Composite solid polymer electrolyte and preparing method and application thereof

A solid polymer and electrolyte technology, applied in the field of lithium ion batteries, can solve the problems of poor contact stability and low mechanical strength, and achieve the effects of large migration steric hindrance, improved lithium ion migration coefficient, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

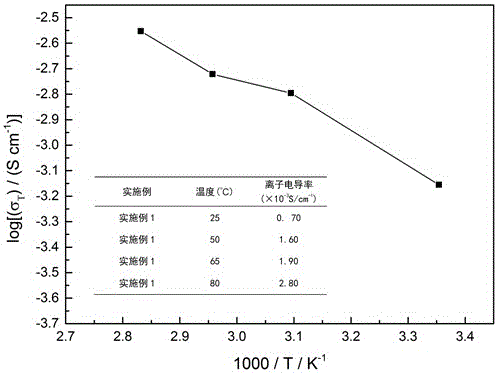

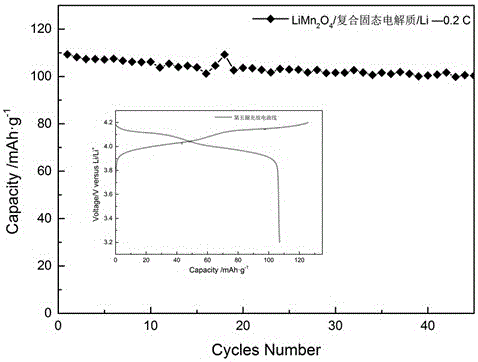

[0052] A composite solid polymer electrolyte prepared from enolate monomers, lithium salts, porous support matrix, additives, and initiators; its thickness is 120 μm, and its ion conductivity at 25°C is 7.0×10 -4 S / cm -1 , the ionic conductivity can reach 1.6×10 at 50°C -3 S / cm -1 ,Such as figure 1 shown. The specific preparation method is as follows:

[0053] (1) Under the condition of nitrogen atmosphere protection, take 2.6g tripropylene glycol dipropylene ester (TPGDA), 0.5g succinonitrile and 0.5g lithium bistrifluoromethanesulfonylimide, mix them, and stir at 40°C for 3h , after dissolving evenly, a viscous mixture is obtained;

[0054] (2) Add 0.12 g of azobisisobutyronitrile to the mixture obtained in (1), and stir at 20°C for 3 hours;

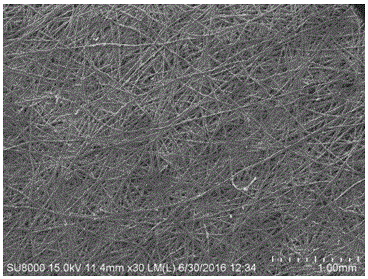

[0055] (3) Immerse the cut and dried polyimide non-woven fabric in the mixture obtained in (2), first ultrasonically treat it for 15 minutes, and then continue to soak for 5 hours until the non-woven fabric is completely saturat...

Embodiment 2

[0059] The difference between this embodiment and Example 1 is that the acrylate monomer is a mixture of propoxylated trimethylolpropane triacrylate (TPPTA) and ethylene glycol methacrylate (EGMEM) ; Propoxylated trimethylolpropane triacrylate (TPPTA): ethylene glycol methacrylate (EGMEM): succinonitrile: the mass ratio of bistrifluoromethylsulfonimide lithium is 3:1: 1:1; the initiator is azobisisobutyronitrile, and the mass is 5wt% of the mixed monomer; the baking temperature after sealing is 80°C; the thickness of the prepared composite solid polymer electrolyte is about 110 μm.

Embodiment 3

[0061] The difference between this embodiment and Example 1 is that the acrylate monomers are two kinds of propoxylated trimethylolpropane triacrylate (TPPTA) and ethoxylated trimethylolpropane triacrylate (ETPTA). A mixture of monomers; the lithium salt is composed of two lithium salts, lithium trifluoromethanesulfonate and lithium bistrifluoromethylsulfonimide (LiTFSI); propoxylated trimethylolpropane triacrylate (TPPTA ): ethoxylated trimethylolpropane triacrylate (ETPTA): succinonitrile: lithium bistrifluoromethanesulfonimide: lithium trifluoromethanesulfonate in a mass ratio of 6:2:2: 1:1; the initiator is azobisisobutyronitrile, and the mass is 6wt% of the mixed monomer; the baking temperature after sealing is 80°C; the thickness of the prepared composite solid polymer electrolyte is about 115 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com