Reverse circulation construction technique and apparatus of single rope impact drill

A technology of construction device and construction process, applied in the field of reverse circulation construction process and device, can solve the problems of complex operation, limited adaptability, high equipment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be explained in more detail below through examples, but the present invention is not limited thereto.

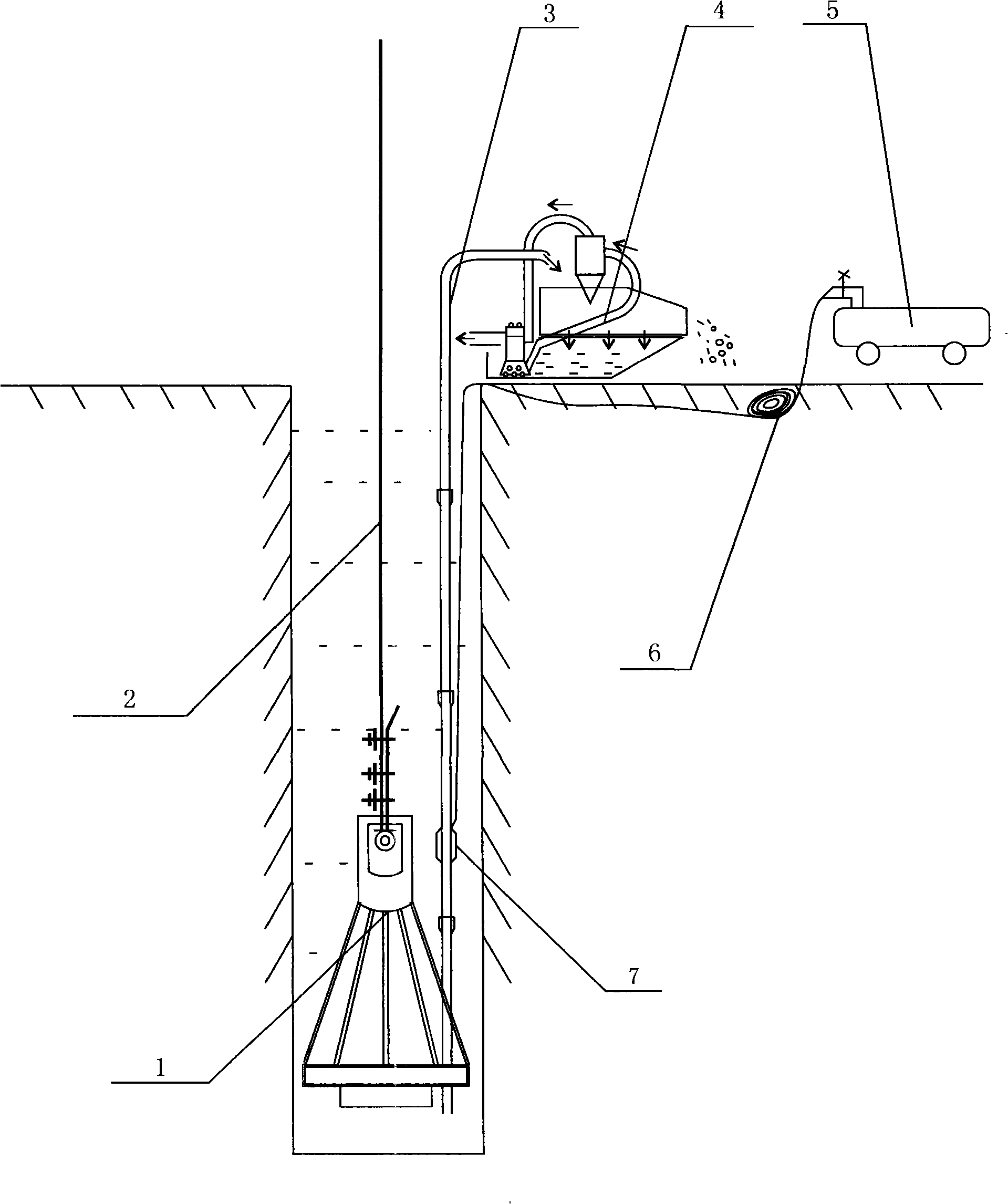

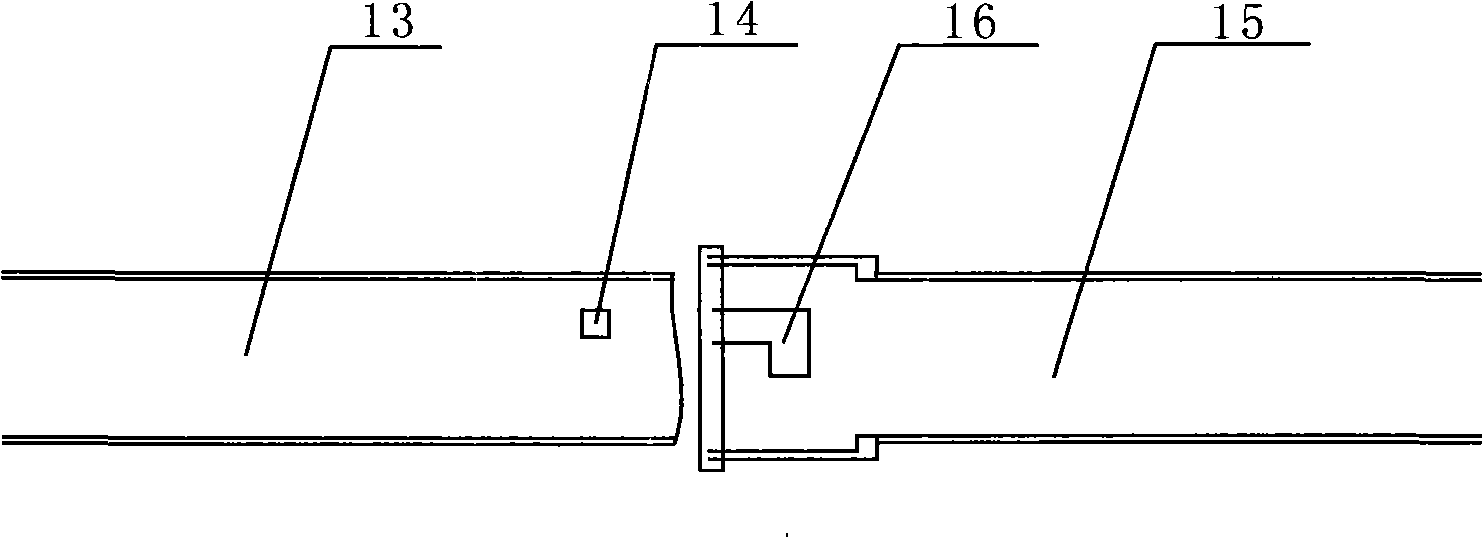

[0028] Such as figure 1 , 2 , Shown in 3 and 4, the reverse circulation construction device of this single-rope percussion drill includes a percussion drill, a slurry pumping pipe deep into the bottom of the hole, and a mud purifier positioned at the orifice; wherein,

