High quality aluminum titanium boron refiner and preparation method thereof

An aluminum-titanium-boron refiner and high-quality technology are applied in the field of aluminum alloy smelting, which can solve the problems of difficult application and increase the preparation cost, and achieve the effects of shortening the residence time, simple operation and low preparation process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

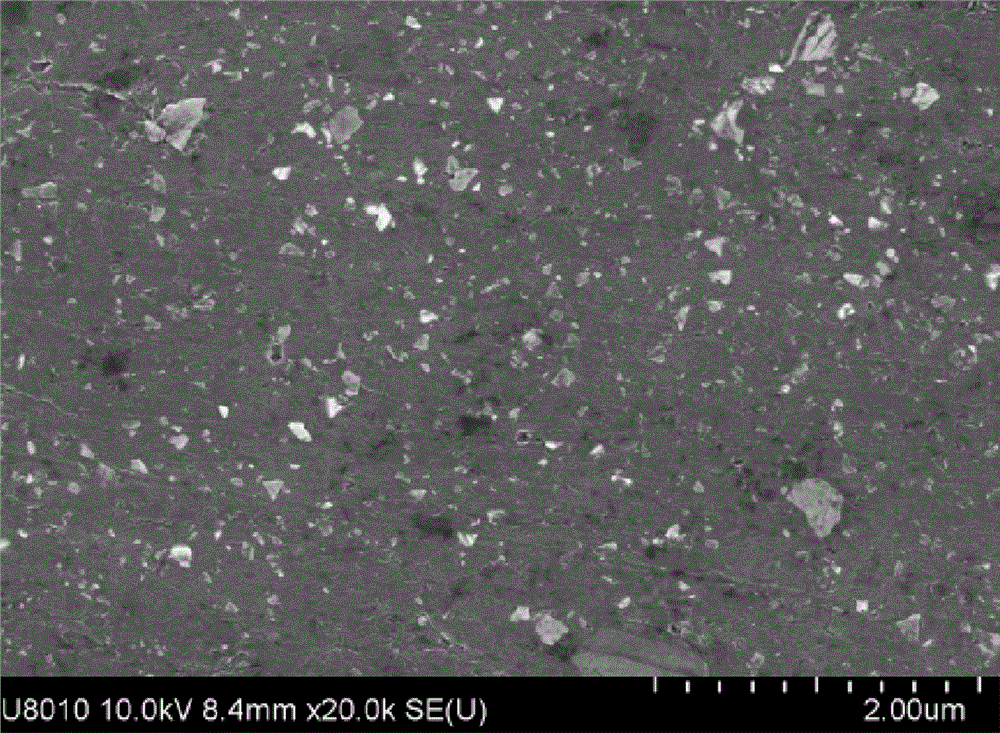

[0036] The preparation method of described high-quality aluminum-titanium-boron refiner, the method comprises the steps:

[0037] (1) Raw materials: Potassium fluoroborate, potassium fluorotitanate and pure aluminum;

[0038] (2) Use a high-purity graphite crucible to melt pure aluminum in a resistance furnace and raise the temperature to 800°C;

[0039] (3) Mix potassium fluorotitanate and potassium fluorotitanate evenly, dry them, and add them to the pure aluminum melt twice at a constant speed. +10Al=3TiB2+9KAlF4+K3AlF6 and 3K2TiF6+13Al=3TiAl3+3KAlF4+K3AlF6 are calculated;

[0040] (4) Let the melt stand and stir for 3 to 5 minutes;

[0041] (5) Add calcium fluoride, let it stand for 2 to 5 minutes, remove water slag, and pour into rods.

[0042] In the step (3), it is preferred to determine that the feeding mass ratio of potassium fluoroborate in the two feedings is 0~0.2, that is, the feeding quality of potassium fluoroborate in the second feeding is 83.3% of the total...

