Water lubricating thrust bearing possessing annular groove

A technology of thrust bearings and water lubrication, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of easy wear of grinding discs, poor friction and wear performance, unreliable working process, etc., and achieve easy hydrodynamic pressure The effect of lubrication, small axial size, good development potential and market prospect

Inactive Publication Date: 2008-10-15

HARBIN INST OF TECH

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem of poor friction and wear performance of existing thrust bearings, easy wear and cracks on the grinding disc, small bearing area, low bearing capacity, short service life, not easy to form hydrodynamic pressure lubrication, and work process Unreliable, complex structure, large axial dimension, complex processing technology and high cost, and then provide a water-lubricated thrust bearing with ring groove

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

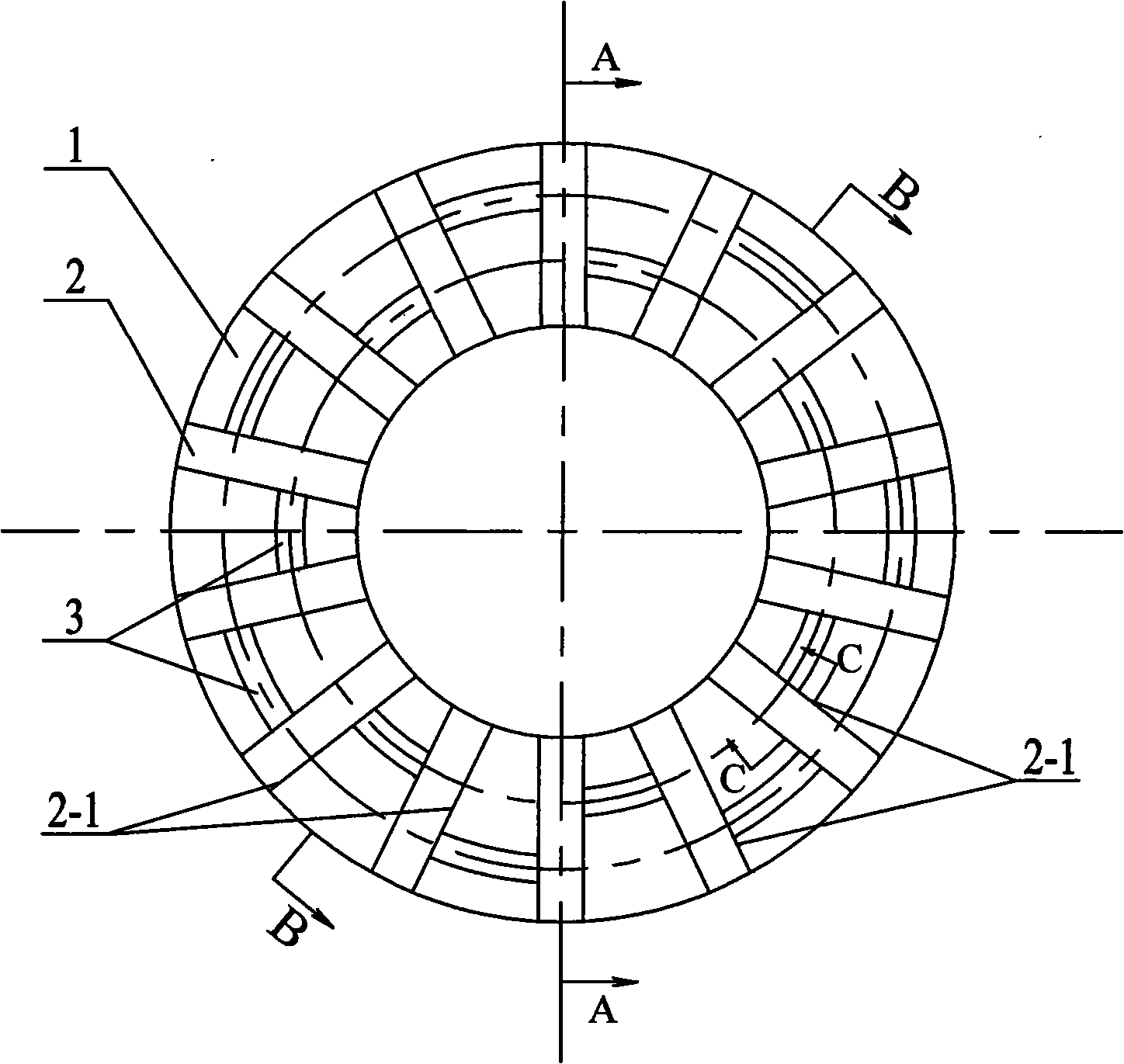

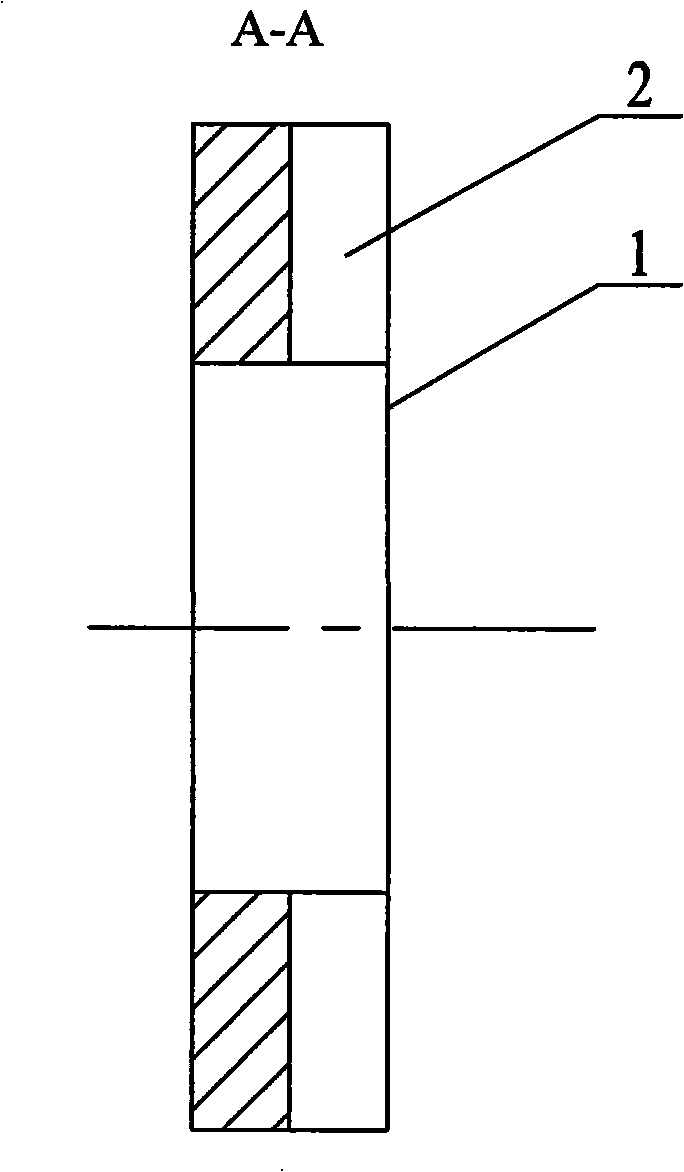

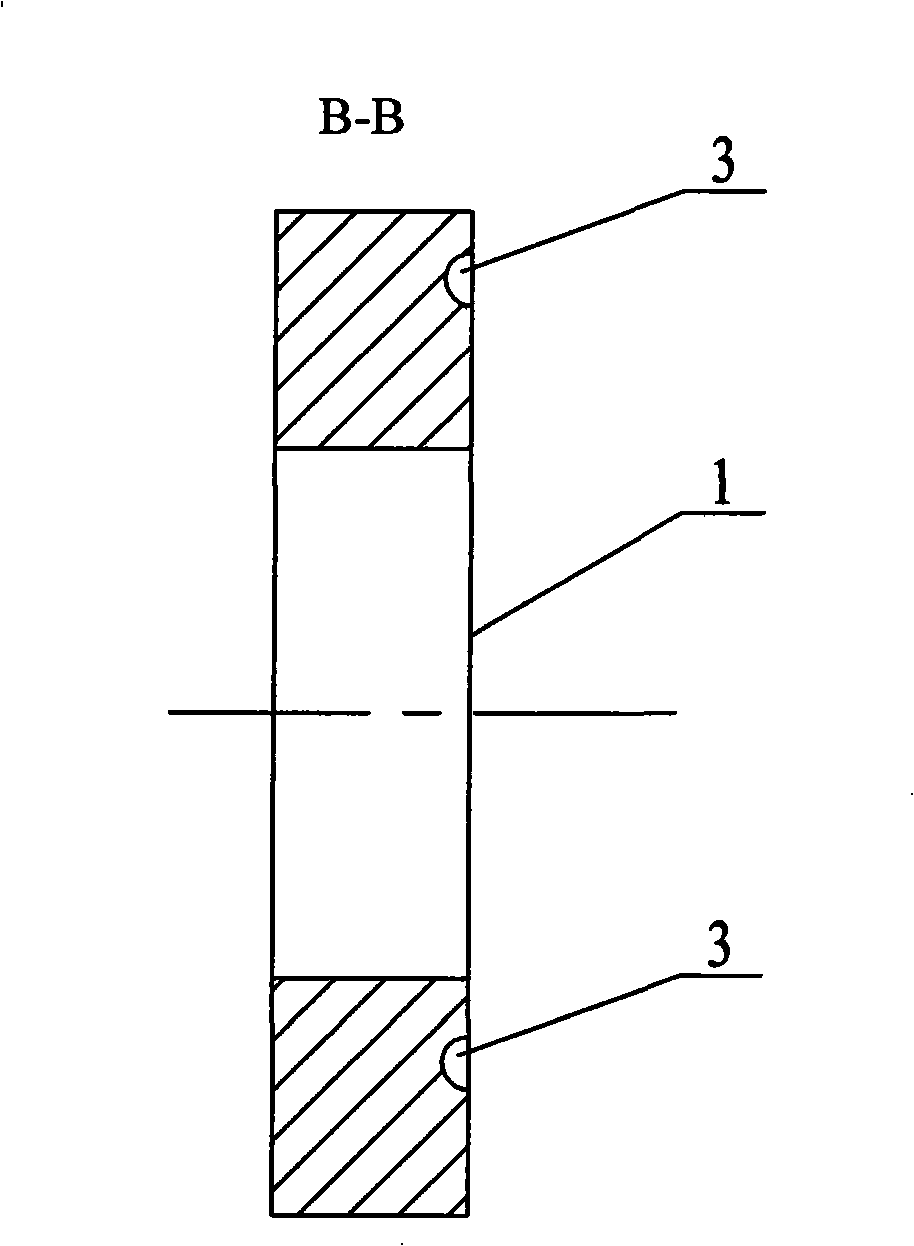

