Patents

Literature

81 results about "Succinonitrile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Succinonitrile, also butanedinitrile, is a nitrile, with the formula of C₂H₄(CN)₂. It is a colorless solid that melts at 57 °C, hence its waxy consistency.

Formation method of lithium ion battery

InactiveCN102637903AOvercoming the Leakage ProblemAvoid influenceFinal product manufactureSecondary cells charging/dischargingPower flowCurrent range

The invention belongs to the technical field of lithium ion batteries and particularly relates to a formation method of a lithium ion battery. The formation method comprises the following steps of: vacuumizing a battery to be injected and performing first injection on the battery; performing opening formation on the battery subjected to the first injection, wherein a formation current ranges from 0.1C to 1.5C; and performing second injection and encapsulation on the battery subjected to the formation, wherein electrolyte for the second injection comprises high-temperature additives including at least one of trimethylene sulfite, ethylene sulfate, succinonitrile and adiponitrile. Compared with the prior art, the formation method disclosed by the invention avoids the electrolyte leakage caused by quick gas production during deformation with a large current by virtue of the way of twice injection, and avoids the influence on the components of an SEI (Solid Electrolyte Interface) membrane due to adding the electrolyte additives once, thereby improving the low temperature performance of a battery cell; and as the battery cell has high temperature performance by virtue of the additives injected after the formation, and the formation time is shortened greatly, the process efficiency is enhanced greatly, and the production cost is reduced.

Owner:NINGDE AMPEREX TECH +1

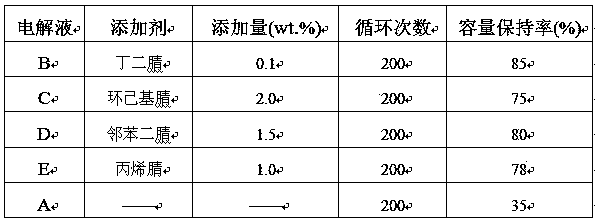

Electrolyte for 4.5 V lithium ion battery

InactiveCN103441303AImprove high-pressure cycle performanceImprove cycle performanceSecondary cellsElectrolytic agentAcrylonitrile

The invention relates to an electrolyte for a 4.5 V lithium ion battery. The electrolyte comprises the following components in percentage by weight: 80%-89% of organic solvents, 10%-15% of lithium salt and 0.1%-5.0% of additives, wherein the additives are nitrile compounds, and the nitrile compounds include one of butanedinitrile, adiponitrile, sebaconitrile, acrylonitrile, cyclohexyl nitrile, 1,2-cyclohexyl dinitrile, phthalonitrile and cyanopyridine. According to the invention, the additives effectively improve the high-pressure cycle property of the lithium ion battery, can enhance the voltage of a common electrolyte to 4.5 V and are obvious in effect. The electrolyte disclosed by the invention is difficult to decompose under high voltage of 4.5 V, obviously enhances the cycle property of the lithium ion battery, and less influences the battery capacity.

Owner:嘉德力电源科技(苏州)有限公司

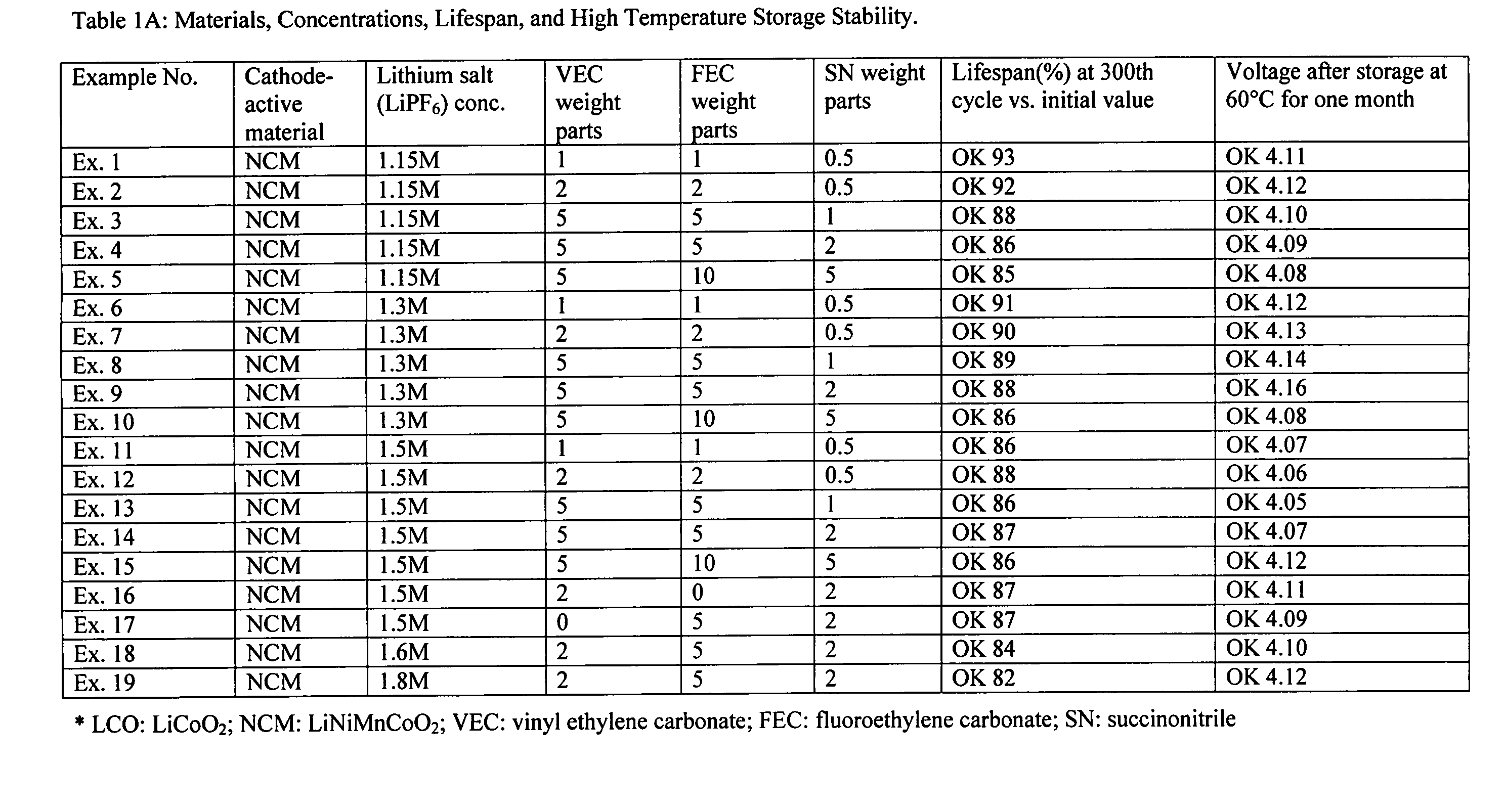

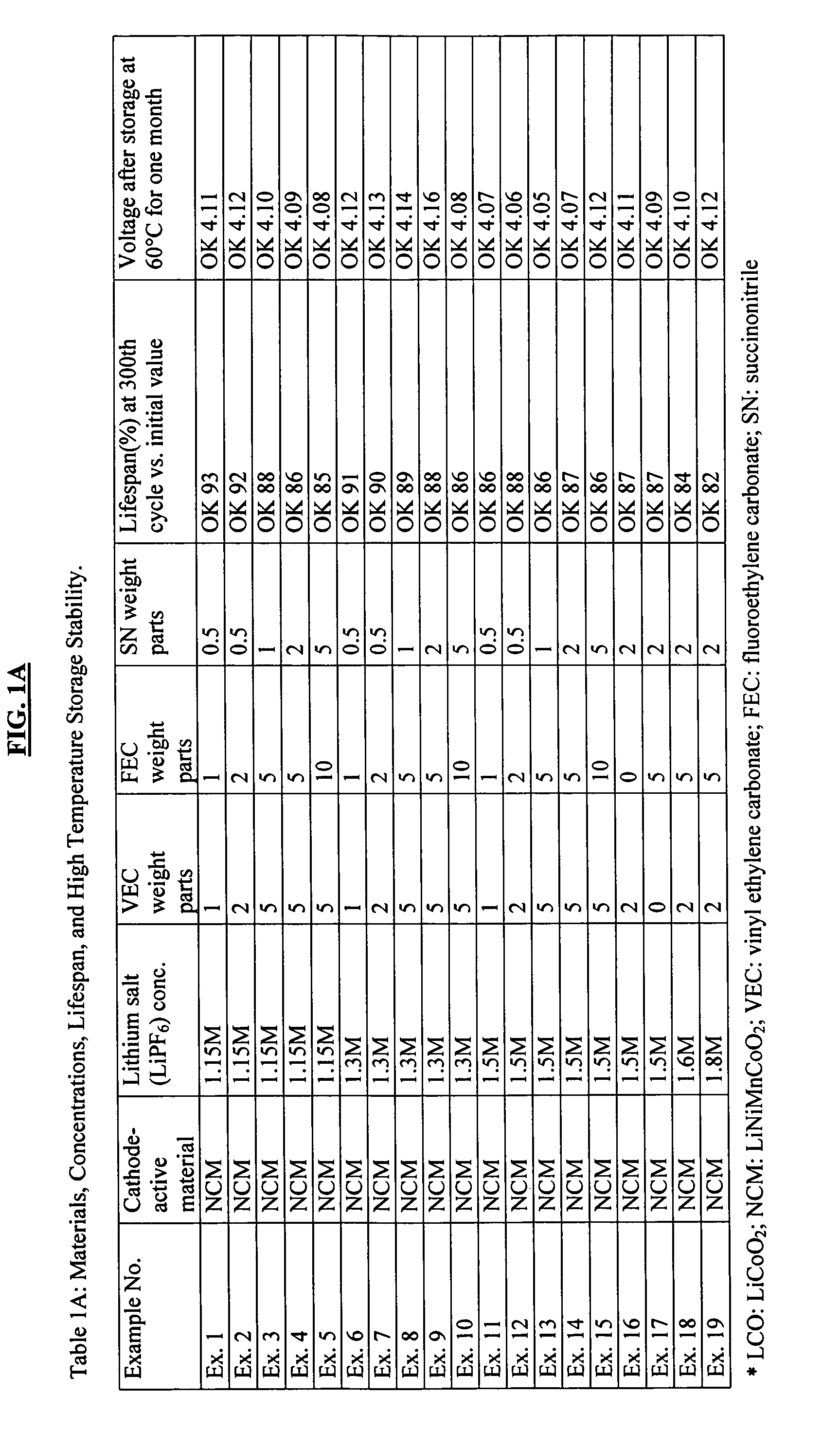

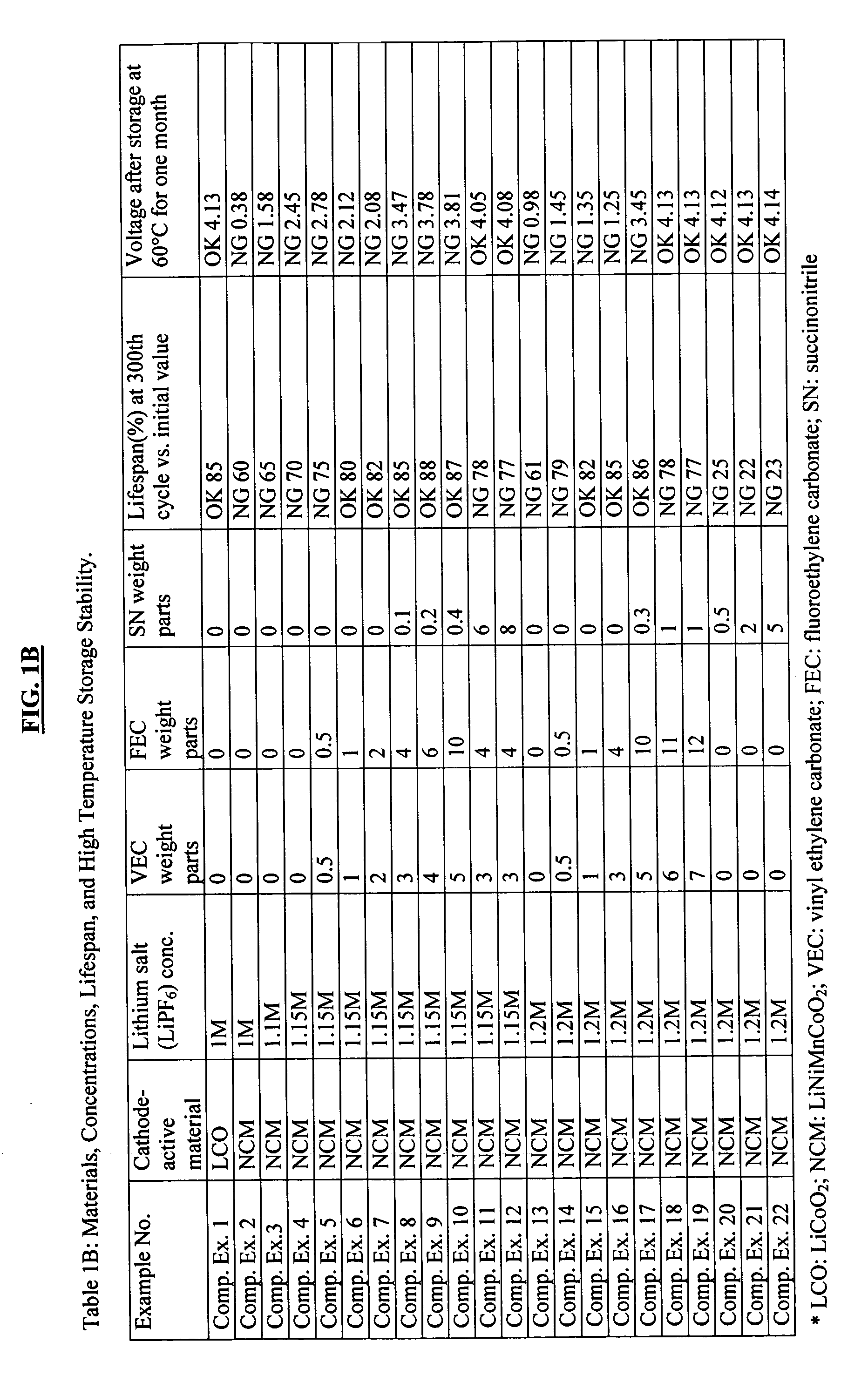

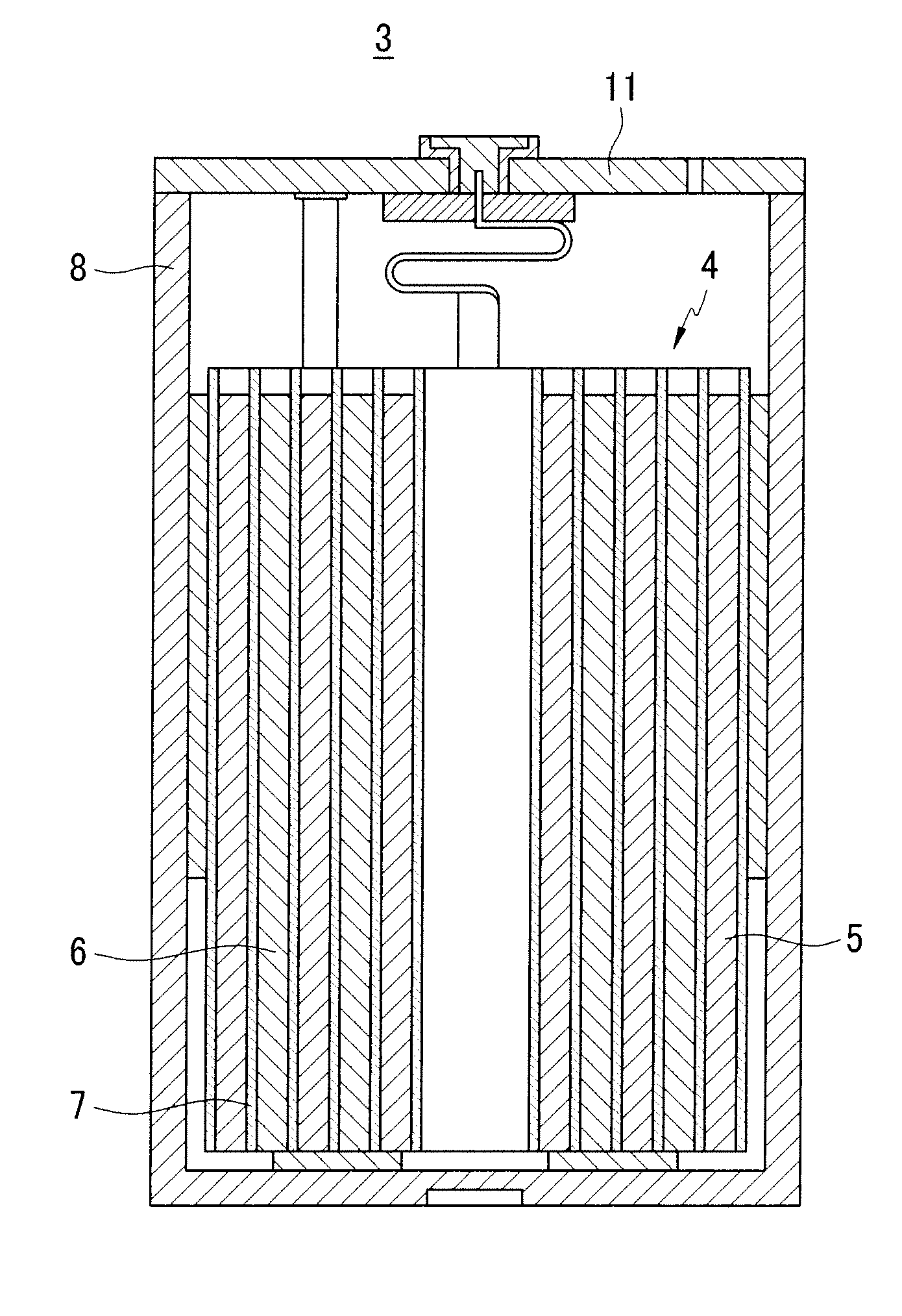

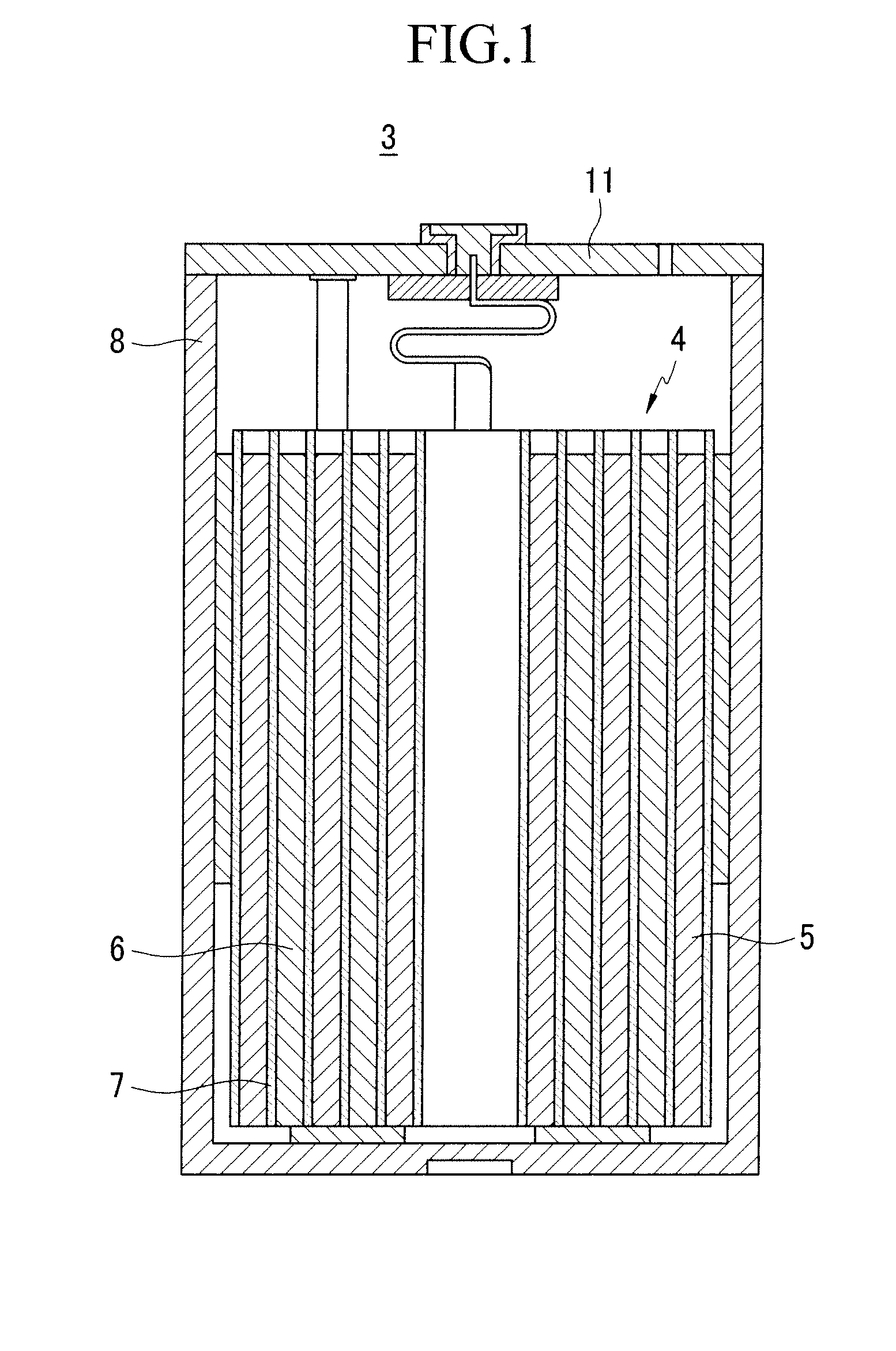

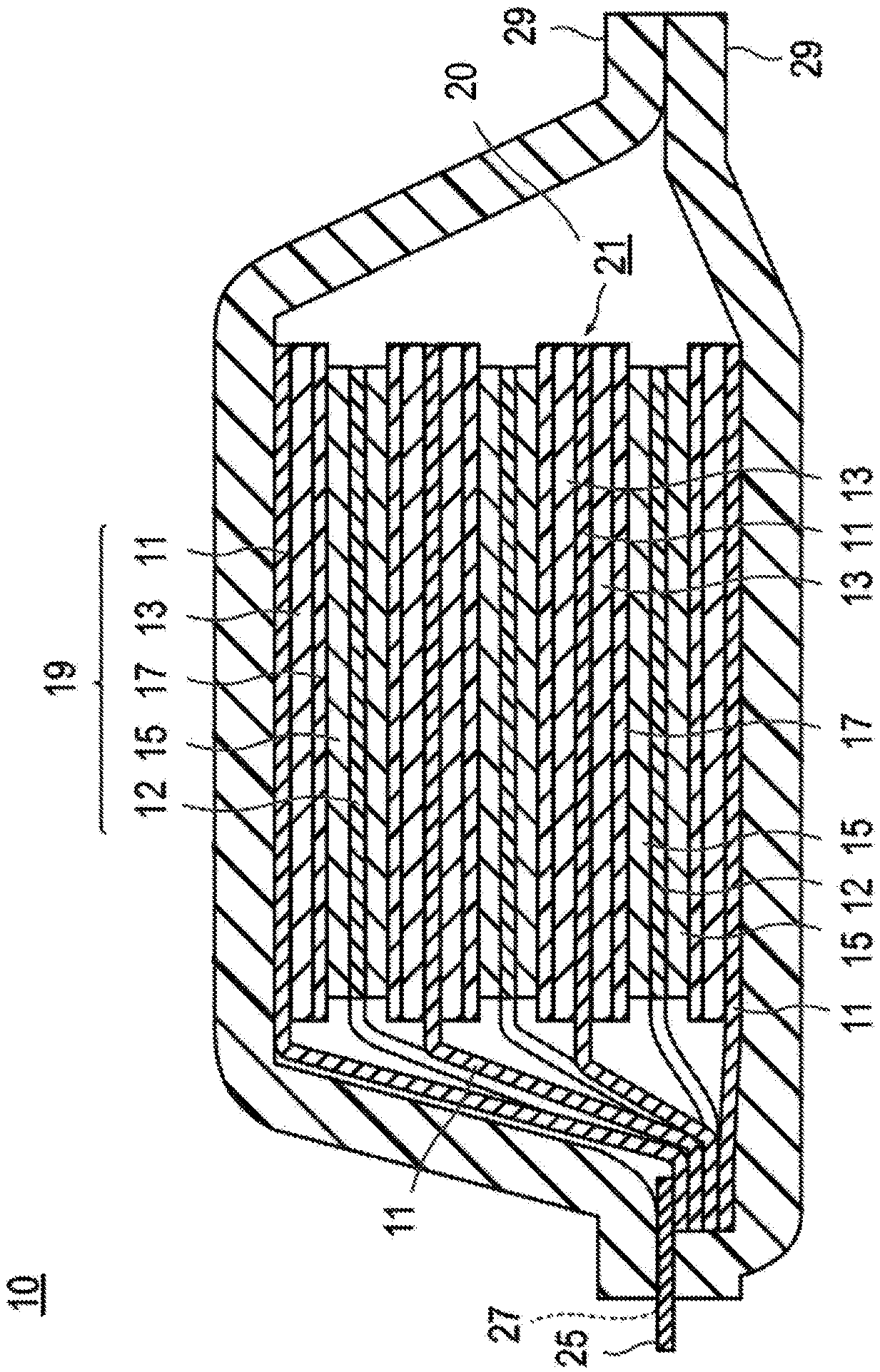

Rechargeable battery and associated methods

ActiveUS20100015521A1Excellent lifespan and storage characteristicLow production costElectrode carriers/collectorsOrganic electrolyte cellsOrganic solventRechargeable cell

A rechargeable battery and associated methods, the rechargeable battery including an anode, a cathode, wherein the cathode includes a ternary cathode-active material, a separator interposed between the cathode and the anode, an electrolyte, and a housing enclosing the electrolyte, the anode, and the cathode, wherein the electrolyte includes a lithium salt, a non-aqueous organic solvent, about 0.5 weight % to about 5 weight % of succinonitrile, and at least one of about 1 weight % to about 10 weight % of halogenated ethylene carbonate and about 1 weight % to about 5 weight % of vinyl ethylene carbonate.

