Method for producing alkyl alcohol amine

A technology of alkyl alcohol amine and alkyl amine, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of reducing product quality, increasing energy consumption, limiting production capacity, etc., to expand the adjustment range , the effect of reducing side effects and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

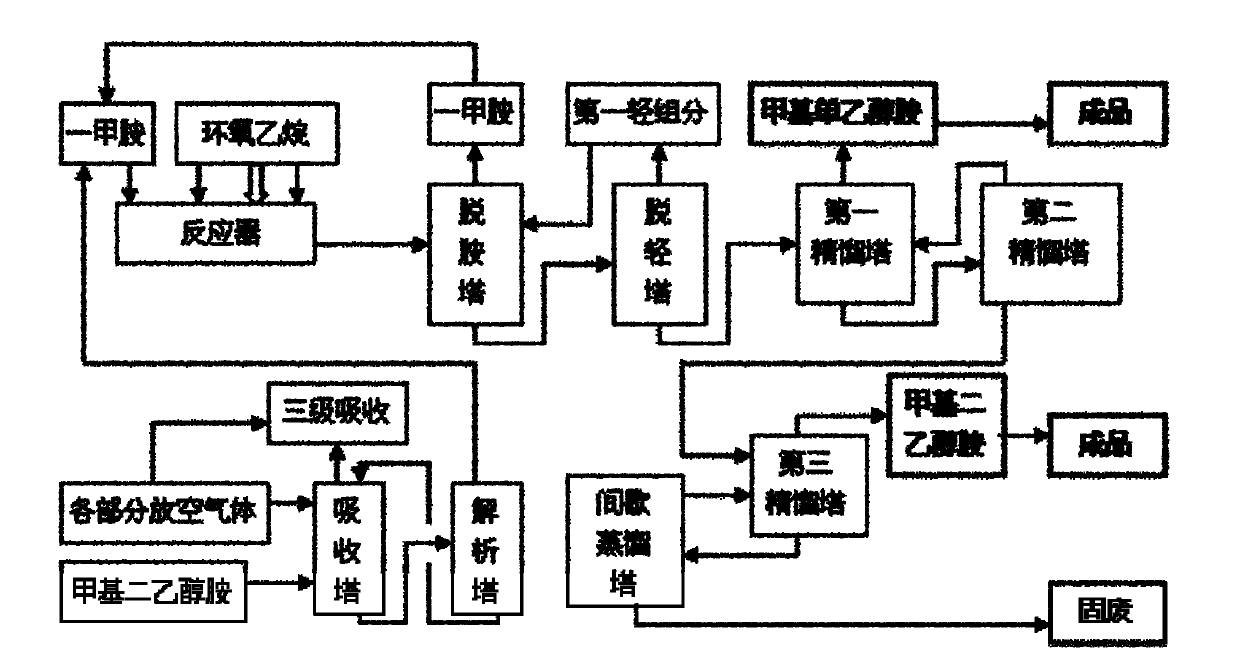

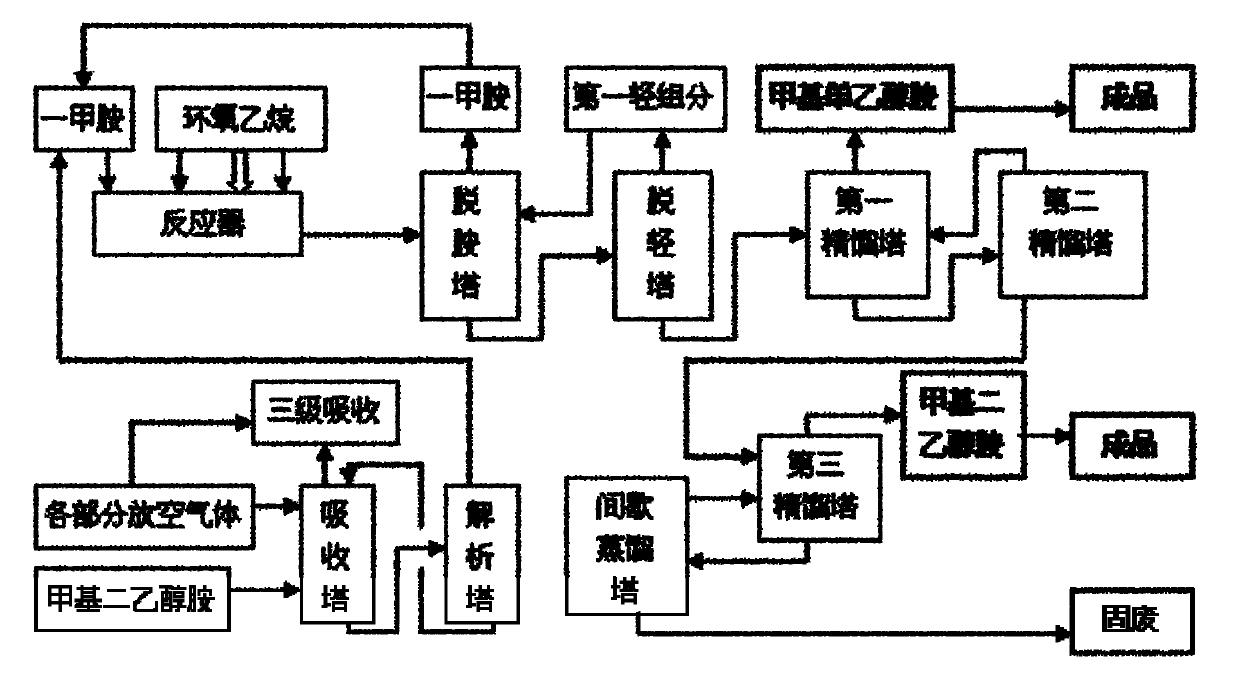

[0051] This embodiment is used to illustrate a kind of method of continuous production alkanolamine of the present invention, as figure 1 as shown,

[0052](1) Synthetic reaction: raw material ethylene oxide (EO) and raw material monomethylamine (MMA, purity 99% by weight, wherein, the content of water is less than 0.1% by weight) are pumped into multi-point continuous reactor by metering pump respectively React within, wherein, the molar ratio of monomethylamine and ethylene oxide total amount is 3: 1, take ethylene oxide total amount as the basis, the ethylene oxide of each ethylene oxide feed port feed The amount is 25 mol%, wherein, the feeding amount of monomethylamine makes its flow velocity in the pipeline be 1m / s, and the feeding amount of each feeding port ethylene oxide makes its flow velocity in the pipeline be 1m / s; the pressure in the reactor is 3.6MPa, and the temperature is 110°C to obtain a mixture containing methyl monoethanolamine and methyldiethanolamine, w...

Embodiment 2

[0067] This embodiment is used to illustrate a kind of method of continuous production alkanolamine of the present invention, as figure 1 as shown,

