Patents

Literature

61results about How to "Rapid serial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

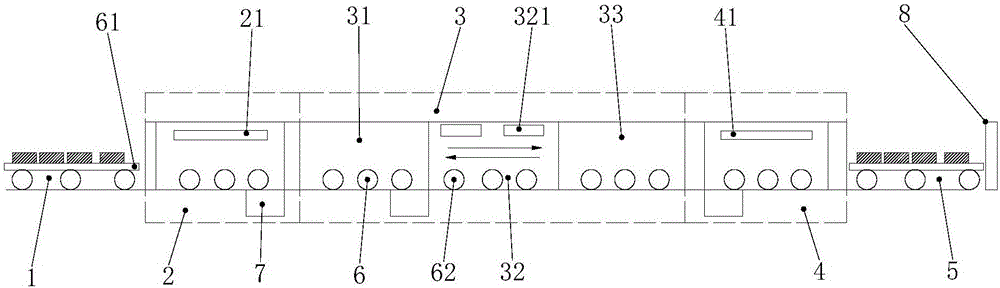

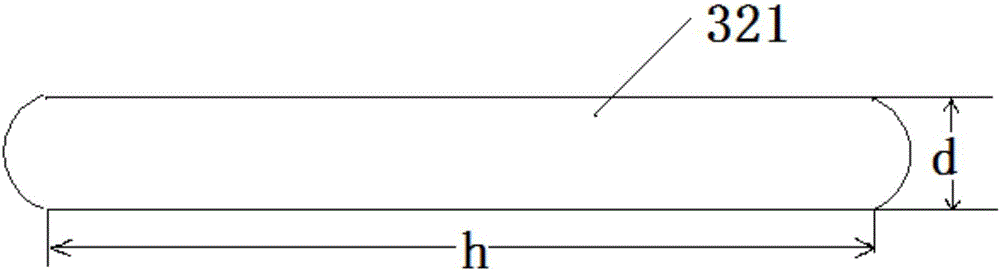

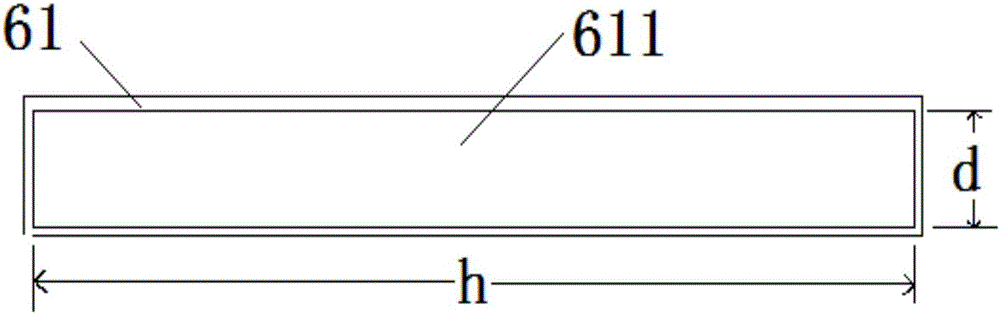

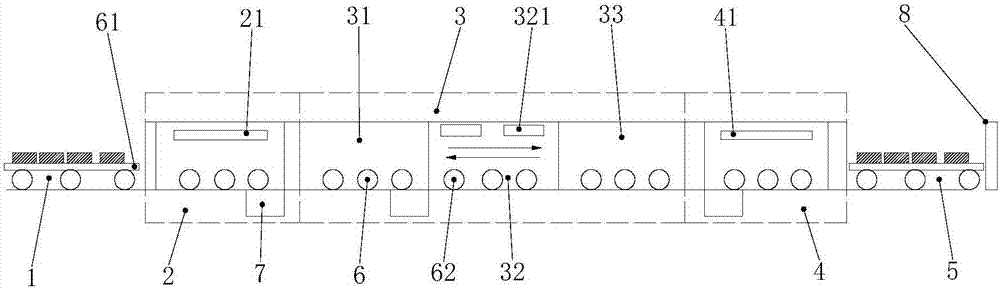

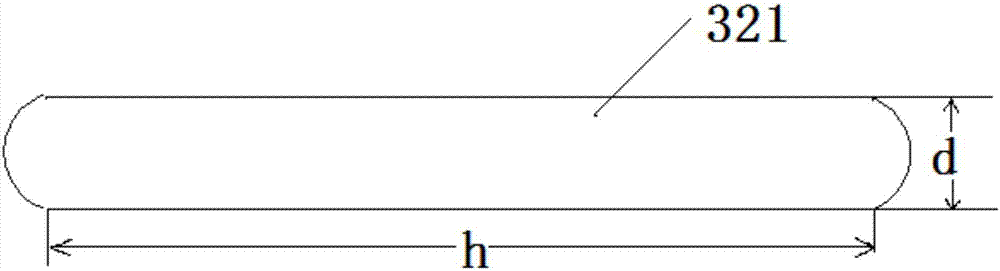

Coating method, coating system and method for preparing rare-earth magnet

ActiveCN106282948AImprove consistencyEffective thickness controlVacuum evaporation coatingSputtering coatingSputteringCoating system

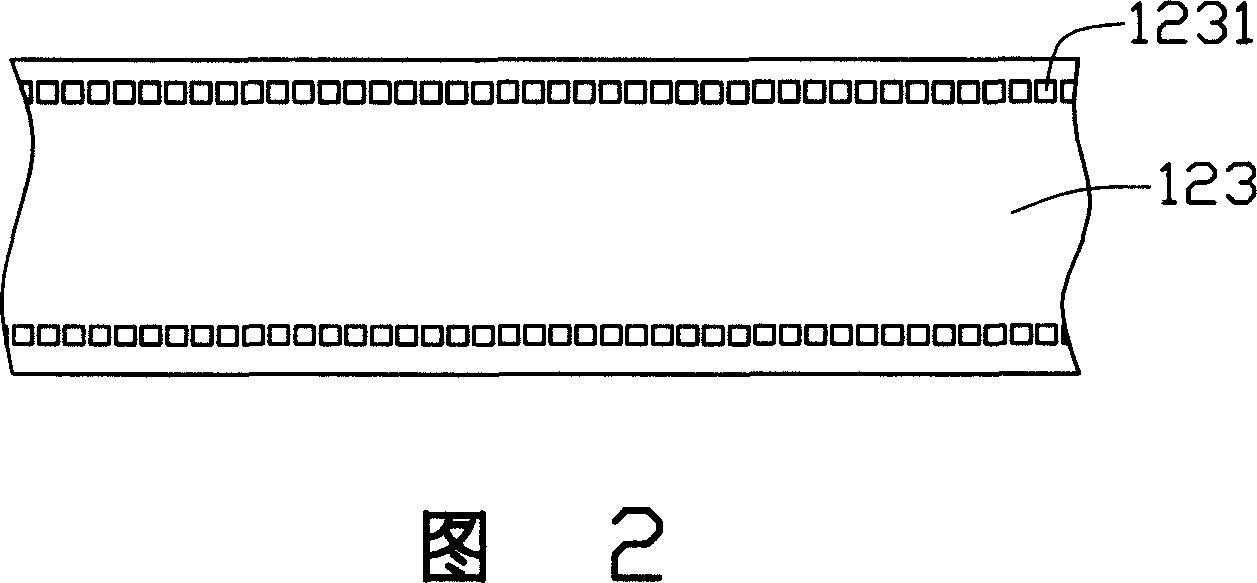

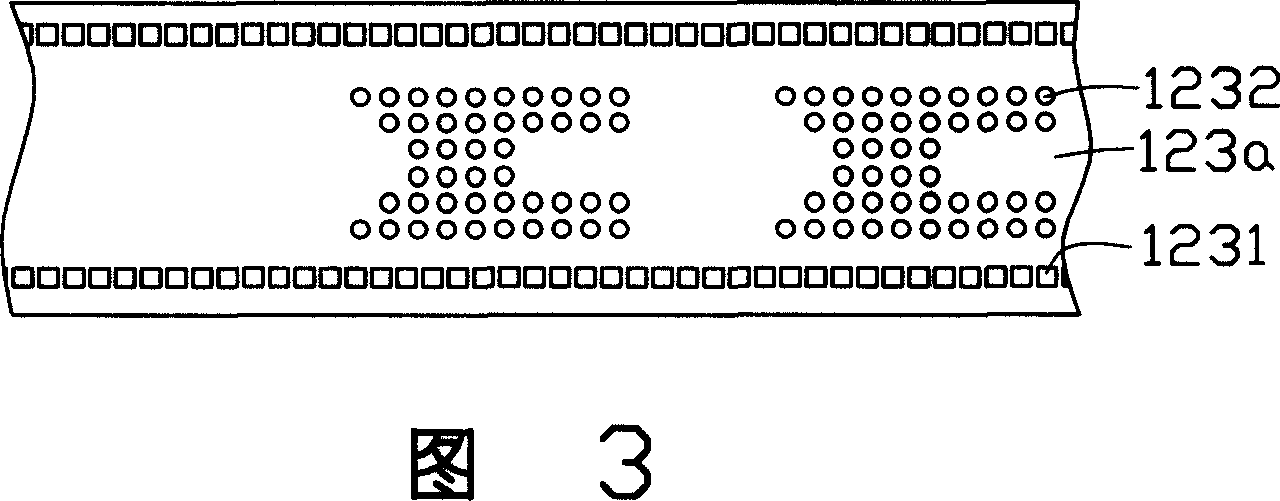

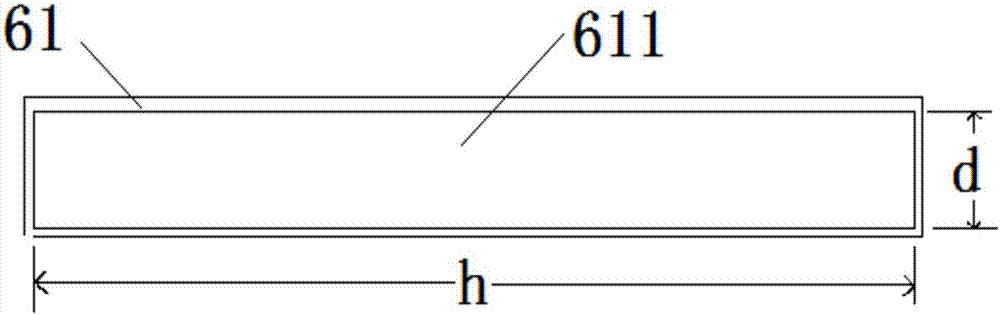

The invention discloses a coating method, a coating system and a method for preparing rare-earth magnets. In the method and the system disclosed by the invention, magnets are arranged on a conveying device in a plurality of rows in a horizontal direction; the magnets which are arranged in the plurality of rows sequentially pass through a sputtering area of sputter coating equipment to complete coating; a vertical distance between the sputter coating equipment and the upper surface of the magnets is 10mm to 200mm. The method and the system disclosed by the invention adopt continuous pass type magnetron sputtering equipment to sputter heavy rare earth such as Dy and Tb onto the surfaces of the magnets, the thickness of the sputtering layer is effectively controlled, the uniformity of the sputtering layer is guaranteed, thereby the uniformity of the magnetic property of magnetic sheets obtained by performing grain boundary diffusion to the sputtered magnets is guaranteed, and the rapid and continuous production of magnets by adopting the grain boundary diffusion technique can be realized.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

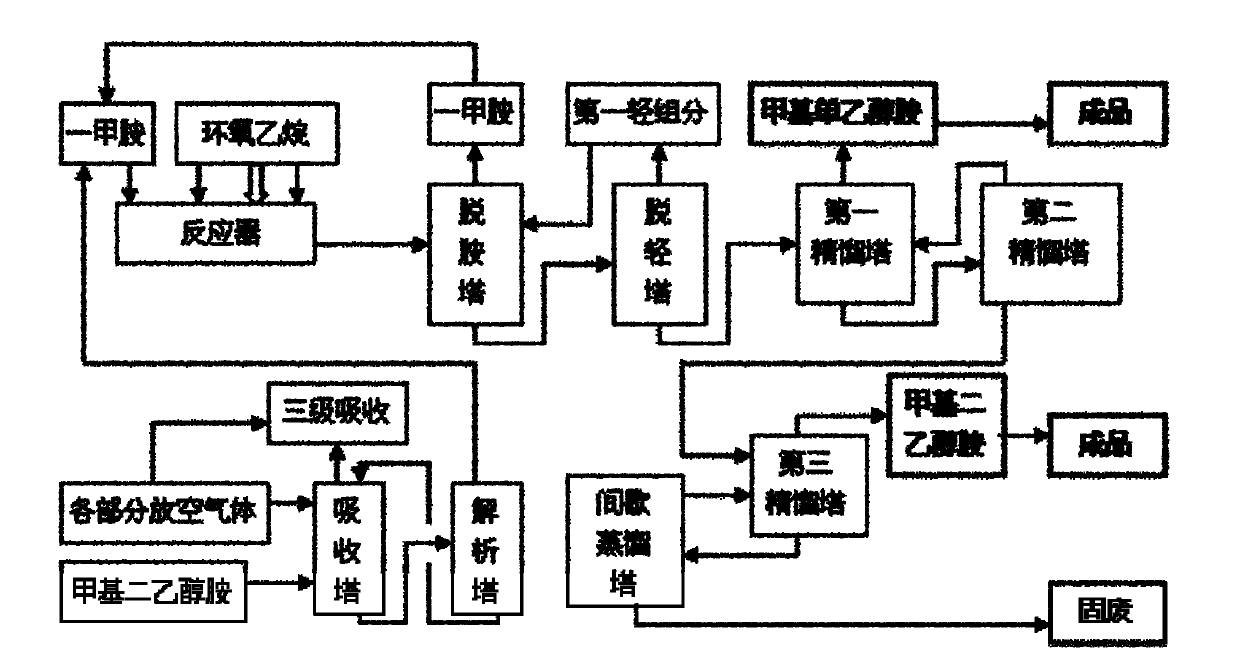

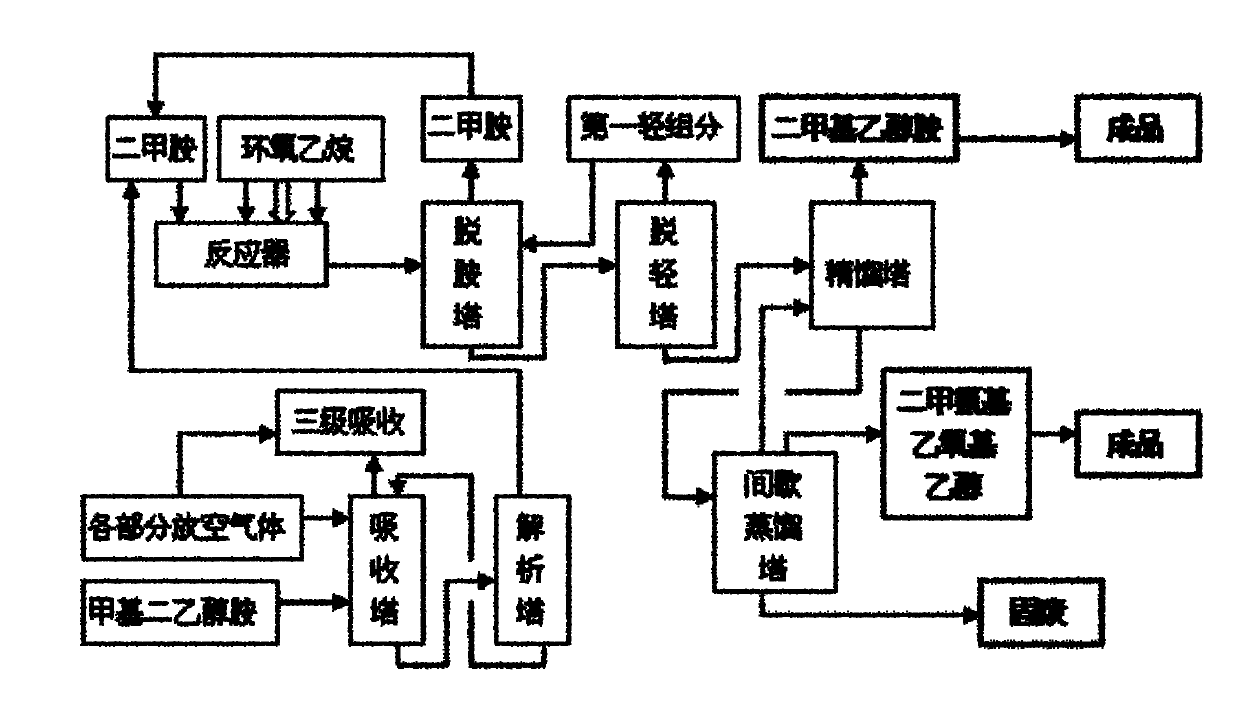

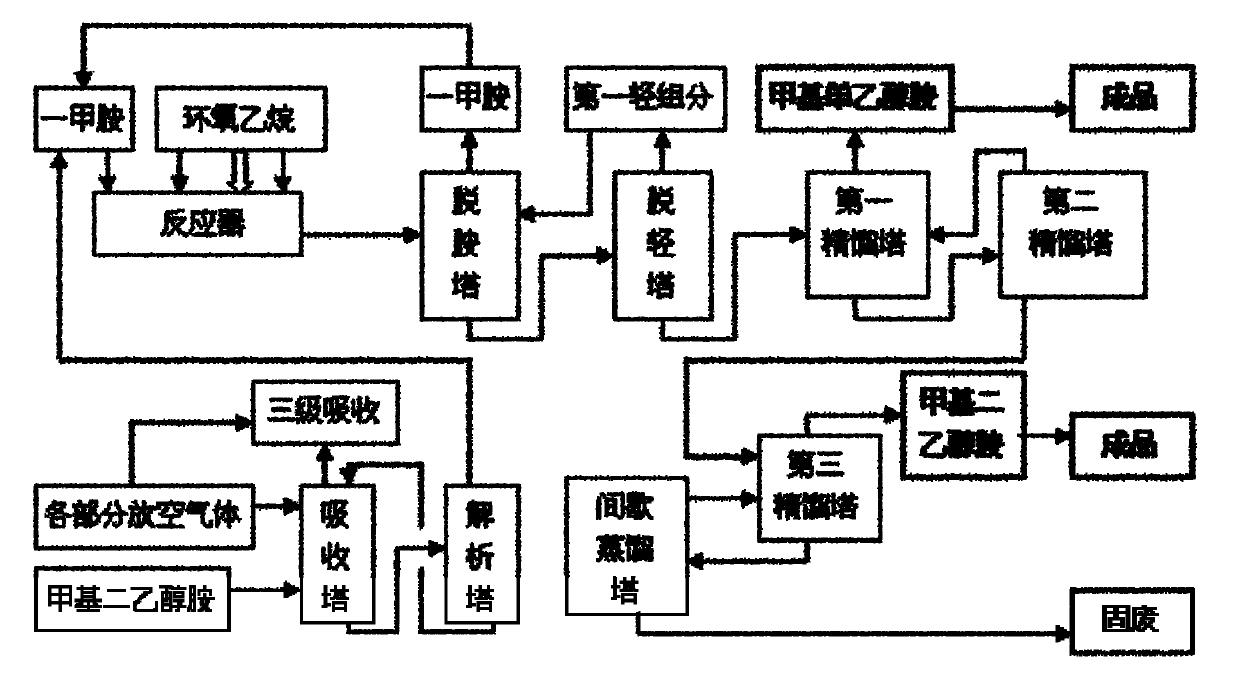

Method for producing alkyl alcohol amine

ActiveCN102557960ALess side effectsExpand the range of output ratio adjustmentOrganic compound preparationAmino compound preparationAlkyl transferAlcohol

The invention provides a method for producing alkyl alcohol amine. The method is characterized by comprising the following steps of: under an alkylation reaction condition, repeatedly contacting alkylene oxide with alkylamine in a reactor; and repeatedly reacting alkylene oxide with alkylamine. On one hand, the side reaction of the alkylene oxide is reduced, and the yield proportion adjusting ranges of alkyl mono-alkylol amine and alkyl di-alkylol amine are expanded; meanwhile, raw materials are not required to be mixed in advance, and the safety of production is improved; moreover, alkylene oxide enters segmentally in a multipoint way, so that reaction heat is segmentally released, and a reaction is more stable; and furthermore, the content of the mono-alkyl alkylol amine can be controlled, so that the mono-alkyl alkylol amine is not required to be taken as a circulating liquid, and the yield of the reaction is increased.

