Anti-carbon metal-supported solid oxide fuel cell and preparation method thereof

A solid oxide, metal-supported technology, used in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve problems such as carbon deposition, achieve wide application prospects, enhance interface contact, and low cost of preparation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

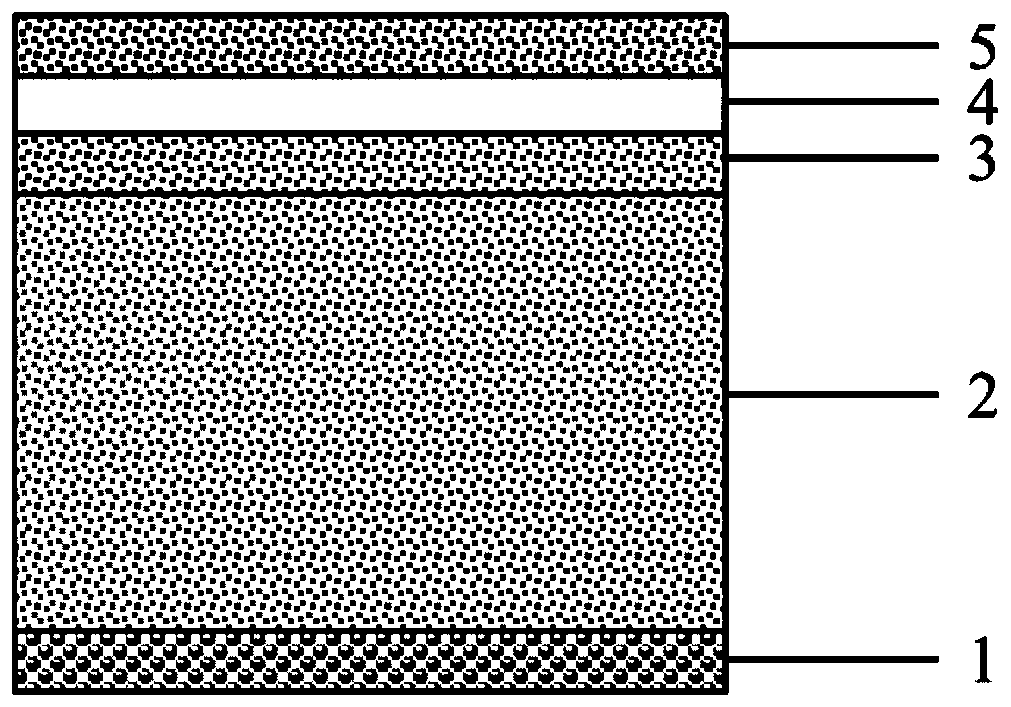

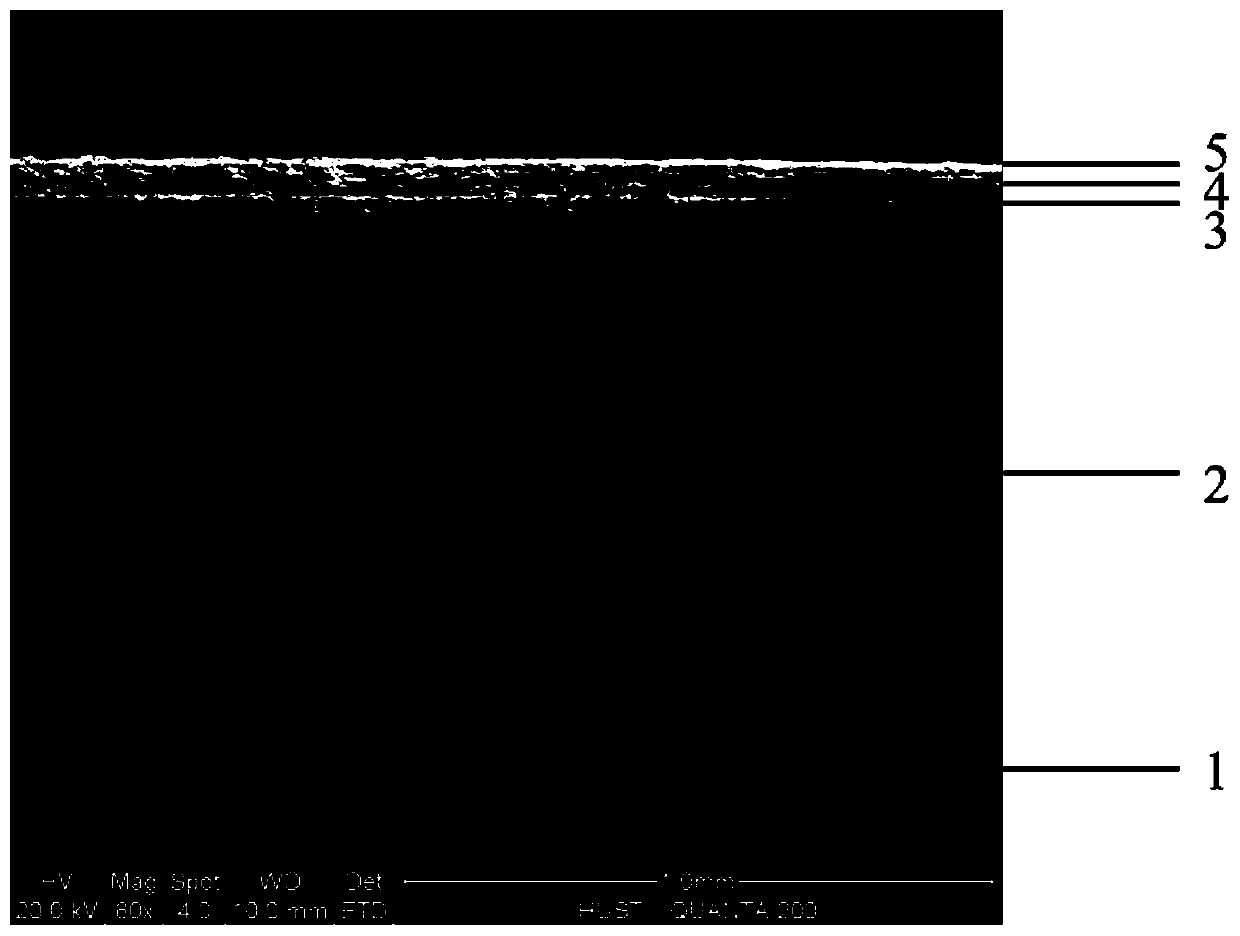

[0050] According to another aspect of the present invention, there is provided a method for preparing an anti-carbon deposition metal-supported solid oxide fuel cell, comprising the following steps:

[0051] S1 Anhydrous ethanol and xylene are mixed evenly and a dispersant is added as a solvent, the mixed powder formed by the first precursor and a pore-forming agent is added to the solvent and ball milled, and the plasticizer, the first binder and the first binder are added in sequence The defoaming agent is ball-milled again to form a casting slurry, which is cast after defoaming and dried to obtain a support body green layer; the first binder is polyvinyl butyral; the MgO powder The mass is 0.05%-0.1% of the mass of the first precursor.

[0052] S2 Mix the second precursor and the fluorite structure oxide or the second precursor and the ion-conductive perovskite structure oxide evenly, add the second binder, and grind to obtain the slurry of the anode functional layer, and m...

Embodiment 1

[0076] (1) Take 60ml of absolute ethanol and xylene and mix them evenly as a solvent, add 4.5g of fish oil as a dispersant, weigh 207g of NiO powder, 23g of Fe 2 o 3 Powder and 1.15g MgO powder were added to the above solvent, then 5g of starch was added as a pore-forming agent, stirred evenly