Patents

Literature

347results about How to "Low manufacturing process cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

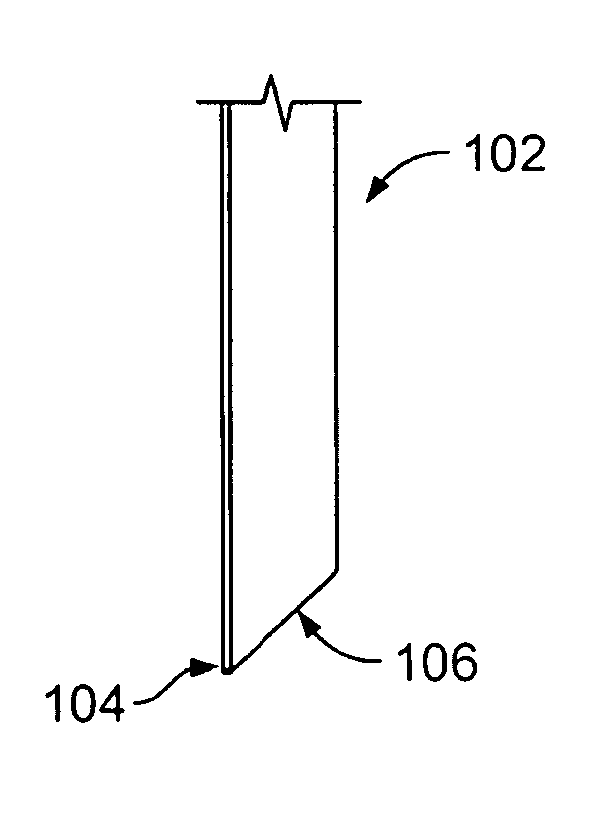

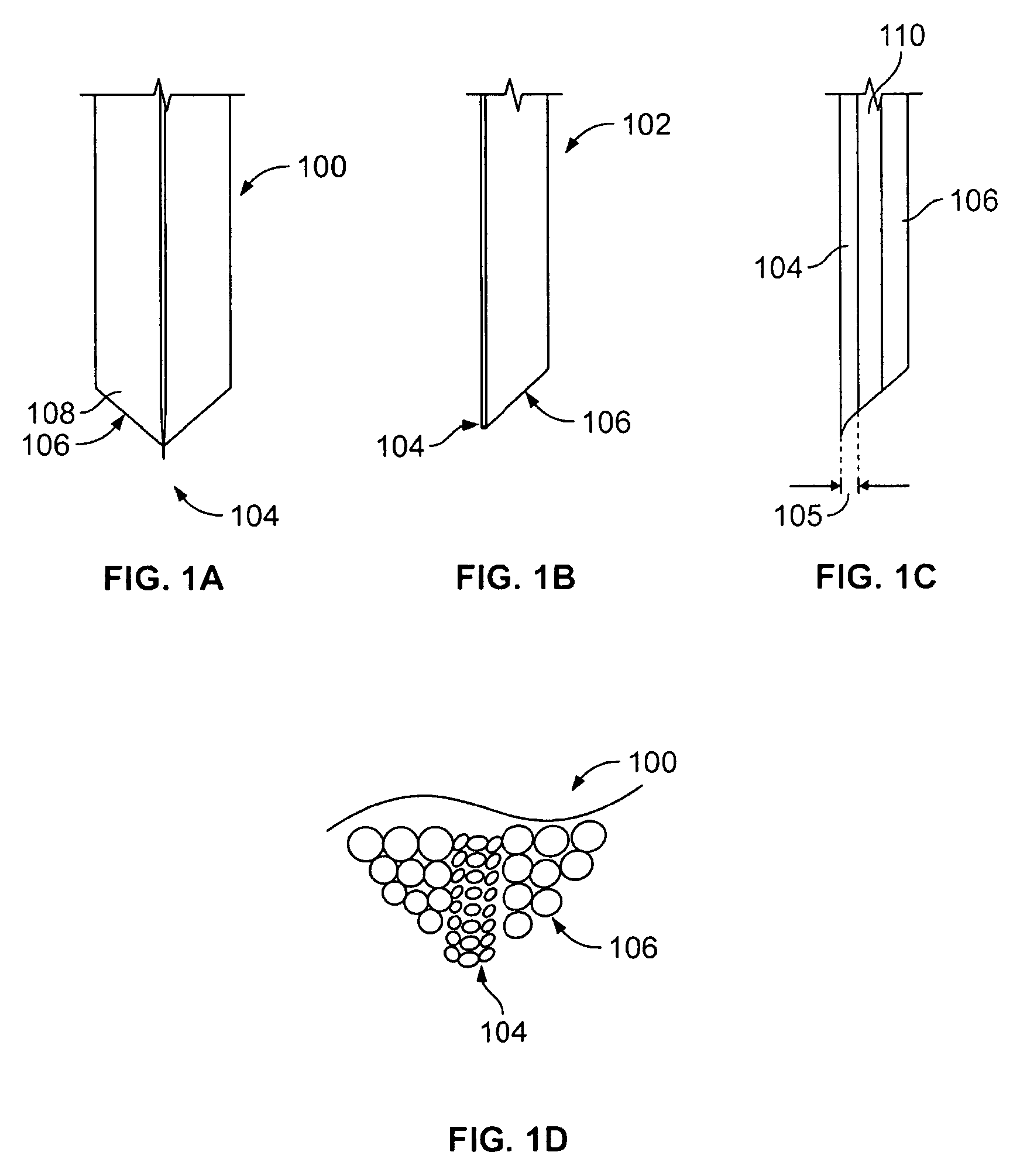

Microsurgical cutting instruments

InactiveUS8499673B2Reduce probabilityLow manufacturing process costIncision instrumentsLapping machinesSurgical bladeKnife blades

The present invention relates to methods and apparatus for self-sharpening micro surgical blades, knives and assemblies including those having a cutting edge that is less than 500 angstroms thick where the cutting edge is an exposed section of a thin planar layer or region that is supported on one or both sides by a material having a higher wear rate.

