Organic photovoltaic battery with cesium acetate as cathode modification layer and preparation method thereof

An organic photovoltaic cell and cathode modification layer technology, which is applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of difficult to accurately control the film thickness, complicated methods, high price, etc., and achieves improvement of photoelectric conversion efficiency and stability. The effect of simple conditions and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

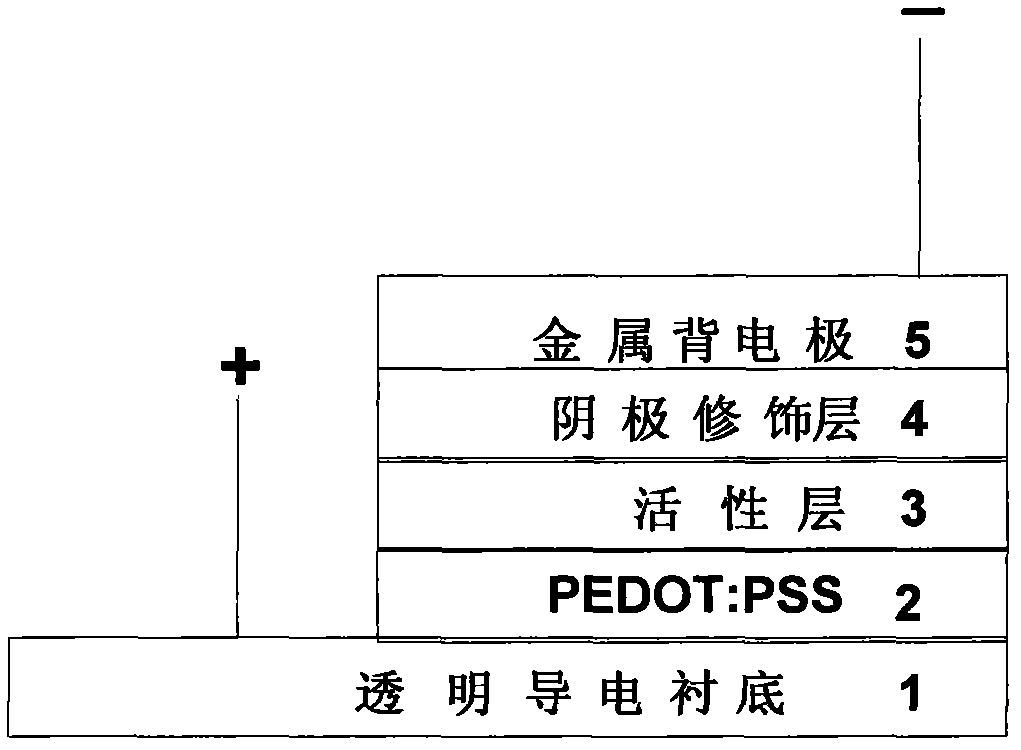

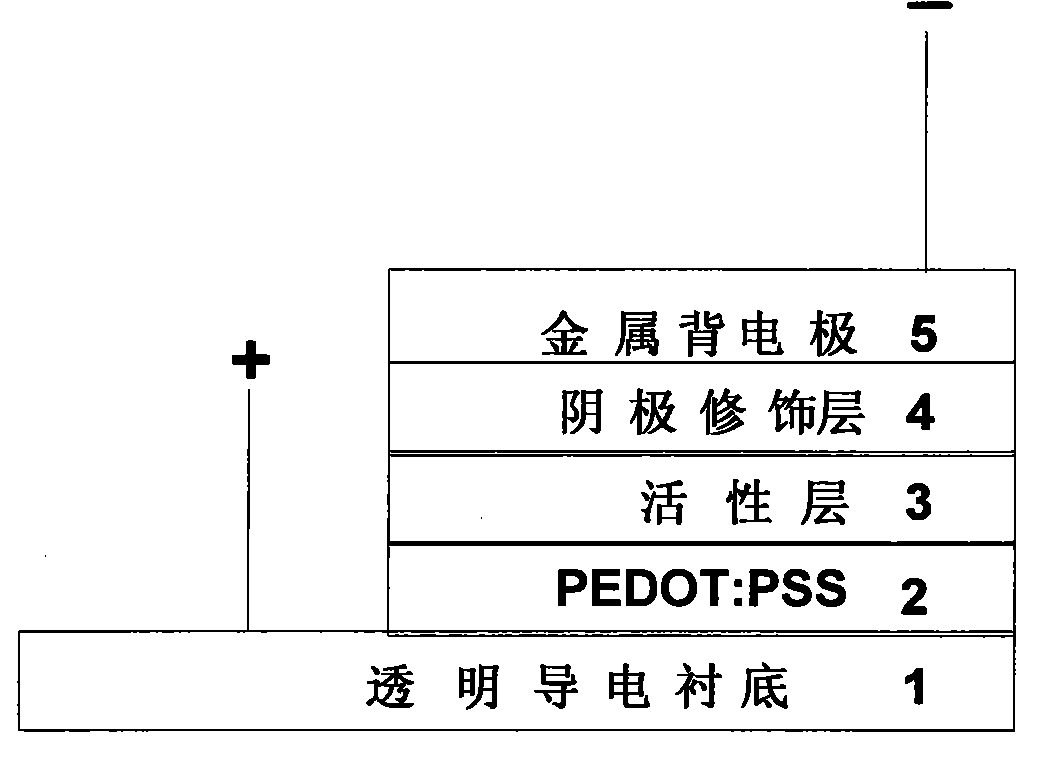

[0024] (1) After repeated cleaning of 3mm×3mm ITO glass in detergent, immersion in isopropanol, acetone and chloroform solutions and ultrasonic cleaning, and finally drying in an infrared oven for use;

[0025] (2) Spin-coating the anode buffer layer PEDOT:PSS on the transparent conductive glass substrate in the air or under the protection of inert gas, and dry at 120 degrees for 10 minutes;

[0026] (3) Spin-coating the organic active layer P3HT:PCBM on the anode buffer layer PEDOT:PSS, and dry at 150 degrees for 30 minutes.

[0027] (4) The cathode buffer layer cesium acetate is made into a thin film with a thickness of 0.2 nm by a vacuum evaporation method.

[0028] (5) With the help of a strip mask, 100nm of Al is vacuum evaporated on the cesium acetate layer as a back electrode. Thus, an organic photovoltaic cell device is made, and the device structure: ITO / PEDOT:PSS / P3HT:PCBM / cesium acetate / Al. A similar method was used to prepare comparative device 1 with LiF as the cathode b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com