Sintered ring magnet and method of manufacturing the same

a technology of sintered rings and rings, which is applied in the field of radially oriented sintered rings, can solve the problems of deterioration of a magnetic alignment property, reduction of the alignment coefficient of magnetic powder, and inability to achieve a high magnetic property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(1) Structure of the Sintered Ring Magnet of the First Embodiment

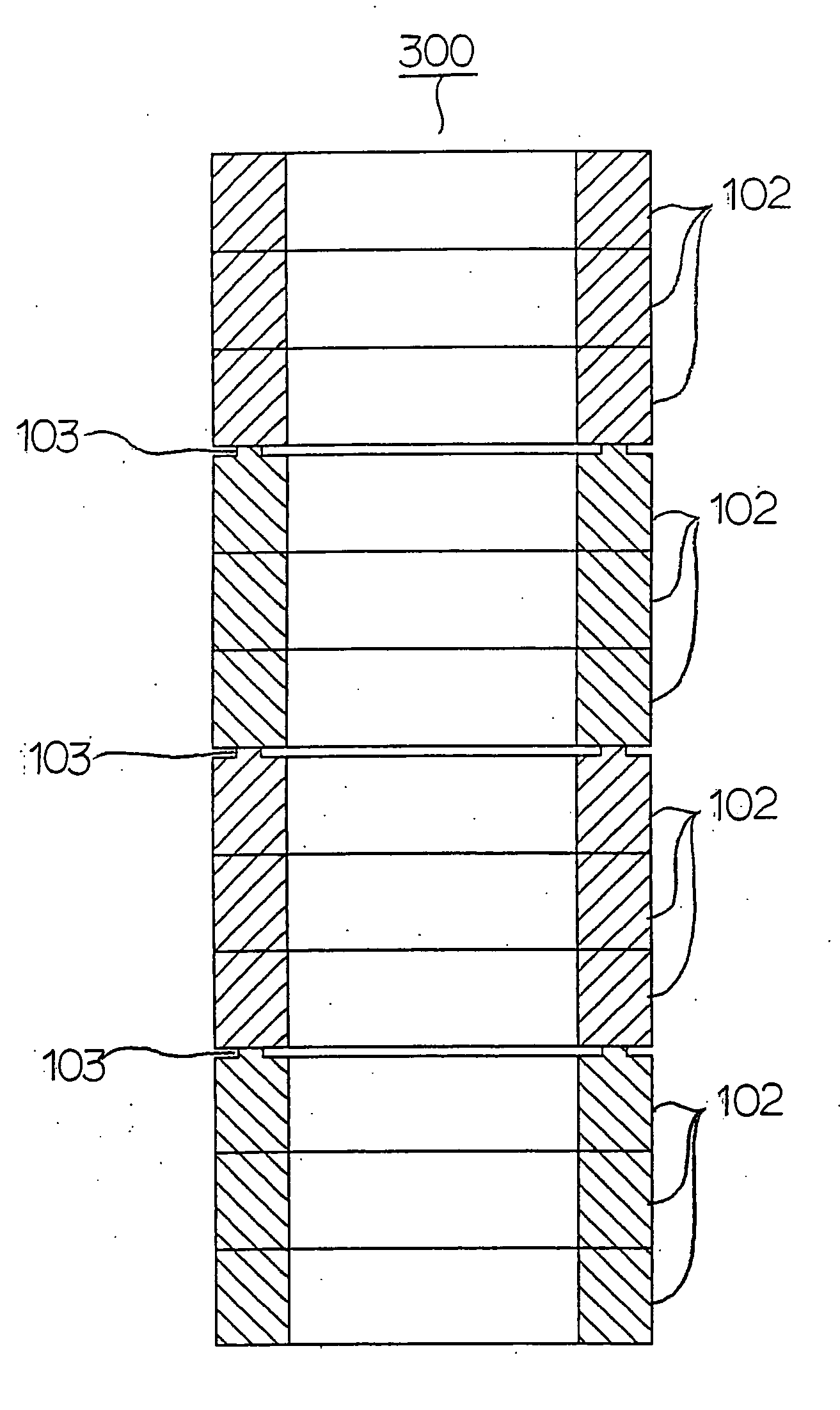

[0045] First, the structure of a sintered ring magnet 100 according to a first embodiment of the invention is described with reference to FIG. 1 which is a perspective view of the sintered ring magnet 100.

