Patents

Literature

711results about "Permanent magnet manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

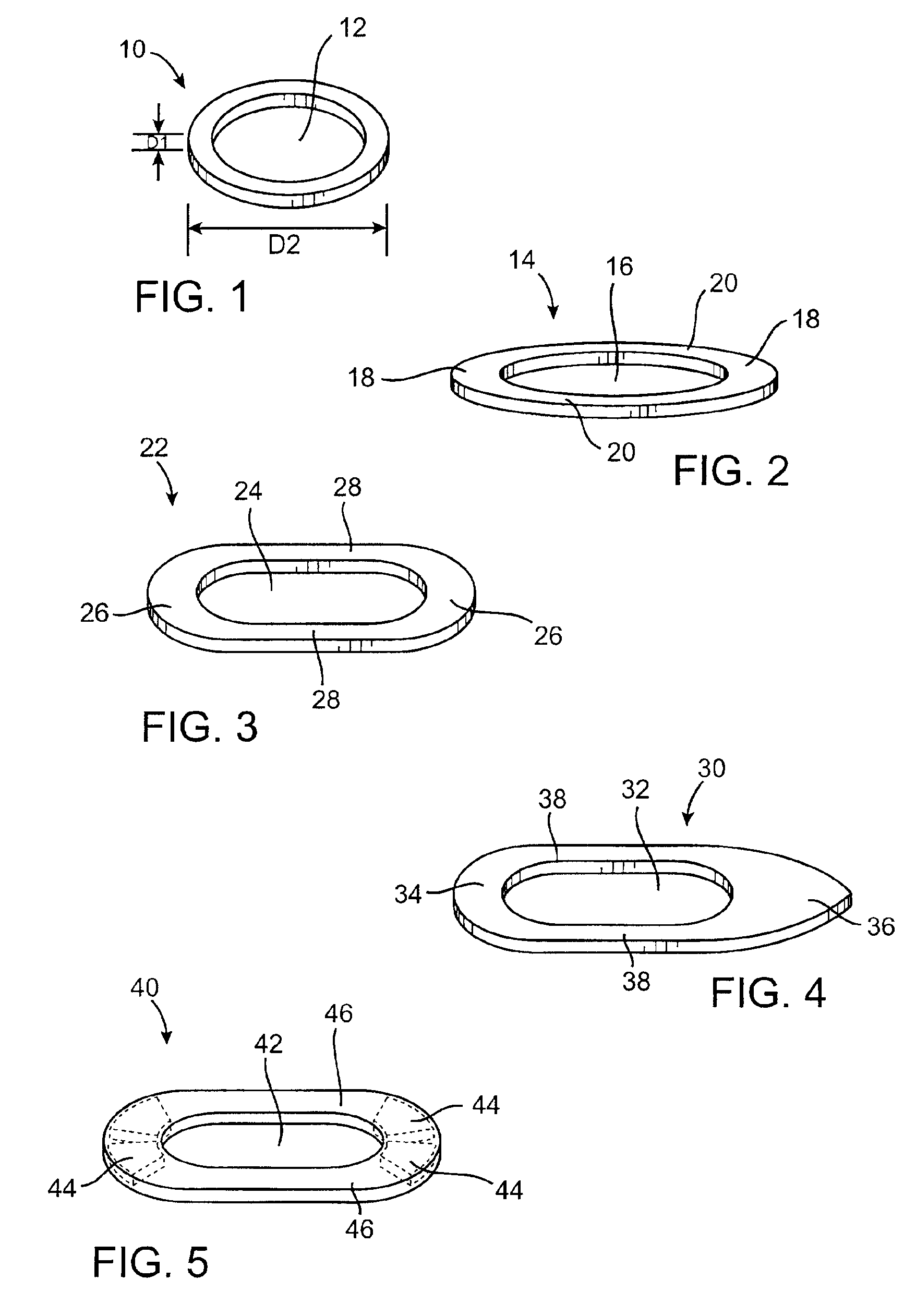

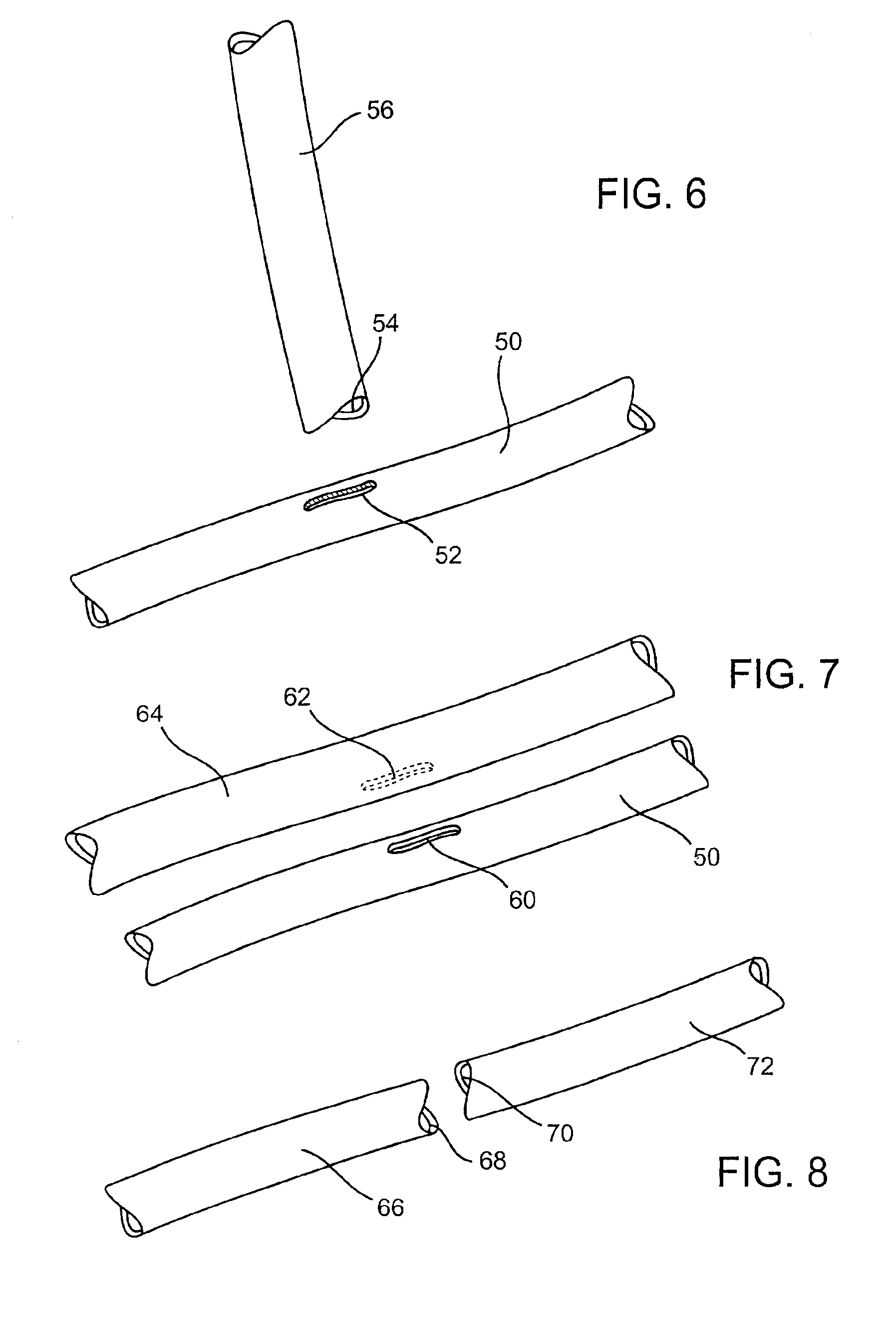

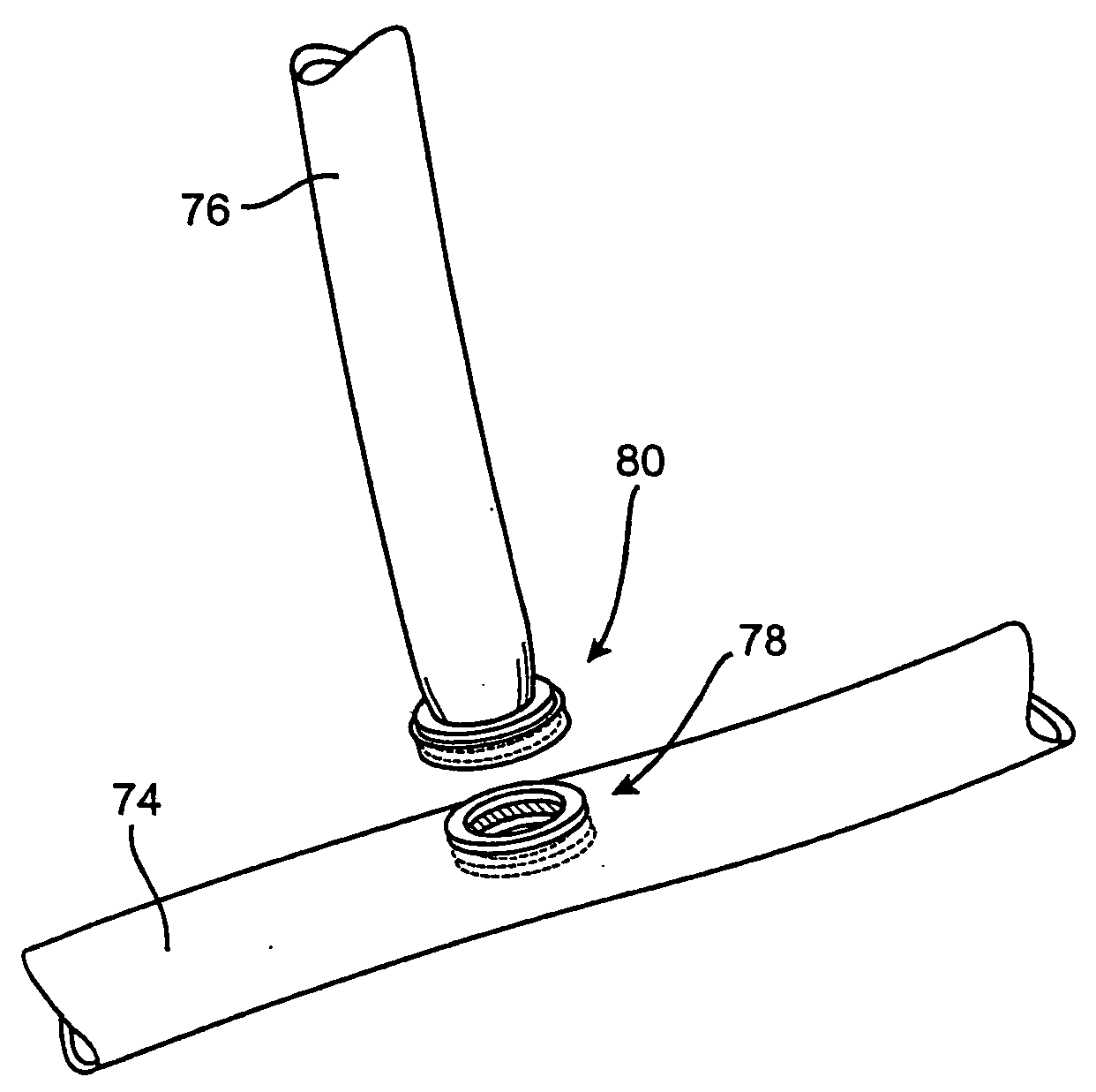

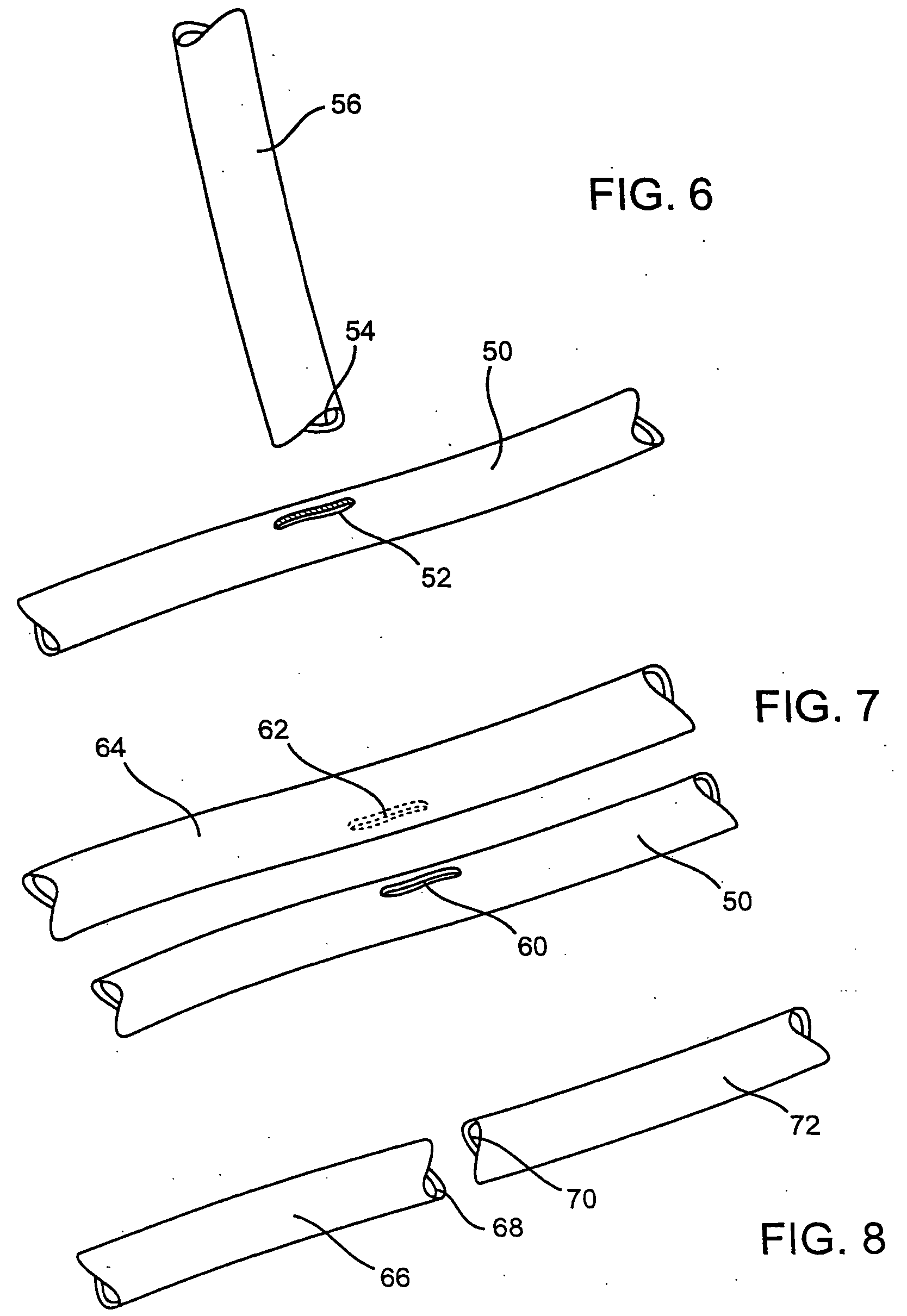

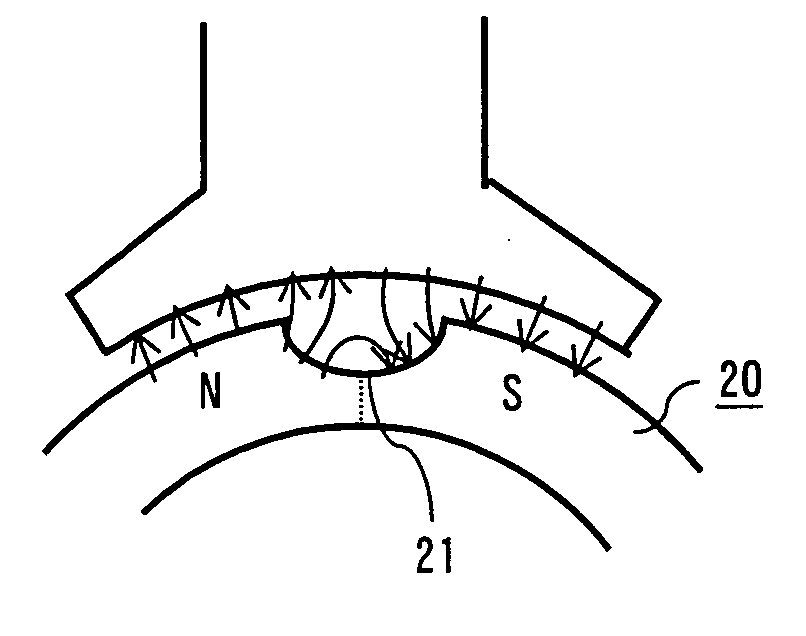

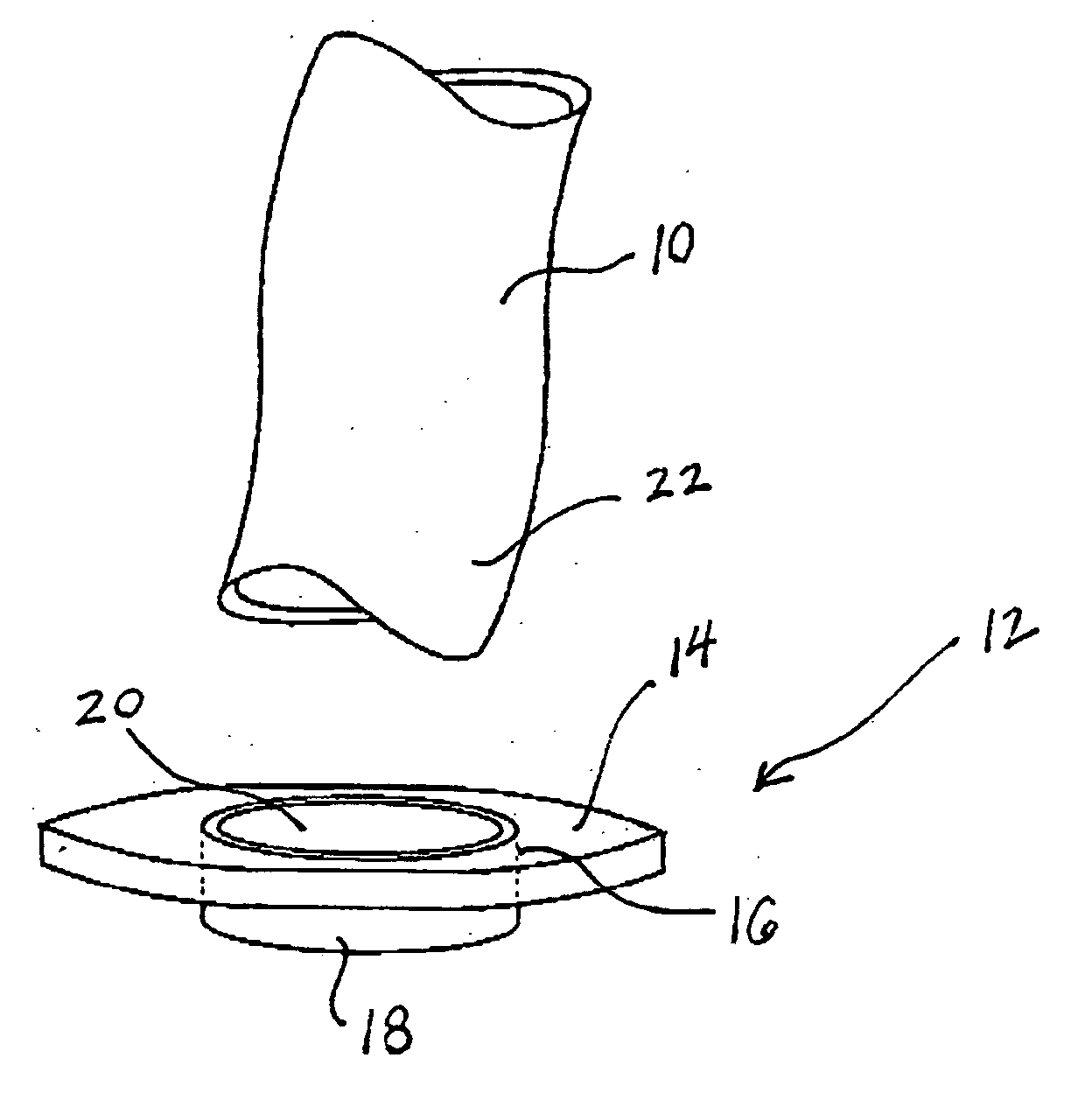

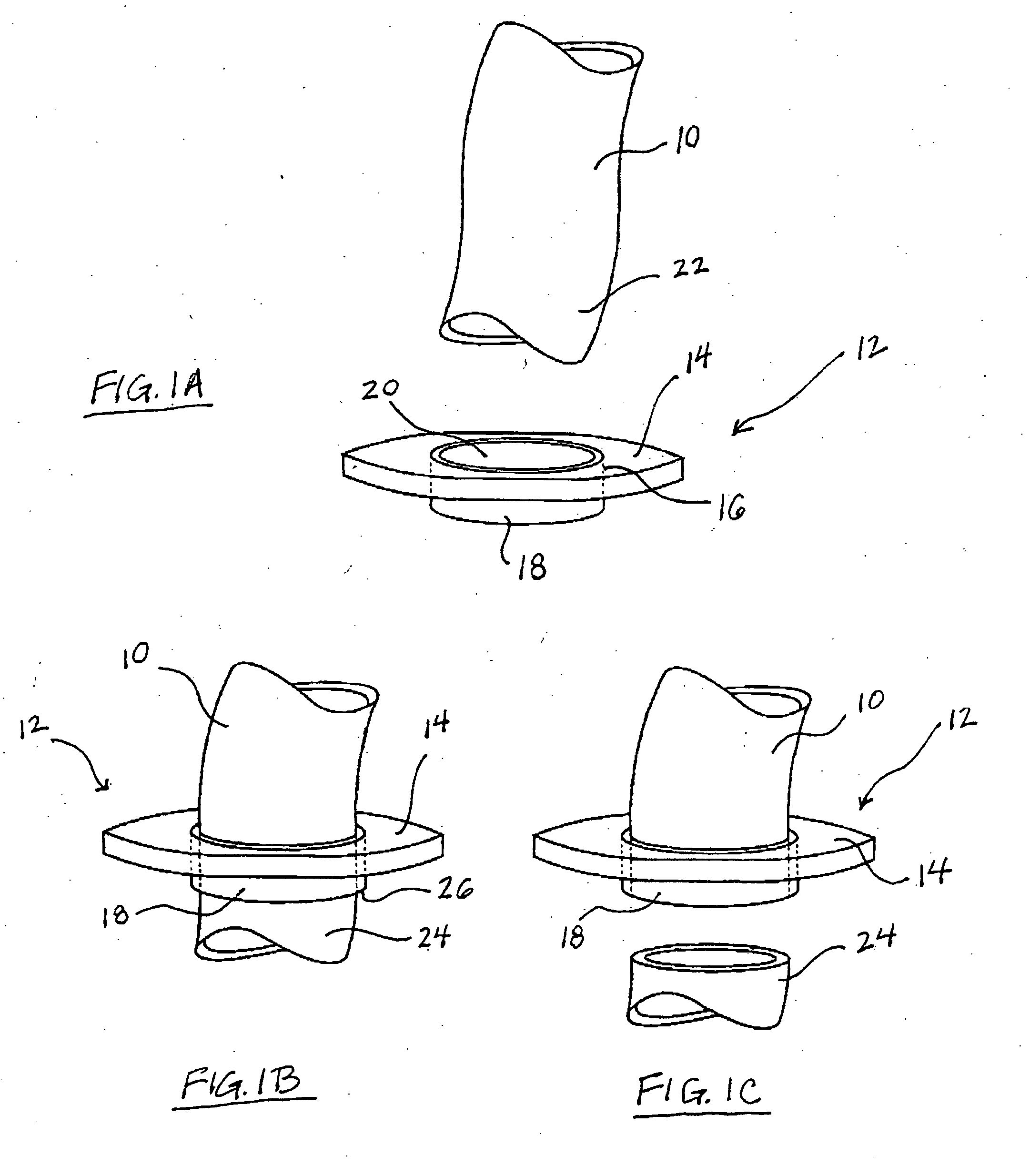

Components, systems and methods for forming anastomoses using magnetism or other coupling means

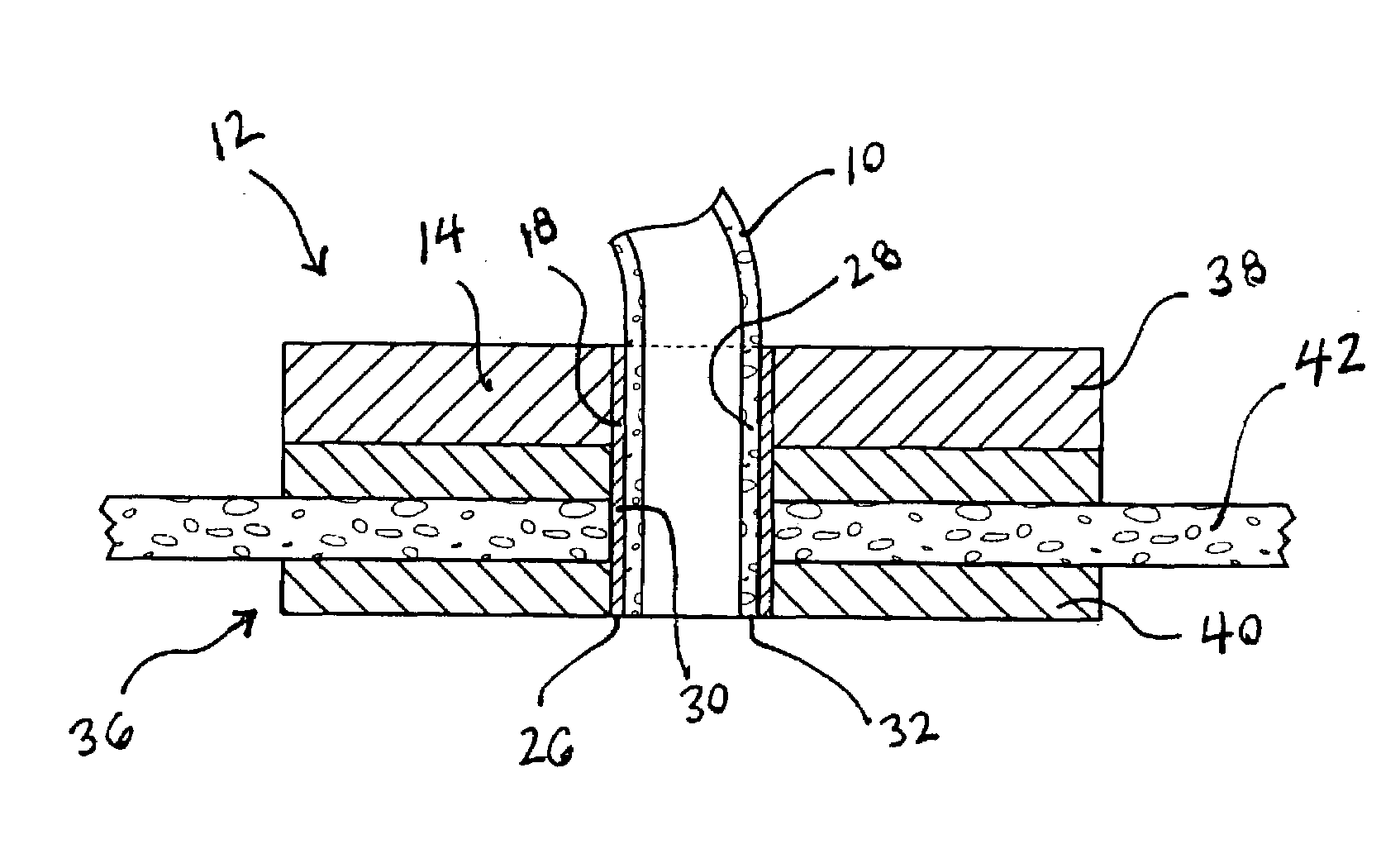

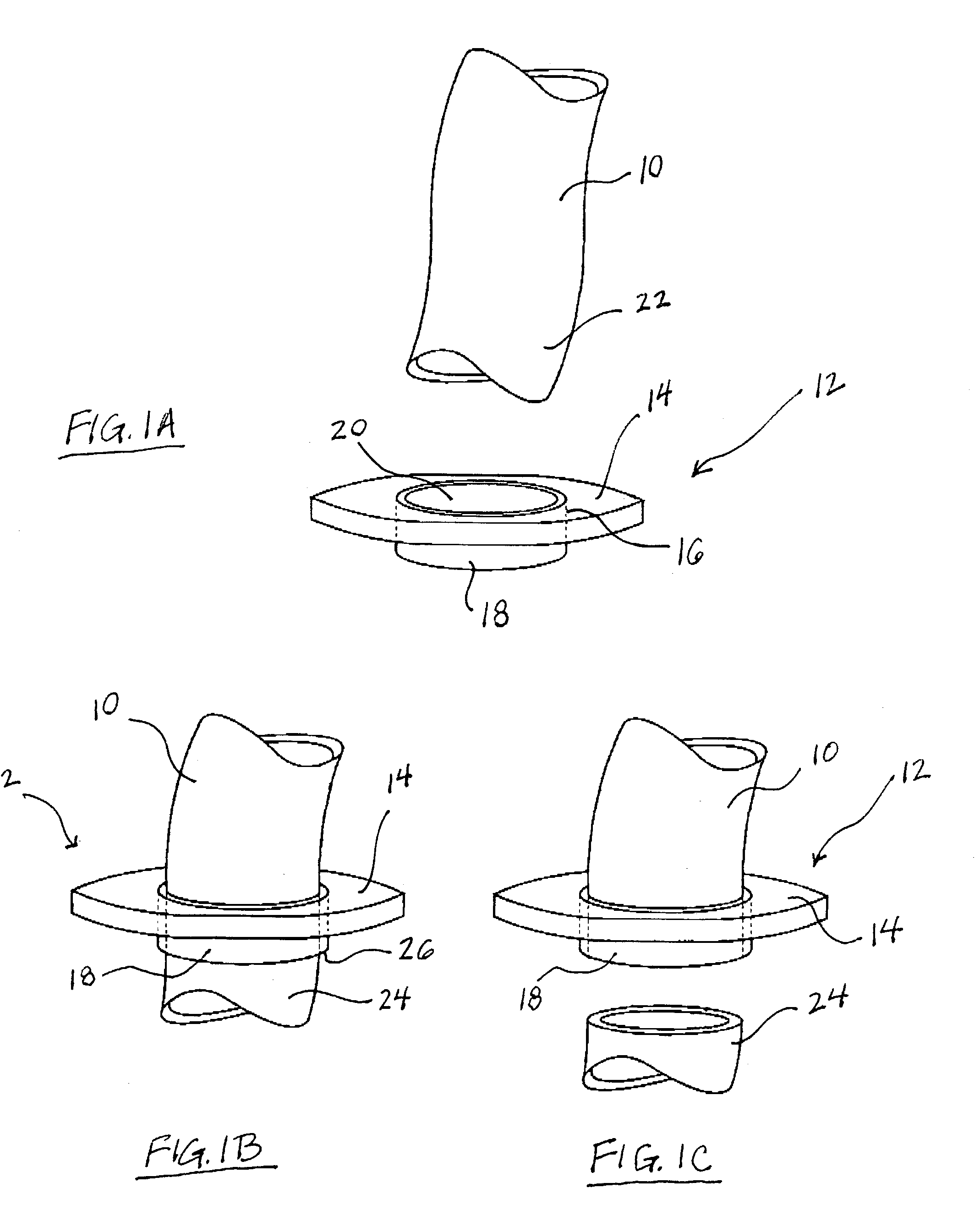

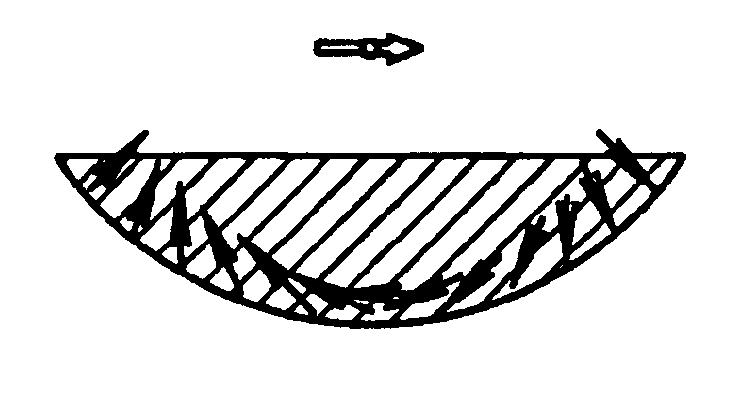

Anastomotic components may be attached to hollow bodies or vessels by magnetic or mechanical force to create an anastomosis, form a port in a vessel, or repair a diseased vessel lumen. Anastomoses are created by coupling a first connection to an end of a vessel and then attracting it to a second connector secured to the side wall of another vessel. The connection between the first and second connectors may be solidly magnetic, solely mechanical, or a combination thereof. Also disclosed are methods and devices for treating diseased vessel lumens, for example abdominal aortic aneurysm. A plurality of docking members is attached to the vessel at solicited positions, and then one or more grafts is secured to the docking members in any suitable manner.

