Patents

Literature

896 results about "Crumb rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crumb rubber is recycled rubber produced from automotive and truck scrap tires. During the recycling process, steel and tire cord (fluff) are removed, leaving tire rubber with a granular consistency. Continued processing with a granulator or cracker mill, possibly with the aid of cryogenics or by mechanical means, reduces the size of the particles further. The particles are sized and classified based on various criteria including color (black only or black and white). The granulate is sized by passing through a screen, the size based on a dimension (1/4 inch) or mesh (holes per inch : 10, 20, etc.). Crumb rubber is often used in artificial turf as cushioning.

Products useful as roof shingles and a process for making such products

InactiveUS6194519B1ExpensePromote degradationRoof covering using tiles/slatesOther chemical processesElastomerRubber material

The present invention relates to low-cost, efficiently-manufactured, polymer-based products useful as roofing shingles and similar products. The inventive shingles are weatherproof, inexpensive to manufacture and durable, particularly as contrasted with conventional shingles in areas of the country subject to hail damage. The invention also includes a method of making such shingle products. In a preferred embodiment, products of this invention use rubber material as the polymer base in combination with specific types of polyolefins. The rubber material can be most efficiently provided by the use of crumb rubber particles from spent automobile tires and other recycled rubber debris which are readily available and of very low cost. The products will have an average life far greater than that of current commercial roofing shingles, which are made using fiberglass or asphalt.The products of the instant invention are produced by extrusion as a mixture of materials, which product and its materials can be summarized as follows as a roofing shingle product which comprises:a. one or more side-branched polyolefins as an elastomer;b. optionally a blend of additional synthetic polymers, such as ethylene and propylene, as a second elastomer; andc. a rubber fraction, preferably obtained in part from recycled spent automotive or truck tires, and similar sources of waste rubber (sometimes known as "crumb rubber"), ground or recycled into particles having a mesh size of from 10 to 30 (i.e., approximately from about 500 to about 1000 microns).

Owner:MONTY MCWILLIAMS +3

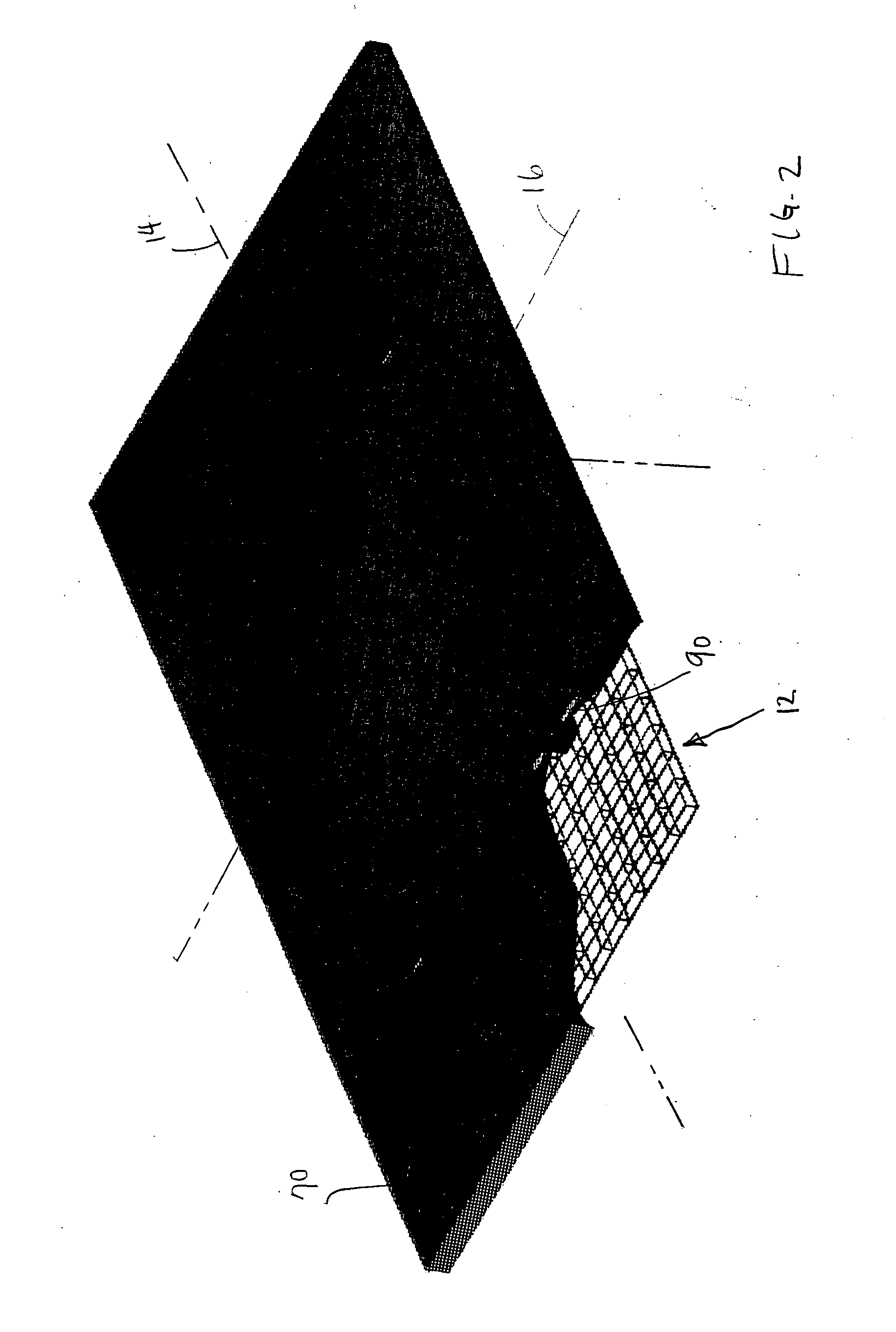

Temporary road element

A road element is formed of a one-piece cage that includes two layers of orthogonally arranged rebars which are welded together. The layers are connected by connecting rebars that are welded to the rebars of the layers at the intersections and the one-piece cage is encased in a flexible material formed of crumb rubber, urethane, and fibers from land vehicle tires. Plates can be included with the one-piece cage to further enhance the strength of the element.

Owner:CHAMPAGNE EDITION

Composite powder, preparation and use thereof

ActiveUS20050031870A1Retains modulus propertyRetains strength propertyPigmenting treatmentSynthetic resin layered productsPolymer scienceInorganic particle

The present invention relates to a composite powder, preparation and use thereof. The composite powder according to the present invention is prepared by intimately mixing an irradiated or non-irradiated rubber latex with a slurry of inorganic particles in a ratio corresponding to that of rubber particles to inorganic particles in the composite powder according to the present invention, and then drying the resultant mixture. The composite powder according to the present invention comprises agglomerates composed of powdery rubber particles and inorganic particles, with inorganic particles being uniformly distributed either inside the agglomerats or both inside the agglomerates and on the surfaces thereof. The composite powder according to the present invention can be easily dispersed in plastic matrixes and thus can be compounded with plastics to produce toughened plastics and thermoplastic elastomers.

Owner:CHINA PETROCHEMICAL CORP +1

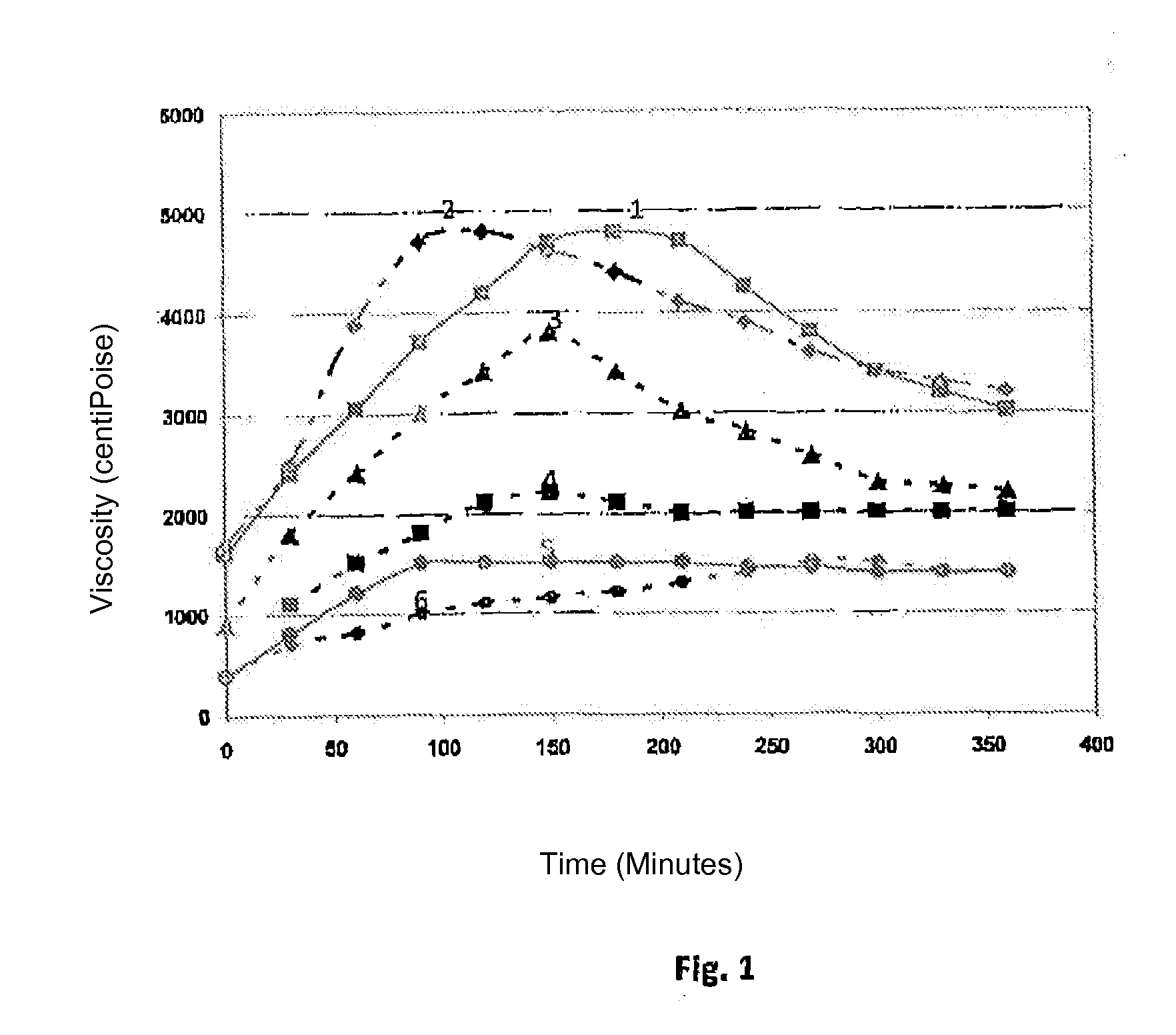

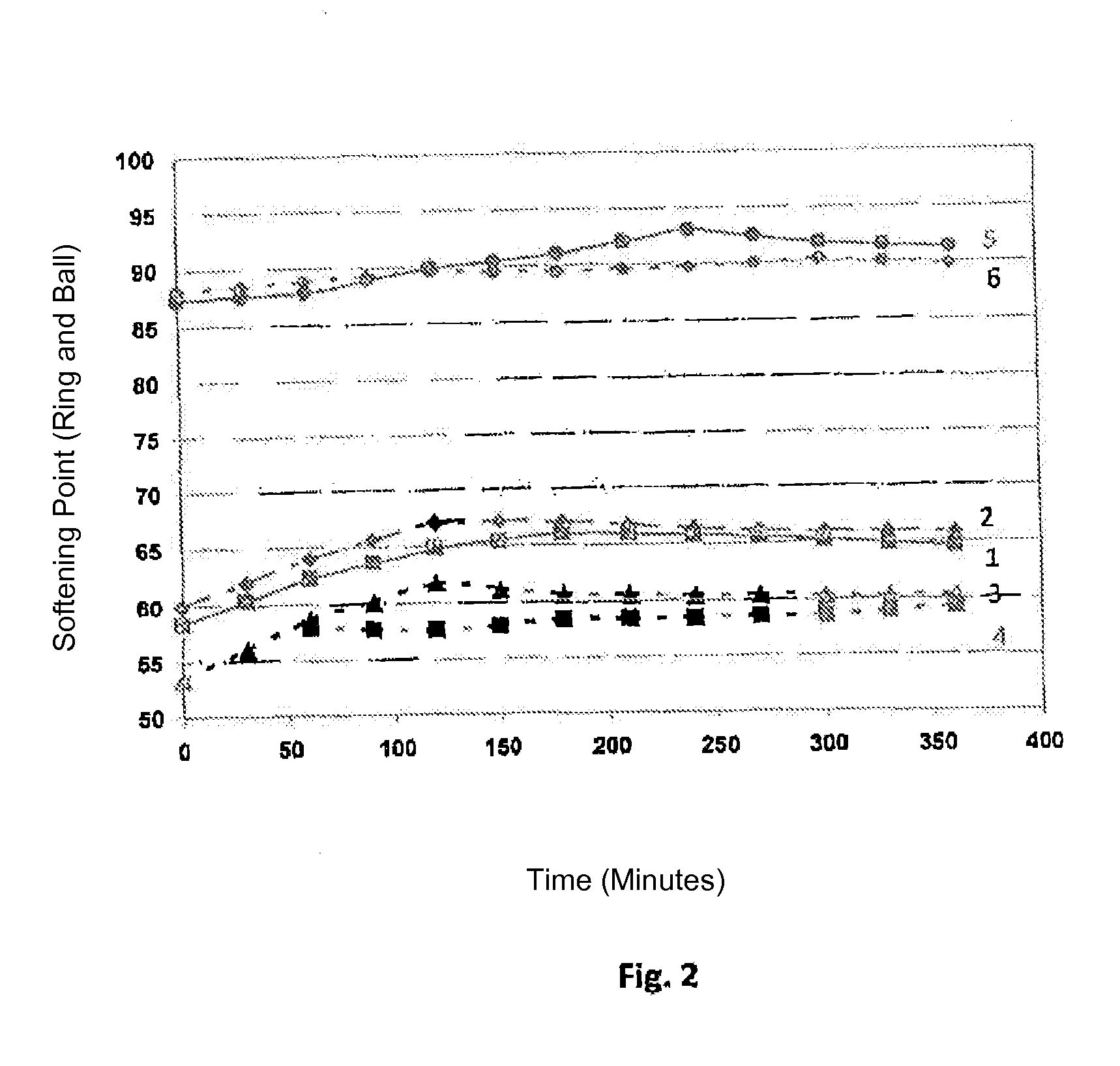

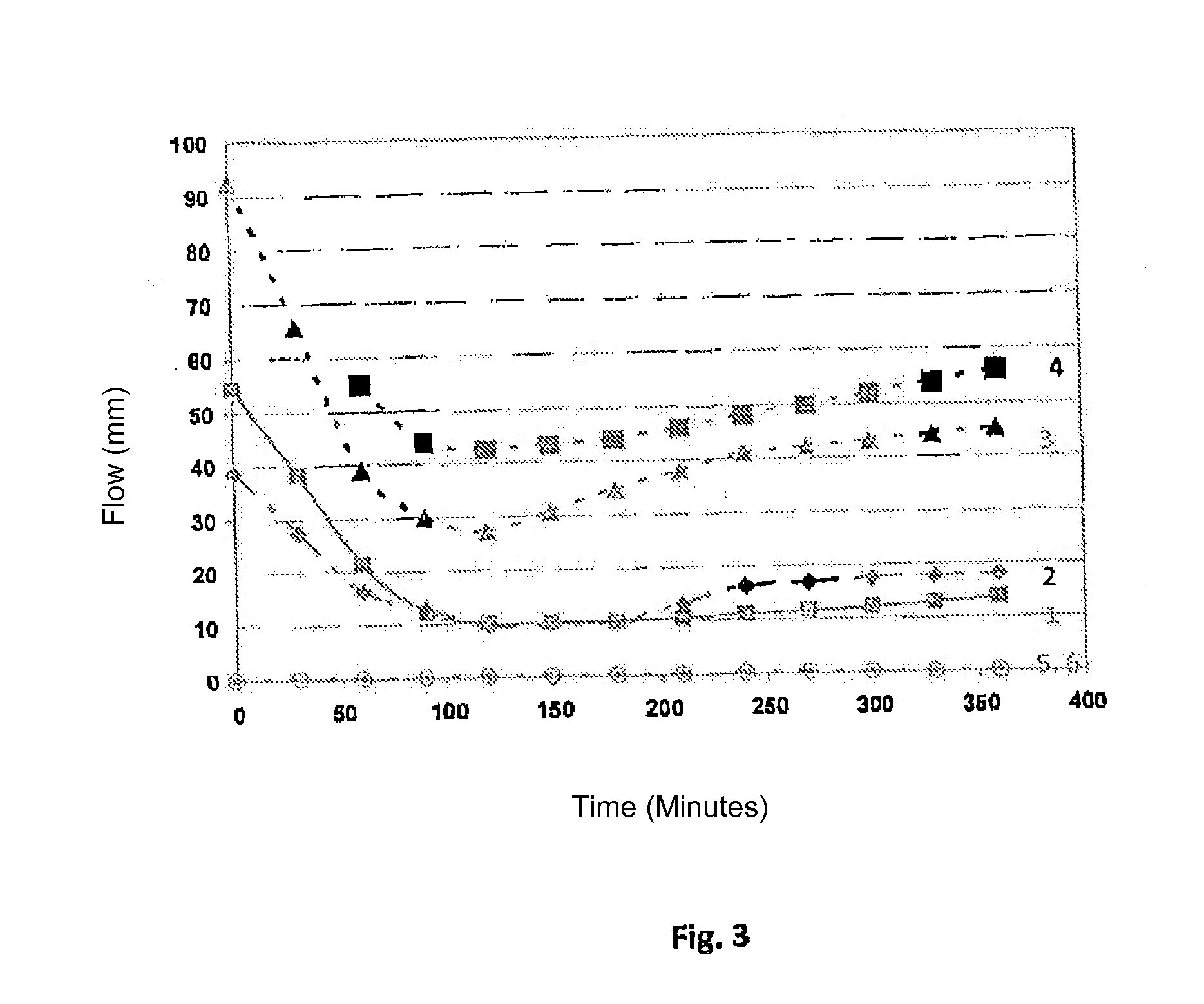

Modified asphalt binder material using crosslinked crumb rubber and methods of manufacturing the modified asphalt binder

ActiveUS20060249049A1Increase elasticityAcceptable rotational viscosityIn situ pavingsCoatingsCross-linkPolymer science

Bituminous asphalt binder materials which are modified by the addition of crumb rubber or ground tire rubber and a cross-linking agent are described. In addition, methods are provided for producing a modified asphalt binder containing crumb rubber or ground tire rubber and a cross-linking agent. The modified asphalt binders comprise neat asphalt, crumb rubber, one or more acids and a cross-linking agent. Optionally, the modified asphalt binder may include one or more polymer additives. The crumb rubber may be obtained from recycled truck and / or automobile tires. The addition of crumb rubber in asphalt binders can improve the consistency and properties of the asphalt binders at high and low temperatures. In particular, the modified asphalt binders of the present invention exhibit improved elastic behavior, resulting in improved performance of roads or other surfaces paved using the modified asphalt binder. Road resistance to permanent deformation, fatigue cracking and thermal cracking is improved by use of the modified asphalt binder.

Owner:INNOPHOS INC

Graft copolymer particles and thermoplastic resin compositions

PCT No. PCT / JP98 / 03304 Sec. 371 Date Mar. 25, 1999 Sec. 102(e) Date Mar. 25, 1999 PCT Filed Jul. 24, 1998 PCT Pub. No. WO99 / 06457 PCT Pub. Date Feb. 11, 1999There is provided graft copolymer particles prepared by graft-polymerizing a vinyl monomer to a coagglomerated rubber, wherein said rubber is prepared by coagglomerating rubber particles of mixed latexes obtained by mixing (A) a silicone rubber latex with (B) an acrylic rubber latex and / or a conjugated diene rubber latex in such an amount as a silicone content is from 1 to 90% by weight based on the total rubber component. A physical property of a thermoplastic resin is improved using the graft copolymer particles. The thermoplastic resin composition using the graft copolymer particles is excellent in impact resistance, weather resistance, processability, thermal discoloration resistance and appearance of molded products.

