Patents

Literature

582results about How to "Lower turn-on voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

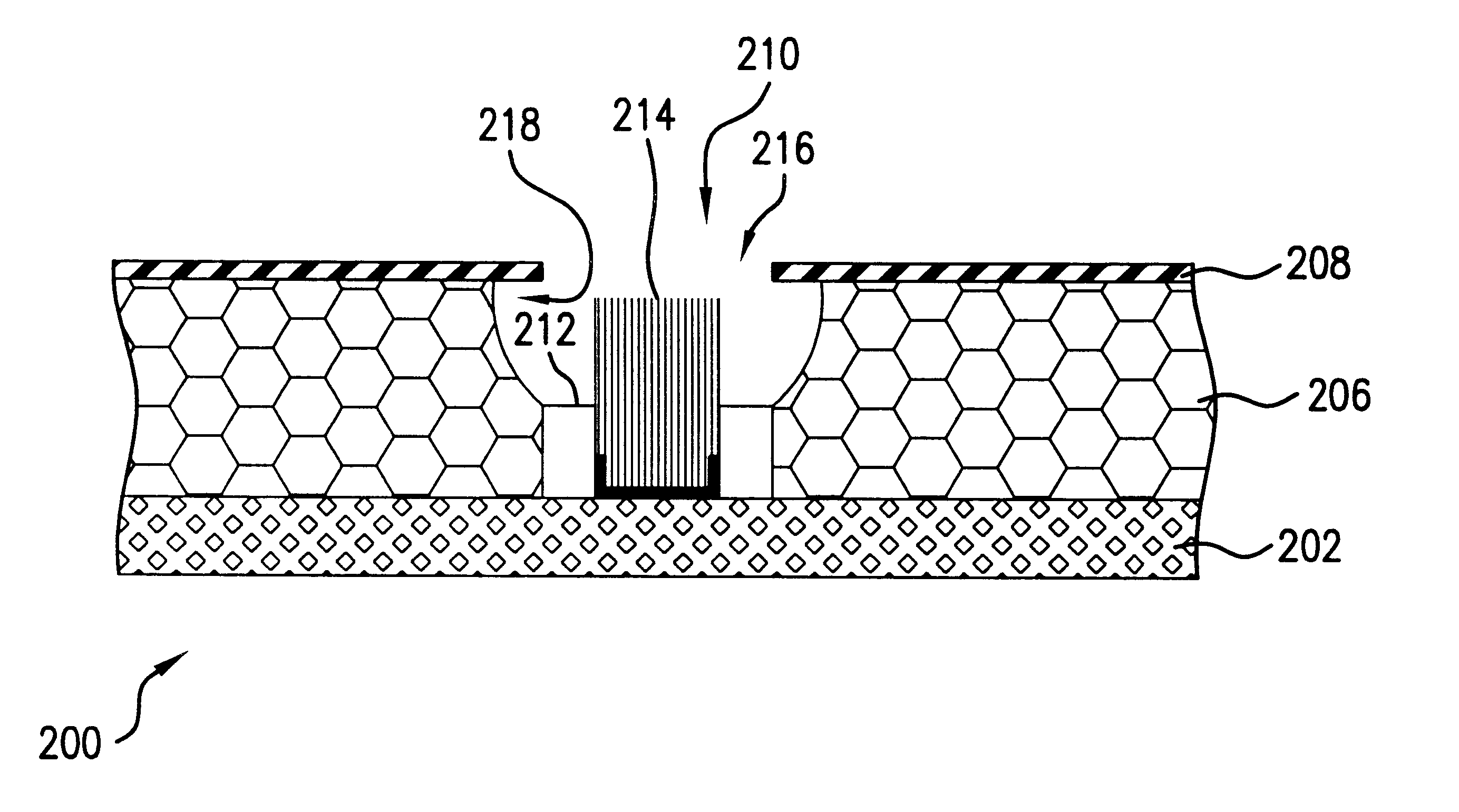

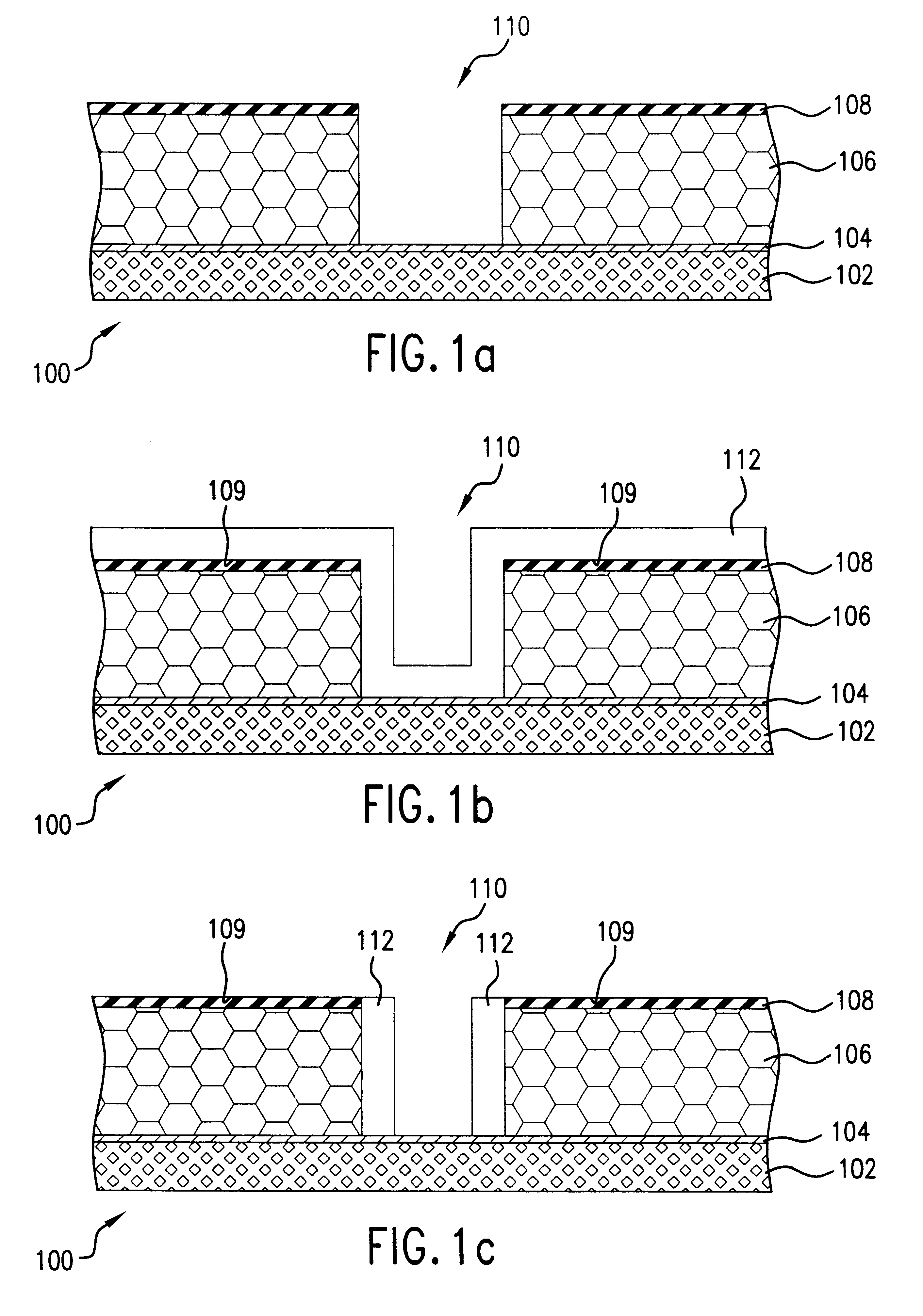

Methods for manufacture of self-aligned integrally gated nanofilament field emitter cell and array

InactiveUS6440763B1Clean and inert surfaceImprove stabilityElectric discharge tubesNanoinformaticsEngineeringNanometre

The present invention discloses a new field emitter cell and array consisting of groups of nanofilaments forming emitter cathodes. Control gates are microprocessed to be integrally formed with groups of nanofilament emitter cathodes on a substrate. Groups of nanofilaments are grown directly on the substrate material. As a result, the control gates and groups of nanofilaments are self-aligned with one another.

Owner:SEC OF THE NAVY AS REPRESENTED BY THE UNITED STATES OF AMERICA THE

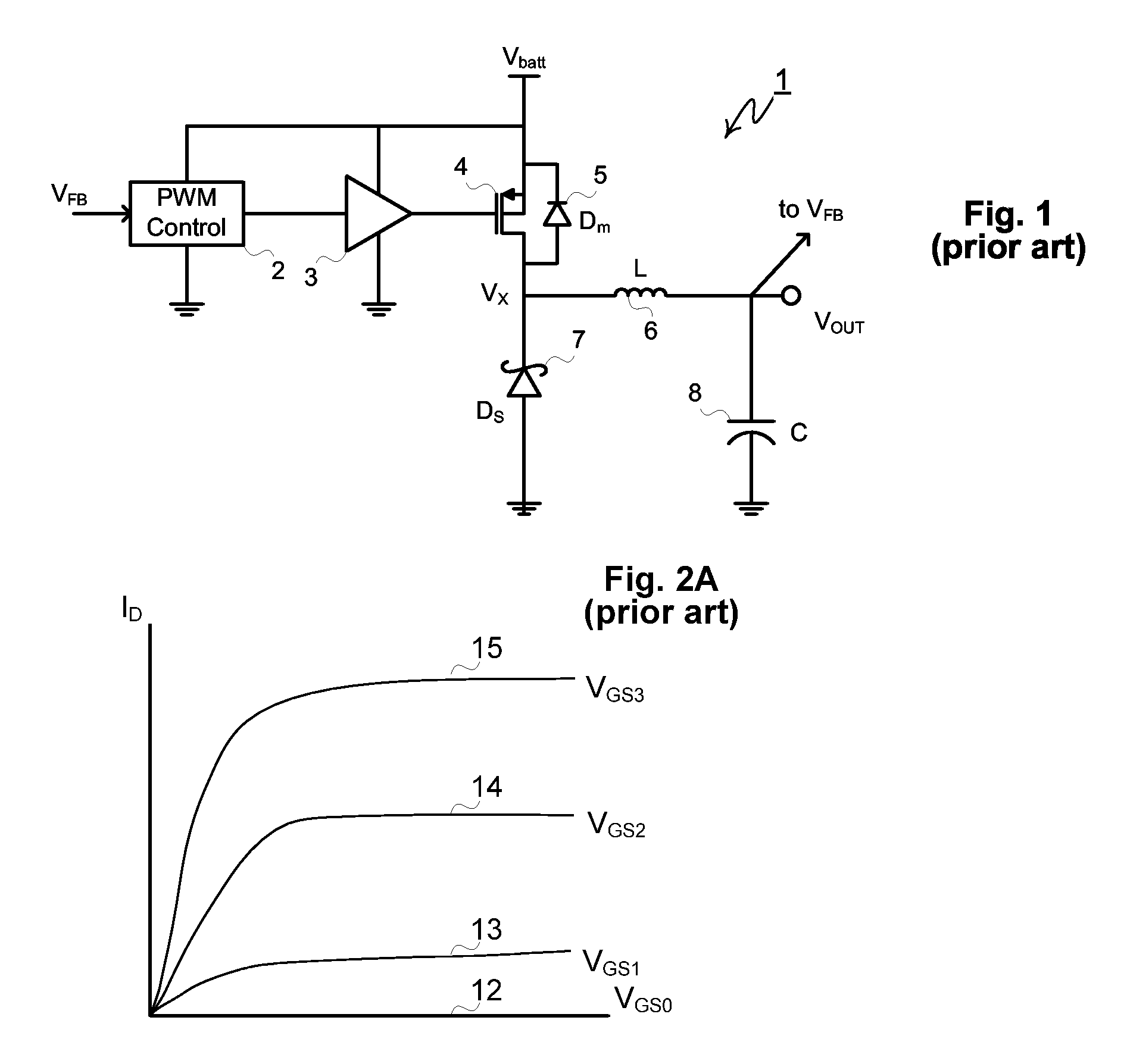

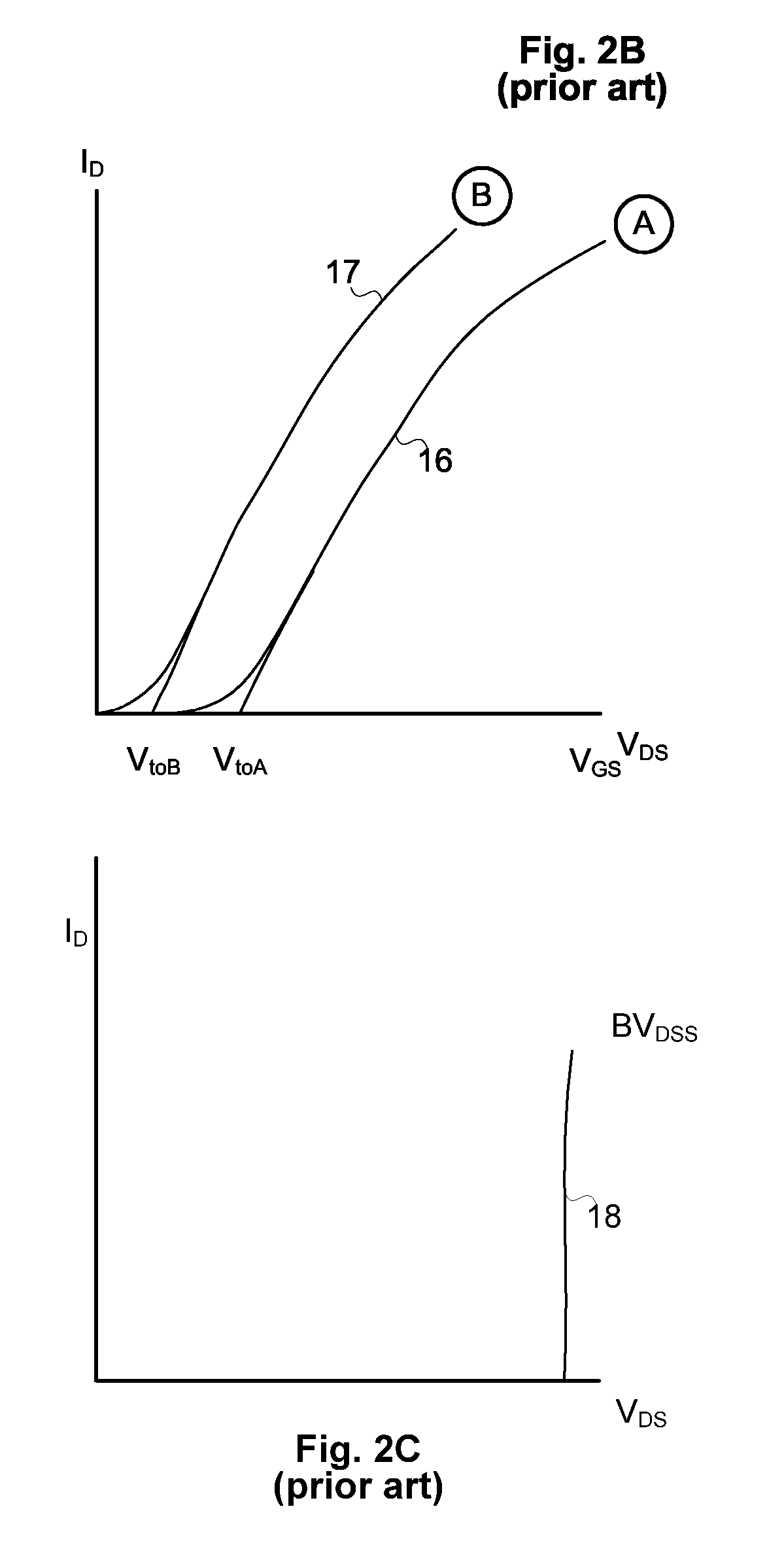

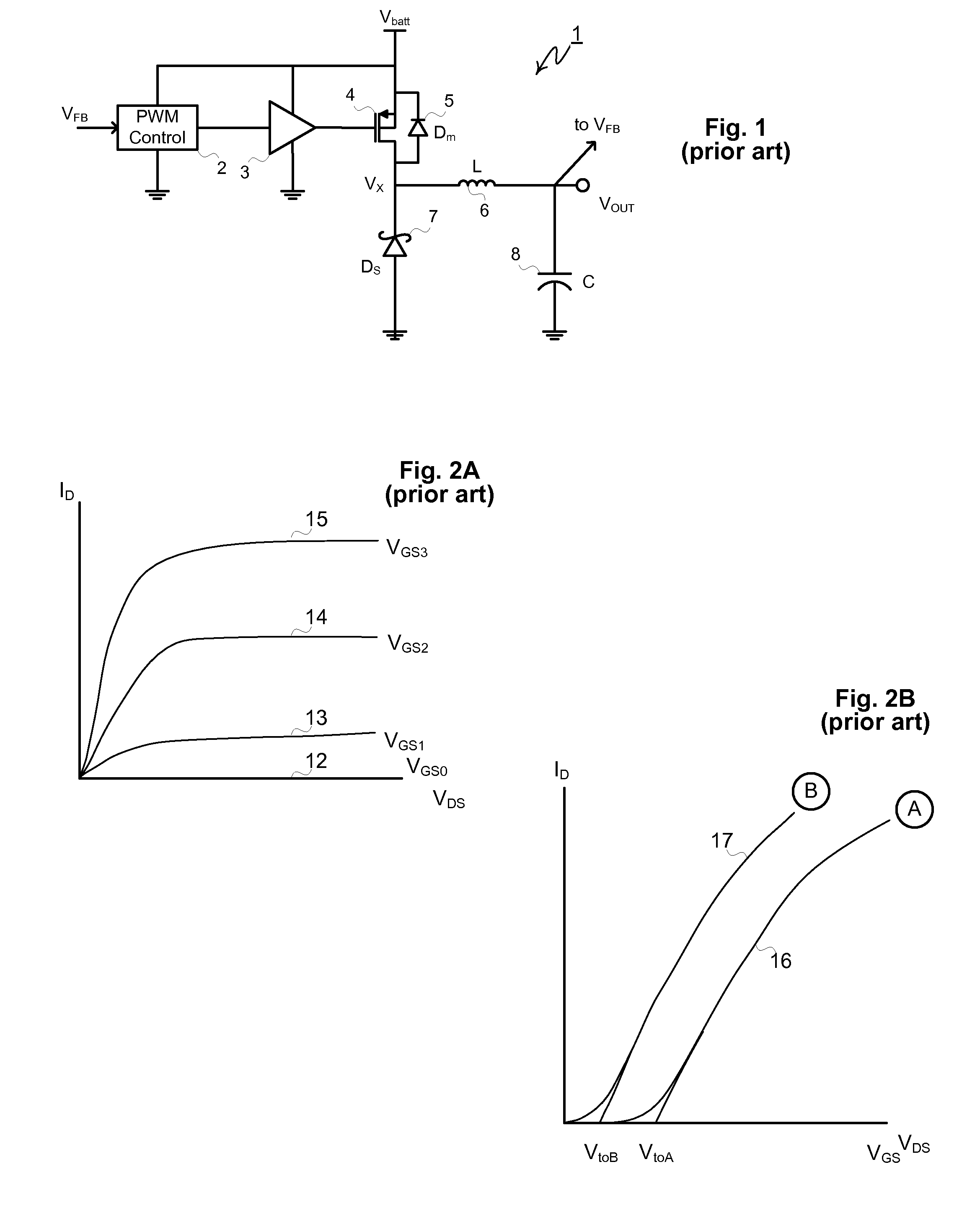

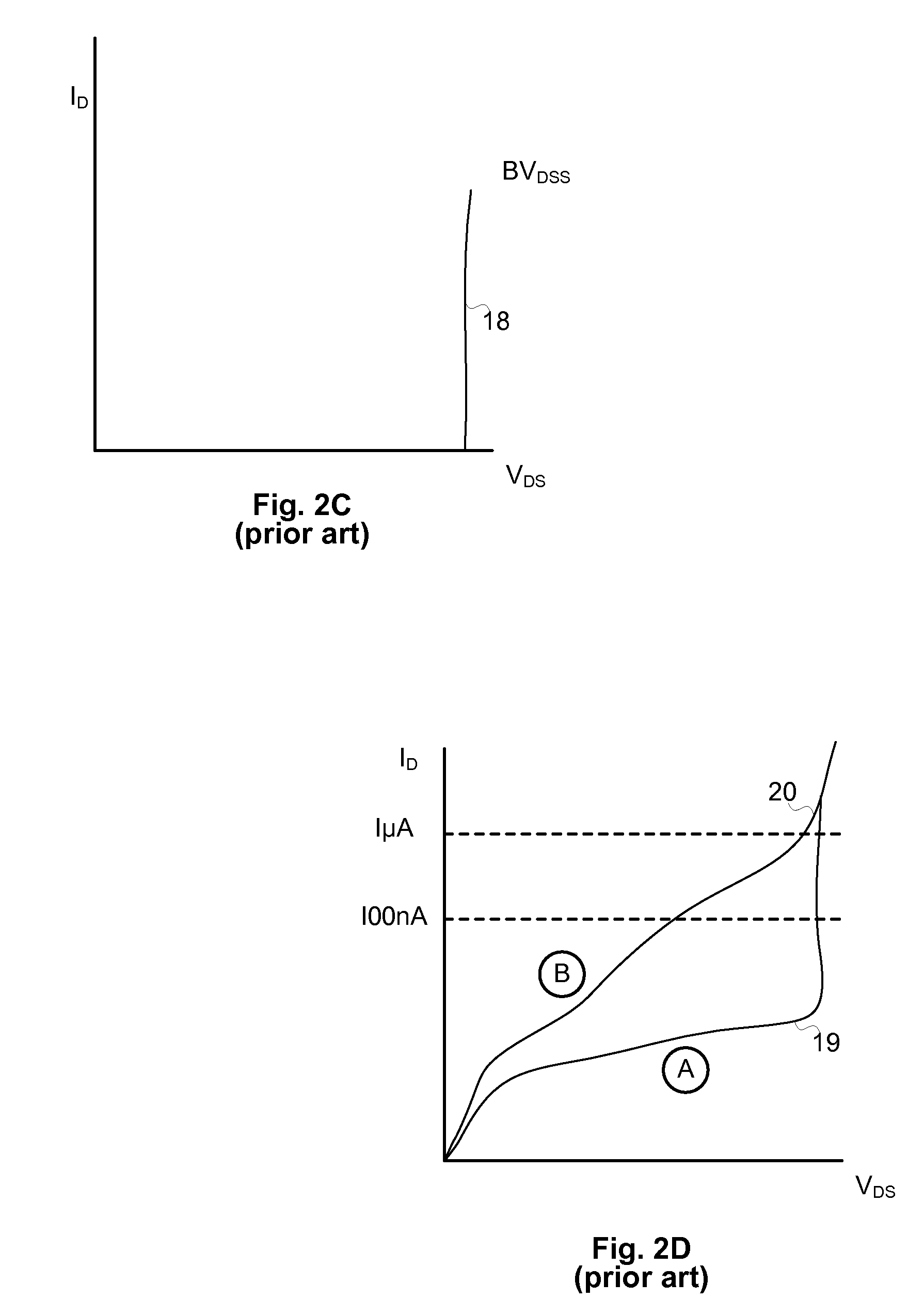

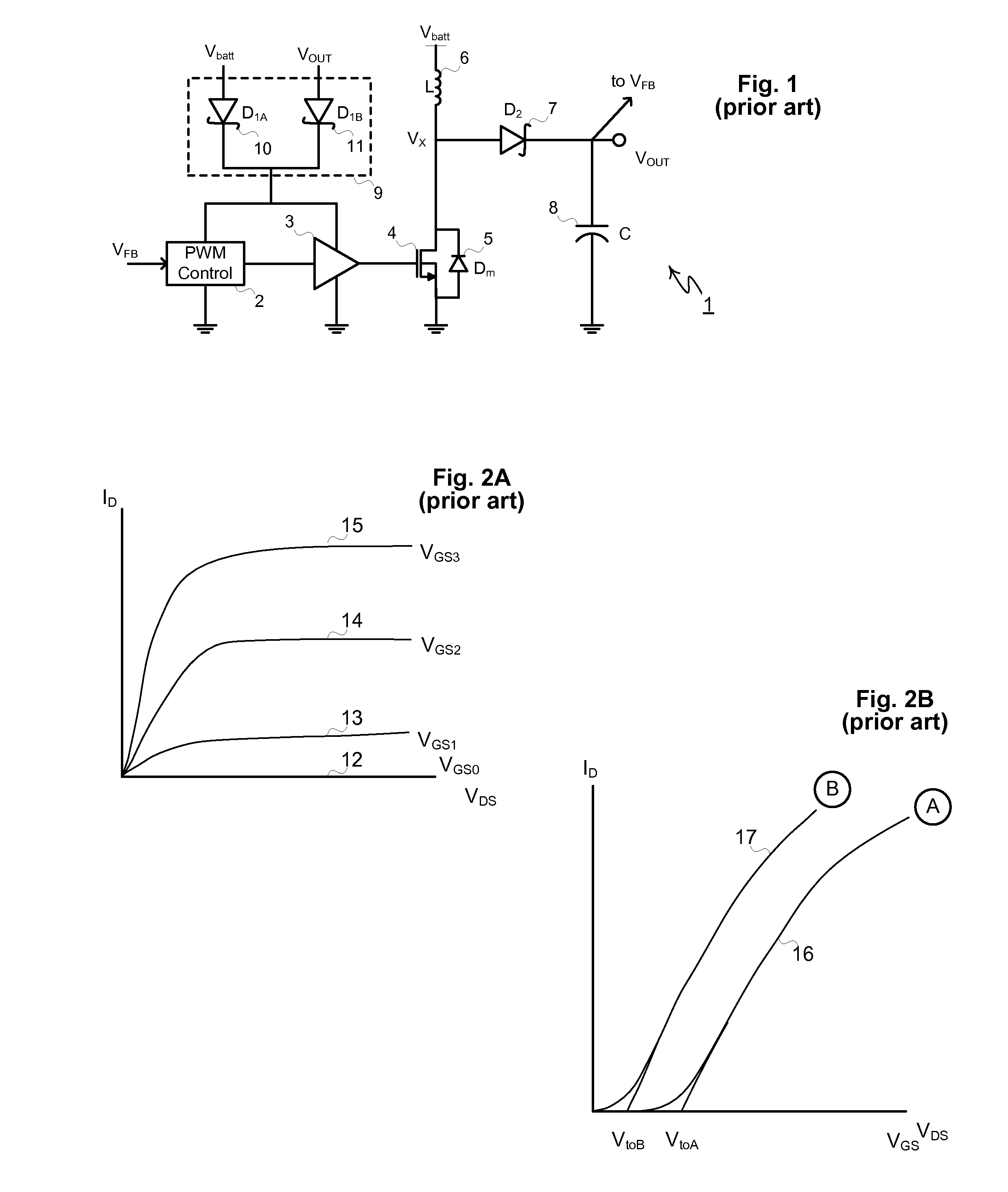

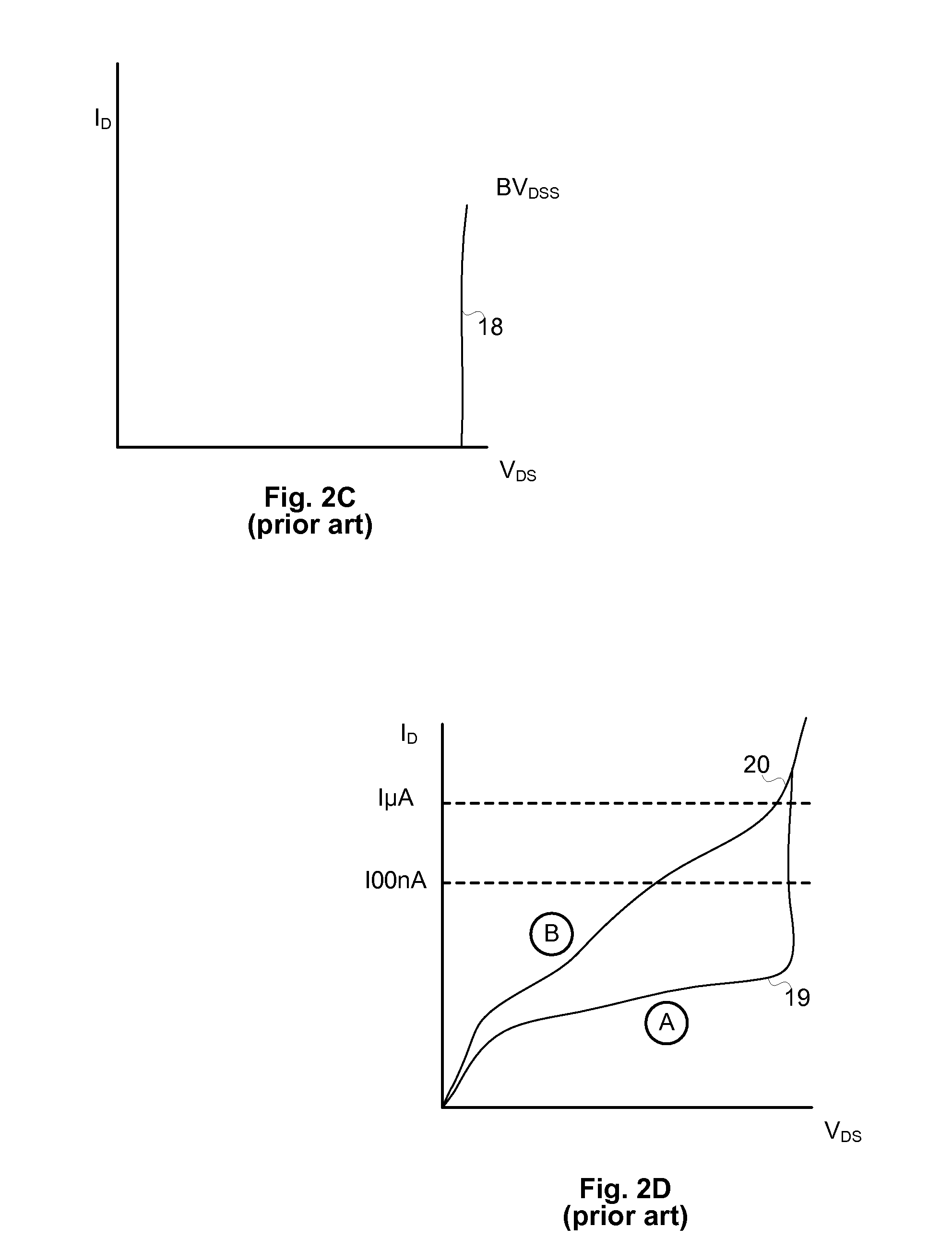

High Frequency Power MESFET Gate Drive Circuits

InactiveUS20070146020A1Lower on-resistanceRobust avalancheTransistorDc-dc conversionDriver circuitHigh frequency power

A series of gate drive circuits for MESFETs are provided. The gate drive circuits are intended to be used in switching regulators where at least one switching device is an N-channel MESFET. For regulators of this type, the gate drive circuits provide gate drive at the correct voltage to ensure that MESFETs are neither under driven (resulting in incorrect circuit operation) nor over driven (resulting in MESFET damage or excess current or power loss).