The invention discloses a water lubrication thrust bearing wit a ring grooves, relating to a thrust bearing. The invention solves the problems of bad performance of frictional wear, easy wear and cracking to a grinding disc, small bearing area, low bearing capacity, short service life, difficult fluid hydrodynamic lubrication, unreliable work process, complicated structure, large axial size, complicated processing process and high cost and so on of the prior thrust bearing. A friction surface (1) of the thrust bearing is provided with aequilate water grooves (2) along the radial direction, sector massive bearing surfaces is formed on the friction surface (1), and the sector massive bearing surfaces are provided with ring grooves (3). The water lubrication thrust bearing with the ring grooves has the advantages of high bearing capacity, long service life, easy fluid hydrodynamic lubrication, stable and reliable work process, simple structure, small axial size, simple processing process and low cost and so on. Practical application of the water lubrication thrust bearing with the ring grooves can improve whole device efficiency and reliability of water environment work machinery to a large extent, which brings better economic benefit and social benefit, and has better development potential and market prospect.

Description

Water-lubricated thrust bearings with ring grooves technical field The invention relates to a thrust bearing. Background technique At present, the thrust bearing adopts an integral self-aligning straight groove structure, that is, several radially equal-width water grooves are processed on the circular friction surface to form a fan-shaped block-shaped bearing surface. Self-aligning structure with spherical support. This structure is mainly to increase the fluidity of water, improve the cooling effect, reduce the frictional surface and internal temperature of the thrust bearing, and make the load uniform everywhere. In addition, Japan has developed a spiral groove water-lubricated thrust bearing; the invention patent with the announcement number CN1719055 and the announcement date is January 11, 2006 discloses "Spiral groove water-lubricated rubber alloy bearing"; the announcement number is CN1124827, the announcement date is For the invention patent on June 19, 1996, "D...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16C17/08F16C33/10

Inventor 曲建俊代汉达

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com