Patents

Literature

140results about How to "Optimize the force structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

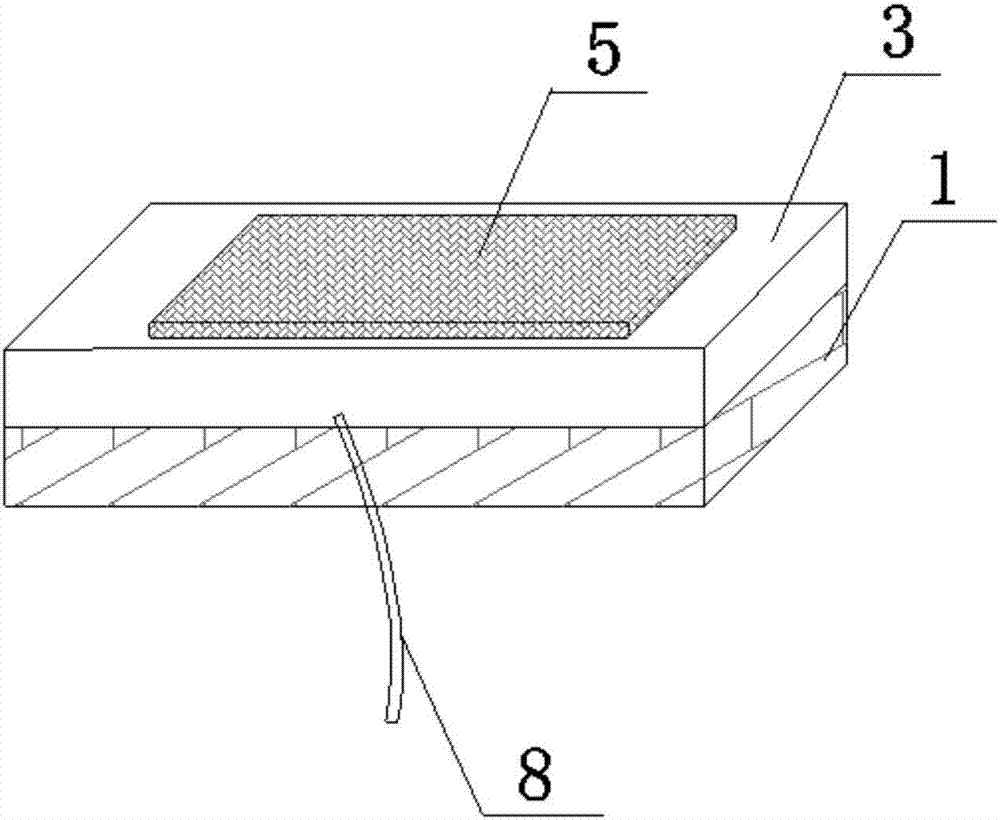

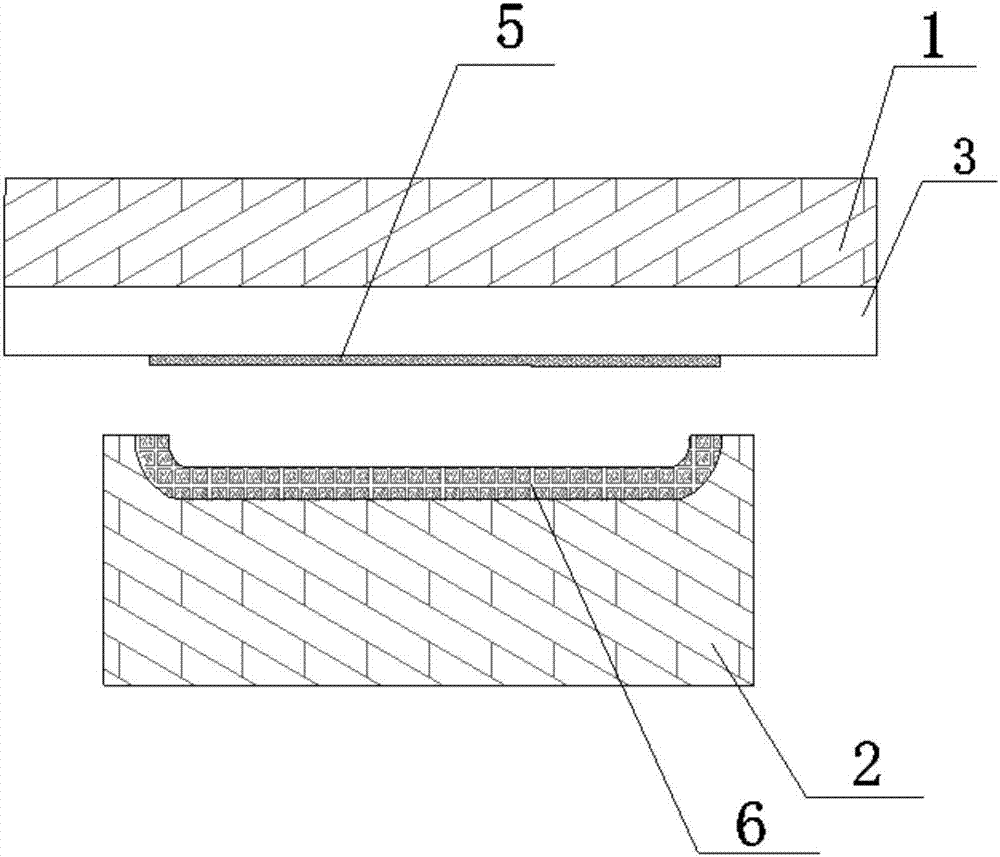

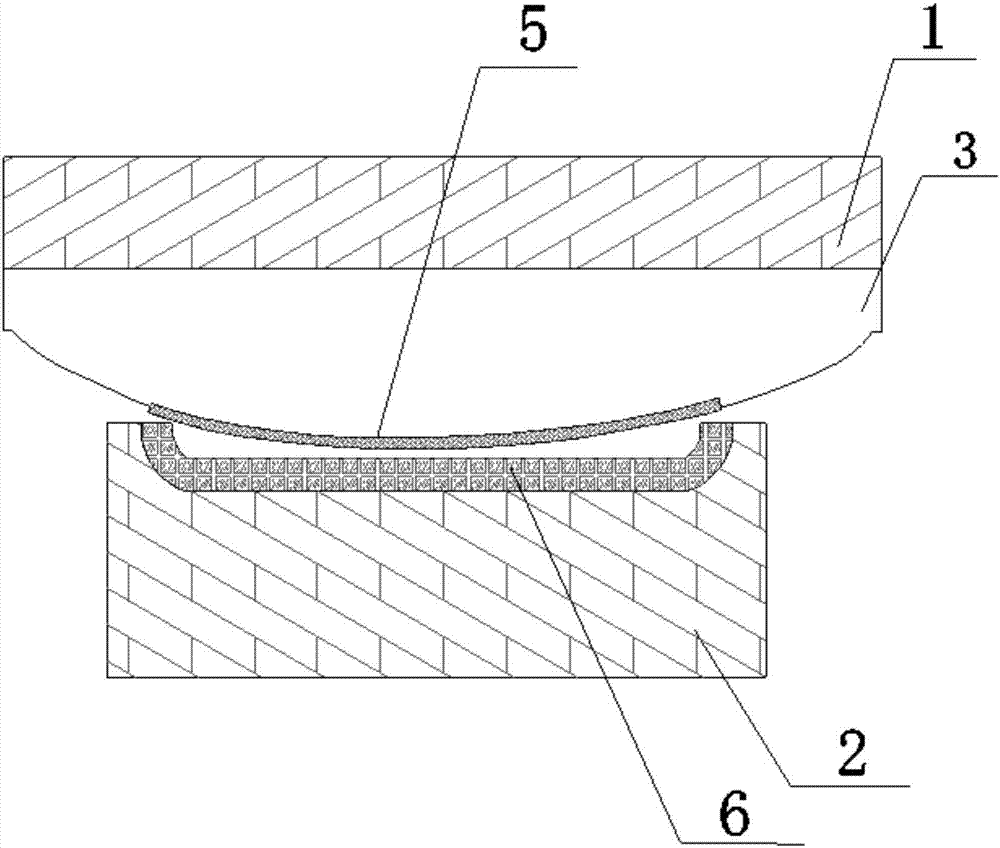

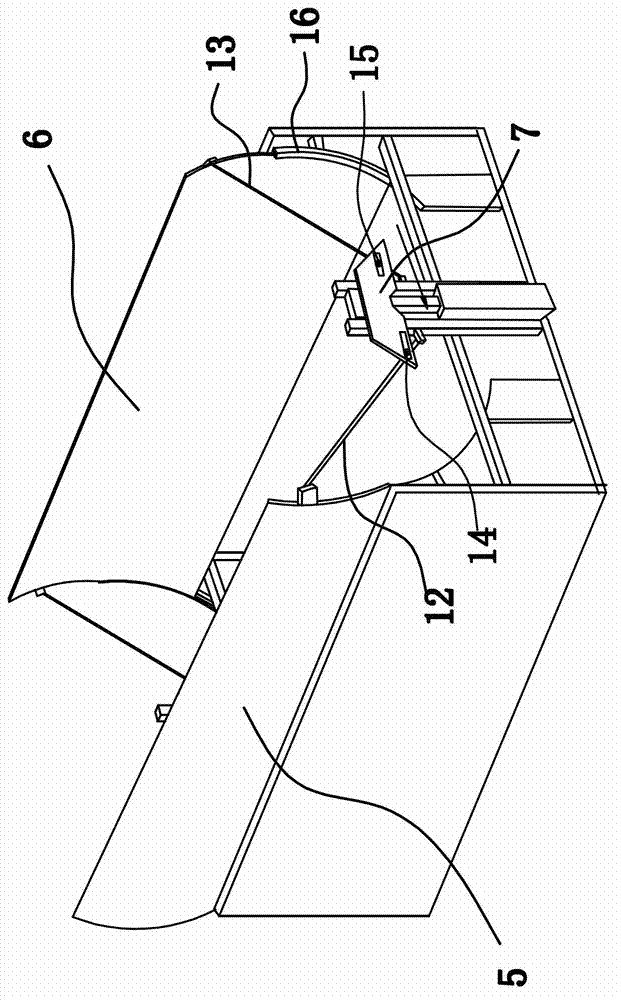

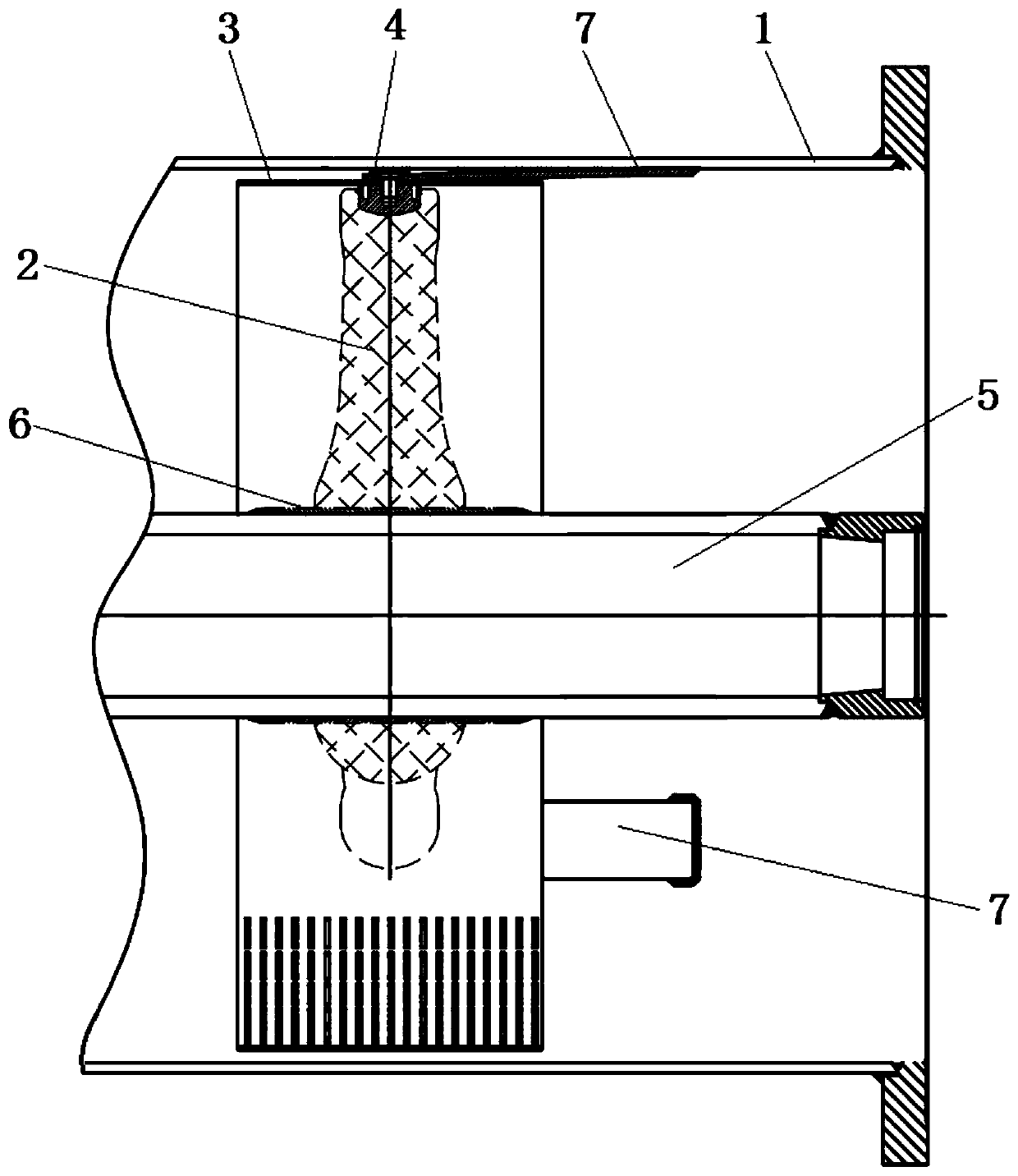

Airbag laminating device and method for curved glass on touch screen

ActiveCN107020785AOptimize the force structureIncrease pressureLaminationLamination apparatusEngineeringAirbag deployment

The invention discloses an airbag laminating device and method for curved glass on a touch screen. The airbag laminating device comprises a support plate and a fixture platform located below the support plate, wherein the fixture platform is used for positioning the curved glass; a main airbag is arranged on one side of the support plate close to the fixture platform; an auxiliary airbag is arranged at a position inside the main airbag corresponding to a bent part of the curved glass; the auxiliary airbag is used for tightly laminating a flexible film to the bent part of the curved glass. The airbag laminating device improves a stress structure of the bent part of the curved glass during lamination by arranging the auxiliary airbag corresponding to the bent part of the curved glass in the main airbag, and increases pressure of the bent part during lamination, so that the flexible film is further laminated to the bent part of the curved glass under compression effect of the auxiliary airbag, thereby eliminating the lamination bubbles of the flexible film and the curved glass, increasing the lamination quality and reducing yield loss.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

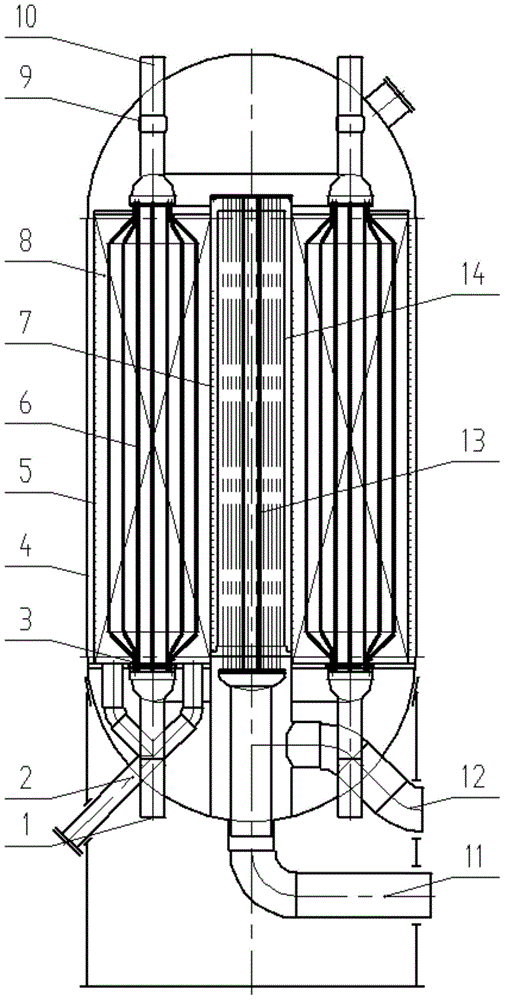

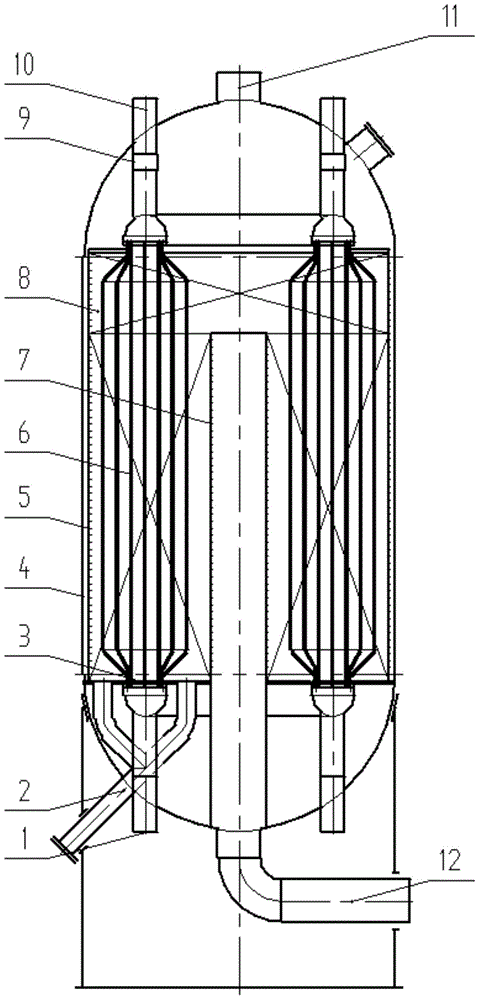

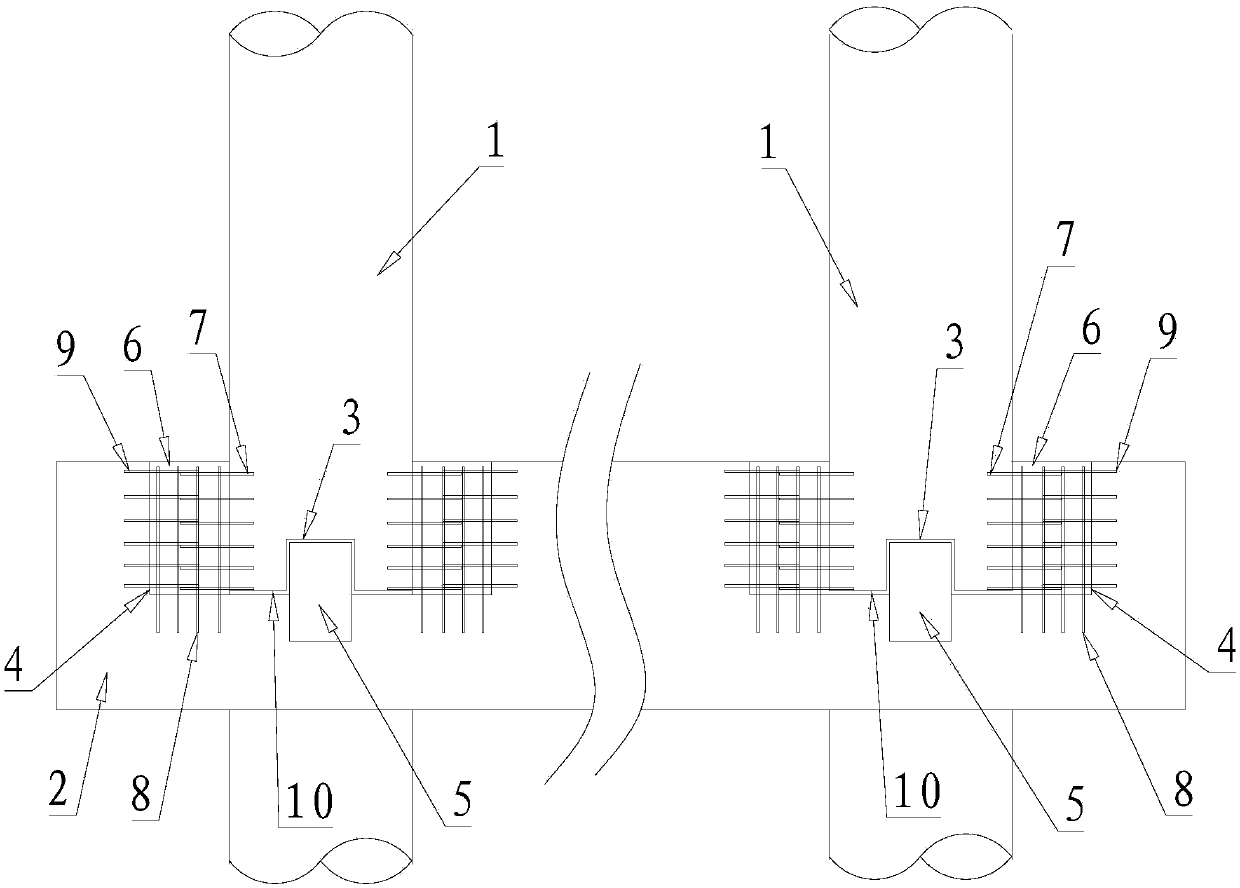

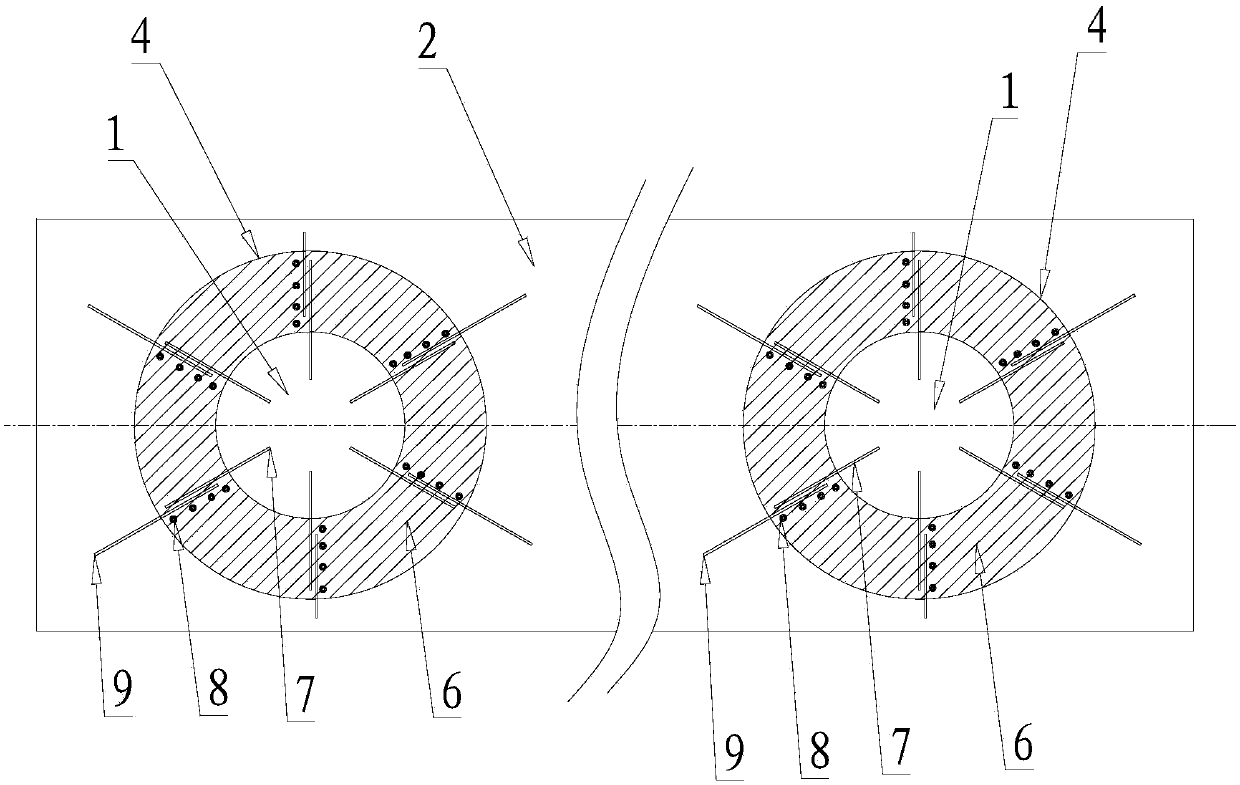

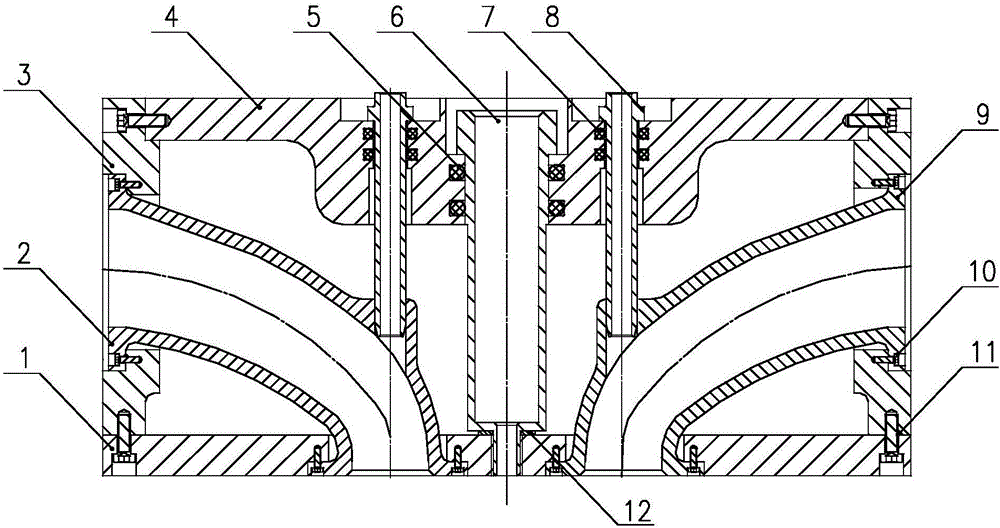

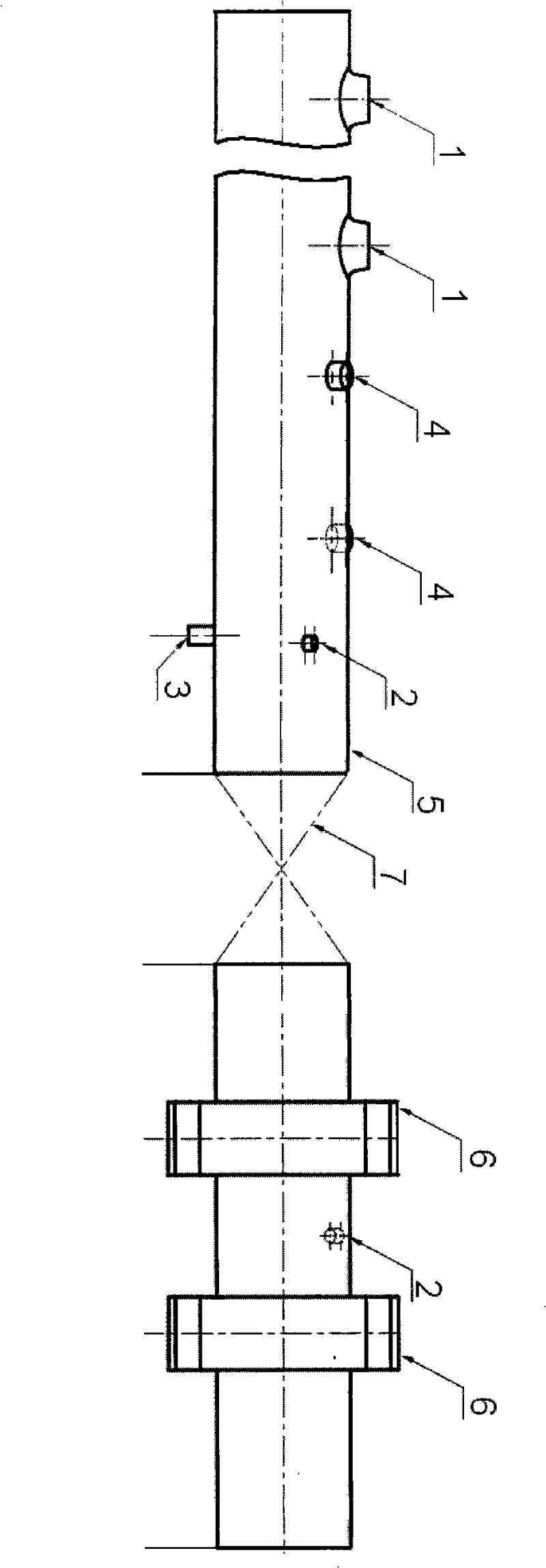

Pipe-bundle-builtin isothermal-shift reactor

ActiveCN105457563AFrom burningExtend your lifeHydrogenChemical/physical processesEngineeringHigh heat

The invention relates to a pipe-bundle-builtin isothermal-shift reactor. According to the pipe-bundle-builtin isothermal-shift reactor, axial annular pipe bundles, which are builtin and are uniformly distributed in a catalyst bed layer along circumferential direction, are adopted to shift out heat of reaction, so as to realize isothermal shift; and a central pipe bundle which is built in a central pipe is adopted to preheat raw material gas entering the reactor, so as to realize the builtin of a gas-gas heat exchanger. The isothermal-shift reactor comprises a pressure-bearing shell, a catalyst basket, the axial annular pipe bundles, the central pipe and the central pipe bundle; and the axial annular pipe bundles consist of upper and lower annular pipe boxes, upper and lower annular pipe sheets and heat exchange tubes. According to the pipe-bundle-builtin isothermal-shift reactor, due to builtin pipe bundles, the manufacturing cost of equipment is effectively reduced; due to an end-part bent structure for the heat exchange tubes, the size of the pipe sheets is effectively reduced; due to a heat insulating layer laid between the pipe sheets and the high-temperature catalyst bed layer, the contact between pipe end weld spots and a bed layer high-temperature area is effectively isolated, the probability of leakage is lowered, and the reliability of equipment is improved; and the pipe-bundle-builtin isothermal-shift reactor is compact in structure, low in manufacturing cost, relatively easy in maintenance, high in reliability, complete in function and high in applicability.

