Preparation method and application of succinonitrile-based double-layer composite polymer electrolyte

A double-layer composite, polymer technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problem of reducing battery energy density and cycle performance, unstable compatibility of lithium metal, low lithium ion transfer It can improve the performance, respond quickly, and reduce the interface resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

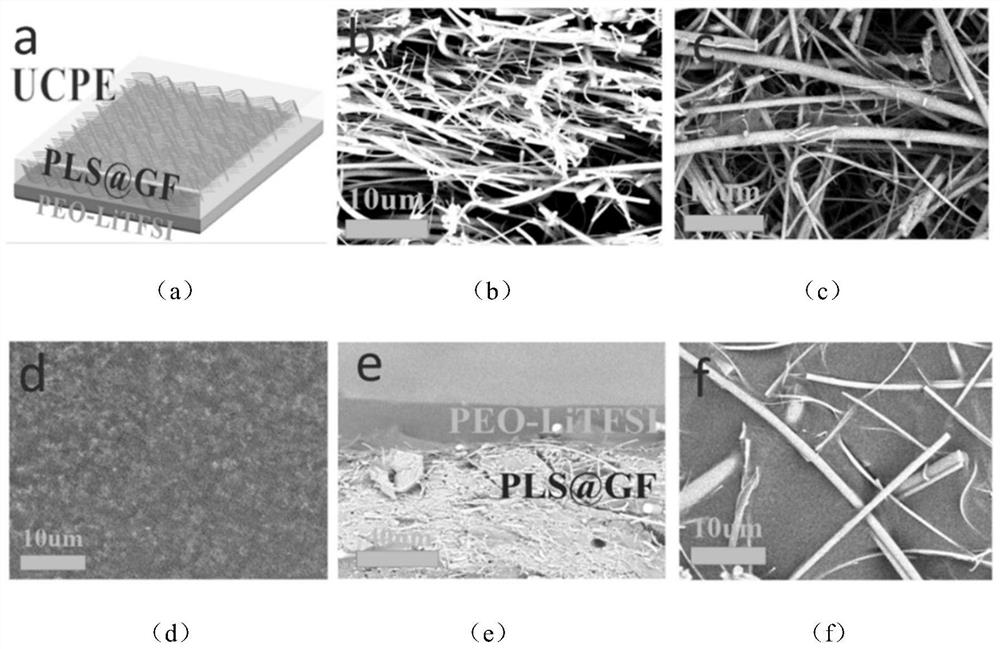

[0042] The invention discloses a method for preparing a succinonitrile-based double-layer composite polymer electrolyte, using succinonitrile as a substrate, polyethylene oxide-bistrifluoromethanesulfonimide lithium and polyethylene glycol diacrylate-bistrifluoromethanesulfonimide Lithium fluoromethanesulfonimide-succinonitrile was used as a stable polymer electrolyte for negative and positive electrodes, respectively, and all experiments were performed in a glove box (H 2 O and O 2 <0.1ppm) under an argon atmosphere, the specific steps are as follows:

[0043] S1. Dry lithium bistrifluoromethanesulfonimide (LiTFSI) under vacuum conditions at 80-110°C for 24-72 hours;

[0044] S2. Dissolve succinonitrile (SN) and lithium bistrifluoromethanesulfonimide (LiTFSI) in polyethylene glycol diacrylate (PEGDA) solvent, add photoinitiator (CIBA) and heat to 50-80 ℃, and then continuously stirred for 24 to 72 hours, the prepared mixed solvent is the precursor of the photocurable polyme...

Embodiment 1

[0054] SN and LiTFSI were dissolved in PEGDA solvent under dark conditions in an argon atmosphere glove box, the mass ratio of PEGDA, LiTFSI and SN was kept at 1:2:2, the CIBA photoinitiator was 1wt%, and the configured PEGDA The solvent was heated to 50 ° C, and then continuously stirred for 24 hours to prepare a PEGDA-LiTFSI-SN (PLS) solution, which was used as a precursor solvent for a UV-curable polymer electrolyte;

[0055] Using the method of slurry casting and drying, a PEO polymer electrolyte membrane with a thickness of 10 μm was prepared, wherein the added lithium salt was LiTFSI, and the molar ratio of PEO to LiTFSI was 10:1;