Owner:SAMSUNG SDI CO LTD

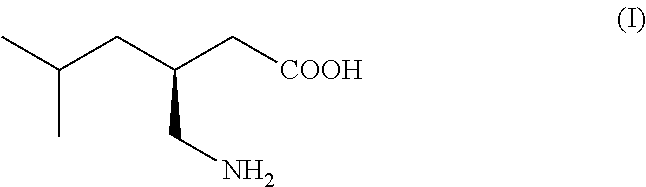

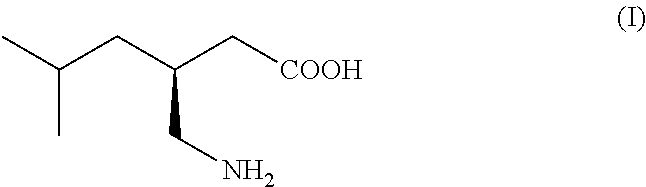

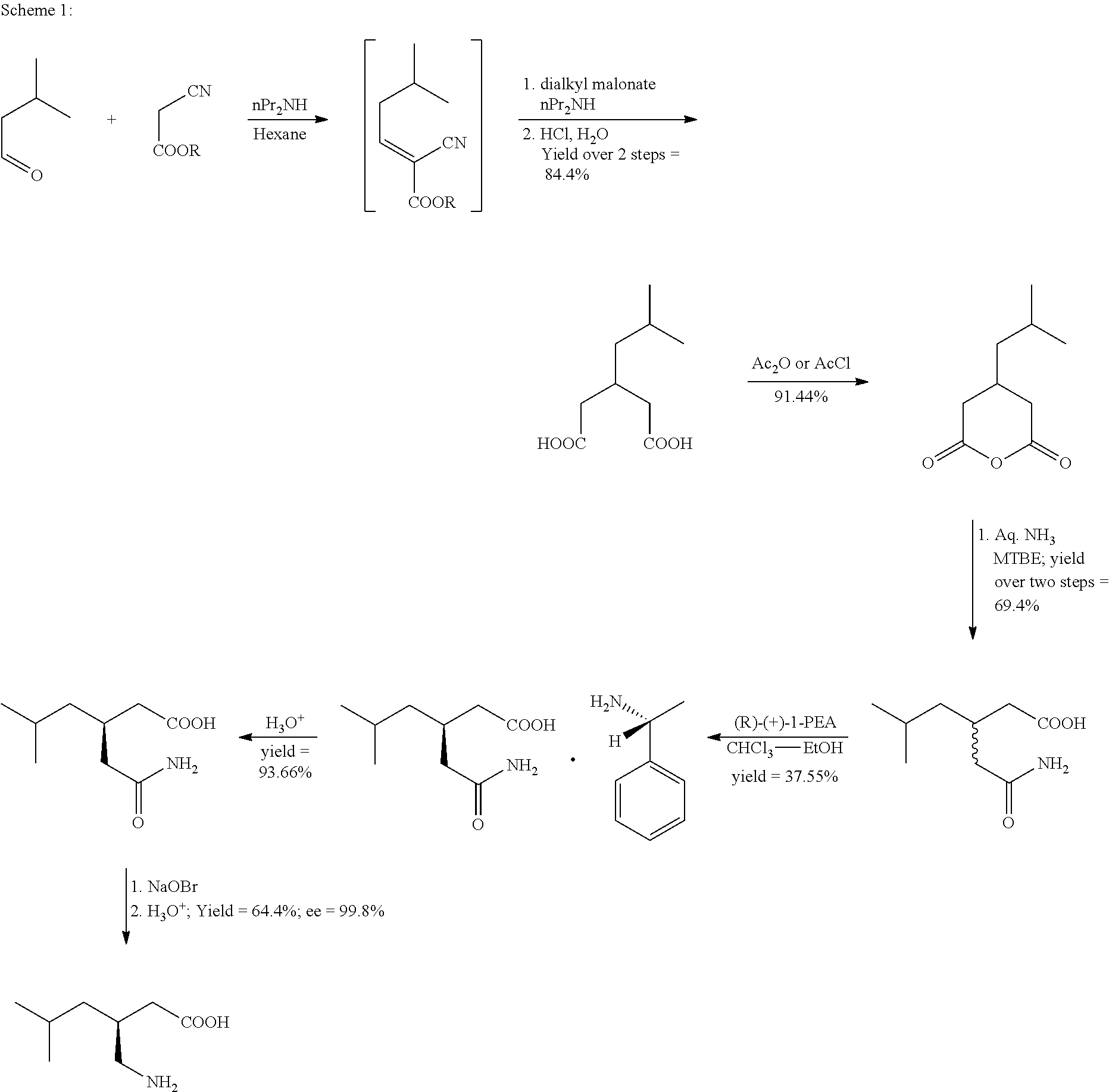

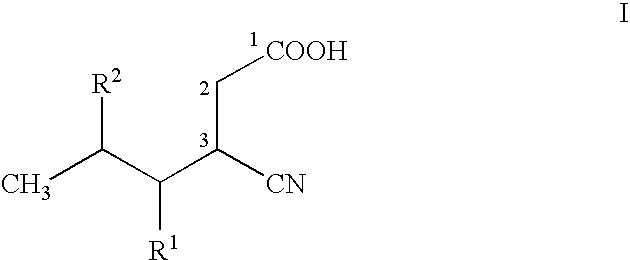

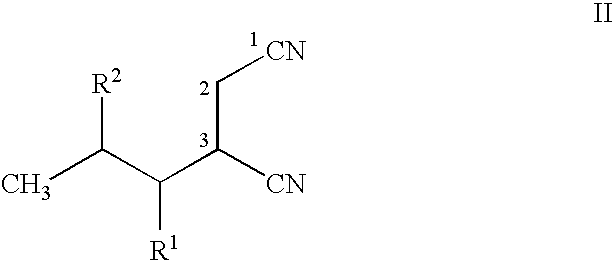

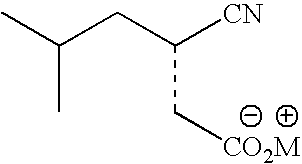

Process for the preparation of pregabalin

ActiveUS20150344919A1Economical and simpleEasy to implementOrganic compound preparationAmino-carboxyl compound preparationAlkaline earth metalMethyl group

The present invention provides an improved process for the preparation of a compound of formula (I), which comprises the steps of: formula (I), (a) reacting isovaleraldehyde of formula (II) and alkyl cyanoacetate of formula (III) optionally in presence of salts of weak acid and weak base or weak base in a suitable solvent to get 2-cyano-5-methyl-hex-2-enoic acid alkyl ester of formula (IV); (b) reacting 2-cyano-5-methyl-hex-2-enoic acid alkyl ester of formula (IV) with a suitable cyanide source in water or in an organic solvent or mixture thereof to get 2-isobutylsuccinonitrile of formula (V); (c) obtaining optionally 2-isobutylsuccinonitrile of formula (V) by reacting isovaleraldehyde of formula (II) and alkyl cyanoacetate of formula (III) in presence of suitable cyanide source in water or in an organic solvent or mixture thereof in single step; (d) converting 2-isobutylsuccinonitrile of formula pa (V) to racemic 3-cyano-5-methyl-hexanoic acid or salt thereof of formula (VI) with a genetically modified nitrilase enzyme (Nit pt 9N_56_2) in water or optionally with an organic co-solvent at appropriate pH and temperature; (e) converting racemic 3-cyano-5-methyl-hexanoic acid or salt thereof of formula (VI) to racemic alkyl 3-cyano-5-methyl-hexanoate of formula (VII) by treatment with alcohol (R3OH) and acidic catalyst or alkyl halide (R3X) in presence of a base in a suitable solvent or a mixture of solvents thereof; (f) obtaining (S)-alkyl 3-cyano-5-methyl-hexanoate of formula (VIII) and (R)-3-cyano-5-methyl-hexanoic acid or salt thereof of formula (X) by enzymatic enantioselective hydrolysis in water or organic solvent or a mixture thereof from racemic alkyl 3-cyano-5-methyl-hexanoate of formula (VII); (g) obtaining optionally the compound of formula (VII) by racemizing unwanted (R)-3-cyano-5-methyl-hexanoic acid or salt thereof of formula (X) or substantially enriched (R)-3-cyano-5-methyl-hexanoic acid salt thereof of formula (X) in presence of a base in organic solvent or a mixture thereof; (h) converting (S)-alkyl 3-cyano-5-methyl-hexanoate of formula (VIII) to pregabalin of formula (I) by hydrolyzing ester group with suitable alkali or alkaline earth metal base followed by hydrogenation optionally in one pot in a solvent selected from water or other organic solvents or a mixture thereof in presence of a suitable hydrogenation catalyst.

Owner:HIKAL

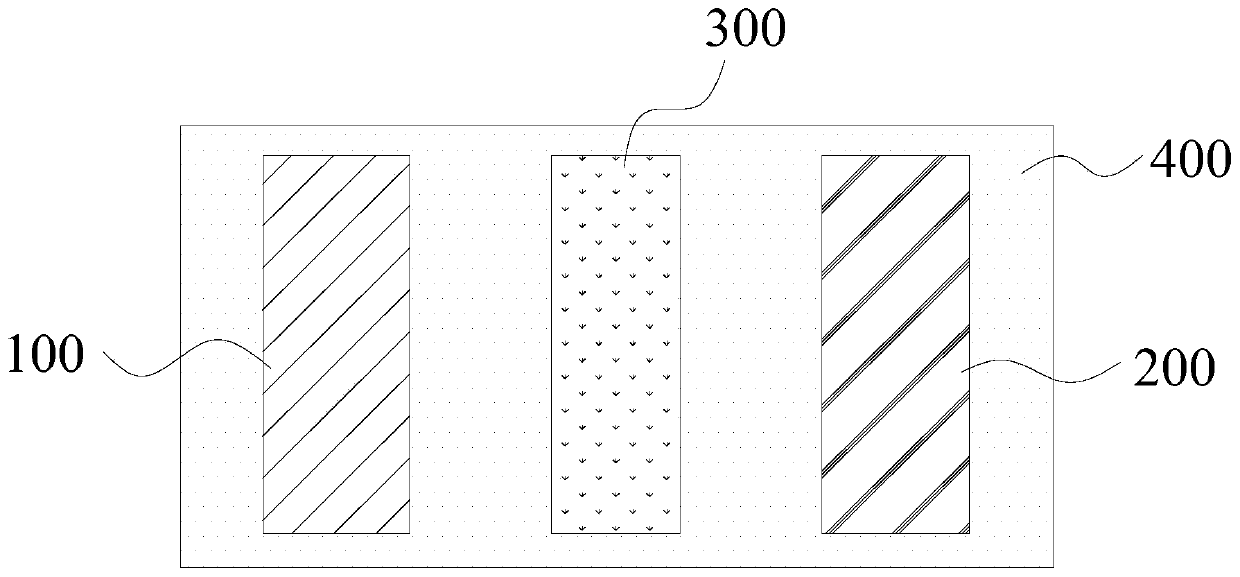

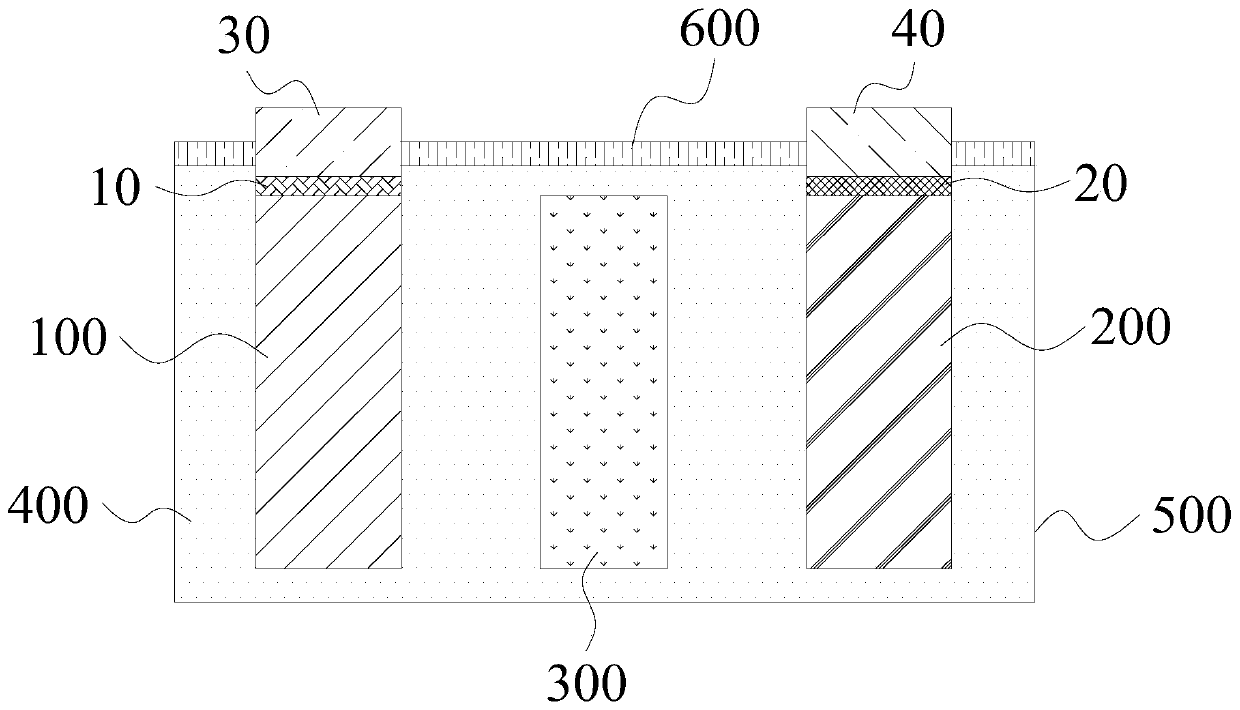

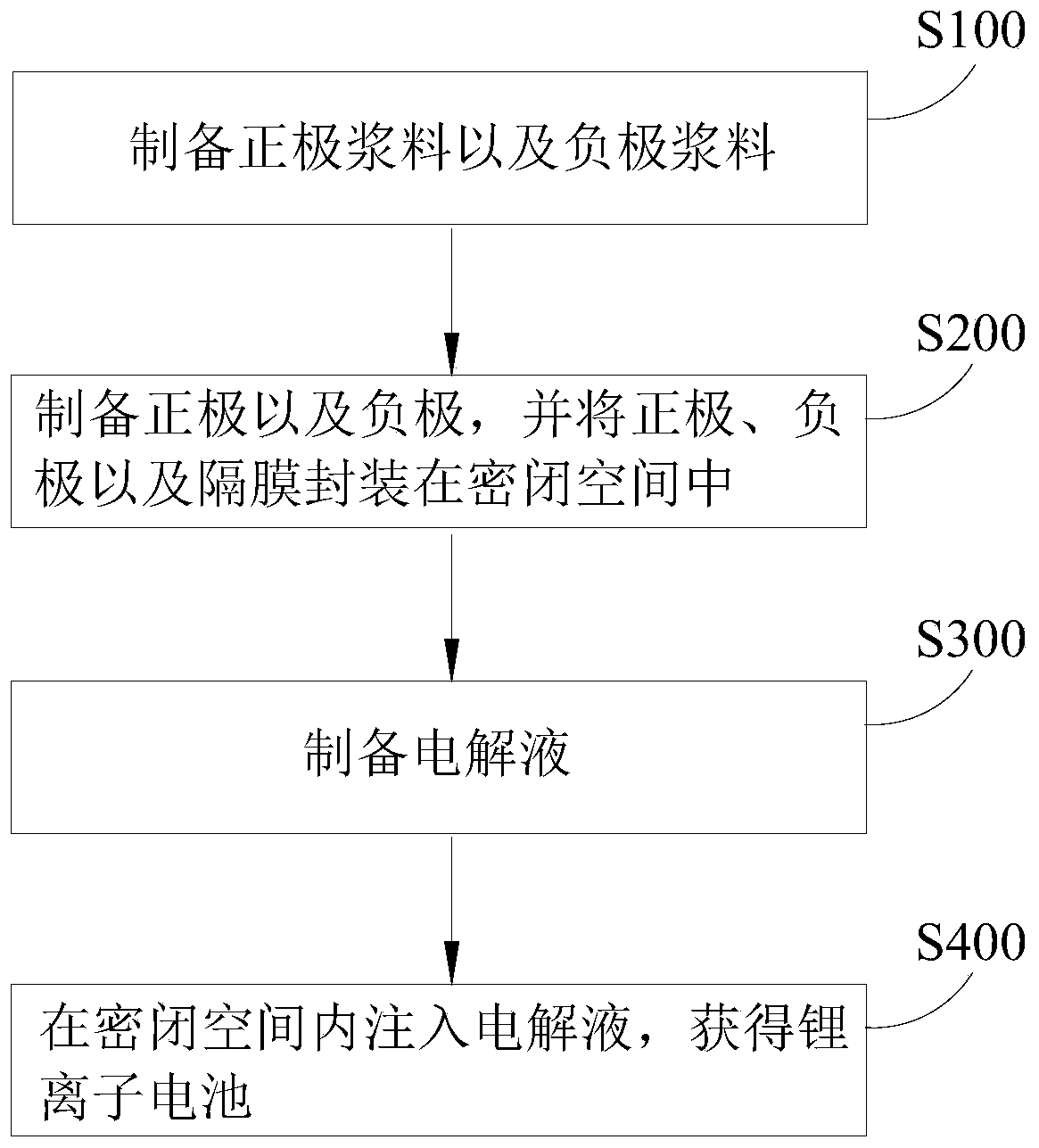

Lithium ion battery and preparation method

ActiveCN109713298ALow costExtended service lifeCell electrodesFinal product manufactureDifluorophosphateAluminium-ion battery

The invention provides a lithium ion battery and a preparation method. The lithium ion battery includes a positive electrode, a negative electrode, a diaphragm, and an electrolyte. The positive electrode and the negative electrode are separated by the diaphragm; the positive electrode, the negative electrode and the diaphragm are encapsulated in an enclosed space; the electrolyte is filled in theenclosed space; the positive electrode includes a positive active material, the positive active material includes a nickel-cobalt-manganese ternary material, and the percentage of the amount of a substance of nickel in the nickel-cobalt-manganese ternary material is 50-60%; the negative electrode includes a negative active material, the negative active material includes graphite, and the degree ofgraphitization of the graphite is 91-94%, and an OI value is 6-7; and the electrolyte includes a lithium salt, a solvent and an additive, wherein the lithium salt includes lithium hexafluorophosphateand lithium bis(fluorosulfonyl)imide, the solvent includes ethylene carbonate, ethyl methyl carbonate, dimethyl carbonate and propyl propionate, and the additive includes lithium difluorophosphate, lithium bis(oxalate)borate, tris(trimethylsiloxy)boron, vinylene carbonate, and succinonitrile. The lithium ion battery has the characteristics of high safety, low cost, long service life and excellentusage performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Electrolyte for Rechargeable Lithium Battery Including Additives, and Rechargeable Lithium Battery Including the Same

ActiveUS20100255369A1Improve featuresHigh voltageNon-aqueous electrolyte accumulatorsElectrolytic capacitorsOrganic solventPhysical chemistry

An electrolyte for a rechargeable lithium battery that includes a non-aqueous organic solvent, a lithium salt, and an electrolyte additive. The electrolyte additive includes 2 to 6 wt % of succinonitrile, 2 to 6 wt % of alkane sultone, and 1 to 3 wt % of vinylethylene carbonate based on the total weight of the electrolyte.

Owner:SAMSUNG SDI CO LTD

Stereoselective bioconversion of aliphatic dinitriles into cyano carboxylic acids

The present invention is directed to a regio- and stereoselective bioconversion of selected aliphatic dinitriles into corresponding cyanocarboxylic acids. More particularly, the present invention provides methods for the conversion of 2-isobutyl-succinonitrile into (S)-3 cyano-5-methylhexanoic acid, which is a useful intermediate in the synthesis of (S)-3(aminomethyl)-5-methylhexanoic acid (pregabalin). Pregabalin can be used for treating certain cerebral diseases, for example, in the treatment and prevention of seizure disorders, pain, and psychotic disorders.

