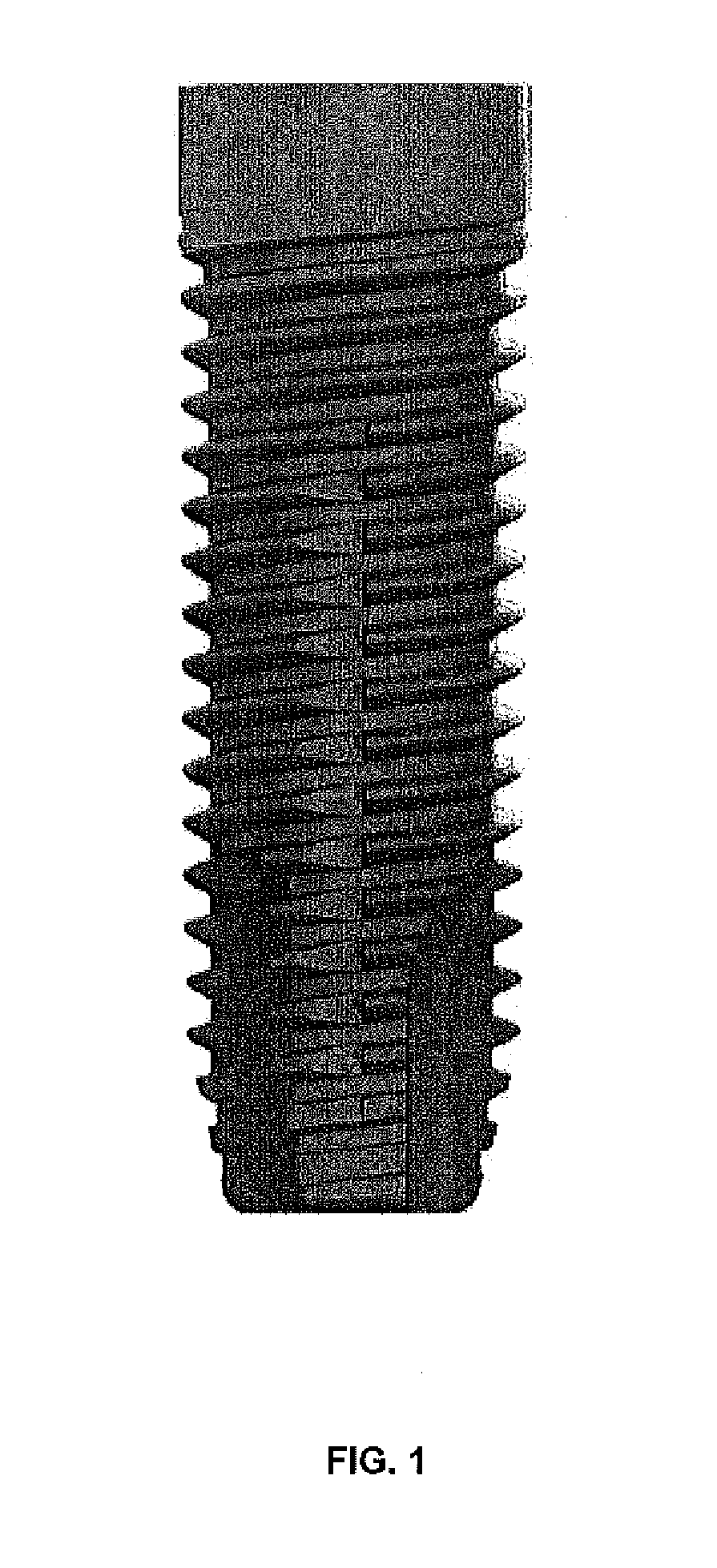

Dental implant and preparation method of bioactive antibacterial surface of dental implant

InactiveCN107096068AReduce releaseAvoid uneven loadSurface reaction electrolytic coatingPharmaceutical delivery mechanismOsteoblastNa k atpase activity

The invention relates to a dental implant and a preparation method of a bioactive antibacterial surface of the dental implant. The dental implant is characterized in that medical titanium or a titanium alloy is taken a substrate; a nanotube morphology is constructed on the surface of the substrate through anodic oxidation; the surface of the substrate is uniformly coated with a polydopamine bionic membrane layer formed by auto-polymerization; the dental implant with the bioactive antibacterial surface provided with in-situ grafted silver nanoparticles is obtained by means of the adsorption and reduction capabilities of a polydopamine surface for silver ions. By adopting the dental implant, a uniform discrete nanotube oxide layer is formed in situ on the surface of the titanium substrate to be taken as a storage carrier of a large quantity of antibacterial silver particles, and the bioactive antibacterial surface which grows in situ is prepared through the steps of surface dopamine auto-polymerization and in-situ soaking and reduction and the like, so that the implant surface has more durable antibacterial property, the hydrophilic performance and bioactivity of the surface are improved, the alkaline phosphatase activity of osteoblast on the implant surface is increased, the differentiation of the osteoblast is facilitated, the infection risk of the implant after the implant is implanted is lowered, and the implanting success rate is increased.

Owner:UNIV OF SCI & TECH BEIJING

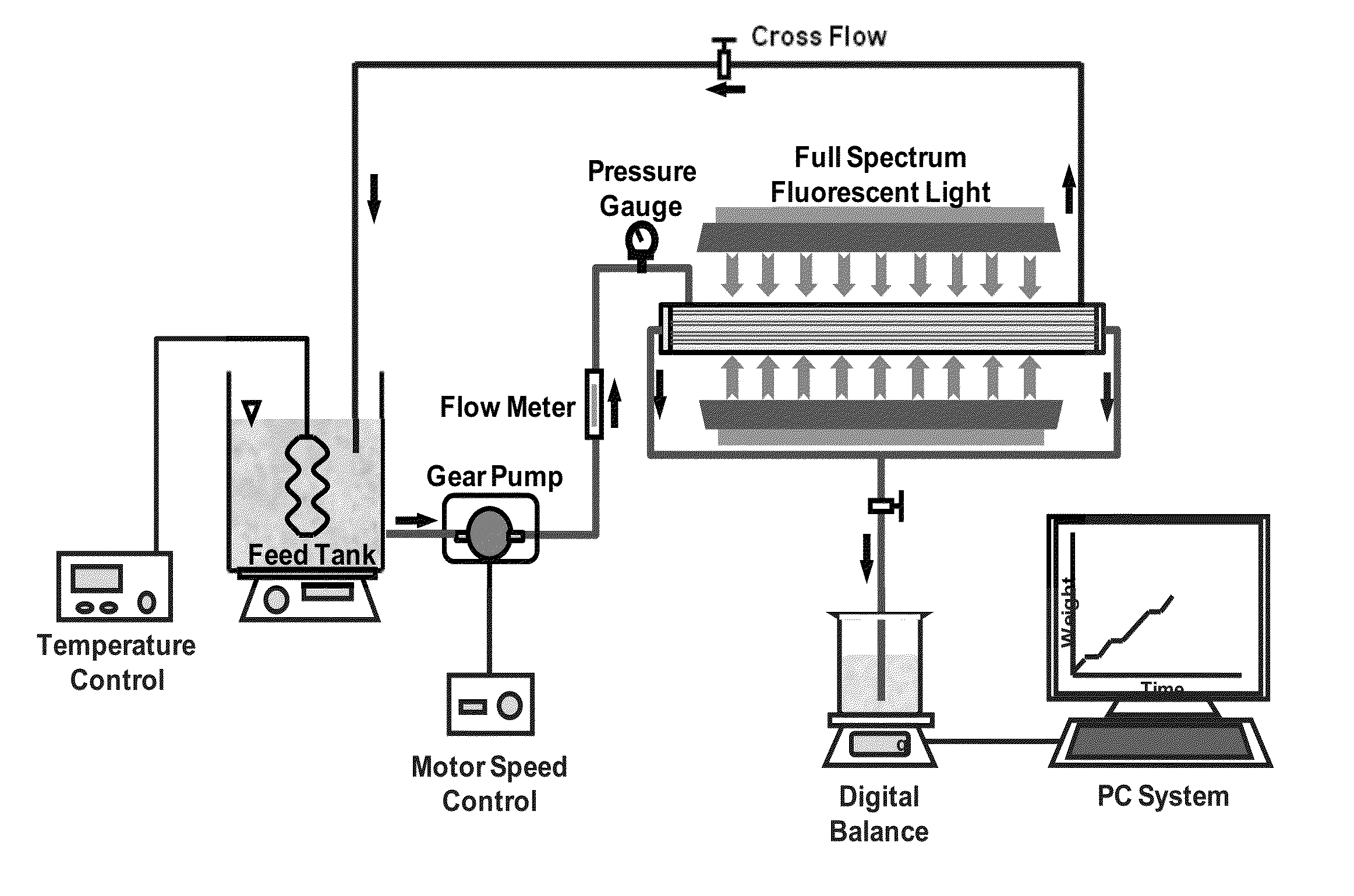

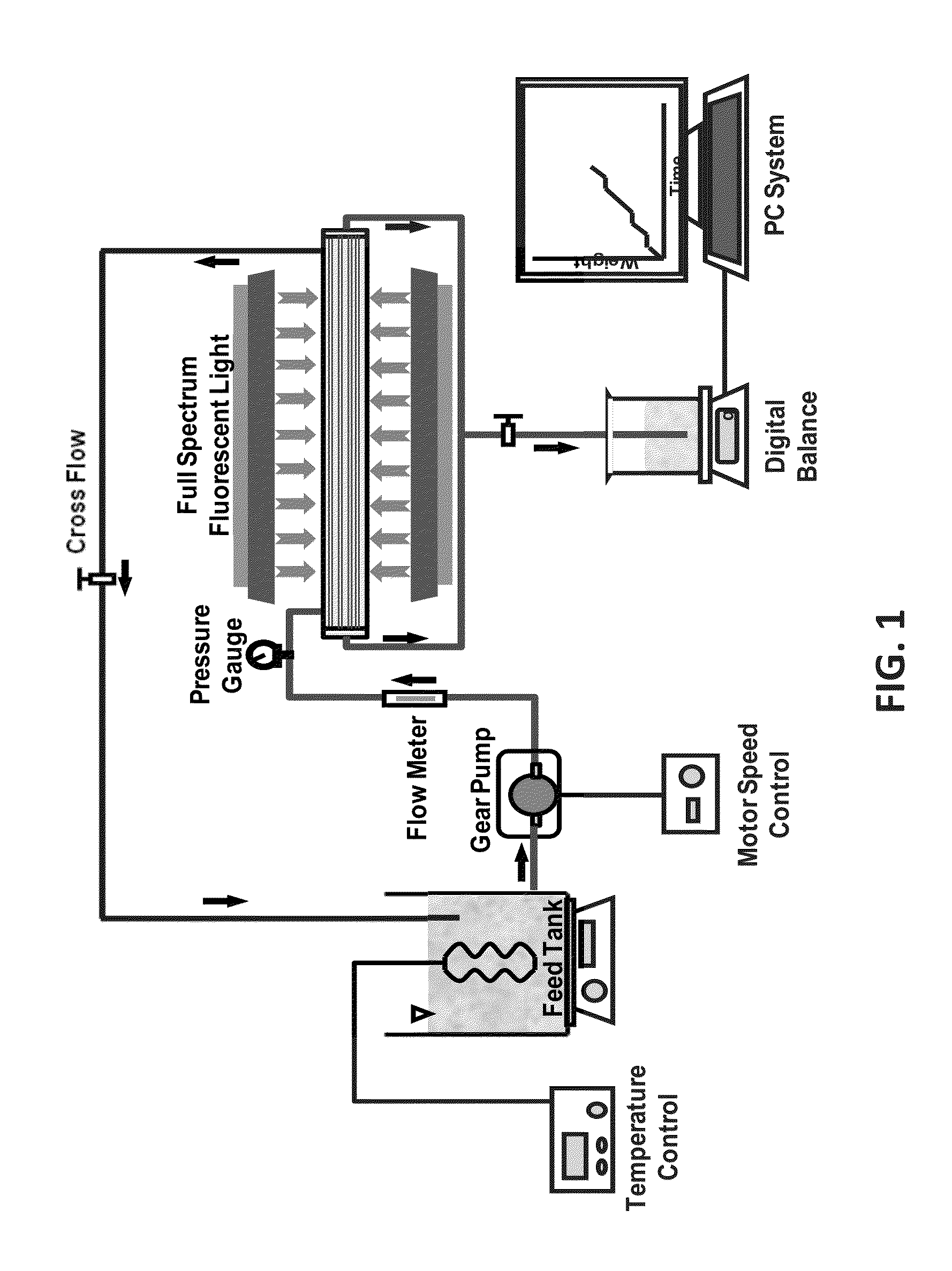

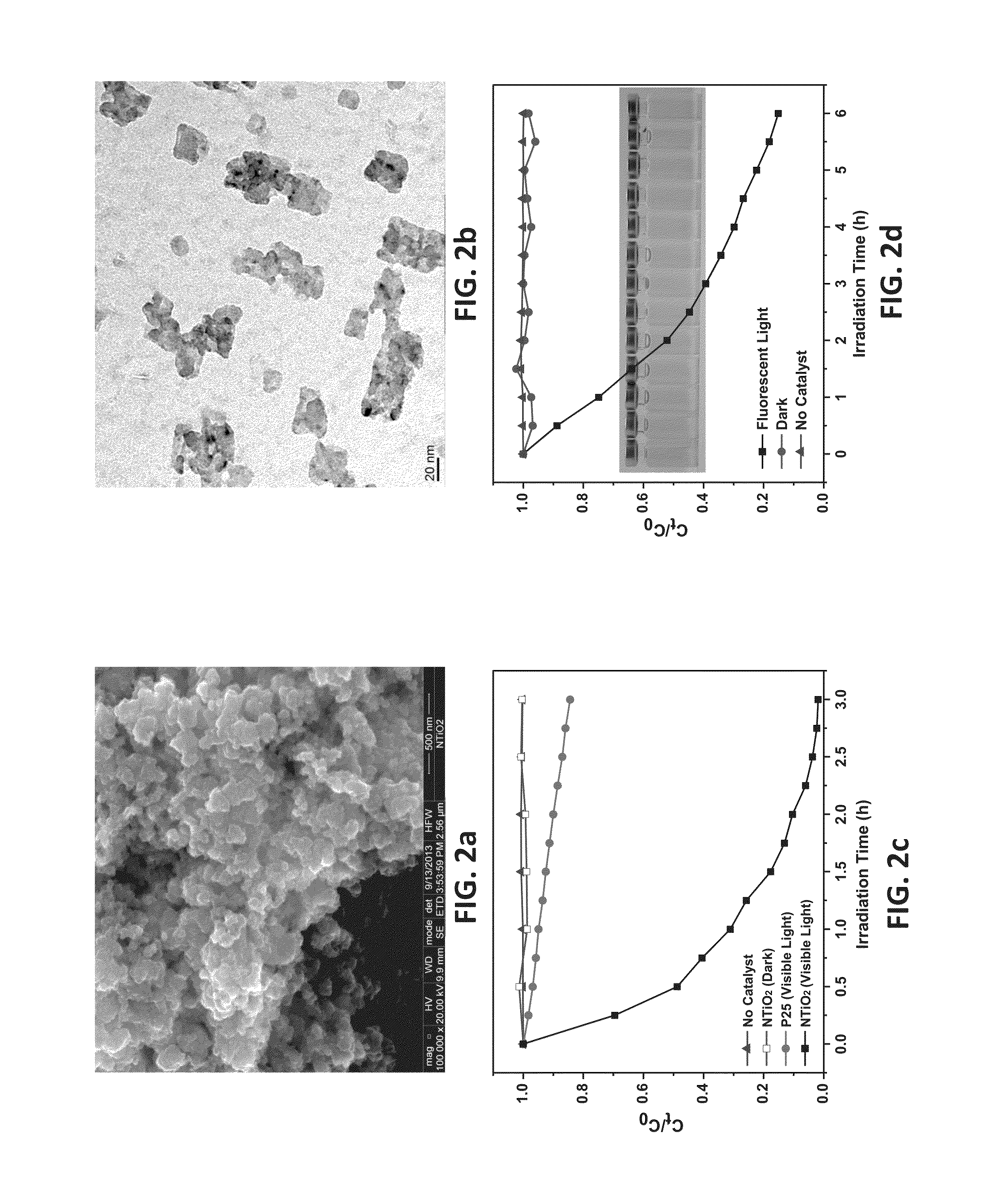

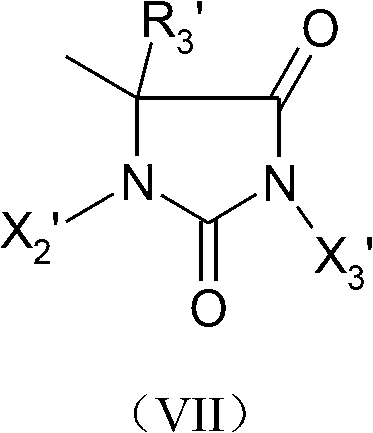

Nanocomposite membranes with advanced antifouling properties under visible light irradiation

ActiveUS20160045874A1Increase hydrophilicity of surfaceFouling resistance can be improvedSemi-permeable membranesMoving filtering element filtersHumic acidNanoparticle

Nitrogen doped TiO2 (N—TiO2) is used to fabricate Poly(vinylene fluoride) (PVDF) / N—TiO2 mixed matrix hollow fiber membranes (HFMs) through a phase inversion method to improve filtration efficiencies and antifouling properties. The membranes performances were evaluated based on the water permeability, humic acid (HA) rejection and antifouling properties. Resulting membranes showed brown color and improved hydrophilicity, especially under light irradiation. When compared to original PVDF and PVDF / P25 membrane, mixed matrix membranes containing N—TiO2 nanoparticles (NPs) showed clear photocatalytic activities under visible light irradiation. Also, membrane performance assessments indicated that PVDF / N—TiO2 membranes possessed enhanced water flux, similar HA rejection (e.g., above 96%) and improved fouling resistance with PVDF membranes as a control. The results demonstrate the potential of the suggested methodology for development of membranes with improved water permeability and superior antifouling properties based on photo-degradation processes and photo-induced hydrophilicity enhancement driven by solar light as a renewable energy source.

