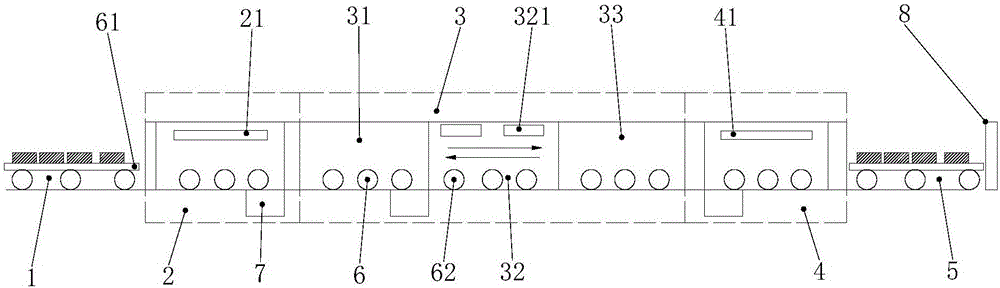

Coating method, coating system and method for preparing rare-earth magnet

A coating system, rare earth magnet technology, applied in the manufacture of permanent magnets, the application of magnetic films to substrates, the manufacture of inductors/transformers/magnets, etc., can solve problems such as unfavorable mass production, long time, and unfavorable production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] Third, an embodiment of the present invention provides a method for preparing a rare earth magnet, including:

[0081] Coating process: using the above-mentioned coating method to coat the magnet;

[0082] Grain boundary diffusion treatment process: heat-diffusion treatment is carried out on the coated magnet, and in 10 -1 Pa-10 -4 Pa vacuum state or 1Pa-80kPa inert gas environment, keep warm for 1h-60h in the range of 750°C-1000°C, and keep warm in the range of 800-900°C for 6h-30h; use the thermal diffusion-treated magnetic sheet as the second-level heat preservation For treatment, the temperature is 450°C-600°C, and the treatment time is 1h-10h.

[0083]In the embodiment of the present invention, before coating the magnet, oil removal, rust removal and drying are required, and the thickness of the magnet is less than 10 mm.

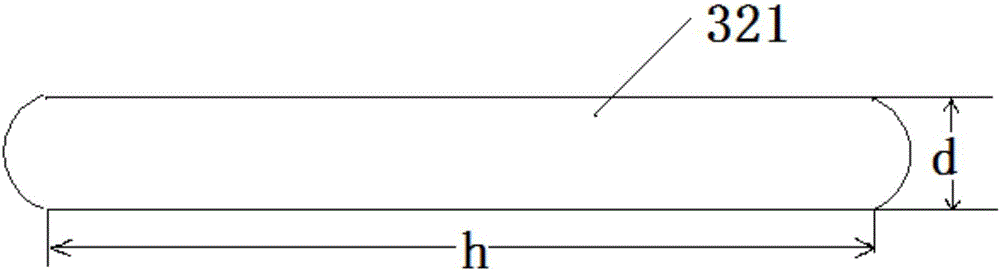

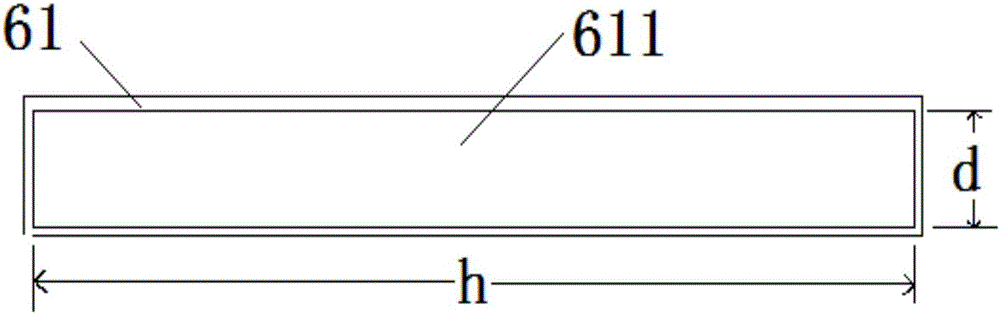

[0084] The coating method, coating system and preparation method of the rare earth magnet proposed in the embodiment of the present inventio...

Embodiment 1

[0087] 1. According to atomic percentage: (NdPr)-13.6%, Dy-1.8%, Tb-0.2%, Cu-0.1%, Co-1.0%, A-l0.52%, Ga-0.4%, B-5.7%, Fe-bal (bal is the abbreviation of balance) is used for proportioning and proportioning. The alloy thin strip is prepared by smelting alloy stripping method, and the thickness of the thin strip is controlled to 0.5-2mm. After hydrogen explosion and jet milling, the powder particle size D50=4.5μm, Under the protection of protective gas, the blank is pressed through a 1.8T magnetic field orientation, and vacuum sintered in a vacuum sintering furnace. The sintering temperature is 1040 ° C, kept for 4 hours, and then released after cooling. The sintered NdFeB magnet is processed into a magnetic sheet with a specification of 39mm×20mm×2.5mm, and the direction of 2.5mm is the magnetization direction of the magnet. The disks are cleaned by degreasing, pickling, activation and deionized water cleaning.

[0088] 2. Put the cleaned magnetic sheets on the tray in an ali...

Embodiment 2

[0110] The atomic percentage of ingredients is (NdPr)-13.2%, Dy-0.6%, Tb-0.2%, Cu-0.1%, Co-1.1%, Al-0.2%, Ga-0.1%, B-5.7%, Fe-bal , all the other processes are the same as in Example 1. After machining, the size is 34.5×11.2×1.95mm. 3000 pieces were taken for batch experiments, and 60 pieces were randomly taken out for testing to verify the magnetic performance and efficiency. The magnetic performance test results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com