Owner:PFIZER INC

Nonaqueous electrolyte secondary battery

ActiveCN107851832ACompromise and improve durabilityCompromise and improve cycle durabilityCell seperators/membranes/diaphragms/spacersNegative electrodesElectrolysisSolvent

A nonaqueous electrolyte secondary battery, wherein: an electrolyte is configured to contain an electrolyte salt, a nonaqueous solvent into which the electrolyte salt is able to be dissolved, a firstadditive selected from among specific oxalate compounds and disulfonic acid ester compounds, and a second additive that has a reduction potential lower than the reduction potential of the first additive and is selected from among vinylene carbonate, fluoroethylene carbonate, vinyl ethylene carbonate, 1, 3-propane sultone, 1, 4-butane sultone, 1, 3-propene sultone, succinonitrile and adiponitrile;and 0.21 <= A * L / SSA <= 0.69 and 0.51 <= B * L / SSA <= 1.5 are satisfied, where SSA (m2 / g) is the BET specific area of the negative electrode active material, L is the ratio (liquid coefficient) of the electrolyte amount to the total void volume of the positive electrode, the negative electrode and the separator, A (mass%) is the ratio of the addition amount of the first additive to the total amount of the nonaqueous solvent and the electrolyte salt in the electrolyte, and B (mass%) is the ratio of the addition amount of the second additive to the total amount of the nonaqueous solvent and theelectrolyte salt in the electrolyte.

Owner:ENVISION AESC JAPAN LTD

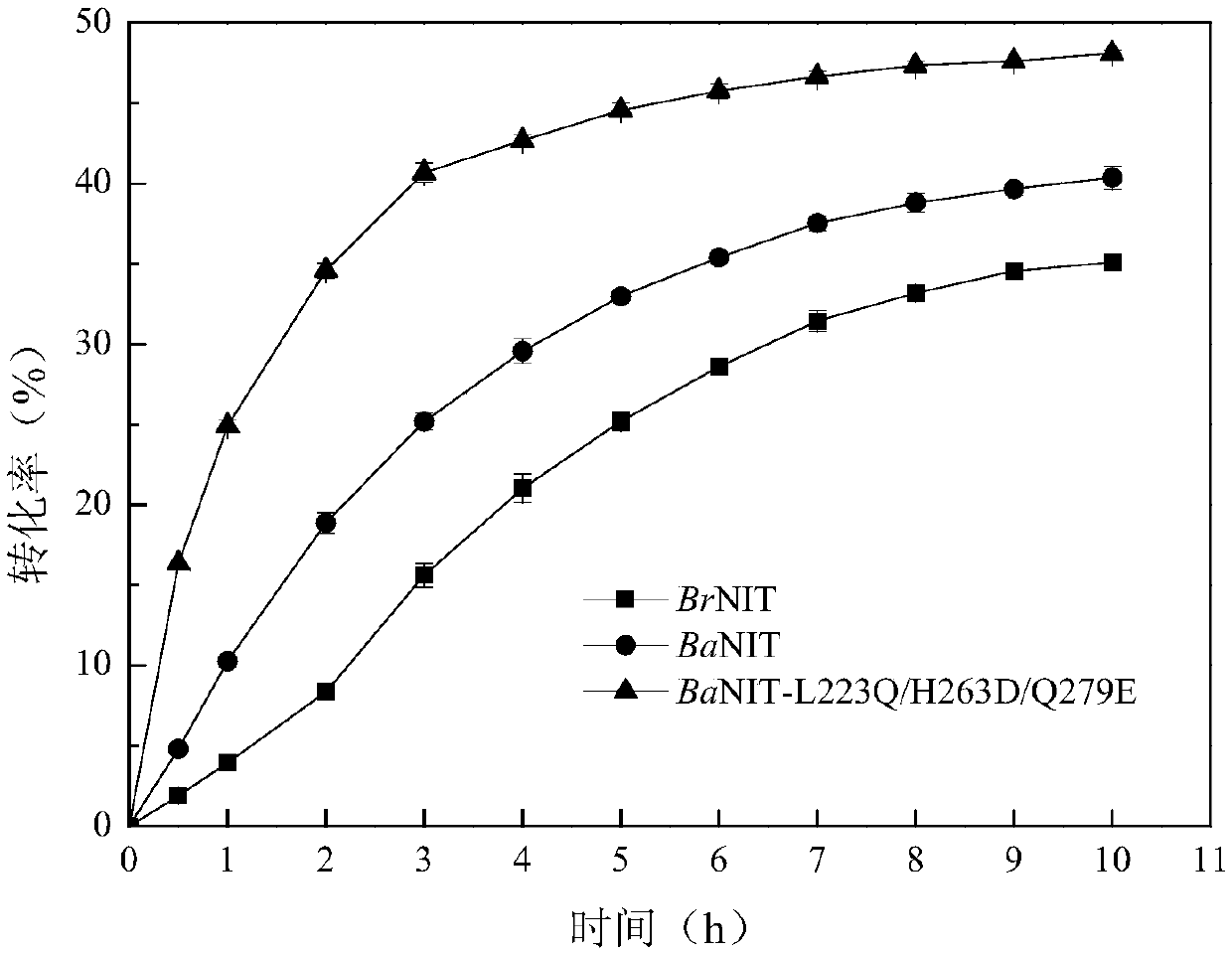

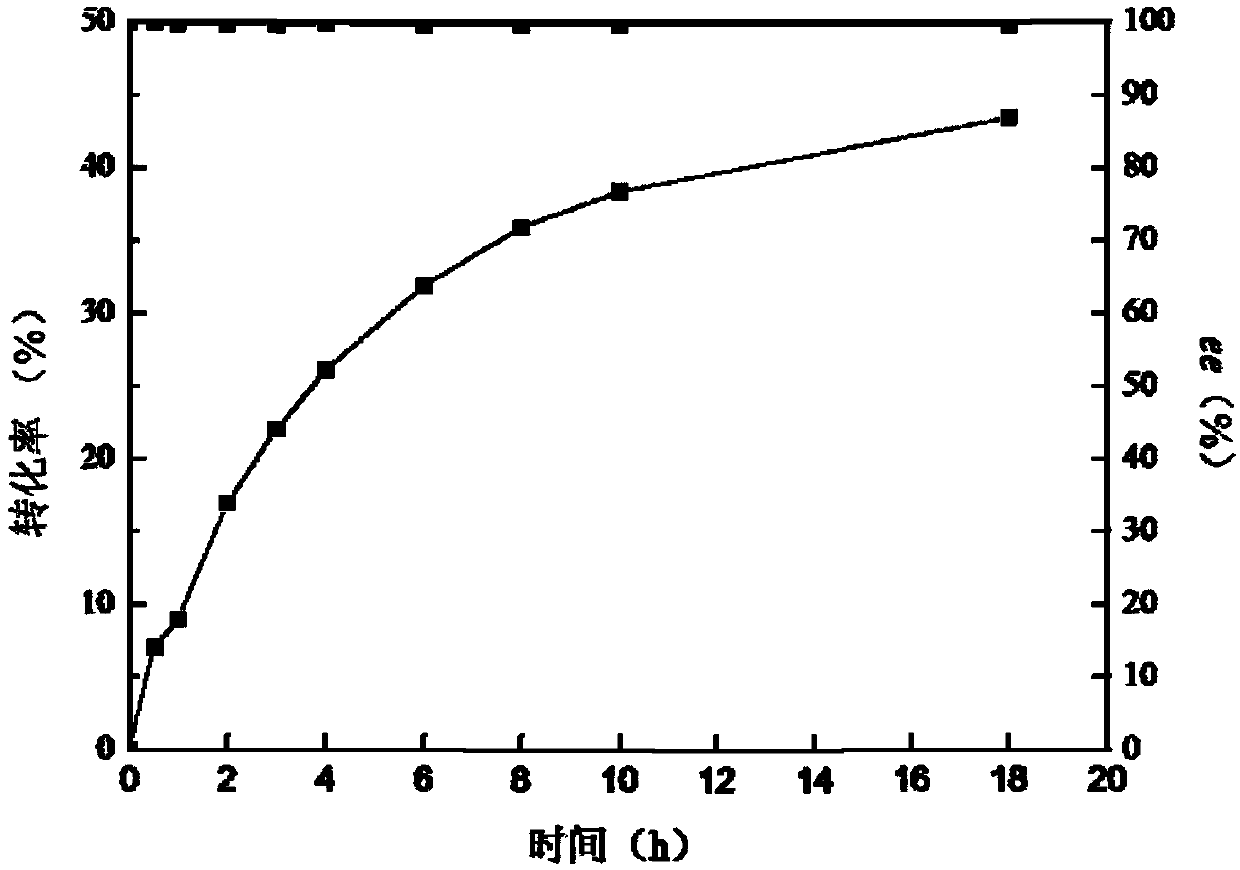

Plant nitrilase mutant, coding gene and application of plant nitrilase mutant

ActiveCN110714002AImprove solubilityHigh catalytic activityBacteriaHydrolasesBrassicaceaeArabis alpina

Owner:ZHEJIANG UNIV OF TECH

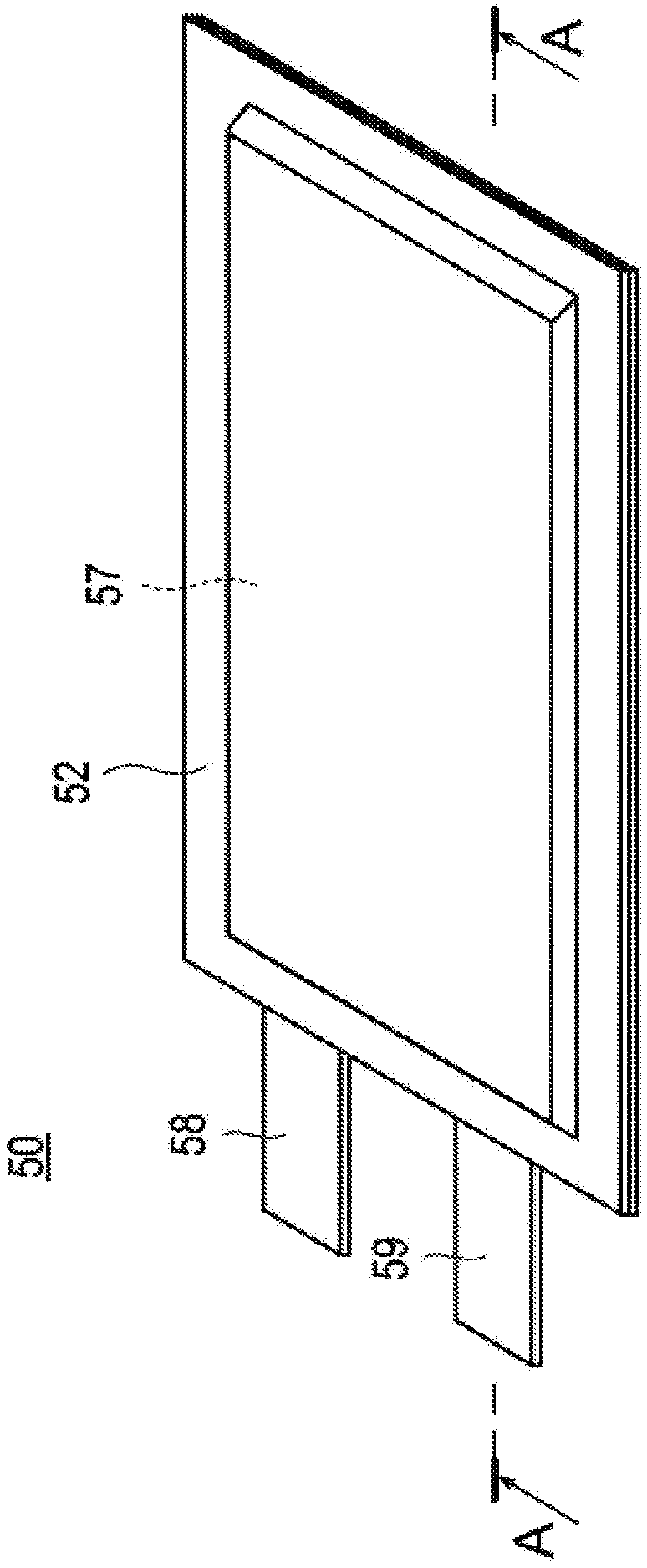

Electrolyte

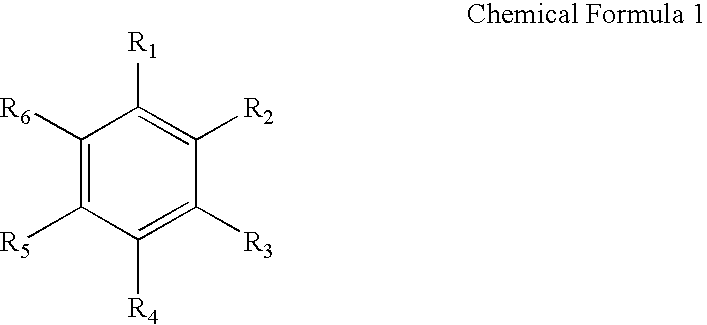

InactiveUS20140098466A1Good operational characteristicImprove stabilityHybrid capacitor electrolytesElectrolytic capacitorsCapacitanceBenzene

An electrolyte system suitable for use in an energy storage device (such as a supercapacitor), and energy devices which comprising the electrolyte system which is made up of an ionic liquid, such as Li or EMI TFSI and a stabilising amount of a stabilising additive. The stabilising additive preferably contains nitrile and or aromatic (benzene) groups, and may be advantageously benzonitrile, cinnamonitrile or succinonitrile. The stabilising additive stabilises the energy storage device against ESR rise and / or capacitance loss but does not adversely affect other performance characteristics of the ionic liquid.

Owner:CAP XX LTD

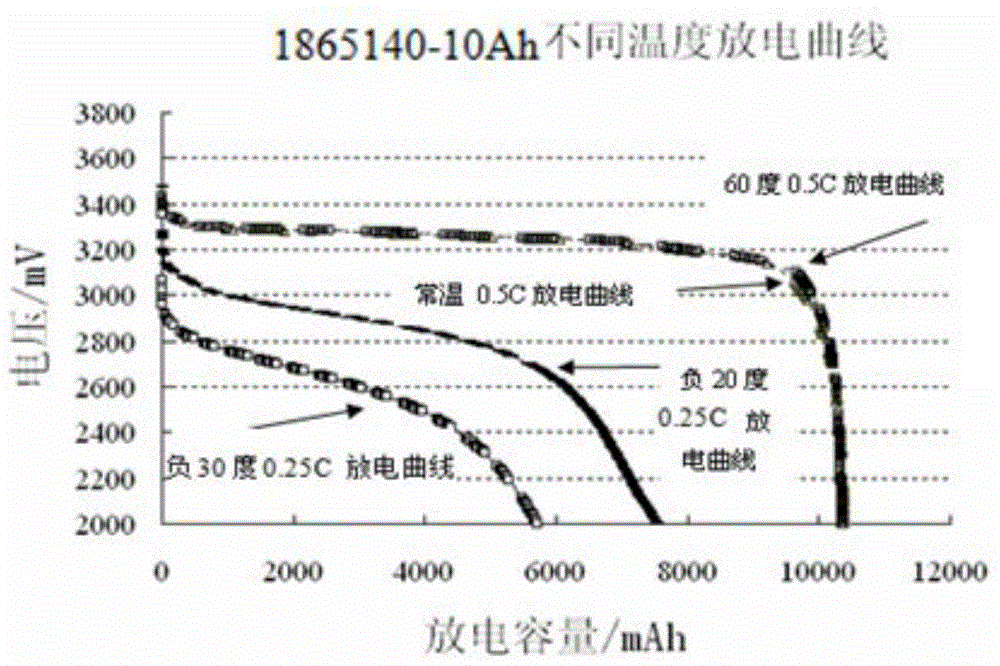

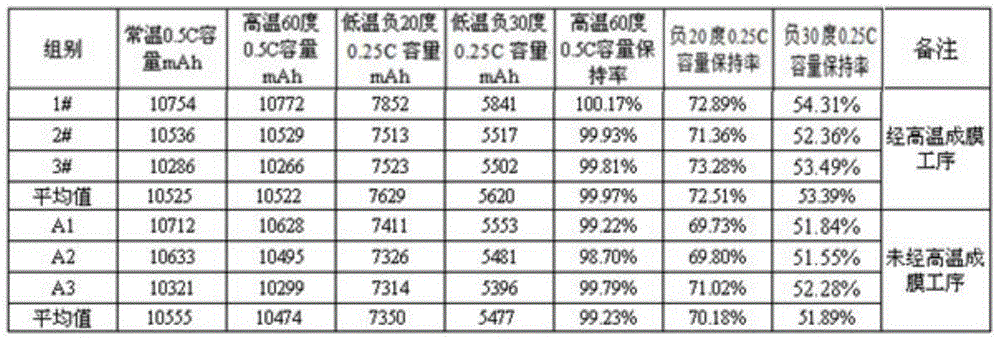

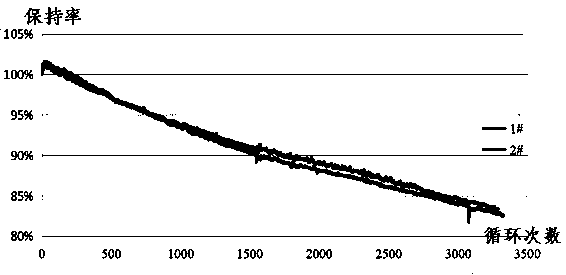

Lithium iron phosphate power battery and preparation method thereof

InactiveCN104393331ABoth high and low temperatureImprove high temperature performanceFinal product manufactureCell electrodesCooking & bakingMethyl carbonate

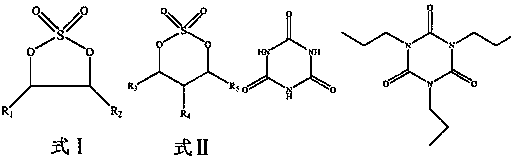

The invention discloses a lithium iron phosphate power battery and a preparation method thereof. Secondary particle lithium iron phosphate, which is agglomerated by primary nano particles and has the D50 value of 1-3 mu m, is taken as a positive active material; a negative electrode utilizes high-interlayer-spacing synthetic graphite with an amorphous carbon coating structure; a diaphragm utilizes a high-air-permeability diaphragm with PP, PE and PP as a base material, and the air permeability is not greater than 300 s / 100 ml; an electrolyte liquid comprises the following ingredients: 25-35% ethylene carbonate (EC), 5-10% propylene carbonate (PC), 25-35% ethyl methyl carbonate (EMC) and 10-15% diethyl carbonate (DEC); lithium salt is a composite conductive salt of lithium hexafluorophosphate and lithium difluoroborate, and the concentration of the lithium salt is 10-15%; and the additive comprises butanedinitrile, ethylene sulfite and fluorinated hydrocarbon. Square aluminum shell lithium-ion battery positive and negative electrode plates are subjected to treatment of winding, core-winding, cover plate welding, shelling, baking, laser welding, secondary baking, injecting, forming, air exhausting, steel ball pressing, volume dividing and 45-75 DEG C high-temperature aging for 120-24 hours at a high temperature to form the film.

Owner:YUNNAN TIN GROUP HLDG

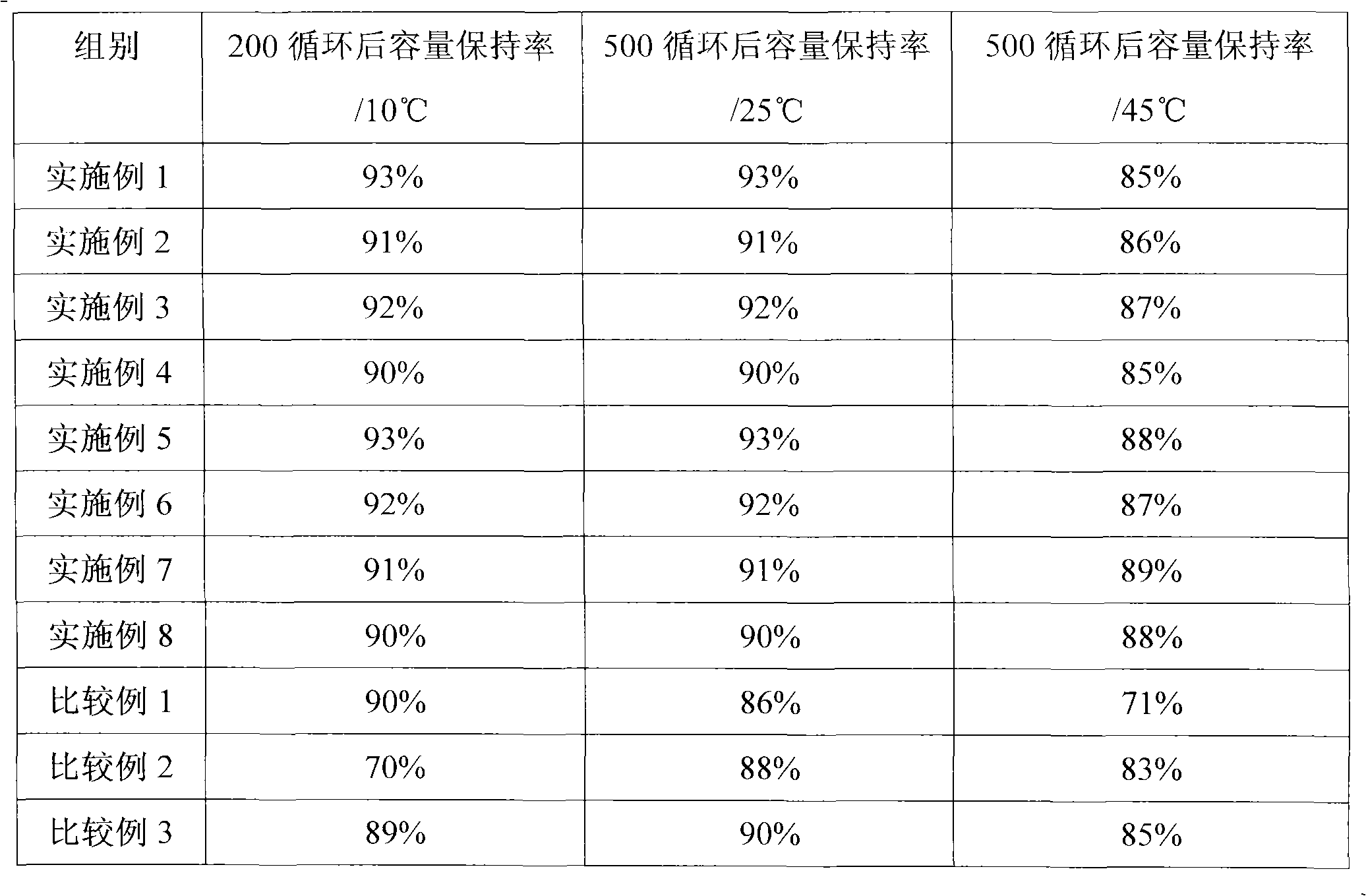

Ternary high-nickel electrolyte and high-nickel anode lithium ion battery containing same

InactiveCN109687010AReduced low temperature performanceGood low temperature performance, lowCell electrodesSecondary cellsHigh temperature storageSlurry

The invention provides ternary high-nickel electrolyte and a high-nickel anode lithium ion battery containing the electrolyte. The ternary high-nickel electrolyte is characterized by comprising, by weight, 13-15% of lithium salt, 80-85% of a non-aqueous organic solvent and 0.1-5% of an additive; wherein the additive comprises vinylene sulfate, vinylene carbonate, succinonitrile, tris (trimethyl silicon-based) phosphorus, lithium bifluroflavin imide and lithium dioxalate borate; the lithium salt is lithium hexafluorophosphate; the non-aqueous organic solvent comprises a cyclic carbonate compound, dimethyl carbonate and ethoxy pentafluoro tripolyphosphate; the high-nickel anode lithium ion battery containing the ternary high-nickel electrolyte adopts anode slurry prepared from high-nickel ternary anode powder, a conductive agent, a functional composite binder, a solvent N-methyl pyrrolidone to prepare the anode membrane, the high-nickel anode lithium ion battery has excellent normal-temperature cycle performance, high-temperature cycle performance and high-temperature storage service life, and can obviously reduce the gas yield in the high-temperature storage process.