Owner:UNIVERSITY OF MISSOURI

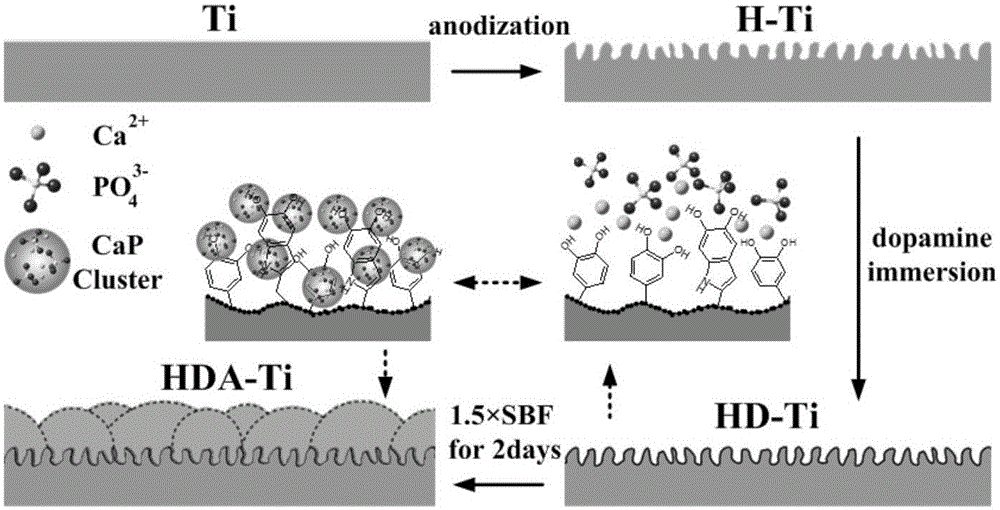

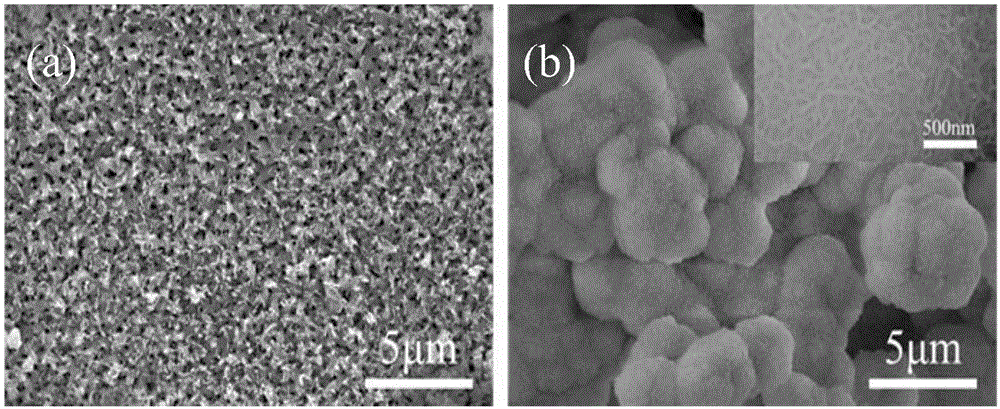

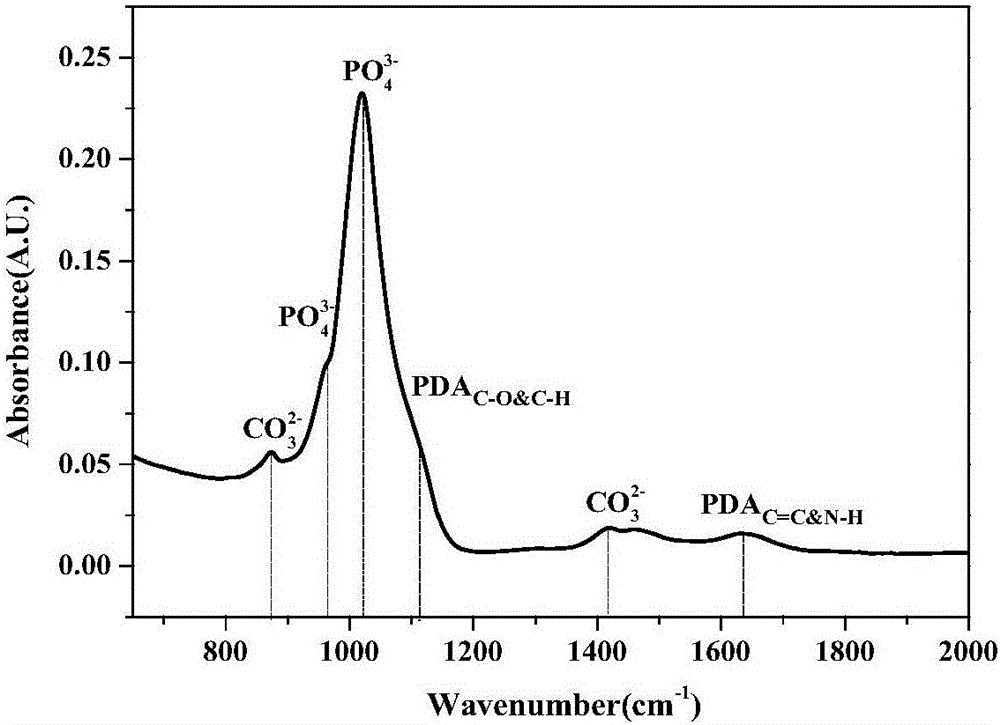

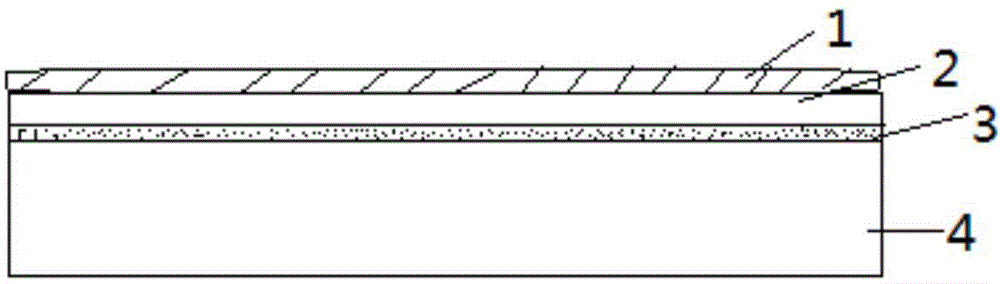

Preparation method of dental implant and composite surface thereof

InactiveCN105903076AImprove corrosion resistanceImprove surface hydrophilicityPharmaceutical delivery mechanismTissue regenerationOsteoblastNa k atpase activity

The invention relates to a preparation method of a dental implant and a composite surface thereof. In the dental implant, medical titanium or titanium alloy is used as a substrate, and porous morphology is prepared on the surface while polydopamine and hydroxyapatite are deposited to obtain a dental implant composite surface with good bioactivity. In the invention, a uniform multi-layer pore oxidation film is quickly formed on the surface of the titanium substrate to obtain nano porous morphology; and by enabling a thin layer of protein analogue (polydopamine) to tightly adhere to the surface, the surface hydrophilicity and the corrosion resistance of the dental implant can be improved. Finally, the hydroxyapatite deposition is induced on the surface to obtain a three-layer composite surface; moreover, the nano porous composite surface can effectively reinforce the adhesion and spreading of osteoblast on the implant surface as well as the alkaline phosphatase activity, early bone integration of the implant is accelerated, and firm combination of the material and the organism interface is realized so as to improve the stability and success rate of the implant.

Owner:UNIV OF SCI & TECH BEIJING

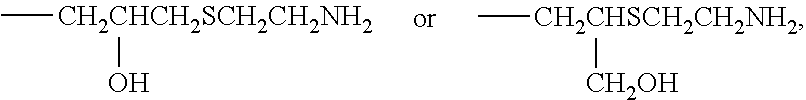

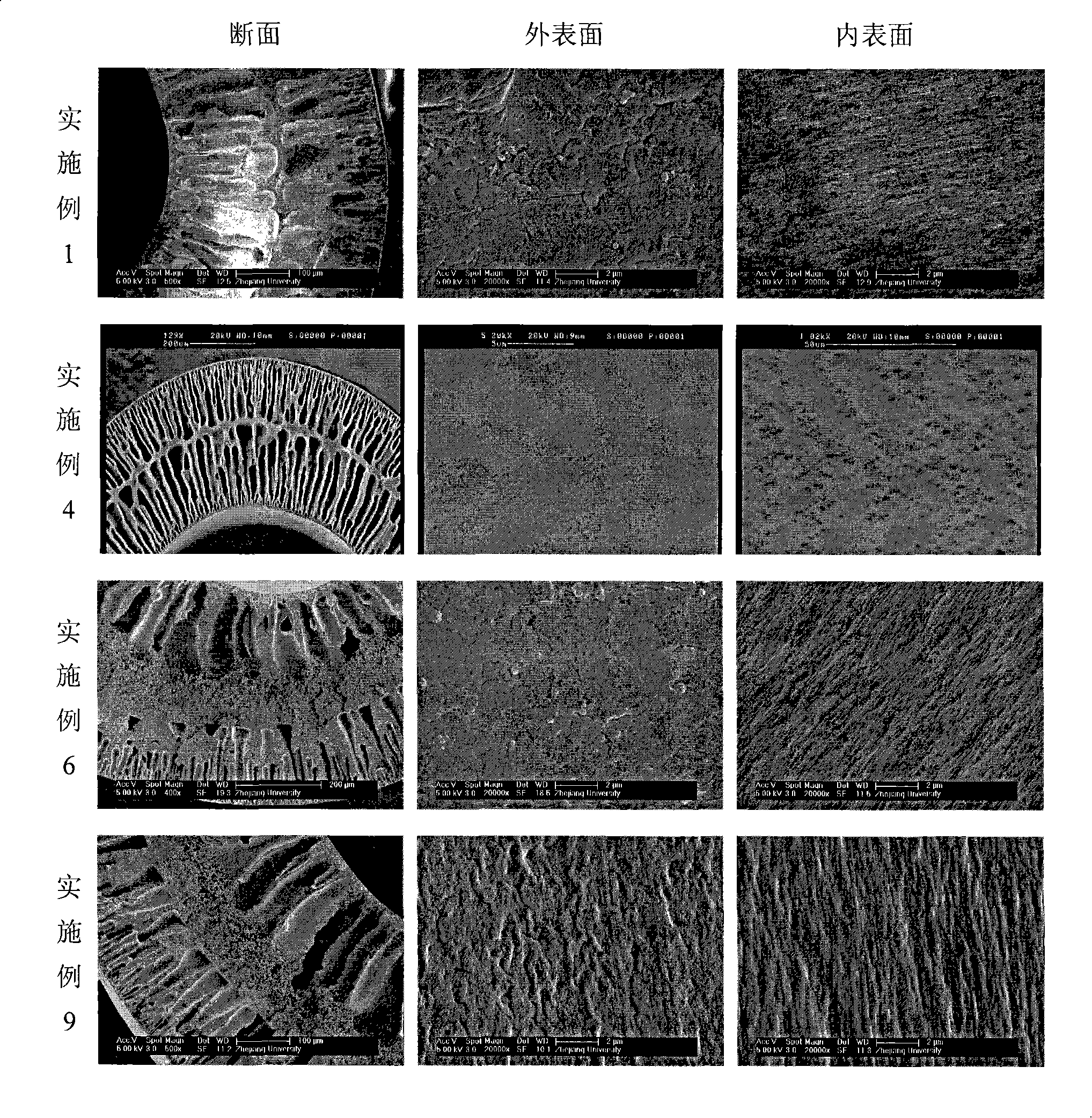

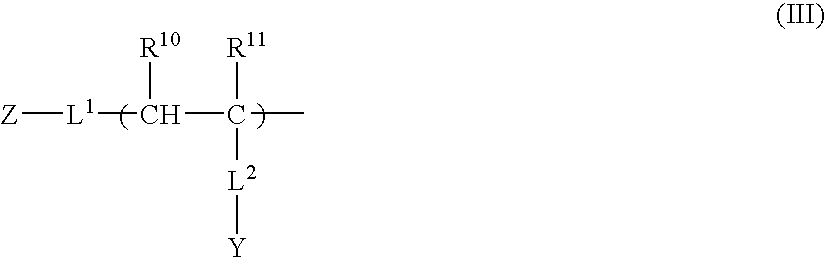

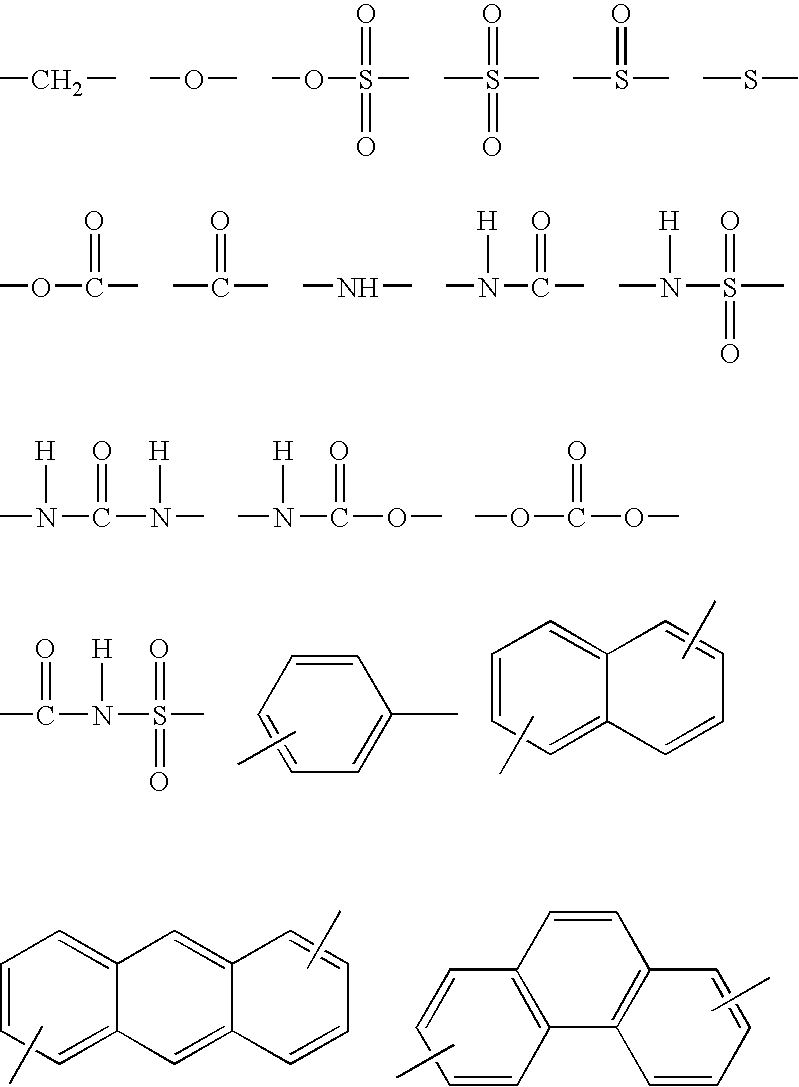

Polymer and method for producing same

ActiveUS9127099B2Low cytotoxicityImparting biocompatibilityCoatingsBiocompatibility TestingStructural unit