Owner:MYNOSYS CELLULAR DEVICES INC

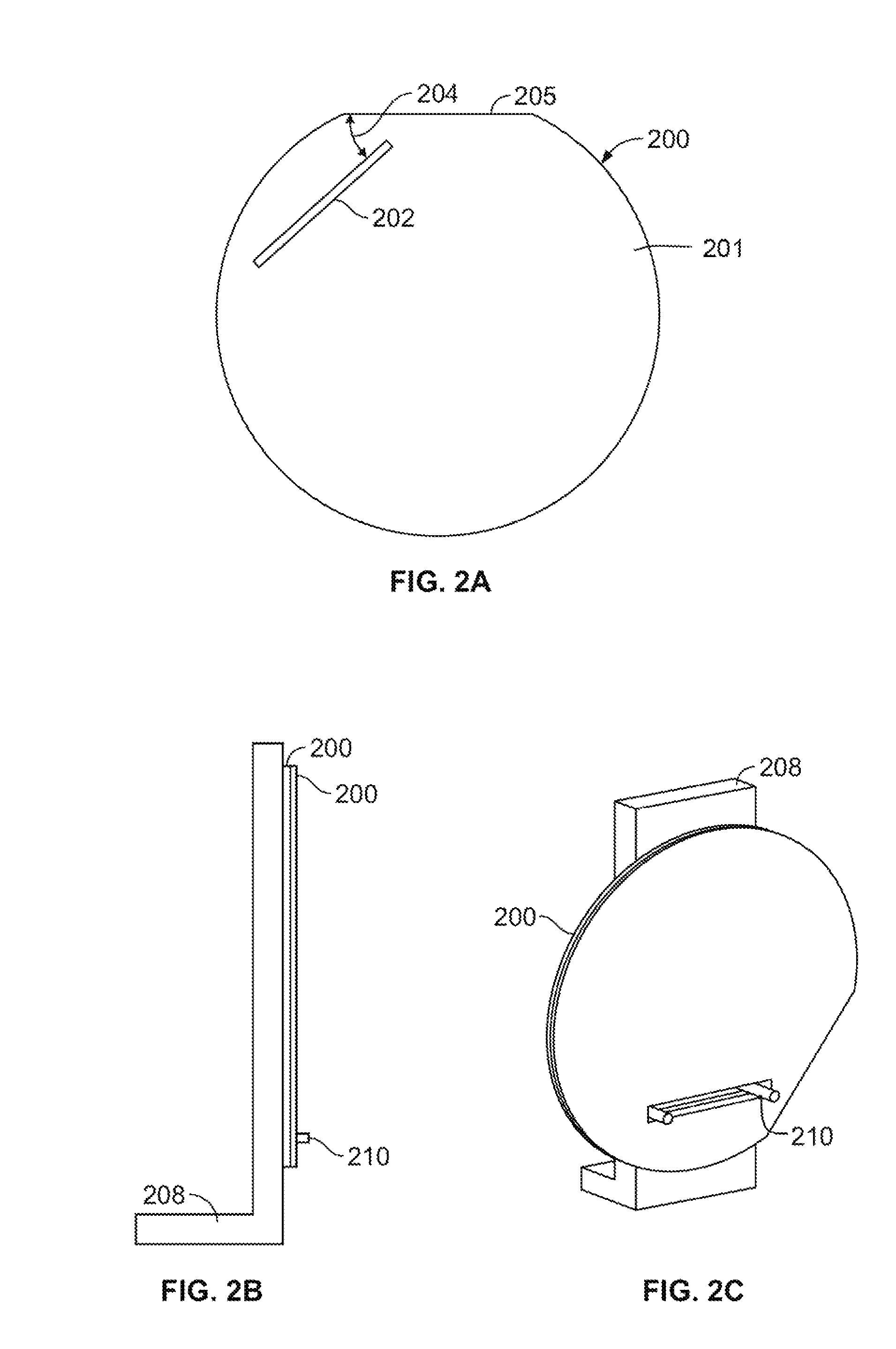

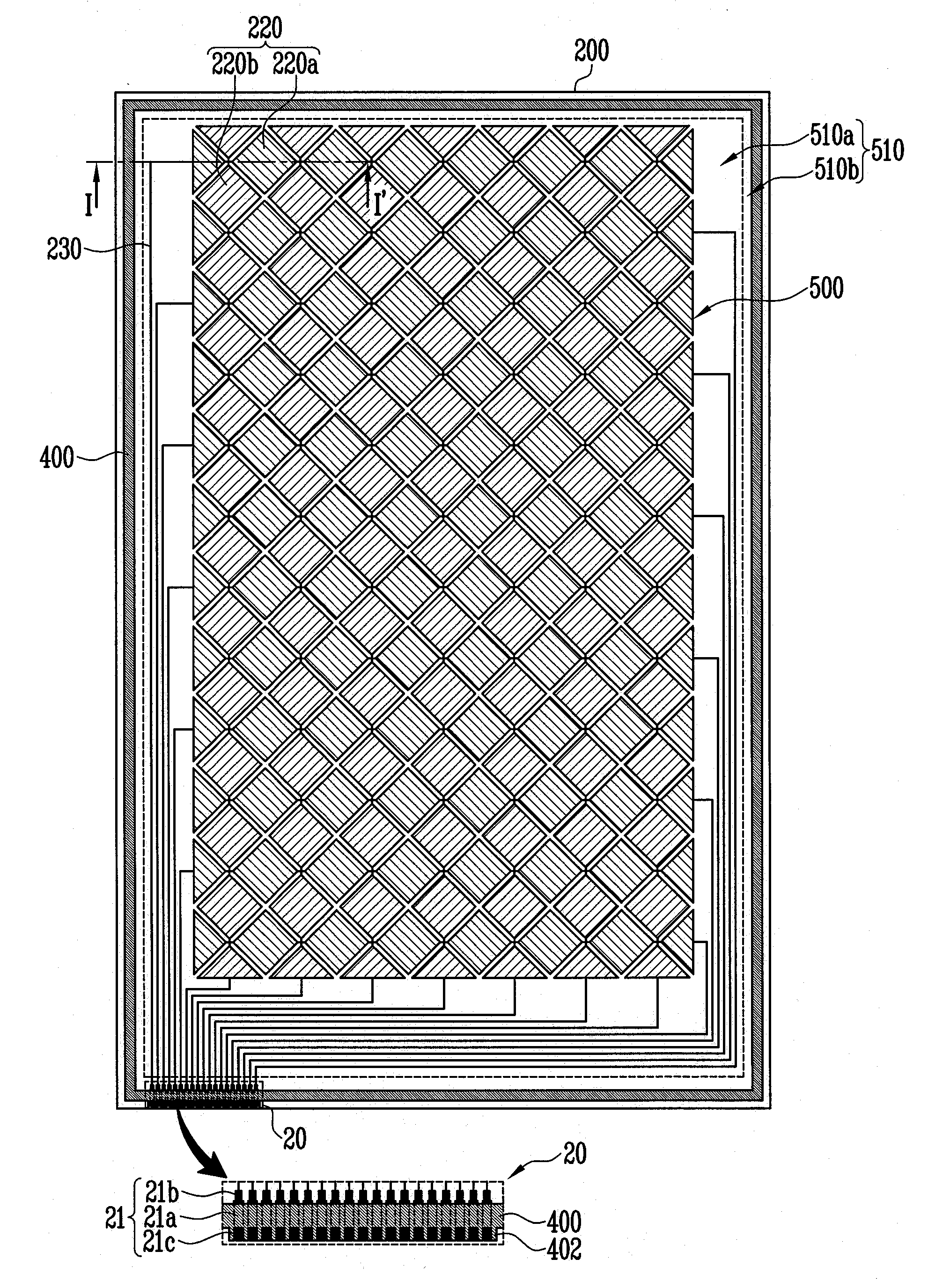

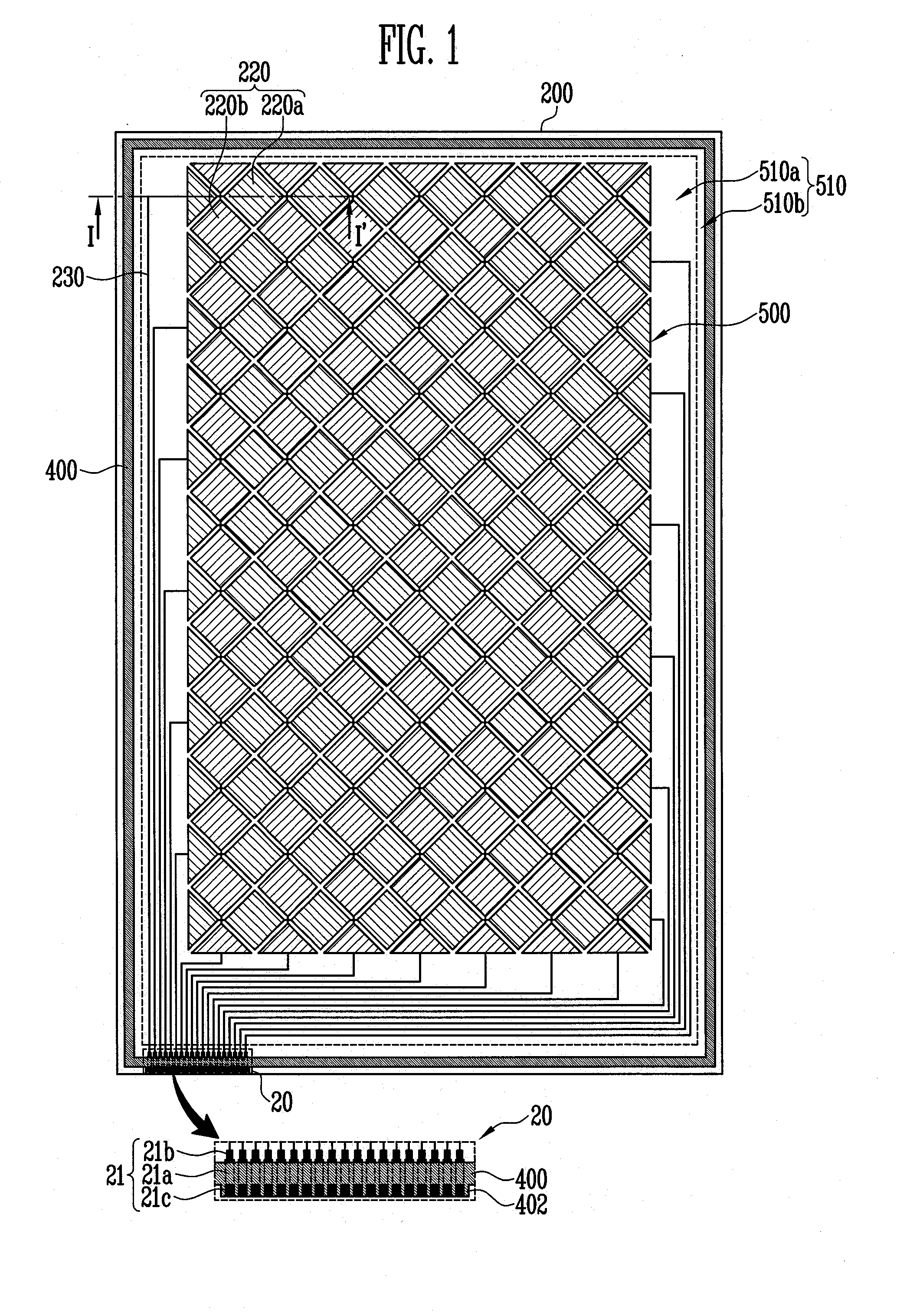

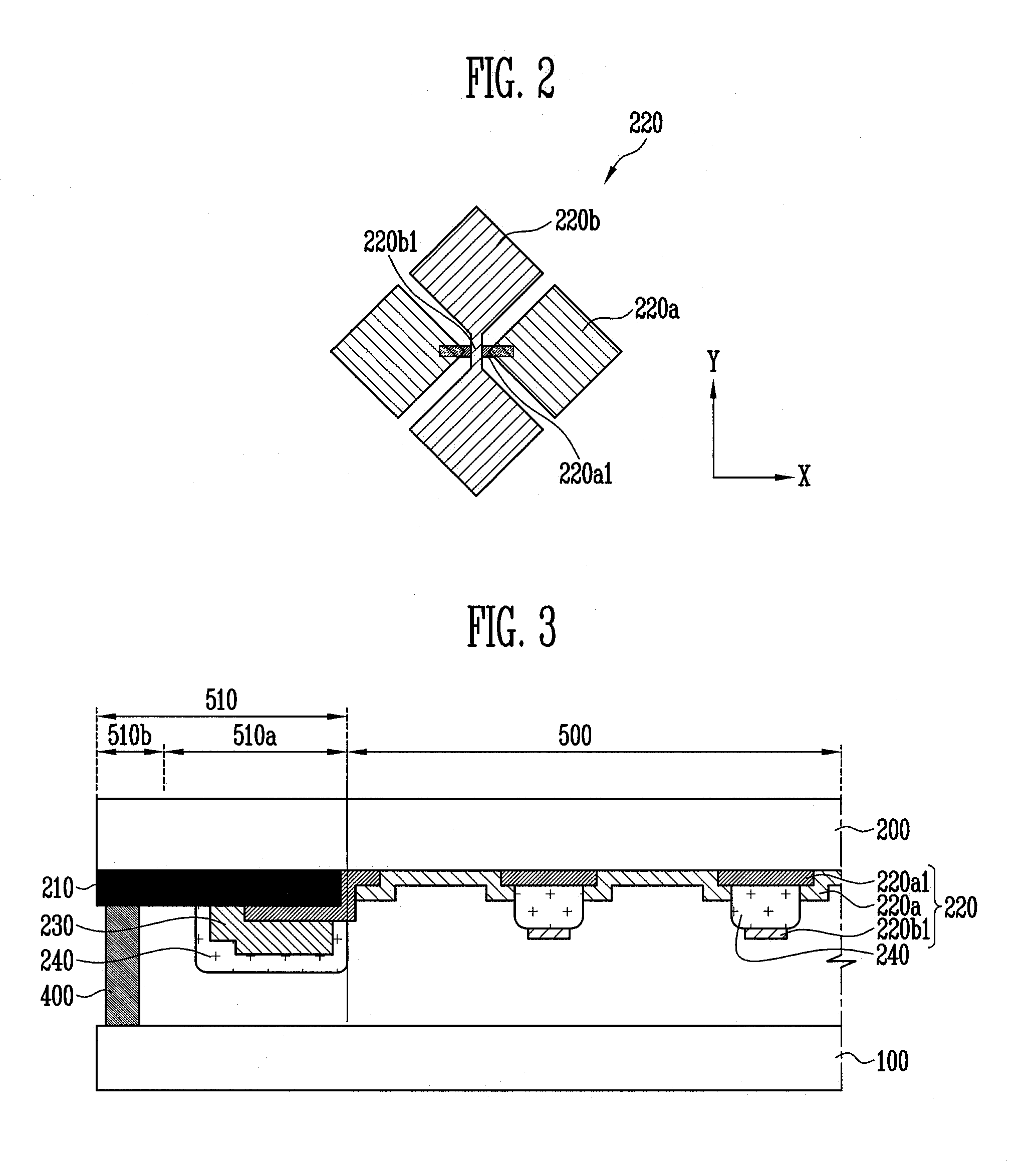

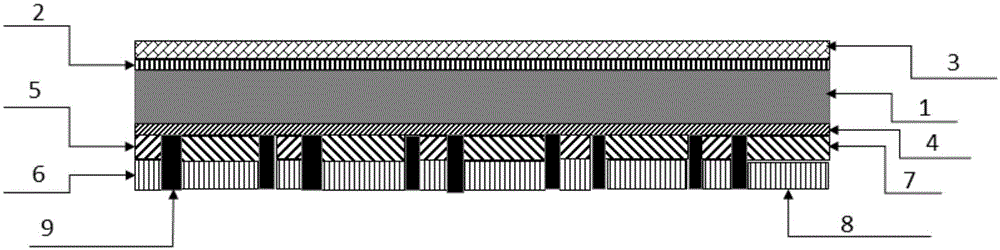

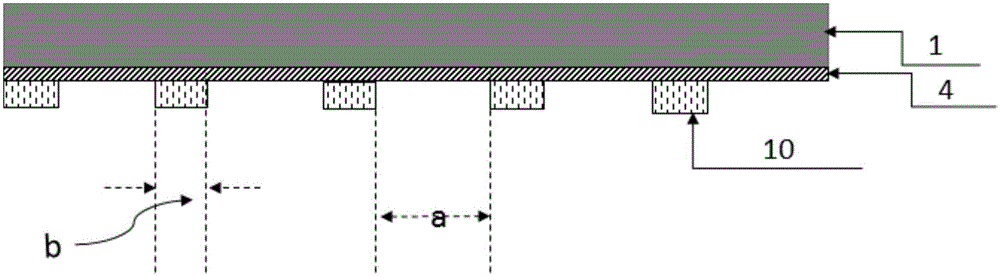

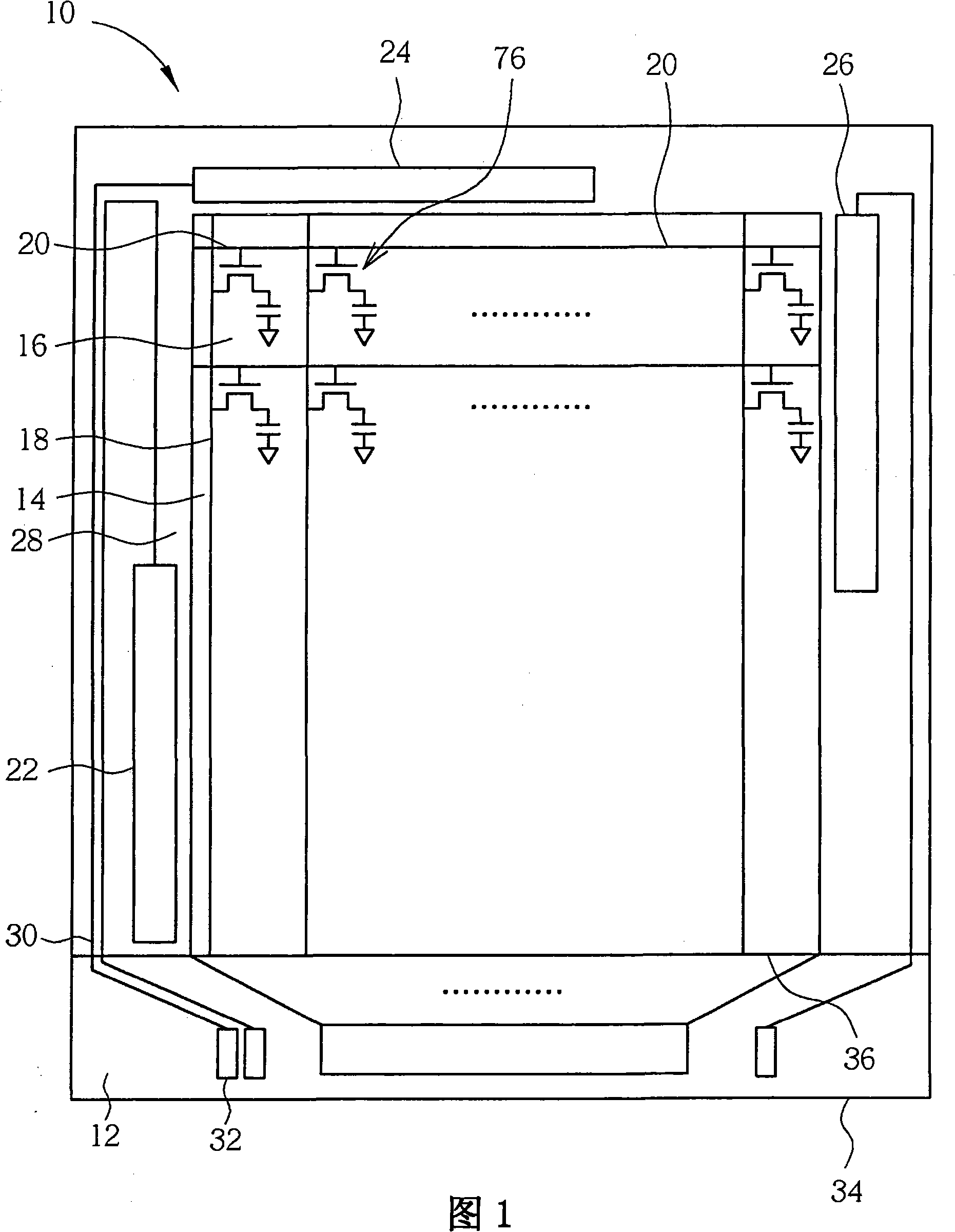

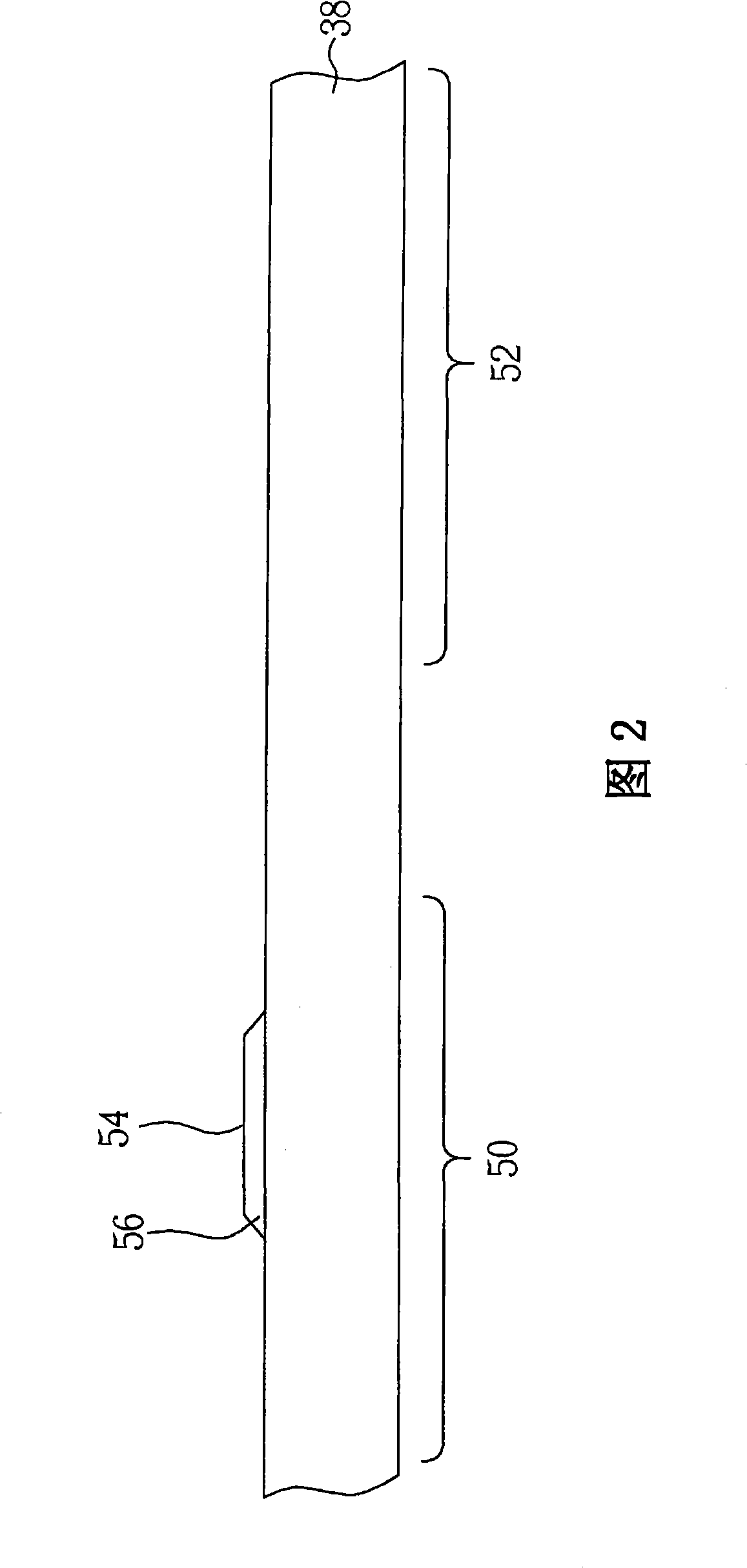

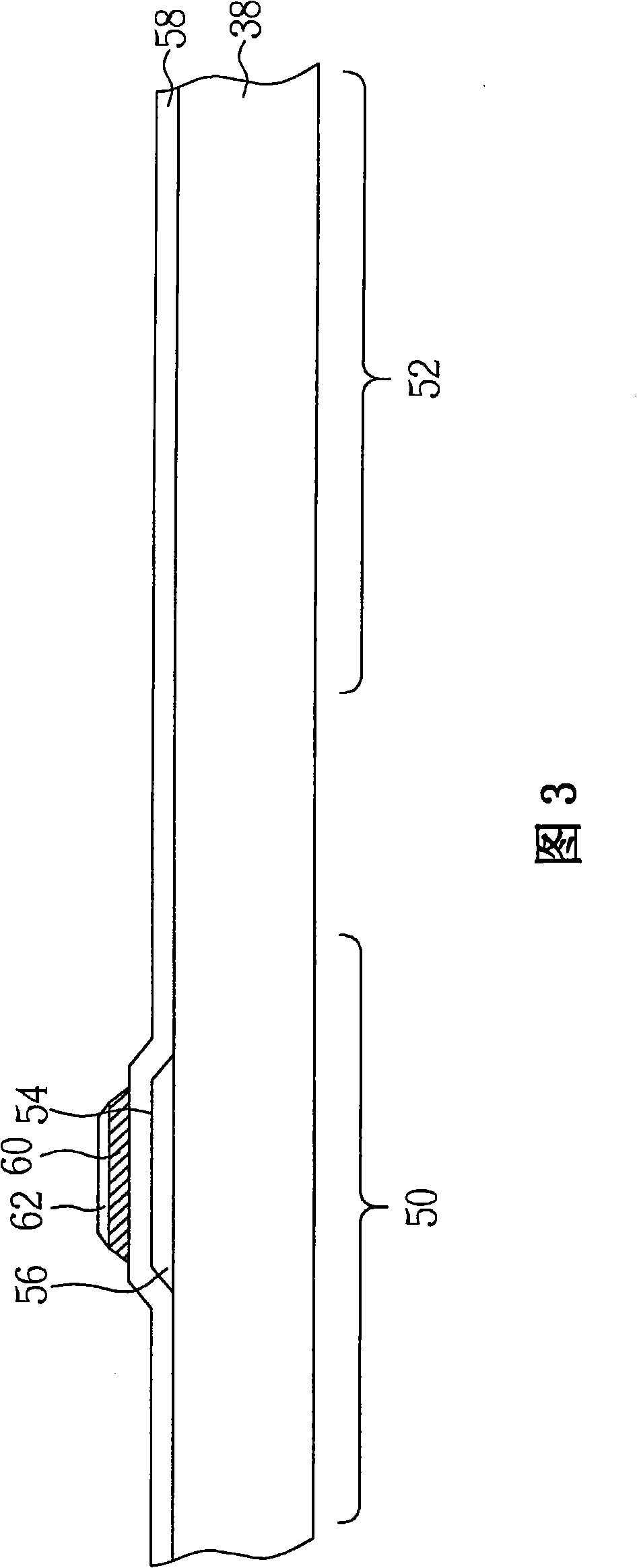

Flat panel display with an integrated touch screen panel

InactiveUS20120127095A1Reduce and minimize thicknessHigh light transmittanceNon-linear opticsInput/output processes for data processingDisplay deviceTouchscreen

A flat panel display with an integrated touch screen panel according to an embodiment of the present invention includes: an upper substrate and a lower substrate; a plurality of sensing patterns in a display region of the upper substrate facing the lower substrate; a plurality of sensing lines coupled with the sensing patterns, respectively, in a first non-display region of the upper substrate; a sensing pad unit including a plurality of sensing pads coupled with the sensing lines, at a second non-display region of the upper substrate; a sealant between the upper substrate and a second non-display region of the lower substrate; seal patterns protruding from and perpendicular to the sealant in a region overlapping the sensing pads, the seal patterns being between the sensing pads; and a plurality of metal patterns at the second non-display region of the lower substrate overlapping the regions between the seal patterns.

Owner:SAMSUNG DISPLAY CO LTD

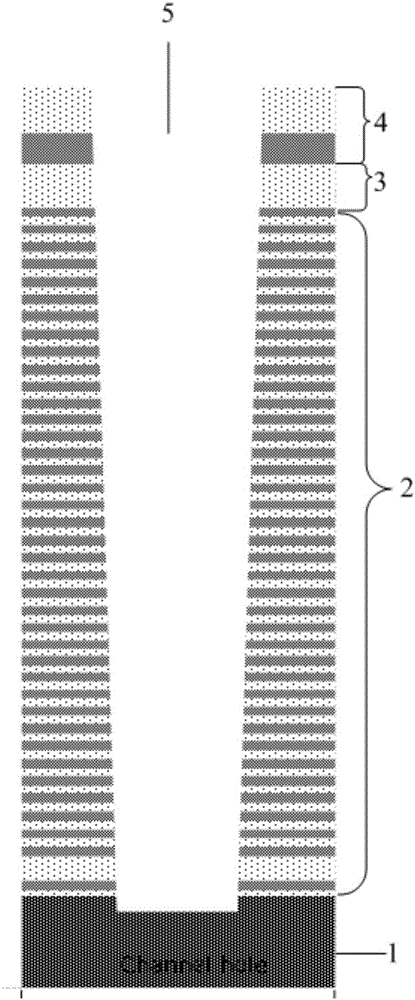

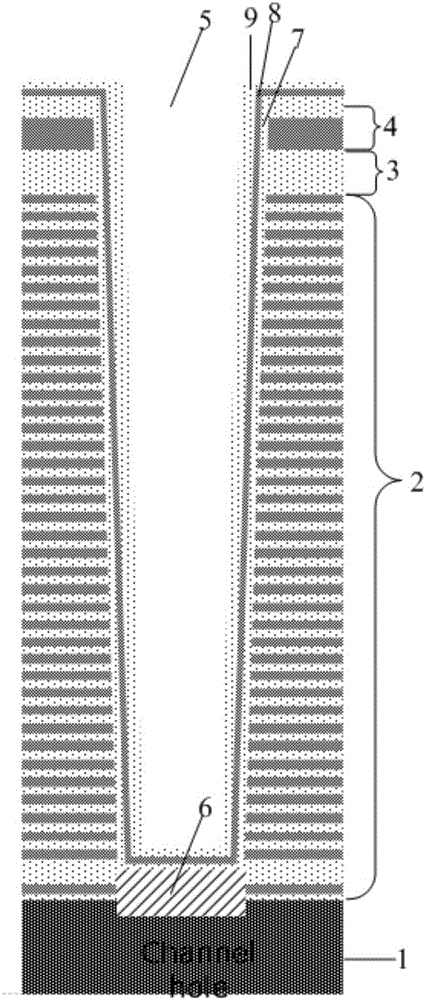

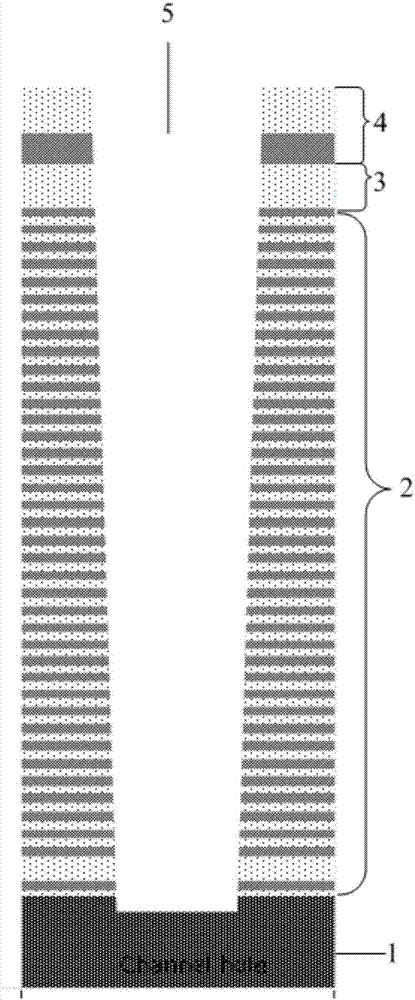

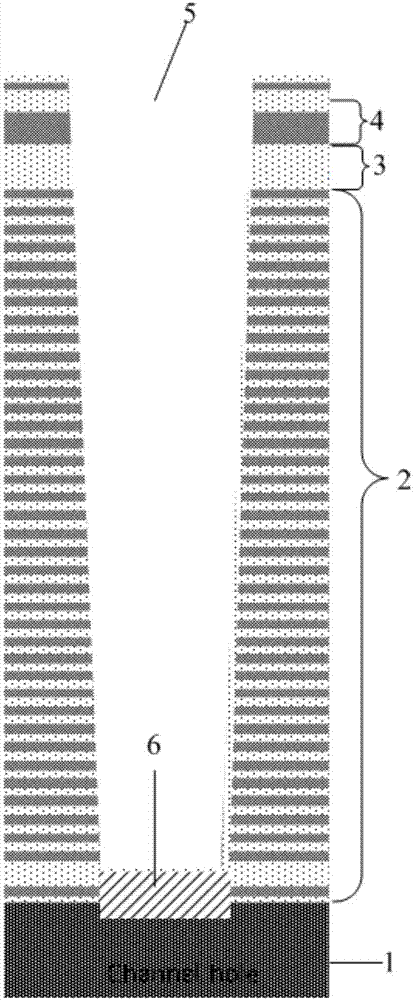

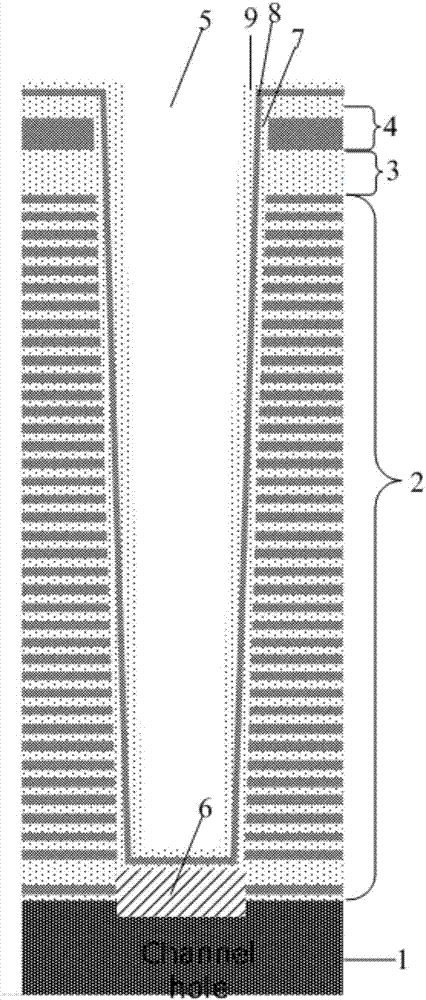

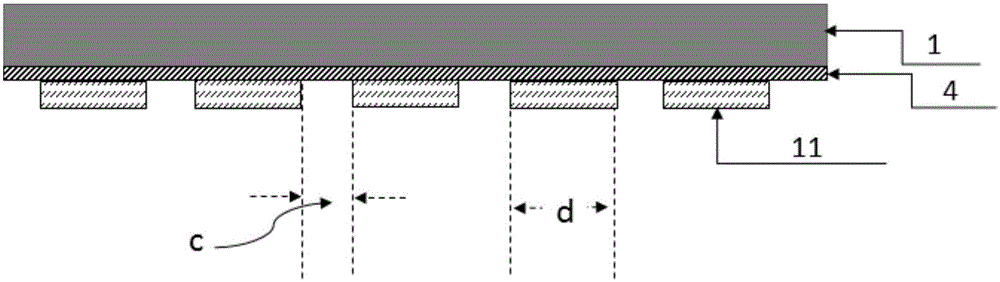

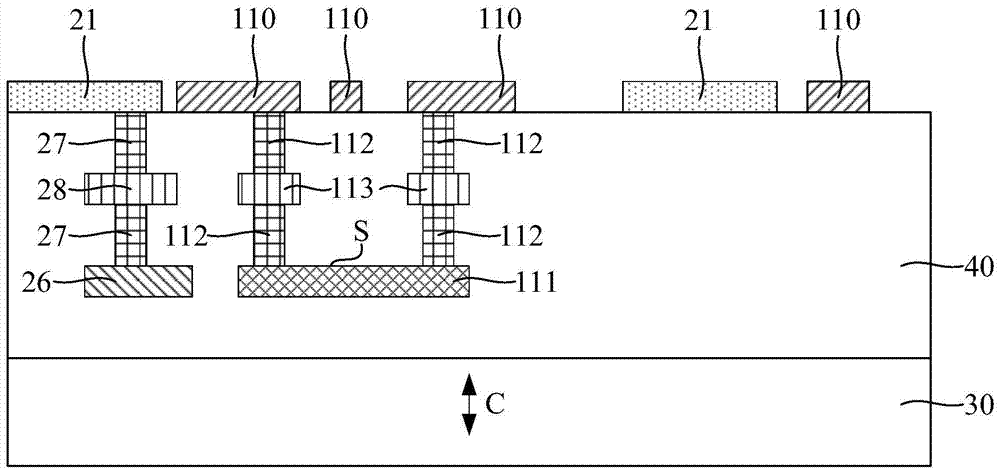

Three-dimensional memory and formation method of channel pore structure thereof

ActiveCN106653684AReduce the difficulty of manufacturing processLow manufacturing process costSemiconductor/solid-state device manufacturingGeomorphologyWidth ratio

The embodiment of the invention discloses a three-dimensional memory and a formation method of a channel pore structure thereof. According to the method, the channel pore structure in the three-dimensional memory is formed through a twice through-hole formation technology of a first through hole and a second through hole, so that the process difficulty and cost of the channel pore structure are greatly reduced, the problems of high process difficulty and high cost caused by ultrahigh through hole depth-to-width ratio under the same caliber are solved, and meanwhile the manufacturing process difficulty and cost of the three-dimensional memory are also reduced.

Owner:YANGTZE MEMORY TECH CO LTD

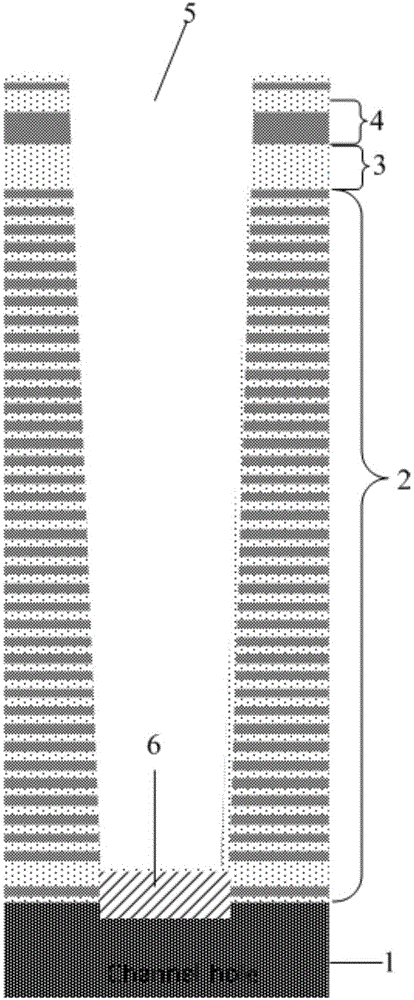

Three-dimensional memory and formation method for channel hole structure of three-dimensional memory

ActiveCN106920772AReduce the difficulty of manufacturing processLow manufacturing process costSolid-state devicesSemiconductor/solid-state device manufacturingWidth ratioEngineering

Embodiments of the invention disclose a three-dimensional memory and a formation method for a channel hole structure of the three-dimensional memory. By implementing two times of a through hole formation process of a first through hole and a second through hole, the channel hole structure in the three-dimensional memory is formed, so that the process difficulty and cost of the channel hole structure can be greatly lowered; the problem of high process difficulty and high cost caused by overhigh depth-to-width ratio of the through holes under the same caliber are solved; and meanwhile, the manufacturing process difficulty and cost of the three-dimensional memory are lowered.