Owner:FEIXIANG NEW MATERIAL R & D SUZHOU INST

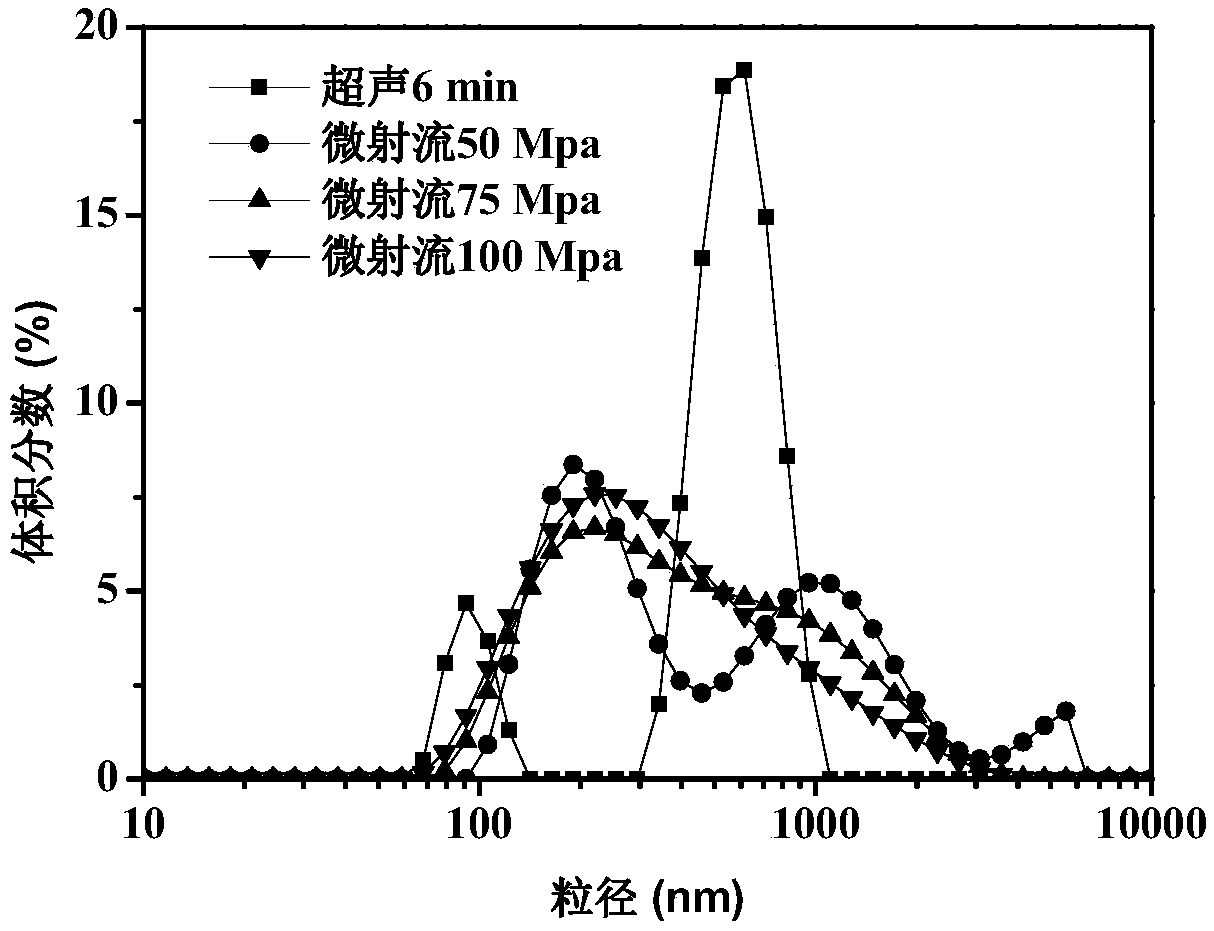

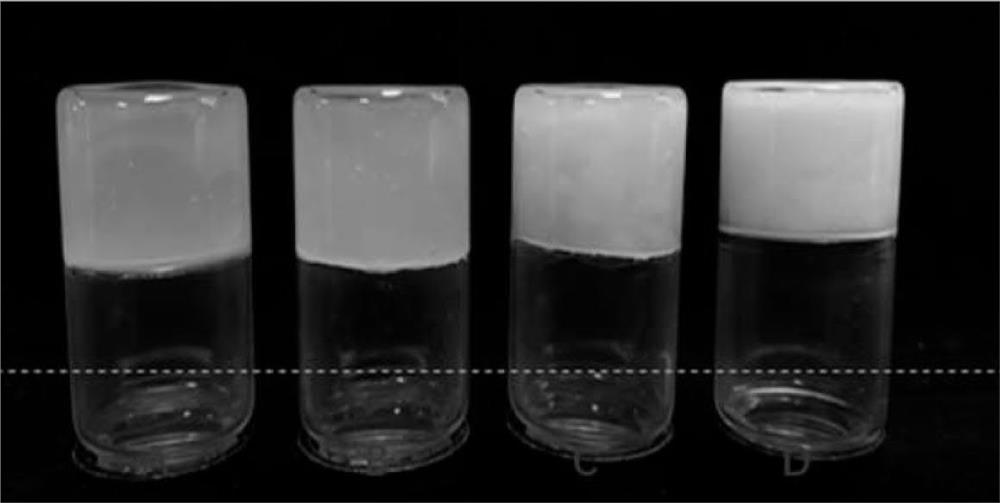

Stable phytosterol nanometer emulsion compounded by soy protein-stevioside, and preparation method and application thereof

ActiveCN108618146AGood resolubilityUniform particlesMilk preparationFood ingredientsProtein solutionOil phase

The invention discloses stable phytosterol nanometer emulsion compounded by soy protein-stevioside, and a preparation method and application thereof. The method comprises the steps of mixing a soy isolate protein solution and a stevioside solution to prepare a composite stable system; dissolving phytosterol into sunflower seed oil being 90 to 99 DEG C to obtain an oil phase; adding thw oil phase dissolved with the phytosterol into a water phase of soy protein-stevioside; controlling the mass ratio of the oil phase to the water phase to be 10:90-50:50; after the homogenizing, performing ultrasonic treatment or high-pressure micro jet flow treatment to obtain the stable phytosterol nanometer emulsion compounded by soy protein-stevioside. A powder product with high redissolving performance loaded with phytosterol can be prepared through spray drying treatment on the nanometer emulsion. The process conditions are simple and mild; the natural effect and safety are realized; the fast continuous production can be performed; products applied to food, medicine and cosmetics can be prepared through operating and controlling the process conditions; the industrialized and scaled application values are realized.

Owner:SOUTH CHINA UNIV OF TECH

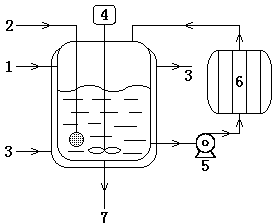

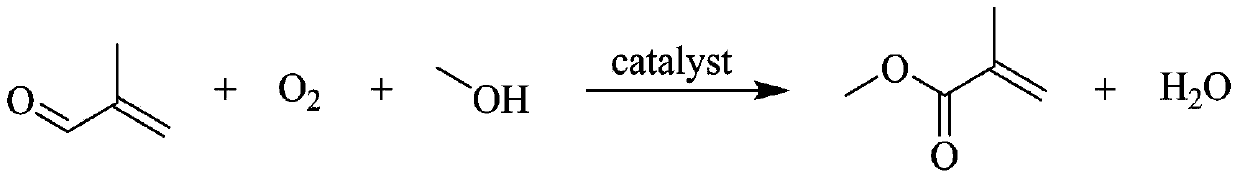

Method for preparing methyl methacrylate by using methacrolein

InactiveCN103420835AEfficient removalIncrease profitOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention relates to a method for preparing methyl methacrylate by using methacrolein, and mainly solves the problem that the conversion rate of the methacrolein in the production process of the heavy chemical product, namely the methyl methacrylate in the prior art is low. The method comprises the comprises the following steps: using the methacrolein, oxygen and methanol as raw materials and heating up to the reaction temperature, and performing oxidative esterification reaction under the action of a catalyst, namely a palladium compound, wherein in the reaction process, the reaction mixture is conveyed into an external cycle dehydration system in a certain flow rate for realizing dehydration in a cycling manner, so that the reaction can be balanced and performed in the positive direction, which improves the conversion rata of the methacrolein, and realizes low-power-consumption, simple, fast and continuous production; the yield of the obtained reaction product (namely the methyl methacrylate) is greater than 93%.

Owner:TAICANG HENGYI MEDICINE CHEM MATERIAL FACTORY

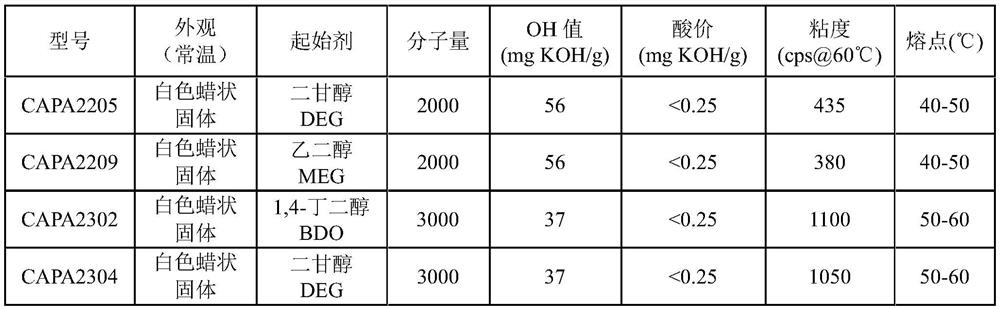

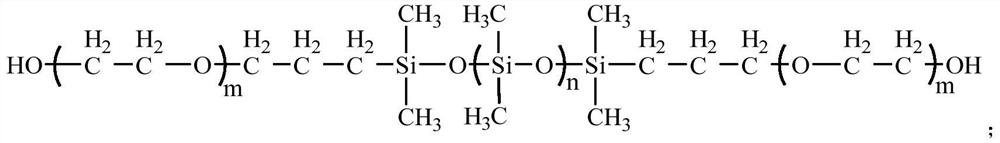

UV skin-feeling wood coating as well as preparation method and application thereof

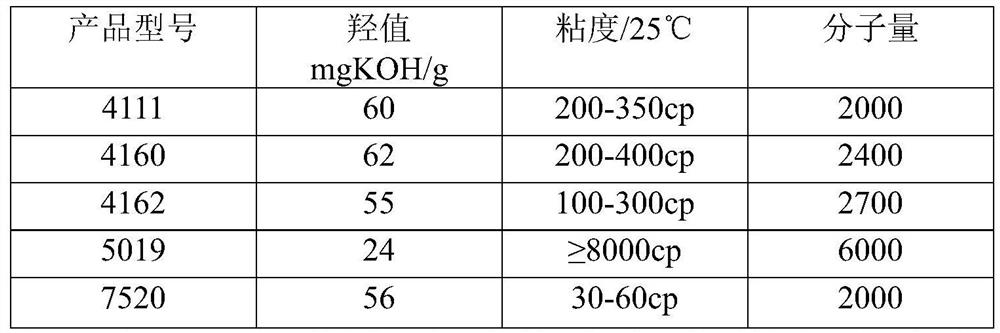

PendingCN113122125AGood flexibilityImprove adhesionPolyurea/polyurethane coatingsPolymer sciencePolyethylene glycol

The invention discloses a UV skin-feeling wood coating which comprises the following raw materials in parts by weight: 10-40 parts of UV cured resin, 50-80 parts of a reactive diluent, 0.1-5 parts of a functional aid, 1-10 parts of functional filler and 1-10 parts of a photoinitiator; wherein the UV curing resin is a combination of 2-functionality elastic polyurethane acrylate, 2-functionality polysiloxane type polyurethane acrylate and 6-functionality polyurethane acrylate, and the reactive diluent is a combination of polyethylene glycol (200) diacrylate and ethyoxyl ethyoxyl ethyl acrylate. The invention further discloses application of the UV skin-feeling wood coating in preparation of wood finishing paint. According to the invention, the UV skin-feeling wood coating is coated on woodware, and the coating of the skin-touch paint can be realized and the skin-touch effect can be generated by curing by using an ultraviolet curing machine; the paint film is good in adhesive force, soft, smooth, fine, comfortable, good in skin-touch effect, low in cost and free of pollution.

Owner:JIANGSU LITIAN TECH

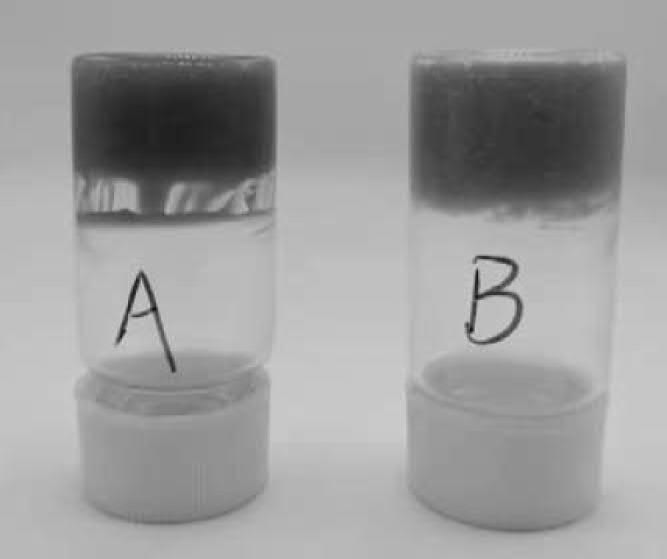

Method for industrial co-production of phycocyanin, spirulina polysaccharide and protein feed from fresh spirulina

ActiveCN109593128ASolve the problem with the extraction methodSolve the real problemAnimal feeding stuffDepsipeptidesFiltrationUltrafiltration

The invention discloses a method for industrial co-production of phycocyanin, spirulina polysaccharide and protein feed from fresh spirulina. The method comprises the following steps: (1), taking cleaned fresh spirulina sludge into an ultrasonic extraction tank; (2), uniformly stirring the mixed solution, and performing ultrasonic wall breaking extraction; (3), extracting the mixed solution for solid-liquid separation; (4), performing separation on an algae residue / grinding bead mixture by a filter screen; (5), cleaning and recycling grinding beads; (6), performing solid-liquid separation on the algae residue mixed solution again by a fine filter; (7), passing the combined phycocyanin extract through cross-flow membrane filtration equipment; (8), passing the supernatant in the previous step through 30 KDa ultrafiltration membrane equipment; (9), spray drying an ultrafiltration concentrated solution. The method has the following advantages that no chemical additive is used, physical wall breaking is conducted, pure water extraction is conducted in the whole process, the extraction cost is reduced, no chemical sewage is discharged, the method is environmentally friendly, and the application requirement of the natural and healthy product of phycocyanin is met.

Owner:张德智 +2

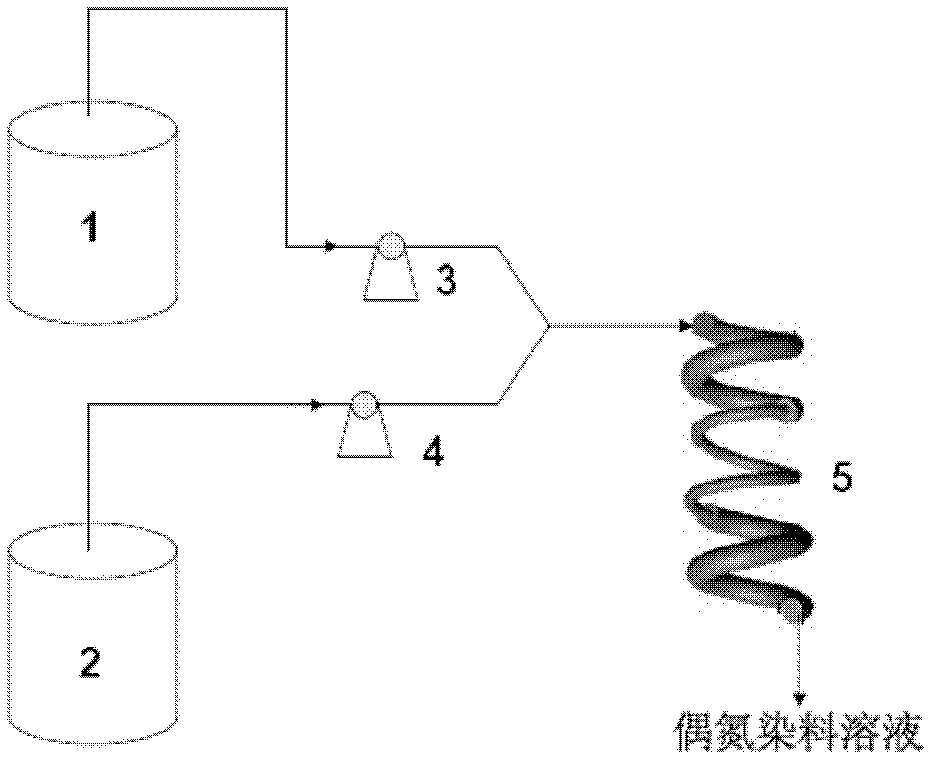

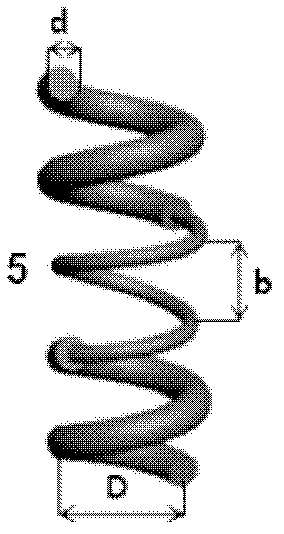

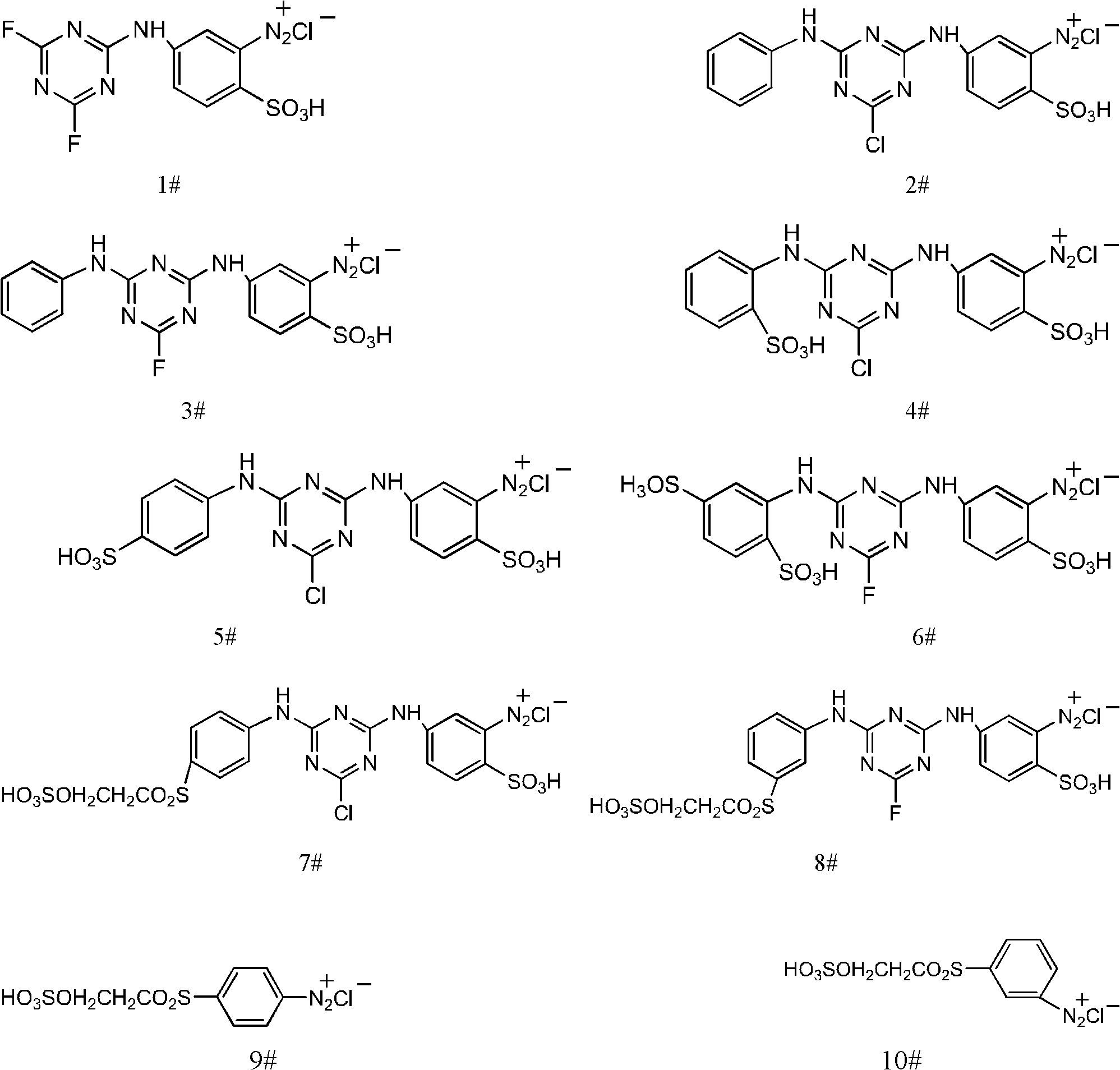

Method for preparing water-soluble azo dye continuously by chaos mixing of spiral tube

ActiveCN102618063BRapid serial productionFully contactedMonoazo dyesDisazo dyesMicroreactorStraight tube

The invention provides a method for preparing a water-soluble azo dye continuously by the chaos mixing of a spiral tube. The core is that a spiral tube sudden-expansion and sudden-contraction structure is adopted; compared with pure straight tube sudden-expansion and sudden-contraction mixed reaction, the method has the advantages that a mixed effect of a transverse secondary flow generated by fluid in a curved pipeline is far stronger than that of pure diffusion of a straight tube part; compared with the conventional spiral tube, the sudden-expansion and sudden-contraction part has the advantages that the motion trail of the fluid can be changed, the superficial area of a mixed interface can be increased and a chaos mixing effect can be enhanced; and the mixer has the advantages of quick and uniform mixing, stirring prevention, short retention time, high quality stability of the product, high speed of removing reaction heat by a tube wall and the like of a microreactor, and also overcomes the defects of small internal diameter and high possibility of blockage of the microreactor, so that the dye can be produced quickly and continuously, and the method is wide in industrial prospect.