Owner:CHANGZHENG ENG

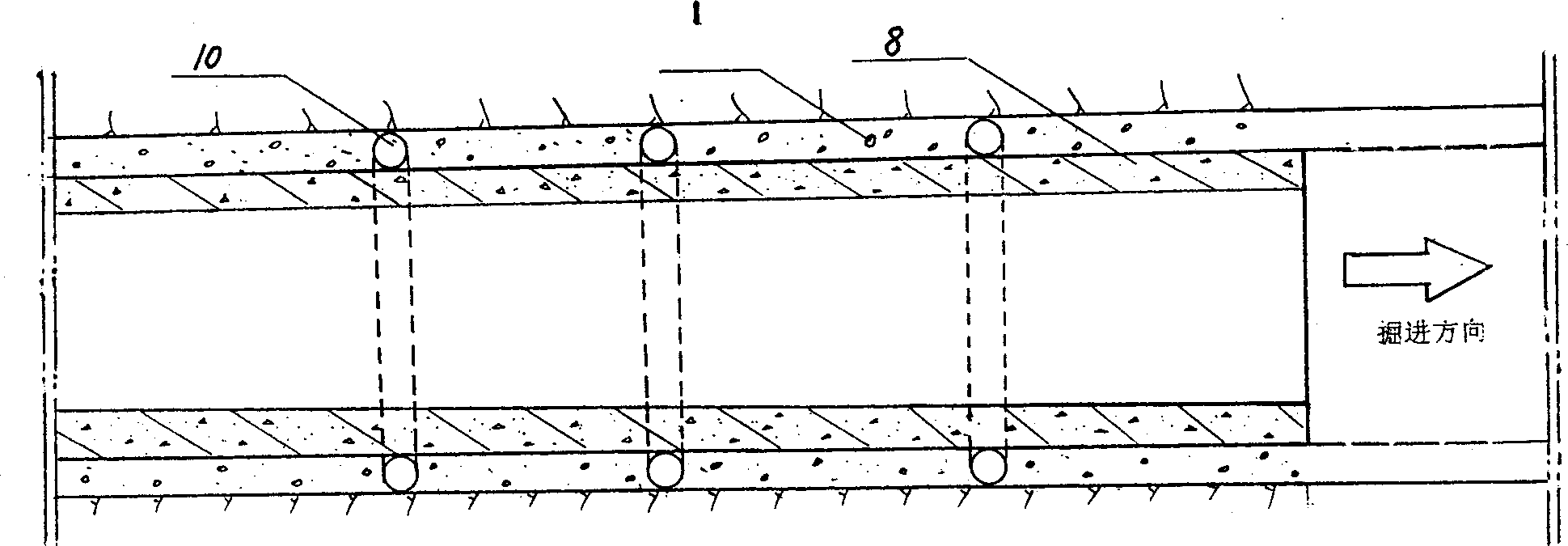

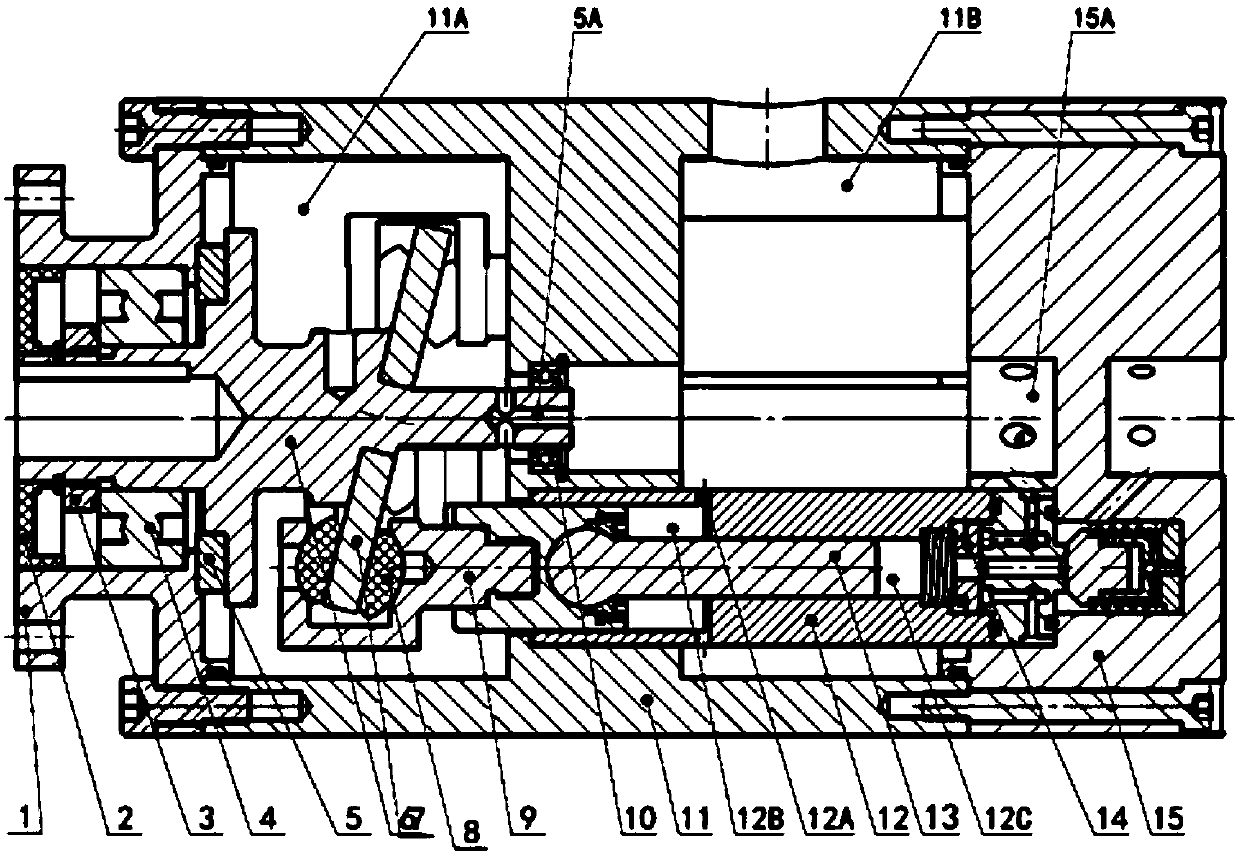

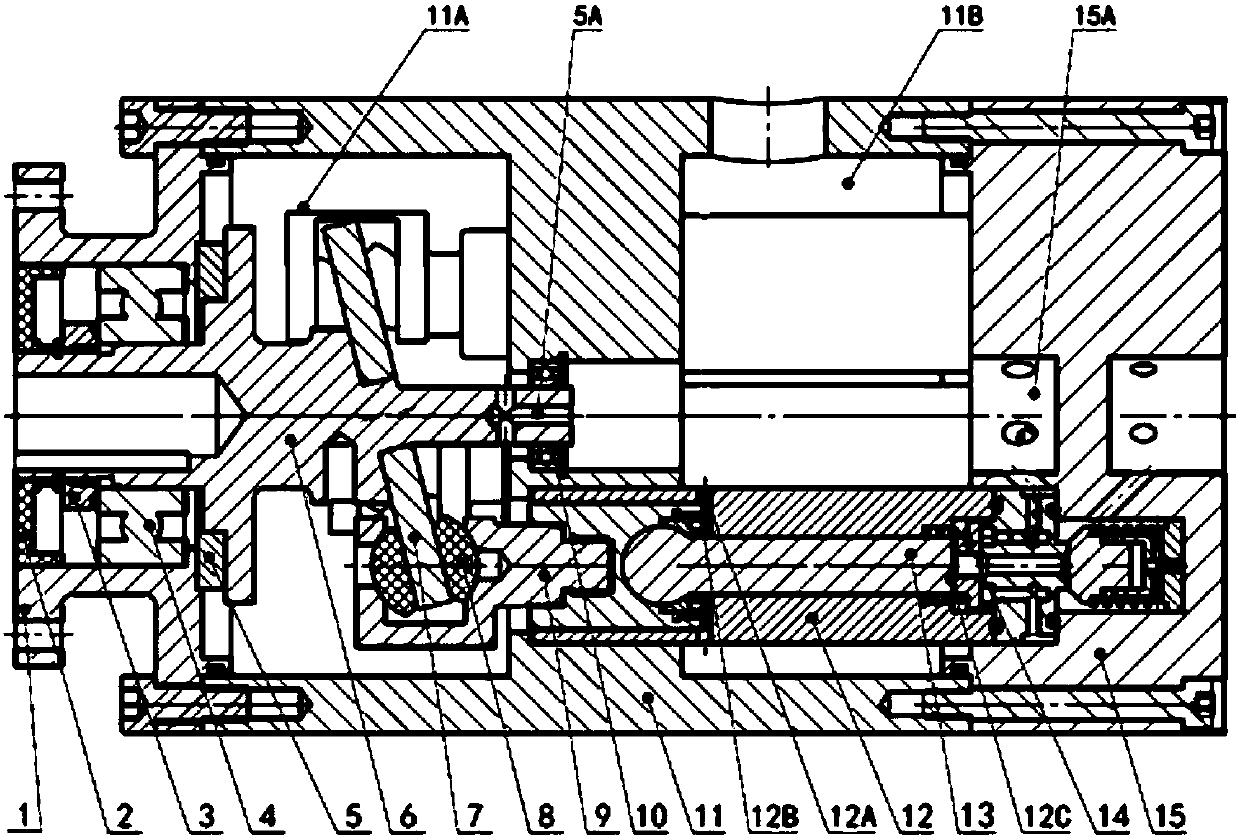

High-speed energy absorption anti-impact retreat hydraulic support for coal mine

InactiveCN102418538AOptimize the force structureIncrease profitProps/chocksEnergy absorptionEngineering

The invention provides a high-speed energy absorption anti-impact retreat hydraulic support for a coal mine. The hydraulic support comprises a bottom beam, energy absorption retreat members, connecting rods, hydraulic props and top beams, wherein two top beams are connected together in a hinged mode; an energy absorption material is filled at the hinged position of the two top beams; the bottom beam is connected with the top beams through the connecting rods; energy absorption materials are filled in the energy absorption retreat members; one end of each energy absorption retreat member is connected with the bottom beam or each top beam, and the other end of each energy absorption retreat member is matched with one end of each hydraulic prop; and the other end of each hydraulic prop is arranged in a needling of each top beam or the bottom beam. The hydraulic support has the characteristics of a rigid support and a flexible support simultaneously, the whole hydraulic support can be prevented from being damaged, the damage degree of surrounding rocks is effectively reduced, and the safety of underground operating personnel is ensured; in addition, production recovery time can be greatly shortened after rock burst occurs.

Owner:辽宁工大太阳石科技园有限公司 +1

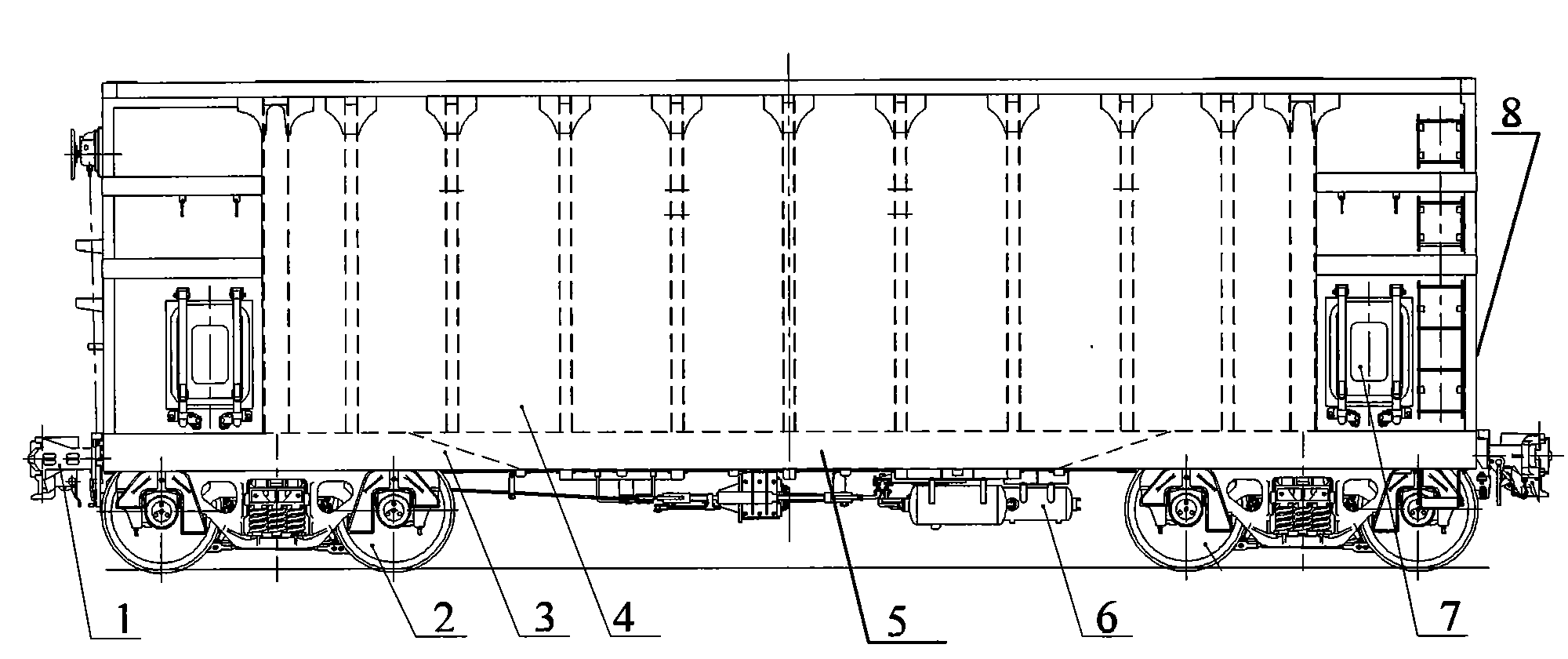

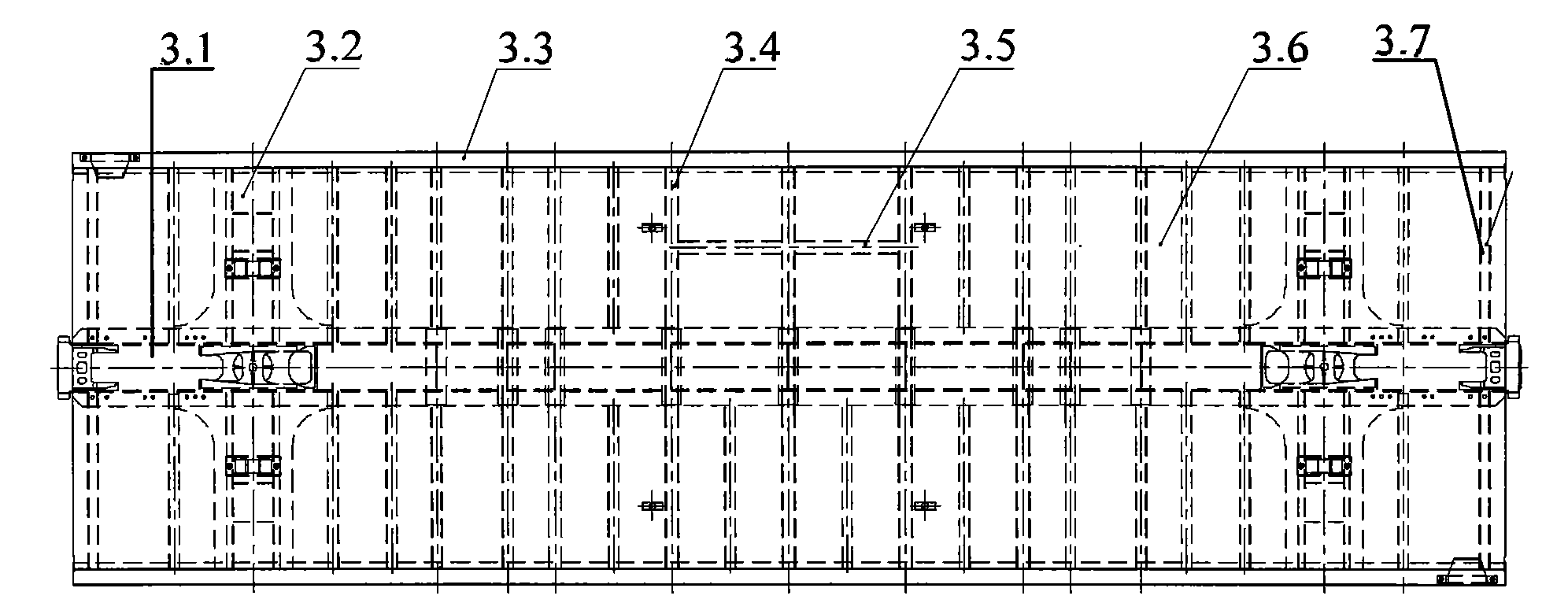

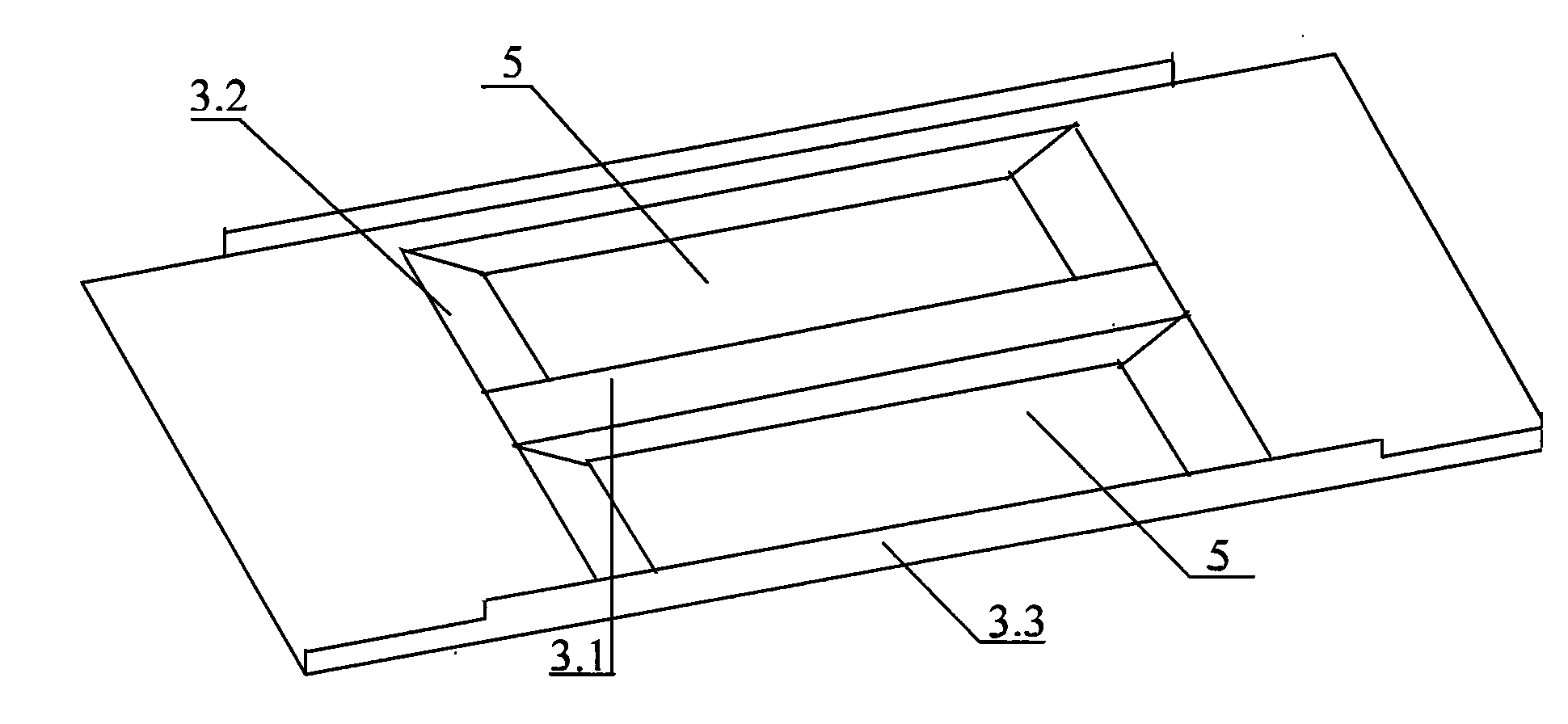

Special gondola vehicle with a shallow concave bottom for coal transportation

ActiveCN101585364ALower center of gravityEasy maintenance and repairRailway transportAxle-box lubricationBogieEngineering

A special gondola vehicle with a shallow concave bottom for coal transportation belongs to the transportation facilities, in particular to a railway truck gondola vehicle. The gondola vehicle comprises a vehicle body, a vehicle coupler buffer device, a braking device and a bogie. The vehicle body comprises a chassis, a side wall and an end wall. The key technique is that the chassis comprises a centre sill, a sleeper beam, a lower side beam and an end beam, two downwards concave shallow concave bottoms are arranged between the two sides of the centre sill and between the lower side beam and the sleeper beam in the middle of the side wall, the depths of the shallow concave bottoms are aligned with the lower plane of the centre sill, the side wall comprises a side wall board and a side post, the two ends of the side wall are end door panels which are inwards concave with respect to the side wall board to form stages, so as to form the end door plate with a concave structure. The invention not only effectively increases the vehicle body volume, but also decreases vehicle height of center of gravity, and improves vehicle riding quality.