Owner:YANGTZE MEMORY TECH CO LTD

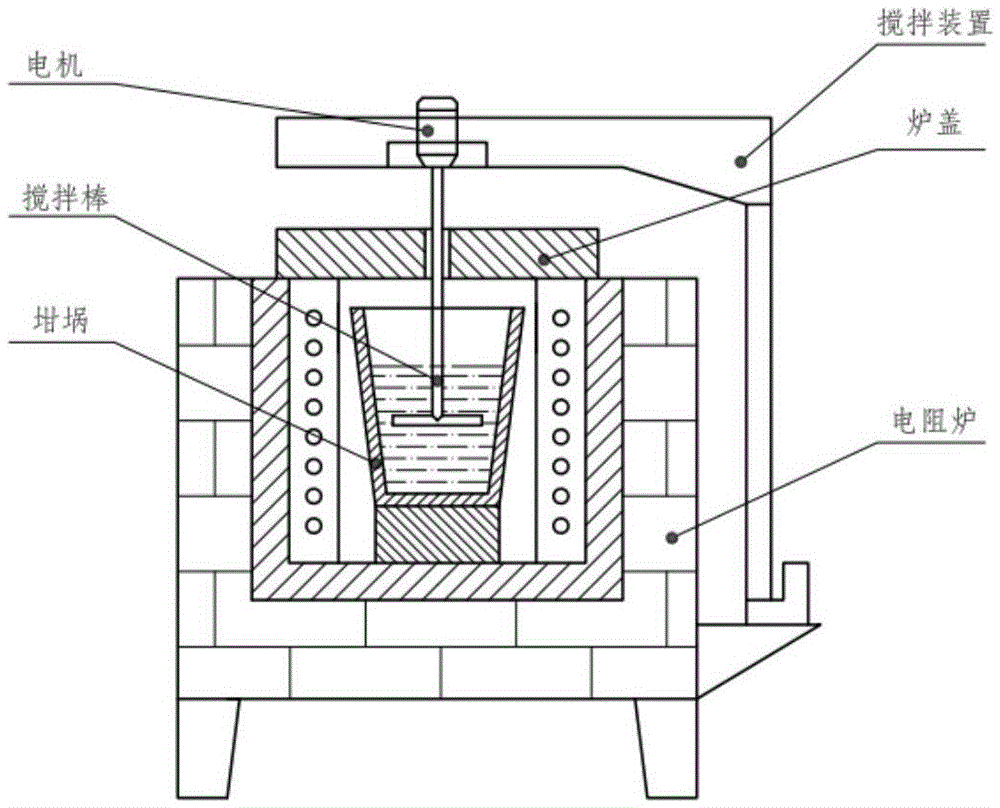

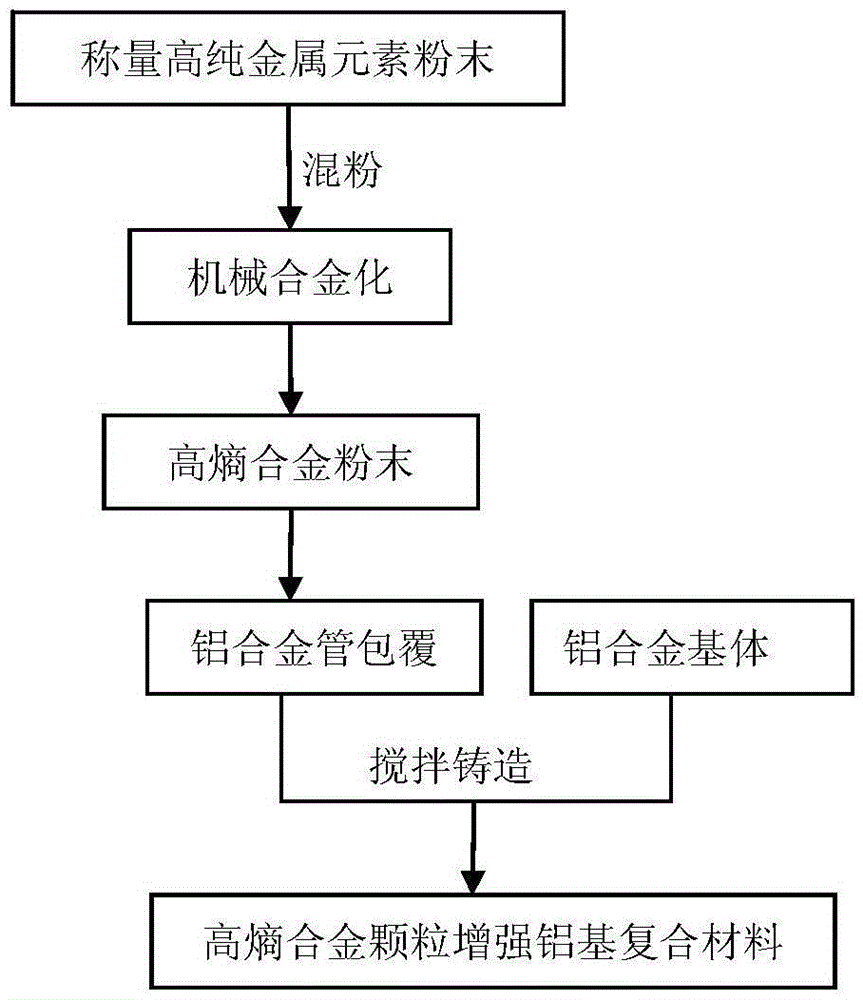

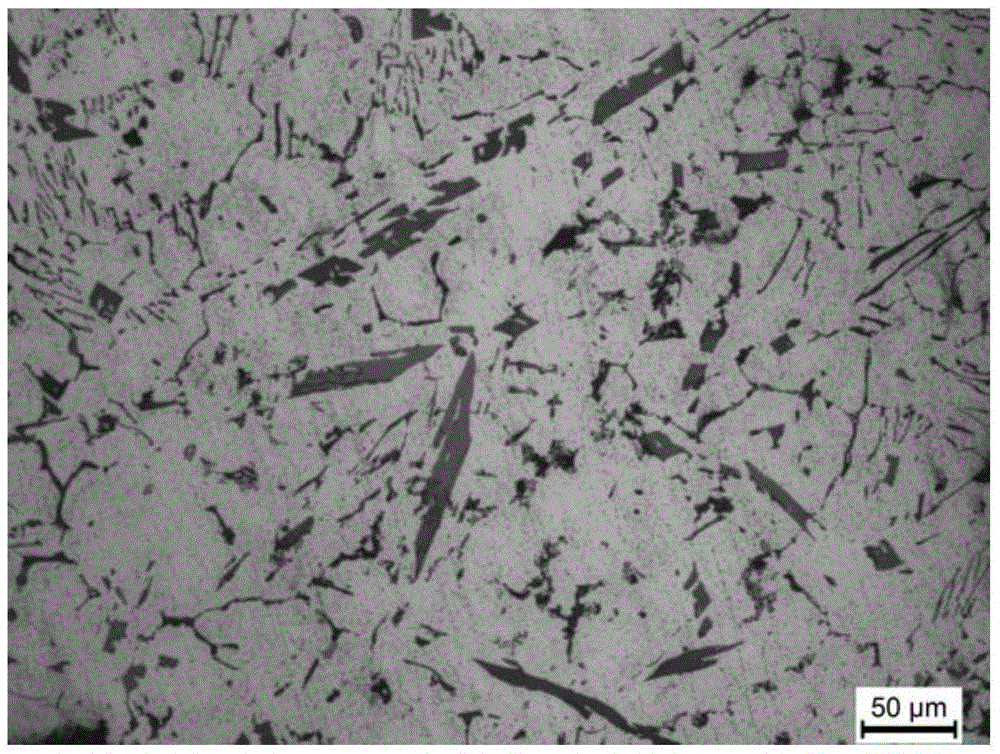

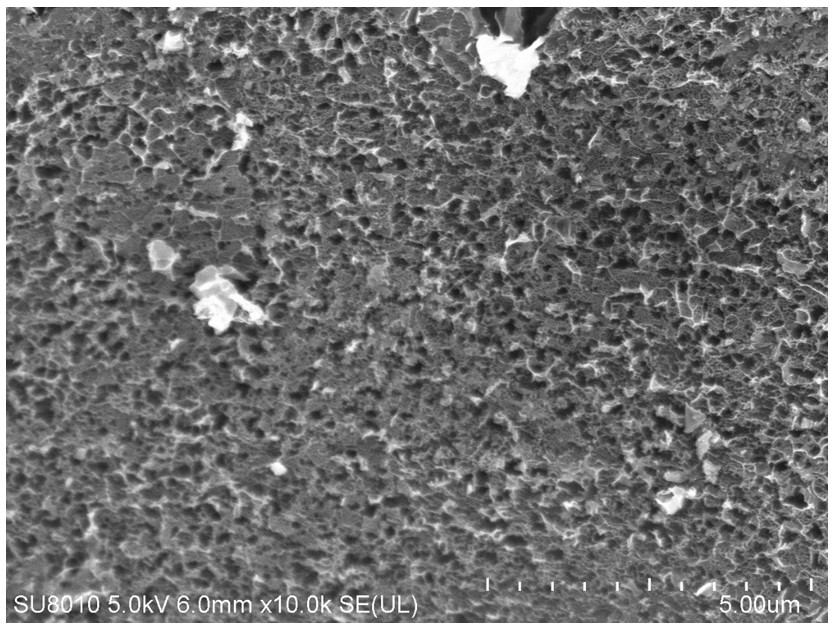

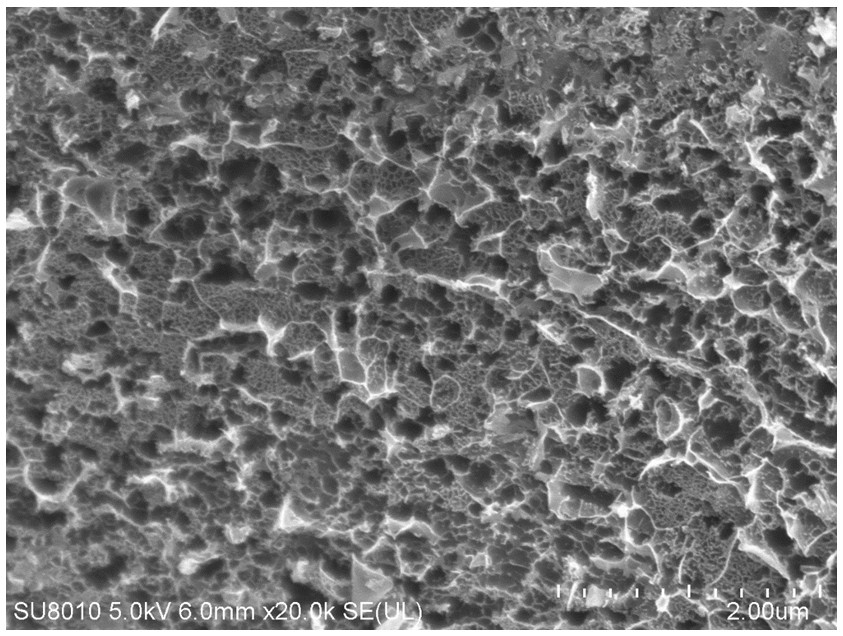

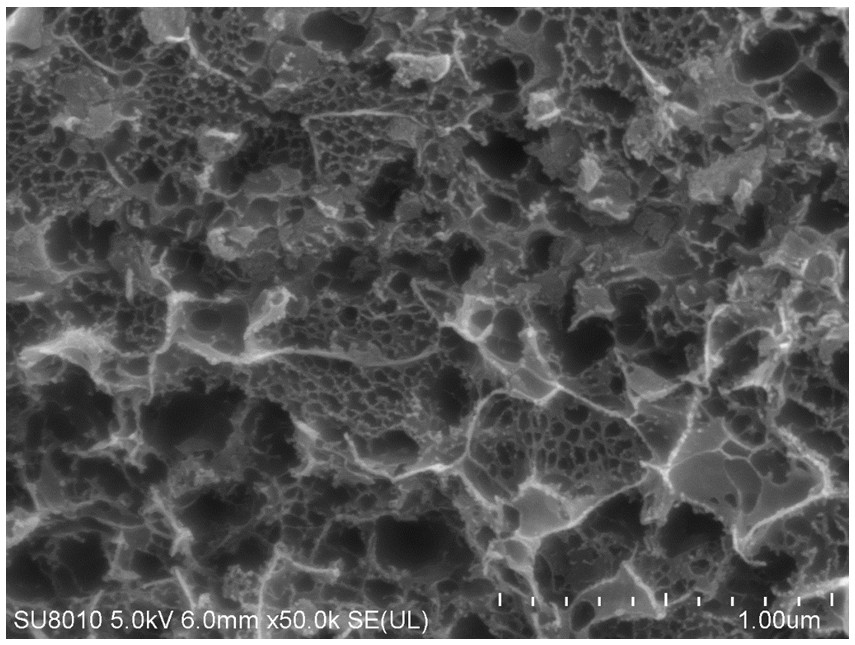

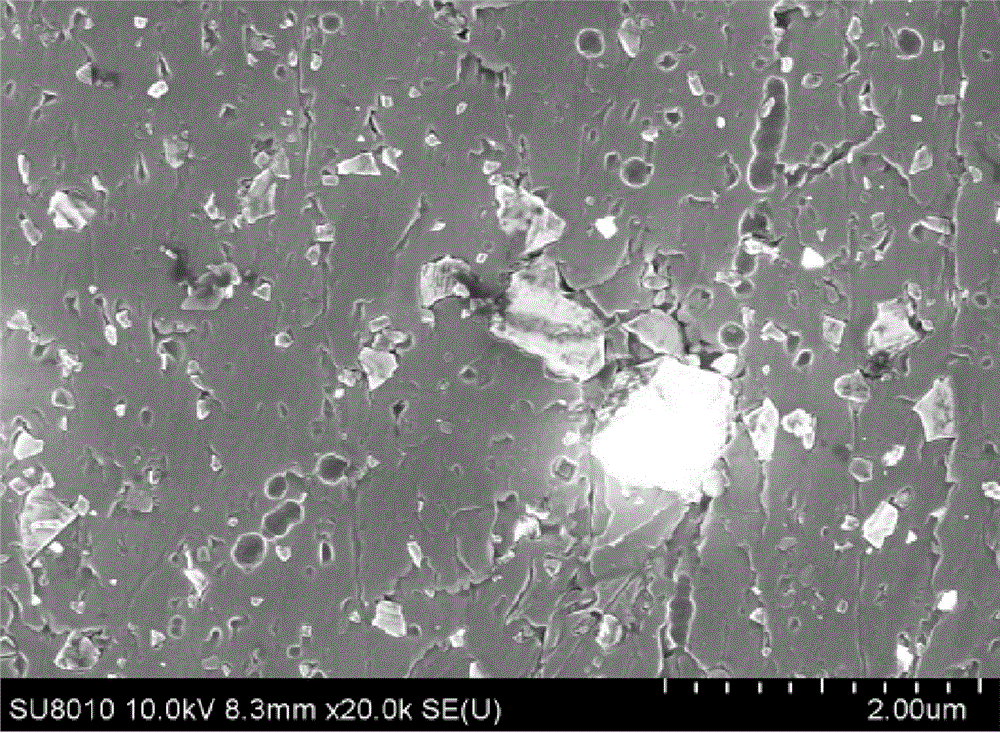

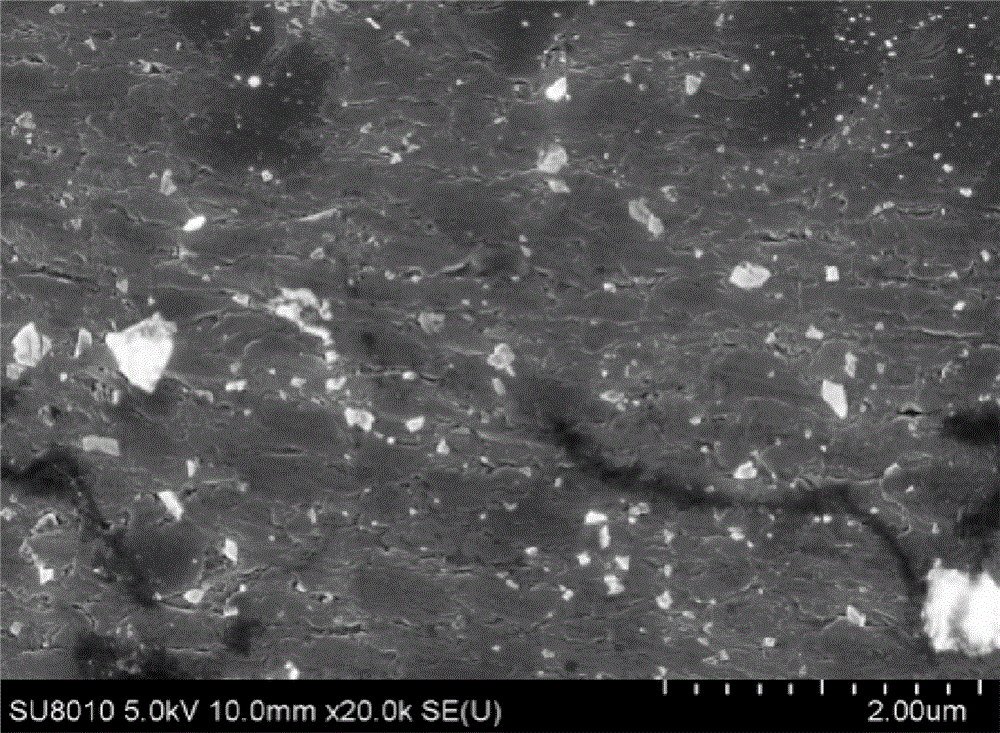

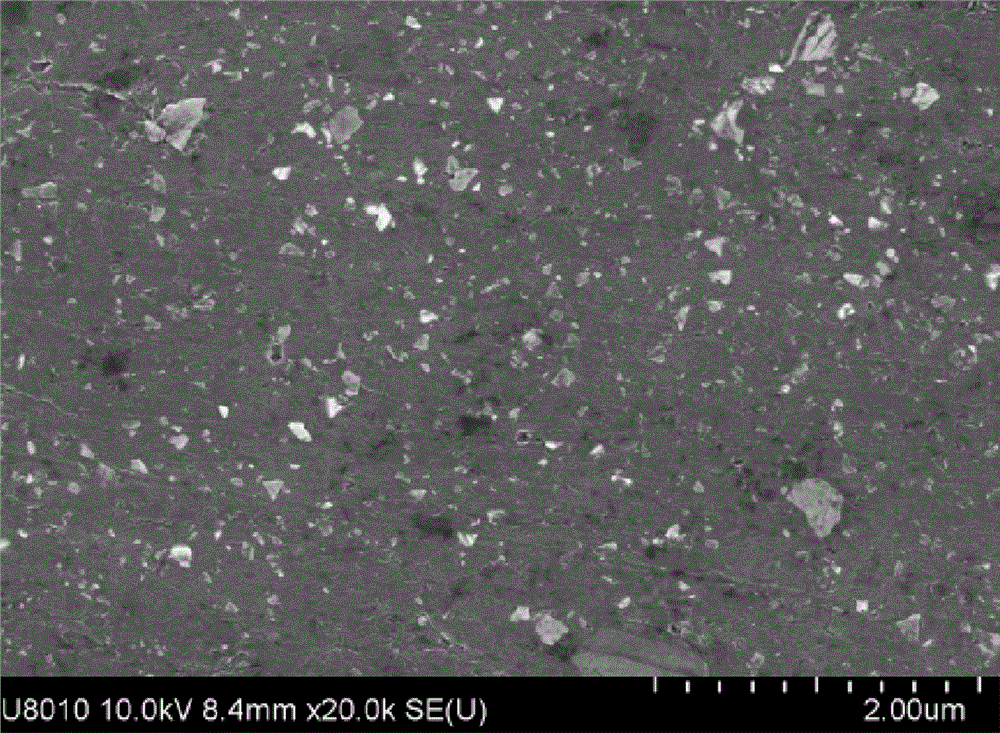

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

Method for preparing magnetic sludge-based biochar material from sludge and application of magnetic sludge-based biochar material

ActiveCN112354516AEasy to separateLarge specific surface areaOther chemical processesSludge treatment by pyrolysisSludgeRed mud

The invention discloses a method for preparing a magnetic sludge-based biochar material from sludge and the application of the magnetic sludge-based biochar material, and belongs to the technical field of sludge resource utilization. The invention aims to fully utilize municipal and industrial wastes such as sewage sludge, hematite, rust, Bayer process red mud, high-iron-content fly ash, picklingwastewater and the like, and prepare magnetic sludge-based biochar from a solid waste iron source: dried sludge with the water content of less than 15% and a solid iron source are mechanically crushedand uniformly mixed; continuous pyrolysis is carried out, the pyrolysis temperature is 400-800 DEG C, the solid material stays in the device for 20-120 min, and fine ball milling and smashing are carried out until the particle size is 100 [mu] m or below; in the nano Fe3O4 / magnetic sludge-based biochar core-shell material prepared by the method, both the material core and the shell have magnetism, so that efficient recycling can be realized.