Owner:MEDTRONIC INC

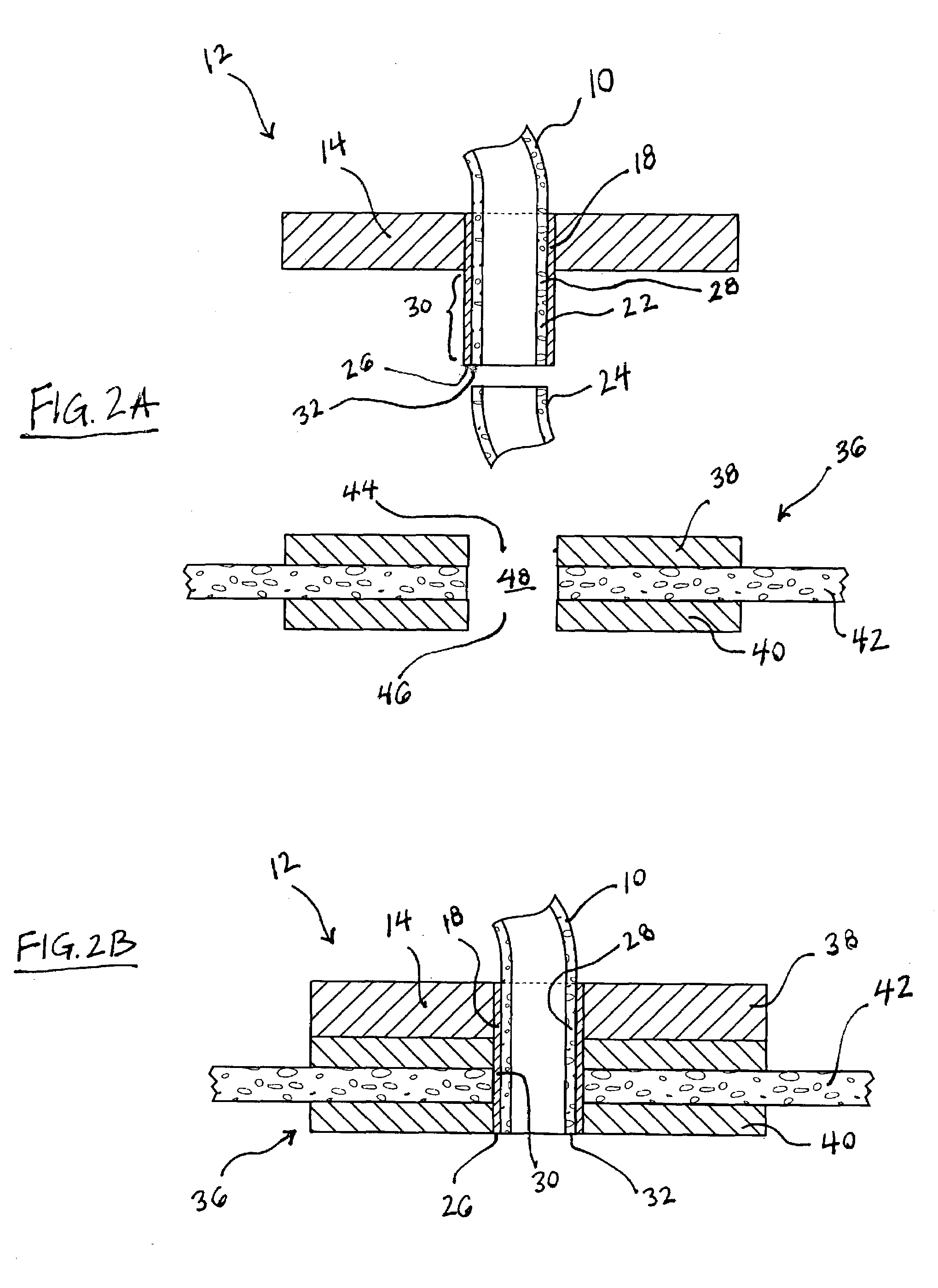

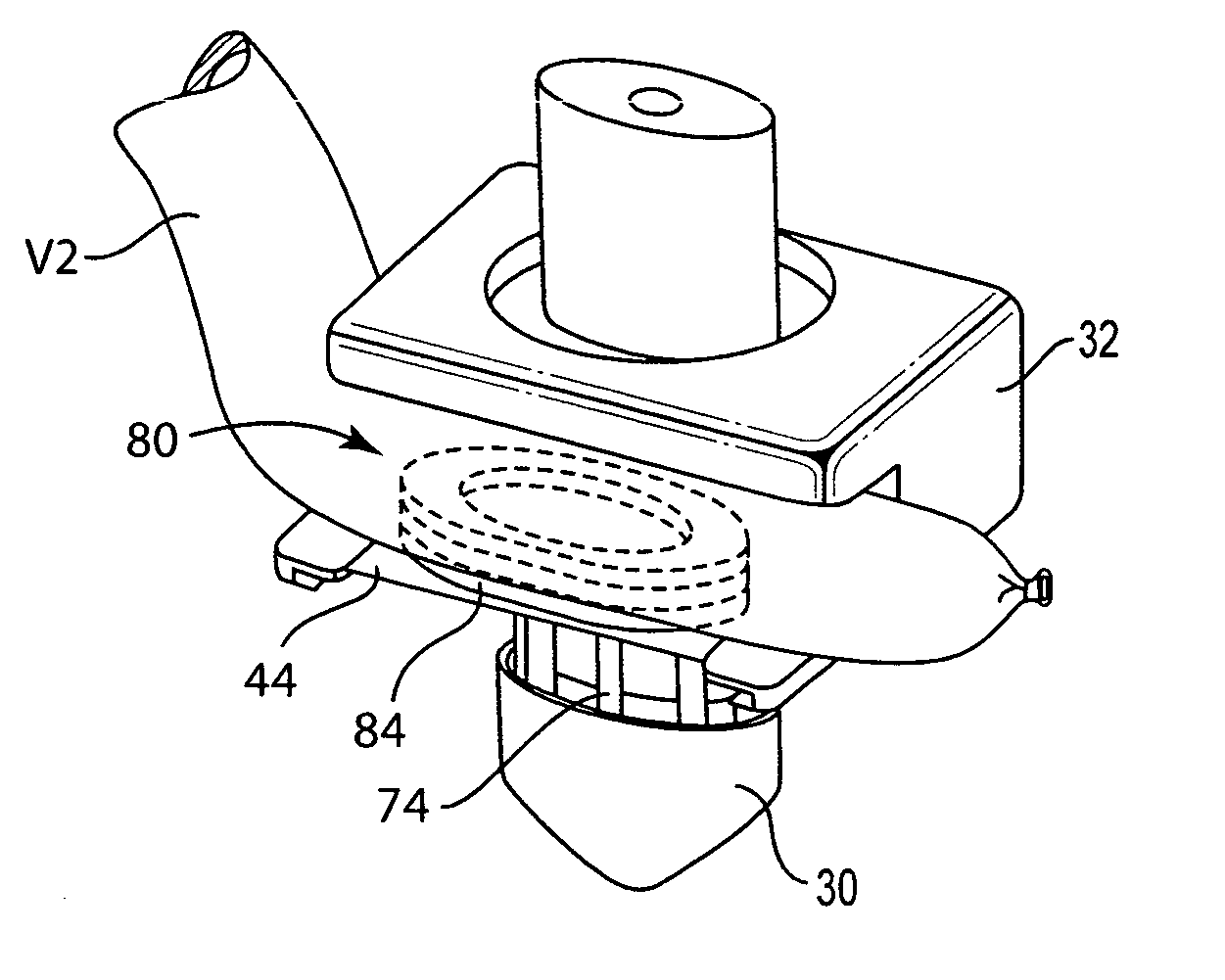

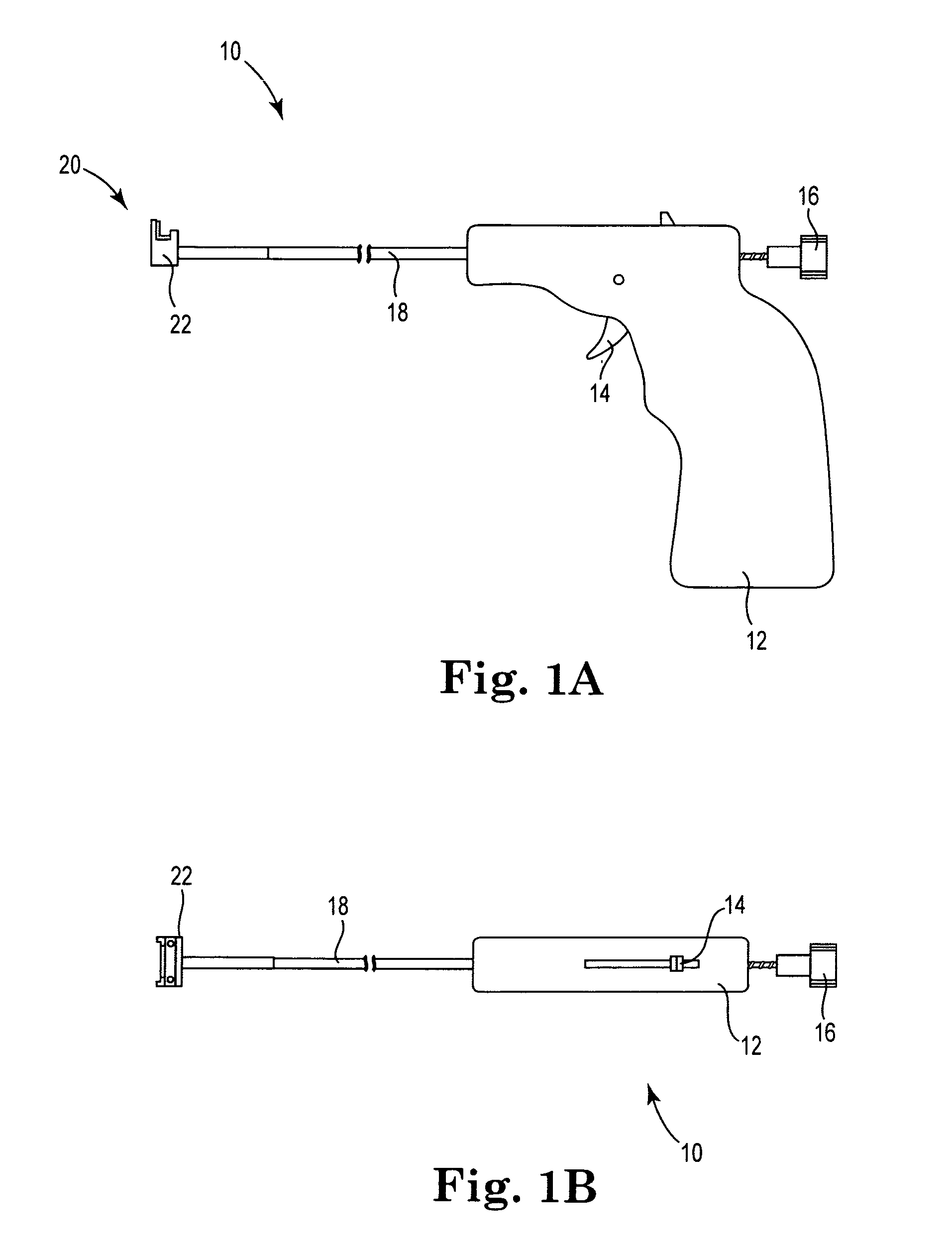

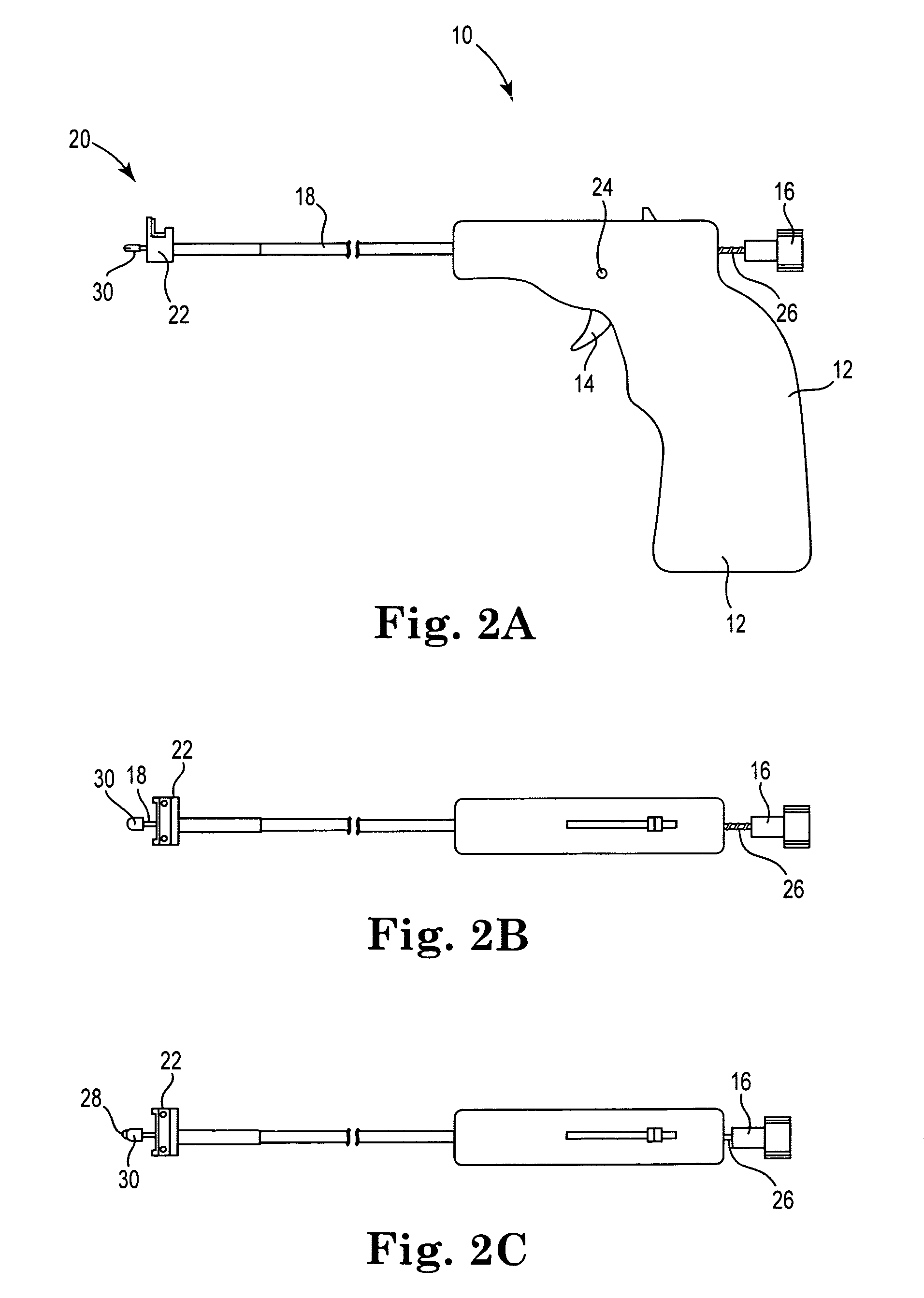

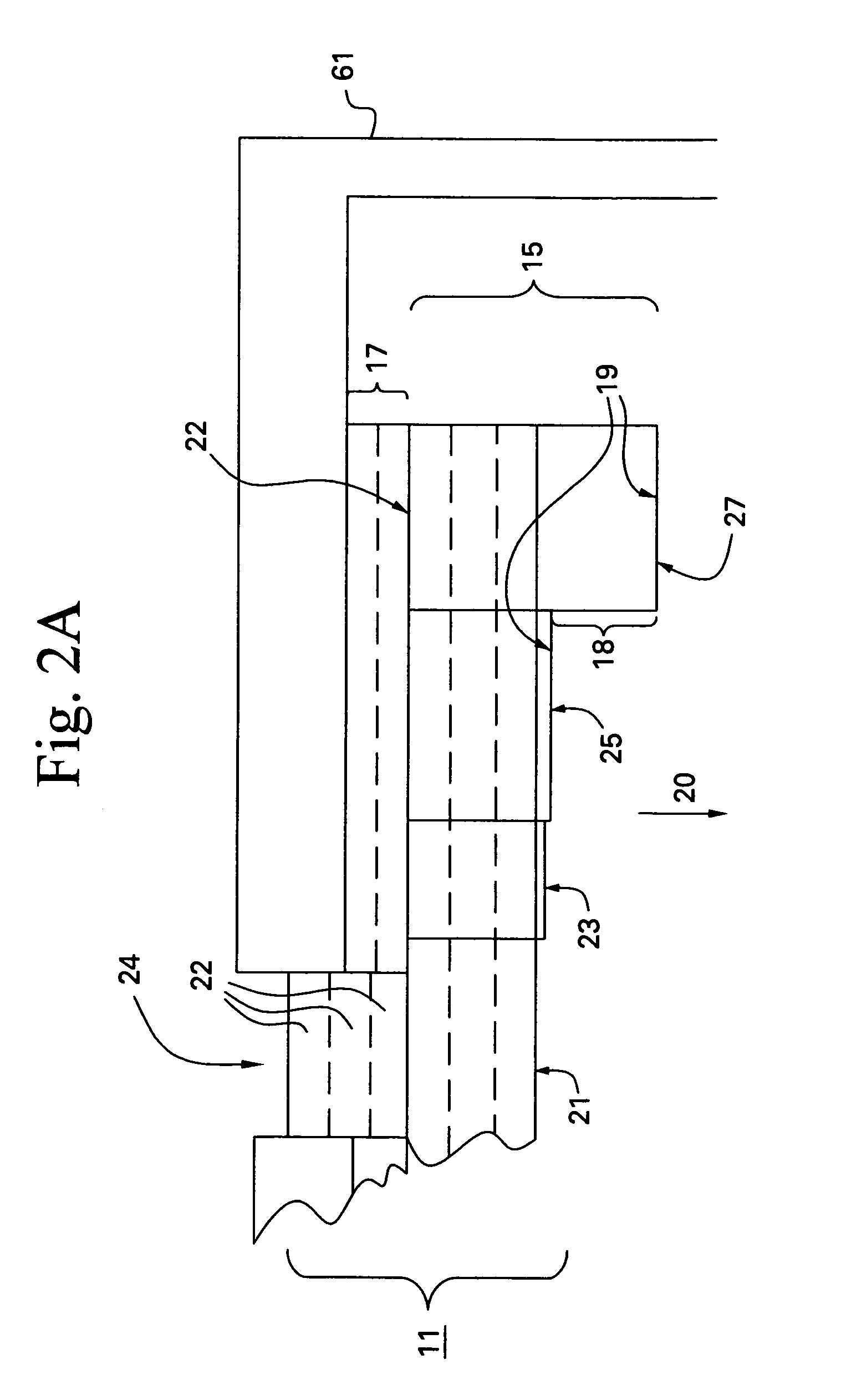

Methods, devices and systems for forming magnetic anastomoses

Methods, devices and systems for forming magnetic anastomoses between two blood vessels. A first anastomotic component is removably supported by the distal end of a delivery device for attachment to a first vessel. The delivery device also supports a second anastomotic component that has been secured to a second blood vessel. The device is operated to secure the first component to the first vessel, couple the second component to the first component, and then release the components to complete the anastomosis. A robotic anastomosis system includes several robotic instruments that may be positioned through ports in a patient, used to secure an anastomotic component to a vessel, and then used to magnetically couple the components. Delivery devices for deploying magnetic anastomotic components include an actuator that uses magnetic repulsion to move the components into engagement with the inner and outer surfaces of the vessel wall. The anastomotic components are secured to the vessel wall by magnetic force and in addition may be secured by mechanical attachment.

Owner:MEDTRONIC INC

Methods and devices using magnetic force to form an anastomosis between hollow bodies

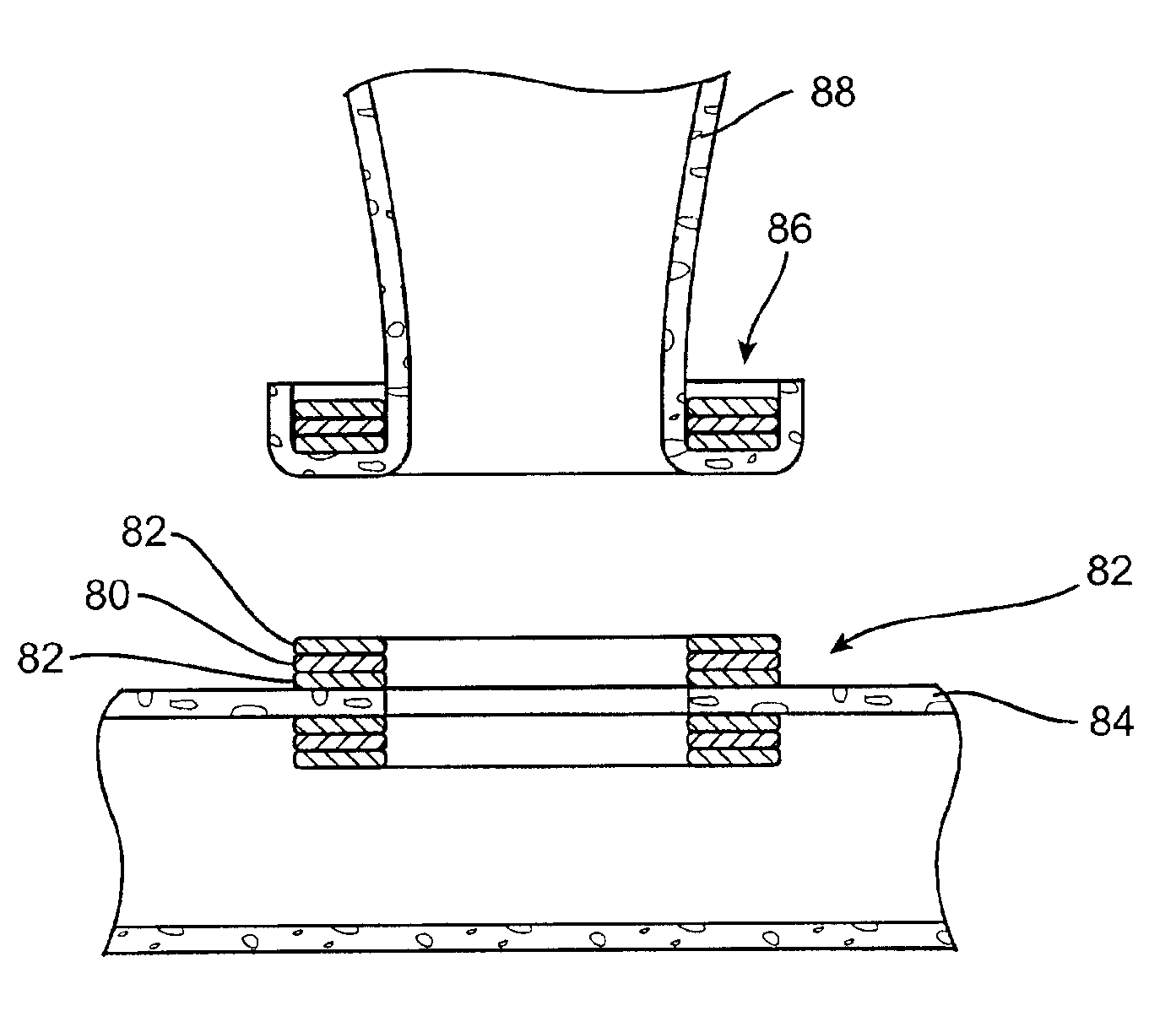

Methods and devices for forming an anastomosis between hollow bodies utilizes magnetic force to couple anastomotic securing components and create a fluid-tight connection between the lumens of the hollow bodies. End-to-side, side-to-side and end-to-end anastomoses can be created without using suture or any other type of mechanical fasteners, although any such attachment means may be used in conjunction with the magnetic attachment. The securing components have magnetic, ferromagnetic or electromagnetic properties and may include one or more materials, for example, magnetic and nonmagnetic materials arranged in a laminated structure. The system of anastomotic securing components may be used in many different applications including the treatment of cardiovascular disease, peripheral vascular disease, forming AV shunts for dialysis patients, etc., and may be sized and configured for forming an anastomosis to a specific hollow body, for example, a coronary artery or the aorta.