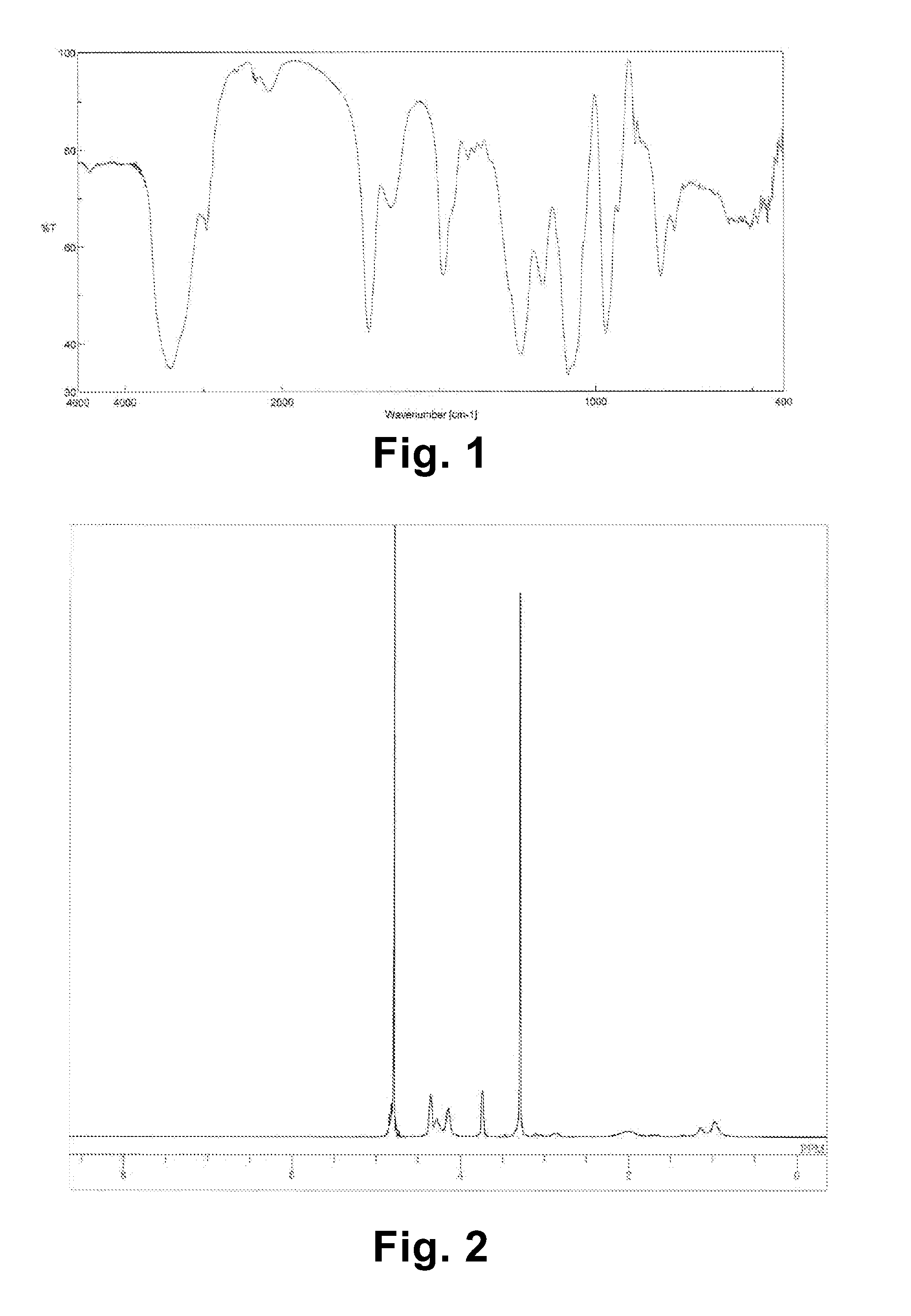

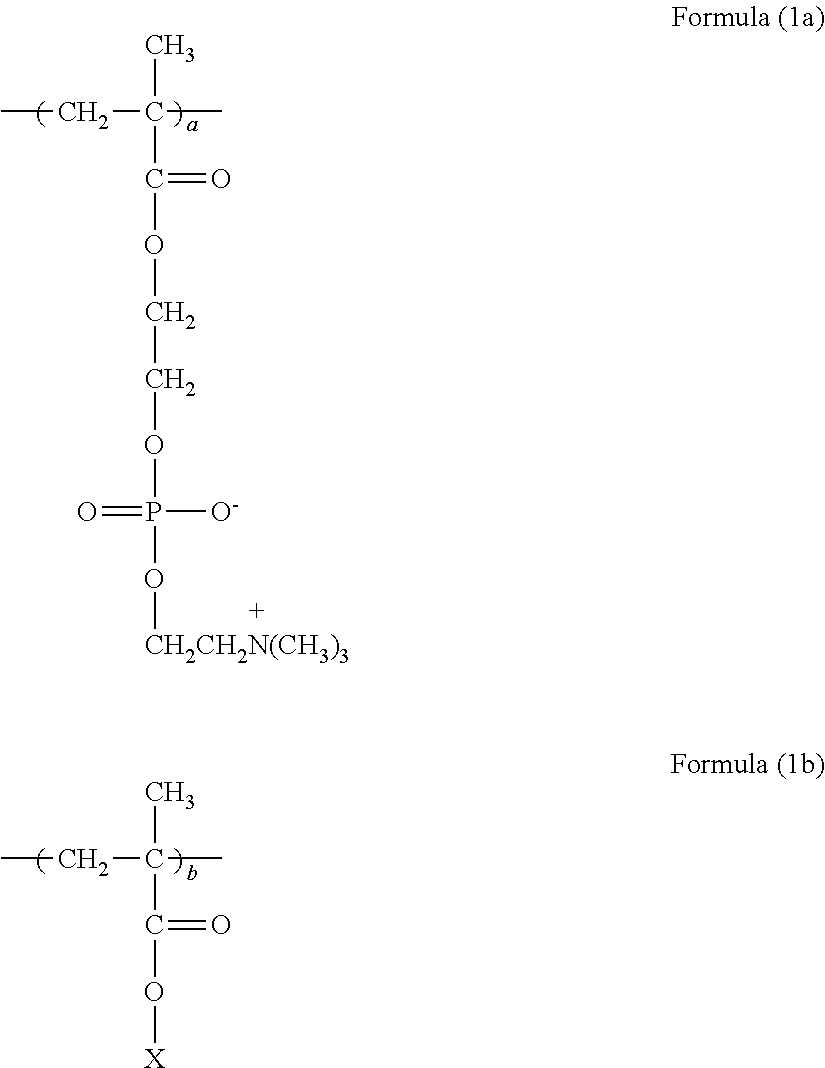

Provided are a polymer having low cytotoxicity and capable of imparting surface hydrophilicity and biocompatibility to medical device surfaces by simple processing, a method for producing the polymer, and a surface treatment agent for medical devices. The polymer of the present invention has a particular ratio of structural units represented by the formulae (1a) and (1b), and a particular weight average molecular weight, and is useful as a surface treatment agent for various medical devices.

Owner:NOF CORP

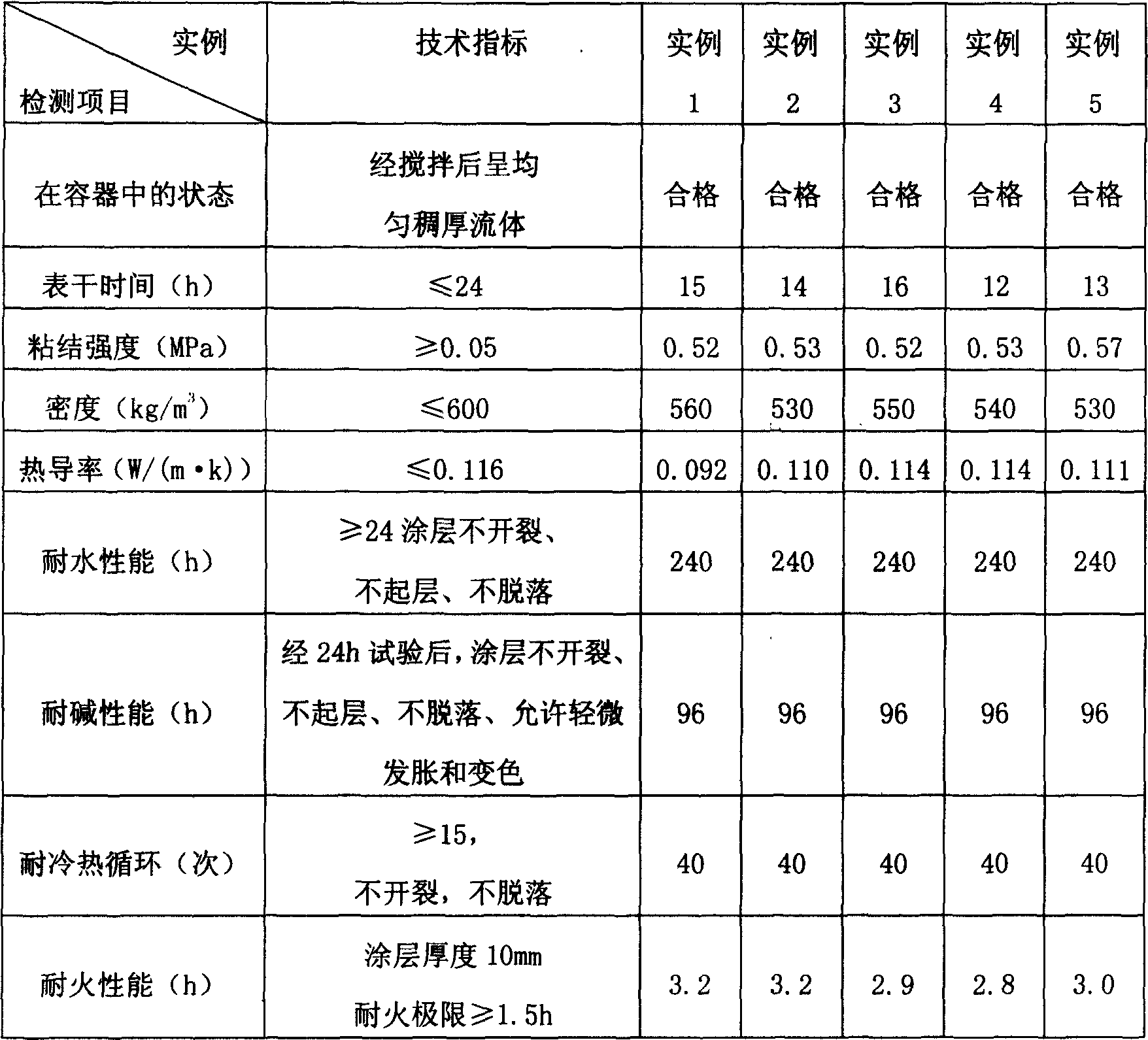

Single system and composite fire retardant coating for tunnel

InactiveCN1687254AAvoid self-strength lossImprove performanceFireproof paintsCement coatingsAdhesiveUltimate tensile strength

The present invention relates to a production method of single system compounded tunnel fire-resisting paint. Its composition includes (by weight portion) 20.0-50.0 portions of adhesive formed from redispersible latex powder and aluminous cement, 55.0-85.0 portions of inorganic heat-insulating filler and 0.1-5.0 portions of adjuvant. Said fire-resisting paint not only has good fire-resisting property, but also has good water-proof and sound-insulating properties.