Owner:SHANGHAI FUTING TECH CO LTD

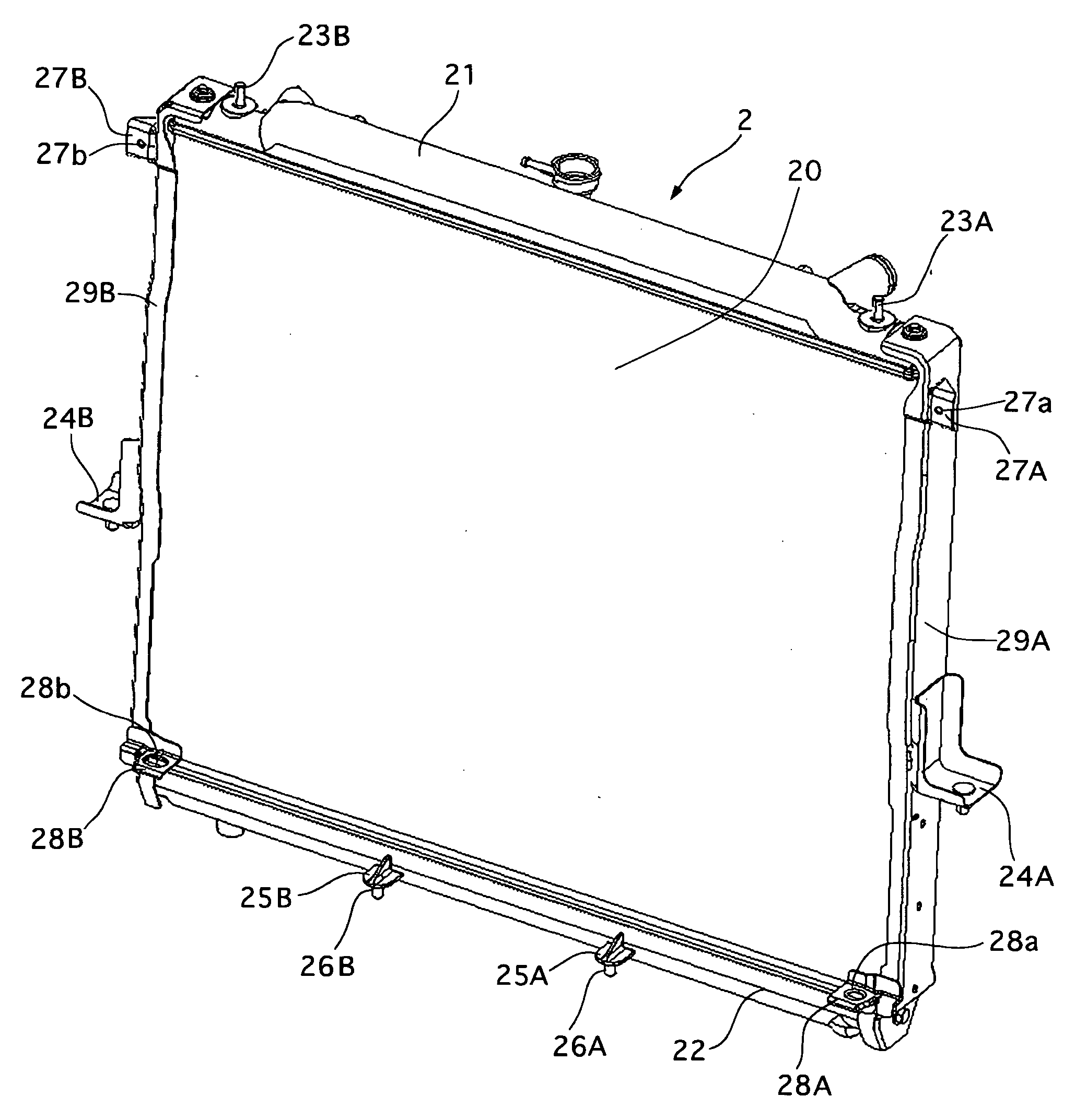

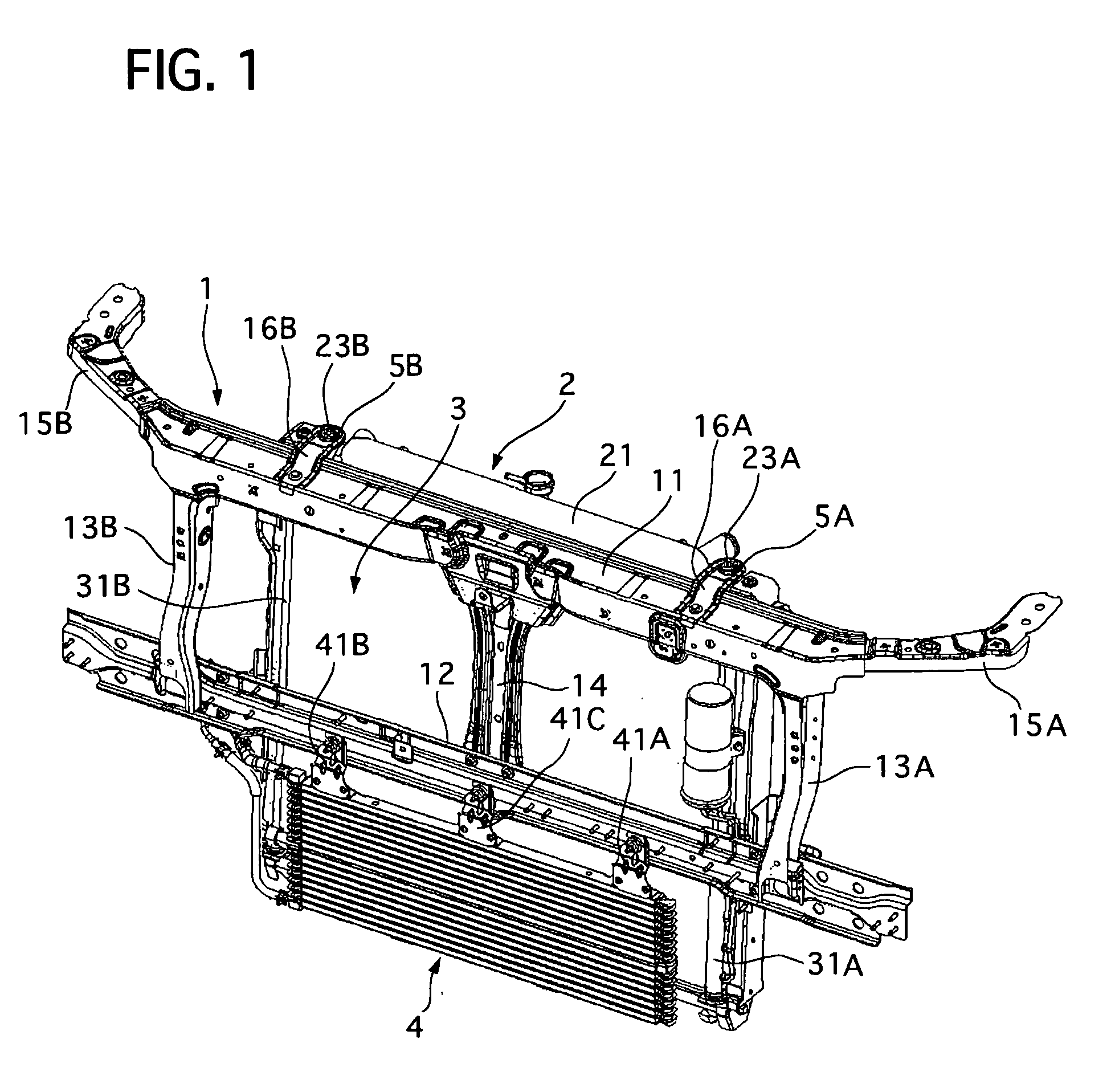

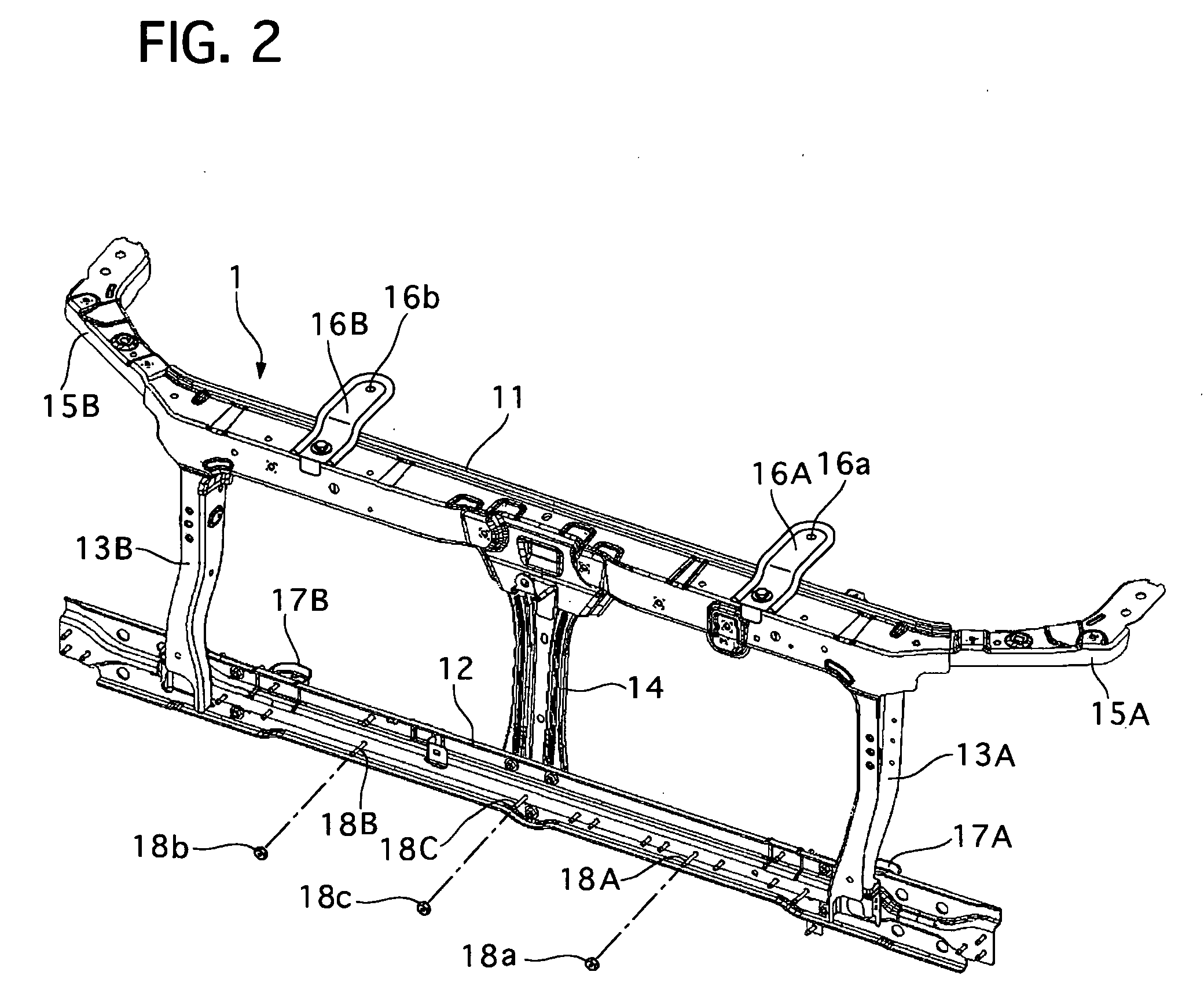

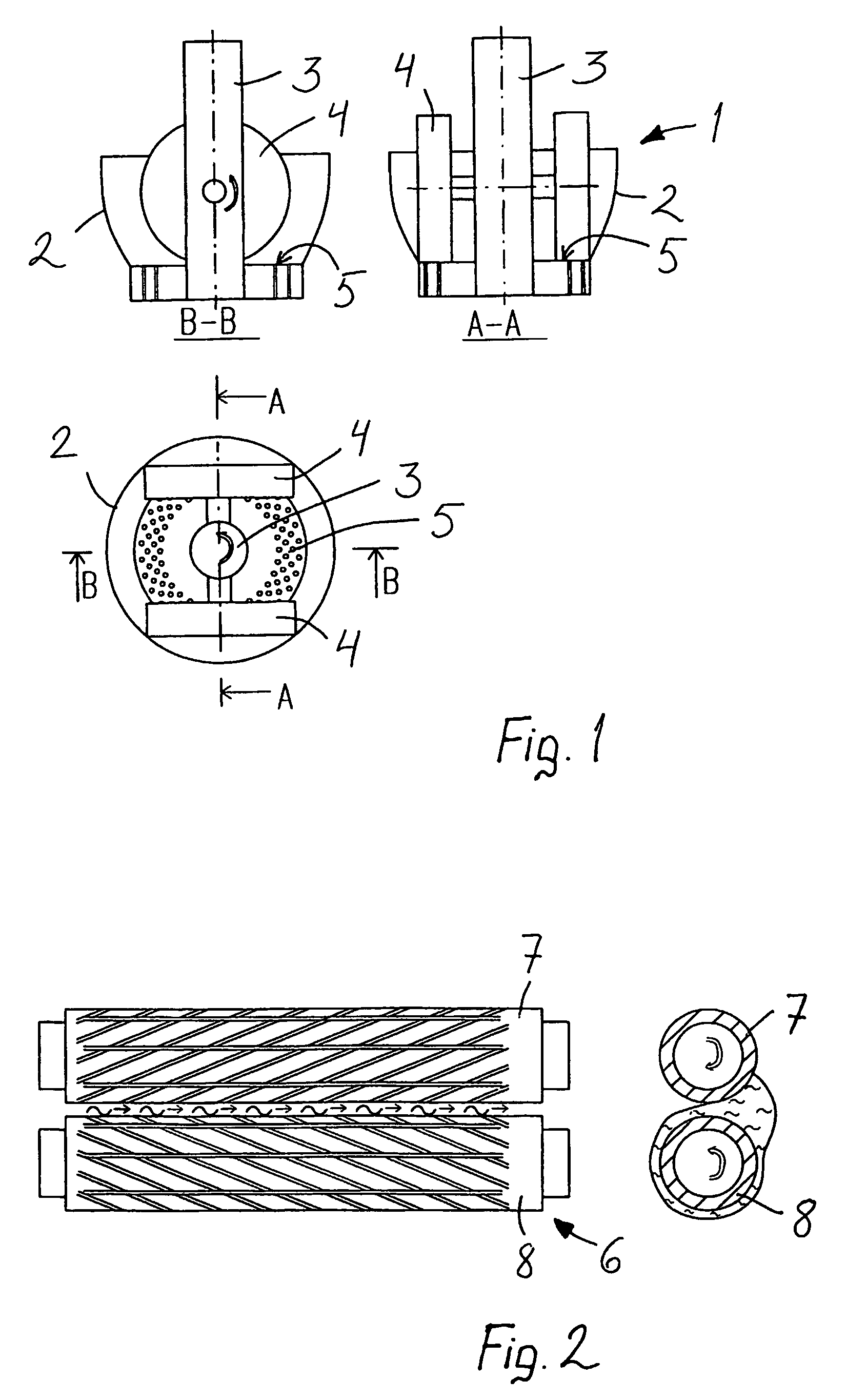

Heat exchanger support structure and heat exchanger supporting method

InactiveUS20060213640A1Reduce manufacturing costLow manufacturing process costLiquid coolingMachines/enginesEngineeringHeat spreader

A heat exchanger support structure has a first heat exchanger, a second heat exchanger, and a radiator core support for supporting the first heat exchanger. The first heat exchanger has a lower supporting pin projecting downward from a lower portion of the first heat exchanger. The second heat exchanger arranged in front of the first heat exchanger and having an upper portion and a lower portion The upper portion is supported by the radiator core support and the lower portion is supported by the lower supporting pin of the first heat exchanger so that the lower supporting pin restricts a horizontal movement of the second heat exchanger and allows a vertical movement of the second heat changer.

Owner:CALSONIC KANSEI CORP

Method for preparing low-density high-performance SiO2 aerogel at constant pressure

The invention discloses a method for preparing low-density high-performance SiO2 aerogel at constant pressure, which comprises the following steps of: performing ion exchange to mixed solution of industrial water glass and deionized water with cation exchange resin by using a two-step method of sol-gel so as to remove Na<+>; adjusting a pH value by using HC1 to obtain sol; keeping stand of the sol and adjusting the pH value by using NH2.H2O to obtain wet gel; carrying out fractional aging and solvent exchange; putting the wet gel into aging liquid which is obtained by mixing ethyl orthosilicate and ethanol for aging; putting the aged wet gel into normal hexane for carrying out solvent exchange; performing surface modification; putting the wet gel subjected to the solvent exchange into mixed liquid of trimethylchlorosilane and normal hexane for performing surface modification; and finally, drying the mixture at the constant pressure and putting the wet gel subjected to the surface modification into normal hexane for drying at the constant pressure. The method has the advantages of low preparation process cost, excellent product performance and controlled reaction process.

Owner:陕西得波材料科技有限公司

Grain refinement and modification master alloy for aluminum and aluminum alloy and method for preparing same

The invention discloses a grain refinement and modification master alloy for aluminum and an aluminum alloy, which comprises the following components by weight percentage: 3.0 to 10.0 percent of titanium, 1.0 to 3.0 percent of boron, 0.5 to 5.0 percent of strontium, 0.5 to 2.0 percent of cerium-enriched rare earth, and the balance of aluminum. The preparation method for the master alloy comprises the following steps: weighting potassium fluotitanate, potassium fluoborate, a mixed rare earth ingot, an alloy, and a pure aluminum ingot in proportion; drying the potassium fluotitanate and the potassium fluoborate; heating and melting the aluminum ingot and the aluminum rare earth ingot, adding the mixture of the potassium fluotitanate and the potassium fluoborate, and stirring until the melted mass is completely reacted; adding a Al-Sr master alloy, stirring, and performing heat preservation and slagging off; adding hexachloroethane and evenly stirring; and standing, performing heat preservation for 20 to 30 minutes, casting into an ingot and then extruding into a wire. The master alloy can be well combined with an interface of an aluminum matrix; the particle phase is evenly distributed; the grain size of the refinement phase is small; the activated Sr is enough to ensure the following modification; the conglobation of the refinement phase is effectively reduced, and the degradation is inhibited; and the preparation process is low in cost.

Owner:广州工业投资控股集团有限公司 +1

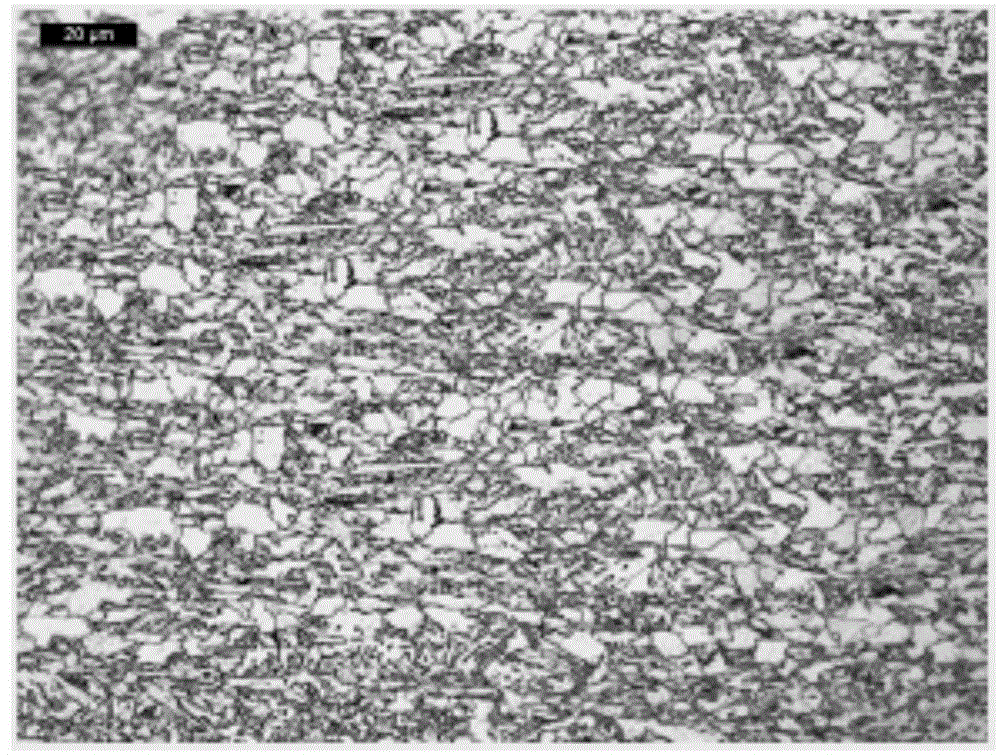

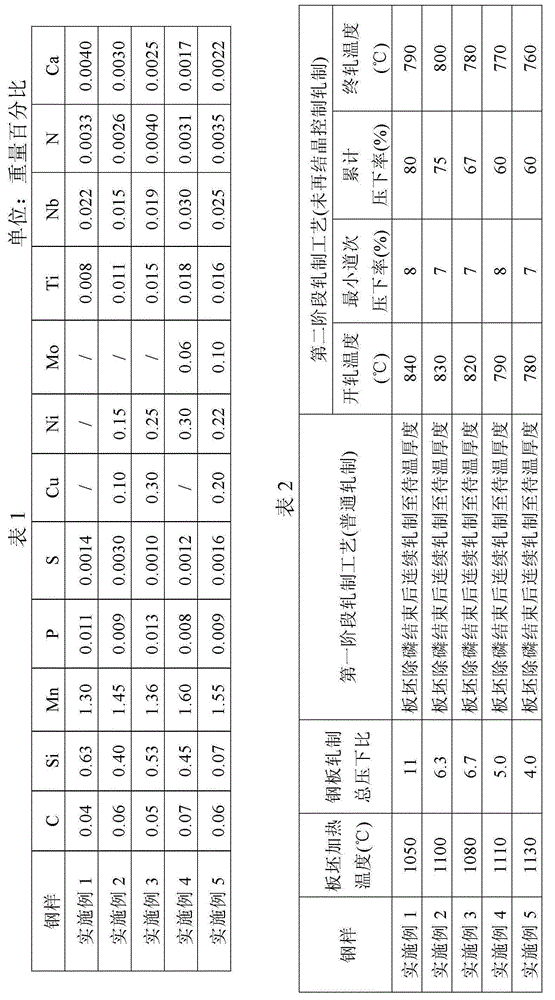

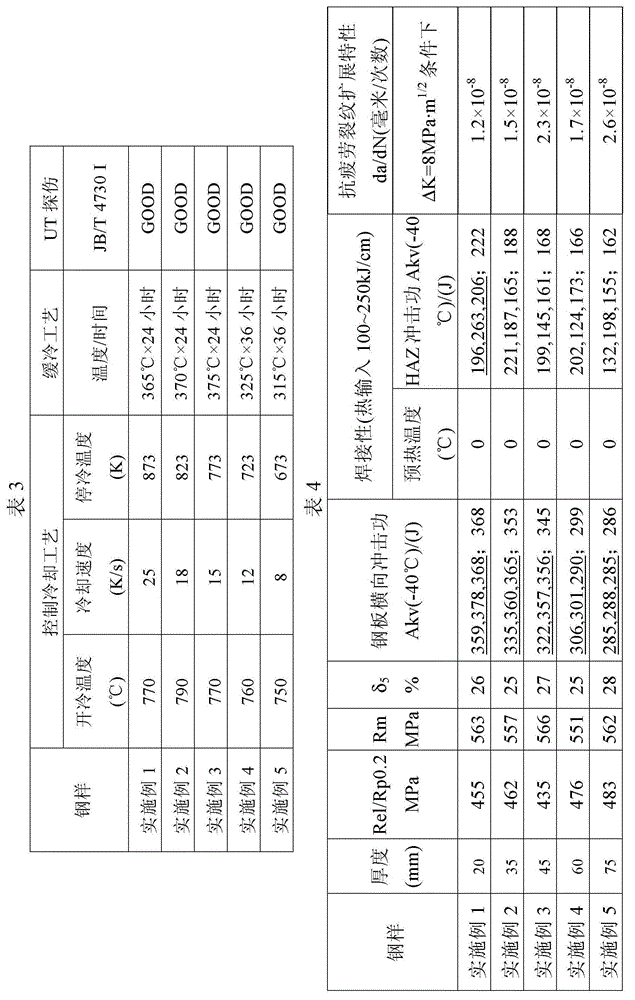

High-quality steel plate capable of resisting fatigue crack growth and manufacturing method thereof

ActiveCN104561796AShorten the manufacturing cycleIncrease added valueFurnace typesHeat treatment furnacesMetallurgyImpurity

The invention discloses a high-quality steel plate capable of resisting fatigue crack growth and a manufacturing method thereof. The high-quality steel plate comprises the following constituents in percentage by weight: 0.040-0.070% of C, 0.40-0.70% of Si, 1.30-1.60% of Mn, less than or equal to 0.013% of P, less than or equal to 0.003% of S, less than or equal to 0.30% of Cu, less than or equal to 0.30% of Ni, less than or equal to 0.10% of Mo, 0.008-0.018% of Ti, 0.015-0.030% of Nb, less than or equal to 0.0040% of N, 0.0010-0.0040% of Ca, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps: using the ultra-low carbon C-high Si-intermediate Mn-Nb system low alloy steel as a base, controlling [%C]*[%Si] to be 0.022-0.042 and {([%C]+3.33[%Nb])*[%Si]}*V cooling velocity / T cold shutdown to be from 1.15*10<-4> to 2.2*10<-3>, carrying out Ca treatment, enabling Ca / S to be equal to 1.0-3.0 and (%Ca)*(%S)<0.28> to be smaller than or equal to 1.0*10<-3>, optimizing the TMCP technology, enabling the finished product steel plate microscopic structure to become a ferrite and uniformly dispersed bainite dual-phase structure, and allowing the average grain size of the microscopic structure to be 10 microns below.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