Owner:MEDTRONIC INC

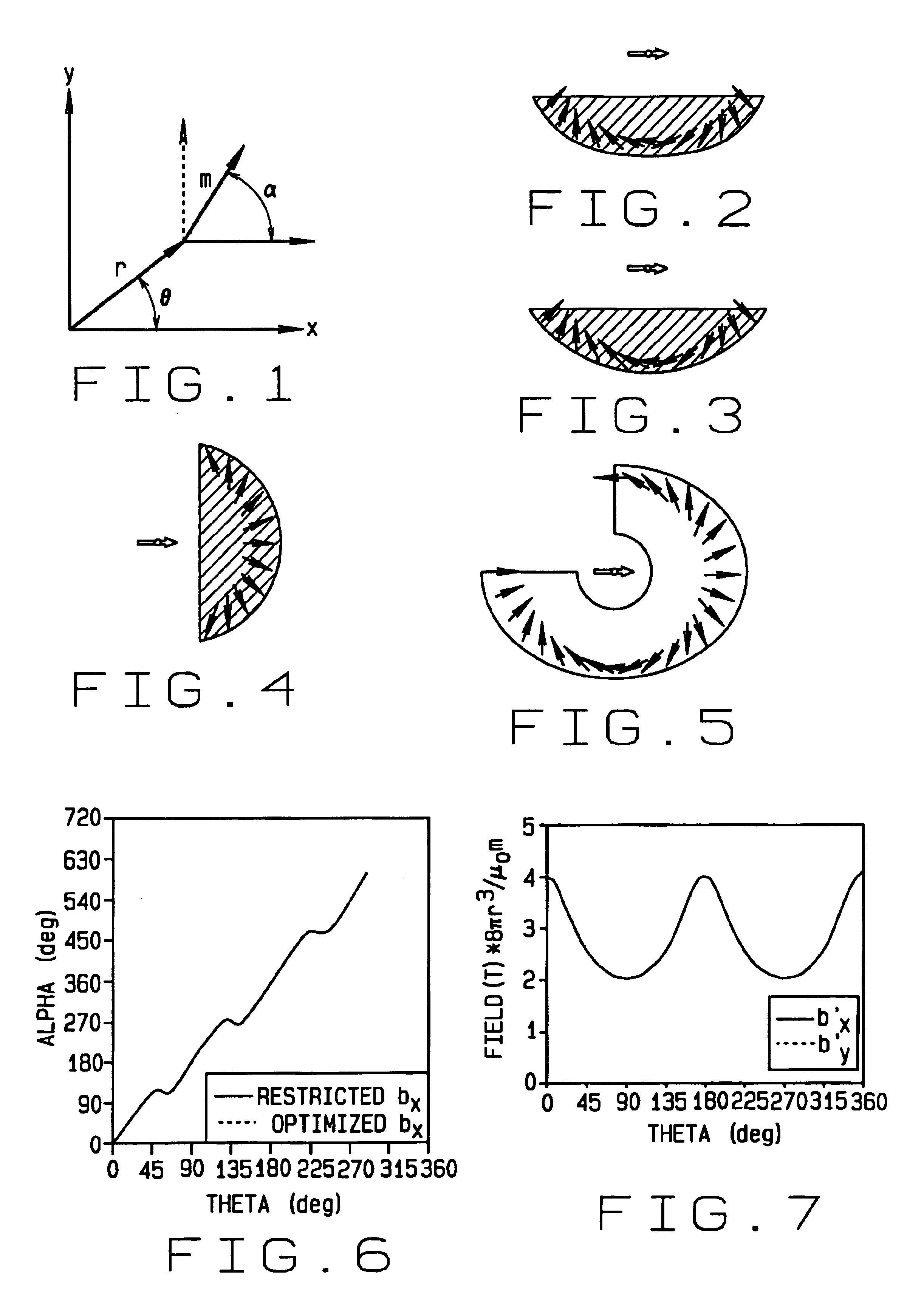

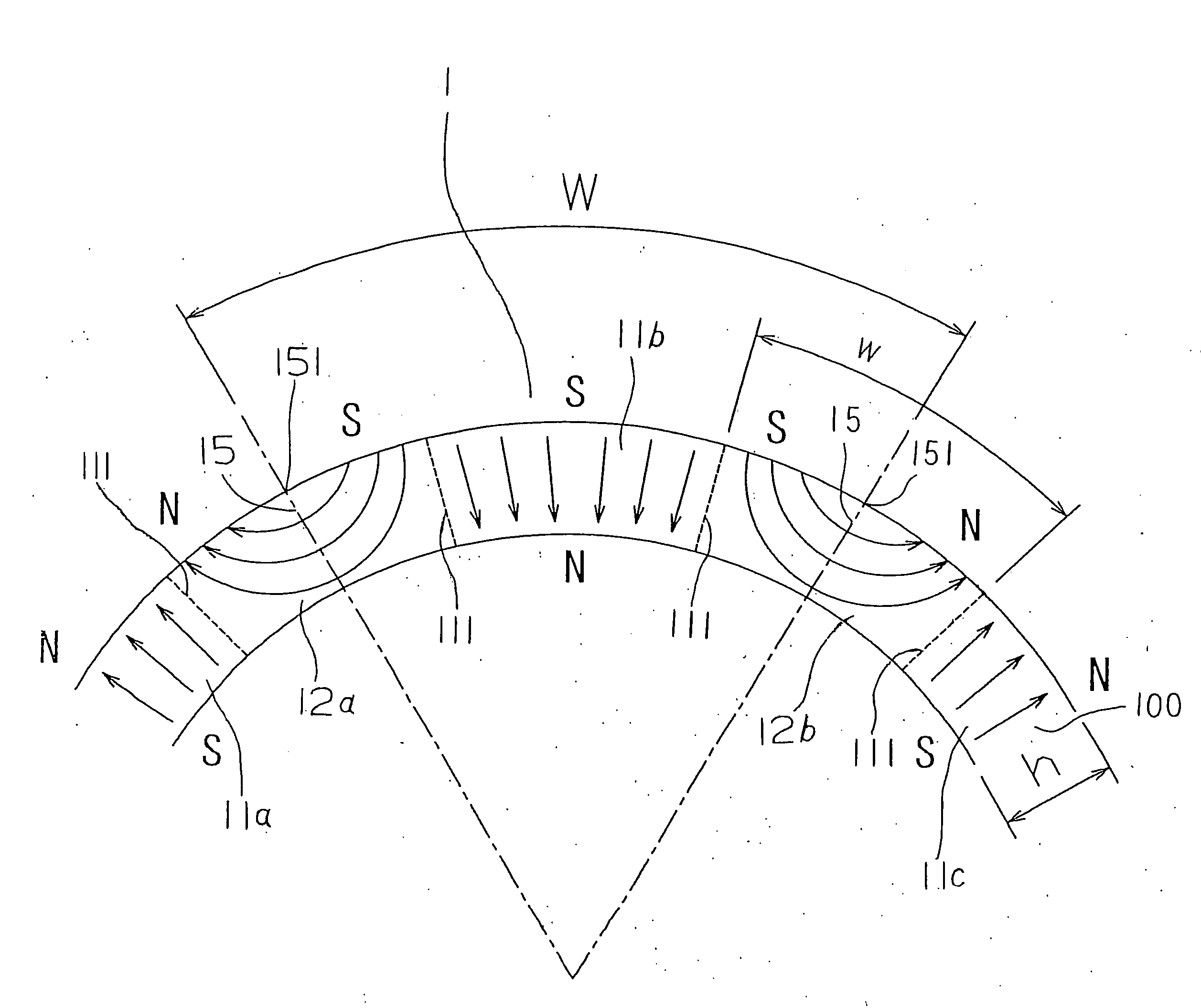

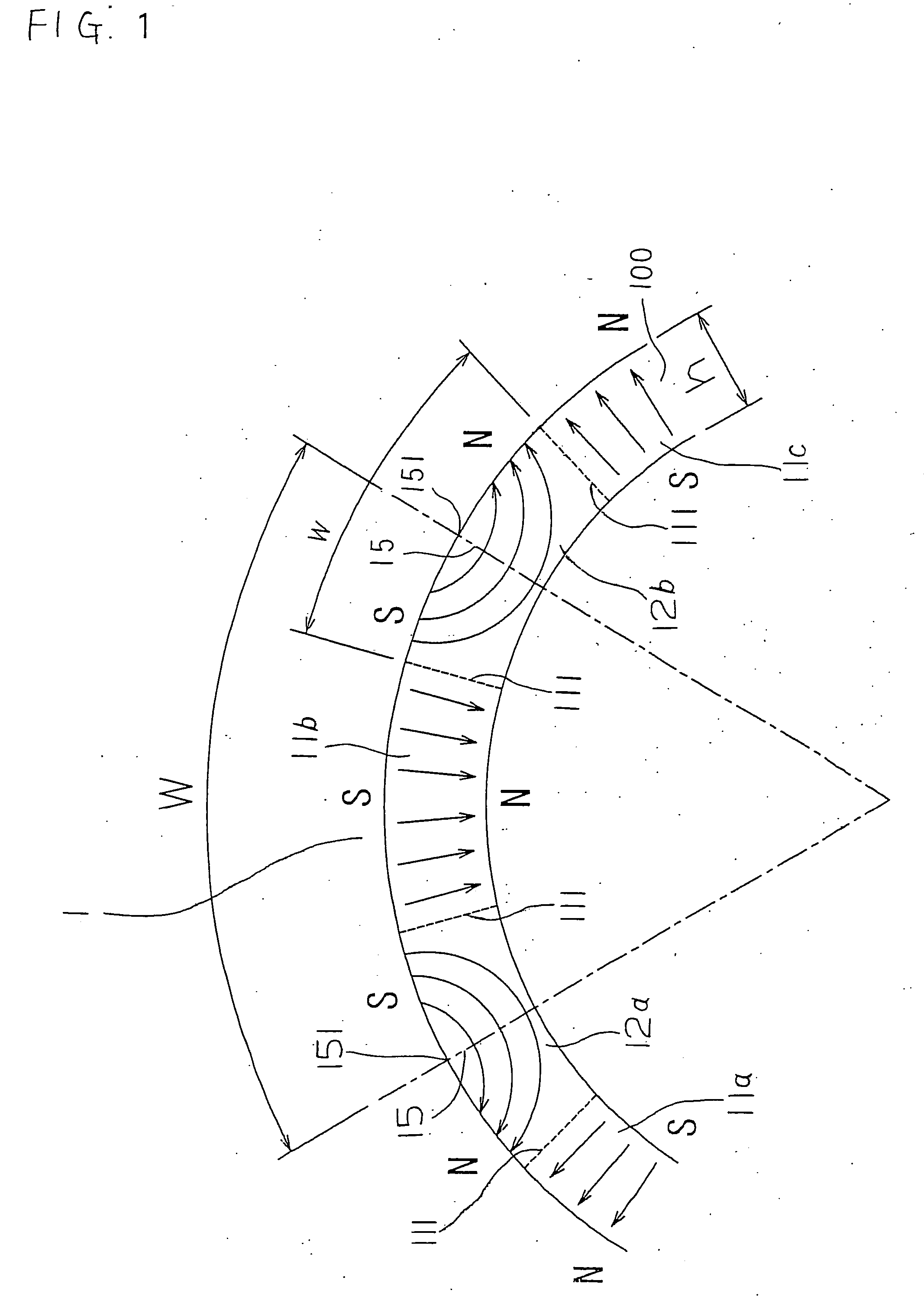

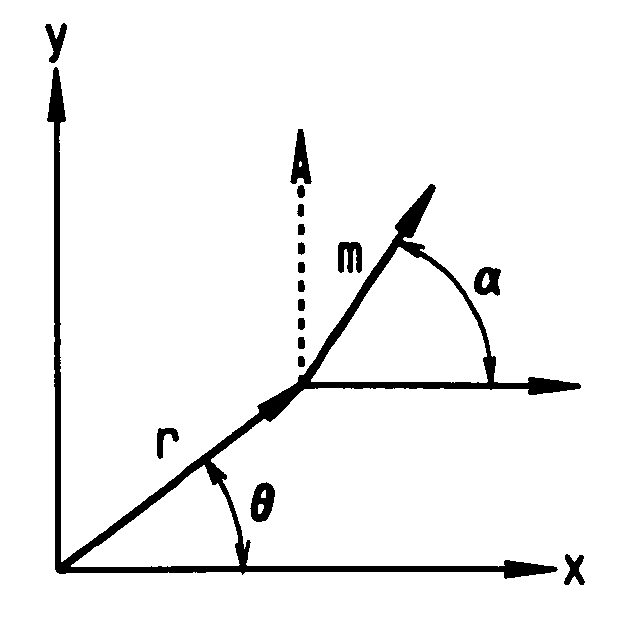

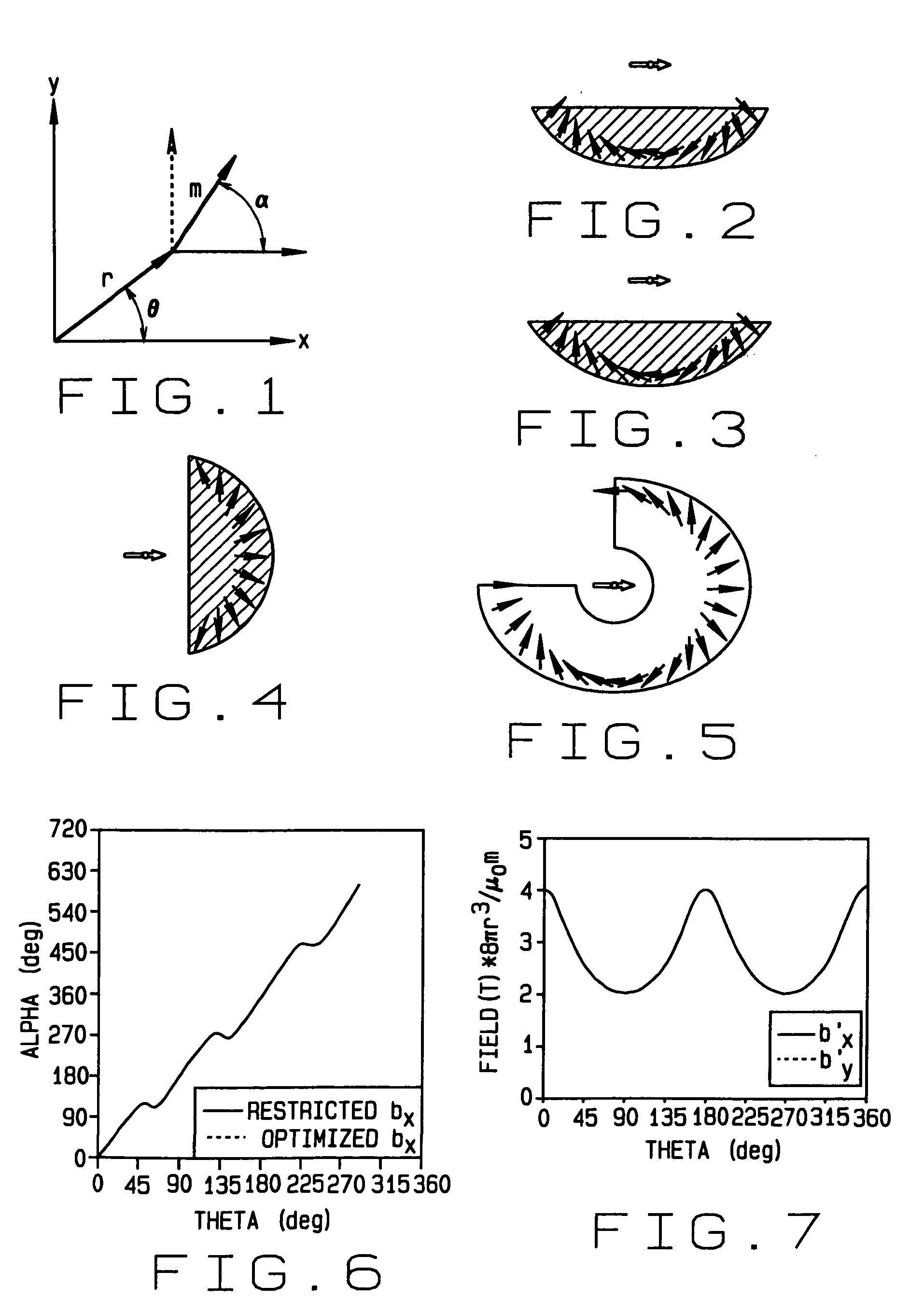

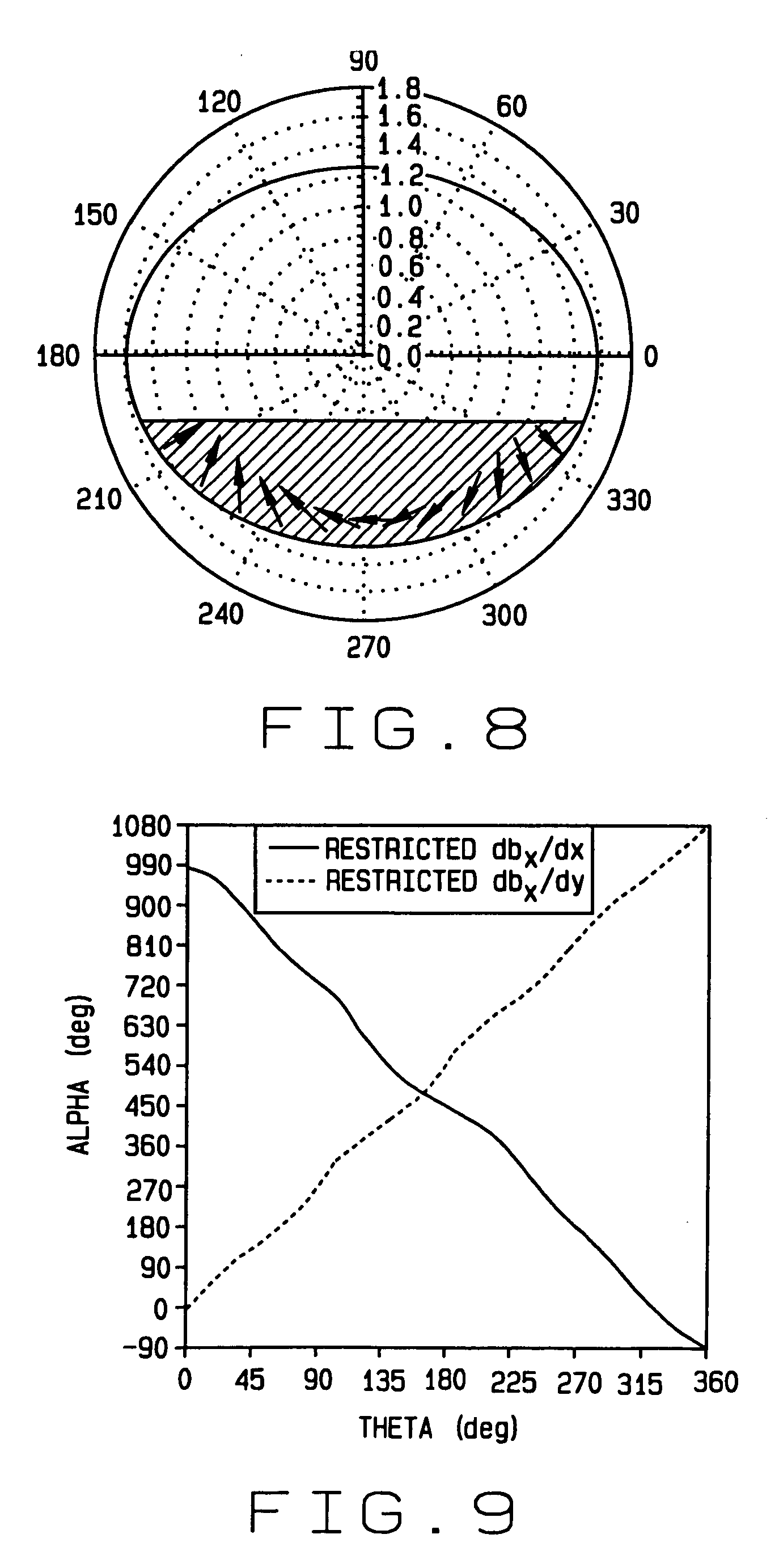

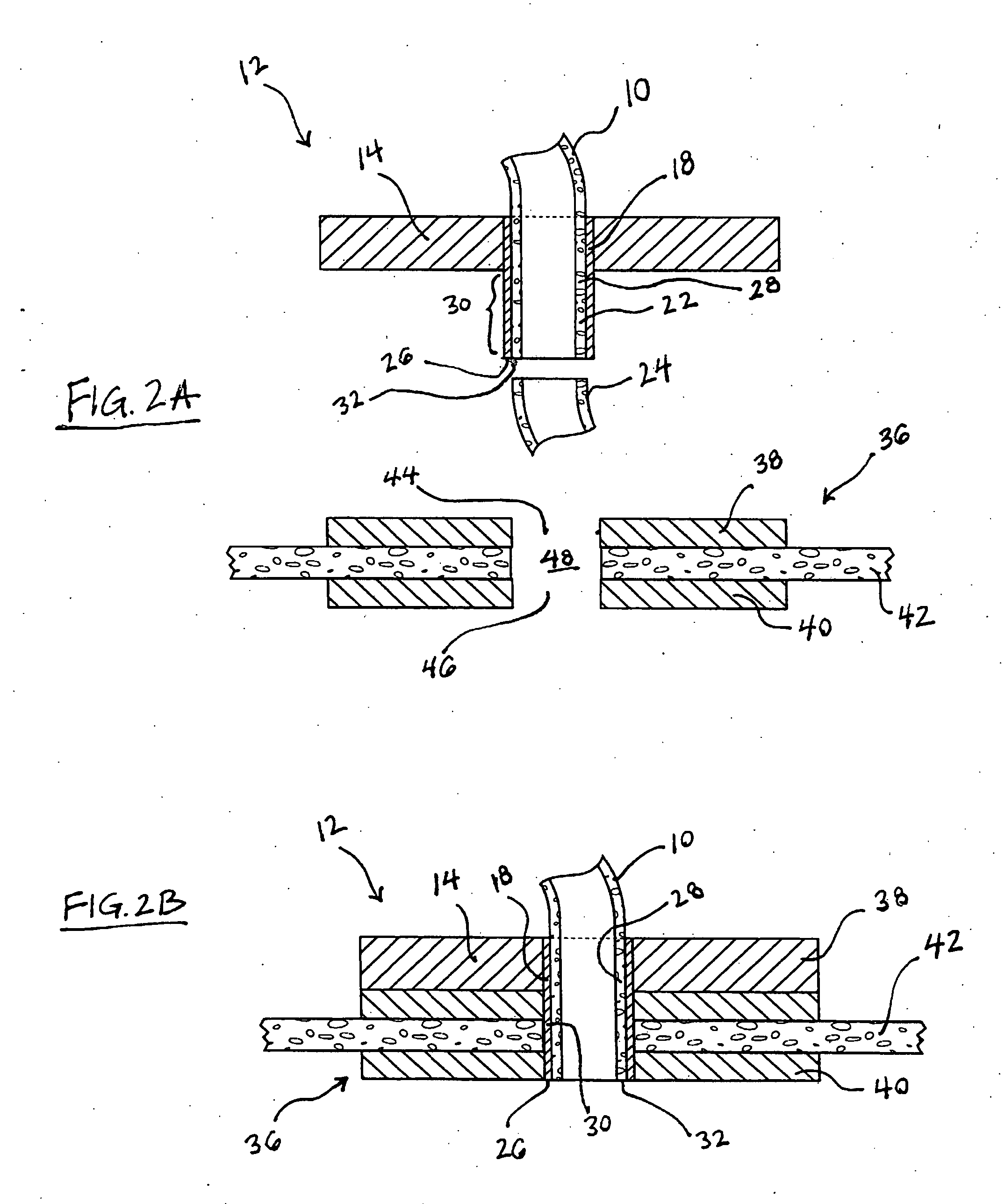

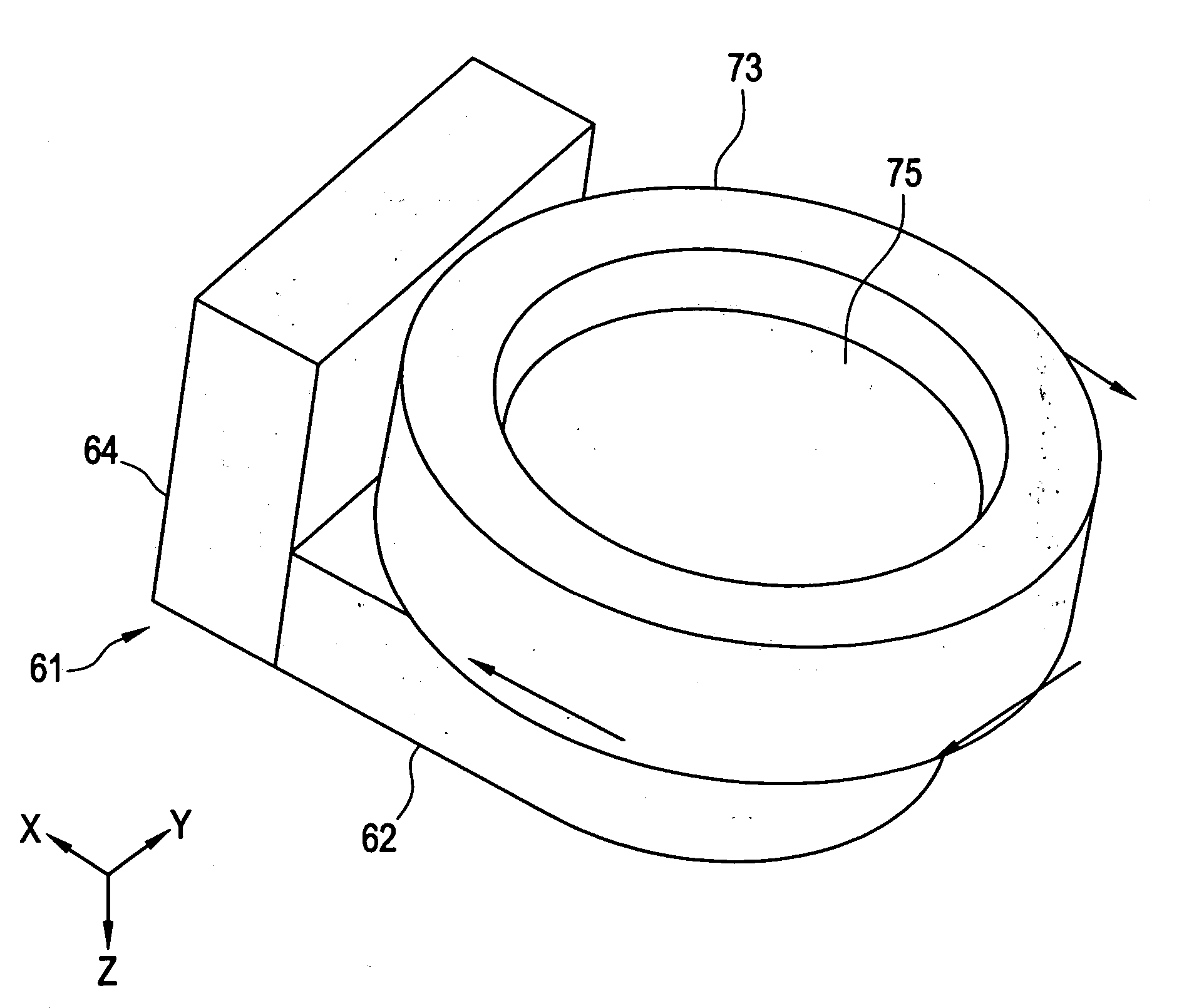

Magnets with varying magnetization direction and method of making such magnets

InactiveUS6940379B2Improve magnetic propertiesSmall sizePermanent magnetsDiagnostic recording/measuringMagnetizationTransverse magnetic field

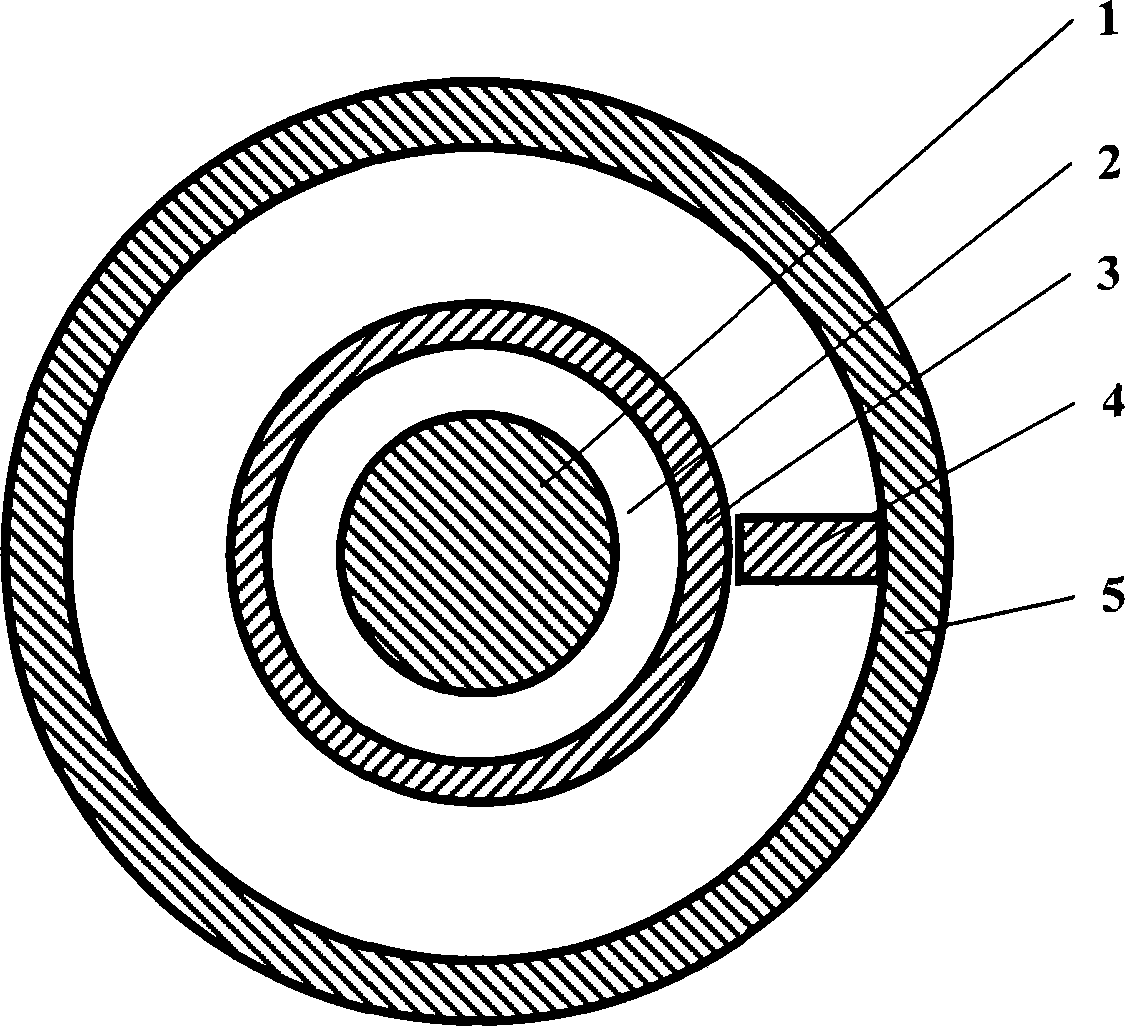

A permanent magnet in which the magnetization direction varies with location to optimize or restrict a magnetic field property in a selected direction at a selected point. The magnetic field property may be, for example, the transverse magnetic field, axial magnetic field, axial gradient of the transverse magnetic field, transverse gradient of the transverse magnetic field, axis gradient of the axial magnetic field, transverse gradient of the axial magnetic field, the product of the transverse magnetic field and the transverse gradient of the transverse magnetic field, the product of the transverse magnetic field and the axial gradient of the transverse magnetic field, the product of the axial magnetic field and the transverse gradient of the axial magnetic field, or the product of the axial magnetic field and the axial gradient of the axial magnetic field. The magnet may be formed of one or more segments in which the magnetization direction varies smoothly and continuously, or the magnet may be formed of a plurality of segments in which the magnetization direction is constant. A method of making and using such magnets is also disclosed.

Owner:STEREOTAXIS

Devices and methods for forming magnetic anastomoses and ports in vessels

Owner:MEDTRONIC INC

Copper plating solution and method for copper plating

InactiveCN1514889AImprove bindingReduce adverse effectsLiquid/solution decomposition chemical coatingPermanent magnet manufactureAcetic acidEthylenediamine

A copper plating solution which comprises 0.03 mol / L to 0.5 mol / L of copper sulfate, 0.05 mol / L to 0.7 mol / L of ethylenetetraacetic acid and 0.02 mol / L to 0.3 mol / L of a sulfite salt, and has a pH adjusted to 5.0 to 8.5; and a method for copper plating which comprises using the copper plating solution. The method for copper plating allows a copper plating film being uniform and excellent in adhesion to be formed with stability on the surface of an article to be plated.

Owner:HITACHI METALS LTD

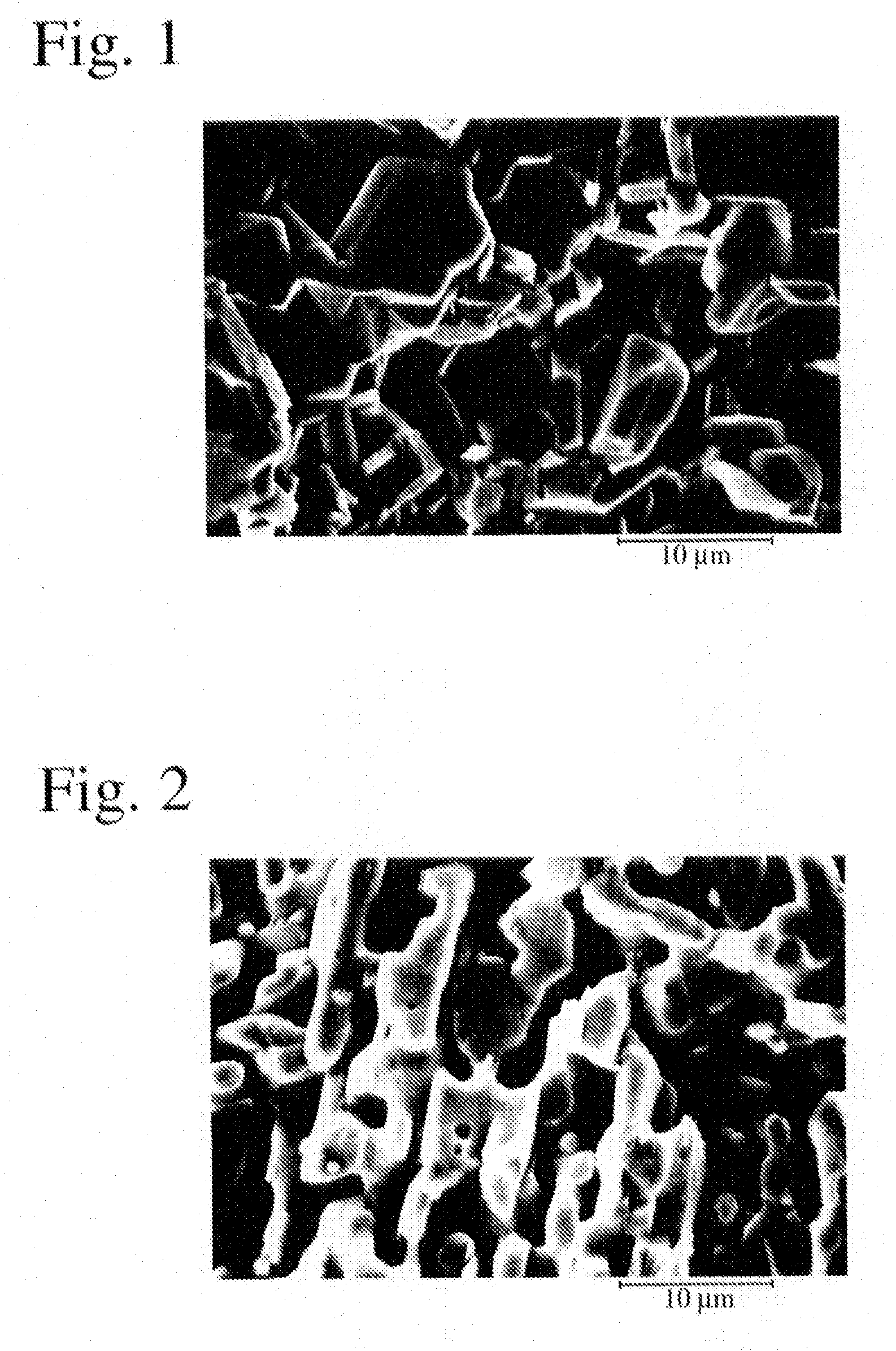

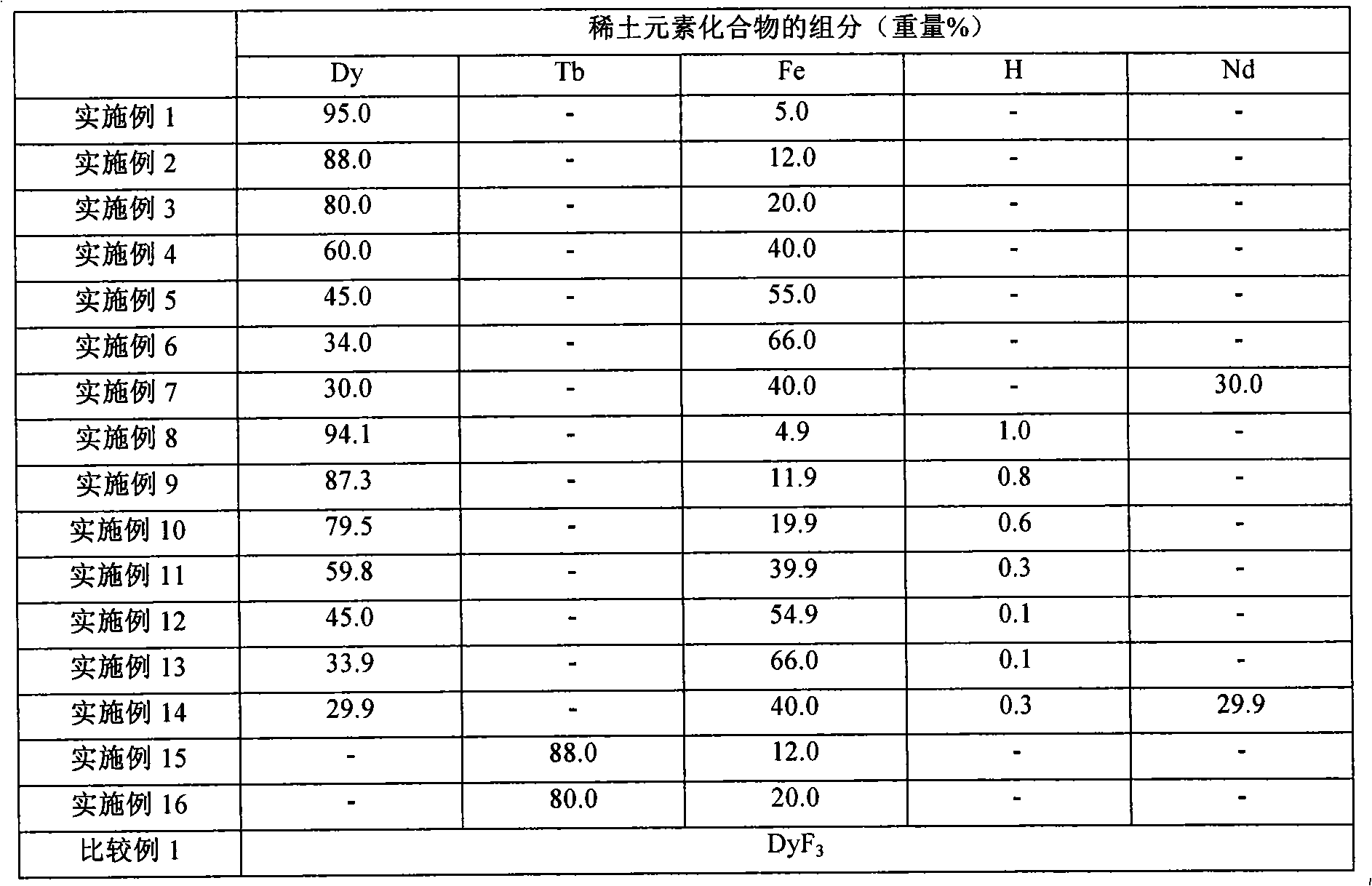

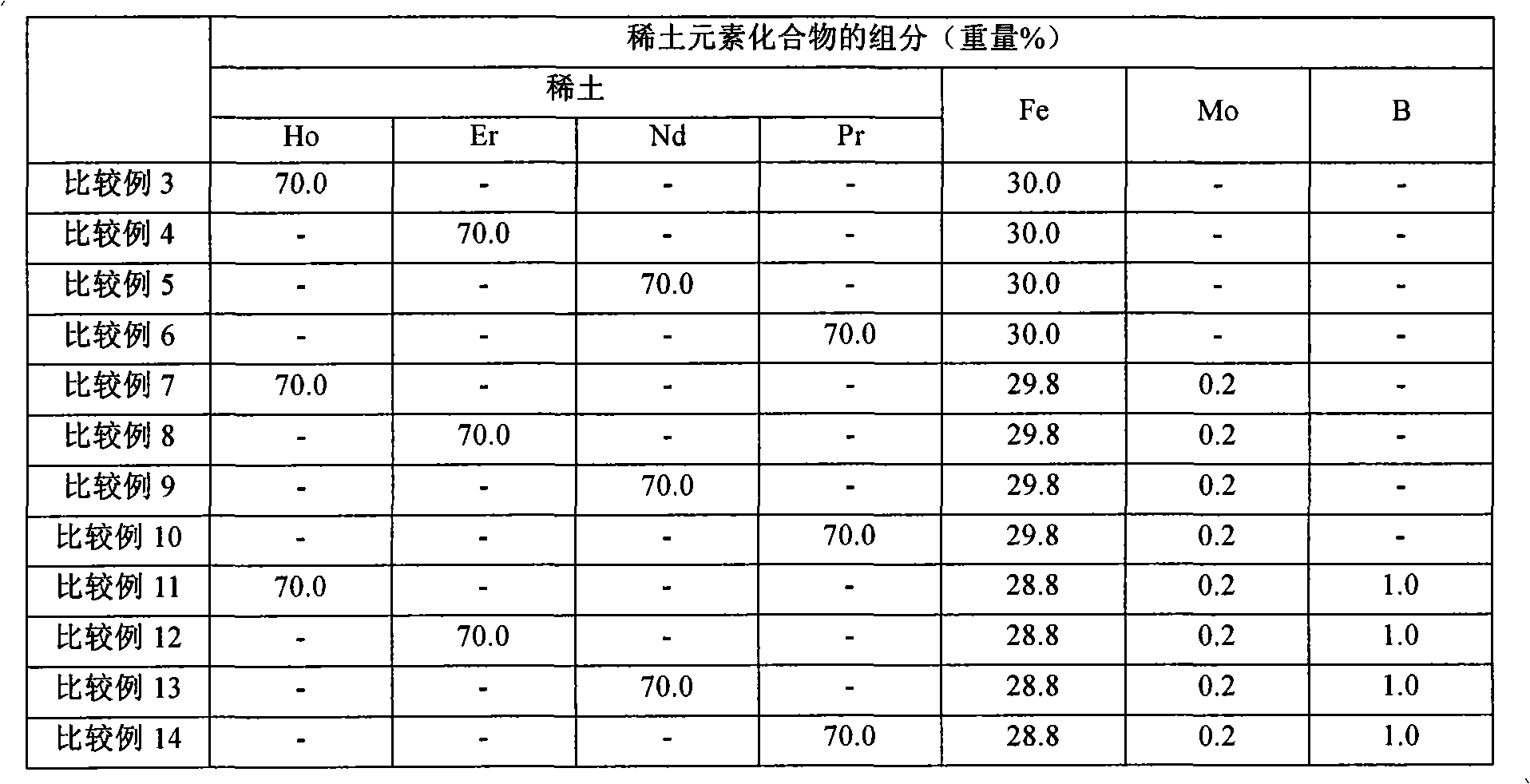

Method for preparing rare earth permanent magnet material

ActiveUS20070240789A1Improve performanceMinimizing contentInorganic material magnetismPermanent magnet manufactureRare-earth elementSintered magnets

A rare earth permanent magnet material is prepared by covering a sintered magnet body of R1—Fe—B composition wherein R1 is a rare earth element, with a powder comprising at least 30% by weight of an alloy of R2aTbMcAdHe wherein R2 is a rare earth element, T is Fe and / or Co, and M is Al, Cu or the like, and having an average particle size up to 100 μm, and heat treating the powder-covered magnet body at a suitable temperature, for causing R2, T, M and A in the powder to be absorbed in the magnet body.