Owner:ADVANCED ANALOGIC TECHNOLOGIES INCORPORATED

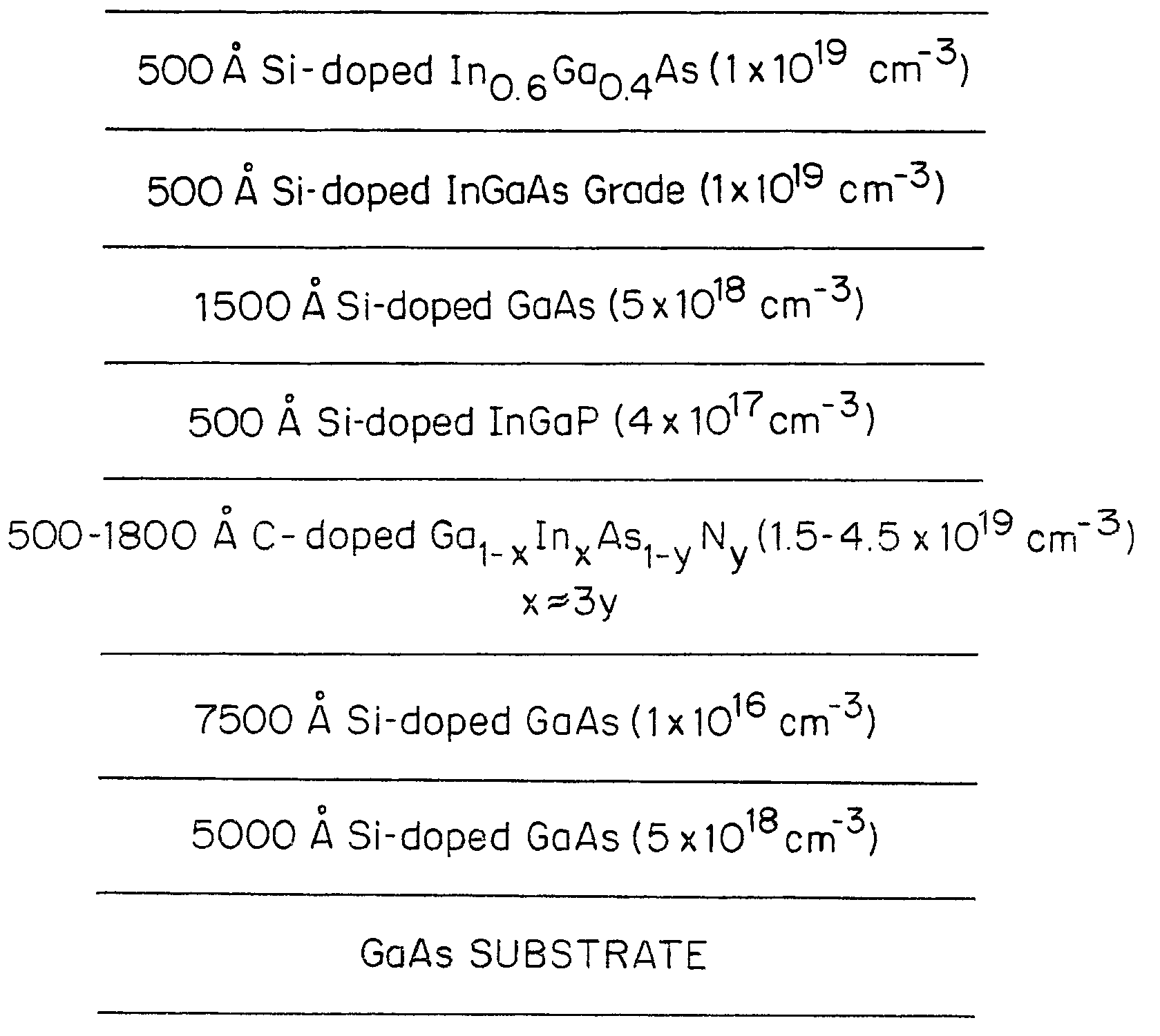

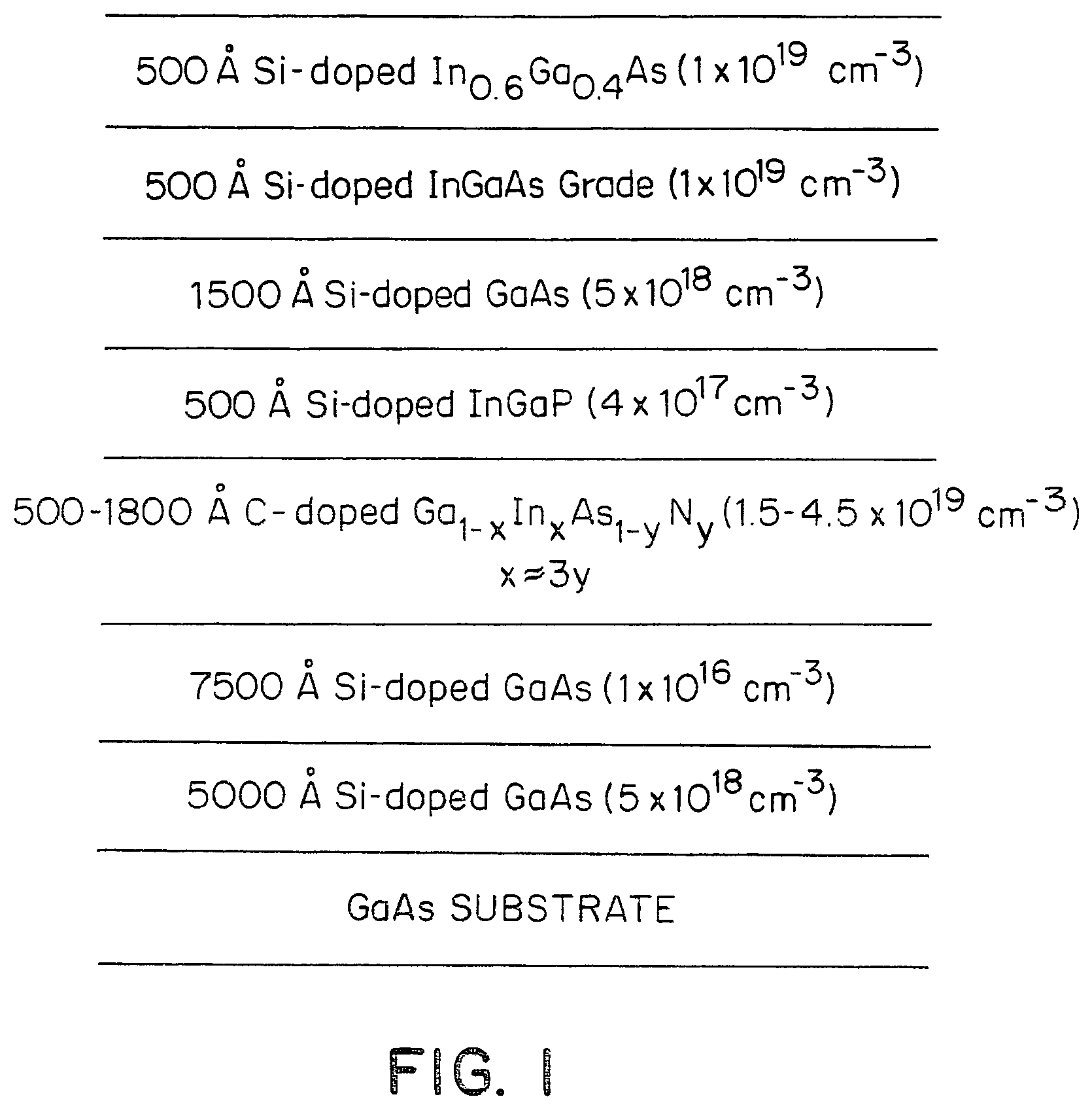

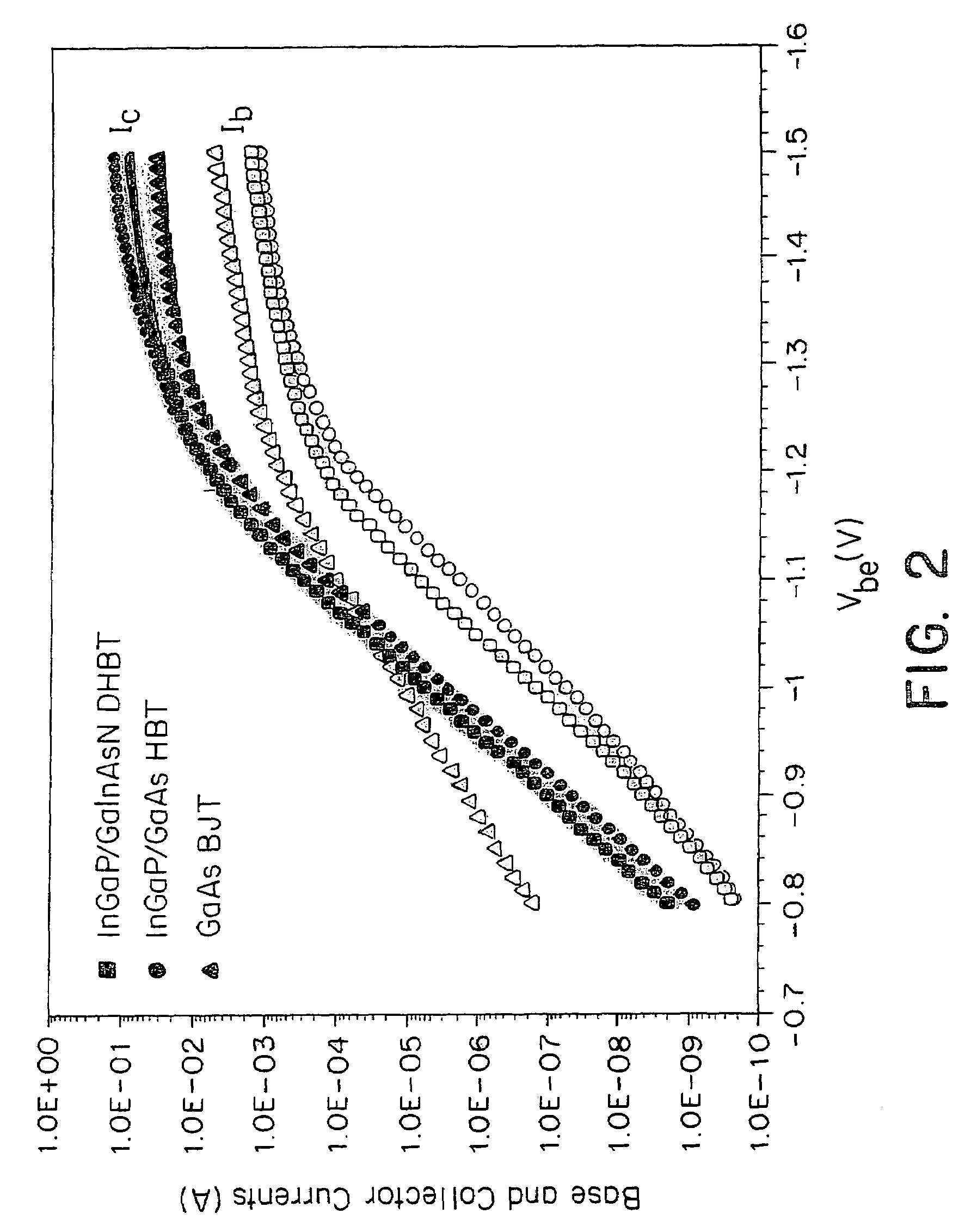

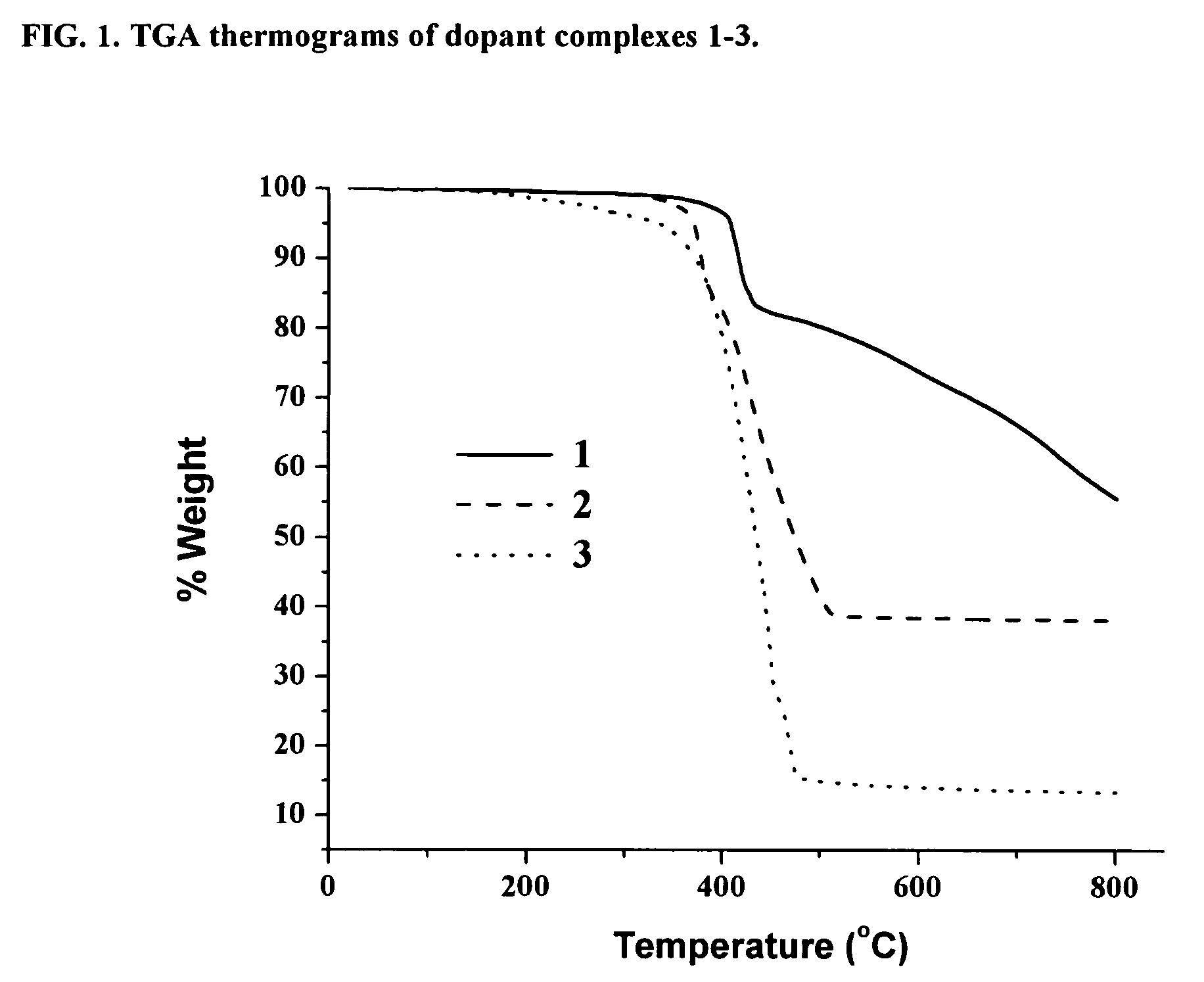

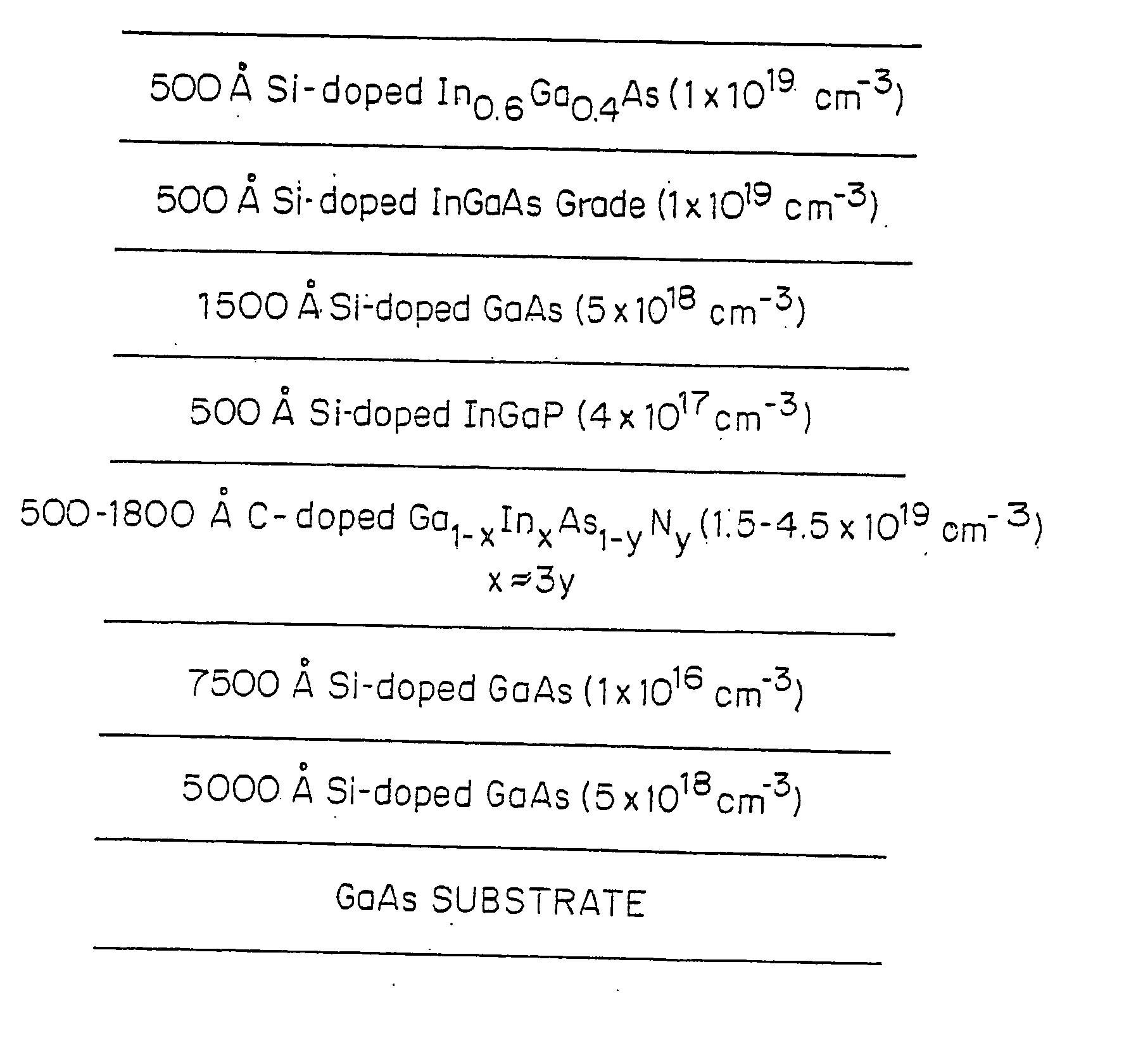

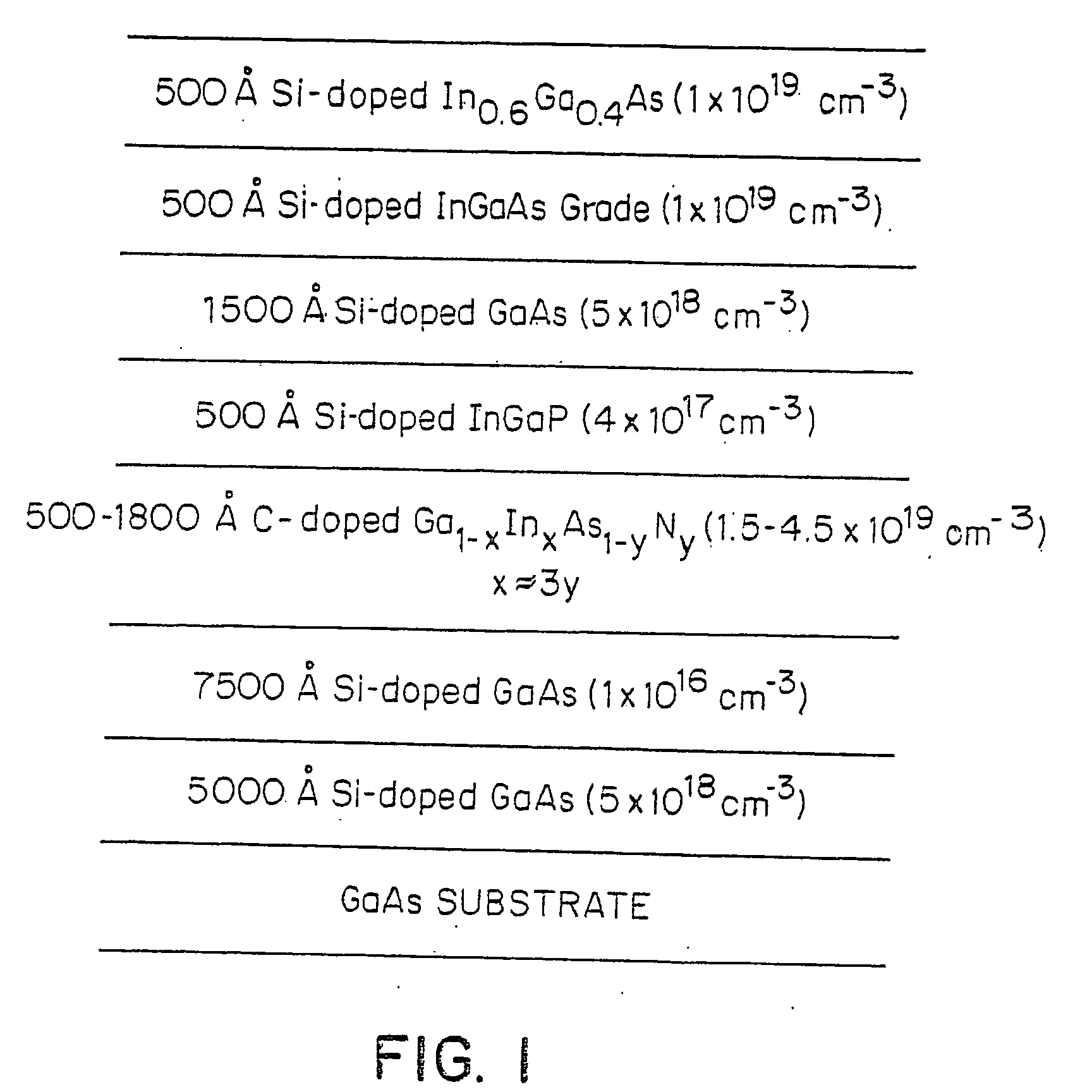

Bipolar transistor with lattice matched base layer

InactiveUS7186624B2Reduce gapLow resistivitySemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionDopant

A semiconductor material which has a high carbon dopant concentration and is composed of gallium, indium, arsenic and nitrogen is disclosed. The material is useful in forming the base layer of gallium arsenide based heterojunction bipolar transistors because it can be lattice matched to gallium arsenide by controlling the concentration of indium and nitrogen. The disclosed semiconductor materials have a low sheet resistivity because of the high carbon dopant concentration obtained.