Owner:KANEKA CORP

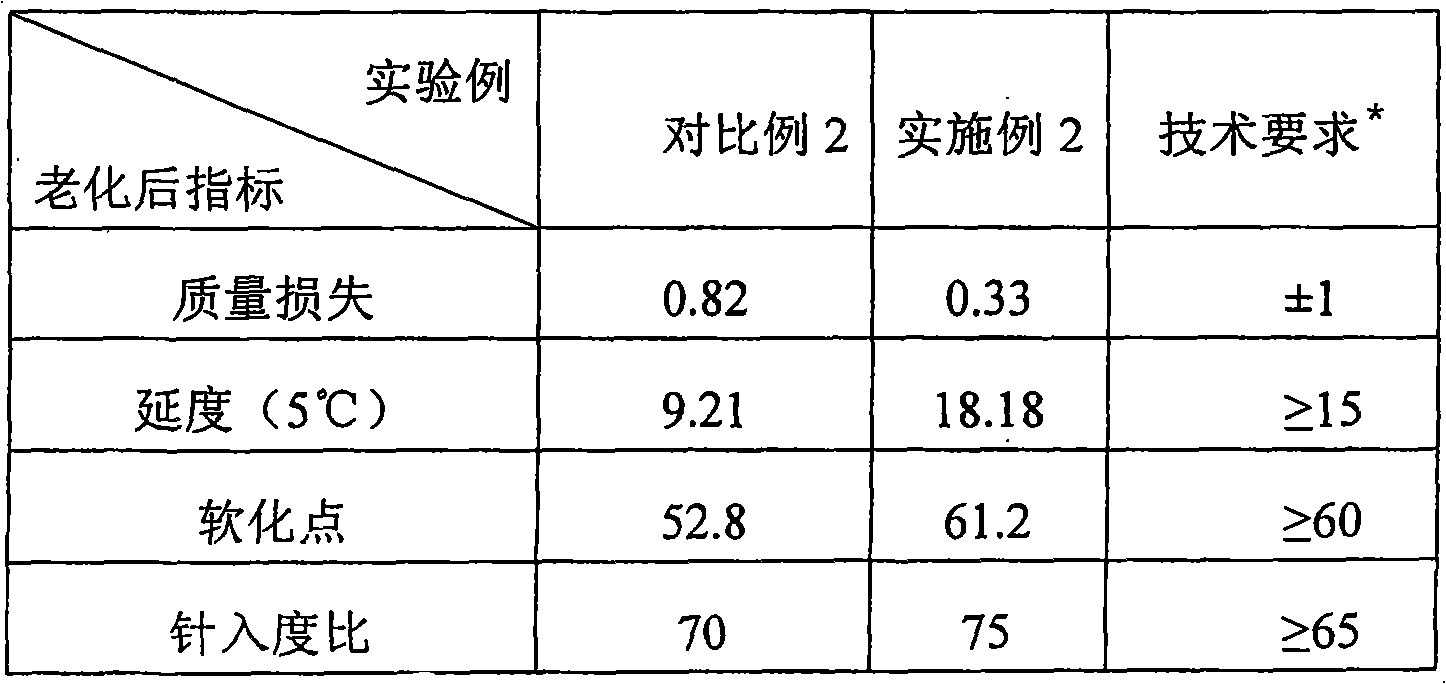

Waste Crumb rubber modified asphalt and preparation method thereof

InactiveCN101538409AImprove stabilityImprove liquidityBuilding insulationsEngineeringWaste recycling

The invention relates to waste crumb rubber modified asphalt and a preparation method thereof. The waste crumb rubber modified asphalt is prepared by high-shearing mixing of asphalt, a modifier and waste crumb rubber at a temperature of between 150 and 170 DEG C. The interface modifier is made to produce the highest efficacy and the compatibility between the waste crumb rubber and rubber is improved, so as to improve the high-low temperature performance and antiaging performance of the asphalt during use. At the same time, process simplification, cost reduction, waste recycling and environmental pollution reduction are realized.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

Thermoplastic elastomer composition, process for producing the same and golf ball using the same for cover

Disclosed is a thermoplastic elastomer composition having characteristics of both thermoplastic resin and rubber, and a golf ball using the thermoplastic elastomer composition as the cover. The thermoplastic elastomer composition of the present invention comprises a thermoplastic resin and crosslinked diene rubber particles having an average diameter of not more than 10 mu m dispersed in the thermoplastic resin, which is prepared by dynamic crosslinking diene rubber dispersed in the thermoplastic resin with crosslinking agent.

Owner:DUNLOP SPORTS CO LTD

Quick-setting cationic aqueous emulsions using pre-treated rubber modified asphalt cement

Cationic aqueous emulsions of rubber modified asphalt cement (RMAC) useable for paving, seal coat, slurry seal, roofing, coating and other applications. First, a RMAC is prepared by combining 45 to 90% by weight asphalt with about 5% to about 55% by weight solid recycled rubber (e.g., crumb rubber from used vehicle tires) under conditions that cause at least a substantial portion of the solid rubber to become liquified or otherwise incorporated into the asphalt. The RMAC may be treated with dodecyl benzenesulfonic acid (DDBSA) which causes reaction(s) to occur and results in a lowering of the viscosity of the RMAC. The RMAC (or DDBSA-treated RMAC) may then be emulsified in an aqueous medium to provide an aqueous emulsion.

Owner:SABUR DIANA +1

Raw paper of high-performance environment-friendly paper based friction material and manufacturing method of friction plate

ActiveCN101805589AGood physical and mechanical propertiesIncrease coefficient of frictionOther chemical processesNon-macromolecular organic additionAdhesiveStatic friction

The invention discloses raw paper of a high-performance environment-friendly paper based friction material and a manufacturing method of a friction plate. The high-performance environment-friendly paper based friction material is characterized by comprising the following components in percentage by weight: a substrate comprises 7-15% of carbon fiber, 5-10% of chopped aramid fiber, 5-10% of aramidpulp and 9-30% of bamboo fiber pulp; a friction agent comprises 10-20% of kieselguhr and 8-12% of cashew nut shell powder; a frictional property regulator adopts 2-4% of rubber particles, 5-10% of calcium carbonate and 10-15% of flake graphite; and a forming adhesive comprises 1-2% of fluororubber, 3-15% of silicone resin and 3-15% of phenolic resin. The invention fully forms the materials of thefriction material into a whole by changing the traditional impregnation process, effectively improves the physical and mechanical properties of the friction plate, improves the friction factors, regulates the dynamic and static friction ratio factors, and reduces the abrasion ratio of the friction plate.