Owner:CRRC MEISHAN

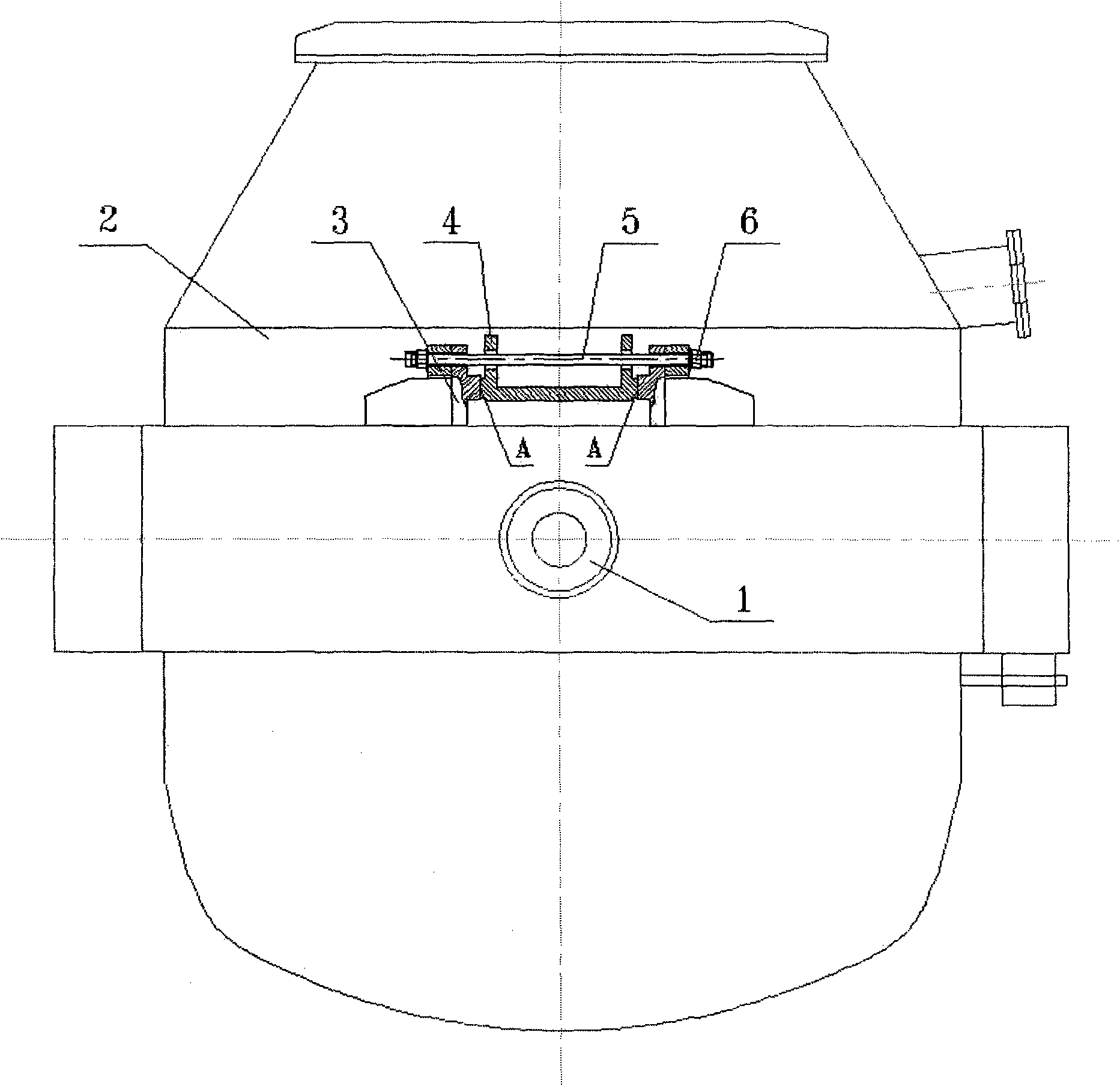

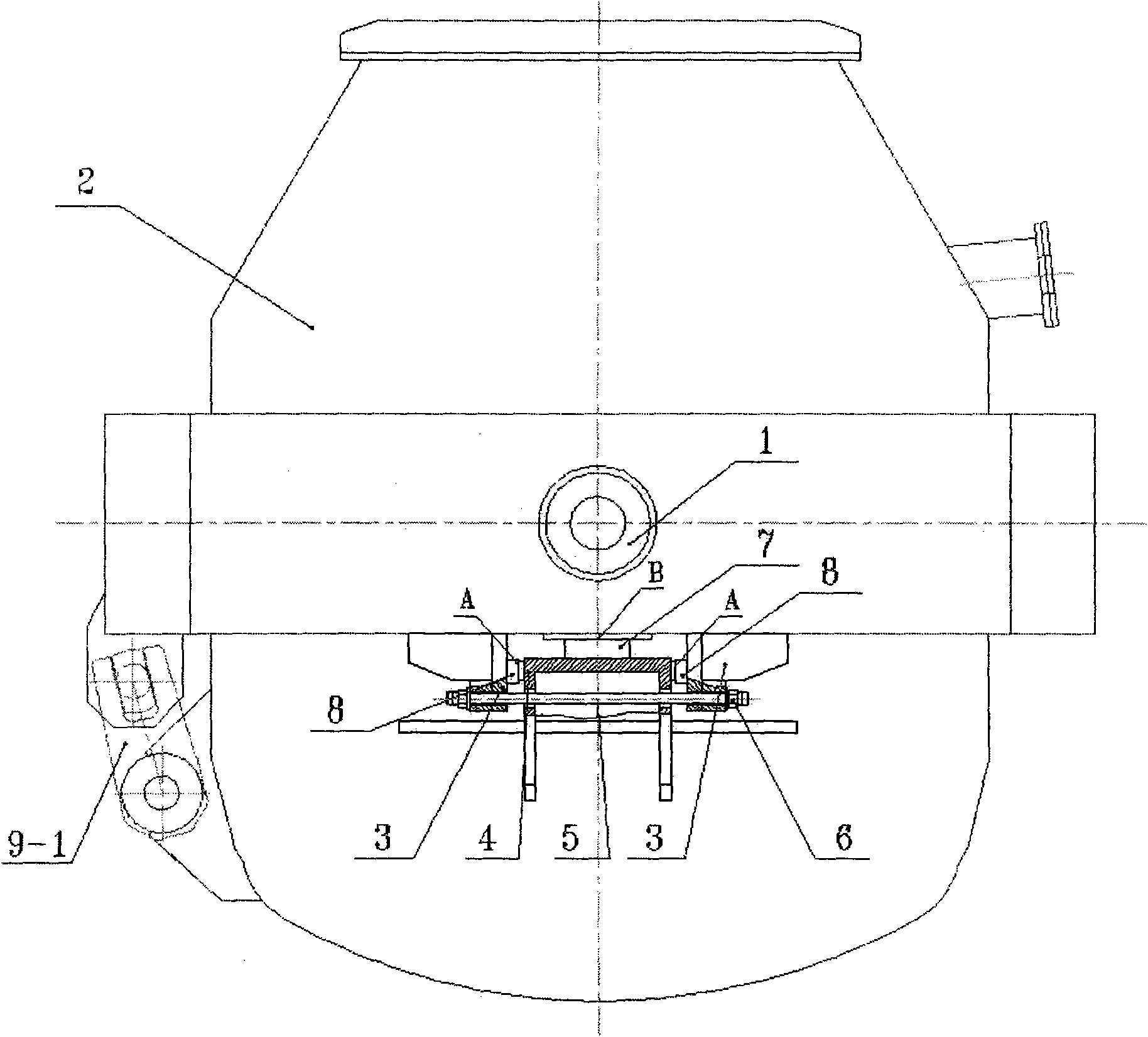

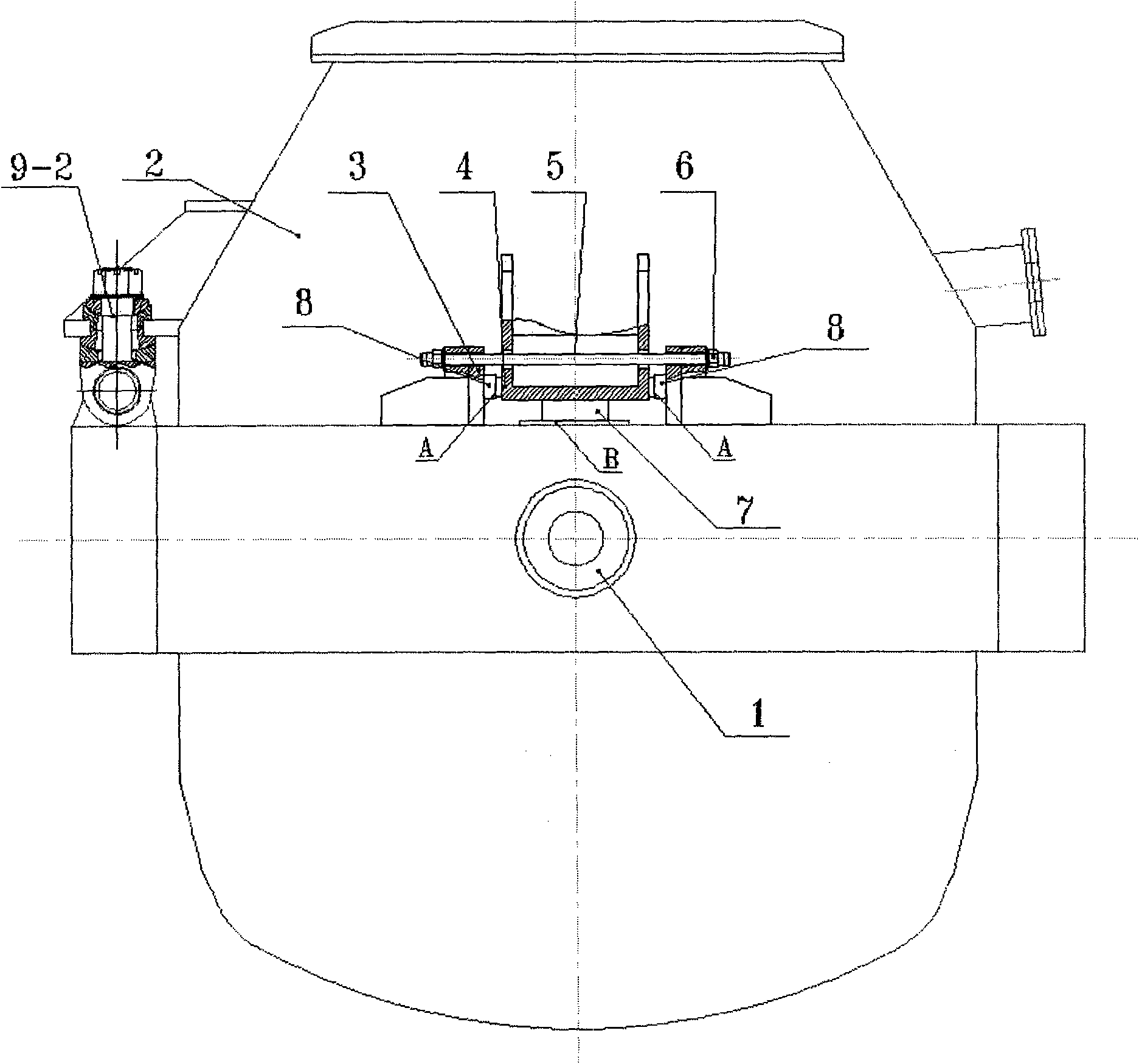

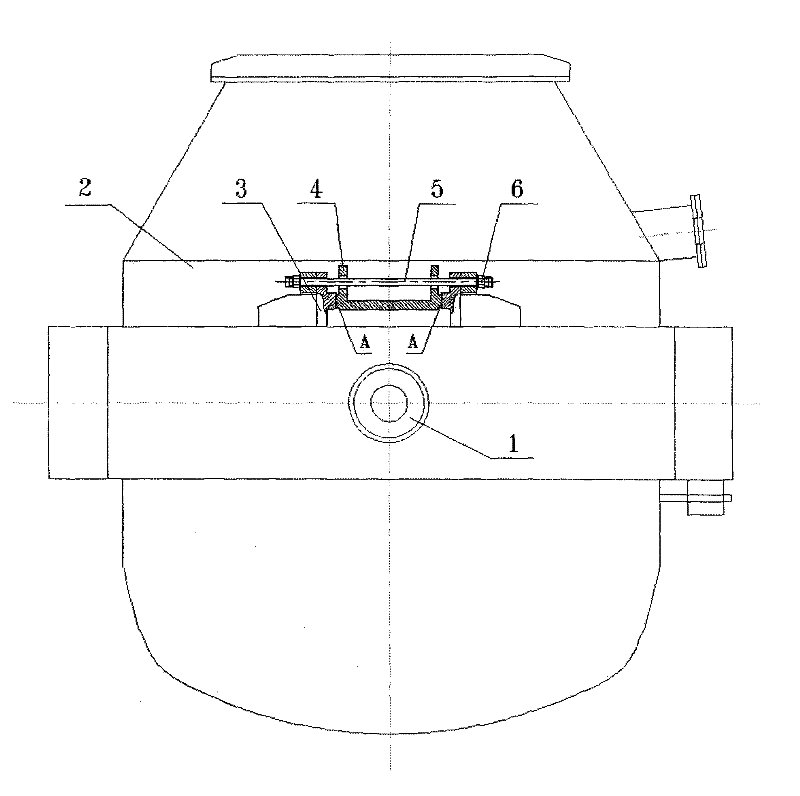

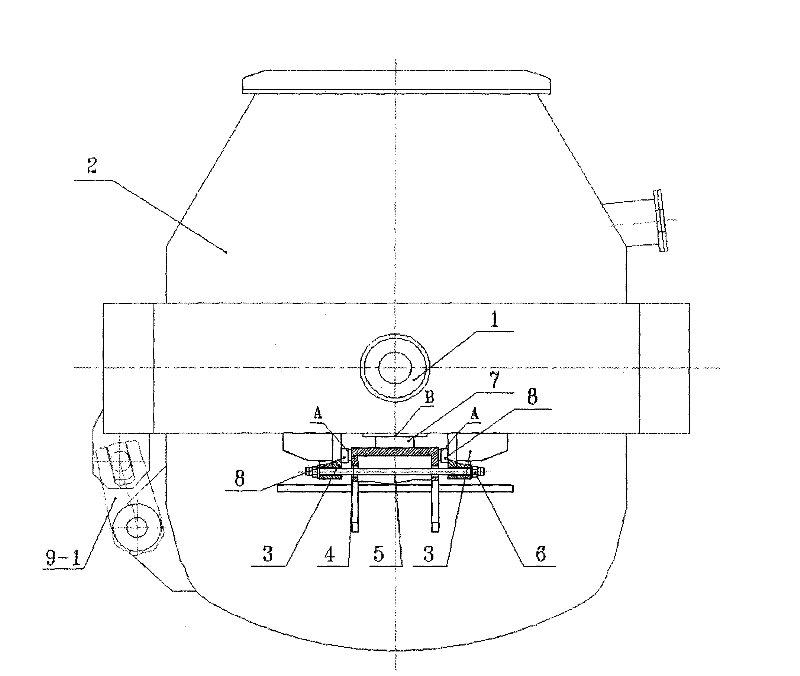

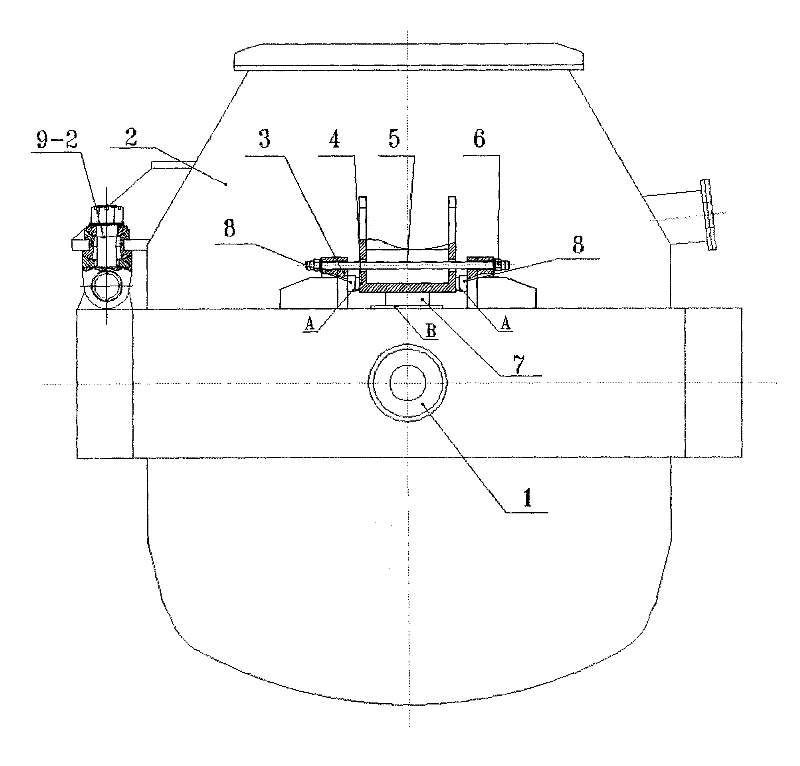

Three-supporting surface prestress blocking seat mechanism of converter

InactiveCN101638710AImprove stressChange the way of forceManufacturing convertersEngineeringSupport surface

The invention belongs to the technical field of metallurgical machinery and discloses a three-supporting surface prestress blocking seat mechanism of a converter. The three-supporting surface prestress blocking seat mechanism of the converter mainly comprises a supporting ring, a converter shell, supporting ring blocking seats and a converter shell seat assembly, wherein the supporting ring blocking seats are welded on the supporting ring, the converter shell seat is welded on the converter shell, the upper parts of the supporting ring blocking seats of both sides are connected by a pretensionpull rod and a linking member and are pretensioned inwards, the converter shell seat is clamped between the supporting ring blocking seats, the converter shell seat and the supporting ring blocking seats are provided with two lateral contact supporting surfaces, a longitudinal contact cushion block is additionally arranged between the supporting ring and the converter shell seat, and a longitudinal contact supporting surface is arranged between the supporting ring and the converter shell seat. The three-supporting surface prestress blocking seat mechanism effectively restricts a lateral gap and longitudinal elastic displacement of a converter body in the supporting ring, increases the operation stability of the converter, prolongs the service life, improves the reliability of the converter and is a novel technology with a popularization value on the converter.

Owner:CISDI ENG CO LTD

Splicing structure and splicing method of prefabricated bridge piers and prefabricated bearing platform

PendingCN108049305APrecise positioningShorten the construction periodBridge structural detailsFoundation engineeringShear capacityUltimate tensile strength

The invention provides a splicing structure and a splicing method of prefabricated bridge piers and a prefabricated bearing platform. By utilizing the joggling of hollow steel tubes in first concave grooves in the bottoms of the prefabricated bridge piers and concrete filled steel tube tenons enclosed by the inner walls of annular grooves in the top of the prefabricated bearing platform, on one hand, favorable positioning effects are achieved for the mounting, on the bearing platform, of the prefabricated bridge piers, and on the other hand, the shear capacity and the flexural capacity at splicing positions are improved; post-poured concrete is poured into the annular grooves to enwrap the splicing positions of the prefabricated bridge piers and the prefabricated bearing platform; the prefabricated bridge piers and the prefabricated bearing platform are connected into a whole; an overall stress structure is ameliorated; the splicing strength of the prefabricated bride piers and the prefabricated bearing platform is greatly improved, and is not less than the strength of a cast-in-place bridge pier. By adopting a way of splicing the prefabricated bride piers and the prefabricated bearing platform, the field pouring workload of concrete is effectively reduced; the field operation is facilitated; a road is not occupied; influences on an urban traffic environment during the operation are effectively relieved, and meanwhile, a construction period of a bridge is shortened.

Owner:FUJIAN UNIV OF TECH

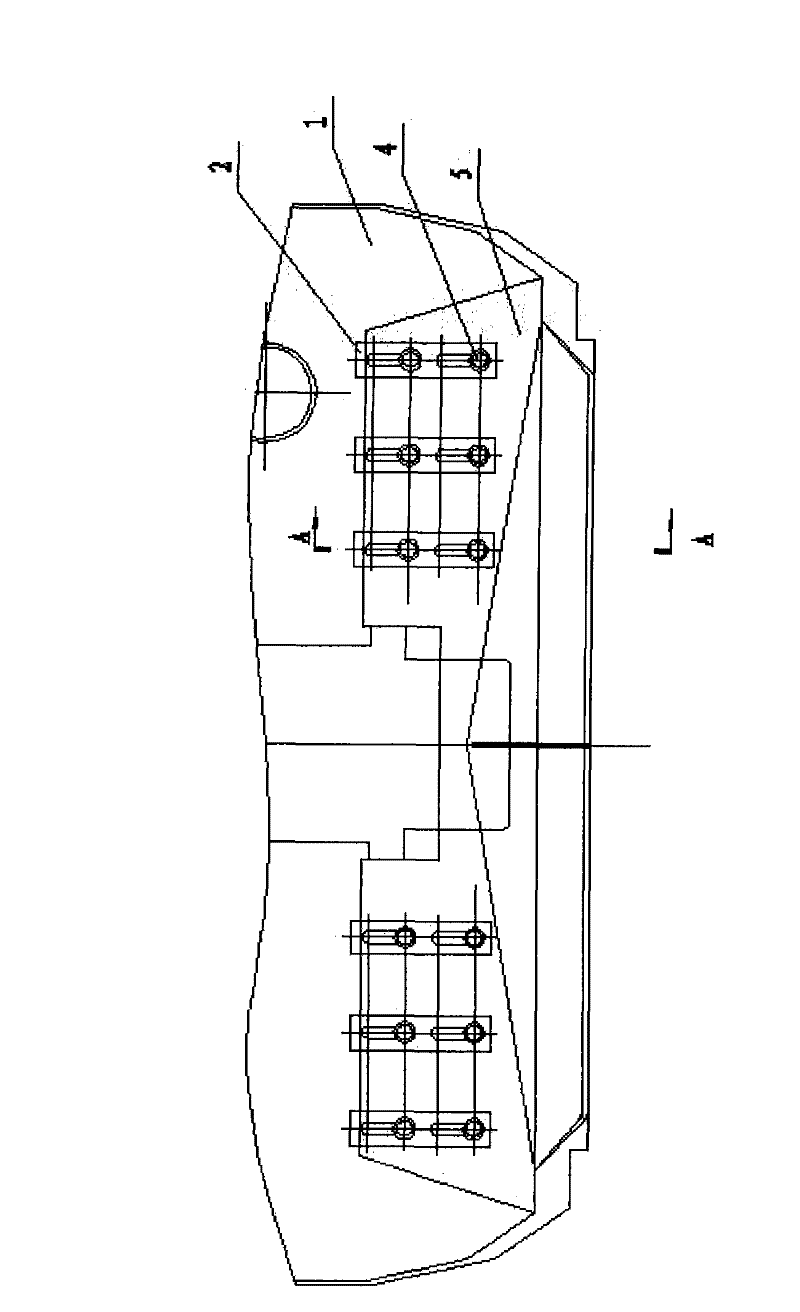

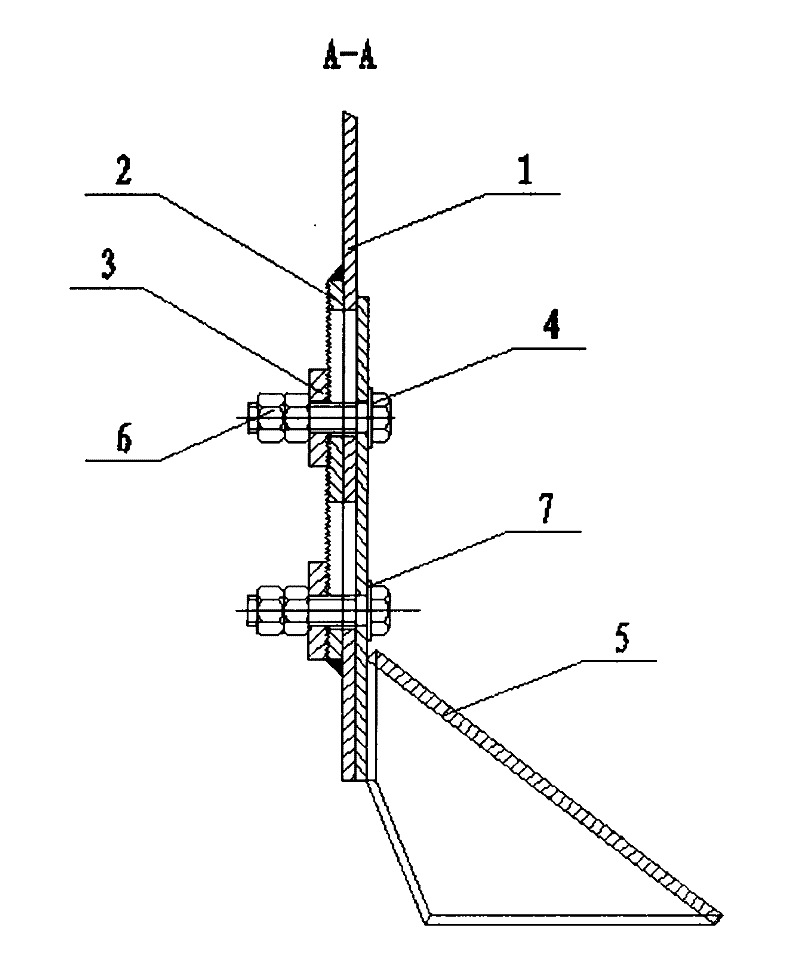

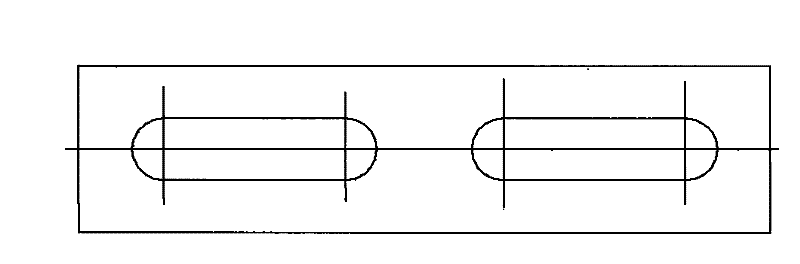

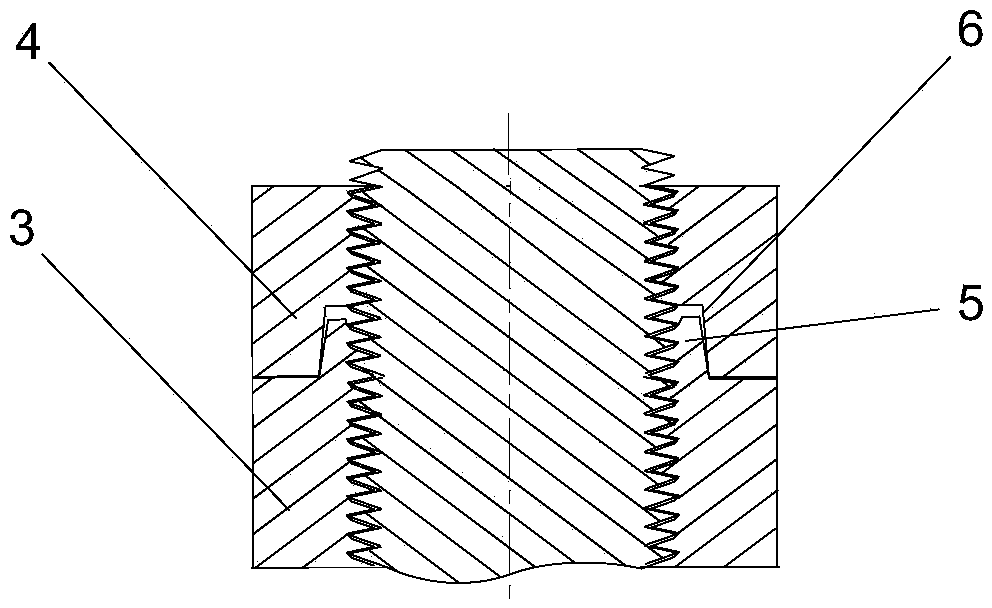

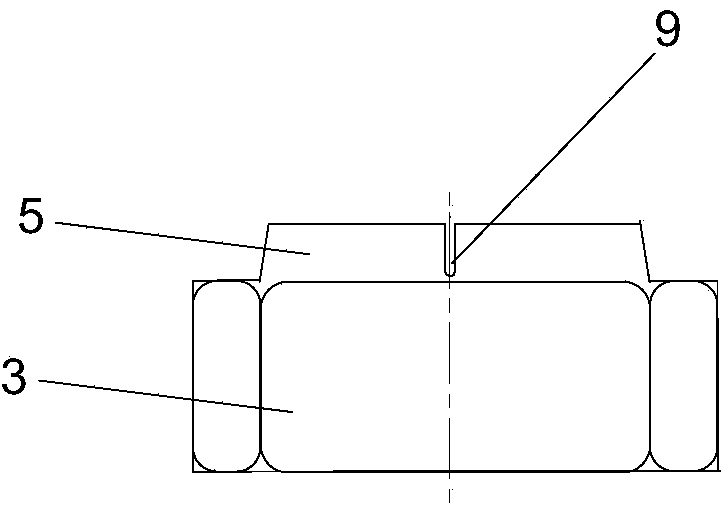

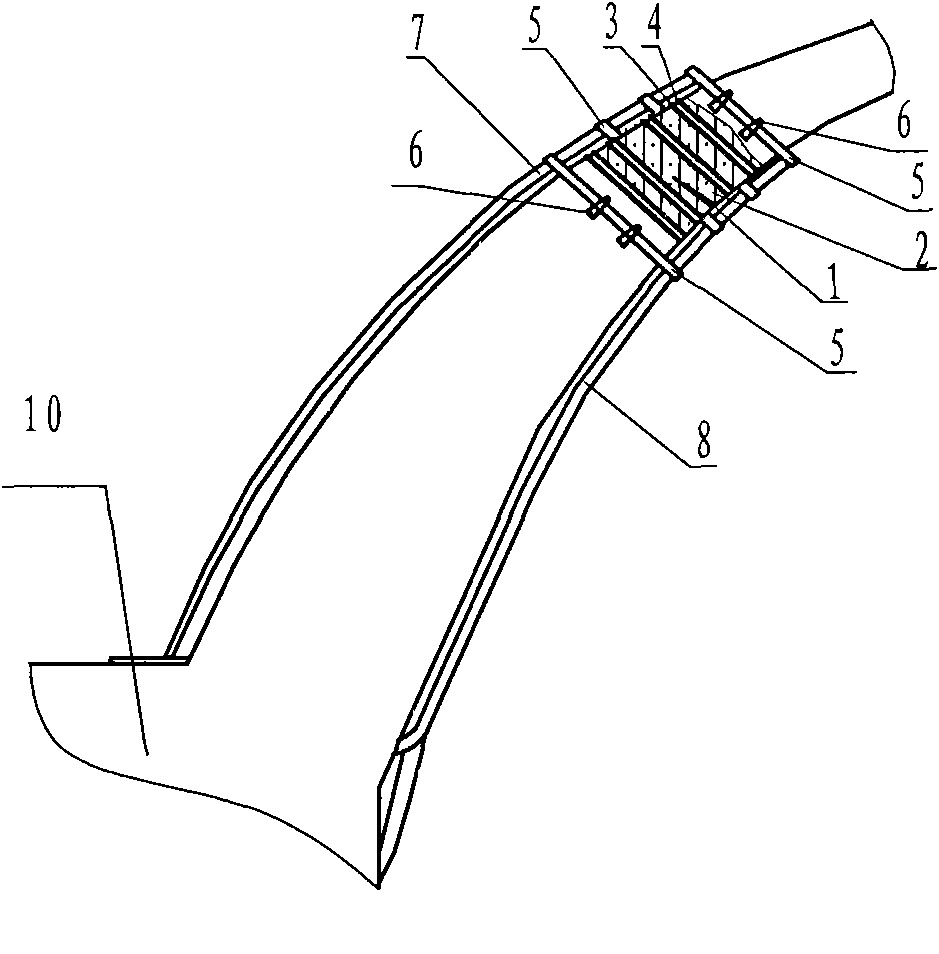

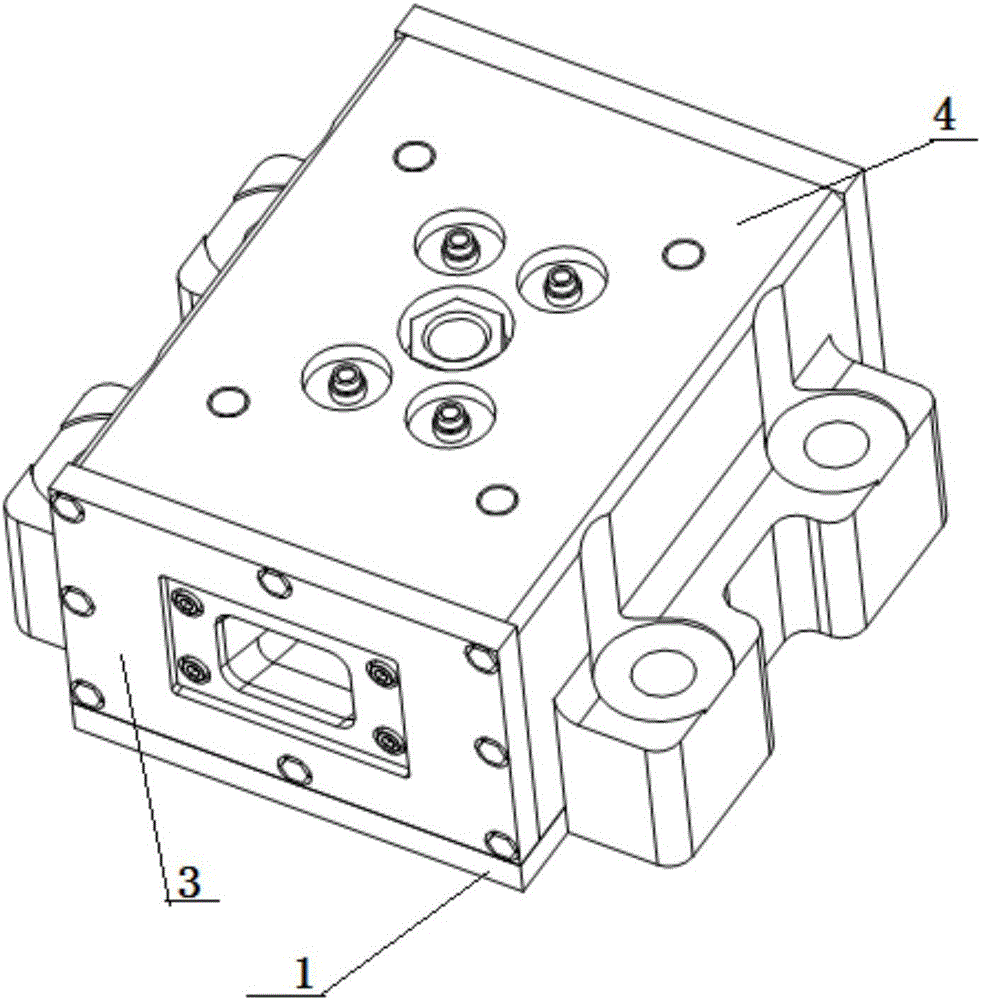

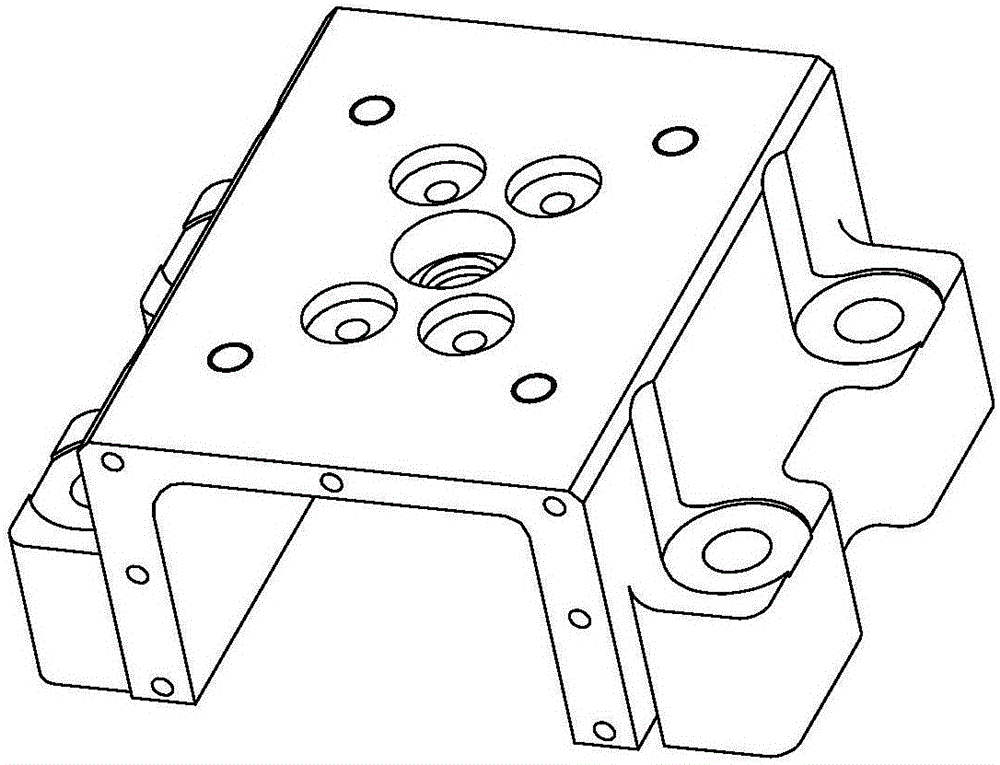

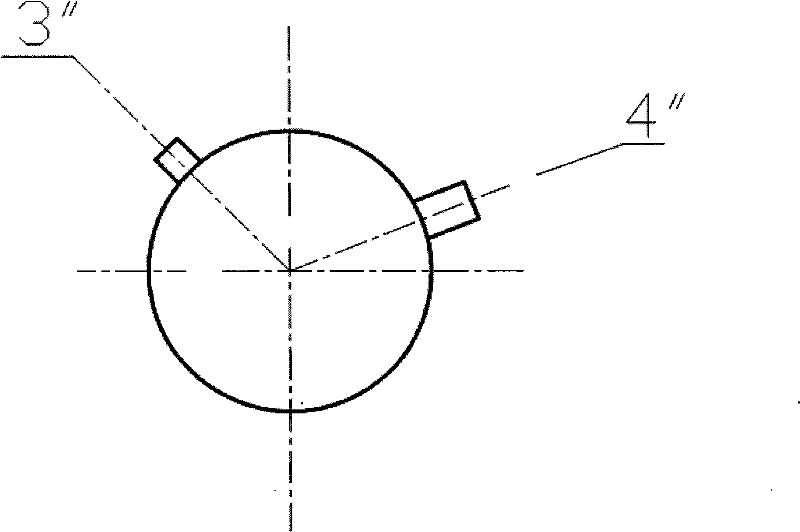

Connection device of locomotive cowcatcher

The invention discloses a connection device of a locomotive cowcatcher. A front end plate (1) of the locomotive is provided with a fixed plate (2); both the fixed plate (2) and a loose piece (3) have a surface which is processed into a surface with a zigzag section; the fixed plate (2) and the loose piece (3) have the same zigzag shape; a bolt (4) passes through a gasket (7), a cowcatcher (5), the front end plate (1), the fixed plate (2) and the loose piece (3); the other end of the bolt is fastened by double nuts (6); and the saw teeth of the zigzag surfaces of the fixed plate (2) and the loose piece (3) are meshed. By adopting the connection device disclosed by the invention, the connection between the cowcatcher and the front end plate of the locomotive is more reliable, the bolt fastening operation is more standard, and the height of the cowcatcher is easier to adjust.