Owner:IQE KC

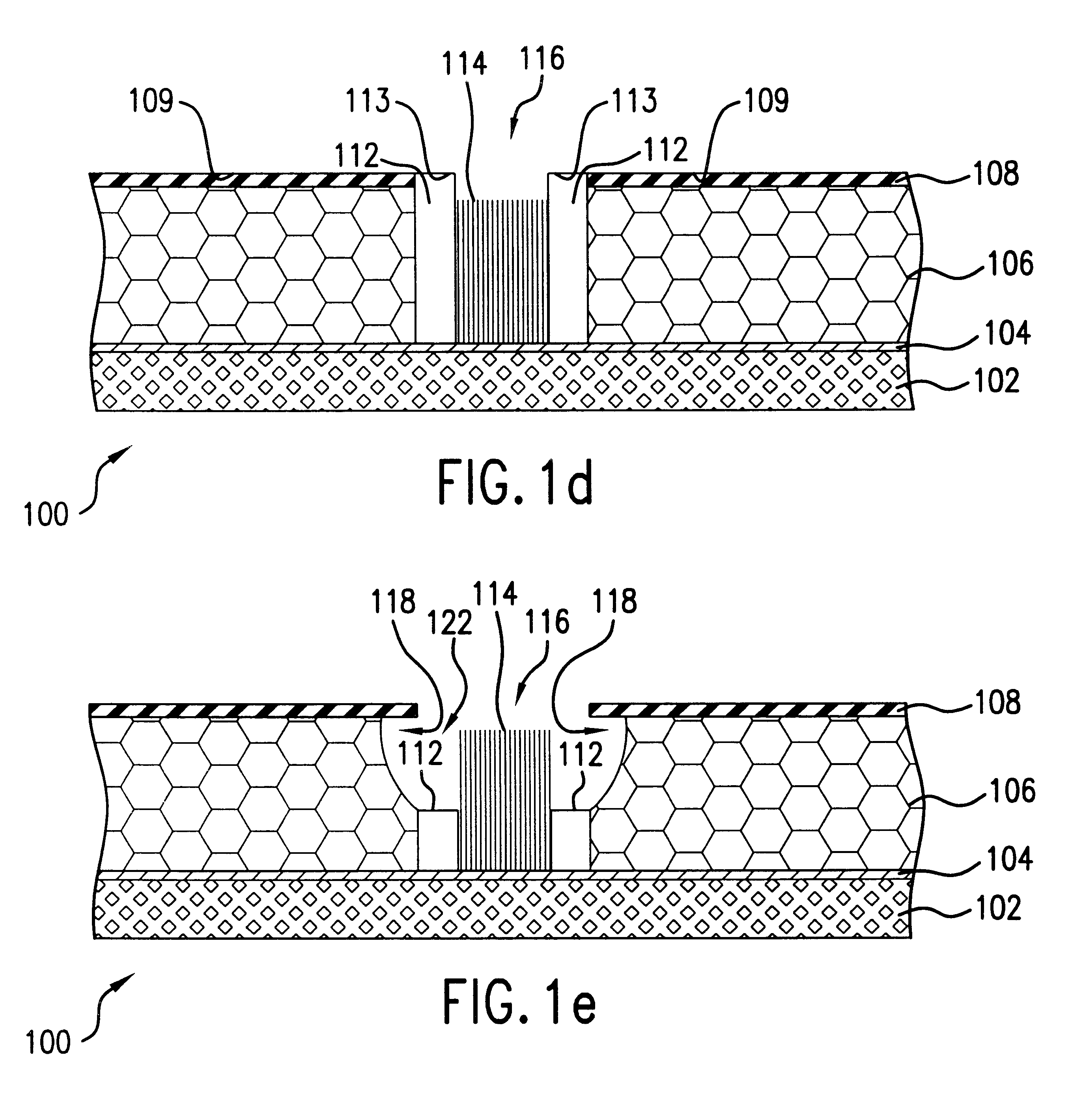

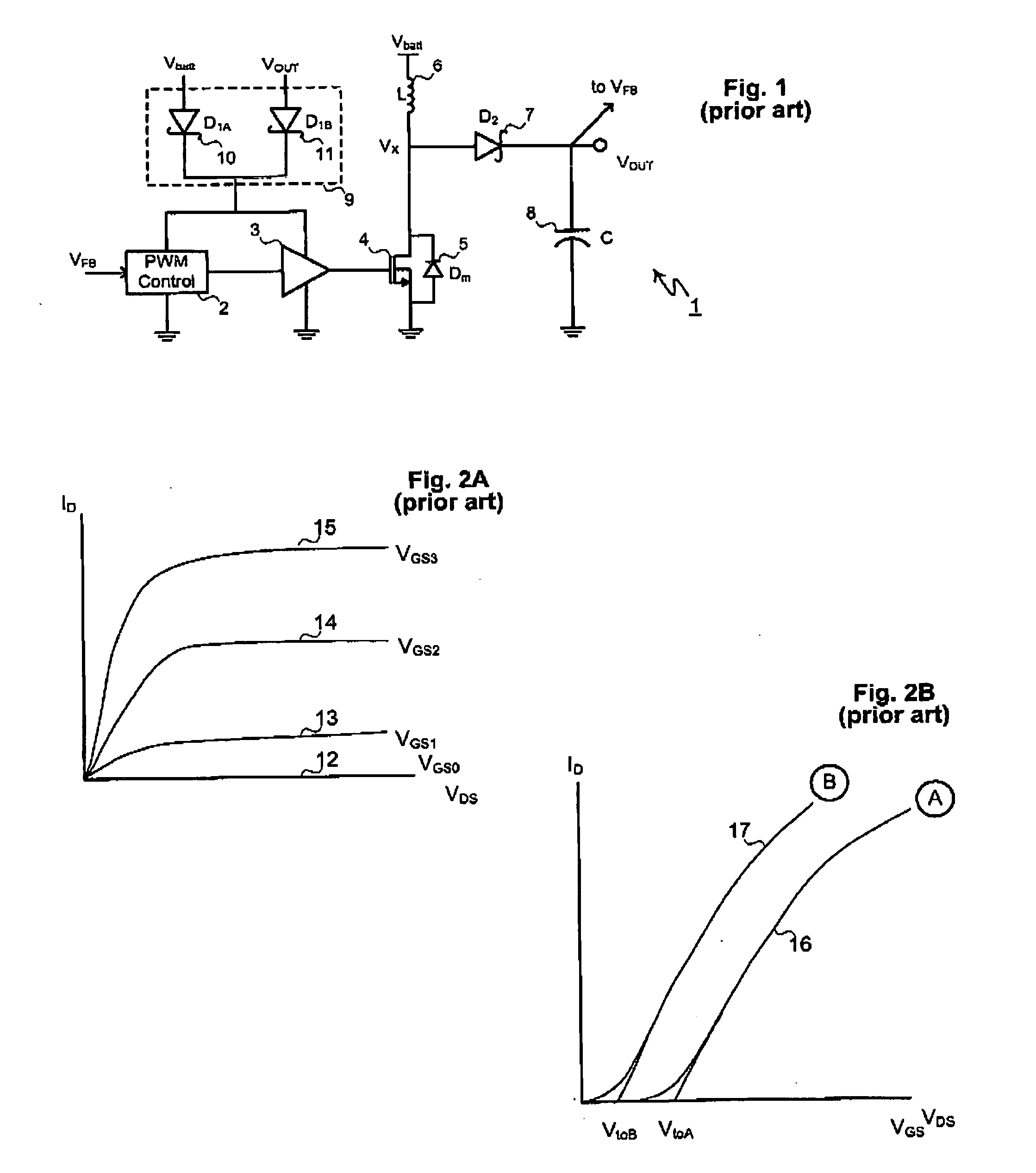

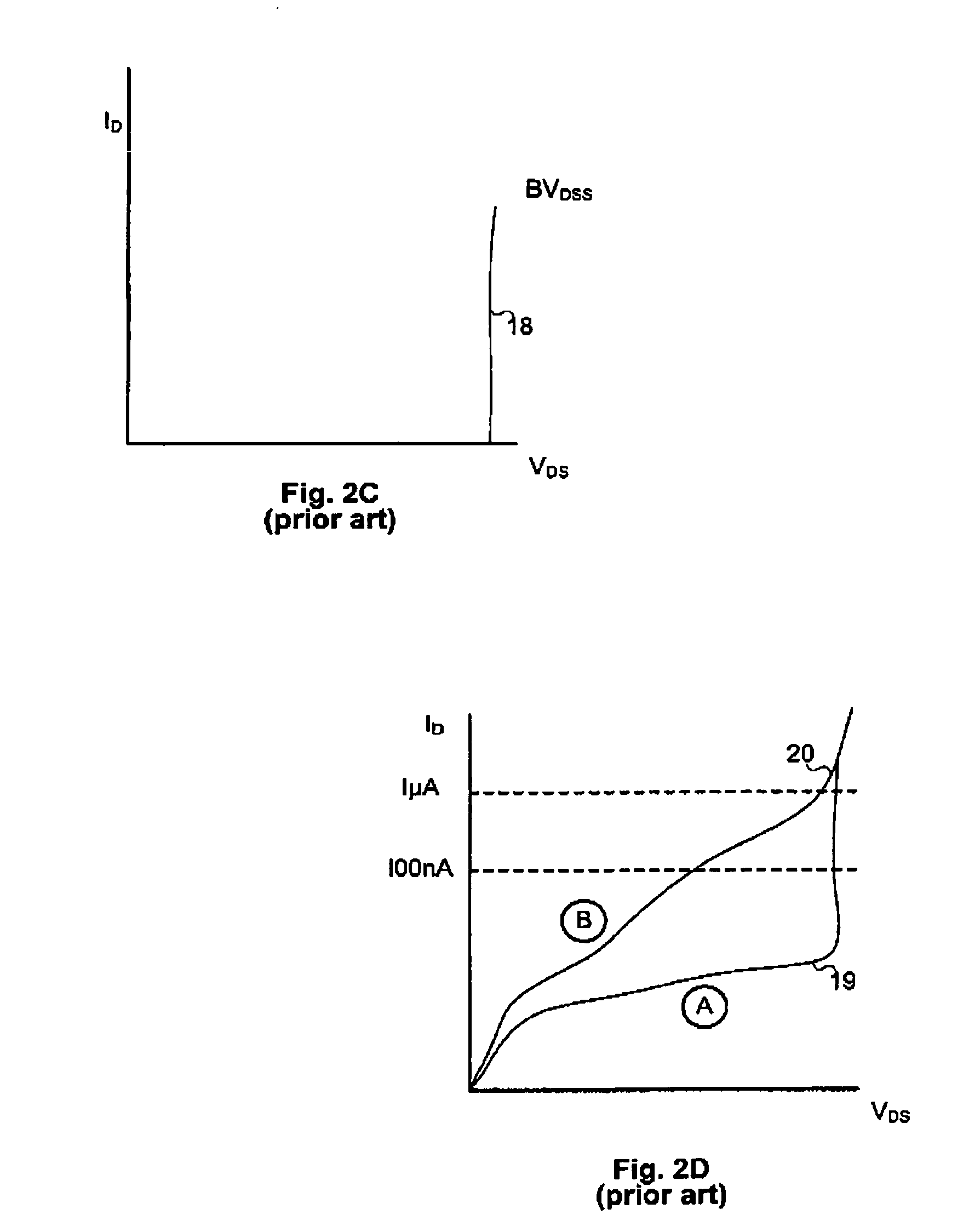

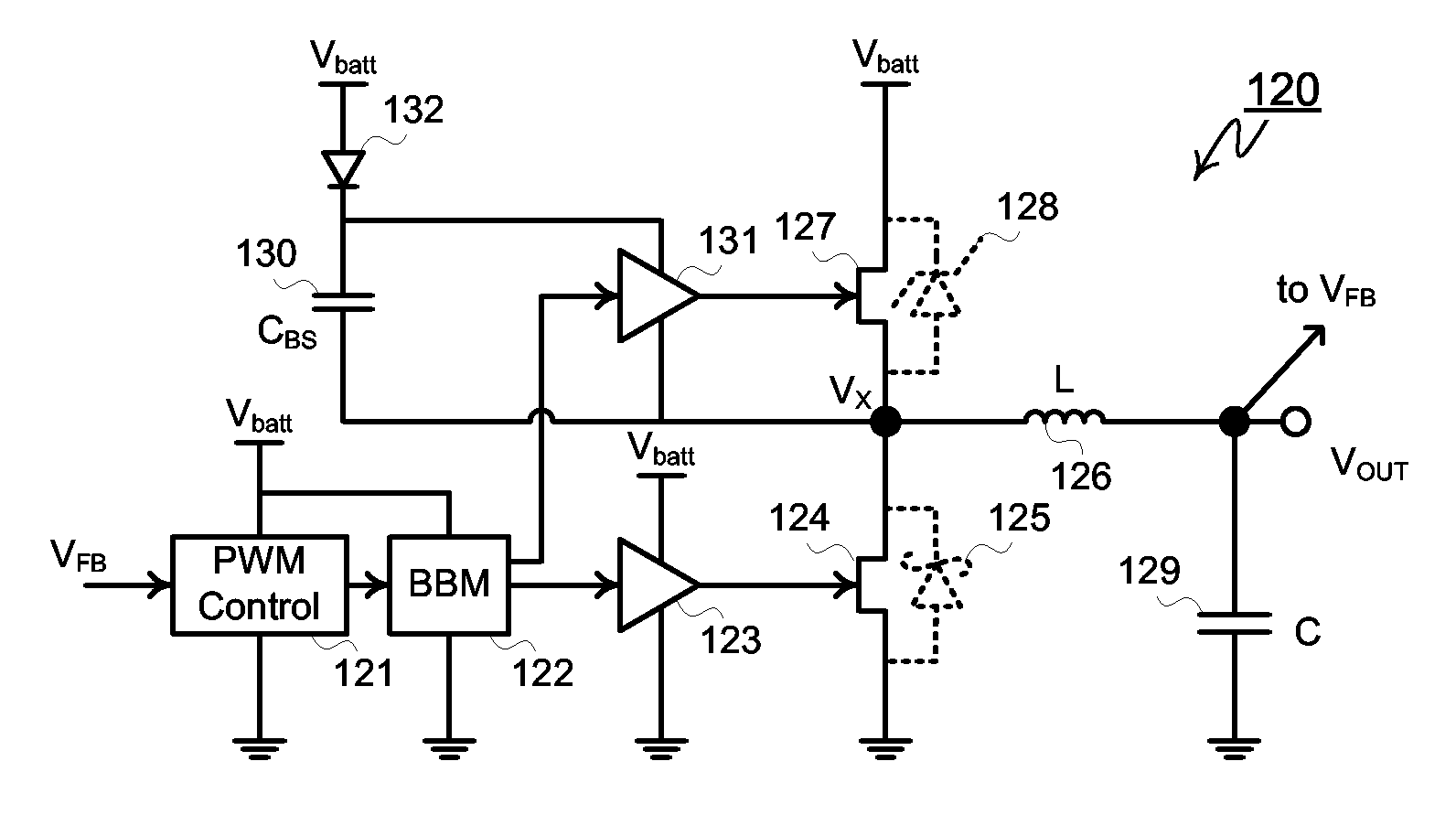

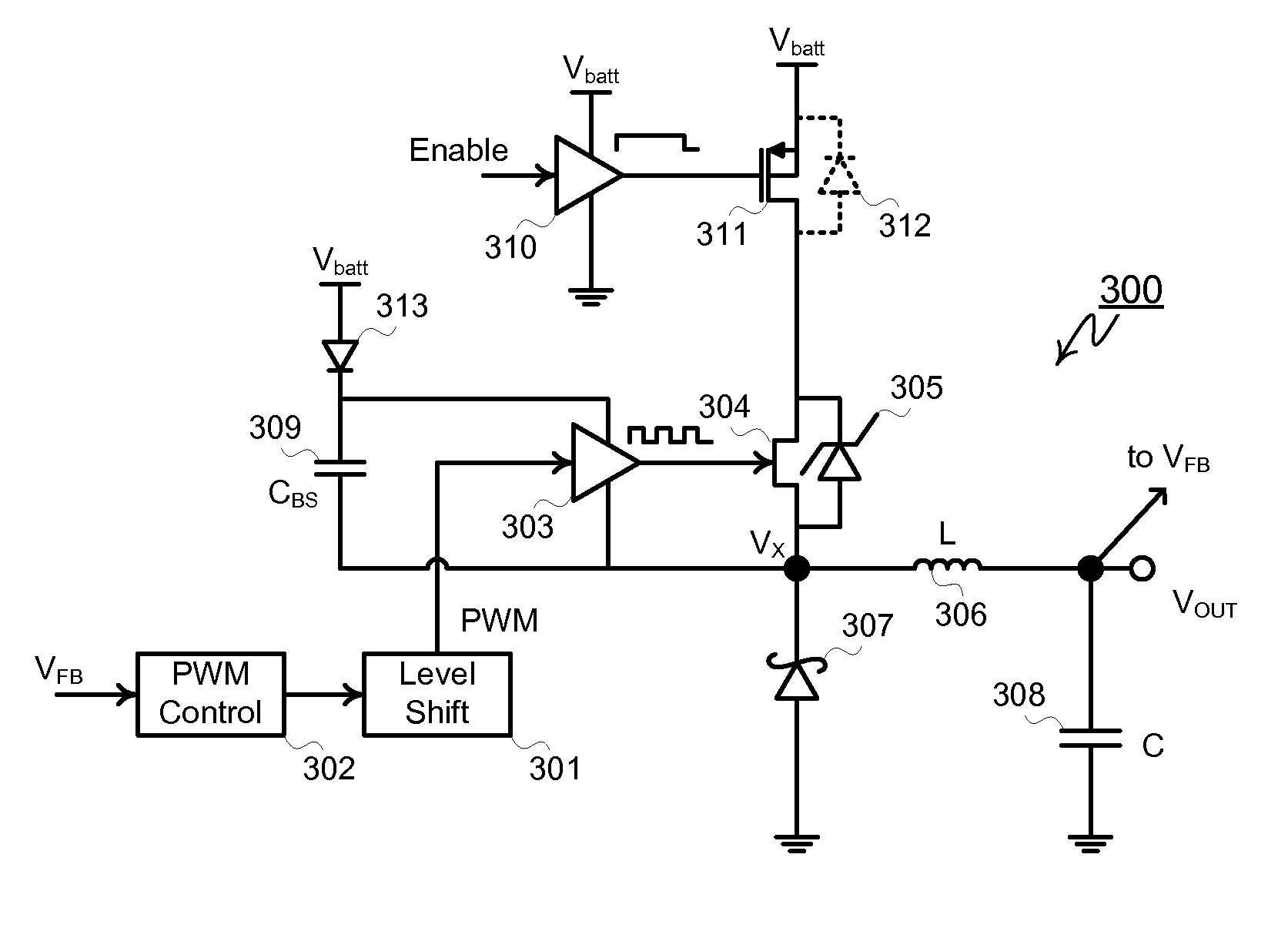

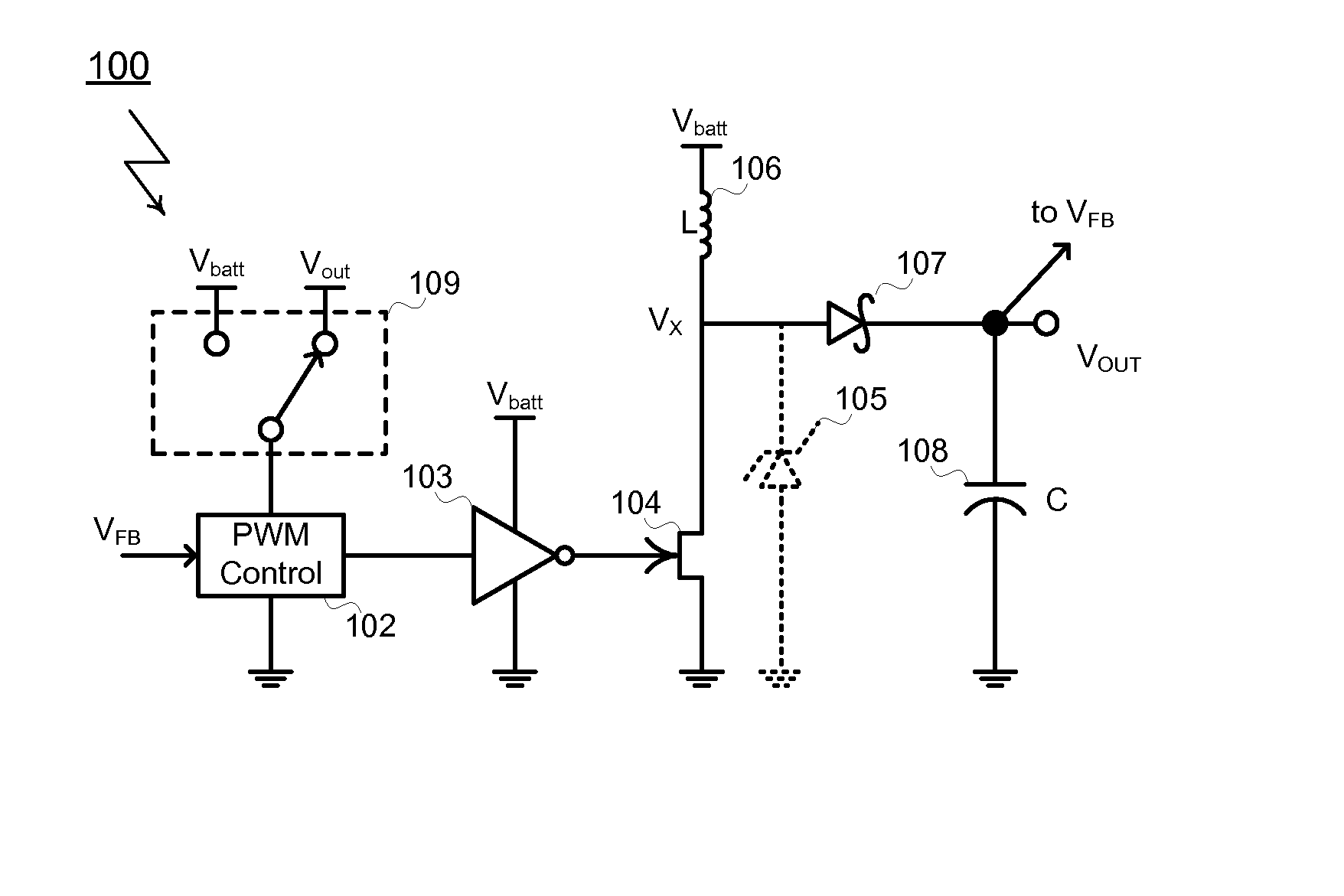

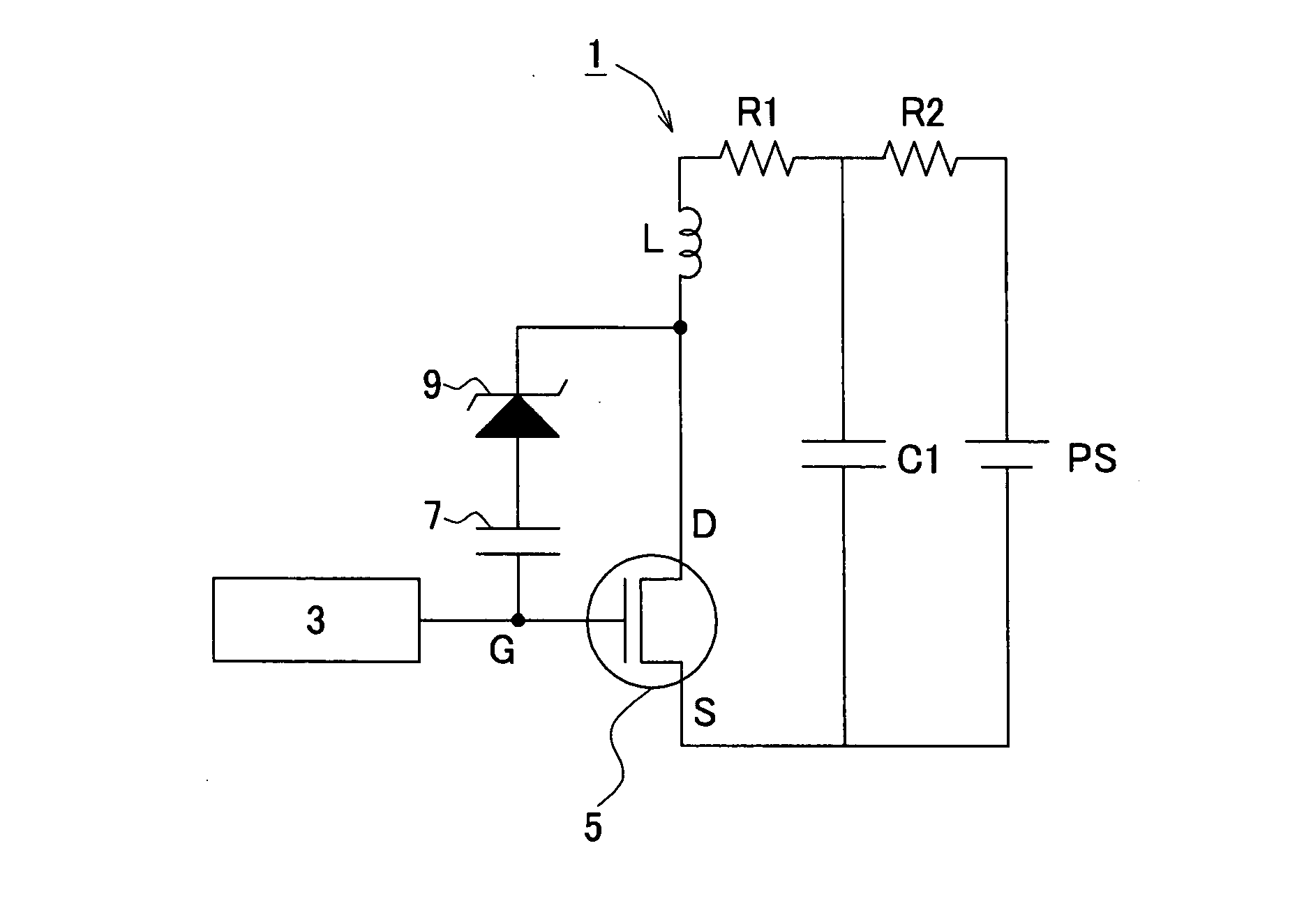

High-Frequency Power MESFET Buck Switching Power Supply

InactiveUS20070170897A1Lower on-resistanceLower turn-on voltageDc-dc conversionElectric variable regulationMOSFETInductor

A MESFET based buck converter includes an N-channel MESFET between a battery or other power source and a node Vx. The node Vx is connected to an output node via an inductor and to ground via a Schottky diode or a second MESFET or both. A control circuit drives the MESFET (and the second MESFET) so that the inductor is alternately connected to the battery and to ground. The maximum voltage impressed across the high side MESFET is optionally clamped by a Zener diode. In some implementations, the MESFET is connected in series with a MOSFET. The MOSFET is switched off during sleep or standby modes to minimize leakage current through the MESFET. The MOSFET is therefore switched at a low frequency compared to the MESFET and does not contribute significantly to switching losses in the converter. In other implementations, more than one MESFET is connected in series with a MOSFET the MOSFETs being switched off during periods of inactivity to suppress leakage currents.

Owner:ADVANCED ANALOGIC TECHNOLOGIES INCORPORATED

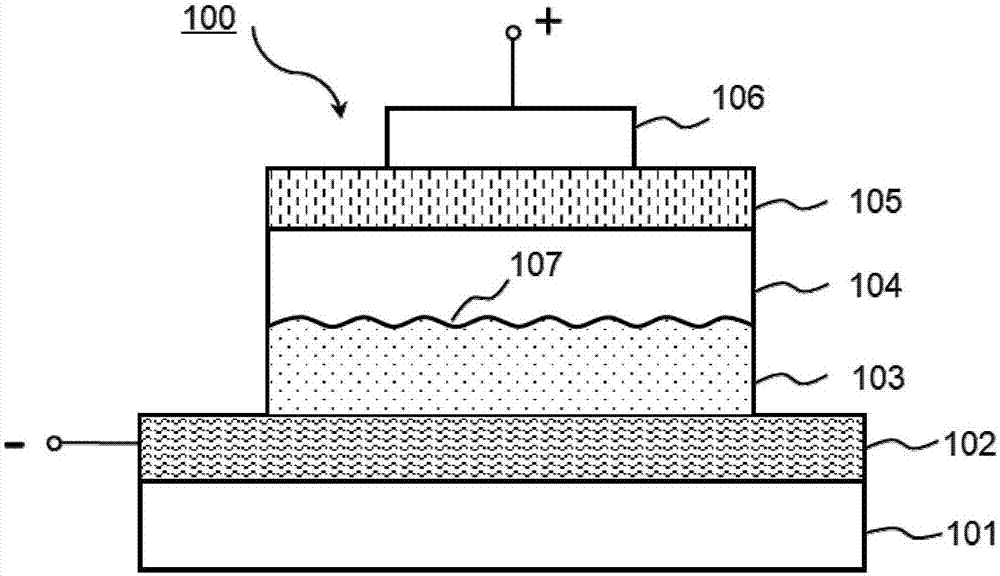

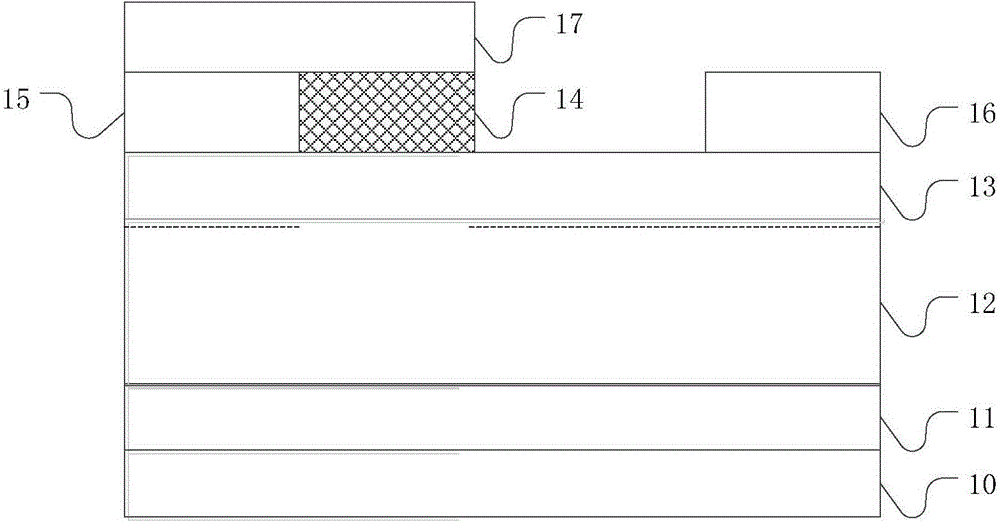

Perovskite type electroluminescence device and preparation method thereof

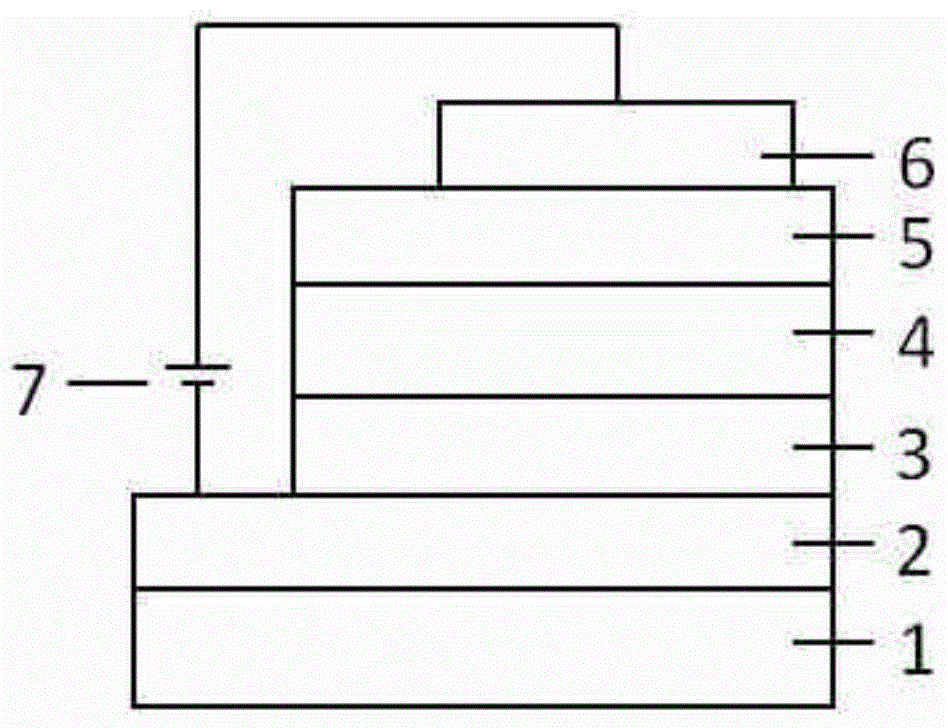

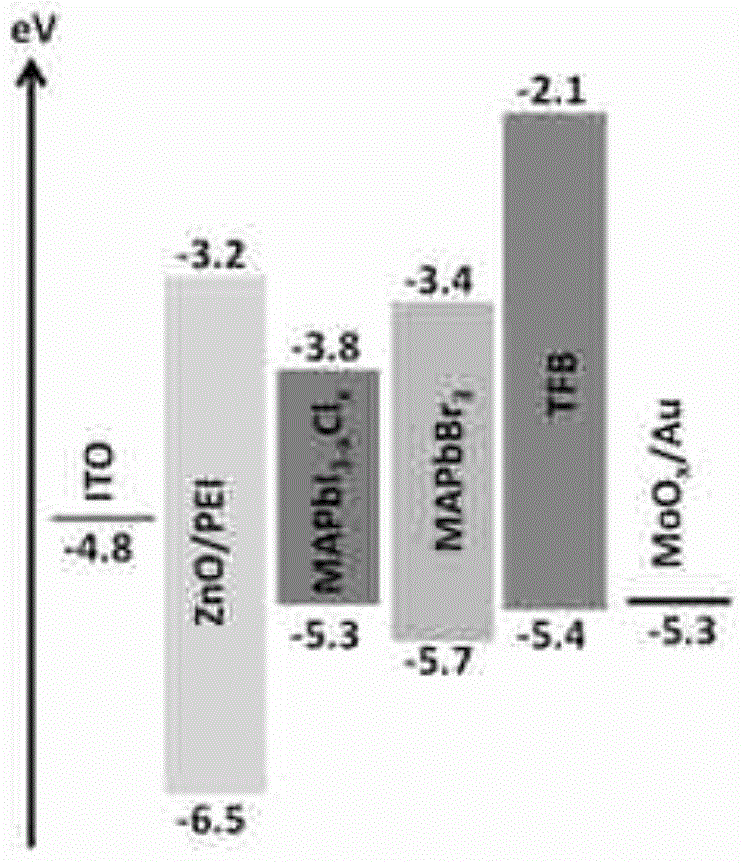

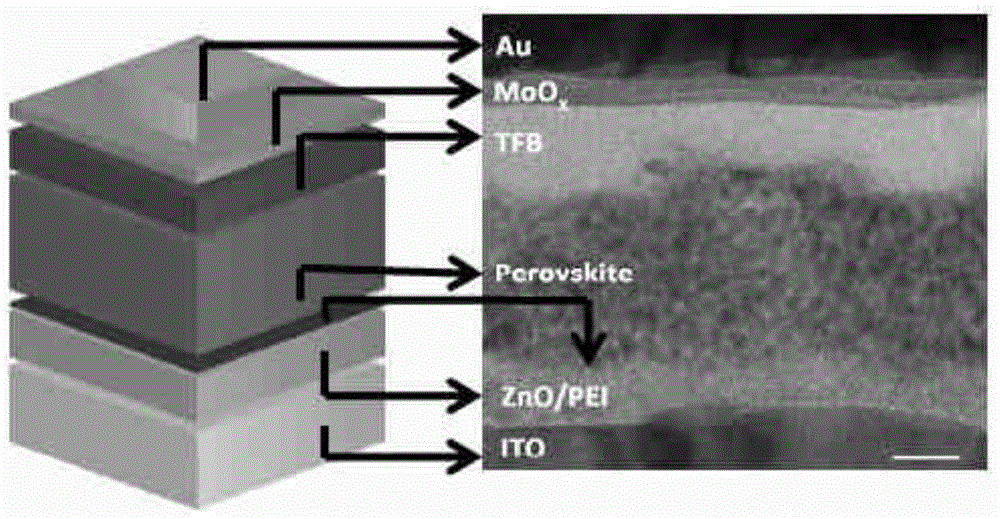

ActiveCN104681731AIncrease brightnessEasy to filmSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionBlocking layer

The invention discloses a perovskite type electroluminescence device. The device comprises a substrate, a cathode, an electronic transmission-hole blocking layer, a luminescent layer, a hole transmission-electron blocking layer and an anode, wherein the luminescent layer is made of a material of a perovskite structure; the structure of the device can effectively promote injection and transmission of the charge carriers, restrict the sufficient recombination luminescence of the charge carriers / excitons, and adjust the emission color from the near ultraviolet light band, the visible light band to the near-infrared band by means of changing the components of the luminescent material. The electroluminescence device provided by the invention is high in efficiency, low in turn-on voltage, excellent in color saturation and stable in spectrum changed along with the voltage, meanwhile, the perovskite type electroluminescence device is simple in process, low in cost and is suitable for being widely used in the products of the display and illumination field, in particular suitable for the large-sized industrial production of the high-performance electroluminescence devices with low cost and flexible substrate.