Owner:SHIN ETSU CHEM IND CO LTD

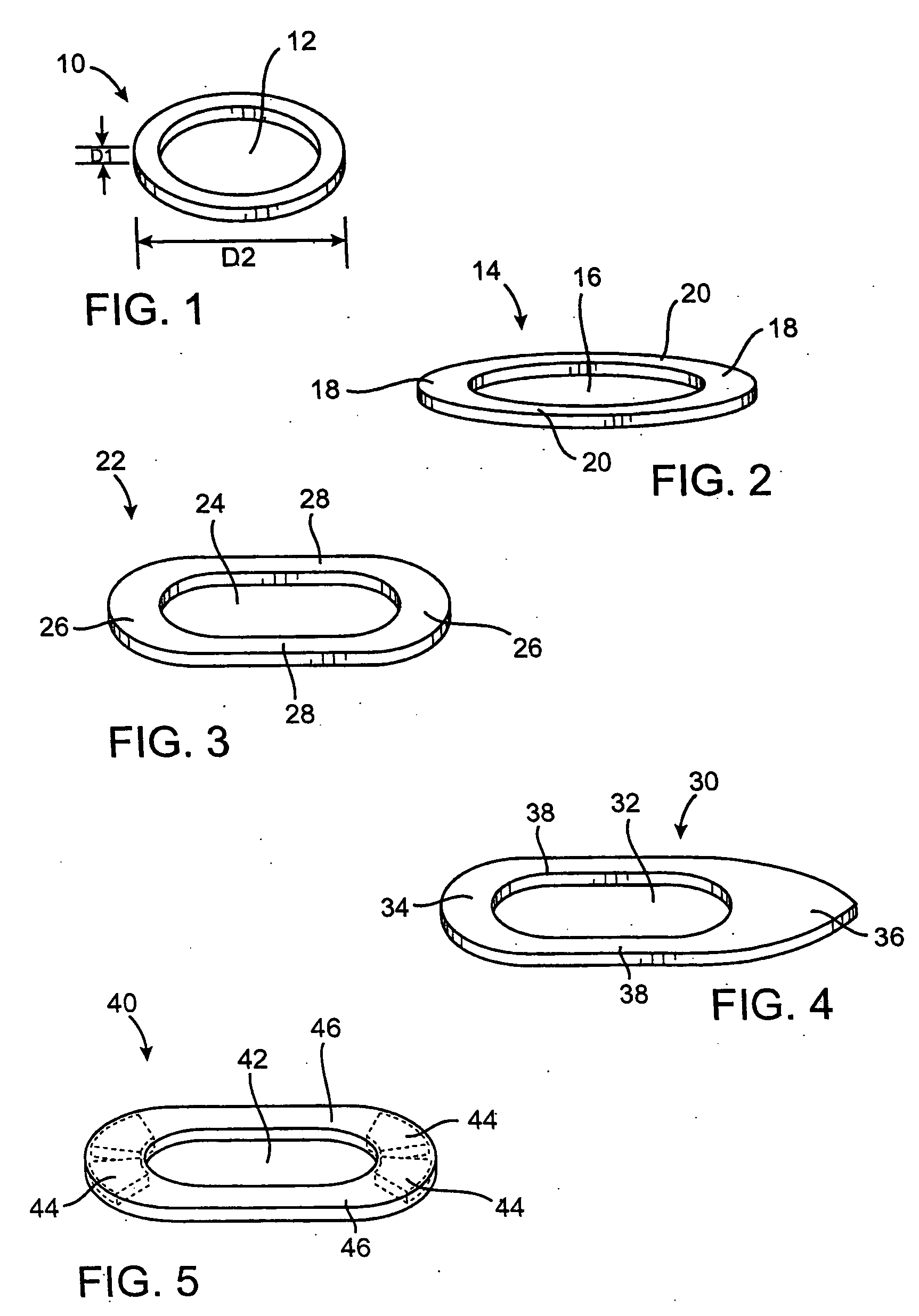

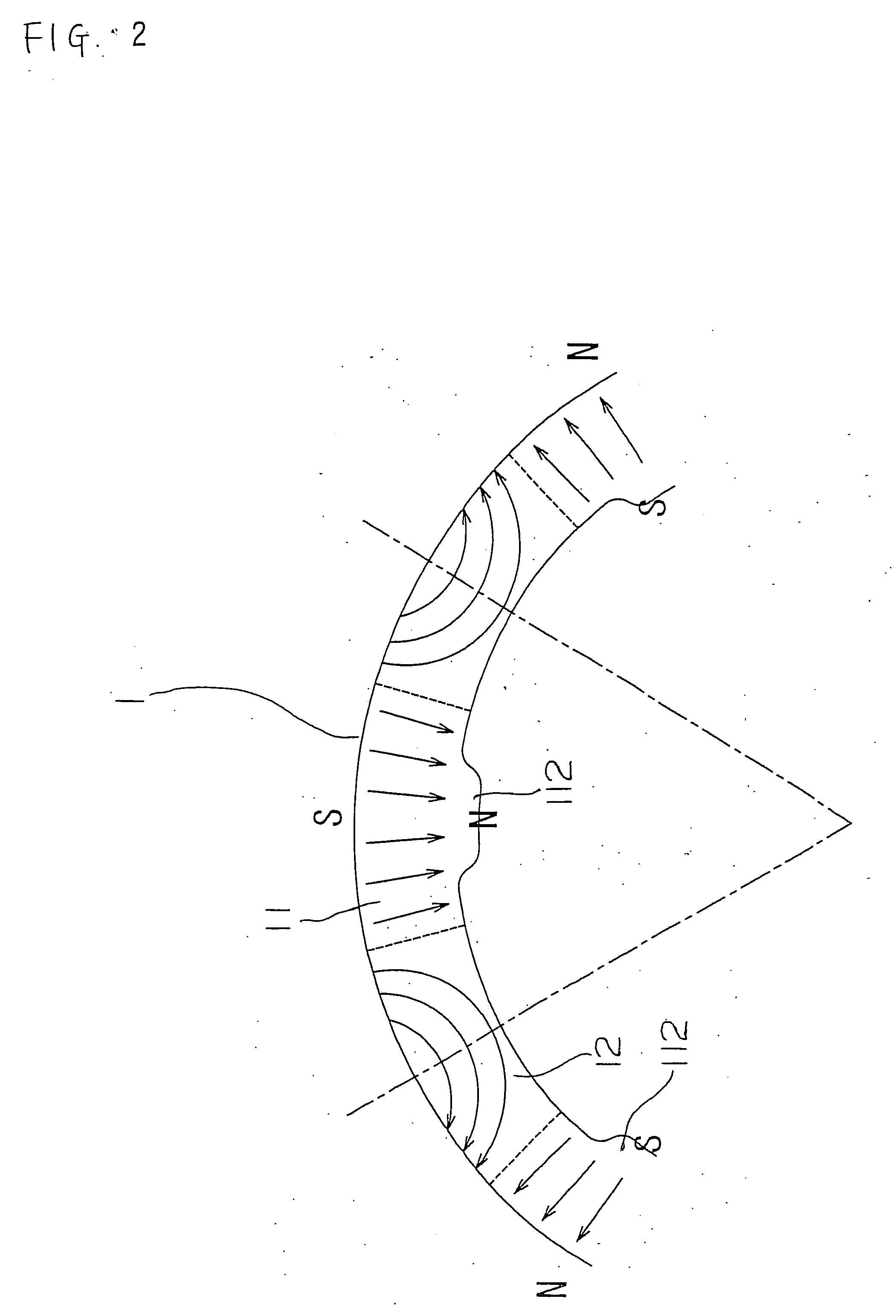

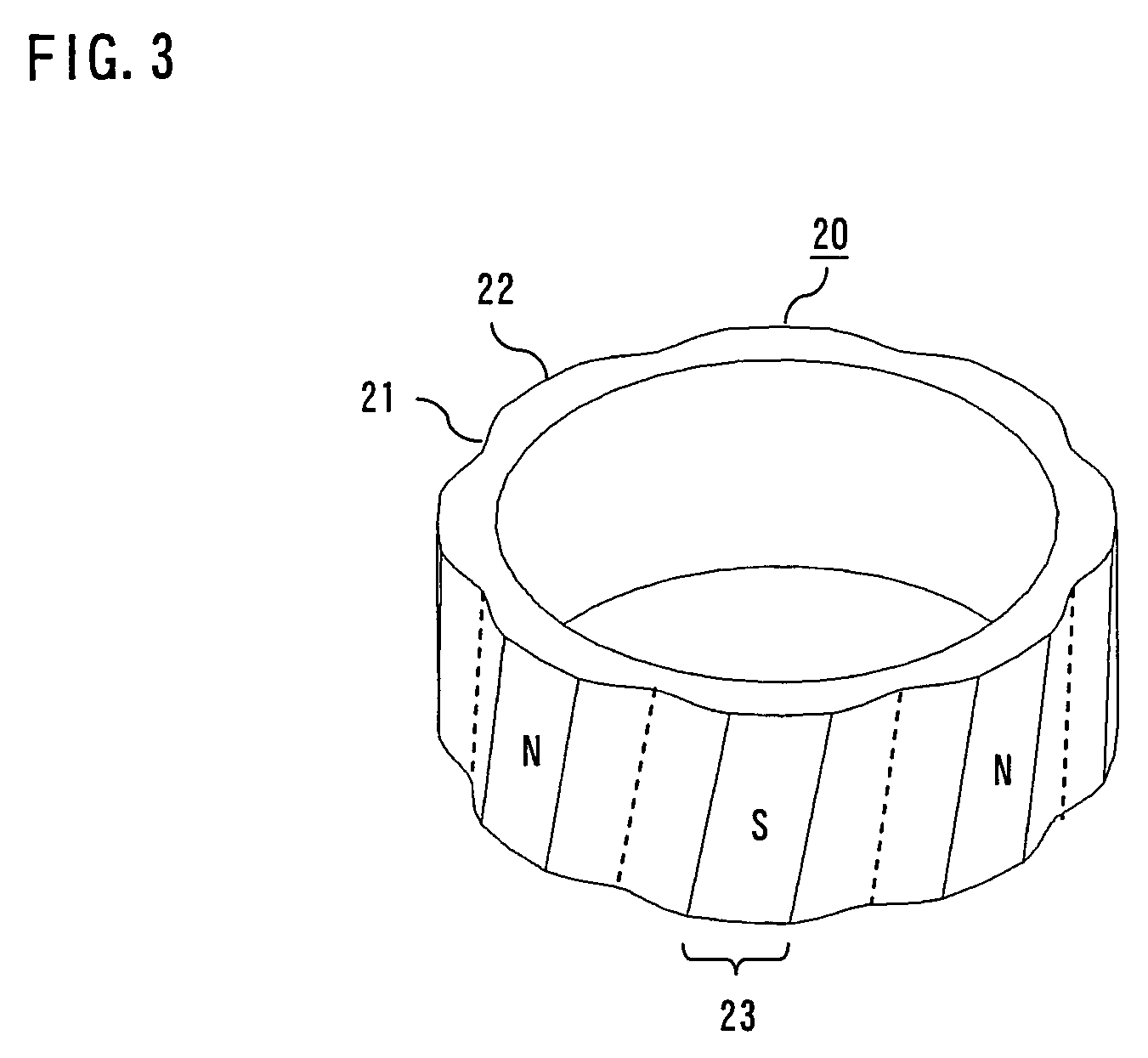

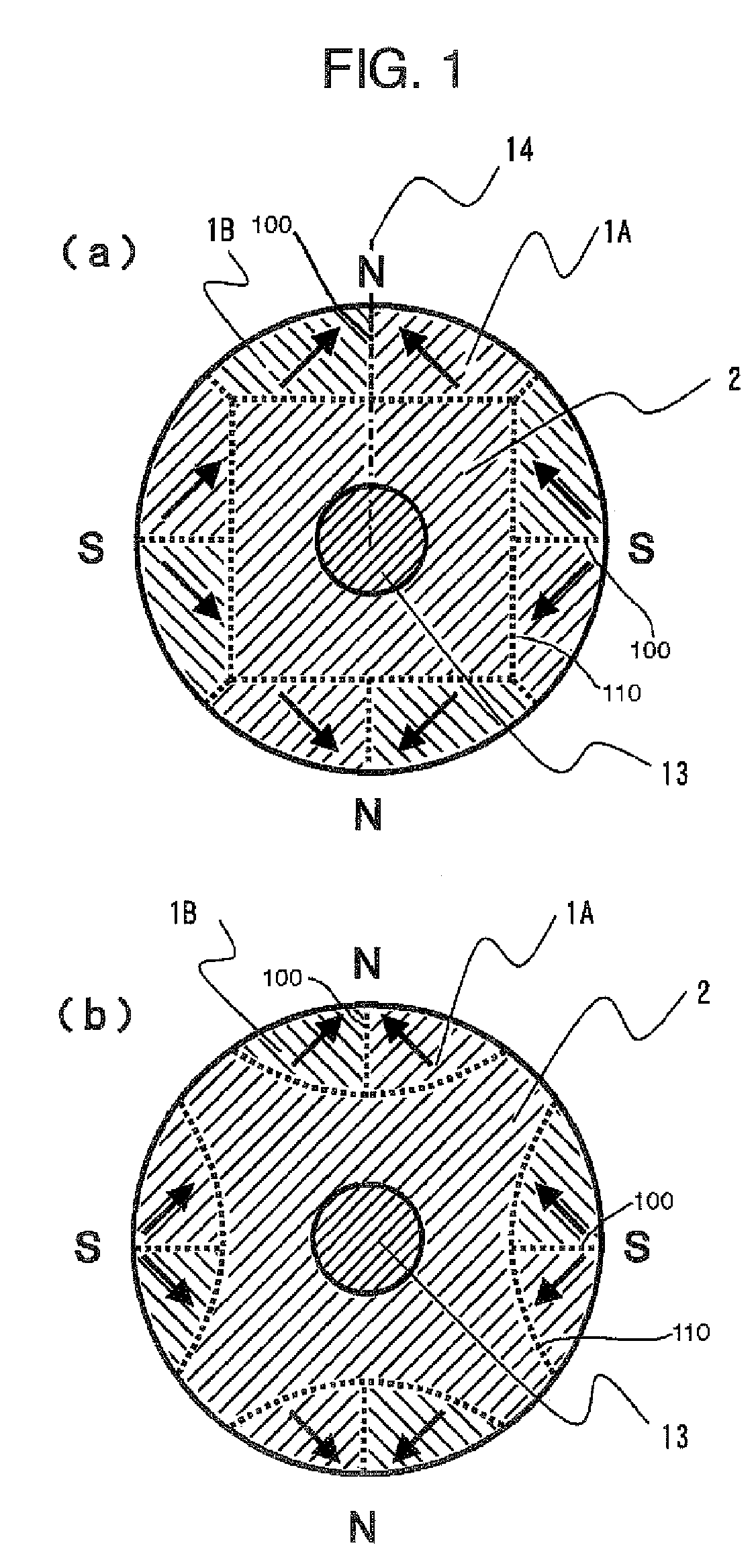

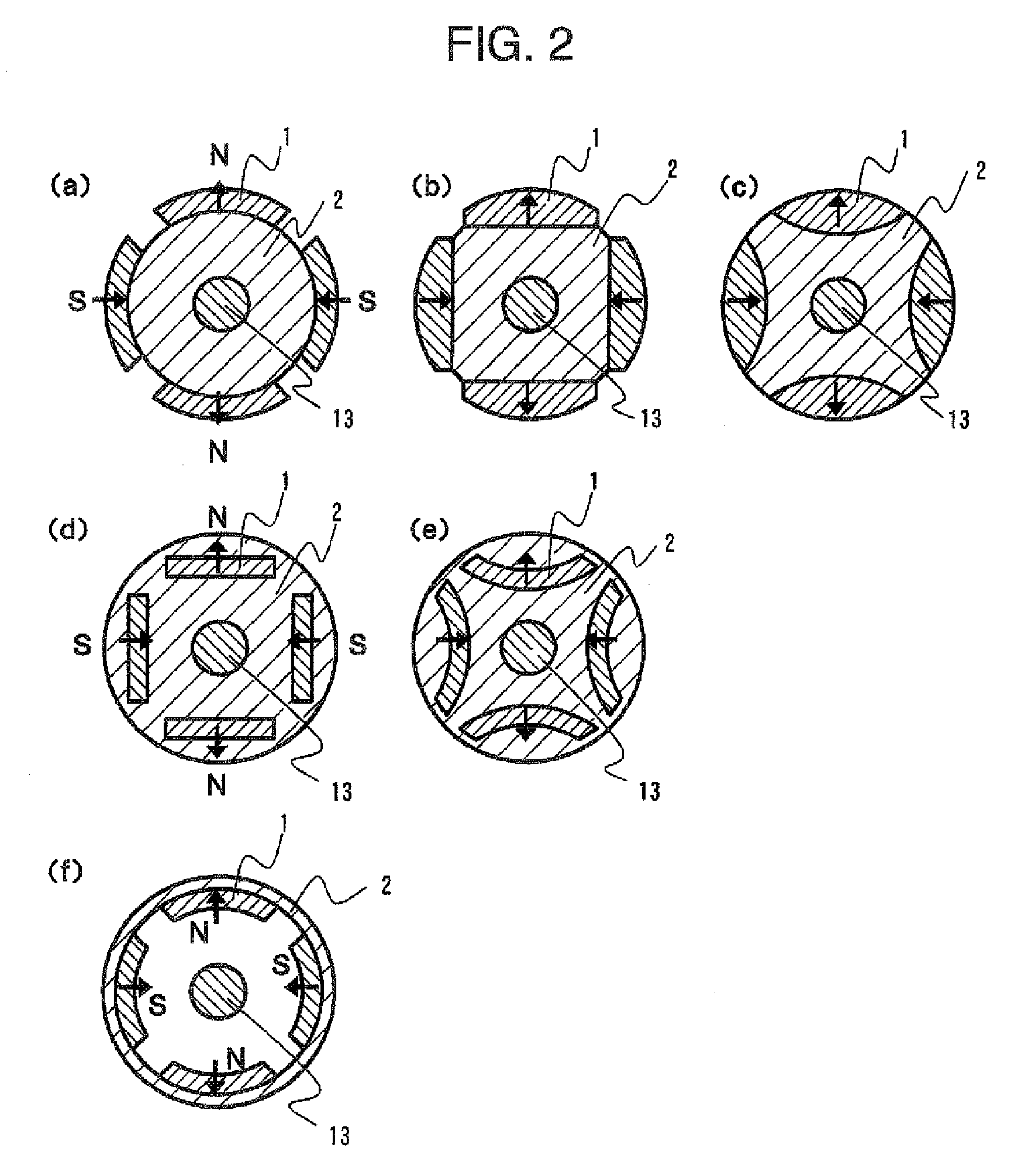

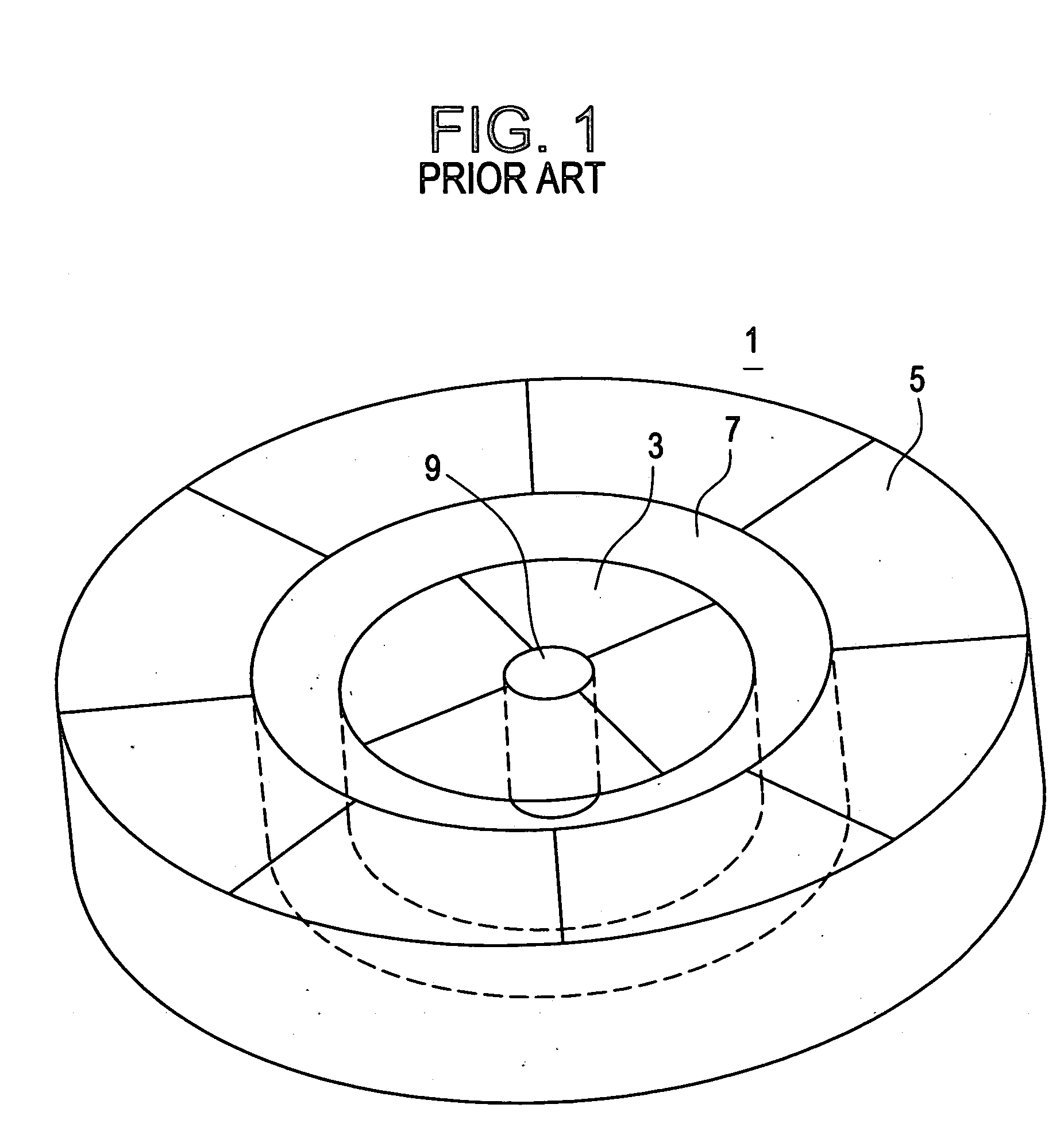

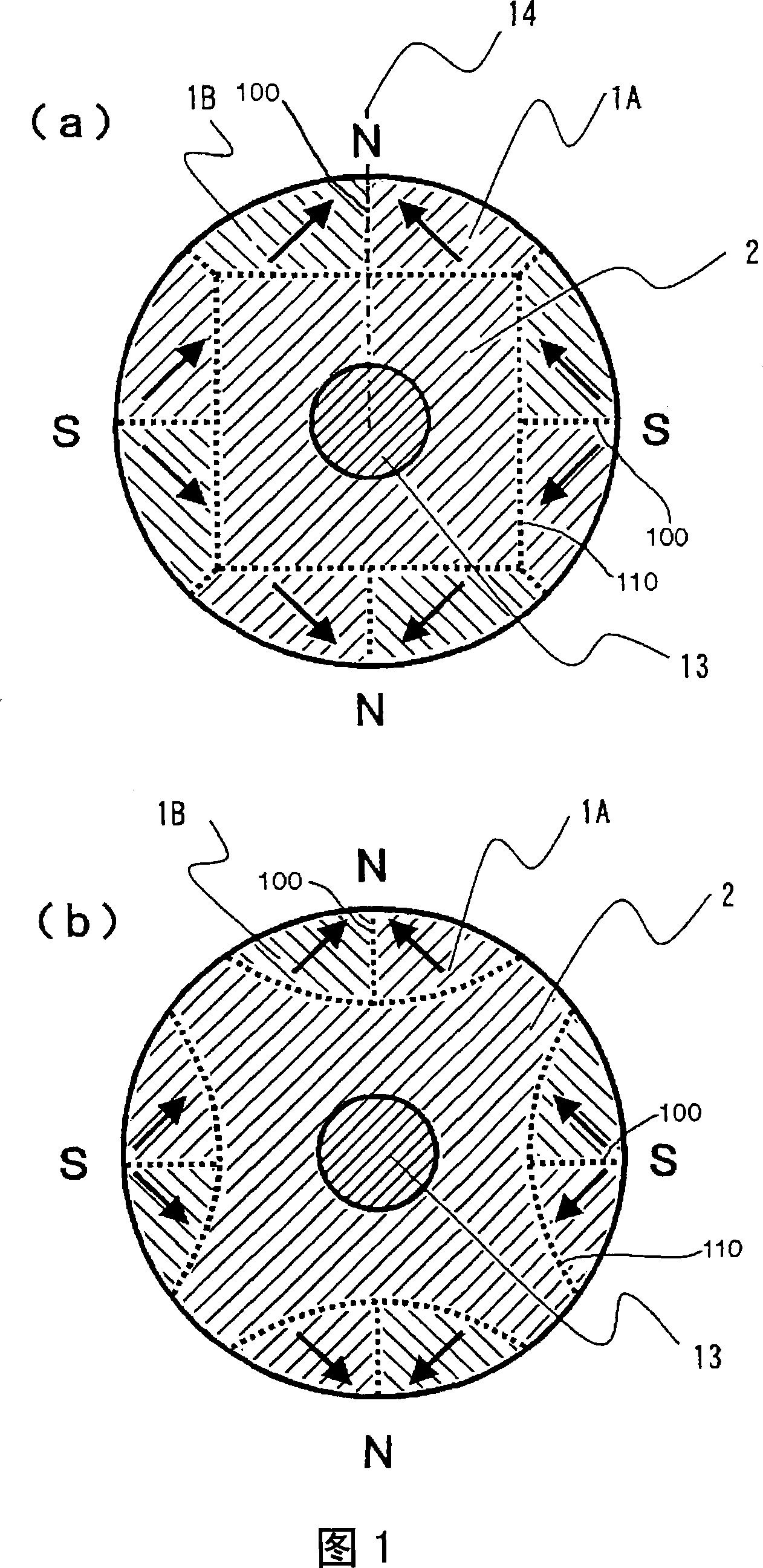

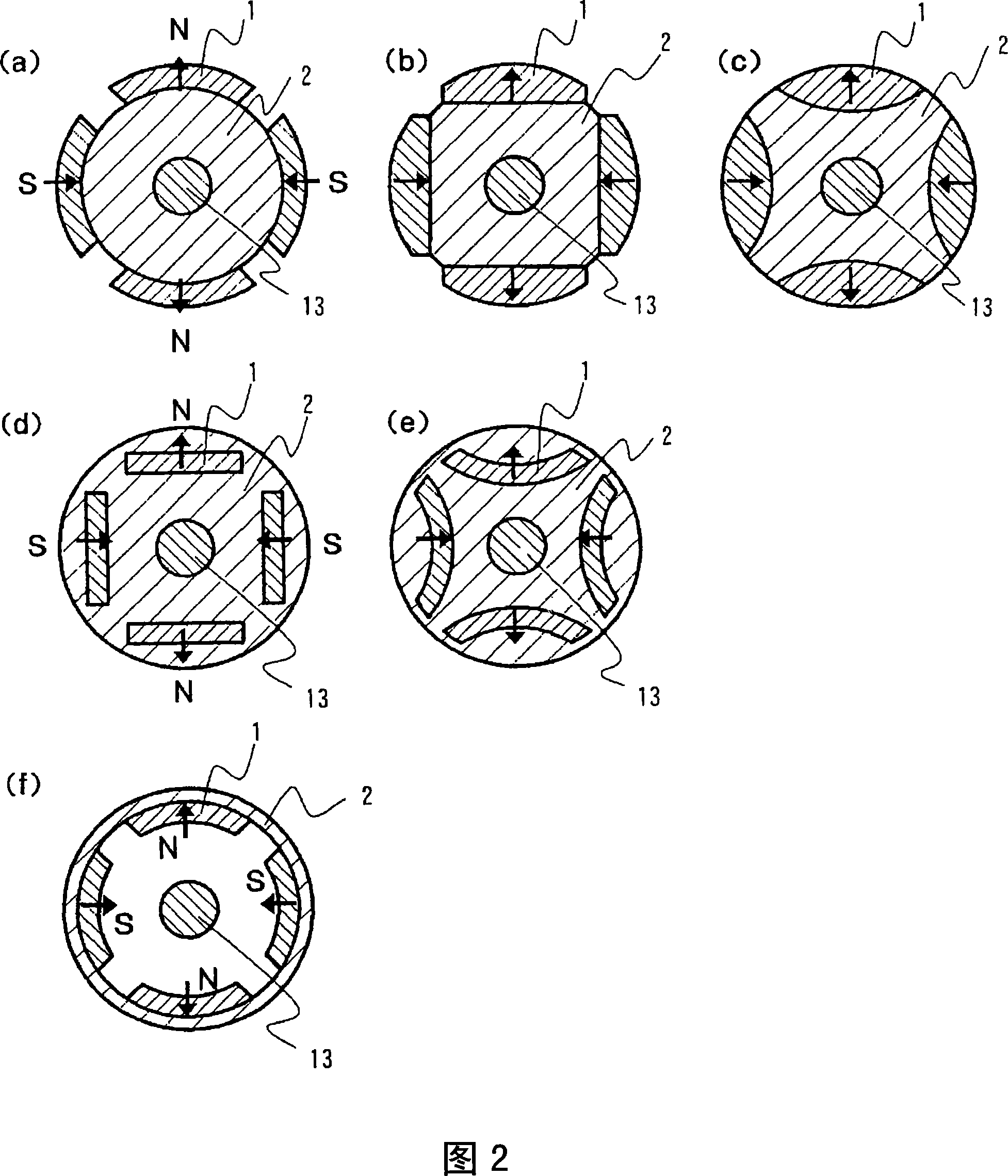

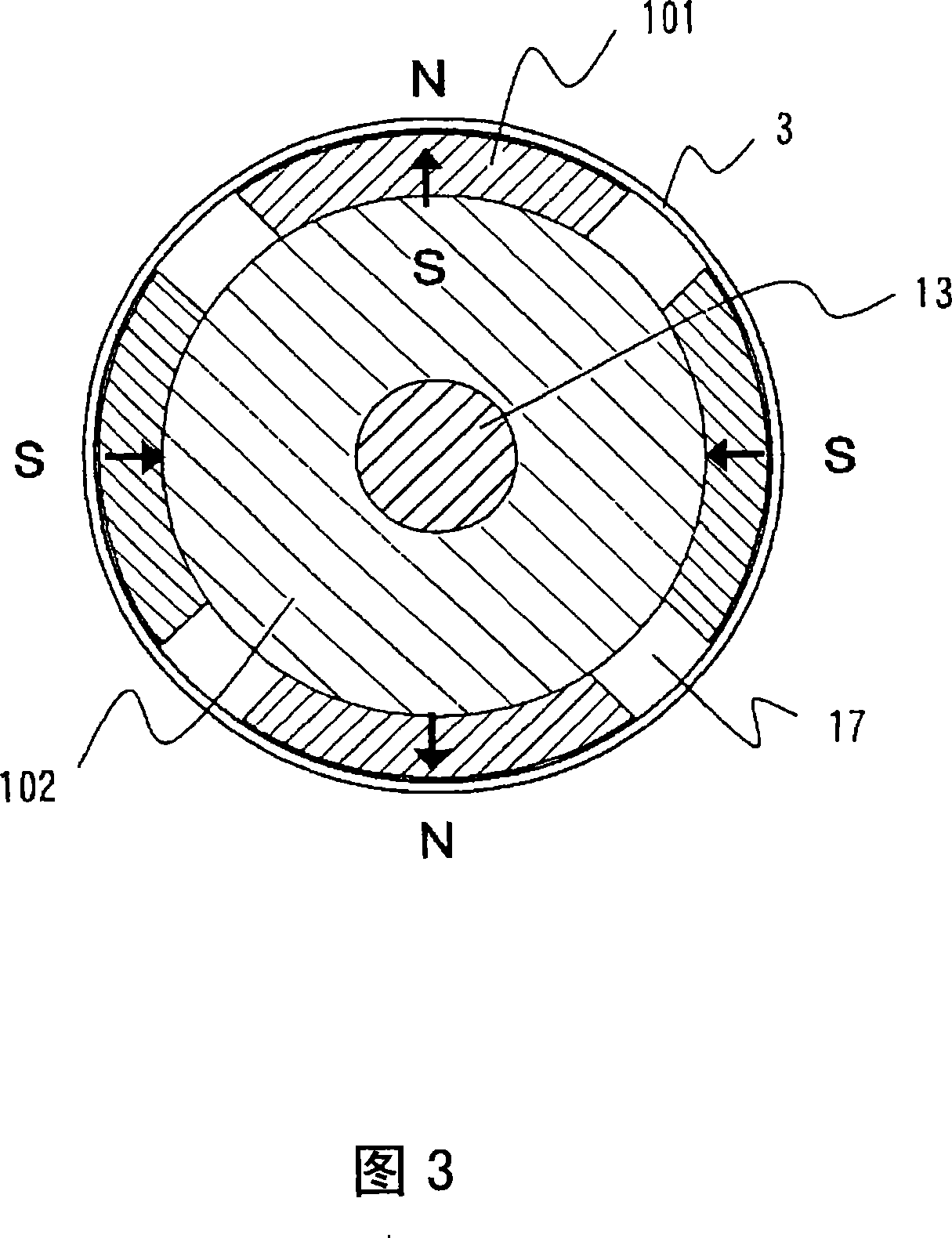

Thin hybrid magnetization type ring magnet, yoke-equipped thin hybrid magnetization type ring magnet, and brush-less motor