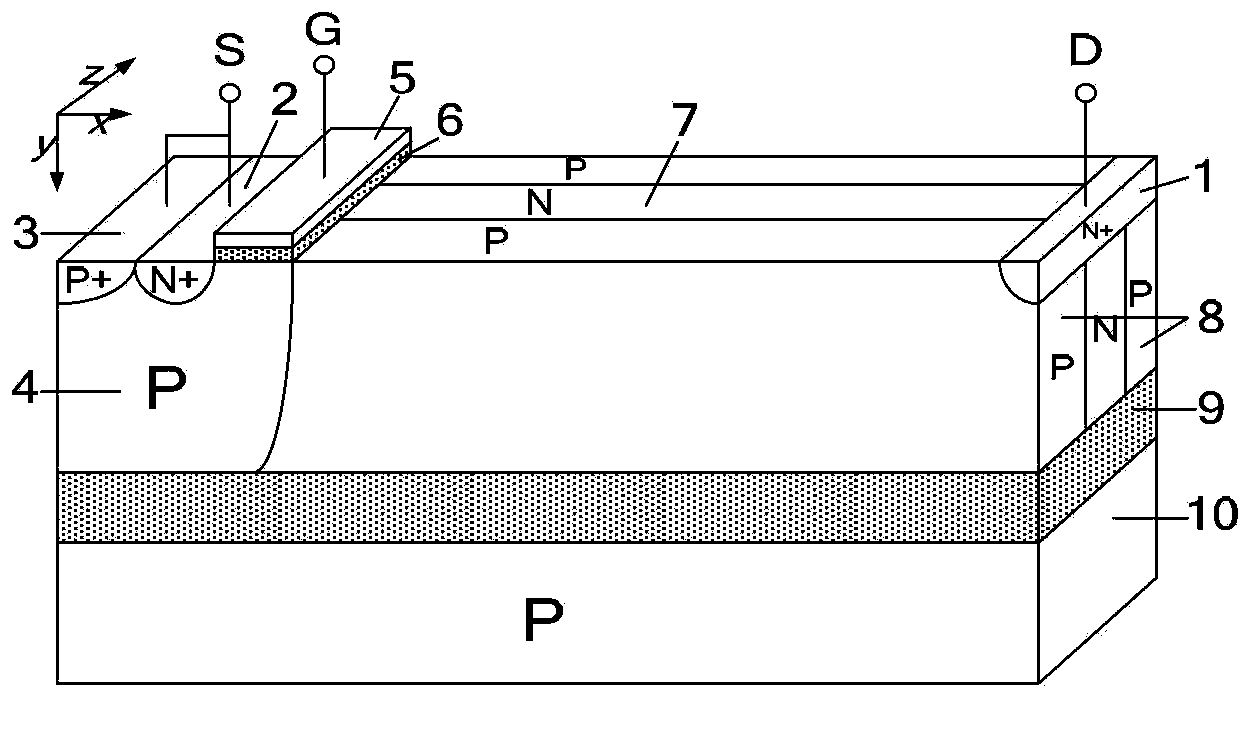

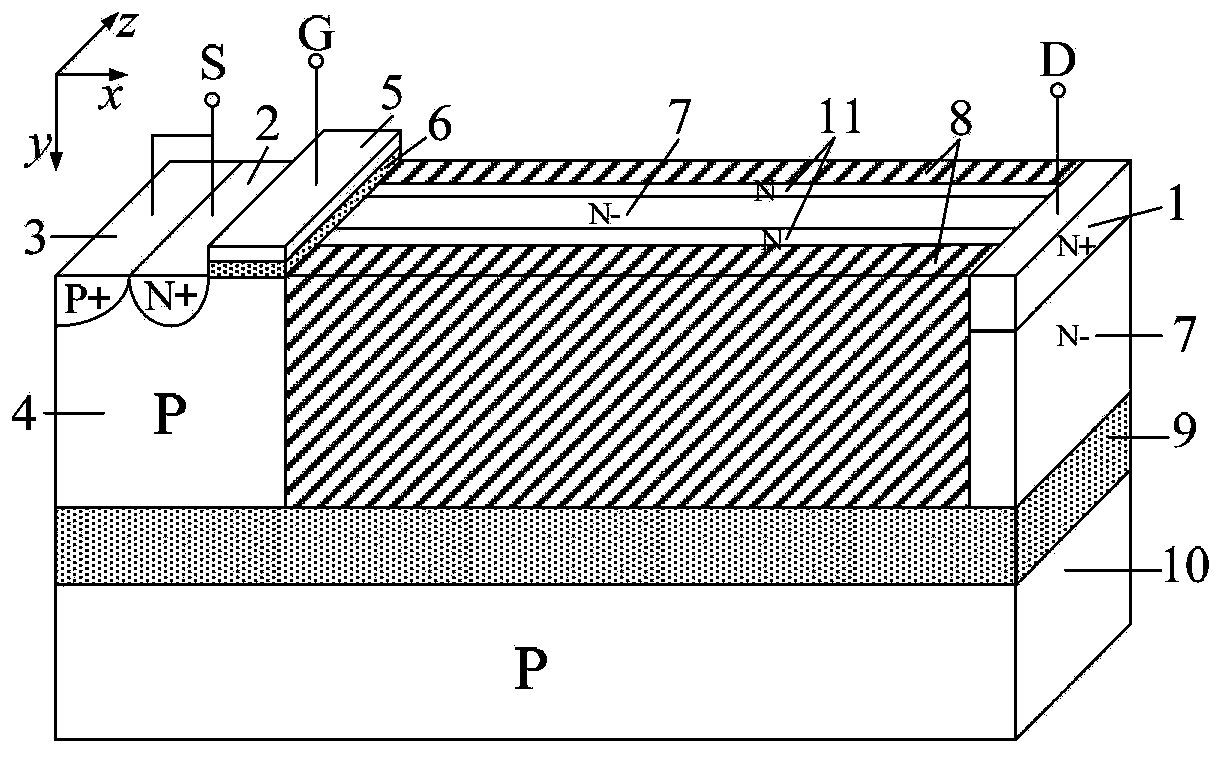

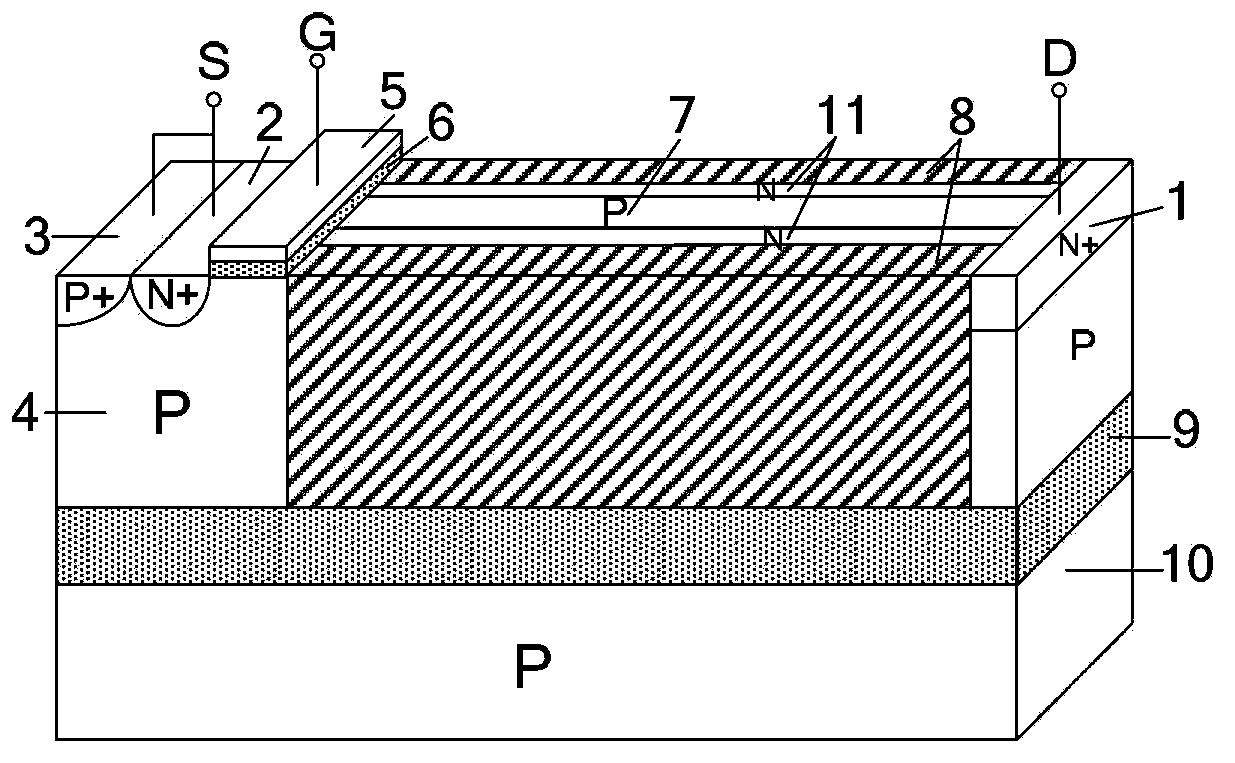

Lateral direction SOI power semiconductor device

InactiveCN103441147AIncrease the doping concentrationLower on-resistanceSemiconductor devicesPower semiconductor deviceMedia layer

The invention provides a lateral direction SOI power semiconductor device, and belongs to the technical field of power semiconductor devices. The cellular structure of the lateral direction SOI power semiconductor device comprises a substrate, an insulating dielectric layer and a device active layer arranged on the insulating medium layer, wherein the device active layer comprises a source region, a drain region, grids and a drift region. The drift region between the source region and the drain region is a sandwich structure formed by sandwiching a second semiconductor doping region between two first semiconductor doping regions parallel to the lateral direction of the device, the conduction type of the first semiconductor doping regions is different from that of a first conduction type semiconductor region in a source region structure, and the outer side faces of the two first semiconductor doping areas are respectively provided with a high k dielectric layer. The lateral direction SOI power semiconductor device can remit the substrate-assisted depletion effect existing in lateral direction super junction SOI power semiconductor devices, is free of the problem that charge balance of a super junction structure needs to be taken into consideration in the super junction power semiconductor devices, has higher reverse voltage resistant performance and lower forward on-resistance, and is relatively low in difficulty and cost of the manufacturing technology.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

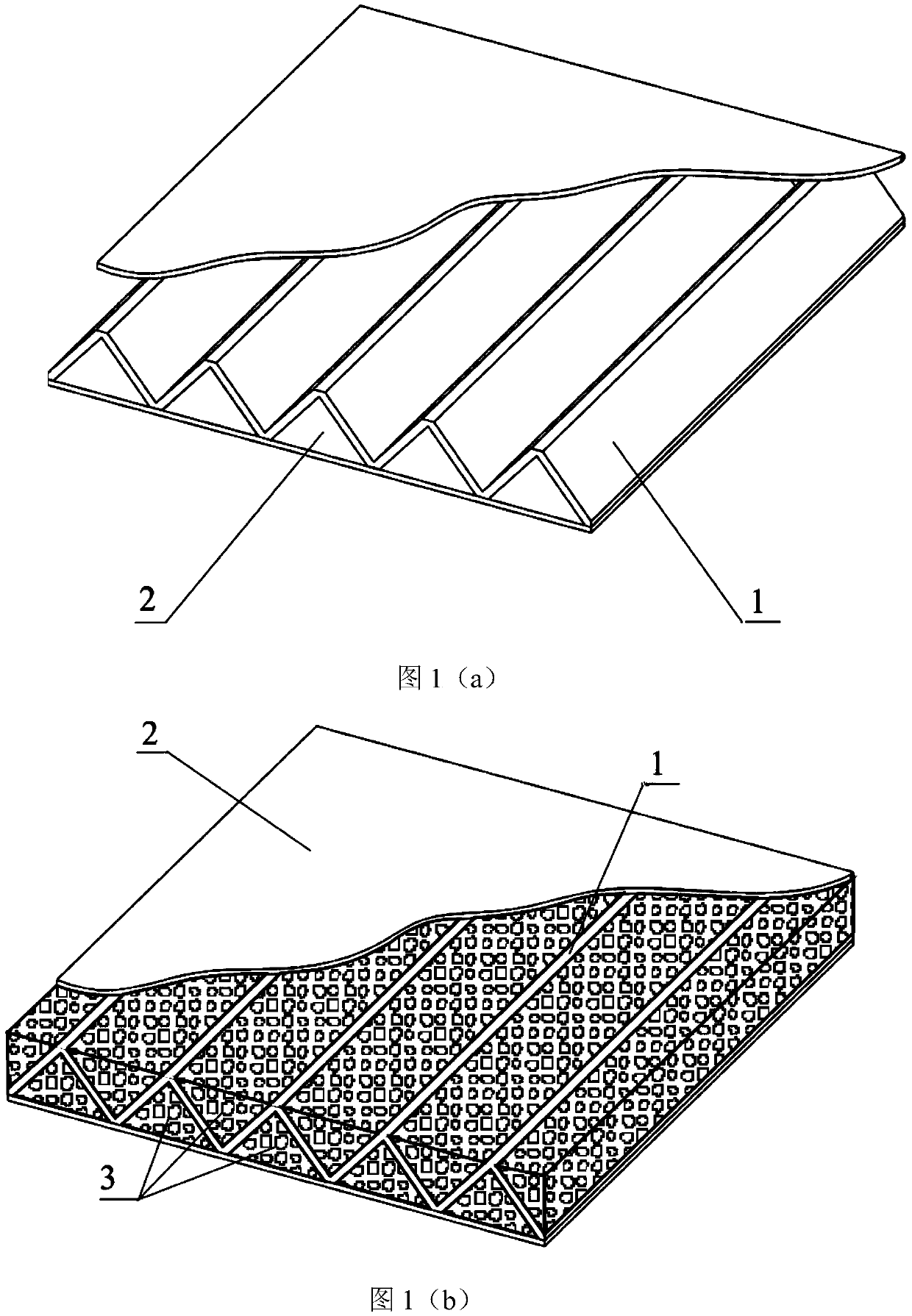

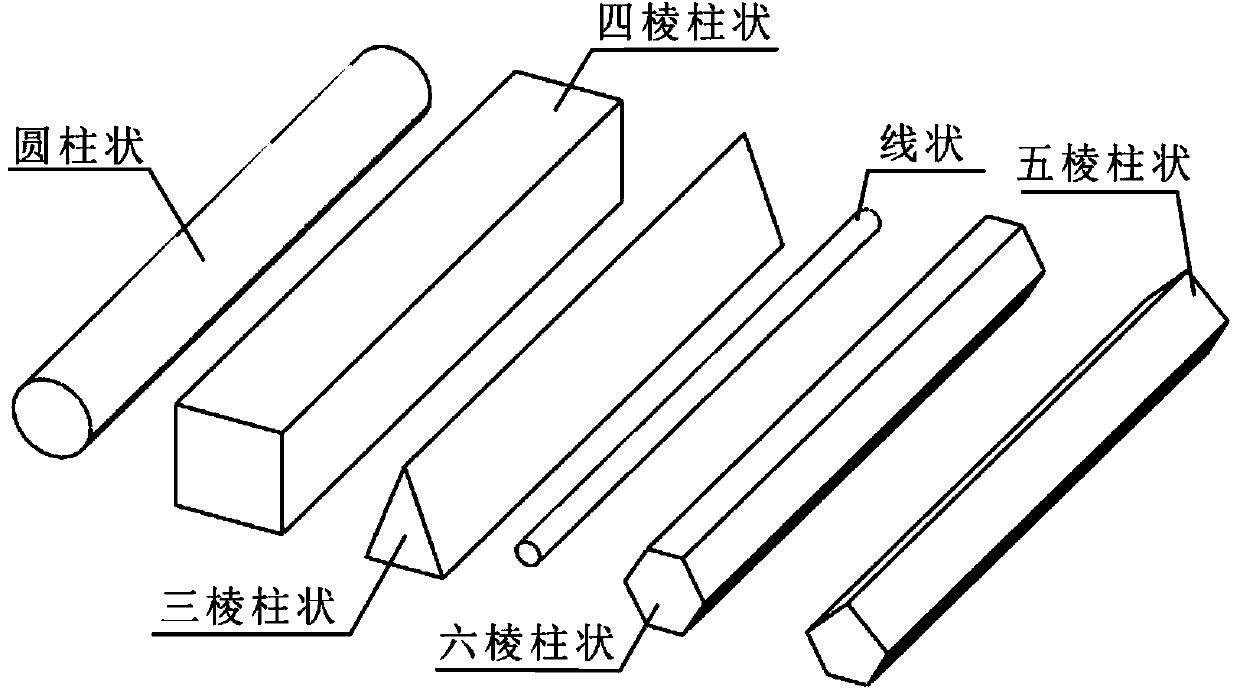

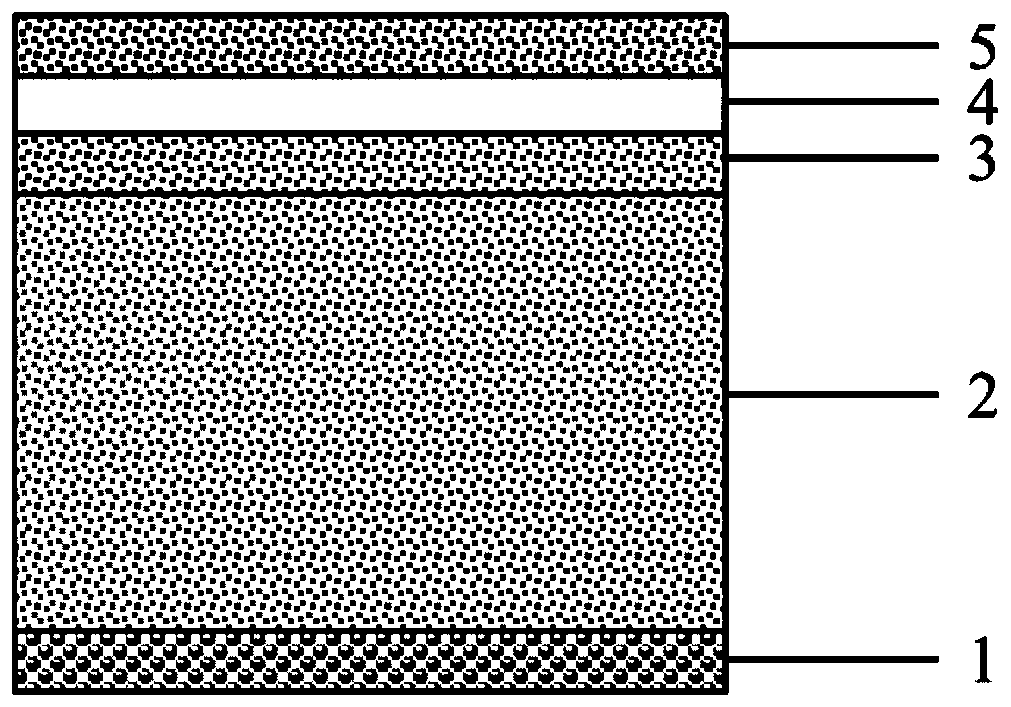

Foamed aluminum-corrugated plate composite sandwich plate and preparation method thereof

InactiveCN104175623AHigh shear mechanical propertiesWith heat insulationLamination ancillary operationsLaminationFoaming agentEnergy absorption

The invention relates to a foamed aluminum-corrugated plate composite sandwich plate and a preparation method thereof. The method comprises the following steps: firstly, manufacturing a corrugated core body; welding the corrugated core body to a panel to form a corrugated plate; putting basal powder and a foaming agent in a mixing machine for uniform mixing, and then extruding the mixed powder into a primary blank; putting the blank in a mould for pressing, filling the inside of the corrugated plate with a pressed foaming prefabricated body, and putting the corrugated plate in an atmosphere furnace for foaming; and heating and keeping warm until the prefabricated body is expanded to form foamed aluminum with which pores of the corrugated plate are completely filled, and then cooling. By using a powder metallurgy method, the inside of lattice metal is foamed in situ to form the metallurgical-bonding foamed aluminum-corrugated plate composite sandwich plate. The excellent mechanical property of the lattice metal and the advantages of energy absorption, sound insulation, shock absorption and thermal insulation of the foamed aluminum are utilized, so that the multifunctional coupling is realized, and the structure and function integration material with the relatively excellent comprehensive performance is obtained. The bonding strength is effectively improved by virtue of metallurgical bonding, and the performance of the composite material is further improved.