Owner:NANJING UNIV OF TECH

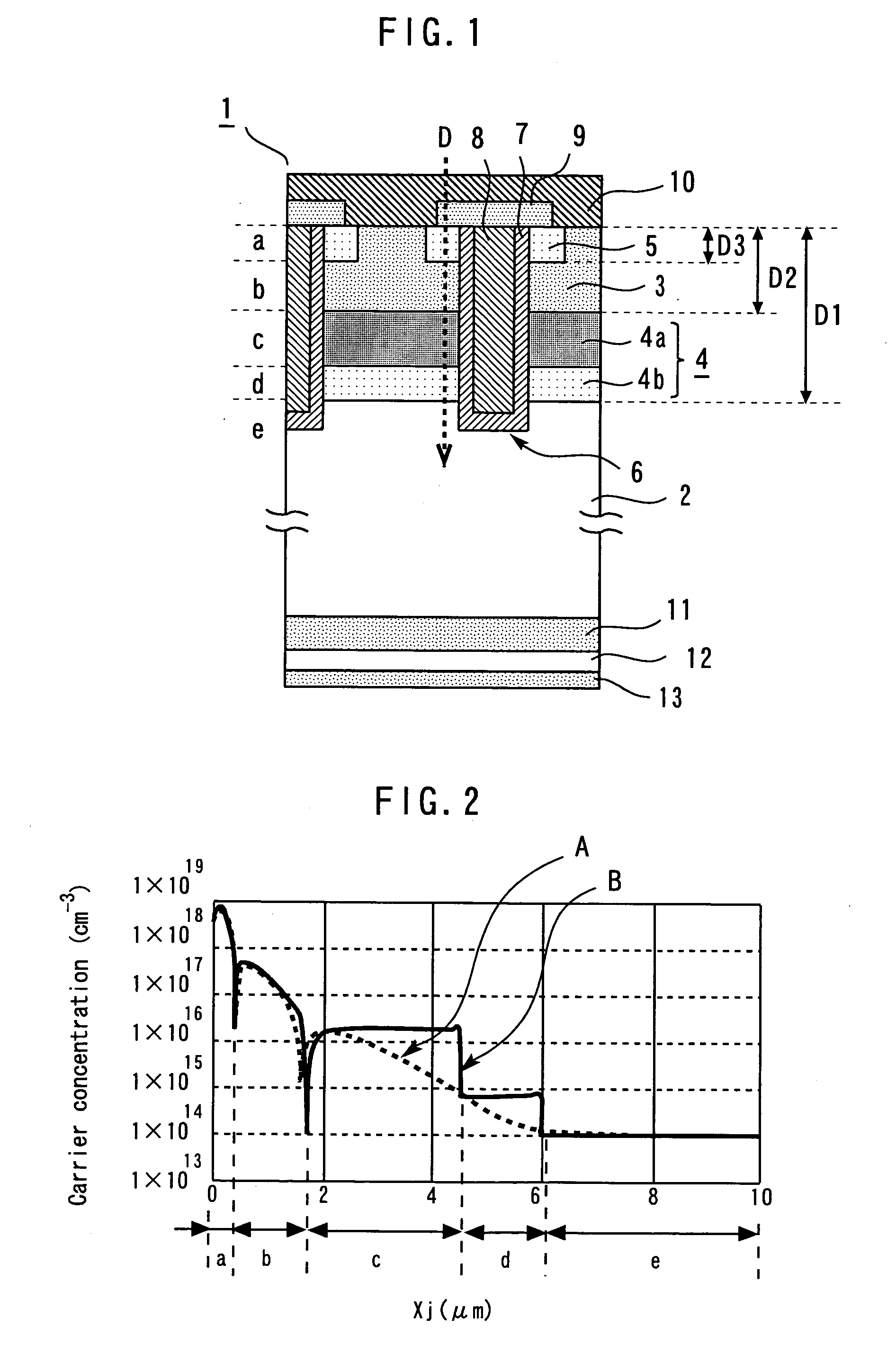

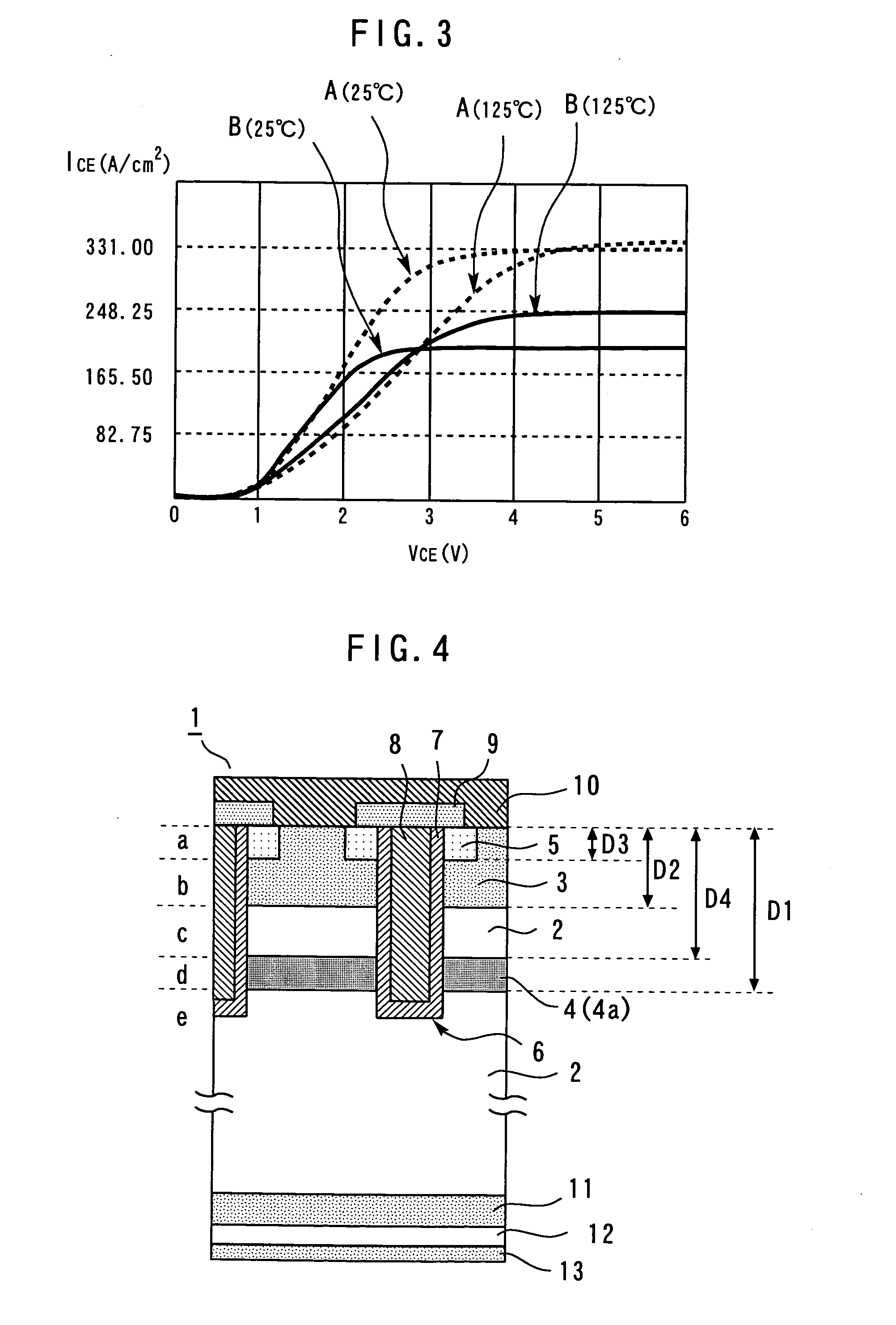

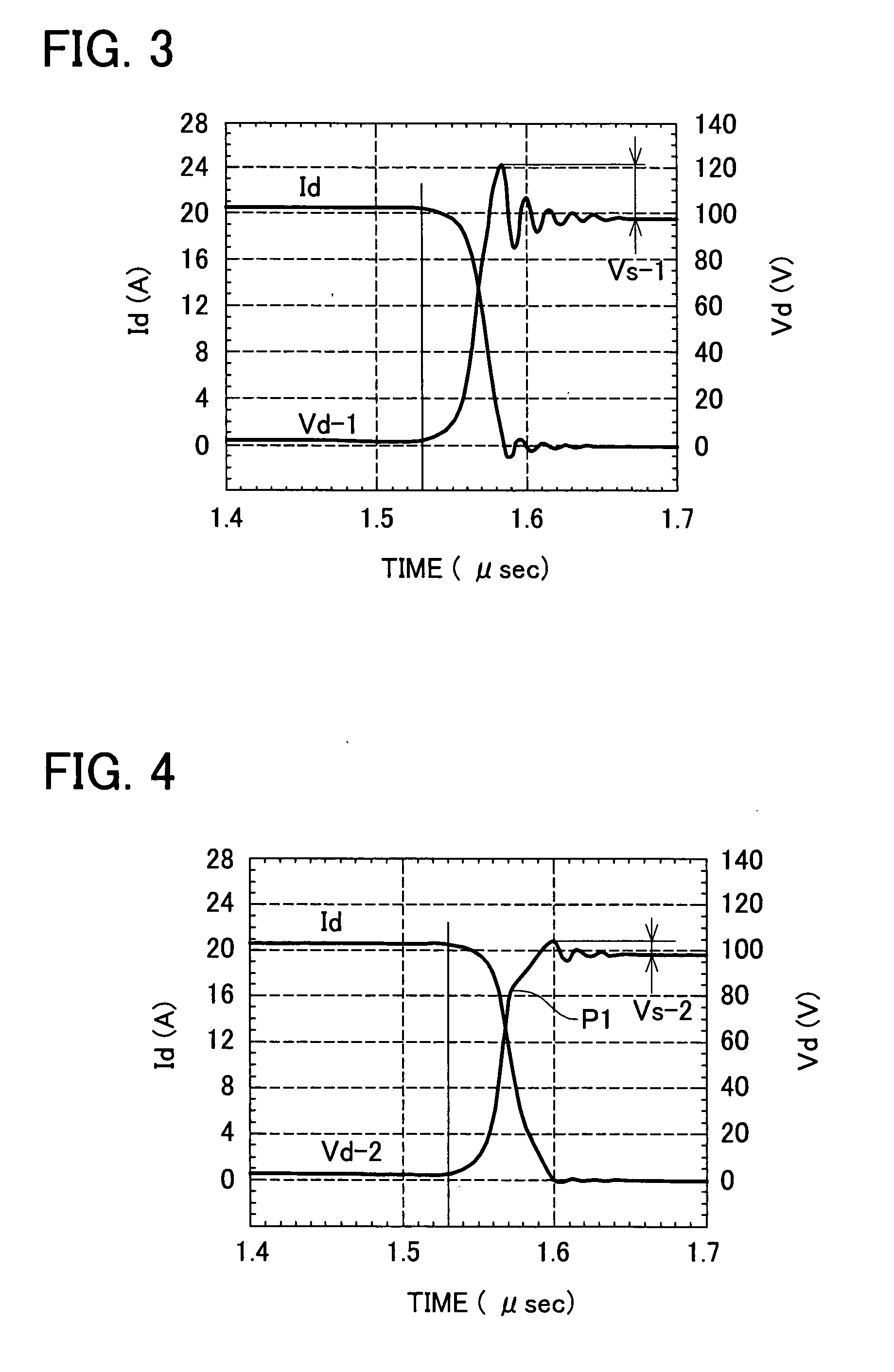

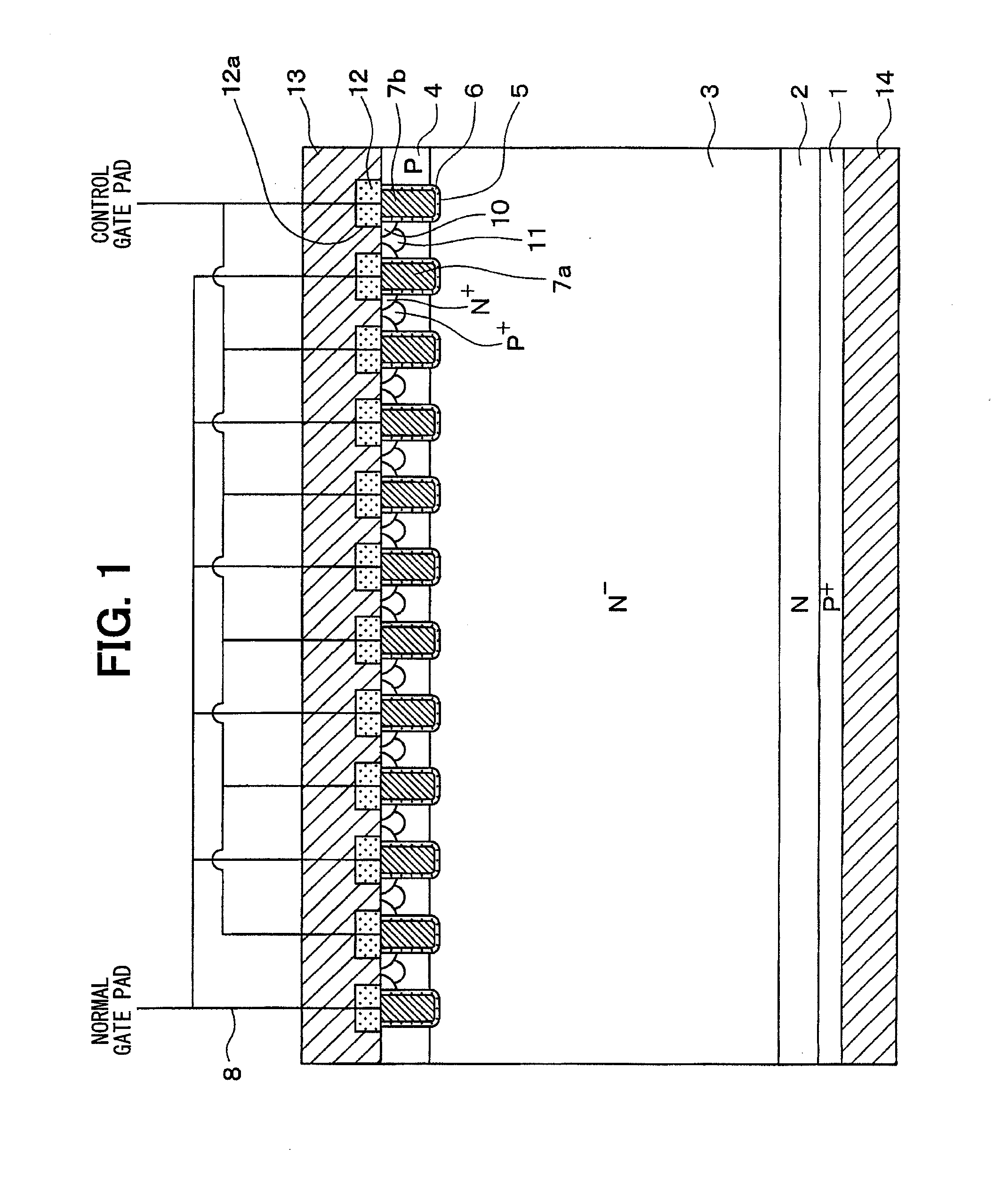

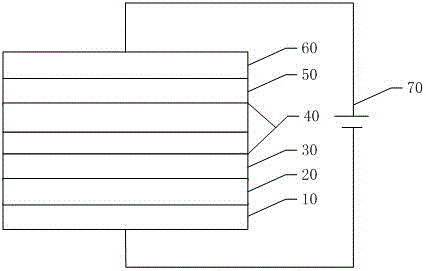

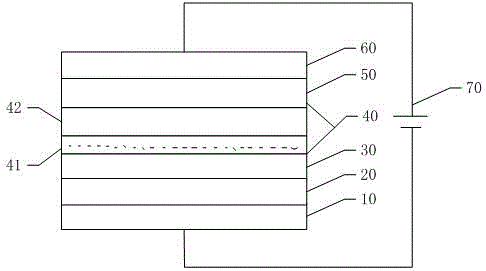

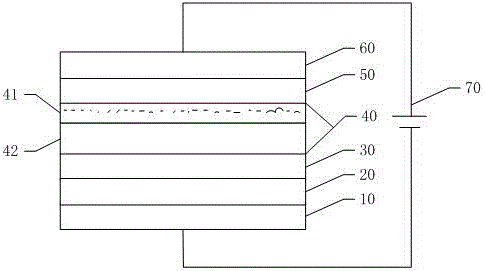

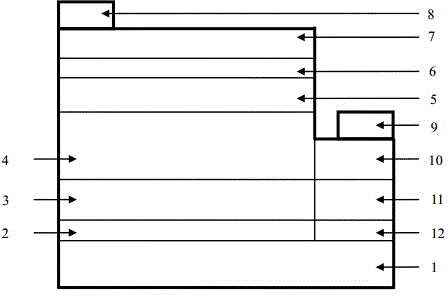

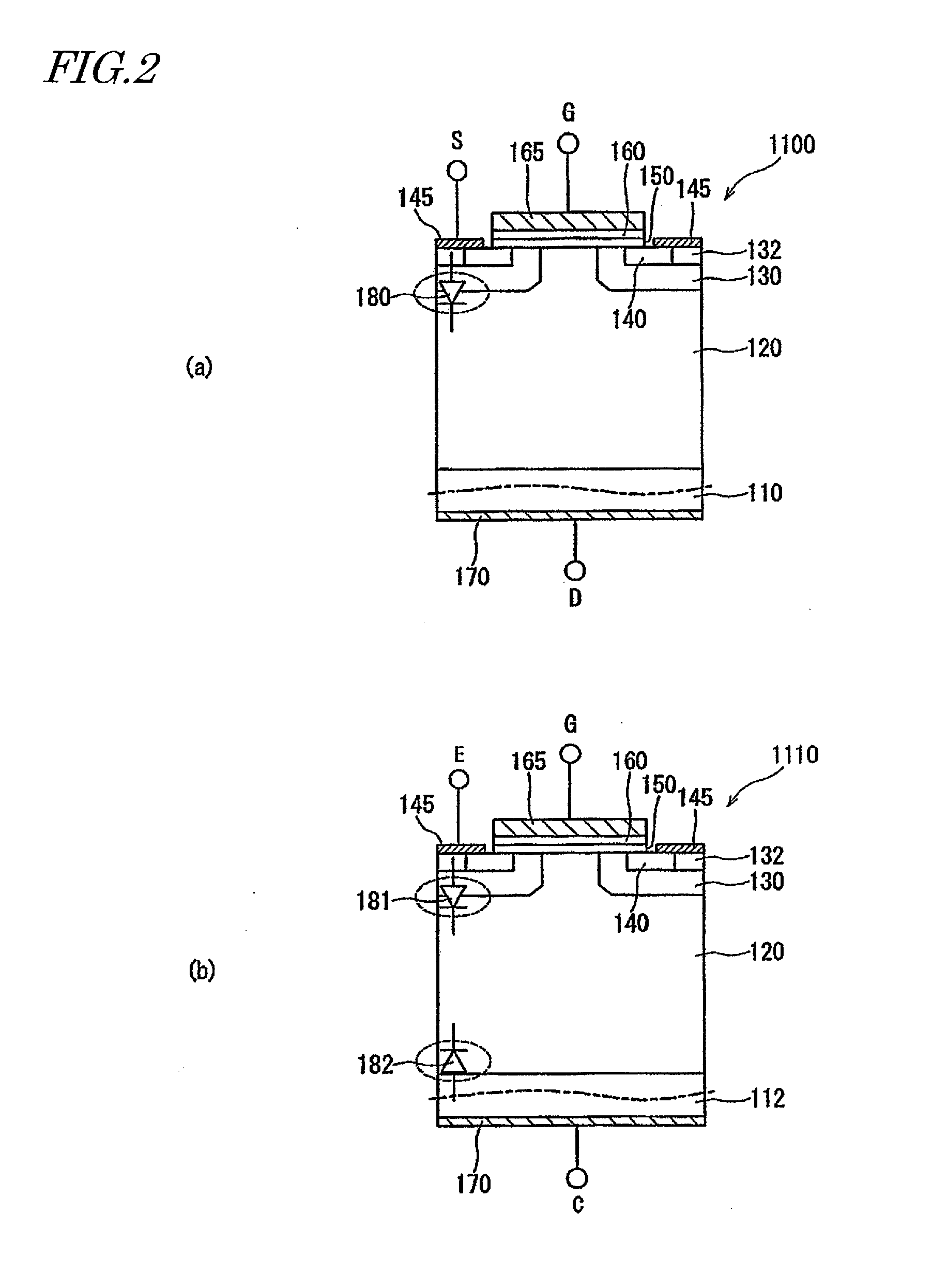

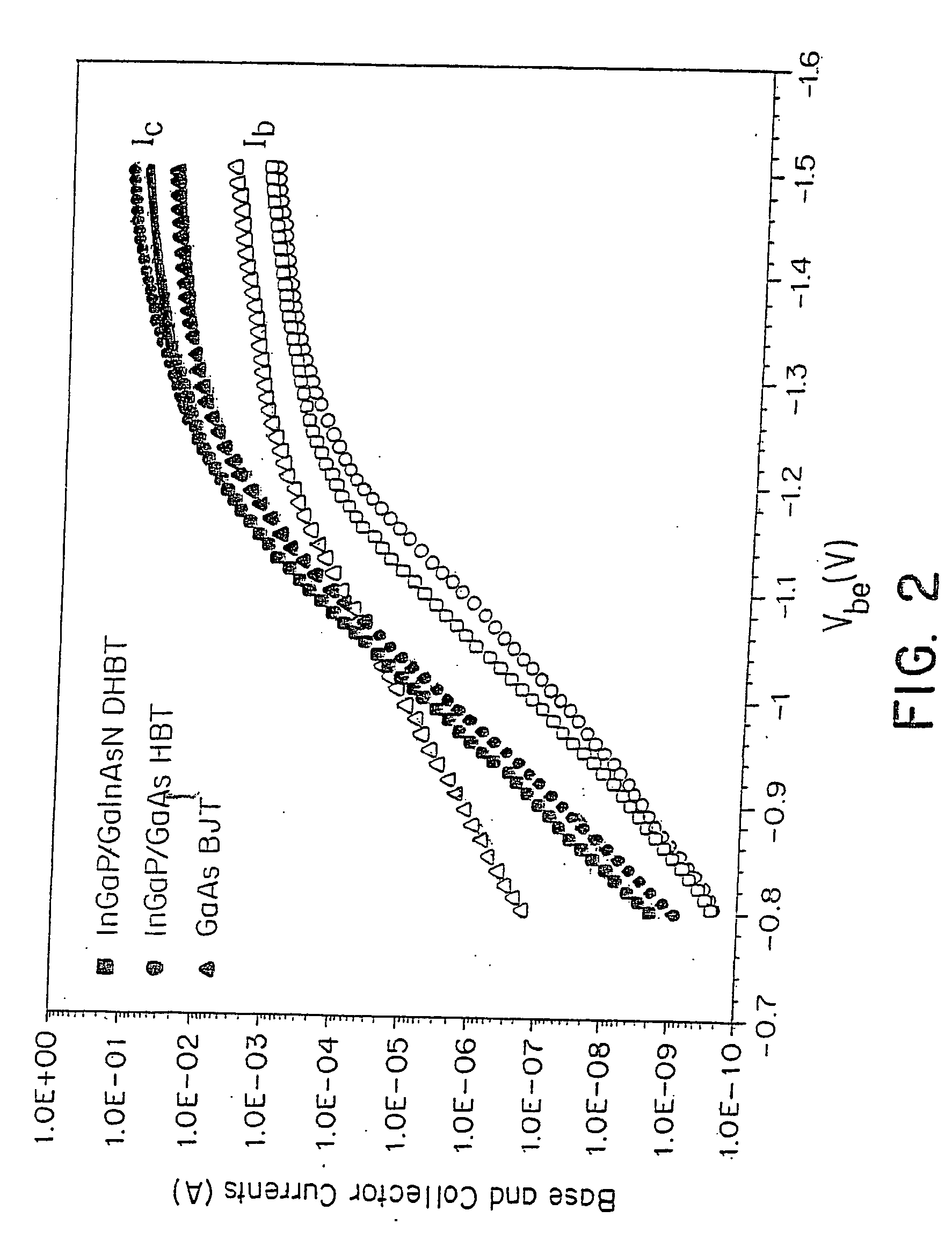

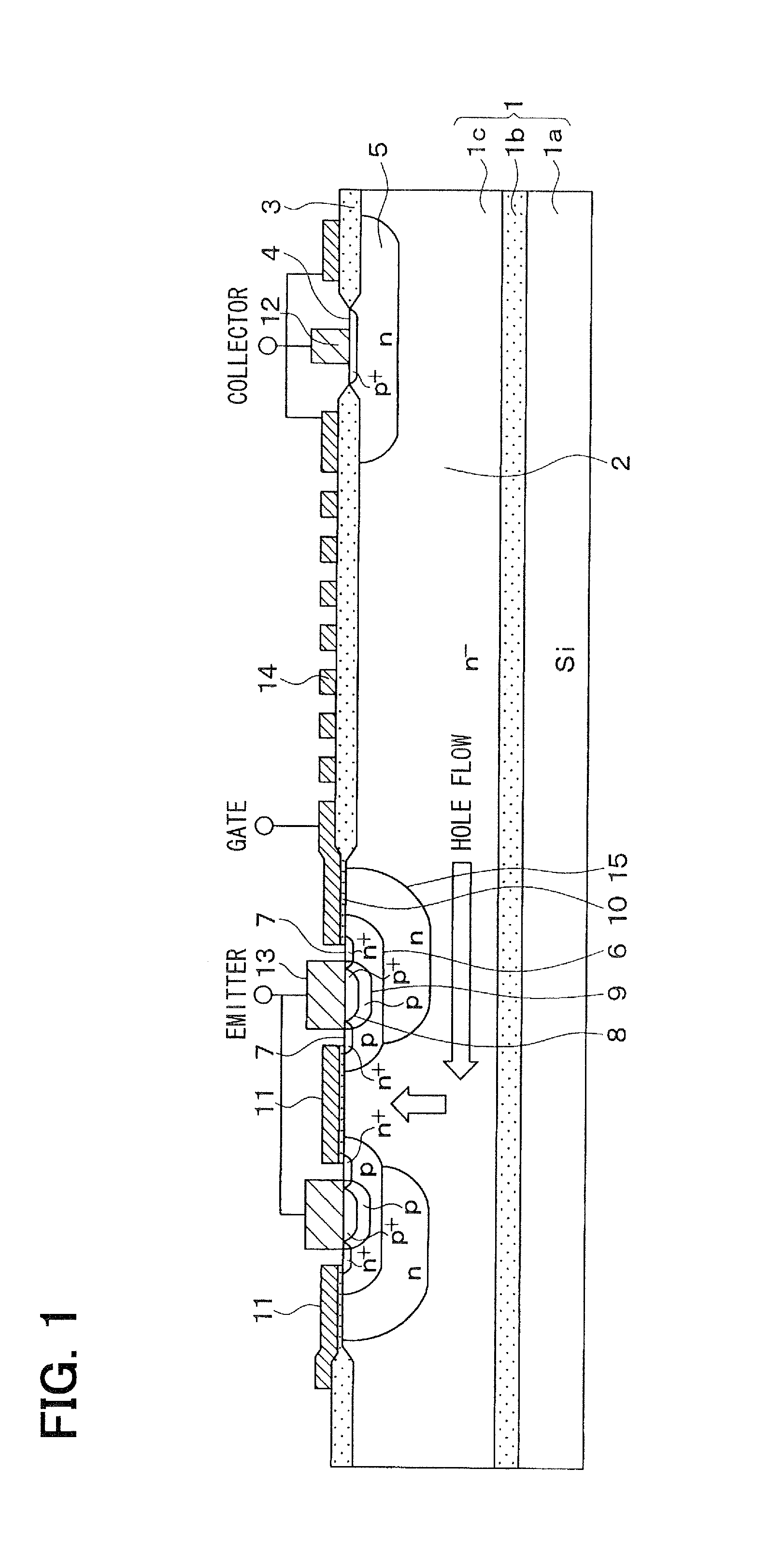

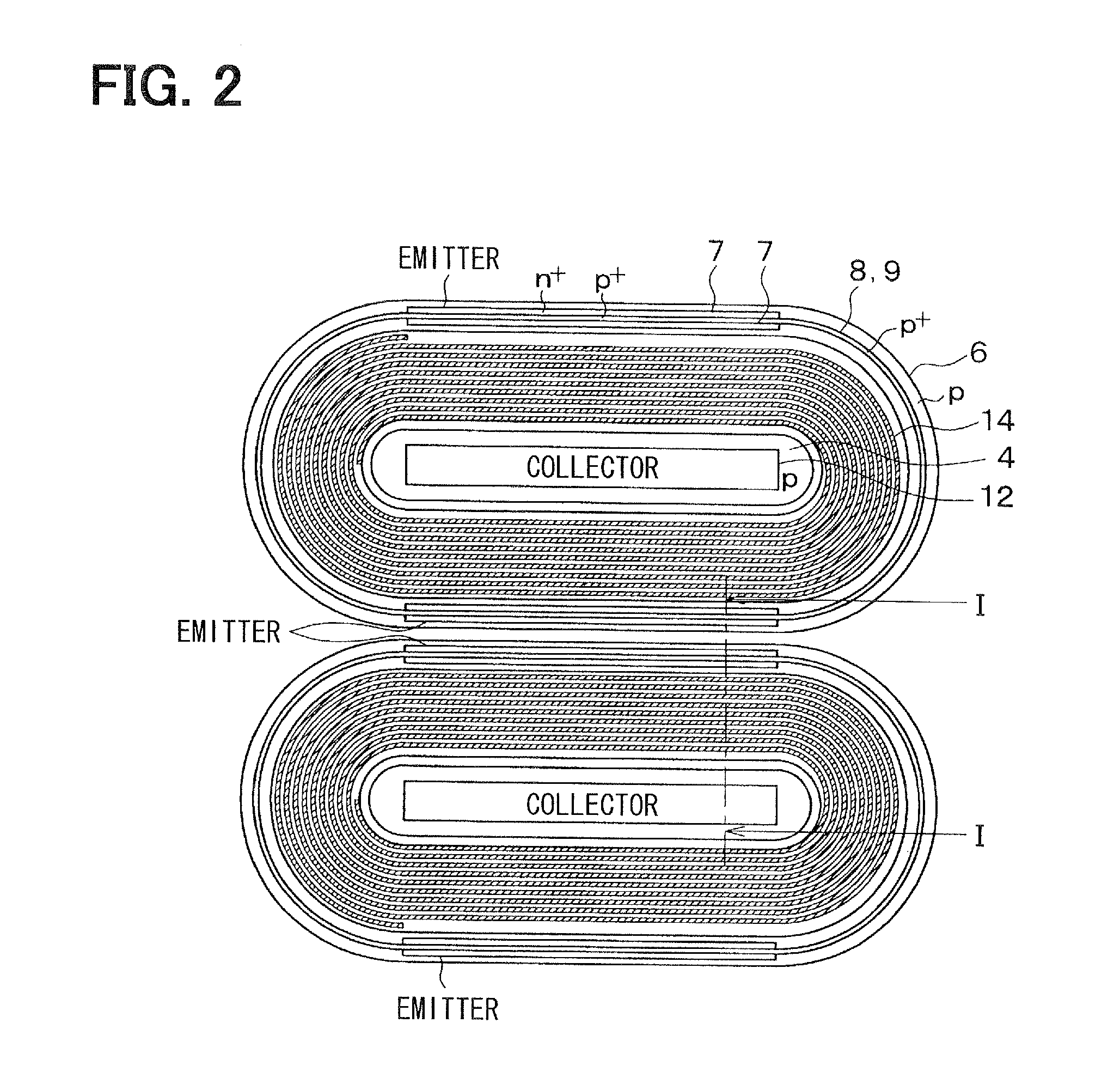

Semiconductor device having improved insulated gate bipolar transistor and method for manufacturing the same

InactiveUS20070267663A1Lower turn-on voltageSuppress power lossTransistorSemiconductor/solid-state device manufacturingHigh concentrationEngineering

An n-type first base layer is formed on a semiconductor substrate 1 having a first major surface and a second major surface, and a p-type second base layer is formed thereon. Between the first base layer and the second base layer, a carrier stored layer is formed. The carrier stored layer has a high-concentration impurity layer and a low concentration impurity layer, and the high-concentration impurity layer has a thickness of 1.5 μm or more and an impurity concentration therethrough is made to be 1.0×1016 cm−3 or more throughout the layer.

Owner:MITSUBISHI ELECTRIC CORP

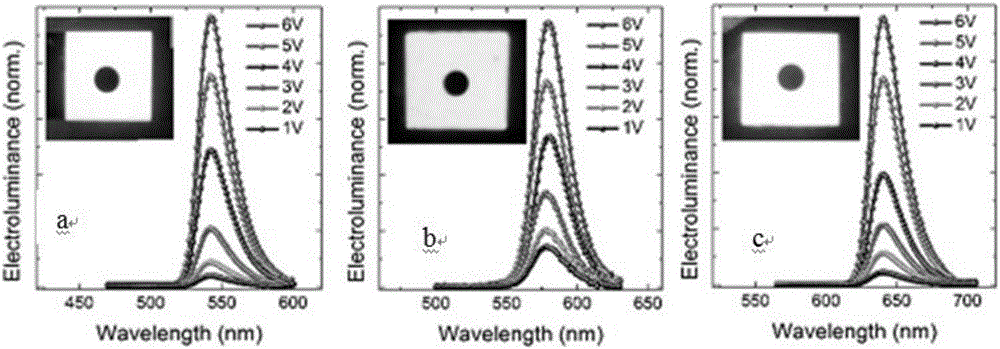

Top radiation organic EL part with optical spectrum adjustable

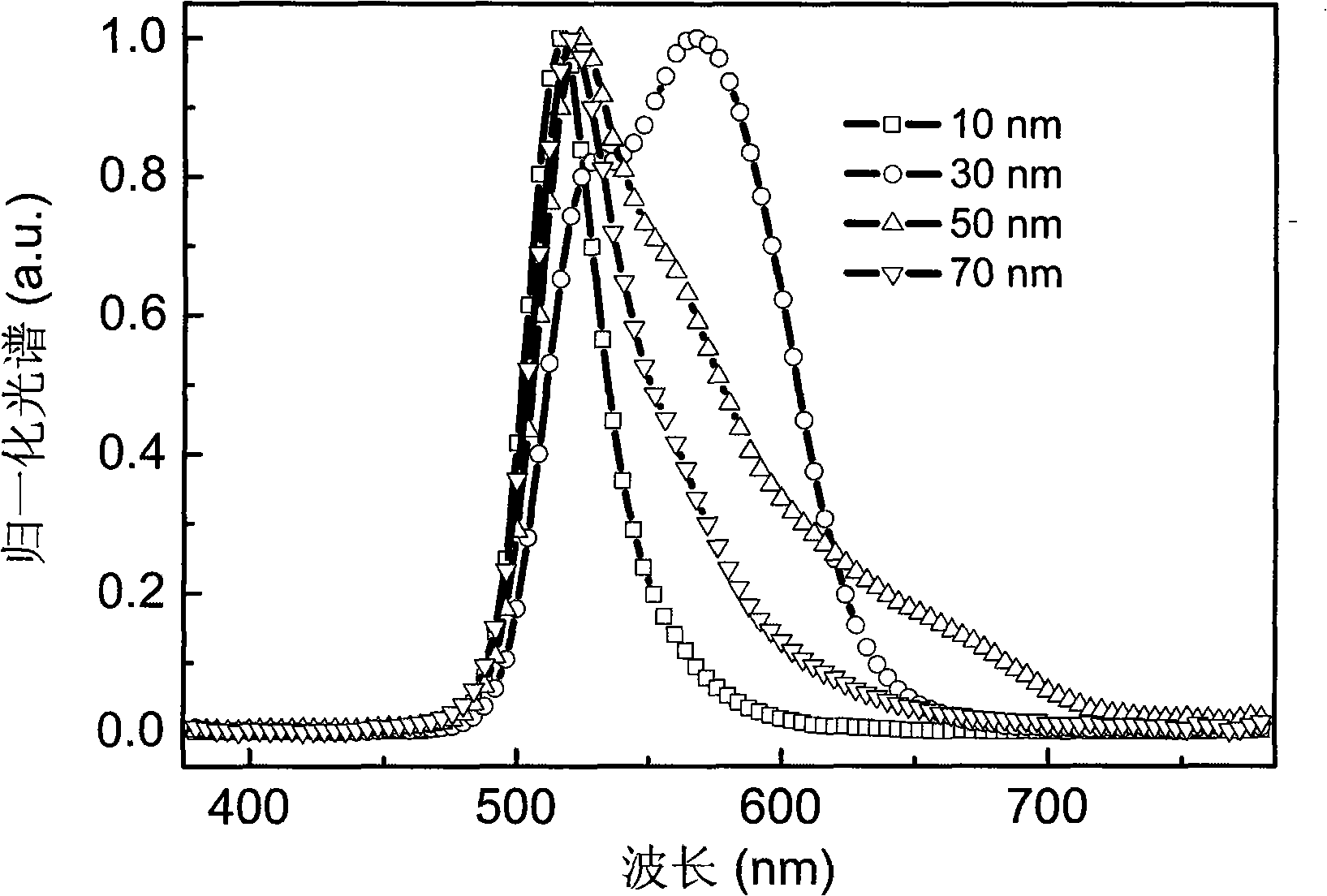

InactiveCN101359721ATuning the resonance wavelengthSimple processSolid-state devicesSemiconductor/solid-state device manufacturingSpectral widthPeak value

The invention belongs to the organic electroluminescence field, in particular to a top-emitting organic electroluminescent device having two structures and being capable of adjusting luminescent spectrums. The top-emitting device adopting an upright structure sequentially comprises a substrate, a metal anode, an organic function layer and a metal cathode, and a spectrum adjustment layer structure is introduced between the metal cathode and the organic function layer; and the top-emitting device adopting an inverted structure sequentially includes a substrate, a metal cathode, an organic function layer and a metal anode in structure, and a spectrum adjustment layer structure is introduced between the metal anode and the organic function layer. The introduction of the spectrum adjustment layer can adjust the spectral width of luminescent spectrum and the emission spectrum peak value of the top-emitting organic electroluminescent device, thereby changing the luminescent color of the device and finally realizing the top-emitting white light organic electroluminescent device with high brightness and high color-rendering indexes. The prepared top-emitting organic electroluminescent device with multiple photo-peaks and adjustable spectrums has the advantages of high brightness, high efficiency, less working procedure and simple process.

Owner:JILIN UNIV

High-Frequency Buck Converter that Includes a Cascode MESFET-MOSFET Power Switch

InactiveUS20080191679A1Lower on-resistanceLow off-state drain leakageDc-dc conversionElectric variable regulationMOSFETElectrical battery

A Buck converter that includes a cascode switch comprising a series connected MESFET and MOSFET power switch. The cascode power switch is typically connected in between a power source and a node Vx. The node Vx is connected to an output node via an inductor and to ground via a Schottky diode or a second MESFET or both. A control circuit drives the MESFET (and the second MESFET) so that the inductor is alternately connected to the battery and to ground. The MOSFET is switched off during sleep or standby modes to minimize leakage current through the MESFET. The MOSFET is therefore switched at a low frequency compared to the MESFET and does not contribute significantly to switching losses in the converter.

Owner:ADVANCED ANALOGIC TECHNOLOGIES INCORPORATED

DC-DC Converter that Includes a High Frequency Power MESFET Gate Drive Circuit

InactiveUS20080203991A1Lower on-resistanceLow off-state drain leakageTransistorDc-dc conversionDc dc converterHigh frequency power

Owner:ADVANCED ANALOGIC TECHNOLOGIES INCORPORATED

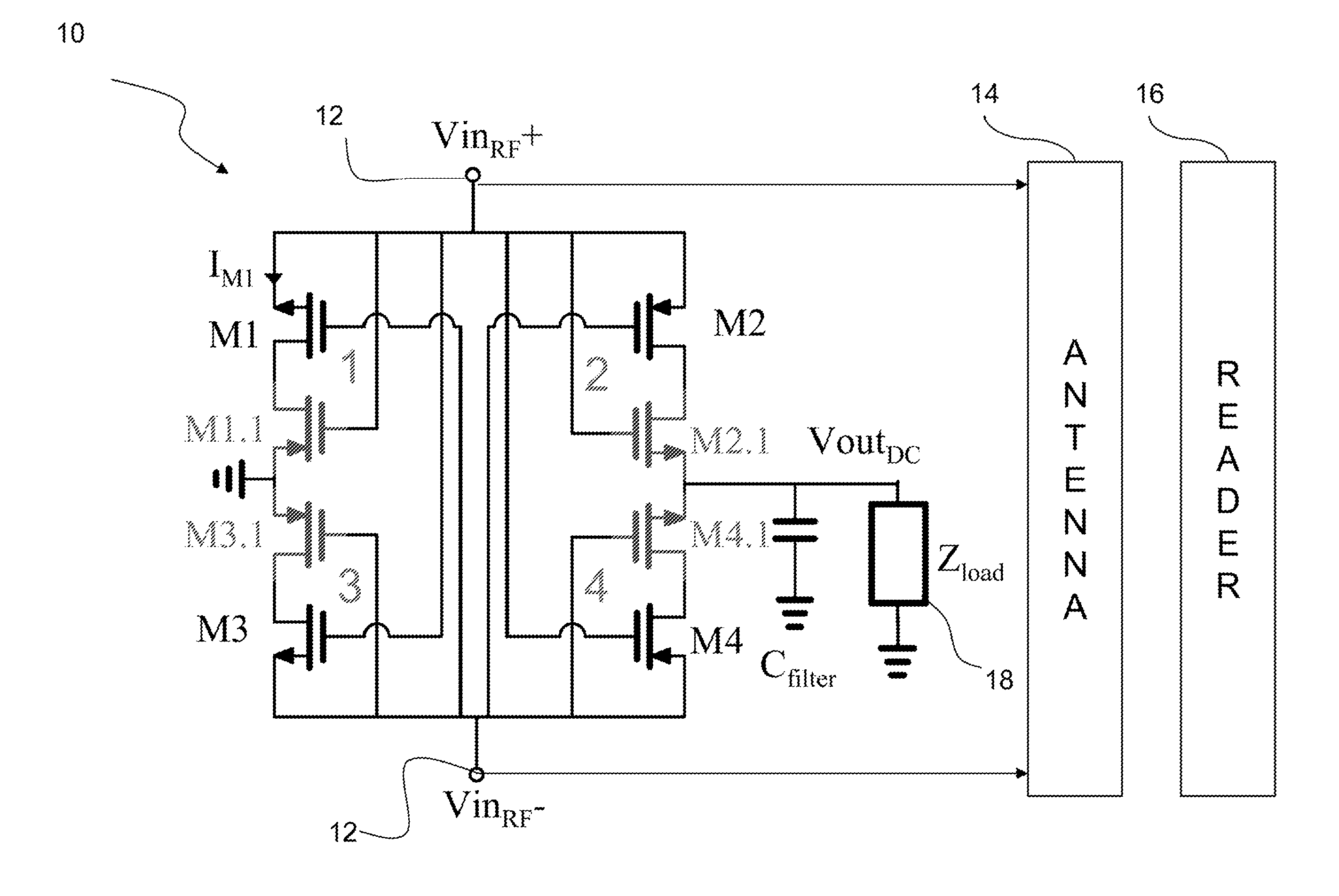

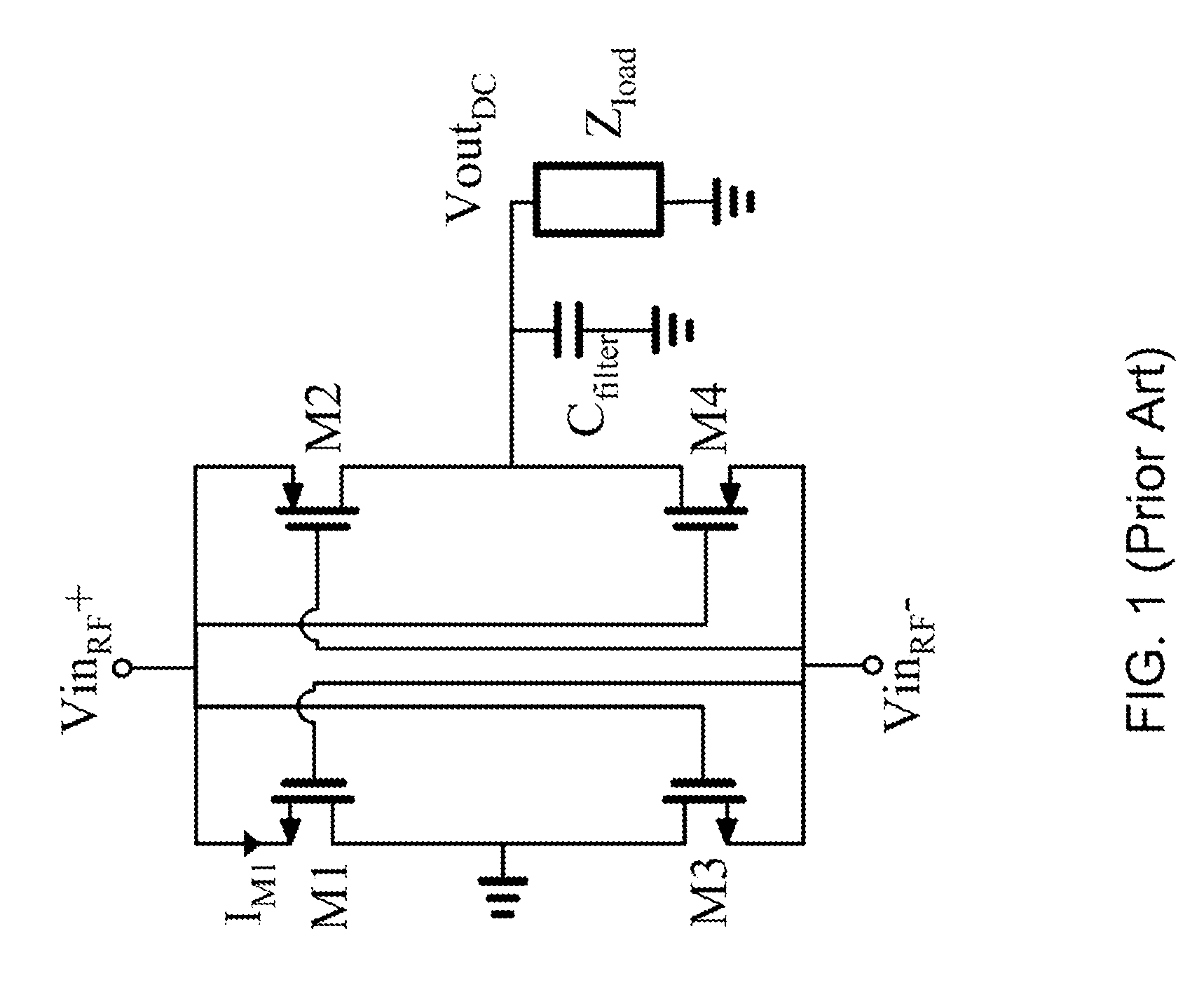

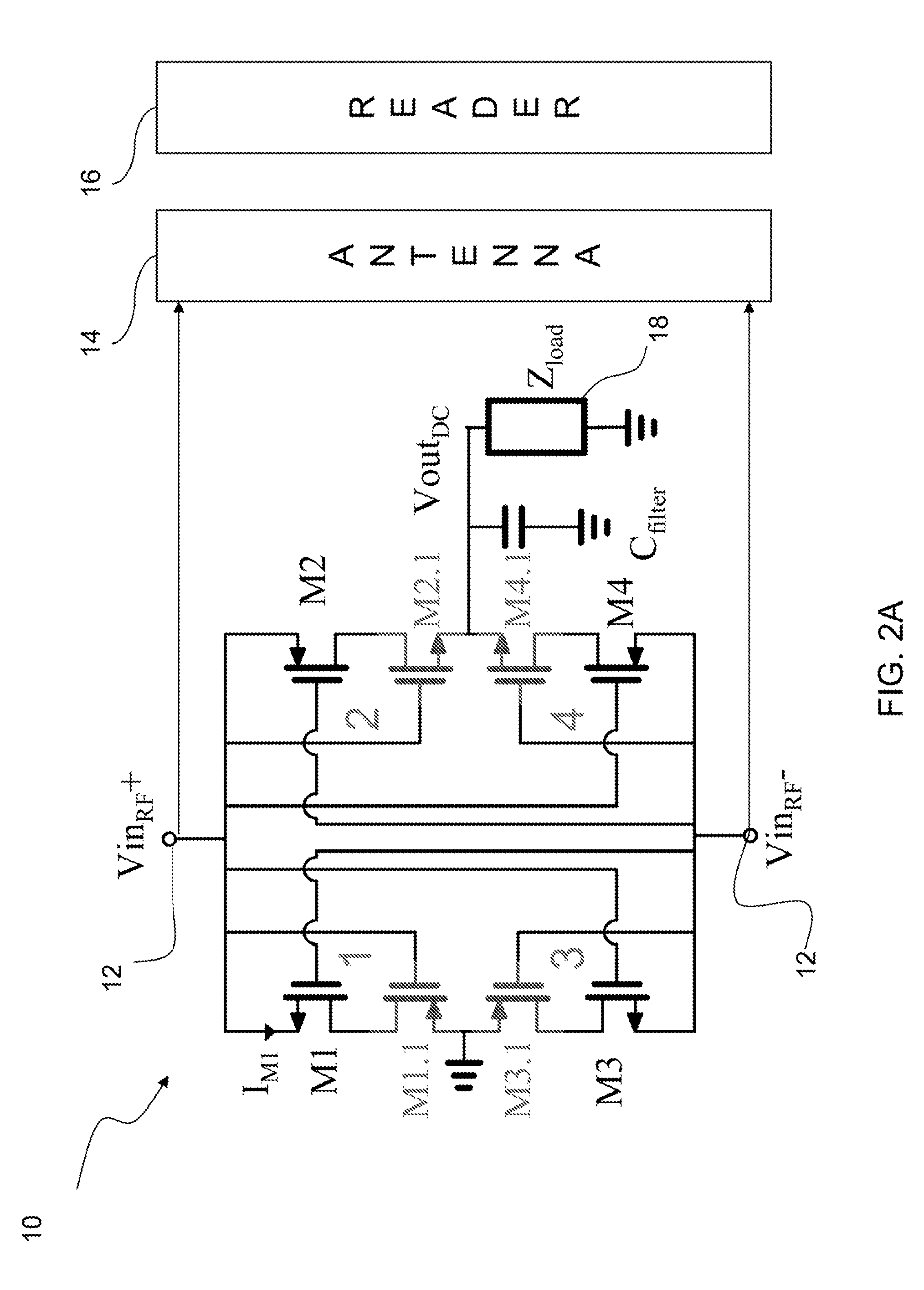

Switch mode voltage rectifier, RF energy conversion and wireless power supplies

InactiveUS20110124310A1Avoids reverse conduction problemIncrease the on-resistanceEfficient power electronics conversionCircuit arrangementsEngineeringDc voltage

Embodiments of the present invention provide cross-coupled rectifiers that use near zero-threshold transistors in a switching topology, but provide a topology that avoids reverse conduction problems. Importantly, preferred embodiment rectifiers of the invention only provide a slightly increased on-resistance in each branch, while providing both very high operating efficiency and very low turn-on voltage. An embodiment of the invention is a voltage rectifier for the conversion of RF energy into DC voltage with a turn-on threshold voltages approaching 0V.

Owner:RGT UNIV OF CALIFORNIA

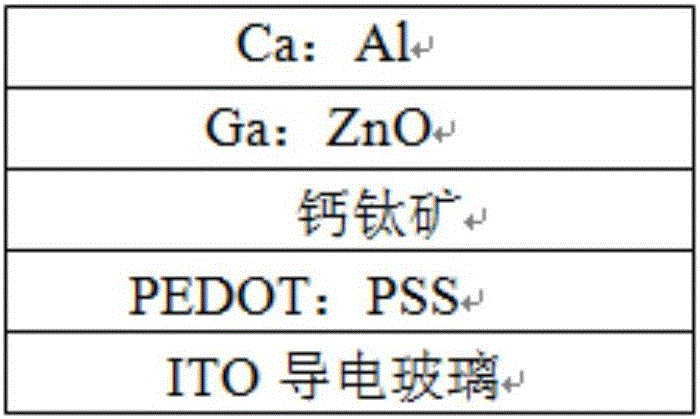

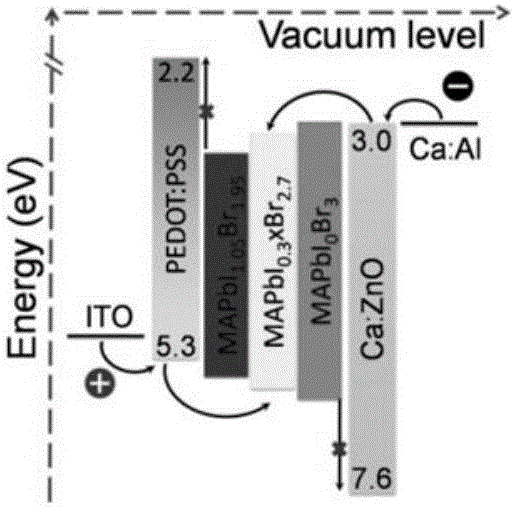

Dual-layer perovskite light emitting diode and preparation method therefor

ActiveCN106450009AIncrease contentReduce processing costsSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerLight-emitting diode

The invention relates to a dual-layer perovskite light emitting diode and a preparation method therefor. The dual-layer perovskite light emitting diode comprises the following components from the bottom up separately: ITO conductive glass is used as a positive electrode; a layer of poly 3, 4-ethylenedioxythiophene-polystyrolsulfon acid (PEDOT-PSS) with a thickness of about 20nm is used as a hole transport layer; a dual-layer perovskite light emitting layer is prepared by a spin-coating method in two times; the adopted dual-layer perovskite light emitting layer can be perovskite with different halogen ratios; a layer of calcium-doped zinc oxide (Ca:ZnO) with the thickness of about 50nm is spin-coated on the perovskite layer to be used as an electron transport layer; and finally metal calcium and aluminum are evaporated to be used as a negative electrode. According to the dual-layer perovskite light emitting diode and the preparation method therefor, on one hand, by regulating and controlling the Ca concentration in the Ca:ZnO, an optimal band gap is obtained, so that the barrier between the electron transport layer and the perovskite is reduced, and the cut-in voltage of the light emitting diode is lowered consequently, and the light emitting efficiency and internal quantum efficiency of the light emitting diode are improved at the same time; and on the other hand, by regulating the halogen ratios in the perovskite, light emission with different colors can be realized.