Owner:湖北诺邦科技股份有限公司

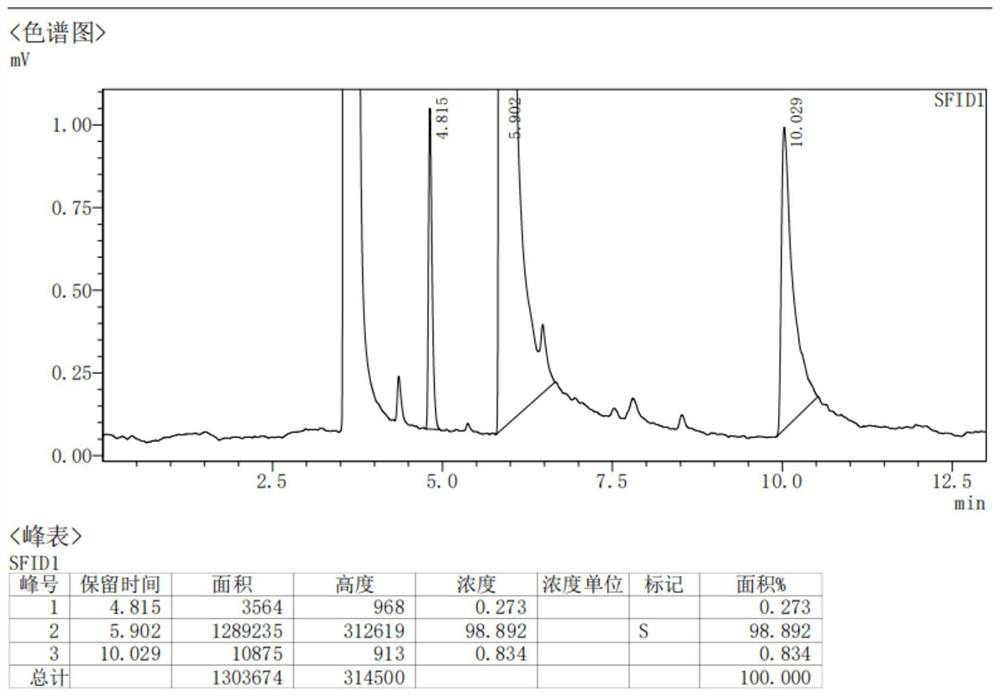

Method for adopting melting crystallization technology to separate and purify succinonitrile

InactiveCN107721878AHigh purityShort operating timeCarboxylic acid nitrile purification/separationDissolutionSolvent

The invention relates to a method for adopting a melting crystallization technology to separate and purify succinonitrile. According to the method, succinonitrile coarse products are added into a melting crystallizer and heated to 59 DEG C for complete dissolution, then programmed heating is started to raise the temperature to 45-52 DEG C, after the temperature is stabilized for 10-180 min, crystallization mother liquor is released, and succinonitrile coarse crystals are obtained; then programmed heating is started, sweating is conducted, the temperature is stabilized for 10-180 min after reaching final sweating temperature, and high-purity succinonitrilee crystals with the purity of 99.95% or above are obtained. According to the method, a separation method of melting crystallization is adopted, no solvents or vacuum drying is needed, and the operation time is short; the operation is simple, the method is environmentally friendly, the product purity is high, and the crystallization mother liquor and sweating liquid can be recycled and purified again through melting crystallization; compared with an existing decompression batch distillation method, the energy consumption, operatingtemperature and cost are low, no polymerization coking phenomena occur in the operating process, and the yield and quality are not affected.

Owner:TIANJIN UNIV

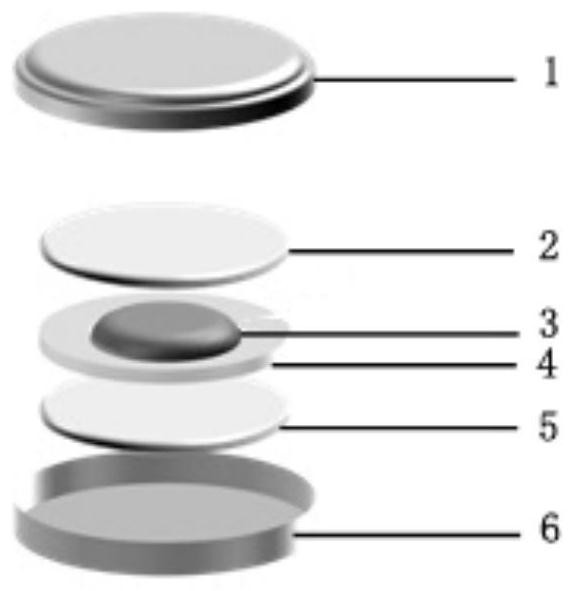

Preparation method of all-solid-state battery interface layer and all-solid-state battery

PendingCN112563568AImproves fluid retentionImprove contact effectSolid electrolytesLi-accumulatorsAll solid statePolyvinyl alcohol

The invention discloses a preparation method of an interface layer of an all-solid-state battery and the all-solid-state battery, the interface layer is arranged between a solid electrolyte and an electrode, and the method comprises the following steps: step 1, heating, dissolving and uniformly mixing a lithium salt, a stabilizer for stabilizing lithium and succinonitrile to obtain a mixed solution; step 2, adding a polymer into the mixed solution, dissolving, uniformly mixing, and cooling to obtain an interface layer in a gel state; wherein the polymer comprises one or more than two of polyoxyethylene, polyvinyl alcohol and polyacrylonitrile. The added polymer can improve the liquid retention capacity of the interface layer, and the interface layer is a colorless and transparent gel-statesubstance. Besides, due to the addition of the polymer, the interface layer has good viscosity, the contact performance of the interface layer with the electrode and the solid electrolyte can be improved, and the interface impedance is reduced.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Electrolyte

Provided are an electrolyte system suitable for use in an energy storage device (such as a supercapacitor), energy devices which comprising the electrolyte system which is made up of an ionic liquid, such as Li or EMI TFSI and a stabilising amount of a stabilising additive. The stabilising additive preferably contains nitrile and or aromatic (benzene) groups, and may be advantageously benzonitrile, cinnamonitrile or succinonitrile. The stabilising additive stabilises the energy storage device against ESR rise and / or capacitance loss but does not adversely affect other performance characteristics of the ionic liquid.

Owner:CAP XX LTD

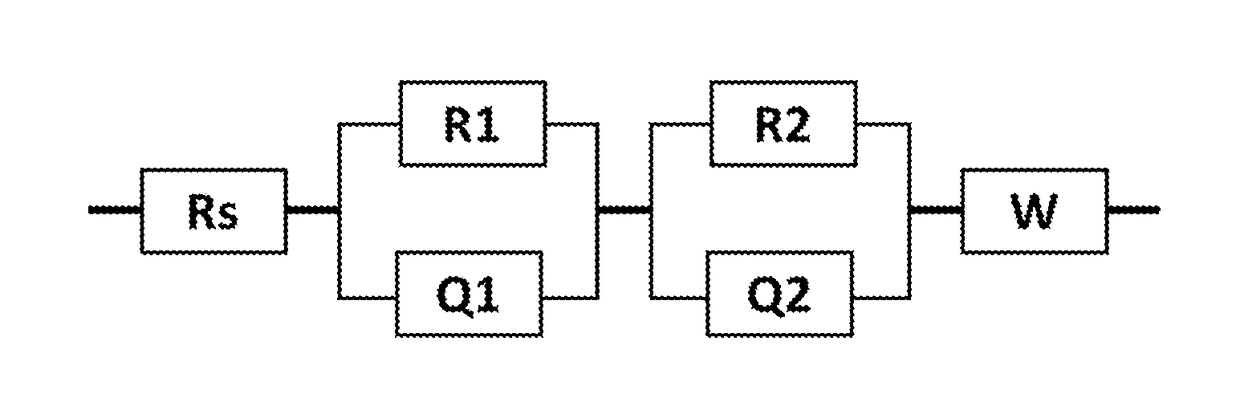

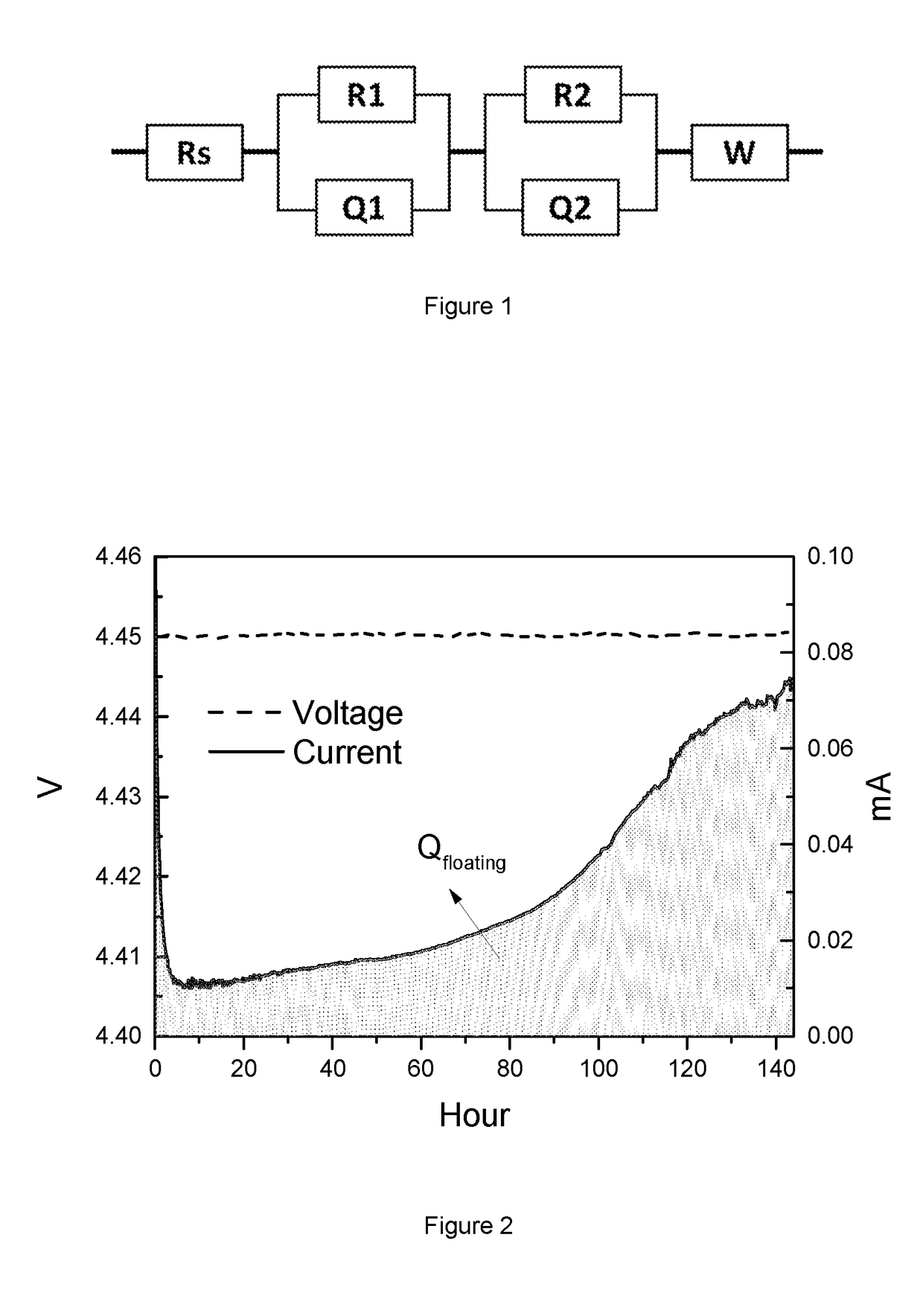

Electrolyte solution and lithium ion battery using said electrolyte solution

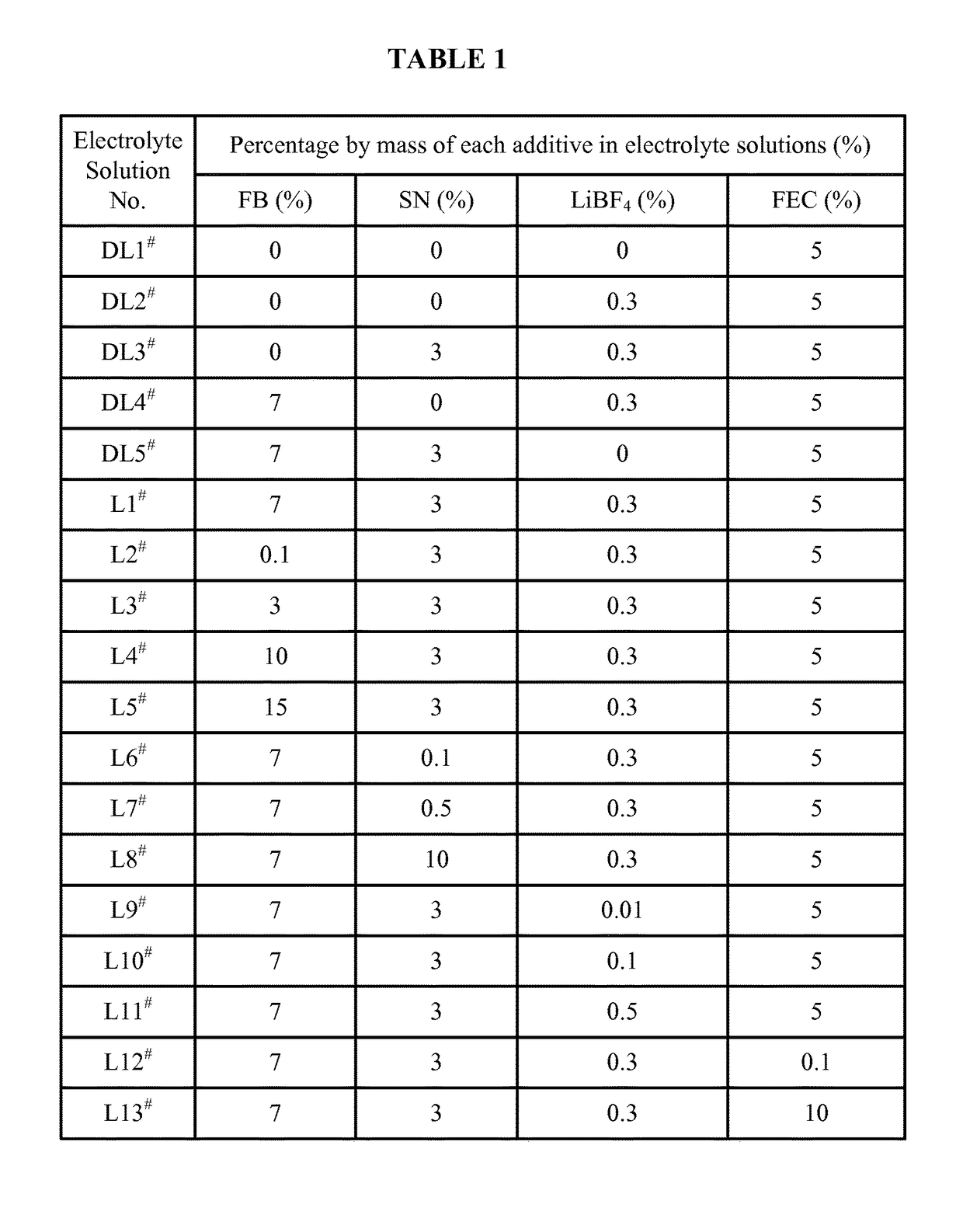

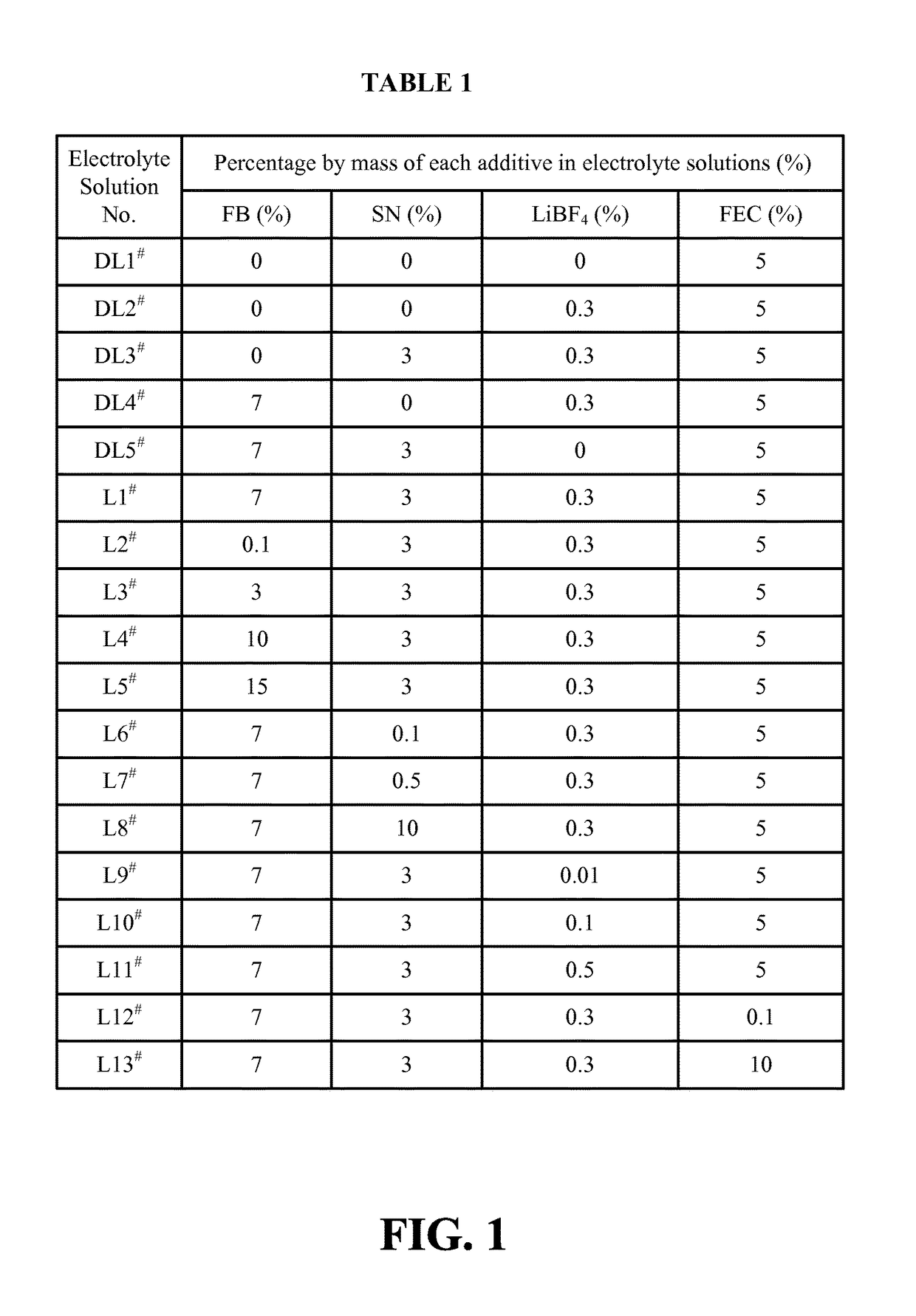

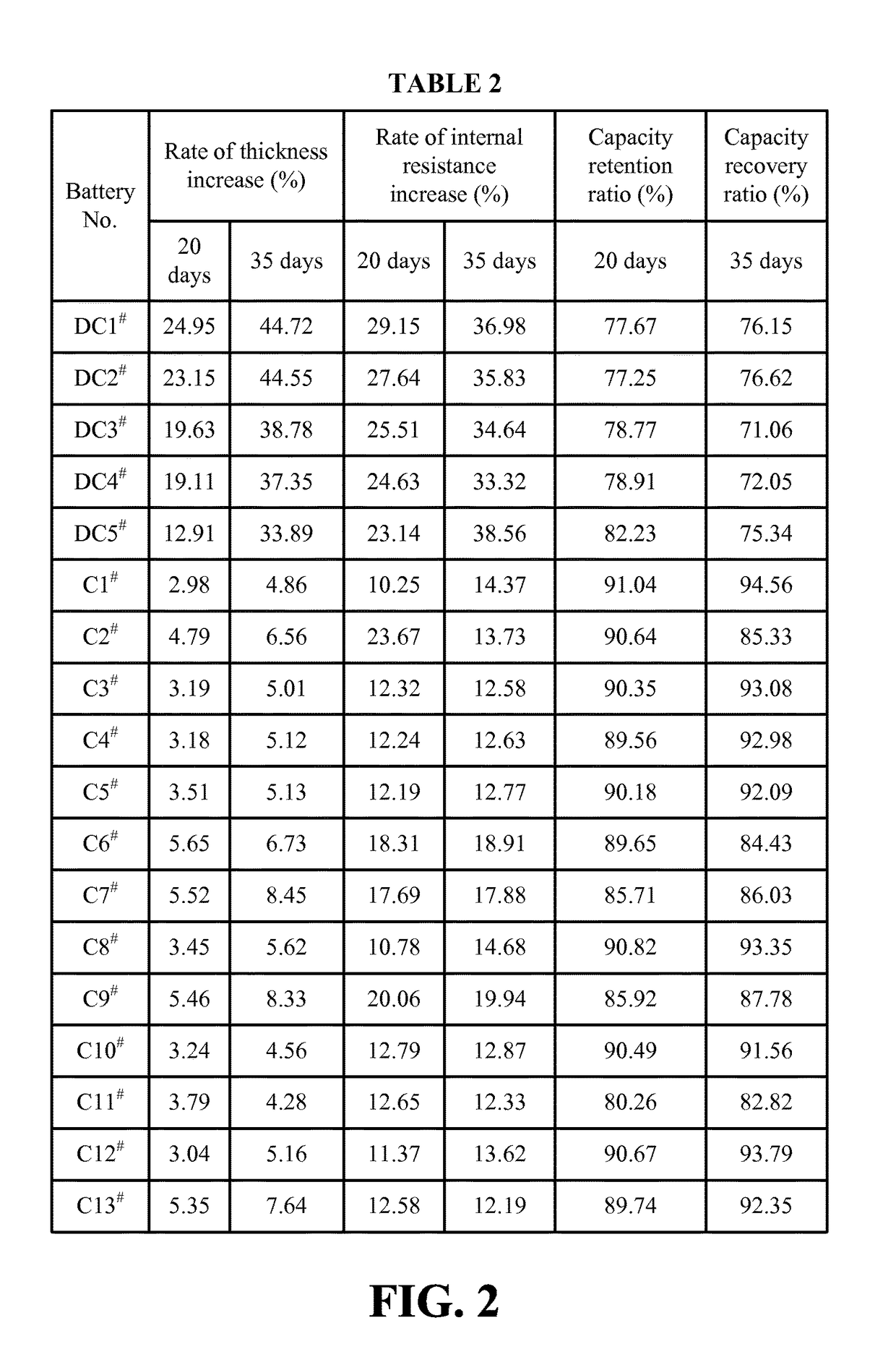

ActiveUS9601807B2Increase charging voltageImprove high-temperature intermittent cyclabilitySecondary cells servicing/maintenanceOrganic electrolytesOrganic solventInternal resistance

An electrolyte solution for a lithium-ion battery and a lithium-ion battery using the electrolyte solution are provided. The electrolyte solution includes organic solvents, an electrolyte lithium salt, and additives. The additives include succinonitrile, fluorobenzene, and lithium tetrafluoroborate. The percentage by mass of the fluorobenzene in the electrolyte solution is 0.1%-15%. The percentage by mass of the succinonitrile in the electrolyte solution is 0.1%-10%. The percentage by mass of the lithium tetrafluoroborate in the electrolyte solution is 0.01%-1%. The electrolyte solution may increase the charging voltage upper limit and improve the high-temperature intermittent cyclability of the lithium-ion battery. At the same time, the electrolyte may lower the battery swelling rate, reduce the internal resistance, and improve the stability and safety of the lithium-ion battery.

