Process for preparing biomedical beta-titanium alloy

A preparation process and biomedical technology, applied in metal rolling, manufacturing tools, dental preparations, etc., can solve problems such as affecting material composition and performance, affecting comprehensive performance, and ineffectiveness, improving strength, maintaining processing and forming. performance, the effect of lowering the elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

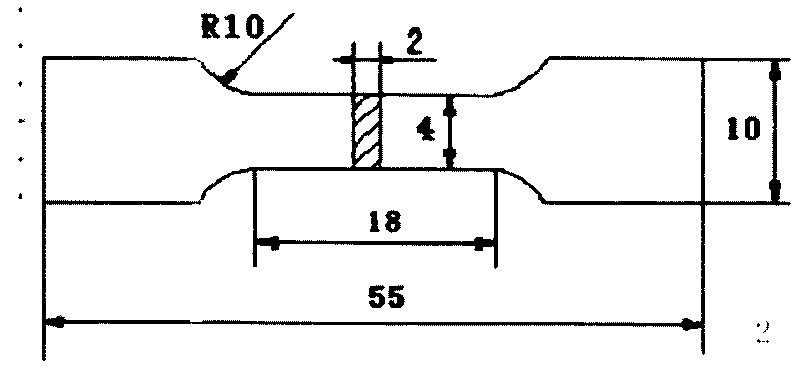

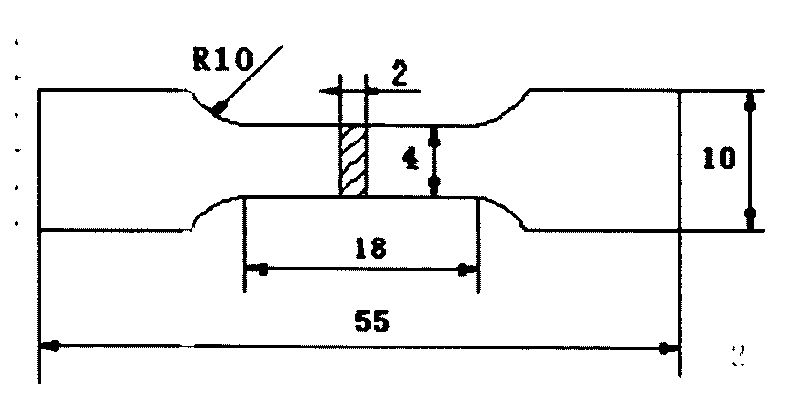

Image

Examples

Embodiment 1

[0025] A) Alloy preparation

[0026] Ti-25Nb-5Zr-0.2Fe-15Ta alloy, Ti, Nb, Zr, Fe pure metal and Ti-Ta master alloy are proportioned according to the mass percentage of the alloy composition, melted in a high vacuum arc furnace, fully stirred, and cast into a 100× 60×20mm ingot, after fully cooling, sample the solid-liquid phase temperature of the alloy through DTA analysis, and perform homogenization annealing in a vacuum furnace (with Ar gas protection), the homogenization temperature is 1000 ° C, and the time is 10 hours;

[0027] B) Surface coating

[0028] Coating a layer of coating with boron nitride as the main component on the surface of the alloy to prevent oxidation and increase lubrication during high temperature processing;

[0029] C) hot forging billet

[0030] The heating temperature of the ingot is 1100°C, and the temperature is kept for 2 hours. Free forging is adopted, and the final forging temperature is 800°C. After repeated repetitions, it is forged into...

Embodiment 2

[0040] A) Alloy preparation

[0041] Ti-28Nb-3Zr-0.6Fe-12Ta alloy, Ti, Nb, Zr, Fe pure metal and Ti-Ta master alloy are proportioned according to the mass percentage of the alloy composition, melted in a high vacuum arc furnace, fully stirred, and cast into a 100× 60×20mm ingot, after fully cooling, sample the solid-liquid phase temperature of the alloy by DTA analysis, and perform homogenization annealing in a vacuum furnace (with Ar gas protection), the homogenization temperature is 950 ° C, and the time is 12 hours;

[0042] B) Surface coating

[0043] Coating a layer of coating with boron nitride as the main component on the surface of the alloy to prevent oxidation and increase lubrication during high temperature processing;

[0044] C) hot forging billet

[0045] The heating temperature of the ingot is 1150°C, and it is kept for 2 hours. Free forging is adopted, and the final forging temperature is 780°C. After repeated repetitions, it is forged into a 10mm thick plate...

Embodiment 3

[0055] A) Alloy preparation

[0056]Ti-30Nb-1Zr-1Fe-10Ta alloy, Ti, Nb, Zr, Fe pure metal and Ti-Ta master alloy are proportioned according to the mass percentage of the alloy composition, melted in a high vacuum arc heating furnace, fully stirred, and cast into a 100×60 ×20mm ingot, after fully cooling, take a sample and analyze the solid-liquid phase temperature of the alloy by DTA, and perform homogenization annealing (with Ar gas protection) in a vacuum furnace, the homogenization temperature is 980°C, and the time is 8h;

[0057] B) Surface coating

[0058] Coating a layer of boron nitride-based coating on the surface of the ingot to prevent oxidation and increase lubrication during high temperature processing;

[0059] C) hot forging billet

[0060] The heating temperature of the ingot is 1100°C, and the heat preservation is 1.5 hours. Free forging is adopted, and the final forging temperature is 800°C. After repeated repetitions, it is forged into a 10mm thick plate; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com