Owner:SICHUAN UNIV

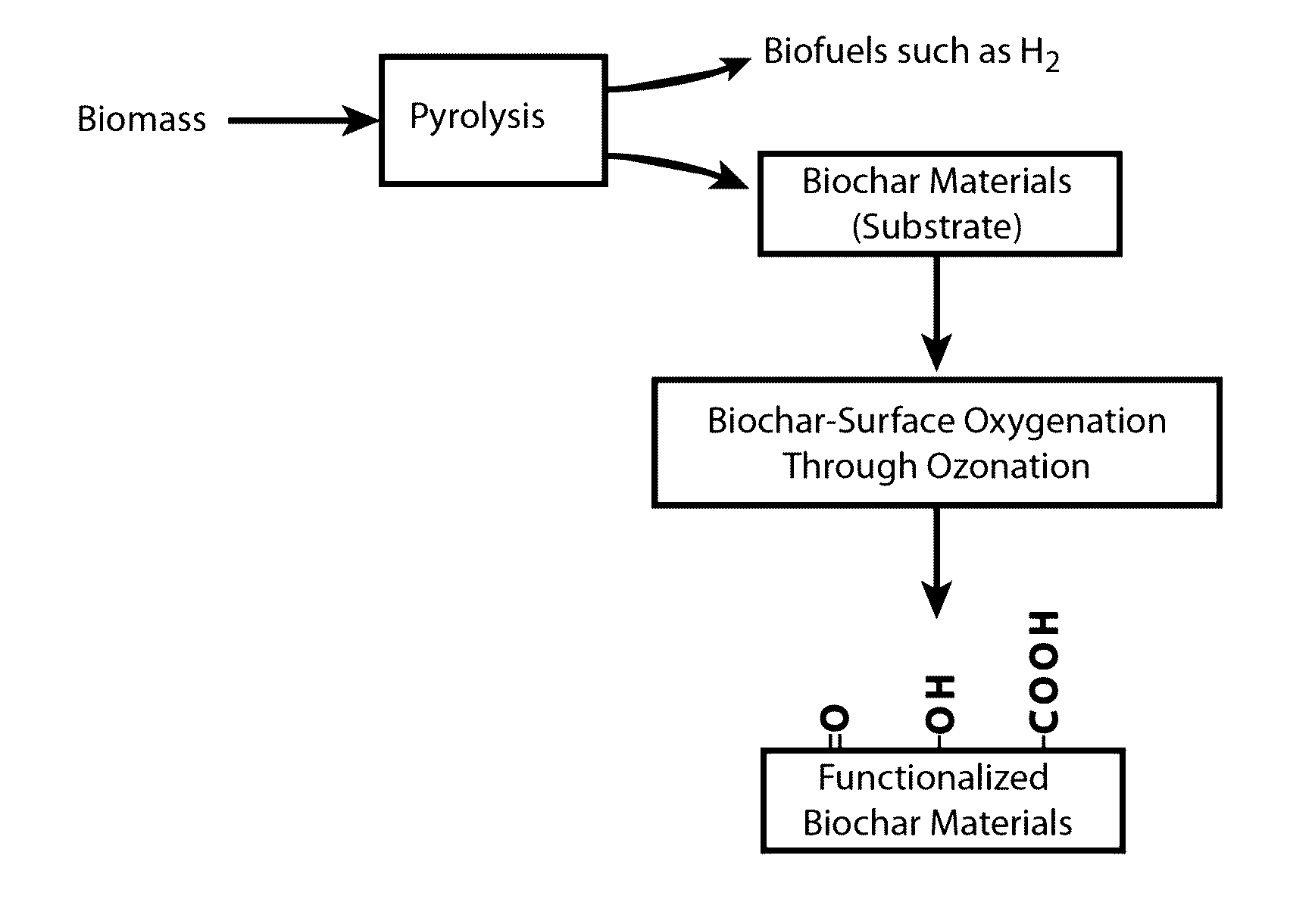

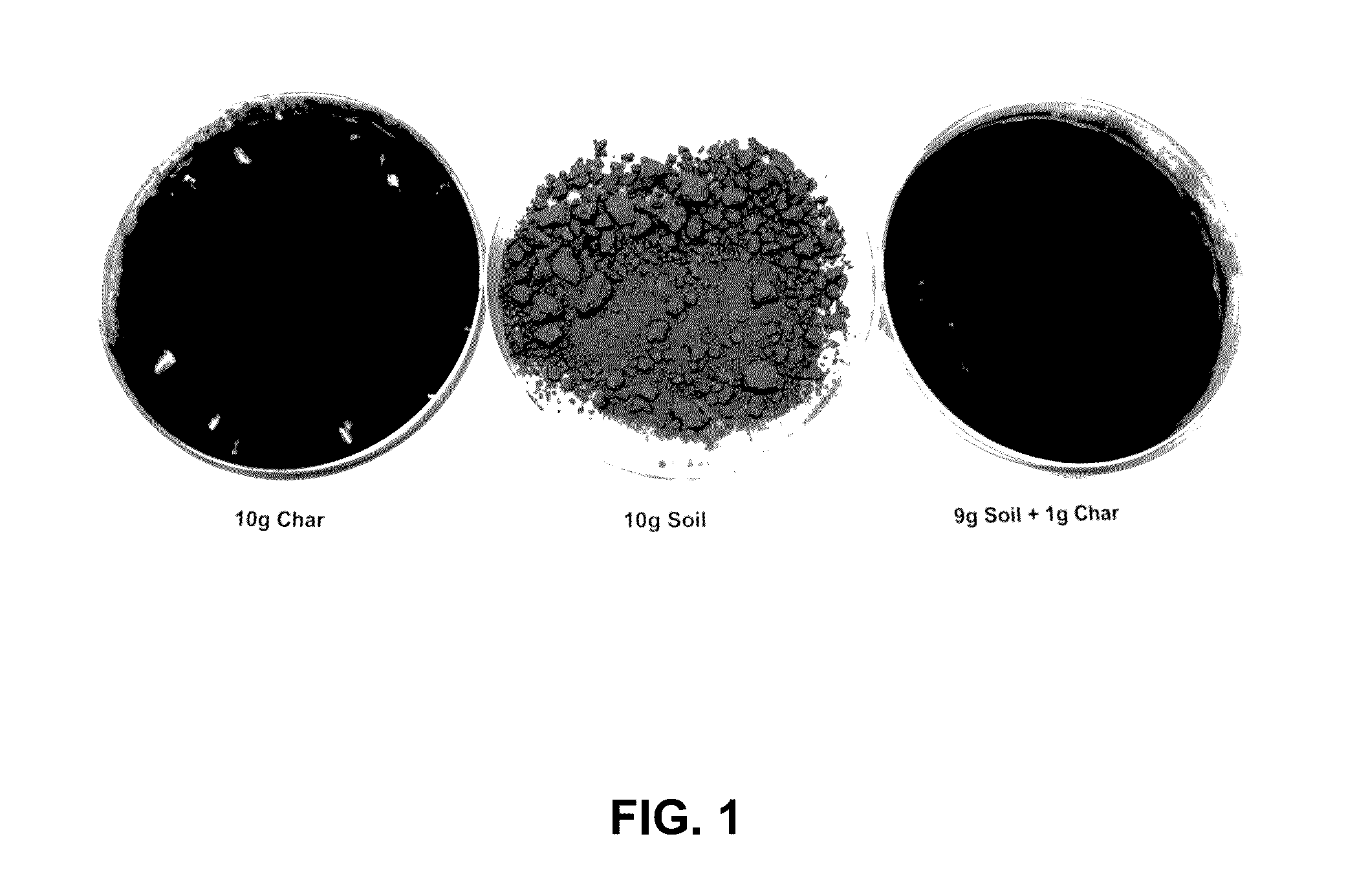

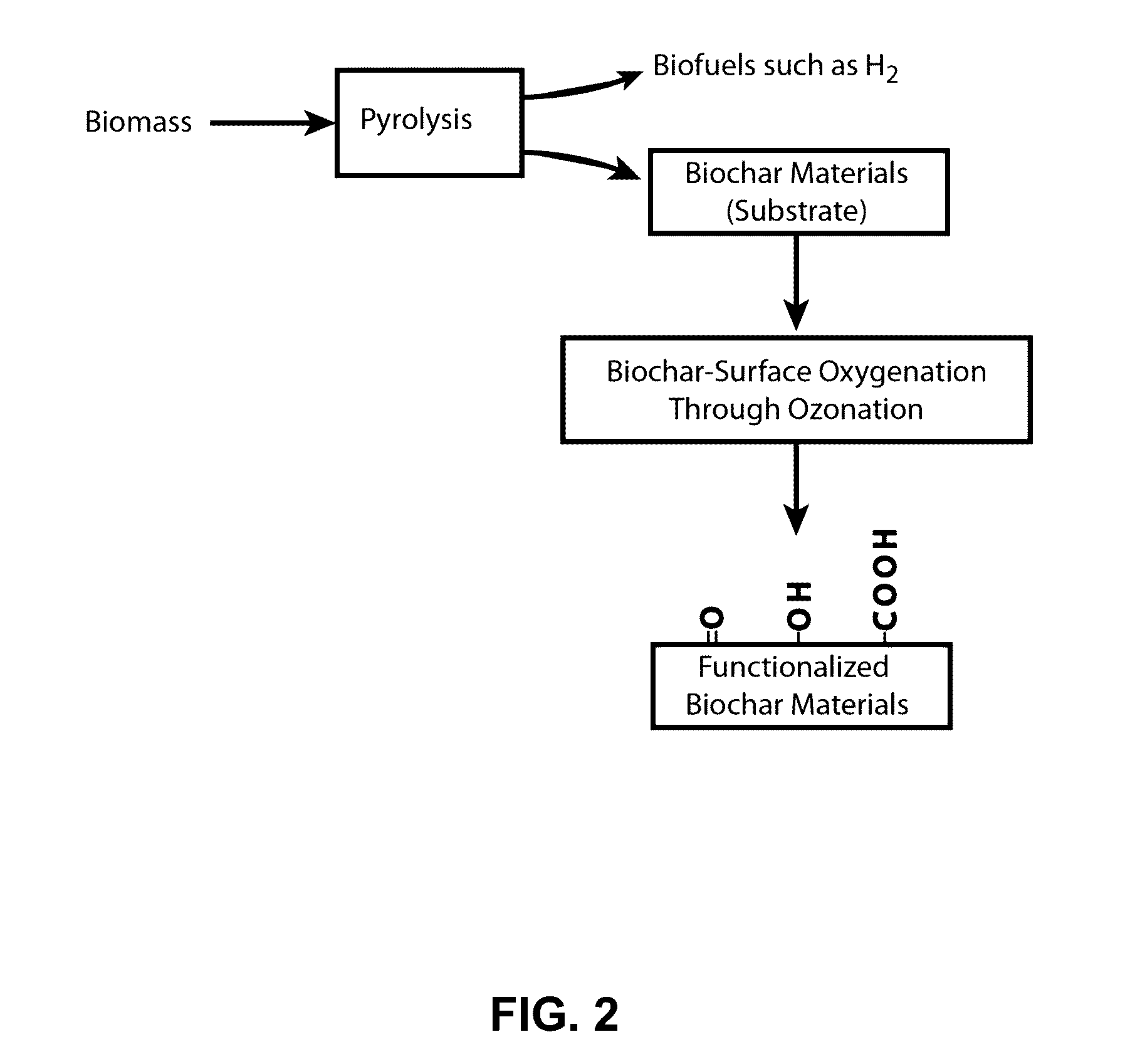

Ozonized biochar compositions and methods of making and using the same

ActiveUS20170036983A1Improve propertyHigh exchange capacityPreparation by oxidation reactionsCation exchanger materialsChemistrySustainability

Ozonized biochar compositions and methods for creating advanced hydrophilic biochar materials are provided with higher cation exchange capacity, optimized pH, improved wettability, and free of potential toxic components. These ozonized biochar compositions are used as filtration materials, as biochar soil additives and as carbon sequestration agents to help control climate change for energy and environmental sustainability on Earth.

Owner:LEE JAMES WEIFU

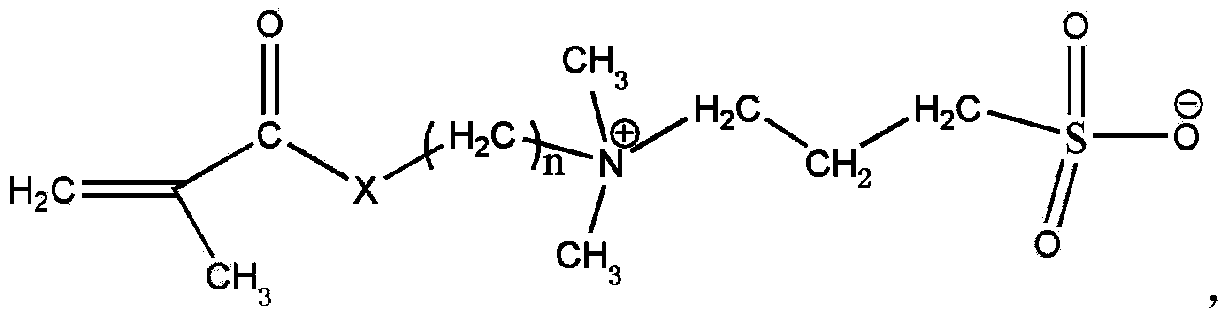

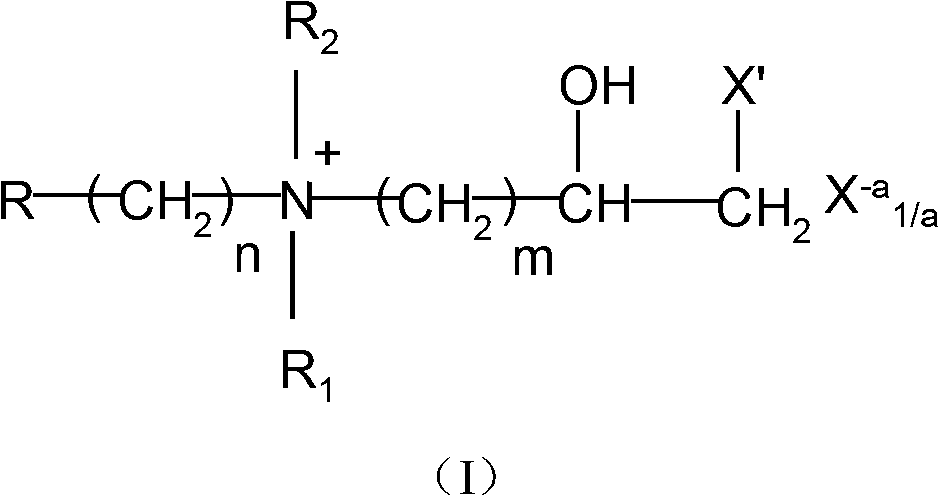

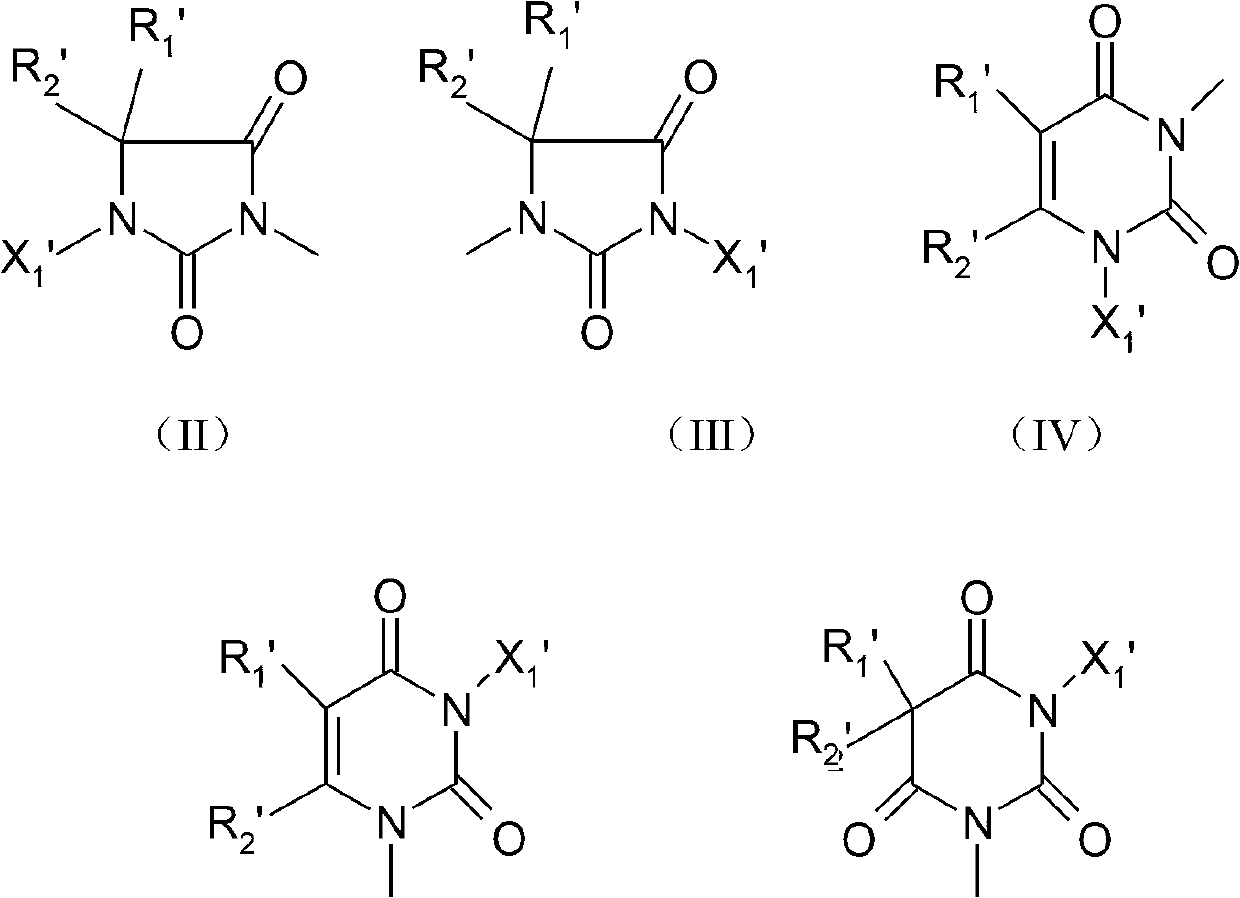

Hydroxy halogen amine compound containing quaternary ammonium salt functional group and preparation method and application thereof

InactiveCN102786477AEfficientImprove surface hydrophilicityBiocideOrganic chemistryQuaternary ammonium cationOrganic synthesis

The invention relates to the field of organic synthesis and discloses hydroxy halogen amine compound containing quaternary ammonium salt functional group with a structure shown in a formula (I), wherein R1 and R2 are C1-C20 alkyl or alkene groups, C1-C8 haloalkyl or alkenyl halide groups or C1-C8 hydroxy alkyl, or R1 and R2 are combined into C3-C7 naphthene base or cycloalkene group, and R is selected from hydantoins group, 2-imidazole ketone group, 4-imidazole ketone group, isocyanurates group, 1,3,8-tri-azaspiro [4.5] decane-2,4-diketones group, and piperidines group. The compound can be used for preparing an antibacterial agent and an antibacterial material.

Owner:SHANGHAI NORMAL UNIVERSITY

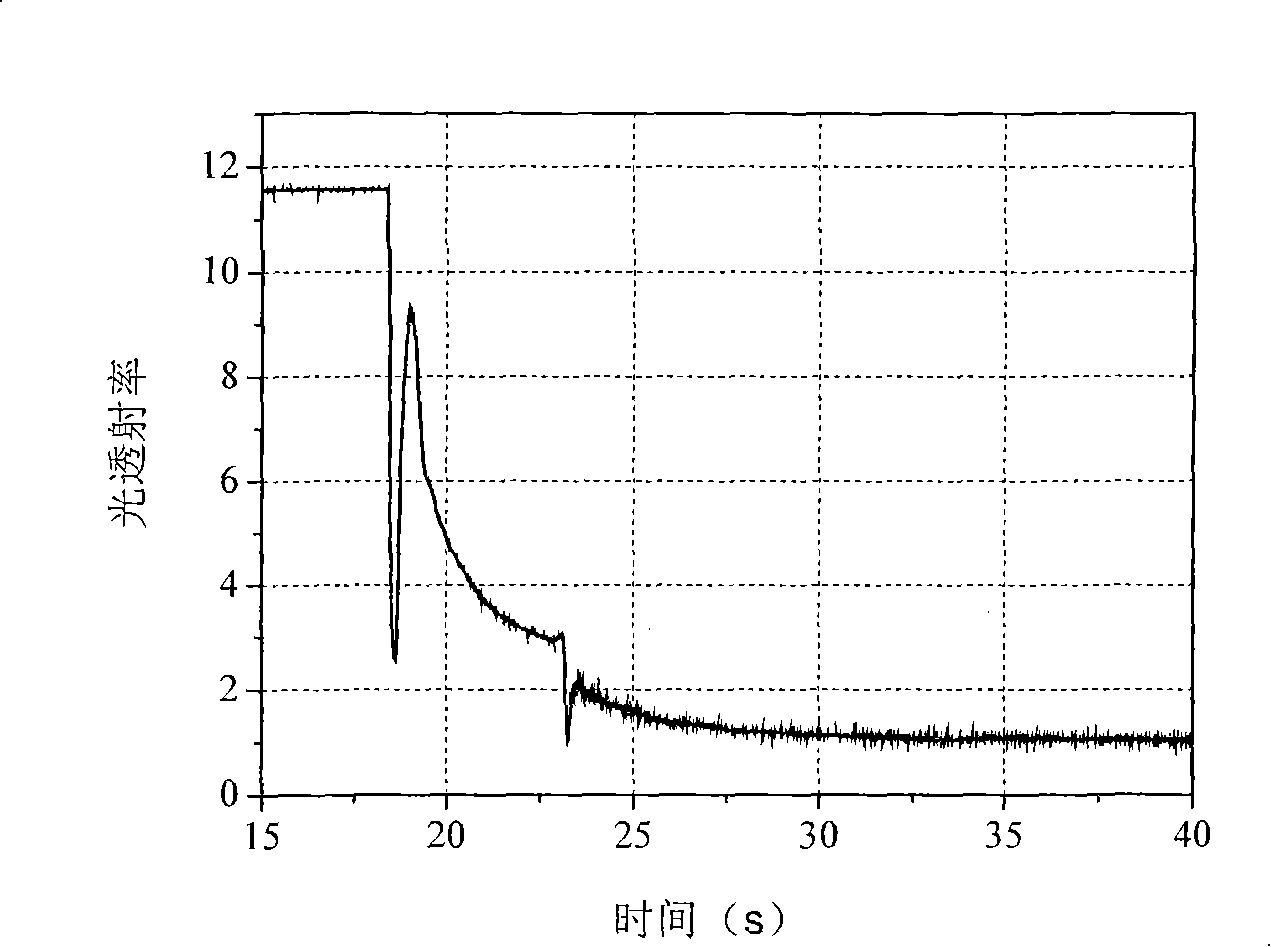

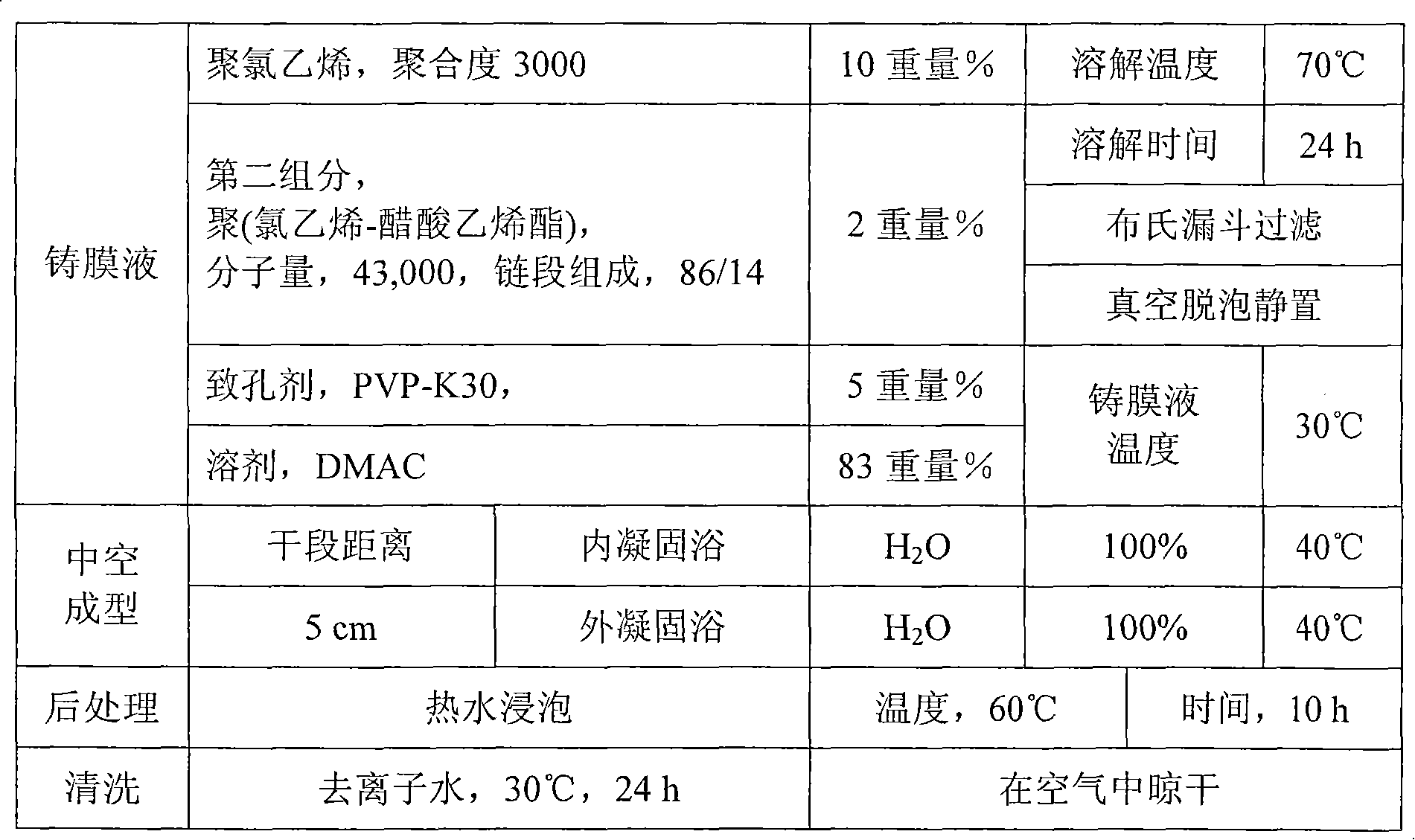

Hydrophilic polyvinyl chloride alloy ultrafiltration membrane and production method thereof

