Phototransistor preparation method based on femtosecond laser and transistor array

A technology of phototransistors and femtosecond lasers, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as the inability to guarantee the stability of transistor devices, reduce uncertain factors, improve uniformity and stability, and reduce preparation processes cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

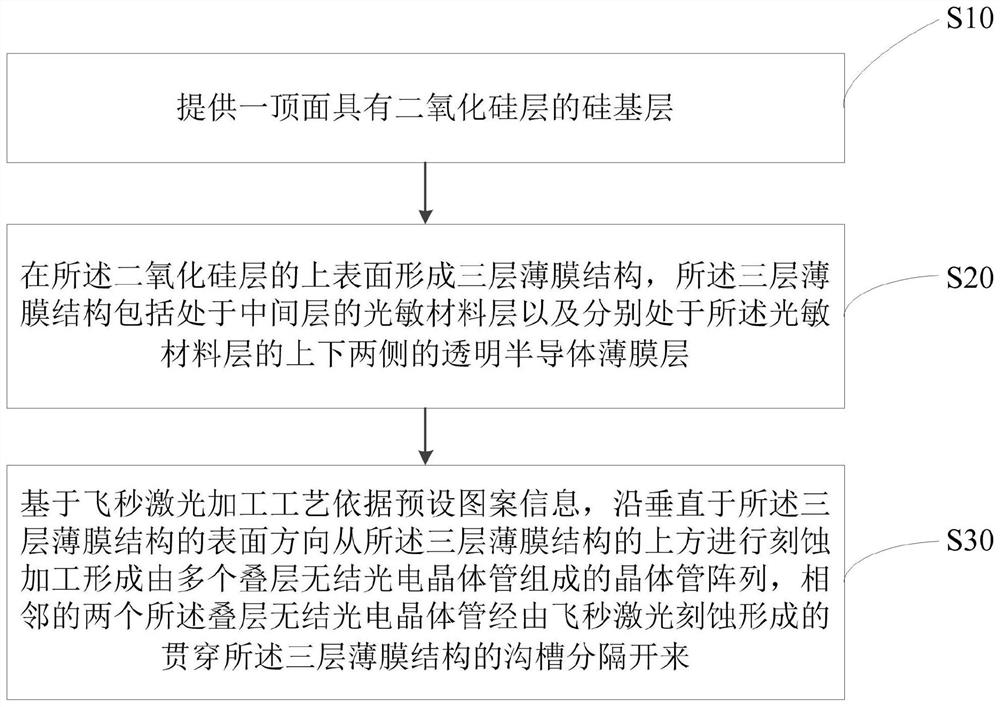

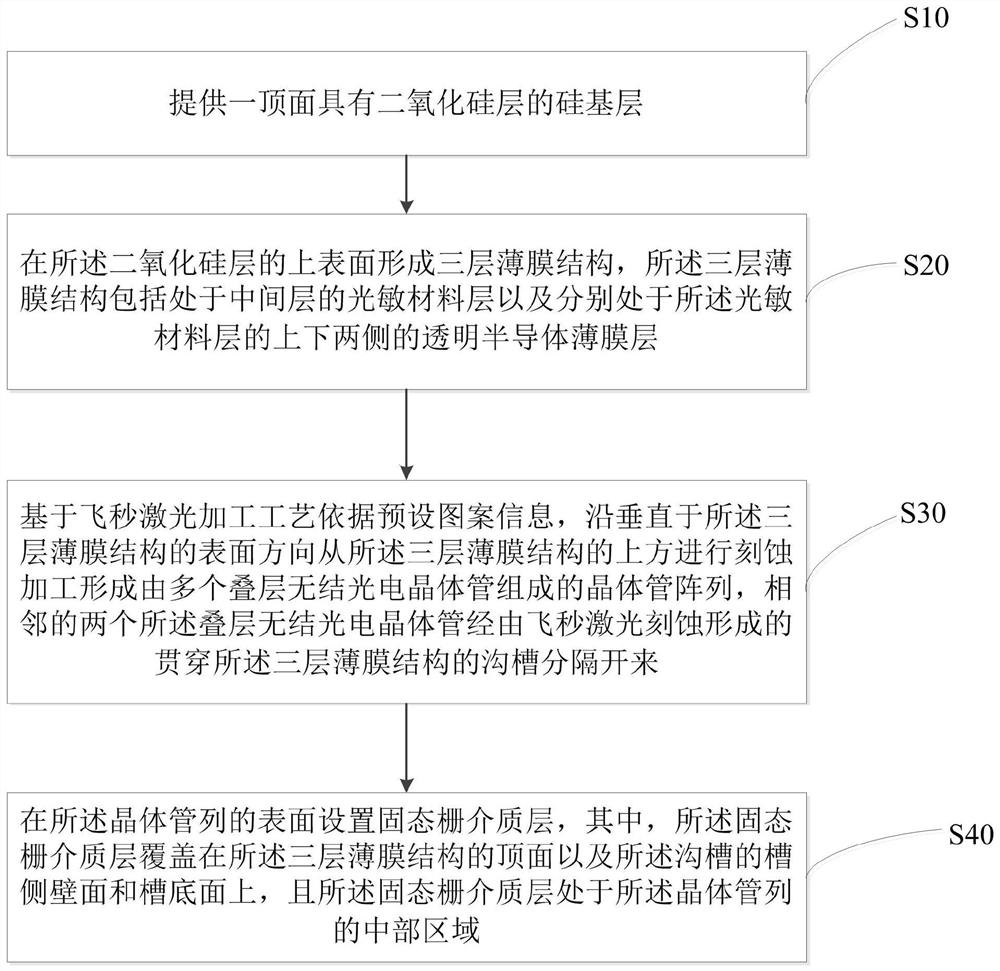

[0029] Please refer to figure 1 , image 3 , Figure 4 and Figure 5 , a method for preparing a phototransistor based on a femtosecond laser in a preferred embodiment provided by the present invention includes the steps:

[0030] S10, providing a silicon base layer with a silicon dioxide layer on the top surface;

[0031] S20, a three-layer thin film structure is formed on the upper surface of the silicon dioxide layer, and the three-layer thin film structure includes a photosensitive material layer in the middle layer and a transparent semiconductor thin film layer (transparent conductive semiconductor oxide thin film on the upper and lower sides of the photosensitive material layer, respectively). Floor);

[0032] S30, based on a femtosecond laser processing process and according to preset pattern information, etching is performed from above the three-layer thin-film structure along a surface direction perpendicular to the three-layer thin-film structure to form a transi...

Embodiment approach

[0058] The present invention provides a specific embodiment as follows:

[0059] Select heavily doped P-type silicon with 300nm thermally grown silicon dioxide (gate dielectric) on it as the substrate, select indium tin oxide (ITO) thin film layer for the transparent semiconductor film (heavy doped semiconductor layer) layer, and select photosensitive material for the photosensitive material. Quantum dots, solid-state ionic electrolytes and selective ionic liquids.

[0060] The fabrication method of phototransistor based on femtosecond laser includes the following steps:

[0061] Step 1: successively use acetone, alcohol and deionized water to ultrasonically clean the heavily doped silicon wafer substrate with 300nm thermally grown silicon dioxide and perform drying treatment;

[0062] Step 2: put the silicon wafer substrate (silicon base layer) into the vacuum chamber of radio frequency magnetron sputtering, and deposit a layer of transparent ITO thin film as a heavily doped s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com