Owner:SUZHOU UNIV

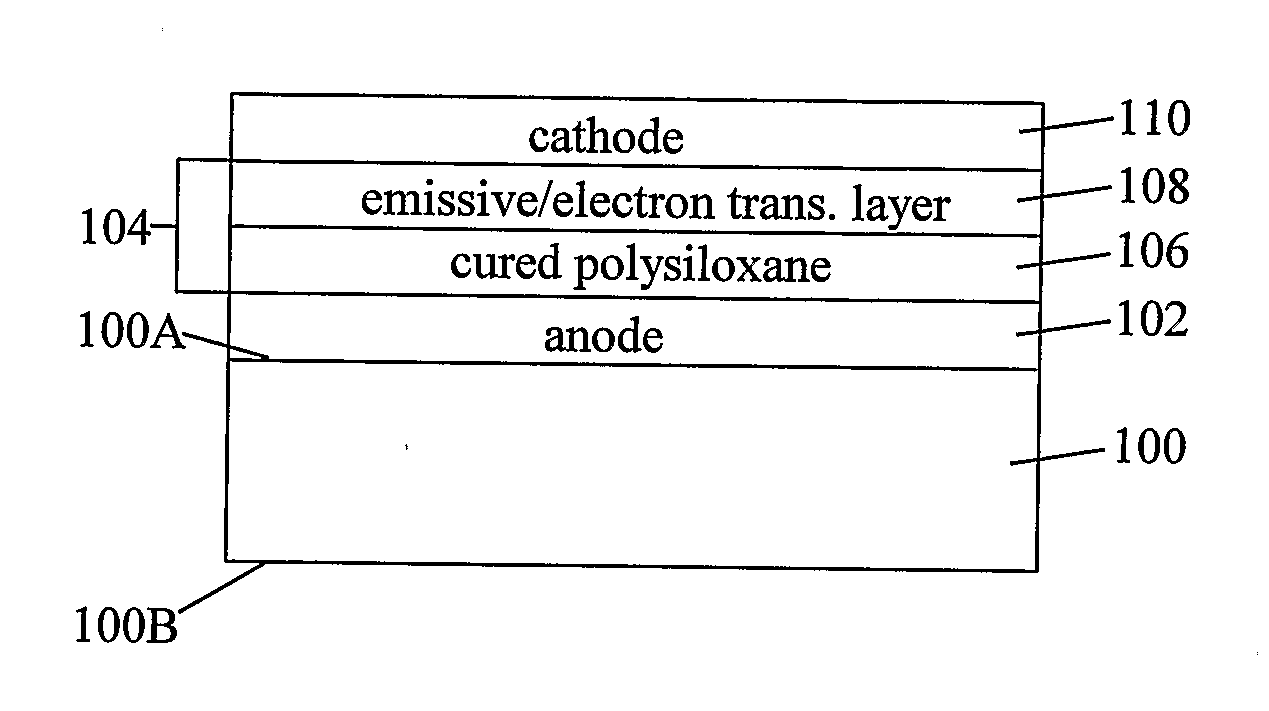

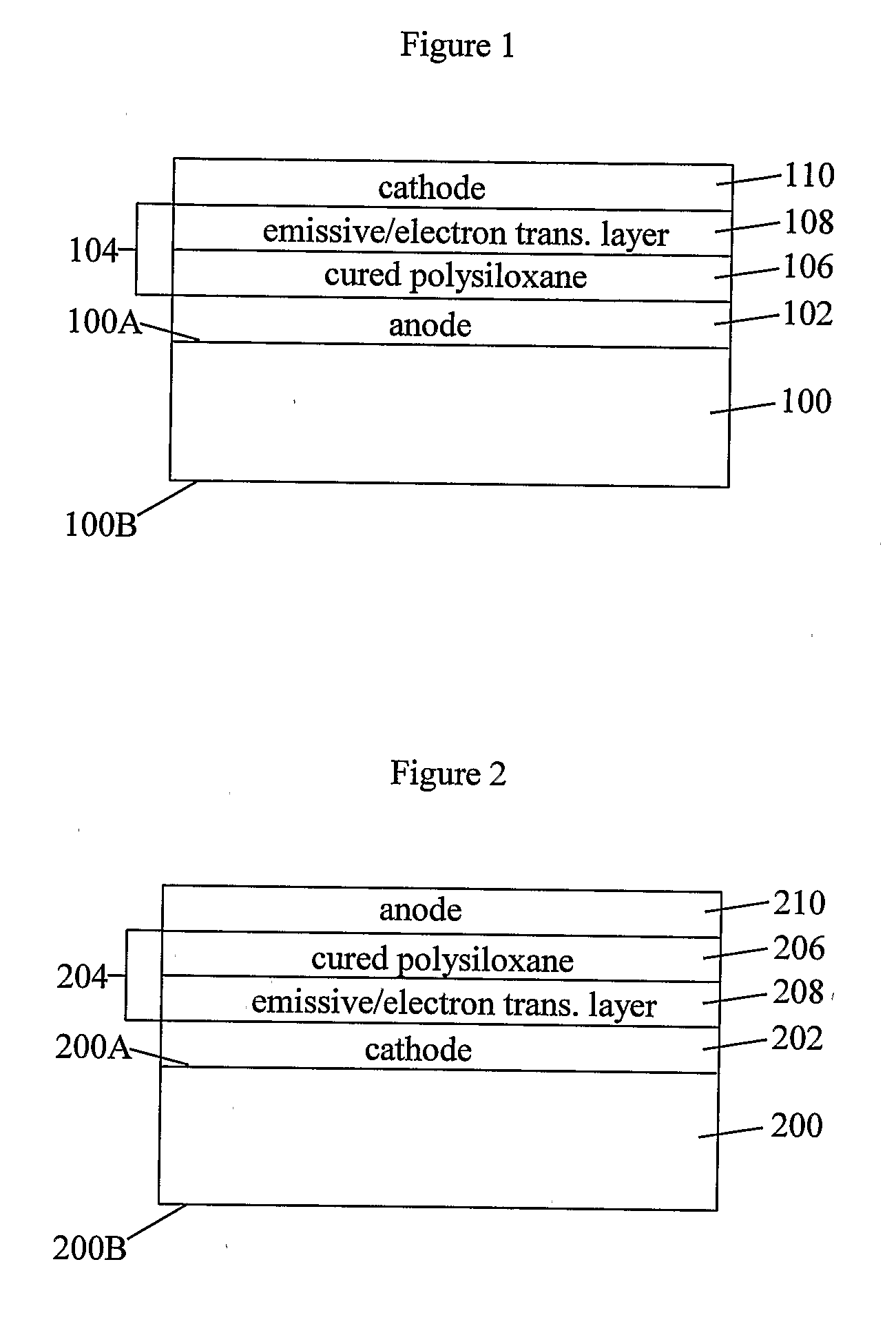

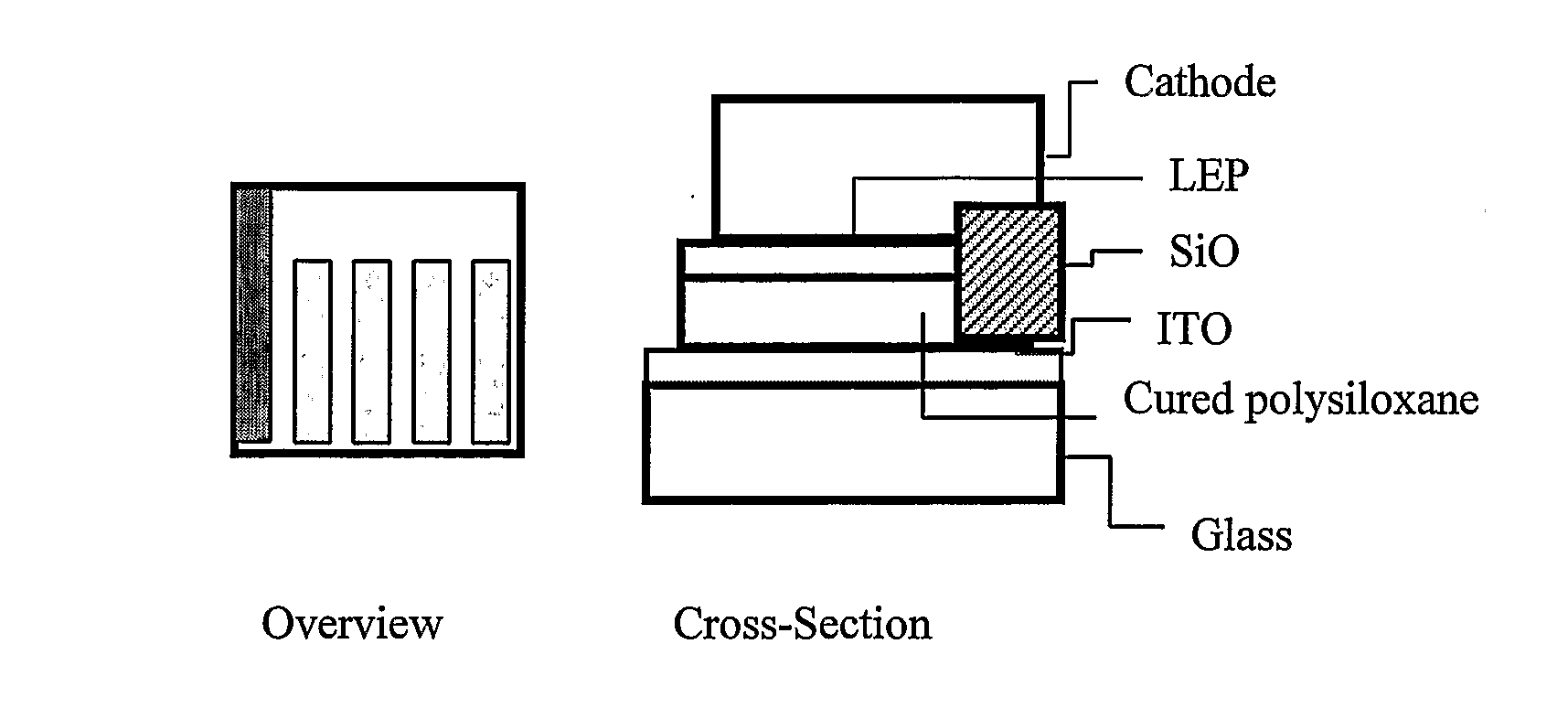

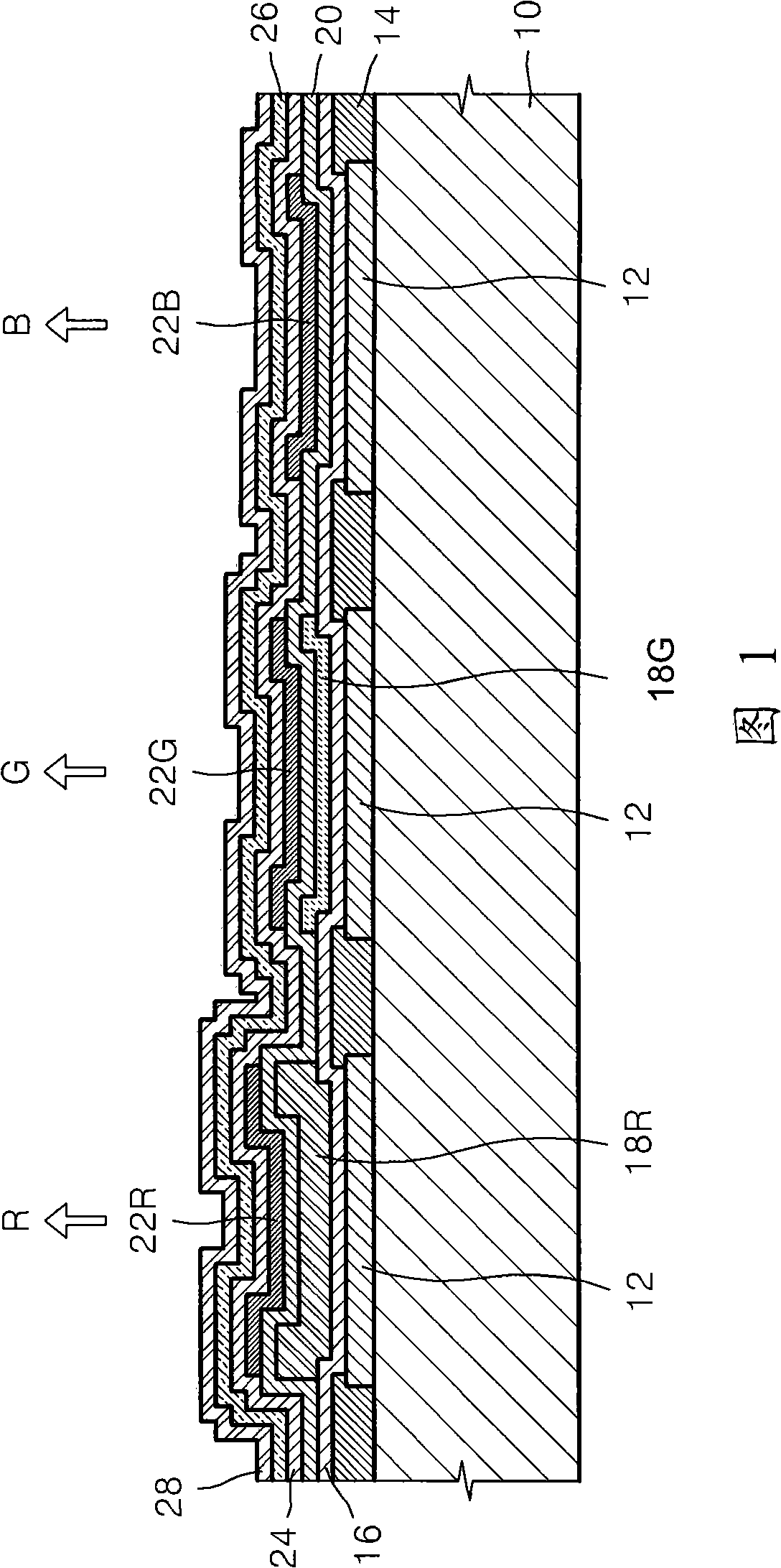

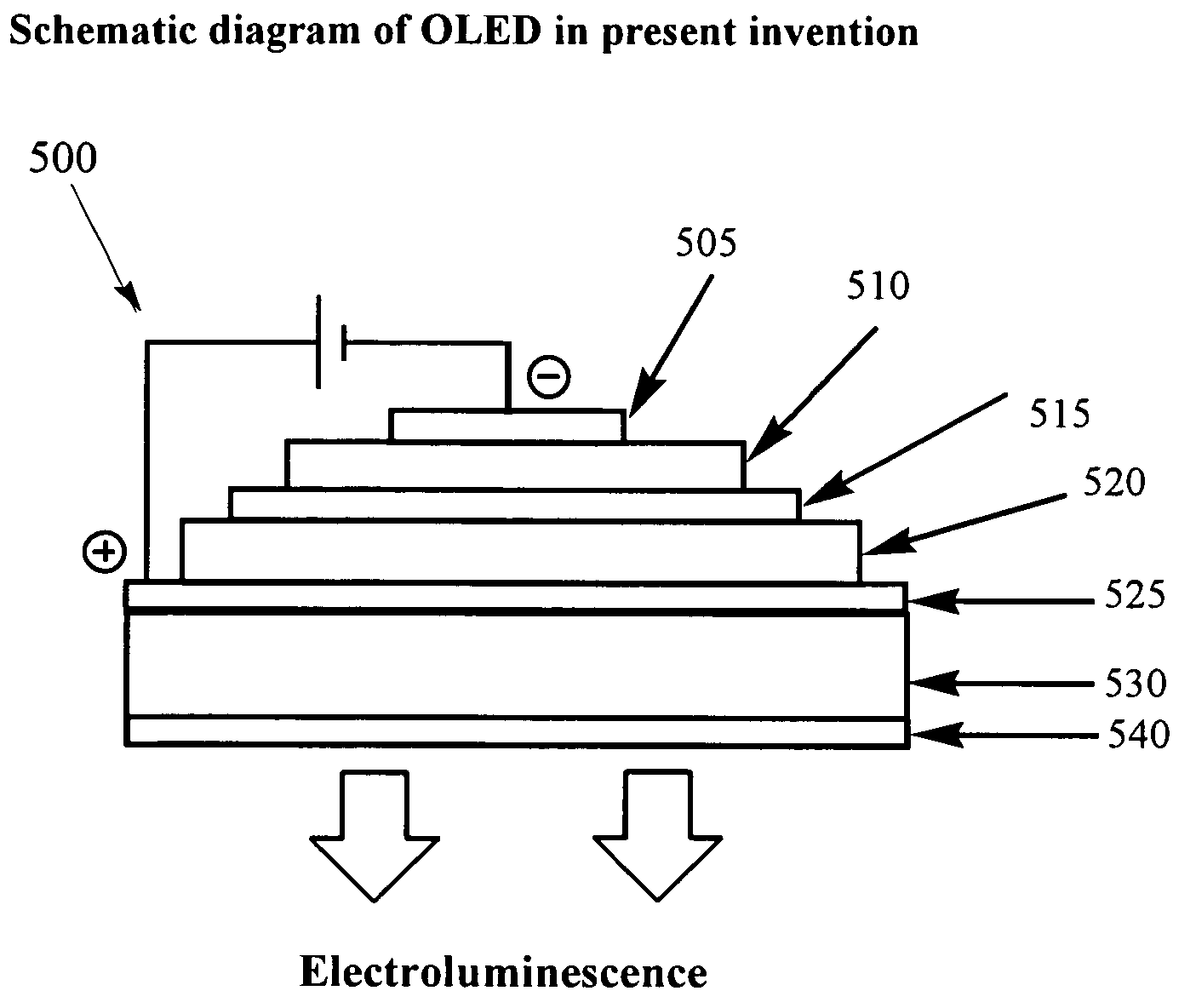

Organic light-emitting diode

InactiveUS20070131925A1Lower turn-on voltageIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerElectron transport layer

An organic light-emitting diode comprising a substrate having a first opposing surface and a second opposing surface; a first electrode layer overlying the first opposing surface; a lightemitting element overlying the first electrode layer, the light-emitting element comprising a hole-transport layer and an emissive / electron-transport layer, wherein the hole-transport layer and the emissive / electron-transport layer lie directly on one another, and the hole-transport layer comprises a cured polysiloxane prepared by applying a silicone composition to form a film and curing the film, wherein the silicone composition comprises a polysiloxane having a group selected from carbazolyl, fluoroalkyl, and pentafluorophenylalkyl; and a second electrode layer overlying the light-emitting element.

Owner:SHALK PAUL +2

Quantum dot light emitting diode and manufacturing method thereof

InactiveCN107293647AReduce reflectionEasy injectionSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeQuantum dot

The invention discloses a quantum dot light emitting diode and a manufacturing method thereof. The quantum dot light emitting diode comprises a substrate, a cathode, an electron transport layer, a quantum dot light emitting layer, a hole transport layer, and an anode stacked in sequence. The quantum dot light emitting diode is characterized in that the upper surface of the electron transport layer is provided with a nano convex-concave structure which is in quasi-periodic or aperiodic shape, and refractive index of the nano convex-concave structure shows gradient changes along an emergent light direction. Efficiency of an inverted structure quantum dot light emitting diode is obviously improved, and the efficiency is far ahead efficiency of other inverted quantum dot devices.

Owner:SUZHOU UNIV

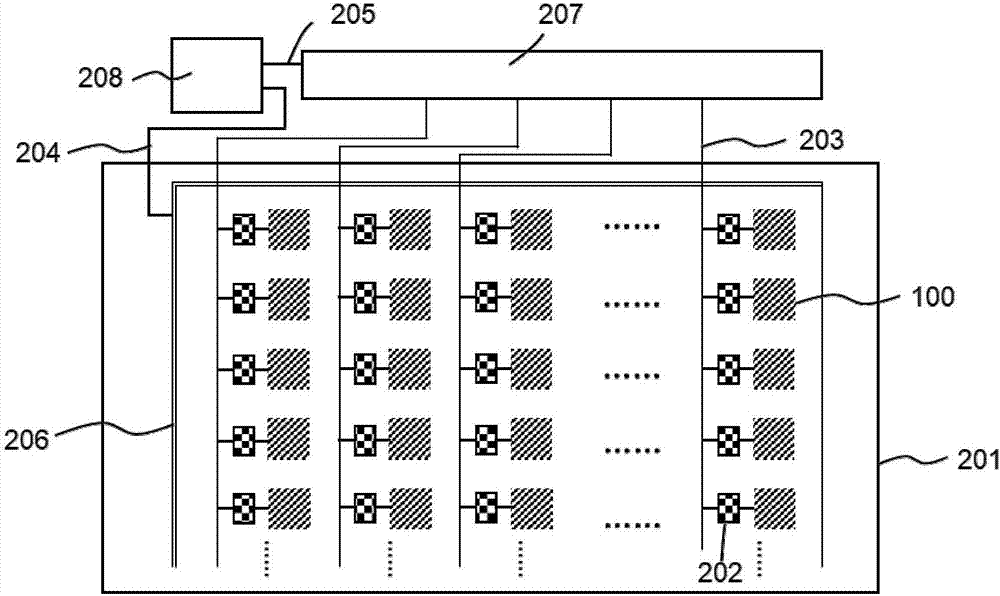

Organic light emitting device

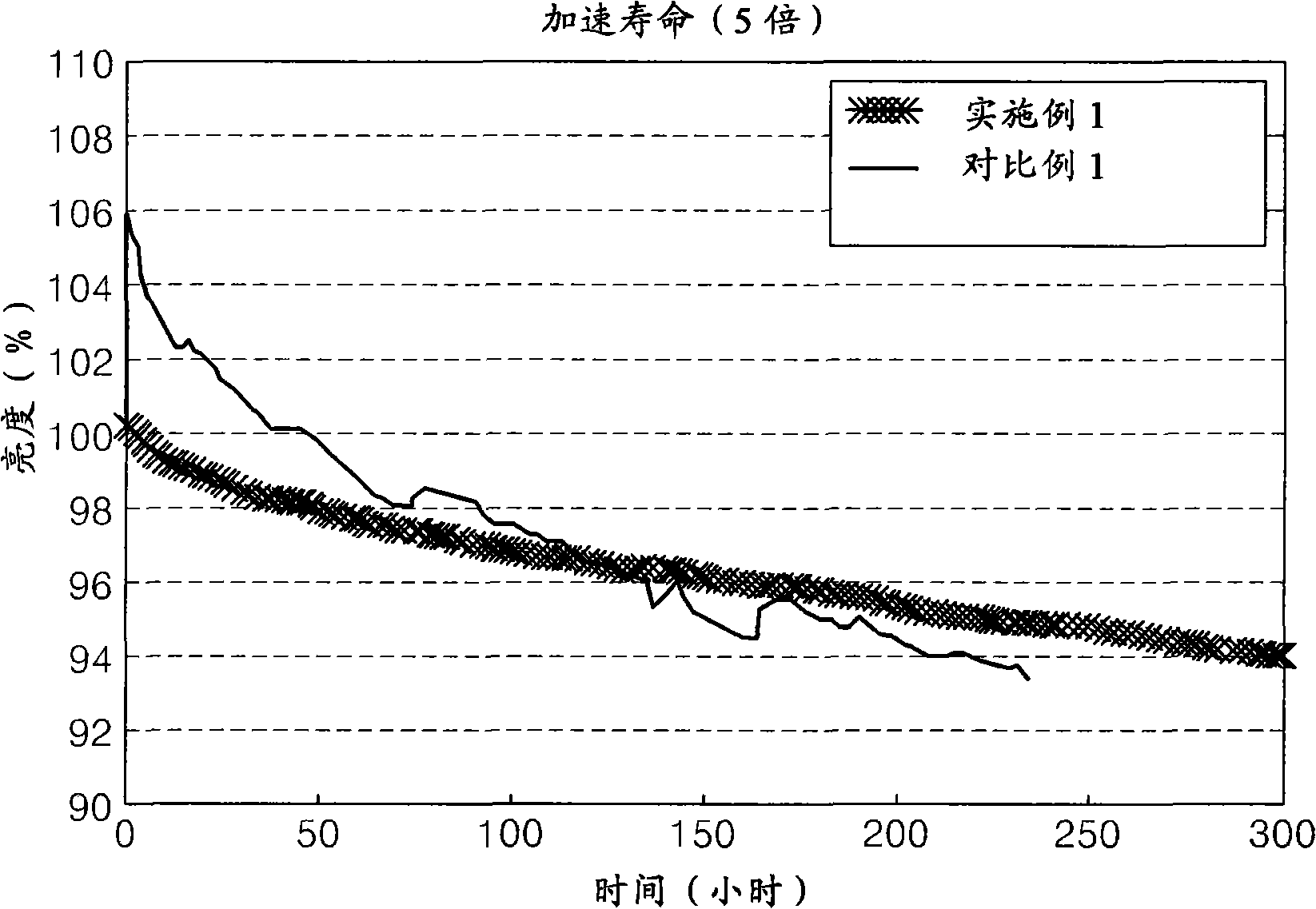

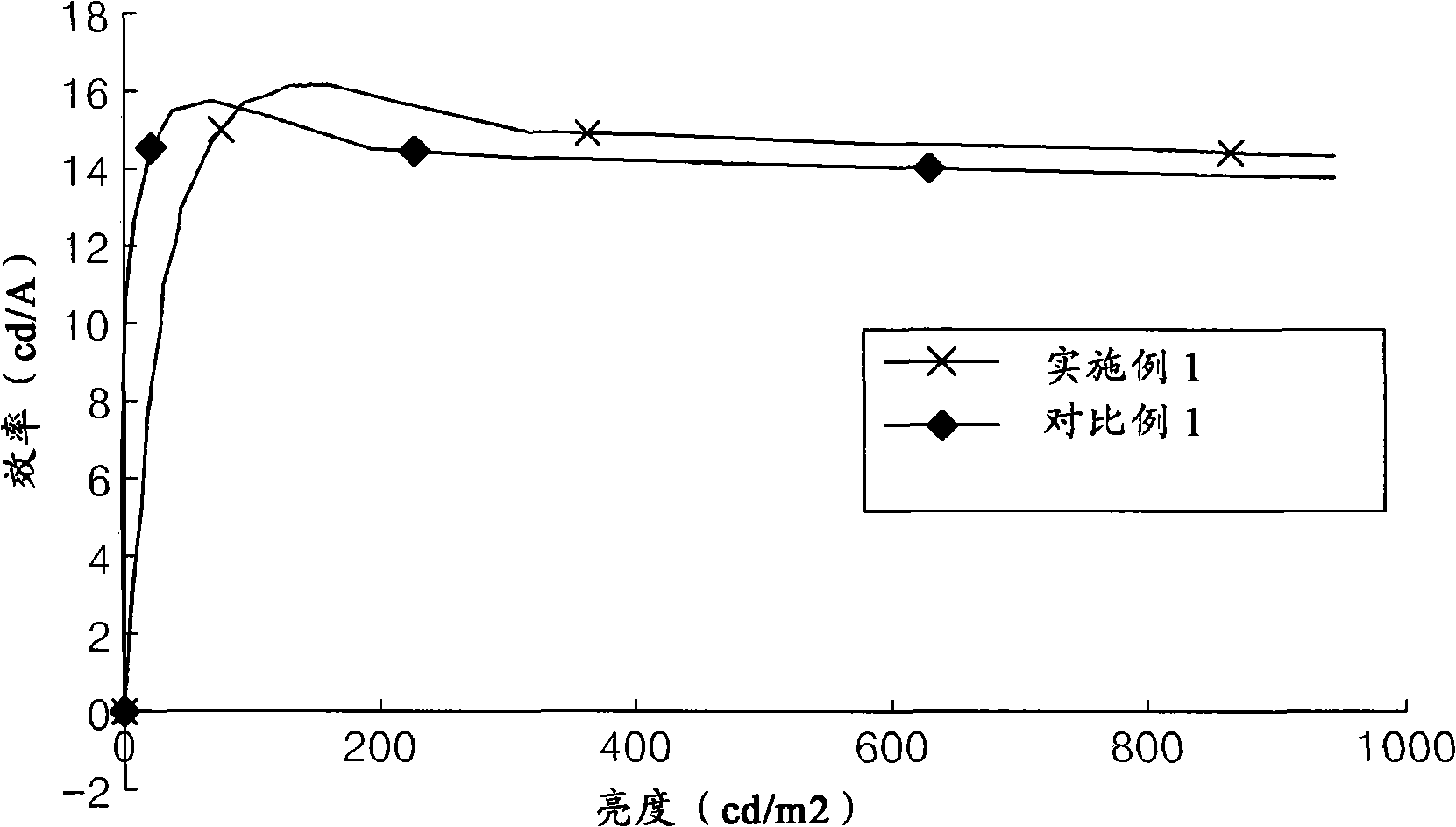

ActiveCN101308863ALower turn-on voltageIncrease current densityElectroluminescent light sourcesSolid-state devicesHigh current densityOrganic layer

Organic light emitting devices (OLEDs) are provided. An exemplary OLED includes a substrate, a first electrode, a second electrode, and an organic layer between the first and second electrodes having a hole injection layer and an emissive layer. The emissive layer includes red, green and blue emissive layers. The organic layer further includes an auxiliary layer selected from a first auxiliary layer between the hole injection layer and the red emissive layer for adjusting the resonance cycle of red light, a second auxiliary layer between the hole injection layer and the green emissive layer for adjusting the resonance cycle of green light, and combinations thereof. The material of the auxiliary layer is different from the material of the hole injection layer. The organic light emitting device has low turn-on voltage, high current density, high luminance, high current efficiency, high power, long life-time, and excellent color purity.

Owner:SAMSUNG DISPLAY CO LTD

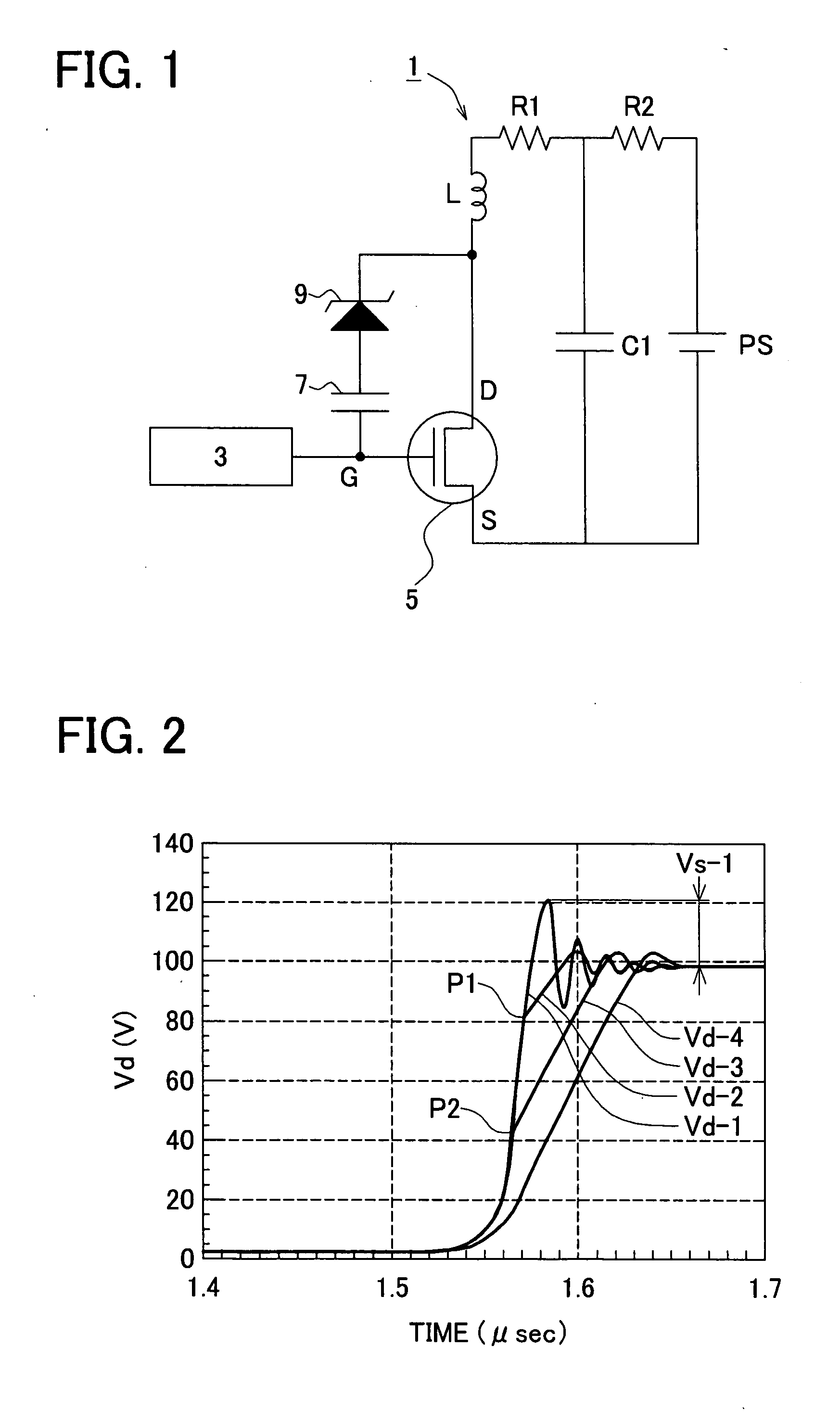

Switching circuit and driving circuit for transistor

InactiveUS20080012610A1Small surge voltageLower on-resistanceTransistorPulse automatic controlZener diodeEngineering

A switching circuit includes: a transistor having a first electrode, a second electrode and a control electrode; a zener diode; and a capacitor. A connection between the first electrode and the second electrode is capable of temporally switching between a condition state and a non-conduction state by switching a control voltage of the transistor. The zener diode and the capacitor are coupled in series between the first electrode and the control electrode of the transistor. The first electrode is a drain or a collector.

Owner:DENSO CORP

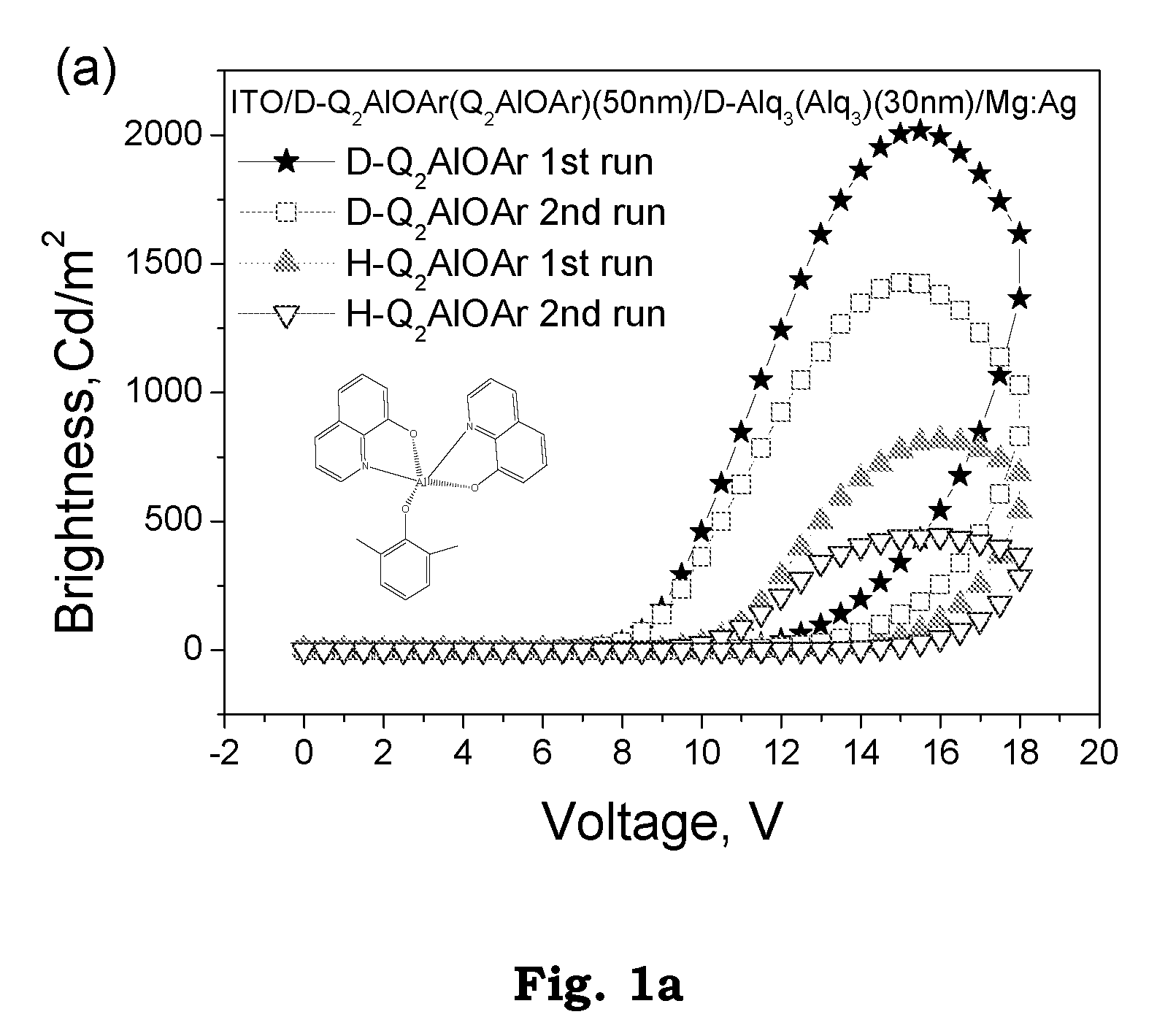

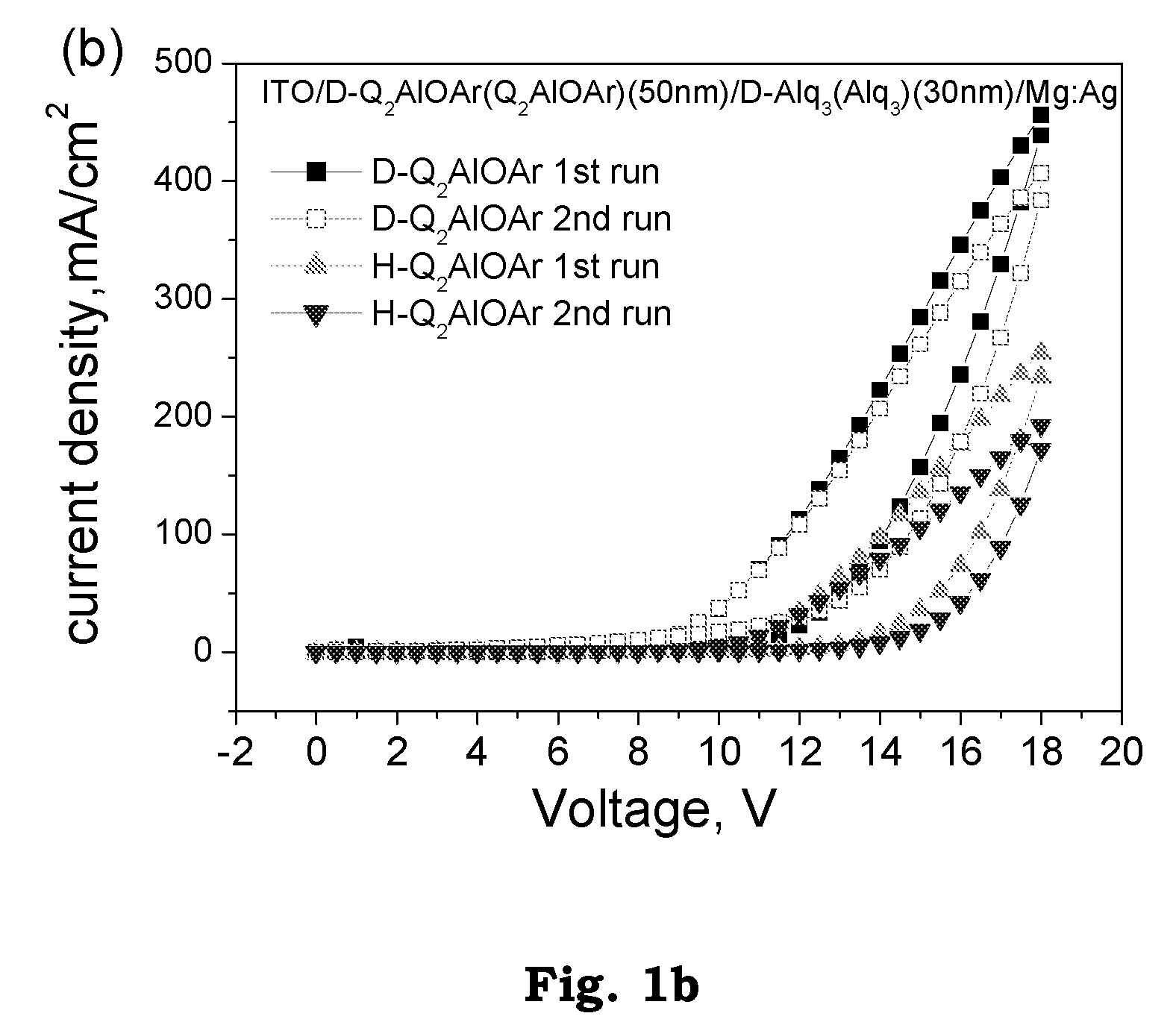

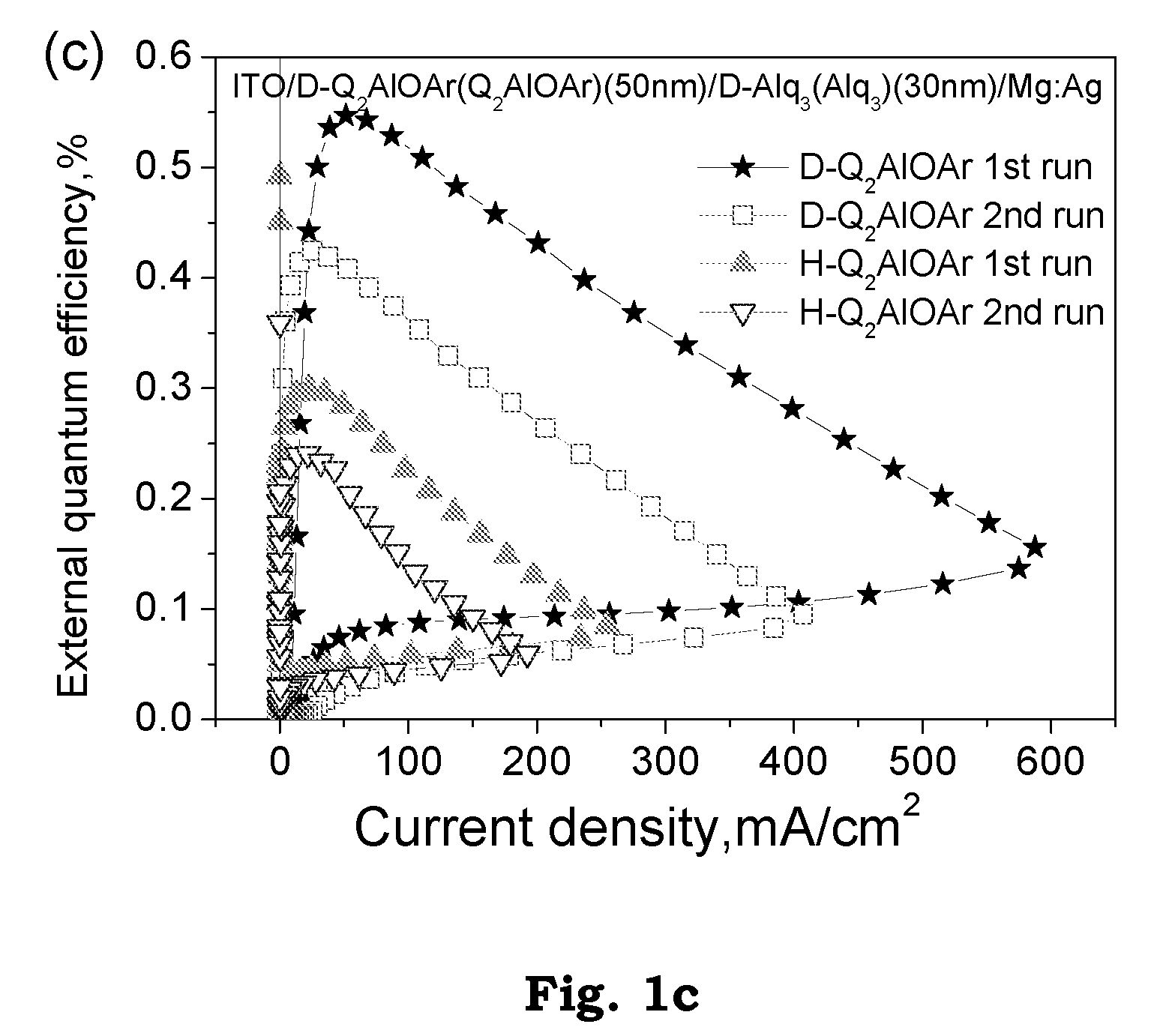

Deuterated Semiconducting Organic Compounds for Use in Light-Emitting Devices

InactiveUS20090295274A1Improve voltage stabilityLower turn-on voltageGroup 4/14 element organic compoundsGroup 1/11 element organic compoundsEnergy transferTransport layer

The present invention discloses deuterated semiconducting organic compounds. The deuterated semiconducting organic compounds comprise at least one partially or fully deuterated non-conjugated portion linked to the conjugated portion. The mentioned deuterated semiconducting organic compounds can be used in optoelectronic devices, such as light-emitting devices and photodiodes, with enhanced performance and lifetime. The deuterated semiconducting organic compounds of this application can be employed as emissive layer, charge-transporting layer, or energy transfer material in organic light-emitting devices.