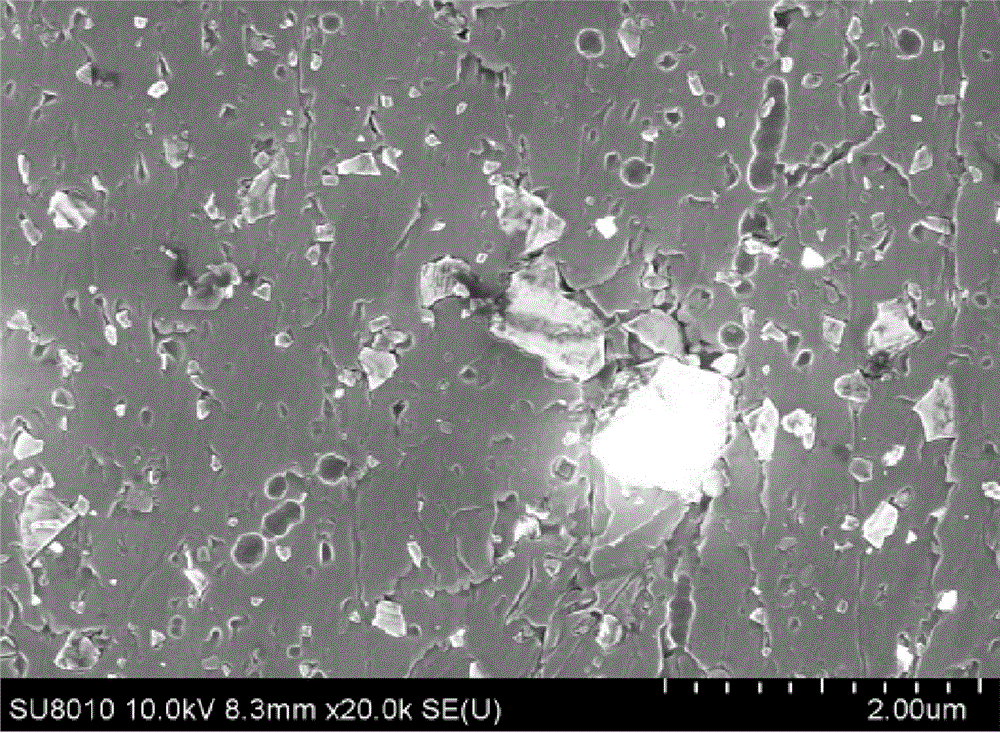

Embodiment 1

[0048] (1) According to the generated weight percentage, Ti is 5%, B is 1%, and aluminum is the balance, respectively weigh 66.3g of potassium fluoroborate, 132.5g of potassium fluorotitanate and 552.3g of pure aluminum.

[0049] (2) Divide the weighed potassium fluoroborate into 2 parts according to the mass ratio of the first and second additions as 1:5; divide the weighed potassium fluoroborate into 2 parts; Good potassium fluotitanate is divided into 2 parts.

[0050] (3) Mix the potassium fluoborate and potassium fluotitanate required for each addition evenly, and dry them in a drying oven at 80°C.

[0051] (4) Using a high-purity graphite crucible, melt industrially pure aluminum in a resistance furnace and raise the temperature to 800°C.

[0052] (5) For the first feeding, use the funnel to feed the prepared mixed fluoride salt at a constant speed for 7 minutes, stir with a graphite rod during feeding, and let stand for 15 minutes after feeding.

[0053] (6) Remove wa...

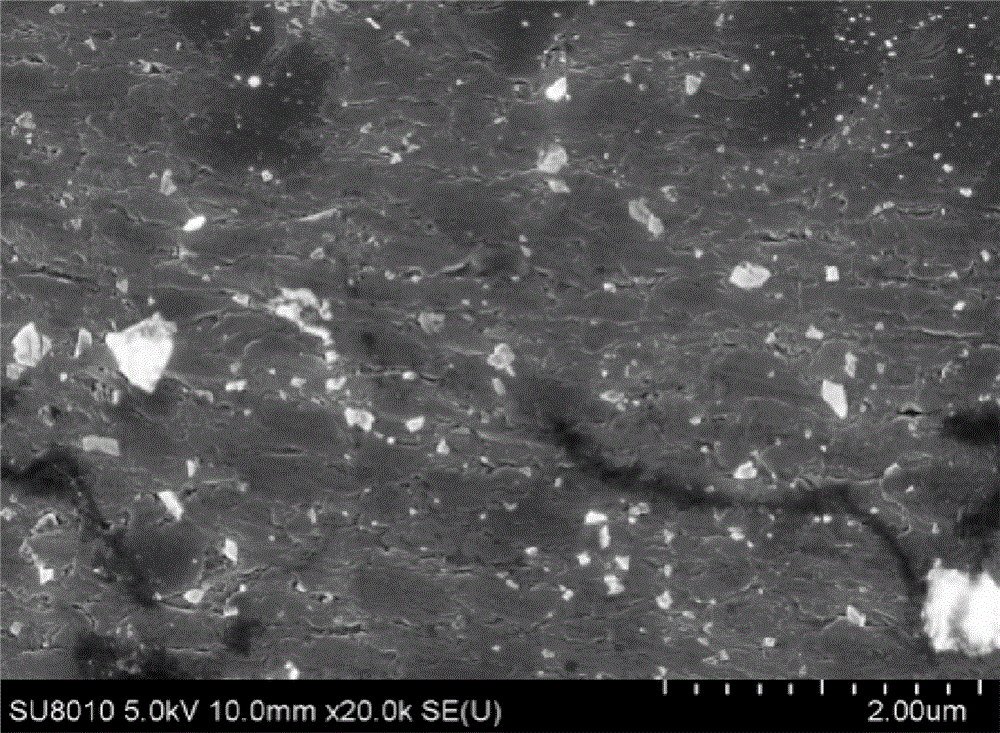

Embodiment 2

[0058] (1) According to the generated weight percentage, Ti is 5%, B is 1%, and aluminum is the balance, respectively weigh 67.81g of potassium fluoroborate, 135.6g of potassium fluorotitanate and 565.1g of pure aluminum.

[0059] (2) Divide the weighed potassium fluoroborate into 2 parts according to the mass ratio of the first and second additions of 0:1; according to the mass ratio of the first and second additions of 1.09:1, weigh Good potassium fluotitanate is divided into 2 parts.

[0060] (3) Mix the potassium fluoborate and potassium fluotitanate required for each addition evenly, and dry them in a drying oven at 80°C.

[0061] (4) Using a high-purity graphite crucible, melt industrially pure aluminum in a resistance furnace and raise the temperature to 800°C.

[0062] (5) For the first feeding, use the funnel to feed the prepared mixed fluoride salt at a constant speed for 7 minutes, stir with a graphite rod during feeding, and let stand for 15 minutes after feeding....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com