Owner:DONGGUAN AMPEREX TECH +1

Lithium ion battery comprising electrolyte solutions with improved safety and storage performance

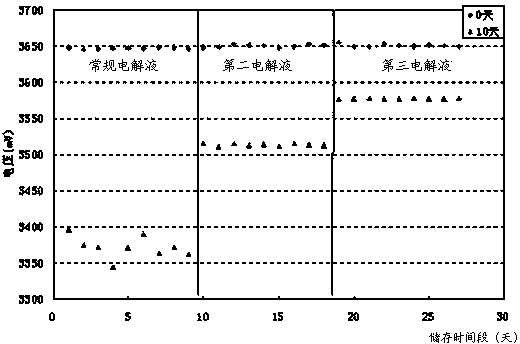

InactiveCN103474708AImprove securityImprove storage effectSecondary cells servicing/maintenanceOrganic solventPhysical chemistry

The invention discloses a lithium ion battery comprising electrolyte solutions with improved safety and storage performance. The lithium ion battery comprises conventional electrolyte solutions which comprise electrolyte salt, organic solvents and conventional additives. The electrolyte salt comprises solid solute LiPF6, the organic solvents comprise EC, DMC and EMC, and the conventional additives comprise VC and FEC. Overcharge additives and function additives are further added in the conventional electrolyte solutions. The overcharge additives comprise at least one of biphenyl, terphenyl and phenylcyclohexane, and the function additives comprise succinonitrile or adiponitrile. According to the lithium ion battery comprising the electrolyte solutions with improved safety and storage performance, the electrolyte solutions can prevent a lithium ion battery from being overcharged, and meanwhile the side reaction of the overcharge additives within the normal charging voltage range of a battery is restrained.

Owner:TIANJIN LISHEN BATTERY

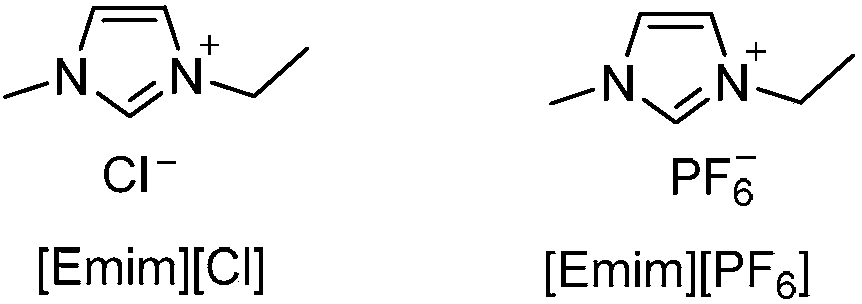

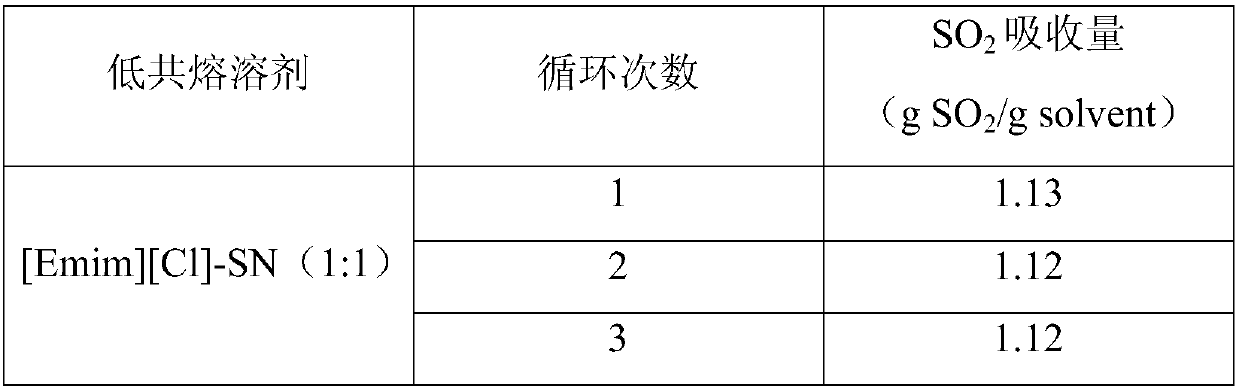

Eutecticevaporate solvent based on non-proton organic matter and method for efficiently absorbing SO2 by utilizing same

ActiveCN109529555AEfficient reversible absorptionStrong absorption capacityDispersed particle separationAbsorption capacityHigh absorption

The invention provides a eutecticevaporate solvent system based on a non-proton organic matter. The eutecticevaporate solvent system is prepared from imidazolium salt and the non-proton organic matterSN (Succinonitrile), wherein a molar ratio of the imidazolium salt to the SN is 1 : (1 to 8). The invention also provides a method for absorbing / capturing SO2. The method comprises the following stepof: enabling the eutecticevaporate solvent system to be in contact with a SO2-containing gas for absorption, thus absorbing / capturing the SO2. The eutecticevaporate solvent adopted by the invention has higher absorption capacity to the SO2, has a good recycling effect and is capable of realizing efficient and reversible absorption on the SO2.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

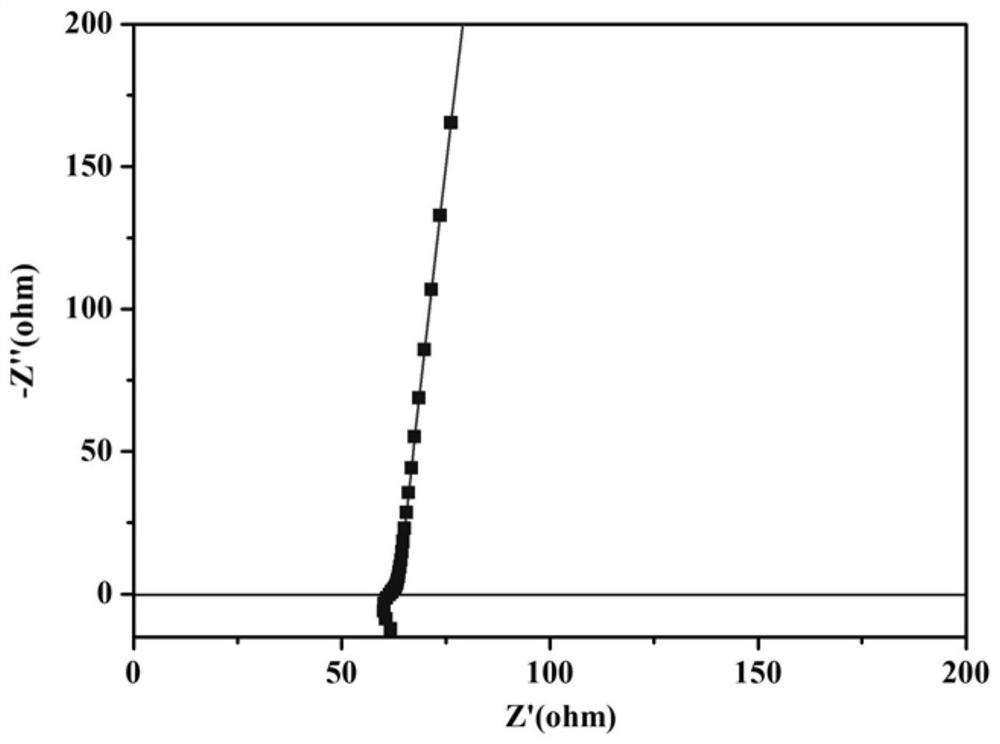

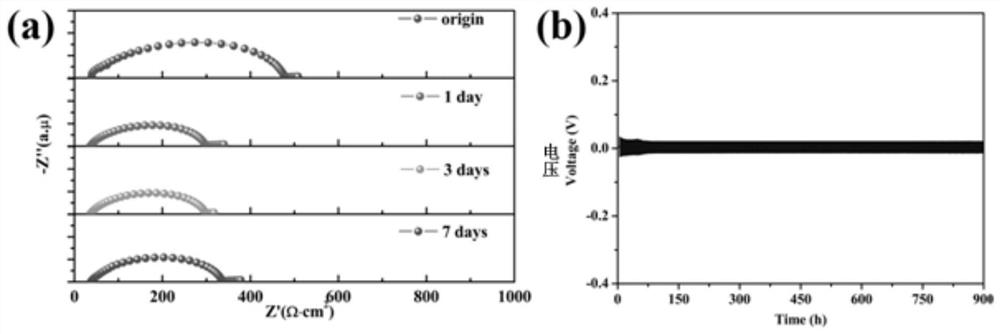

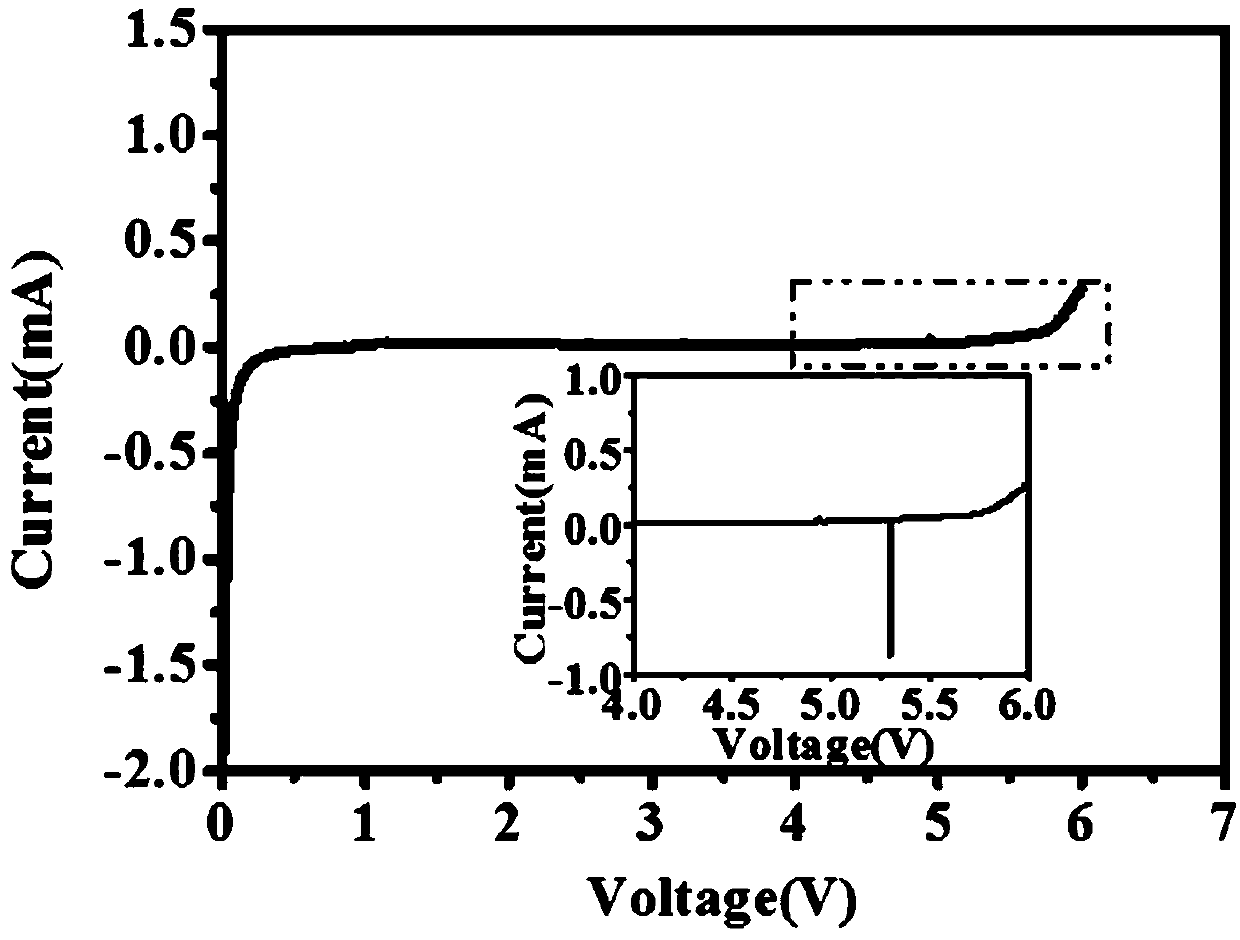

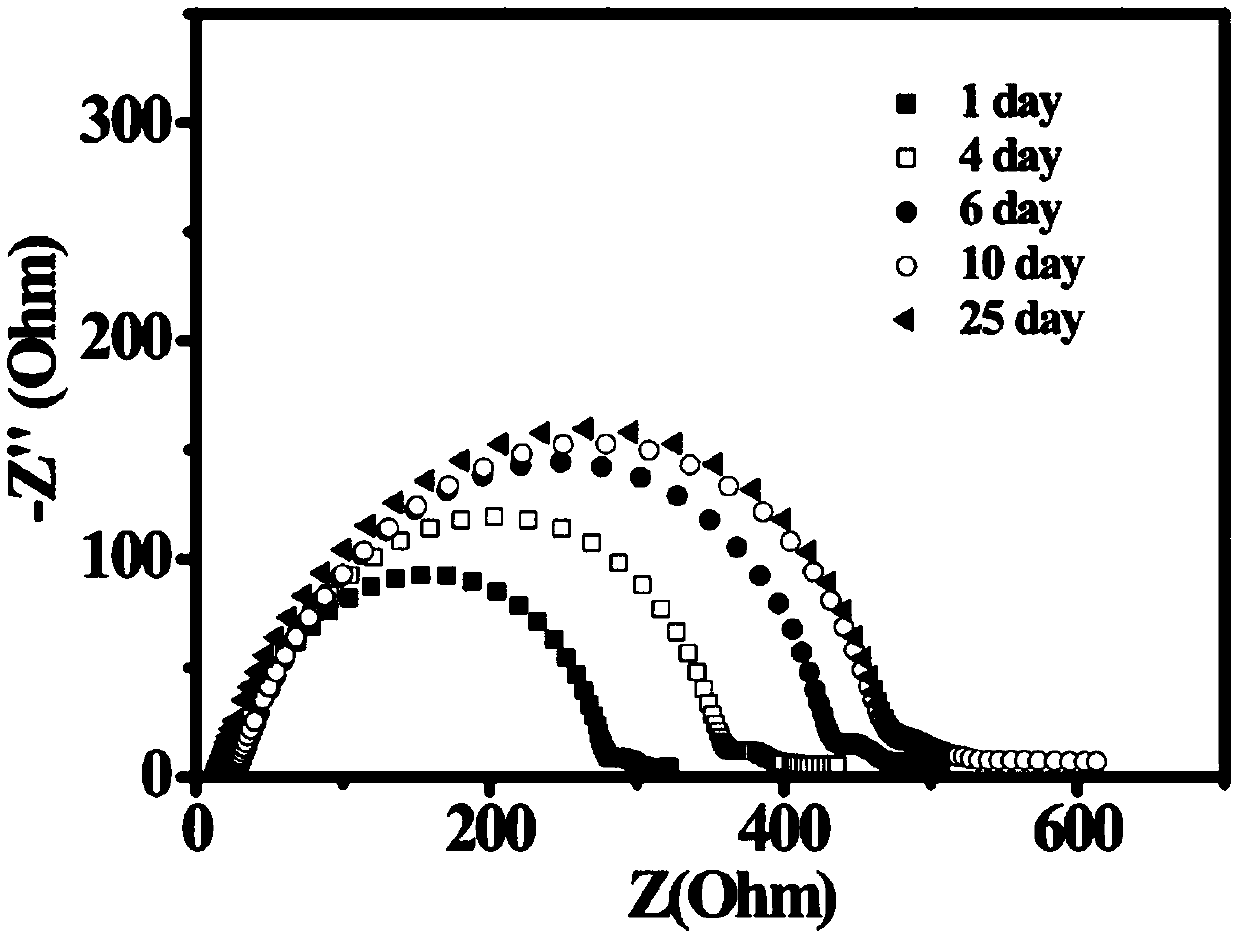

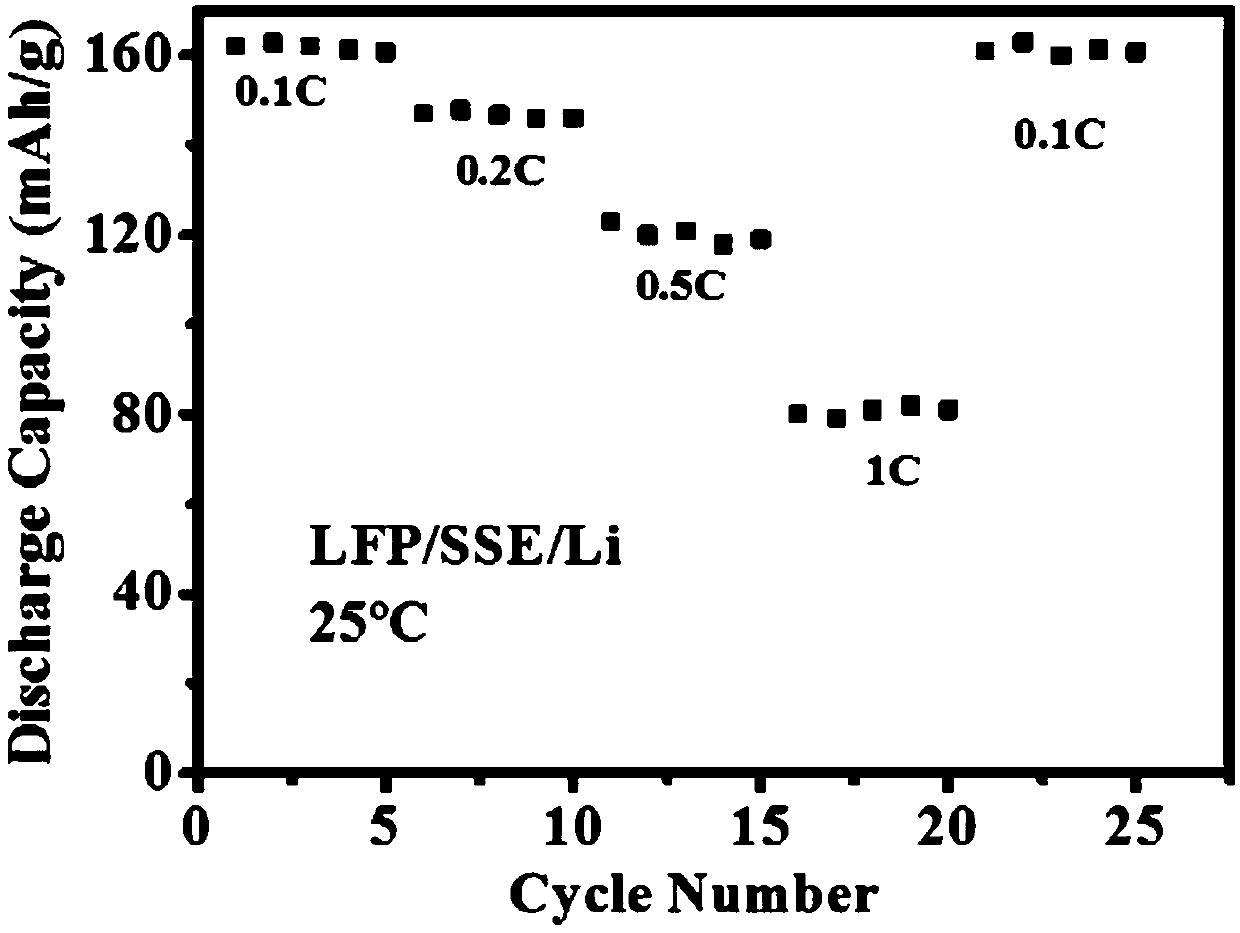

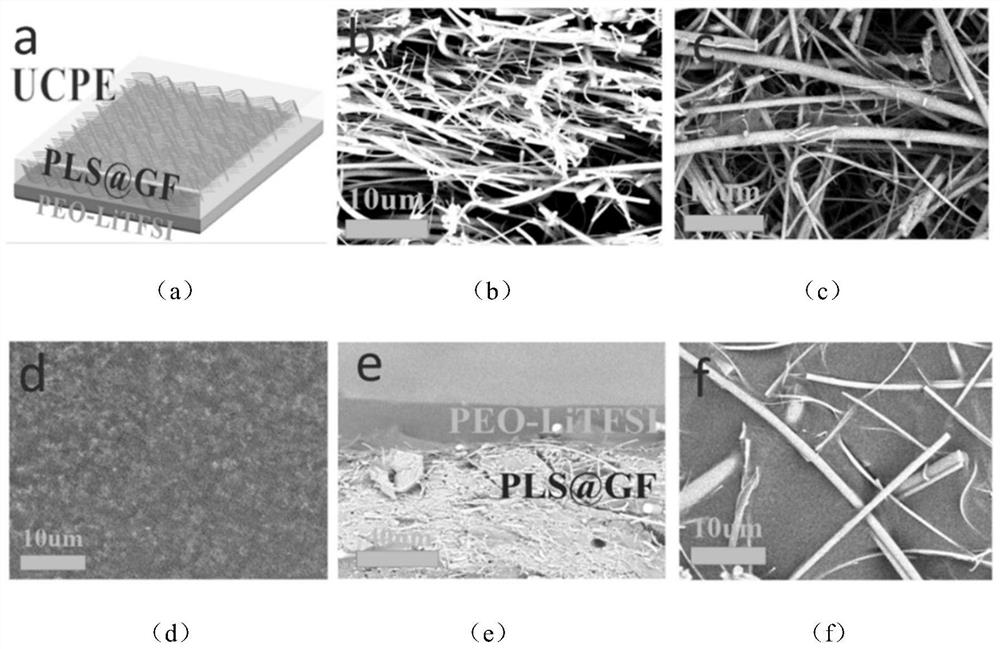

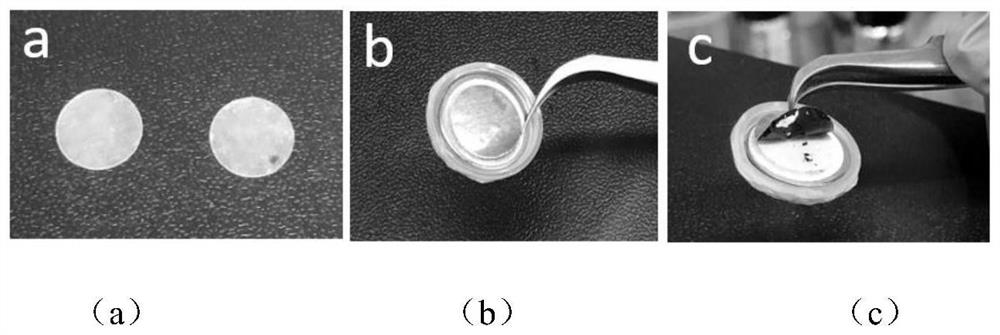

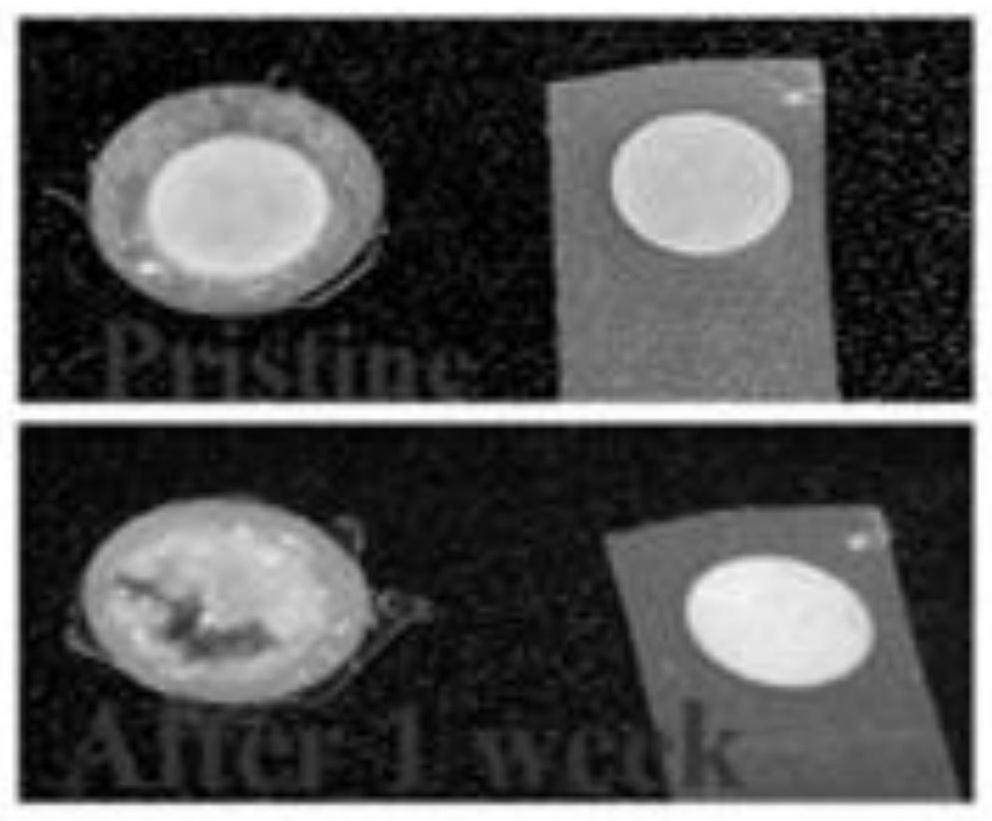

Lithium-stable succinonitrile-based solid electrolyte, preparation method and application thereof