Owner:XI AN JIAOTONG UNIV +1

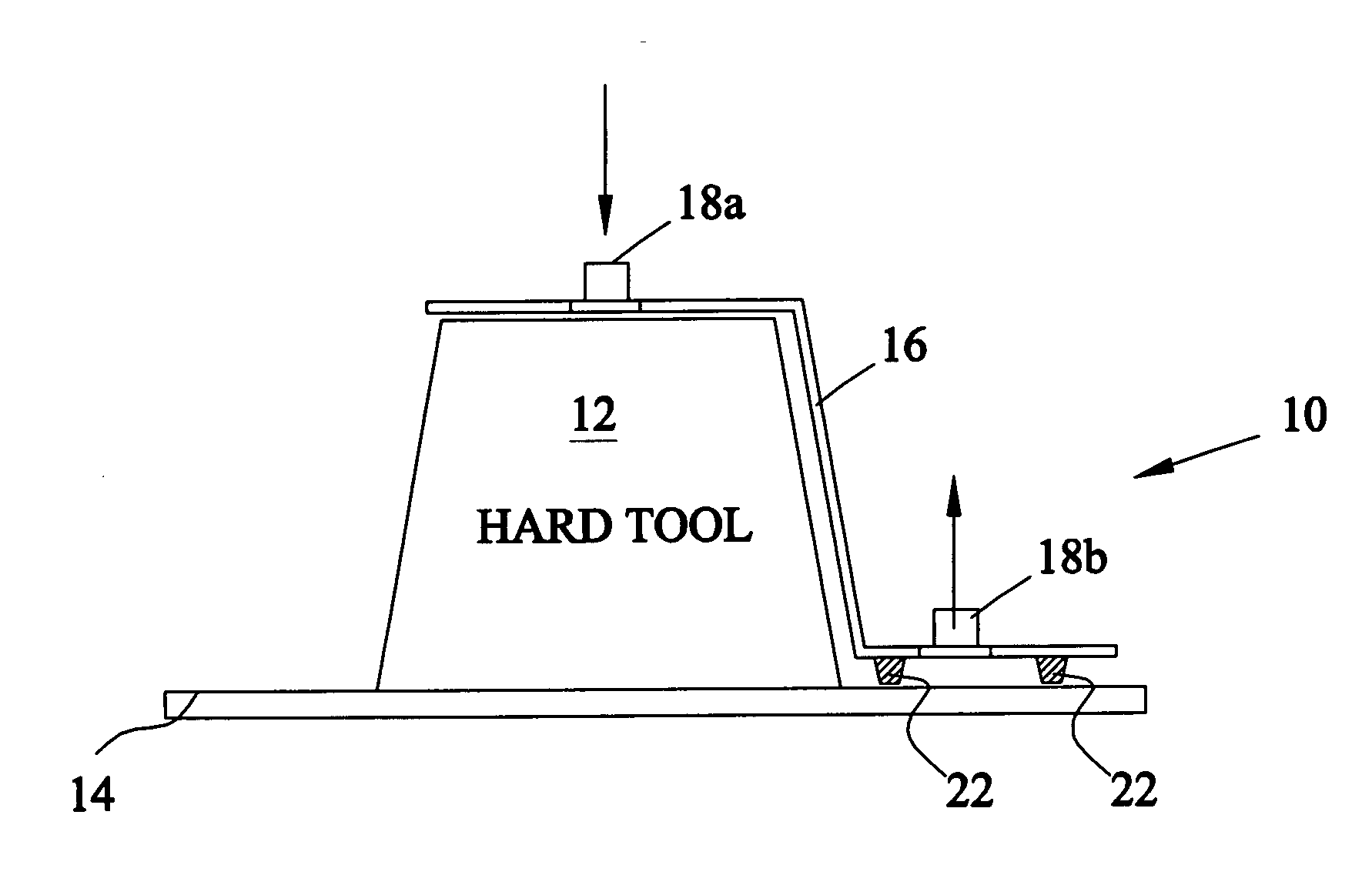

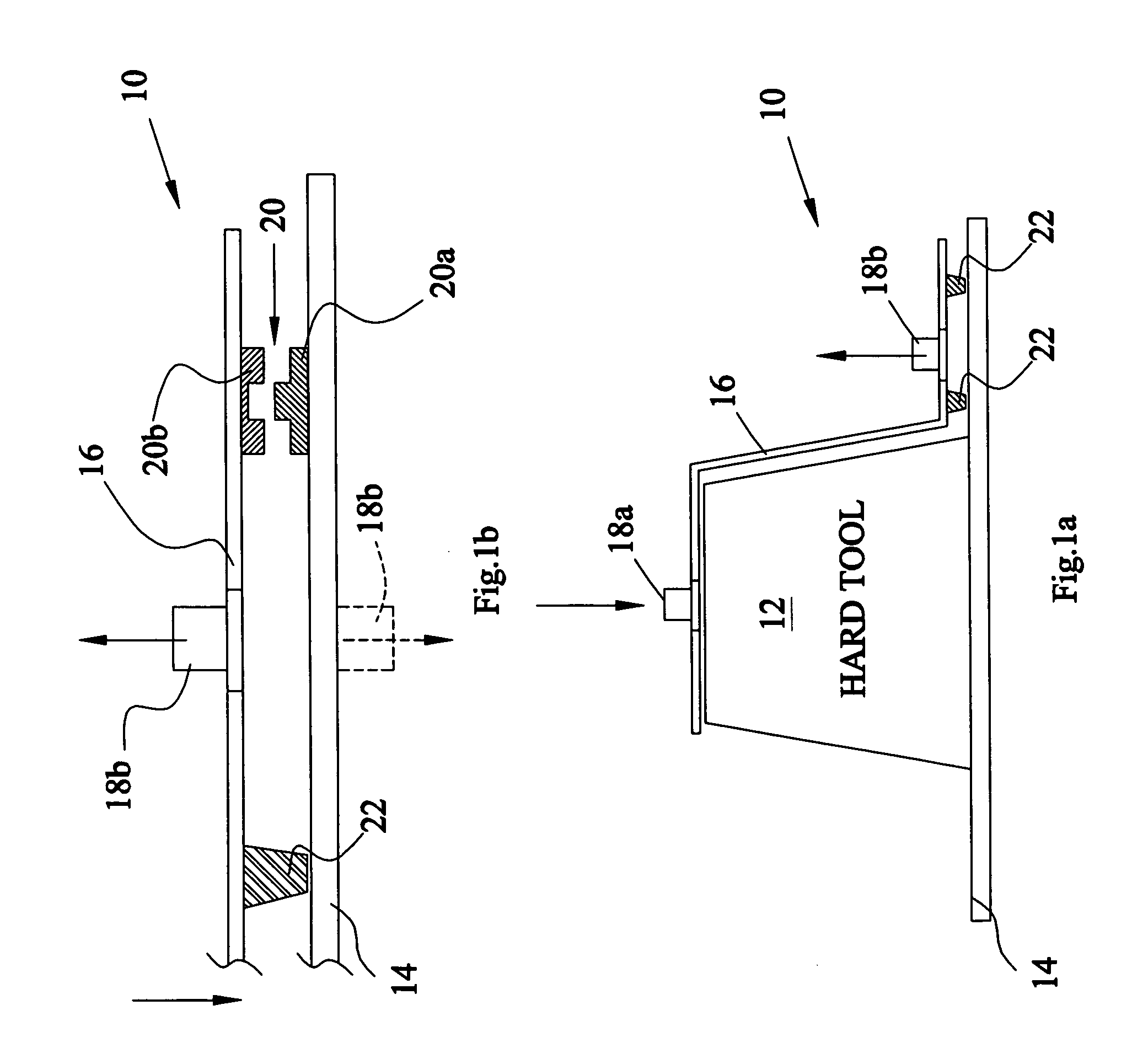

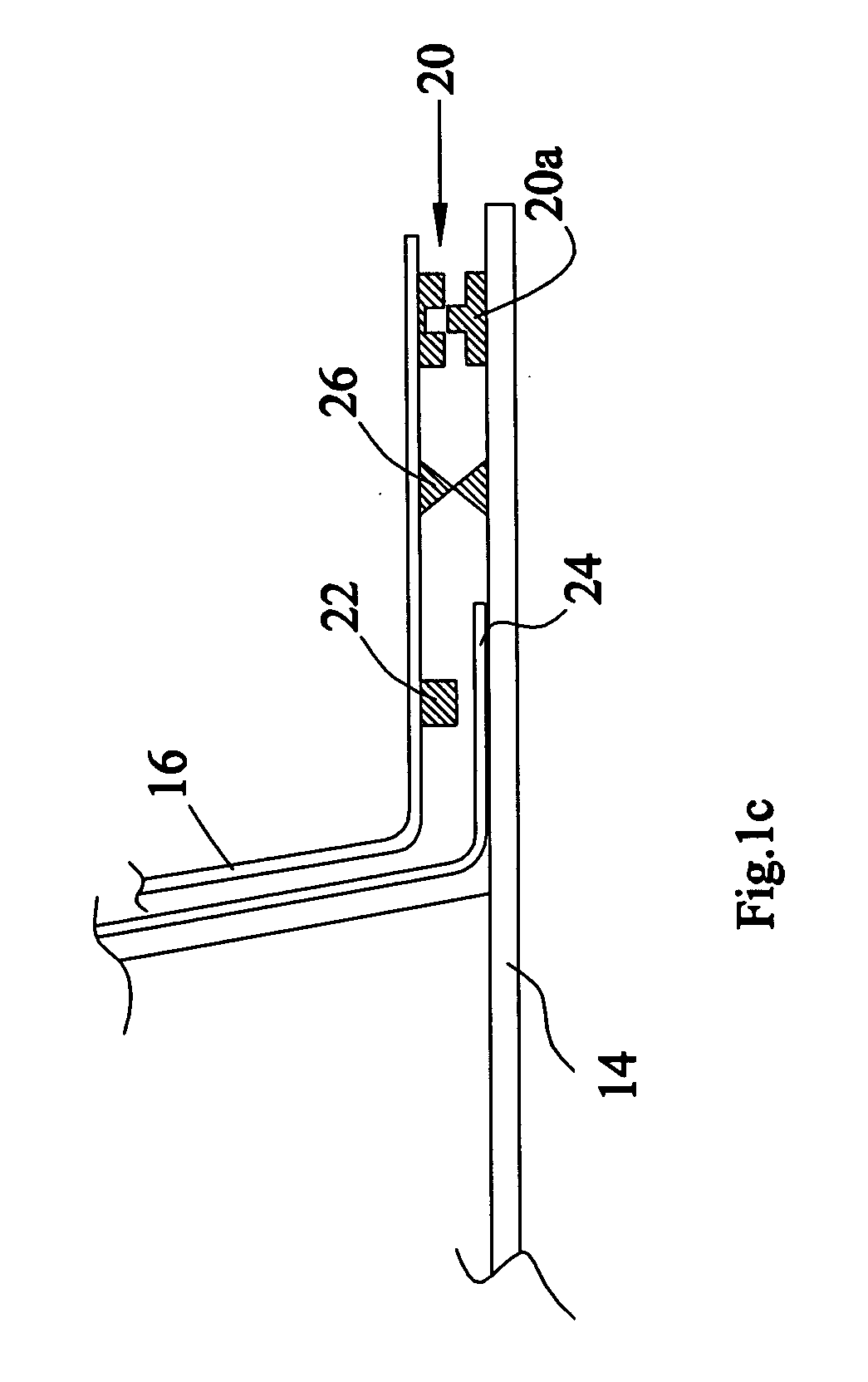

Reusable silicone vacuum bag/tool flange sealing method

An improvement to a process for making plastic parts in infusion processes using a reusable polymer soft flexible bag, wherein the bag is sealed directly to the tool flange portion using an interlocking press sealing device. The interlocking device has one mating portion bonded to the tool flange and the other mating portion either bonded to the bag or integrally assimilated into the bag during its manufacture by spraying or swirl spraying one or more multiple layers or coats of a polymer made from one or plural component polymer material, such as that described in U.S. Pat. No. 7,014,809 dated Mar. 21, 2006. Alternative seals include seals made from material suitable for providing a breathable seal against composite materials allow for the passage of air through or underneath a resultant seal during the infusion process. Seals can also be used between soft bags.

Owner:AUDETTE LAWRENCE F

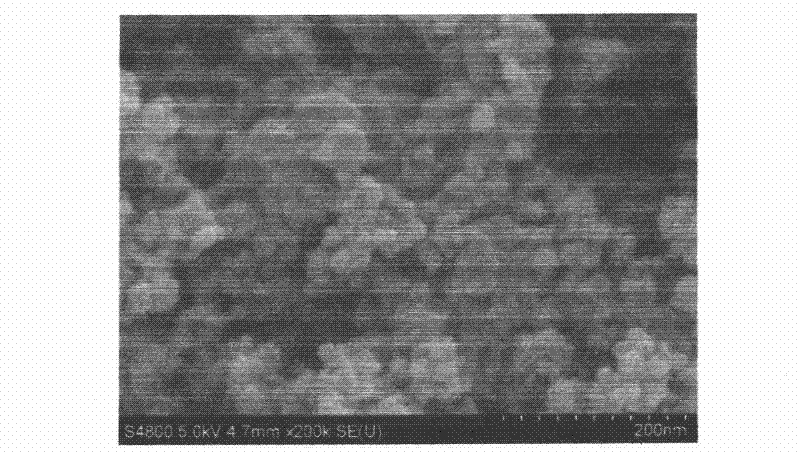

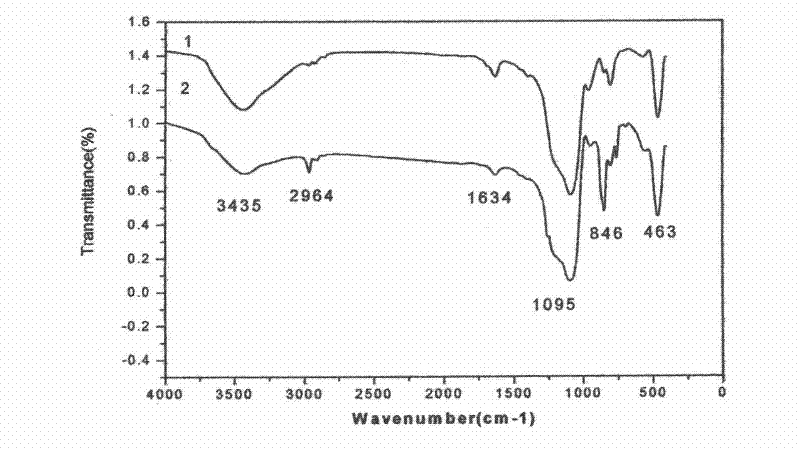

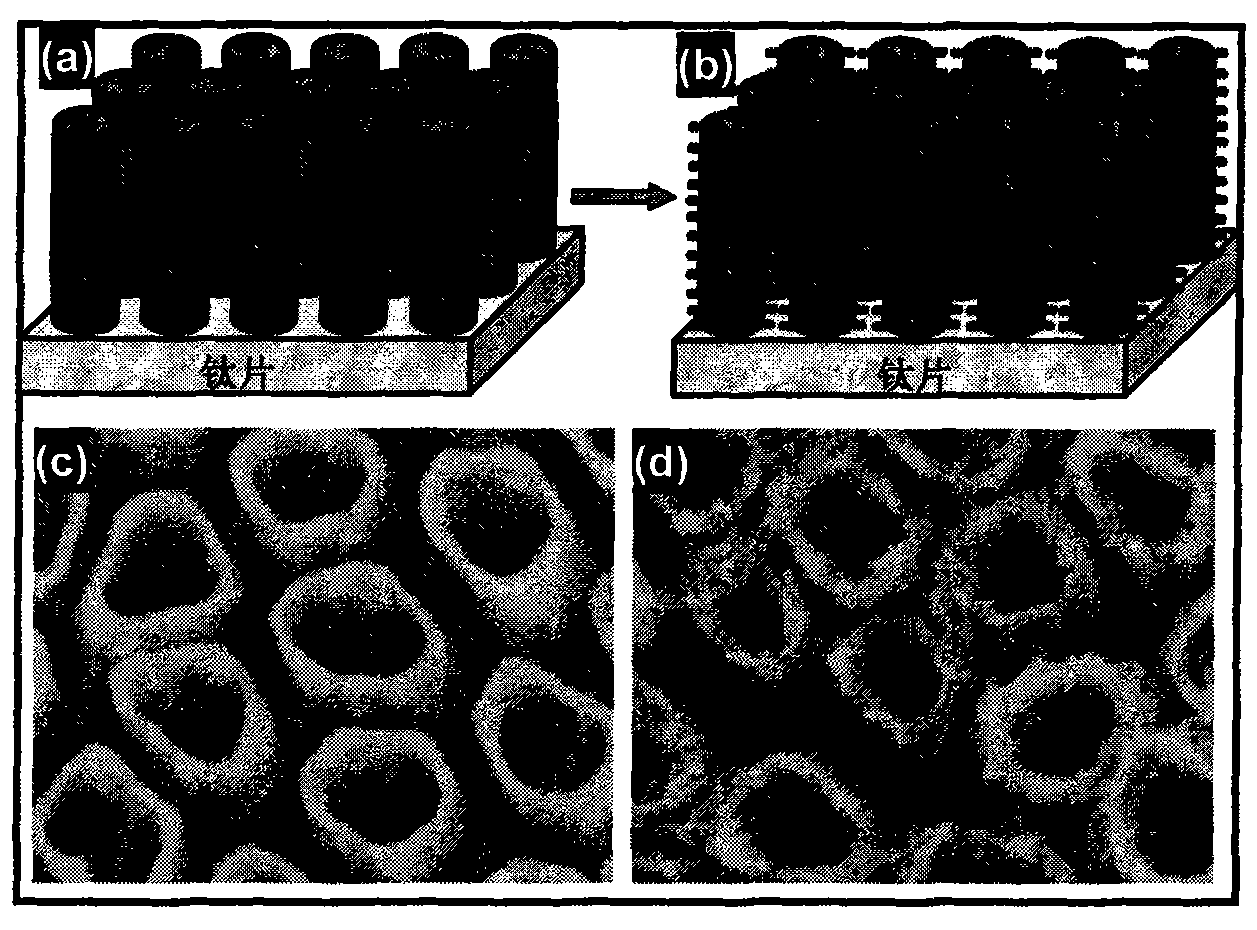

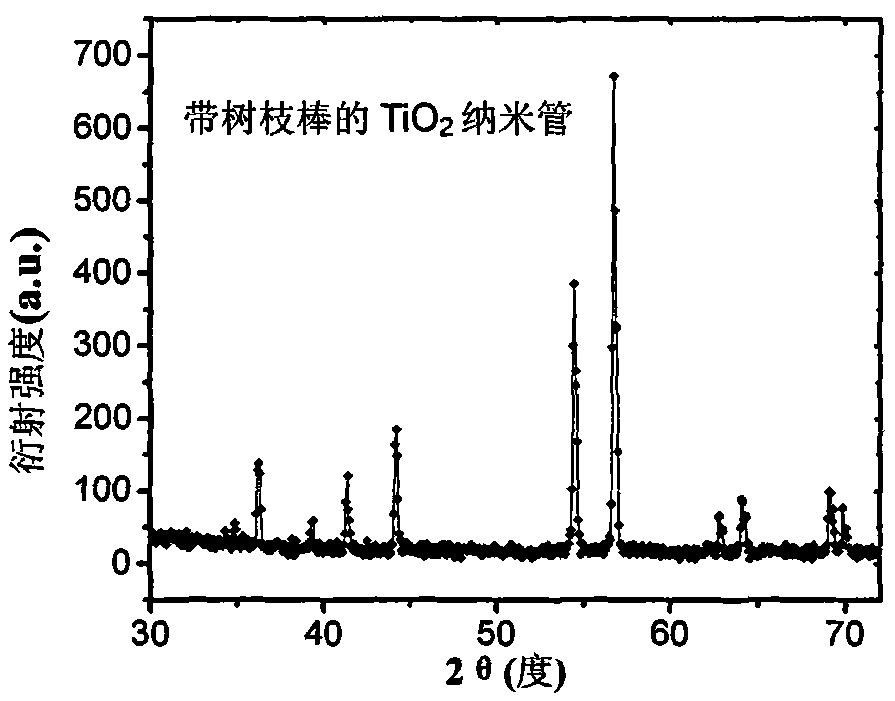

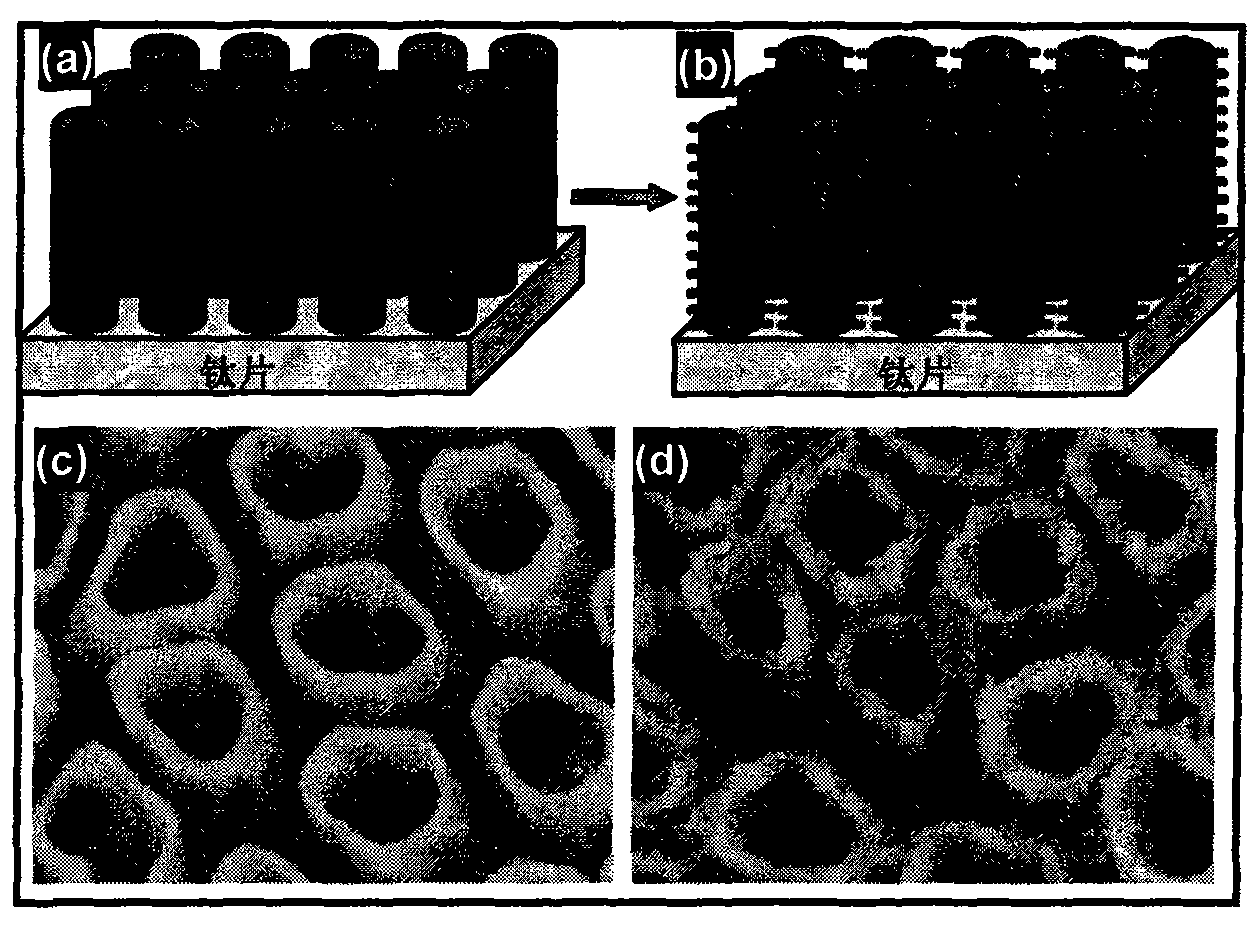

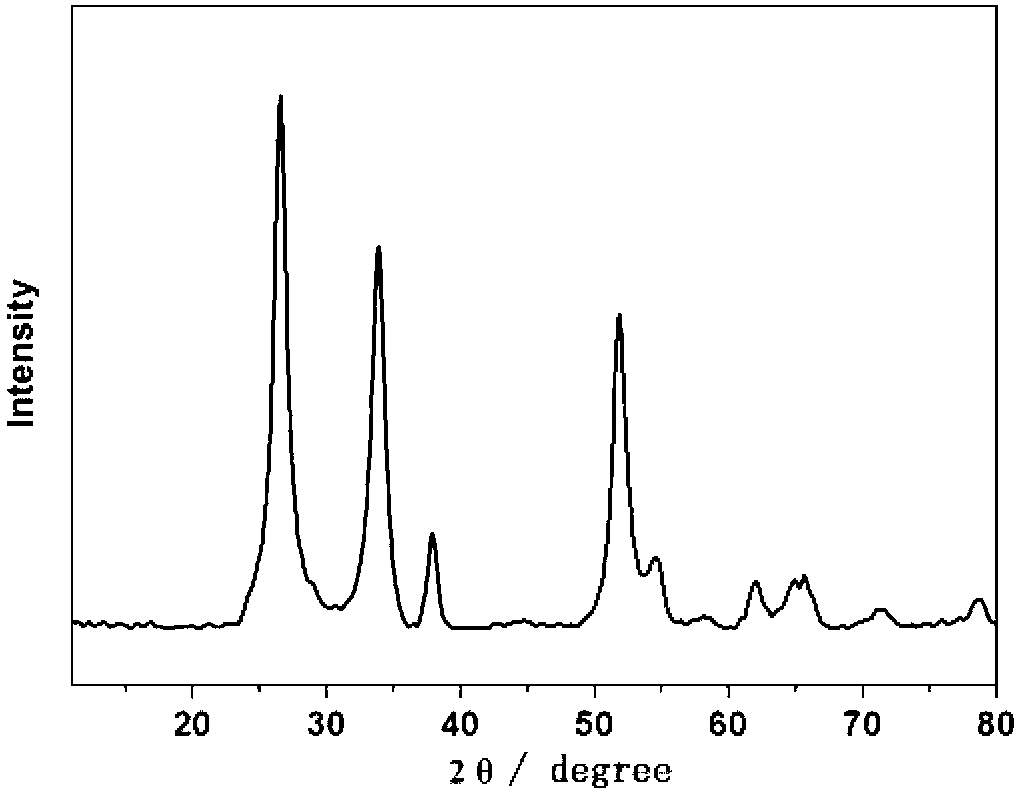

Preparation process of dendritic titanium dioxide nanotube array electrode

InactiveCN101969109ALarge specific surface areaLow manufacturing process costNanostructure manufactureLight-sensitive devicesTio2 nanotubeSolar cell

The invention provides a preparation process of a dendritic titanium dioxide nanotube array electrode, which comprises: firstly, pre-preparing a titanium dioxide nanotube array by using an anodizing method and by using pure titanium foil as an anode and mixed solution of ammonium fluoride, lactic acid and dimethyl sulphoxide as electrolyte; secondly, growing nanorods with dendritic titanium dioxide on the pre-prepared titanium dioxide nanotubes serving as a host skeleton by using a low-temperature liquid-phase method and by using aqueous solution of hydrochloric acid and TTIP as growing solution, and thus obtaining the required dendritic titanium dioxide nanotube array; and finally, using the dendritic titanium dioxide nanotube array as a material to assemble the working electrodes of dye-sensitized solar cells, photoelectrochemical cells, photocatalysis devices and the like. The dendritic titanium dioxide nanotube array can improve the conversion efficiency of the cells and the efficiency of the photocatalytic pollutant degradation considerably; and the preparation process is low in cost, simple in process and easy in production.

