Support device of large-scale vertical axis wind turbine and wind turbine

A technology of supporting device and vertical axis, applied in the fields of wind energy utilization, wind machinery and wind power generation, can solve problems such as unfavorable development of large or super-large wind turbines, large-scale wind power, limiting the rotation radius of the wind wheel and the height of the wind wheel, etc., to achieve optimization The main shaft stress structure, the effect of expanding the bearing area and reducing the quality of the wind rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

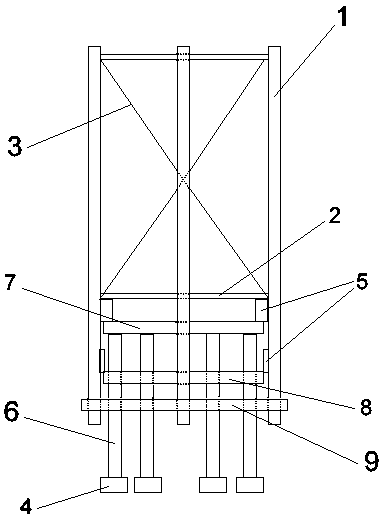

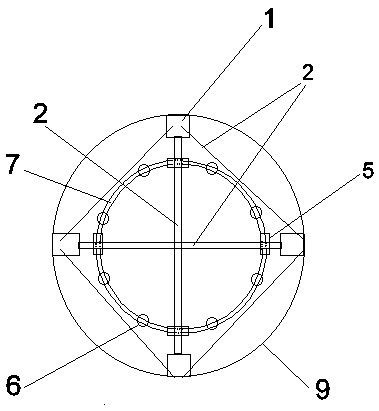

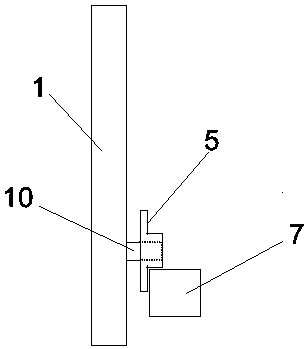

[0071] Such as Figure 1-5 As shown, the support structure of the large vertical axis fan according to the present invention or the invention includes an annular horizontal track 7, a track support column 6 and a foundation 4, the track support column 6 is fixedly installed on the foundation 4, and the annular horizontal track 7 is fixedly installed on the track support On the column 6, rollers 5 are arranged on the annular horizontal track 7, and the rollers 5 are installed on the supporting columns 1 or connecting wings 2, and between two or four supporting columns 1, there are a plurality of connecting wings 2 or / and inclined The pull wings 3 are connected; the two or four support columns and at least two connecting wings 2 or inclined stay wings 3 form an integral member in a ring. The overall member in the ring can freely rotate on the circular horizontal track 7 through the roller 5 .

[0072] In the present invention or in the invention, the foundation 4 is located on ...

Embodiment 2

[0082] Such as Figure 6 , 7 As shown, an upper support wing 13 and a lower support wing 14 are installed on the support column 1 , one end of the upper or / and lower support wing is connected to the support column 1 , and the other end is connected to the blade 12 .

[0083]Between the support column 1, the upper and lower support wings 13, 14 and the blades 12, there are connecting wings 2 or / and obliquely-stayed wings 3 connected, the support column 1, the upper and lower support wings 13, 14, the blades 12 and the connecting wing 2 or the inclined-stayed wing 3 form an integral component outside the ring.

[0084] Such as Figure 6 As shown, there is a diagonally-stayed wing 3 connected between the upper end of the support column 1 and the upper end of the integral member outside the ring; the upper end of the integral member outside the ring refers to the upper support wing 13 here. Between the lower end of the support column 1 and the lower end of the integral member o...

Embodiment 3

[0089] Such as Figure 8 as shown, Figure 8 It is a partial plan view of the connection structure between the present invention or the invention's supporting wing 15 and the lower supporting wing 14; the supporting wing 15 is arranged on the top of the annular horizontal track 7, and intersects and connects with the bottom connecting wing 2 of the integral member in the ring, the supporting wing 15 is provided with a roller 5 below, and the roller 5 is supported on the circular horizontal rail 7 and can rotate freely. At both ends of the supporting wing 15, there is respectively a diagonally-stayed wing 3 and a lower supporting wing 14 close to the direction of the blade. Connected at one end. The inclined-stayed wing 3 plays a role of supporting or tightening the lower supporting wing 14 .

[0090] In order to simplify the description, this embodiment only draws a partial top view of the connection structure between the two supporting wings 15 and the lower supporting wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com