Owner:陕西帕若德新材料科技有限公司

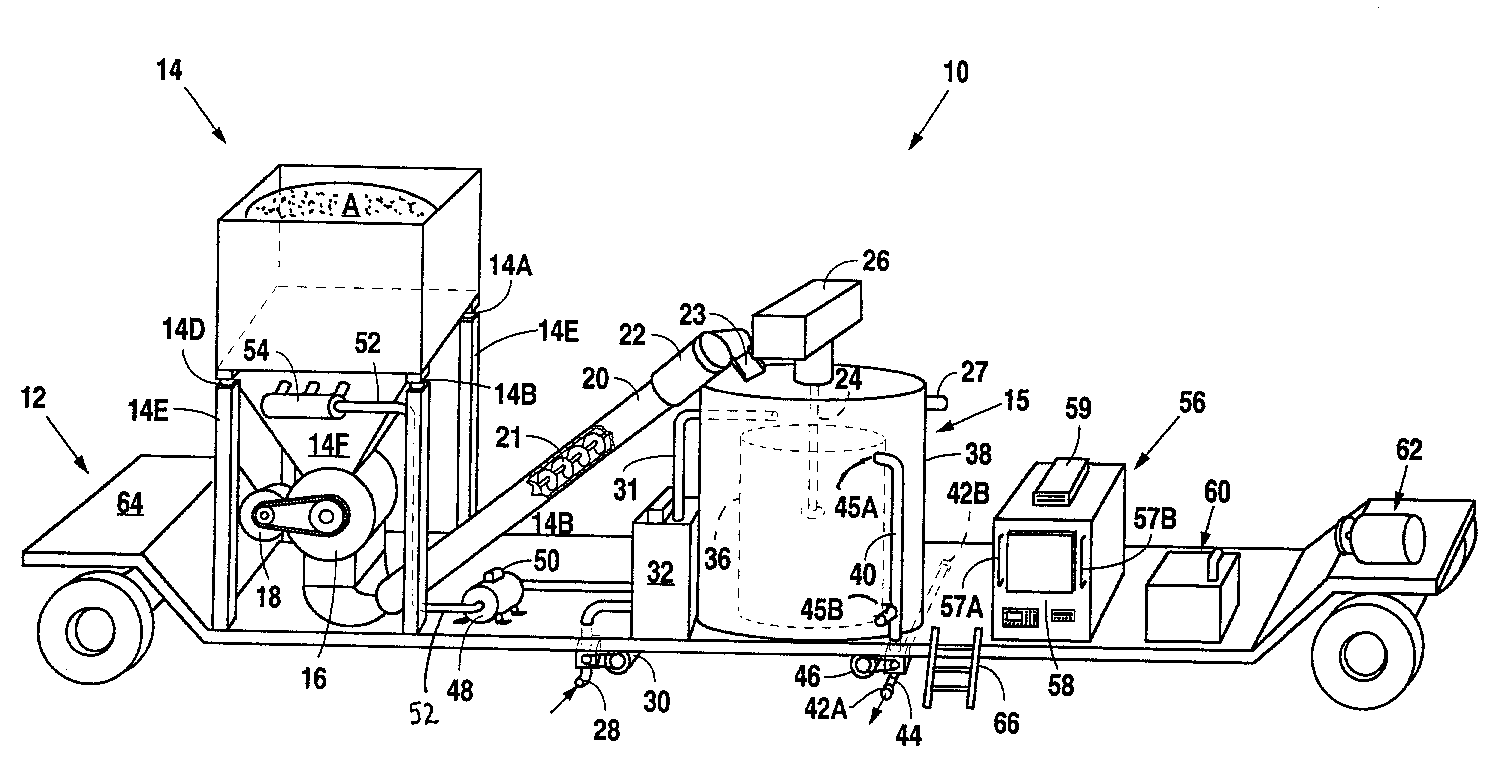

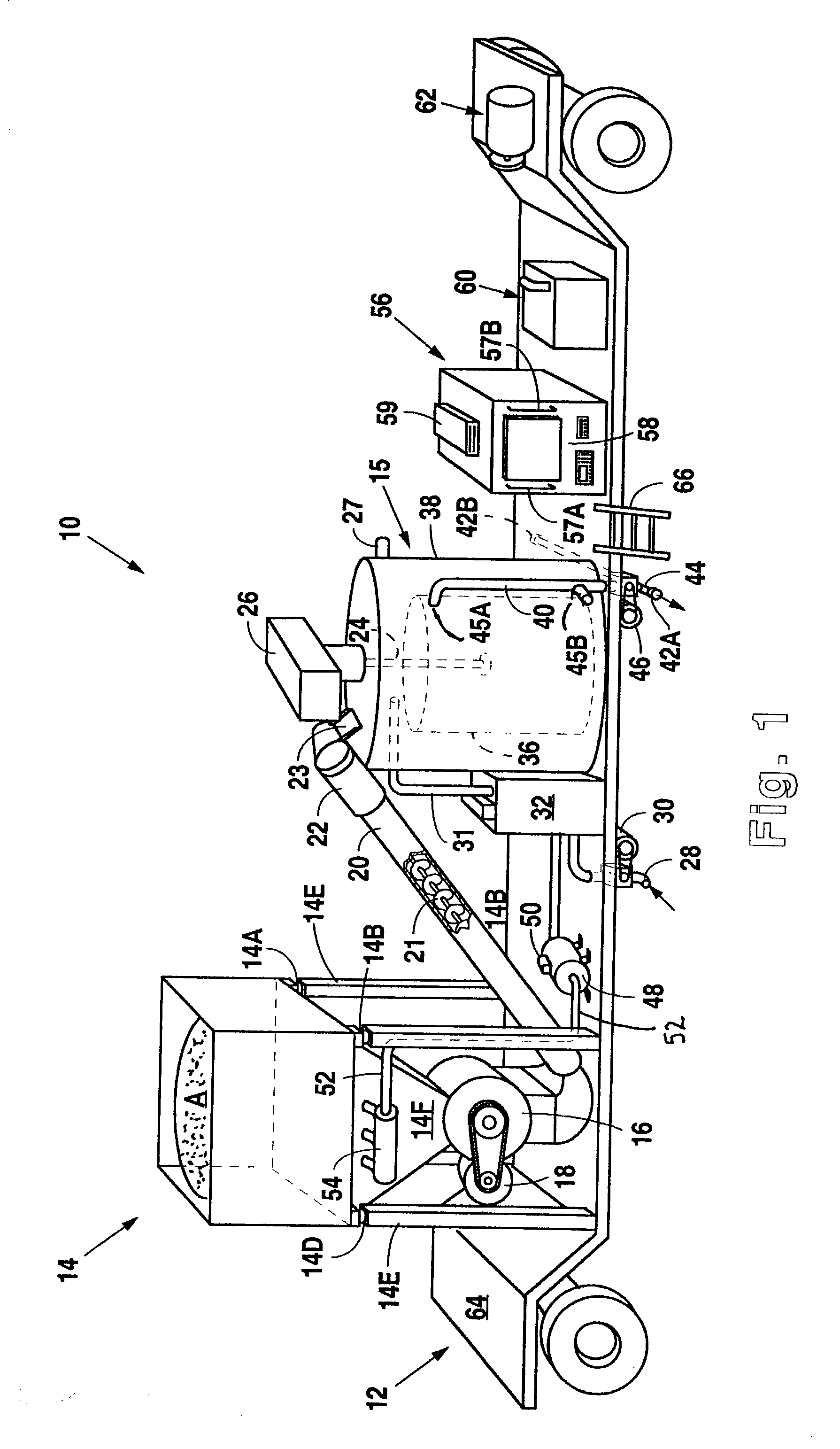

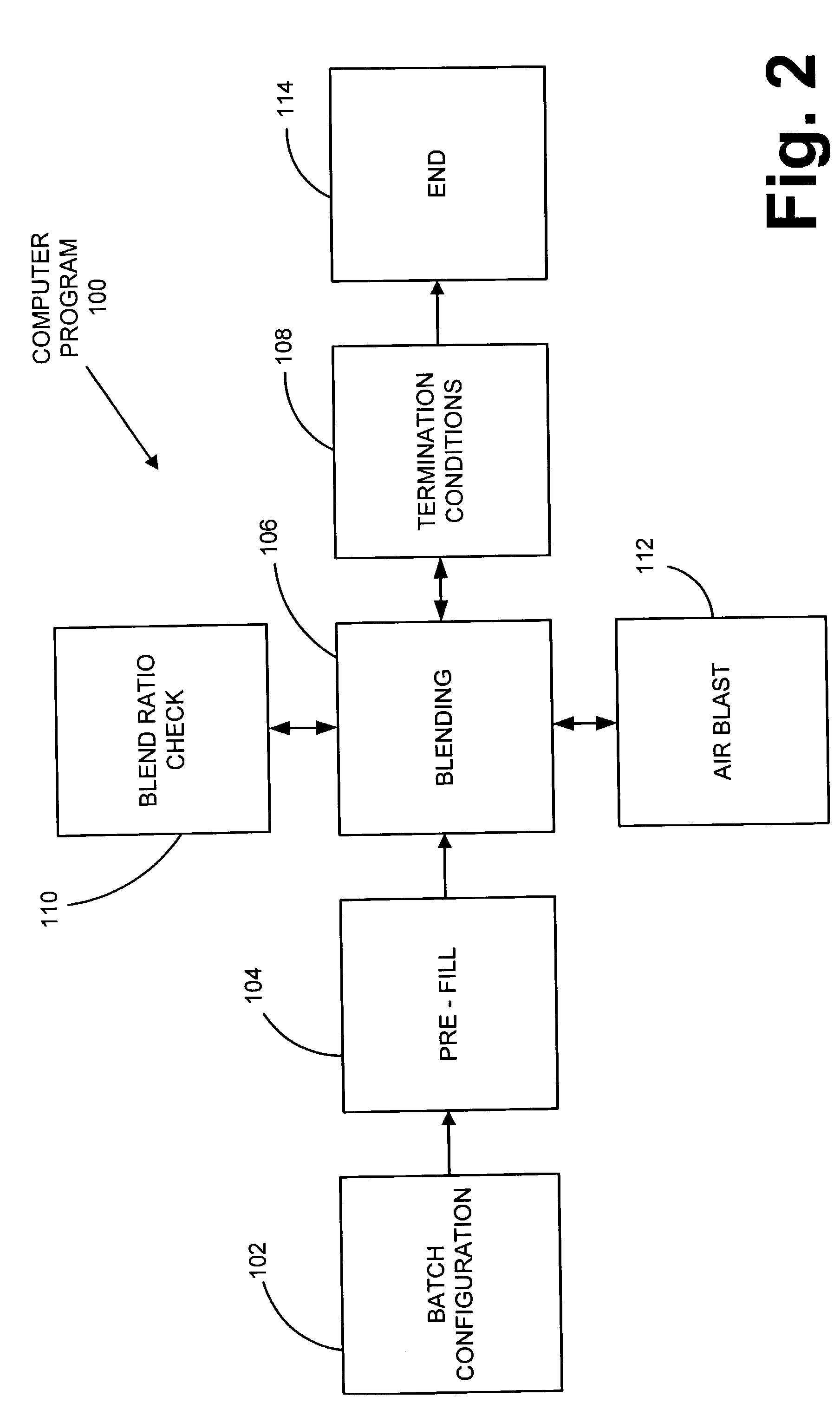

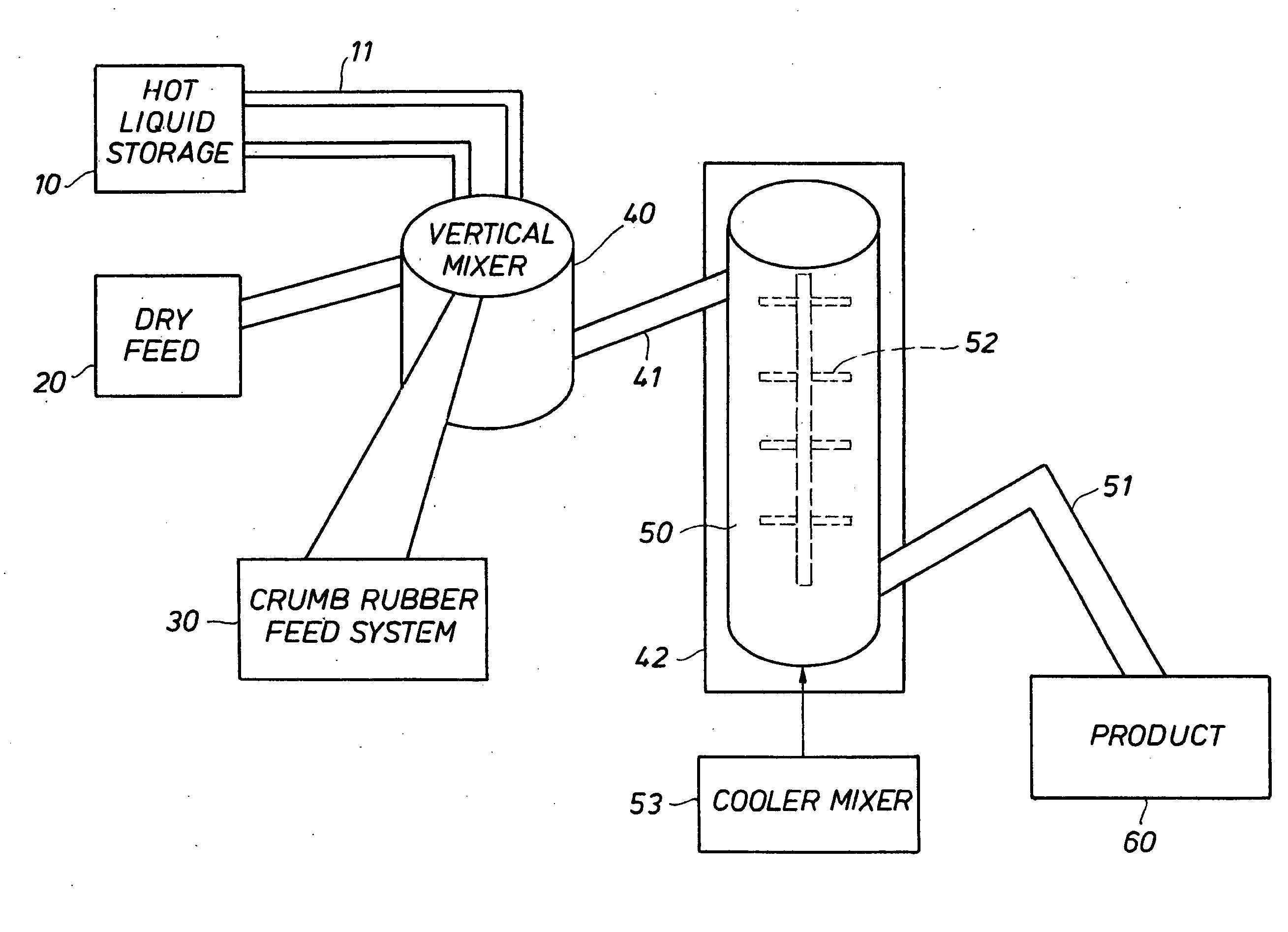

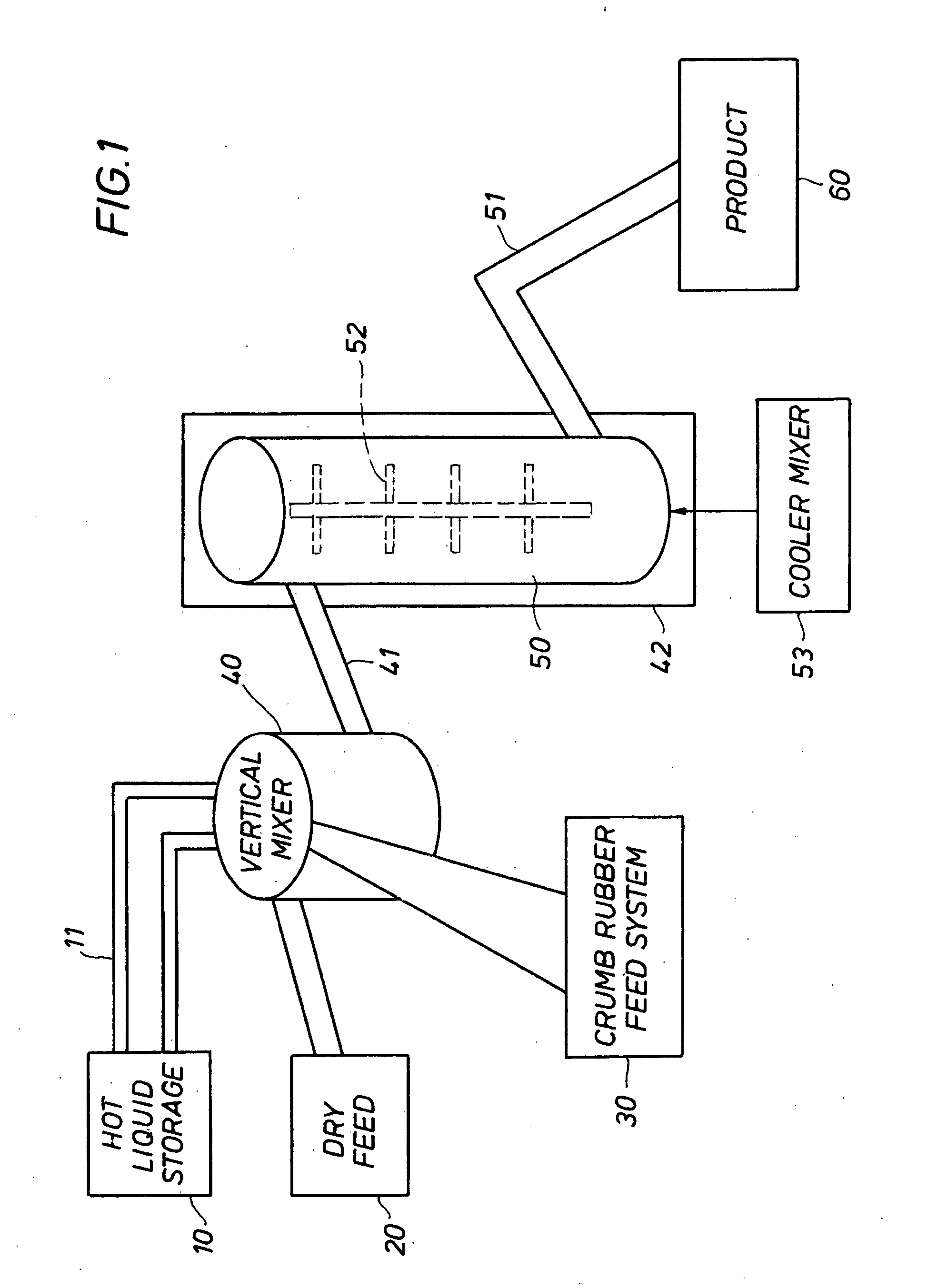

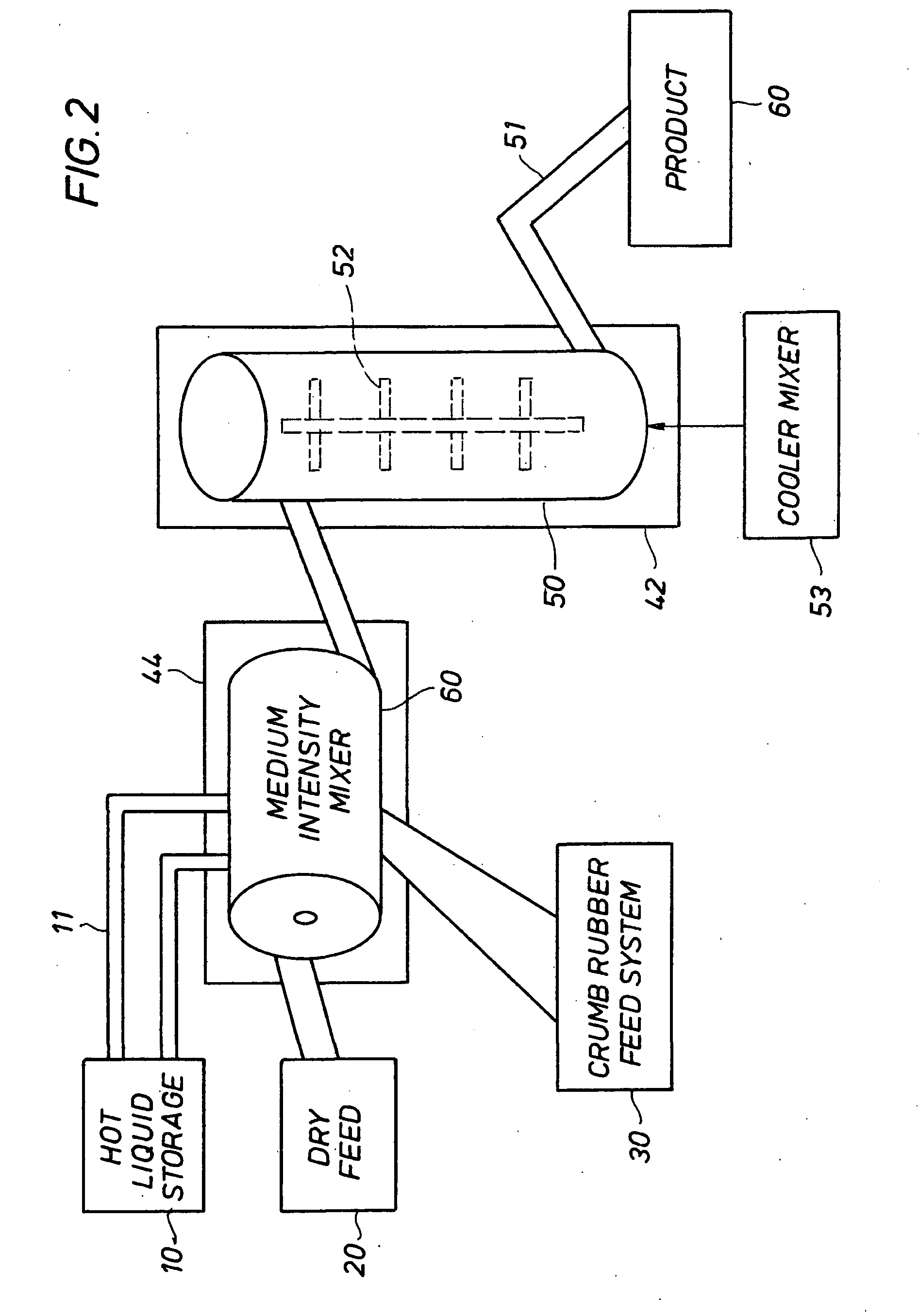

Portable plant for mixing asphalt and rubber

InactiveUS20020191481A1Sampled-variable control systemsTransportation and packagingMotor driveControl system

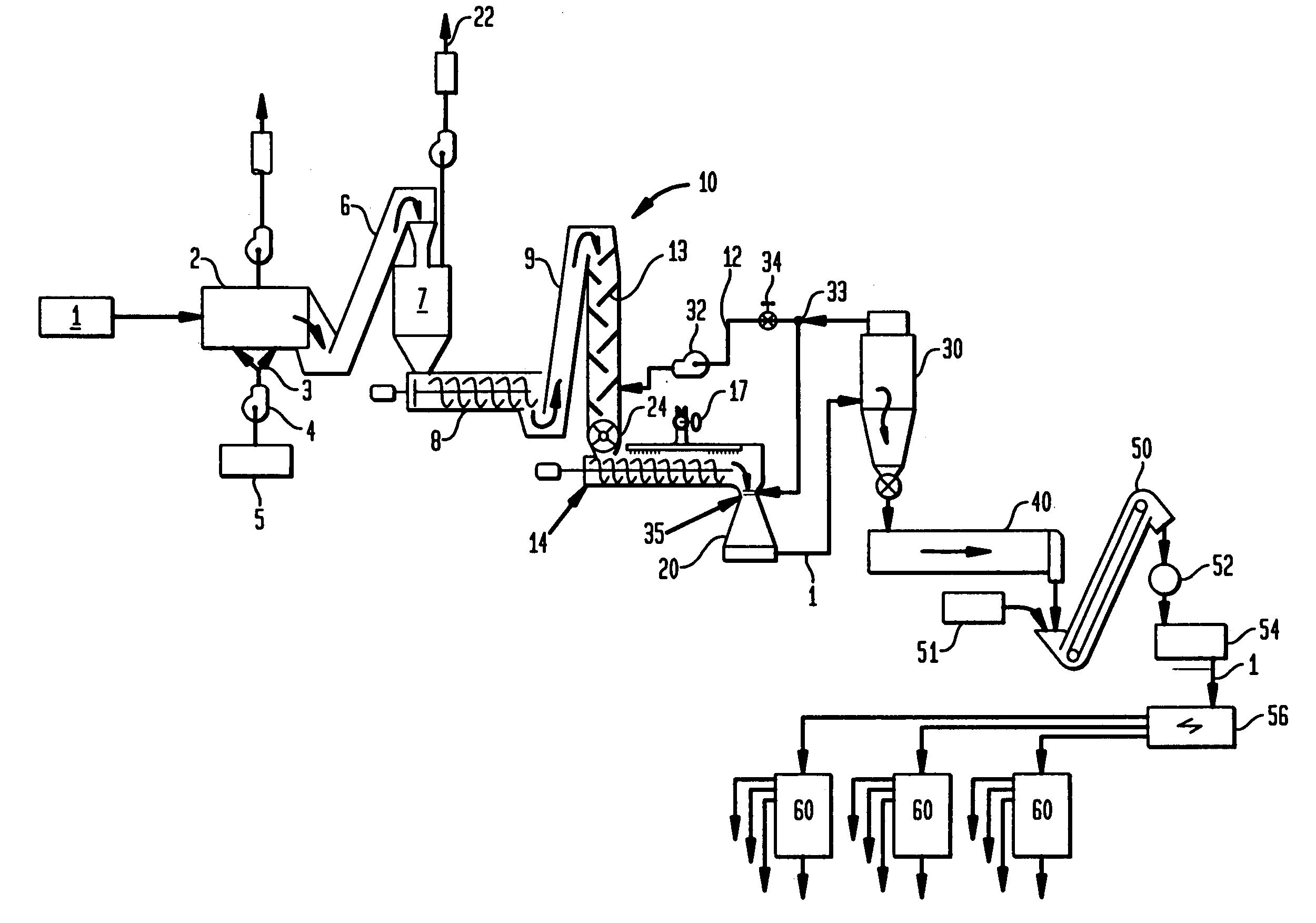

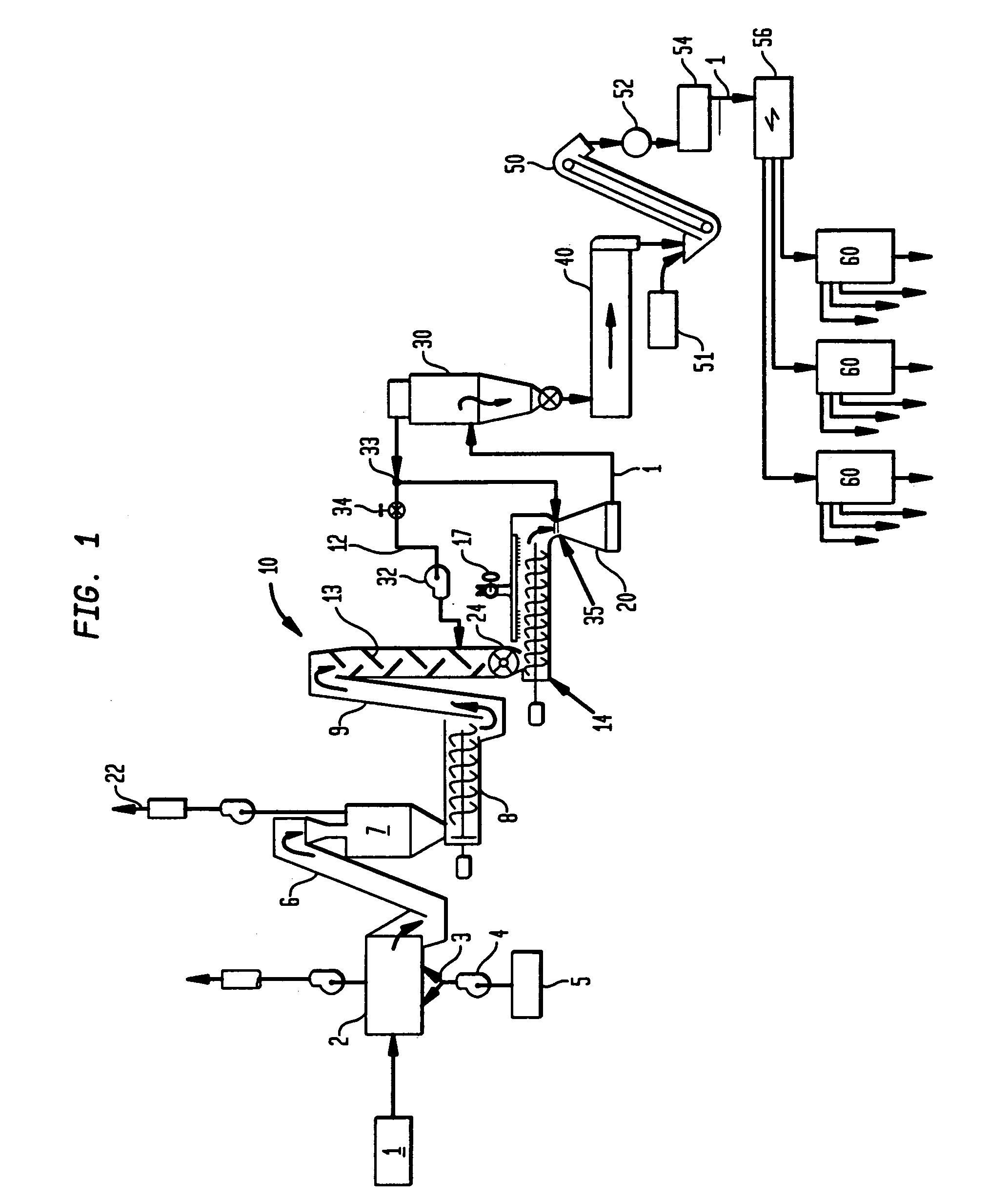

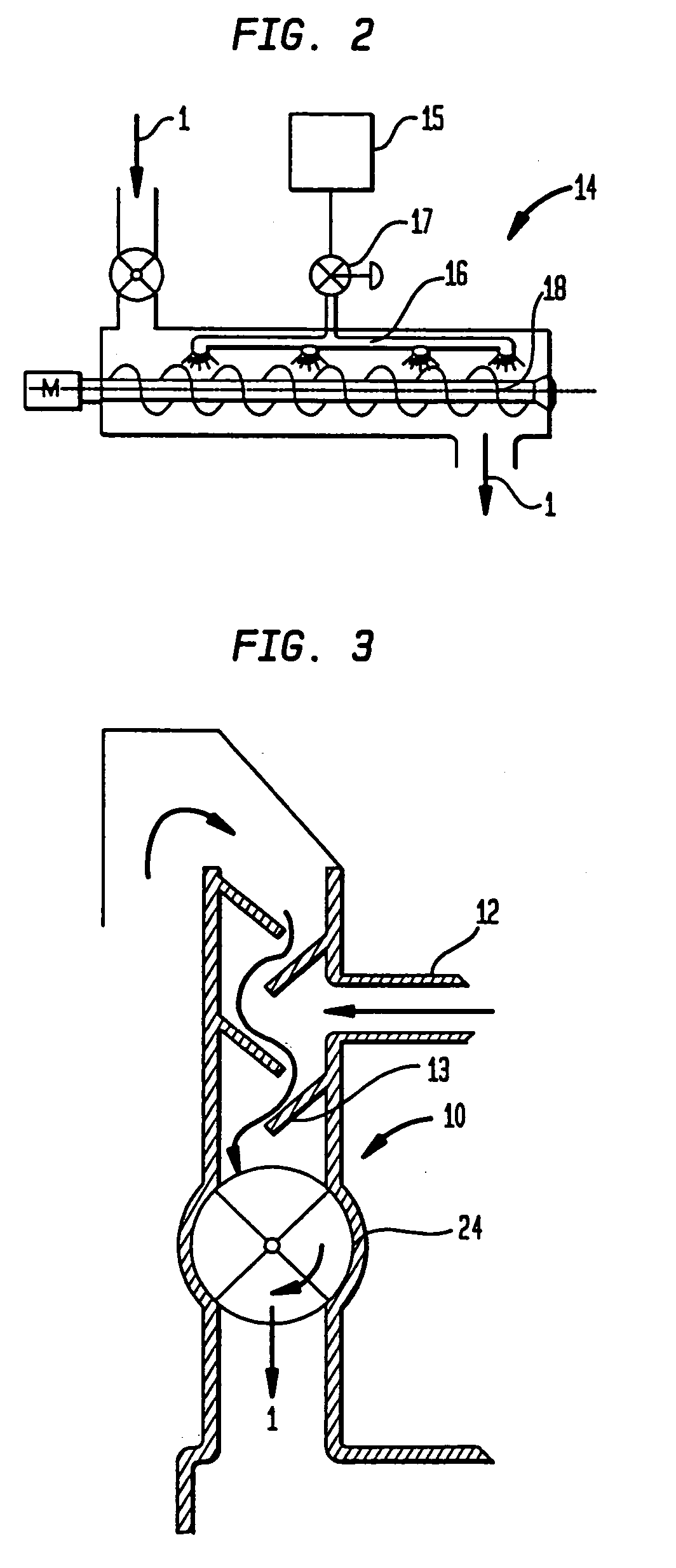

The present invention to provides for a novel asphalt mixing plant which is portable, that is, capable of being transported from one site to another. The portable asphalt mixing plant has a control system that adjusts the rate at which crumb rubber is added to oil so as to maintain a constant oil / rubber ratio in a mixer. The blending control process has a CPU to control the rate at which asphalt is pumped into a mixer and the rate at which crumb rubber is fed to the same mixer so as to maintain a constant asphalt rubber ratio in the produced asphalt. The main components of the portable asphalt mixing plant are located on a flatbed trailer and include the following: a hopper for storing loose crumb rubber; a crumb rubber delivery system for delivery of the crumb rubber from the hopper to the mixing chamber; a mixing chamber for the mixing therein; a delivery system for the delivery of asphalt (from a tank off the trailer) to the mixing chamber; a control system including motors, motor drives, a central processing unit, sensors, and computer program for the controlled delivery of crumb rubber and asphalt to the mixing chamber; a crumb rubber and asphalt mixing means including a motor and a onboard generator for powering the electrical elements of Applicant's system.