ActiveUS20060113857A1Decrease in cogging torqueIncrease in torque per unit volume of magnetMagnetic circuit rotating partsPermanent magnetsBrushless motorsMagnetization

The present invention provides miniaturization of brushless motors and brush motors used in electric devices, a ring magnet which simultaneously achieves both high torque and a reduction in cogging torque, a ring magnet with yoke, and a brushless motor. The thin hybrid magnetized ring magnet of the present invention is structured of, in a ring magnet comprised of a plurality of magnetic poles, a radially magnetized main pole and an interface for which the interface of the adjoining main pole is polar anisotropic. When the thin hybrid magnetized ring magnet structured in this manner is applied to a brushless motor, in the case of radial magnetizing, the abrupt change in magnetic flux of the interface between the magnetic poles becomes smooth and cogging torque is greatly reduced due to polar anisotropic magnetization of the interface. At the same time, by polar anisotropically magnetizing the interface between the magnetic poles, magnetic flux is concentrated on the radially magnetized main pole, and in comparison to only radial magnetization, maximum surface magnetic flux improves and it is possible to attain high torque.

Owner:AICHI STEEL

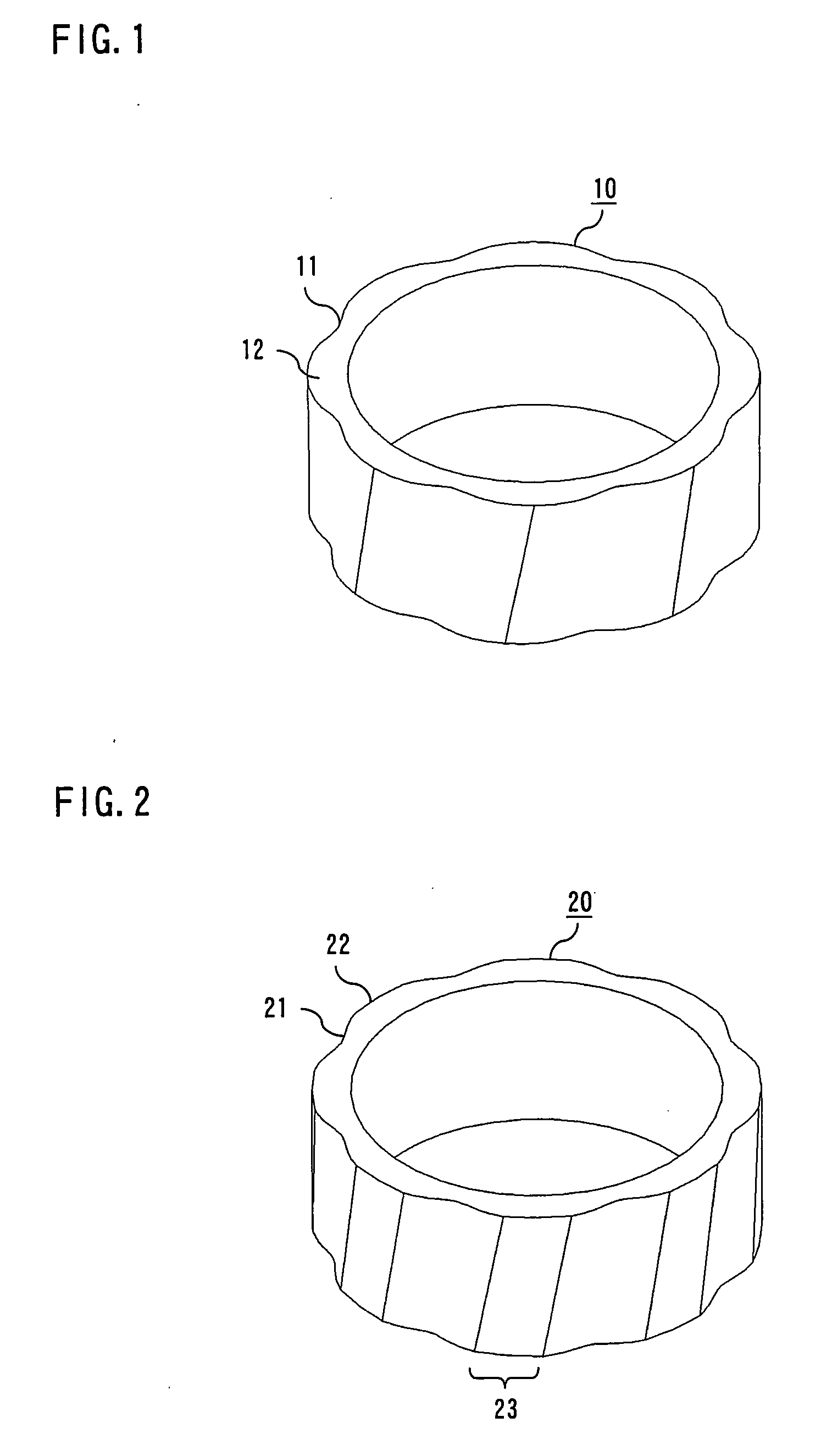

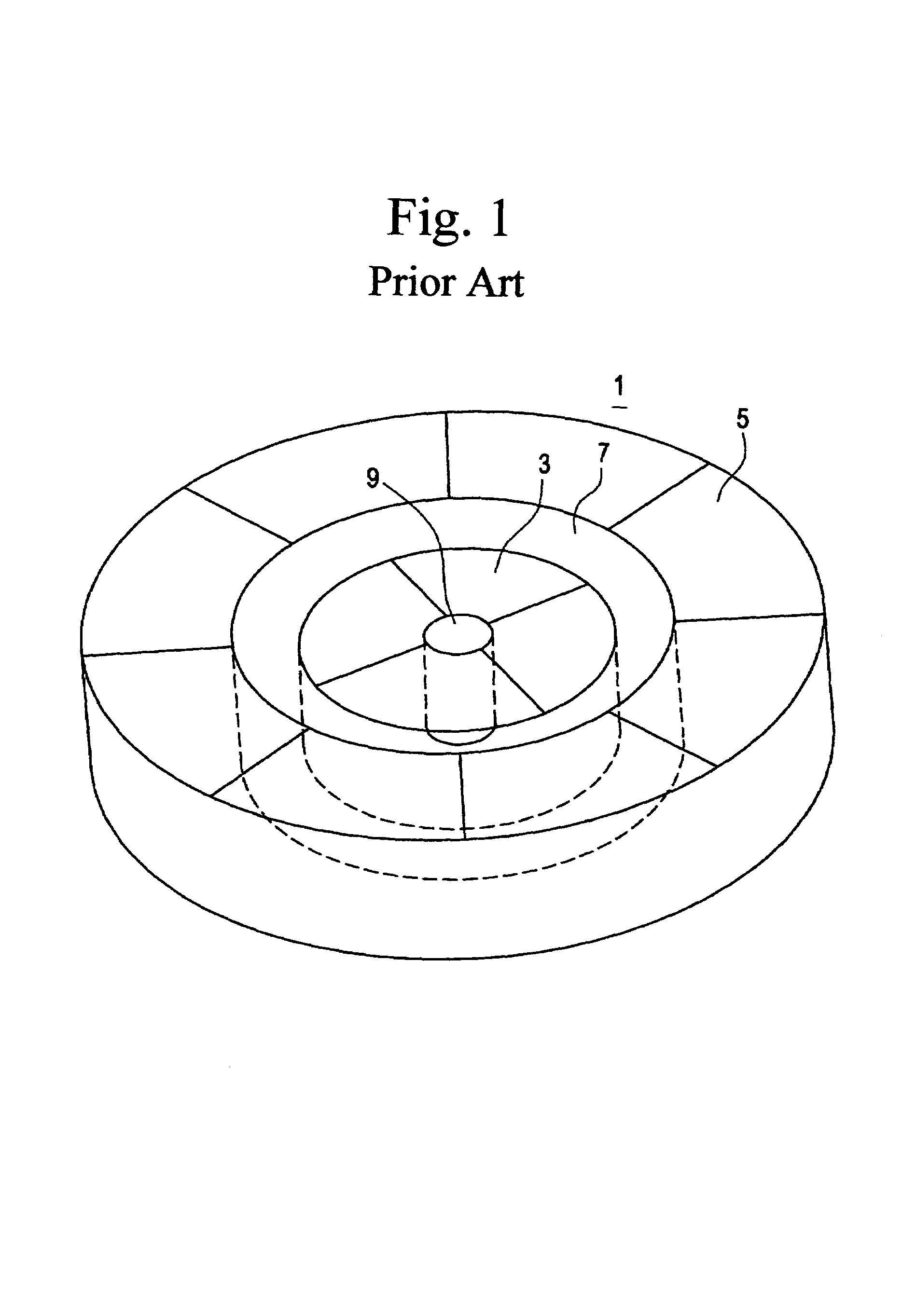

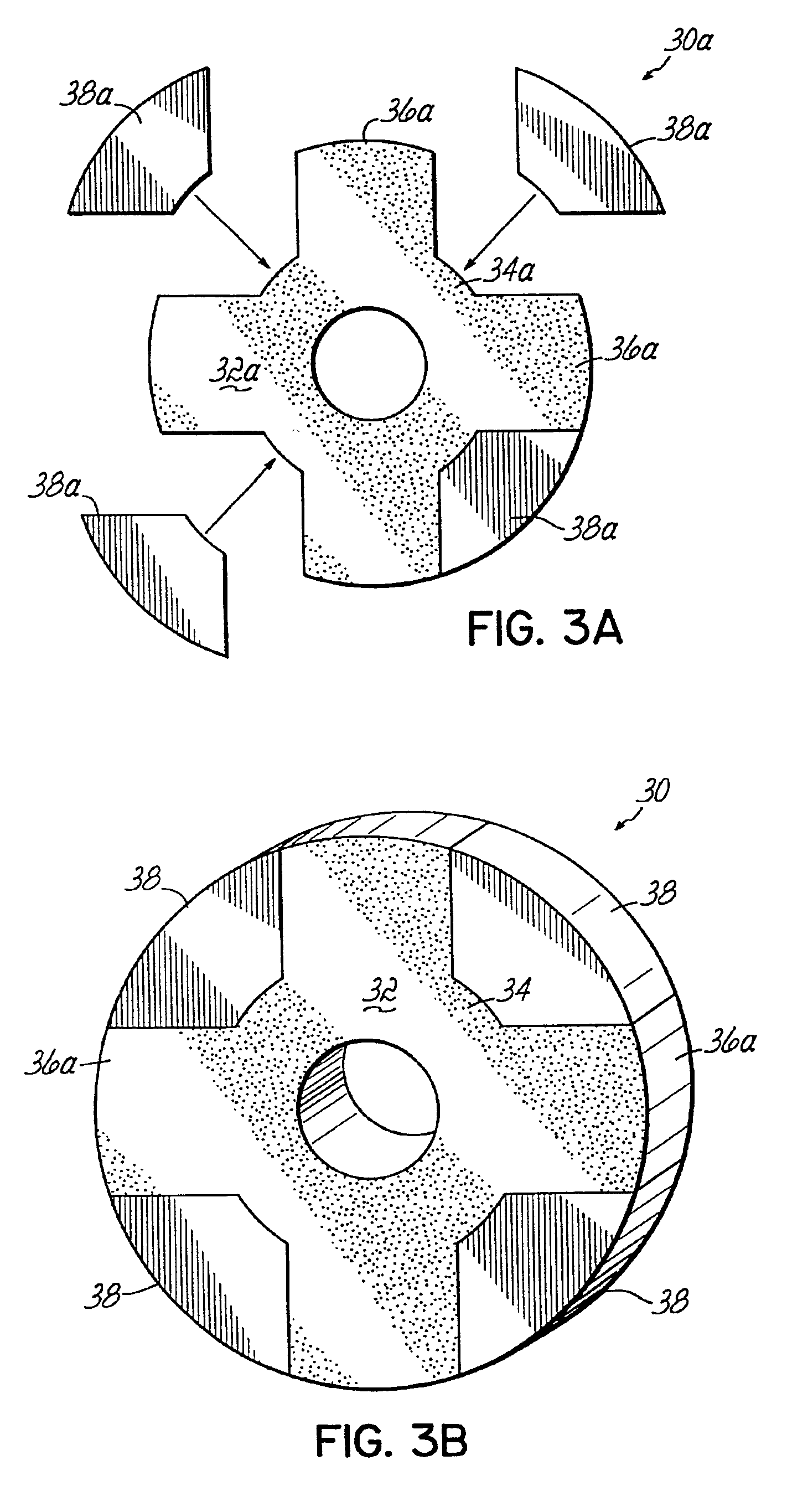

Sintered ring magnet

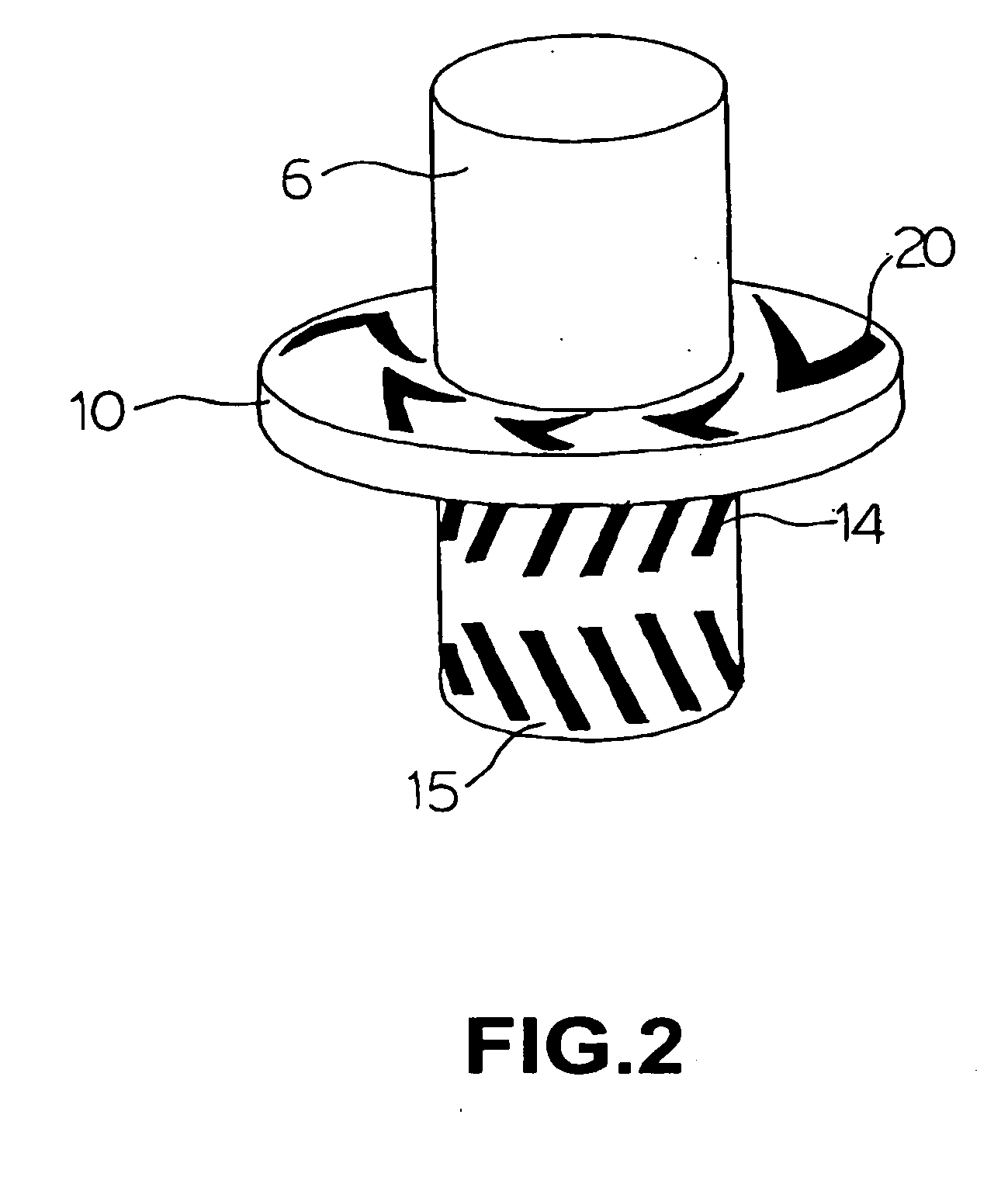

InactiveUS20060055266A1Reduce distortion problemsReducing cogging torqueMagnetic circuit rotating partsManufacturing dynamo-electric machinesMagnetic polesMaterials science

A sintered ring magnet (10) is produced through processes of magnetically orienting magnetic powder by applying a magnetic field, pressing the magnetic powder and sintering a ring-shaped powder compact (30) thus formed. The sintered ring magnet (10) has a generally cylindrical outer surface with surface corrugations formed by alternating hollows (11) and protrusions (12) at regular intervals around the sintered ring magnet (10) at least in part along an axial direction thereof, wherein the sintered ring magnet (10) varies in cross-sectional shape from one position to next along the axial direction, and magnetic poles are formed along the surface corrugations with boundaries of the magnetic poles located in the hollows (11). The hollows (11) and the protrusions (12) are skewed about a longitudinal axis of the sintered ring magnet (10). The surface corrugations are shaped into a wavy pattern expressed approximately by absolute values of a sine wave.

Owner:MITSUBISHI ELECTRIC CORP

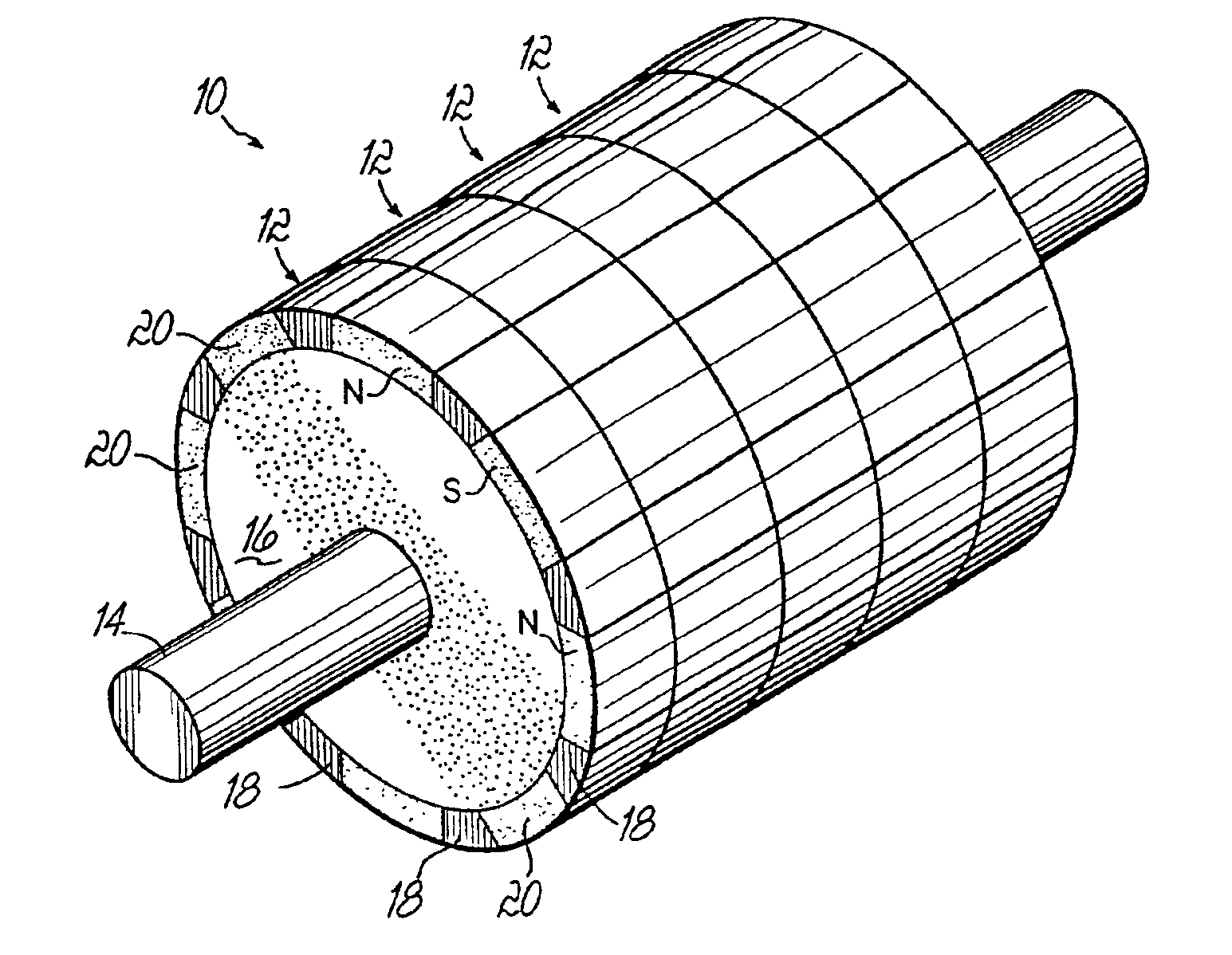

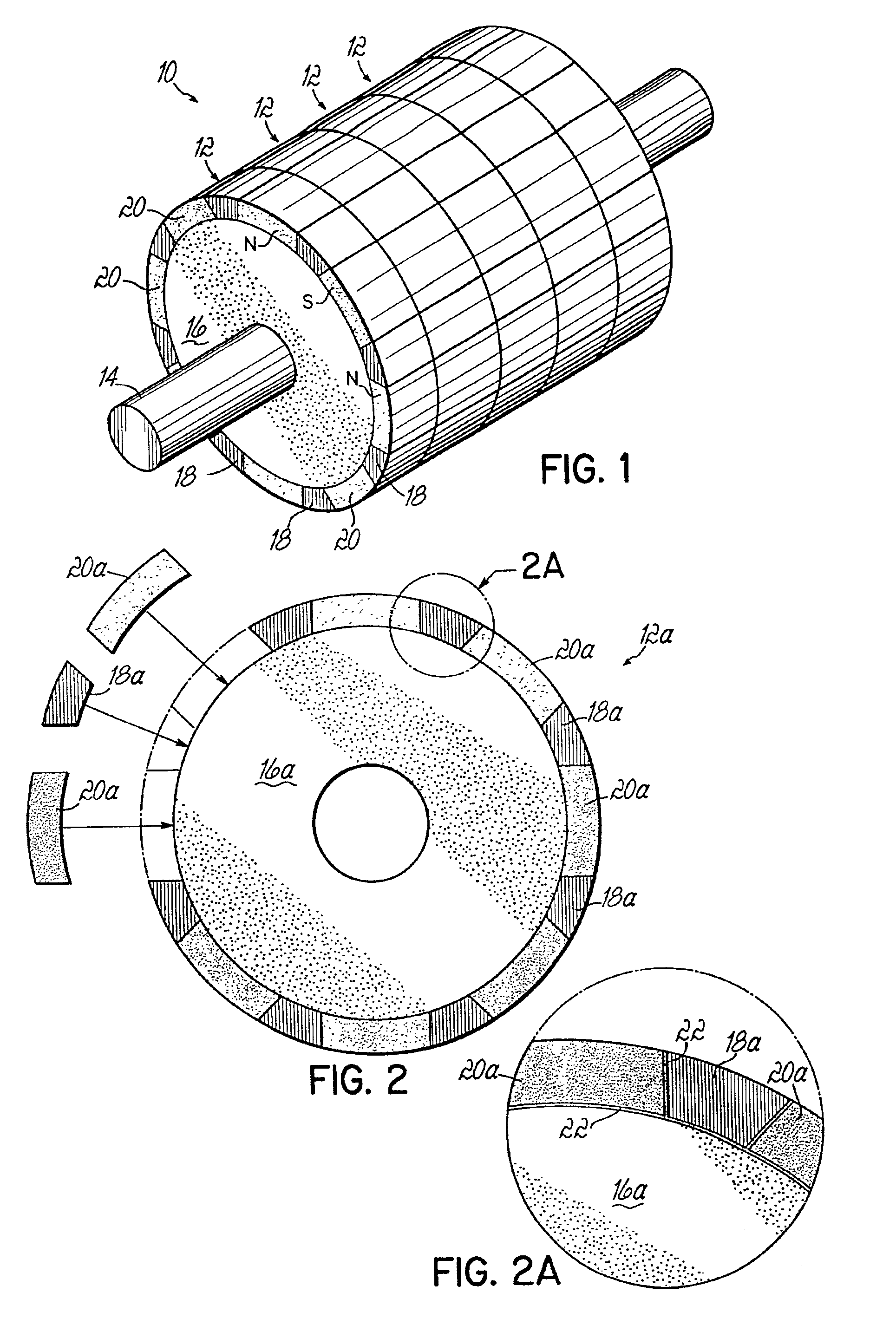

Magnets with varying magnetization direction and method of making such magnets

InactiveUS20060061445A1Maximize selected magnetic propertyReduces opportunity of interferenceDiagnosticsPermanent magnetsMagnetizationTransverse magnetic field

A permanent magnet in which the magnetization direction varies with location to optimize or restrict a magnetic field property in a selected direction at a selected point. The magnetic field property may be, for example, the transverse magnetic field, axial magnetic field, axial gradient of the transverse magnetic field, transverse gradient of the transverse magnetic field, axis gradient of the axial magnetic field, transverse gradient of the axial magnetic field, the product of the transverse magnetic field and the transverse gradient of the transverse magnetic field, the product of the transverse magnetic field and the axial gradient of the transverse magnetic field, the product of the axial magnetic field and the transverse gradient of the axial magnetic field, or the product of the axial magnetic field and the axial gradient of the axial magnetic field. The magnet may be formed of one or more segments in which the magnetization direction varies smoothly and continuously, or the magnet may be formed of a plurality of segments in which the magnetization direction is constant. A method of making and using such magnets is also disclosed.

Owner:STEREOTAXIS

Components, systems, and methods for forming anastomoses using magnetism or other coupling means

Anastomotic components may be attached to hollow bodies or vessels by magnetic or mechanical force to create an anastomosis, form a port in a vessel, or repair a diseased vessel lumen. Anastomoses are created by coupling a first connection to an end of a vessel and then attracting it to a second connector secured to the side wall of another vessel. The connection between the first and second connectors may be solidly magnetic, solely mechanical, or a combination thereof. Also disclosed are methods and devices for treating diseased vessel lumens, for example abdominal aortic aneurysm. A plurality of docking members is attached to the vessel at solicited positions, and then one or more grafts is secured to the docking members in any suitable manner.

Owner:SHARKAWY A +6

Rotor for Motor and Method for Producing the Same

InactiveUS20080218007A1Stable and small in pole pitchSimple structureMagnetic circuit rotating partsPermanent magnetsStructural reliabilityMagnetization

A surface magnet type rotor and an inner magnet type rotor having good motor characteristics in which bonding strength is high between a magnet section and a soft magnetic yoke section, and structural reliability is high even in high speed use, and its producing method. The rotor comprises an anisotropic bond magnet section and a soft magnetic section wherein the anisotropic bond magnet section is preformed in magnetic field and then formed to be integrated with the soft magnetic section in nonmagnetic field. Subsequently, it is heat hardened to produce a surface magnet type rotor. Magnet units, each having a magnetic pole composed by bonding a pair of permanent magnets such that the directions of magnetization become symmetric with respect to the bonding surface, are linked such that magnetic poles of different polarities appear alternately on the magnetic action surface thus forming an anisotropic magnet body. Good motor characteristics can be attained by setting an angle to 5-40° between the direction of magnetization of the permanent magnet and a diametral direction passing the bonding surface.