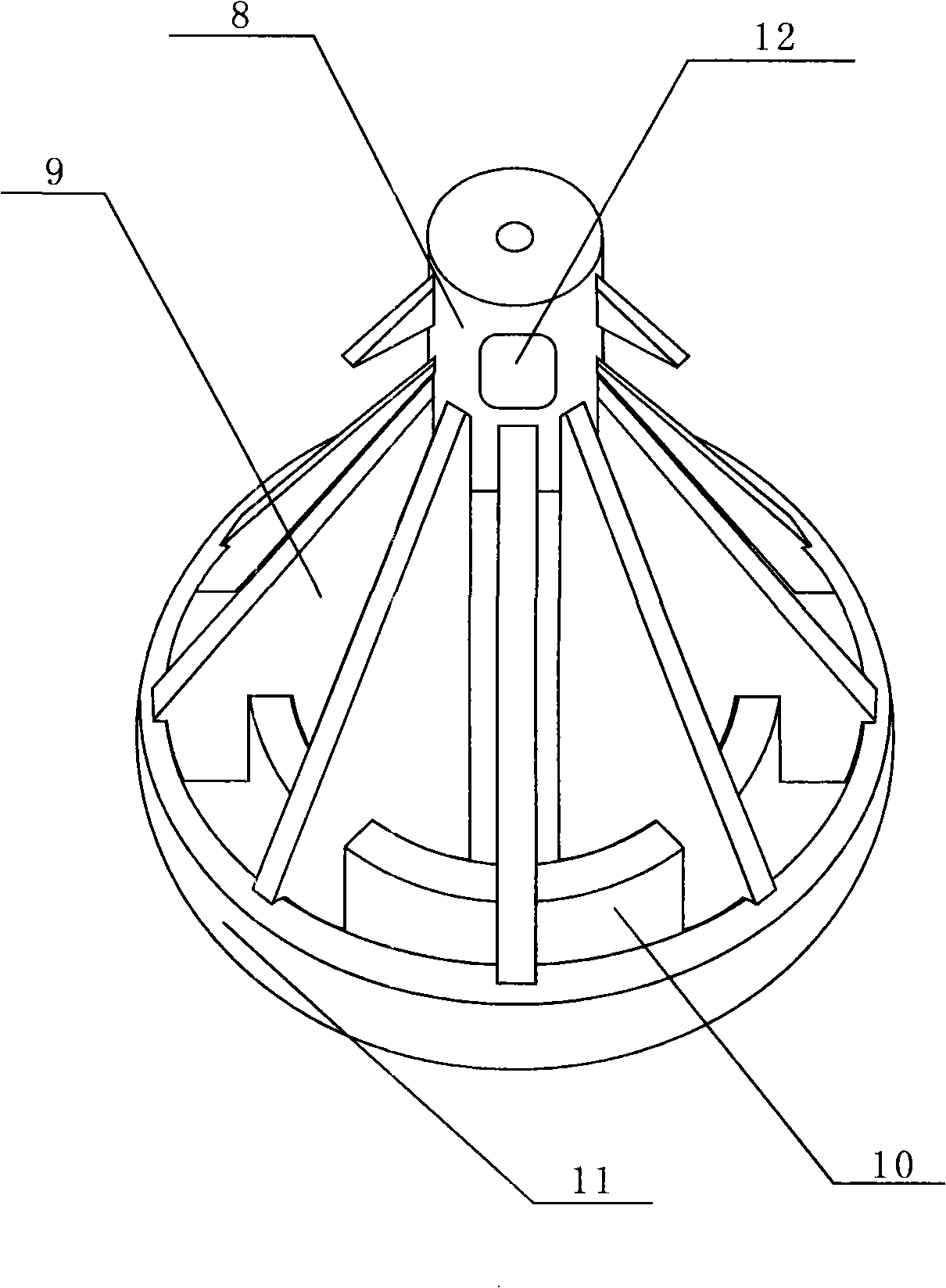

[0029] In the percussion drilling machine, the drill bit 1 is composed of a drill body and a cutting blade. The drill body is composed of a hammer body, a corner plate and a base. There is a connecting hole 12 at the upper end of the hammer body 8. The drill bit 1 and the non-rotating steel wire rope 2 pass through the connecting hole 12. Knotted and fastened with a steering gear, a plurality of angled plates 9 are distributed at the same angle in the axial direction on the cylindrical or tubular hammer body 8, and the base is composed of an inner base 10 and an outer base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com