Owner:COX PAVING

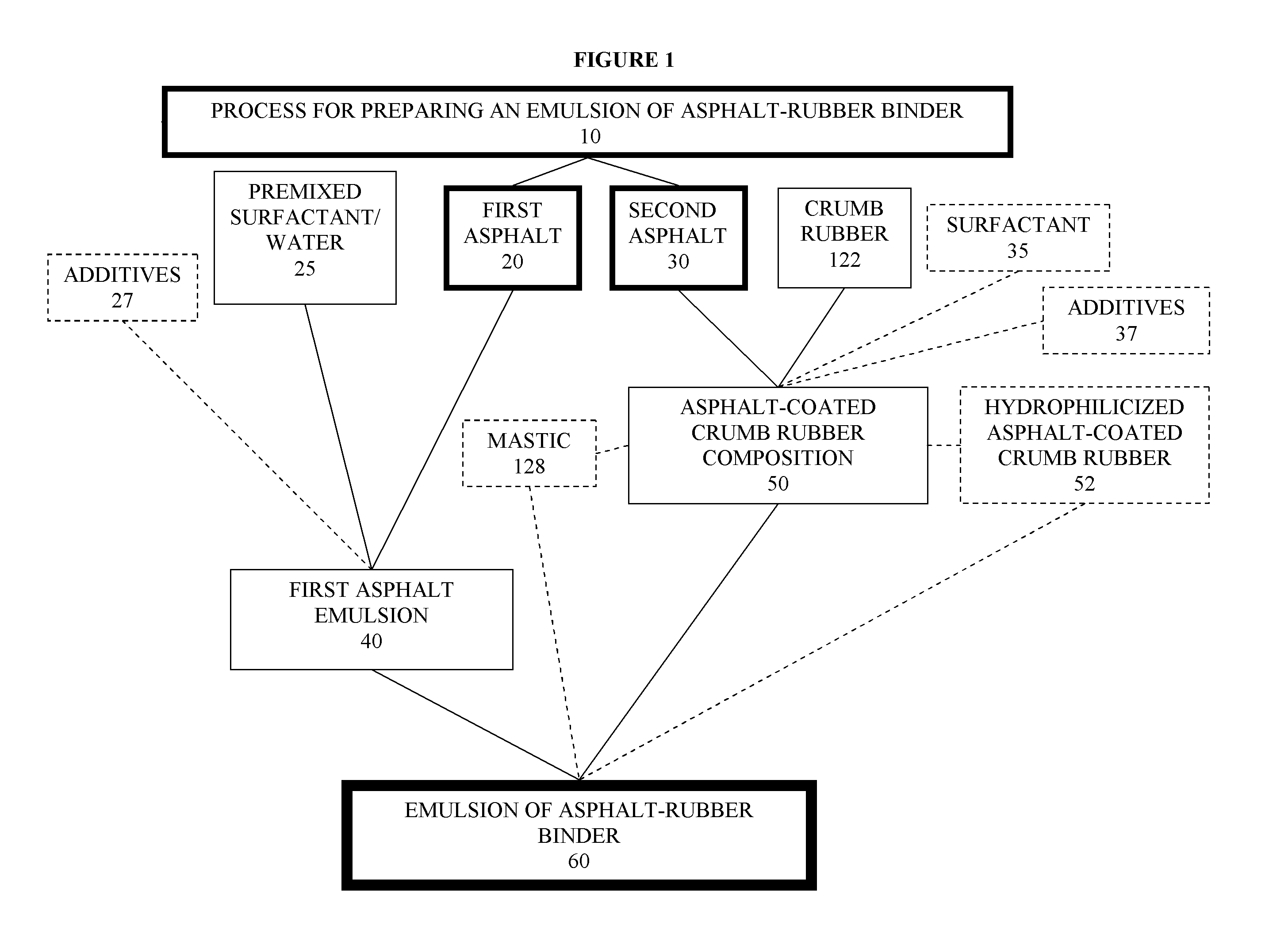

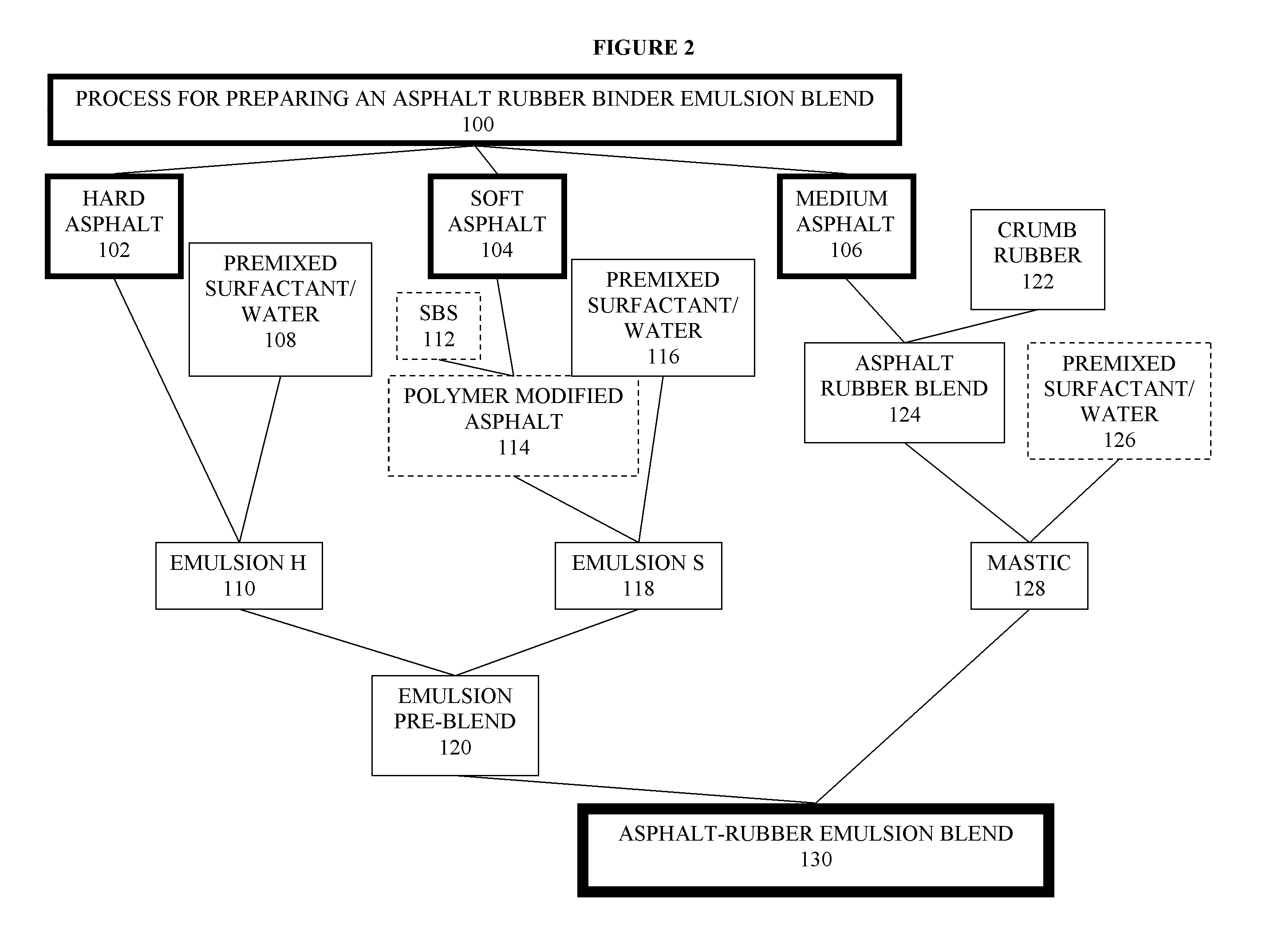

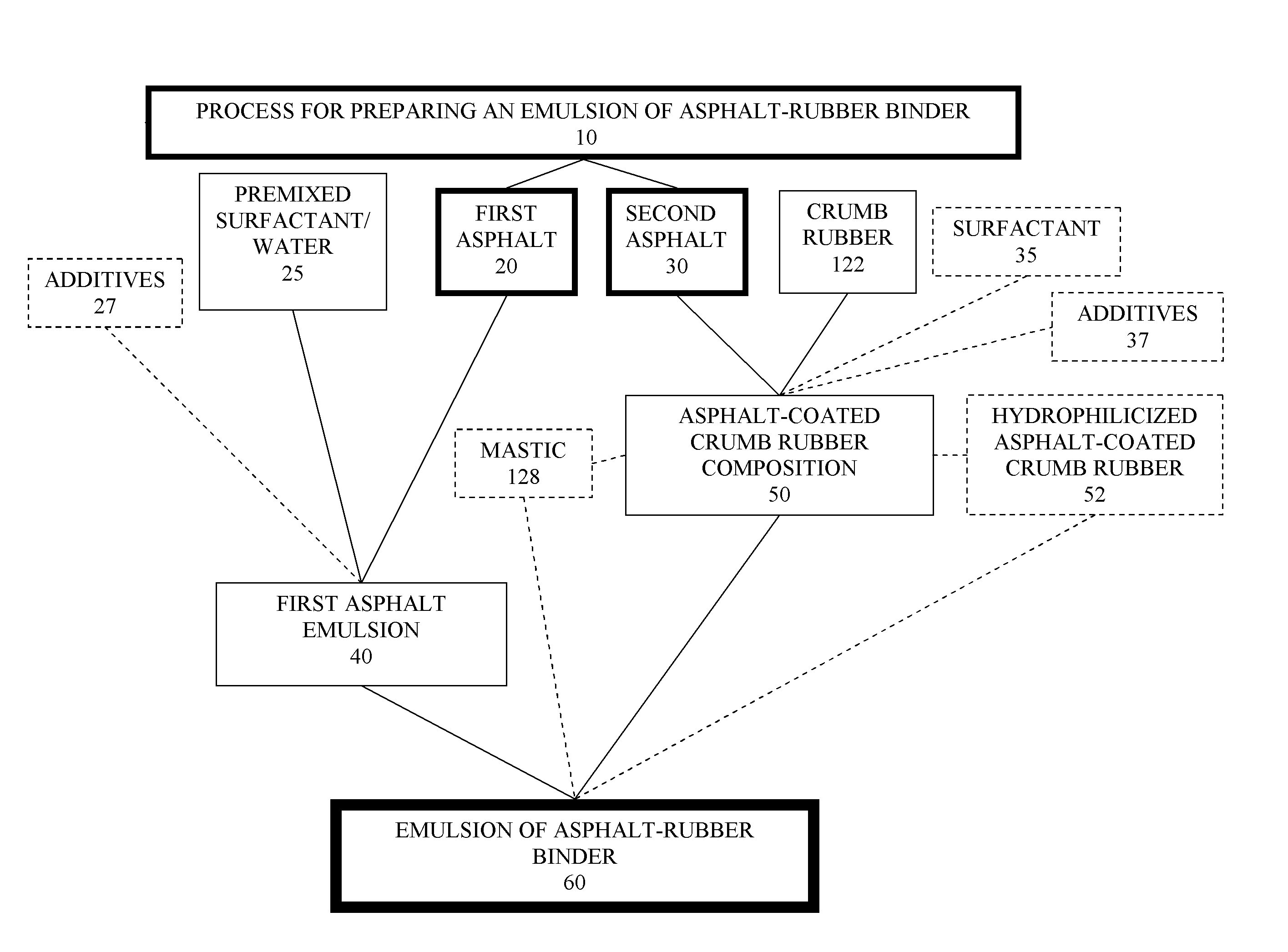

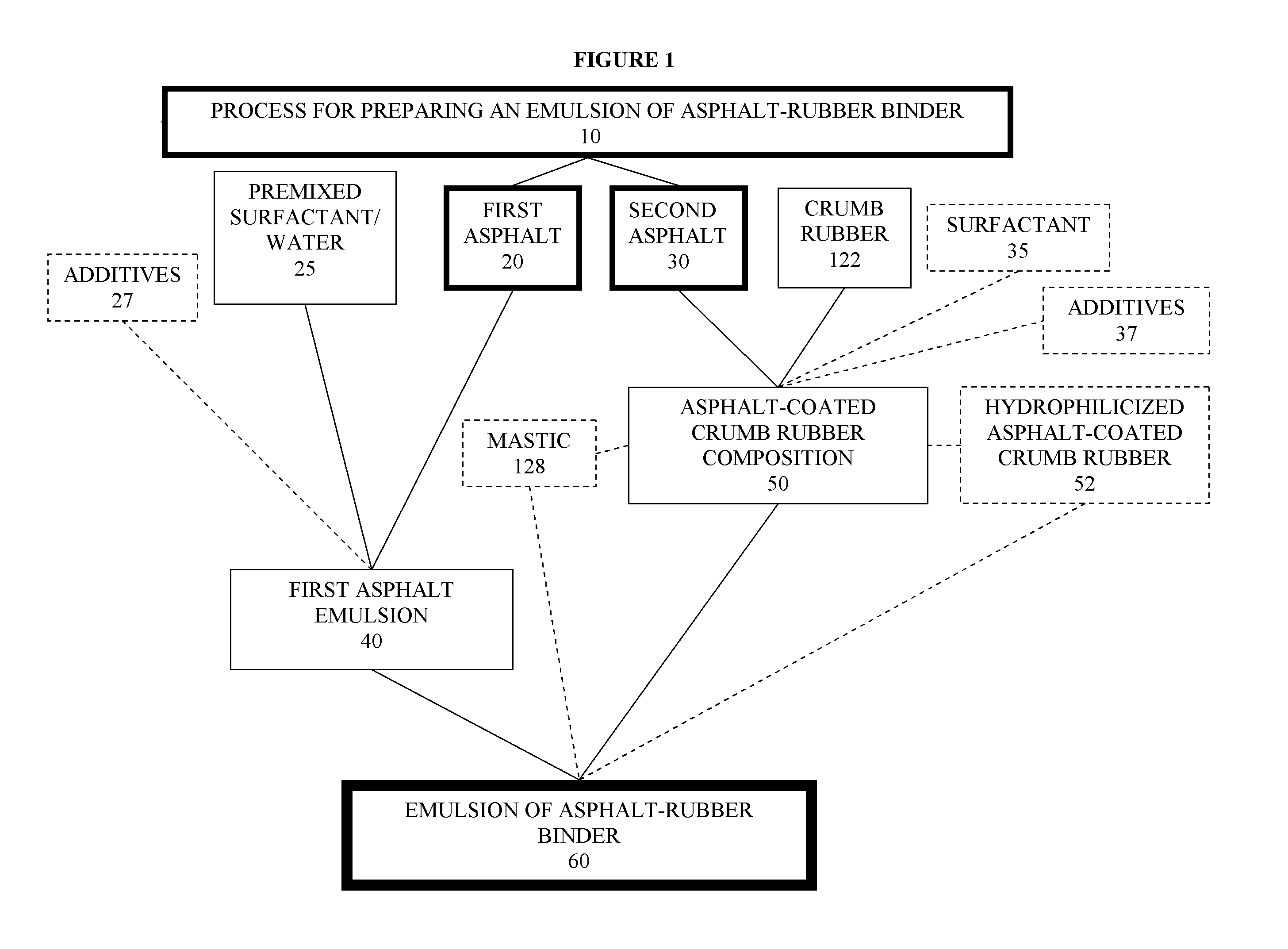

Asphalt-rubber compositions and systems and methods for preparing same

ActiveUS8808445B2Temperature insensitiveEasily applied to road surfaceBituminous material adhesivesBuilding insulationsEngineeringCrumb rubber