Owner:HITACHI METALS LTD

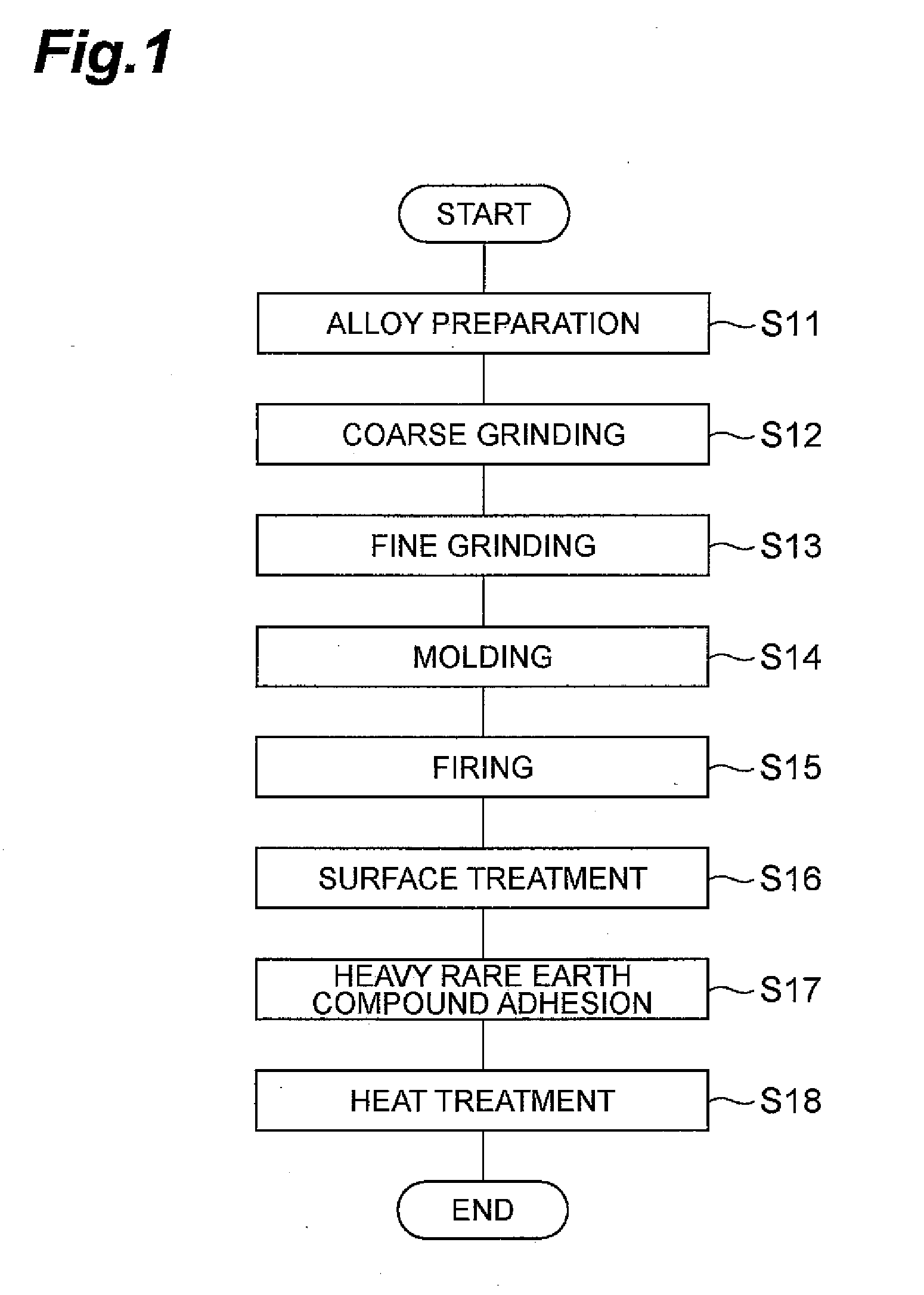

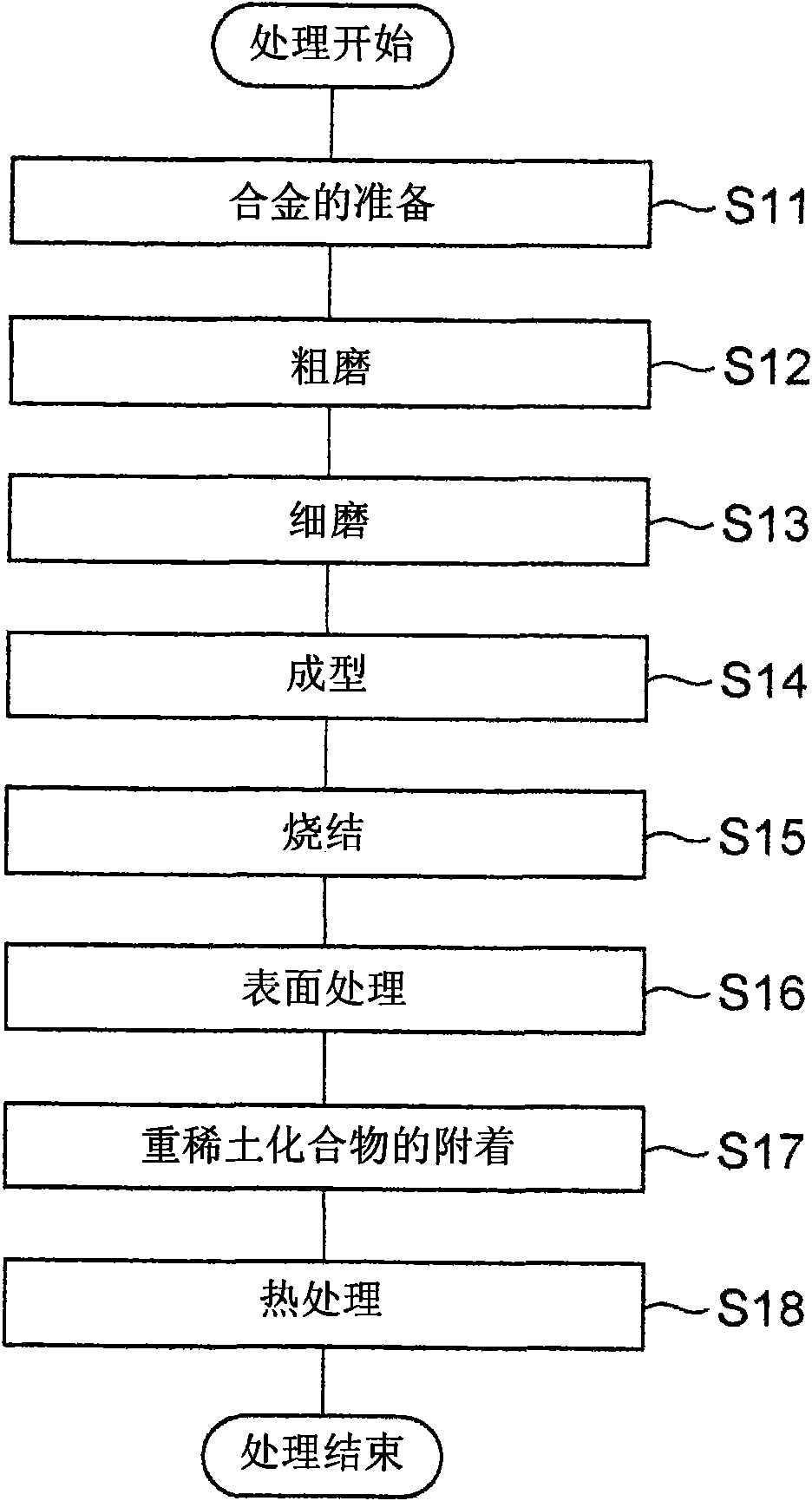

Process for producing magnet

ActiveUS20090297699A1Excellent high magnetic propertyEvenly bondedSpecial surfacesCoatingsRare-earth elementRare-earth magnet

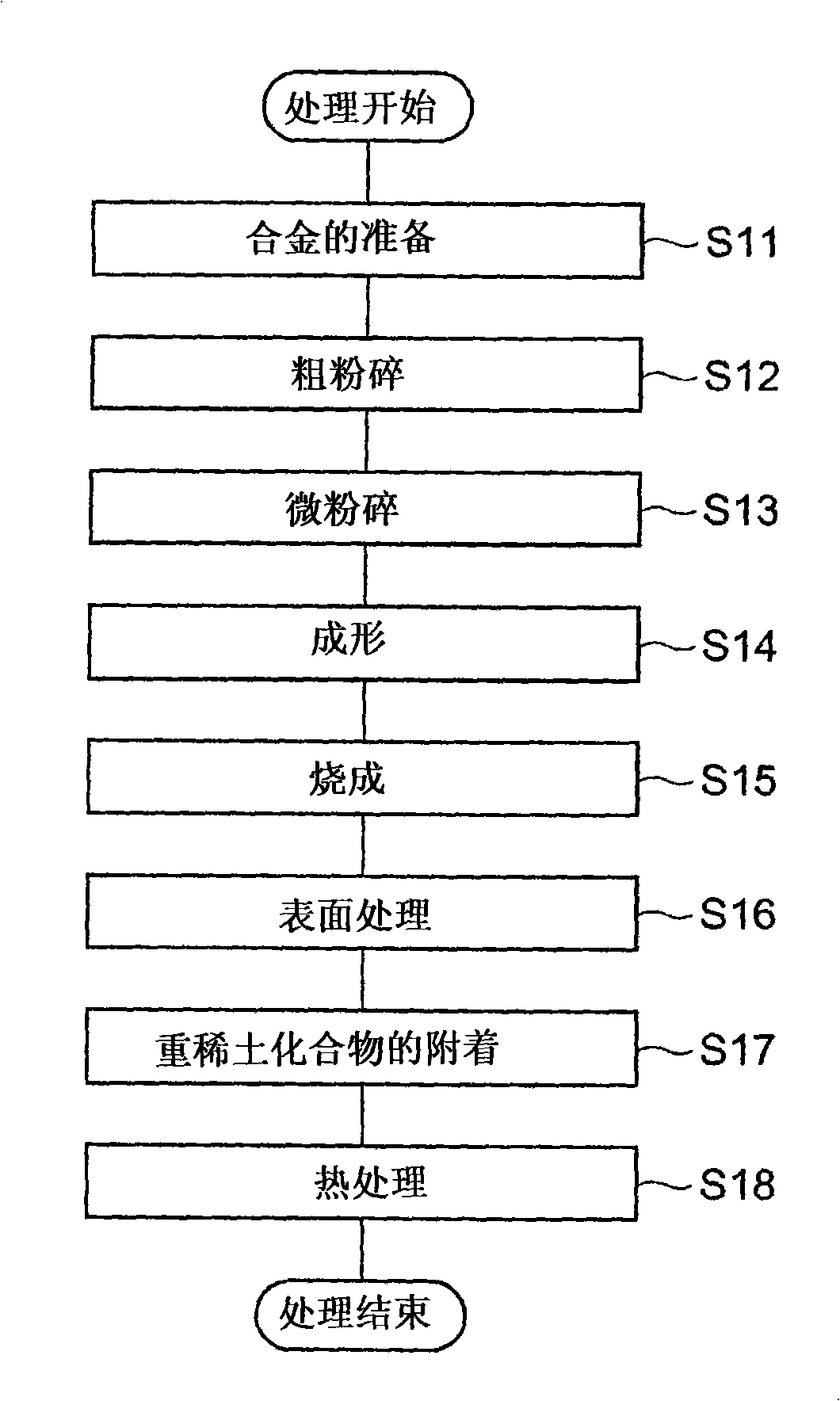

The process for producing a magnet according to the invention is characterized by comprising a first step in which a heavy rare earth compound containing Dy or Th as a heavy rare earth element is adhered onto a sintered compact of a rare earth magnet and a second step in which the heavy rare earth compound-adhered sintered compact is subjected to heat treatment, wherein the heavy rare earth compound is a Dy or Th iron compound.

Owner:TDK CORPARATION

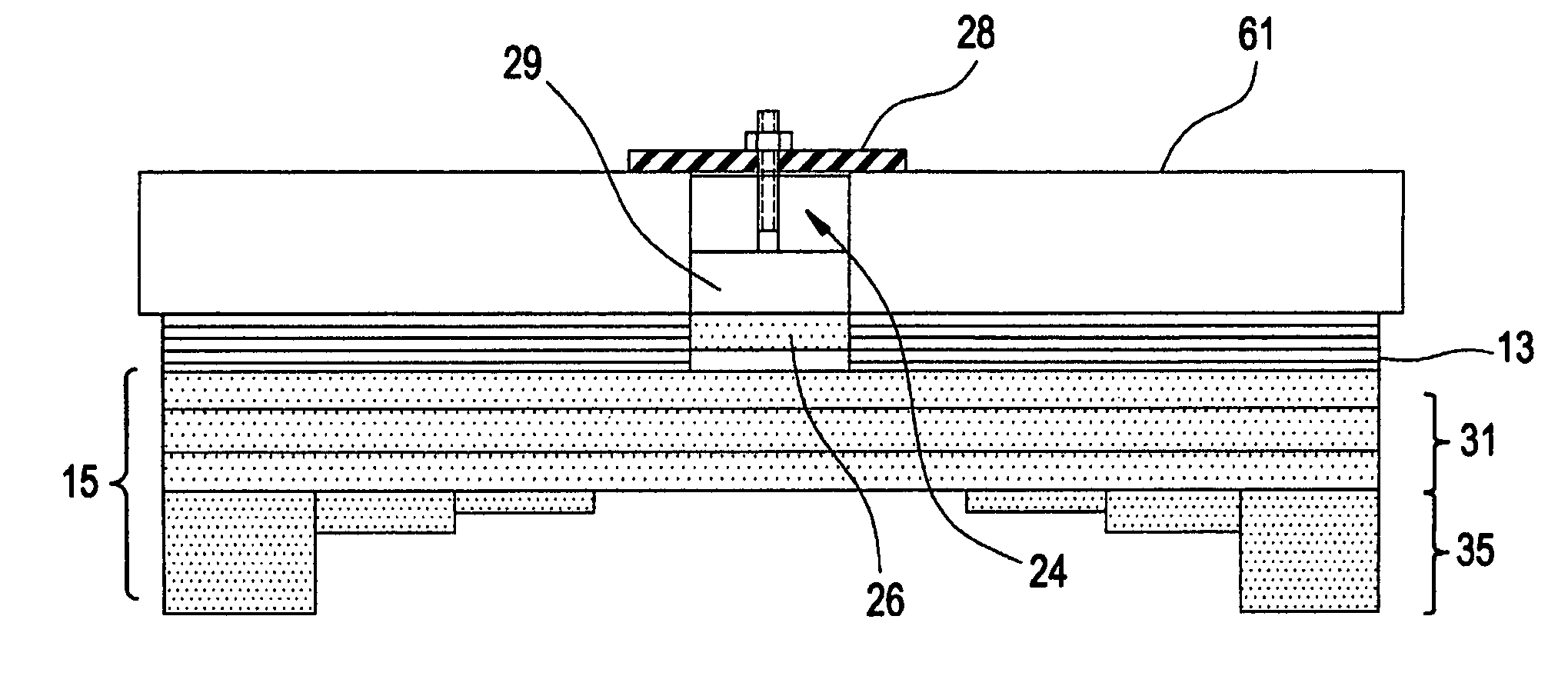

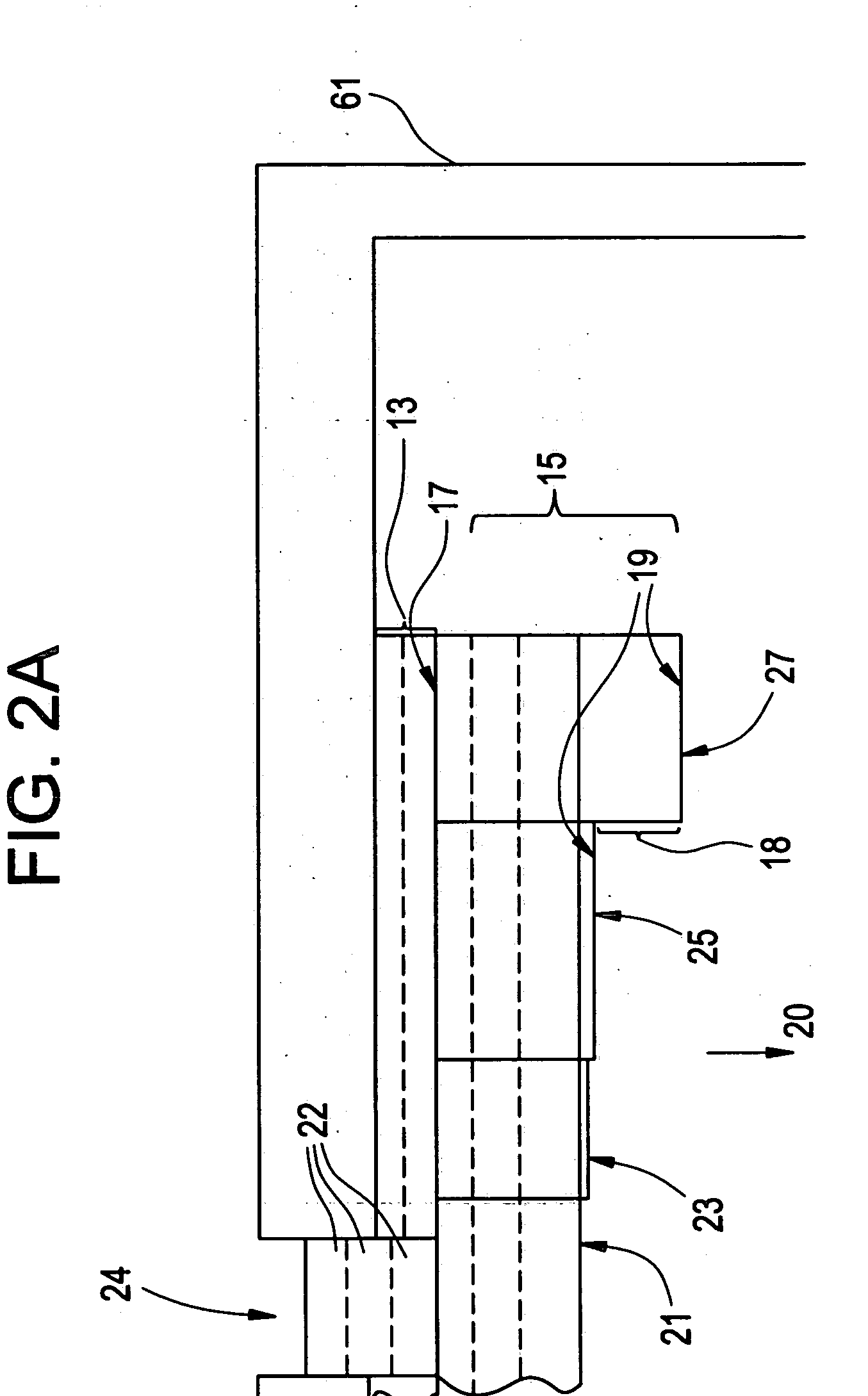

Method of making a composite electric machine component of a desired magnetic pattern

InactiveUS6889419B2More powerLow costManufacturing stator/rotor bodiesApplying solid insulationElectric machineNon magnetic

A method of making composite electric machine components. Magnetic segments and non-magnetic segments are separately formed to green strength, and then arranged adjacent to each other in a desired magnetic pattern. A small amount of powder material is added in-between the segments, and the whole assembly is then sintered to form a sinterbonded composite component of high structural integrity.

Owner:DELPHI TECH INC

Multiple ring polefaceless permanent magnet and method of making

Owner:GENERAL ELECTRIC CO

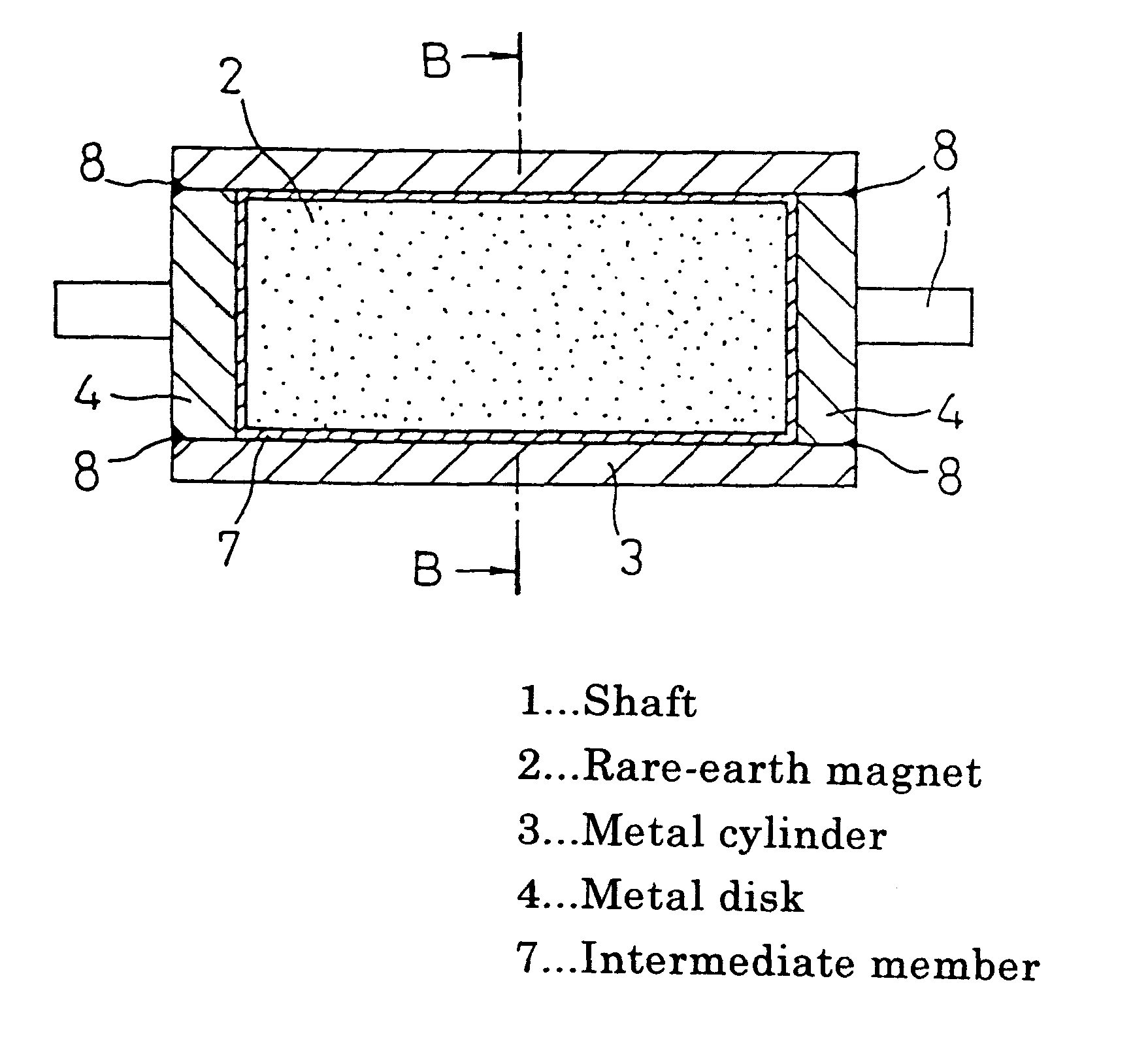

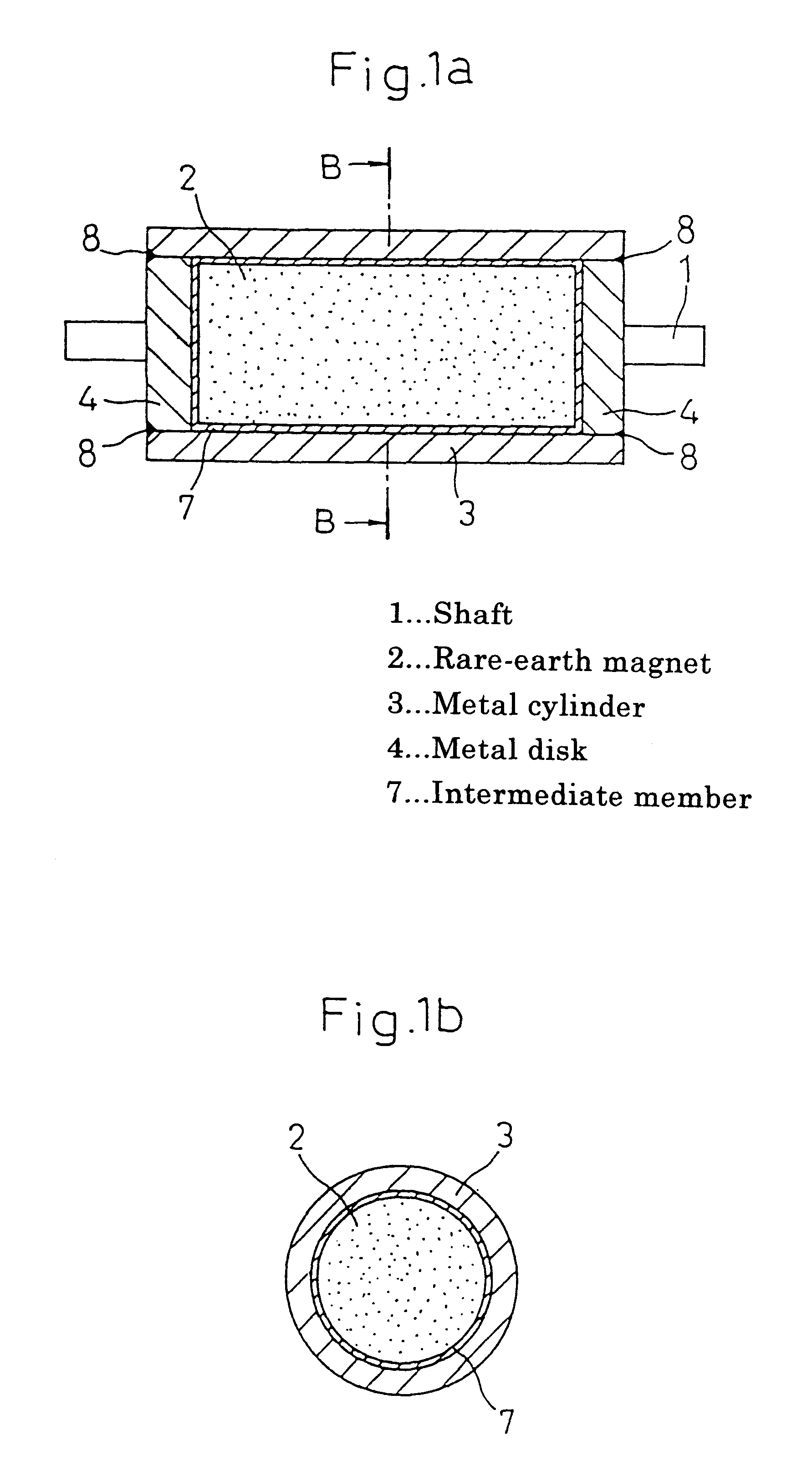

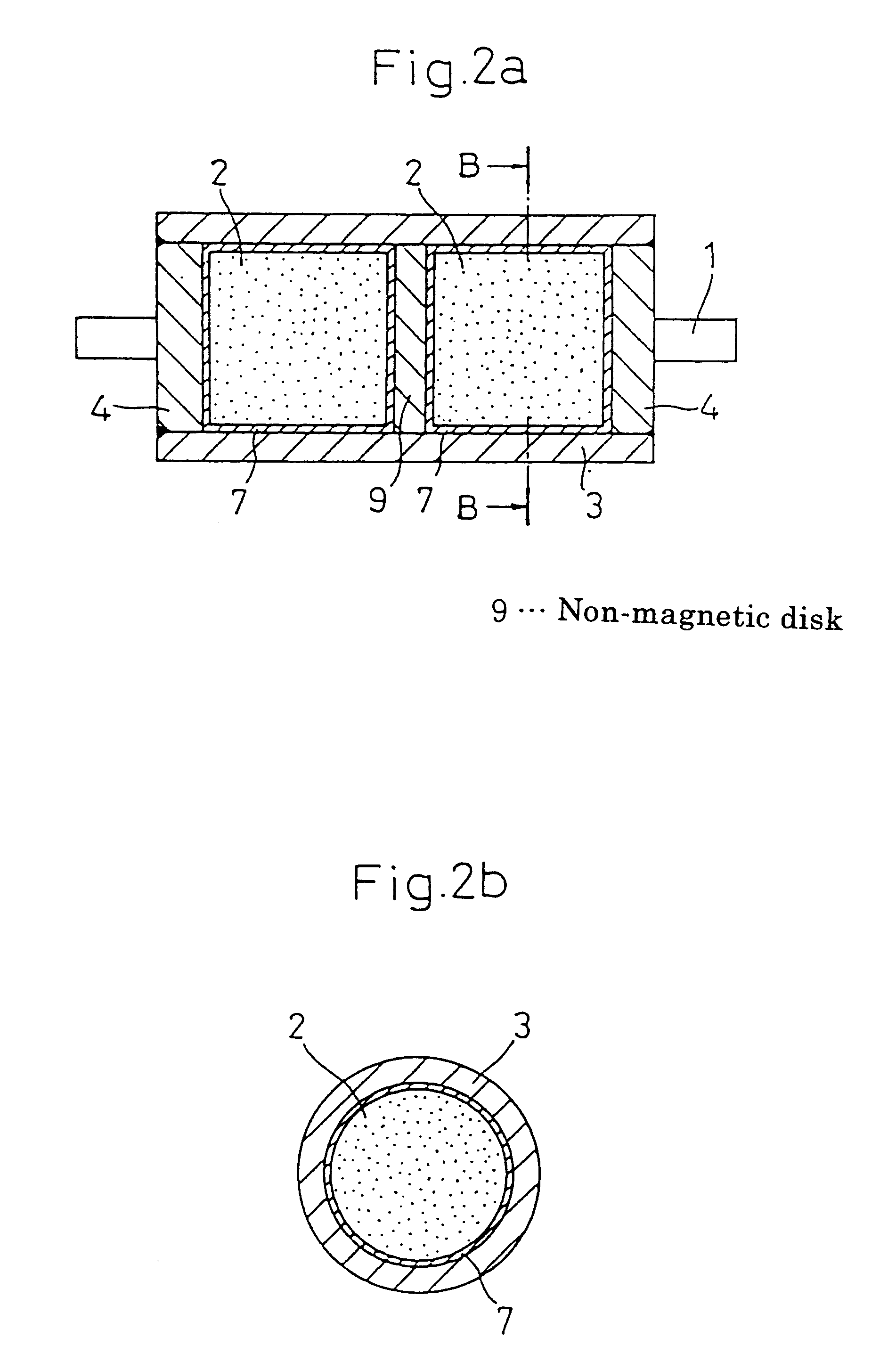

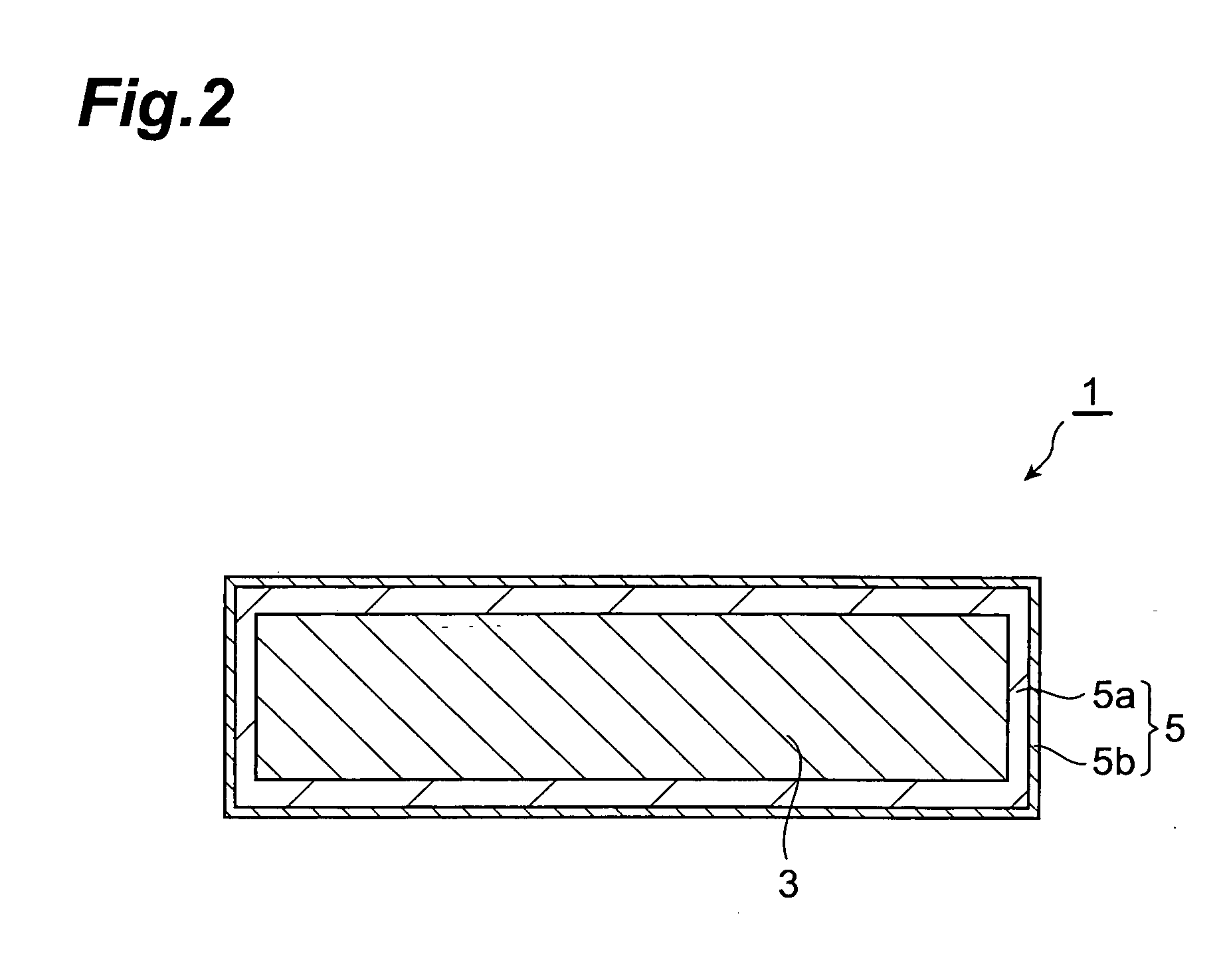

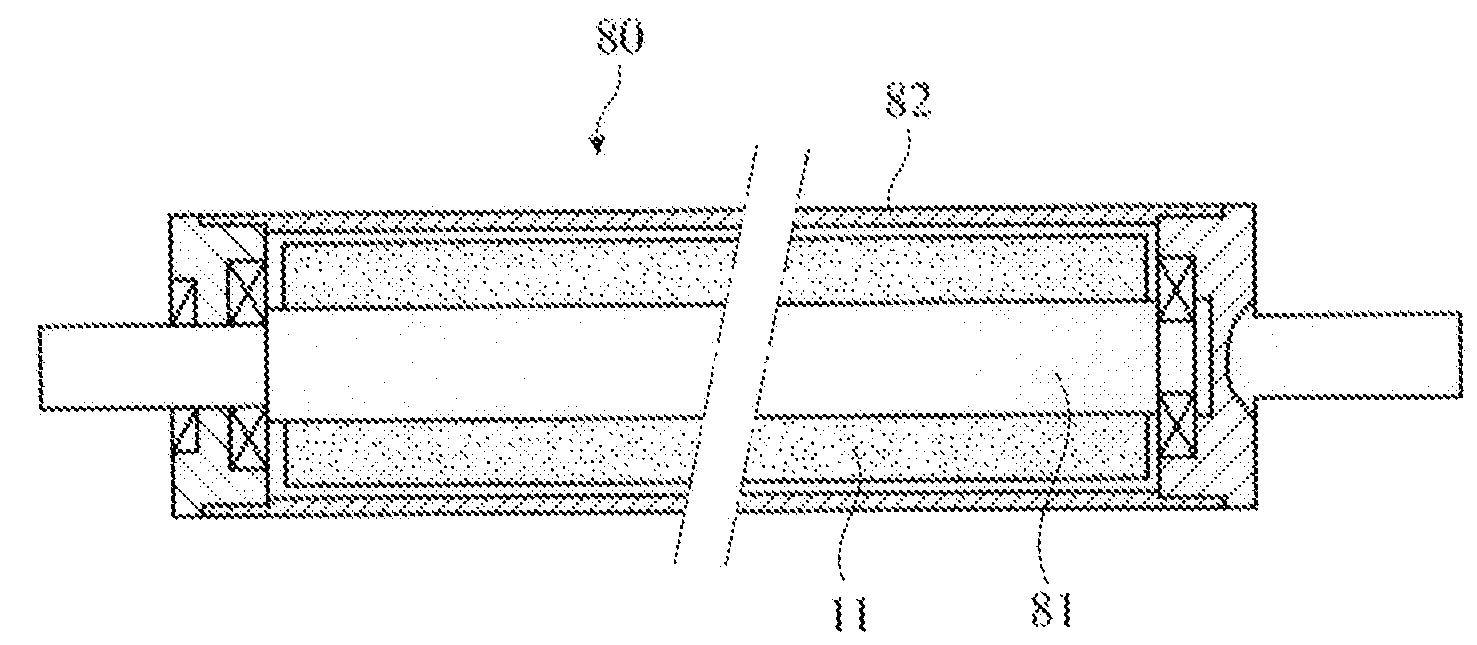

Monolithically bonded construct of rare-earth magnet and metal material and method for bonding same

InactiveUS6331214B1Manufacturing stator/rotor bodiesThin material handlingMetallic materialsHigh pressure

Its basic means is a monolithically bonded construct prepared by monolithically bonding together a rare-earth magnet 2 and a an alloy material that is a high melting point metal or a high specific-tenacity material through the solid phase diffusion bonding by the hot isostatic pressing treatment, and a monolithically bonded construct with an interposal of a thin layer of the high melting point metal between a rare-earth magnet 2 and an alloy material 3, 4 that is a high specific-tenacity material. As a method for the bonding, there is used a hot isostatic pressing treatment method in which a rare-earth An magnet and a high melting-point metal are laminated together, thereby to prepare an object to be treated, then the object is put into a hermetic-type high pressure container having an inner wall portion equipped with a heater, then the object is uniformly pressurized in all directions by a synergistic effect caused by pressure and temperature, while the object is maintained for a certain period of time under a certain pressure and temperature condition in an atmosphere of an inert gas, thereby to monolithically bond the object. With this, it is possible to obtain a bonded construct in which a magnet can monolithically be bonded with another metal member with a high strength, without deteriorating magnetic characteristics, such that the rare-earth magnet's insufficiency in brittleness, rigidity, tenacity and the like is compensated.