ActiveCN101195084AEasy to manufactureImprove performanceSemi-permeable membranesHydrophilizationOrganic solvent

The invention relates to a surface self-assembly hydrophilised modified method for a polychloroethylene ally hyperfiltration membrane, which comprises first, dissolving polychloroethylene, a second component of amphipathic nature polybasic multipolymer and pore-foaming agent in organic solvent, and forming casting solution, second, immersing the casting solution into the coagulating bath after being hollow-shaped, shaping films by gel through a method for converting wetness and humidity, regulating the separating time for the hydrophilous nature chain segment to be transferred to the surface and self-assemble, third, hydrophilised-processing polychloroethylene ally hyperfiltration membrane after being hardened by gel, fourth, cleaning the hyperfiltration membrane after being processed, and obtaining the polychloroethylene ally hyperfiltration membrane after dried.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

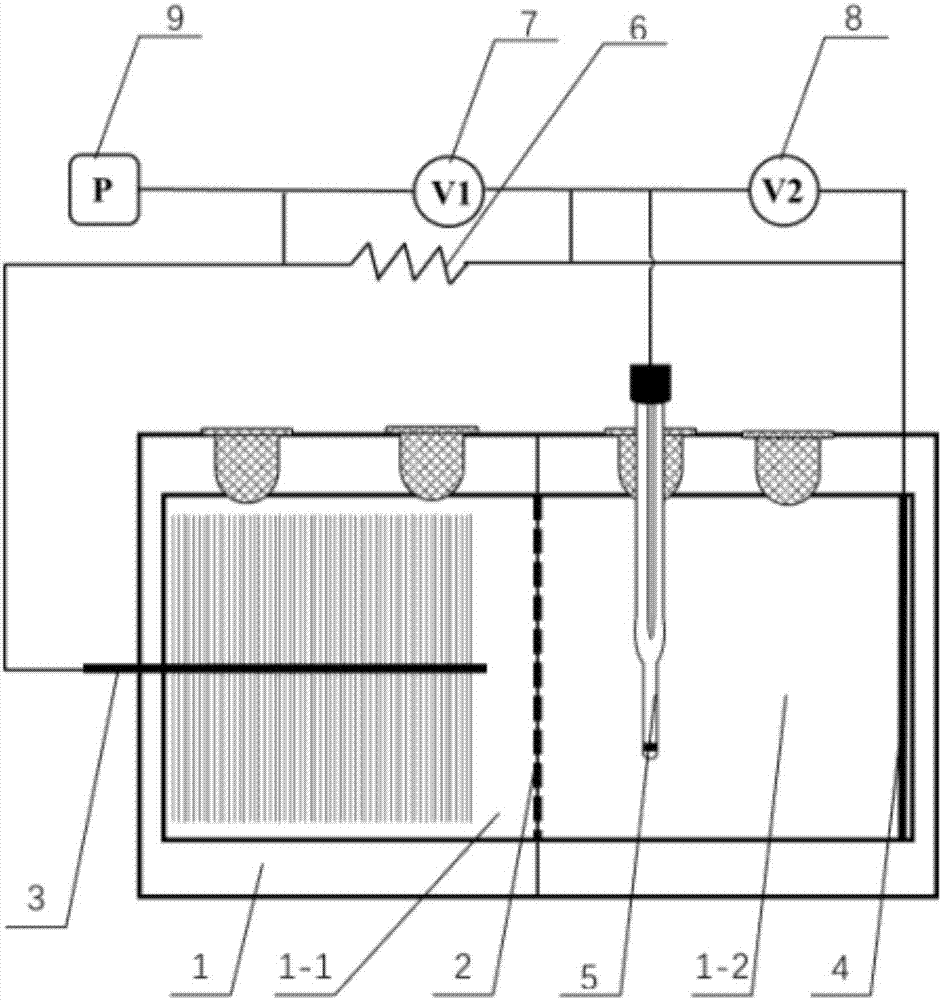

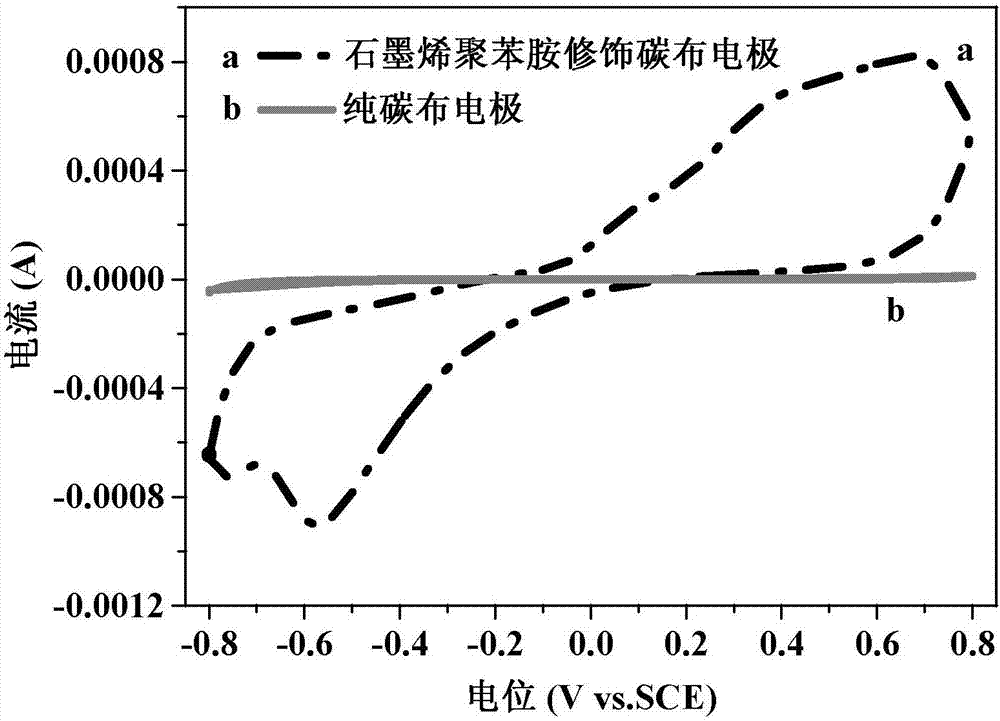

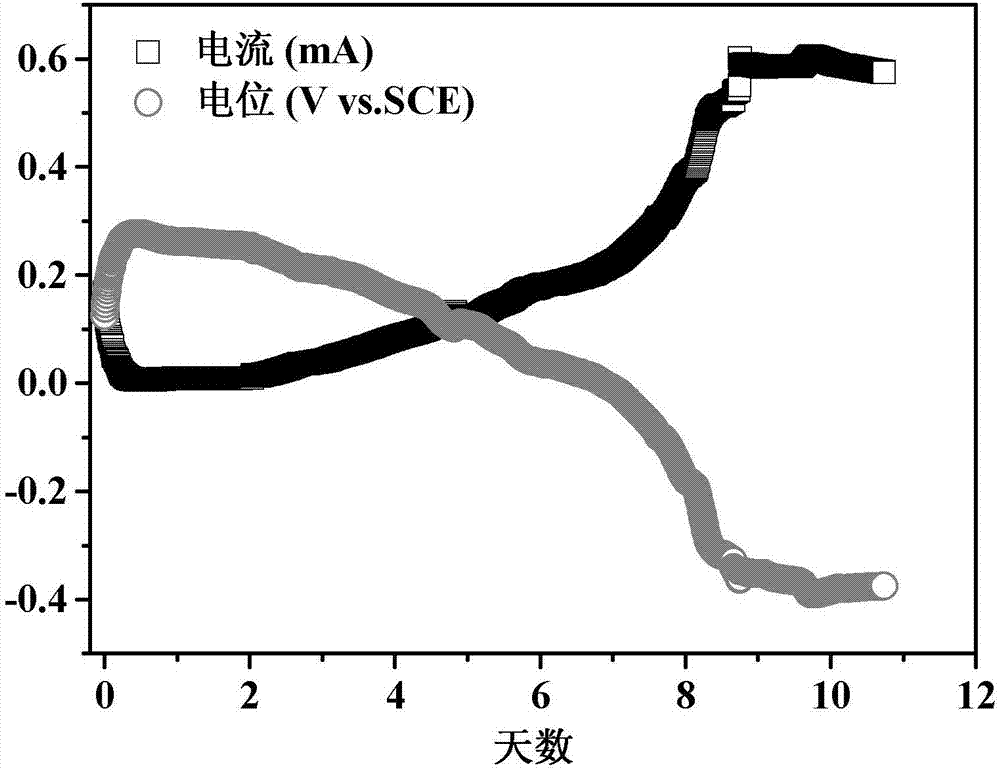

Preparation of graphene polyaniline modified carbon cloth electrode material, and method for accelerating acclimation of bio-anode

InactiveCN106941179AImprove transfer efficiencyLower resistanceTreatment by combined electrochemical biological processesCell electrodesModified carbonWastewater

The invention provides preparation of a graphene polyaniline modified carbon cloth electrode material, and a method for accelerating the acclimation of a bio-anode, and relates to electrode preparation and bio-anode acclimation. A purpose of the present invention is to solve the technical problem of poor electron transfer efficiency of existing bioelectrochemical anode. The graphene polyaniline modified carbon cloth electrode material preparation method comprises: loading graphene oxide onto a carbon cloth, immersing into a sodium borohydride solution, reducing, immersing into an aniline monomer solution, adding a curing agent solution in a dropwise manner, and polymerizing to obtain the graphene polyaniline modified carbon cloth electrode material. According to the present invention, with the application of the graphene polyaniline modified carbon cloth electrode material as the anode in the bioelectrochemical system reactor, the operation is performed after the starting until the output potential is stable so as to complete the acclimation; and the graphene polyaniline modified carbon cloth electrode material can be used in wastewater treatment.

Owner:HARBIN INST OF TECH

Polypropylene fiber concrete sleeper

ActiveCN1743551AImprove surface hydrophilicityPrevent early cracksBallastwayRebarPolypropylene fiber

This invention relates to a PP fiber concrete sleeper, in which, modified PP fibers are added into the concrete, the doped volume is 0.2-1kg / cum to increase its shock resistance, anti-freezeness, its fatigue strength and eliminate the longitudinal crack and surface crack.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP +2

Hydrophilic coating composition and hydrophilic member using the same

InactiveUS20100243221A1Improve hydrophilicityIncrease crosslink densityNon-fibrous pulp additionConductive materialSilyleneCarboxylic acid

To provide a hydrophilic coating composition excellent in hydrophilicity, wear resistance, transparency, storage stability, antifogging properties, antifouling properties, visible light transmittivity, adhesion properties, chemical resistance, weather resistance, and water resistance and a hydrophilic member using the composition. The hydrophilic coating composition has (A) a ternary copolymer having a1) a repeating unit having a hydrophilic group, a2) a repeating unit having a hydroxyl group, an epoxy group, an isocyanato group, a blocked isocyanato group, a carboxylic acid anhydride group, or an amino group, and a3) a repeating unit having a hydrolyzable silyl group; and (B) a metal complex catalyst, wherein a content of the repeating unit a1) having a hydrophilic group is 50 mol % or greater.