Owner:COE WILLIAM B

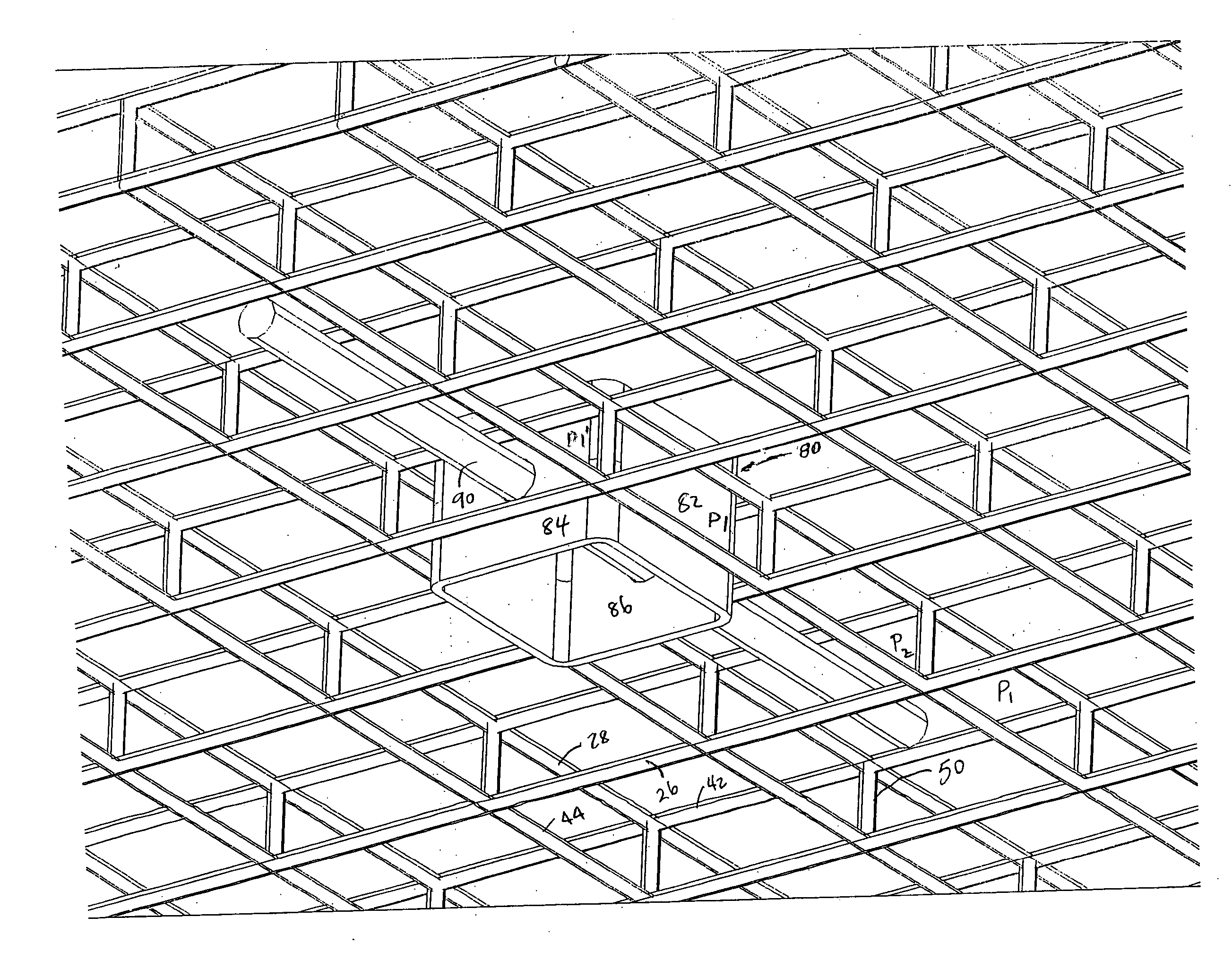

Temporary road element

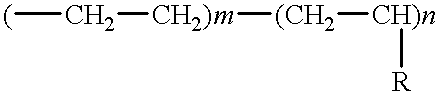

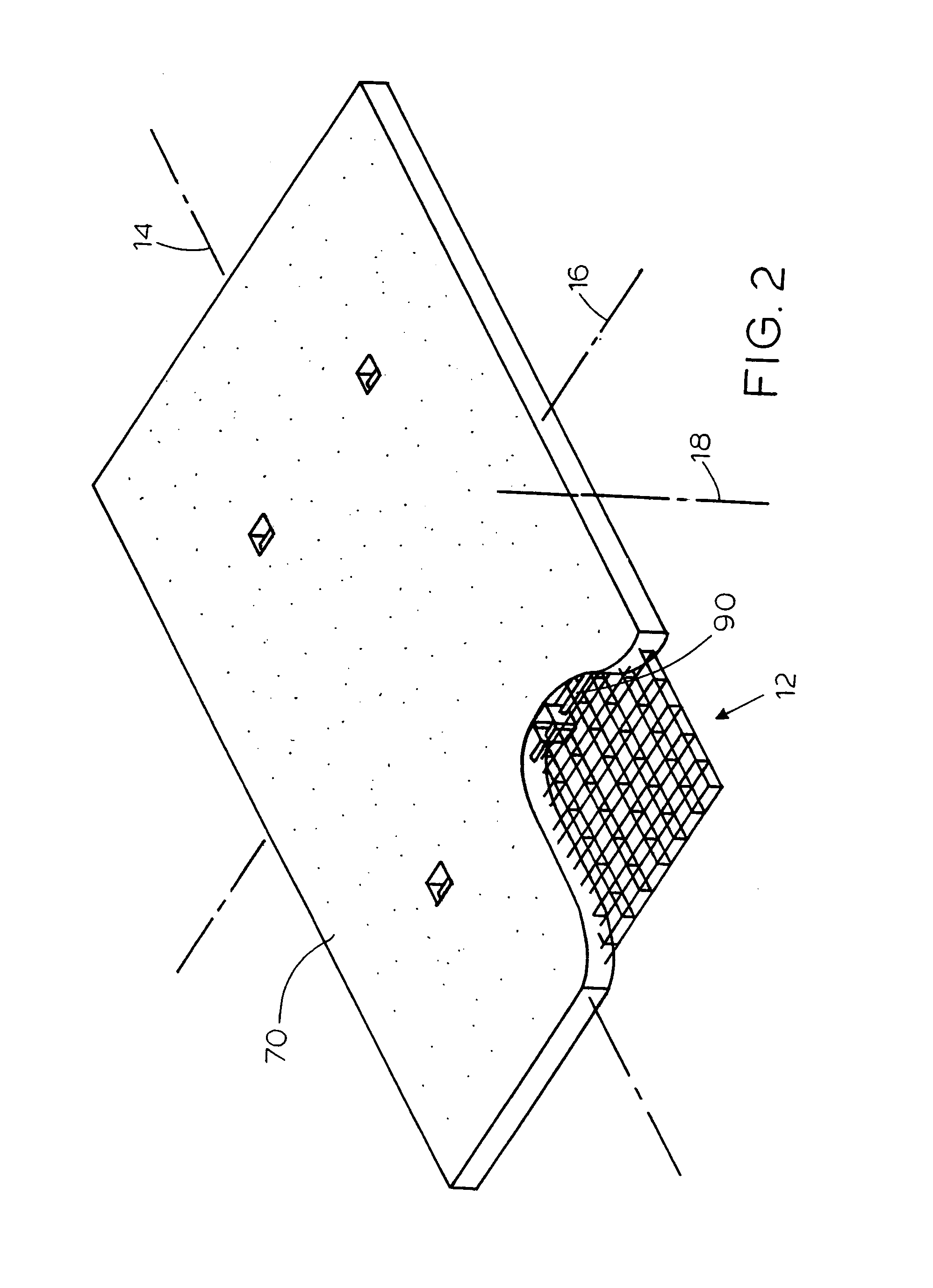

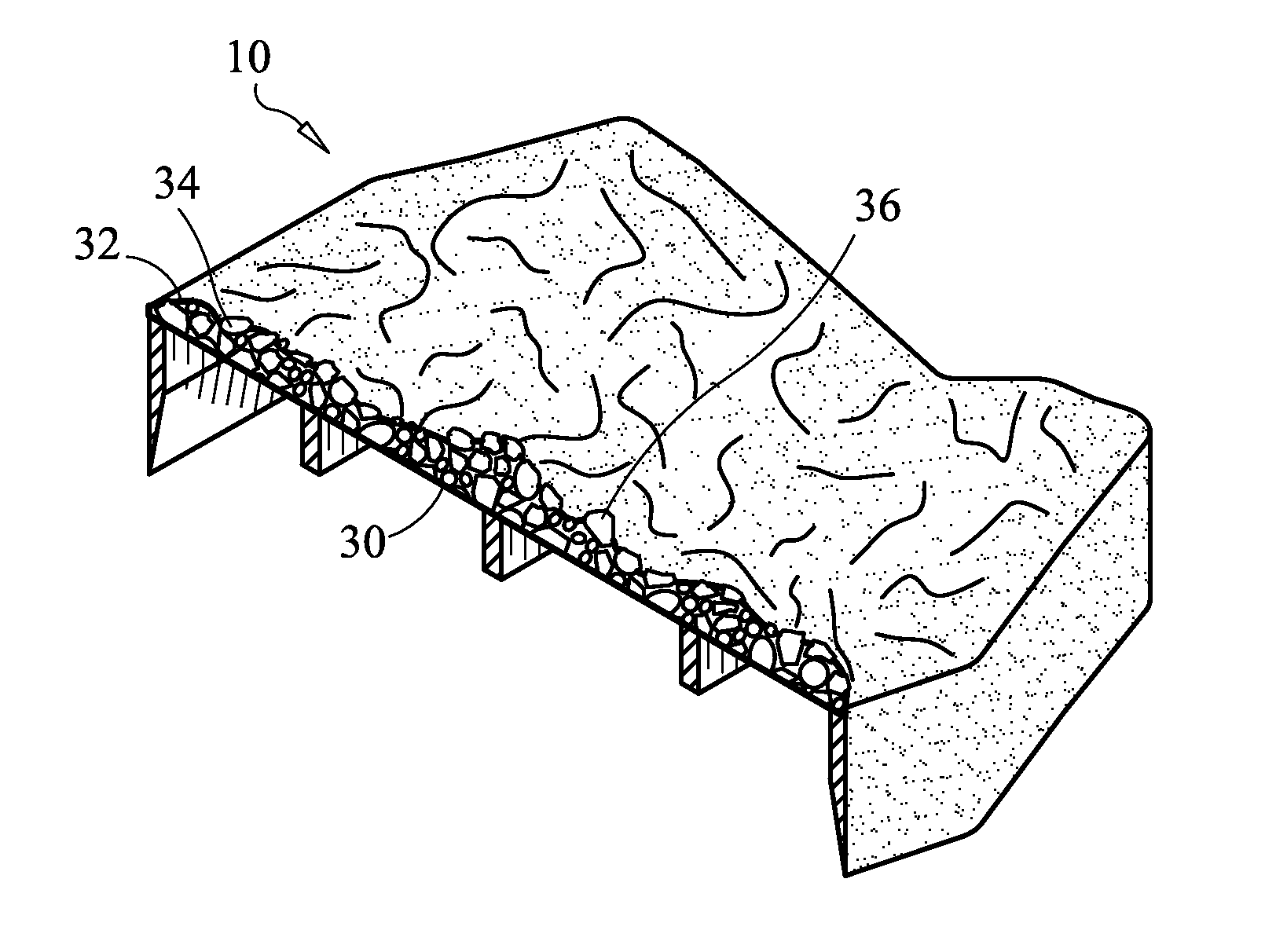

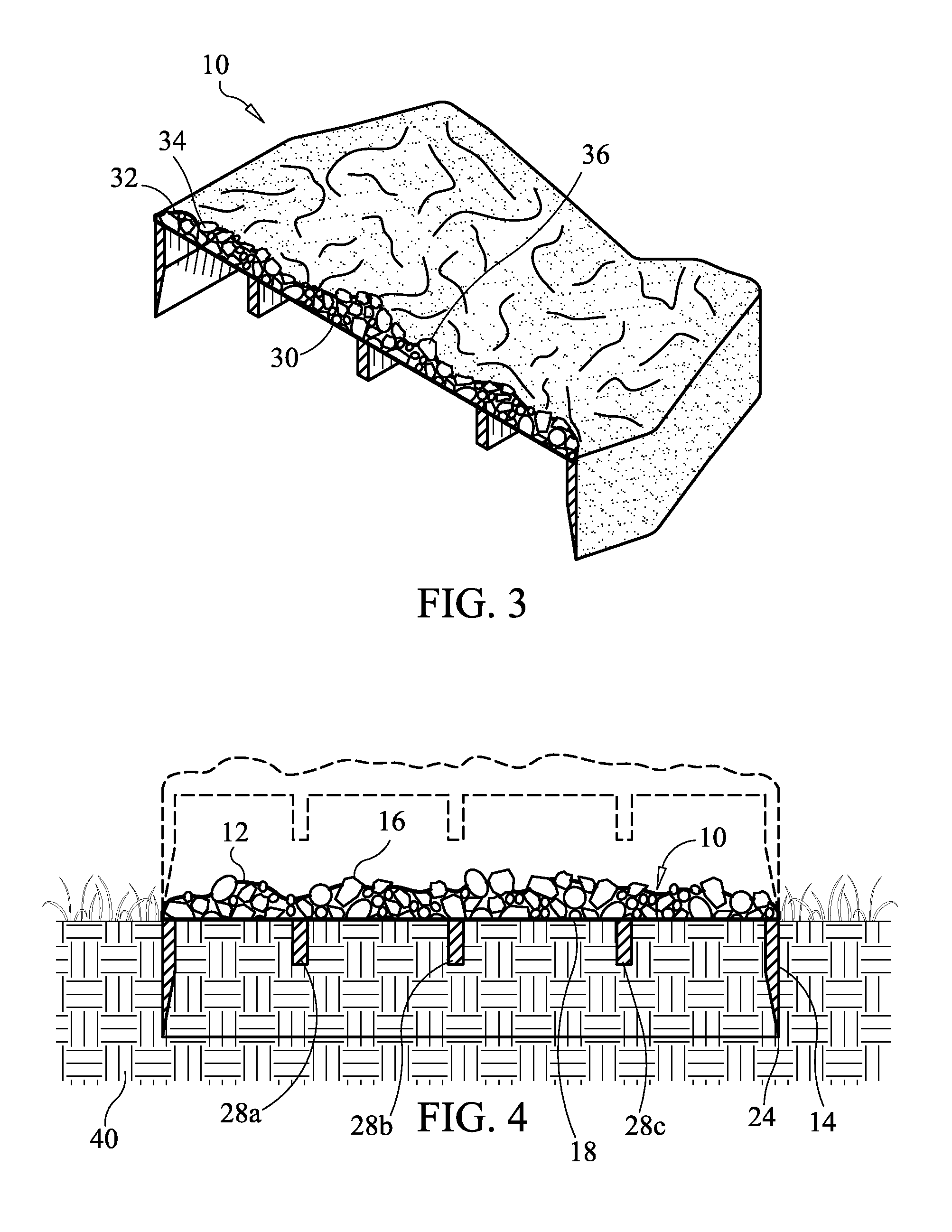

ActiveUS20070237581A1Stable and secure and long lastingSingle unit pavingsTemporary pavingsFiberRebar

A road element is formed of a one-piece cage that includes two layers of orthogonally arranged rebars which are welded together. The layers are connected by connecting rebars that are welded to the rebars of the layers at the intersections and the one-piece cage is encased in a flexible material formed of crumb rubber, urethane, and fibers from land vehicle tires. Plates can be included with the one-piece cage to further enhance the strength of the element.

Owner:CHAMPAGNE EDITION

Method for producing agglomerates having rubber and wax, agglomerates produced according to the method, and use of the agglomerates in asphalt or bitumen masses

A method for producing bulk good of agglomerates made of rubber particles and wax. A composition of the agglomerate and the use of the bulk good to produce asphalt or bitumen masses are created in that rubber is activated by swelling and using a swelling agent and a melt made of viscosity-reducing wax and of optional polyoctenamer is added, the activated rubber particles are agglomerated by means of the viscosity-reducing wax and optional adhesion-improving substances. The resulting larger volume leads to a viscosity reduction and the softening leads to a more intimate and more homogeneous wetting with the wax and, in the mixed good to be produced, a viscosity reduction remaining stable in the mixed good for <180 min and an increased stability of the cross-linking of the rubber molecules among each other after the agglomerates have been incorporated are achieved.

Owner:STORIMPEX ASPHALTEC GMBH +1

Resilient floor surface

InactiveUS20040069924A1Easy to installEasy maintenanceSynthetic resin layered productsGround pavingsEngineeringSynthetic rubber

A resilient floor surface for indoor and outdoor, residential, commercial and sporting applications includes a resilient underpad formed of expanded polypropylene product ("EPP") and suitable for being laid down directly on the ground or other subfloor surface in a floating arrangement not requiring securing to the ground or other subfloor surface, and a floor covering material applied upon the resilient underpad as a covering for the resilient underpad. The surface covering is of the type suitable for floor surfacings, sport playing surfacings and decorative and sports surface coatings, and is selected from hardwood flooring, synthetic rubber and / or plastic flooring tiles and panels, rubber flooring tiles and panels, laminated wood flooring, residential and commercial carpets, crumb rubber surface coatings, EPDM (ethylene-propylene terpolymer) surface coatings, polyurethane surface coatings and any other suitable coatings. The resulting floor surface is shock-absorbing, sound and heat insulating, waterproof, lightweight, and durable, and is less expensive and easier to install than other flooring systems, due to the elimination of the multiple components required in prior flooring systems.

Owner:LEMIEUX ALAIN +1

Aqueous crumb rubber composition

A fluid or semifluid additive composition useful for asphalt paving comprises between about 10% and about 50% crumb rubber, about 10% and about 50% petroleum hydrocarbon having at least about 50% aromatics, between about 10% and about 50% surface active clay, and water, by weight.

Owner:FLEX PROD LLC

Modified asphalt binder material using crumb rubber and methods of manufacturing a modified asphalt binder

ActiveUS20060243163A1Increase elasticityAcceptable rotational viscosityIn situ pavingsBuilding insulationsEngineeringTruck

In a first aspect, bituminous asphalt binder materials which are modified by the addition of crumb rubber or ground tire rubber are described. In a second aspect, the present invention is directed to methods of producing a modified asphalt binder containing crumb rubber or ground tire rubber. The modified asphalt binders comprise neat asphalt, crumb rubber, one or more synthetic polymers, and one or more acids. The crumb rubber may be obtained from recycled truck and / or automobile tires.

Owner:INNOPHOS INC

Process and apparatus for manufacturing powder rubber

Owner:LEHIGH TECH INC

Rubber Compositions, Methods of Making Rubber Compositions Rubber and Rubber-Containing Articles

InactiveUS20070231532A1Improve bindingEnhancing tuft lockTextile/flexible product manufactureConstructions elementsCompression moldingPolymer science

