Cold-cathode focusing type X ray tube

An X-ray tube and cold cathode technology, applied in the field of X-ray tubes, can solve the problems of increased process complexity, high working electric field, unfavorable spatial resolution of X-ray imaging, etc., so as to reduce production costs and maintenance costs, and reduce electron emission capabilities. Strong, improve the effect of spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

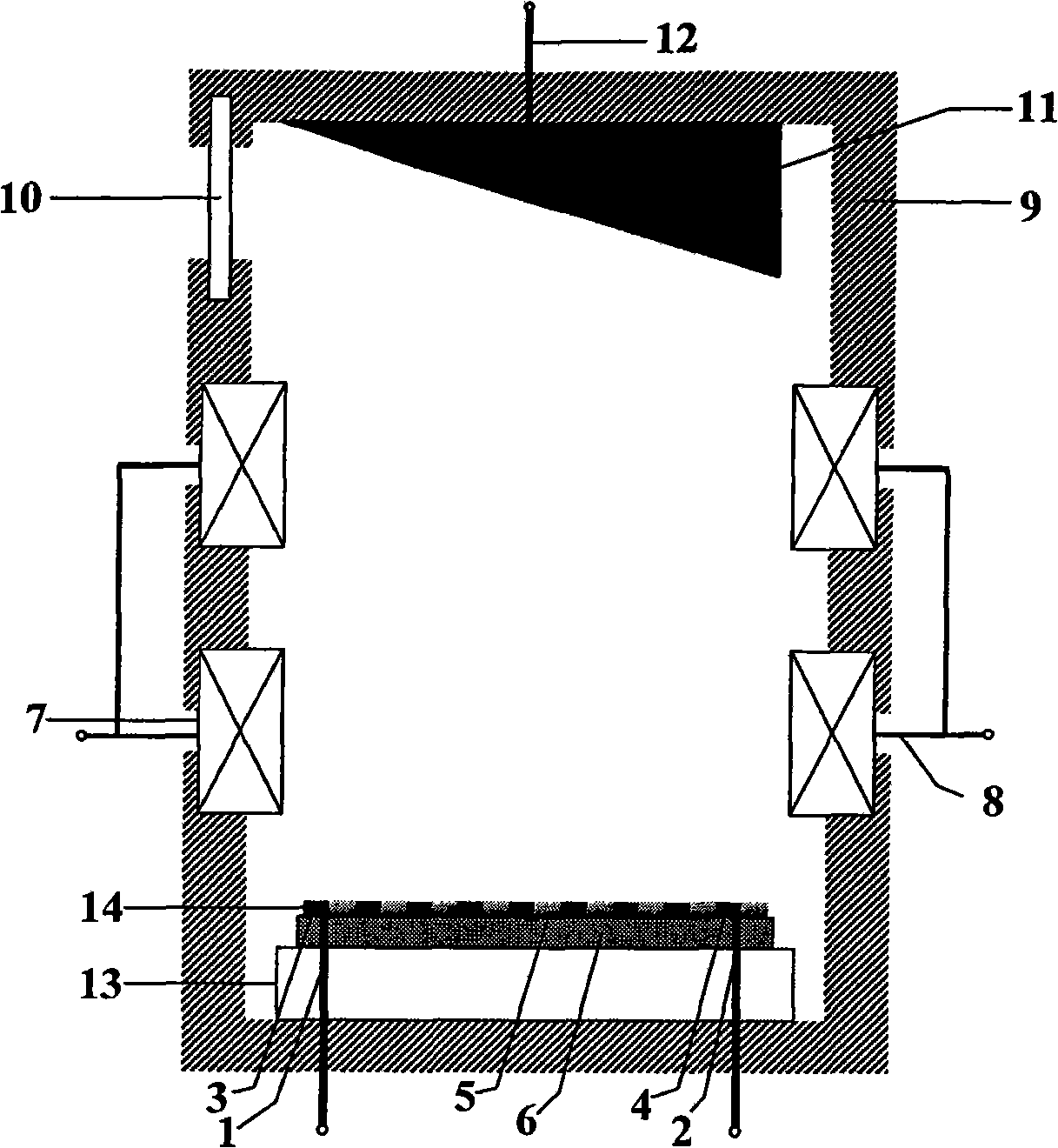

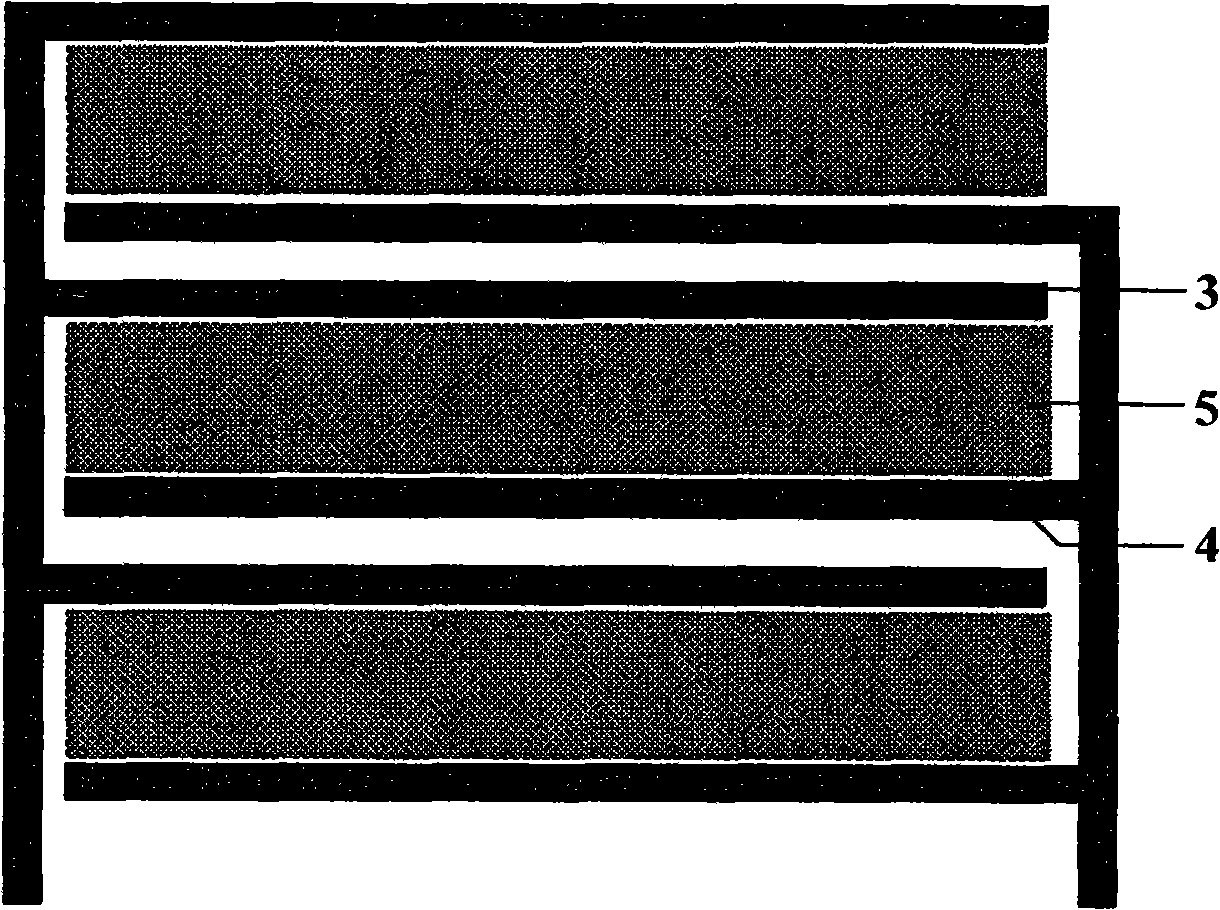

[0020] Refer to attached figure 1, the structure of the cold cathode X-ray tube in the present invention includes: a cold cathode electron source composed of a planar grid structure and a zinc oxide emitter, fixed on the bottom of the vacuum housing; an anode target made of oxygen-free copper, installed in a vacuum The top of the housing is directly above the cold cathode electron source, and the focusing electrode between the two electrodes; each electrode is connected to an external power source through a wire spot-welded on it. The lead wire of the electron source passes through the via hole reserved at the bottom of the ceramic housing to fix it. A metal electrode with a focusing structure is installed thereon, and its lower end is at a certain distance from the surface of the electron source, which is 250 microns in this embodiment. The part of the ceramic structure in contact with the metal electrode has been metallized during processing, making it easy to carry out Kov...

Embodiment 2

[0022] Refer to attached figure 1 , the structure of the cold cathode X-ray tube in the present invention includes: a cold cathode electron source composed of a planar grid structure and a zinc oxide emitter, which is fixed on the bottom of the vacuum housing; an anode target made of metal molybdenum is installed in the vacuum housing The top of the body is directly above the cold cathode electron source, and the focusing electrode between the two electrodes; each electrode is connected to an external power source through a wire spot-welded on it. The lead wire of the electron source passes through the via hole reserved at the bottom of the ceramic housing to fix it. A metal electrode with a focusing structure is installed thereon, and its lower end is at a certain distance from the surface of the electron source, which is 500 microns in this embodiment. The part of the ceramic structure in contact with the metal electrode has been metallized during processing, making it easy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com