Owner:FUJIFILM CORP

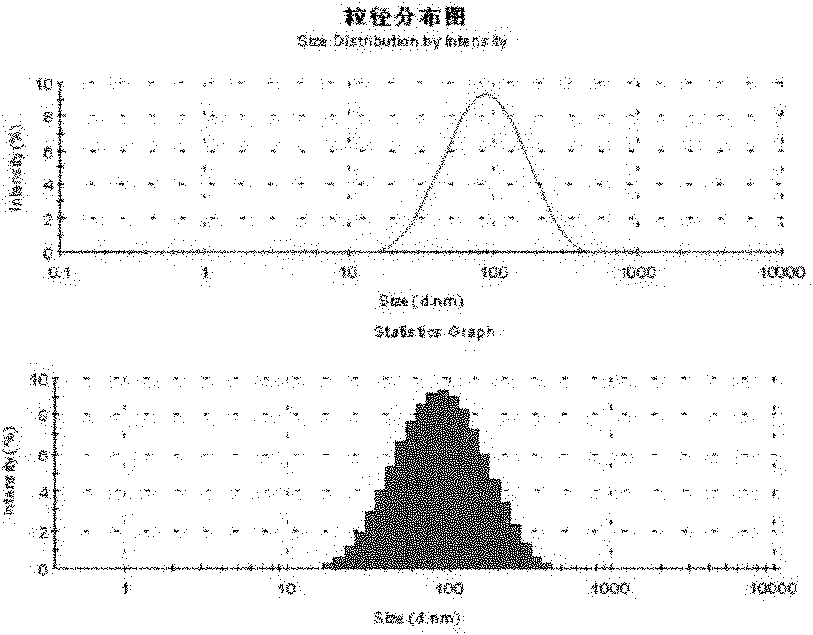

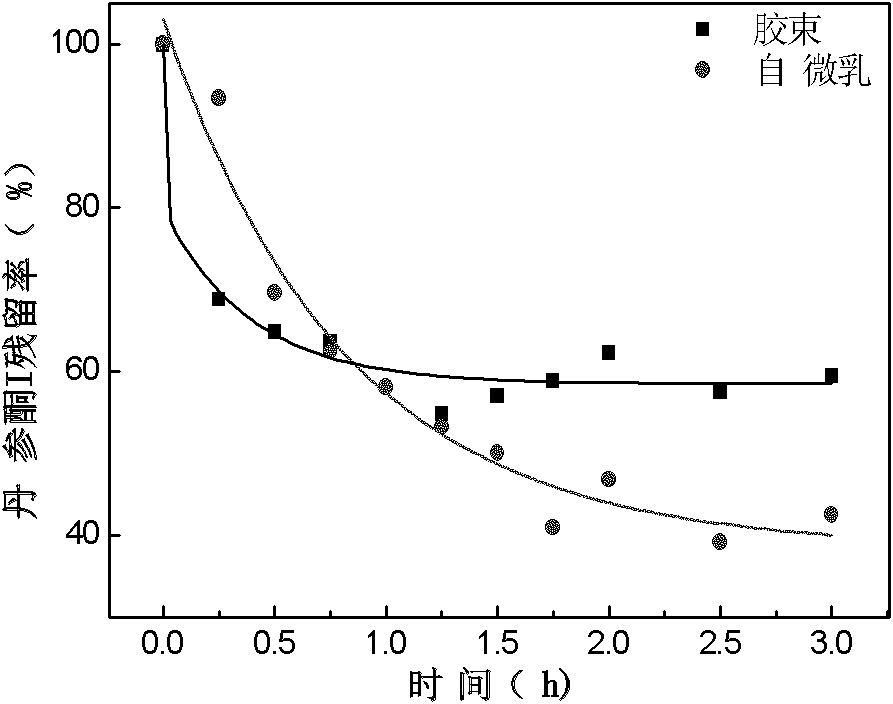

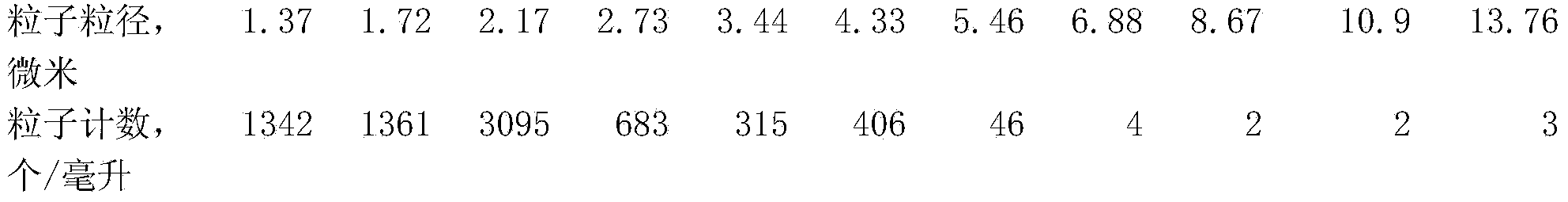

Total tanshinone composite preparation

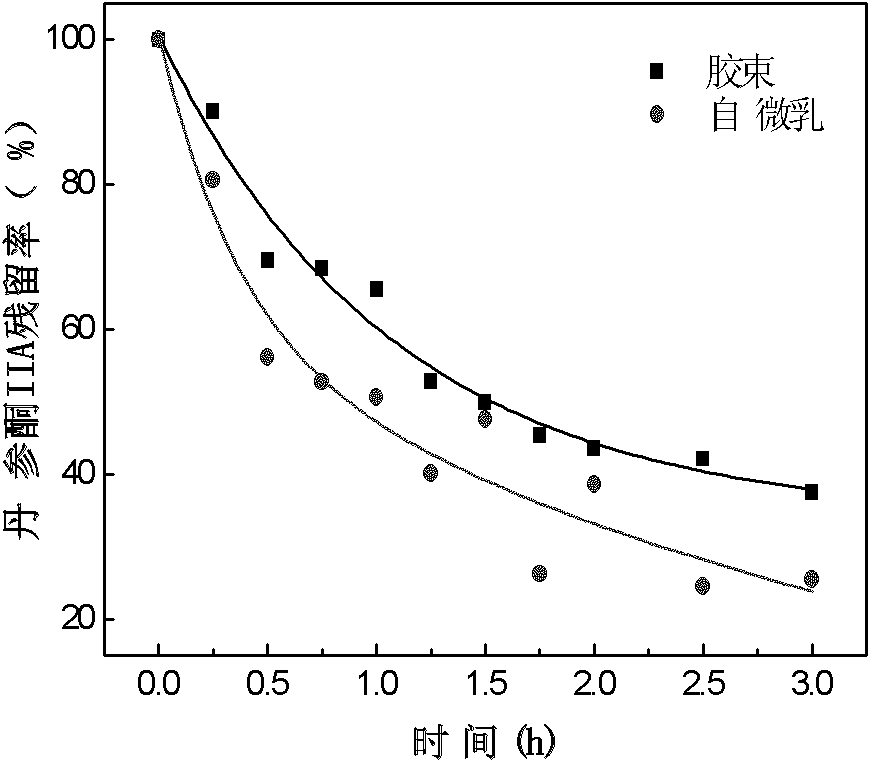

InactiveCN102100741AMild preparation conditionsOptimal control methodAntibacterial agentsPowder deliverySalvia miltiorrhizaOral medication

The invention relates to a total tanshinone composite preparation, in particular to a self-microemulsion medicine carrying composite preparation for improving the oral administration bioavailability of total tanshinone, which comprises the following components in part by mass: 0.5 to 5 parts of tanshinone, 25 to 75 parts of oil phase, 35 to 70 parts of surfactant and 0 to 25 parts of cosurfactant. In addition, the preparation can be prepared into a solid preparation or a liquid preparation by combining with other solid materials or water, and after entering a gastrointestinal tract, the solidpreparation or the liquid preparation can be emulsified automatically to form microemulsion of which the grain diameter is less than 100 nanometers when contacting water so as to increase the dissolution speed of the tanshinone, promote the absorption of the tanshinone and improve the oral administration bioavailability of the tanshinone; and the preparation conditions of the total tanshinone composite preparation is mild, a control method is simple and convenient, and special equipment is not required.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

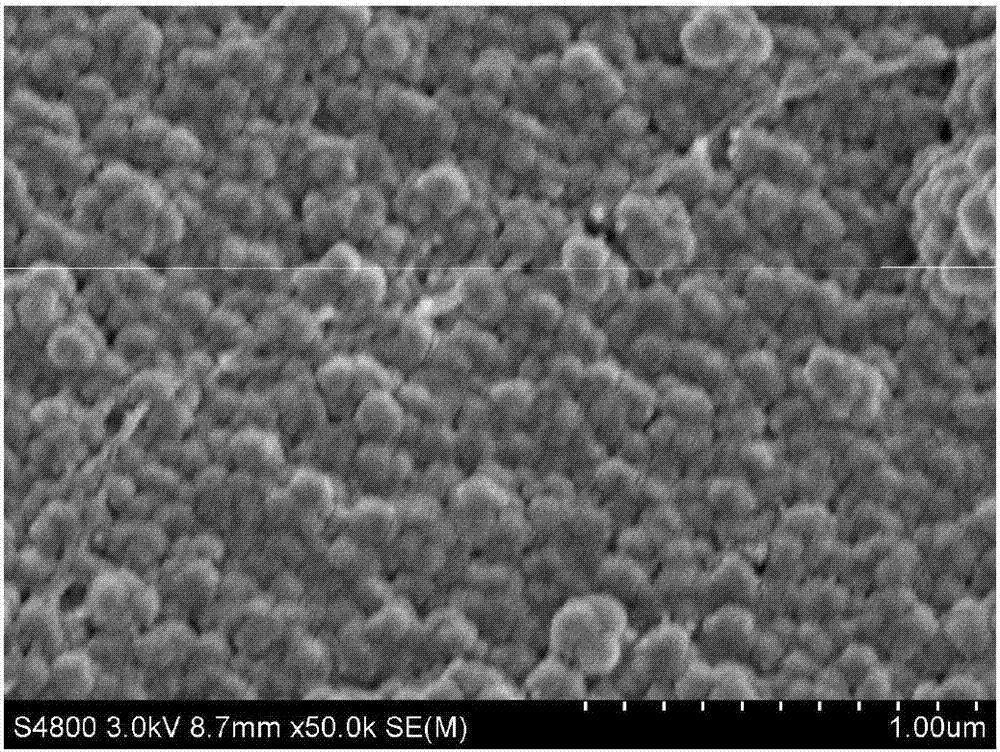

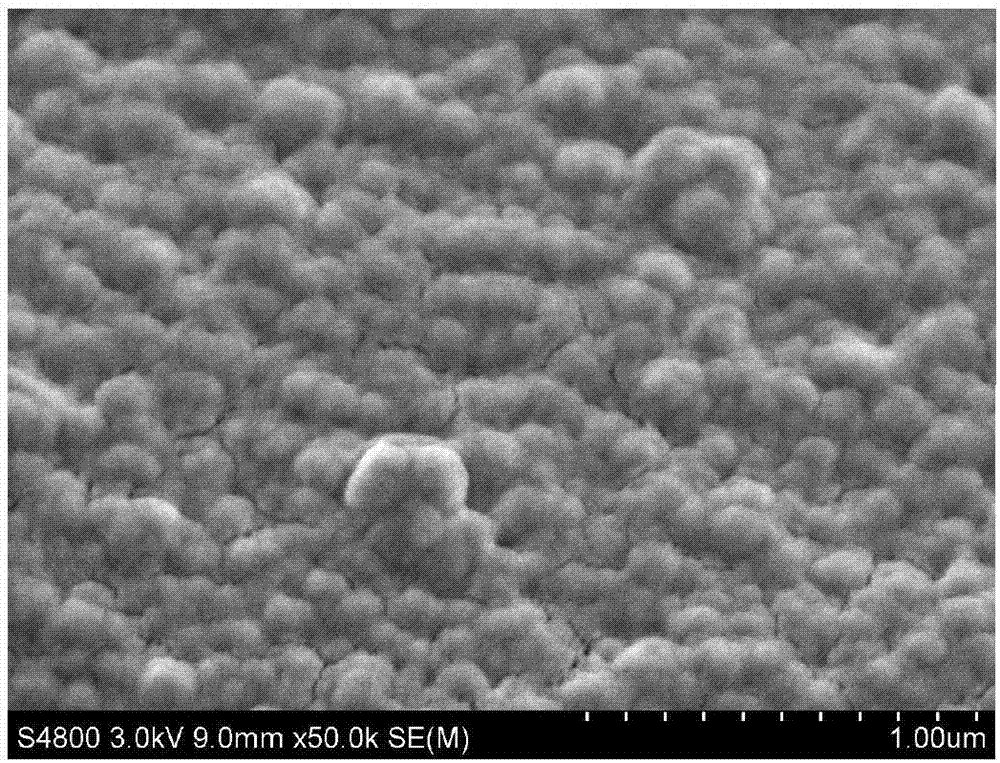

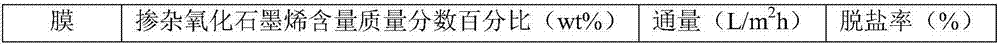

Preparation method of oxidized graphene doped hollow fiber nanofiltration membrane

InactiveCN106890570AHigh mechanical strengthExcellent salt rejectionReverse osmosisHollow fibreFiber

The invention provides a preparation method of an oxidized graphene doped hollow fiber nanofiltration membrane. The preparation method comprises the steps that a plurality of hollow fiber nanofiltration membrane serve as basic membranes to be packaged into a component shell to obtain a membrane component for usage; oxidized graphene, an active monomer and an acid absorbing agent are added into a solvent A for uniform ultrasonic mixing to obtain a solution A; multielementacyl chloride is dissolved in a solvent B to obtain a solution B; the solution A is introduced into the inner cavity of the hollow fiber nanofiltration membrane of the membrane component for full infiltration, the solution A is removed, drying is performed, the solvent B is introduced into the inner cavity of the membrane for interfacial polymerization reaction, then the solution B is removed, drying is performed, andpure-water rinsing and drying are performed to obtain the membrane. The oxidized graphene is added in the membrane preparation process and has the very good effect on the aspects of surface hydrophilicity improvement, membrane flux increase and pollution resistance. The product is good in mechanical strength andcontamination resistance and is higher than an oxidized-graphene-free pure polyamide nanofiltration membraneindesalting rate and water flux.

Owner:ZHEJIANG UNIV OF TECH

Polarizing plate manufacturing method

InactiveUS20120057230A1Improve throughputGood lookingLamination ancillary operationsAdhesive processes with surface pretreatmentPolarizerComposite material

Owner:NITTO DENKO CORP

Novel compositions and methods

InactiveUS20090312380A1Lesser and high rateOvercome problemsPowder deliveryBiocideAdditive ingredientPhotochemistry

Owner:GENERICS UK LTD

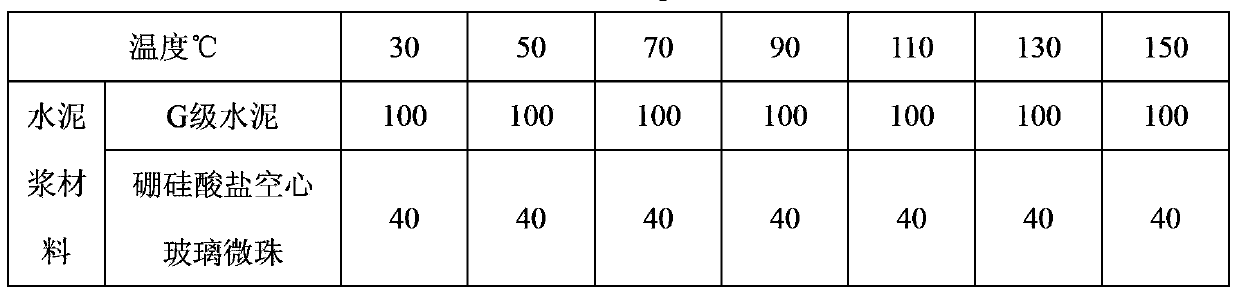

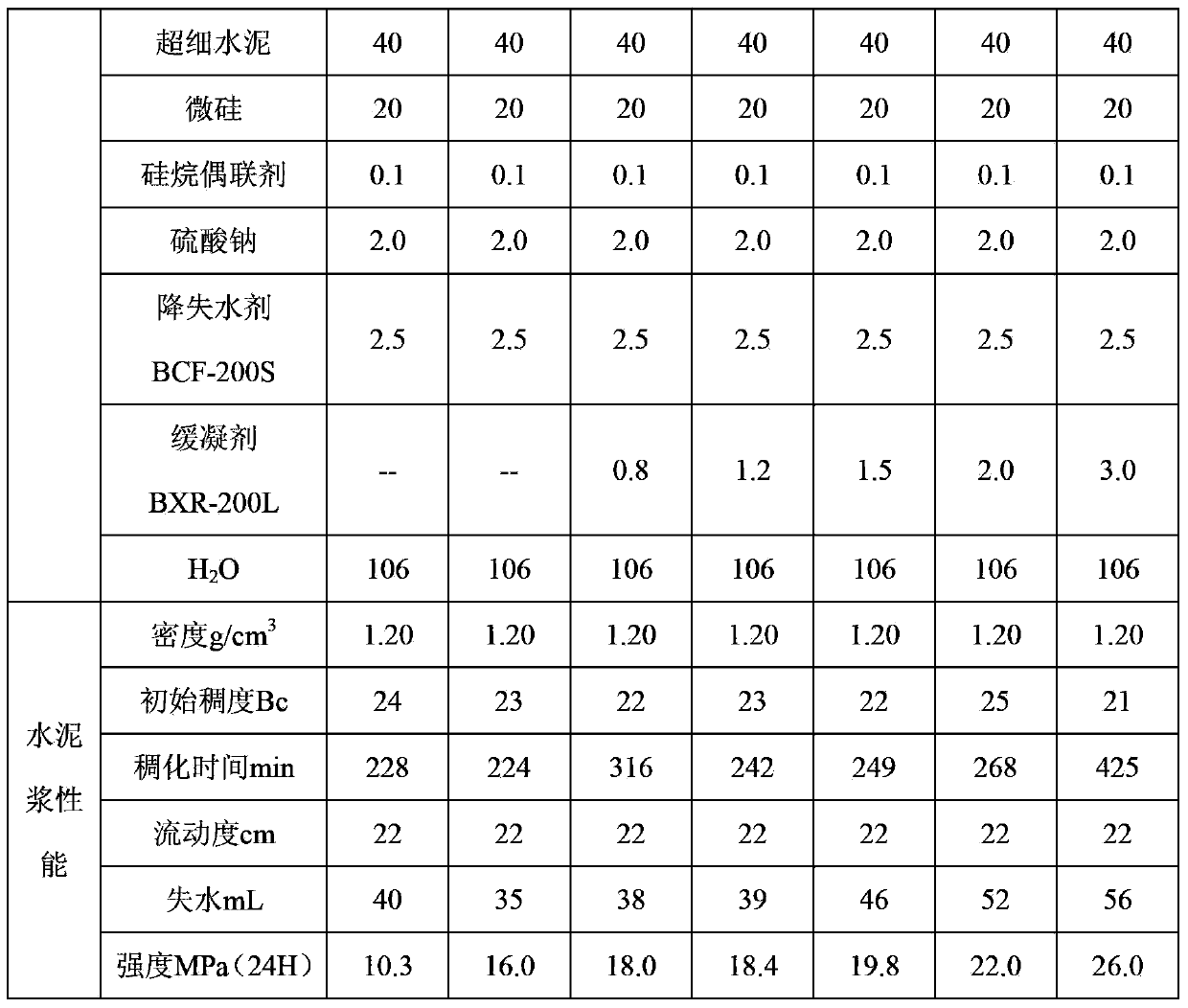

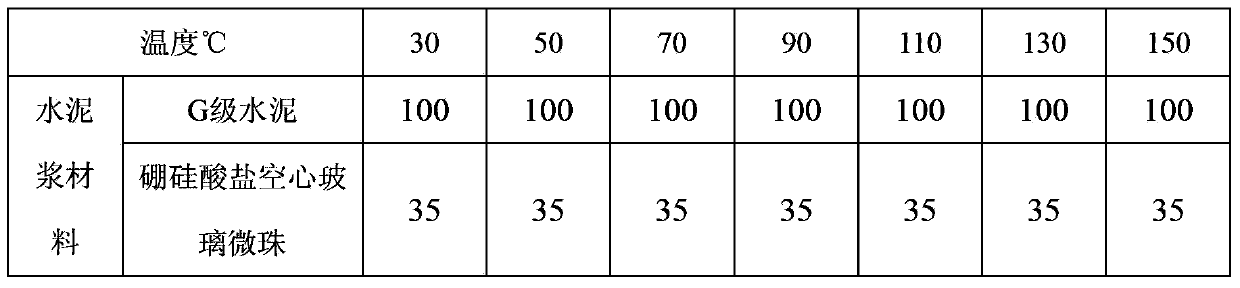

Low-density cement paste system

InactiveCN104178096AStrong hydration abilityFast hydrationDrilling compositionWell cementingVolumetric Mass Density