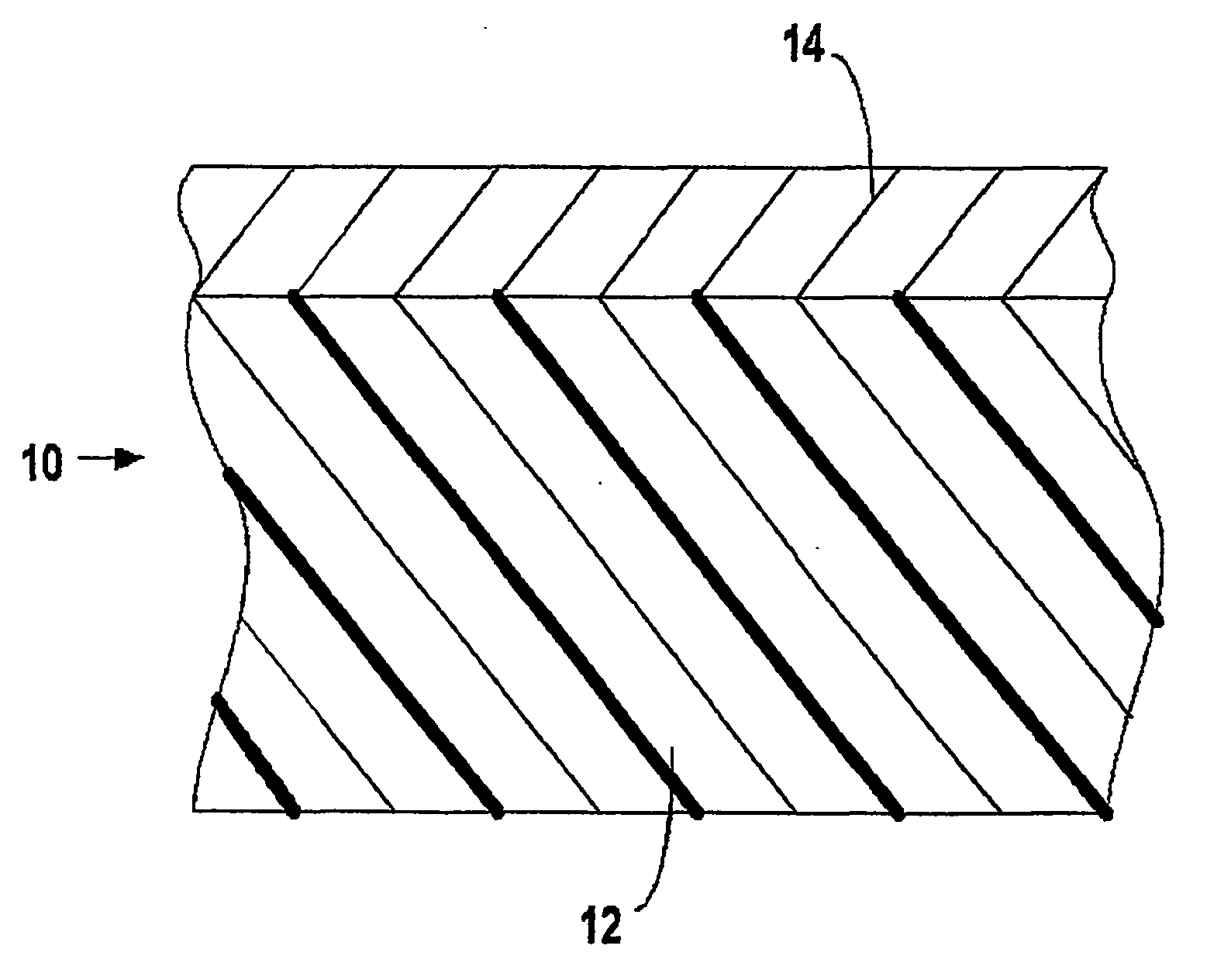

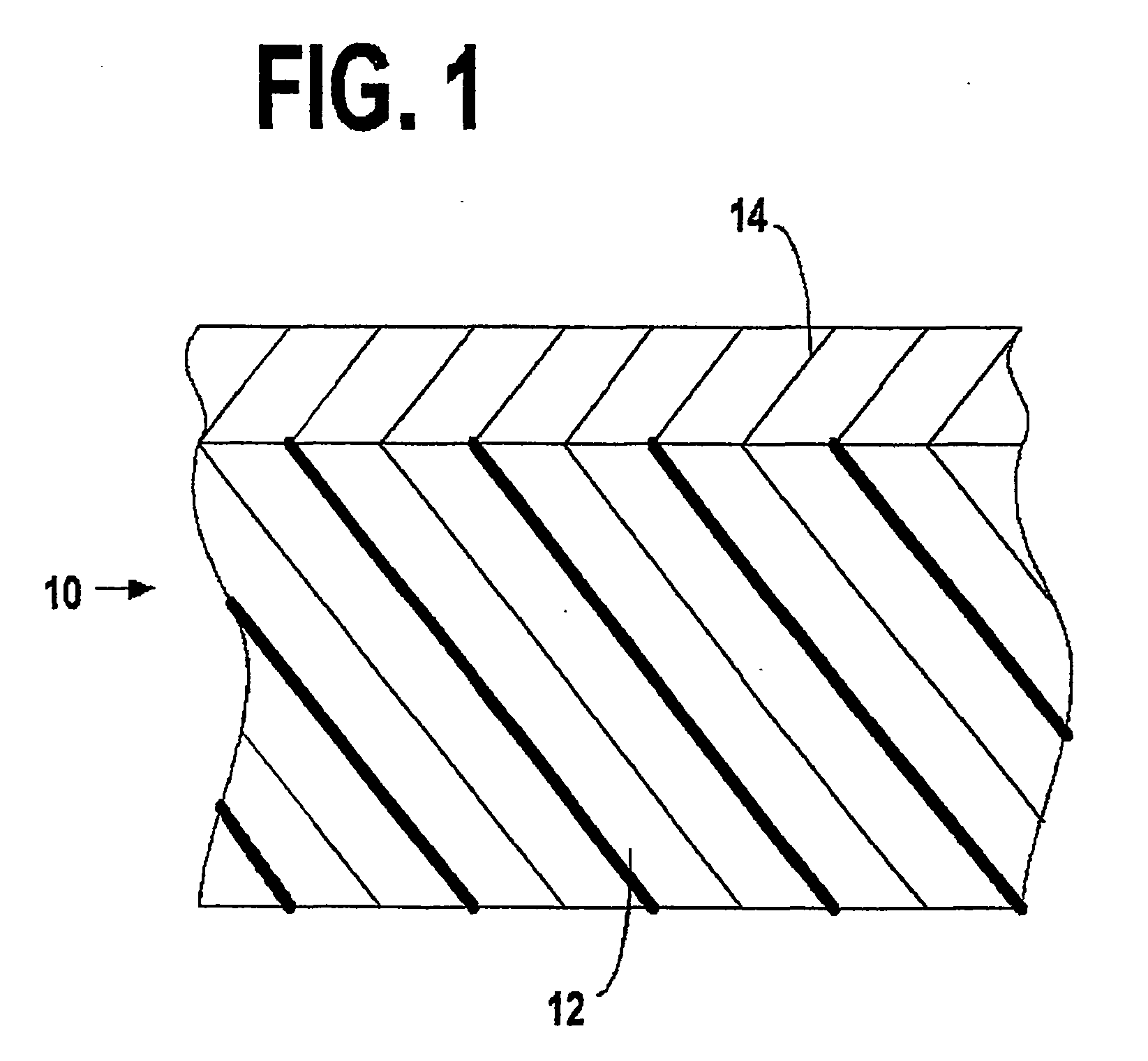

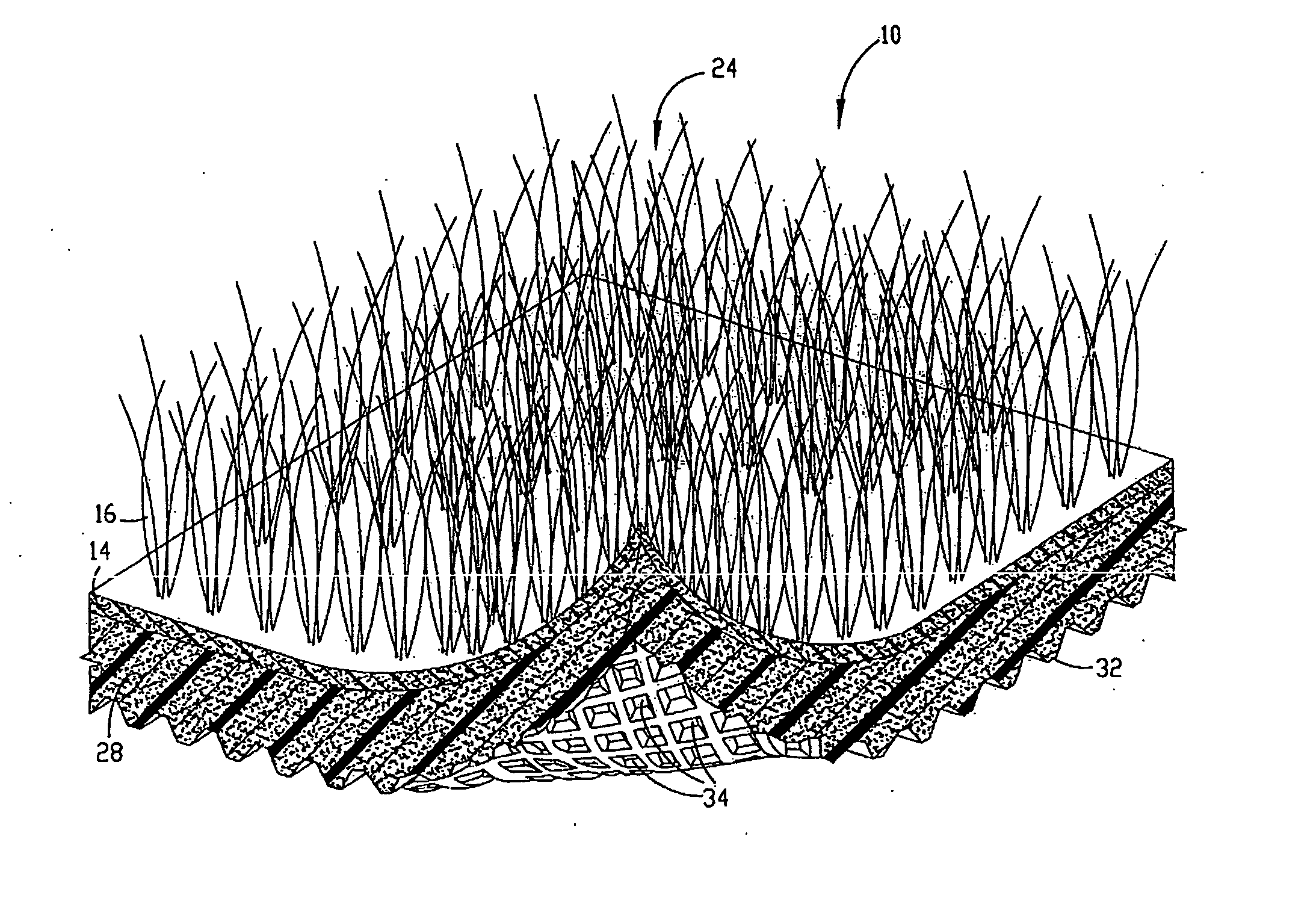

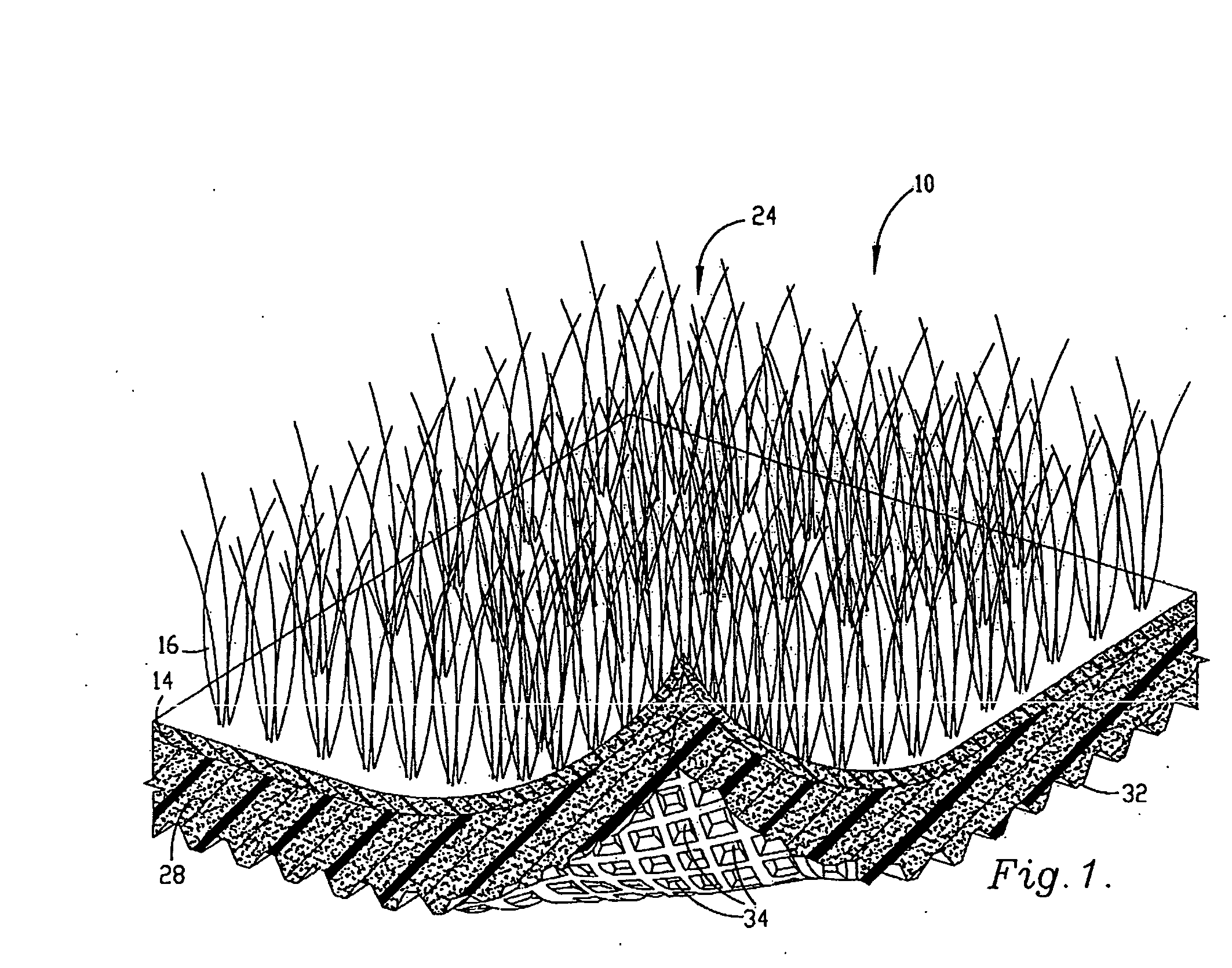

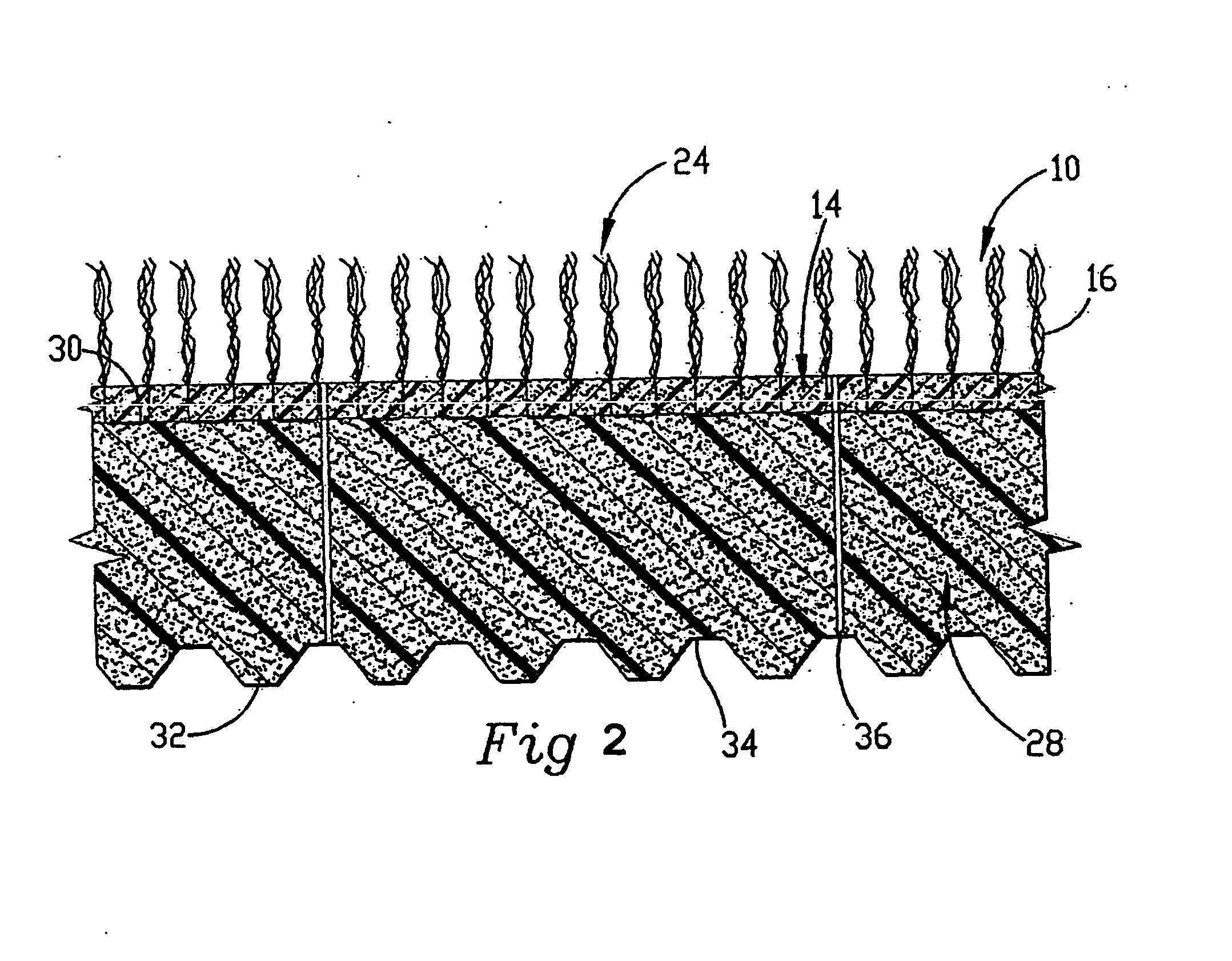

The application discloses coherent, processable rubber compositions containing cured rubber particles, especially recycled crumb rubber, dispersed in a curable base rubber. A processable composition, particularly one which can be roll-processed into a self-sustaining web is achieved by including in the curable rubber a low-viscosity curable rubber component such as a liquid rubber. This component wets the crumb rubber enabling it to disperse fully during mixing and connect intimately into the structure upon curing. This technique enables larger quantities and / or smaller particle sizes of the crumb rubber to be successfully incorporated while maintaining processability. Inert fillers can be used or omitted, reducing density. The novel rubber compounds are particularly suitable for making into layer products such as mats and flooring materials. Desirably these are laminated with fabric such as tufted textiles. This can be done in a compression moulding process.

Owner:HAYDALE

Energy saving soundproof mortar for house wall

The invention relates to energy saving soundproof mortar for a house wall. The energy saving soundproof mortar is characterized in that (1) the thermal performance and the soundproof effect of the mortar are improved by adopting a tri-admixture composite technology and the internal composite superimposed effect of materials; and (2) composite mixing is carried out on hollow float beads with closed cavity structures, EPS particles, rubber particles, cement, rubber powder, cellulose ether and fibers under the conditions that the temperature is greater than or equal to 5 DEG C, and the humidity is greater than or equal to 50%. The energy saving soundproof mortar has the advantages of simplicity in operation, strong cohesive force, non pollution, good thermal performance and soundproof performance and application to the soundproof and thermal insulation aspects of the house wall.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

