Modified rubber particle lightweight ultra-high performance concrete and preparation method thereof

A modified rubber, ultra-high-performance technology, applied in the field of building materials, can solve the problems of restricting the development and application of prefabricated assembly construction technology, the size and self-weight of bridge prefabricated components, transportation and hoisting construction difficulties, etc., to avoid alkali aggregates. Reaction problems, life extension, effect of improving hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

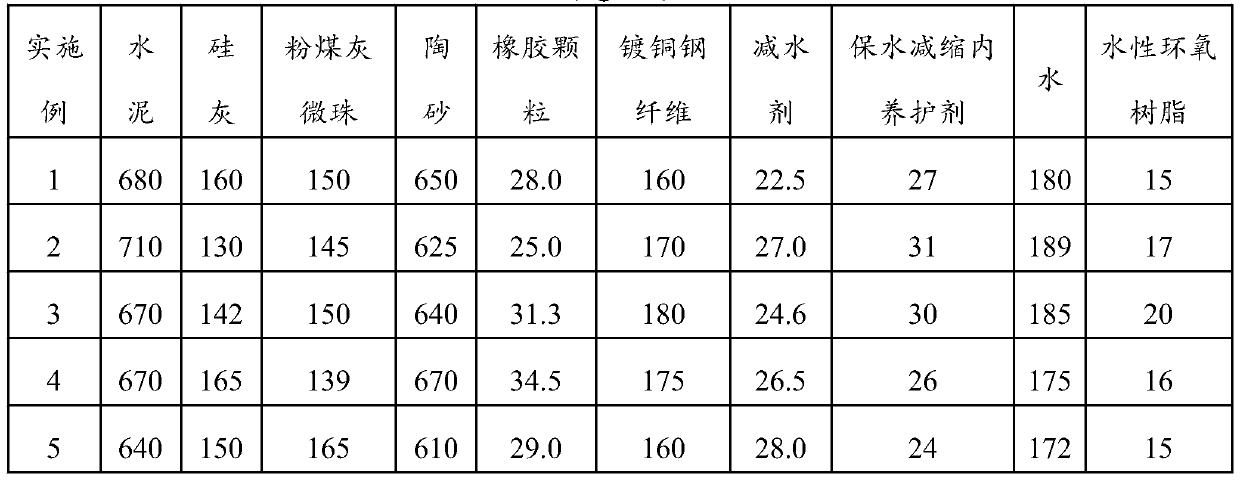

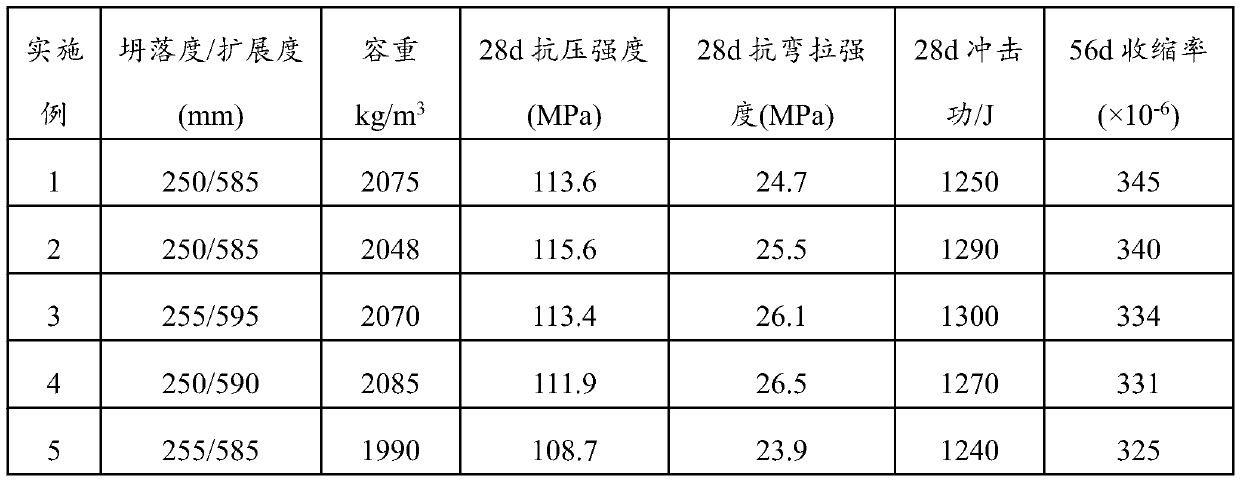

Embodiment 1~5

[0045] A modified rubber particle lightweight ultra-high performance concrete, the preparation method of which comprises the following steps:

[0046] 1) take each raw material according to the proportioning described in Table 1;

[0047] 2) Soak the pottery sand in water until it is saturated with water to obtain pre-wet pottery sand, add the pre-wet pottery sand, cement, silica fume and rubber particles into the concrete mixer for pre-mixing for 2 minutes, add fly ash microbeads and water retention and shrinkage reduction internal curing Add the agent and continue to dry mix for 1 minute, then pour water and water reducing agent and stir for 3 minutes, pour water-based epoxy resin and stir for 1 minute, then evenly add copper-plated steel fiber and stir for 3 minutes; After the permeable film is cured, the formwork is removed, and the curing is carried out according to the standard curing regulations for concrete in GB / T50081-2019 "Standards for Test Methods of Physical and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com