The invention relates to a low-density cement paste system. The cement paste system comprises following components by weight: 100 parts of oil well cement, 65-106 parts of water, 6-40 parts of borosilicate hollow glass beads, 0.05-0.1 part of a silicone coupling agent, 25-40 parts of ultrafine cement, 10-20 parts of microsilica, 2-2.5 parts of a fluid loss agent, and 0.5-1.5 parts of sodium sulfate. The particle size of the microsilica having a SiO2 content larger than 94% is 0.1-0.5 [mu]m. The particle size of the ultrafine cement is 2-10 [mu]m. The density range of the cement paste is 1.20-1.60 g / cm<3>. The particle size of the borosilicate hollow glass beads is 25 [mu]m. The thickening time of the cement paste is adjustable. The 24-h compressive strength (taking 1.50 g / cm<3> as an example) is higher than 16 MPa. The cement paste system has good sedimentation stability and incompressibility, and improves construction safety of the low-density cement paste in well cementing operation.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

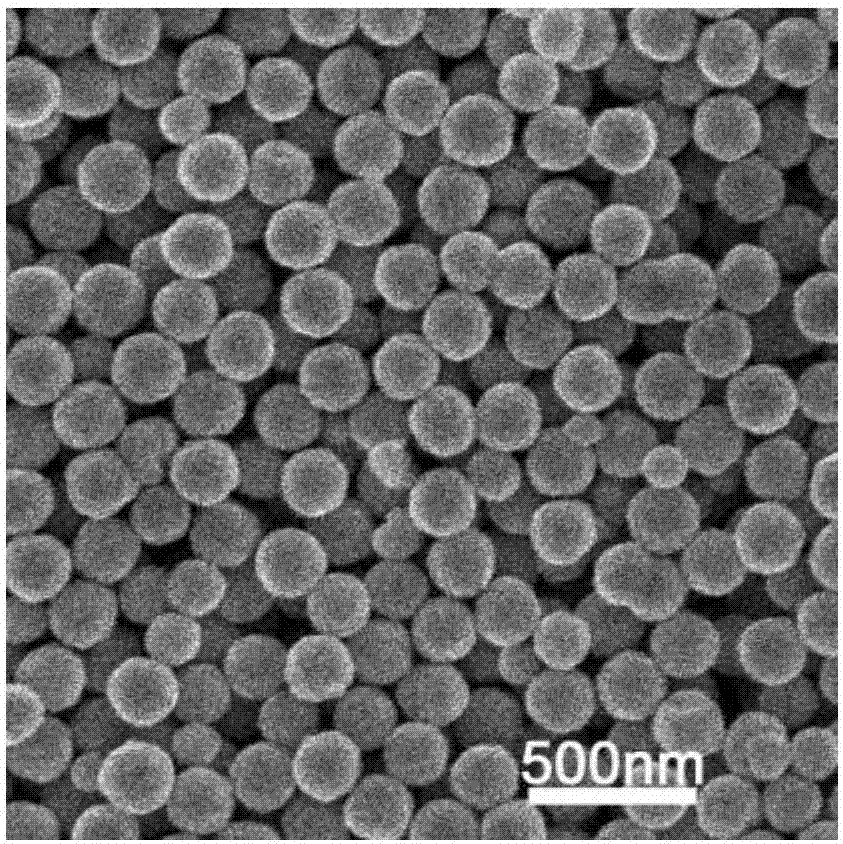

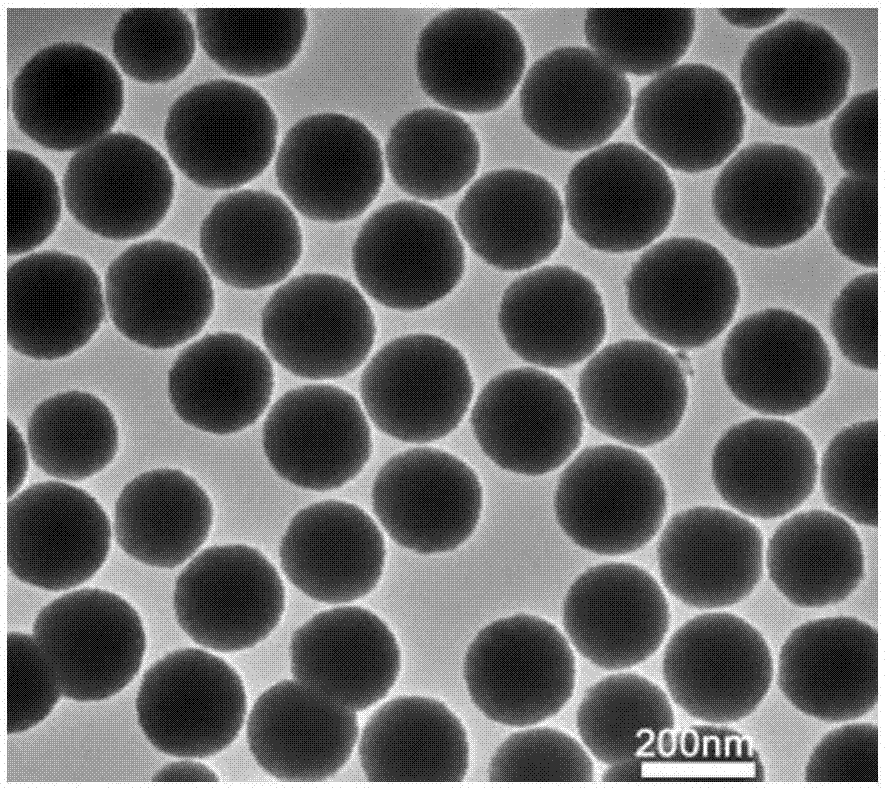

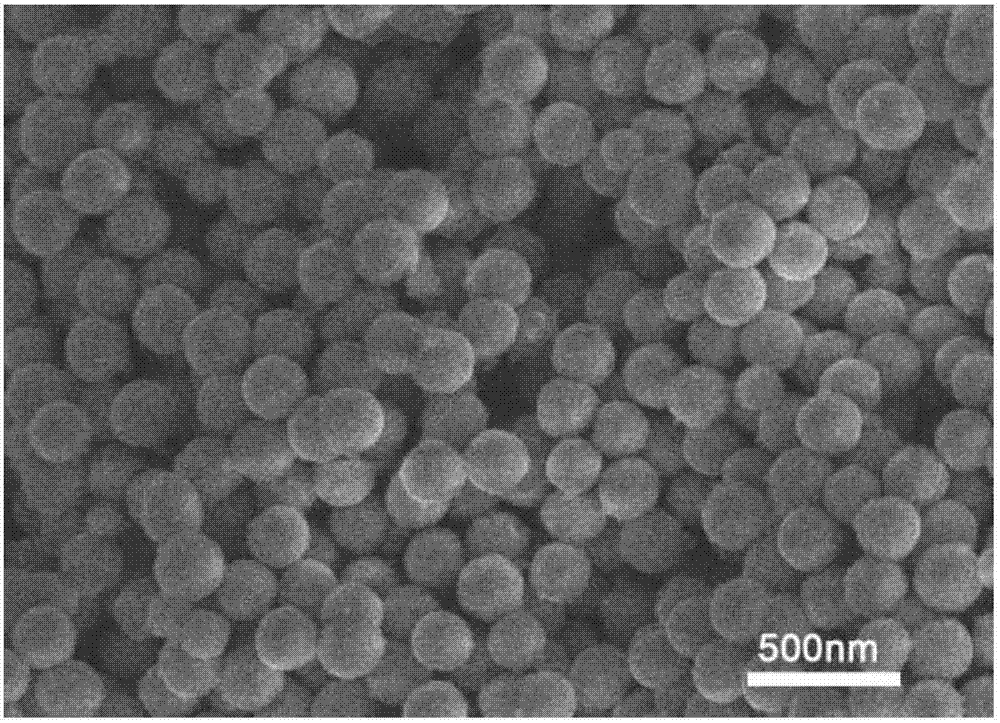

Preparation method of visible-light-driven photocatalyst Fe3O4@PDA@Ag composite microsphere

ActiveCN107442178AHigh reuse rateAvoid secondary pollutionWater/sewage treatment by irradiationWater treatment compoundsSodium acetateWater baths

The invention belongs to the technical field of photocatalysts and specifically relates to a preparation method of a visible-light-driven photocatalyst Fe3O4@PDA@Ag composite microsphere. The preparation method comprises step 1 of respectively dissolving ferric chloride hexahydrate and sodium acetate into equivalent ethylene glycol, then evenly mixing and stirring two solutions, adding a 10 to 30wt% polyacrylic acid solution to continue stirring for 6 to 12h, putting into a reaction kettle, heating to 180 to 210 DEG C and keeping reaction for 4 to 12h to obtain a black product of ferroferric oxide; step 2 of dispersing the ferroferric oxide into an ethanol solution of polyvinyl pyrrolidone, then adding a water solution of dopamine hydrochloride, performing water bath and fully and ultrasonically dispersing to obtain a mixed solution b; step 3 of dropwise adding ammonium hydroxide into the mixed solution b, continuing ultrasonic reaction for 2 to 5 hours to obtain Fe3O4@PDA composite microspheres; step 4 of adding the prepared Fe3O4@PDA composite microspheres into ammonium hydroxide and silver nitrate to be prepared into a tollens' reagent, putting in a table concentrator to be vibrated for 8 to 16hours, performing magnetic separation and performing aftertreatment to obtain the Fe3O4@PDA@Ag composite microspheres. The Fe3O4@PDA@Ag composite microspheres have an obvious effect on degrading methyl orange and can be used repeatedly.

Owner:ZHEJIANG SCI-TECH UNIV

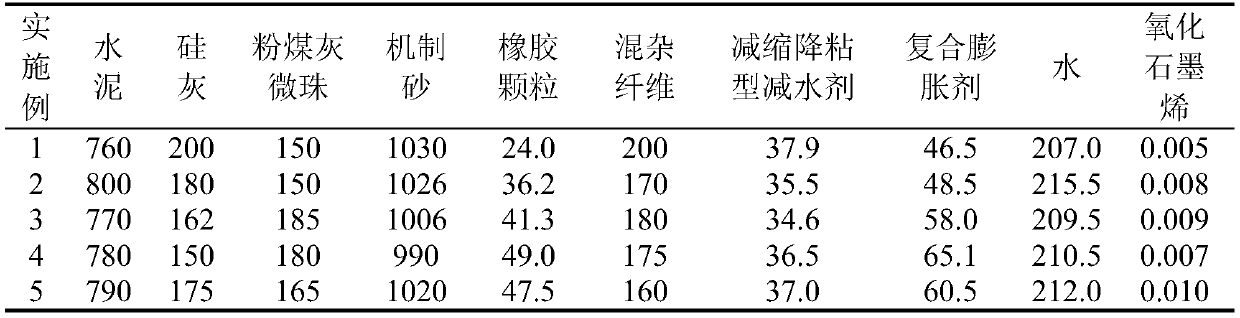

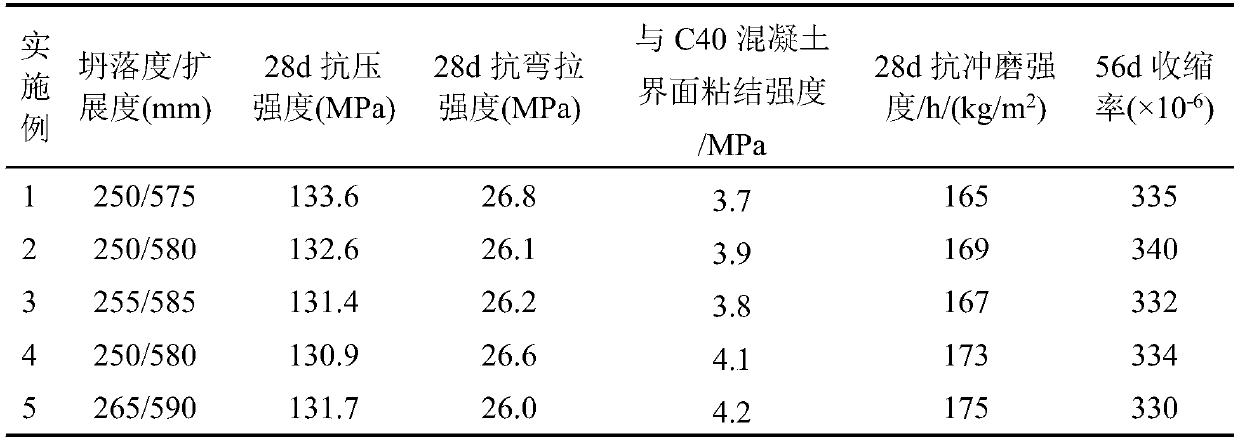

Graphene oxide anti-abrasion ultra-high toughness concrete and preparation method and application thereof

InactiveCN110683809AImprove impact toughnessImprove wear resistanceSolid waste managementWater reducerSilica fume

The invention discloses a graphene oxide anti-abrasion ultra-high toughness concrete. The concrete comprises the following raw materials in parts by weight: 700 to 800 parts by mass of cement, 150 to200 parts by mass of fly ash microbead, 150 to 200 parts by mass of silica fume, 900 to 1080 parts by mass of machine-made sand, 23 to 50 parts of hydrophilic rubber particle, 160 to 200 parts of hybrid fibers, 34.5 to 37.95 parts of shrinkage and viscosity reducing water reducing agent, 0.005 to 0.01 part of graphene oxide, 46 to 69 parts of composite expansion agent and 207 to 218.5 parts of water; the hybrid fiber is formed by mixing copper plated flat steel fiber, multi-anchor steel fiber and PVA fiber according to the mass ratio of 6-8: 1-2: 1-2. The graphene oxide anti-impact and anti-wear ultra-high toughness concrete prepared by the invention has excellent impact toughness and anti-wear performance, good volume stability and high interface bonding strength between new and old concrete.

Owner:湖北省高创公路工程咨询监理有限公司 +2

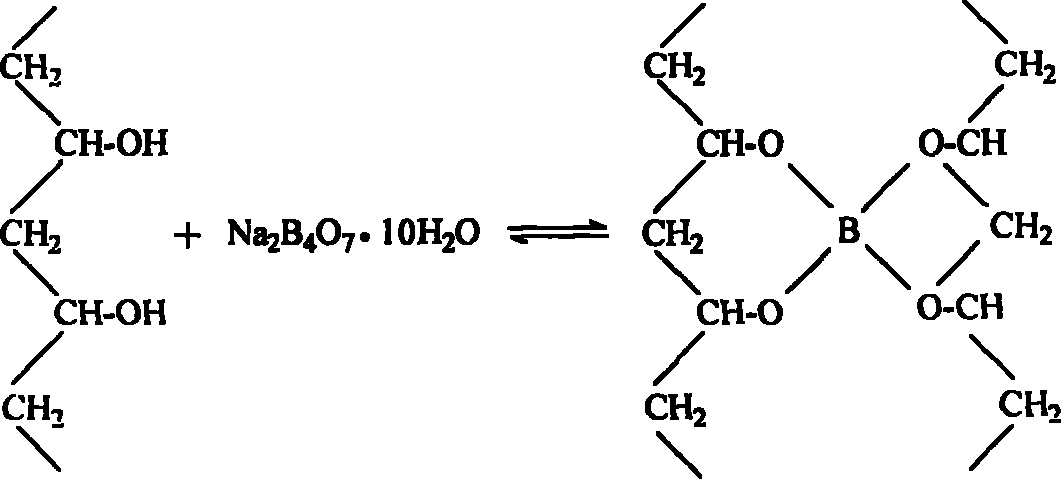

Method for preparing ultrafiltration film of poly-ether-sulfone and anti-protein-contamination type

A process for preparing the ultrafiltering polyethersulfone membrane resisting against protein pollution includes such steps as preparing PVC solution and borax solution, washing the raw ultrafiltering polyethersulfone membrane, drying in the air, immersing in the PVC solution, washing, drying, immersing in the borax solution, washing, drying, and repeating the last 6 steps several times.

Owner:TIANJIN UNIV

Surface treatment process for implantable medical device

InactiveUS20140172028A1Improve hydrophilicityImprove surface hydrophilicitySuture equipmentsDental implantsMedical deviceBiomedical engineering

A surface treatment process for improving the hydrophilicity of at least part of an implantable medical device. The process comprises applying to the surface of the implantable medical device a solution of a non-ionic substance having at least one polar covalently-bonded group and drying the implantable medical device to form a hydrophilic deposition of the substance on the surface of the implantable medical device.