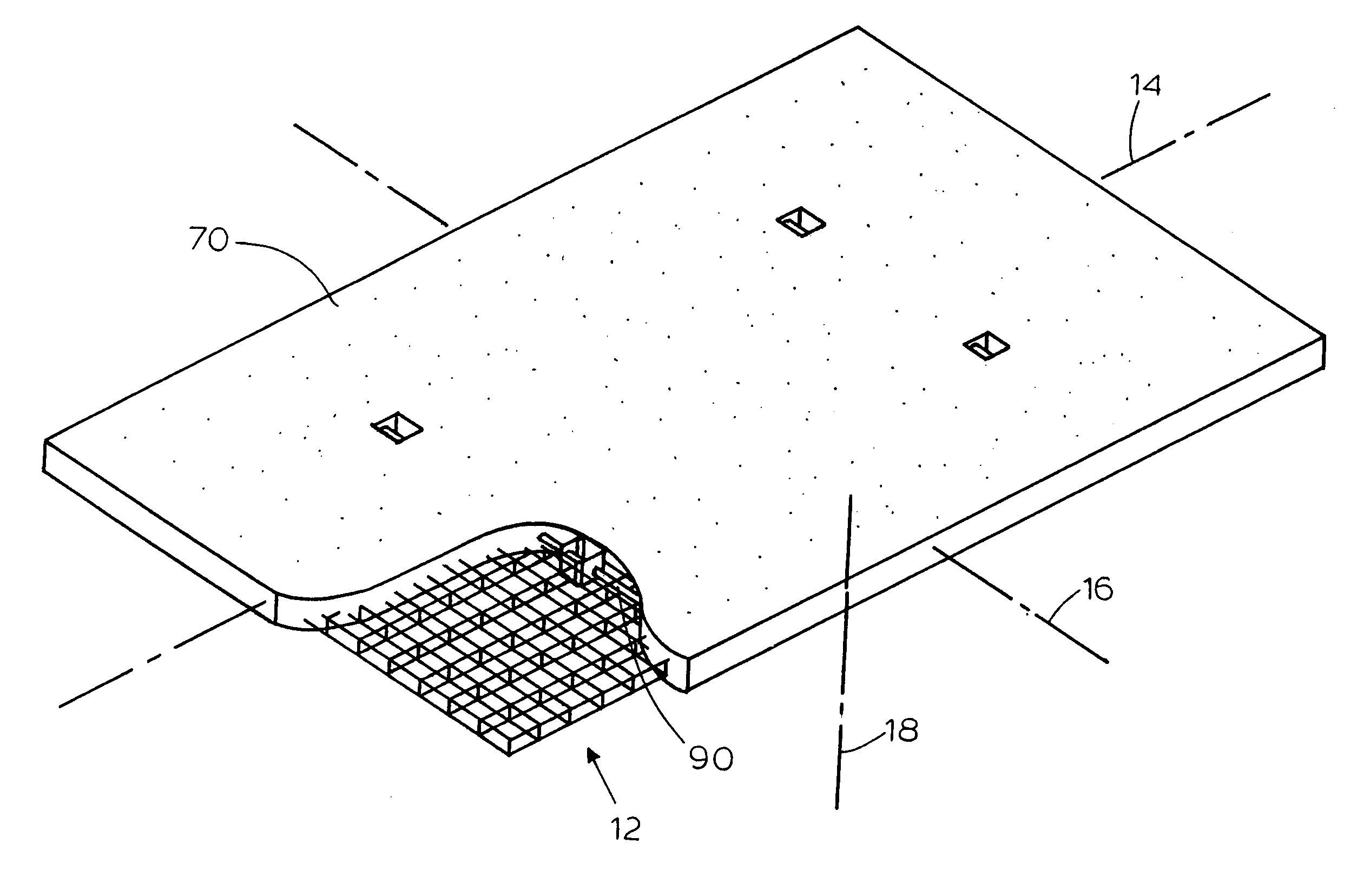

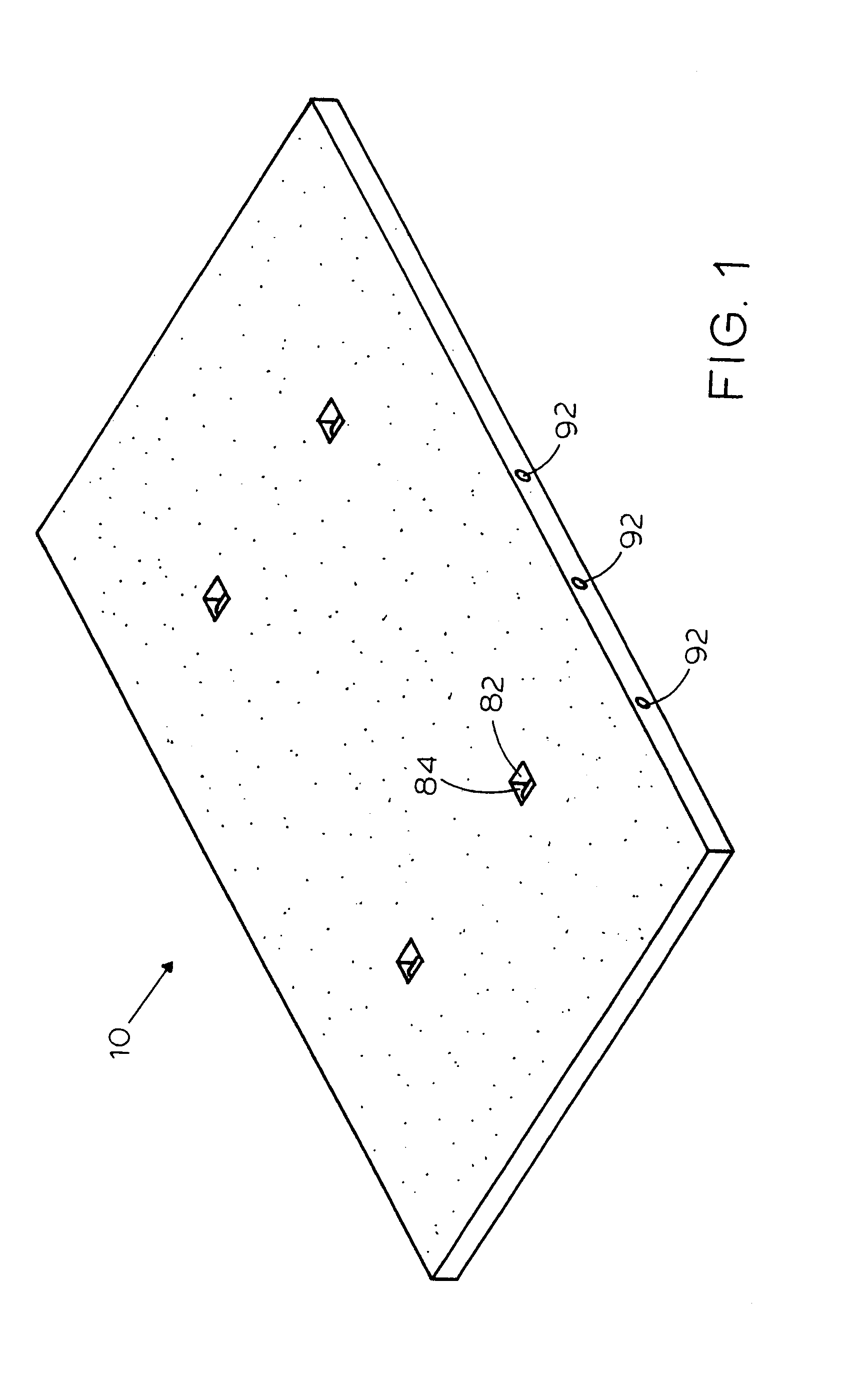

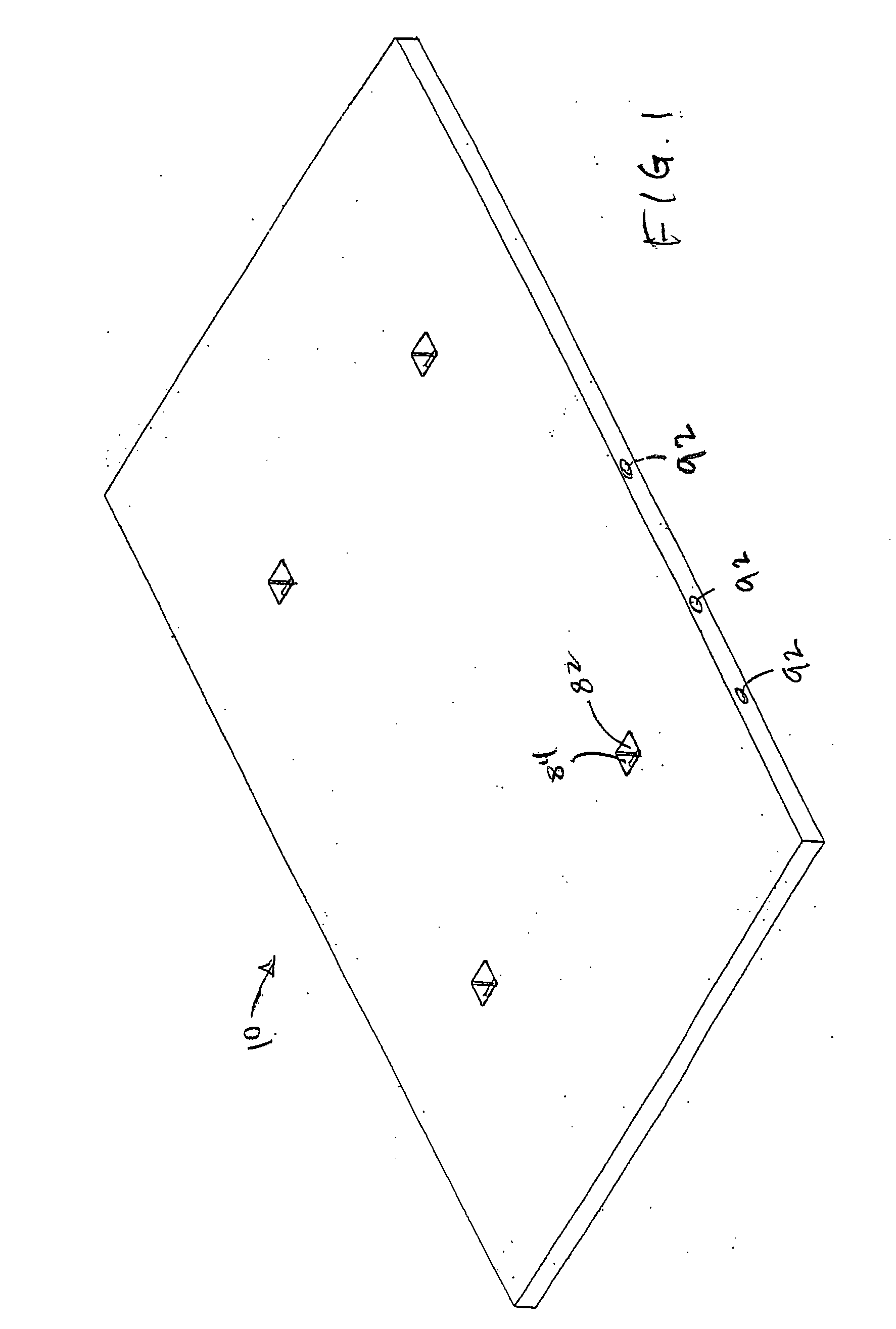

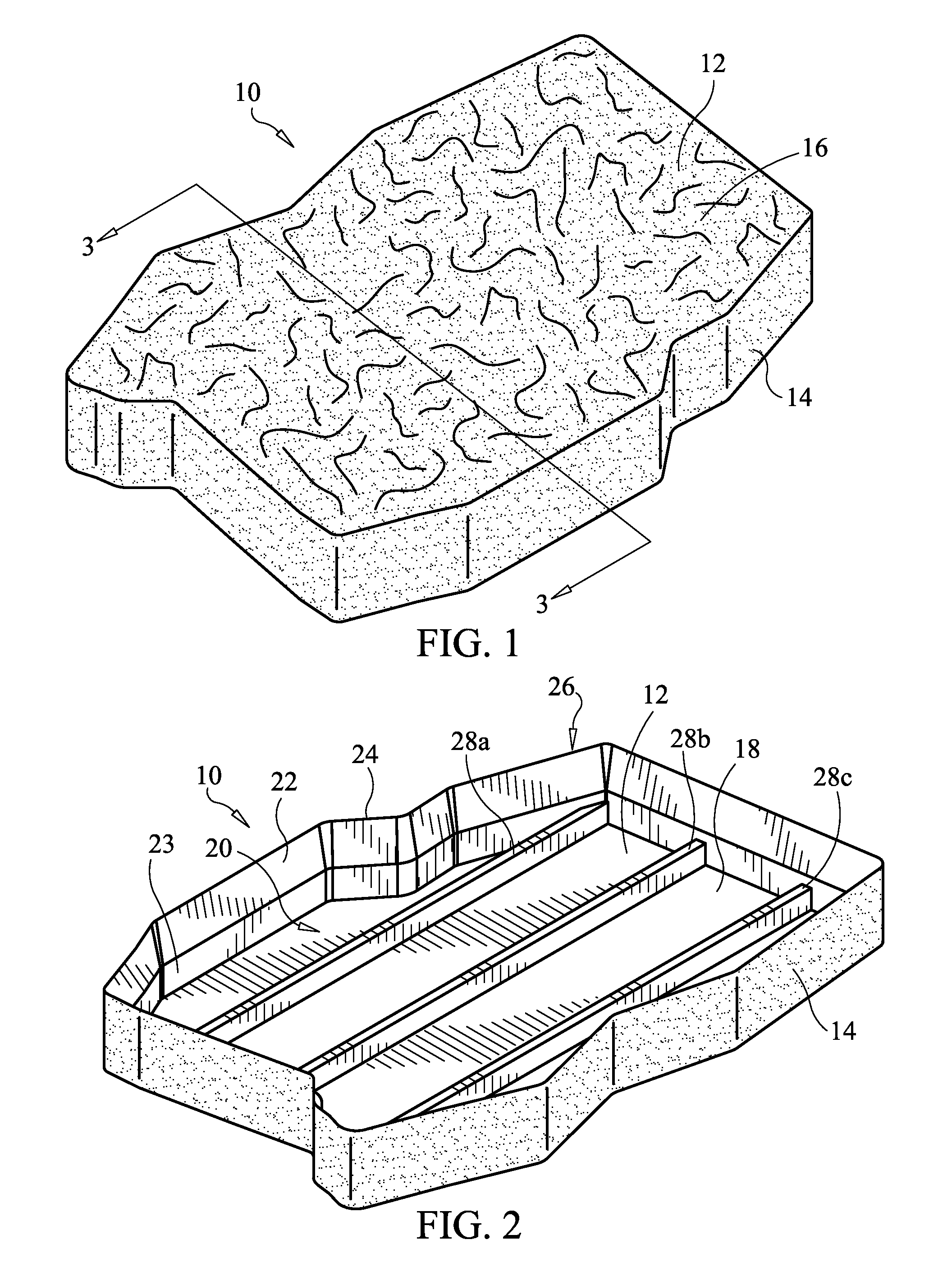

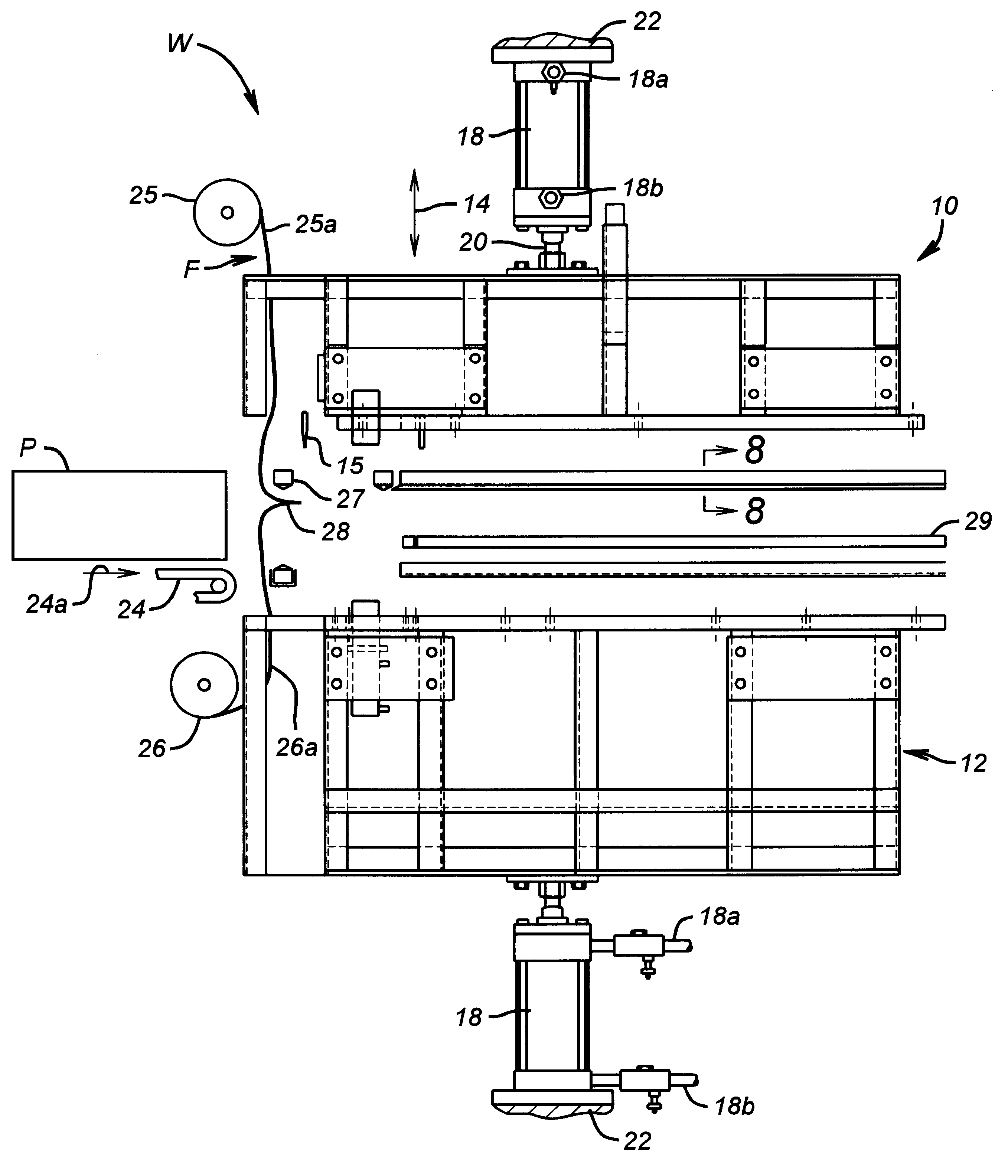

Paving block formed of rubber crumb and a method of manufacturing the same

ActiveUS8282311B2Easy to set upRestricts lateral movementSingle unit pavingsSidewalk pavingsPolyolefinEngineering

A hollow paving block comprises a substantially planar member having a first surface and a second surface opposite the first surface. The first surface of the planar member is a textured surface which functions as a top of the paving block. A side wall extends along and away from a periphery of the second surface of the planar member to define a cavity in the paving block. The side wall has a bevelled edge which extends about a mouth of the cavity. At least one protrusion extends along the second surface of the planar member. The paving block is formed in part from crumb rubber and polyolefin.

Owner:INPRESS TECH

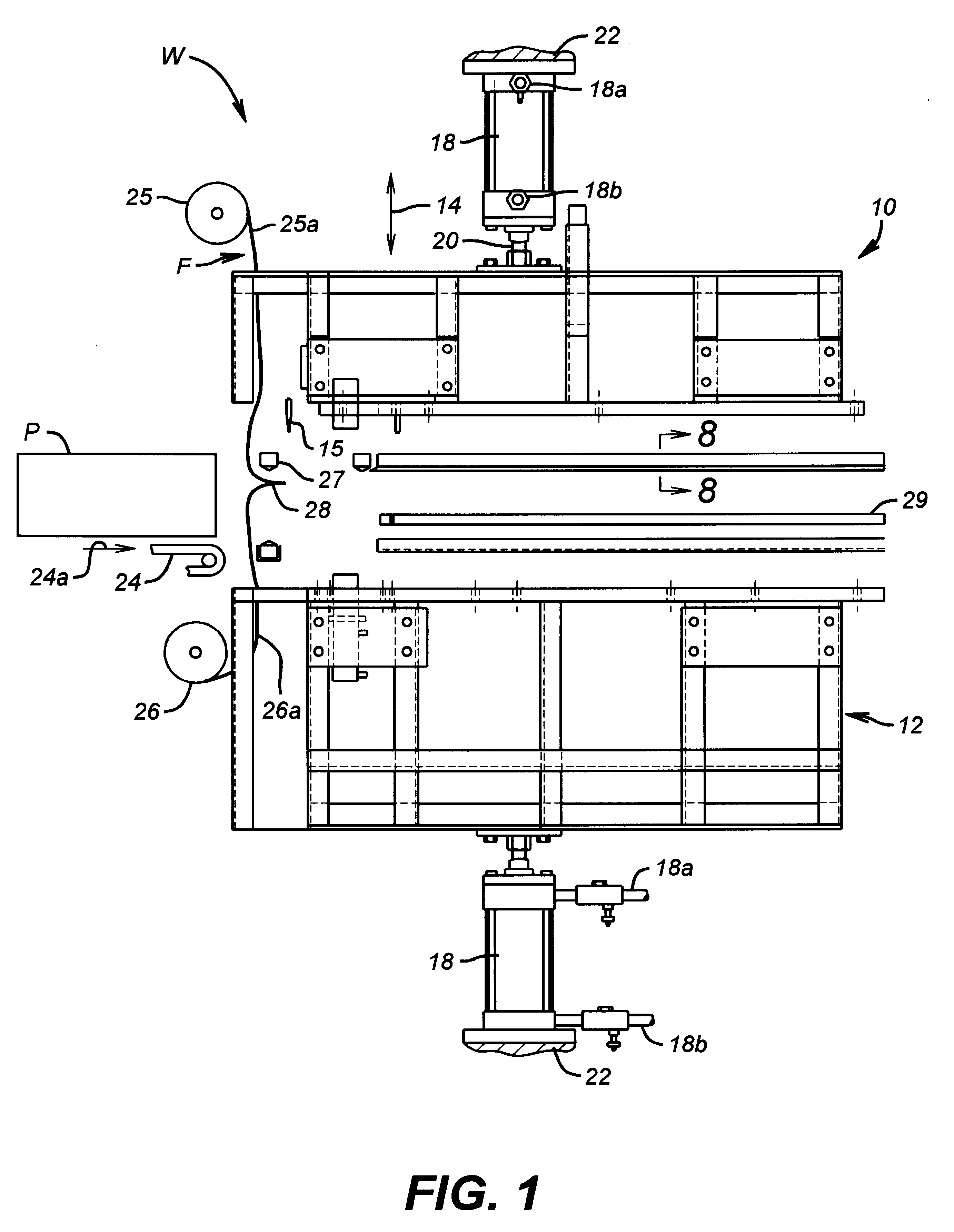

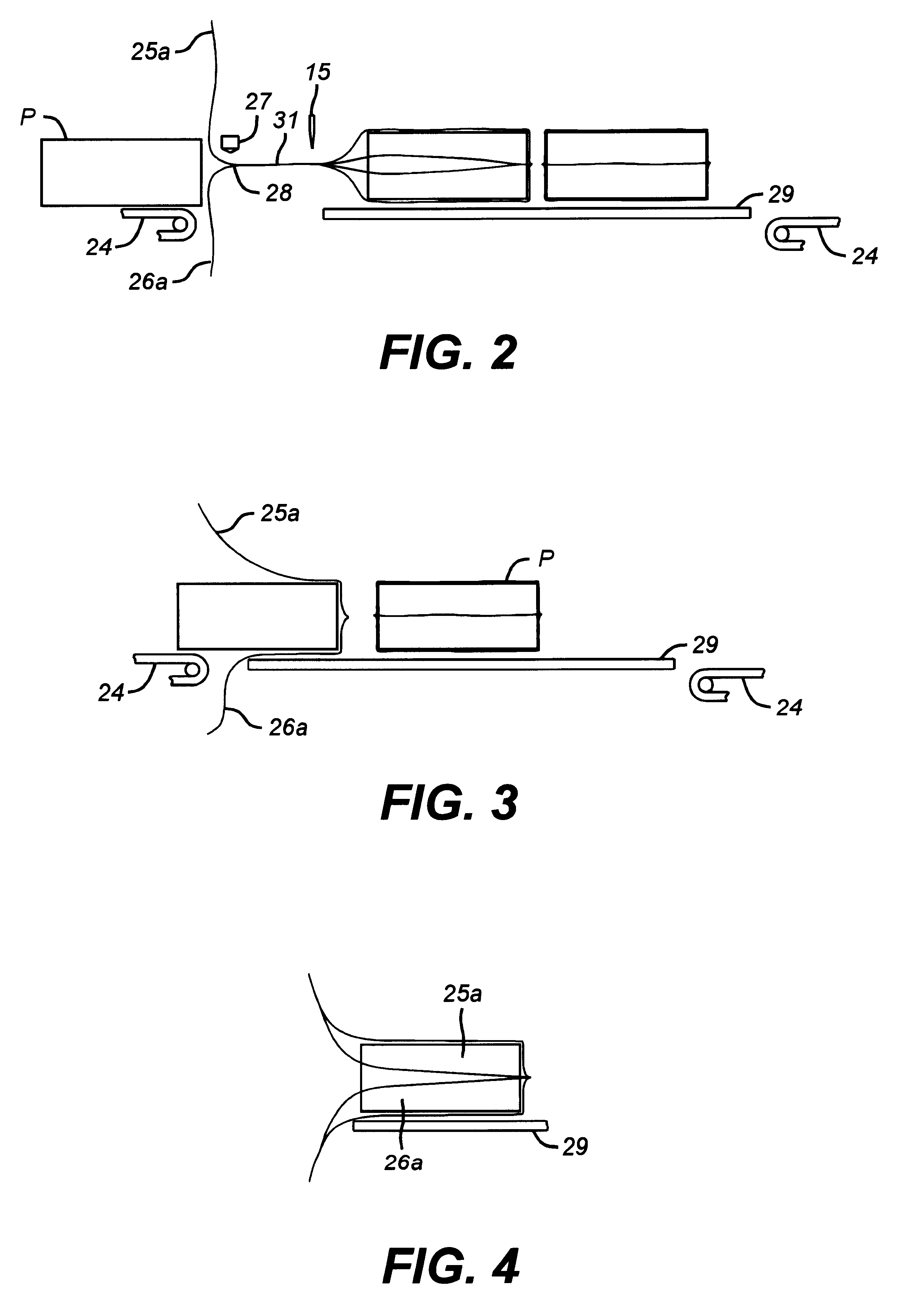

Wrapping machine with sealing jaw assembly for baled products and packages

InactiveUS6256969B1More uniformly heatedEliminating hot and cold spot in heating elementWrapper twisting/gatheringPressesCold spotEngineering

A machine wraps packages such as bales of crumb rubber, or other containers of goods, into a protective synthetic resin film bag or cover. The machine is provided with a set of movable jaws each having a heat-sealing frame assembly having improved heat transfer characteristics. The heat-sealing frame assembly is composed of heat sealing units which have enhanced heat distribution and reduced cold spot or no-seal areas, and also reduced hot spot burn-through. Heat transfer from the heat sealing elements to the remaining portions of the baling assembly is also reduced.