Owner:DALIAN UNIV OF TECH

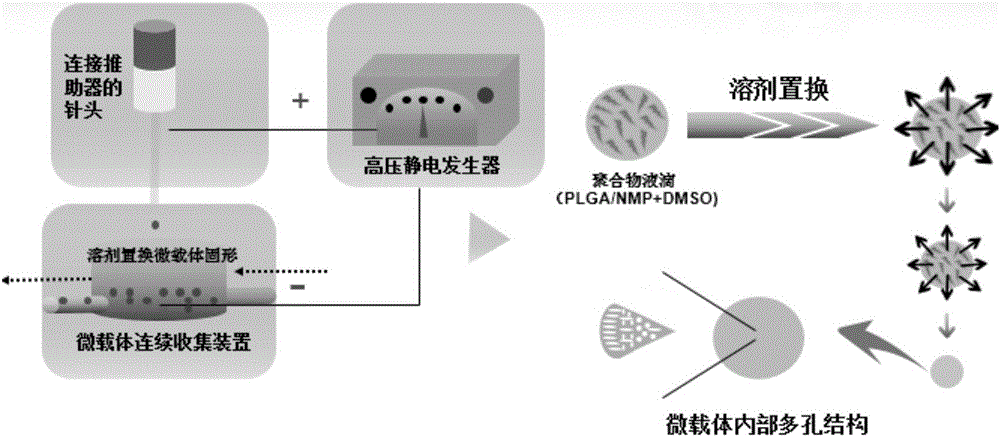

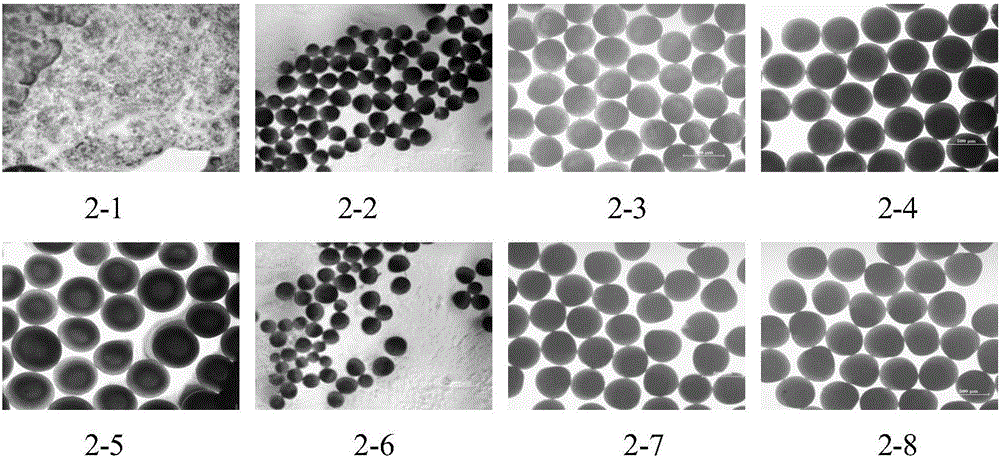

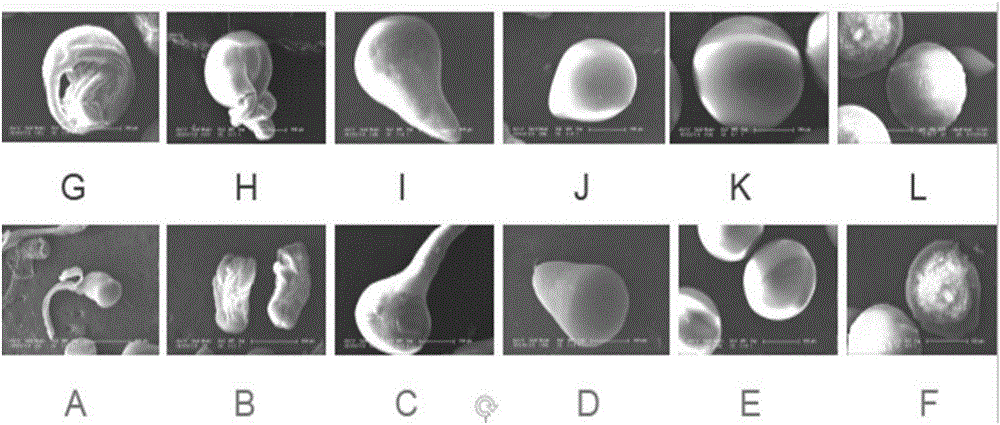

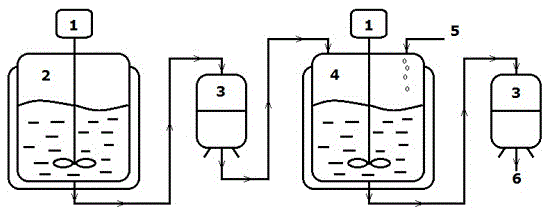

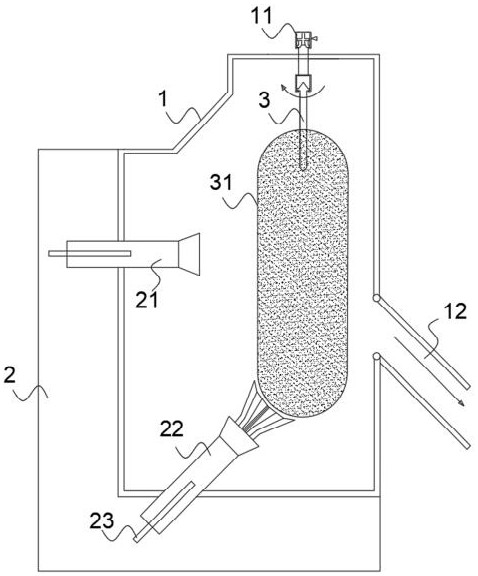

Preparation method of microcarrier

ActiveCN106282088AThe preparation process is easy to controlEasy to makeGeneral culture methodsPolymer sciencePolymer solution

The invention relates to the technical field of cell culture, in particular to a preparation method of a microcarrier. The preparation method of the microcarrier comprises the steps that a high-molecular polymer is dissolved in mixed solvent prepared from DMSO and NMP or pure NMP to obtain a high-molecular polymer solution; the high-molecular polymer solution is put into an electrostatic generator with a needle injection device, the high-molecular polymer solution is charged through high voltage static electricity, a liquid drop is formed at the tail end of a needle and drops into extracting solvent, and organic solvent in the liquid drop is quickly removed through a solvent extracting principle, so that the microcarrier is quickly prepared. According to the preparation method, the time needed by the microcarrier preparation process is shortened, and the advantages of being simple and efficient are achieved; the high-molecular polymer microcarriers with the uniform particle size can be continuously and controllably produced, and the purpose of precisely regulating and controlling the size and morphology of the microcarriers is achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