and then ball-milled for 24h; then 9g of butyl benzyl phthalate (BBP), 9g of polyalkylene glycol ( PAG), 21g polyvinyl butyral (PVB) and 0.2g cyclohexanone, and ball milled for 24h after stirring evenly. The slurry obtained after ball milling was subjected to vacuum defoaming treatment for 30 minutes, and tape casting and drying were performed on a tape casting machine to obtain a support body green body with a thickness of 1 mm.

[0077] (2) Ethyl cellulose was dissolved in terpineol to prepare an ethyl cellulose terpineol solution with an ethyl cellulose content of 4wt.%, which was used as a binder for preparing screen printing paste.

[0078] (3) 1.8gNiO powder and 1.2gCe 0.8 Gd 0...

Embodiment 2

[0084] (1) Take 60ml of absolute ethanol and xylene and mix them evenly as a solvent, add 4.5g of fish oil as a dispersant, weigh 115g of NiO powder, 115g of Fe 2 o 3 Powder and 1.15g MgO powder were added to the above solvent, then 5g of starch was added as a pore-forming agent, stirred evenly and then ball-milled for 24h; then 11g of butyl benzyl phthalate (BBP), 11g of polyalkylene glycol ( PAG), 23g polyvinyl butyral (PVB) and 0.25g cyclohexanone, and ball milled for 24h after stirring evenly. The slurry obtained after ball milling was subjected to vacuum defoaming treatment for 30 minutes, and tape casting and drying were performed on a tape casting machine to obtain a support body green body with a thickness of 1 mm.

[0085] (2) Ethyl cellulose was dissolved in terpineol to prepare an ethyl cellulose terpineol solution with an ethyl cellulose content of 4wt.%, which was used as a binder for preparing screen printing paste.

[0086] (3) 1.8gNiO powder and 1.2gCe 0.9 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com