ActiveCN109638350AImprove performanceInhibit side effectsSolid electrolytesSecondary cellsSolid state electrolyteInterface impedance

The invention discloses a lithium-stable succinonitrile-based solid electrolyte, which is prepared from the following components by weight: 50-89% of succinonitrile, 10%-40% of lithium salt, 0.1%-10%of a film-forming additive. The invention also discloses a preparation method of the lithium-stable succinonitrile-based solid electrolyte, which comprises the following steps: S1, weighing the succinonitrile, the lithium salt, the film-forming additive according to the weight percentage; S2, heating the succinonitrile weighed in the S1 to melt, and adding the lithium salt weighed in S1, performing stirring for 8 hours to obtain a mixed solution, and then adding the film-forming additive weighed in S1, and performing stirring at 60 to 100 DEG C for 8 to 12 hours to obtain an electrolyte, and then dropping the electrolyte on a surface of the porous membrane to obtain a succinonitrile-based solid electrolyte. The invention also discloses the application of the solid electrolyte to an all-solid lithium battery, and the solid electrolyte can reduce the interface impedance between the solid electrolyte and the Li sheet and improve the performance of the battery.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

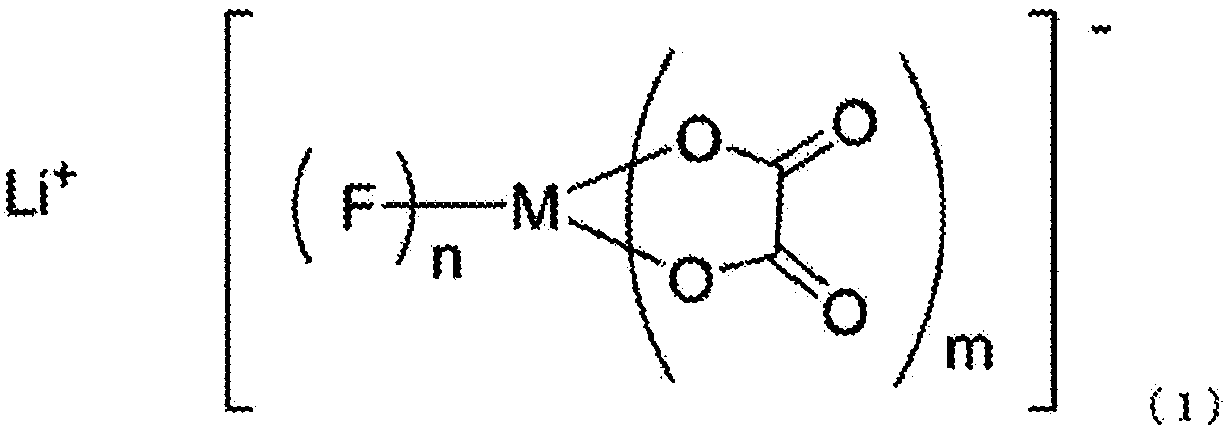

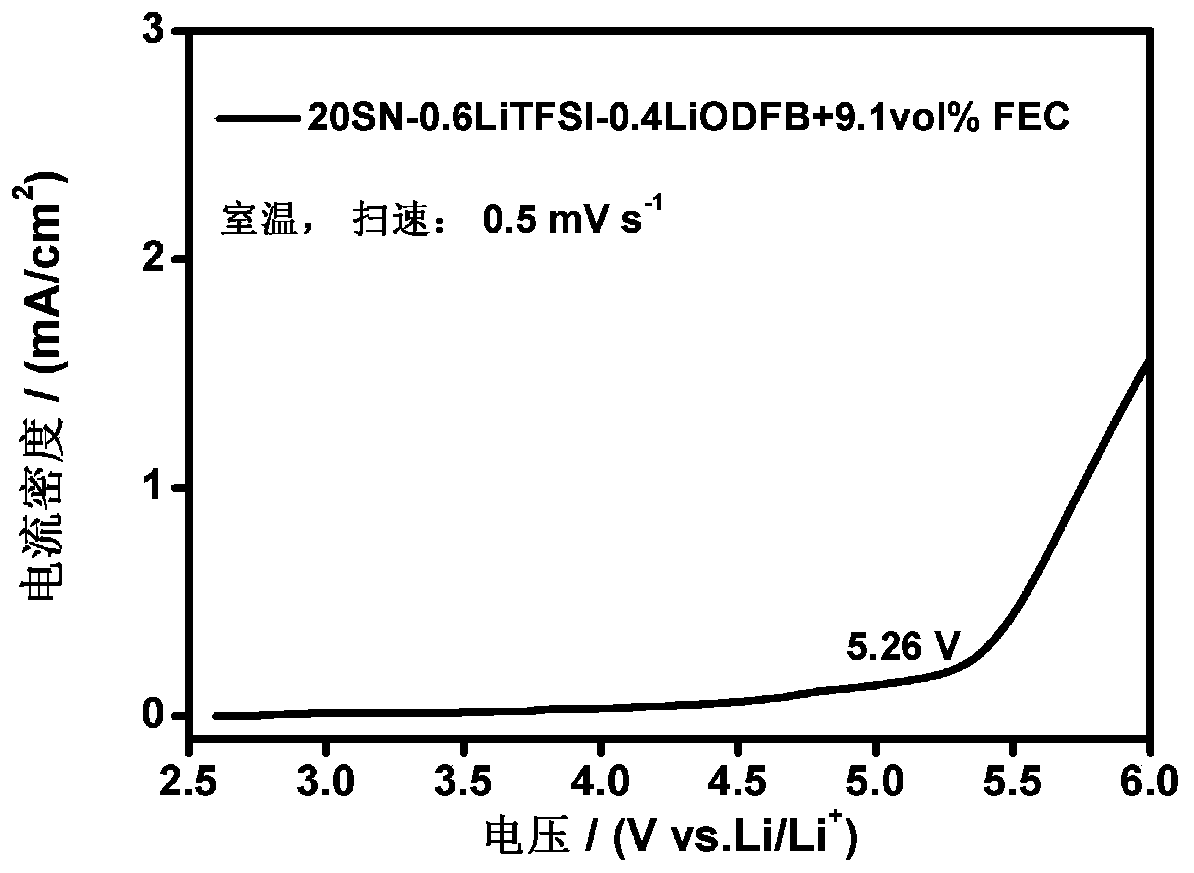

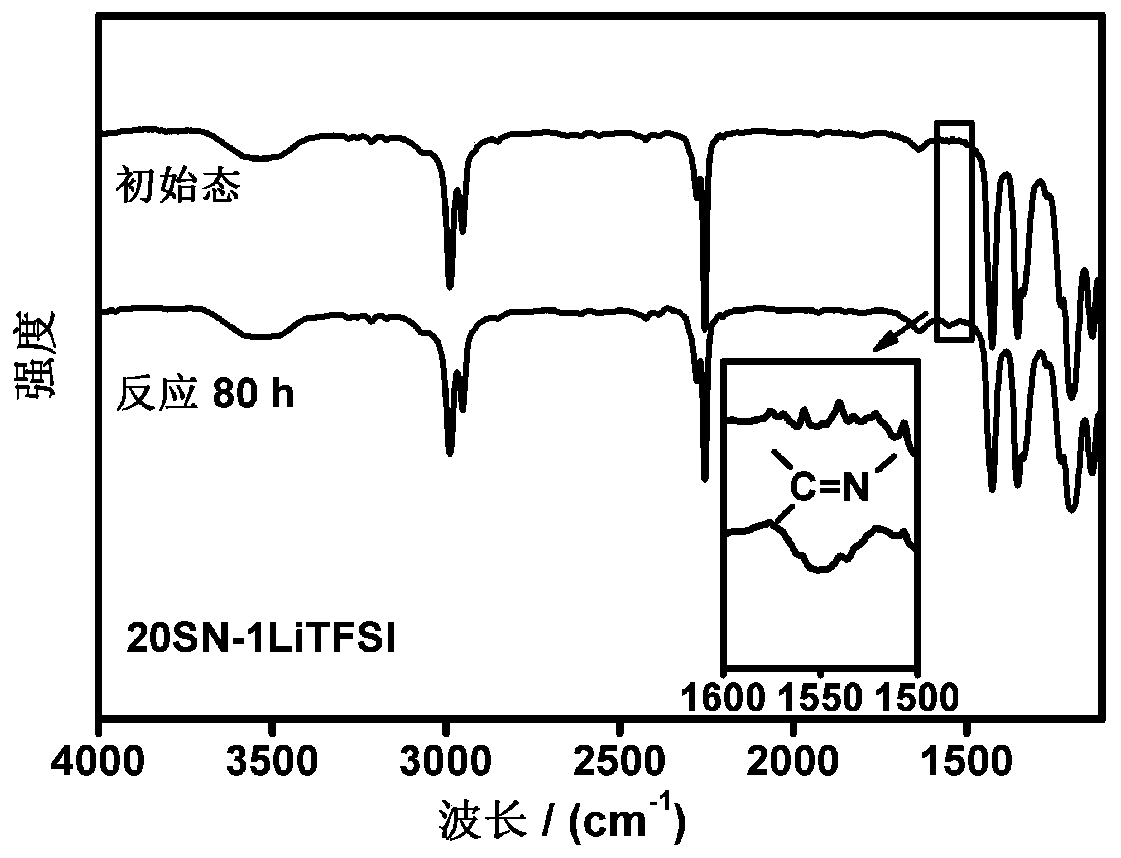

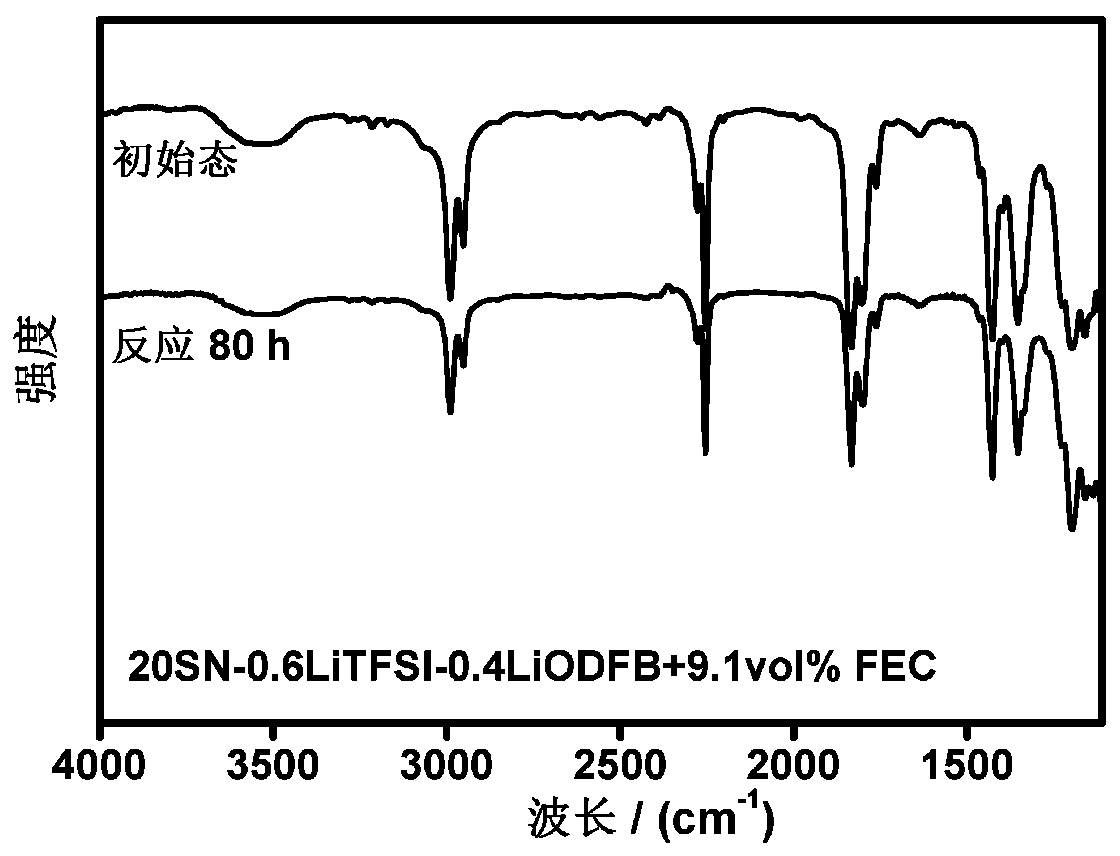

Succinonitrile-based electrolyte coupled with organic lithium salt and fluoroethylene carbonate as well as preparation method and application of electrolyte

ActiveCN110931875AImprove interfacial wettabilityGood dissociation effectSecondary cellsOrganic electrolytesElectrolytic agentMetallic lithium

The invention discloses a succinonitrile-based electrolyte coupled with an organic lithium salt and fluoroethylene carbonate, and relates to the technical field of lithium-ion batteries. The specificscheme is as follows: the succinonitrile-based electrolyte coupled with an organic lithium salt and fluoroethylene carbonate comprises succinonitrile, an organic lithium salt and fluoroethylene carbonate, wherein the molar ratio of the succinonitrile to the organic lithium salt is 100: 1-1:1, the organic lithium salt is a combination of a sulfonyl imide lithium salt and lithium oxalyldifluoroborate, the molar ratio of the sulfonyl imide lithium salt to the lithium oxalyldifluoroborate is 100: 1-1: 1, and the fluoroethylene carbonate accounts for 5-50% of the total volume of the succinonitrile-based electrolyte. The invention further discloses a preparation method of the succinonitrile-based electrolyte and application of the succinonitrile-based electrolyte to a lithium metal battery, theelectrolyte can form an organic-inorganic composite SEI film on the surface of metal lithium, side reaction of succinonitrile and metal lithium is avoided, and the interface stability and electrochemical performance of the battery are remarkably improved.

Owner:HARBIN INST OF TECH

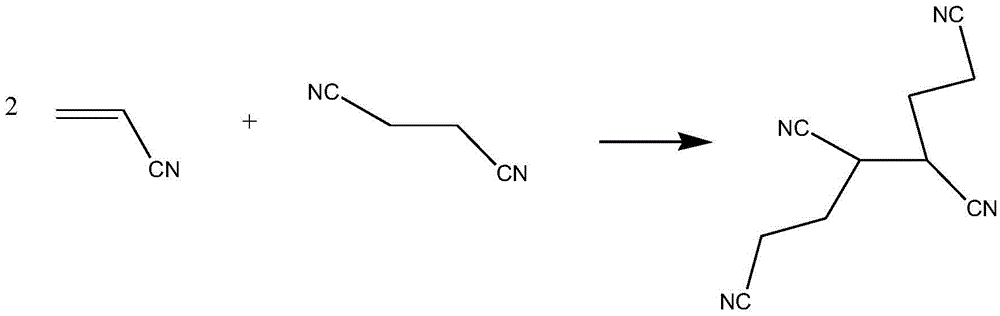

Preparation method of 1,4,5,8-octane tetranitrile

ActiveCN105481719AHigh acid valueShortened battery lifeOrganic compound preparationSecondary cellsDecompositionElectrolyte

The invention discloses a preparation method of 1,4,5,8-octane tetranitrile. 1,4,5,8-octane tetranitrile is prepared by adopting acrylonitrile and butanedinitrile as raw materials. The preparation method also has the advantages of high yield, easily-available raw materials, simplicity in reaction control, high product purity, and the like. The prepared material can form a film on the positive electrode surface to prevent transition metal ions from catalyzing electrolyte decomposition under high voltage, thus improving the battery performances.