Owner:XIANGFAN UNIVERSITY

Method of manufacturing back contact heterojunction single crystalline silicon solar cell

InactiveCN105118870ASimple processIncrease unit capacityFinal product manufacturePhotovoltaic energy generationHeterojunctionChemical plating

The invention provides a method of manufacturing a back contact heterojunction single crystalline silicon solar cell, which belongs to the technical field of solar photovoltaics. The method comprises the following steps: (1) cleaning of single crystalline silicon, removal of a damage layer and etching are carried out; (2) a single crystalline silicon front surface passivation layer is formed, and coating of an anti-reflective layer is carried out; (3) coating of a single crystalline silicon back surface passivation layer is carried out; (4) a mask technology is adopted to form a P-type amorphous silicon pattern through coating of the single crystalline silicon back surface; (5) a mask technology is adopted to form an N-type amorphous silicon pattern through coating of the single crystalline silicon back surface; (6) a mask technology is adopted to form a protection film pattern through coating of the back surface; and (7) a chemical plating plus electroplating technology is adopted to form a contact electrode for a transmitting electrode and a base electrode on the back surface. the method of the invention has the advantages of simple process and low manufacturing cost whether for coating and positioning of a P / N junction or for back electrode manufacturing, and can be applied to mass production of the back contact heterojunction single crystalline silicon solar cells.

Owner:深圳市科纳能薄膜科技有限公司

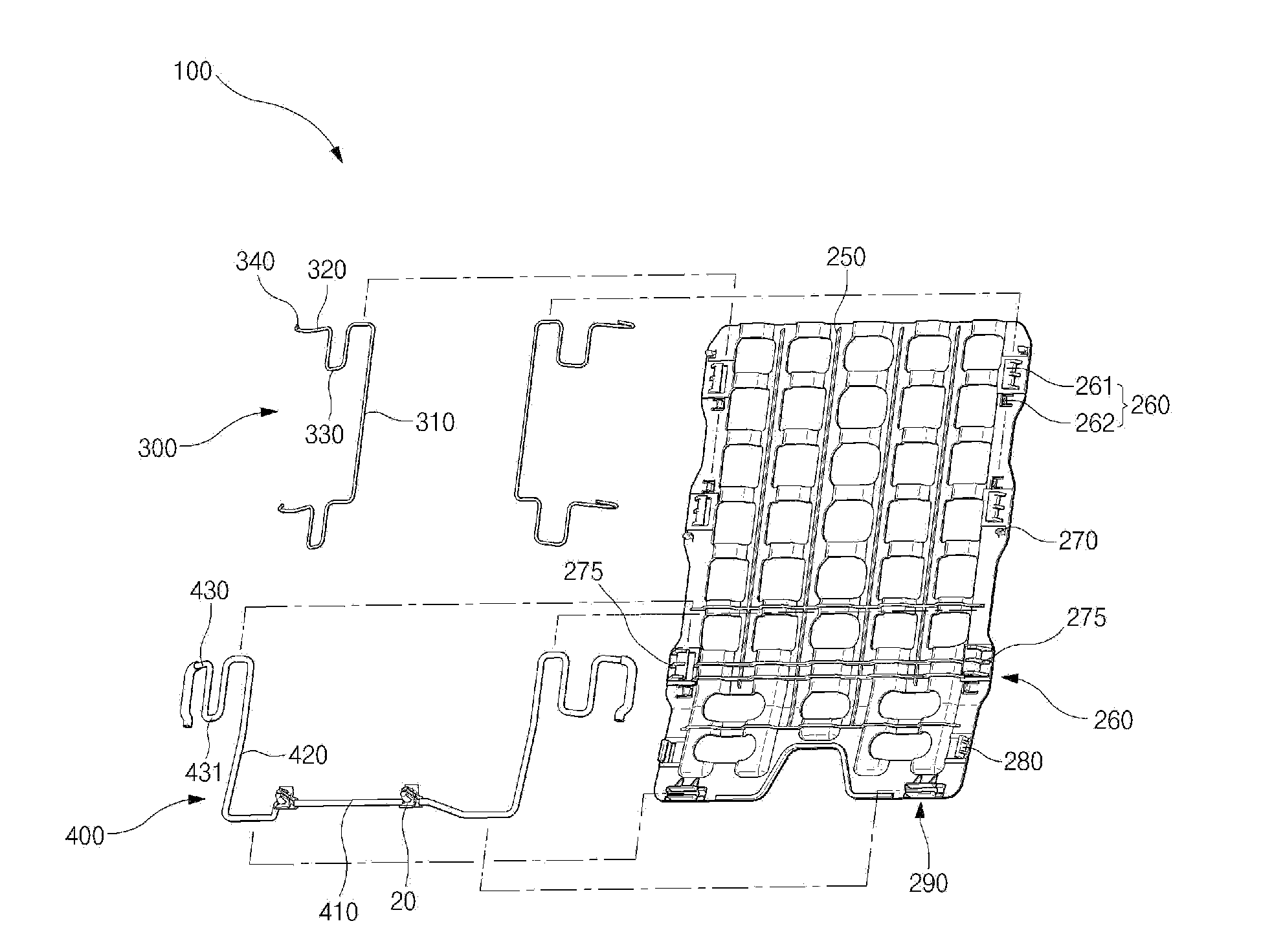

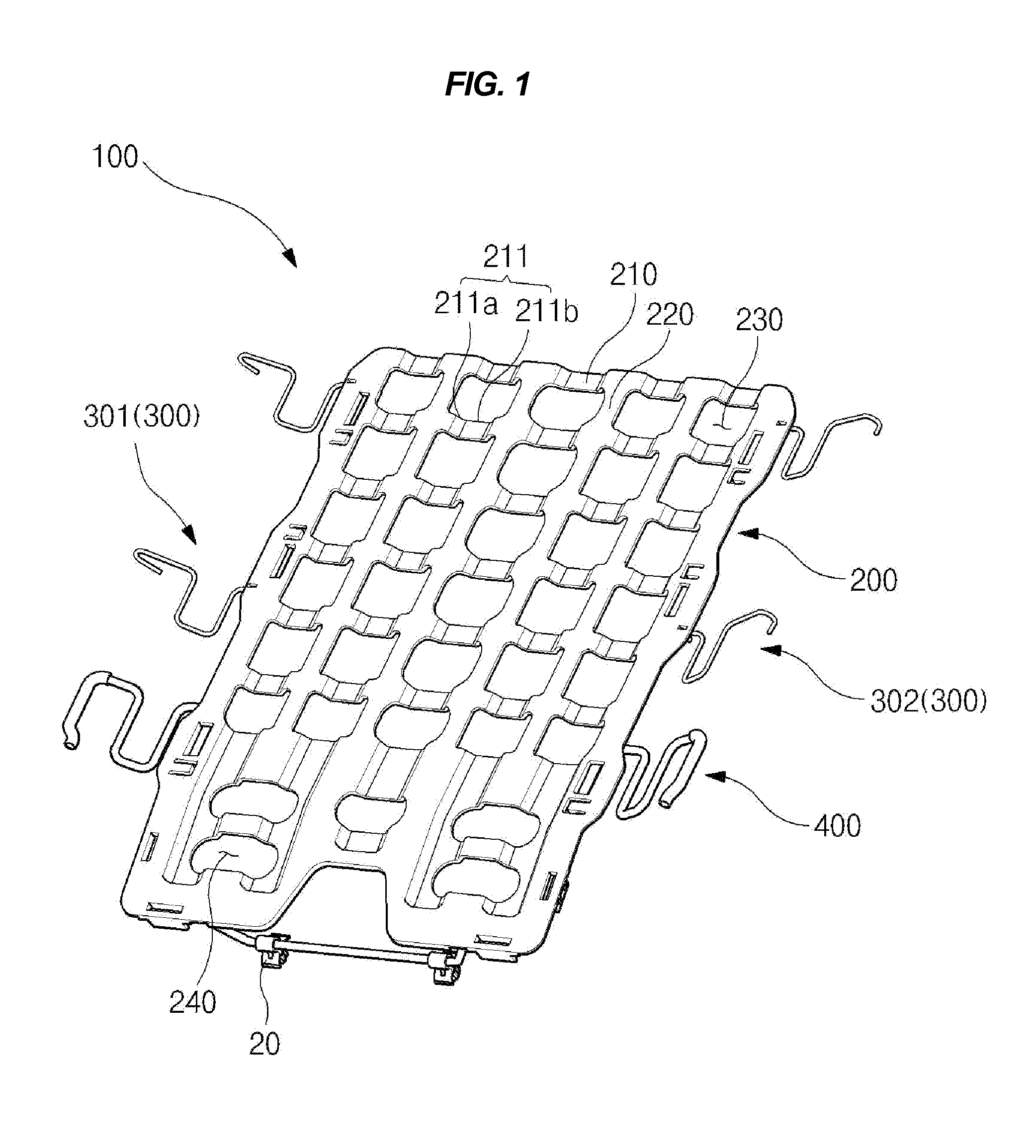

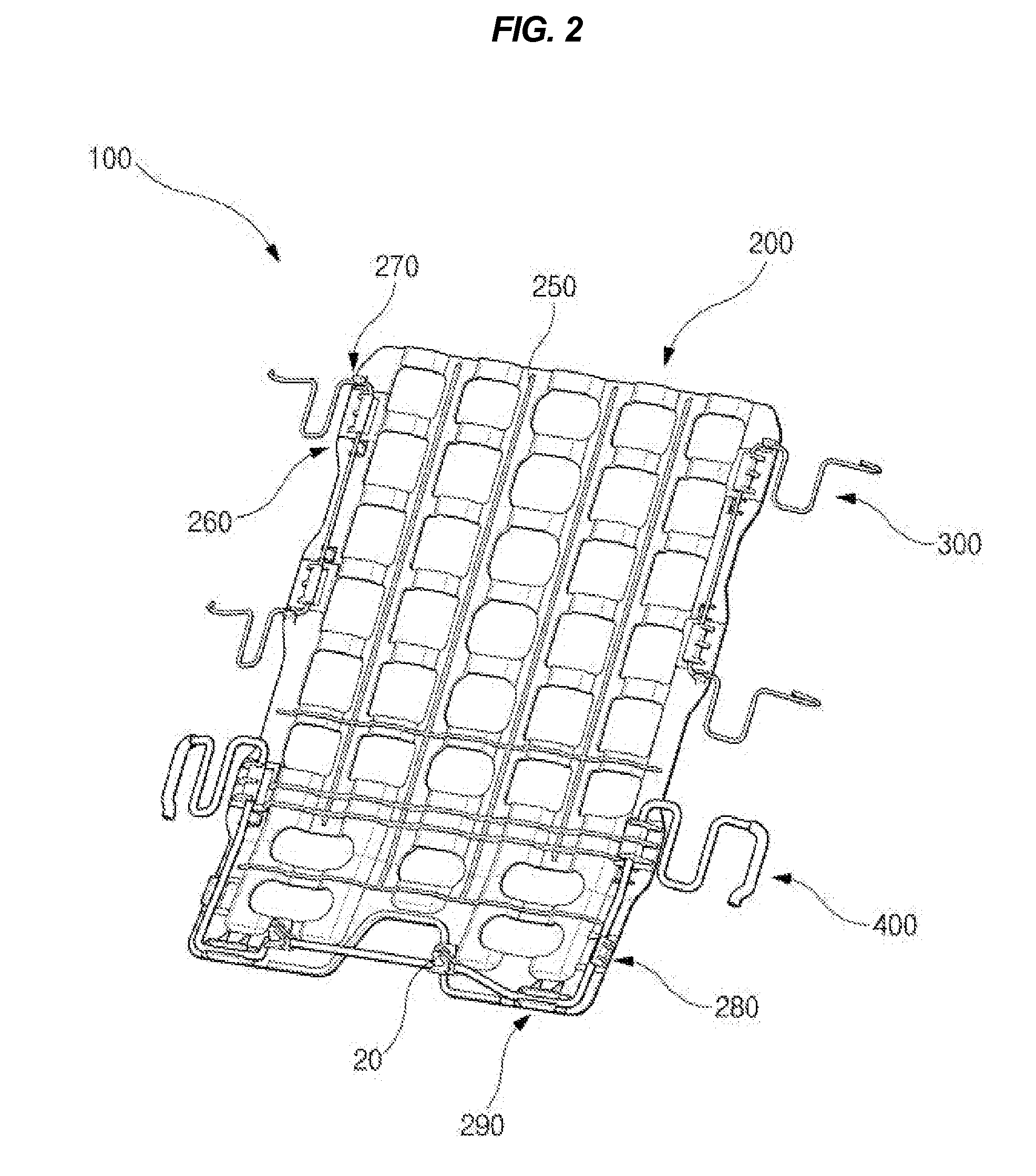

Suspension assembly of vehicle seat

InactiveUS20120133183A1Effectively absorbs shockIncrease contact areaBack restsSeat framesEngineeringMechanical engineering

A suspension assembly of a vehicle seat may include a lumbar plate disposed within an edge of a seat back frame, and an elastic wire section connecting the edge of the seat back frame with a side of the lumbar plate, wherein the elastic wire section includes a first elastic wire, opposite ends of which may be connected to one edge of the seat back frame and at least a portion thereof may be supported by one side of the lumbar plate, and a second elastic wire, opposite ends of which may be connected to the other edge of the seat back frame and at least a portion thereof may be supported by the other side of the lumbar plate.

Owner:HYUNDAI MOTOR CO LTD +2

Prepn process of in-situ grain reinforced refractory aluminium-base composite material

The in-situ grain reinforced refractory aluminum-base composite material consists of Si 11-13 wt%, Mg 0.5-1.5 wt%, Cu 0.8-1.3 wt%, Ni 0.5-1.5 wt%, and TiB2 1-20 wt% except Al. The preparation process includes the following steps: 1. adding ZL102 alloy and Al-Si intermediate alloy or industrial pure aluminum into crucible, melting, heating and covering with covering agent; 2. mixing KFB4 and KTiF6, stoving and adding into the melt via stirring; 3. taking out the side product after reaction, adding industrial pure Mg, Al-Ni intermediate alloy and Al-Cu intermediate alloy, scumming, pumping vacuum and letting stand; and 4. low pressure casting formation. The composite material of the present invention has reinforcing TiB2 grains with clean interface and even distribution, excellent structure and performance, excellent high temperature strength, high plasticity and high modulus, and the present invention is suitable for industrial production.