Owner:CRRC DALIAN CO LTD

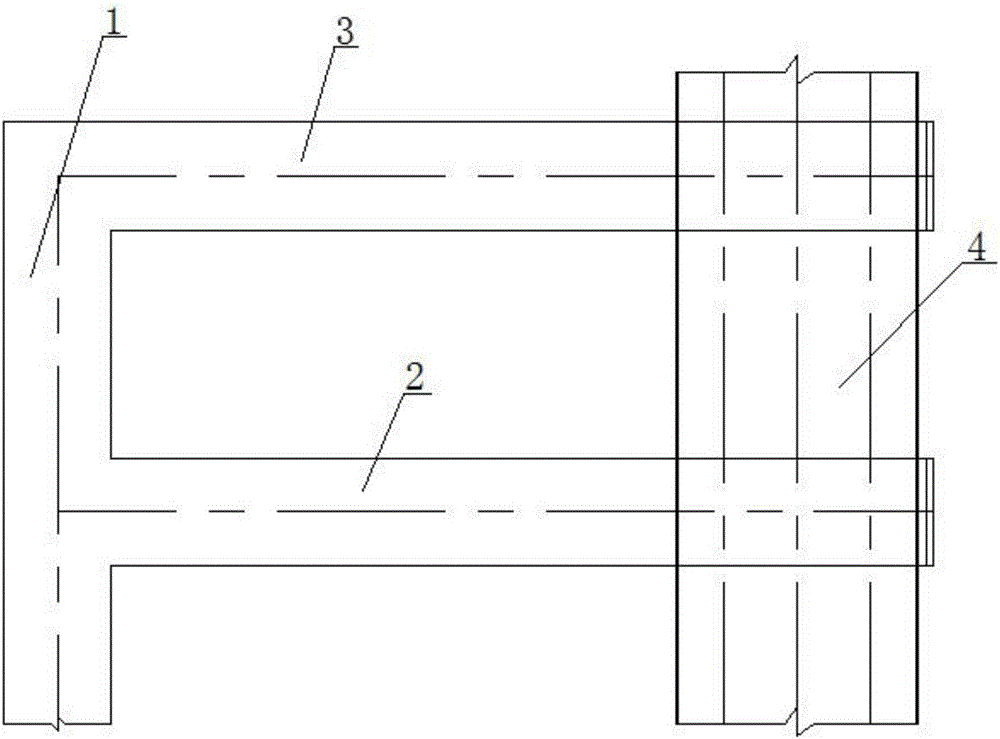

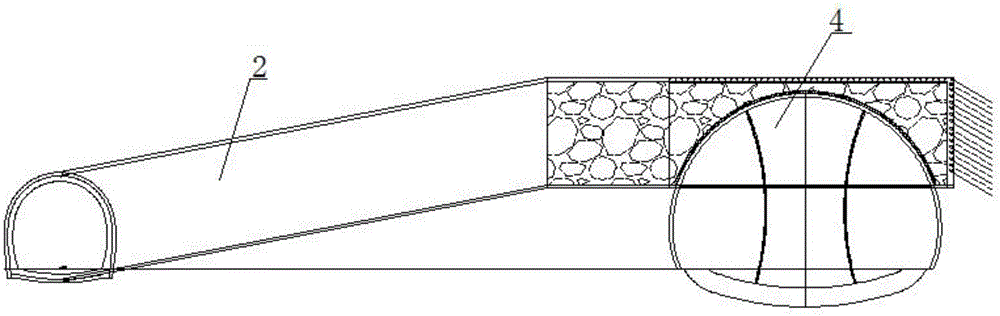

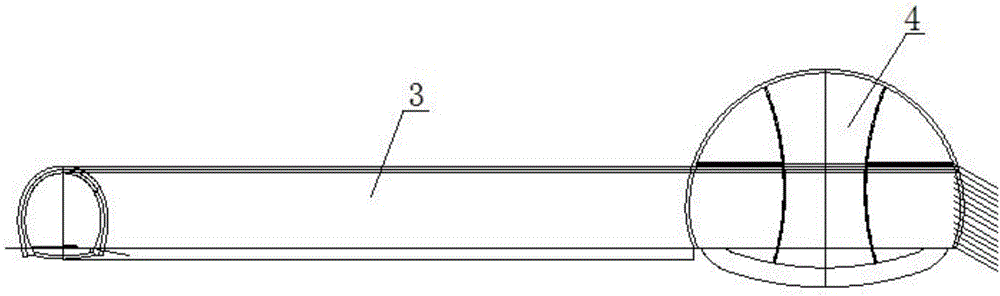

Construction mode with full cross-section tunneller

The full-section entry-driving machine construction method includes the following processes of cutting rock, lining pipe-sheet, pipe-sheet water-stopping, backfilling gravel and pouring cement slurry, in which the pipe-sheet water-stopping process includes the following steps: butt-jointing pipe-sheets, placing the filling strip on the butt joint of bottom of filling groove, inserting the plasticwater-stopping material into filling groove, wedging iron wedge from top of filling groove and backfilling high-strength cement slurry into butt-joint seam is pipe-sheet surface, and the process of backfilling gravel and pouring cement slurry includes the following steps: sectionalizing periphery of pipe-sheet, placing rubber hose along the periphery of pipe-sheet, air-inflating hose, backfillinggravel, pouring cement slurry, finally releasing air from hose and pouring cement slurry.

Owner:刘丽萍

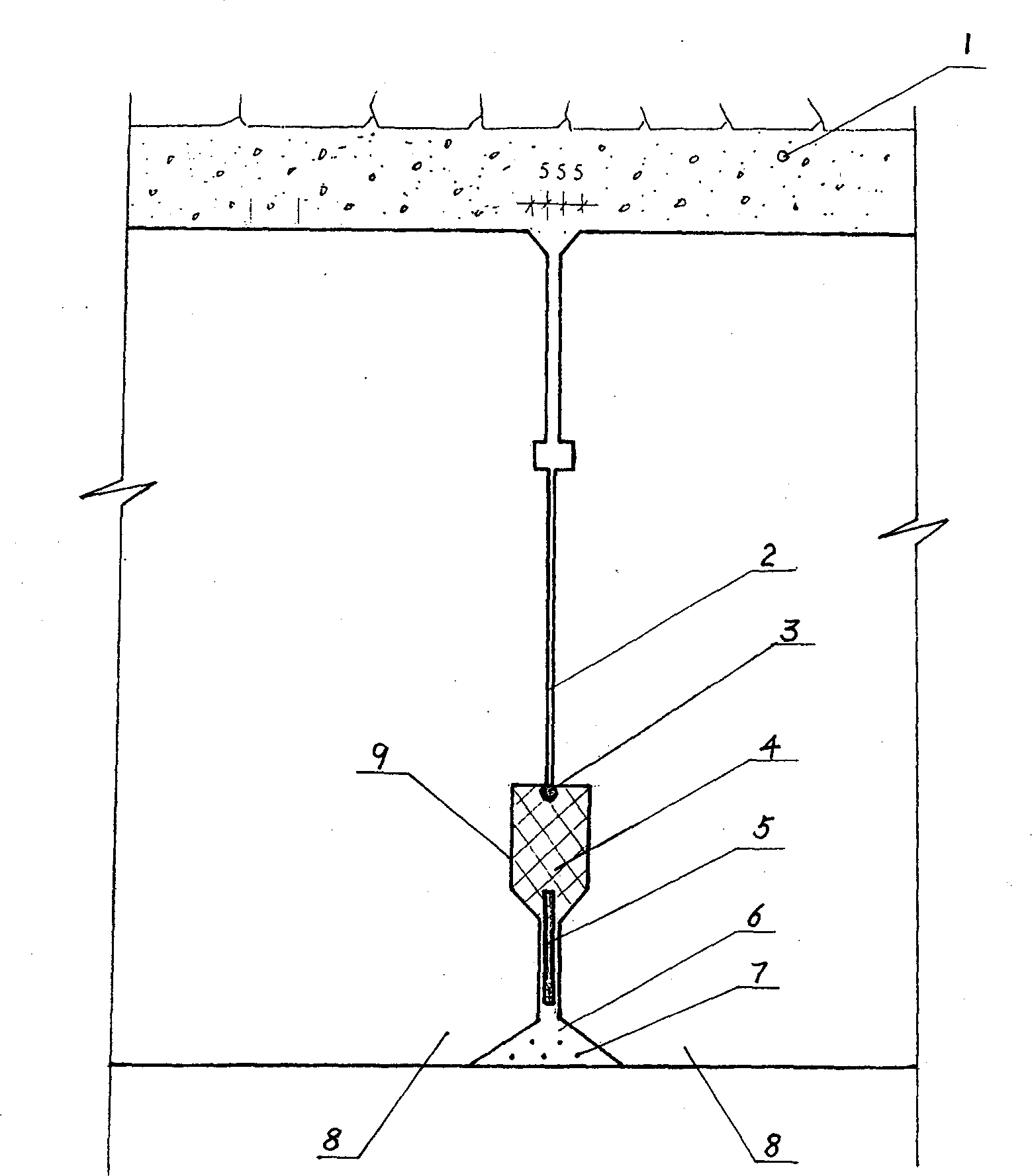

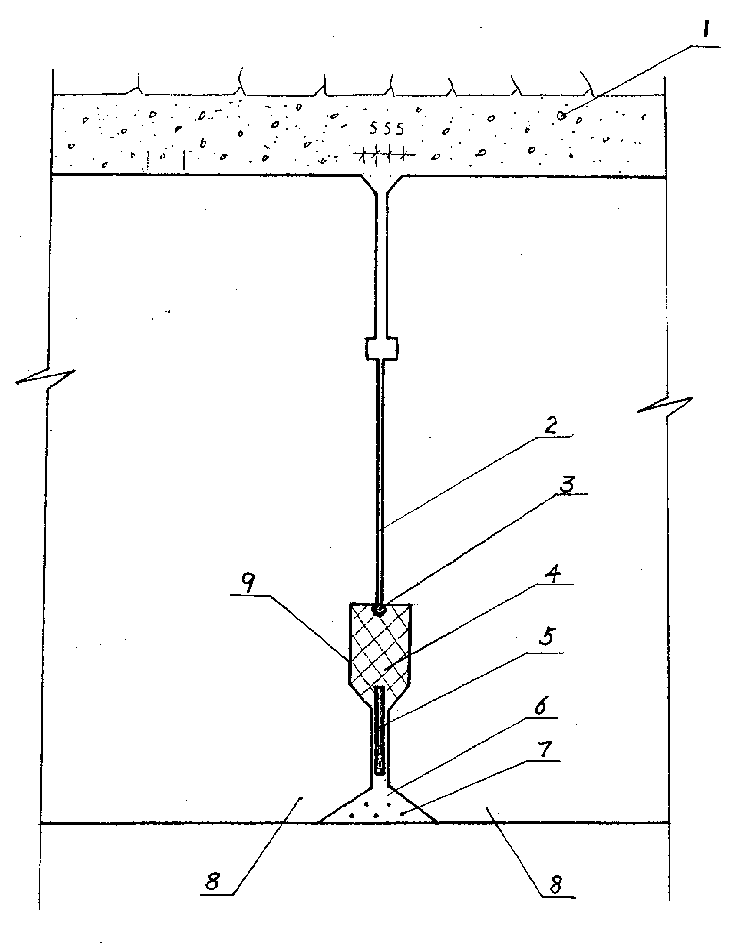

Recoverable side slope anchor rod grout stop device

ActiveCN106436705AOptimize the force structureImprove ultimate carrying capacityBulkheads/pilesAnchoring boltsStops deviceEngineering

A recoverable side slope anchor rod grout stop device is provided with a casing pipe, a sliding sleeve, a check ring, a compression spring, a switch mechanism, a grout stop face and a plurality of frameworks. The grout stop face is formed by annularly distributing and combining a plurality of sector-ring-shaped steel sheets. Every two adjacent sector-ring-shaped steel sheets are hinged to each other, and each sector-ring-shaped steel sheet is connected with the check ring. The frameworks and the sector-ring-shaped steel sheets are in one-to-one correspondence. One end of each framework is hinged to the sliding sleeve, and the other end of each framework is hinged to the sector-ring-shaped steel sheet corresponding to the framework. A grout inlet hole connected with a grouting pipe and an exhaust hole connected with an exhaust pipe are formed in the grout stop face, and the casing pipe is provided with a groove which cooperates with a switch to enable the sliding sleeve to be located on the casing pipe to open the grout stop face. During anchor rod grouting, an anchoring segment can be blocked, a bonding material is prevented from flowing towards the free end, the stress structure of an anchor rod is optimized, grouting materials are saved, and the anchoring effect is increased; and after the grouting task is completed, the grout stop device can be recovered by closing the sector-ring-shaped steel sheets through the switch mechanism.

Owner:河北建科唐秦建筑科技有限公司

Three-supporting surface prestress blocking seat mechanism of converter

InactiveCN101638710BImprove stressChange the way of forceManufacturing convertersSupport surfaceCushion

Owner:CISDI ENG CO LTD

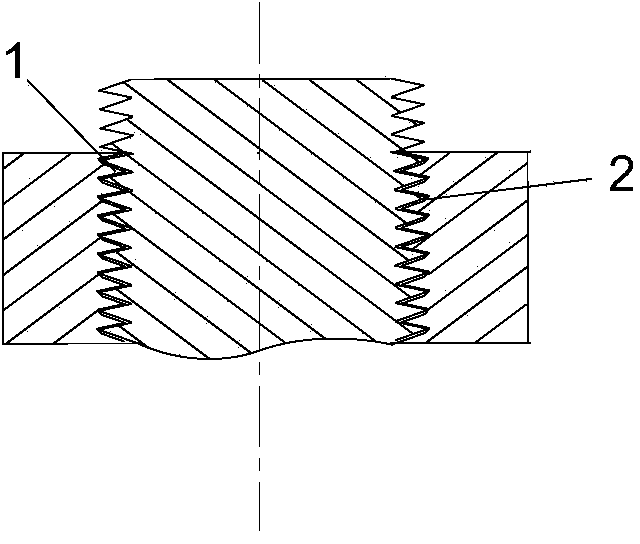

Anti-loose thread fastening structure

InactiveCN104141670AOptimize the force structureUniform force structureNutsBoltsClassical mechanicsScrew thread

The invention discloses an anti-loose thread fastening structure which comprises a bolt and a nut matched with the bolt, wherein variable angle oblique planes are arranged at the root of an internal thread of the nut, and the included angle between each variable angle oblique plane and a bisector of a thread angle of the internal thread is larger than a half of the thread angle of the internal thread. Threads of each pair of matched bolt and nut can be sufficiently contacted and interacted in the spinning length of the anti-loose thread fastening structure, so that load can be uniformly distributed, the stress structure is more balanced, the working life of the structure is prolonged, and the condition that the fastening effect is weakened early and even lost due to fast abrasion damage caused by overlarge local stress of an ordinary screw pair is avoided; and besides, the thread matching gaps between the threads of the bolt and the nut can be eliminated by means of the variable angle oblique planes of the nut, so that the bolt and the nut can be tightly matched in a longer spinning length, higher anti-loose torsional moment can be produced, and an ideal fastening effect can be kept on the use occasion with frequent vibration.

Owner:宁波华路汽车电器有限公司

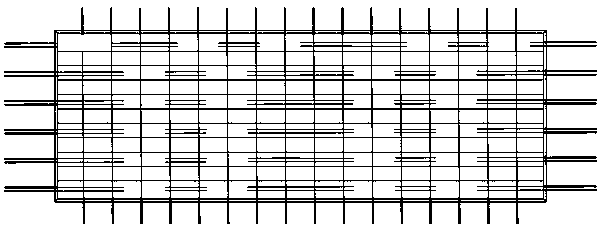

Hollow composite floor slab and construction method thereof

InactiveCN103981987AOptimize the force structureHigh strengthConstruction materialFloorsFloor slabReinforced concrete

The invention provides a hollow composite floor slab and a construction method of the hollow composite floor slab. The hollow composite floor slab is convenient to transport, low in breakage rate, small in self-weight, low in cost, large in rigidity and good in anti-seismic property. To achieve the aim, according to the scheme, the hollow composite floor slab comprises a prefabricated hollow slab body and a rear pouring reinforced concrete layer, and the prefabricated hollow slab body comprises a base board reinforced concrete layer and a porous concrete layer; a plurality of long through holes are longitudinally formed in the porous concrete layer at intervals; the two sides or the single side of the porous concrete layer are concaved in the two side faces of the base plate reinforced concrete layer, and a rear pouring portion is formed on the prefabricated hollow slab body; the rear pouring reinforced concrete layer is arranged above the prefabricated hollow slab body, and the porous concrete layer and the rear pouring reinforced concrete layer are meshed through a groove and beads. The construction method comprises the steps of manufacturing the prefabricated hollow slab body and mounting the hollow composite floor slab.

Owner:王睿敏

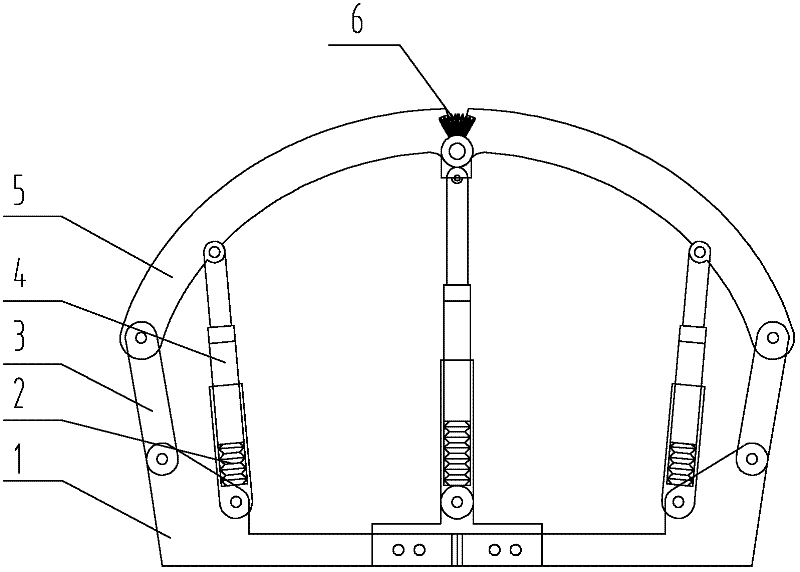

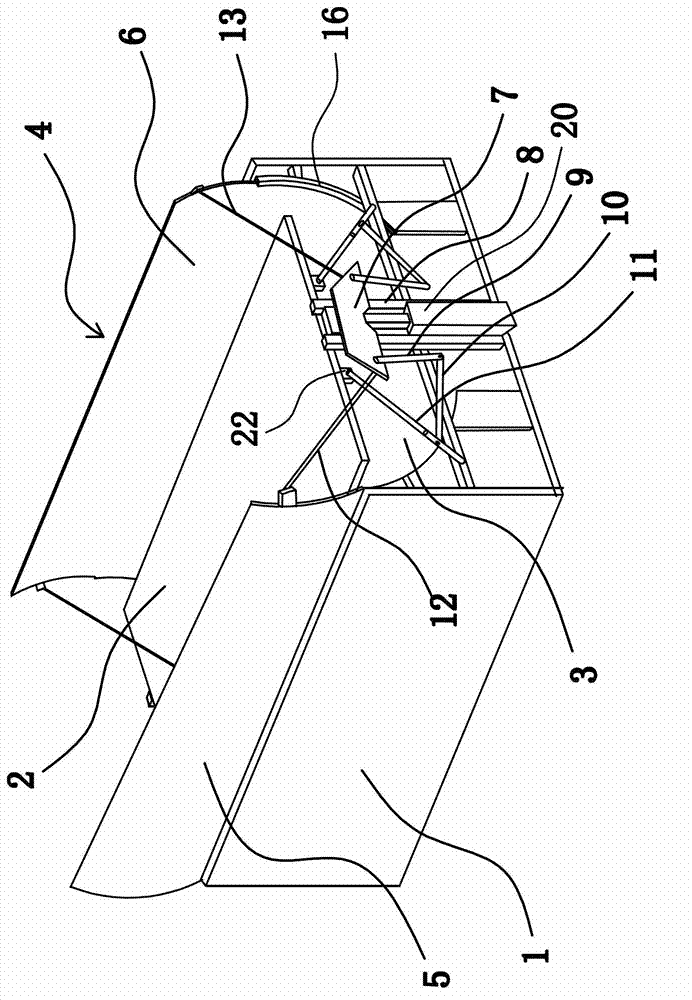

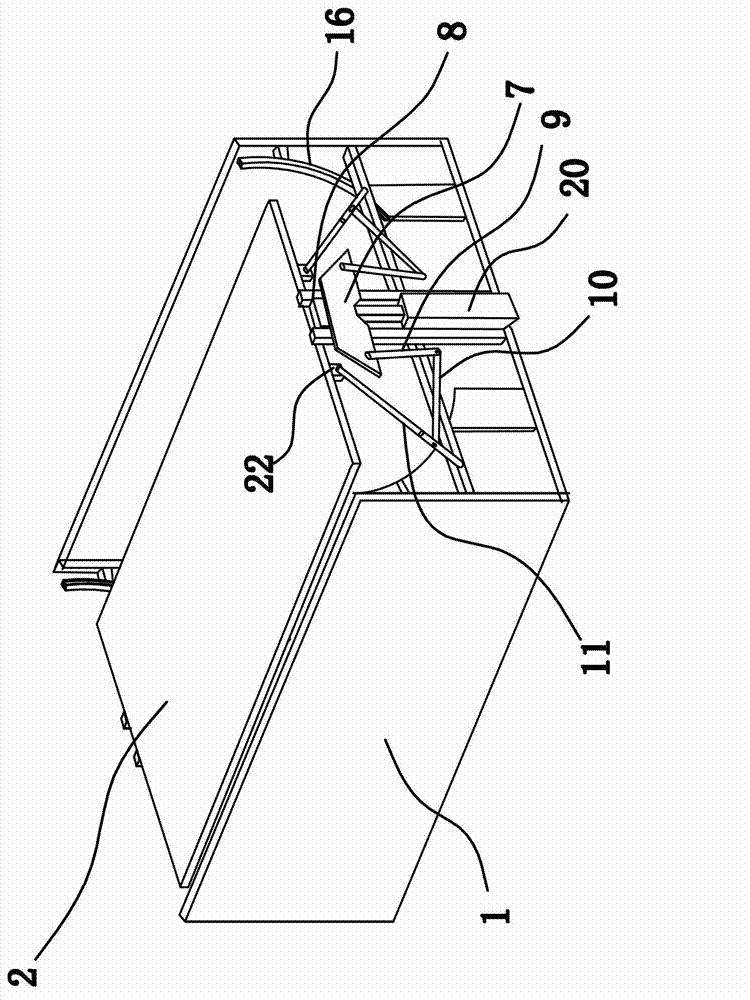

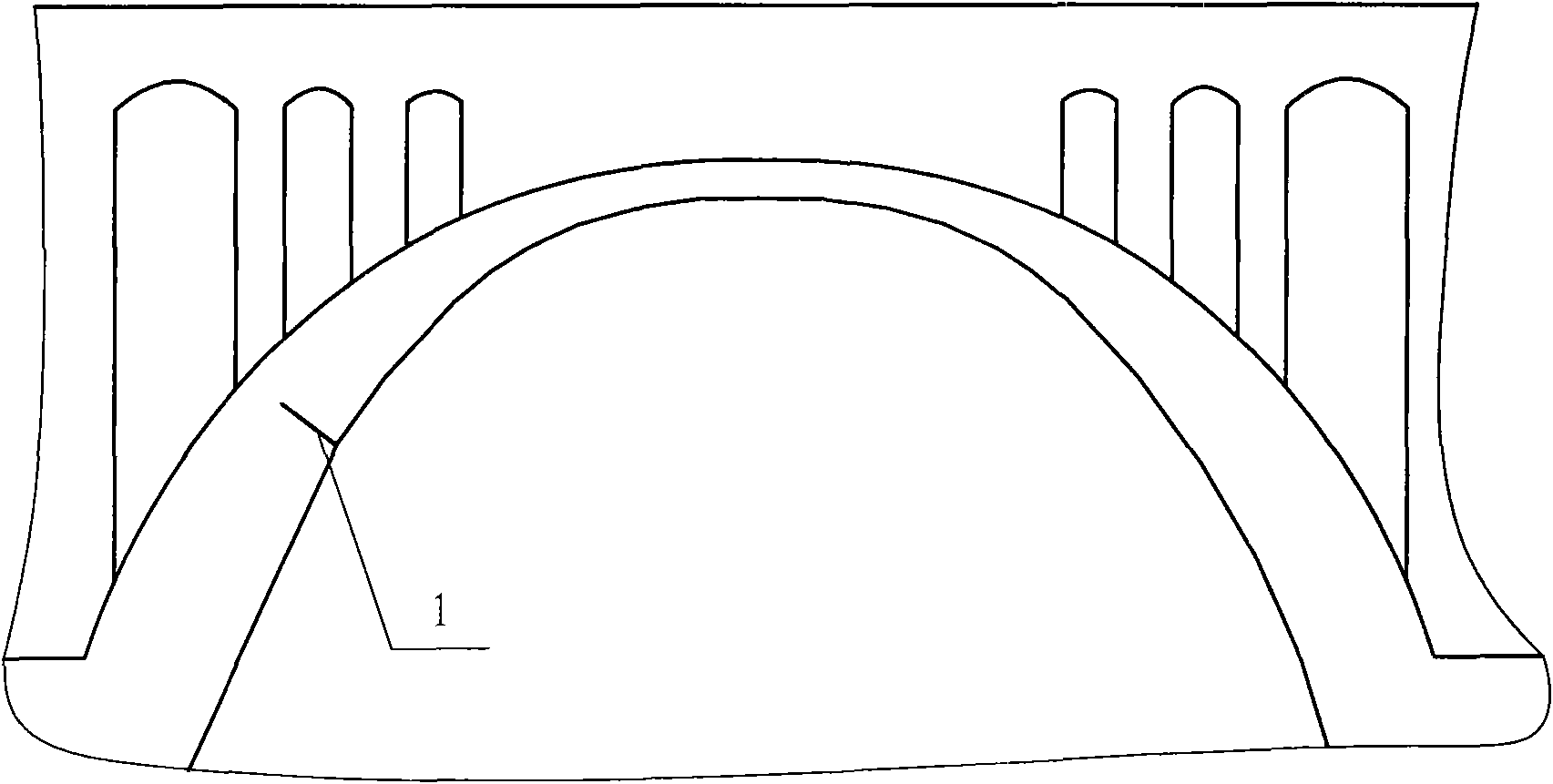

Arch auto-distress shockproof bed

InactiveCN102960977AOptimize the force structureStrong resistanceBreathing protectionSofasBlocked ConnectionEngineering

The invention provides an arch auto-distress shockproof bed, belongs to the technical field of a shockproof device, and solves the technical problem that no auto-distress device is available in the prior art. The shockproof bed comprises a bed frame capable of being arranged on a floor; an extensible locating mechanism for locating a bed plate and the bed frame along the vertical direction is arranged between the edge of the bed plate and the bed frame; an arch protective cover is also arranged inside a hollow cavity at the middle part of the bed frame; a guide structure is arranged between the bed frame and the protective cover; a sliding block connection link mechanism is also arranged on the bed frame; the protective cover can move to the upper part of the bed plate through the sliding block connection link mechanism; and a power mechanism for providing power to the sliding block connection link mechanism is also arranged on the bed frame. The arch protective cover is covered above the bed plate, so that the personnel are protected by the protective cover. The arch protective cover has strong resistance on the impact from each direction due to a good stress structure. Therefore, the shockproof effect is improved.

