Micro internal combustion engine built-in resistor igniter and its making method

A technology for internal combustion engines and igniters, applied to circuits, spark plugs, electrical components, etc., can solve the problems of complex preparation process, slow heat transfer of polysilicon resistors, high requirements for etching process and equipment, and achieve simple preparation process and batch production production, comparative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

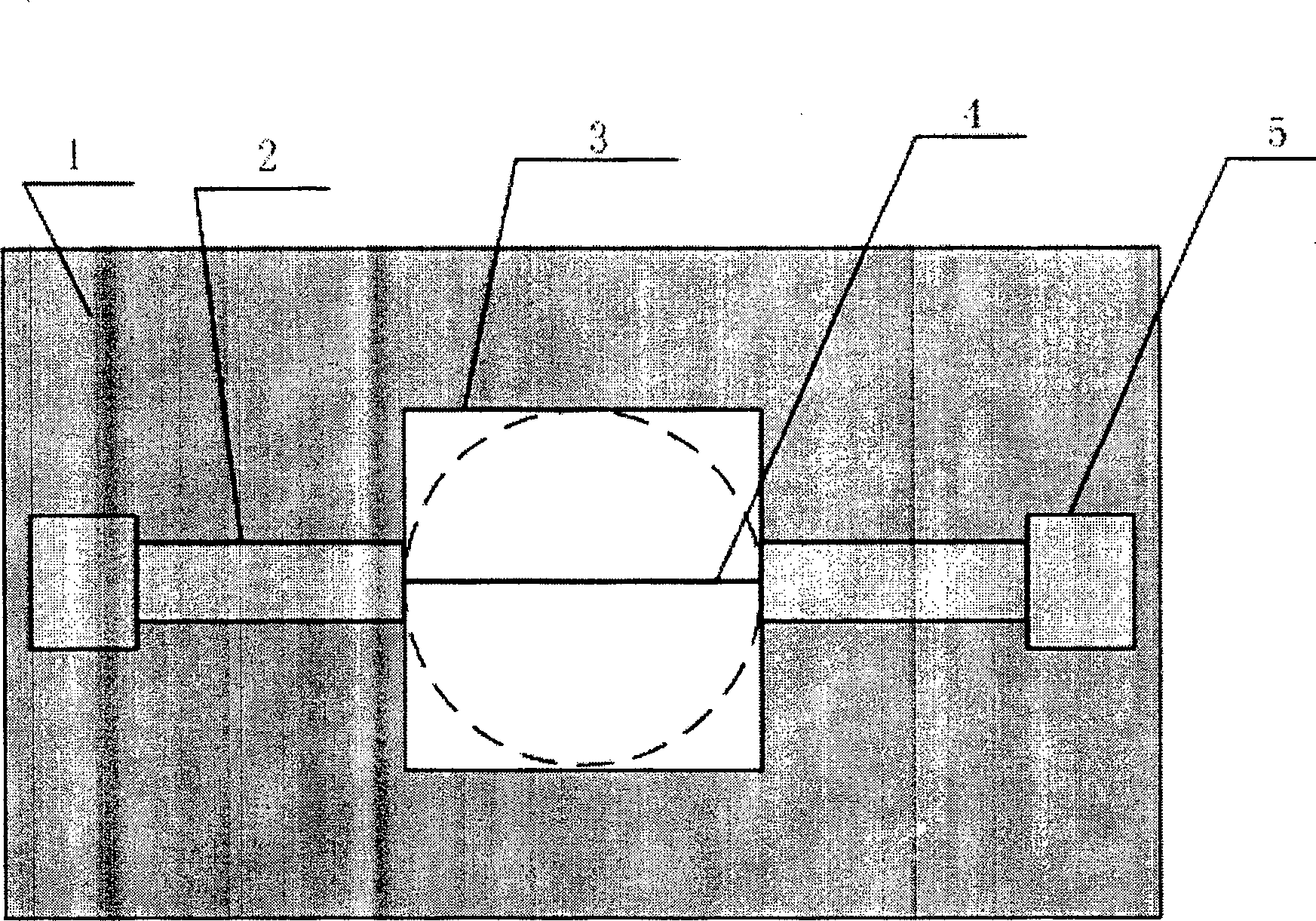

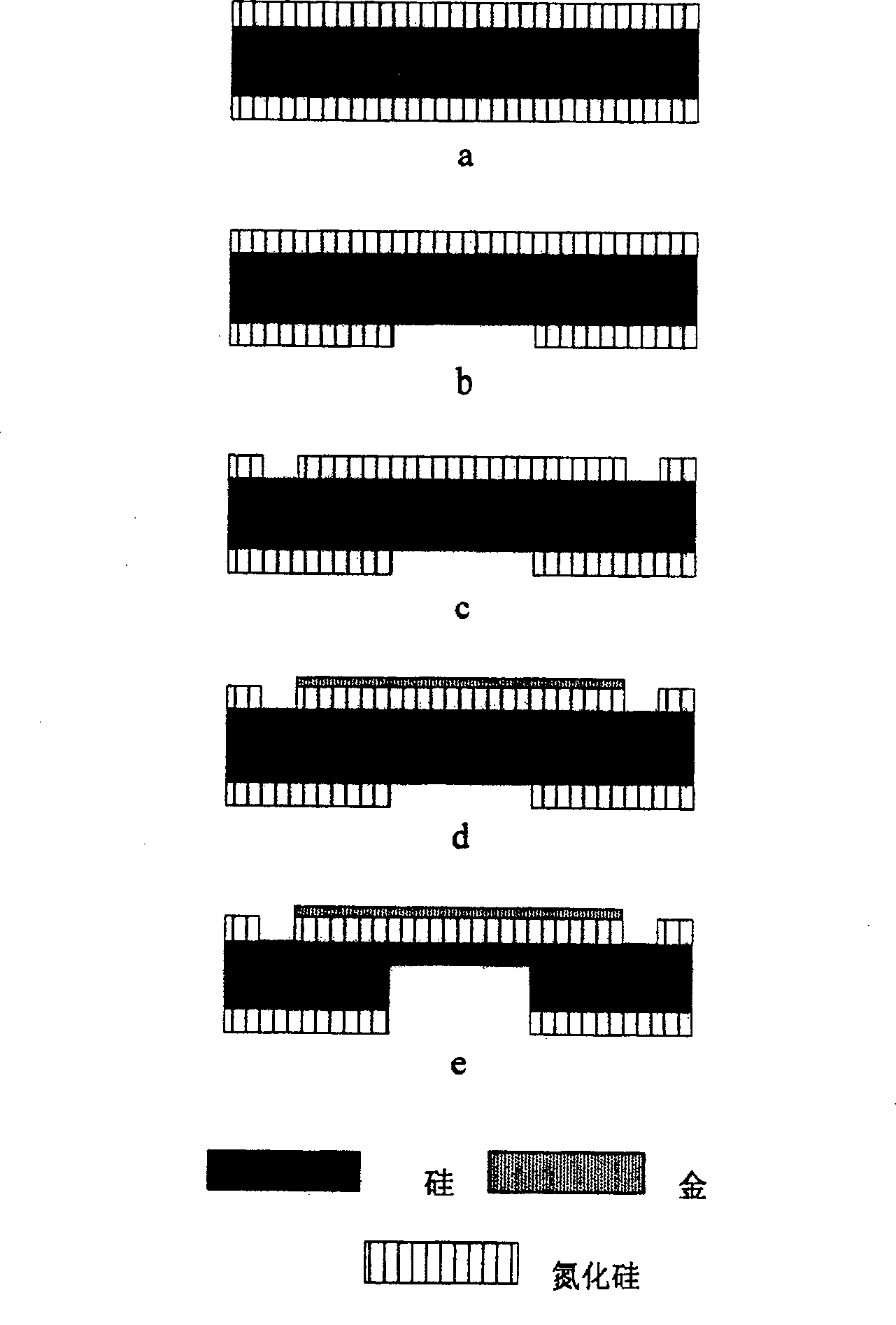

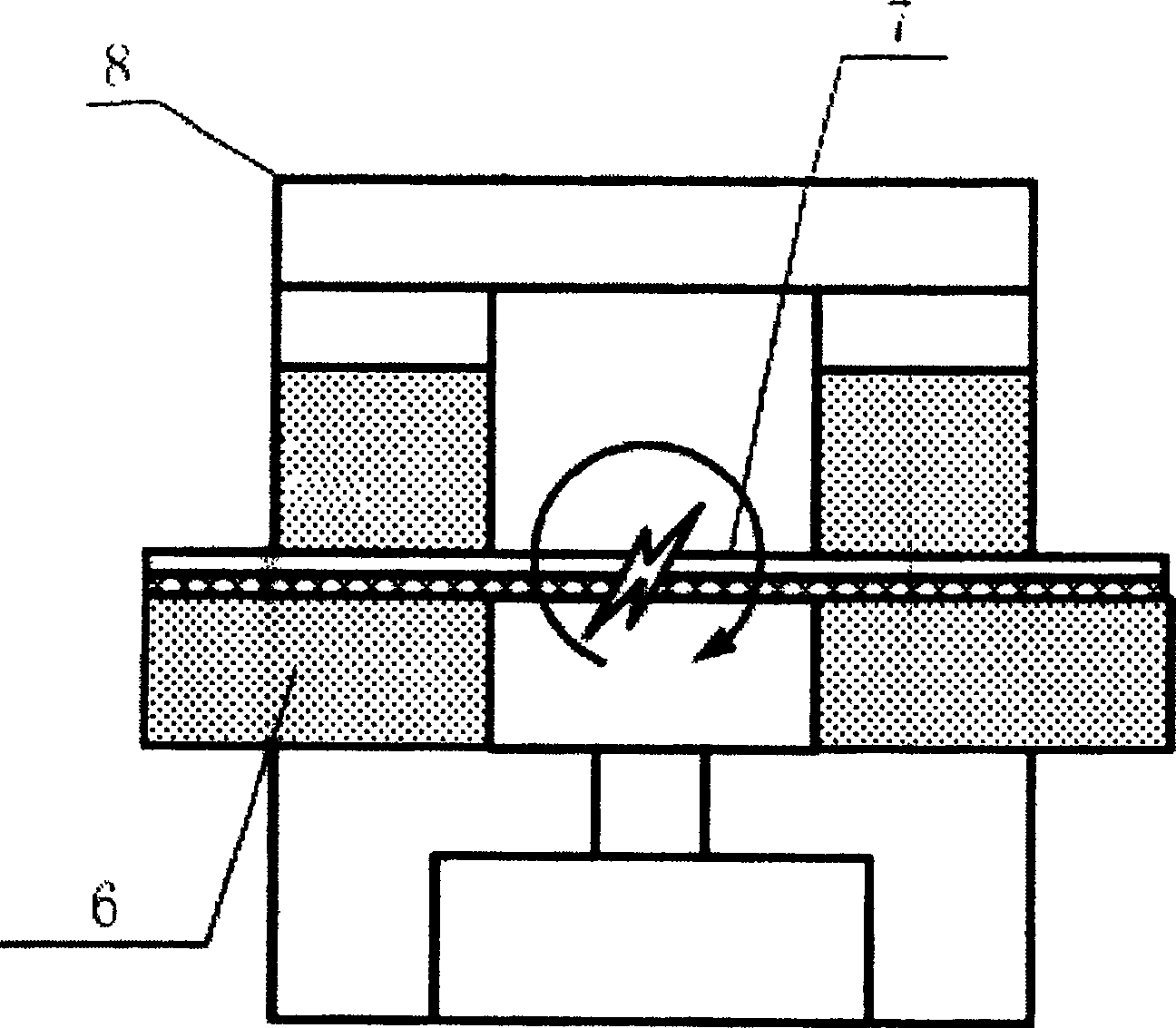

[0017] Such as figure 1 Shown is a structural diagram of a built-in resistance igniter of a miniature internal combustion engine, including a silicon substrate 1, a wire 2, a metal resistor 4, a terminal block 5 and a cavity 3. The cross-sectional shape of the combustion chamber of miniature internal combustion engine adopts square or circle among the present embodiment, and its side length or diameter get 2mm, and the width of metal resistor sheet gets 40 μ m, because the shape and size of miniature internal combustion engine built-in resistance igniter and micro combustion chamber The shape and size design of the cavity of the inlet part correspond to each other, so the cross-sectional shape of the cavity 3 also adopts a square or a circle. The resistance sheet 4 is deposited on the beam structure of the silicon substrate 1 , and its shape corresponds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com