Owner:盘锦鑫百途新材料科技有限公司

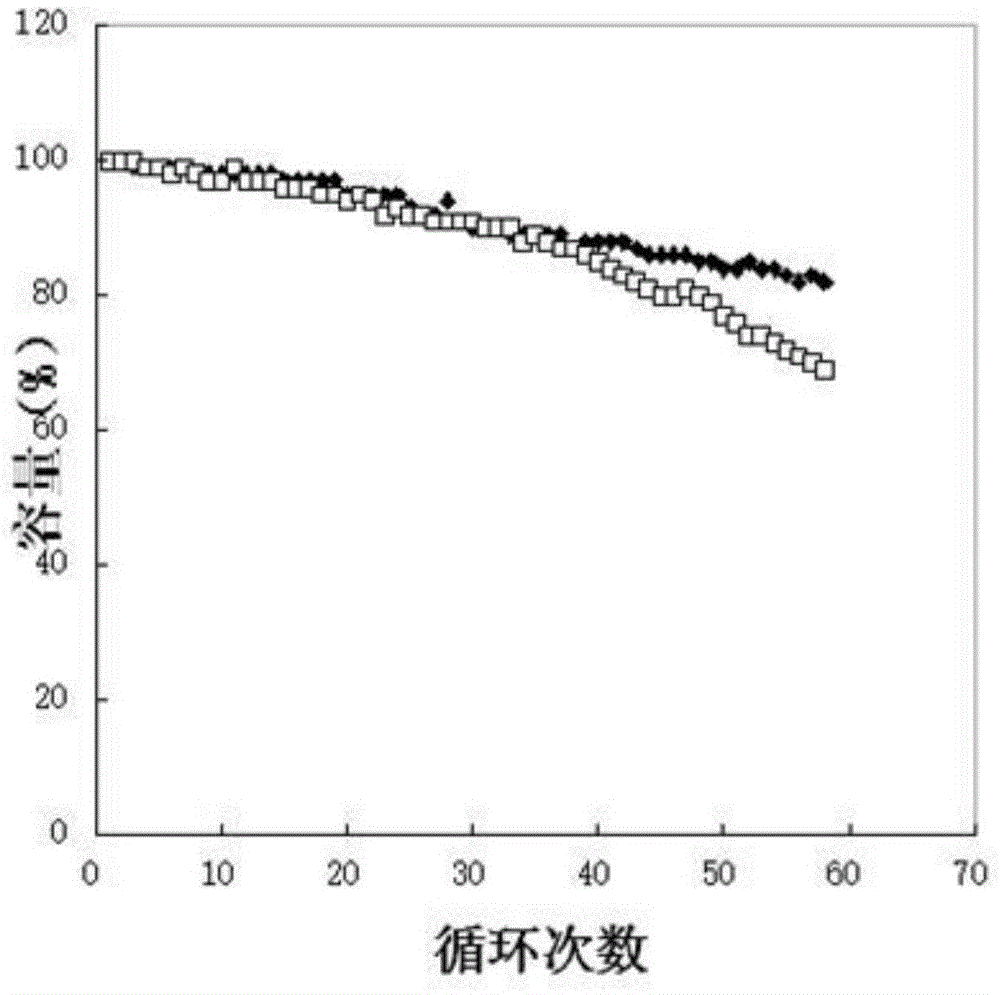

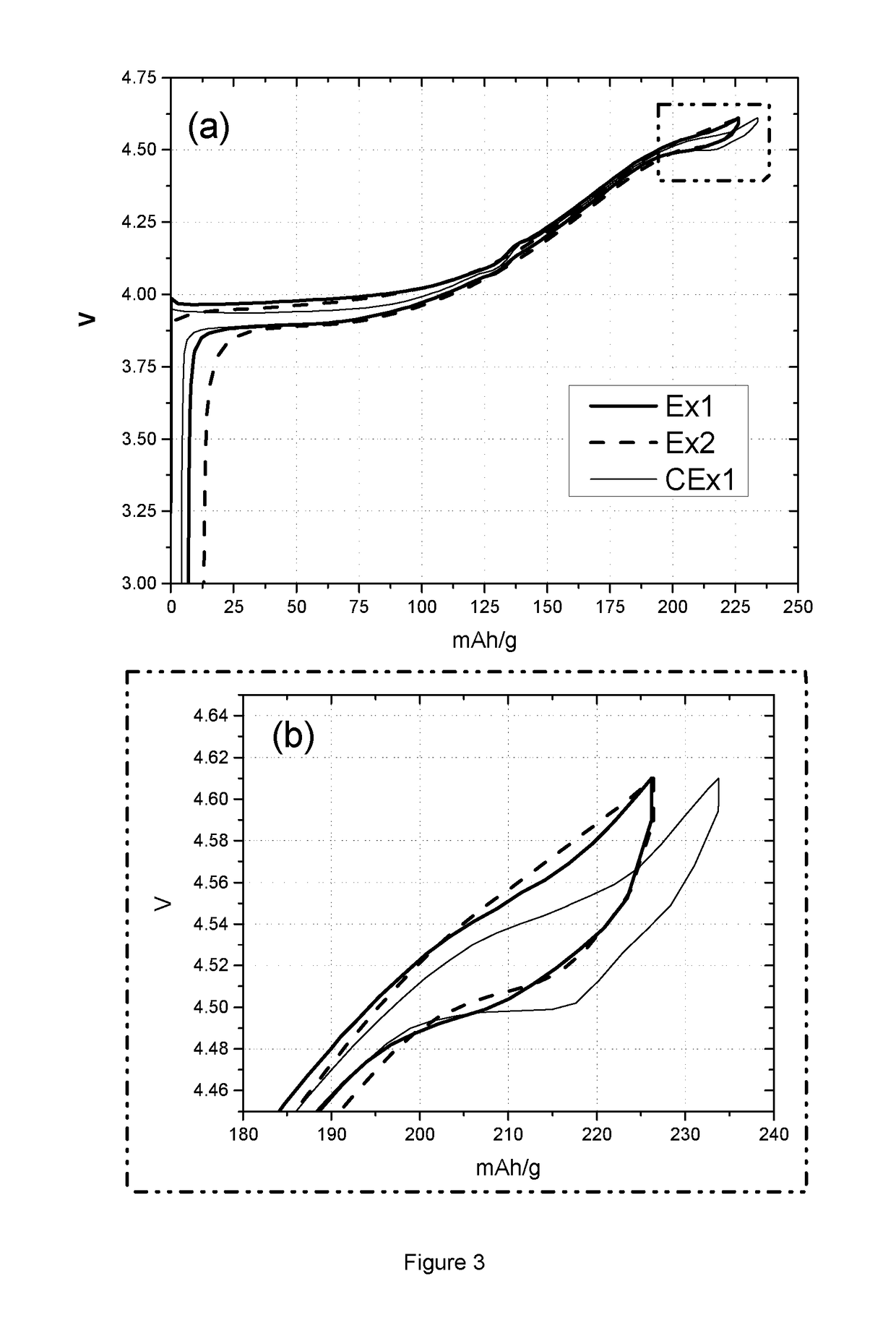

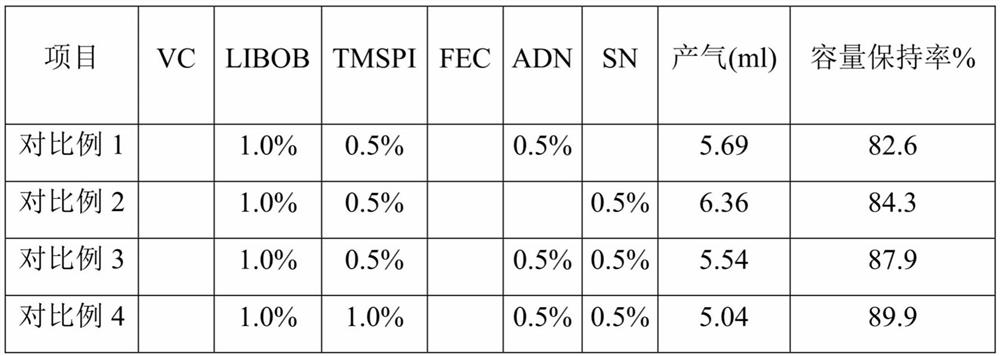

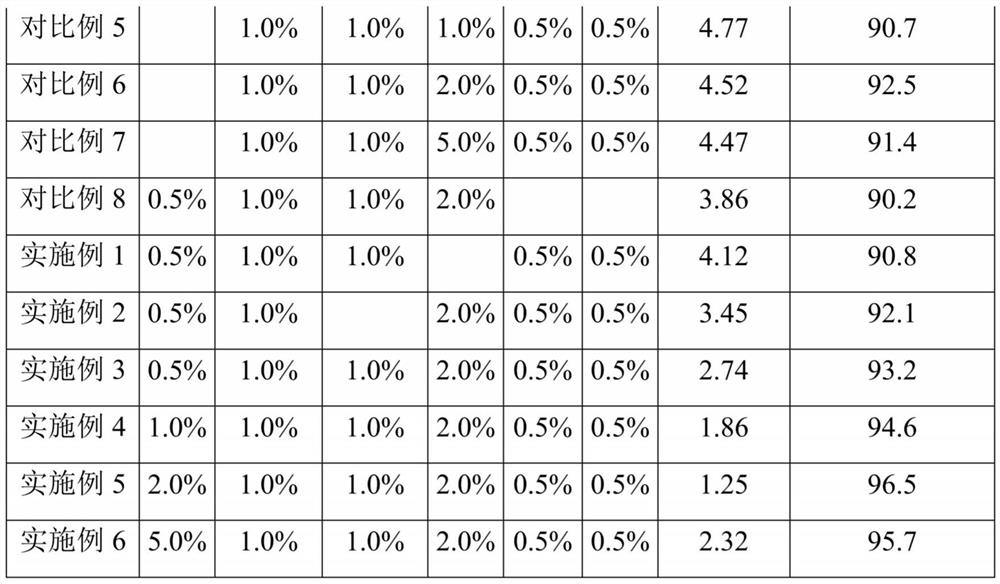

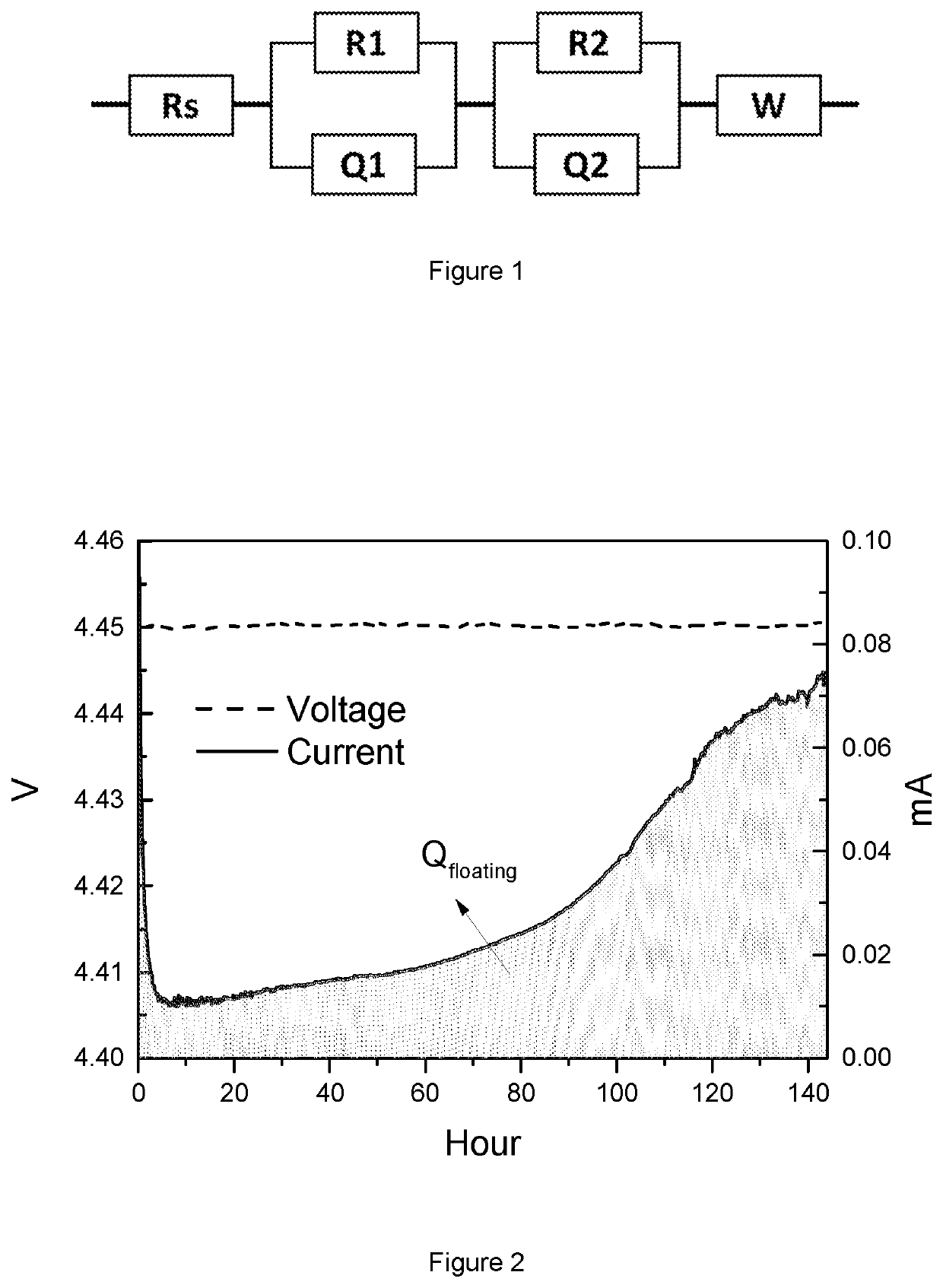

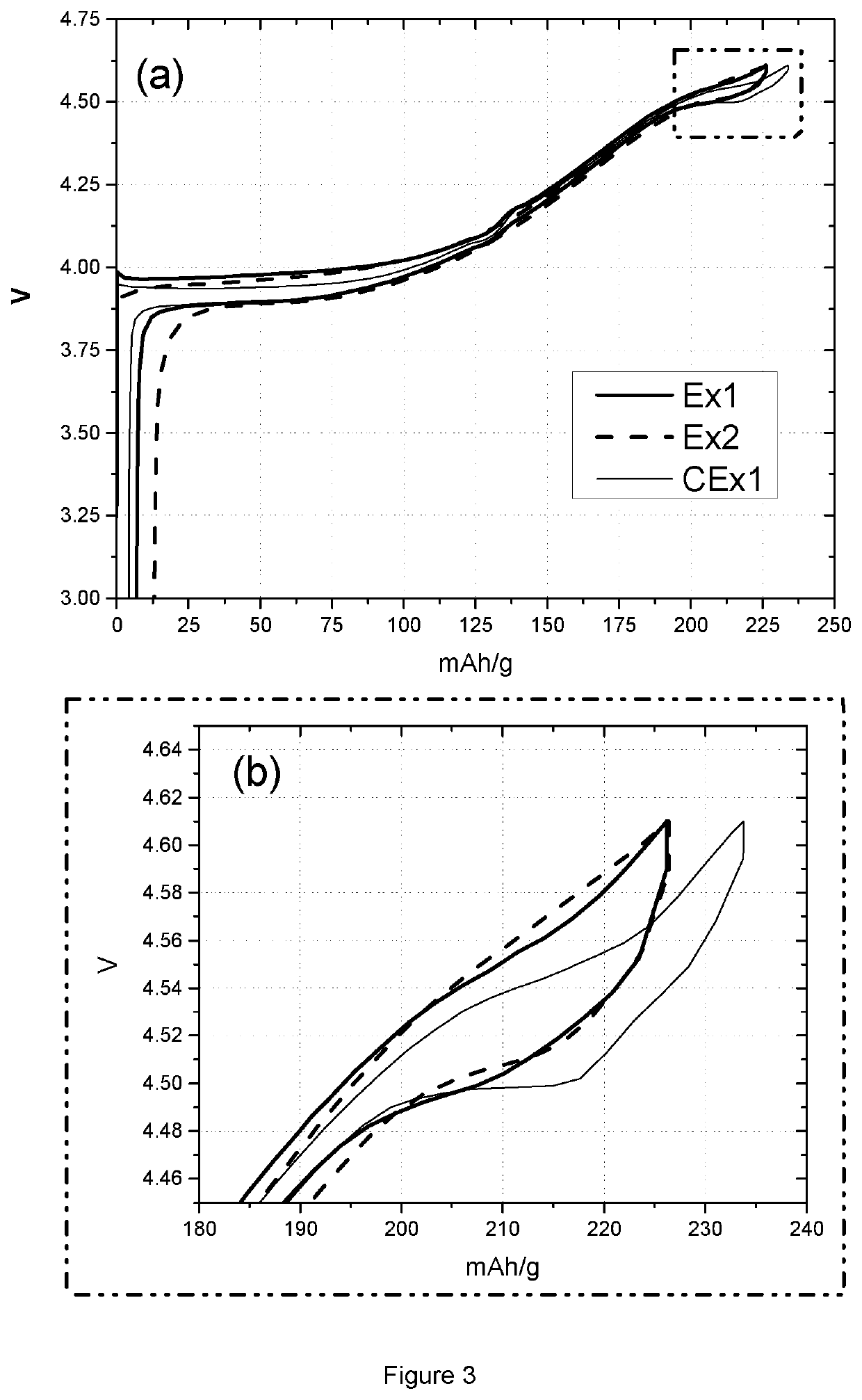

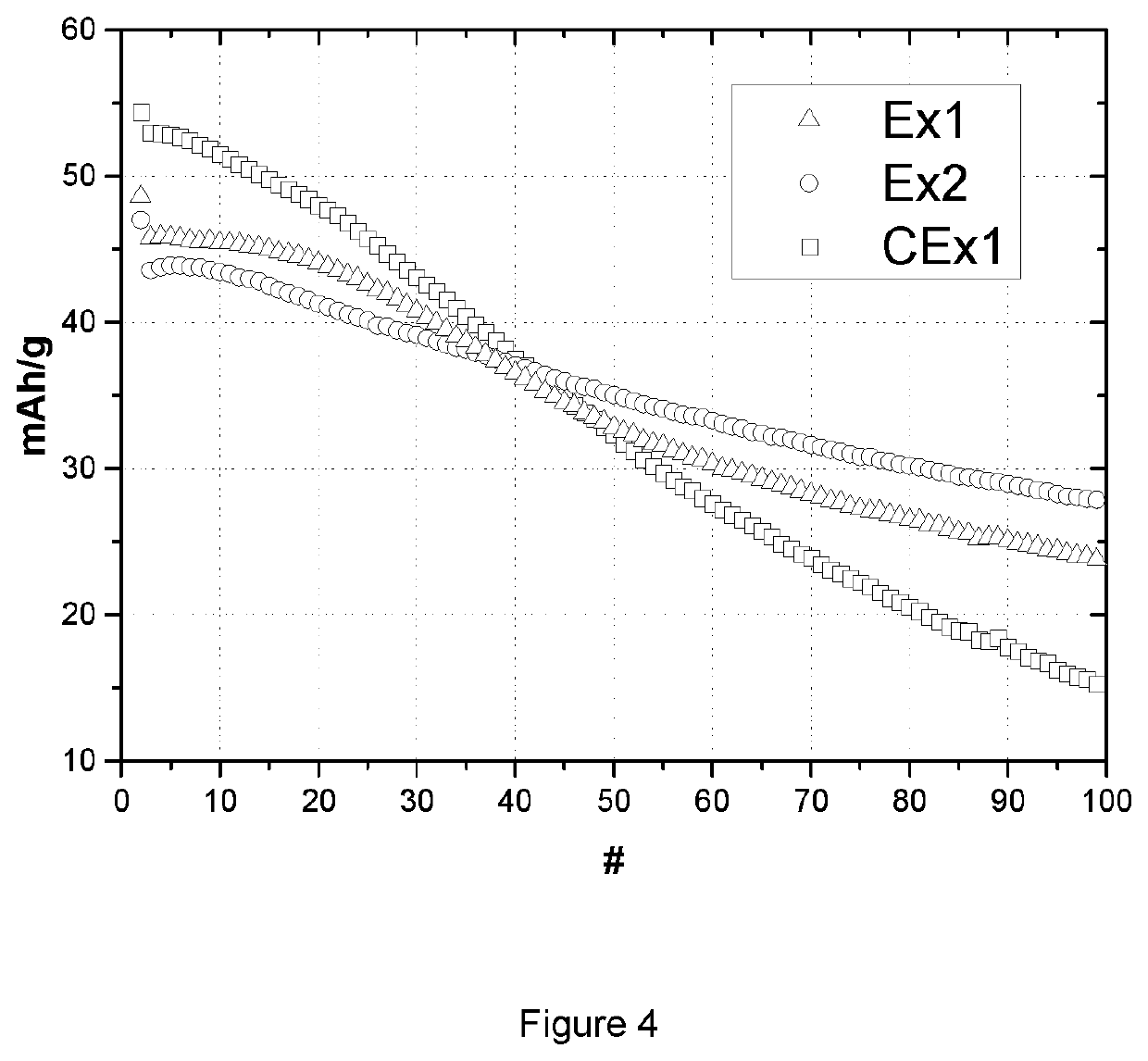

Lithium Battery Containing Cathode Material and Electrolyte Additives for High Voltage Application

ActiveUS20180254525A1Less electrical conductivitySecondary cellsPositive electrodesState of chargeGraphite

A lithium secondary cell having an operating voltage ≥4.35 sV, comprising a cathode comprising a doped L1CoO2 active material, an anode comprising graphite, and an electrolyte comprising a carbonate-based solvent, a lithium salt and both a succinonitrile (SN) and a lithium bis(oxalato)borate (LiBOB) additive wherein during the discharge at 45° C. from a state of charge (SOC) of 100% at 4.5V to a SOC of 0 at 3V at a C / 10 rate the difference of the SOC at 4.42V and 4.35V is at least 7% but less than 14%, and wherein the active material is doped by at least 0.5 mole % of either one or more of Mn, Mg and Ti.