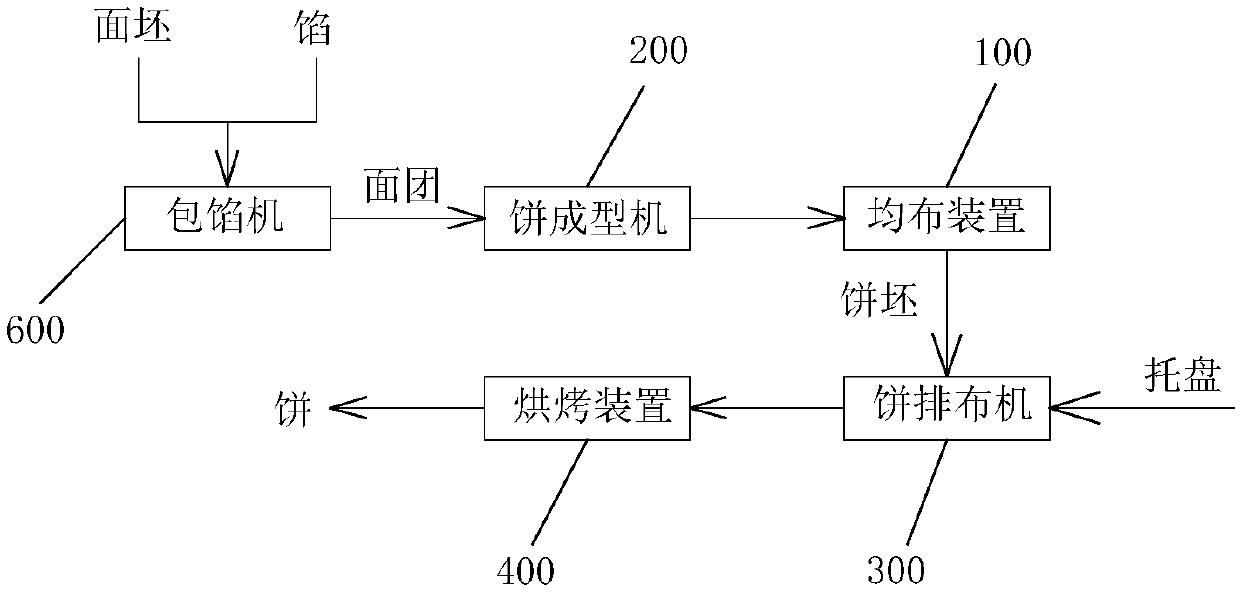

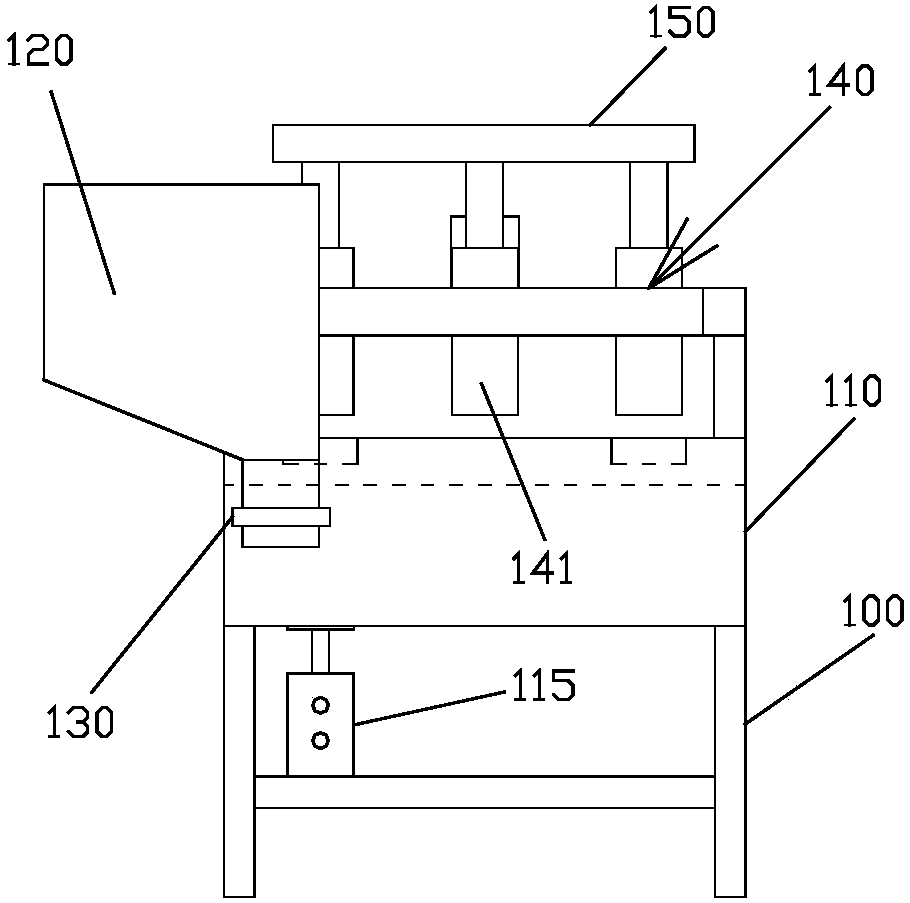

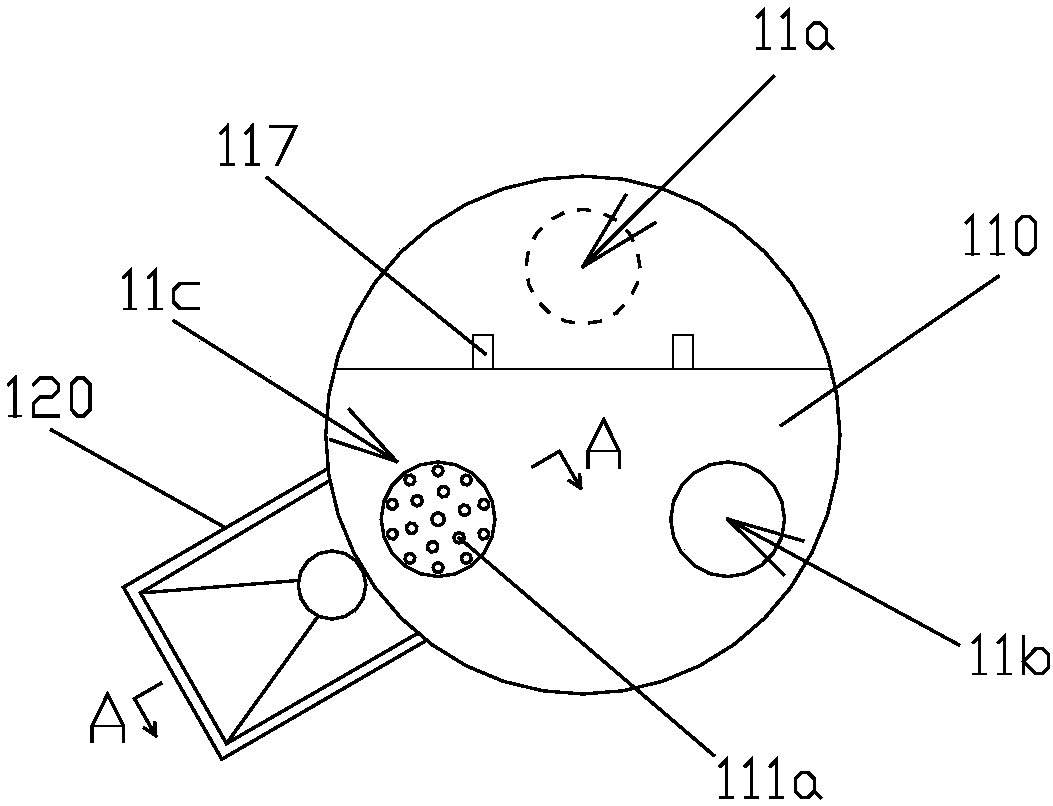

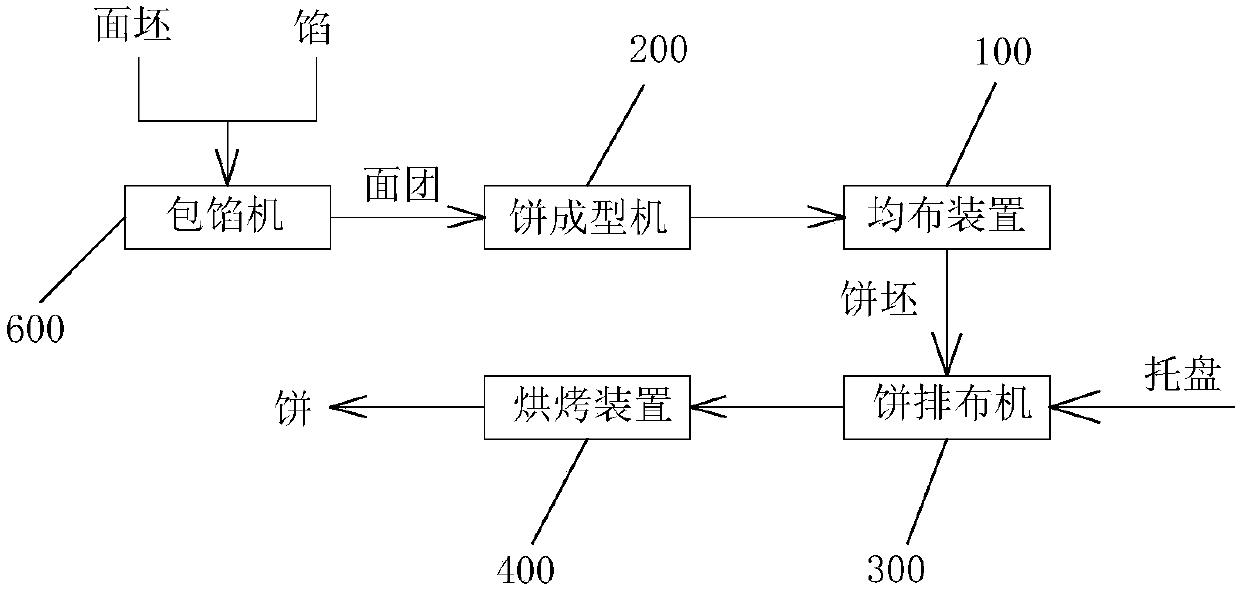

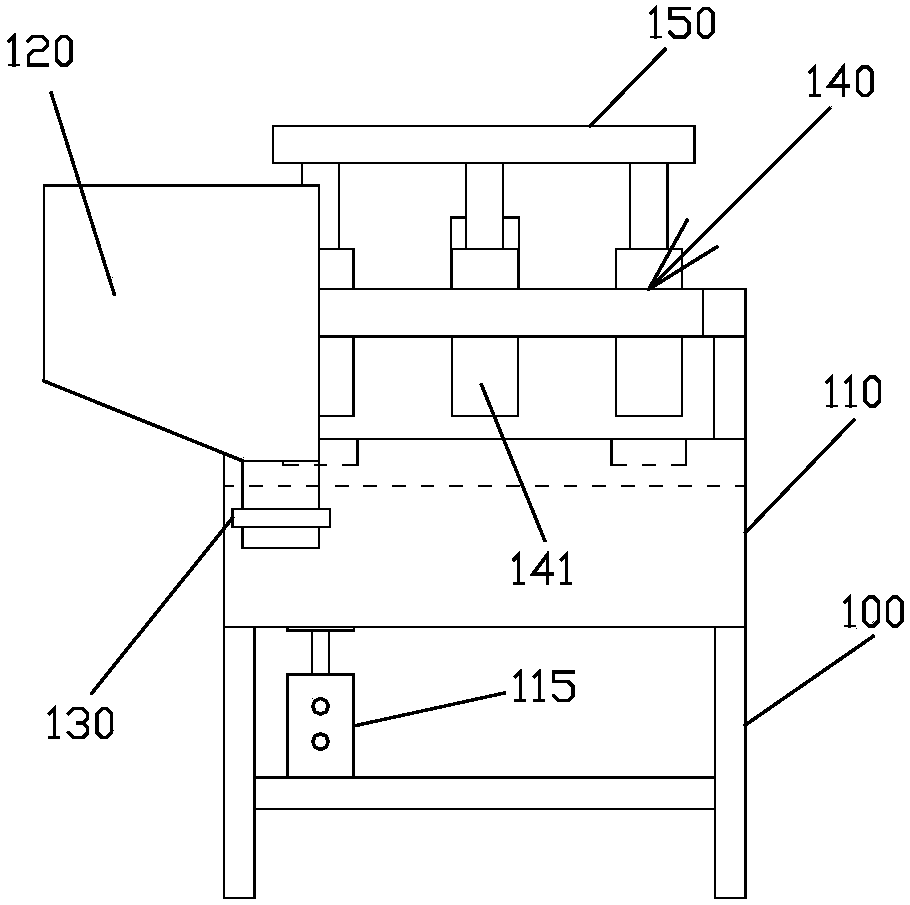

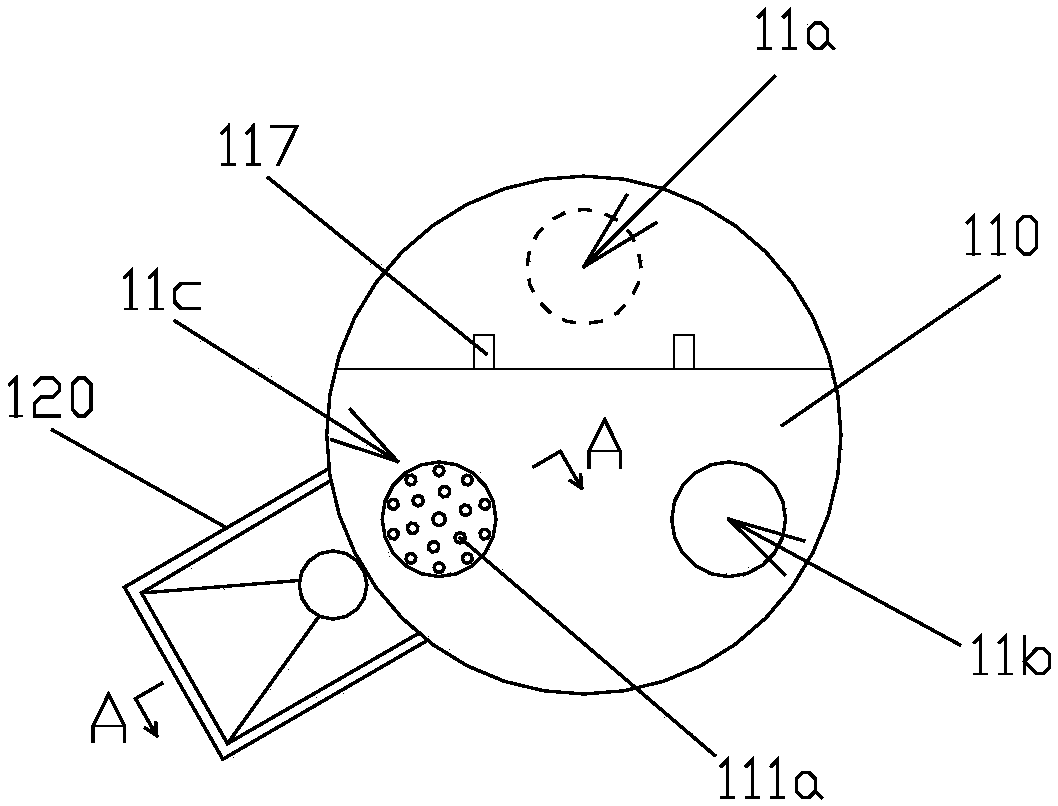

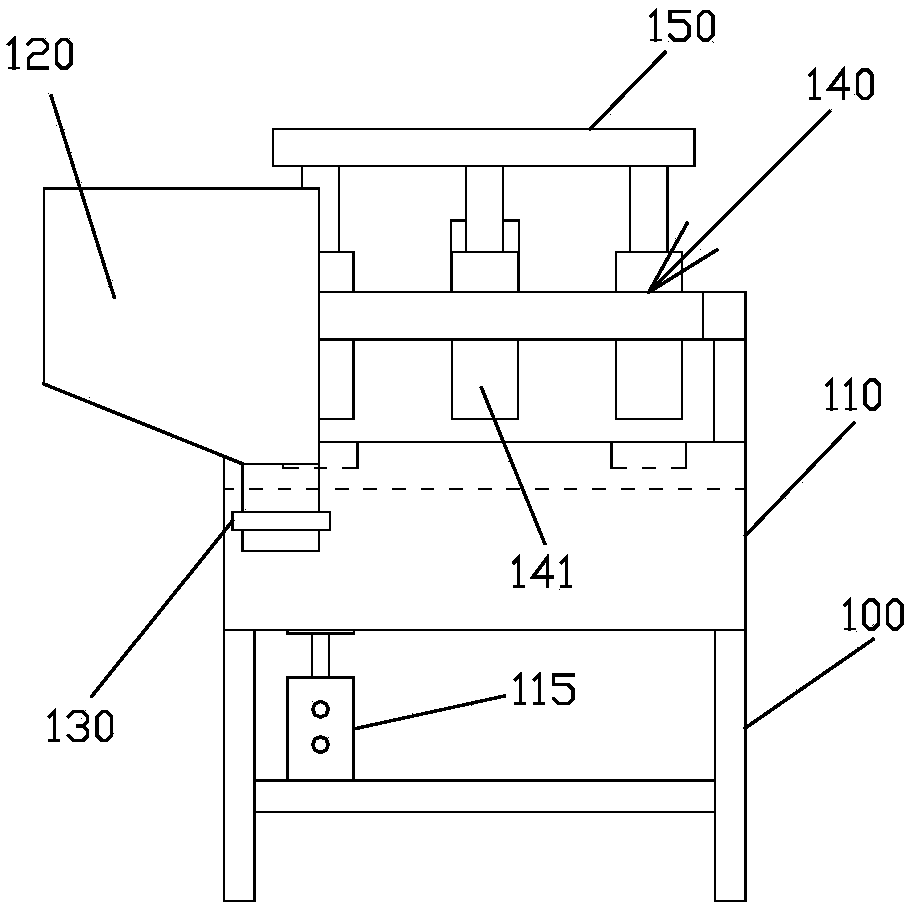

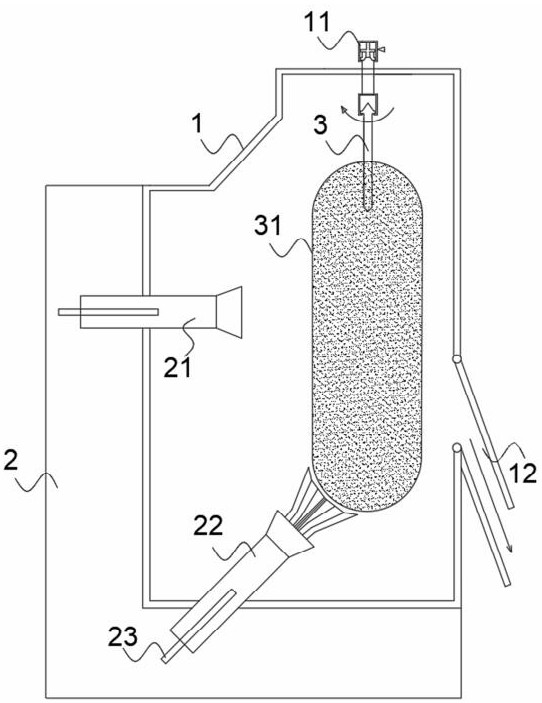

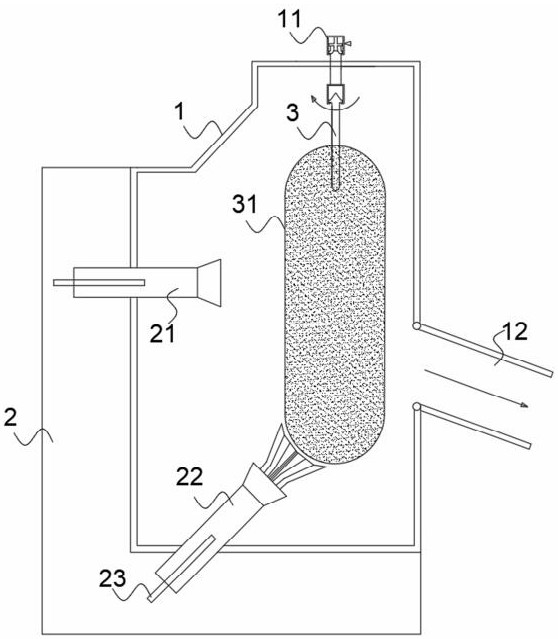

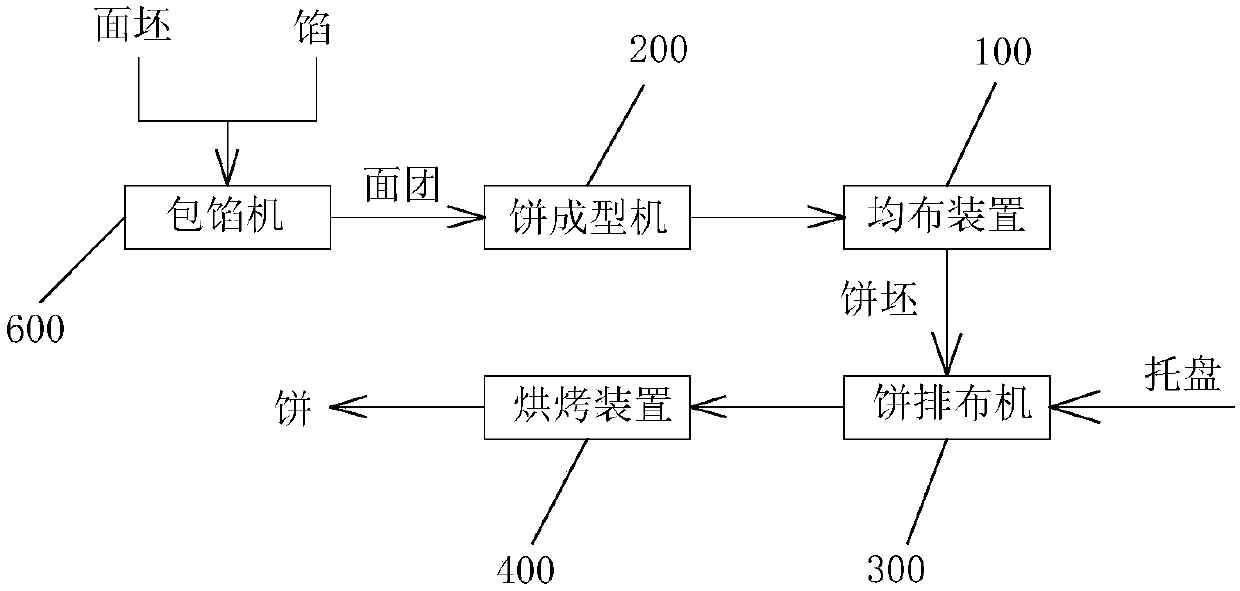

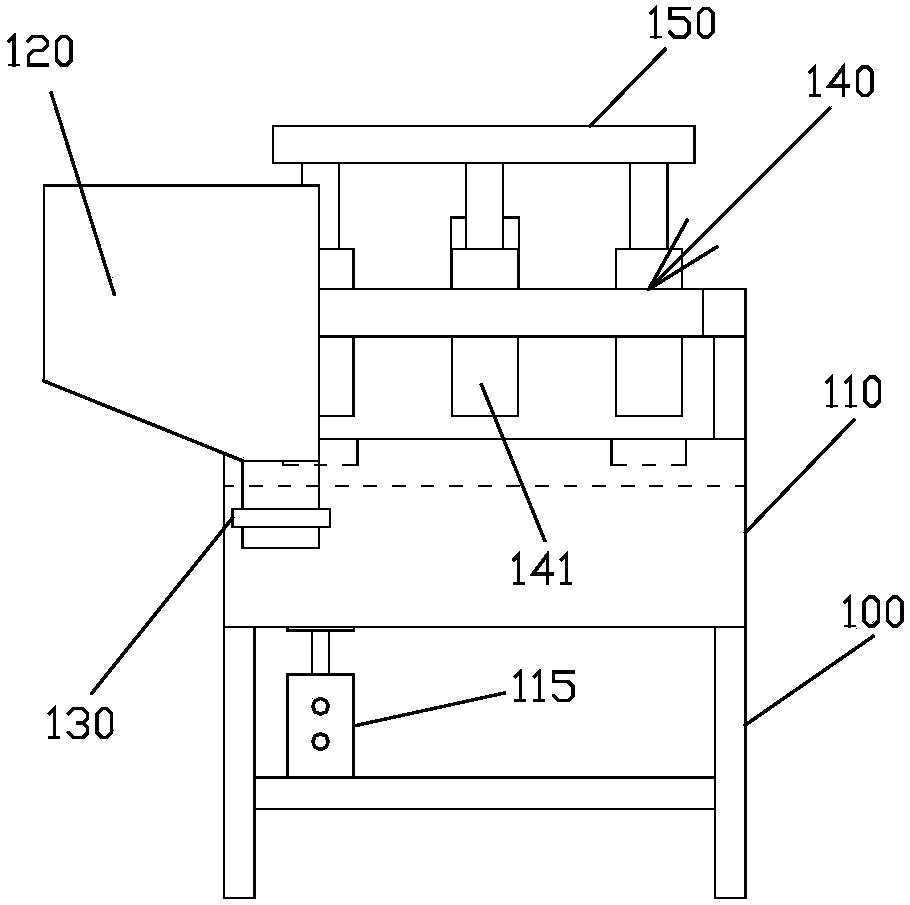

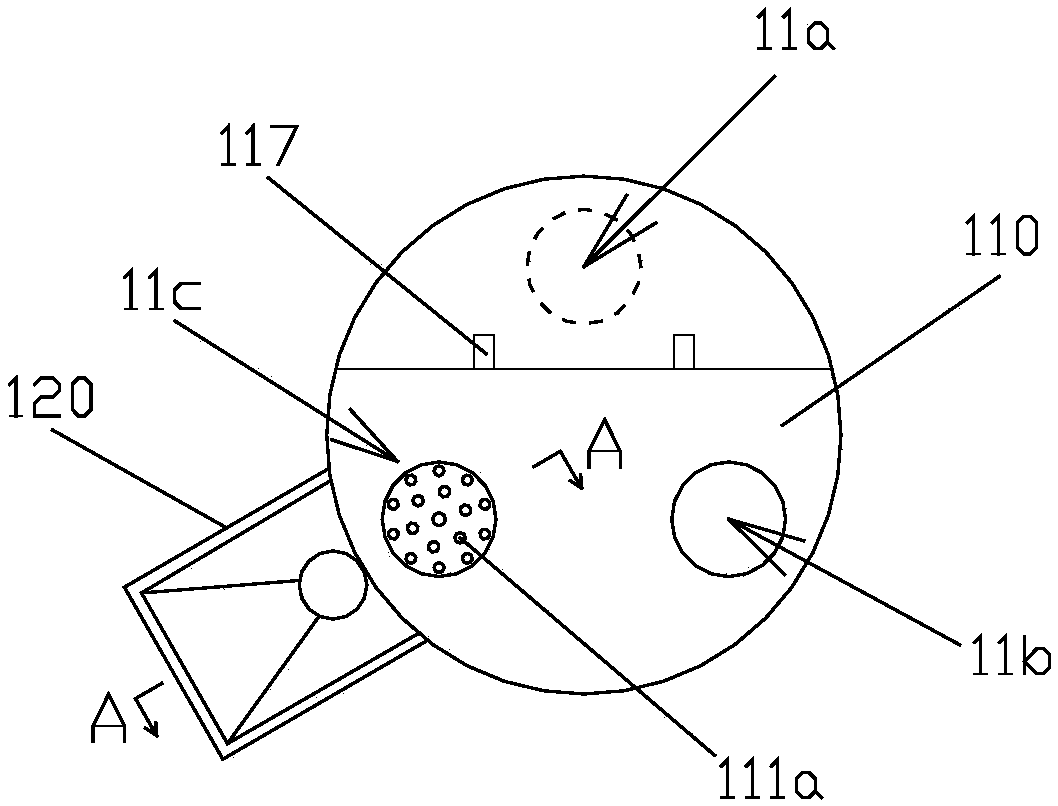

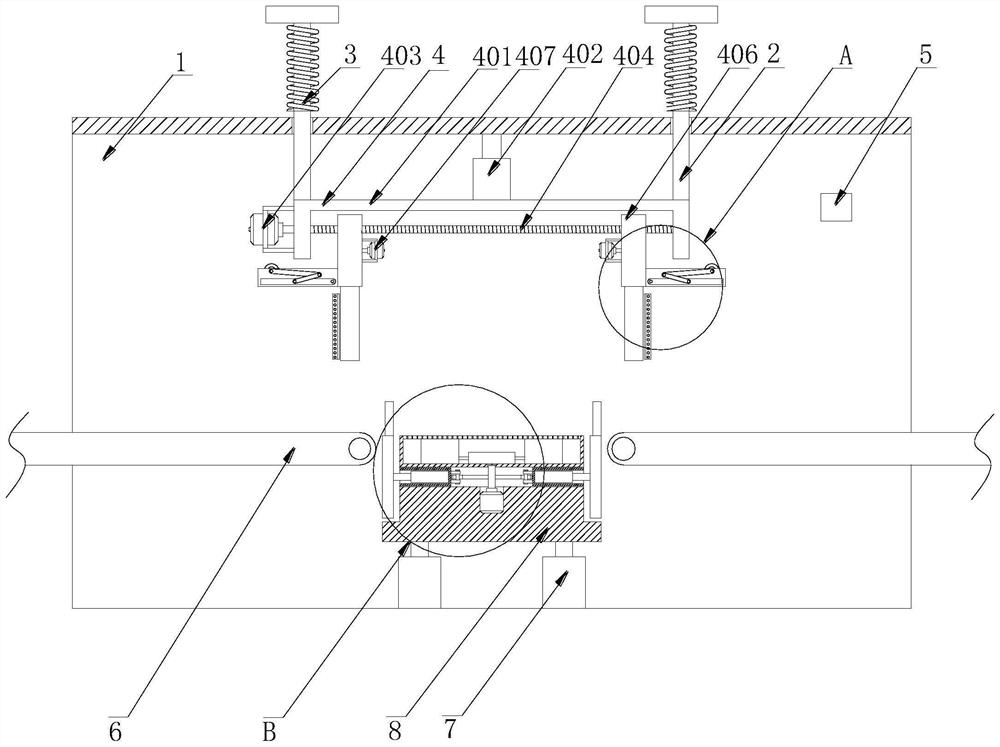

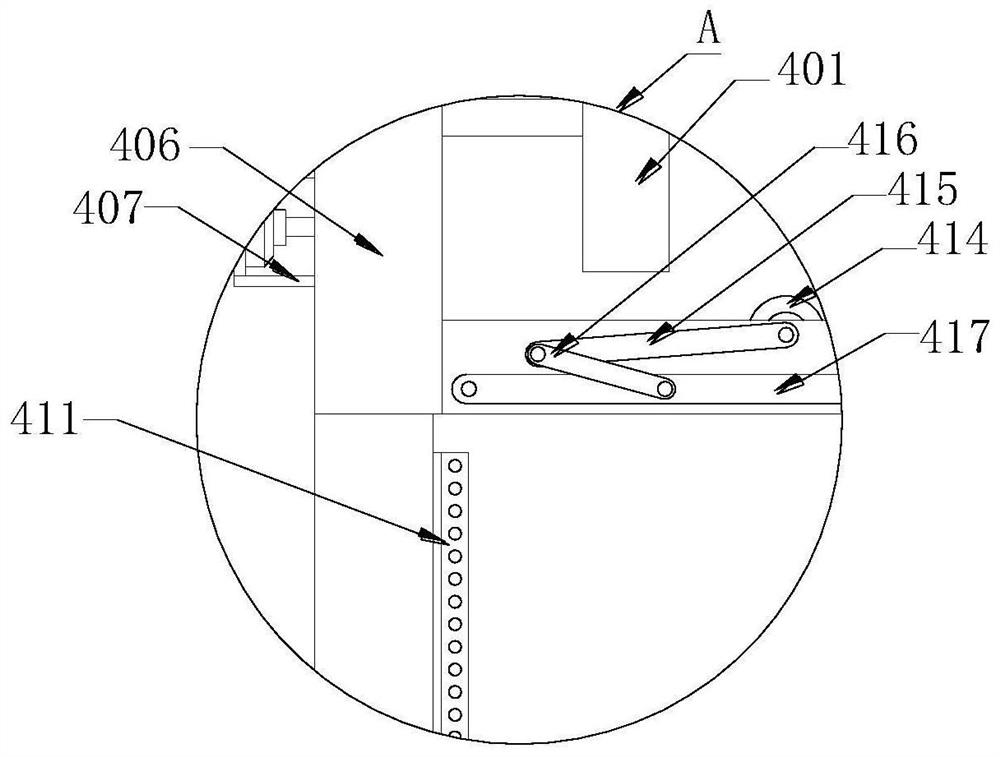

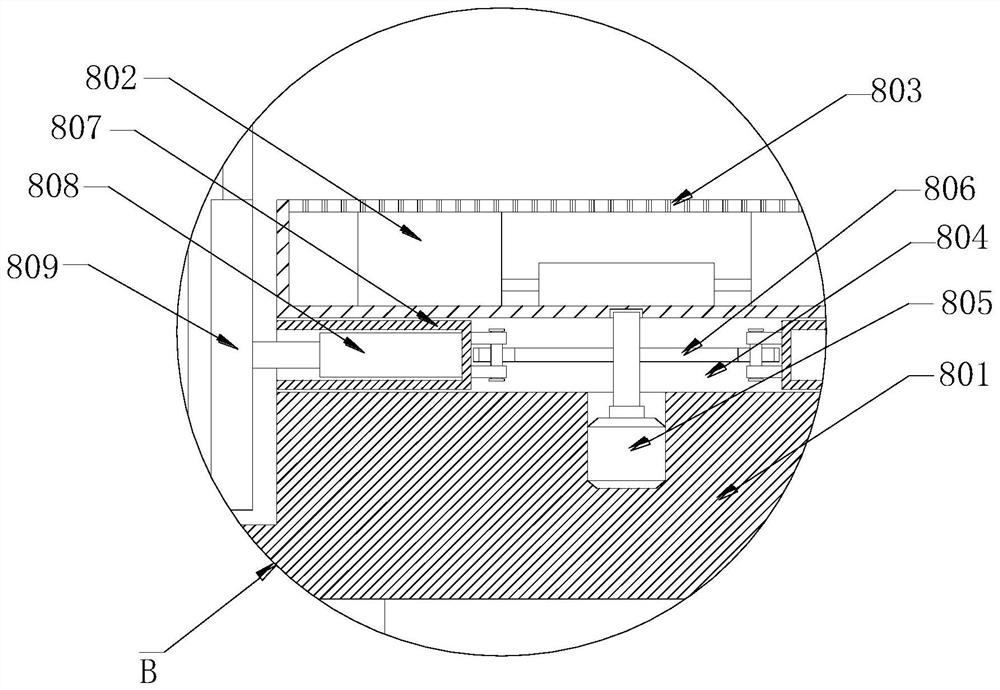

Food production device

InactiveCN107593850ARapid serial productionRapid productionBakery productsEngineeringContinuous production

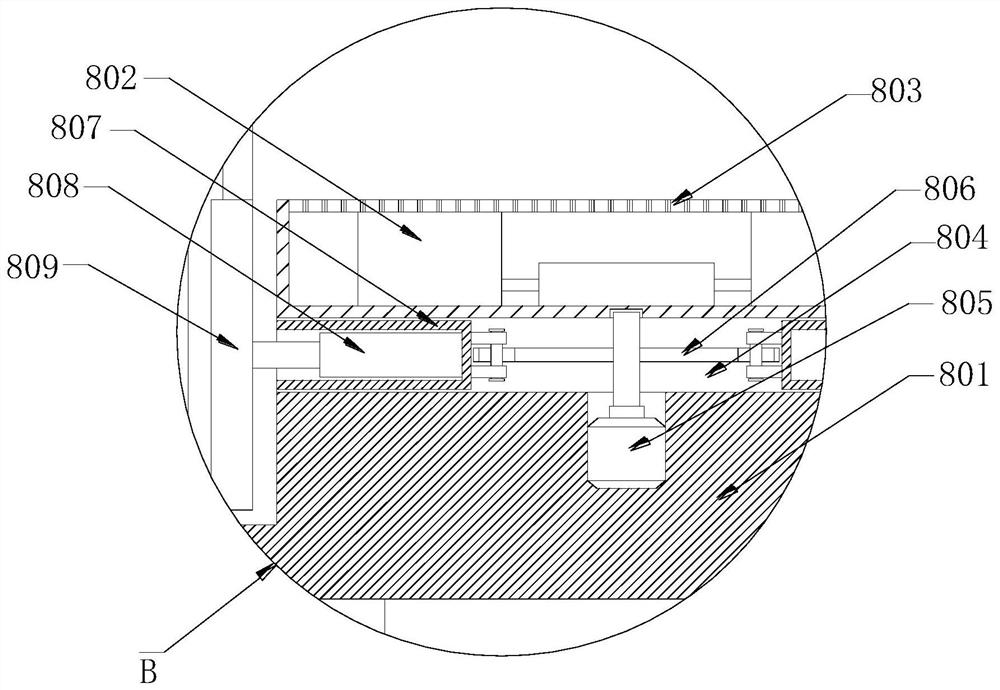

The present invention relates to a food production device. A rotary plate B1 is horizontally arranged at an upper part of a rack B, a column B1 is arranged at a middle part of the rotary plate B1, a column B2 is arranged under the column B1, the column B1 is arranged on the rotary plate B1 in a lifting manner, the column B2 is arranged on the rack B in a lifting manner, the other end of a mountingarm B1 is fixedly arranged on the column B1, the other end of a mounting arm B2 is fixedly arranged on the column B2, a drive mechanism B1 drives rotation of the rotary plate B1, a drive mechanism B3drives the column B1 to lift up and down, and a drive mechanism B4 drives the column B2 to lift up and down. A provided technical solution can be used for rapid and continuous production of cake foods and improves production efficiency.