Owner:ZHEJIANG BUSINESS TECH INST

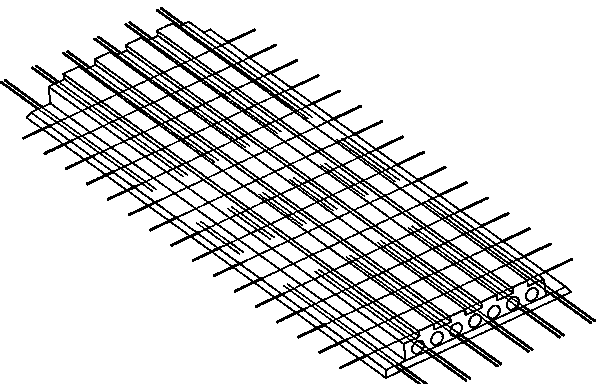

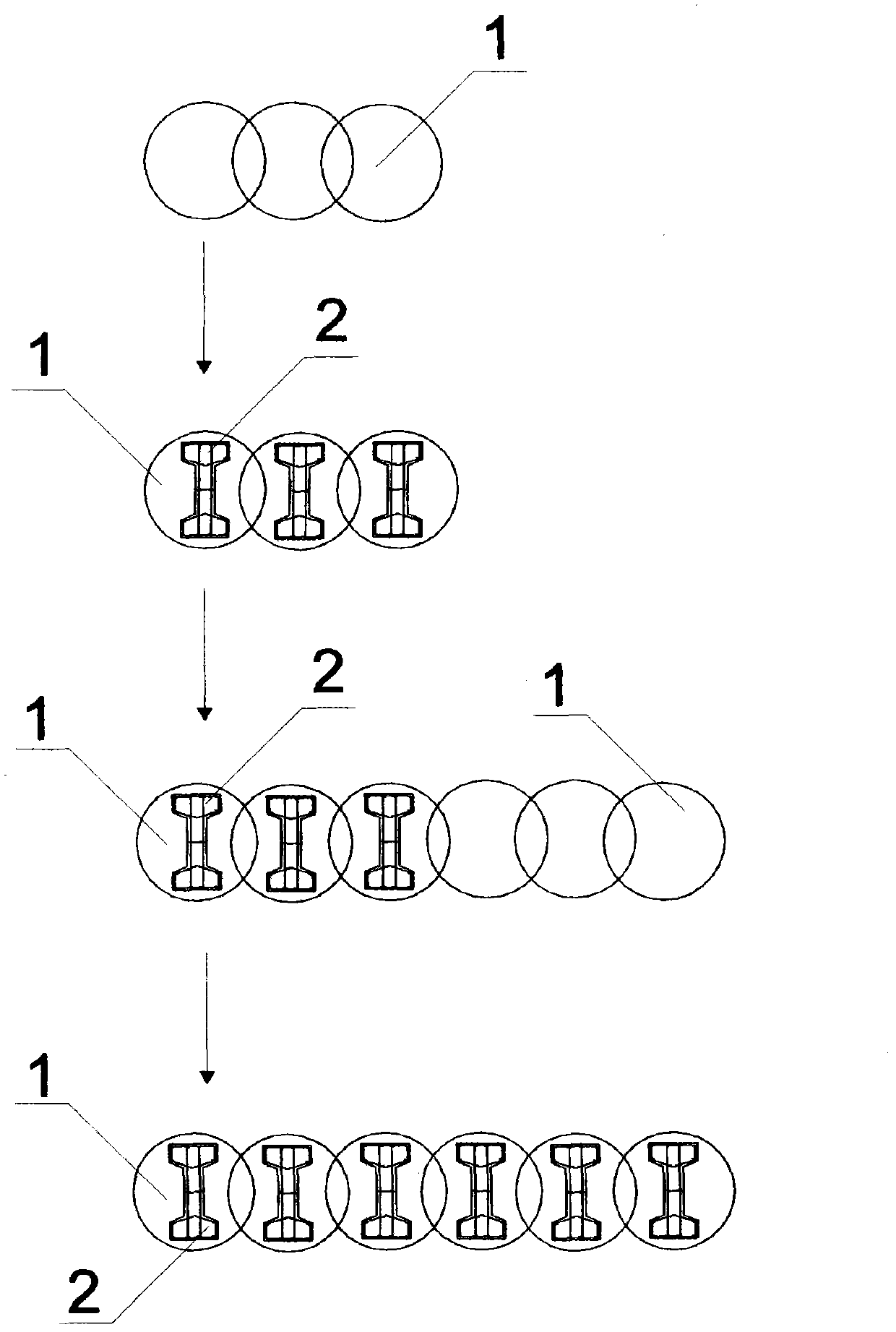

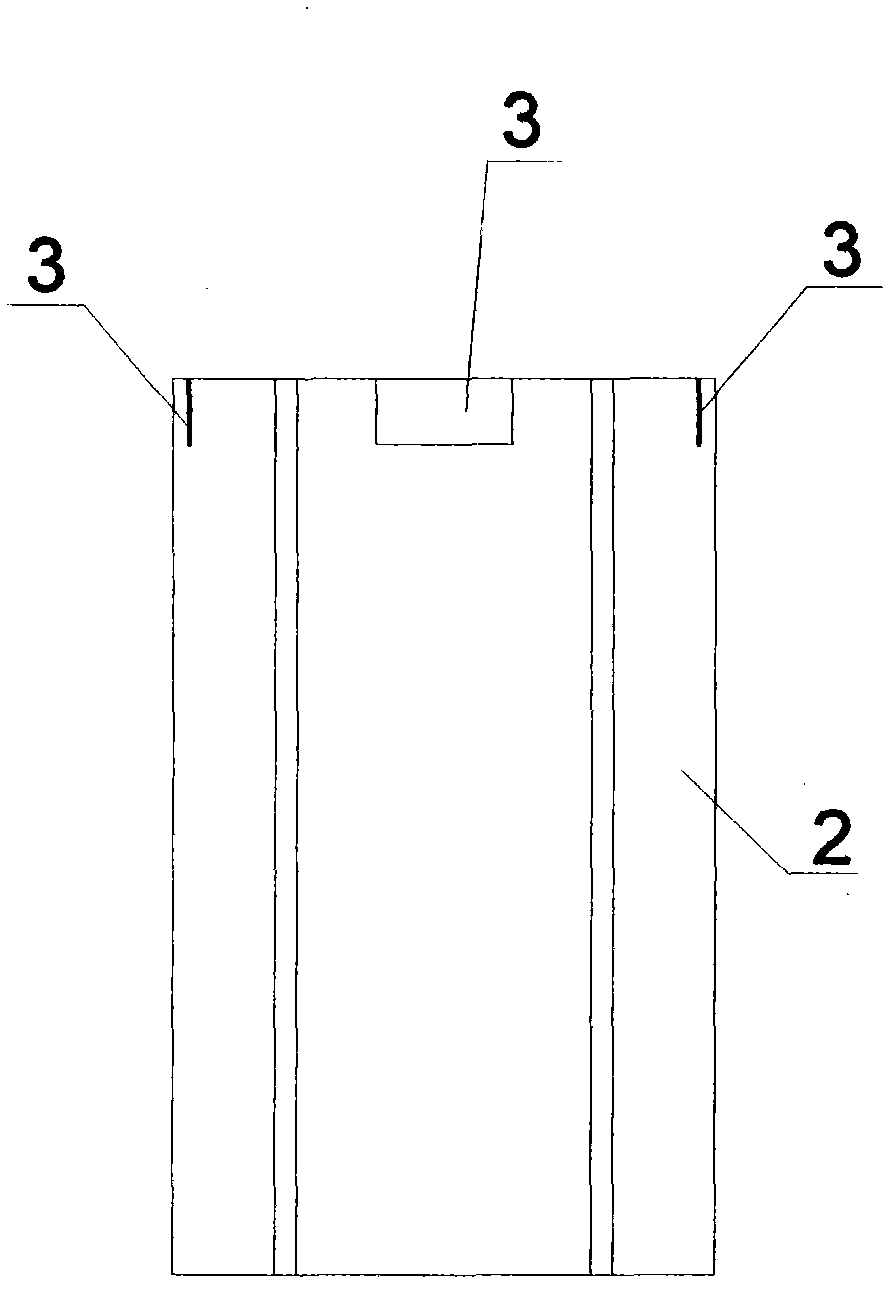

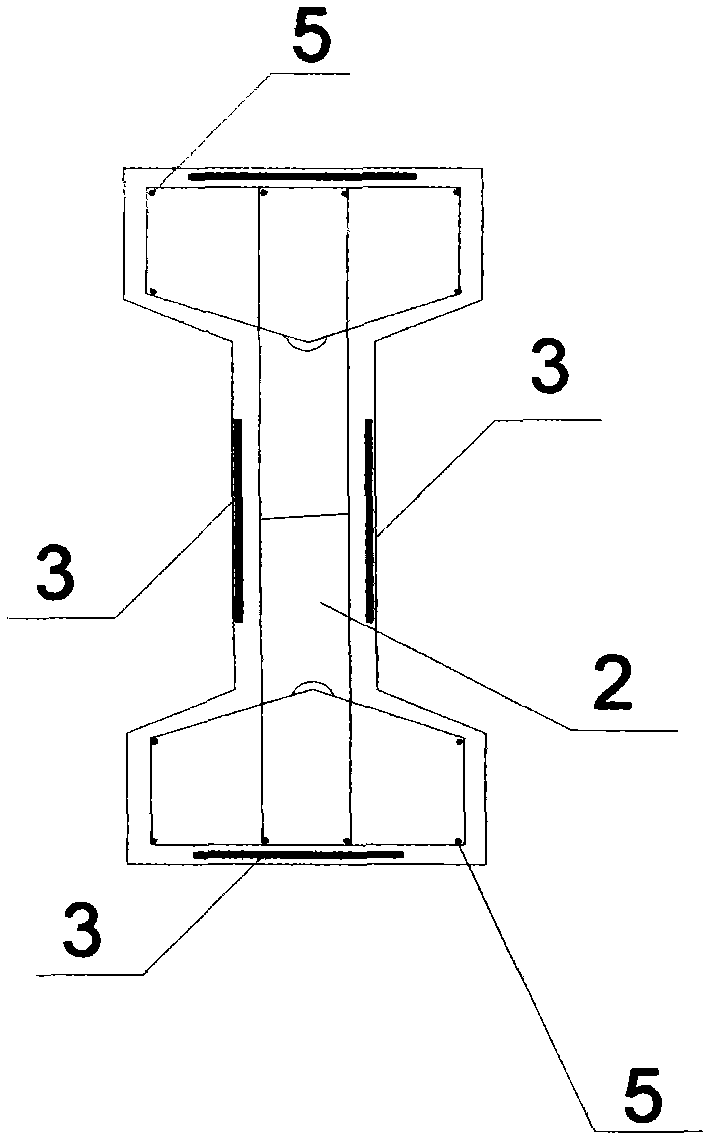

Enclosure method for inserting H-shaped reinforced concrete slab piles in three-axis (two-axis) cement mixing pile

InactiveCN102383432AOptimize the force structureImprove bending resistanceExcavationsBulkheads/pilesRebarPollution

The invention discloses an enclosure method for inserting H-shaped reinforced concrete slab piles in a three-axis (two-axis) cement mixing pile. The method comprises the following three processes of: making the H-shaped reinforced concrete slab piles; digging to obtain the three-axis (two-axis) cement mixing pile; and inserting the H-shaped reinforced concrete slab piles into the three-axis (two-axis) cement mixing pile, wherein multiple reinforcing steel bars are arranged in each H-shaped reinforced concrete slab pile; a plurality of embedded iron are arranged around one end of each H-shaped reinforced concrete slab pile; the three-axis (two-axis) cement mixing pile is formed through digging; multiple sections of the H-shaped reinforced concrete slab piles are welded with each other through welding the embedded iron and lifted by using a crawler crane; the welded H-shaped reinforced concrete slab piles are inserted into the three-axis (two-axis) cement mixing pile; the equipment is moved to a second position, to be dug, of the second three-axis (two-axis) cement mixing pile so as to carry out the same operations; and after a plurality of movements, the enclosure method for inserting the H-shaped reinforced concrete slab piles in the three-axis (two-axis) cement mixing pile can be completed. The enclosure method for inserting the H-shaped reinforced concrete slab piles in the three-axis (two-axis) cement mixing pile, disclosed by the invention, has the advantages of good bending resistance, low cost, high benefit, no noise, no pollution, environment friendliness and the like.

Owner:SHANGHAI CHENGDI CONSTR

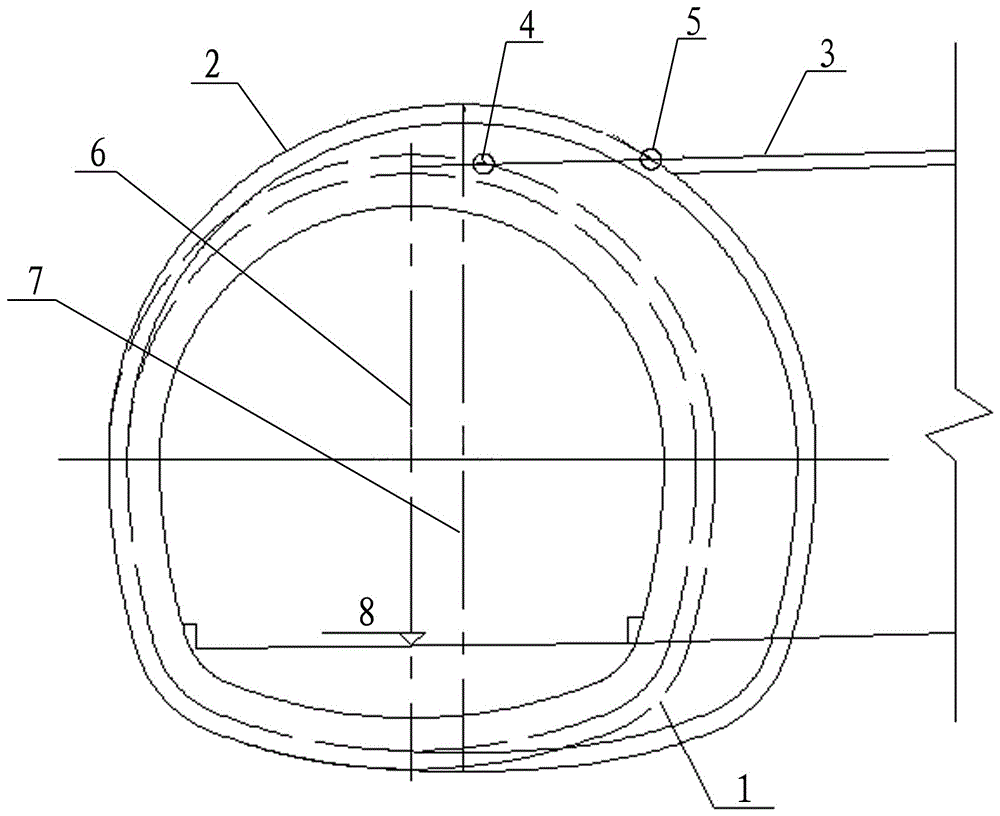

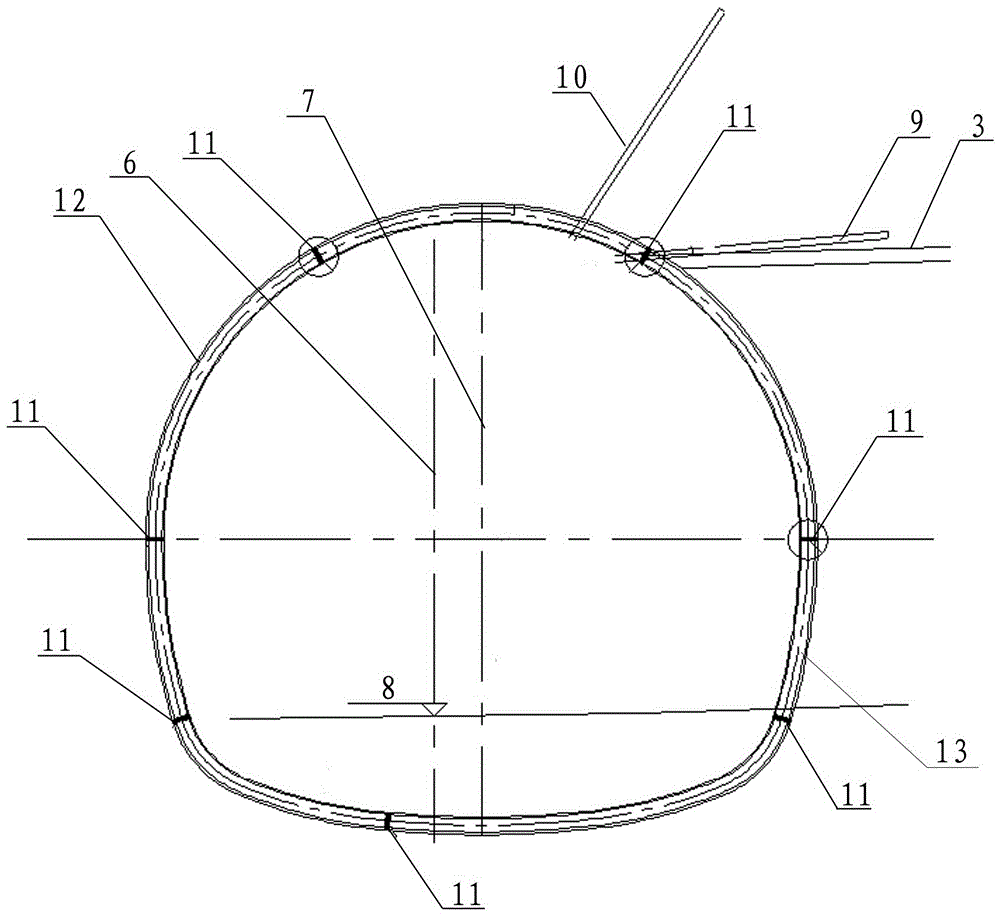

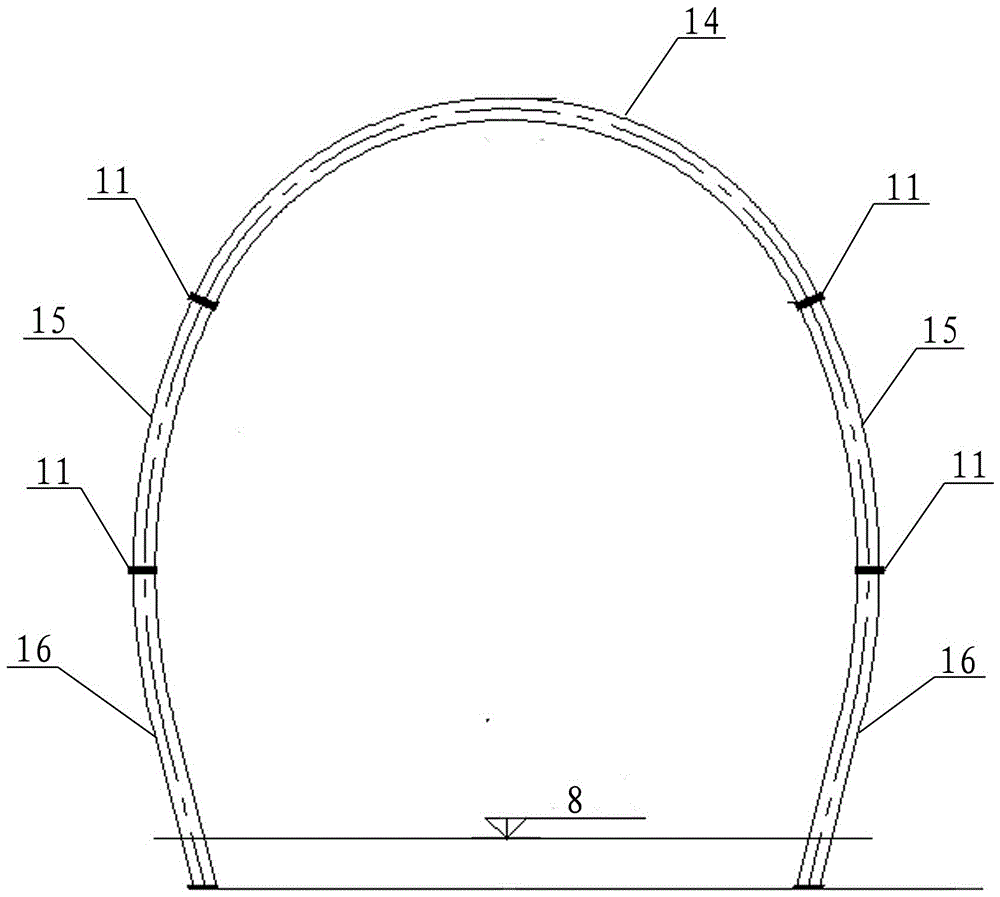

Construction method of opening for allowing highway tunnel parallel pilot tunnel to enter cross passage

The invention belongs to the technical field of tunnel construction, and provides a construction method of an opening for allowing a highway tunnel parallel pilot tunnel to enter a cross passage in order to solve the technical problems that in traditional construction of the opening for allowing the parallel pilot to enter the cross passage, the construction cost is high, the construction cycle is long, and strong construction interference and large construction safety risk exist. Central lines of primary support structures arranged in front of and at back of the intersecting position of the central line of the parallel pilot tunnel and the central line of the cross passage offset in the direction of the cross passage, the radius of an upper step steel arch support is increased according to a designed contour, and the radius of a lower step steel arch support still is the radius adopted in original construction; on the basis of the cross passage steel supports with the normal contour, angle changing treatment is conducted on all arch support units of the steel supports, and grouting locking anchor pipes are distributed on connecting plate joints and arch crowns of the units respectively. According to the construction method, the structure is simple, design is reasonable, machining is easy and convenient, the primary support stress structures at the intersections are improved, primary support stability is guaranteed, the construction technology is simple, operation is easy, and the primary support construction quality of the intersections is conveniently controlled.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

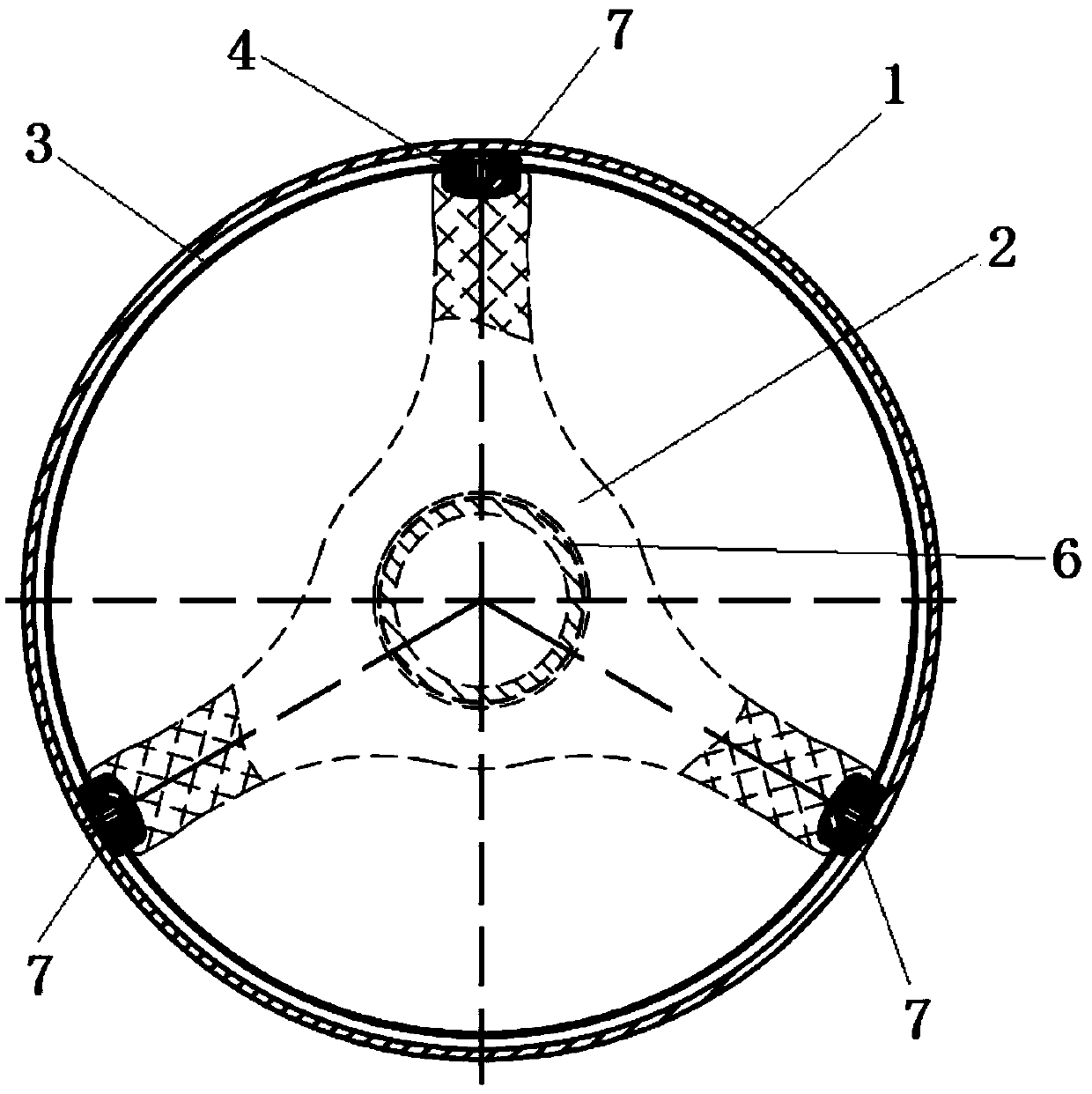

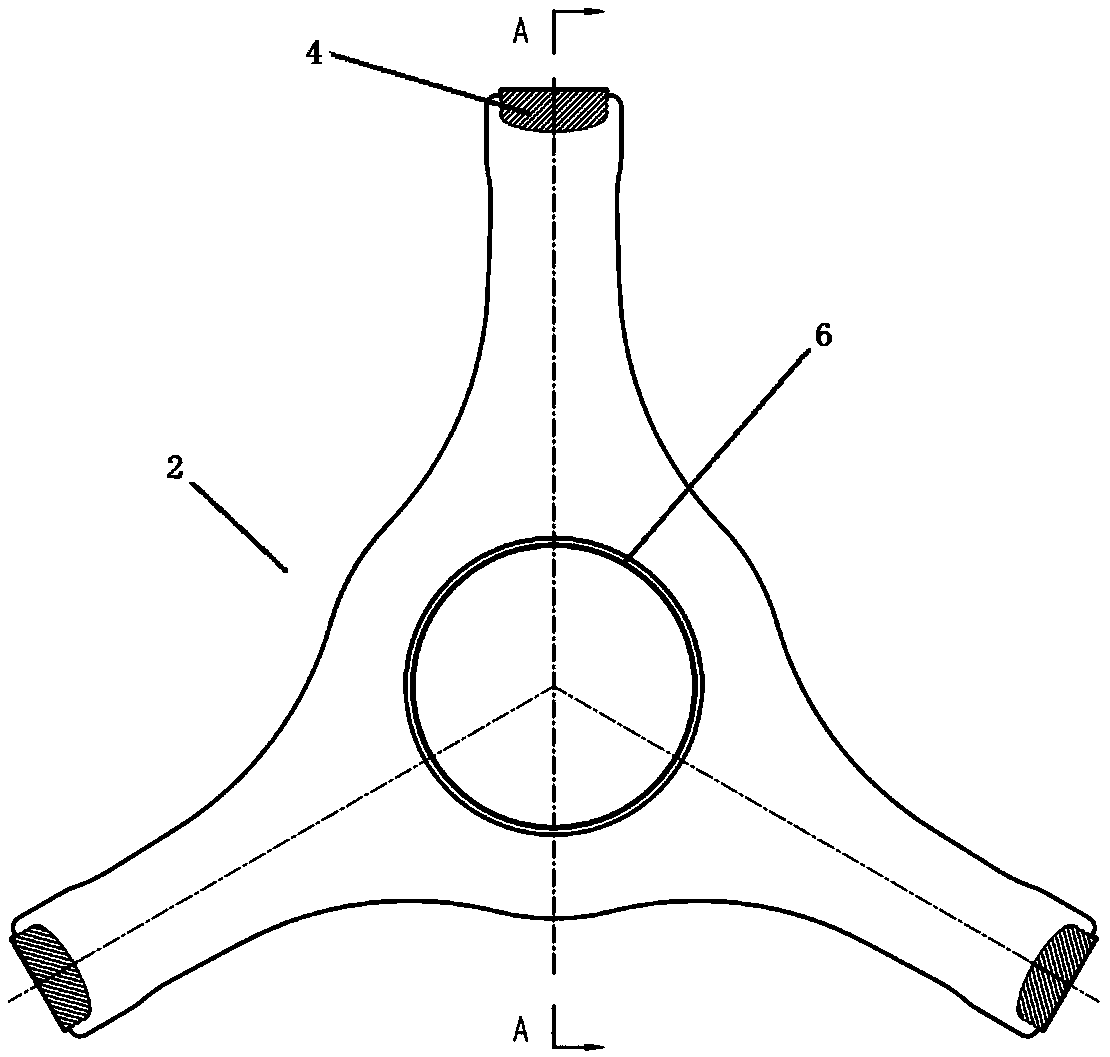

Three-post insulator of GIL

The invention relates to the technical field of high-voltage power transmission, and particularly provides a three-post insulator of a GIL, wherein the three-post insulator comprises a post main bodyand an insert poured at the end part of the post main body, and the end surface, far away from the post main body, of the insert is provided with a stress groove for making the insert radially contract to adapt to the contraction deformation of the post main body. According to the invention, by arranging a stress groove in an insert, when the insert is located in the post insulator, the insert cantransmit the residual stress generated by the post insulator to the insert outwards through the stress groove, so that the stress structure of the insert is improved, and the defects of deformation,micro-cracking and the like of the insert are avoided so as to ensure the assembly relationship between the insert and the post insulator and ensure the insulation capability of the post insulator.