[0068] (1) Synthetic reaction: raw material ethylene oxide and raw material monomethylamine (purity is 99% by weight, wherein, the content of water is less than 0.1% by weight) are respectively pumped in the multi-point continuous reactor by metering pump and reacted, Wherein, the molar ratio of monomethylamine and the total amount of oxirane is 5: 1, taking the total moles of oxirane as the basis, the amount of the oxirane of each oxirane feed inlet feed is 25 mol%, wherein, the feed rate of monomethylamine makes its flow velocity in the pipeline be 0.8m / s, and the feed rate of each feed port ethylene oxide makes its flow velocity in the pipeline 0.8m / s ; The pressure in the reactor is 3.5MPa, and the temperature is 110° C. to obtain a mixture containing methyl monoethanolamine and methyldiethanolamine, and the mixture leaves t...

Embodiment 3

[0083] This embodiment is used to illustrate a kind of method of continuous production alkanolamine of the present invention, as figure 1 as shown,

[0084] (1) Synthetic reaction: raw material ethylene oxide and raw material monomethylamine (purity is 99% by weight, wherein, the content of water is less than 0.1% by weight) are respectively pumped in the multi-point continuous reactor by metering pump and reacted, Wherein, the mol ratio of monomethylamine and oxirane total amount is 1.2: 1, and the total mole number of oxirane is a benchmark, the amount of the oxirane of each oxirane feed inlet feed is equal to It is 25 mol%, and wherein, the feed rate of monomethylamine makes its flow velocity in pipeline be 1.5m / s, and the feed rate of each feeding port ethylene oxide makes its flow velocity in pipeline be 1.5m / s s; the pressure in the reactor is 4MPa, and the temperature is 120° C. to obtain a mixture containing methyl monoethanolamine and methyldiethanolamine, which leav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com