Owner:ANHUI XUANTONG IND DESIGN CO LTD

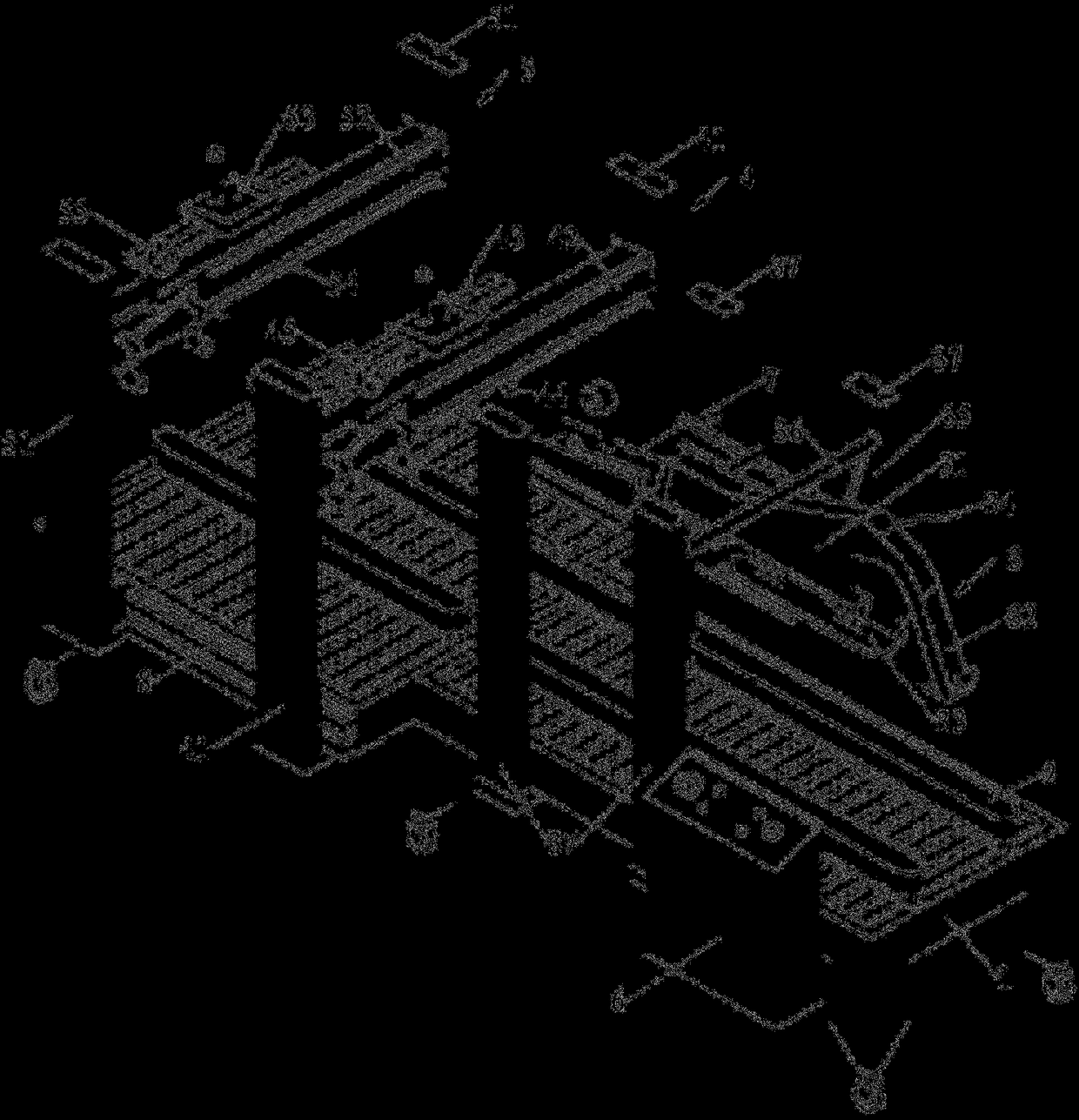

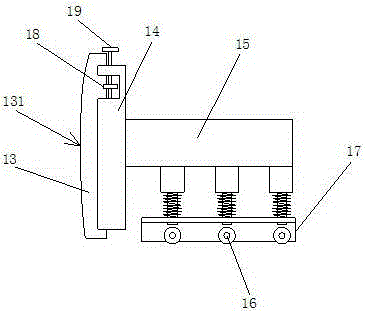

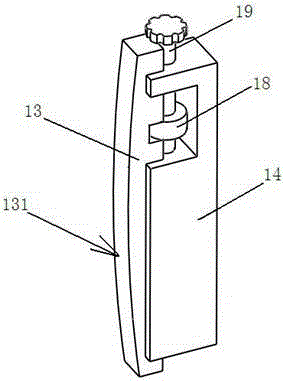

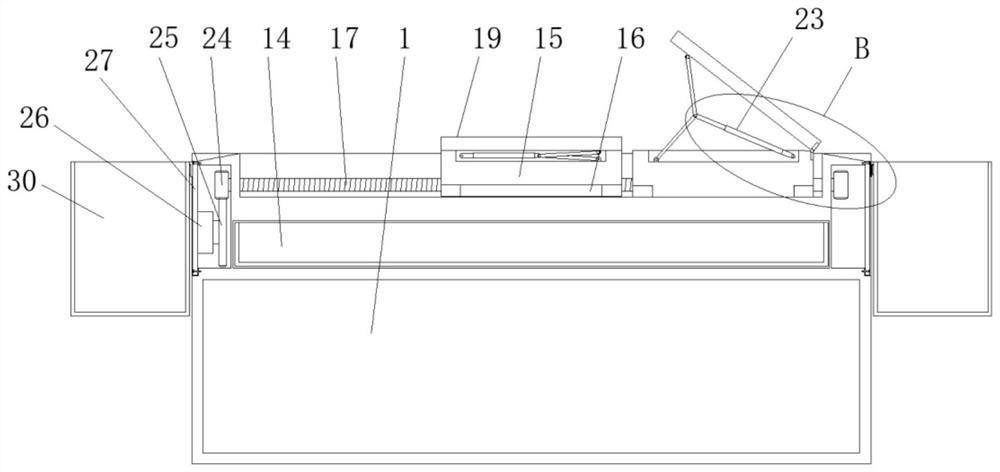

Carton sealing machine

PendingCN108545262ARapid serial productionIncrease productivityWrapper twisting/gatheringCartonContinuous production

The invention discloses a carton sealing machine. The carton sealing machine comprises a machine frame, a conveying device, a cover closing device, a first side seam sealing device, a second side seamsealing device, a control device and adhesive tape sealing devices; the cover closing device, the first side seam sealing device and the second side seam sealing device are sequentially arranged andare all installed on the machine frame, and the conveying device is located below the cover closing device, the first side seam sealing device and the second side seam sealing device; and the conveying device, the cover closing device, the first side seam sealing device and the second side seam sealing device are all electrically connected with the control device and are controlled by the controldevice, and the cover closing device, the first side seam sealing device and the second side seam sealing device each are provided with the adhesive tape sealing device. Side seams can be automatically sealed after a middle seam of a carton is sealed, sealing can be carried out without corner conveying or carton direction turning carried out, rapid continuous production can be realized, and the production efficiency is greatly improved.

Owner:姚焕州

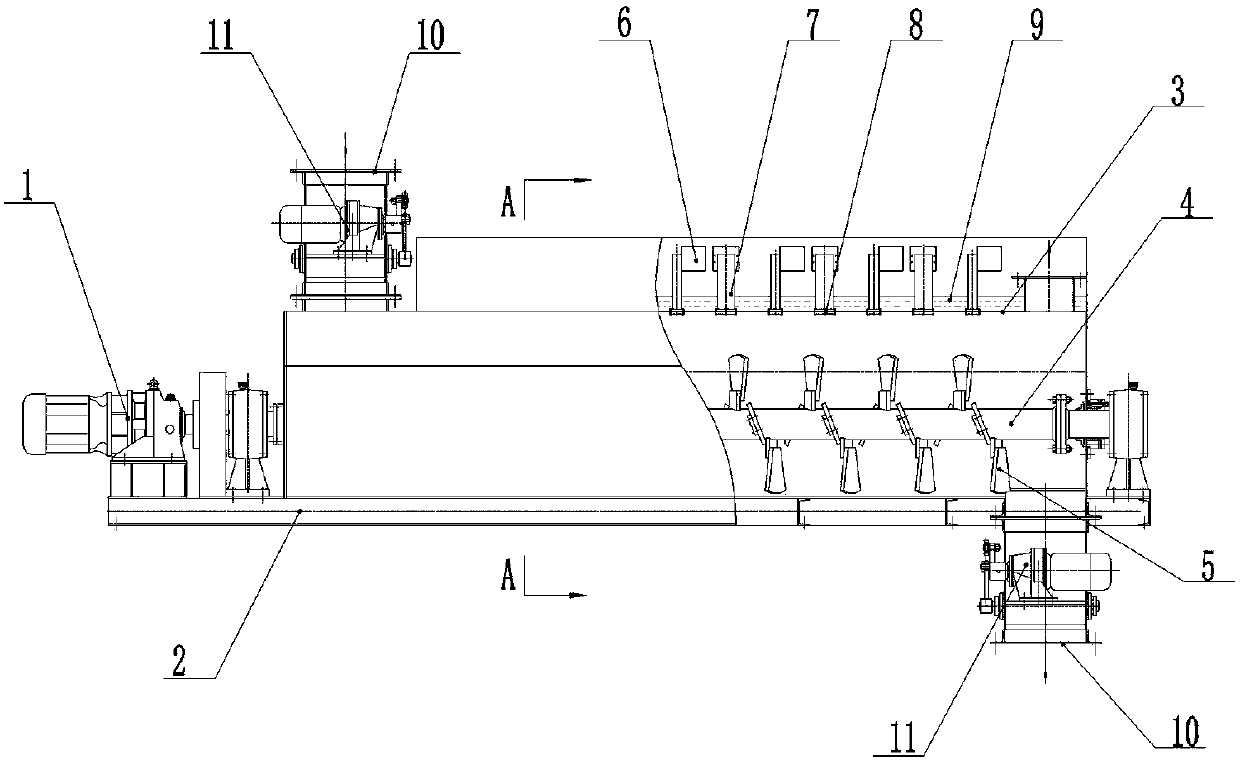

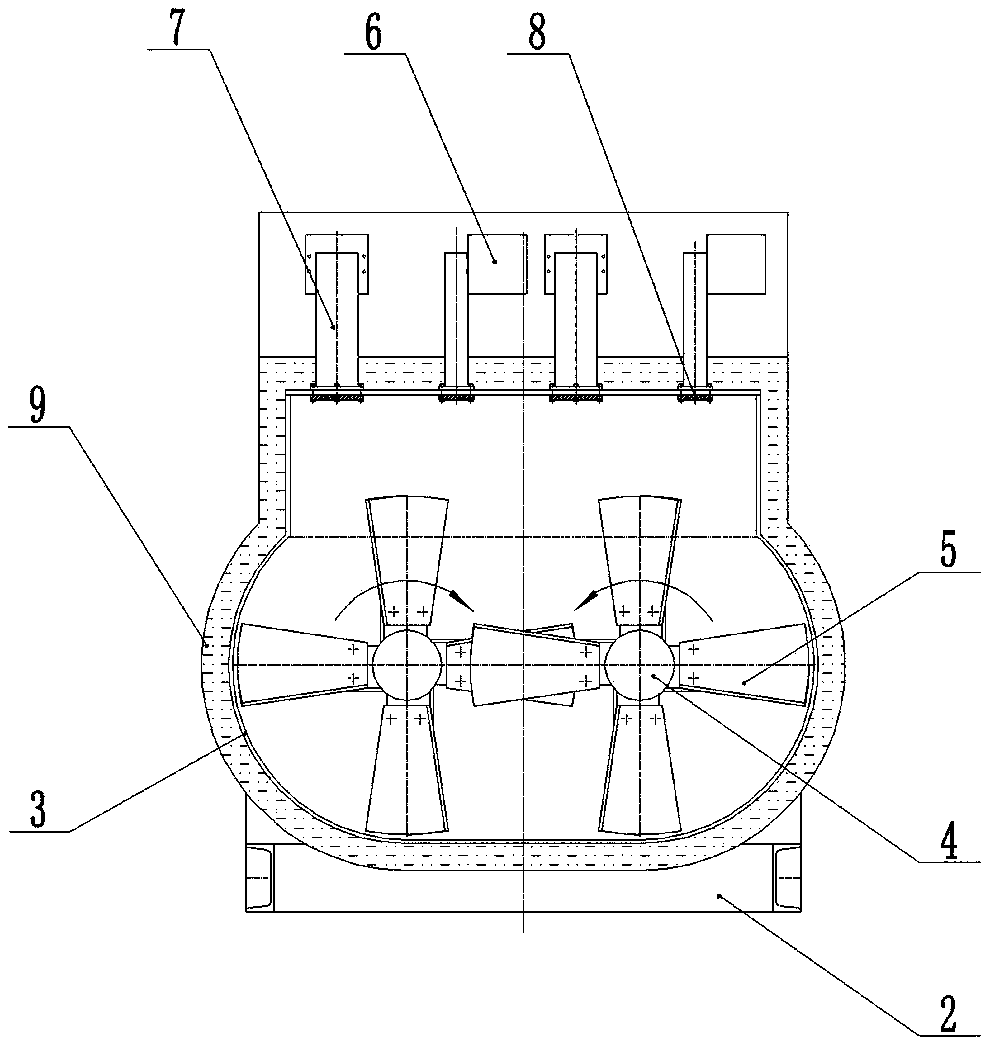

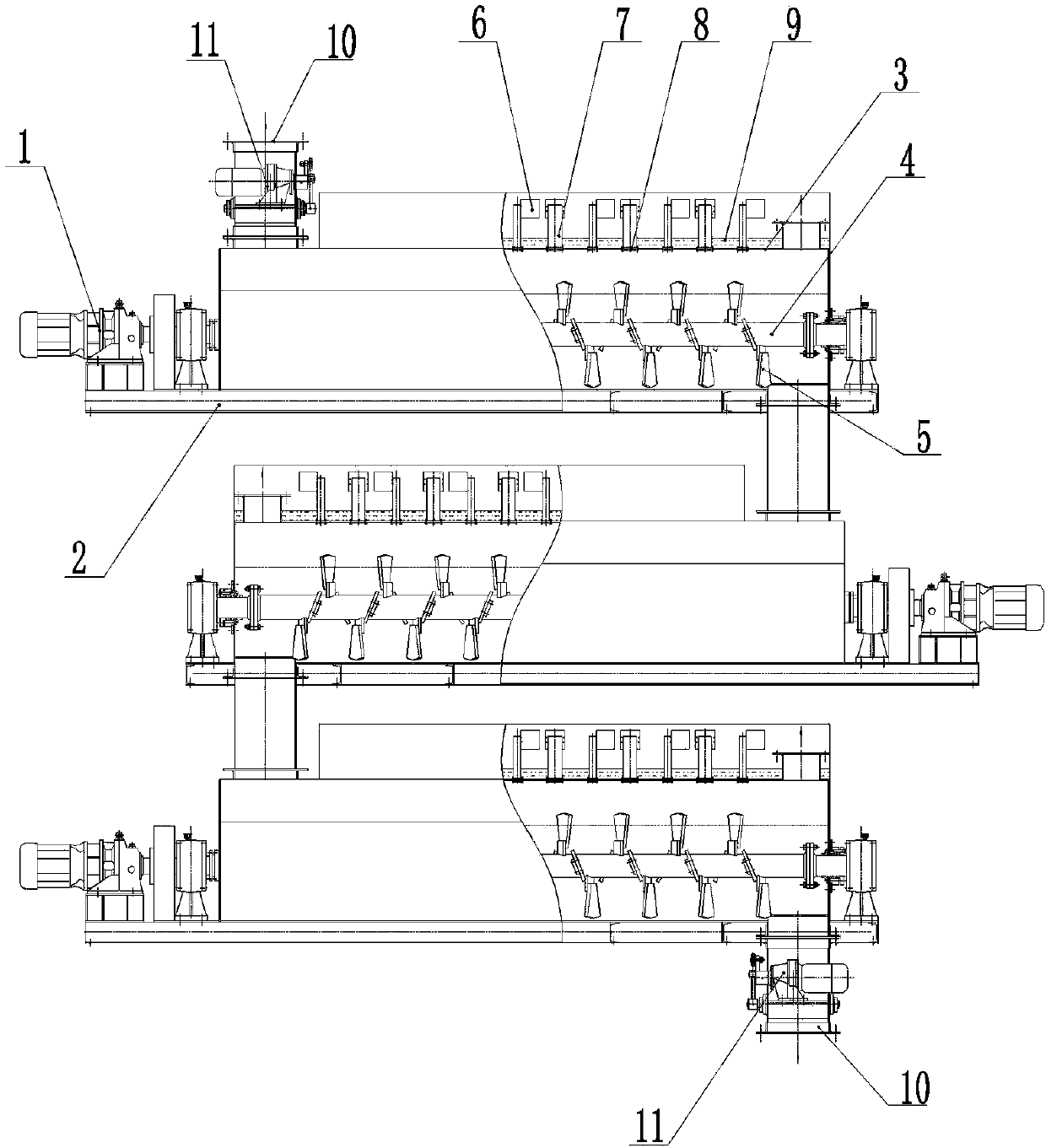

Continuous microwave heating double-shaft mixer

InactiveCN104190291ASimplify complexitySave on multi-functionRotary stirring mixersMixer accessoriesMicrowaveEngineering

The invention belongs to the technical field of microwave heating. A continuous microwave heating double-shaft mixer comprises one double-shaft mixer or a plurality of double-shaft mixers sequentially arranged in a communicating way, wherein a microwave feedthrough is formed in the casing of each double-shaft mixer, a corresponding microwave heating device is arranged on the microwave feedthrough, the microwave heating device comprises a microwave generating source arranged on the outer side of the casing, a waveguide for connecting the microwave generating source and an inner cavity of the double-shaft mixer and a wave transmission isolating window arranged at the end part of the waveguide. According to the invention, a temperature condition required by reaction is provided in an efficient microwave heating mode, and energy consumption is greatly reduced; meanwhile, the complexity of the whole device is greatly simplified, equipment reliability is improved, space is saved, and the cost is lowered.