Owner:PINGGAO GRP +2

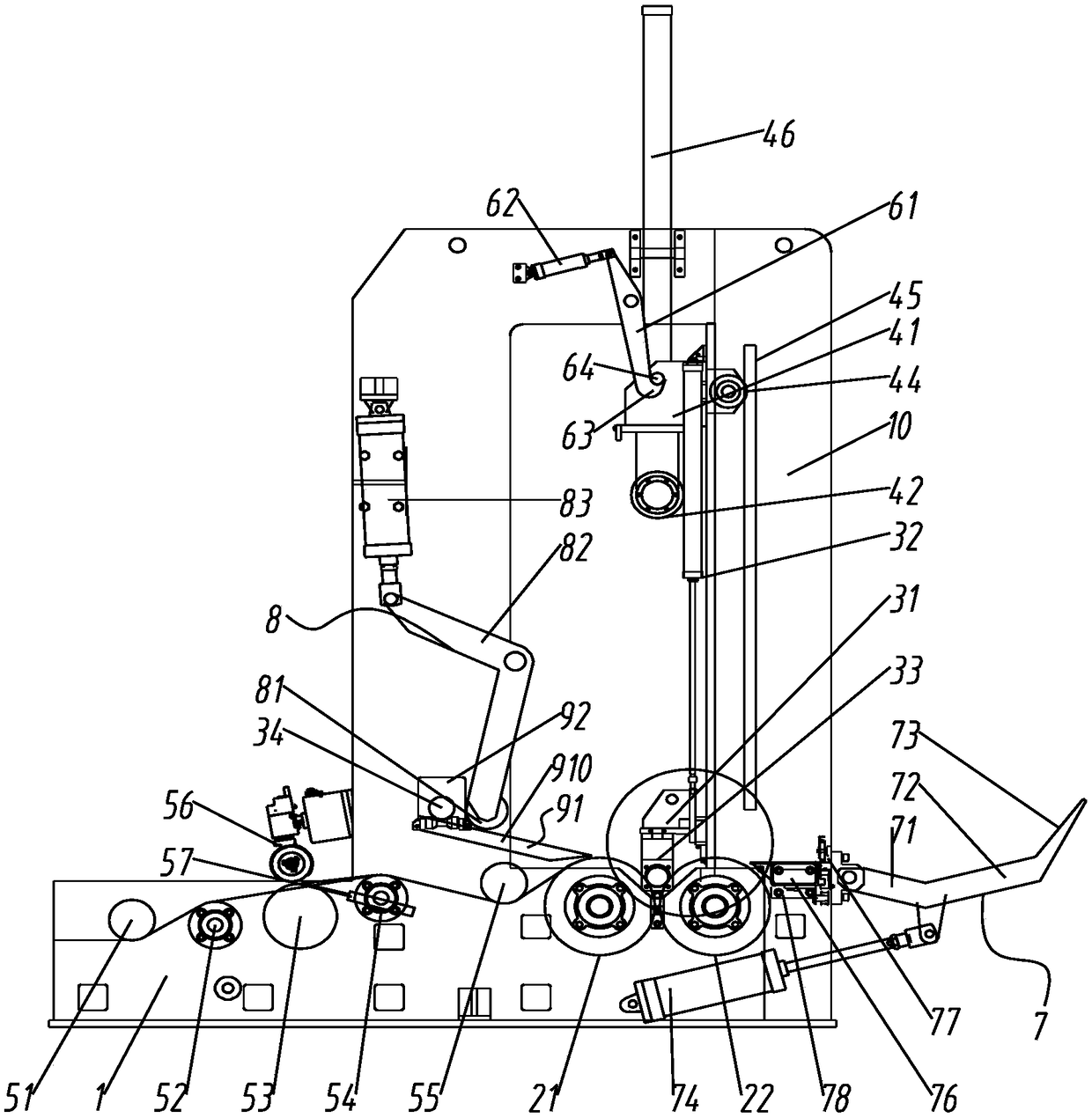

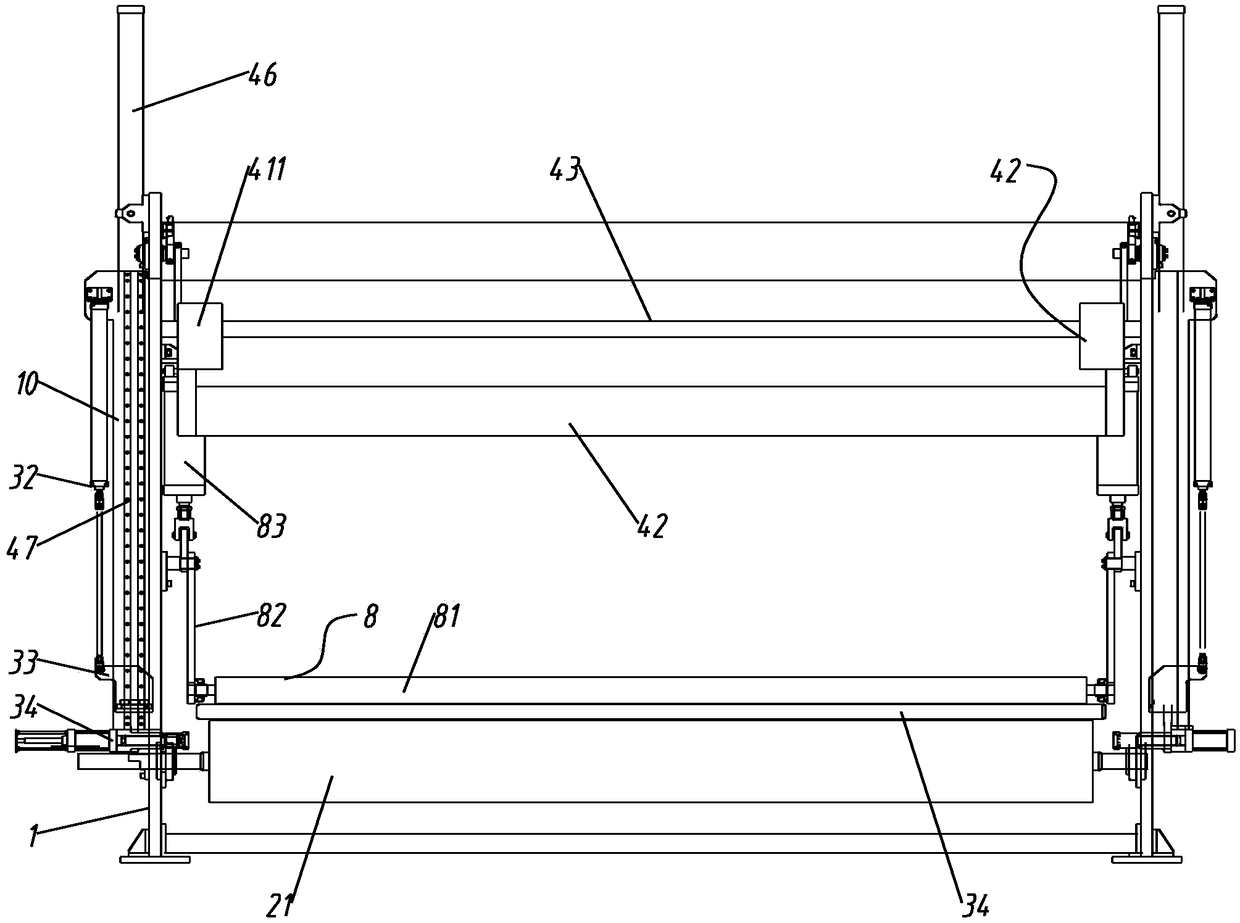

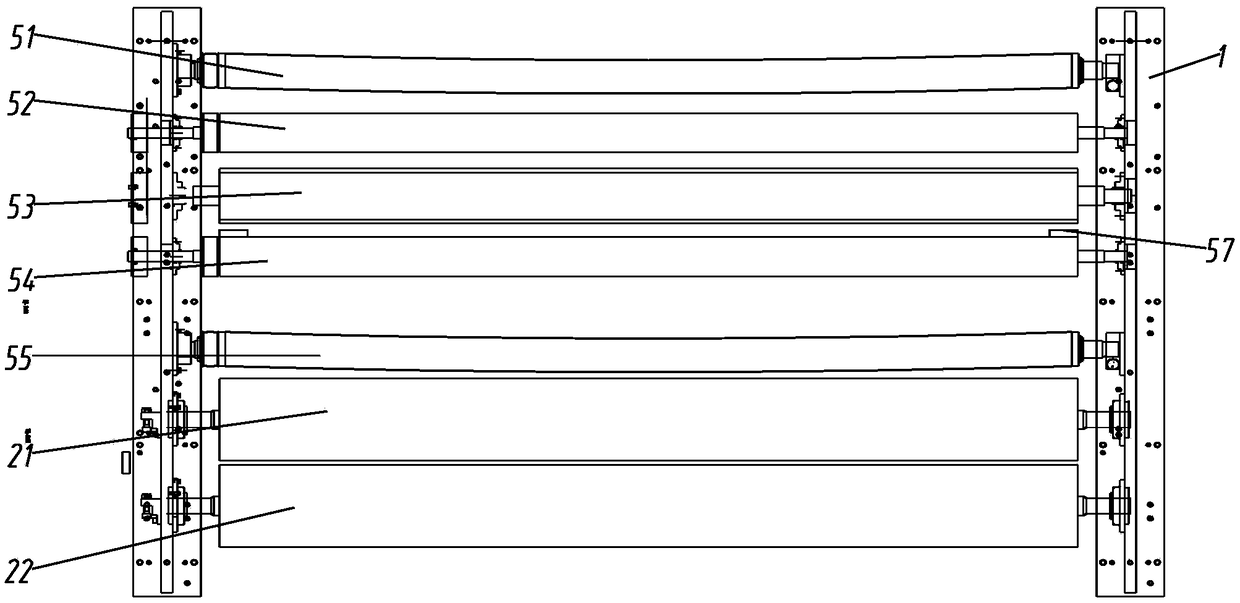

Slitting rewinding machine and raw paper processing production line

ActiveCN108975020AQuality improvementKeep the pressure constantWebs handlingProduction linePulp and paper industry

The invention belongs to the technical field of slitting rewinding machines and provides a slitting rewinding machine and a raw paper processing production line. The slitting rewinding machine comprises a rewinding rack, a first bottom roller and a second bottom roller are arranged at the bottom of the rewinding rack, and two mandrel holders are also slidingly disposed on the two sides of the rewinding rack respectively and connected to the rewinding rack through mandrel lifting air cylinders which are arranged in the vertical direction; the mandrel holders are provided with mandrel clamping parts for clamping mandrels, the surfaces of the first bottom roller and second bottom roller are provided with thermal spray coatings, riding roller frames are also slidingly arranged on the rewindingrack, riding rollers are rotatably arranged on the riding roller frames, a synchronous shaft is also rotated on the riding roller frames, synchronous gears are arranged at both ends of the synchronous shaft, synchronous racks meshed with the synchronous gears are arranged on both sides of the rewinding rack, and riding roller lifting air cylinders are connected with the rewinding rack. Through the technical scheme above, the technical problem of low rewinding precision of slitting rewinding machines in the prior art is solved.

Owner:河北入微能源科技有限公司

Construction method for strengthening arch foot crack of stone arch bridge

InactiveCN101603291AOptimize the force structureAvoid elevationBridge erection/assemblyBridge strengtheningAmbient pressureTransverse plane

The invention discloses a construction method for strengthening an arch foot crack of a stone arch bridge, which comprises the following steps: 1, drilling hole around the arch foot crack of the stone arch bridge, and embedding steel bars into the holes; 2, mounting a plurality of transverse steel bar hoops on an arch ring to encircle the arch ring; 3, inserting wedges into the transverse steel bar hoops to apply ambient pressure to the arch ring; 4, arranging a longitudinal arch back steel bar and a longitudinal arch web steel bar on an arch back and an arch web of the arch ring respectively, and mutually firmly welding the arch back steel bar and the arch web steel bar and the intersections of the transverse steel bar hoops or the embedded steel bars; and 5, inserting the arch back steel bar and the arch web steel bar into a bridge pier to be firmly connected, or arranging the steel bars at the transverse plane of an abutment of the bridge pier to be firmly connected with the abutment. The construction method can enhance the stress strength of the arch ring and improve the stress structure thereof by applying the ambient pressure to the crack of a part to be strengthened and the arch ring, effectively prevent the crack from continuously enlarging, and connect a strengthening body, a strengthened body and a base into a whole to improve the capacity of resisting dynamic load shock, and has the advantages of simple and convenient field construction and low strengthening cost.

Owner:核工业西南勘察设计研究院有限公司

Combined air cylinder cover

ActiveCN106050463AAvoid time costReduce economic costsEngine testingCylinder headsInlet channelEngineering

The invention provides a combined air cylinder cover. The combined air cylinder cover comprises an upper top plate, a plurality of side plates, a lower bottom plate, an air inlet channel movable block, an exhaust channel movable block, an oil atomizer lining and a plurality of guide pipes. A rectangular air cylinder cover structure is formed by the upper top plate, the side plates and the lower bottom plate. Each of the air inlet channel movable block and the exhaust channel movable block comprises a middle air channel and installing flanges at the two ends. One end of the air inlet channel movable block and one end of the exhaust channel movable block are connected with the two oppositely-arranged side plates through the installing flanges correspondingly, and the other end of the air inlet channel movable block and the other end of the exhaust channel movable block are both connected with the lower bottom plate. An integrally-cast cylinder cover is decomposed into the combined machining cylinder cover, the air inlet channel movable block and the exhaust channel movable block are arranged in a matched manner, air inlet channels and an exhaust channels, all of which are different in design parameter, can be conveniently replaced, and the link that the cylinder cover needs to be cast and machined again due to change of the design parameters of the air inlet channel and the exhaust channel is omitted.

Owner:CHINA NORTH ENGINE INST TIANJIN

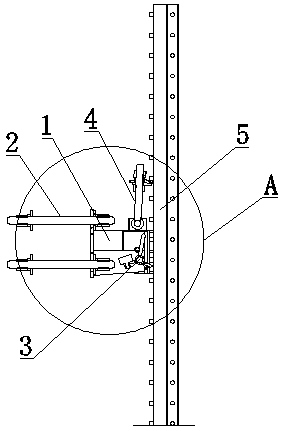

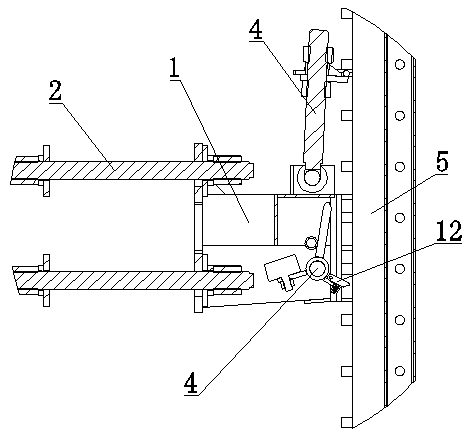

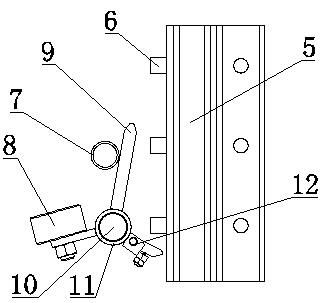

Attached lifting scaffold servo triggering anti-drop device

Disclosed is an attached lifting scaffold servo triggering anti-drop device. The device comprises a fixed steel beam and a guide rail; the fixed steel beam is internally provided with a servo triggering anti-drop device body and an unloading device, and the servo triggering anti-drop device body comprises a shaft sleeve, a clamping plate, a counterweight and a servo trigger; the clamping plate, the counterweight and the servo trigger are installed on the shaft sleeve, the shaft sleeve is installed on a fixed shaft, and the clamping plate, the counterweight and the servo trigger surround the outer circular surface of the shaft sleeve and are fixedly welded to the shaft sleeve; the fixed steel beam is provided with a limiting rod with a limiting function, the clamping plate and the servo trigger are close to one side of the guide rail, the servo trigger comprises a support base fixedly welded to the shaft sleeve, a swing rod and an elastic pin, and the swing rod and the elastic pin are installed on the support base. The anti-drop device is applied to an object which vertically lifts and falls, the object is provided with a sliding guide rail, anti-drop blocks are arranged on the guide rail, and when accidental dropping occurs in the lifting and falling process of the object, braking can be achieved within a limited drop difference range to stop dropping.

Owner:SHANDONG TAIYI METAL SCI & TECH

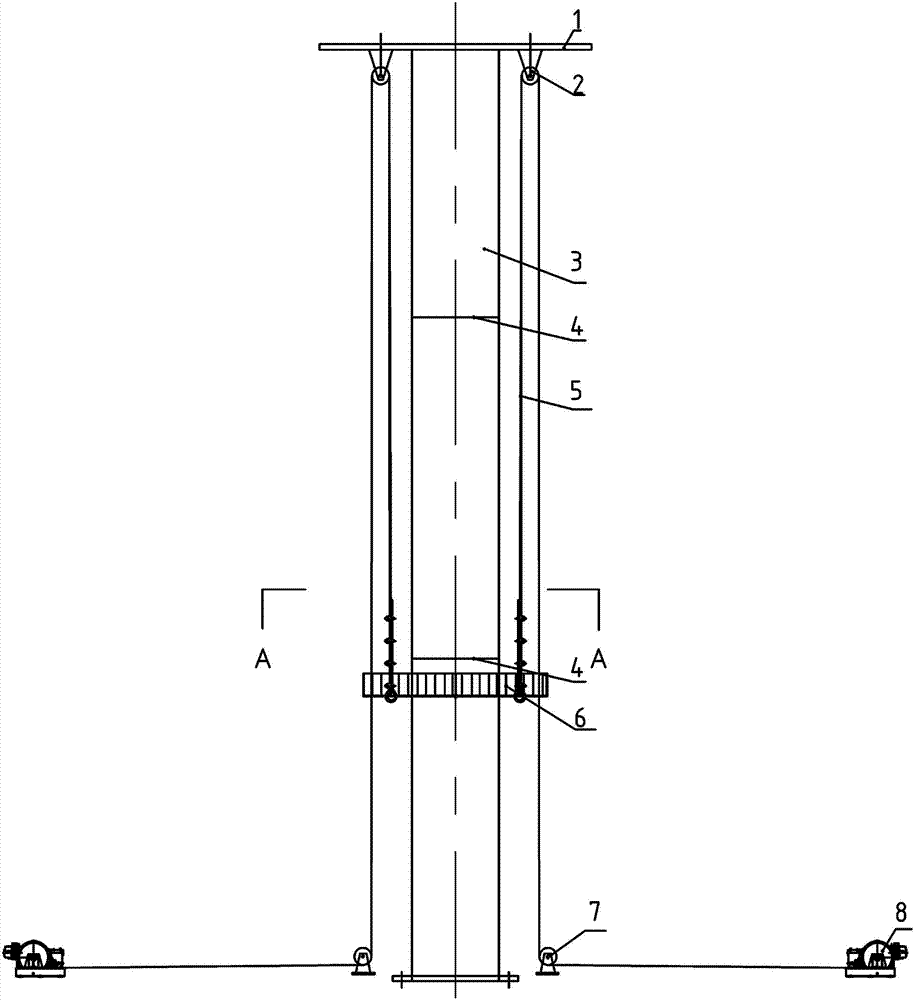

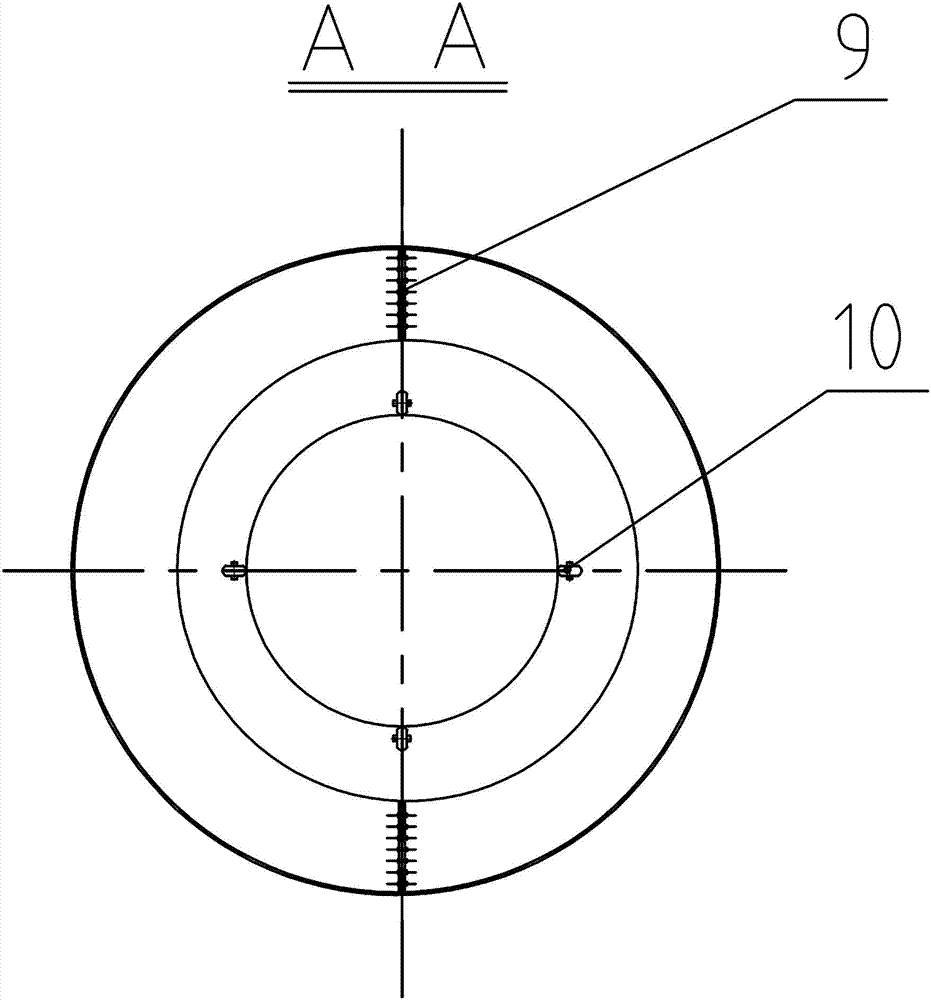

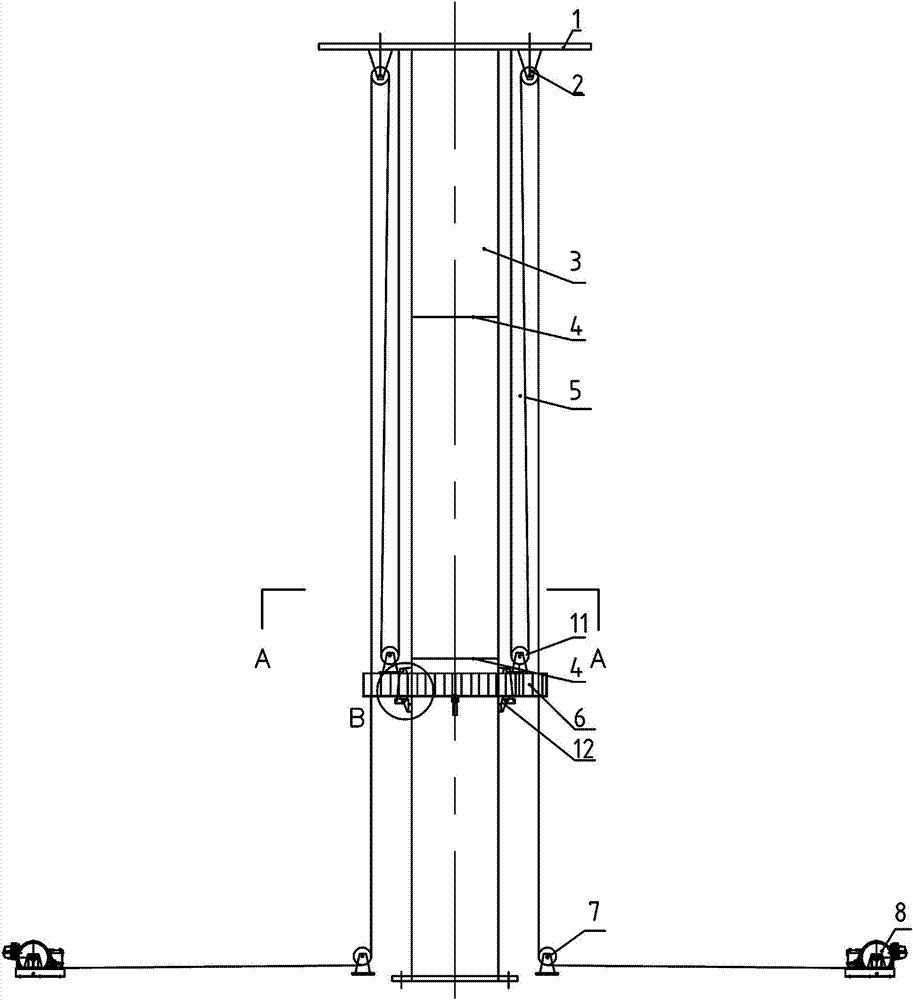

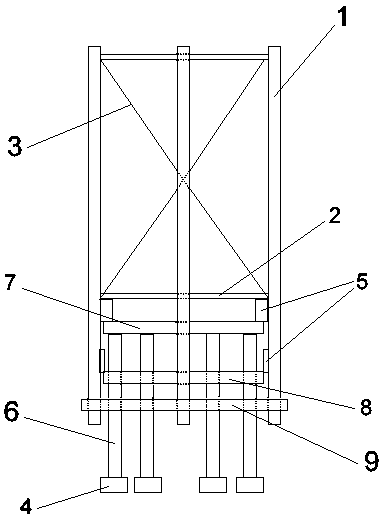

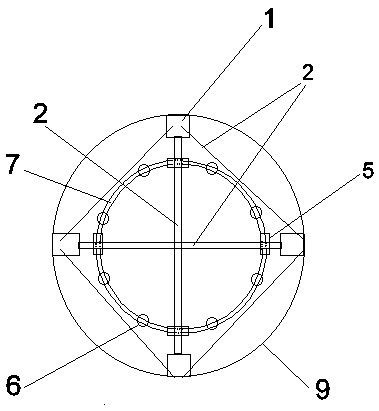

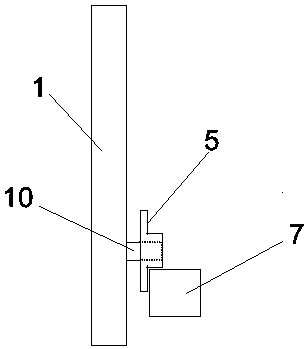

Large-sized stand column extra-column construction platform device and method

ActiveCN102758522AReduce construction costsOptimize the force structureBuilding support scaffoldsWeld seamCorrosion

The invention provides a large-sized stand column extra-column construction platform device comprising a tower cylinder. Construction platforms are symmetrically sleeved on the tower cylinder and a cross beam is fixedly mounted at the upper end of the tower cylinder; hoisting pulleys are symmetrically arranged at two ends of the cross beam; a fixed guide pulley and a winch are arranged at two sides of the tower cylinder along the direction of the cross beam; and a steel wire rope of the winch is connected with the construction platforms through a pulley group. With the adoption of the structure, the structure of a construction auxiliary device and a construction method are simplified and constructors can relatively conveniently carry out back chipping on stand column extra-column welding back seams and welding on the back seams, and work including welding seam flaw detection, corrosion resistance, quality inspection and the like also can be realized; and equipment including a welding machine and the like are convenient to move, the construction cost is reduced, the stressing structure of a stand column is optimized, and the safety of a whole lifting device is greatly improved.