Owner:HWANG KUO CHU

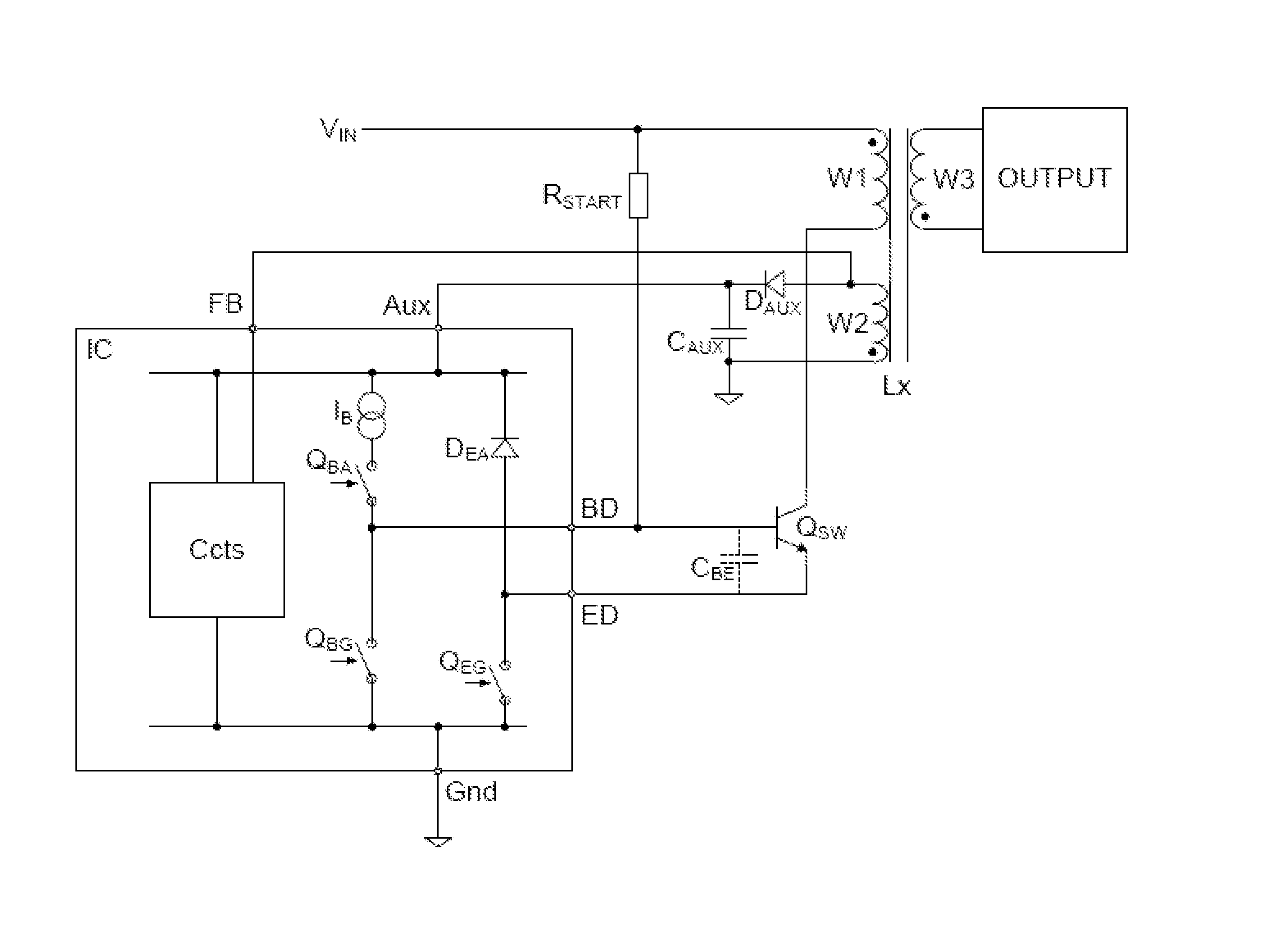

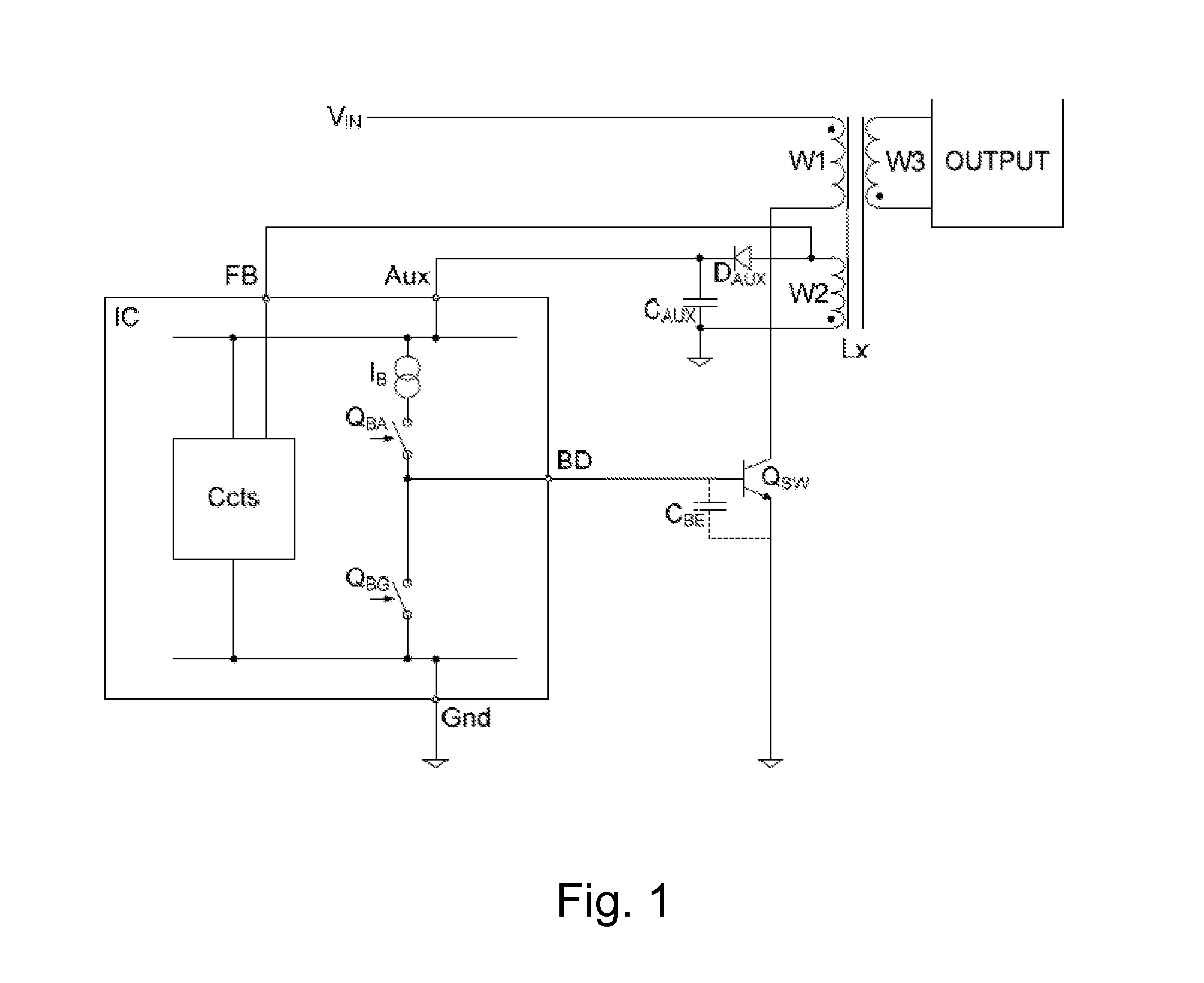

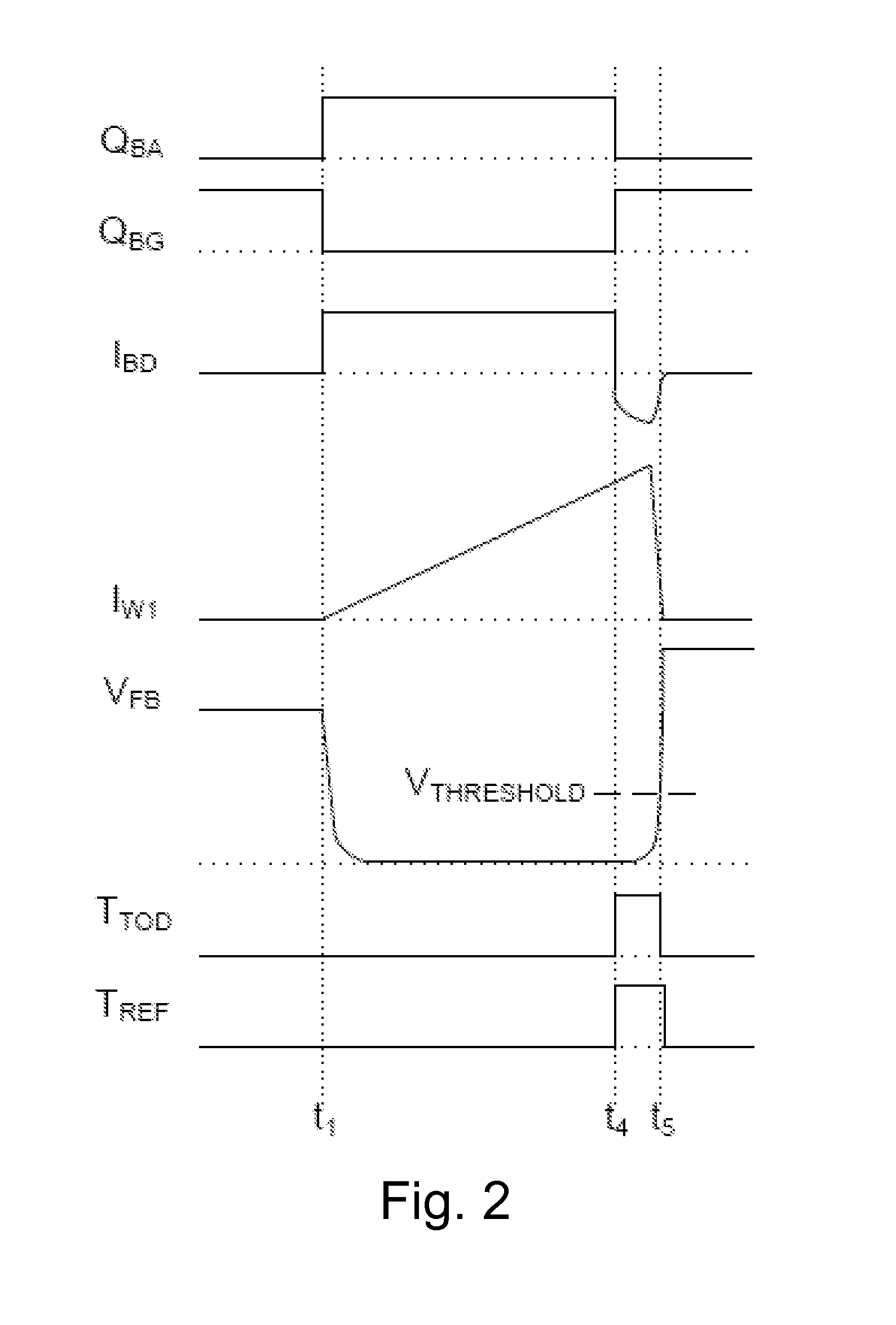

Storage time control

InactiveUS20140355314A1Reduce control signalingHigh first amplitudeTransistorEfficient power electronics conversionSwitching cycleTime delays

We describe a method of controlling turn off time delay of a switching device of a switch mode power converter (SMPC). The SMPC has an inductive component comprising an input winding coupled to receive power from an input; and a switching device to, when on, conduct input winding current. In embodiments the method comprises applying turn on and turn-off signals to the switching device; applying at least one turn off signal, to initiate turning off of the switching device, and detecting a sensing signal from a further winding of the inductive component, inductively coupled to the input winding, to thereby indicate an end of a turn off time delay or duration. The method controls the turn on signal for a subsequent switching cycle of the SMPC device to regulate the turn off delay time.

Owner:POWER INTEGRATIONS INC

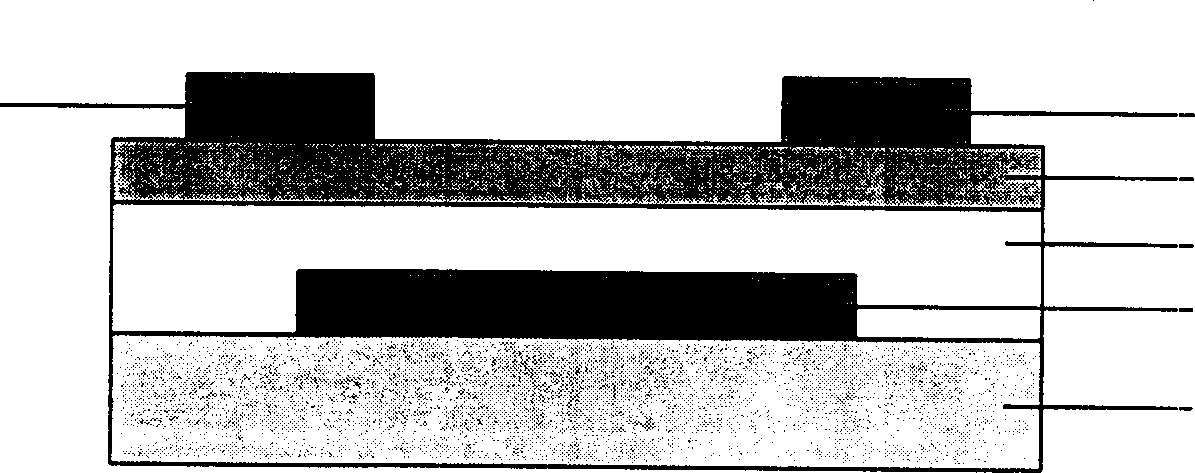

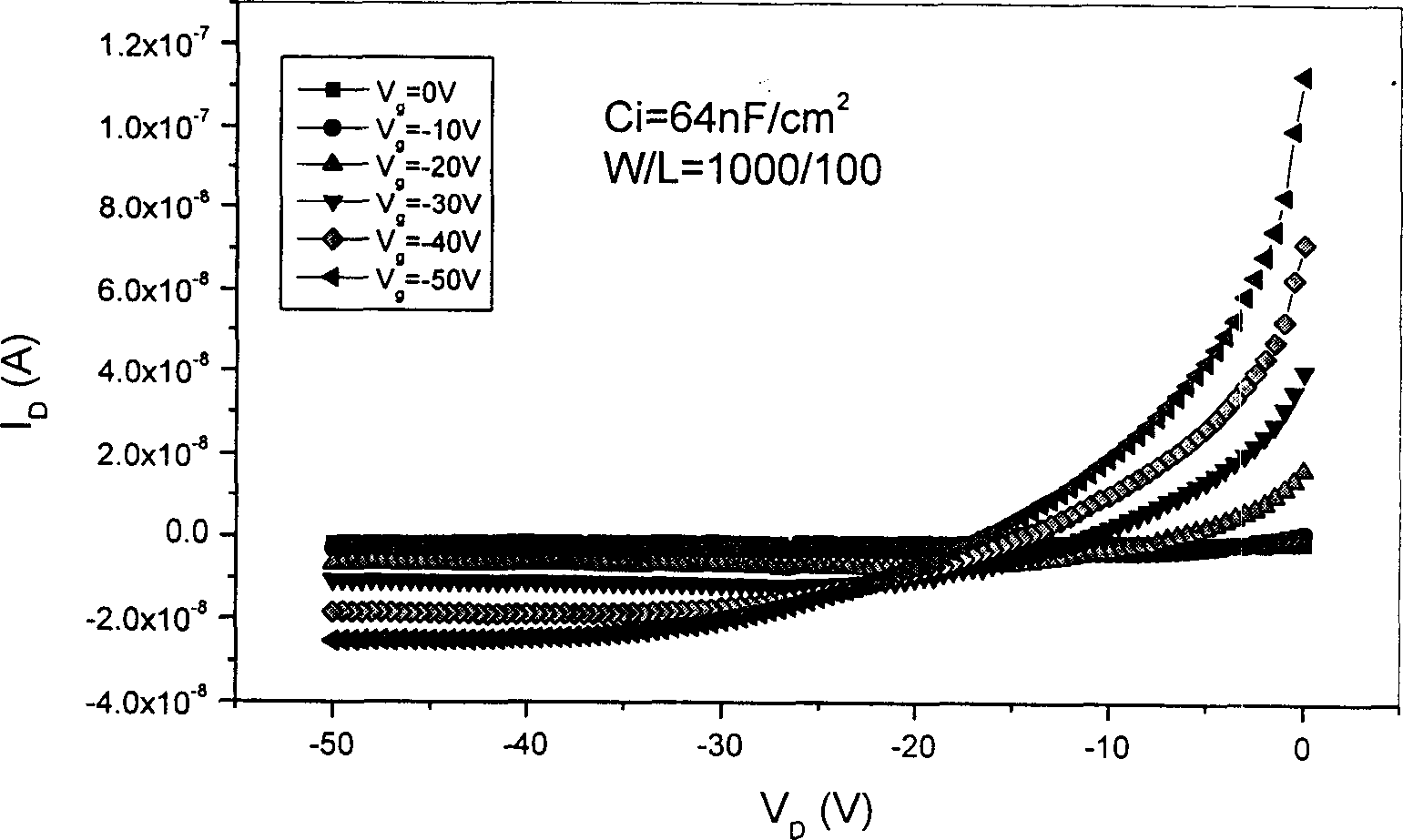

Organic film transistor and preparing method

InactiveCN1409417AGood injection propertiesImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmInsulation layer

Owner:CHANGCHUN FULEBO DISPLAY TECH

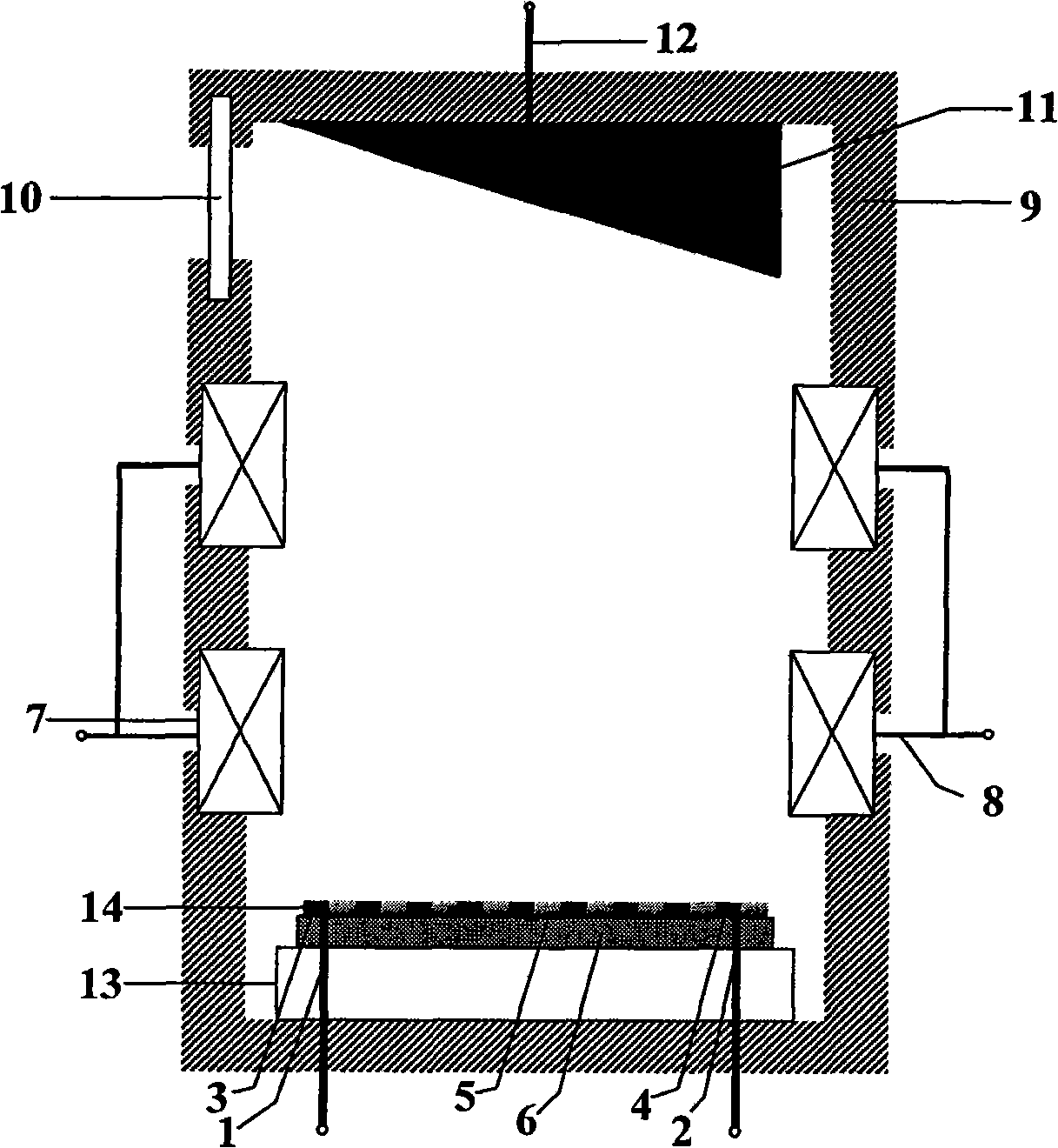

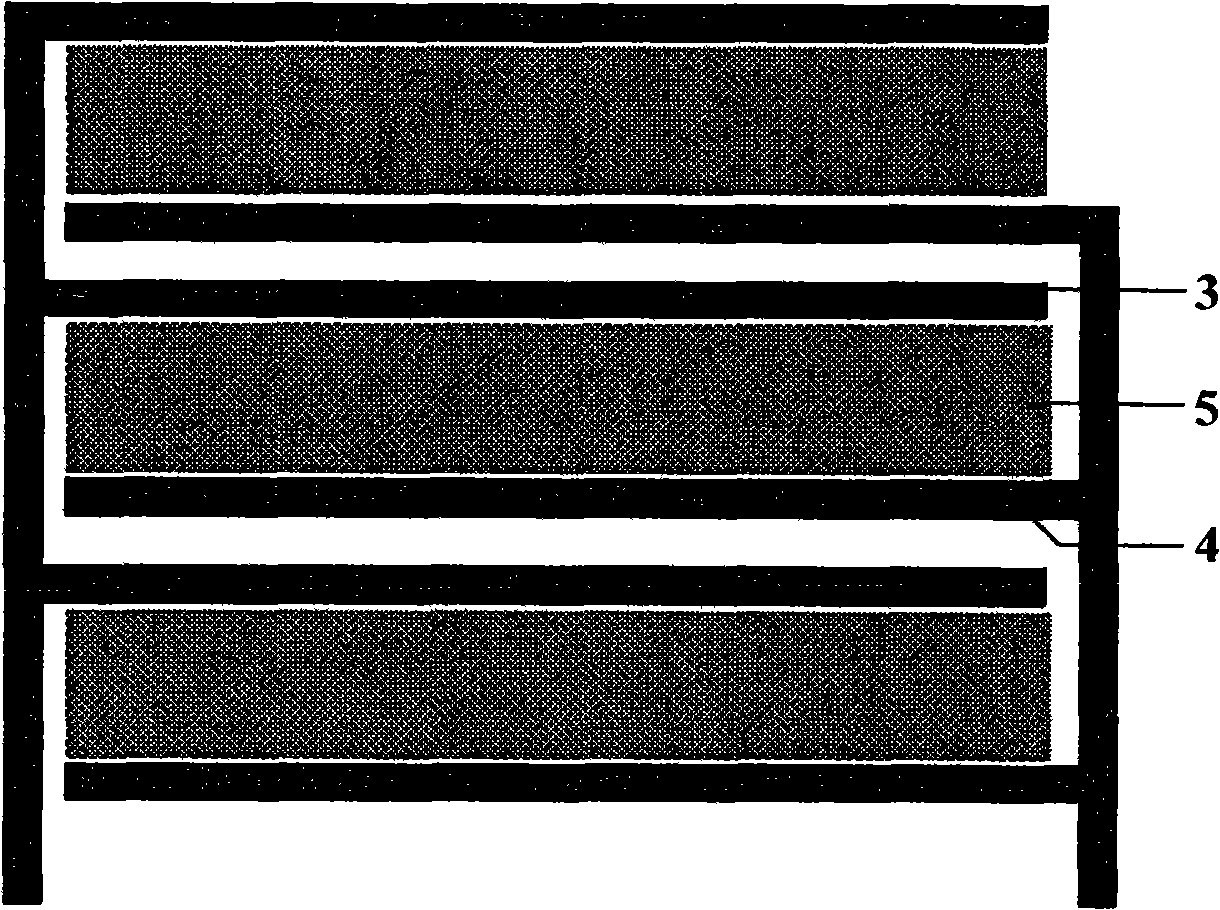

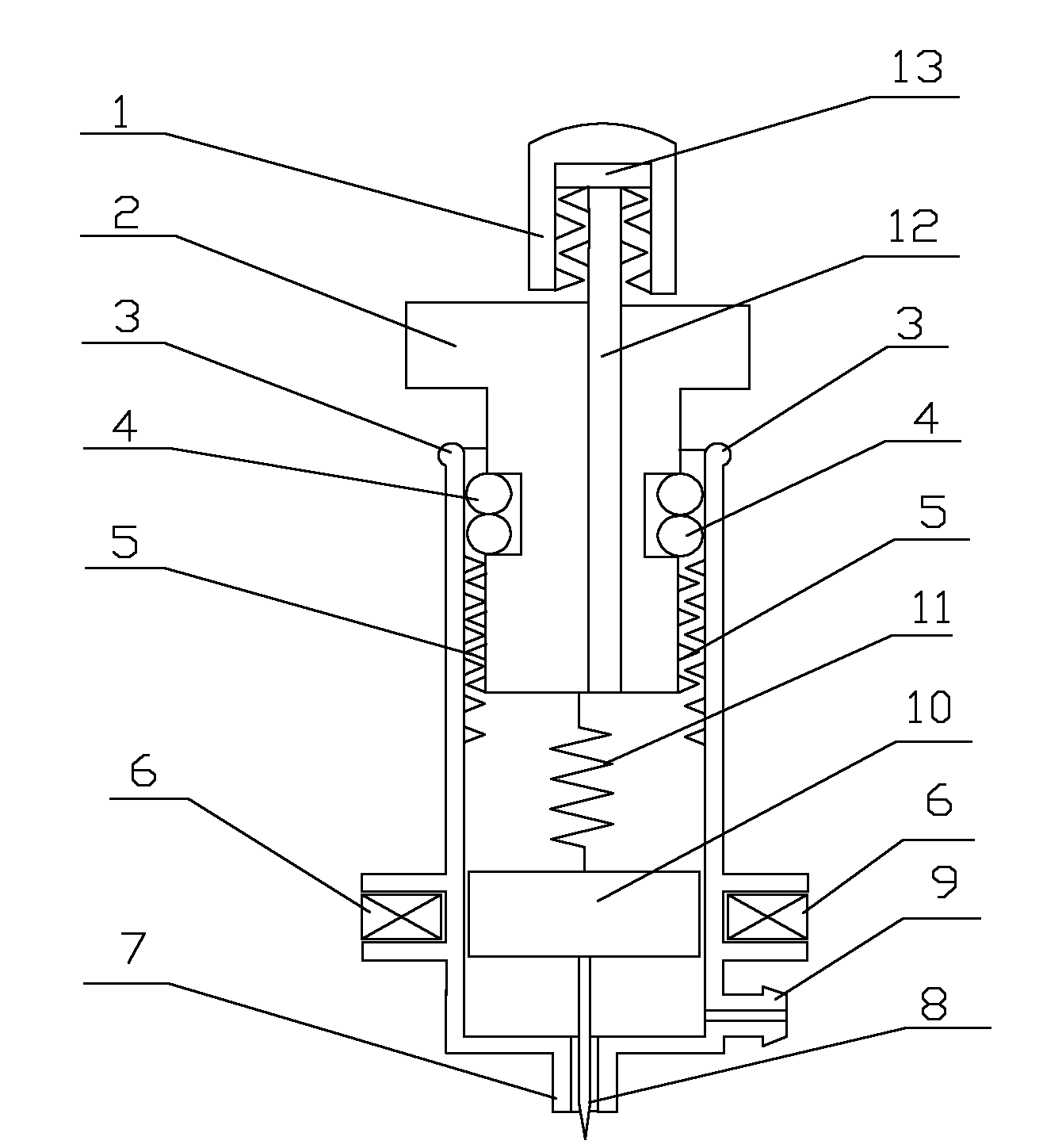

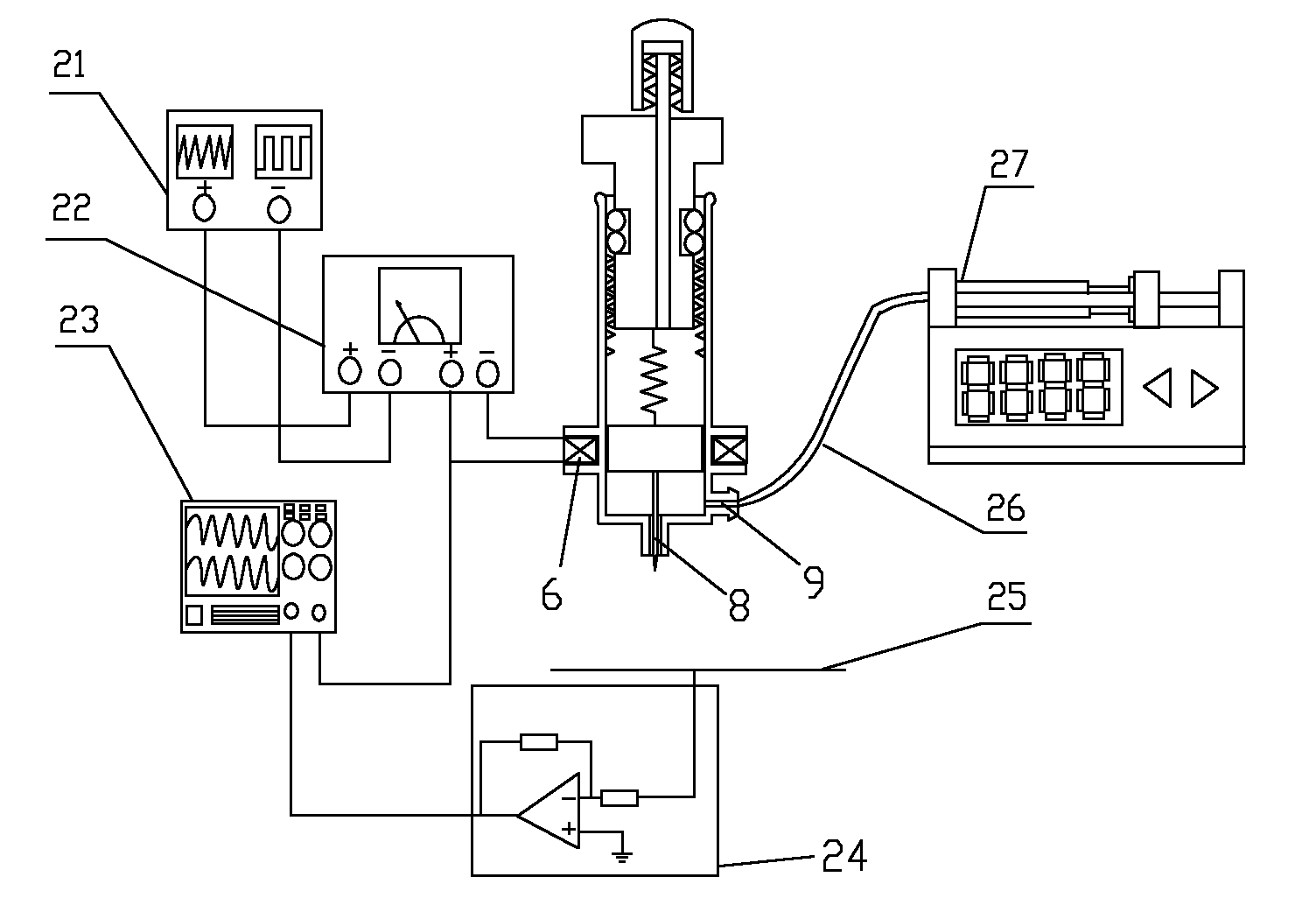

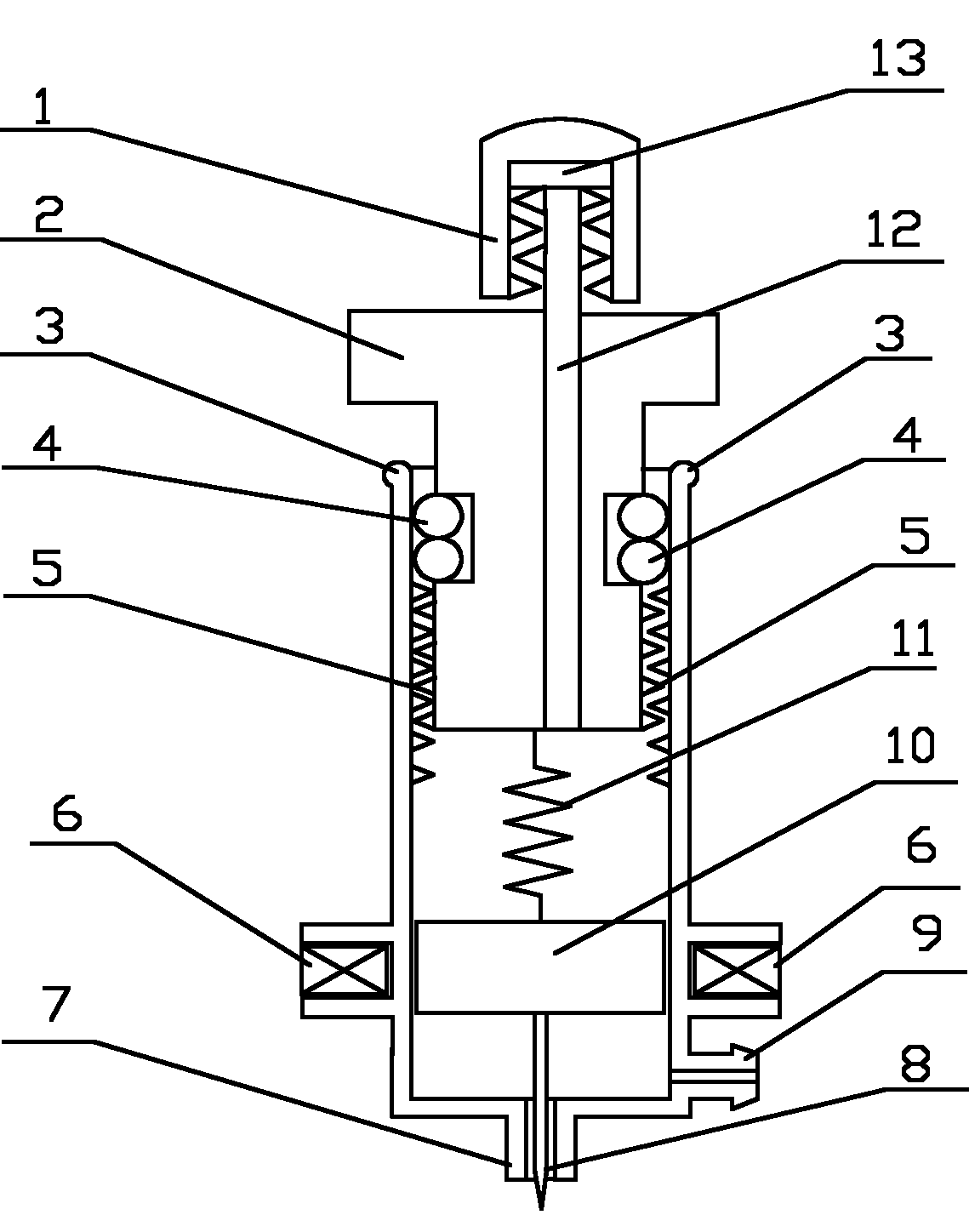

Cold-cathode focusing type X ray tube

The invention relates to a cold cathode focused X-ray tube, wherein, the tube comprises a cold cathode electron source (14), a focused electrode (7), a vacuum sealed shell body (9), a ray emission window (10), a high-voltage anode target (11) and the like, and is characterized in that the tube also comprises a zinc oxide emission layer (5) attached to the cold cathode electron source (14). In the invention, based on a plane grid electrode structure, the electron source is prepared on the surface of a glass substrate (6) in a silk screen printing manner; the high-voltage anode target (11) is fixed right above the electron source; the electrode is arranged in a ceramic vacuum shell body and connected with an external power supply by electrode leads. The ceramic shell body adopts a segmented sealing method; and a metal focused electrode (7) is arranged above the cold cathode electron source (14), and insulation and sealing with ceramics are carried out to the focused electrodes. The focused electrodes can greatly condense electron beams bombarded on the surface of the anode target so as to realize X-ray emission with high resolution factor.