Owner:NEOSS LTD

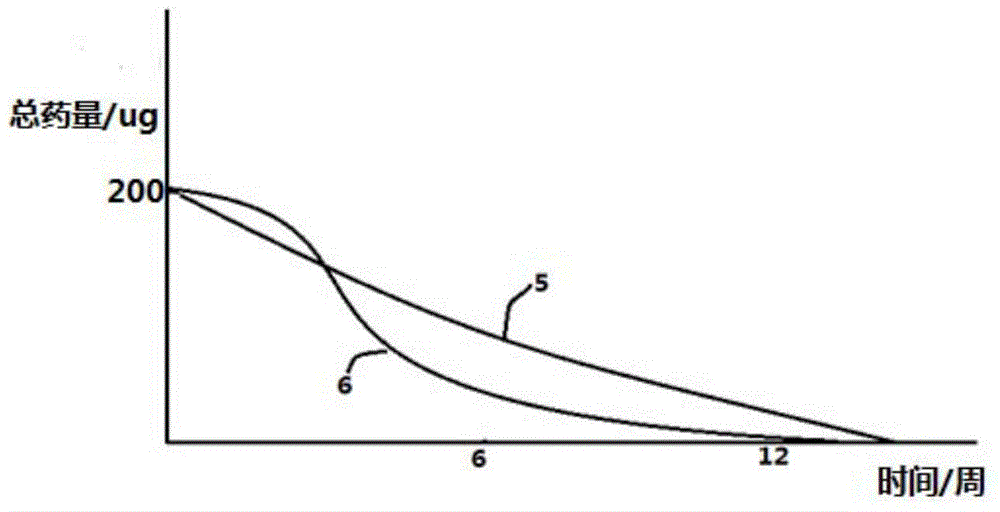

Developing degradable polymer stent and preparation method thereof

The invention provides a developing degradable polymer stent and a preparation method thereof. A plasma vapor deposition method is adopted to deposit a degradable developing material on the surface of a bracket; the prepared developing coating is not transmitted under X ray, so that the stent can be clearly seen under X ray, and therefore, some interferences of a metal developing material on MRI (magnetic resonance imaging) and CT (computed tomography) images are avoided, and problems that side effects are easily produced as biocompatibility of the metal developing material is poor, and the metal developing material cannot be degraded and left in a blood vessel cavity after the stent is degraded are solved; according to the method, activation hydrophilic treatment is carried out on the surface of the polymer bracket, so as to improve affinity between the polymer base body and the developing coating and effectively solve the coating dropping problem; besides, a protective coating which is slow in degradation rate is coated on the surface of the developing coating, so that too quick degradation of the developing coating is prevented, and therefore, follow-up can be still carried out in the later stage of implanting.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

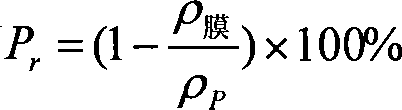

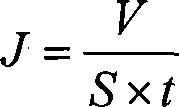

Composite nuclear track membrane and preparation method thereof

ActiveCN104001429AImprove surface hydrophilicityHigh mechanical strengthSemi-permeable membranesPolyesterVolumetric Mass Density

The invention discloses a composite nuclear track membrane and a preparation method thereof. The composite nuclear track membrane comprises a polyester nuclear track membrane or a polycarbonate nuclear track membrane, wherein a porous cellulose acetate membrane is composited on one surface of the polyester nuclear track membrane or the polycarbonate nuclear track membrane so as to form the composite nuclear track membrane of which the thickness is 67-160 microns, the aperture of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 1-10 microns, the pore density of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 2*10<5> / cm<2>-2*10<7> / cm<2>, and the thickness of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 7-25 microns. The composite nuclear track membrane has the advantage that the surface hydrophilicity is good, the mechanical strength is high, the membrane thickness is moderate, the automatic operation can be realized easily, the flux of the filtering liquid is high, and the assimilative capacity is strong; the composite membrane is an integer, is not layered and is suitable for fabricating roll type filter cores; the porous cellulose acetate membrane composited on the nuclear track membrane is taken as a pre-filtering layer or a support layer of the nuclear track membrane, so that the problems about mechanical strength and thickness of the membrane are solved, and meanwhile, the a pre-filtering problem of the membrane is solved.

Owner:天津理源科技有限公司

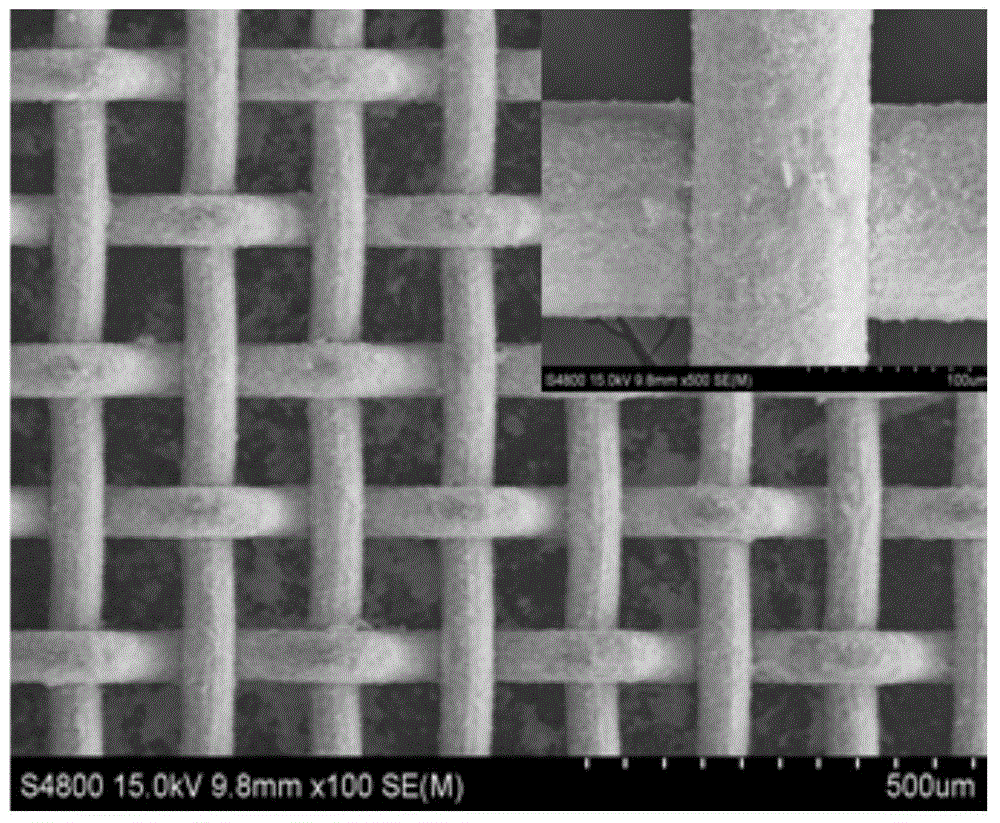

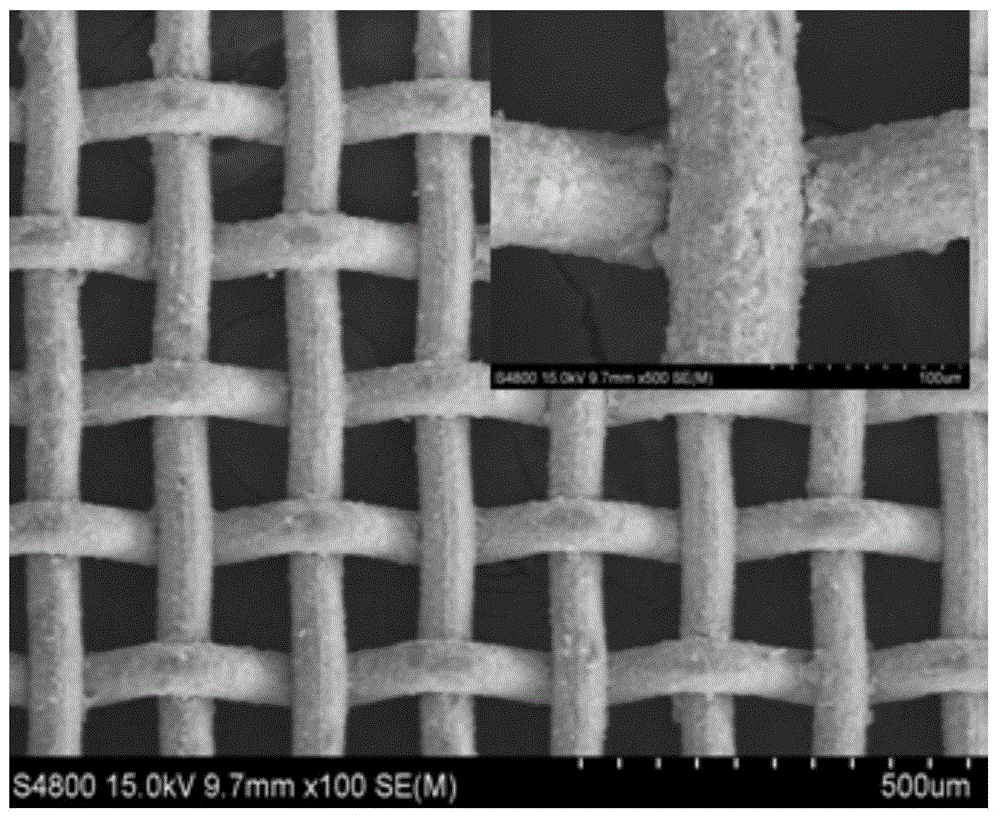

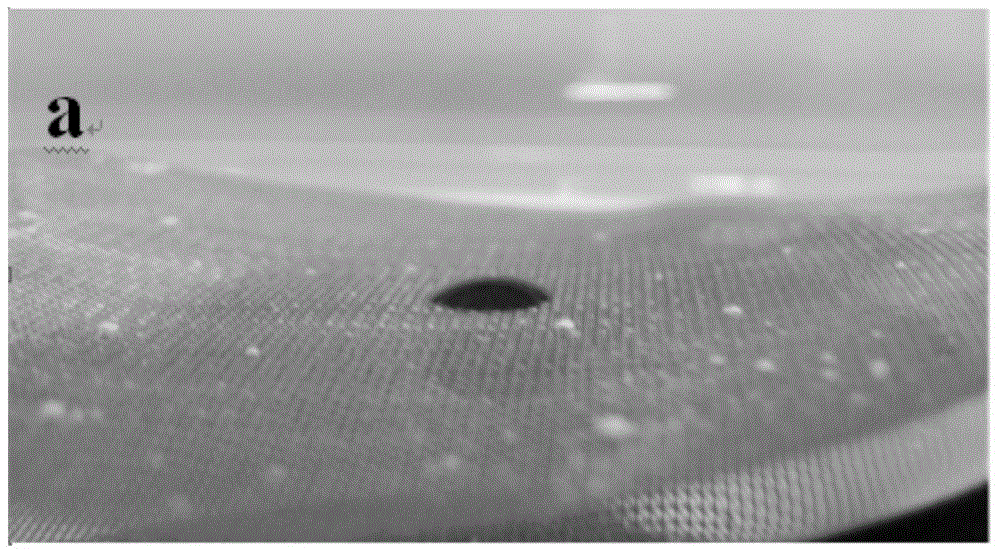

Method for coating surface of underwater oleophobic net film with nano-material

InactiveCN104888496ALow costImprove surface hydrophilicityFatty/oily/floating substances removal devicesLiquid separationWire gauzeNitrogen gas

The invention provides a method for coating the surface of an underwater oleophobic net film with a nano-material. The method comprises the following steps of carrying out chemical etching on a cleaned and dried stainless wire net film by a chemical etching agent, carrying out ultrasonic cleaning and drying, immersing the stainless wire net film in a cation precipitating agent solution so that chemical modification is realized, taking out the stainless wire net film, carrying out washing by deionized water, carrying out blow-drying by a nitrogen flow, immersing the stainless wire net film in a silicon dioxide dispersion liquid of graphene oxide so that a coating process is realized, taking out the treated stainless wire net film, carrying out washing by deionized water, repeating chemical modification-coating processes multiple times to obtain a coated stainless wire net film, carrying out drying, carrying out calcination at a temperature of 500-550 DEG C in a nitrogen protective atmosphere for 3-4h and carrying out cooling to obtain the stainless wire net film finished product. The method is carried out at a normal temperature, has simple processes and a low cost, utilizes an etching agent and a modified agent with low environment pollution and does not cause secondary pollution. The stainless wire net film has strong corrosion resistance, substantial oil-water separation effects, a long service life and good escherichia coli inhibition effects.

Owner:JIANGSU UNIV

Method for promoting rustless steel surface hydrophilicity

The invention discloses an improving method of hydrophilic property on the stainless steel surface, which is characterized by the following: adopting acid or alkaline disposing liquid to react with stainless steel surface with chrome or nickel or titanium under high temperature; generating film with little contact angle; improving the hydrophilic property of stainless steel surface.

Owner:赵蔚

Fabricating method of fiber powder modified polymer microporous film

InactiveCN101224392ASimple preparation processThe preparation process is matureSemi-permeable membranesFiberPolymer science

The invention relates to a macromolecule separation microporous membrane and a preparation method thereof, in particular to a preparation method of modified fiber powder / polymer mixed microporous membrane. The method provided by the invention includes the following steps: the surface of the fiber powder is cleaned and carved; the surface-carved fiber powders, polymer, various additives and solutions are combined to prepare membrane casting liquid, and then the membrane casting liquid is put onto a glass plate for membrane-shaving or spanning and then the liquid membrane is gelatinized into membrane in the coagulation bath process, and finally the membrane is dipped in membrane-dipping liquid and then is dried. The invention can prepare the polymer microporous membrane which has low cost, high strength and better capability through adding various fiber powders into the membrane preparation liquid and changing process conditions.

Owner:WUHAN TEXTILE UNIV

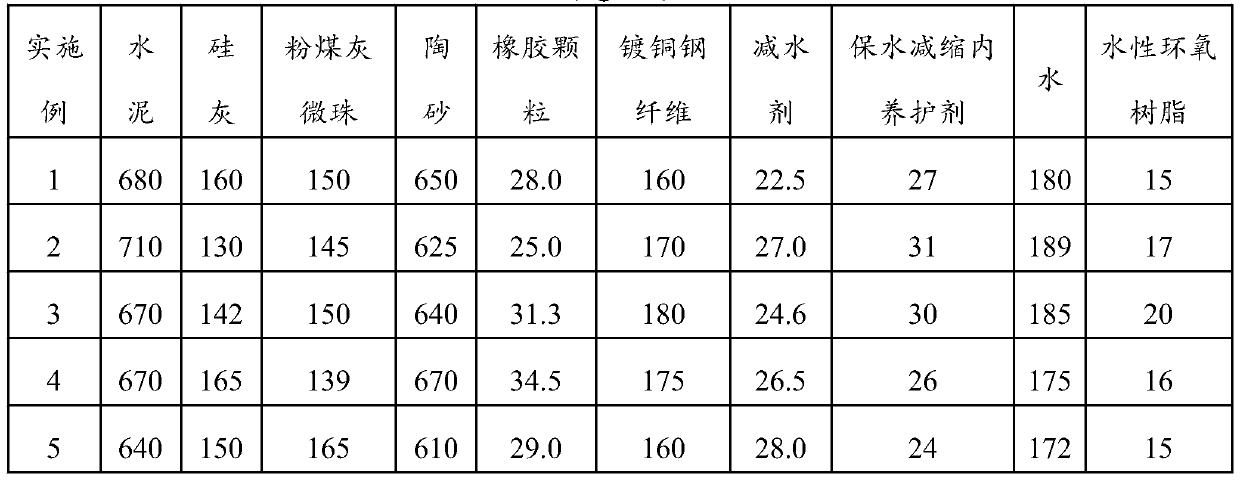

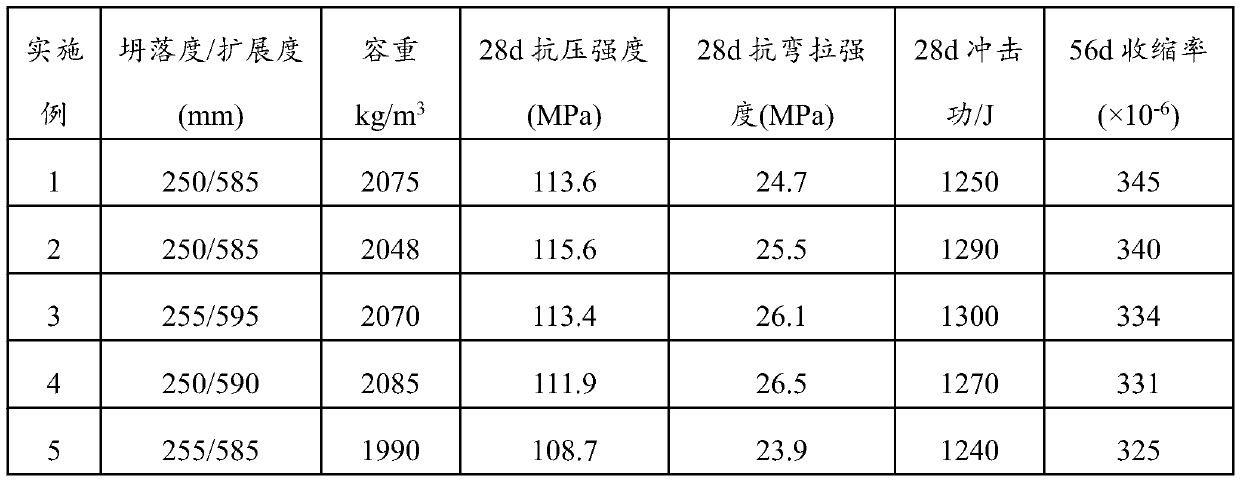

Modified rubber particle lightweight ultra-high performance concrete and preparation method thereof

The invention discloses modified rubber particle lightweight ultra-high performance concrete and a preparation method thereof. The concrete is prepared from cement, fly ash microbeads, silica fume, pottery sand, rubber particles, copper-plated steel fibers, waterborne epoxy resin, a water-retaining shrinkage-reducing internal curing agent, a water reducing agent and water as main raw materials, wherein the rubber particles are prepared by crushing waste tires and then modifying the crushed waste tires. The modified rubber particle lightweight ultra-high performance concrete has the advantagesof light weight, high strength, high impact toughness, abrasion resistance and good volume stability, and has practical application value.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com