Owner:HENAN BODA MICROWAVE EQUIP

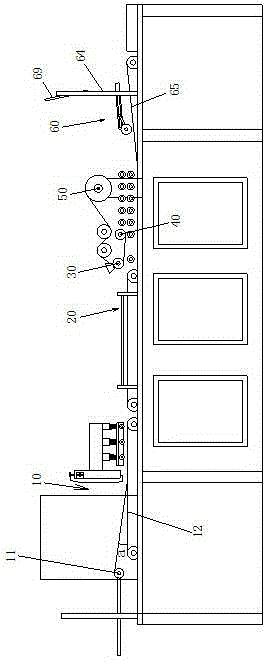

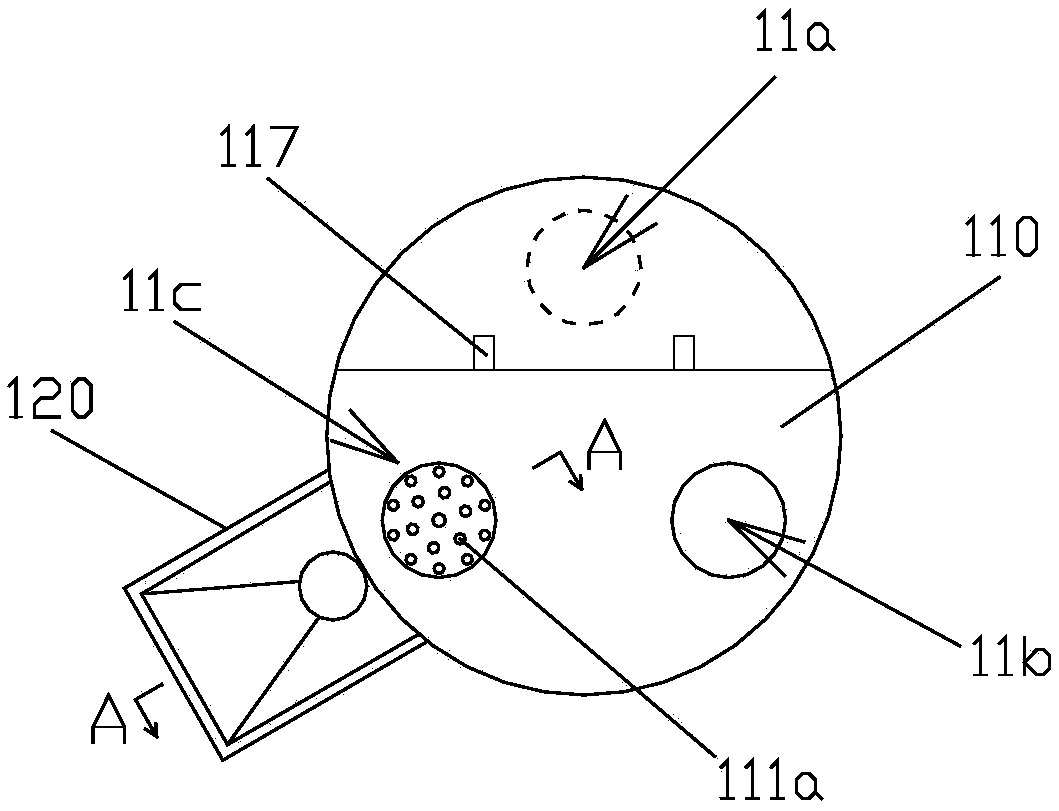

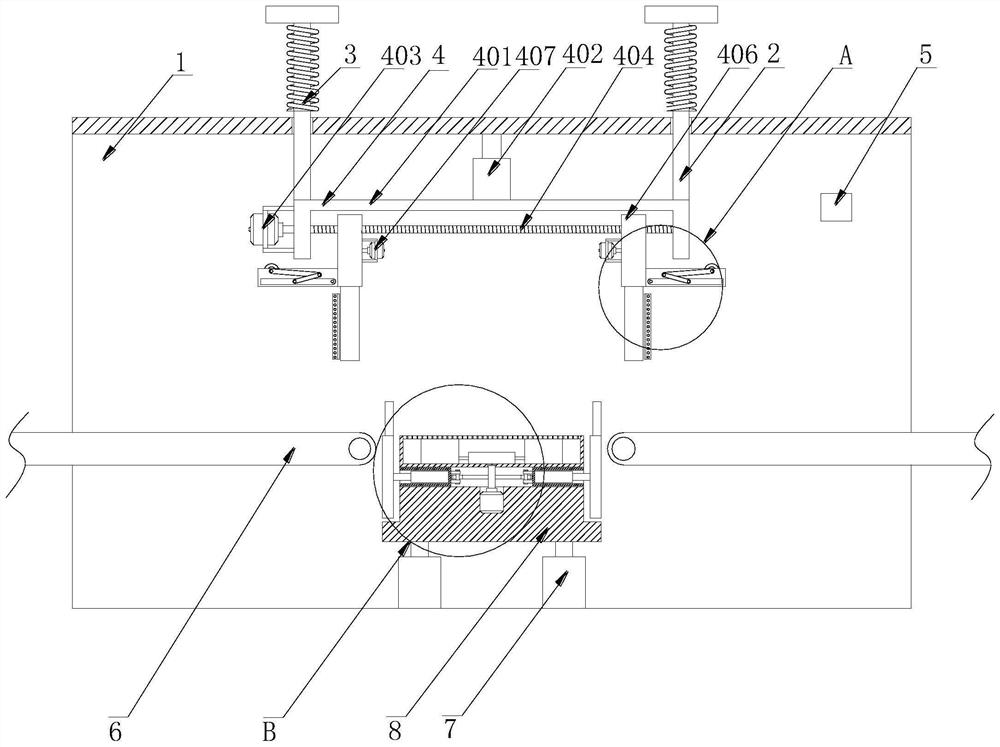

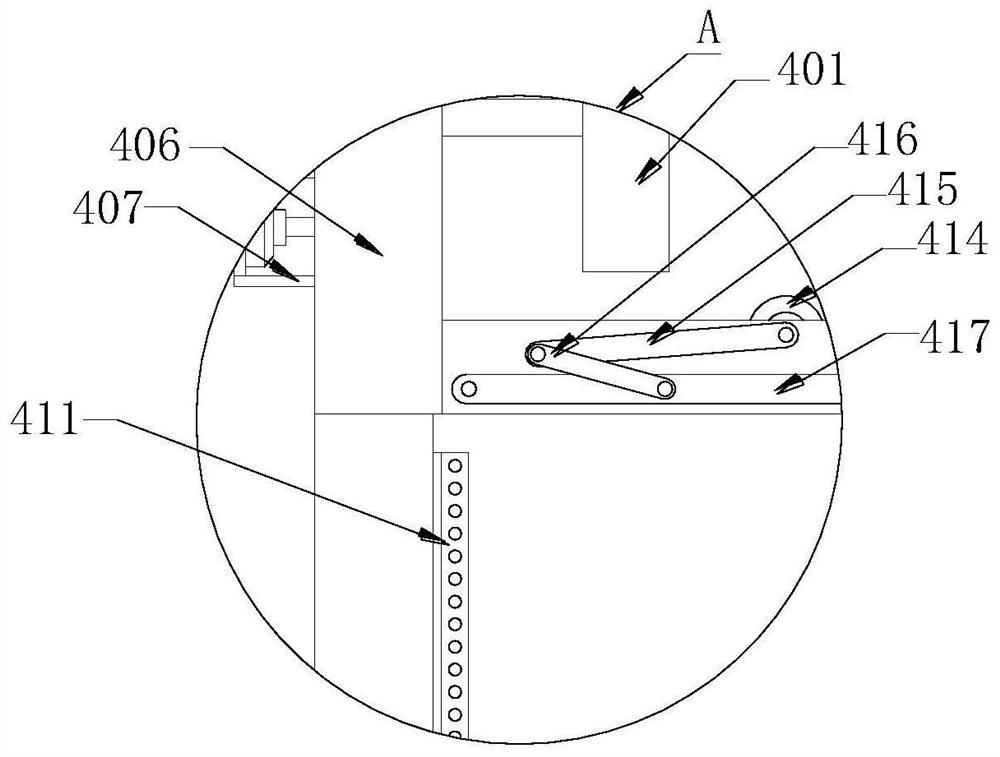

Equipment for improving discharge efficiency in pallet

InactiveCN109548816ARapid serial productionRapid productionDough processingContinuous productionDischarge efficiency

The invention relates to equipment for improving discharge efficiency in a pallet. An arrangement mechanism includes a conveyor belt C for conveying a cake blank, and a guide roller C1 and a guide roller C2 at both ends of the conveyor belt C. The conveying direction of the conveyor belt C is vertically arranged with a direction C, the guide roller C1 is located at one end of the conveyor belt C near an arrangement area, the guide roller C2 is rotatably mounted on a frame C, and the guide roller C1 is rotatably mounted on a guide roller movable mount, the frame C is provided with a horizontally arranged guide rail C, the guide rail C is arranged perpendicular to the direction C, and the guide roller movable mount is slidably mounted on the guide rail C, the guide roller movable mount is connected with a driving mechanism C1 for driving the movement of the guide roller movable mount, a storage mechanism for storing the conveyor belt C is disposed between the guide roller C1 and the guide roller C2, and a control device C regulates the operating state of the driving mechanism C1 and the storage mechanism. The technical scheme provided above can be used for rapid continuous productionof cake-like foods and improve production efficiency.

Owner:ANHUI XUANTONG IND DESIGN CO LTD

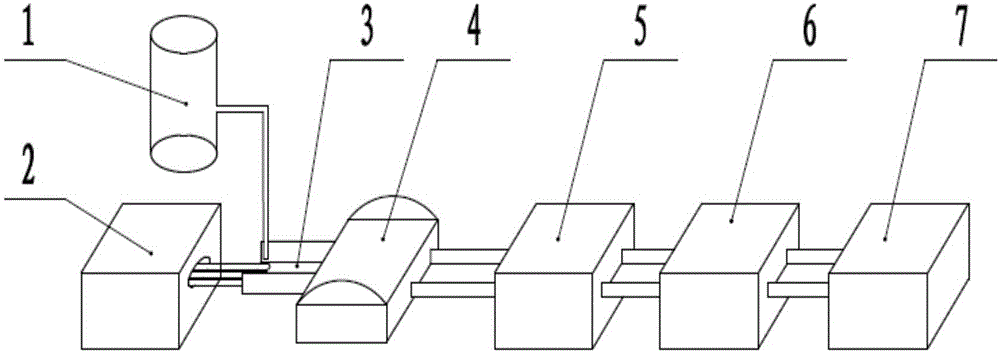

Production system for packaging box with observation window

InactiveCN105196604ARapid serial productionIncrease productivityBox making operationsPaper-makingEngineeringContinuous production

The invention relates to a production system for a packaging box with an observation window. The system sequentially comprises a single corrugating line used for producing corrugated paper, a printing machine used for printing face paper, a paper mounting machine used for pasting the printed face paper to the corrugated paper, a die cutting machine used for carrying out die cutting shaping and window forming on packaging box paper on which the paper is mounted, a window patching machine for pasting films on the packaging box paper with the window, a box pasting machine used for carrying out pasting forming on the packaging box paper with the patched window, and a packaging machine used for packaging the pasted and formed packaging box. By the adoption of the packaging box production system, packaging boxes with observation windows can be rapidly and continuously produced, and production efficiency is improved.

Owner:HEFEI SCHINDLER PACKAGING

Continuous production line technology process of steel wire aluminum

InactiveCN106513602APioneering a continuous production processRapid serial productionProduction lineIngot

The invention discloses a continuous production line technology process of steel wire aluminum. The continuous production line technology process comprises an aluminum melting furnace, a steel wire feeding device, a pouring device, a cooling device, a drawing-straightening transmission device and a shearing device. The pouring device is provided with a pouring water gate, the aluminum melting furnace and the steel wire feeding device are connected to the pouring water gate, and the pouring device, the drawing-straightening transmission device, the cooling device and the shearing device are sequentially connected. Production of steel wire aluminum products specifically includes the steps that steel wires penetrate into the pouring water gate through the steel wire feeding device; aluminum ingots are warmed and molten in the aluminum melting furnace, and molten aluminum is injected into the pouring water gate through a chute; the steel wires and the molten aluminum are mixed and solidified at the pouring water gate to form steel wire aluminum bars; and the solidified steel wire aluminum bars enter the cooling device for being cooled, then are pulled out by the drawing-straightening transmission device and enter the shearing device, and finally the steel wire aluminum products of different lengths can be obtained through shearing. According to the continuous production line technology process, the continuous production technology of the steel wire aluminum is realized, and a method for quickly and continuously producing steel wire aluminum alloy at low cost is realized.

Owner:天津炜润达新材料科技有限公司

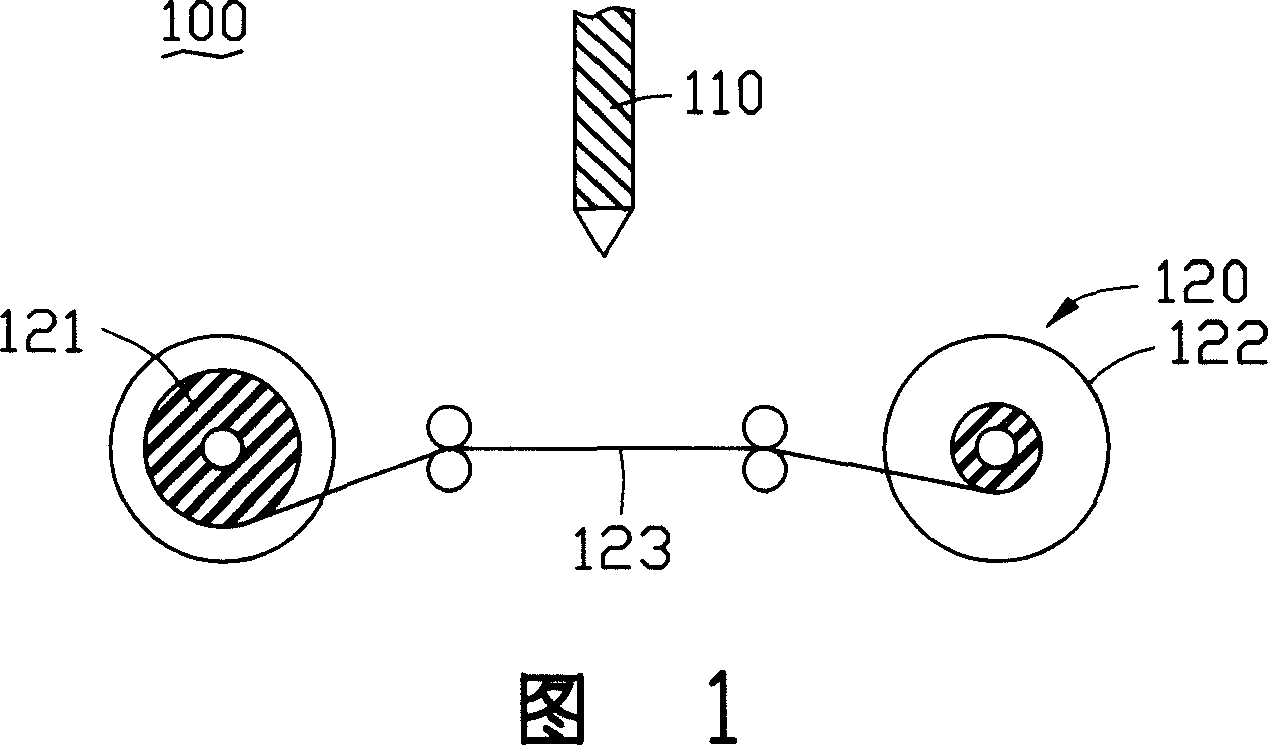

Film hole forming device and method

InactiveCN1933698ASingle materialLow costSemiconductor/solid-state device manufacturingInsulating layers/substrates workingFlexible circuitsEngineering

A method for preparing pin hole on flexible circuit board includes providing flexible board to be etched and forming copper hole on said flexible board, exposing base diaphragm at position corresponding to said copper hole, sending flexible board into chemical etching system to finalize preparation of pin hole by conveying system on pin hole forming device. The pin hole forming device used for realizing said method is also disclosed.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Hot press capable of realizing automatic discharging for thin-film capacitor production

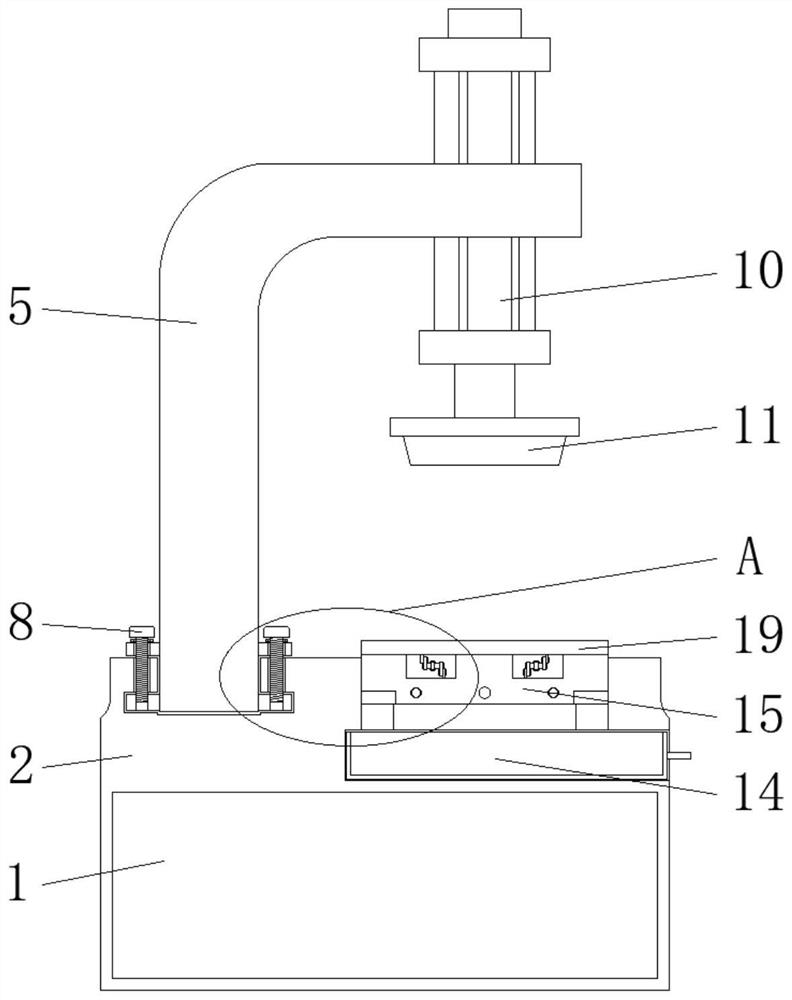

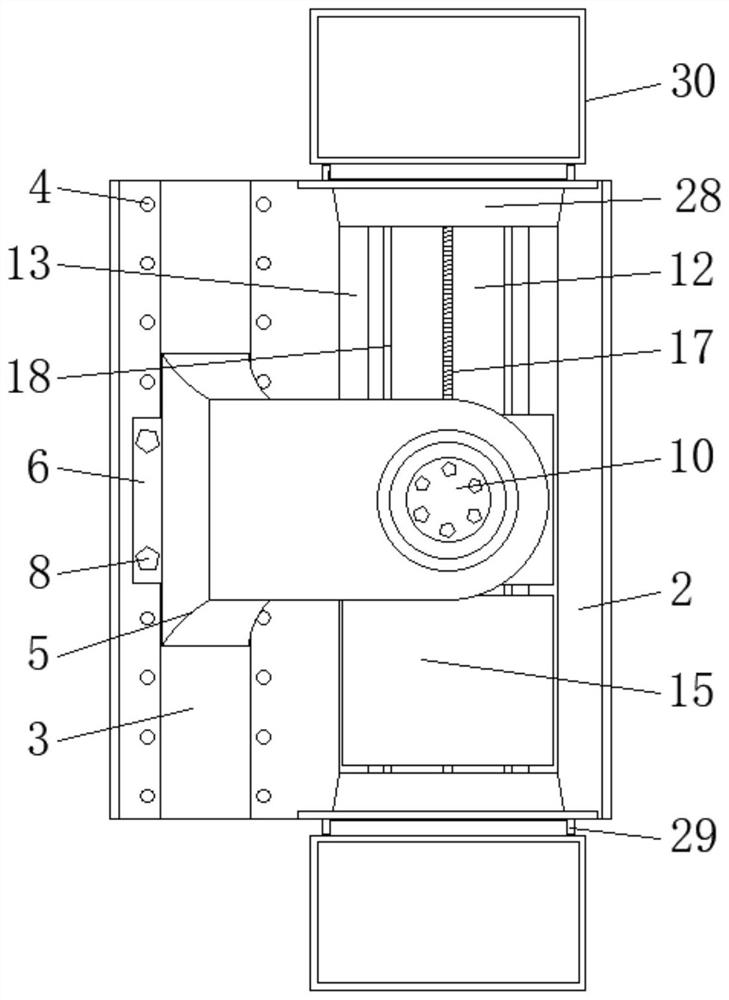

ActiveCN112420406ASafe and stable unloading useRapid serial productionCapacitor manufactureCapacitanceThin membrane

The invention discloses a hot press capable of realizing automatic discharging for thin-film capacitor production. The hot press comprises a cabinet, a heating plate, a screw rod, a telescopic rod anda gliding tabletop, a worktable is fixed on the top end surface of the cabinet, a slideway is formed in the left side of the top end of the cabinet, a connecting hole is formed in the outer side of the slideway, and a supporting column is connected to the inner side of the slideway; a fixing plate is arranged on the outer side of the bottom of the supporting column, a fixing bolt is connected tothe inner side of the fixing plate, a sliding groove located in the top of the workbench is formed in the lower portion of the heating plate, a table plate is arranged in the sliding groove, a bottomplate is fixed to the bottom end of the table plate, and a first supporting rod is connected to the inner side of the base plate. And the top end of the screw rod is connected with a transmission wheel. According to the hot press capable of achieving automatic discharging and used for thin-film capacitor production, adjusting operation can be conducted, discharging and using can be conducted safely and stably, rapid continuous production operation can be conducted conveniently, and the production operation efficiency can be guaranteed.