Owner:SOUTHEAST UNIV

Electrospinning direct-writing nozzle capable of controlling starting and stopping

InactiveCN102019240AOutstanding advantagesHighlight technical effectsLiquid spraying plantsNanostructure manufactureEngineeringDirect writing

The invention provides an electrospinning direct-writing nozzle capable of controlling starting and stopping, relating to an electrospinning direct-writing nozzle and providing an electrospinning direct-writing nozzle which can automatically controls starting and stopping, reduce the spraying opening voltage, organically combines the spraying and the direct-writing pattern characteristic and completes direct writing of micronano structures in complex patterns. The electrospinning direct-writing nozzle is provided with a hollow sleeve with a nozzle, an adjusting plug with threads, a coil, an armature, a return spring, a probe and an exhaust pipeline, wherein the front end of the hollow sleeve with the nozzle is provided with a spray orifice and an injection hole; the adjusting plug with the threads is arranged at the rear end of the hollow sleeve with the nozzle; the coil is sheathed at the outer side of the hollow sleeve with the nozzle; the armature is arranged in the hollow sleeve with the nozzle; the probe is fixedly connected with the armature; the front end of the probe is positioned in the spraying orifice at the front end of the hollow sleeve with the nozzle, and the rear end of the probe is fixedly connected with one end of the return spring; the other end of the return spring is fixedly connected with the inner end of the adjusting plug with the threads; the exhaust pipeline is arranged on the adjusting plug with the threads; and the inner end of the exhaust pipeline is communicated with the hollow sleeve with the nozzle, and the outer end of the exhaust pipeline is communicated with the outside.

Owner:XIAMEN UNIV

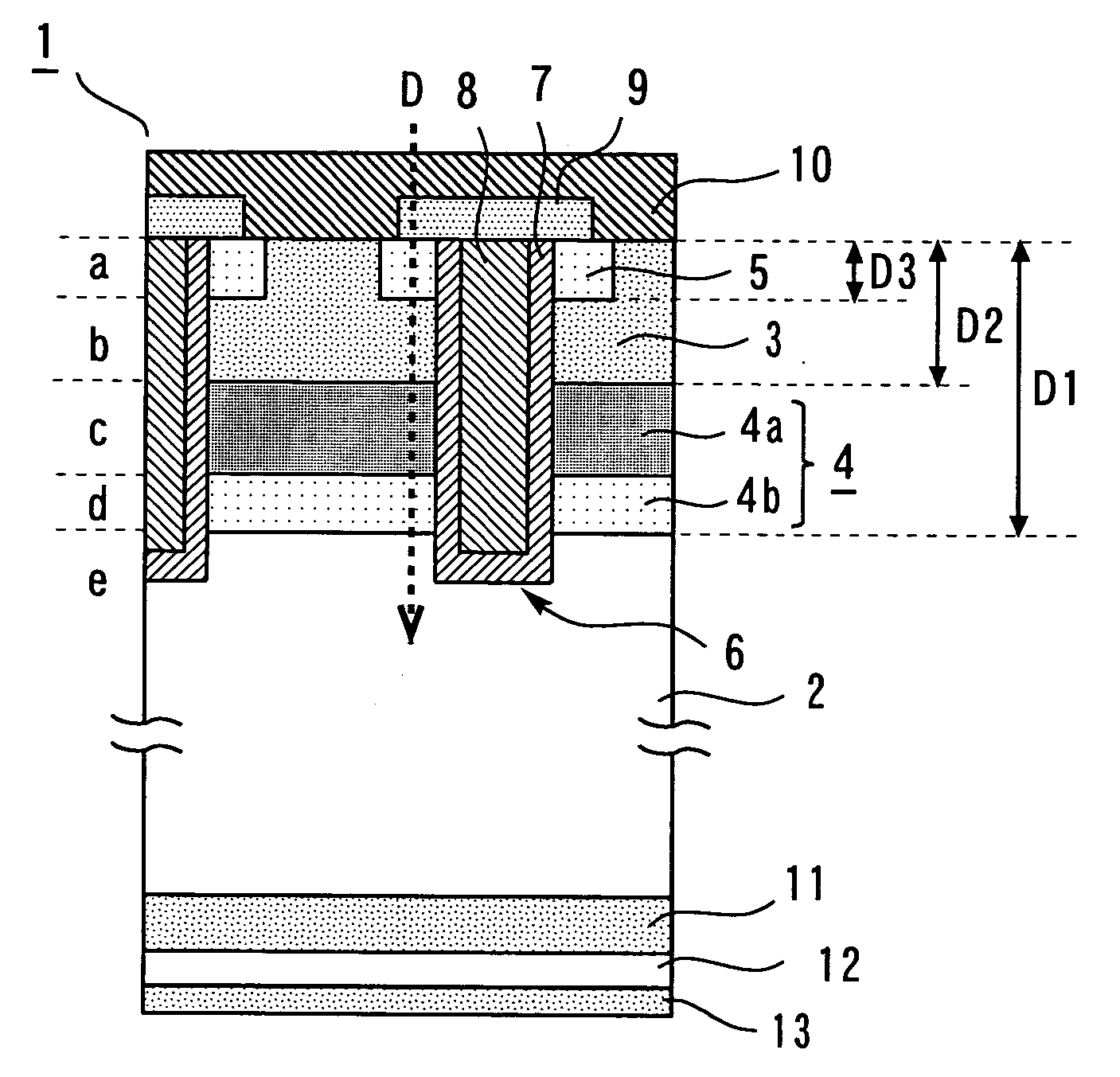

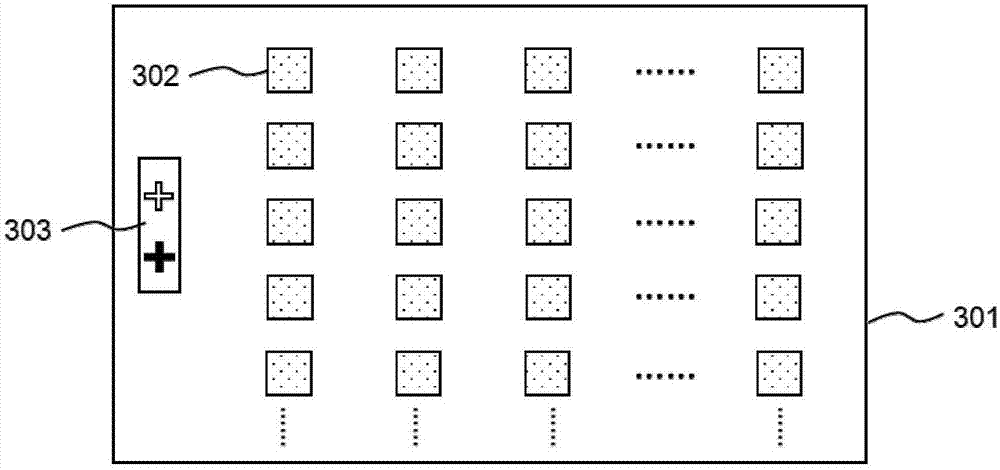

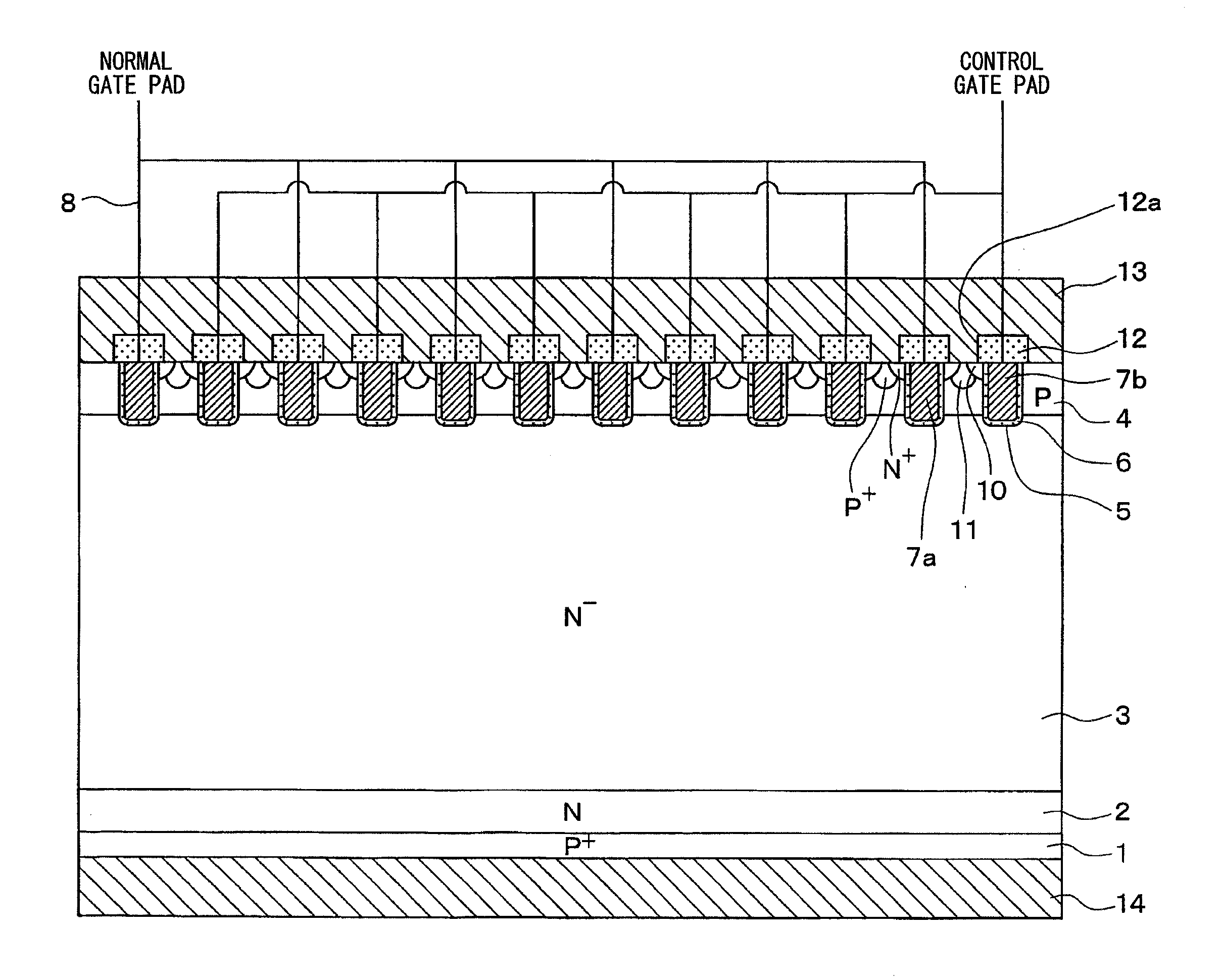

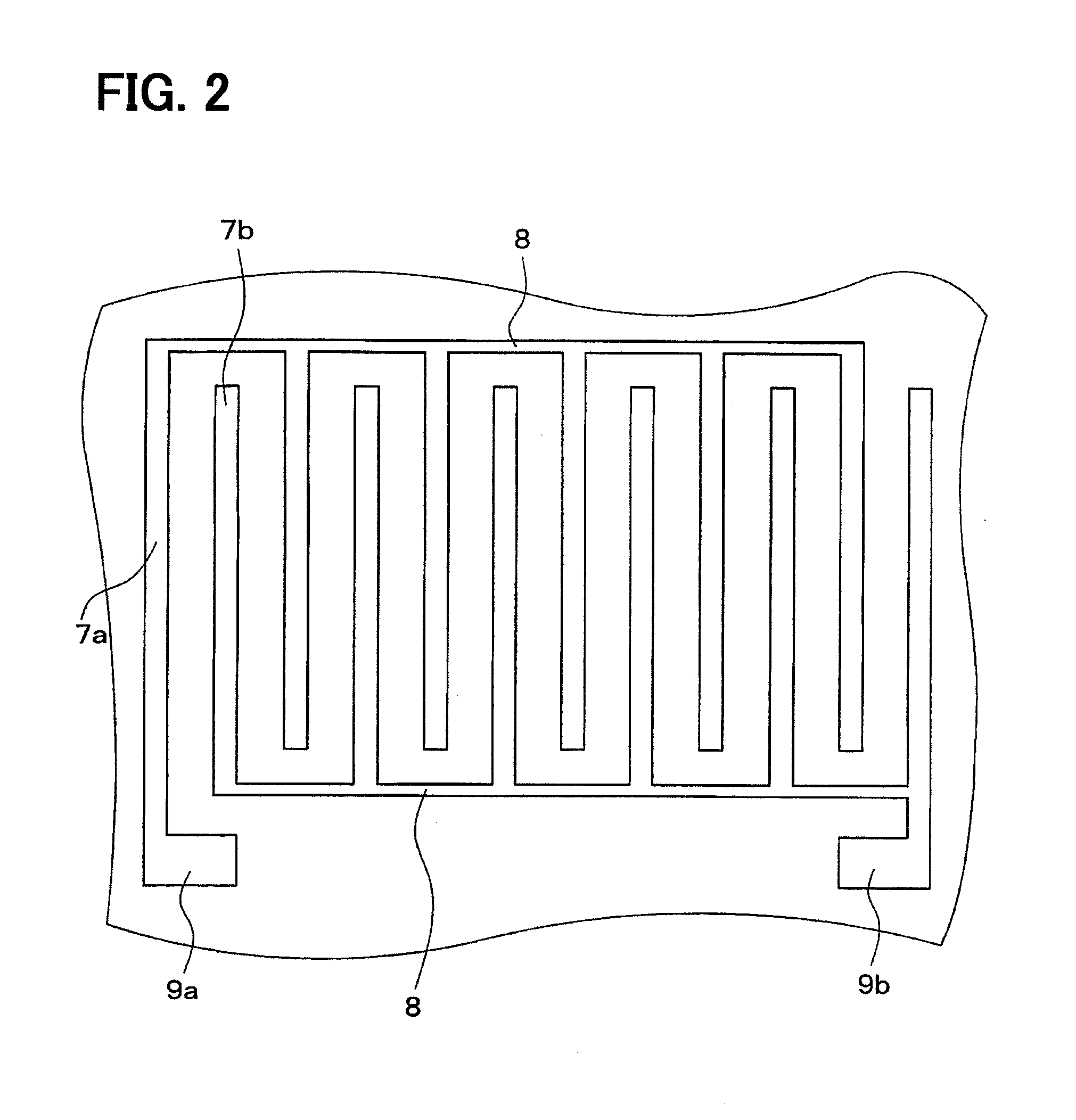

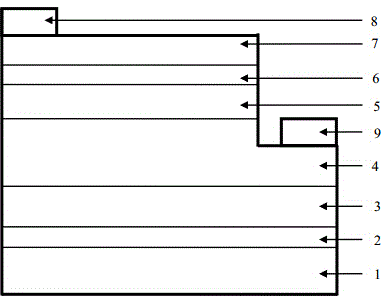

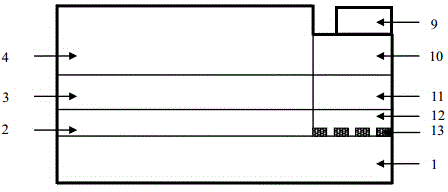

Semiconductor device

InactiveUS20140209972A1Fast switching speedShorten the time periodSemiconductor devicesEngineeringSemiconductor

In a semiconductor device, gate electrodes in a first group are connected with a first gate pad and gate electrodes in a second group are connected with a second gate pad. The gate electrodes in the first group and the gate electrodes in the second group are controllable independently from each other through the first gate pad and the second gate pad. When turning off, after a turn-off voltage with which an inversion layer is not formed is applied to the gate electrodes in the second group, a turn-off voltage with which an inversion layer is not formed is applied to the gate electrodes in the first group.

Owner:DENSO CORP

System and method for producing light with organic light-emitting devices

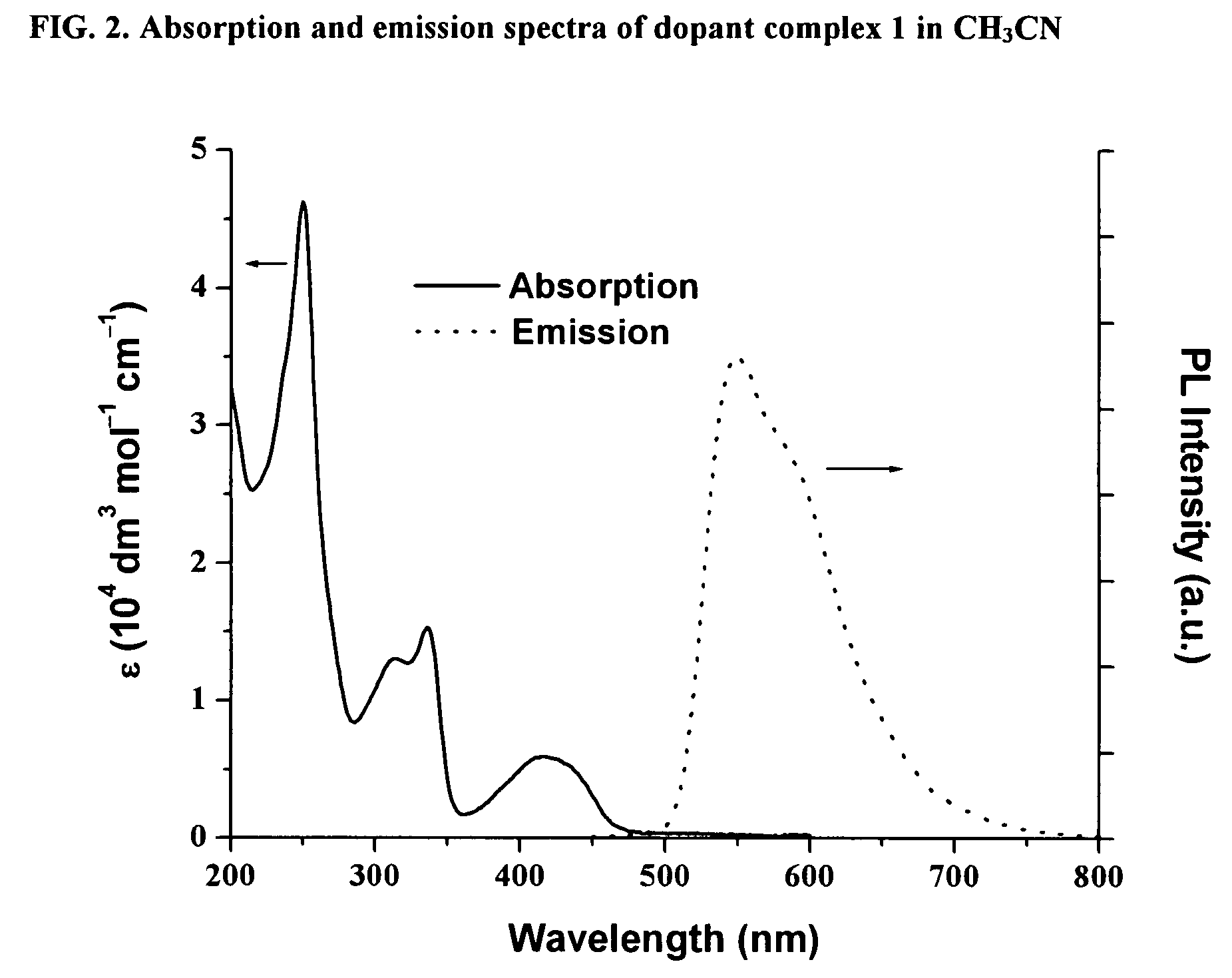

ActiveUS7361415B2Improve stabilityGood control over variationSolid-state devicesCobalt organic compoundsOrganic light emitting deviceLight-emitting diode

Disclosed are emissive materials of formula (I) or (II), comprising two bidentate NO-type ligands, or a tetradentate NOON-type ligand, and a transition metal. The emissive materials are useful as electrophosphorescent emitters in organic light-emitting devices. Also disclosed are methods for preparing organic light-emitting diodes comprising these emissive materials, and the use of such diodes as white and yellow organic light-emitting devices.

Owner:VERSITECH LTD

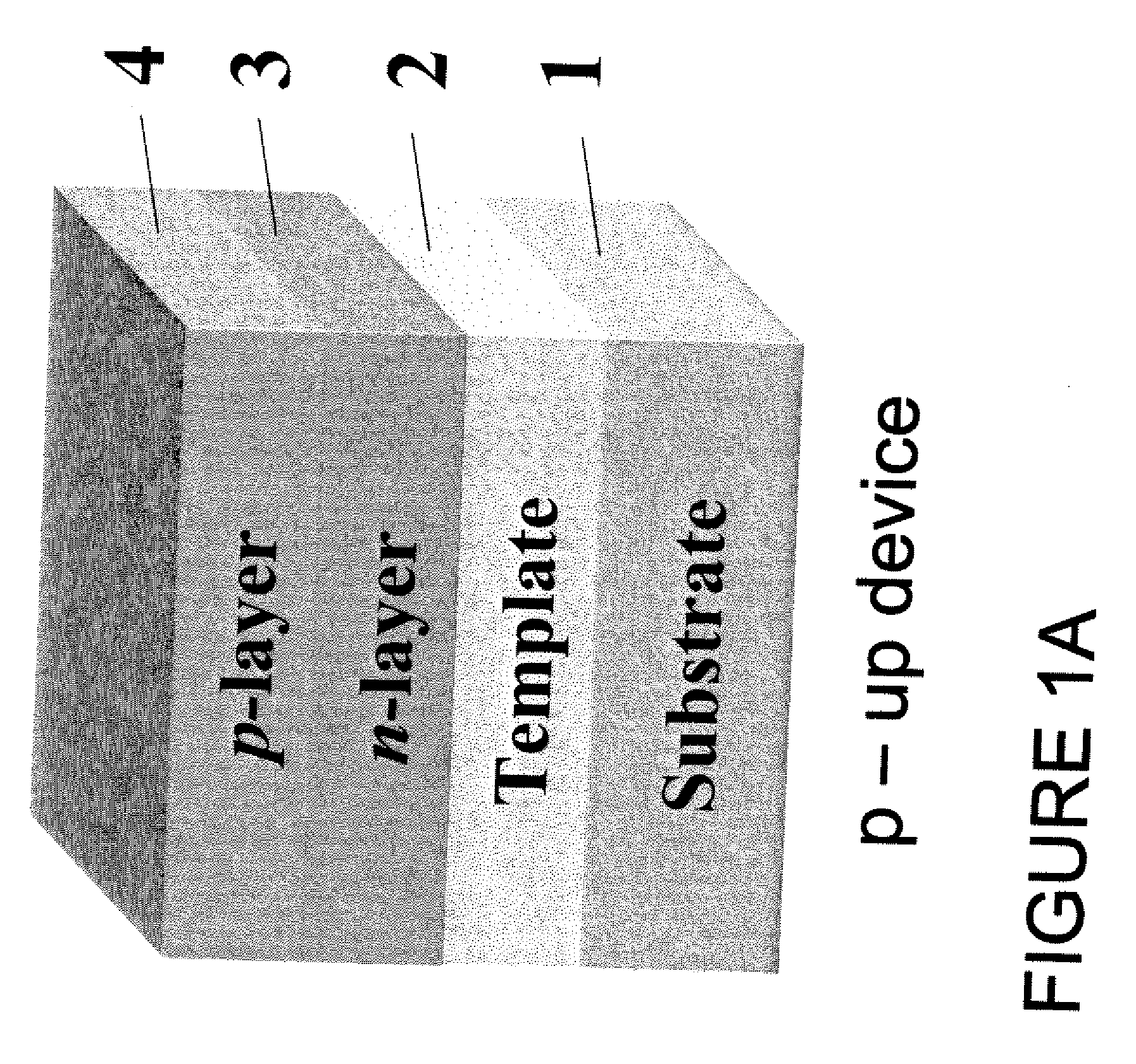

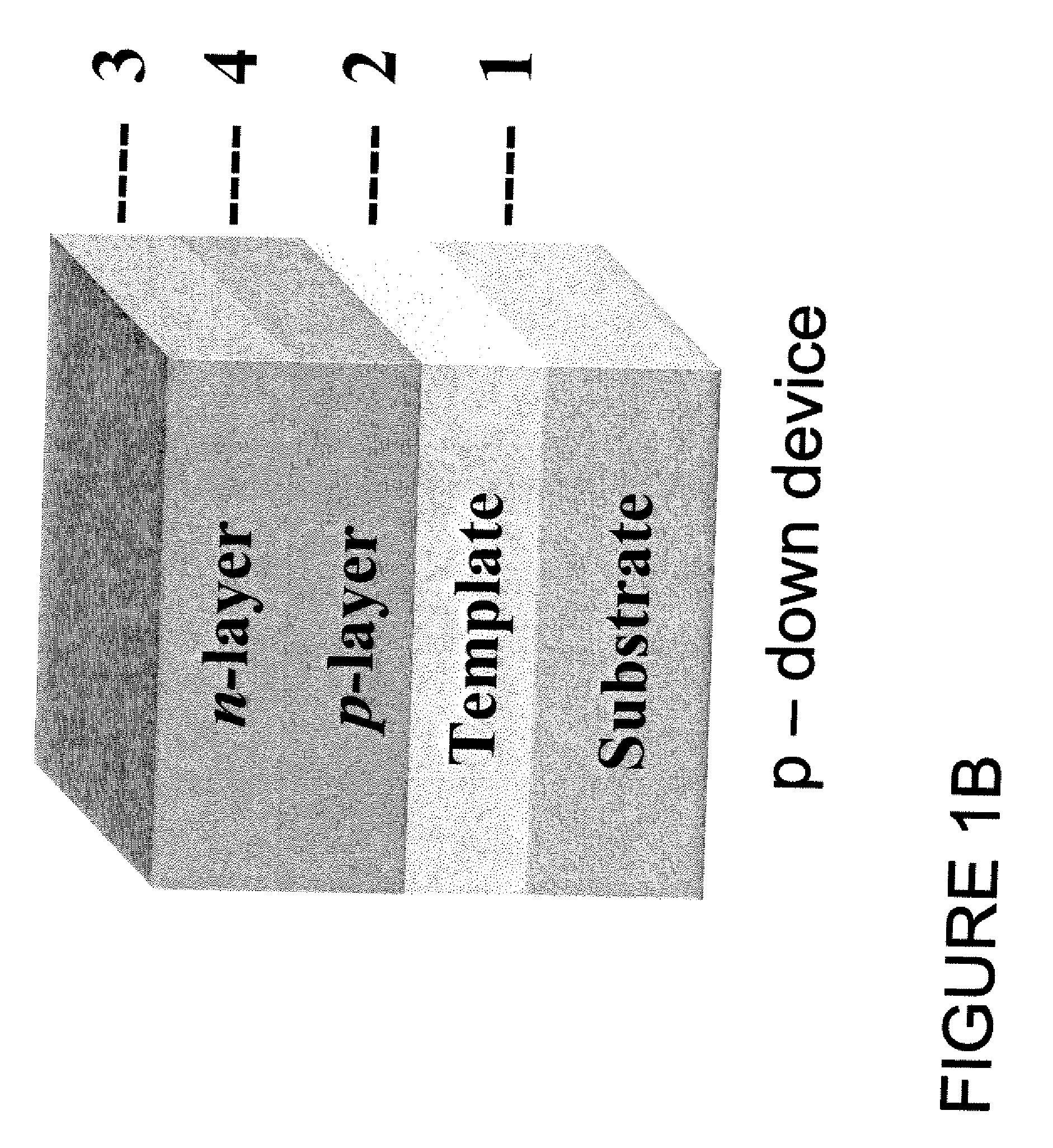

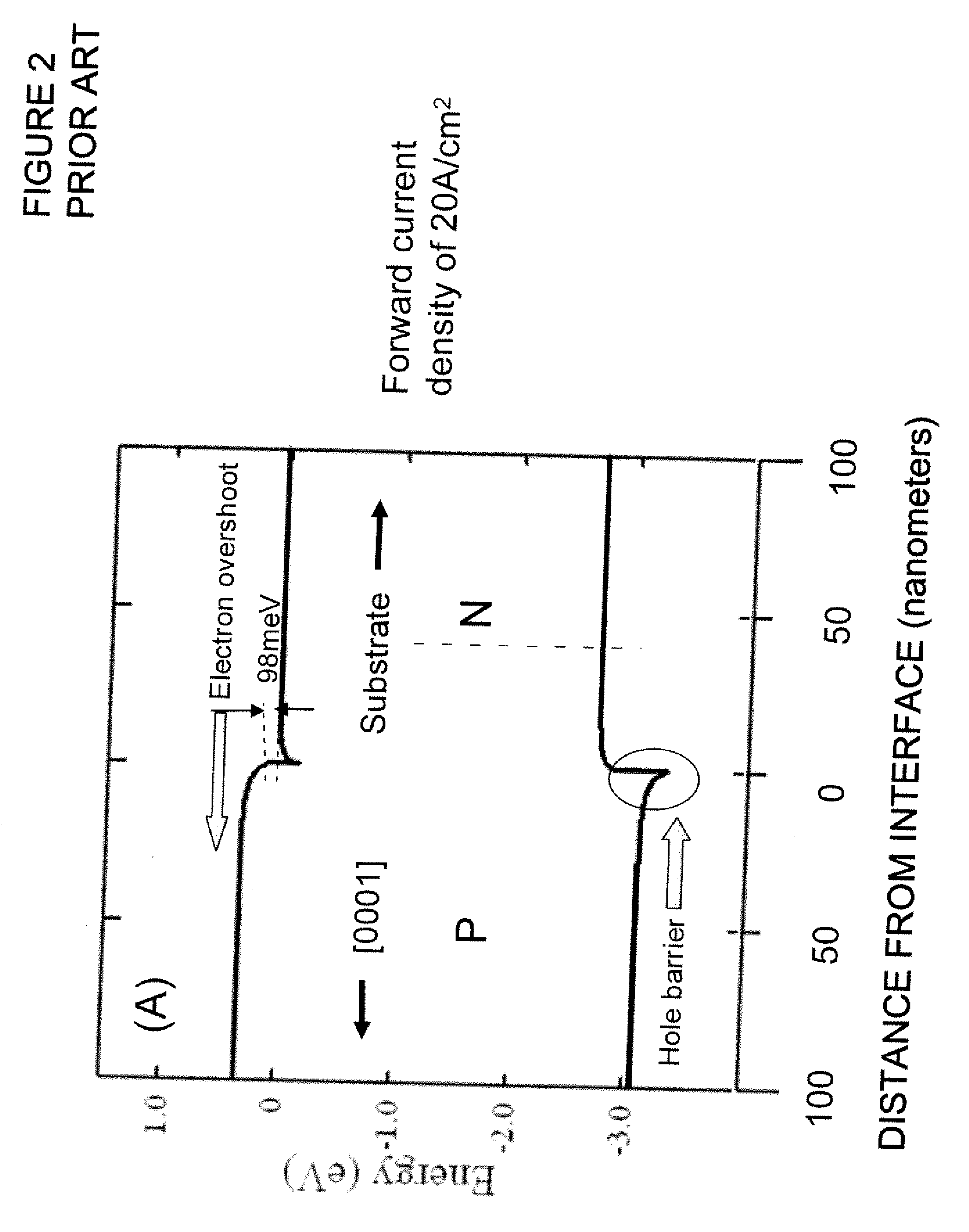

Light emitting diode

InactiveUS20100187550A1Enhancing recombinationIncrease in the electron barrierSemiconductor devicesLight emitting deviceLight-emitting diode

In a preferred embodiment, a light emitting device comprising: a polar template; a p-type layer grown on the polar template; the p-type layer having a first polarization vector; the first polarization vector having a first projection relative to a growth direction; an n-type layer grown on the p-type layer; the n-type layer having a second polarization vector; the second polarization vector having a second projection relative to said growth direction that is larger than the first projection of the first polarization vector for the p-type layer; the n-type layer and p-type layer forming an interface; whereby the first polarization vector in the p-layer and second polarization vector in the n-layer create a discontinuity at the interface resulting in a negative charge appearing at the interface. In another preferred embodiment, a light emitting device comprising: a polar template; a n-type layer grown on the template; the n-type layer having a first polarization vector; the first polarization vector having a first projection relative to a growth direction; an p-type layer grown on the n-type layer; the p-type layer having a second polarization vector; the second polarization vector having a second projection relative to said growth direction that is larger than the first projection of the first polarization vector for the p-type layer; the n-type layer and p-type layer forming an interface; whereby the first polarization vector in the p-layer and second polarization vector in the n-layer create a discontinuity at the interface resulting in a negative charge appearing at the interface.