Owner:UMICORE AG & CO KG +1

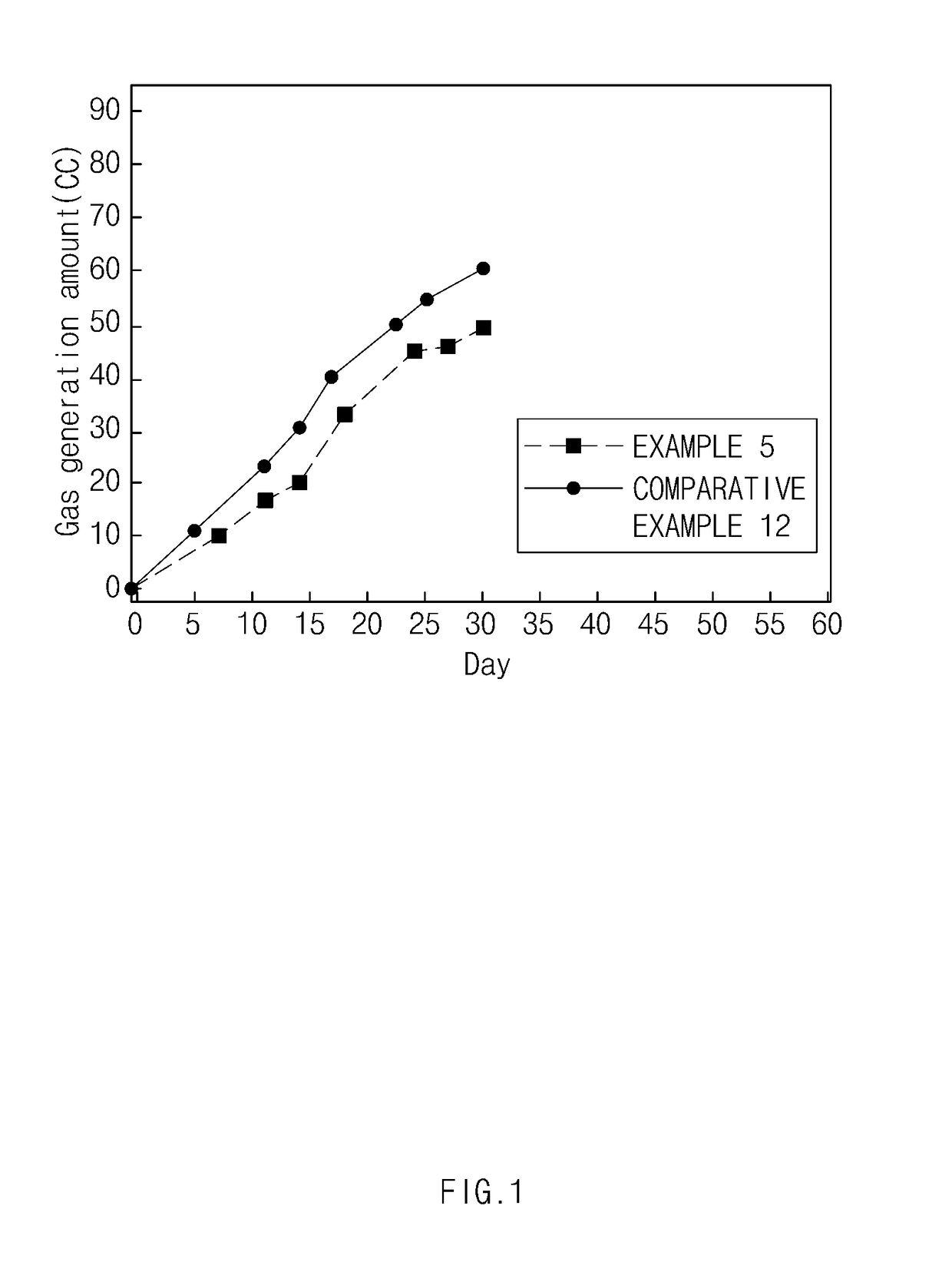

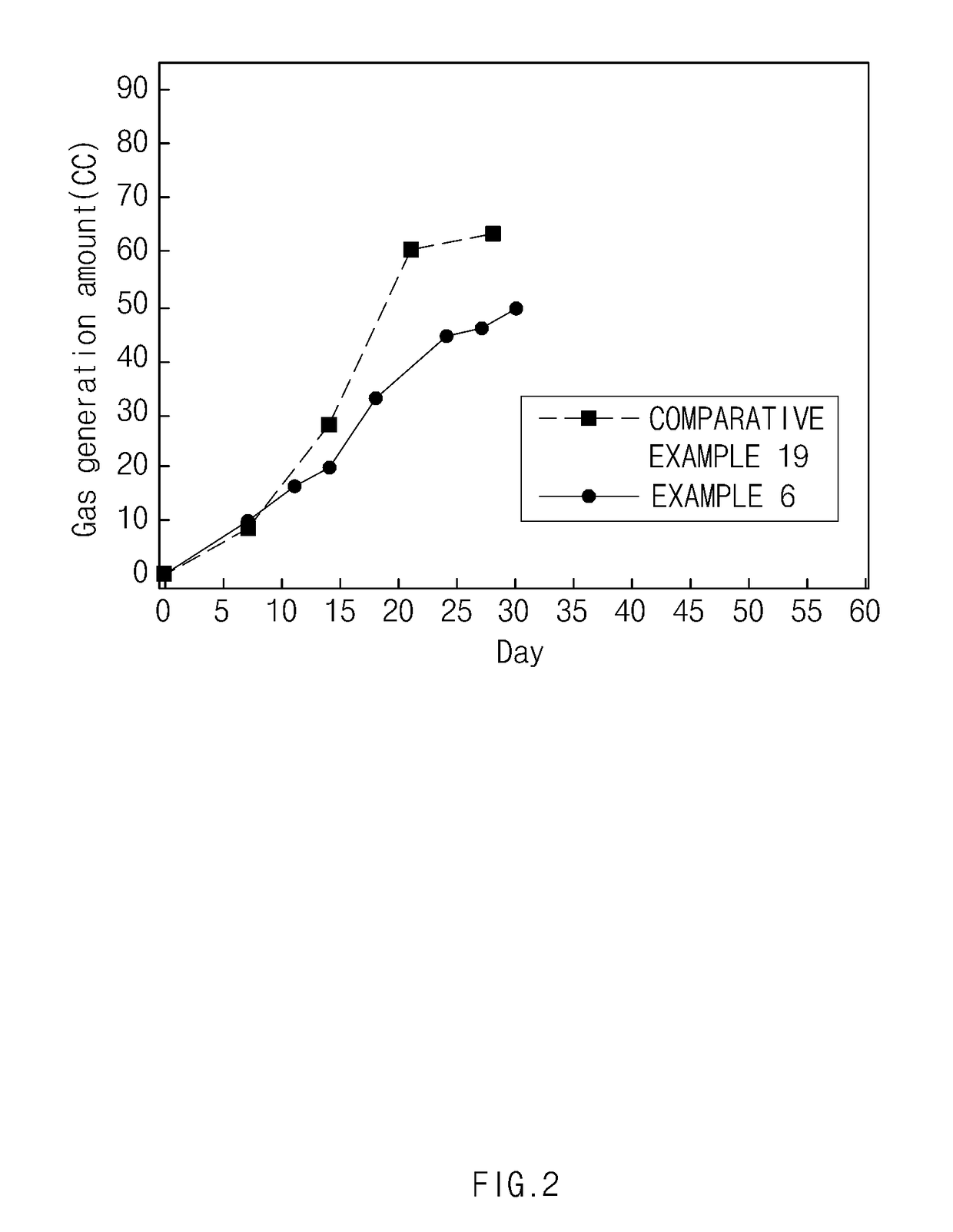

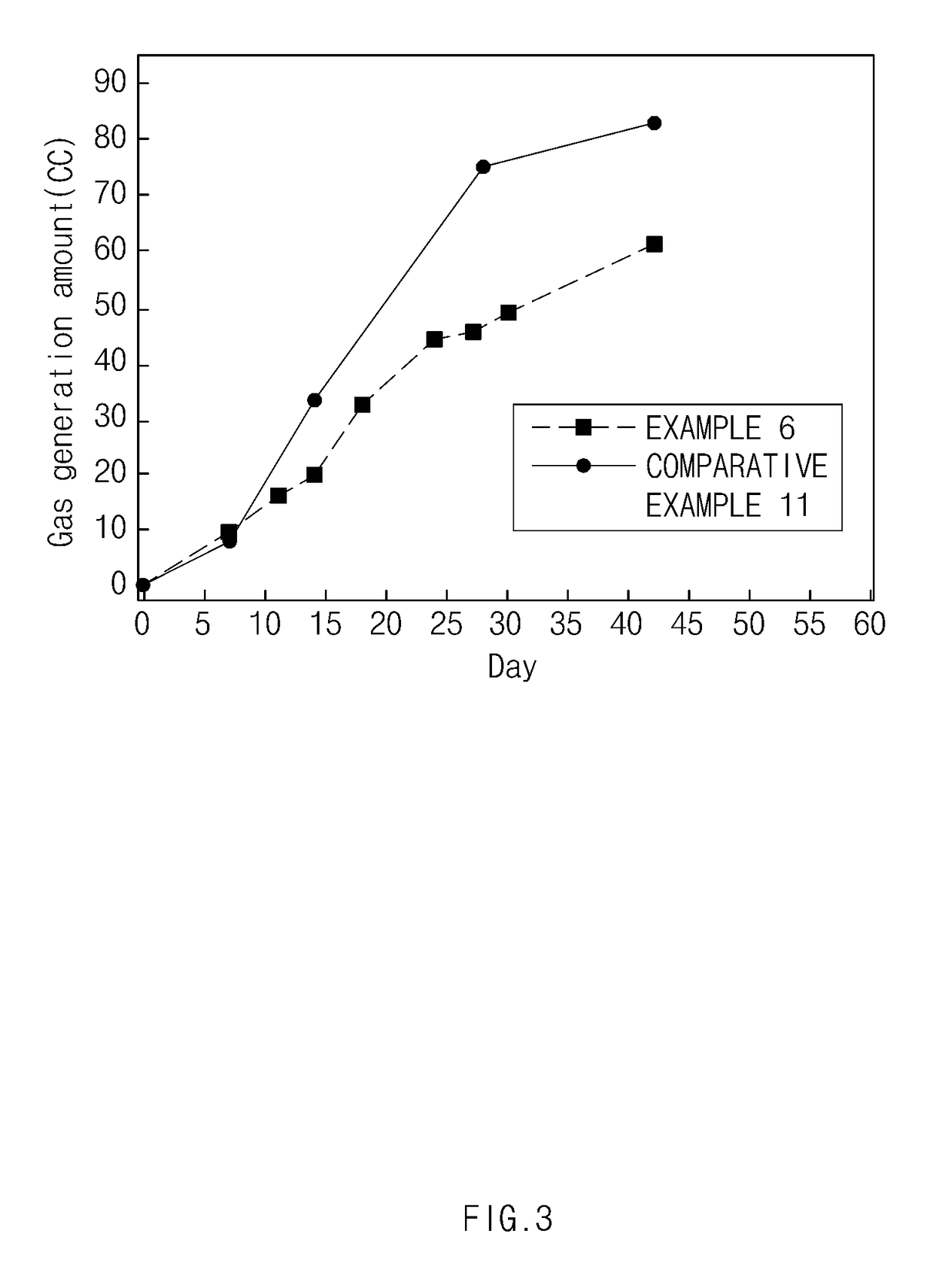

Electrolyte and lithium ion battery

ActiveCN112909334AInhibit gas productionImprove cycle performanceSecondary cells servicing/maintenanceElectrolytic agentPhosphoric Acid Esters

The invention relates to an electrolyte, and the electrolyte contains an organic solvent, a lithium salt and an additive;, the additive comprises a gas production inhibition additive, a negative electrode film-forming additive, a positive electrode film-forming additive and a low-impedance additive, and the gas production inhibition additive is vinylene carbonate; the negative electrode film-forming additive is fluoroethylene carbonate and / or tris (trimethylsilane) phosphite ester; the positive electrode film-forming additive is adiponitrile and / or butanedinitrile; the low-impedance additive is one or more of lithium bis (oxalato) borate, lithium difluoro (oxalato) borate, lithium difluoro (oxalato) phosphate and lithium tetrafluoro (oxalato) phosphate. Through the coordination effect of the additive, the gas production rate of the electrolyte in the pre-charging process can be effectively inhibited, the cycle performance of the battery at high temperature is improved, and the production efficiency of the lithium ion battery is improved.

Owner:宁德国泰华荣新材料有限公司

Lithium battery containing cathode material and electrolyte additives for high voltage application

A lithium secondary cell having an operating voltage ≥4.35 sV, comprising a cathode comprising a doped L1CoO2 active material, an anode comprising graphite, and an electrolyte comprising a carbonate-based solvent, a lithium salt and both a succinonitrile (SN) and a lithium bis(oxalato)borate (LiBOB) additive wherein during the discharge at 45° C. from a state of charge (SOC) of 100% at 4.5V to a SOC of 0 at 3V at a C / 10 rate the difference of the SOC at 4.42V and 4.35V is at least 7% but less than 14%, and wherein the active material is doped by at least 0.5 mole % of either one or more of Mn, Mg and Ti.

Owner:UMICORE AG & CO KG +1

Porous plastic crystal electrolyte for all-solid-state metal-air battery, preparation method of porous plastic crystal electrolyte and all-solid-state metal-air battery

ActiveCN111269509AWith deformationProne to deformationFuel and secondary cellsFinal product manufactureAll solid statePlastic crystal

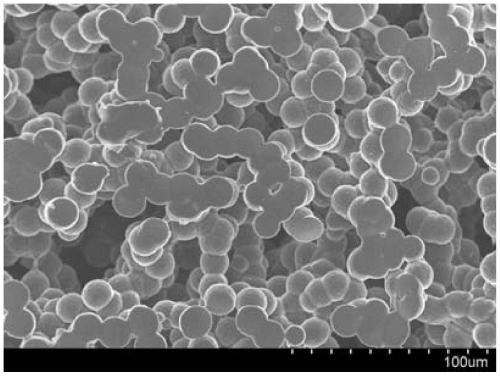

The invention provides a porous plastic crystal compound. The porous plastic crystal compound has a porous morphology formed by stacking sphere-like particles; wherein the plastic crystal comprises succinonitrile. The invention provides a porous plastic crystal compound, which has the characteristics of good stability, high ionic conductivity, adjustable porosity and the like and is applied to anall-solid-state metal-air battery. The porous plastic crystal compound serves as an electrolyte interlayer and is introduced into a solid-state positive electrode; the interface impedance between theelectrolyte interlayer and the electrode can be effectively reduced; besides, due to the adjustable porosity, gas diffusion is not hindered while tight contact with the active material is realized byintroducing into the solid-state positive electrode; according to the invention, the three-phase interface is effectively increased, reaction sites are increased, the problems of high interface impedance and few positive electrode three-phase interfaces of an existing metal-air battery are solved, and the electrochemical properties such as the discharge capacity of the all-solid-state lithium-oxygen battery are improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

PVDF-based composite solid electrolyte and preparation method thereof

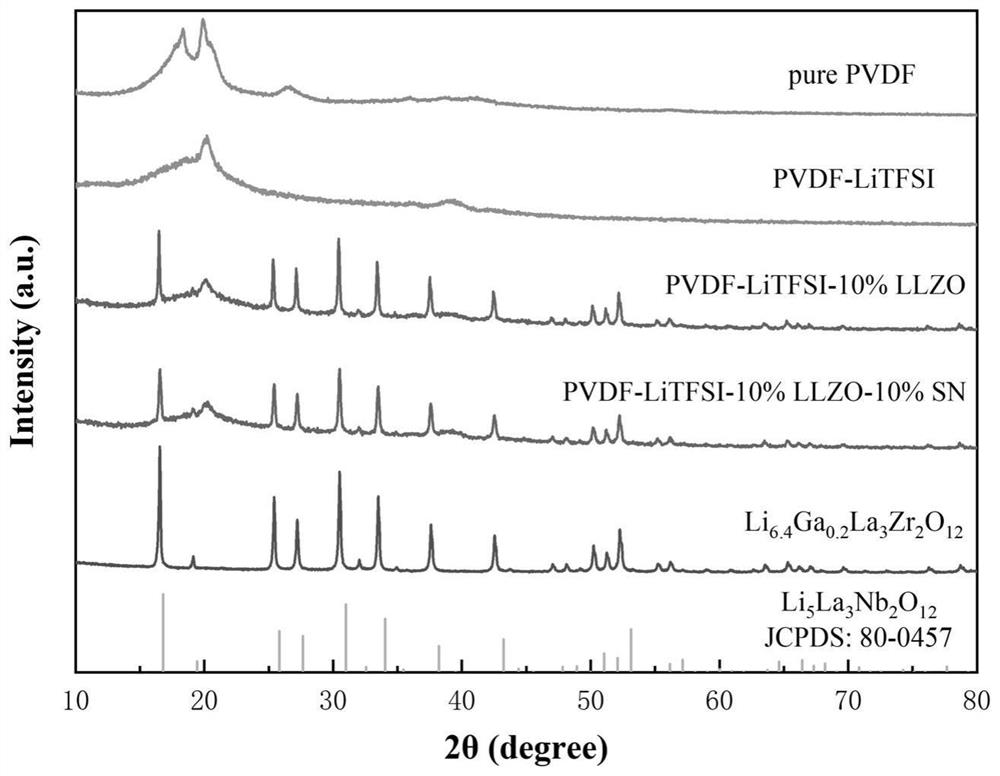

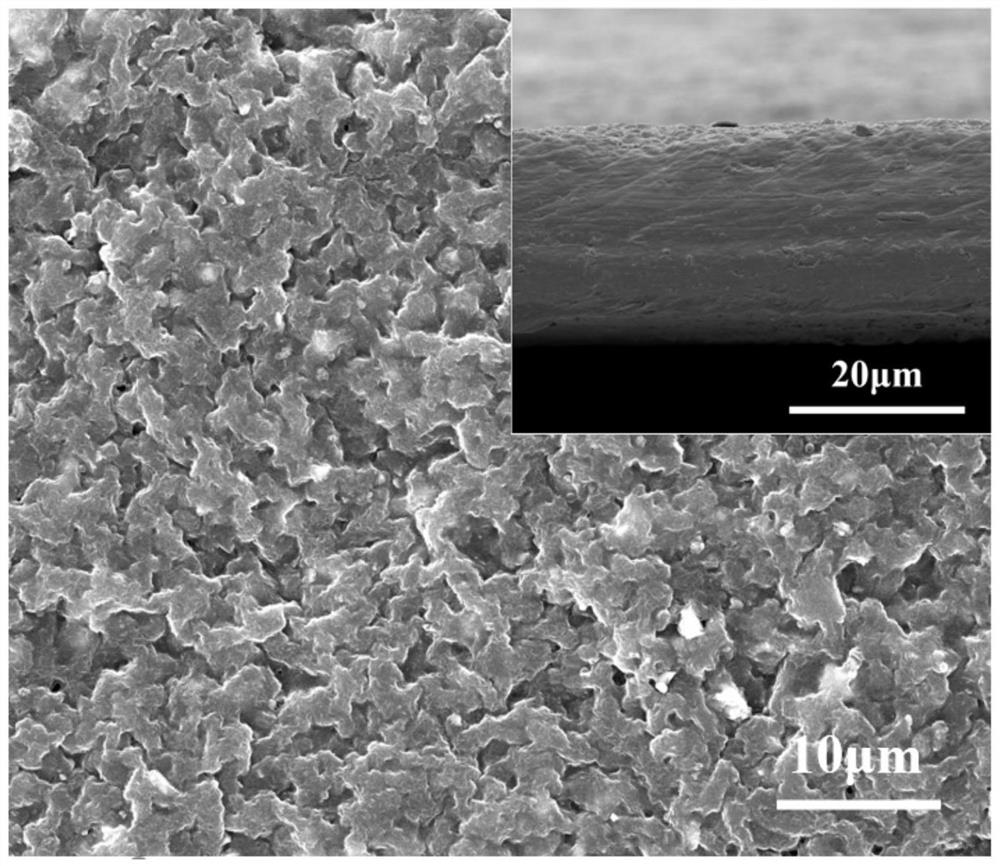

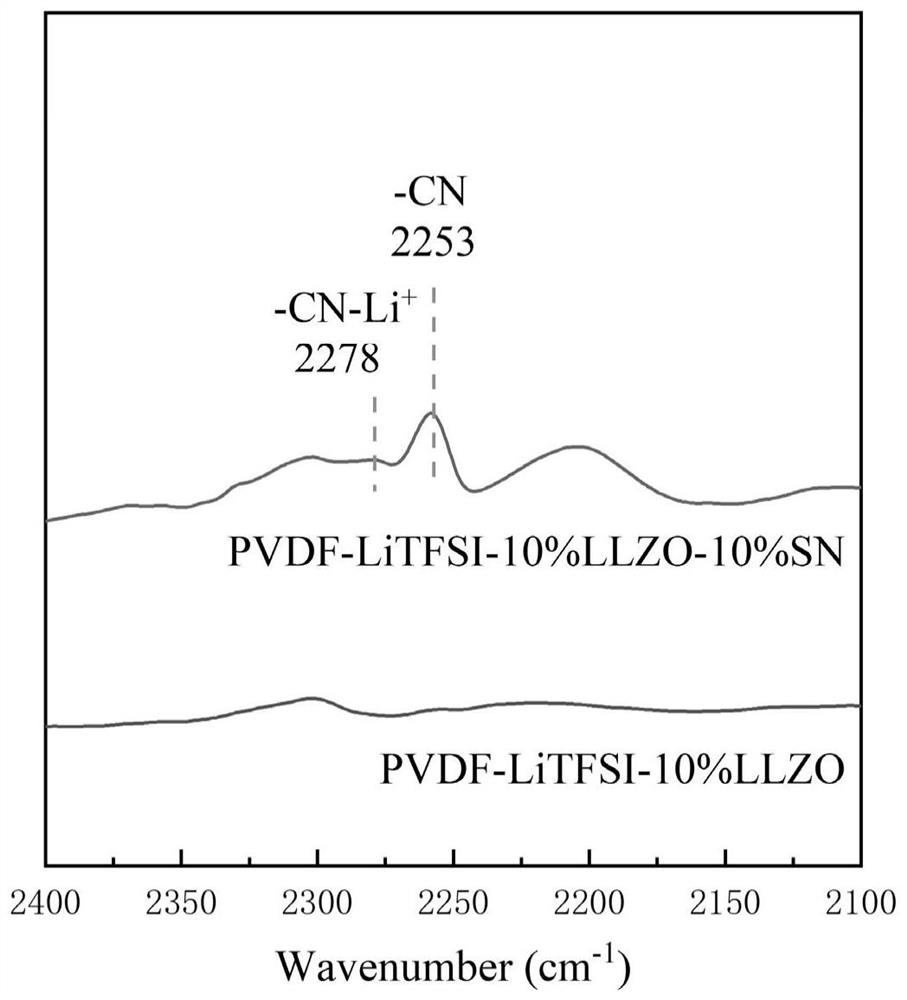

PendingCN114204118AImprove electrochemical performanceImprove chain movement abilitySecondary cellsPlastic crystalInterface impedance

The invention relates to a PVDF-based composite solid electrolyte and a preparation method thereof, the composite solid electrolyte is composed of a PVDF matrix, a lithium salt, an oxide inorganic solid electrolyte powder and a plastic crystal compound succinonitrile, and the PVDF-based composite solid electrolyte is prepared into a film through a solution casting method or a tape casting method and then assembled into an all-solid-state battery. According to the invention, the succinonitrile, the oxide inorganic solid electrolyte and the PVDF matrix are compounded, on one hand, the crystallinity of the polymer matrix is effectively reduced, and the dissociation degree of lithium salt in the polymer matrix is increased, so that the migration ability of lithium ions is improved, and on the other hand, the succinonitrile is used as a plasticizer, so that the flexibility of the composite solid electrolyte membrane is increased to a certain extent; the interface impedance between the positive electrode and the negative electrode is reduced, and the cycle performance and the rate performance of the all-solid-state battery are improved. Experimental results show that the composite solid electrolyte provided by the invention has relatively high ionic conductivity, relatively wide electrochemical window and good mechanical property and thermal stability, and has a wide application prospect in the field of all-solid-state batteries.

Owner:WUHAN UNIV OF TECH

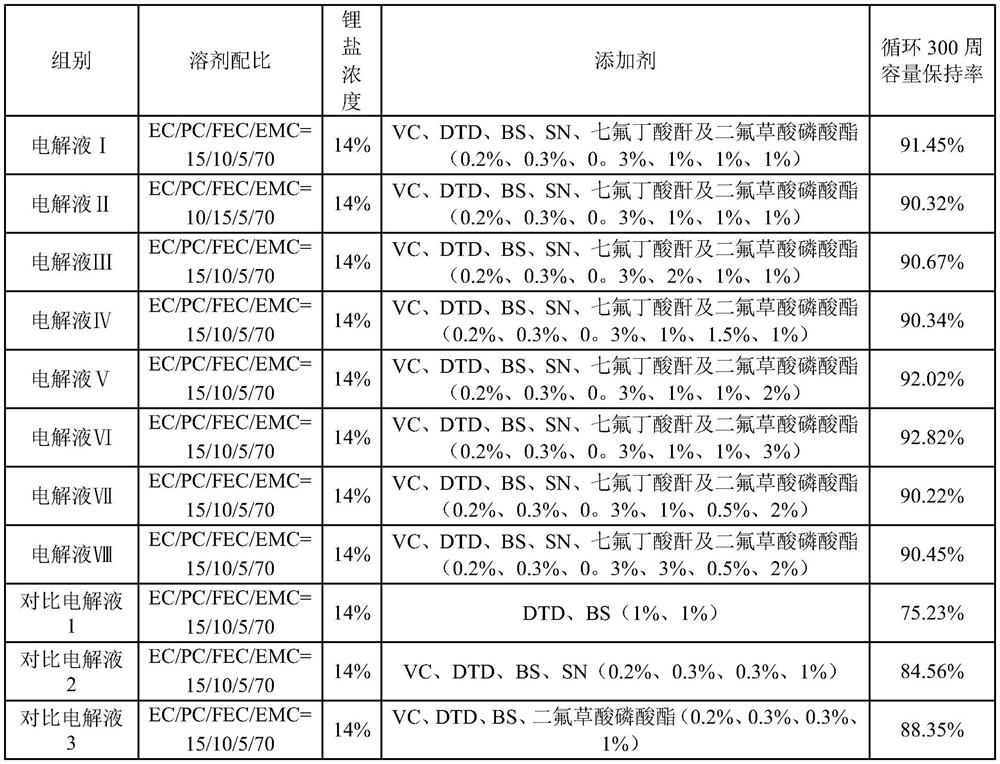

Electrolyte for high-voltage lithium cobalt oxide battery and lithium cobalt oxide battery

InactiveCN112510261AExcellent electrical performanceInhibitory responseFinal product manufactureLi-accumulatorsElectrolytic agentElectrical battery

The invention relates to an electrolyte for a high-voltage lithium cobalt oxide battery and a lithium cobalt oxide battery. The electrolyte comprises a lithium salt electrolyte, an organic solvent andan additive; the additives comprise heptafluorobutyric anhydride, vinylene carbonate VC, difluoro oxalic acid phosphate and succinonitrile SN. Vinylene carbonate only participates in formation of a negative electrode SEI film in first formation and forms stable SEI, and heptafluorobutyric anhydride and a difluoro oxalic acid phosphate additive form stable composite CEI containing LiF and inorganic phosphate at a high voltage at a positive electrode, so that the stability of a battery system is ensured, and a lithium cobalt oxide material is stabilized at the same time. Through the interactionof the four additives, the excellent electrical property of the electrolyte under high voltage is realized.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

Non-aqueous electrolyte solution for lithium secondary battery and lithium secondary battery comprising the same

ActiveUS20170162905A1Improve performanceReduce gas volumeNegative electrodesLi-accumulatorsOrganic solventTrimethylsilyl

The present invention relates to a non-aqueous electrolyte solution for a lithium secondary battery and a lithium secondary battery including the same, and more particularly, to a non-aqueous electrolyte solution for a lithium secondary battery including an ionizable lithium salt, an organic solvent, and an additive, wherein the additive includes 1,3-propane sultone, succinic anhydride, tris(trimethylsilyl)borate, and succinonitrile in a weight ratio of 1:0.5:0.5:0.5 to 1:1:1:1, and a total amount of the additive is in a range of 2.5 wt % to 4 wt % based on a total weight of the non-aqueous electrolyte solution for a lithium secondary battery, and a lithium secondary battery including the same.

Owner:LG ENERGY SOLUTION LTD

Preparation method and application of succinonitrile-based double-layer composite polymer electrolyte

PendingCN113299985AImproved interface contactIncrease the transmission channelFinal product manufactureLi-accumulatorsSolid state electrolyteMetallic lithium

The invention discloses a preparation method and application of a succinonitrile-based double-layer composite polymer electrolyte, succinonitrile has good ionic conductivity and high oxidation stability, and electrolyte taking succinonitrile as a matrix can keep good stability with a metal lithium negative electrode. And high lithium ion conductivity can be maintained at the interface of the electrode, so that the charge-discharge efficiency can be ensured. The ionic conductivity of the composite polymer electrolyte at room temperature can reach 4.27 * 10 <-4 > S cm <-1 >, the electrochemical window width is 0-5.1 V (relative to Li < + > / Li), no short circuit phenomenon exists after the assembled metal lithium symmetrical battery is circulated for more than 250 hours, and the good flexibility of the polymer can enable all interfaces in the battery to be in close contact, so that the interface resistance is reduced. The electrolyte with the double-layer structure is a promising solid-state battery candidate electrolyte, a high-voltage positive electrode and a low-voltage metal negative electrode can coexist in the battery by utilizing the double-layer structure, and the development and commercialization of the solid-state secondary battery can be greatly accelerated by the brand new solid-state electrolyte design.

Owner:杭州阳名新能源设备科技有限公司

Catalyst for catalyzing butyrolactone to obtain succinonitrile and synthesis method

PendingCN114105818AIncrease the active siteEasy to preparePreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCombinatorial chemistry

The invention discloses a catalyst for catalyzing butyrolactone to obtain succinonitrile and a synthesis method, gamma-butyrolactone is taken as a raw material, ammoxidation reaction is carried out in the presence of a supported catalyst, succinonitrile is synthesized in one step, 100% conversion rate of gamma-butyrolactone is realized, succinonitrile can be finally obtained only by trapping, and the preparation method is simple and efficient; the reaction process hardly generates three wastes, and compared with the post-treatment of centrifugal separation and rectification in the traditional process, the method is very environment-friendly, the raw materials are simple, and the method has important significance in practice.

Owner:ANSHAN HIFICHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com