Owner:MEIDENSHA ELECTRIC MFG CO LTD +1

Rare Earth Magnet and Method for Manufacturing Same

InactiveUS20080050581A1Solve the lack of corrosion resistanceSolve the lack of resistancePermanent magnetsRecord information storageRare-earth elementHybrid compound

The object of the present invention is to provide a rare-earth magnet having a sufficient corrosion resistance, and a method of manufacturing the same. The rare-earth element in accordance with a preferred embodiment comprises a magnet body containing a rare-earth element, and a protective layer formed on a surface of the magnet body. The protective layer in accordance with a preferred embodiment includes a first layer covering the magnet body and containing a rare-earth element, and a second layer covering the first layer and containing substantially no rare-earth element. Another protective layer in accordance with a preferred embodiment comprises an inner protective layer and an outer protective layer successively from the magnet body side. The outer protective layer is any of an oxide layer, a resin layer, a metal salt layer, and a layer containing an organic-inorganic hybrid compound.

Owner:TDK CORPARATION

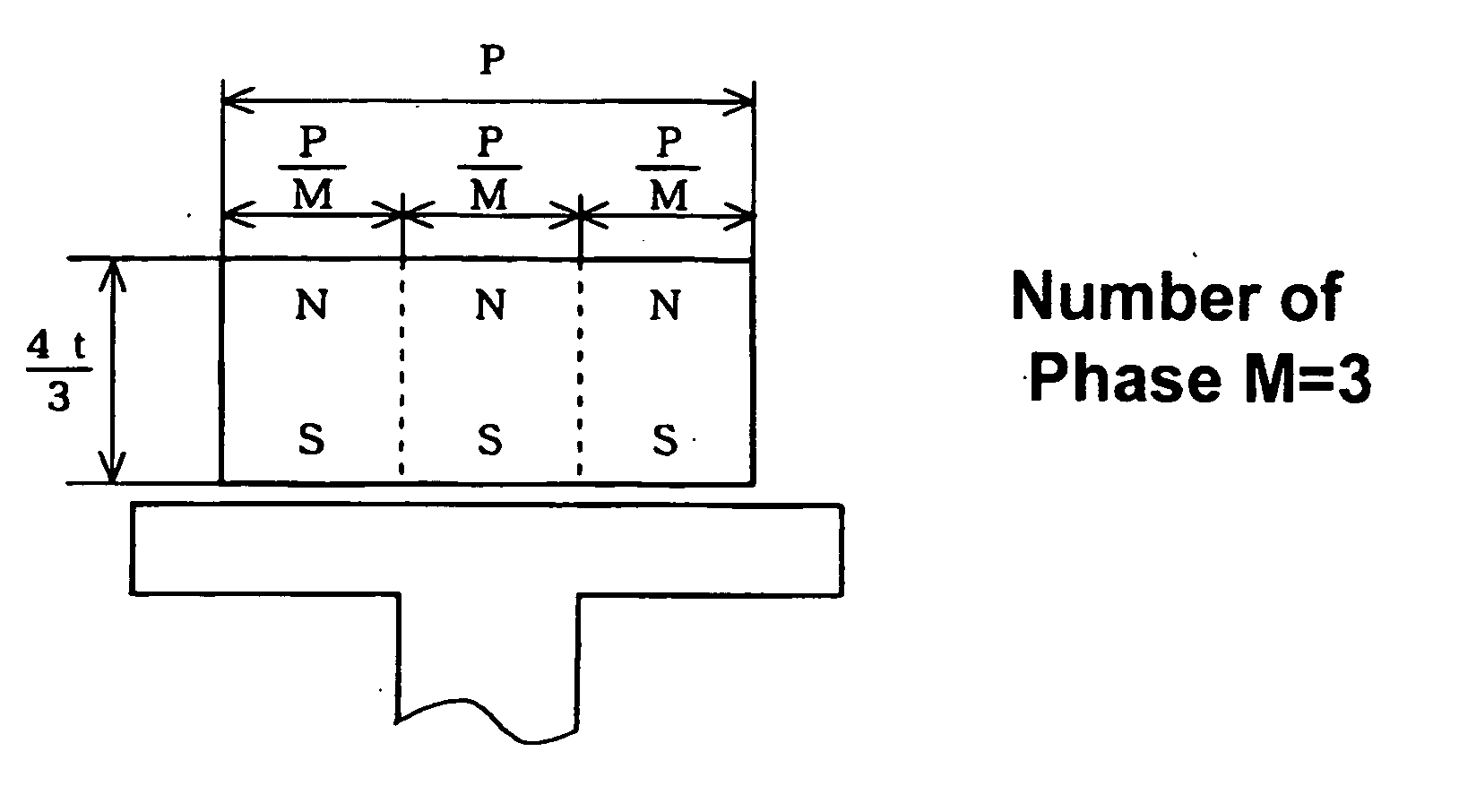

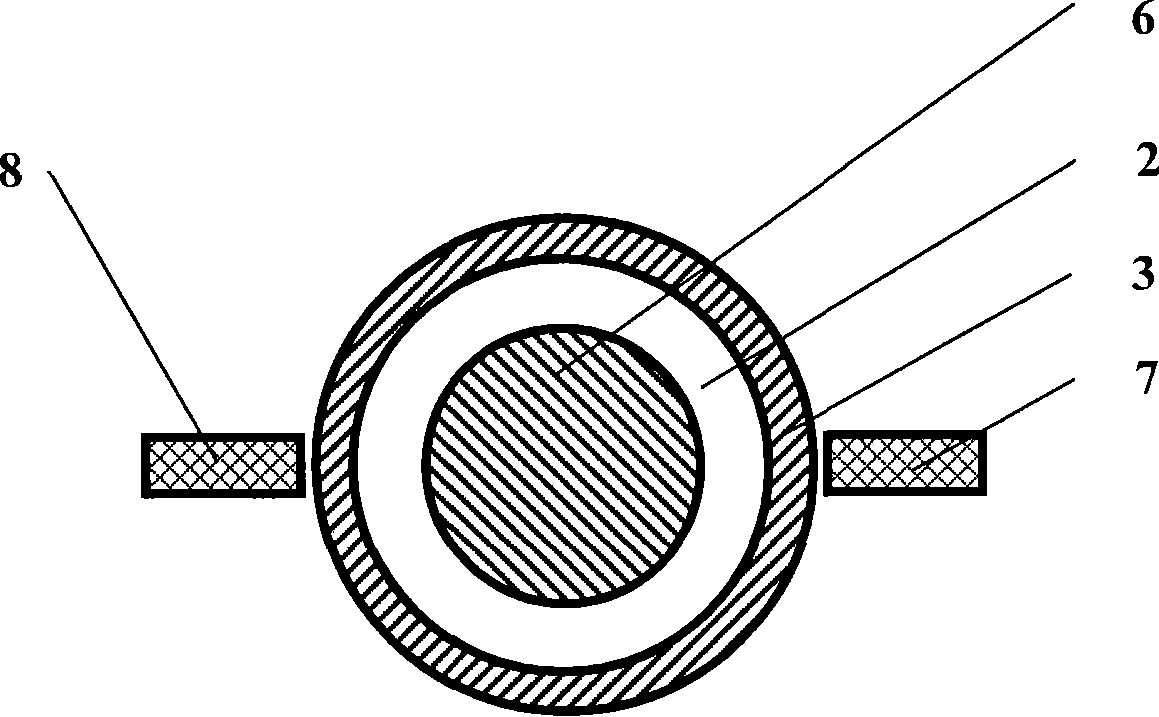

Permanent magnet for motor, motor and magnetizing method

The present invention relates to a cylindrical permanent magnet which is used in a micro DC brushless motor used in a compact hard disc etc. An Sm—Co based magnetic material is used as a magnetic material and the permanent magnet has domains magnetized in a radial direction and arranged at regular intervals in a circumferential direction. Provided that P represents a pitch corresponding to an average of an inner circumferential length and outer circumferential length in one of the domains, D denotes an inner diameter of the permanent magnet, t represents a thickness in the radial direction, N represents the number of domains, and M represents the number of AC phases for driving the motor, D is set to 20 (mm) or smaller and t is set to satisfy the relation of t≦πD / (NM−π).

Owner:SEIKO INSTR INC

Forming method of annular magnetic body orientating along the direction of radius or diameter radiation

The invention discloses a method for forming a circular ring-shaped magnet of which the radiation orientation is along the radius direction or the diameter direction; the key points of the invention are that the oriented magnetic field is changed from the 360-degree distribution(or approximately 360-degree distribution) which is generally adopted at present to a very small part of 360 degrees of the radiation ring; the relative state between the magnetic powders in the forming process and the oriented magnetic field is changed from the relative rest(or approximately relative rest) which is generally adopted at present to the relative motion. The former mainly aims at getting larger oriented magnetic field and the latter aims at magnetizing and orienting the magnetic powders in a molding cavity at the 360-degree direction. The forming method of the invention can preferably resolve the technical problems generally existing in the making of the present radiation ring that the magnetic powders are not completely oriented due to the relatively low oriented magnetic field and the consistency of the magnetic performance of the radiation ring is not good due to the uneven distribution of the oriented magnetic field.

Owner:SHENZHEN RADIMAG TECH CO LTD

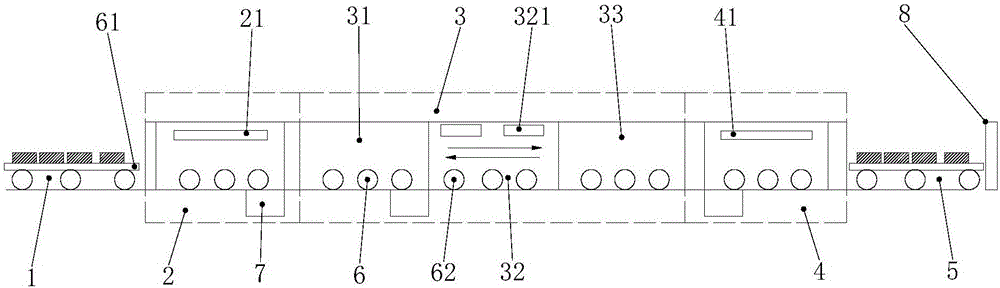

Coating method, coating system and method for preparing rare-earth magnet

ActiveCN106282948AImprove consistencyEffective thickness controlVacuum evaporation coatingSputtering coatingSputteringCoating system

The invention discloses a coating method, a coating system and a method for preparing rare-earth magnets. In the method and the system disclosed by the invention, magnets are arranged on a conveying device in a plurality of rows in a horizontal direction; the magnets which are arranged in the plurality of rows sequentially pass through a sputtering area of sputter coating equipment to complete coating; a vertical distance between the sputter coating equipment and the upper surface of the magnets is 10mm to 200mm. The method and the system disclosed by the invention adopt continuous pass type magnetron sputtering equipment to sputter heavy rare earth such as Dy and Tb onto the surfaces of the magnets, the thickness of the sputtering layer is effectively controlled, the uniformity of the sputtering layer is guaranteed, thereby the uniformity of the magnetic property of magnetic sheets obtained by performing grain boundary diffusion to the sputtered magnets is guaranteed, and the rapid and continuous production of magnets by adopting the grain boundary diffusion technique can be realized.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Rotating machine, bonded magnet, magnet roll, and method for producing sintered ferrite magnet

ActiveUS20090218540A1Little temperature dependenceHigh Br and HcJMangetographic processPermanent magnetsRare-earth elementMetallurgy

A rotating machine comprising a sintered ferrite magnet having an M-type ferrite structure, comprising Ca, an R element that is at least one of rare earth elements and indispensably includes La, Ba, Fe and Co as indispensable elements, and having a composition represented by the formula: Ca1-x-yRxBayFe2n-zCoz, wherein (1−x−y), x, y, z and n represent the contents of Ca, the R element, Ba and Co, and a molar ratio, meeting 0.3≦1−x−y≦0.65, 0.2≦x≦0.65, 0.001≦y≦0.2, 0.03≦z≦0.65, 4≦n≦7, and 1−x−y>y; a bonded magnet comprising ferrite powder having the above composition and a binder, and a magnet roll, at least one magnetic pole portion of which is made of the above bonded magnet.

Owner:HITACHI METALS LTD

Rare earth element sintered magnet and method for producing rare earth element sintered magnet

ActiveUS20050028890A1Incur damageResistance can be maintainedInorganic material magnetismSolid state diffusion coatingRare-earth elementSintered magnets

Owner:SHIN ETSU CHEM IND CO LTD

Refrigerator magnet with clipping action

Owner:AMRON SCOTT L

Coated r-t-b magnet and method for preparation thereof

InactiveUS20030041920A1Promote oxidationIncrease resistanceMagnetic materialsPermanent magnet manufactureRare-earth elementChemical treatment

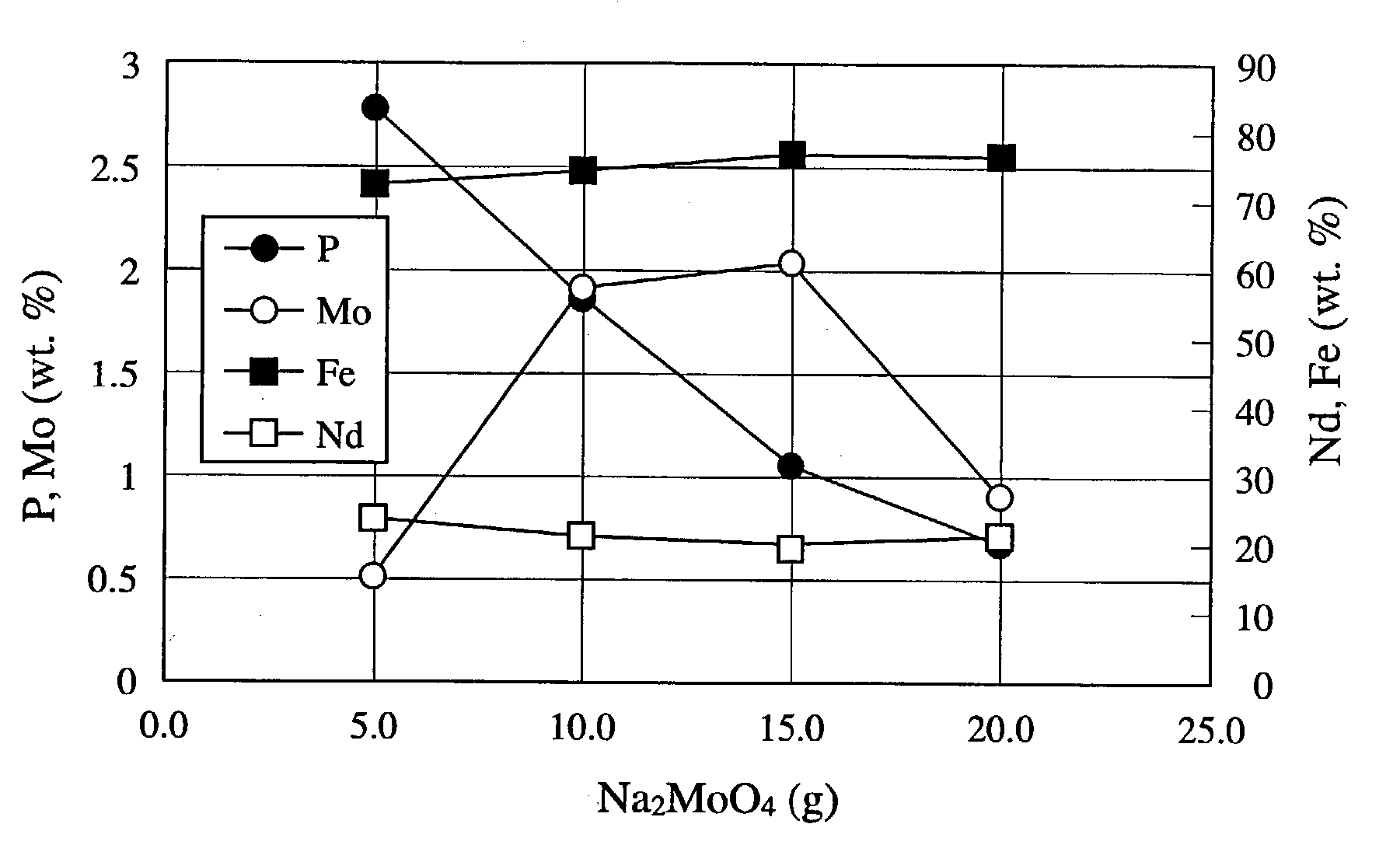

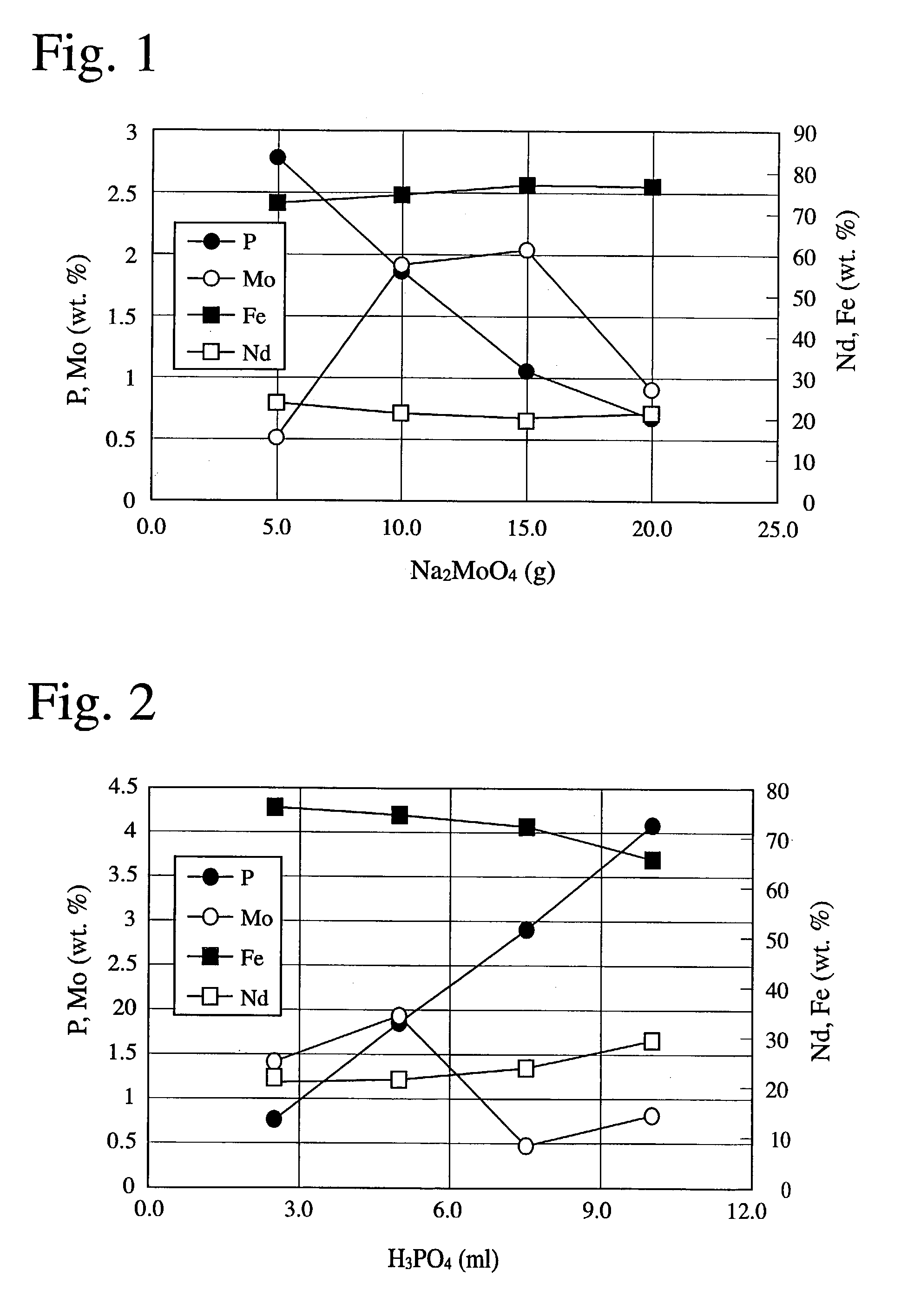

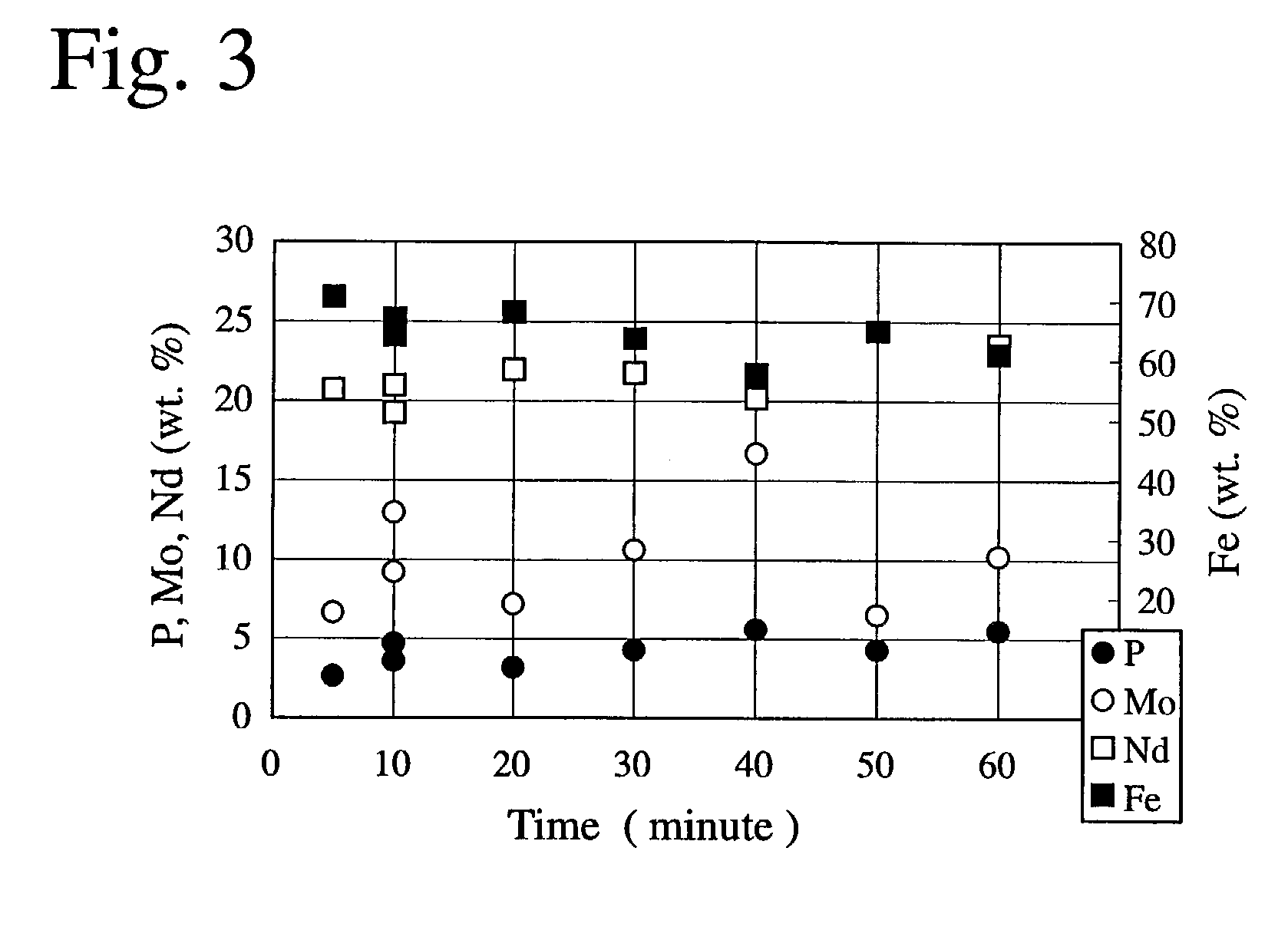

A method for preparing a coated R-T-B magnet wherein a R-T-B magnet having a R2T14B intermetallic compound, wherein R represents al least one of the rare earth elements including Y, T represents Fe or Fe and Co, as a primary phase is subjected to a chemical treatment, characterized in that the R-T-B magnet is treated with a chemical treating solution which has a molar ratio of Mo to P, Mo / P, of 12 to 60, contains a molybdophosphiate ion as a primary component and is adjusted to have a pH of 4.2 to 6. The resultant chemical coating comprises an oxide of Mo and a hydroxide of R. The oxide of Mo consists essentially of amorphous MoO2.