Owner:CHINA GEZHOUBA GROUP CO LTD

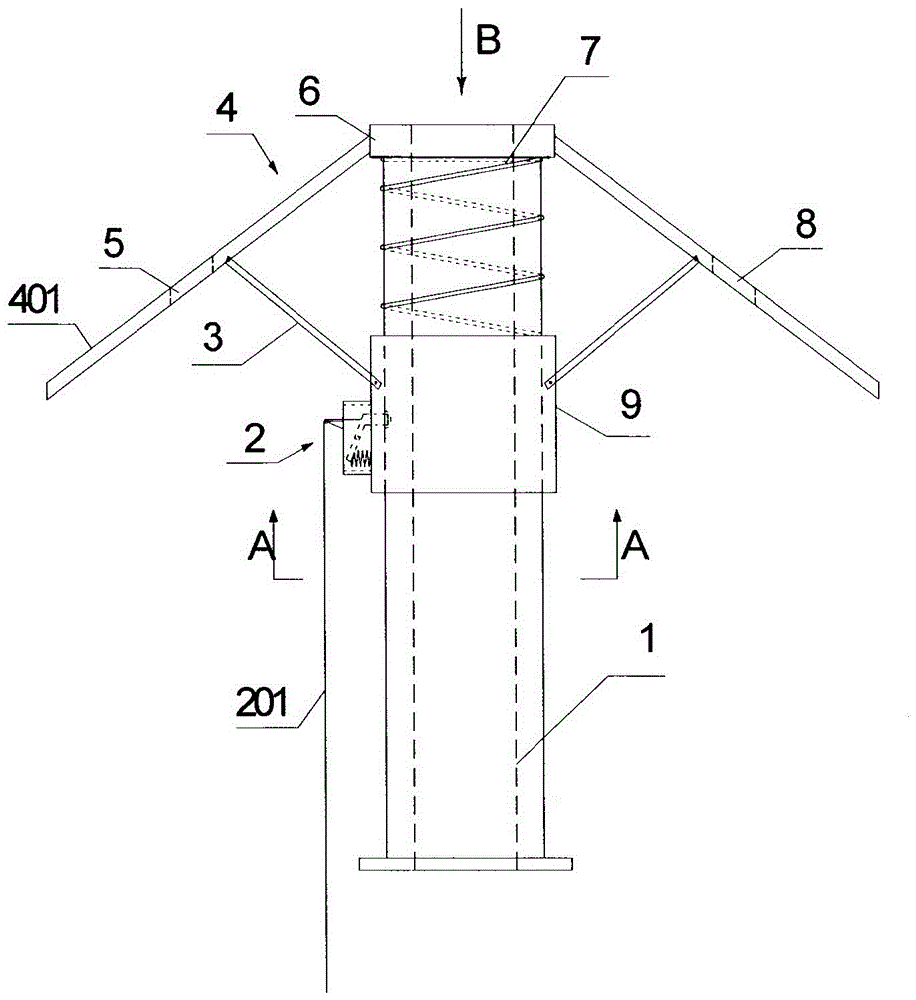

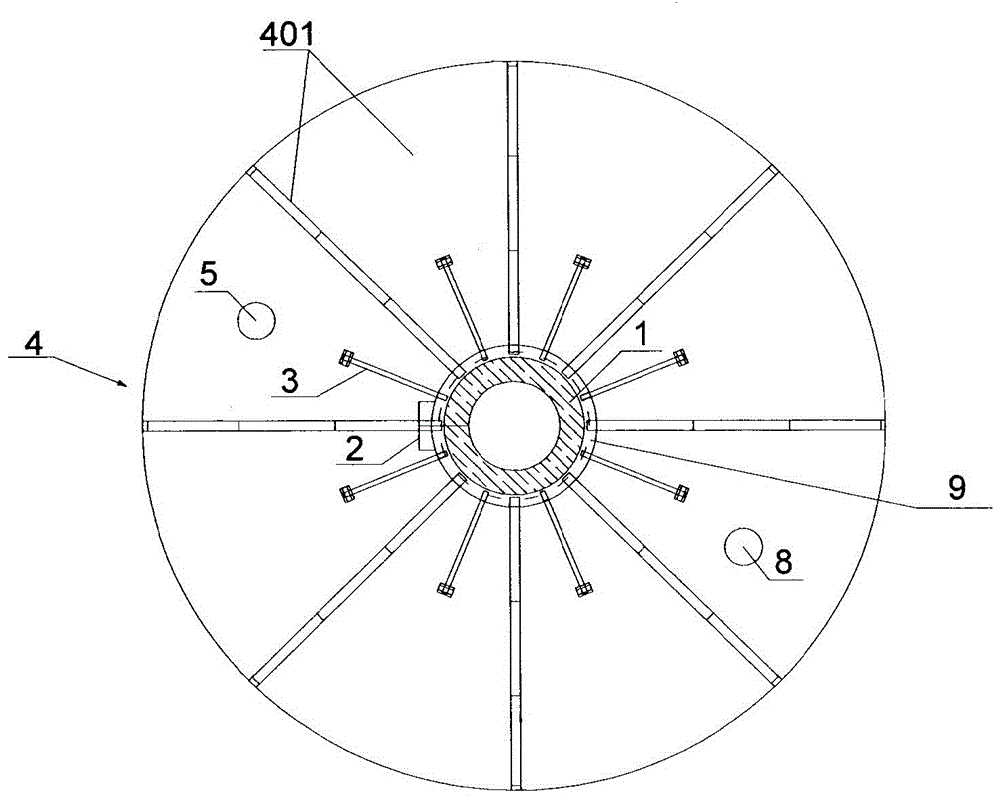

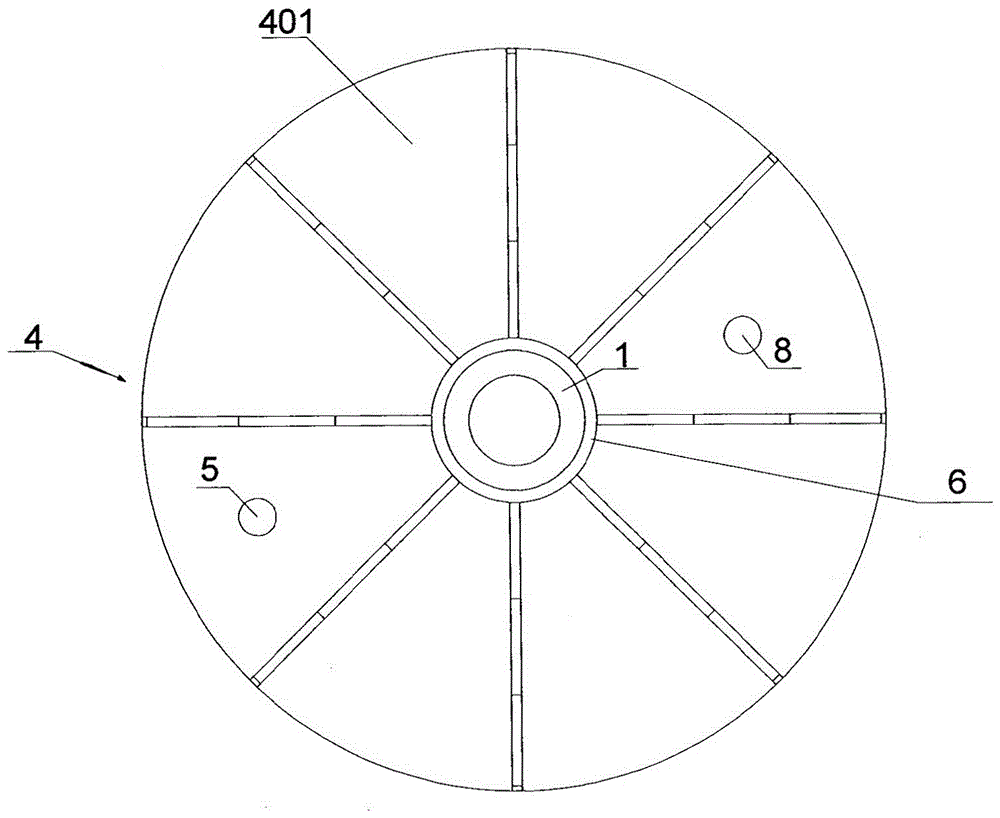

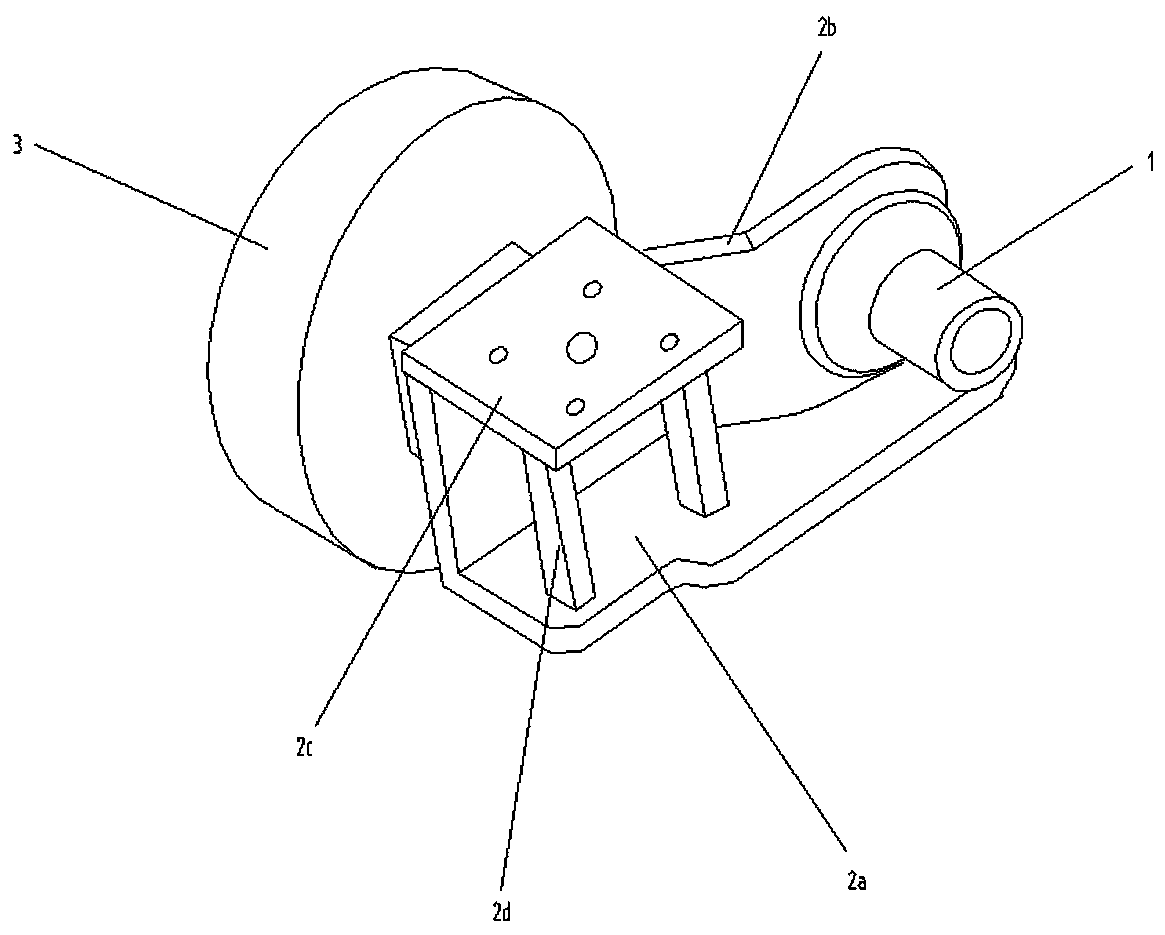

Support device of large-scale vertical axis wind turbine and wind turbine

InactiveCN110195689AIncrease the carrying areaOptimize the main shaft force structureWind motor supports/mountsWind motor combinationsWind forceDynamo

The invention provides a support device of a large-scale vertical axis wind turbine and a wind turbine. The support device comprises at least one ring-shaped horizontal track and track support components; the at least one ring-shaped horizontal track is fixedly arranged on the track support components. The support device is characterized by further comprising chord support wings, at least two blades and a lower support wing, an upper support wing, a support pillar and a connecting wing or stayed swings corresponding to each blade; and the lower support swings, the upper support wings, the support pillars and the connecting wings or the stayed wings are connected with each other to form an integral component. The support device has the beneficial effects that a main shaft no long bears thegravity and the radial force of a wind wheel; the stress structure of the main shaft is optimized; only the turning moment of the wind wheel is transmitted; meanwhile, the wind sweeping radius of thewind wheel is increased; and the use amount of a support material is greatly reduced, so that the weight of the wind wheel is reduced, and the cost is reduced.

Owner:孟英志

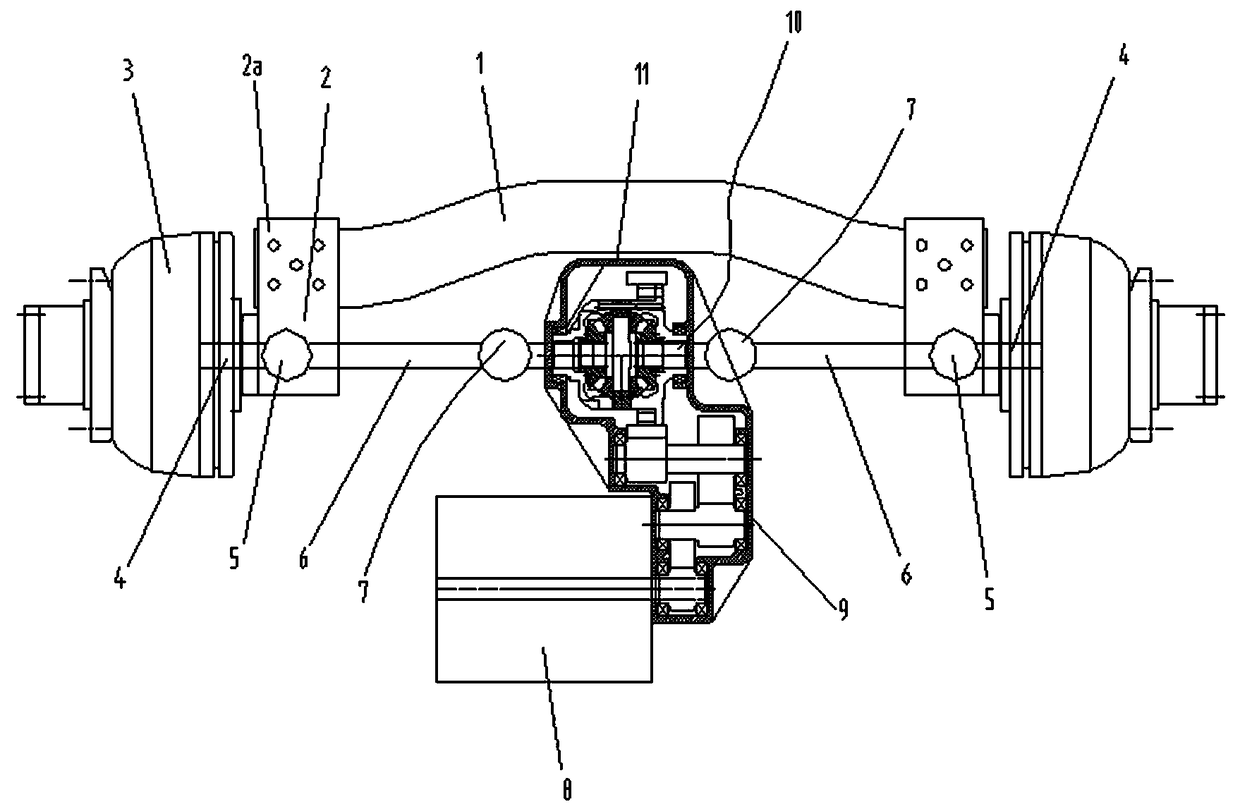

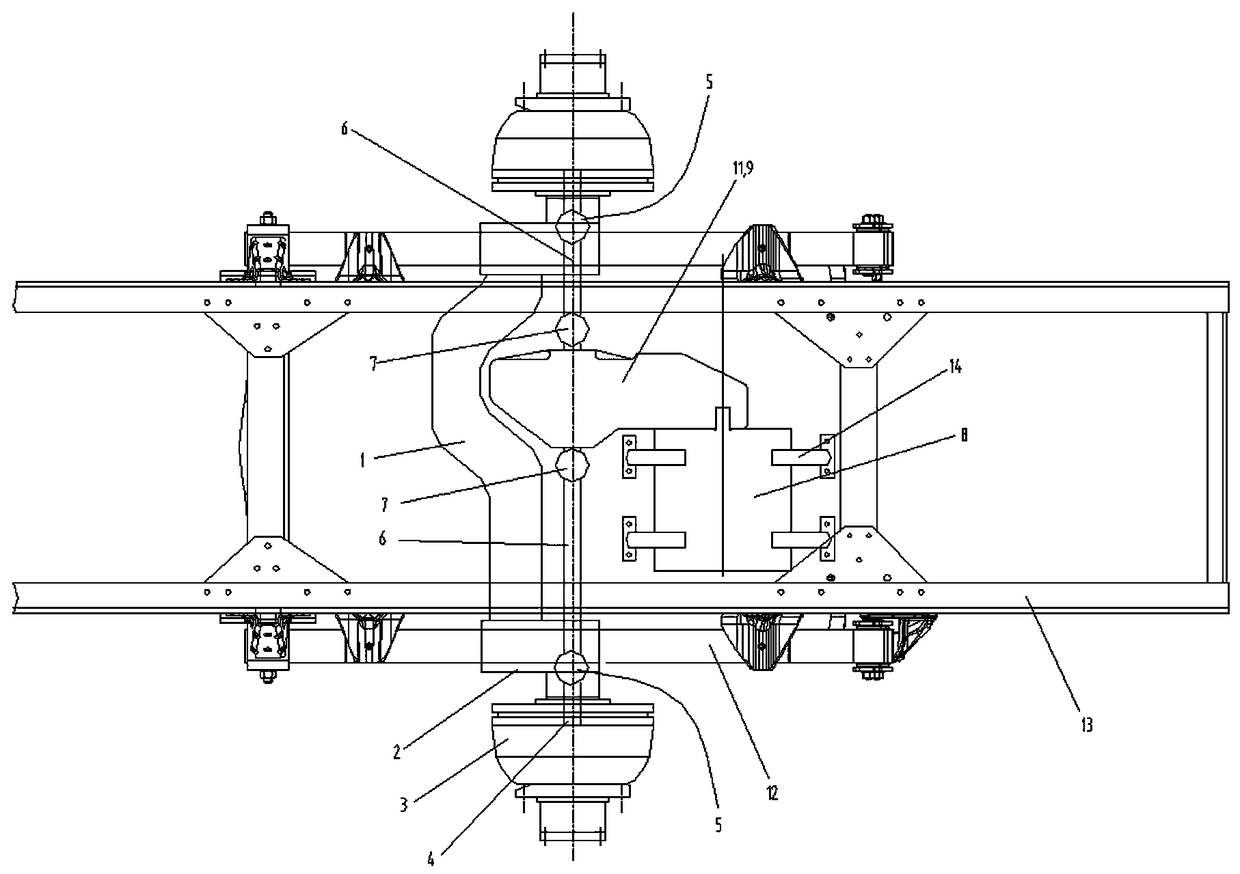

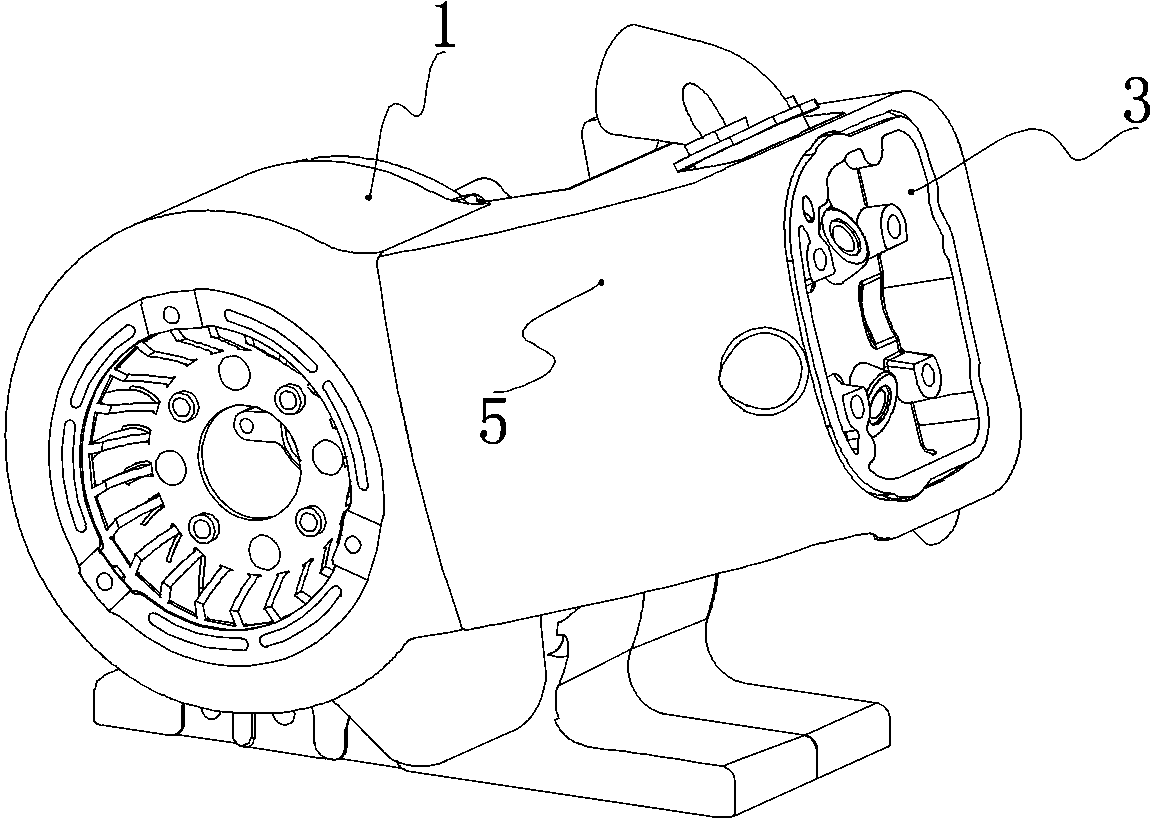

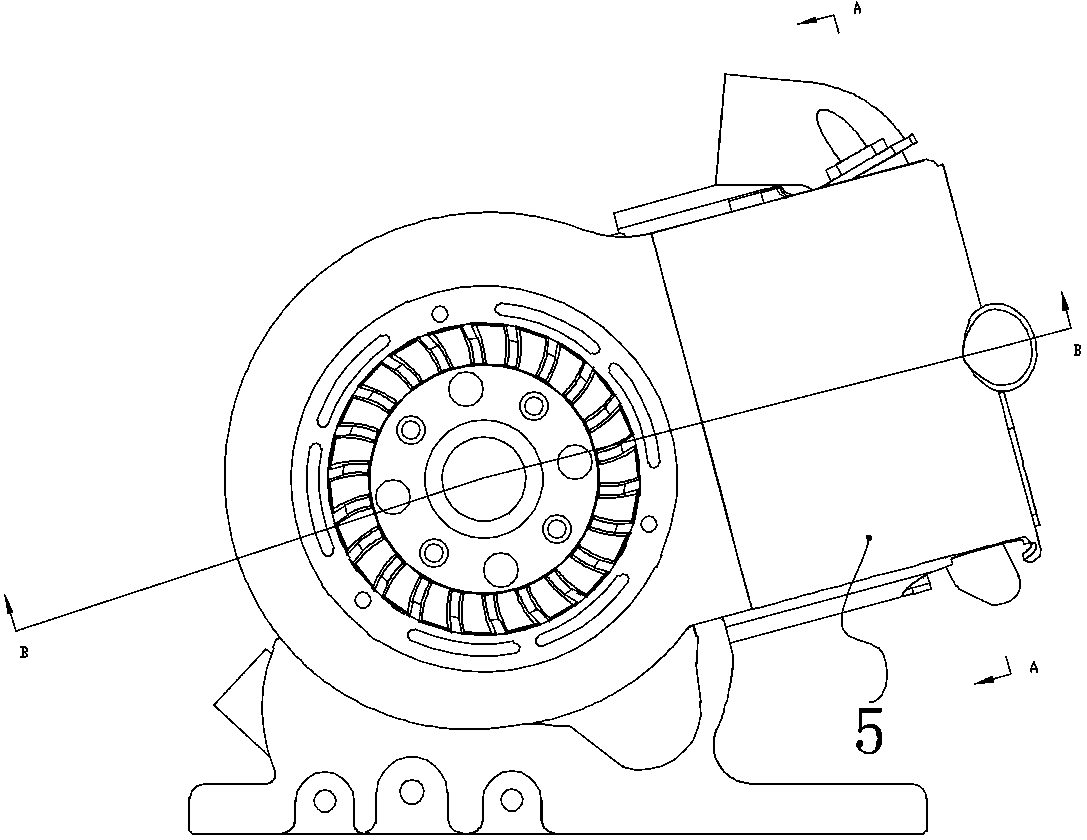

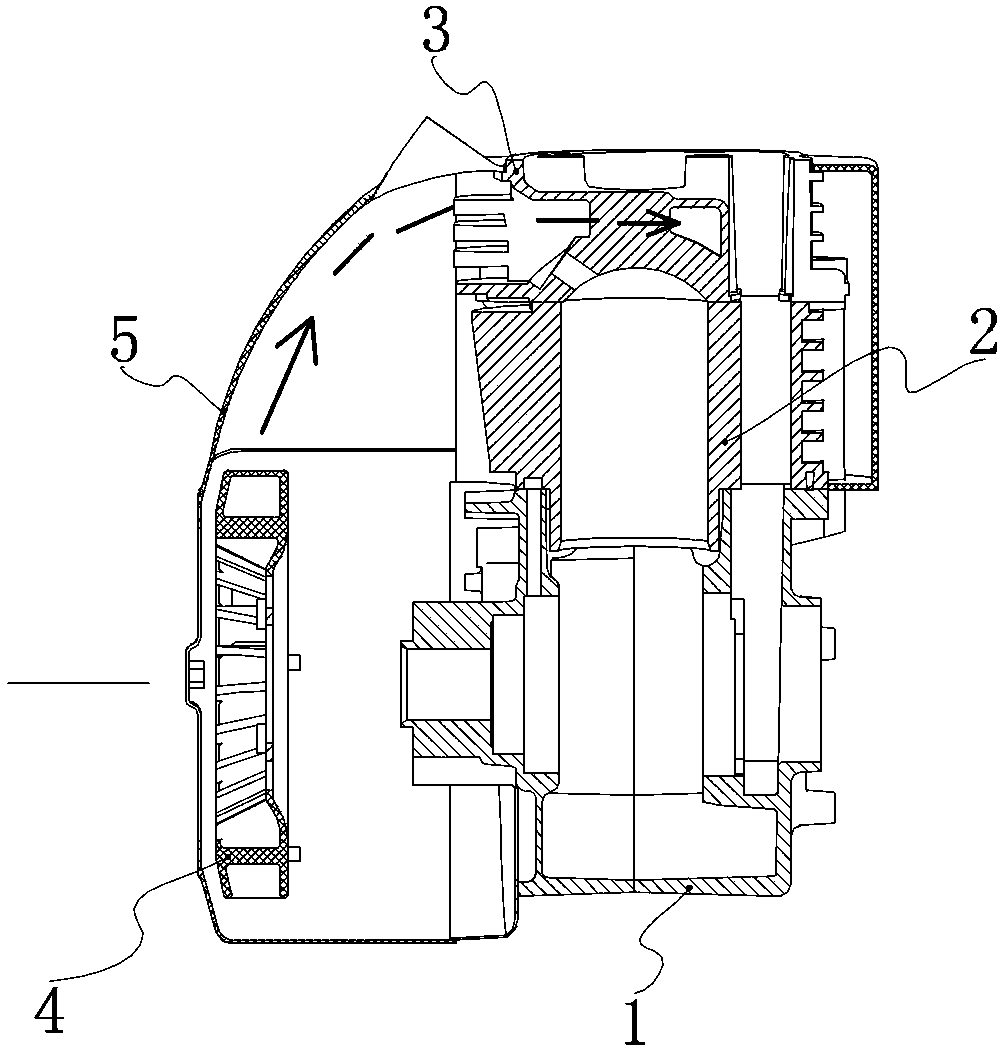

Non-bearing independently driven electric axle

PendingCN109278517AReduce manufacturing processReduced manufacturing and assembly difficultyElectric propulsion mountingAxle unitsElectric driveSteel plates

The invention relates to a non-bearing independently driven electric vehicle axle. The non-bearing independently driven electric vehicle axle is characterized in that a steel bracket (2a) on each wheel end connection bracket (2) is connected with a corresponding steel plate spring on a vehicle frame; each wheel end connection bracket (2) is connected with a corresponding wheel end system (3), andthe two wheel end connection brackets are connected with an integral bearing axle shell (1) which deviates from the axis of the corresponding wheel end system; and the vehicle frame is fixedly connected with a drive motor (8), an integral structural gear box (9) and a differential mechanism (11), and first universal joints (7), oscillating half shafts (6), second universal joints (5) and hub shafts (4) are separately connected to two ends of the differential mechanism. The non-bearing independently driven electric vehicle axle is different from a common electric drive axle structure for a commercial light electric vehicle, an integrated independent electric drive structure and an integral bearing axle shell are adopted, the unsprung mass of a vehicle chassis is effectively reduced, the ground clearance of the electric drive axle is reduced, the advantages of convenient design, manufacture, installation, maintenance and the like are achieved, and in terms of cost economy, an independentsuspension structure with complex use and higher cost due to the use of independent drive is avoided.