Owner:扬州日精电子有限公司

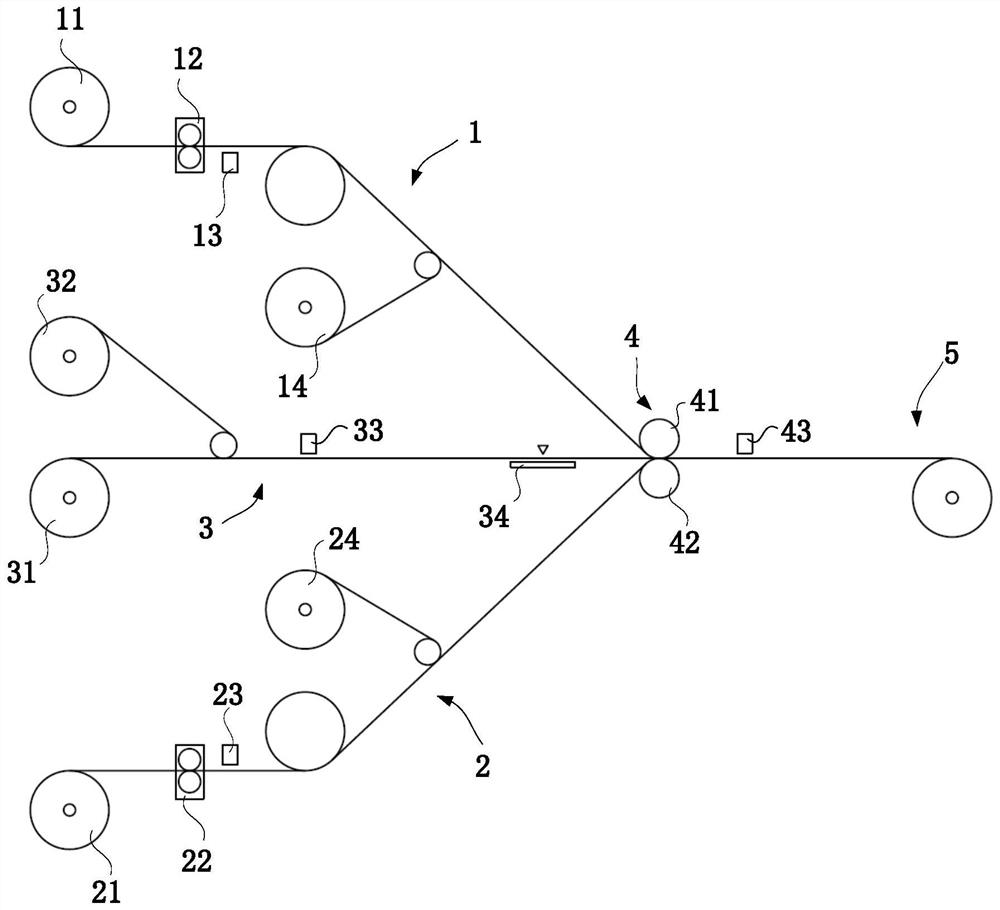

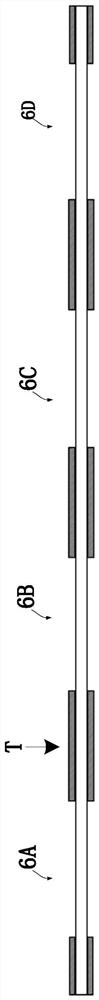

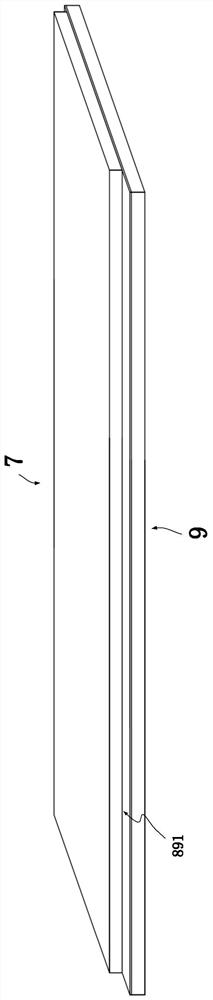

Fuel cell proton exchange sealing membrane preparation method and system

InactiveCN112909289AGuaranteed tightnessRapid serial productionFinal product manufactureSealing/support meansFuel cellsEngineering

The invention relates to a fuel cell proton exchange sealing membrane preparation method and system, and the system comprises a base membrane supply unit which supplies and transmits a proton exchange membrane to a bonding unit; a glue layer supply unit, used for supplying and conveying a sealing glue layer to the bonding unit, the glue layer supply unit being provided with a die-cutting machine, and a central hollow part of a sealing adhesive layer being formed, the glue layer supply unit comprising a first glue layer supply unit and a second glue layer supply unit and used for providing a first sealing glue layer for bonding the upper surface of the proton exchange membrane and a second sealing glue layer for bonding the lower surface of the proton exchange membrane; and a bonding unit, used for bonding the first sealing adhesive layer and the second sealing adhesive layer to the upper surface and the lower surface of the proton exchange membrane to form a proton exchange sealing membrane. The transverse length of the sealing adhesive layer is larger than that of the proton exchange membrane, and after bonding, the sealing adhesive layer seals the transverse edge of the proton exchange membrane, so that the use cost of the proton exchange membrane is reduced, and the sealing performance of the proton exchange membrane and the safety of a membrane electrode are improved.

Owner:SUZHOU TAILUN ELECTRONIC MATERIALS CO LTD

Method for continuously preparing letrozole intermediate 4-((1H-1,2,4-tri-1-zole)methyl) benzonitrile

InactiveCN105622530AResolve separation difficultiesReduce energy consumptionOrganic chemistryState of artCoupling

The invention relates to a method for continuously preparing letrozole intermediate 4-((1H-1,2,4-tri-1-zole)methyl) benzonitrile (I).The problems that in the process of producing a compound (I) in the prior art, the reactant p-cyanobenzyl chloride is low in conversion rate, and a product is difficult to separate are mainly solved.The continuous coupling process of separating and purifying the compound (I) is achieved by adopting reacting, salifying and filtering.The reaction product is continuously separated from a system in time, the compound (I) can be produced continuously, easily and fast with low energy consumption, the yield of the obtained reaction product compound (I) is larger than 80%, and the chemical purity is larger than 98%.

Owner:NANJING UNIV OF TECH

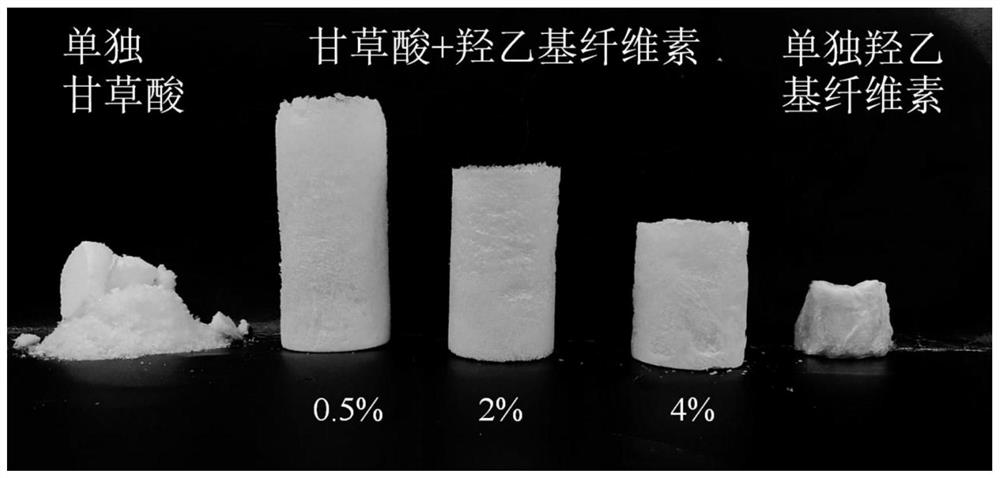

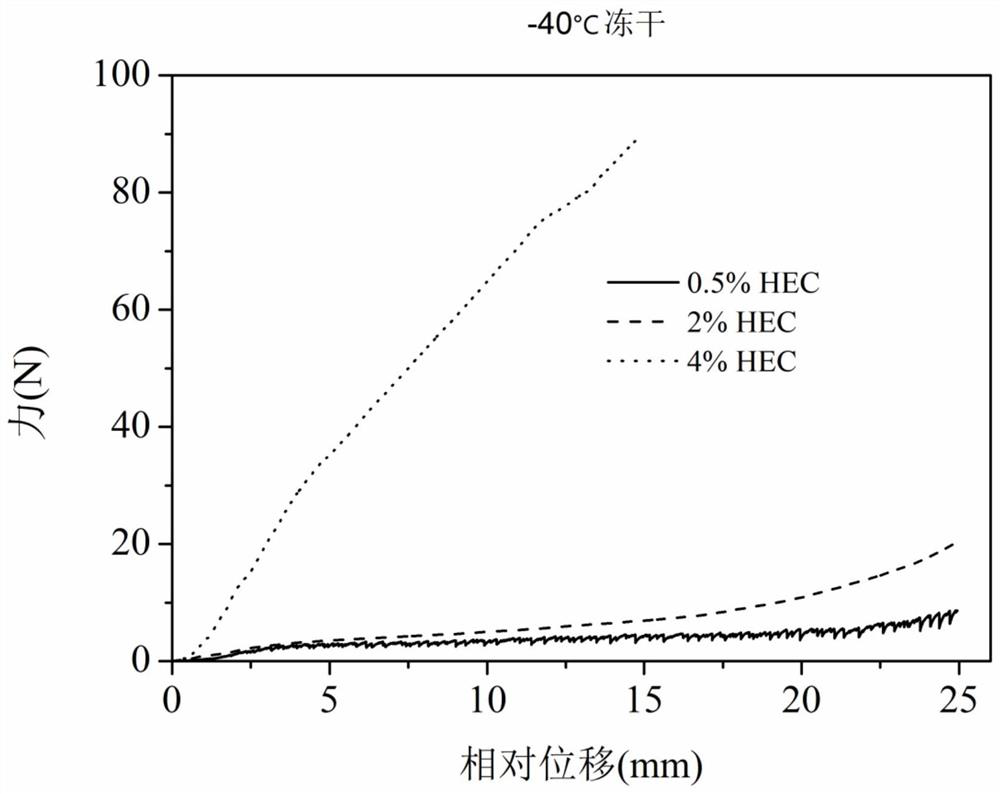

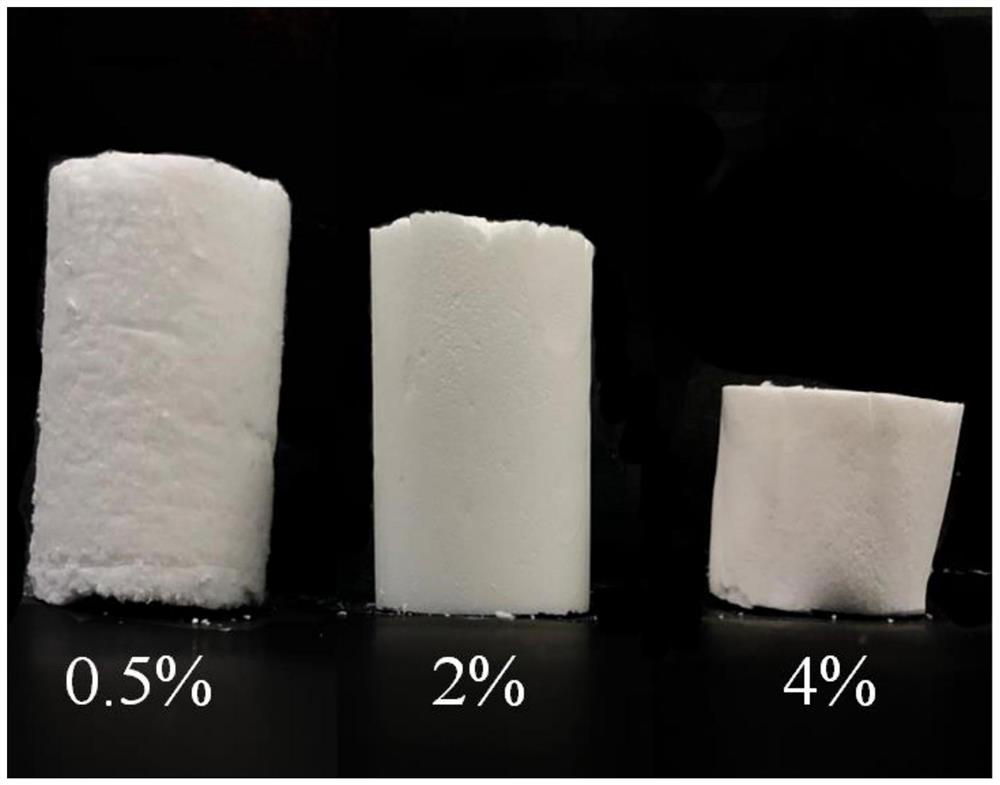

Glycyrrhizic acid-based slow-release porous foam material capable of embedding hydrophilic functional factors and preparation method and application thereof

ActiveCN111840653AImprove stress resistanceComplete structureOrganic active ingredientsMetabolism disorderCelluloseFreeze-drying

The invention discloses a glycyrrhizic acid-based slow-release porous foam material capable of embedding hydrophilic functional factors and a preparation method and application thereof. The method comprises the following steps: respectively and uniformly dispersing glycyrrhizic acid and hydroxyethyl cellulose in water, and heating and stirring to obtain a transparent glycyrrhizic acid solution anda hydroxyethyl cellulose solution; then adding the hydroxyethyl cellulose solution into the glycyrrhizic acid solution, carrying out homogeneous gasification treatment on the mixed solution, and standing in an ice-water bath to obtain foam gel; and carrying out freeze drying treatment on the foam gel to obtain the porous foam material. The obtained product has good mechanical properties, active substance loading capacity and highly controllable release characteristics. The process conditions are simple and rapid, rapid and continuous production can be carried out, foam type products applied to medicine and tissue engineering can be prepared by controlling the process conditions, and the material has industrial and large-scale application value.

Owner:SOUTH CHINA UNIV OF TECH

Operation technology used for increasing material discharge efficiency in trays

InactiveCN109548829ARapid serial productionRapid productionBakery productsBaking plantsDischarge efficiencyEngineering

The invention relates to operation technology used for increasing material discharge efficiency in trays. An arrangement mechanism comprises a conveyer belt C used for conveying cake blanks, and a guide roller C1 and a guide roller C2 at the two ends of the conveyer belt C; the conveying direction of the conveyer belt C is designed to be vertical to a direction C; the guide roller C1 is arranged at the end of the conveyer belt C close to a tray arrangement zone; the guide roller C2 is rotatingly arranged on a machine frame C; the guide roller C1 is rotatingly arranged on a guide roller movableinstallation pedestal; the machine frame C is provided with a horizontal guide rail C; the guide rail C is designed to be vertical to the direction C; the guide roller movable installation pedestal is arranged on the guide rail C in a sliding manner; the guide roller movable installation pedestal is connected with a driving mechanism C1 which is used for driving the guide roller movable installation pedestal to move; a belt storage mechanism used for storing the conveyer belt C is arranged between the guide roller C1 and the guide roller C2; a control device C is used for regulating and controlling the operation states of the driving mechanism C1 and the belt storage mechanism. The above structure can be used for rapid continuous production of cake shaped food, and is capable of increasing production efficiency.

Owner:ANHUI XUANTONG IND DESIGN CO LTD

Method for industrialized co-production of phycocyanin, spirulina polysaccharide and protein feed using fresh spirulina

ActiveCN109593128BSolve the problem with the extraction methodSolve the real problemAnimal feeding stuffPeptide preparation methodsUltrafiltrationFiltration

The invention discloses a method for industrial co-production of phycocyanin, spirulina polysaccharide and protein feed from fresh spirulina. The method comprises the following steps: (1), taking cleaned fresh spirulina sludge into an ultrasonic extraction tank; (2), uniformly stirring the mixed solution, and performing ultrasonic wall breaking extraction; (3), extracting the mixed solution for solid-liquid separation; (4), performing separation on an algae residue / grinding bead mixture by a filter screen; (5), cleaning and recycling grinding beads; (6), performing solid-liquid separation on the algae residue mixed solution again by a fine filter; (7), passing the combined phycocyanin extract through cross-flow membrane filtration equipment; (8), passing the supernatant in the previous step through 30 KDa ultrafiltration membrane equipment; (9), spray drying an ultrafiltration concentrated solution. The method has the following advantages that no chemical additive is used, physical wall breaking is conducted, pure water extraction is conducted in the whole process, the extraction cost is reduced, no chemical sewage is discharged, the method is environmentally friendly, and the application requirement of the natural and healthy product of phycocyanin is met.

Owner:张德智 +2

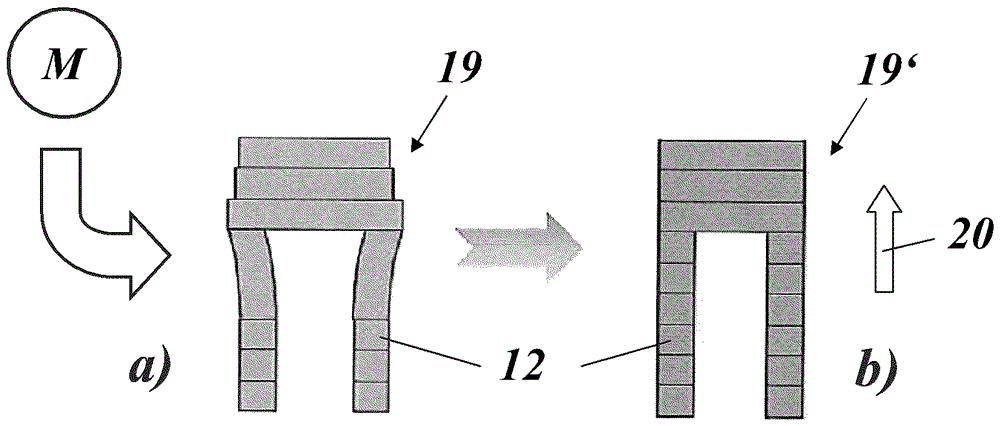

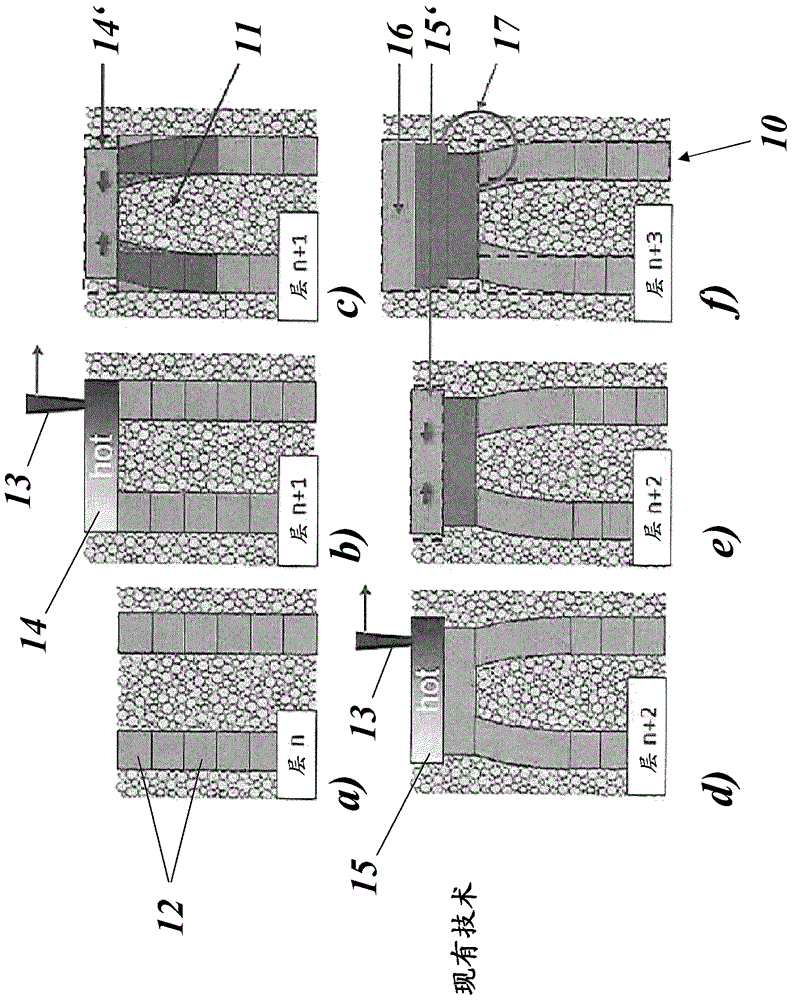

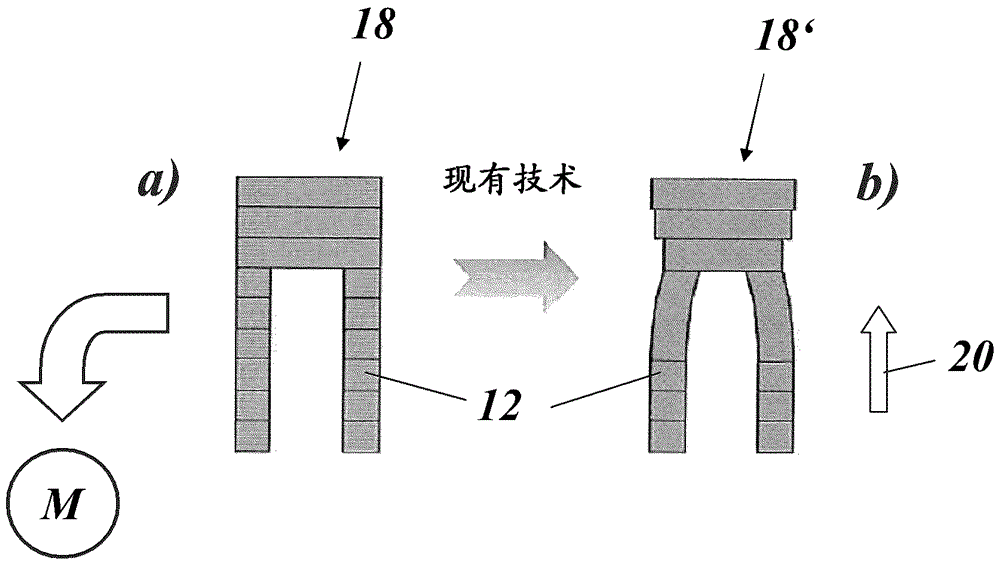

Method for manufacturing part by means of additive manufacturing technique

InactiveCN105965014ACheap serial productionRapid serial productionAdditive manufacturing apparatusIncreasing energy efficiencyMorphingManufacturing technology