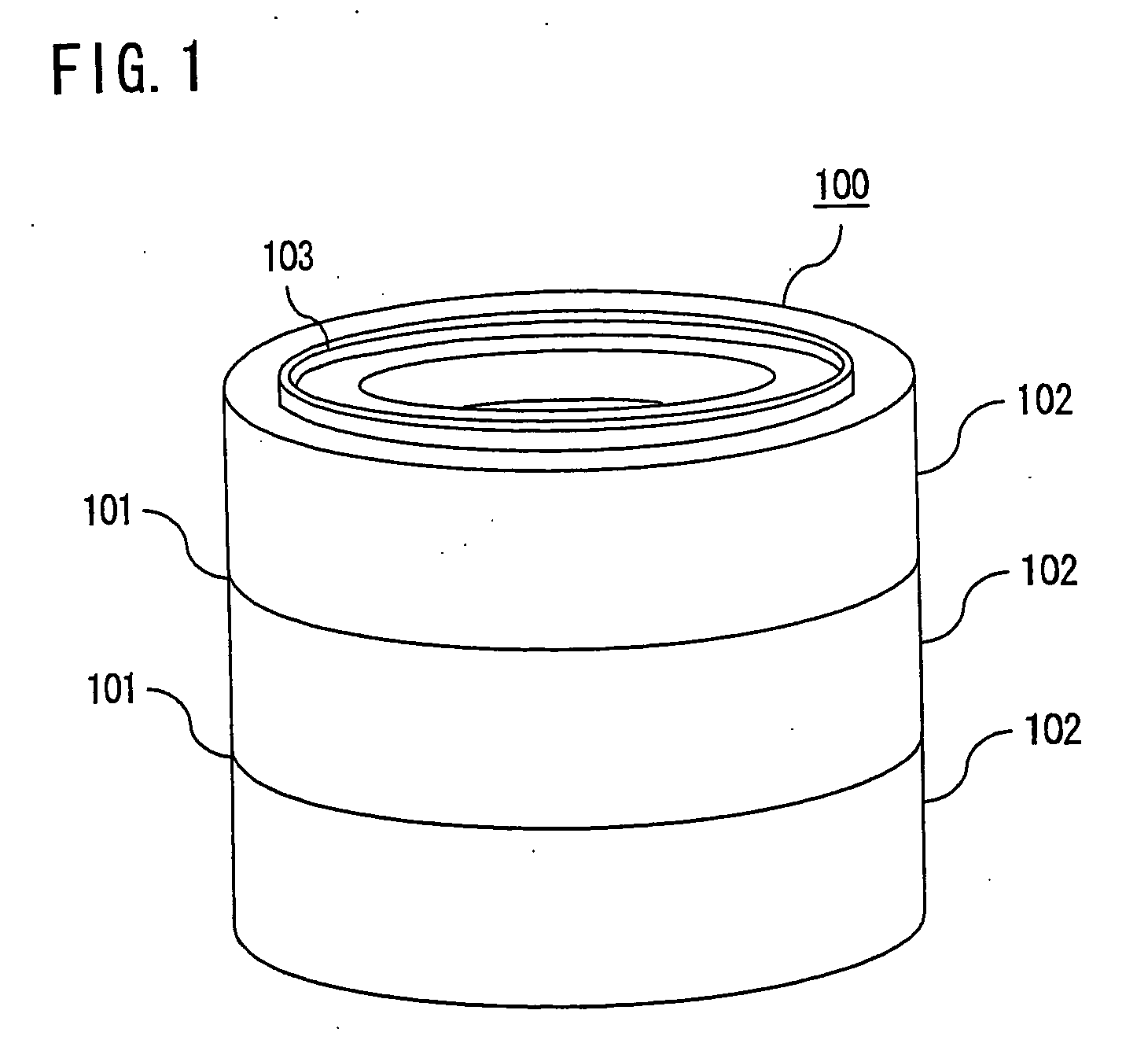

[0046] Referring to FIG. 1, the sintered ring magnet 100 of the embodiment is a ring magnet produced by stacking a plurality of ring-shaped powder compacts 102 in layers (three layers in the illustrated example) in an axial direction and joining the ring-shaped powder compacts 102 by sintering the stacked ring-shaped powder compacts 102. The individual ring-shaped powder compacts 102 are joined at boundaries 101 as a result of sintering operation, together forming a single structure. As depicted in FIG. 1, there is formed a ring-shaped protruding part 103 on an upper end surface of the ring-shaped powder compact 102 in an uppermost layer of the sintered ring magnet 100 in this embodiment. Although not illustrated, ...