Owner:HEFEI AAM AUTOMOBILE DRIVELINE & CHASSIS SYST

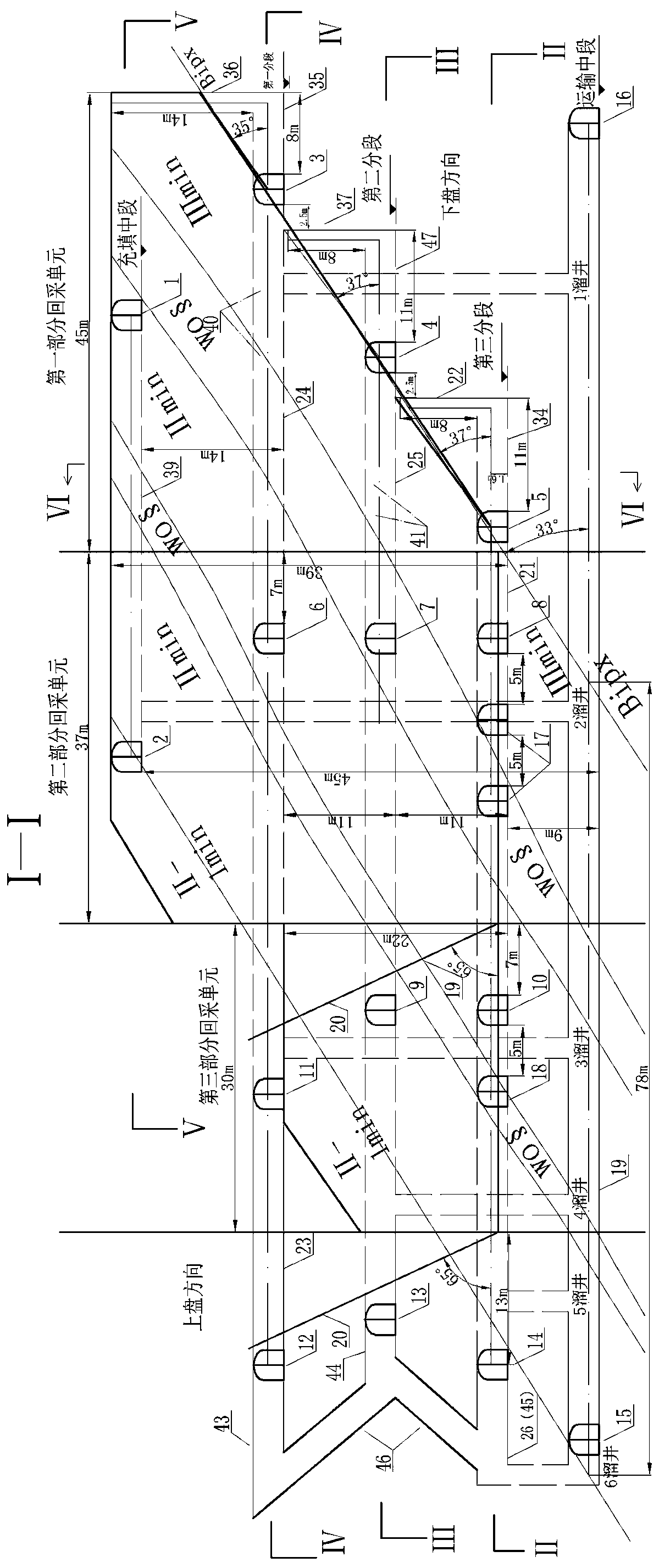

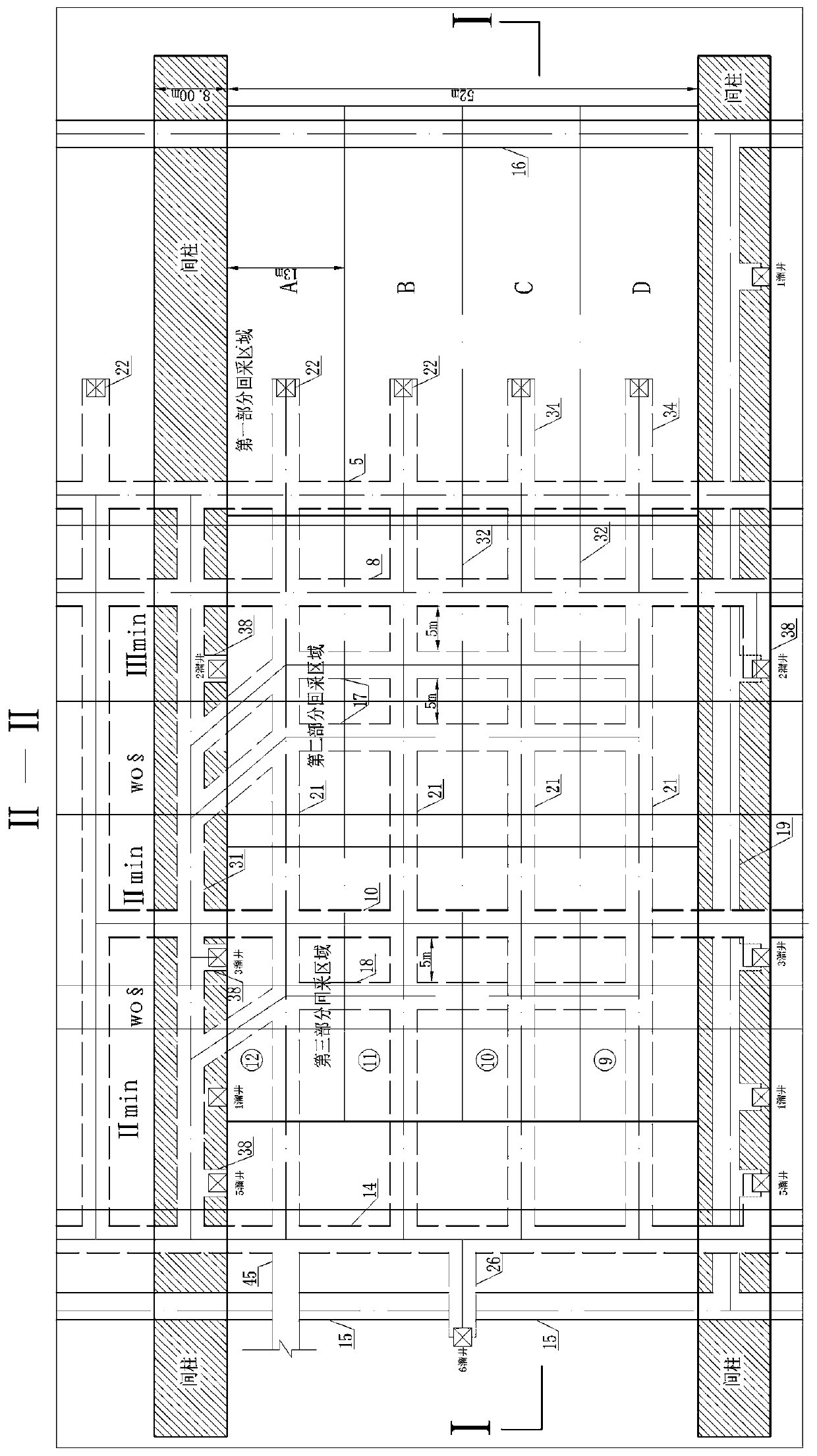

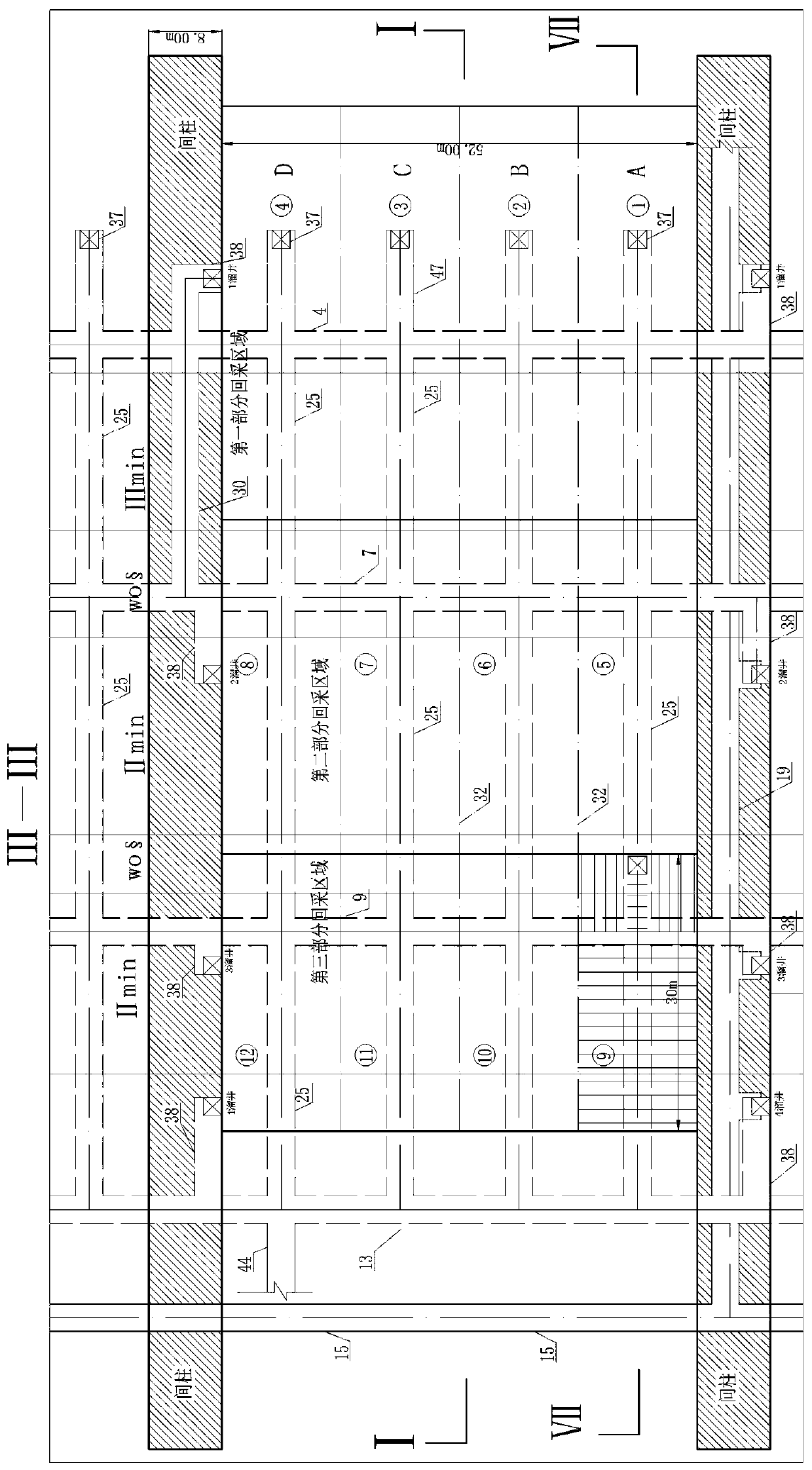

Flat bottom structure sublevel rock drilling stage ore removal subsequent cut-and-filling stoping method

ActiveCN110685737AReduce frictionImprove liquidityMining devicesDisloding machinesRock cuttingStoping

The invention relates to the technical field of mining of metal and non-metal ores, in particular to a flat bottom structure sublevel rock drilling stage ore removal subsequent cut-and-filling stopingmethod. The method is suitable for stoping sharply inclined and inclined ore bodies. According to the method, the mining method is suitable for mining thick ore bodies, extremely thick ore bodies, and the sharply inclined and inclined metal and non-metal ore bodies, wherein the sharply inclined and inclined metal and non-metal ore bodies are characterized in that the friction forces of the contact surfaces between the footwall boundaries of the ore bodies and bottom plate surrounding rocks are small, the ore fluidity is good, and the movement angles of ore footwalls are 30 degrees or above; sublevel open stope mining and mined-out area subsequently-filling are achieved, the mining high efficiency of a caving method is achieved, and the safety of a filling method is achieved; and the mining environment is safe, the mined-out area is treated through utilizing the filling method, the ore recovery rate is improved, and the ore dilution rate is reduced.

Owner:HEBEI PROVINCE FANSHAN PHOSPHORITE CO LTD

Construction method for tunnel double adit roof ripping

ActiveCN106437749AGood for deformation controlSimple supportUnderground chambersTunnel liningAditShotcrete

The invention discloses a construction method for tunnel double adit roof ripping. The construction method for the tunnel double adit roof ripping comprises the following steps that construction is prepared, specifically, the excavation and support of an upper adit (2) and a lower adit (3) is conducted in a staggered mode, a door-shaped steel frame is erected on the intersection port of the lower adit (3) and a positive cave (4), and the upper adit (2) enters the upper portion of the positive cave (4) in a roof ripping mode; a preliminary-stage support steel frame on the upper portion of the positive cave (4) is erected, concrete is sprayed to conduct sealing, and backfill is conducted on the portion between the roof ripping top of the upper adit (2) and the preliminary-stage support steel frame on the upper portion of the positive cave (4); a shape steel frame of the positive cave (4) is erected, an anchor rod is struck to conduct locking, concrete is sprayed to conduct sealing, and the lower adit (3) enters the lower portion of the positive cave (4); the positive cave (4) is excavated from the upper portion to the portion where the lower adit (3) penetrates through the positive cave (4), a circumferential direction steel frame support is formed, and the construction of large section weak surrounding rocks is finished. The collapse risk of a large section tunnel in a weak surrounding rock geological section is lowered.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

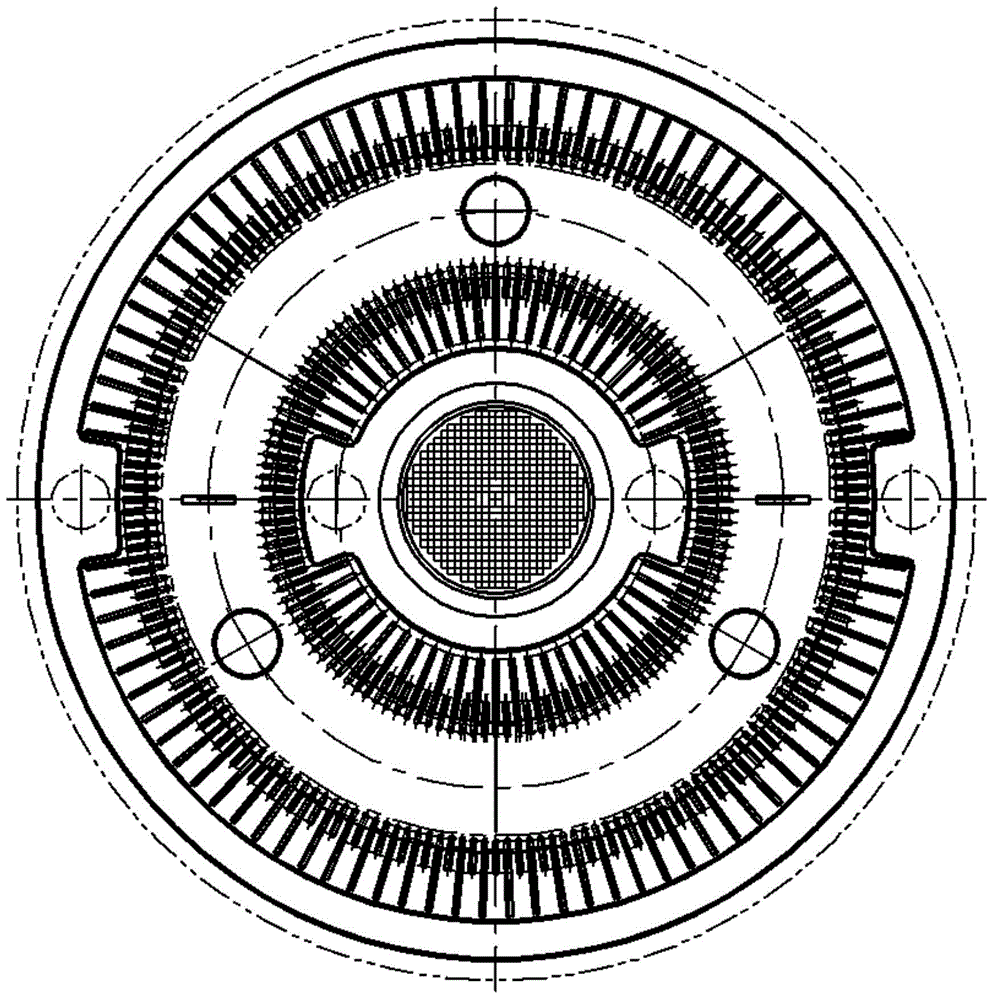

General machine engine cooling structure

InactiveCN104343518AReduce heat loadMeet the requirements of forced air coolingAir coolingCylinder headsElectric machineCylinder head

The invention relates to a general machine engine cooling structure, which comprises a crank shaft box body, a cylinder body, a cylinder head and a magnetic motor, wherein the magnetic motor is positioned in the crank shaft box body, a shaft sleeve arranged on a magnetic motor rotor extends out of the crank shaft box body, a cooling fan is arranged on the shaft sleeve through a fan retainer, the cooling fan, the cylinder body and the cylinder head are covered in an air guide cover, a flow passage blowing to the air cylinder is formed in the air guide cover, three cooing air passages are formed in the cylinder head, the air guide cover gathers cooling air blown out from the fan into the flow passages, the air is blown into the three cooling air passages of the cylinder head through the flow passage, meanwhile, the forced air cooling is carried out on the outside and the inside of the cylinder head, and the cooling effect is greatly improved. The heat load of the engine can be effectively reduced, so that the engine can realize the normal heat radiation at a high rotating speed. The general machine engine cooling structure has the advantages that the structure is simple, the cost is low, the maintenance is convenient, and the forced air cooling heat radiation requirements of a high-speed general machine engine are met.

Owner:CHONGQING DINKING POWER MACHINERY

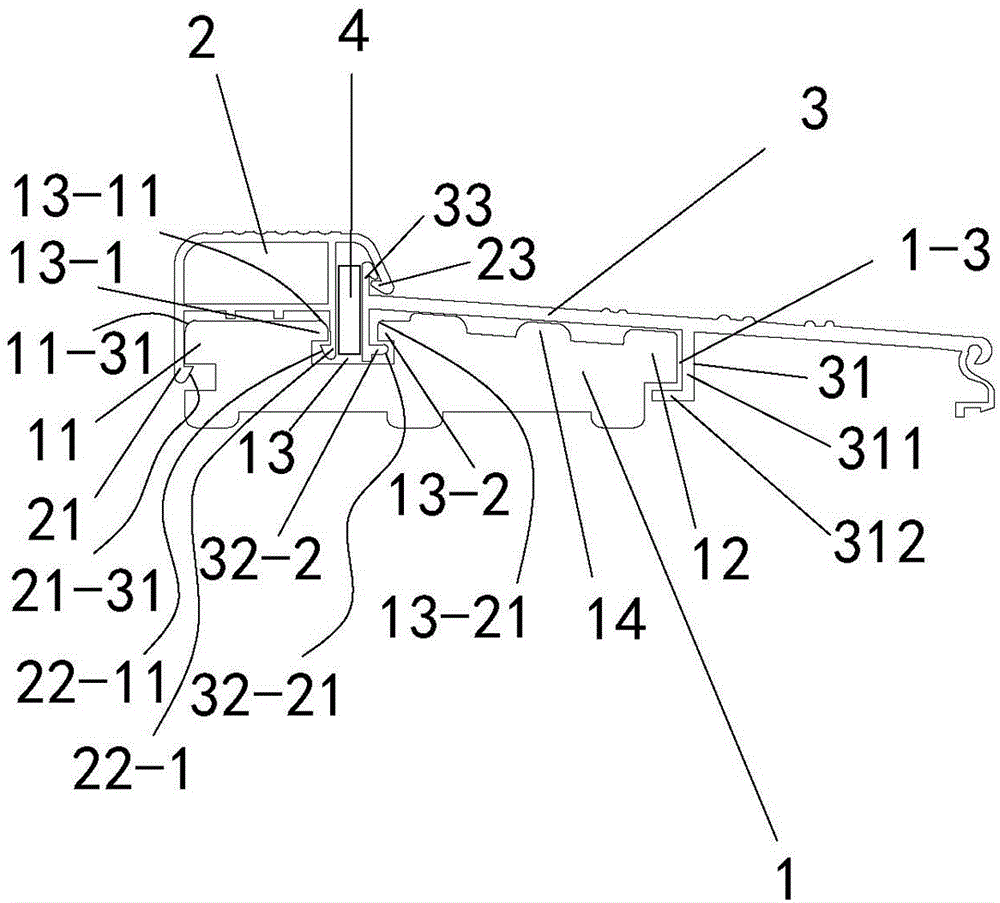

Inclined plane connecting structure of doorsill system

ActiveCN104632008ASimple structureImprove installation efficiencySills/thresholdEngineeringBolt connection

The invention relates to an inclined plane connecting structure of a doorsill system, and belongs to the field of doors and windows of buildings. The inclined plane connecting structure of the doorsill system comprises a pressure block (1) and a doorsill inclined plane (3), wherein the pressure block (1) is provided with a doorsill inclined plane clamping side end (12) and a slot (13) with an upward opening; the slot (13) is provided with a second buckle service portion (13-2); the doorsill inclined plane (3) is provided with an inner buckle (31) and a second buckle (32-2) which are respectively in clamping connection with the doorsill inclined plane clamping side end (12) and the second buckle service portion (13-2) in a matched manner; a second chamfer (13-21) is formed at the upper end of the second buckle service portion (13-2); and a second inserting chamfer (32-21) is formed at the lower end of the second buckle (32-2). A bolt connection mode in the prior art is abandoned, the components of the inclined plane connecting structure of the doorsill system are connected to one another by buckles, the structure is optimized, and the mounting efficiency is improved obviously.

Owner:ZHEJIANG HONGBO NEW BUILDING MATERIALS

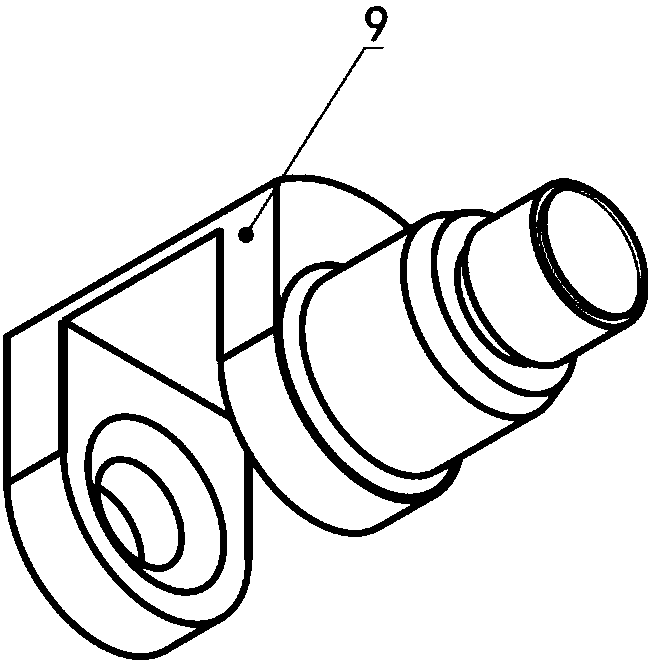

Swash plate type water pump

InactiveCN107859608ASimple structureStable motion transmissionPositive displacement pump componentsPositive-displacement liquid enginesInlet channelReciprocating motion

The invention belongs to the field of water pumps, and discloses a swash plate type water pump. The swash plate type water pump comprises a cylinder body, a left end cover, a right end cover, a spindle assembly, a swash plate, a plurality of groups of plunger compression assemblies and distributing valves, wherein a water inlet channel is formed in the cylinder body, and a drain channel is formedin the right end cover; the spindle assembly comprises a rotary spindle; the swash plate is fixedly installed on the rotary spindle in a penetrating mode; each group of the plunger compression assembly comprises a return block, a plunger assembly, a cylinder sleeve assembly and a distributing valve assembly; the distributing valve assemblies are respectively installed in positions, which correspond to cylinder sleeves, of the right end cover, liquid communication flow channels are respectively formed in positions, which correspond to the distributing valve assemblies, of the right end cover, and all of the liquid communication flow channels communicate with the drain channel in the right end cover. According to the swash plate type water pump, the rotary motion of the spindle is convertedinto a straight reciprocating motion of the plunger assemblies through a spherical hinge and the return block, and the swash plate type water pump has the advantages of simple structure and smooth motion transfer.

Owner:HUAZHONG UNIV OF SCI & TECH

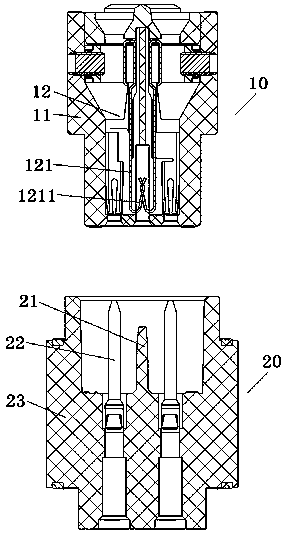

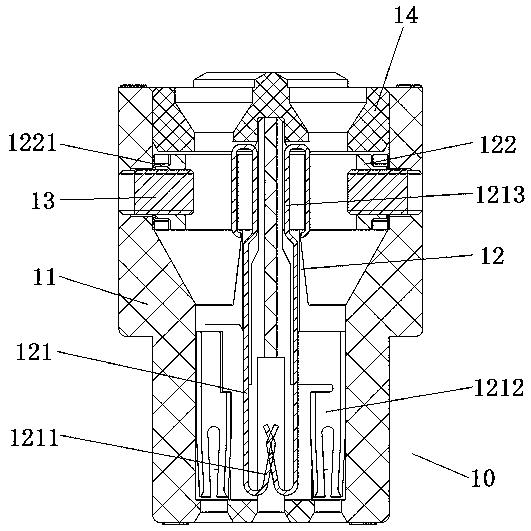

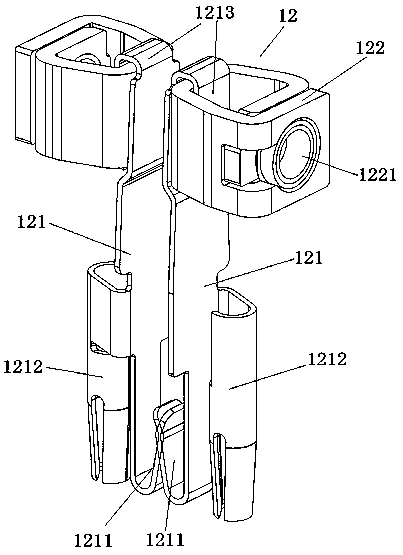

Connector

ActiveCN111200223AWon't moveGuaranteed stabilityCoupling contact membersTwo-part coupling devicesEngineeringMechanical engineering

The invention relates to the technical field of electric connectors, and provides a connector. The connector comprises a connector shell, wherein paired conductive assemblies are arranged in the connector shell; the conductive assembly comprises a contact piece body, one end of the contact piece body is provided with a plug-in structure used for being matched with an adaptive plug-in piece, an elastic arm structure is folded at the end, and the other end of the contact piece body is provided with or connected with a wire pressing structure; the elastic arm structures of the two paired conductive assemblies abut against each other at a position between the two conductive assemblies, and a flaring structure is formed at the side facing the plugging direction, so that an insulator of an adaptive connector can be inserted into the flaring structure to insulate and isolate the two elastic arm structures in use. The elastic arm structures for realizing short circuit of the two conductive assemblies are integrally formed on the contact piece body, the plugging structure, the elastic arm structures and the contact piece body are relatively fixed, and the elastic arm structures can be always located at the accurate matching positions in the plugging process of the connector, so that the elastic arm structures do not move when a short circuit function is realized, and the stability of the connector during working is ensured.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Super pipeline for nuclear power plant as well as manufacturing method thereof

InactiveCN101783191BSmooth shape changeHigh strengthNuclear energy generationNuclear power plant detailsNuclear engineeringUltimate tensile strength

Owner:CHINA NUCLEAR POWER ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com