Owner:ARMY US SEC THE THE

Composite quantum dot light emitting diode device and preparation method thereof

ActiveCN106784392AImprove luminous efficiencyLower turn-on voltageMaterial nanotechnologySolid-state devicesQuantum dotVoltage

The invention discloses a composite quantum dot light emitting diode device and a preparation method thereof. The device comprises an anode substrate, a hole injection layer, a hole transport layer, a luminous layer, an electron transport layer and a cathode layer, wherein the luminous layer is a quantum dot composite luminous layer composed of a quantum dot luminescent material and an organic-inorganic hybrid perovskite material. According to the composite quantum dot light emitting diode device provided by the invention, because the quantum dot luminescent material can produce a synergistic effect with organic-inorganic hybrid perovskite material, the excited state complex electroluminescence is produced, which not only enhances the luminous efficiency of a QLED (Quantum dot light-emitting diode) device and reduces the turn-on voltage of the device, but also enables the QLED device to display light of different colors by changing the bias voltage, moreover, for quantum dot composite luminescent layers with different structures, the applied bias voltage has different degrees of regulation function to the luminous color of the QLED devices; and in addition, the introduction of an organic-inorganic hybrid perovskite layer can also improve the interface property, luminescence uniformity and device stability of the QLED device.

Owner:TCL CORPORATION

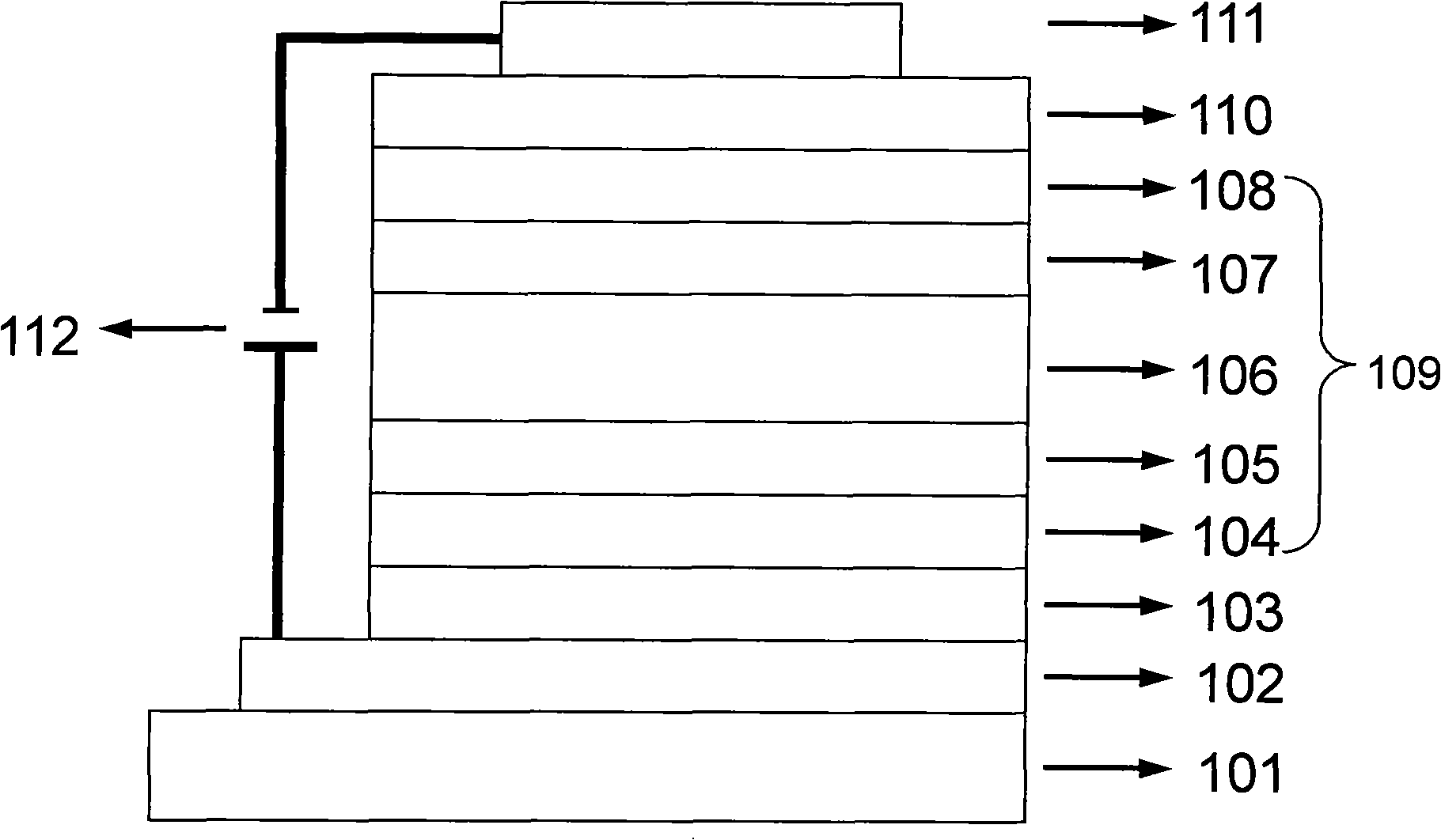

Nitrogen polar surface LED based on metal nitride semiconductor and preparation method

ActiveCN104835893ALower turn-on voltageReduce built-in electric field strengthSemiconductor devicesDevice materialOhmic contact

The invention discloses a nitrogen polar surface LED based on a metal nitride semiconductor, belonging to the technical field of semiconductor devices. The LED successively comprises an n-type semiconductor layer of the nitrogen polar surface, a multi-quantum well active region of the nitrogen polar surface, an electron barrier layer of the nitrogen polar surface and a p-type semiconductor layer of the nitrogen polar surface from bottom to top, and the upper layer of the p-type semiconductor layer of the nitrogen polar surface is provided with a p-type electrode. The LED further comprises an n-type semiconductor layer of a metal polar surface, the n-type semiconductor layer of the metal polar surface is arranged at the lateral side of the n-type semiconductor layer of the nitrogen polar surface and completely bonded to the n-type semiconductor layer of the nitrogen polar surface, and the upper surface of the n-type semiconductor layer of the metal polar surface is provided with an n-type electrode. Compared with the prior art, the n-type semiconductor layer of the metal polar surface serves as an ohmic contact layer of the n-type semiconductor layer of the nitrogen polar surface LED, so as to overcome the problem that an ohmic electrode is not easy to prepare on the n-type semiconductor layer of the nitrogen polar surface, the preparation technology is simple, and the cost is low.

Owner:SOUTHEAST UNIV

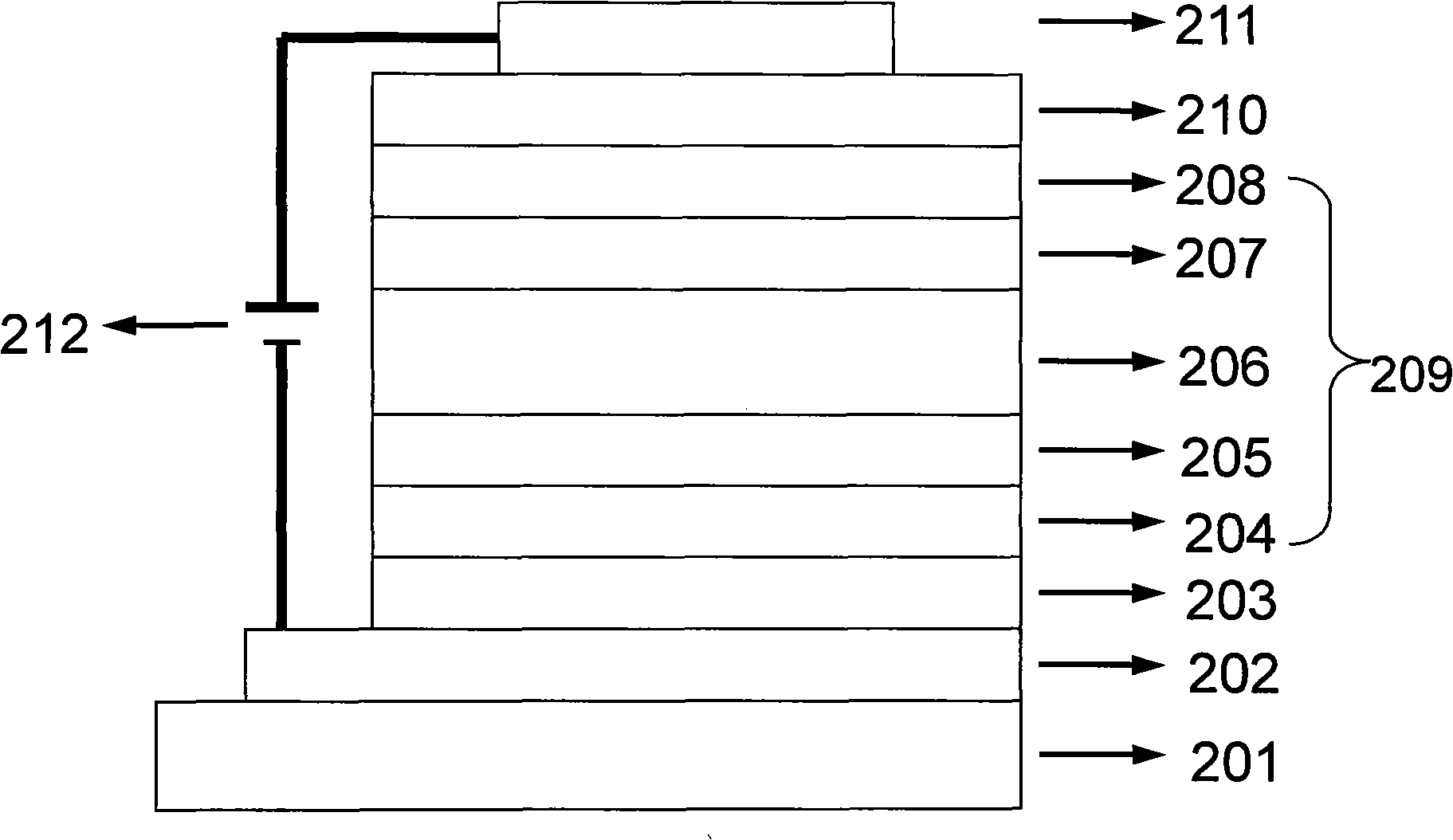

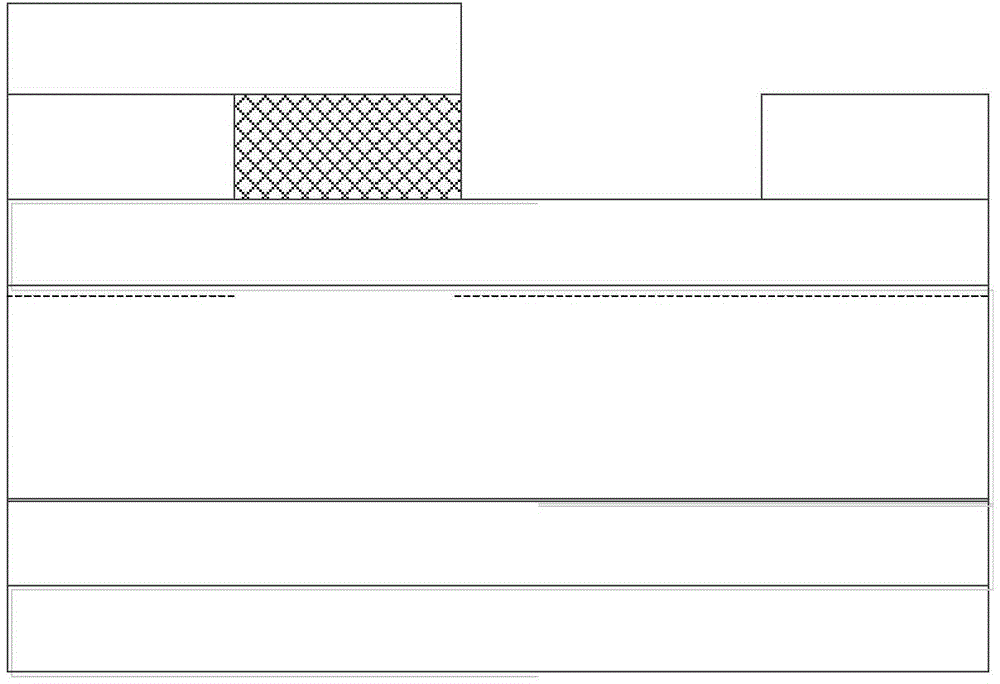

GaN hetero-junction diode device and method for manufacturing same

ActiveCN104362181AAchieve rectification characteristicsLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionPower flow

The invention discloses a GaN hetero-junction diode device and a method for manufacturing the same. The GaN hetero-junction diode device comprises a substrate, a buffer layer, a channel layer, a potential barrier layer, a cap layer, a first Ohm anode, an Ohm cathode and a second Ohm anode. The buffer layer is positioned on the substrate; the channel layer is positioned on the buffer layer; the potential barrier layer is positioned on the channel layer, the potential barrier layer and the channel layer form a hetero-structure, and a two-dimensional electric channel is formed at a hetero-junction interface; the cap layer is positioned on the potential barrier layer; the first Ohm anode and the Ohm cathode are positioned on the upper side of the potential barrier layer and are arranged on two sides of the cap layer, and the first Ohm anode is in contact with the cap layer; the second Ohm anode is positioned on the first Ohm anode and the cap layer and is in Ohm metal contact with the cap layer. The GaN hetero-junction diode device and the method have the advantages that the problem of conflict between forward start voltage control and reverse electric leakage in the prior art can be solved, and a diode has characteristics of low start voltages and turn-on resistance and high reverse withstand voltages and forward turn-on currents.

Owner:GPOWER SEMICON

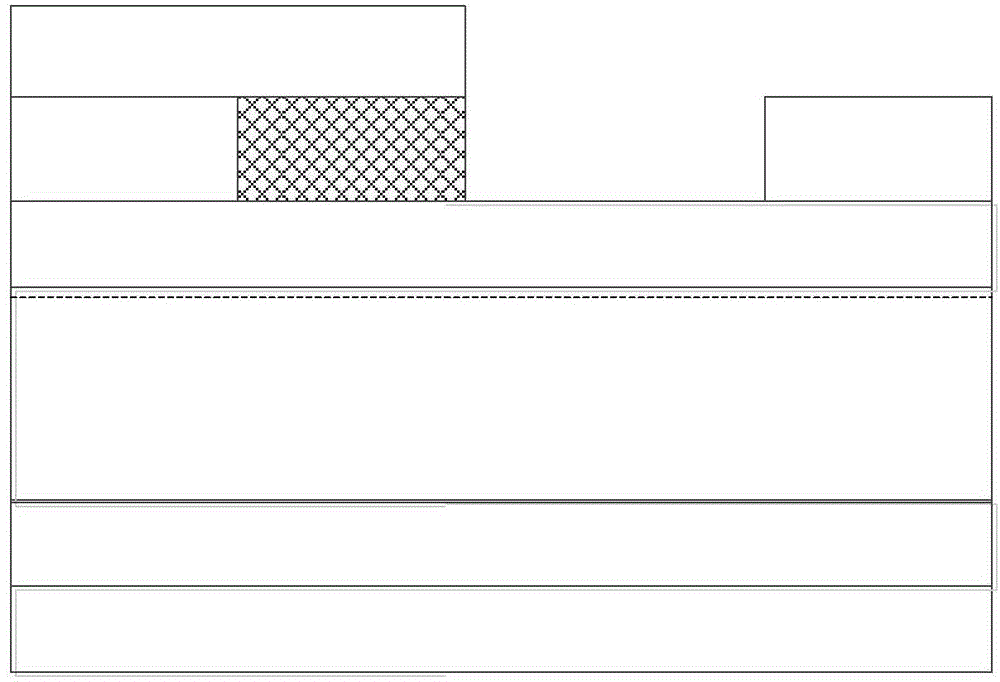

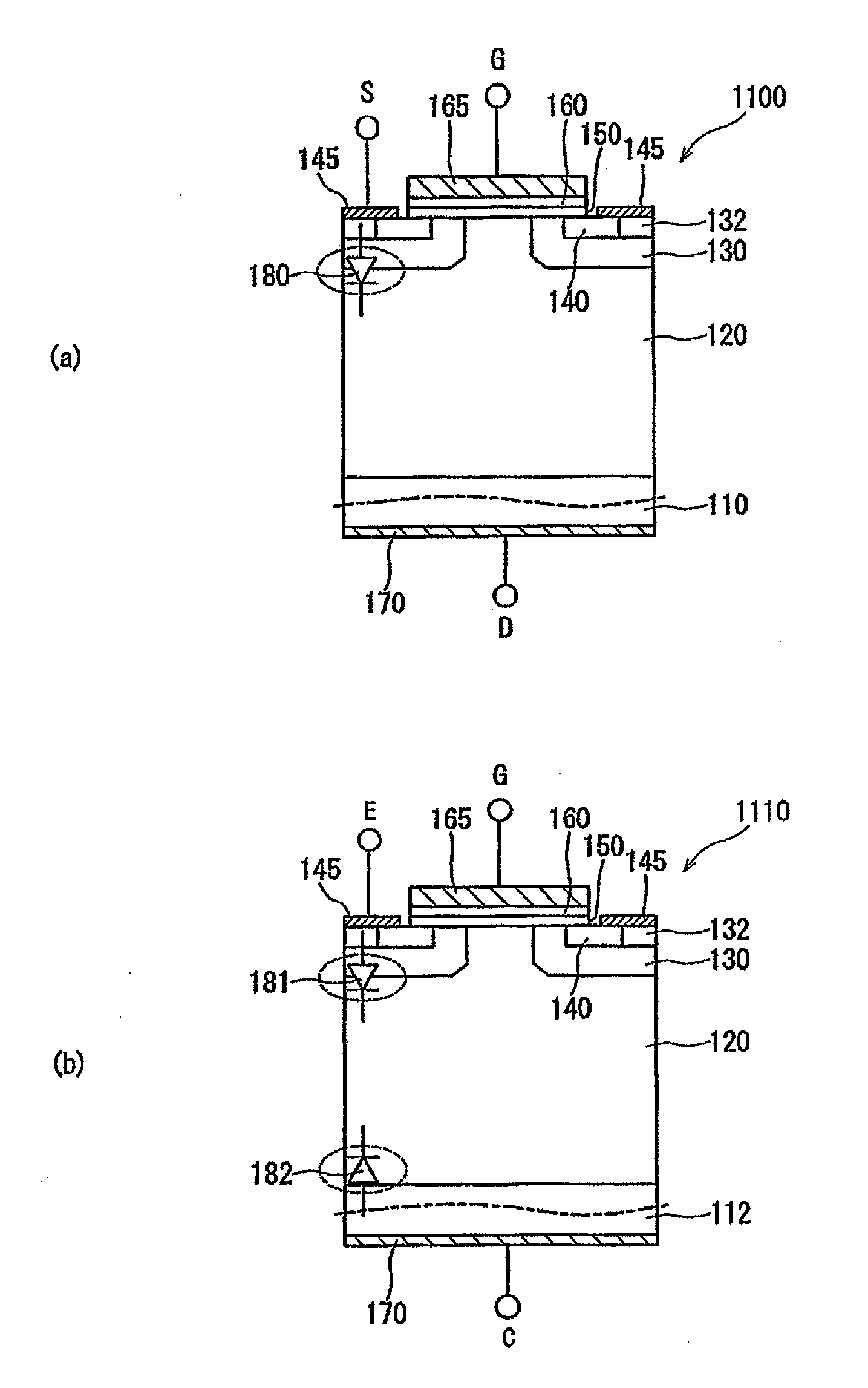

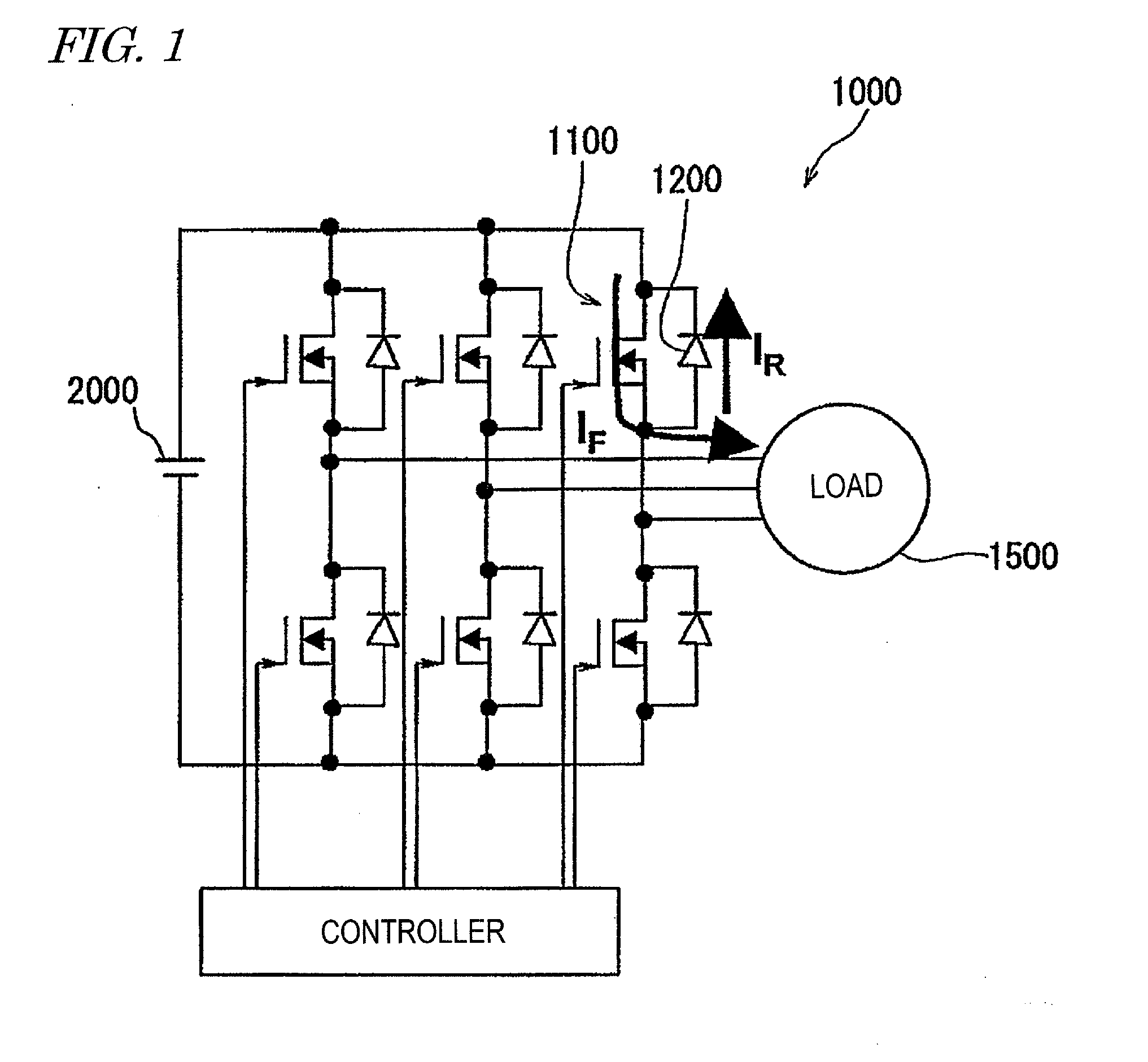

Semiconductor element, semiconductor device, and electric power converter

ActiveUS20120139623A1Increase the number ofIncrease ratingsTransistorEfficient power electronics conversionElectricityDevice material

A semiconductor element 100 including an MISFET according to the present invention is characterized by having diode characteristics in a reverse direction through an epitaxial channel layer 50. The semiconductor element 100 includes a semiconductor layer 20 of a first conductivity type, a body region 30 of a second conductivity type, source and drain regions 40 and 75 of the first conductivity type, an epitaxial channel layer 50 in contact with the body region, source and drain electrodes 45 and 70, a gate insulating film 60, and a gate electrode 65. If the voltage applied to the gate electrode of the MISFET is smaller than a threshold voltage, the semiconductor element 100 functions as a diode in which current flows from the source electrode 45 to the drain electrode 70 through the epitaxial channel layer 50. The absolute value of the turn-on voltage of this diode is smaller than that of the turn-on voltage of a body diode that is formed of the body region and the first silicon carbide semiconductor layer.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

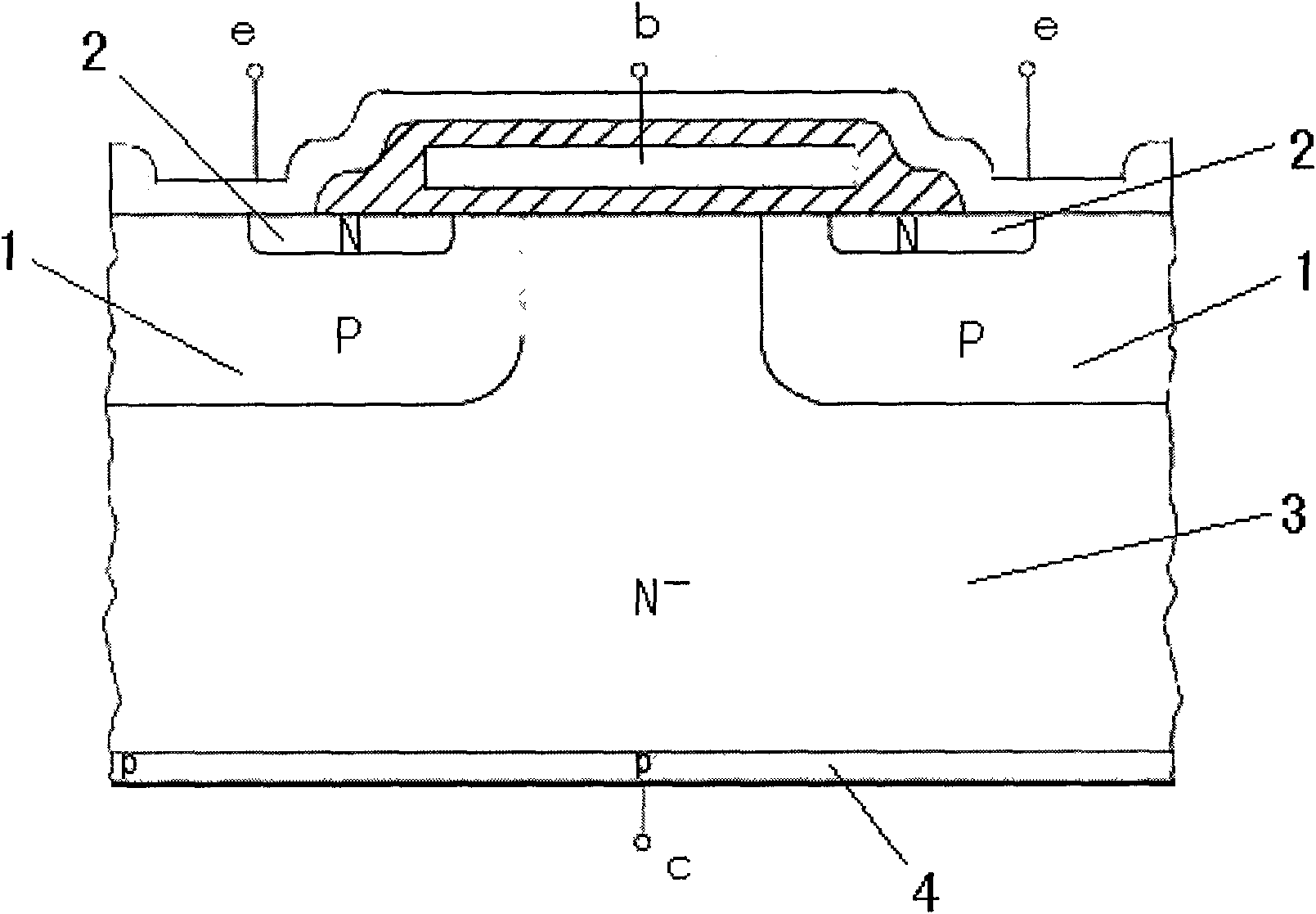

Bipolar transistor with graded base layer

InactiveUS20050139863A1Lower bandgapLow resistivitySemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionSemiconductor materials

A semiconductor material which has a high carbon dopant concentration includes gallium, indium, arsenic and nitrogen. The disclosed semiconductor materials have a low sheet resistivity because of the high carbon dopant concentrations obtained. The material can be the base layer of gallium arsenide-based heterojunction bipolar transistors and can be lattice-matched to gallium arsenide emitter and / or collector layers by controlling concentrations of indium and nitrogen in the base layer. The base layer can have a graded band gap that is formed by changing the flow rates during deposition of III and V additive elements employed to reduce band gap relative to different III-V elements that represent the bulk of the layer. The flow rates of the III and V additive elements maintain an essentially constant doping-mobility product value during deposition and can be regulated to obtain pre-selected base-emitter voltages at junctions within a resulting transistor.

Owner:IQE KC

Lateral insulated gate bipolar transistor

InactiveUS20110291157A1Fast switching speedLower turn-on voltageSemiconductor devicesInsulated-gate bipolar transistorSemiconductor

A lateral insulated gate bipolar transistor includes a semiconductor substrate including a drift layer, a collector region, a channel layer, an emitter region, a gate insulating layer, a gate electrode, a collector electrode, an emitter electrode, and a barrier layer. The barrier layer is disposed along either side of the collector region and is located to a depth deeper than a bottom of the channel layer. The barrier layer has an impurity concentration that is higher than an impurity concentration of the drift layer. The barrier layer has a first end close to the collector region and a second end far from the collector region. The first end is located between the channel layer and the collector region, and the second end is located on the bottom of the channel layer.

Owner:DENSO CORP

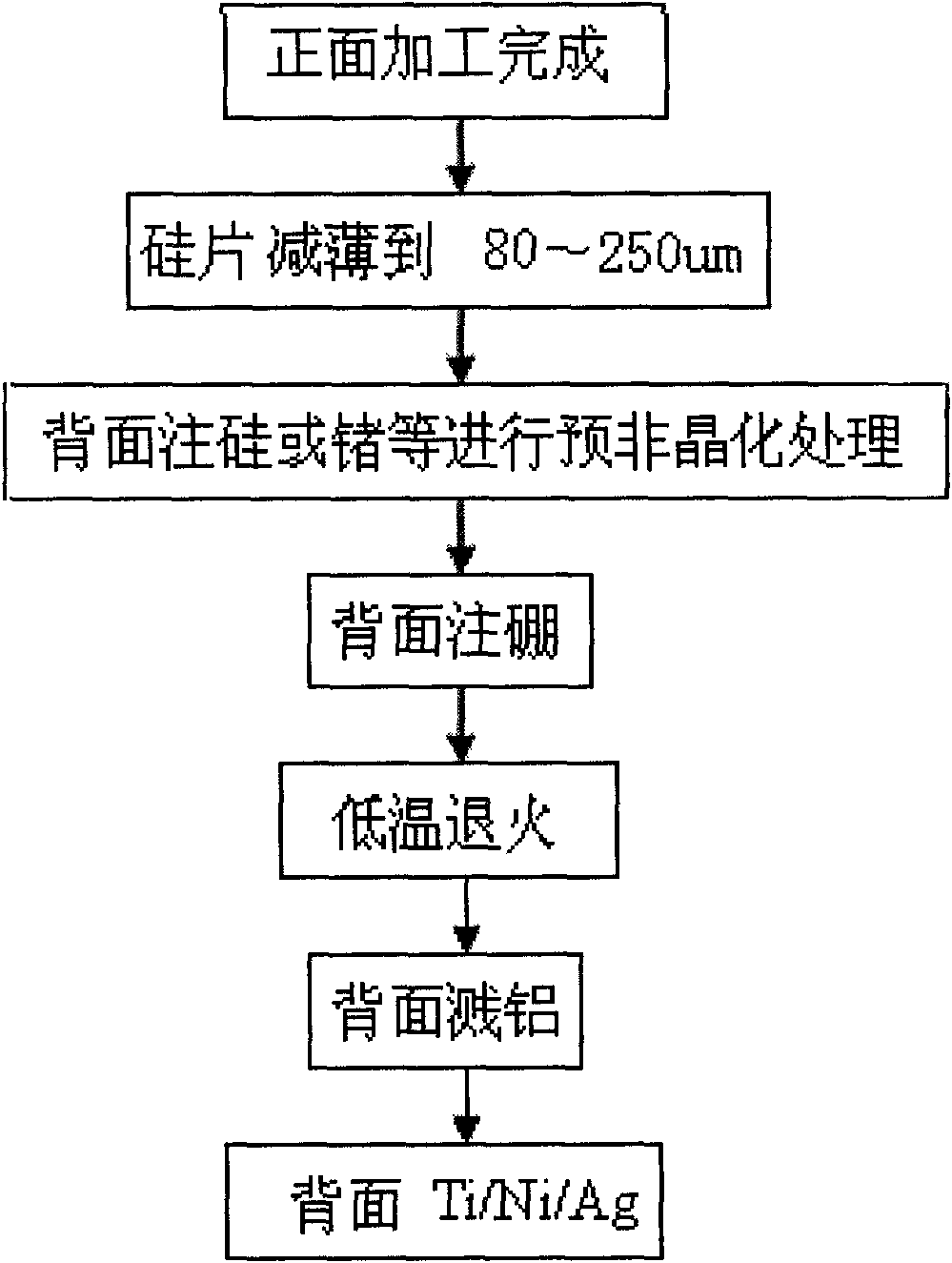

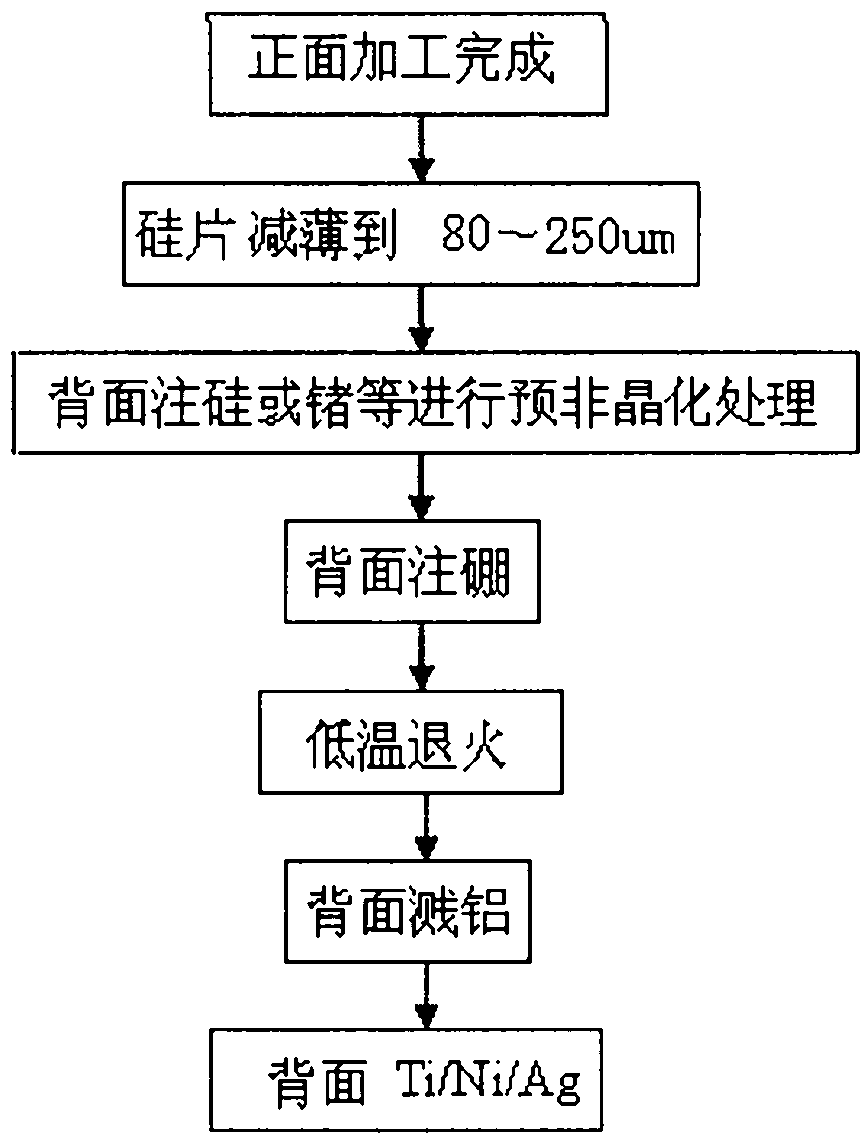

Technique for manufacturing back of non-through insulated-gate bipolar transistor chip

ActiveCN101789375AIncrease activation rateIncrease the number of holesSemiconductor/solid-state device manufacturingIonAluminium

The invention relates to a technique for manufacturing the back of a non-through insulated-gate bipolar transistor chip, comprising the following steps of: (1) finishing a technique for processing the front of the non-through insulated-gate bipolar transistor chip; (2) grinding and thinning the back of a silicon chip, and removing stress; (3) injecting silicon ion, germanium ion or boron difluoride ion at the back of the silicon chip for amorphous pretreatment; (4) injecting boron ion at the back of the silicon chip; (5) carrying out furnace tube low temperature annealing; (6) adopting a sputtering or an evaporating method, generating an aluminium film at the back of the silicon chip, and carrying out alloy treatment; and (7) adopting the sputtering or the evaporating method, respectively preparing a titanium, a nickel and a silver metal layers at the back of the silicon chip. The back of the silicon chip is firstly injected with the silicon ion, the germanium ion or the boron difluoride ion for amorphous pretreatment and then injected with the boron ion for low-temperature annealing, so that the activation rate of injecting the boron impurity is improved, the conductive modulation effect for a drifting area can be enhanced, and the conducting resistance and conducting voltage are effectively reduced. The technique can be widely applied to a manufacturing technique of a semiconductor.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com