Owner:KARLTEX MACHINE

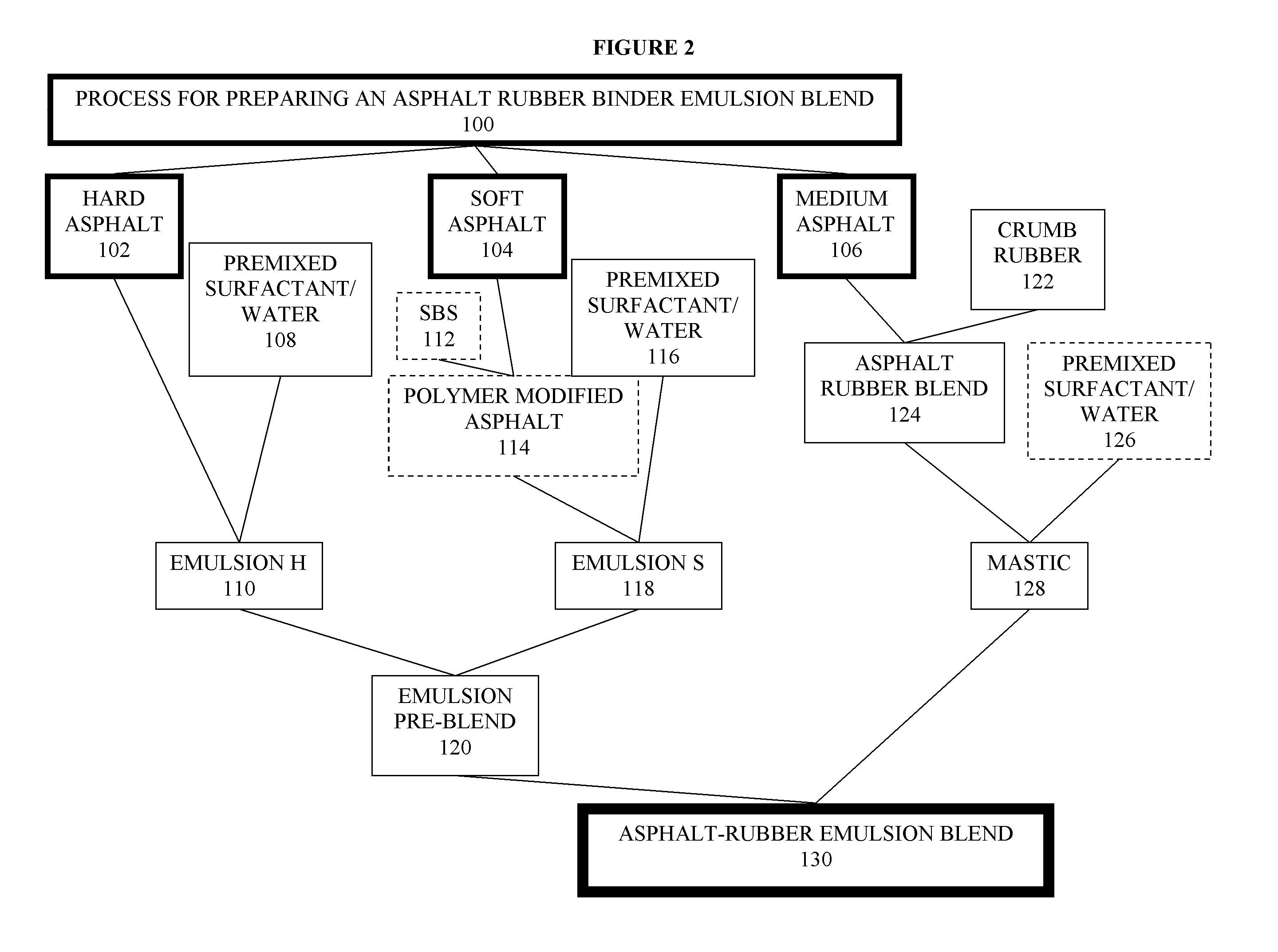

Asphalt-rubber compositions and systems and methods for preparing same

ActiveUS20100168274A1Temperature insensitiveEasily applied to road surfaceBituminous material adhesivesBuilding insulationsEngineeringCrumb rubber

One embodiment provides a process for preparing an asphalt-coated crumb rubber composition that meets the specification set forth in ASTM D80-02 or deviations thereof which may be established by the specifying agency from time to time. The process generally comprises obtaining asphalt of different penetration grades, combining the asphalt of each grade with preselected chemicals to form separate premixed components, blending the premixed components together under predetermined conditions to form, upon curing, an asphalt-coated crumb rubber composition that meets certain physical requirements for asphalt-rubber binder (ARB), such as those set forth in ASTM D8-02. Advantageously, the resulting asphalt-coated crumb rubber composition not only meets the physical requirements of ARB used in road paving but also has improved dispersion of the rubber, such as dispersion of the rubber in an oil-in-water emulsion of an asphalt.

Owner:COE WILLIAM B

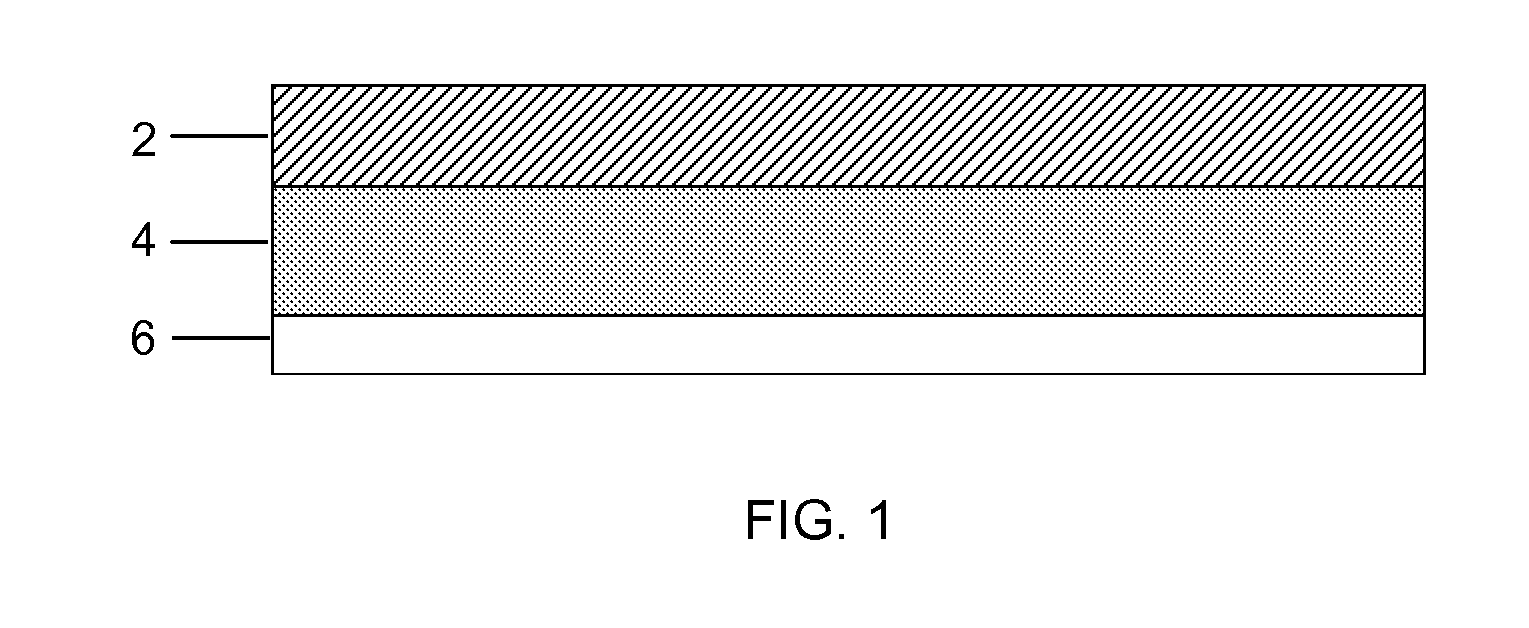

Resin composition for insulating layer for multi-layered printed board

InactiveUS20070264438A1Increase stickinessReduce roughnessLiquid surface applicatorsPrinted circuit manufactureEpoxyElectrical conductor

Epoxy resin compositions, which comprise (A) en epoxy resin having two or more epoxy groups in a molecule; (B) a phenol type curing agent where an average hydroxyl group content in a molecule (a mean value of (the total number of hydroxyl groups) / (the total number of benzene rings)), P, satisfies the equation 0<P<1; (C) a phenoxy resin; and (D) rubber particles, are suitable for use as an insulating layer of a multi-layered printed board in which, in spite of the fact that the roughness of a roughened surface after a roughening treatment is relatively small, an insulating layer having a good tight adhesion with a conductor layer formed by plating is able to be easily introduced into a multi-layered printed board.

Owner:AJINOMOTO CO INC

High strength concrete and preparation method thereof

InactiveCN105367026AHigh strengthSolution to short lifeSolid waste managementHigh strength concreteAggregate (composite)

The invention discloses high strength concrete and its preparation method, and relates to the technical field of building materials. 1 m<3> of the high strength concrete comprises the following ingredients: 200-300 kg of ordinary Portland cement, 40-50 kg of mineral powder, 15-30 kg of rubber particles, 500-800 kg of fine aggregate, 600-900 kg of coarse aggregate, 20-60 kg of a concrete composite additive, 50-100 kg of polypropylene fiber, 100-200 kg of water, 45-90 kg of phosphorous slag powder, 2-3 kg of a corrosion inhibitor, 5-10 kg of a water reducing agent, and 10-20 kg of a reinforcing agent. According to the prepared concrete product, compressive strength is remarkably raised, cracks are minimized, and life of concrete structures is prolonged. In addition, the preparation method is simple, and production efficiency is high.

Owner:张进

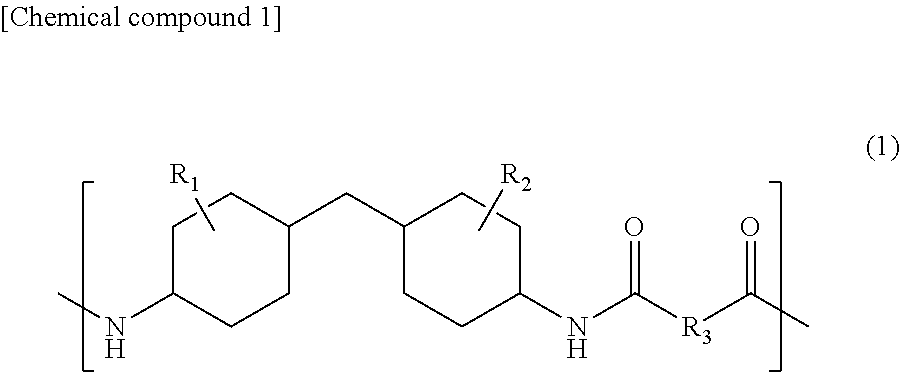

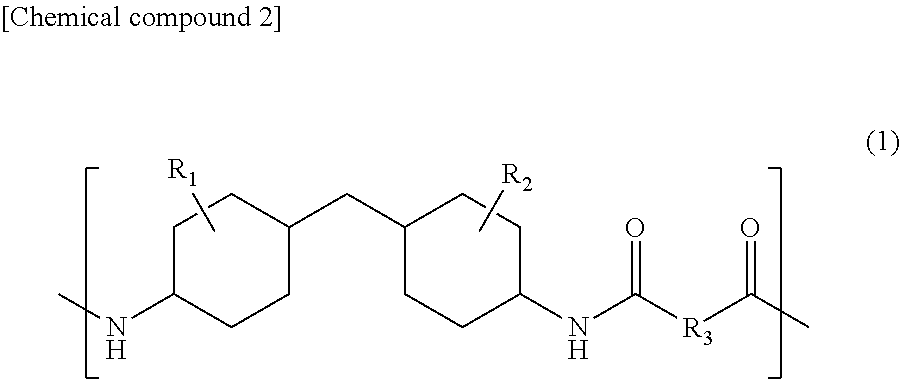

Epoxy resin composition for fiber-reinforced composite materials, prepreg, and fiber-reinforced composite material

Provided are: a fiber-reinforced composite material which has mode I interlaminar fracture toughness, mode II interlaminar fracture toughness and compressive strength under heat and humidity conditions at the same time; an epoxy resin composition for obtaining the fiber-reinforced composite material; and a prepreg which is obtained using the epoxy resin composition. An epoxy resin composition for fiber-reinforced composite materials, which contains at least the following constituent elements (A), (B), (C) and (D). (A) An epoxy resin (B) Resin particles that satisfy the following conditions (b1)-(b3) and are insoluble in an epoxy resin (b1) The particle size distribution index is 1.0-1.8. (b2) The particle sphericity is 90 or more. (b3) The glass transition temperature of the particles is 80-180° C. (C) At least one elastomer component that is selected from among block copolymers containing a block having a glass transition temperature of 20° C. or less and rubber particles (D) An epoxy resin curing agent

Owner:TORAY IND INC

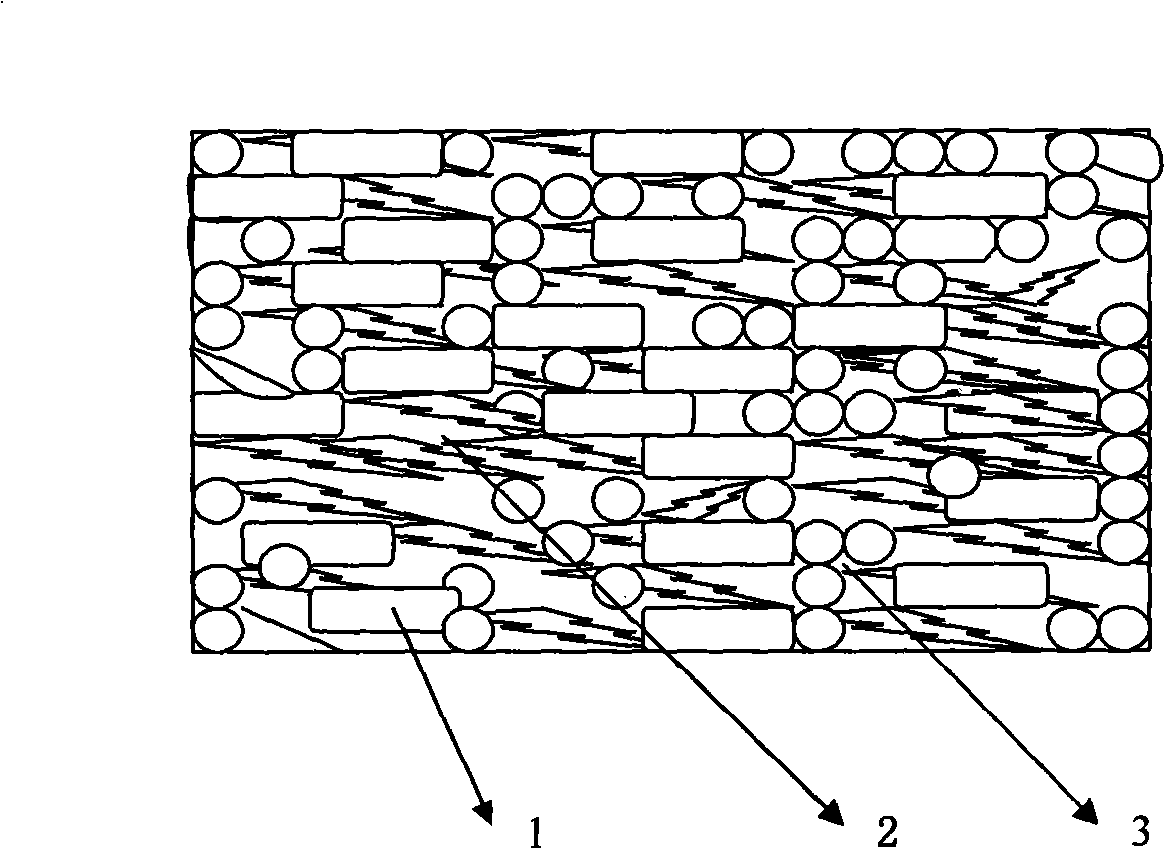

Rubber-wood-cement composite material

ActiveCN101298379AShorten the production cycleHigh degree of continuitySolid waste managementWear resistantAdhesive

The invention provides a rubber-timber-cement functional environment-friendly compound material, which belongs to the field of cement-base compound material. The material adopts the waste tire rubber, waste rubber products, woody material and silicate cement as raw materials, an isocyanate-based adhesive is coated on the surface of the waste rubber particles, then the woody material is soaked and dried, and the treated rubber particles, the woody material and cement are mixed to form a blank material, which is finally laid, pressed and cured so as to obtain the compound material. The compound material provided by the invention can absorb and insulate sound, has high shock resistance and damping property, and is wear-resistant, antistatic, mothproof, waterproof and anticorrosive; also the material is heat-insulating and friendly to the environment, etc.; the production process has no chemical pollution source, no radioactivity, no light pollution and no noise. The invention blazes a new path for solving the 'black pollution' of increasing waste tires, which is a global problem; additionally, the compound material can be used for producing structural lumber.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

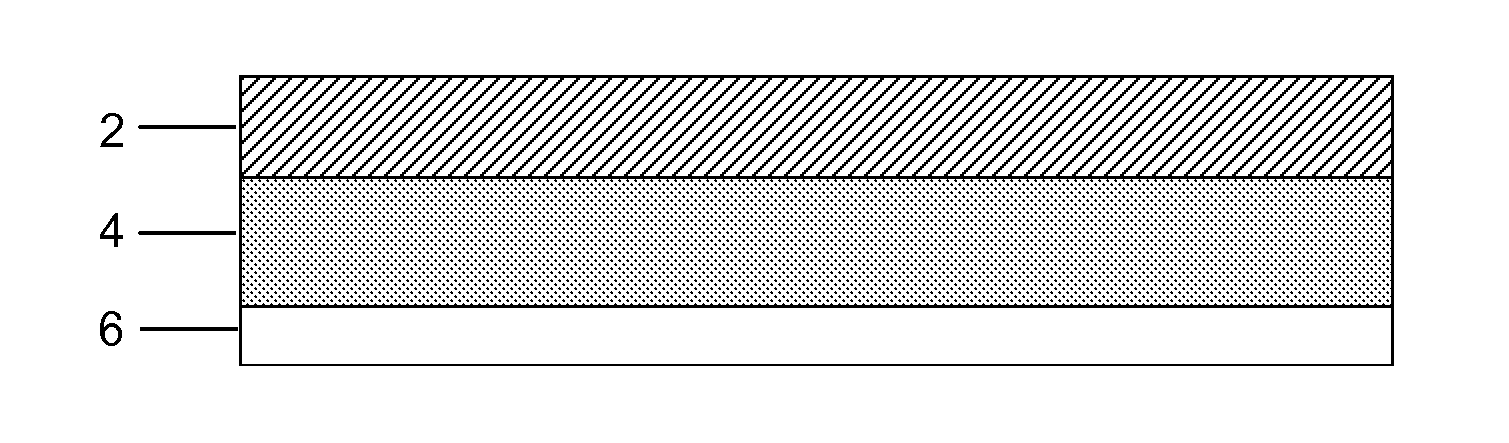

Waterproofing Membrane

ActiveUS20110052852A1Improve adhesionGood anti-sag performanceRoof covering using flexible materialsSynthetic resin layered productsLow-density polyethylenePolyolefin

Disclosed is a waterproofing membrane that performs well at both high and low temperatures. The waterproofing membrane comprises a carrier support layer and an adhesive layer, wherein the adhesive layer comprises a pressure sensitive bitumen composition comprising bitumen (asphalt), synthetic rubber, high density polyethylene, amorphous polyolefin, ground vulcanized crumb rubber and, optionally, a plasticizer. The waterproofing membrane also may optionally include a removable release sheet on the adhesive layer.

Owner:GCP APPL TECH INC

Thermoplastic elastomer composition and process for producing the same

InactiveUS20050038186A1Improve mechanical propertiesImprove scratch resistanceMeth-Thermoplastic elastomer

A thermoplastic elastomer composition of the invention, formed by dynamically crosslinking a polymer composition including a rubber and an olefinic resin and having an average particle size of rubber particles within a specific range, shows an excellent balance of mechanical properties such as flexibility and elastic recovery, and a moldability. Also an inclusion of a (meth)acrylate resin and a hydrogenated diene polymer provides a composition particularly excellent in scratch resistance. Also an inclusion of a maleimide compound provides a composition particularly excellent in injection fusibility. Also an inclusion of an undenatured organopolysiloxane of a specific viscosity and a denatured organopolysiloxane provides a composition particularly excellent in initial slidability and durable slidability.

Owner:ENEOS MATERIALS CORP

Reclaimed asphalt pavement

InactiveUS20100048771A1Improve abilitiesModify performance characteristicAnti-corrosive paintsBuilding insulationsElastomerDistillation

A saturated elastomeric mixture is disclosed having a cured or vulcanized elastomer crumb rubber and atmospheric distillations bottoms residue is disclosed.

Owner:OSBORN JOHN D

Preparing process and application of wet-solidifying single-component polyurethane adhesive

InactiveCN1386815AGood storage stabilityLow toxicityPolyureas/polyurethane adhesivesPolyurethane adhesiveRubber mat

A wet-solidifying single-component polyurethane adhesive for rubber particles used to make plastic-rubber athletic track, elastic rubber mat, etc is prepared from polyetherdiol or polyethertriol and 4,4'-diphenylmethane diisocyanate through reaction. Its advantages are easy control of reaction, high storage stability, high adhesion and no toxicity and pollution.

Owner:丛树枫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com