Owner:HITACHI METALS LTD

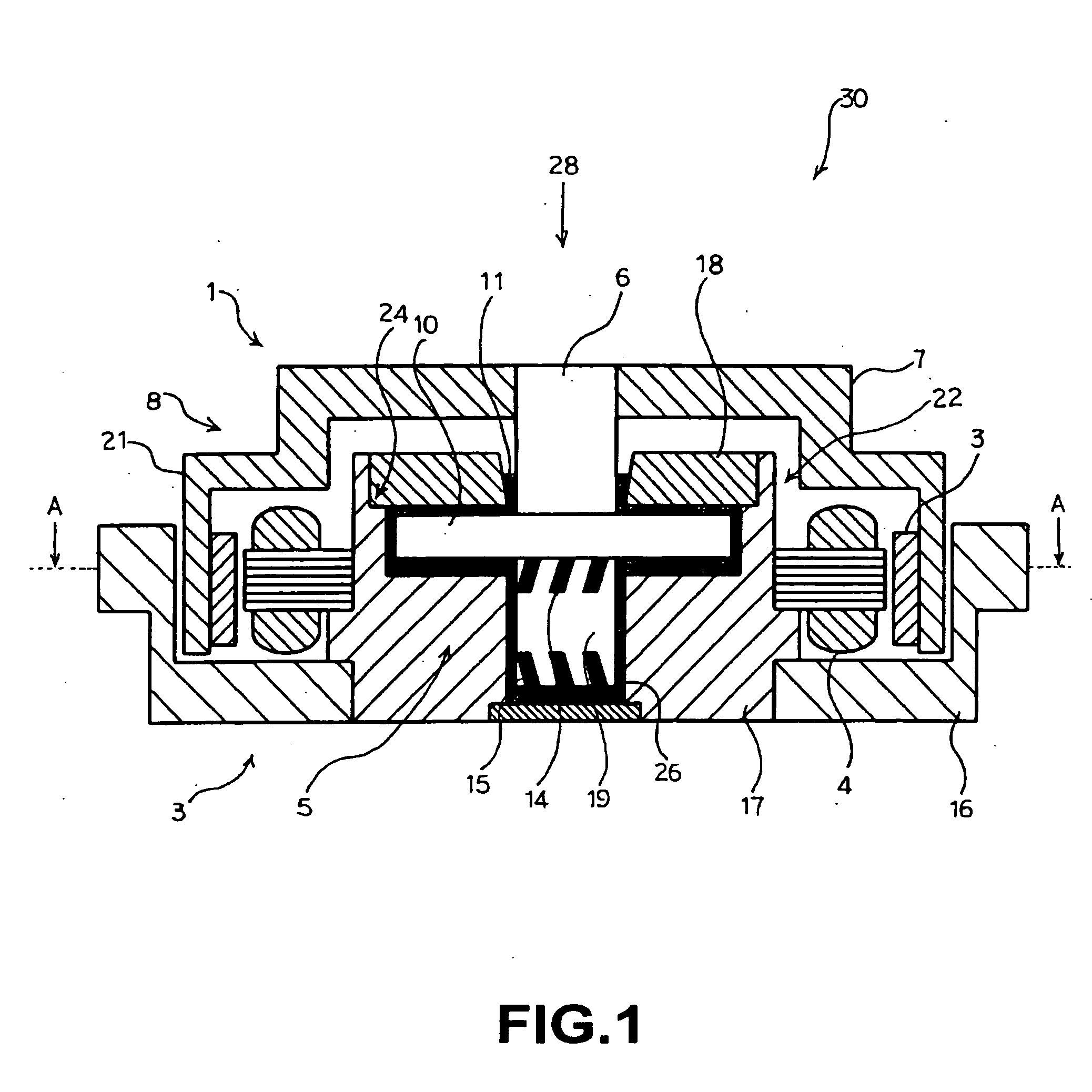

Permanent Magnet For Motor, Motor Housing, and Motor Device

InactiveUS20080124235A1Low densityControl thicknessCircumferential flow pumpsTransverse flow pumpsEpoxyMetallurgy

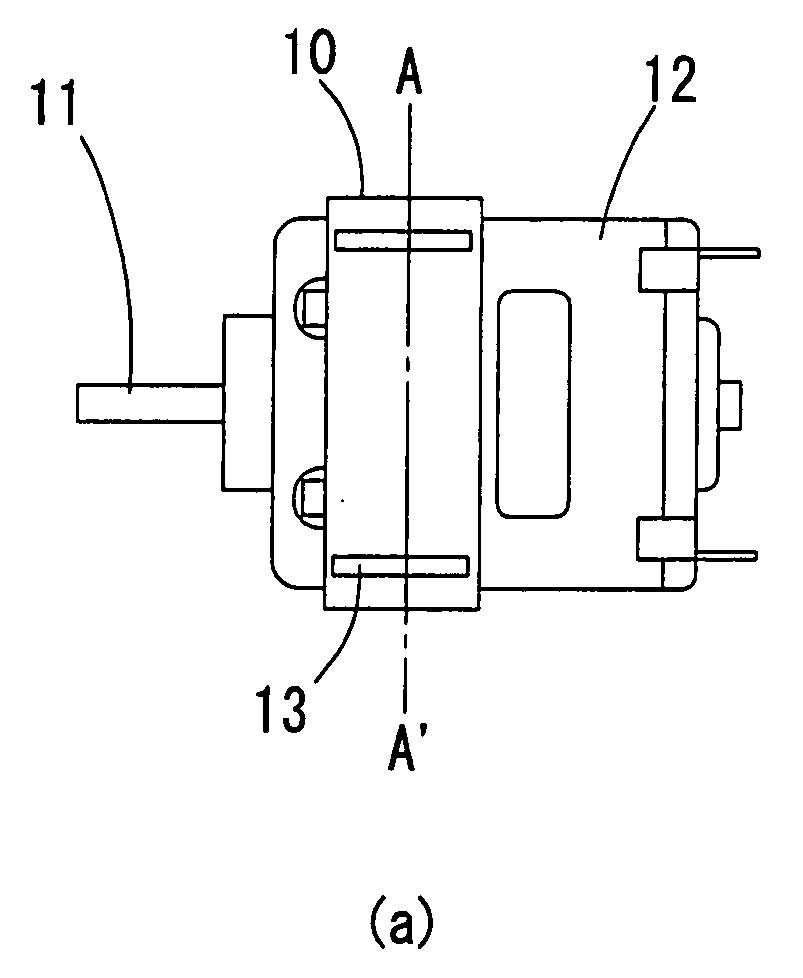

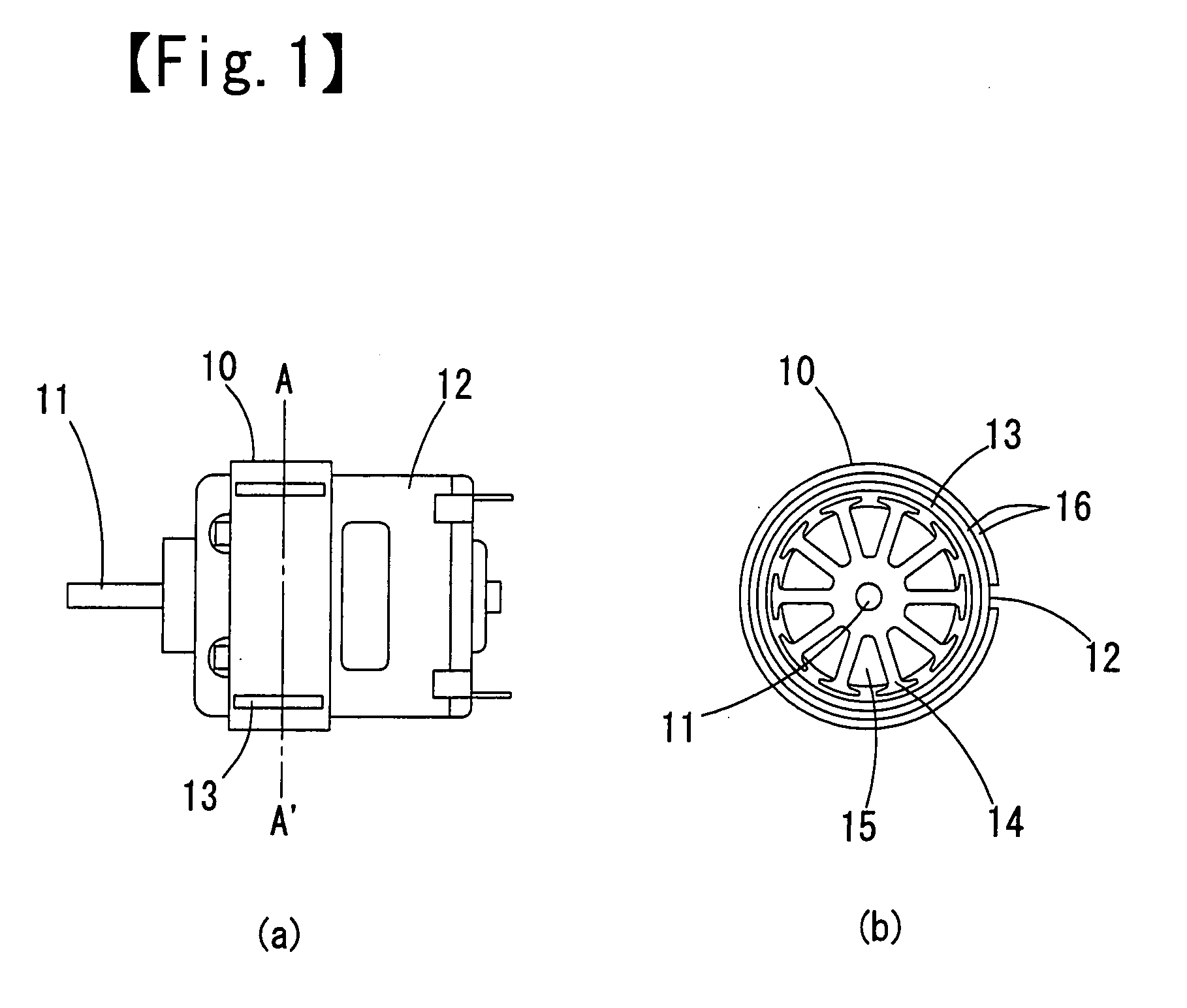

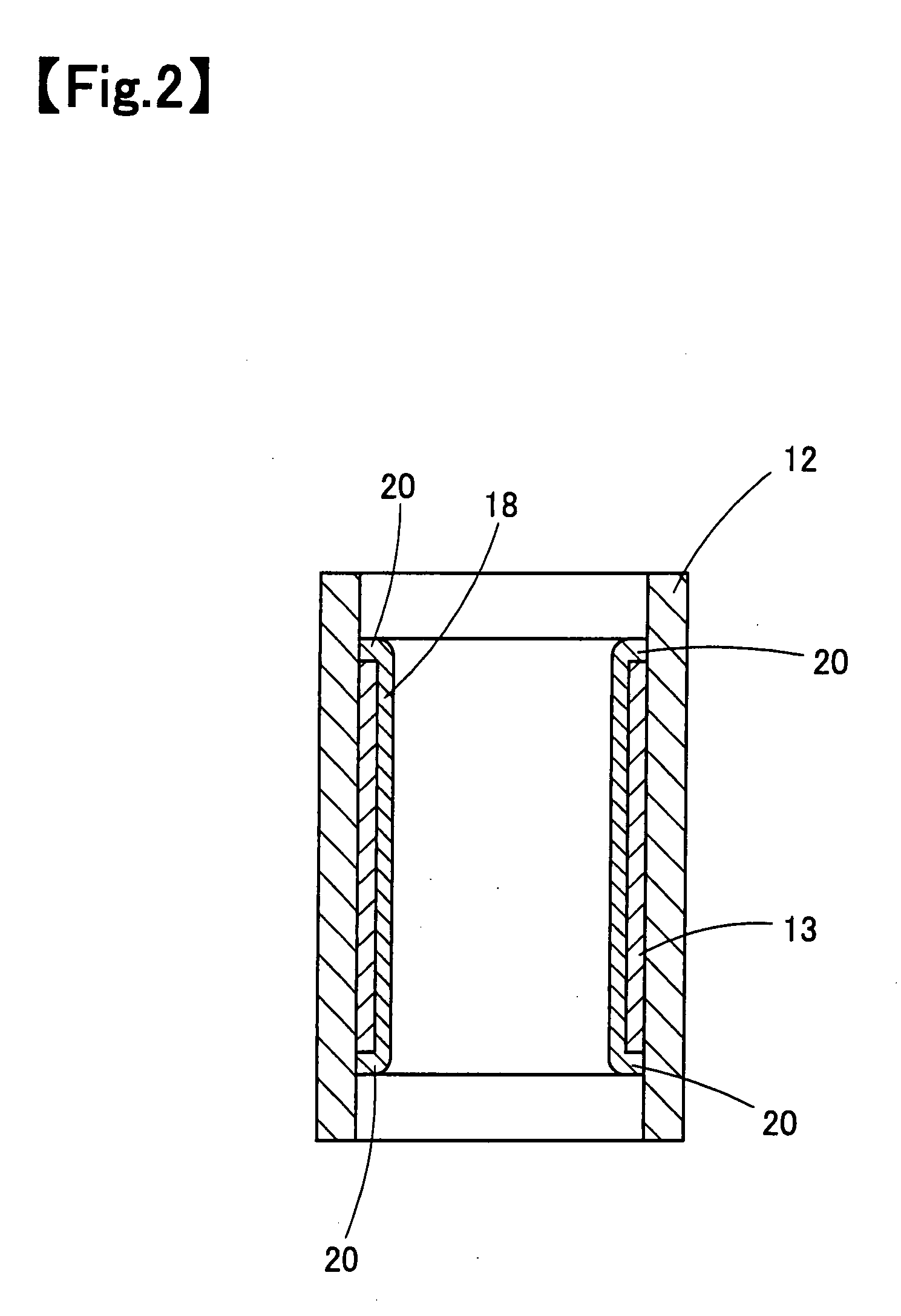

[Object] To improve resistance of a motor device against an organic solvent and to suppress degradation in performance of the motor device with time.[Solving Means] In a motor device, an excitation magnet is formed using a hollow-cylinder shaped anisotropic bonded magnet 13. This bonded magnet 13 is press-fitted in a housing 12 and is held. The bonded magnet 13 is formed of a hollow-cylinder shaped anisotropic rare earth bonded magnet which is obtained by compounding an anisotropic rare earth magnet powder with a phenol-novolac type epoxy resin, followed by molding. The anisotropic rare earth bonded magnet 13 is press-fitted along an inner peripheral portion of the housing 12, and on an exposed surface layer of the anisotropic rare earth bonded magnet press-fitted in the housing, a coating layer is formed by an infiltration treatment using a polyamide-imide-based resin.

Owner:AICHI STEEL

Anisotropic rare earth-iron based resin bonded magnet

InactiveUS20110074531A1Effectively secure magnetic stabilityGood magnetic stabilityPermanent magnetsInorganic material magnetismEpoxyOligomer

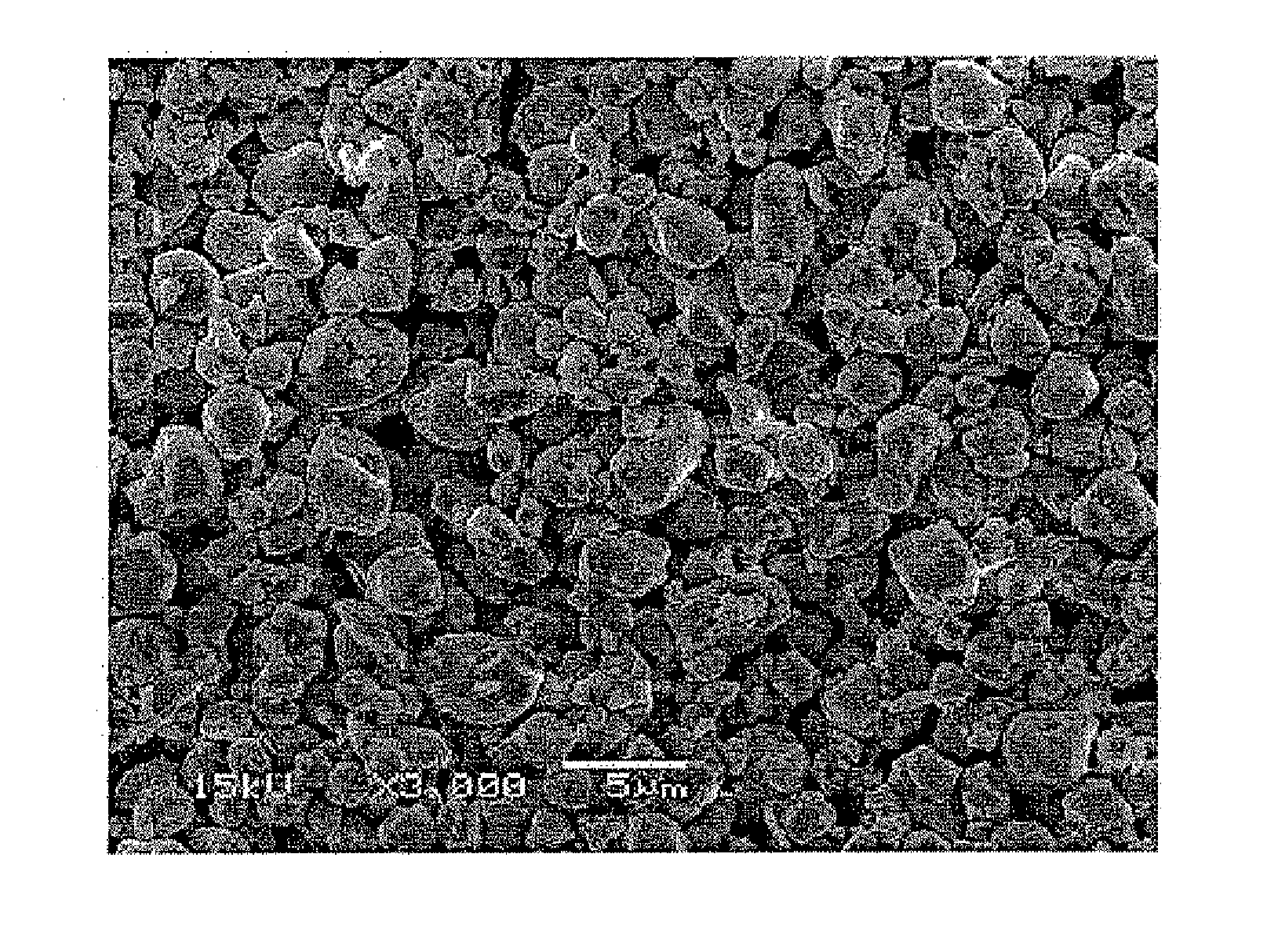

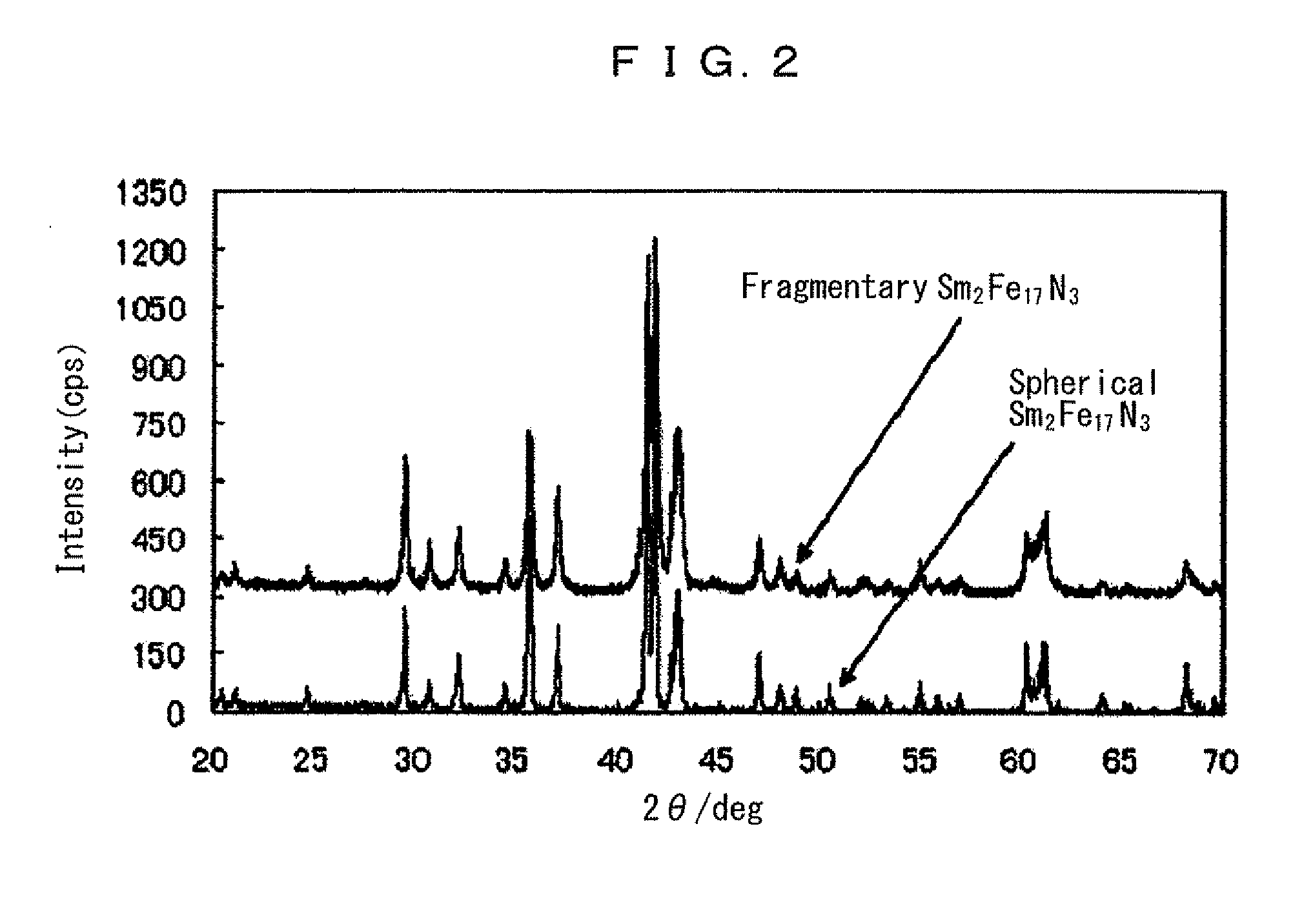

Anisotropic rare earth-iron based resin bonded magnet comprises: [1] a continuous phase including: (1) a spherical Sm2Fe17N3 based magnetic material covered with epoxy oligomer where its average particle size is 1 to 10 μm, its average aspect ratio ARave is 0.8 or more, and mechanical milling is not applied after Sm—Fe alloy is nitrided; (2) a linear polymer with active hydrogen group reacting to the oligomer; and (3) additive; and [2] a discontinuous phase being an Nd2Fe14B based magnetic material coated with the epoxy oligomer where its average particle size is 50 to 150 μm, and its average aspect ratio ARave is 0.65 or more, further satisfying: [3] the air-gap ratio of a granular compound on the phases is 5% or less; and [4] a composition where crosslinking agent with 10 μm or less is adhered on the granular compound is formed at 50 MPa or less.

Owner:MINEBEAMITSUMI INC

Process for producing magnet

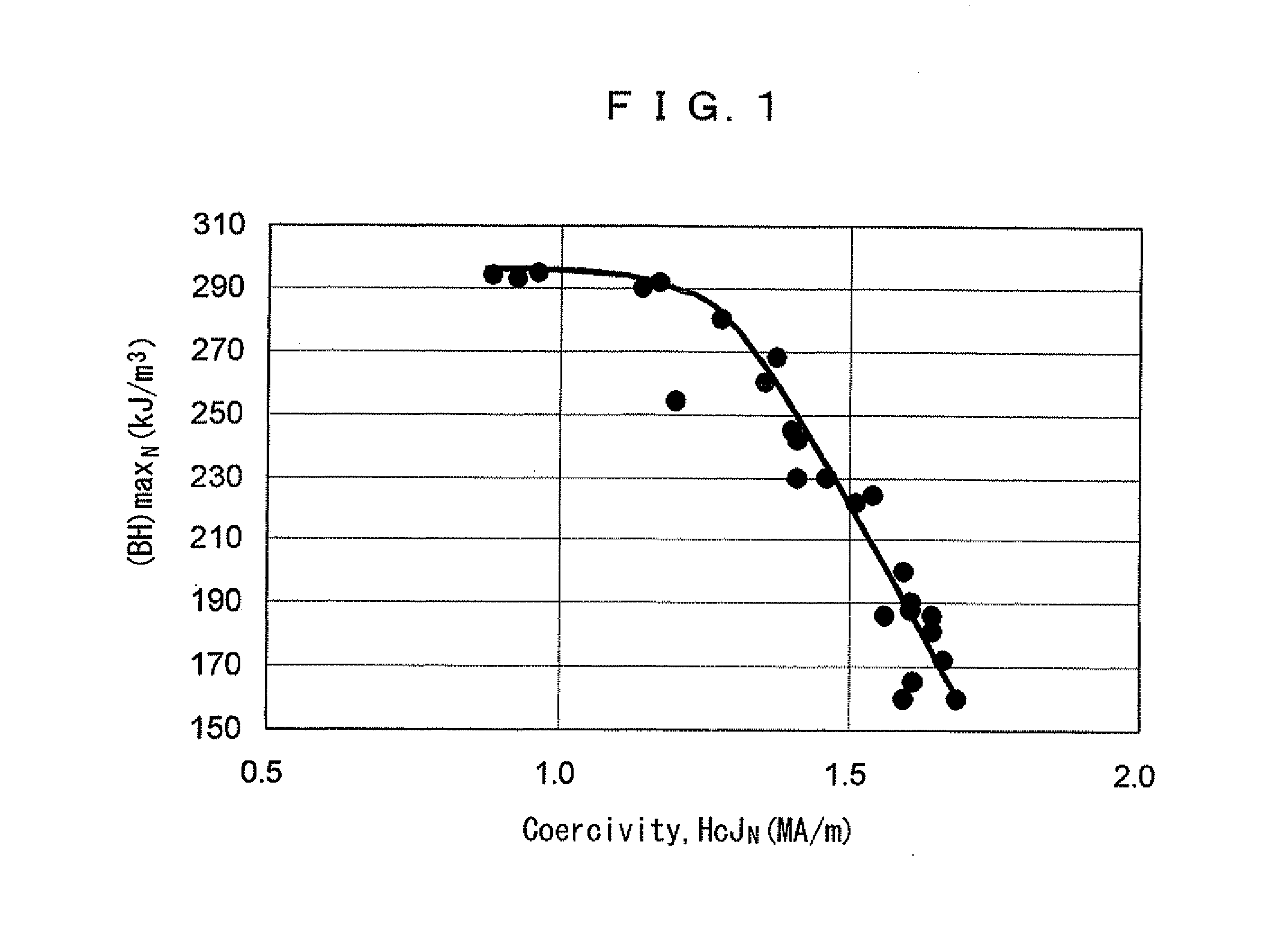

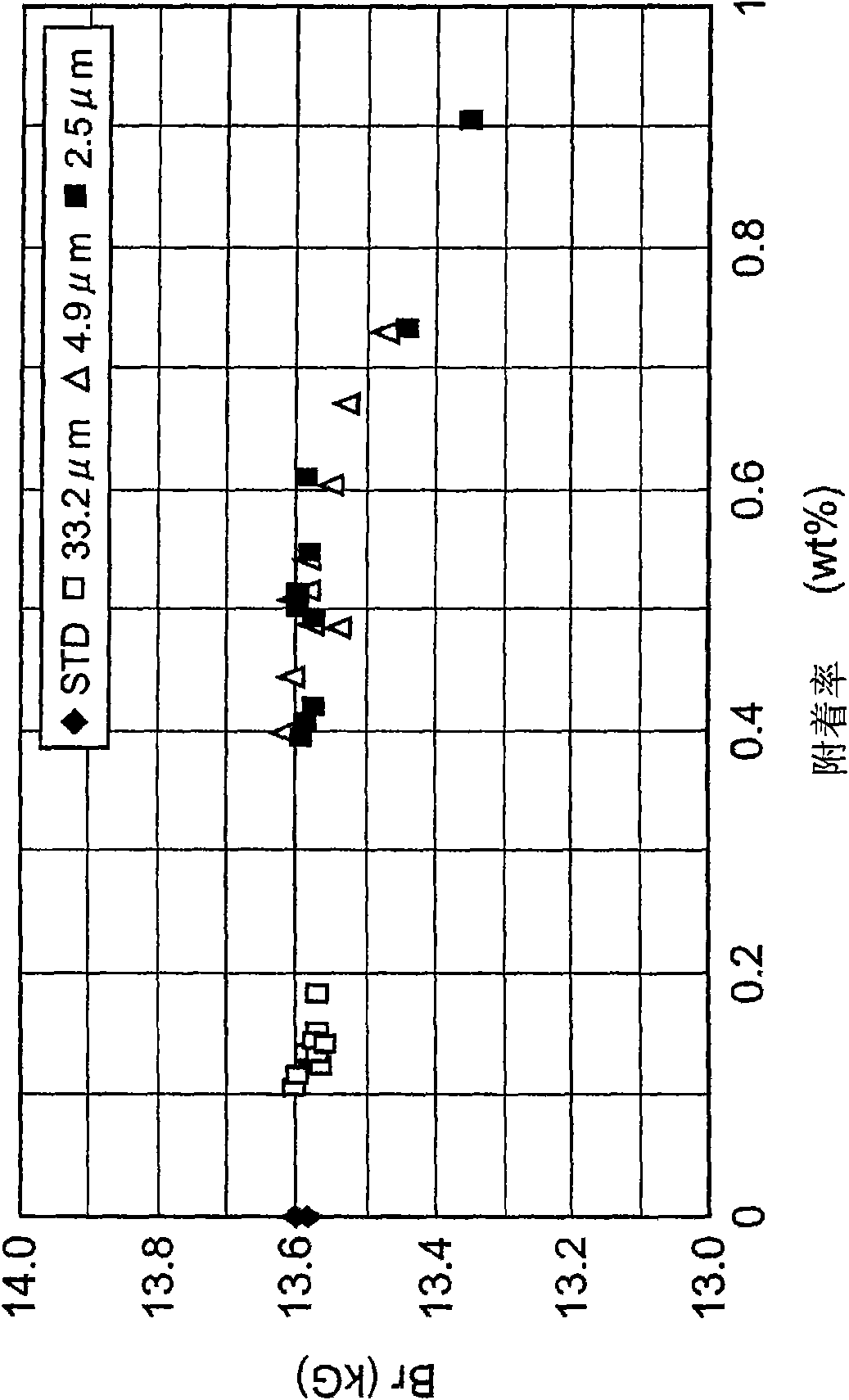

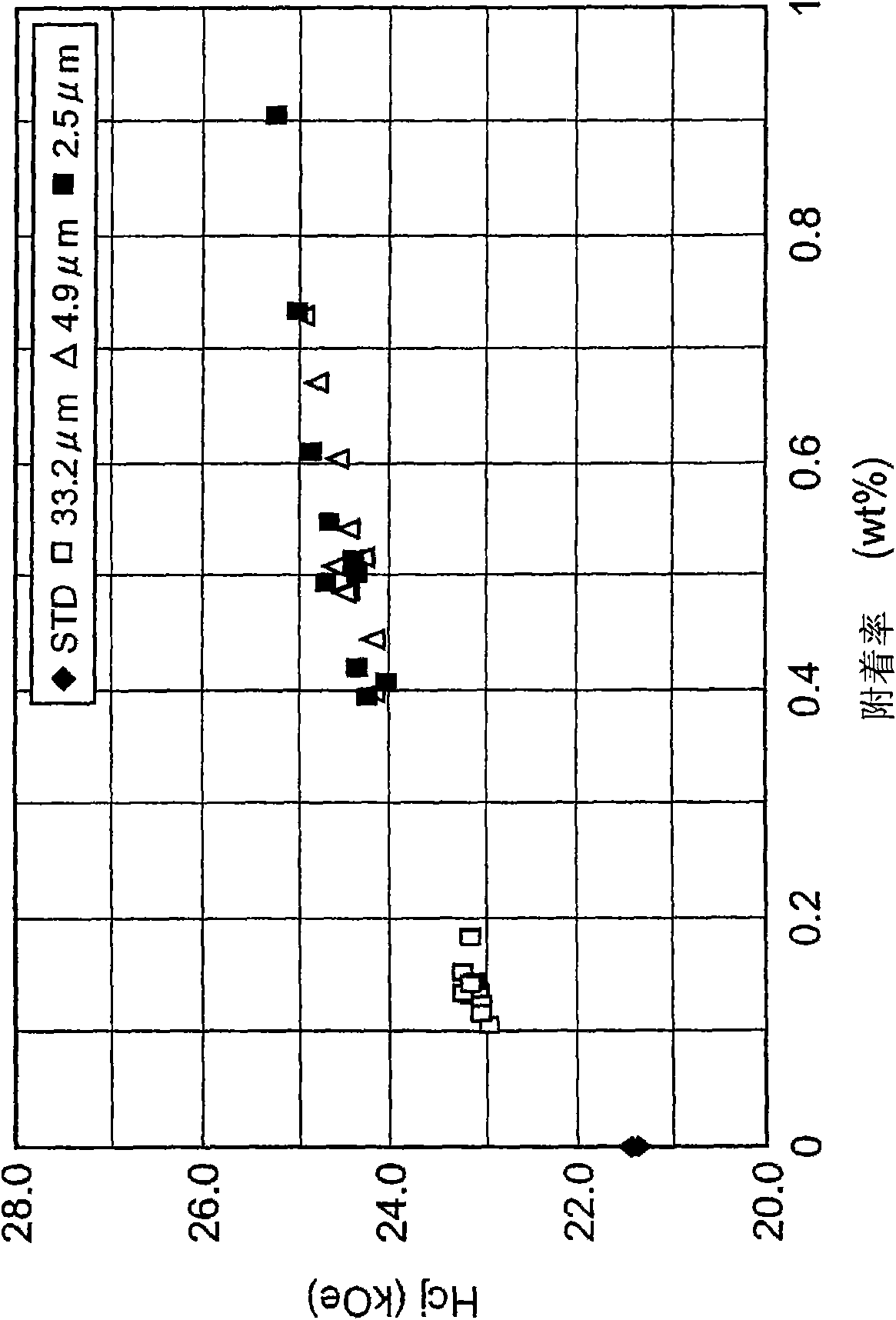

ActiveCN101542654ARectangular ratioTransportation and packagingMetal-working apparatusRare-earth elementRare-earth magnet

The object of the invention is to provide a process for magnet production by which a magnet not only having sufficient values of Br and HcJ but having a sufficiently high squareness ratio can be obtained. The process for magnet production is characterized by comprising a first step in which a heavy rare-earth compound containing a heavy rare-earth element is adhered to a sinter of a rare-earth magnet and a second step in which the sinter having the heavy rare-earth compound adherent thereto is heat-treated, the heavy rare-earth compound being the hydride of a heavy rare-earth element.

Owner:TDK CORPARATION

Rotor for motor and manufacturing method therefor

InactiveCN101080862AImprove crimp strengthHigh structural reliabilityMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsStructural reliabilityMagnetization

A surface magnet-type and inner magnet-type rotors having high bonding strength between a magnet section and a soft magnetic yoke section, and exhibiting high structural reliability and good motor characteristics even in a high-speed application. Methods of manufacturing the rotors are also provided. The surface magnet-type rotor is composed of an anisotropic bond magnet section and a soft magnetic section. To manufacture the surface magnet-type rotor, the anisotropic bond magnet section is preliminarily molded in a magnetic field, and then molded finally in a nonmagnetic field to be integrated with the soft magnetic section and heat cured. Magnetic units each having magnetic poles formed by bonding a pair of permanent magnets such that the directions of magnetization are symmetric about the bonding surface are connected to form an anisotropic magnet body, in which the magnetic units are arranged such that magnetic poles of different polarities appear alternately on a magnetism action surface. Good motor characteristics are attained by setting the direction of magnetization of the permanent magnets at an angle of 5-35 DEG relative to the radial direction passing the bonding surface.

Owner:HITACHI METALS LTD

Process for producing magnet

ActiveCN101620904AHigh BrInorganic material magnetismPermanent magnet manufactureRare-earth elementRare-earth magnet

The process for producing a magnet according to the invention is characterized by comprising a first step in which a heavy rare earth compound containing Dy or Th as a heavy rare earth element is adhered onto a sintered compact of a rare earth magnet and a second step in which the heavy rare earth compound-adhered sintered compact is subjected to heat treatment, wherein the heavy rare earth compound is a Dy or Th iron compound.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com