second embodiment

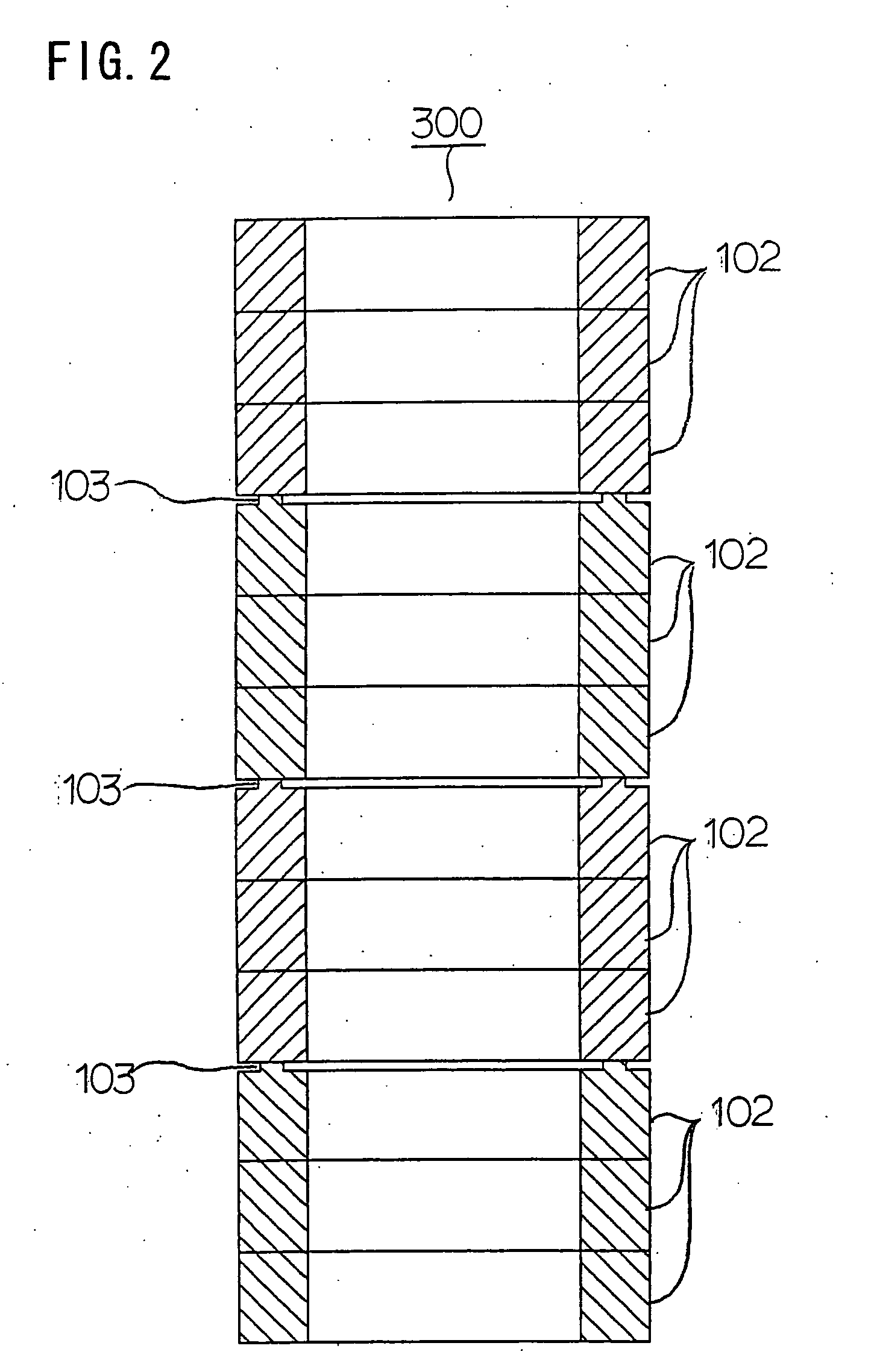

[0100]FIG. 22 is a cross-sectional view of a sintered ring-shaped powder compact rod 301 obtained by a method of manufacturing sintered ring magnets according to a second embodiment of the invention. FIG. 23 is a cross-sectional view of the sintered ring magnets obtained by dividing the sintered ring-shaped powder compact rod of FIG. 22. Specifically, a curved inner surface and a curved outer surface of the sintered ring-shaped powder compact rod 301 formed by sintering a plurality of ring-shaped powder compacts 102, 102B are finished by machining, and the sintered ring-shaped powder compact rod 301 is subjected to an anticorrosion surface treatment. Then, a mechanical bending stress is applied to boundary regions of the sintered ring-shaped powder compact rod 301 and, as a result, the sintered ring-shaped powder compact rod 301 breaks at the boundary regions where ring-shaped protruding parts 103 are formed and the sintered ring magnets of the second embodiment are obtained as show...

third embodiment

[0103]FIG. 24 is a cross-sectional view of a sintered ring-shaped powder compact rod 302 obtained by a method of manufacturing sintered ring magnets according to a third embodiment of the invention. Referring to FIG. 24, alumina powder 104 having an average particle size between 1 micrometer and 100 micrometers is dusted to a thickness between 1 micrometer and 100 micrometers in specific boundary regions of ring-shaped powder compacts 102 which are stacked one on top of another for forming the sintered ring-shaped powder compact rod 302. The alumina powder 104 is dusted in half or less of the area of each boundary region.

[0104] The ring-shaped powder compacts 102 used for producing the sintered ring-shaped powder compact rod 302 of the third embodiment are made by substantially the same manufacturing method as explained earlier with reference to the first embodiment. For example, to produce the sintered ring-shaped powder compact rod 302 of FIG. 24, three ring-shaped powder compact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com