The title of the invention is method for manufacturing part by means of additive manufacturing technique. The invention relates to a method for manufacturing a part (19') by means of an additive manufacturing technique and by post additive manufacturing process steps. A cheaper and faster serial production of such parts is achieved by said method comprising the steps of: providing first CAD data (18) representing the final geometry of the part to be manufactured; converting said first CAD data (18) into second morphed CAD data (19) by means of a morphing process (M), whereby said morphing process (M) takes into consideration all distortions of part geometry, which develop during the additive manufacturing process and the post additive manufacturing process steps such that the part (19') manufactured in accordance with said second morphed CAD data (19) has a geometry in accordance with said first CAD data (18); and manufacturing said part (19') by means of said additive manufacturing technique in accordance with said second morphed CAD data (19).

Owner:ANSALDO ENERGIA IP UK LTD

A kind of coating method and coating system and preparation method of rare earth magnet

ActiveCN106282948BImprove consistencyEffective thickness controlVacuum evaporation coatingSputtering coatingSputteringCoating system

The invention discloses a coating method, a coating system and a method for preparing rare-earth magnets. In the method and the system disclosed by the invention, magnets are arranged on a conveying device in a plurality of rows in a horizontal direction; the magnets which are arranged in the plurality of rows sequentially pass through a sputtering area of sputter coating equipment to complete coating; a vertical distance between the sputter coating equipment and the upper surface of the magnets is 10mm to 200mm. The method and the system disclosed by the invention adopt continuous pass type magnetron sputtering equipment to sputter heavy rare earth such as Dy and Tb onto the surfaces of the magnets, the thickness of the sputtering layer is effectively controlled, the uniformity of the sputtering layer is guaranteed, thereby the uniformity of the magnetic property of magnetic sheets obtained by performing grain boundary diffusion to the sputtered magnets is guaranteed, and the rapid and continuous production of magnets by adopting the grain boundary diffusion technique can be realized.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

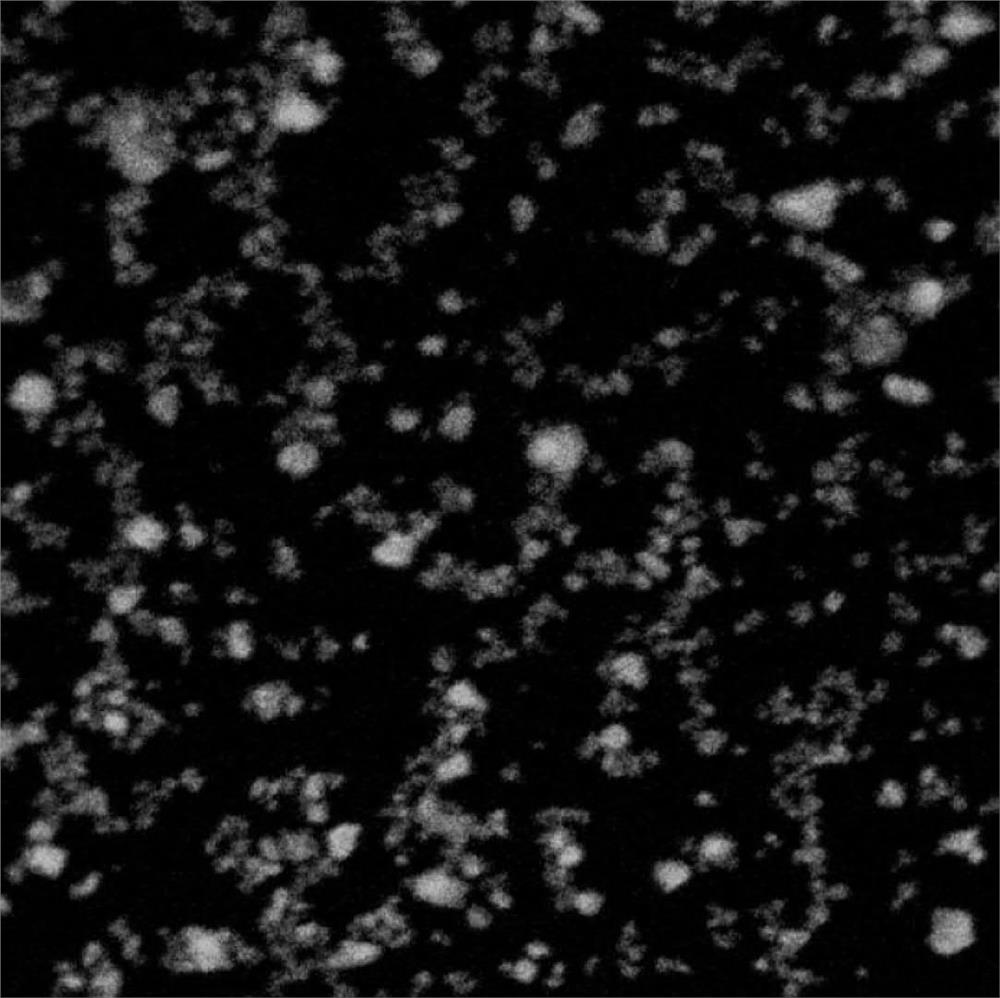

Oil gel and preparation method and use thereof

ActiveCN114158733BImprove plasticityGood application effectOrganic active ingredientsCosmetic preparationsWAS PROTEINThrombus

Provided are oil gels, their preparation methods and uses. The oil gel contains 60-90wt% liquid oil, 6-35wt% structuring agent and 4-15wt% water, wherein the liquid oil contains unsaturated fatty acid, and the structuring agent is protein denatured particles. As an antioxidant edible oil composition rich in unsaturated fatty acids, the oil gel of the present invention has simple components, does not need to add additional stabilizers, avoids the use of thickeners, emulsifiers and organic reagents, and has antioxidant properties , which is beneficial to the long-term storage of the product. The oil gel of the present invention can be used as an oral pharmaceutical preparation for realizing multiple therapeutic effects, such as regulating blood fat and / or clearing thrombus.

Owner:SIRIO PHARMA CO LTD

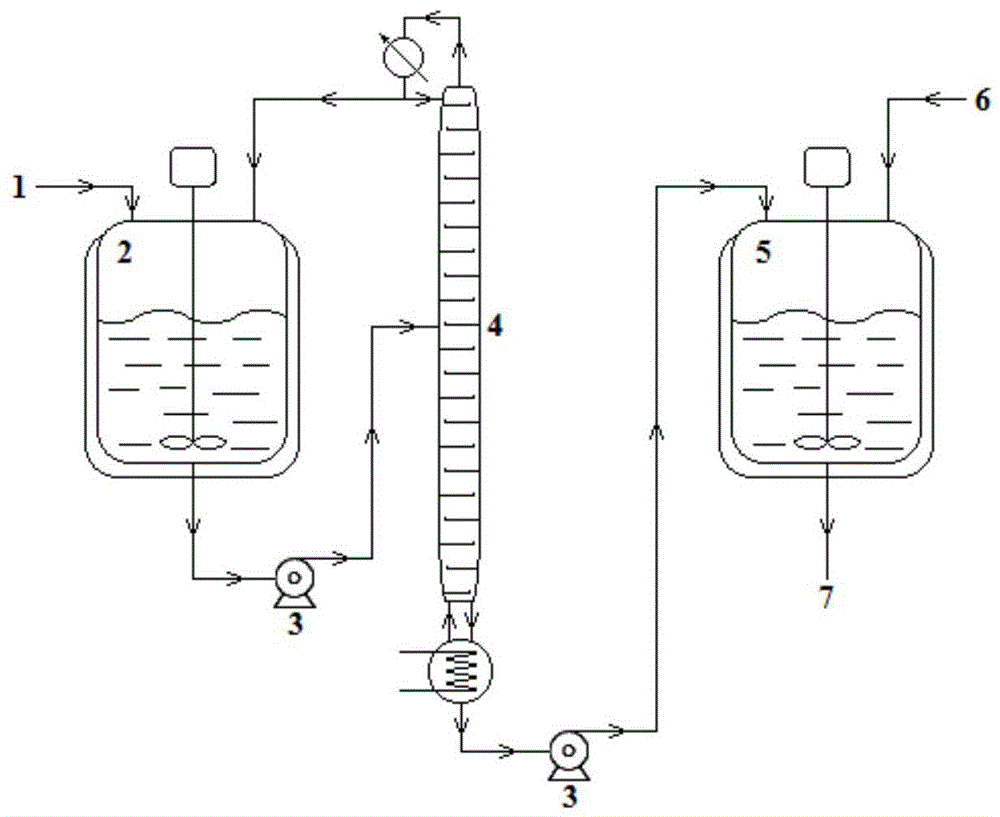

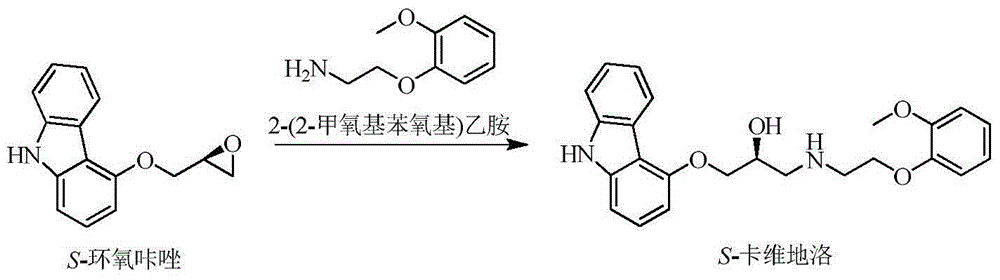

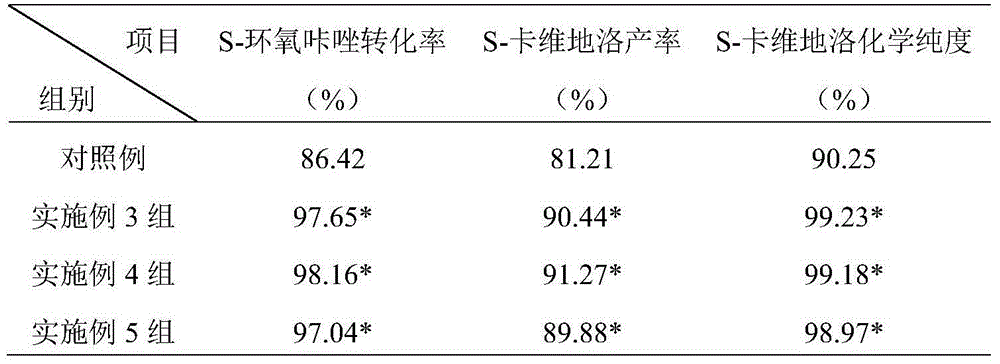

Preparation method for S-carvedilol

InactiveCN104592096AImprove conversion rateReduce the impact of crystallization purificationState of artCarbazole

The invention discloses a preparation method for S-carvedilol, which comprises the processes of product reaction, product rectification separation and recrystallization. Compared with the prior art, the preparation method adopts a reaction-rectification-crystallization continuous coupling process so that a reaction product is continuously and timely separated from a reaction system, the influence of excessive 2-(2-methoxyphenoxy) ethylamine on S-carvedilol crystallization purification can be reduced while the S-epoxy carbazole conversion rate is increased, and finally high-yield and high-purity S-carvedilol is prepared.

Owner:JIANGSU SUNAN PHARMA IND CO LTD

Method and equipment for producing synthetic quartz glass

ActiveCN113354263AIncrease temperatureEvenly distributedGlass furnace apparatusGlass shaping apparatusThermodynamicsCombustor

The invention provides a method and equipment for producing synthetic quartz glass, and solves the problems that the existing indirect method is complex in process and non-uniform in temperature thermal field; after the reaction chamber is corroded, metal impurities volatilize into the loose body; and excessive water molecules enter the loose body and the sintering difficulty is increased. The equipment for producing synthetic quartz glass comprises a reaction chamber provided with an exhaust passage; a lifting traction rod which is mounted at the top of the reaction chamber; an auxiliary combustor, wherein an output port of the auxiliary combustor is positioned in the reaction chamber; a raw material combustor, wherein an output port of the raw material combustor is positioned in the reaction chamber, wherein the lifting traction rod is used for driving the carrying rod to move up and down, the auxiliary combustor is located above the opposite side of the exhaust channel, the exhaust channel is located above the opposite side of the raw material combustor, and an included angle of 20-70 degrees is formed between the gas output direction of the raw material combustor and the vertical direction. When the loose body rises, the lifting traction rod enables the lowest end of the loose body to be kept at the height position lower than the inlet position of the exhaust channel.

Owner:神光光学集团有限公司

A carton folding device for corrugated carton production

ActiveCN113400720BFast implementation of hemmingImprove hemming effectPackage recyclingBox making operationsCardboardCarton

The invention relates to the technical field of carton hemming, in particular to a carton hemming device for corrugated carton production and a method for using the same. The technical problem to be solved by the present invention is that the vertical and horizontal folding of the carton cannot be done flexibly at one time, and the fast glue application and fixation cannot be performed, resulting in the inability to improve the output through continuous production. In order to solve the problems of the above-mentioned technologies, the present invention provides a carton folding device for corrugated box production. The top of the positioning mechanism, and then start the second lifting positioning rod to drive the cardboard to move upwards, and then through the movement of the two movable frames to cooperate with the clamping, so that the two sides of the carton are changed from the original horizontal placement to the vertical downward bending, and then through the With the cooperation of the second electronic hydraulic rod, the glued board bends the edge connection of the carton by 90° again, and finally the cardboards on the other two sides are bonded together by two pressing plates.

Owner:江山市千叶包装有限公司

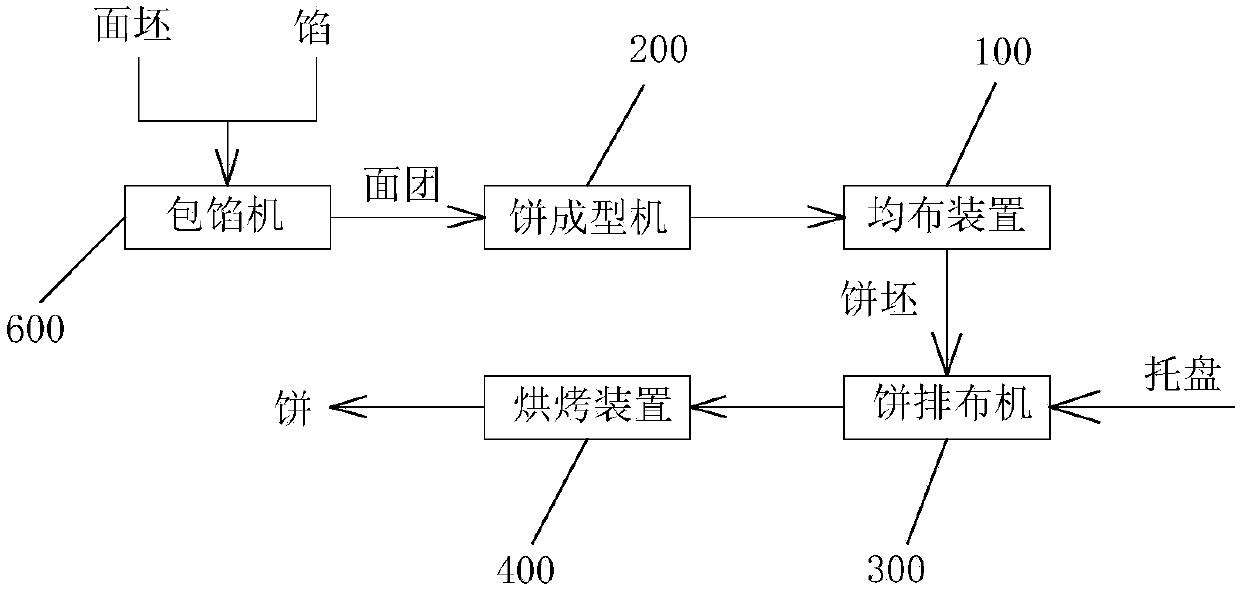

Method used for distributing sesame seeds

InactiveCN109548826ARapid serial productionRapid productionBaking processesBakery productsEngineeringSesame seed

The invention relates to food production technology, and discloses an encrusting machine used for preparing encrusted dough, a cake forming machine used for pressing dough into cake blanks, a uniformdistributing machine used for distributing sesame seeds onto the surfaces of cake blanks obtained through compression, a cake arrangement machine used for arrangement of the cake blanks with sesame seeds in trays, and a baking device used for introducing the cake blanks in the trays into an oven for baking. The food production technology can be used for cake shaped food rapid continuous production, and is capable of increasing production efficiency.

Owner:ANHUI XUANTONG IND DESIGN CO LTD

Imitated silk wallpaper or wall covering coating composition and imitated silk wallpaper or wall covering

PendingCN108589400ASolve Seam StitchingStrong three-dimensional senseCovering/liningsSpecial paperNonwoven fabricReducing agent

The invention relates to the technical field of decorative materials, in particular to an imitated silk wallpaper or wall covering coating composition and an imitated silk wallpaper or a wall covering. The composition is prepared from, by weight, 18-20 parts of PVC paste resin P450, 12-14 parts of plasticizer DINP, 1.2-1.4 parts of titanium white powder, 6-8 parts of calcium carbonate powder, 0.8-1.2 parts of stabilizer, 0.8-1.0 part of aliphatic wetting and dispersing agent, 0.4-0.6 part of high molecular polar acid ester wetting and dispersing agent and 2-3 parts of viscosity reducing agent.The composition is spread on a non-woven fabric or a non-woven paper to obtain a semi-finished coating, the coating is compounded with the non-woven fabric or imitated silk to obtain a compound semi-finished product, and printing is conducted to obtain a finished product. The product does not require a glue or a binder, is more environmentally friendly, and has strong adhesion and good durability.

Owner:ZHEJIANG LIANXIANG EMBROIDERY CO LTD

Carton edge folding device for corrugated carton production

ActiveCN113400720AFast implementation of hemmingImprove hemming effectPackage recyclingPaper-makingCartonPaperboard

The invention relates to the technical field of carton edge folding, in particular to a carton edge folding device for corrugated carton production and a using method of the carton edge folding device, and aims to solve the technical problems that longitudinal and transverse folding of a carton cannot be flexibly completed at a time, rapid gluing and fixing cannot be achieved, continuous production cannot be achieved, and the yield cannot be increased. The carton edge folding device for corrugated carton production comprises a dustproof machine box, an edge folding mechanism and a limiting mechanism, a carton needing edge folding is placed on the top of the limiting mechanism, then a second lifting positioning rod is started to drive paperboards to move upwards, the two sides of the carton are bent downwards vertically instead of being horizontally placed through moving and matched clamping of two movable frames, then the edge connecting position of the carton is bent by 90 degrees again through a gluing plate through cooperation of a second electronic hydraulic rod, and finally the paperboards on other two sides of the carton are attached through two pressing plates.

Owner:江山市千叶包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com