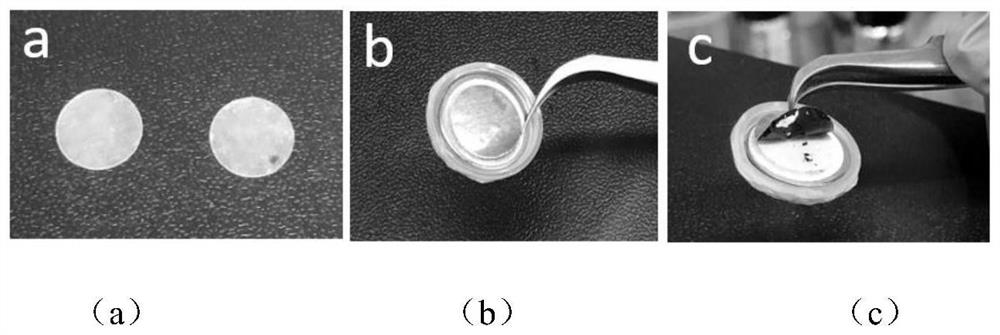

[0056] The glass fibers were adhered to the PEO polymer electrolyte membrane, and excess PLS solvent was added, and pressed with a glass plate to ensure that the glass fibers were completely soaked for 2 hours; finally, the composite polymer electrolyte UCPE was obtained by UV curing for 5 minutes.

[0057] Schematic diagram of the structure ...

Embodiment 2

[0066] A certain amount of SN and LiTFSI were dissolved in PEGDA solvent in an argon atmosphere glove box under the condition of avoiding light, the mass ratio of PEGDA, LiTFSI and SN was kept at 1:2:2, and the CIBA photoinitiator was 1wt%. Heating to 50 ° C, and then continuously stirring for 24 hours to prepare a PEGDA-LiTFSI-SN (PLS) solution as a precursor solvent for UV-curable polymer electrolytes;

[0067] Then immerse the glass fiber in excess PLS solvent, and press it with a glass plate to ensure that the glass fiber is completely soaked for 2 hours. As a control group, this composite polymer electrolyte does not need to coat the PEO polymer electrolyte membrane; finally, it is cured by ultraviolet light for 7 minutes to obtain Photocurable monolayer composite polymer electrolyte. The LiTFSI was dried under vacuum at 100 °C for 48 h before use. All experiments were performed in a glove box (H 2 O and O 2 <0.1ppm) under an argon atmosphere.

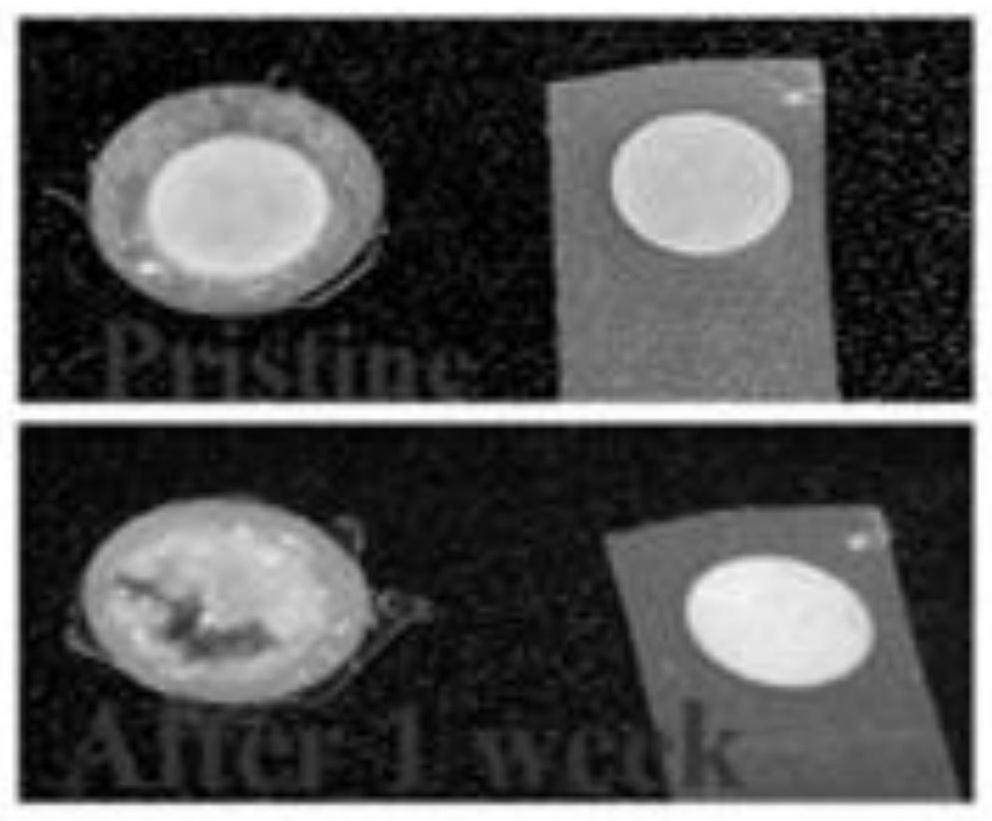

[0068] The prepared li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com