Owner:SHANGHAI JIAO TONG UNIV

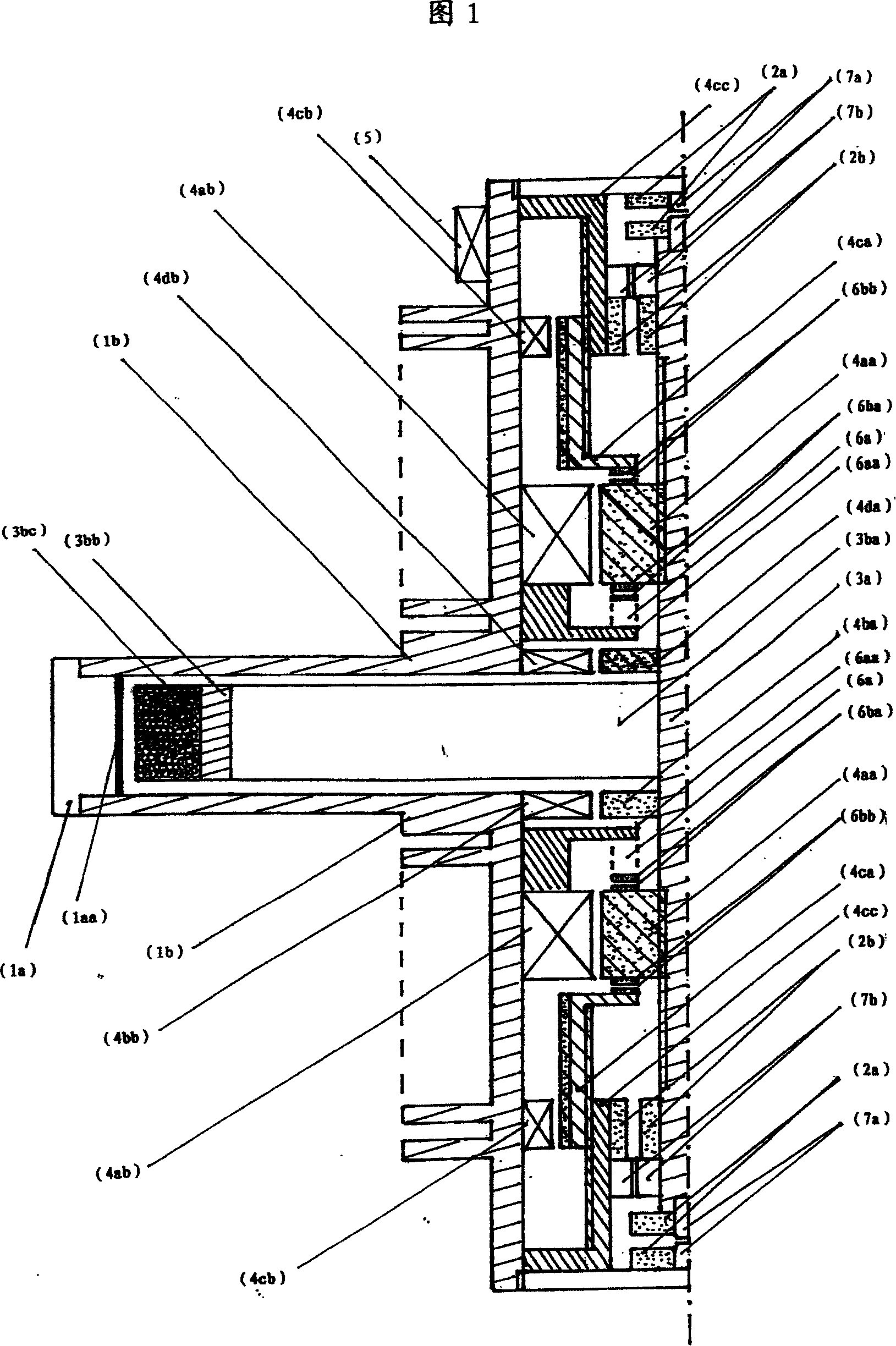

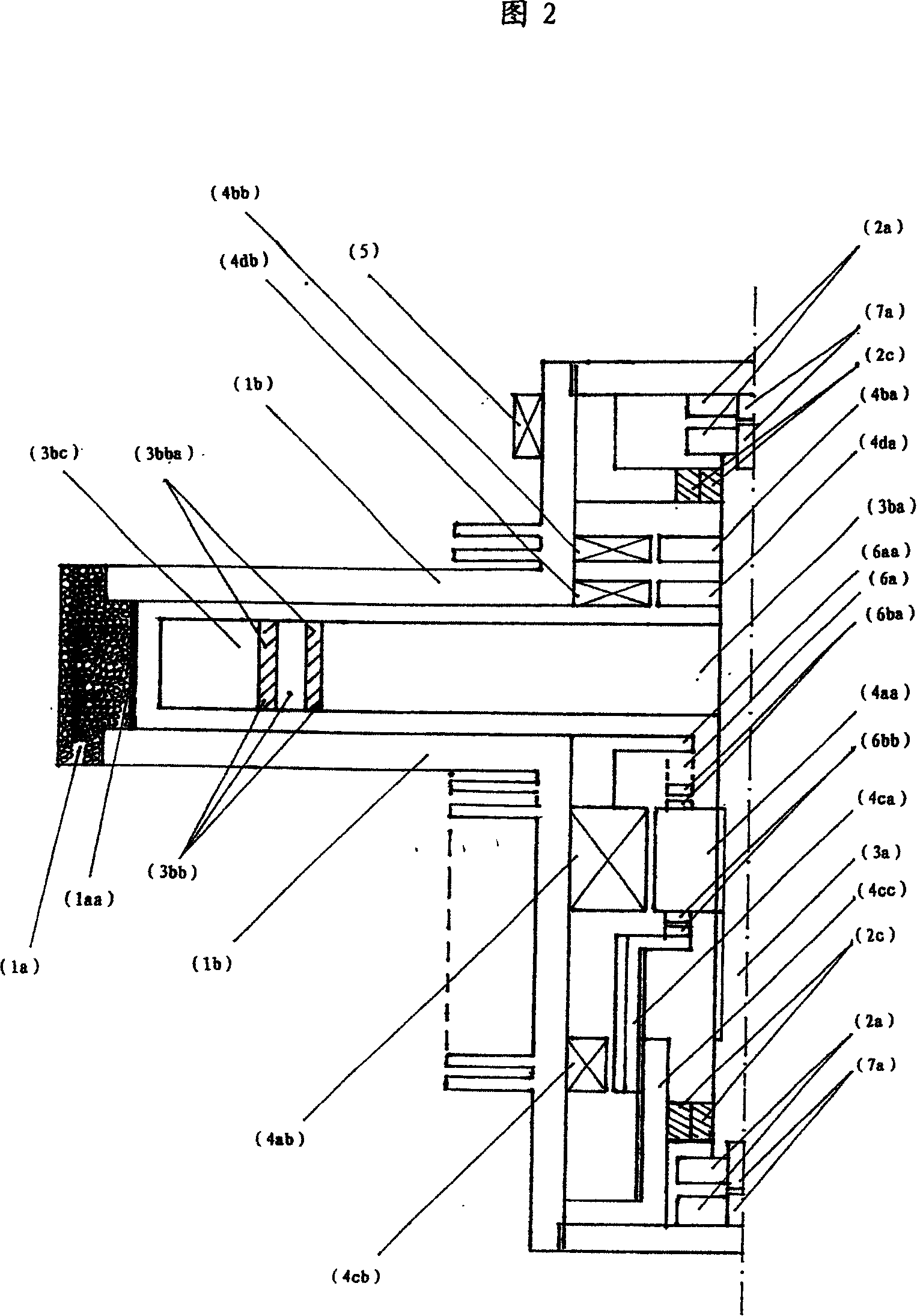

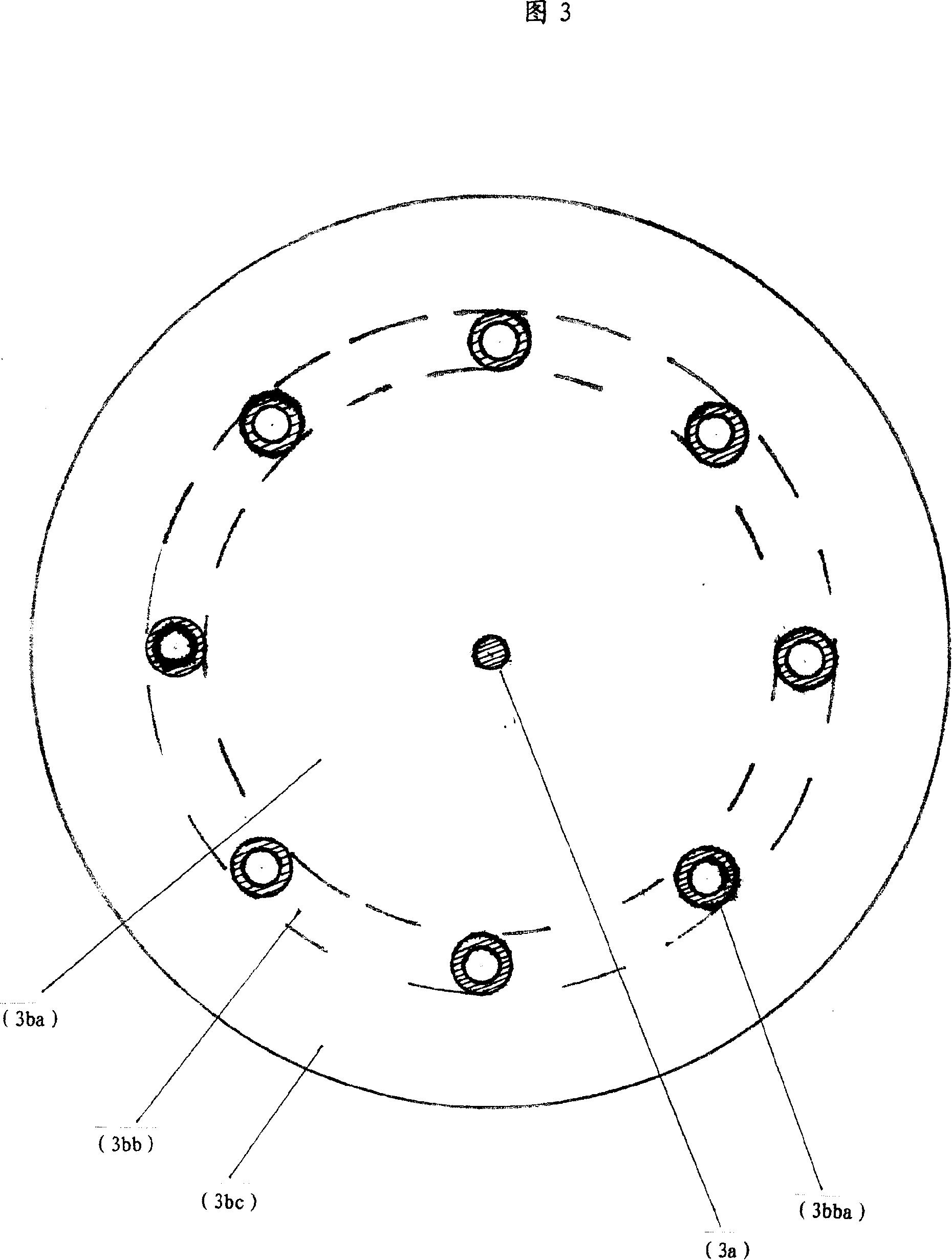

Energy storage system for magnetic floating flywheel

InactiveCN101127465AReduce weightLight weightFlywheelsMechanical energy handlingElectricityLevitation

The utility model discloses a magnetic levitation flywheel energy accumulation system, which has the advantages of small deadweight, large electricity storage, low manufacturing cost, mobile usage, free adjustment of the real-time discharge quantity value to the outside, and quick charge or large real-time discharge; wherein, the axial component of ''the high-vacuum enclosed housing'' is made of materials of low specific gravity. No permanent magnetic material components are positioned on the ''Flywheel'' and the ''Wheel Disk'' is divided into three rings. Four ''Permanent Magnetic Rotating Motor Devices'' are arranged. The ''Magnet bearing'' is ''all magnetic levitation bearing'' or ''semimagnetic levitation bearing''. The utility model is also provided with a device to guarantee the reliability of the mobile usage of the ''Magnet Bearing''.

Owner:严密 +1

Method for preparing light inductor

ActiveCN101281887ALow manufacturing process costImprove reliabilitySemiconductor/solid-state device manufacturingAmorphous siliconInductor

A method for preparing an optical inductor includes steps: providing a substrate comprising a thin film transistor region and an optical induction region; forming a patterned first conductive layer on the substrate; forming a grid dielectric layer on surface of the substrate and a grid; forming a patterned amorphous silicon layer on surface of the grid dielectric layer which is deposed on the grid; forming a patterned second conductive layer on the substrate; forming a patterned silicon-enriched dielectric layer on the substrate; forming a patterned light-transparent conductive layer on the substrate which at least comprises an upper electrode of the optical inductor and is arranged in the optical induction region. The optical inductor includes a bottom electrode, a dielectric layer comprising silicon-enriched material and the upper electrode. The method of present invention can effectively increase reliability of the optical inductor and reduce whole preparation cost of products by integrating thin film transistor preparation technique.

Owner:AU OPTRONICS CORP

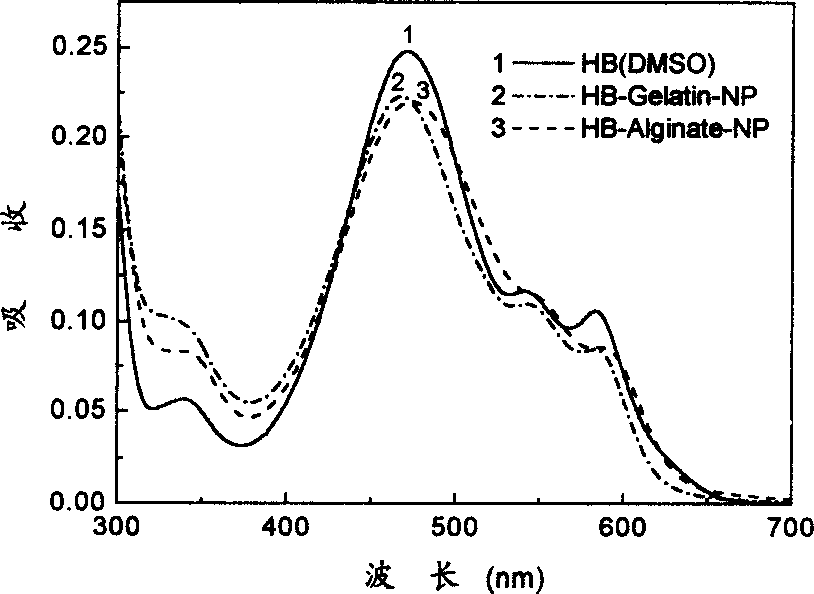

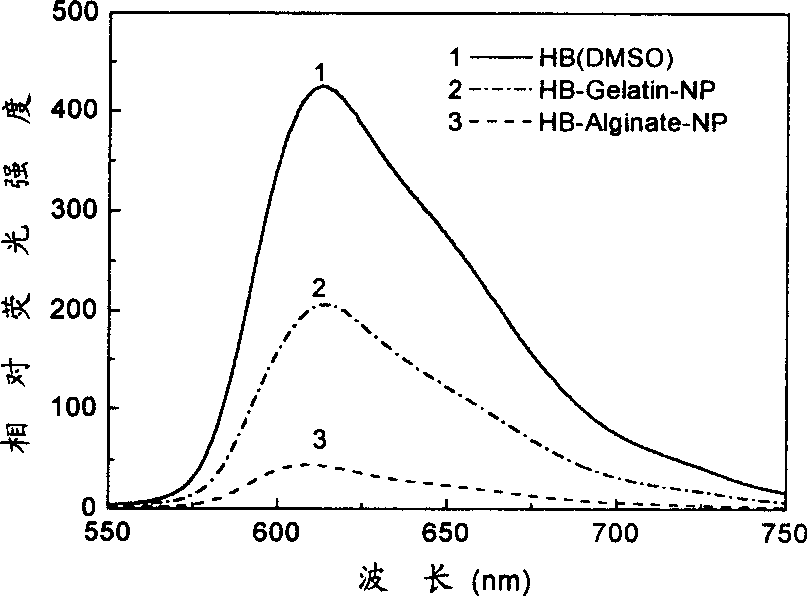

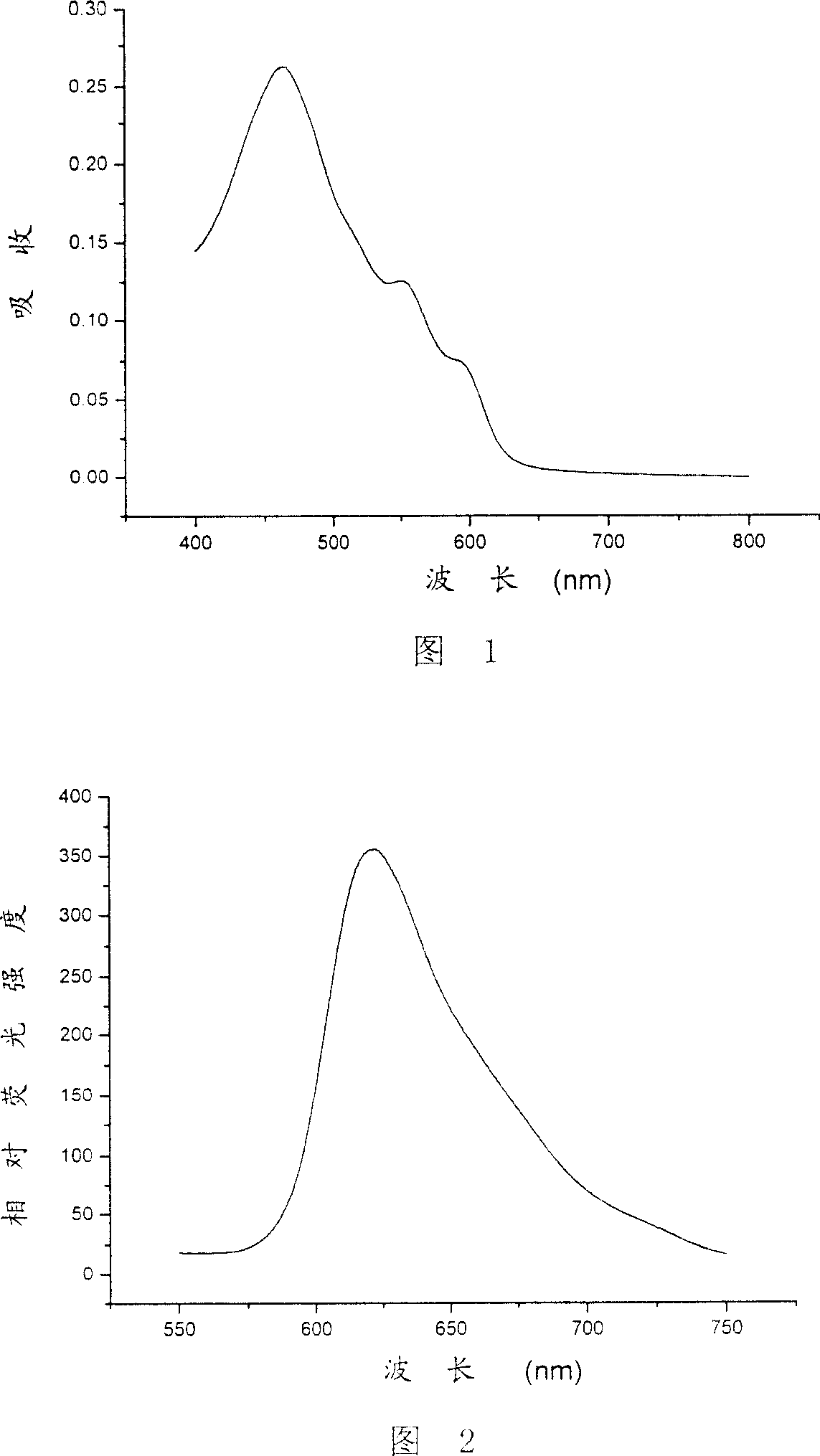

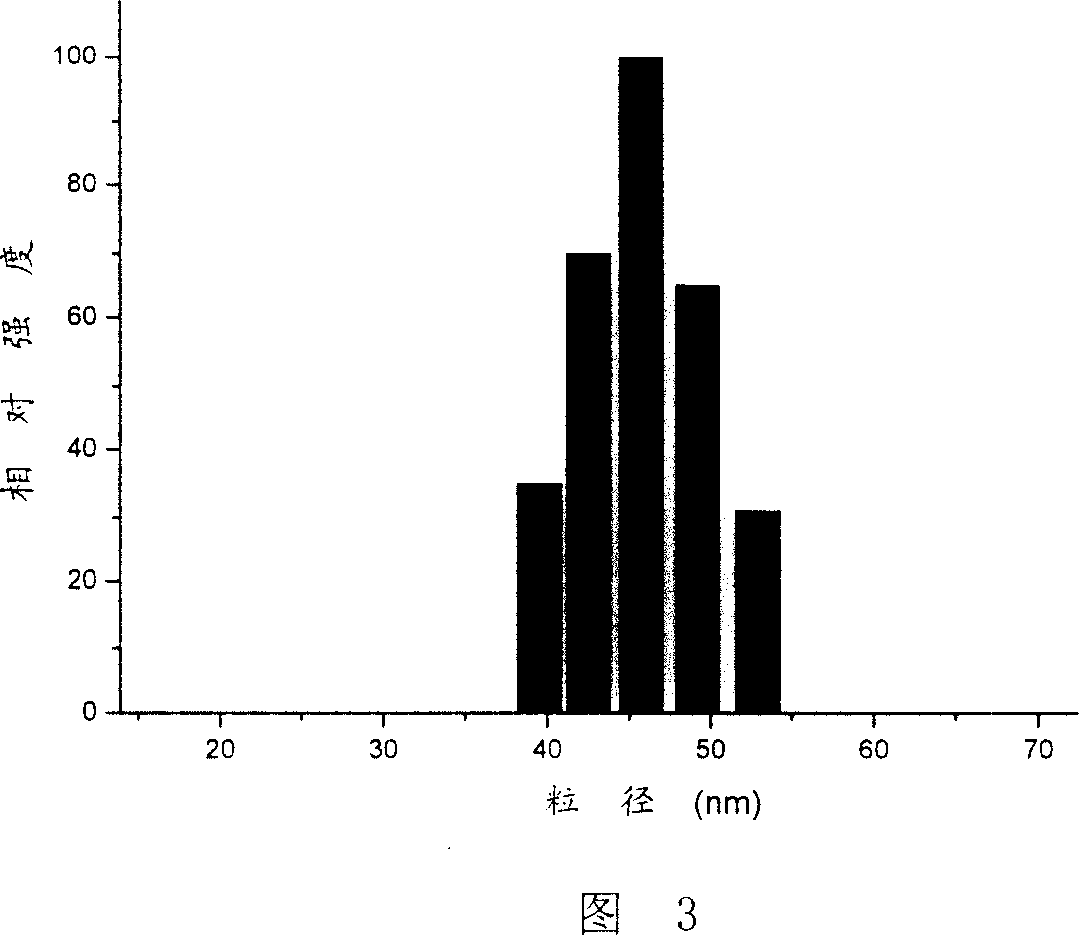

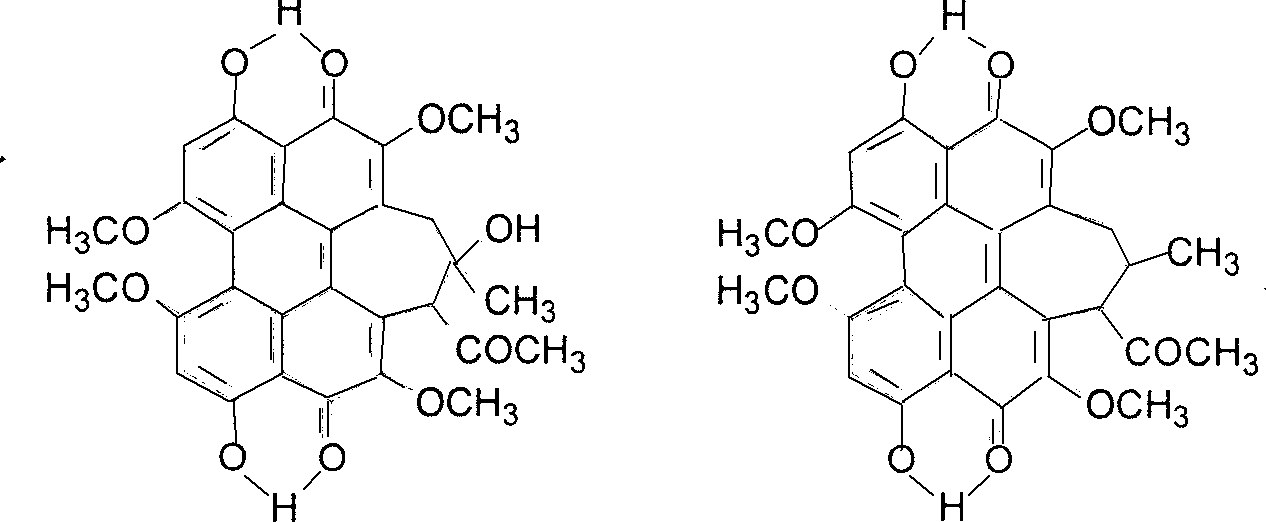

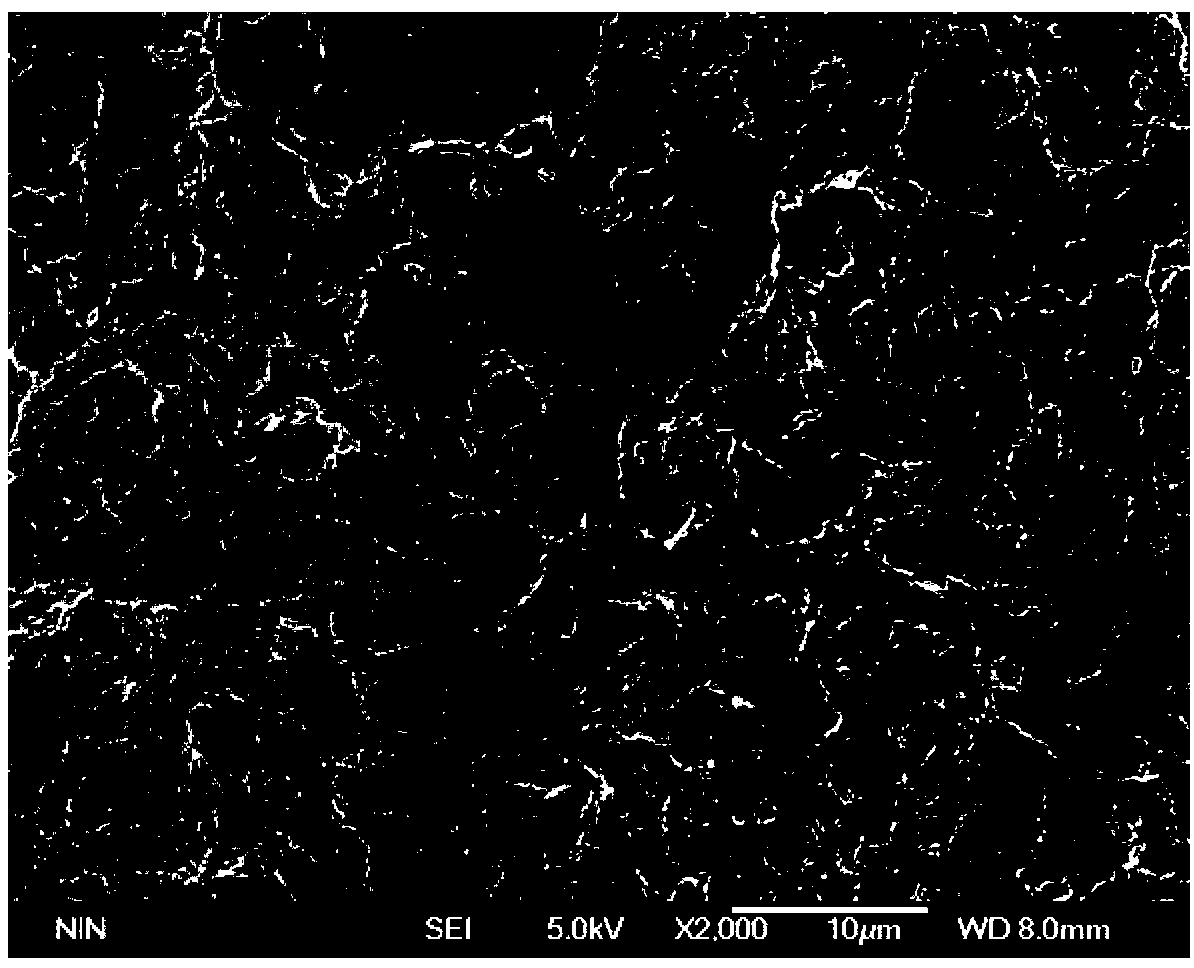

Hypocrellin water-soluble nanogranule and its uses

InactiveCN1565433AEasy to prepareEasy to operatePowder deliveryOrganic active ingredientsWater solubleNative protein

The invention relates to a Hypocrellin water-soluble nanogranule and its uses characterized in that, native protein, polysaccharide macromolecule and biodegradable high molecular polymer can be used as packing material, the liposoluble bamboo bacterioerythrin medicament is packed for preparing ultra-microminiature water-soluble intravenous injection with grain diameter of 20-200nm. These preparations can be used as the intravenous injection for optical dynamic medicament of Hypocrellin.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

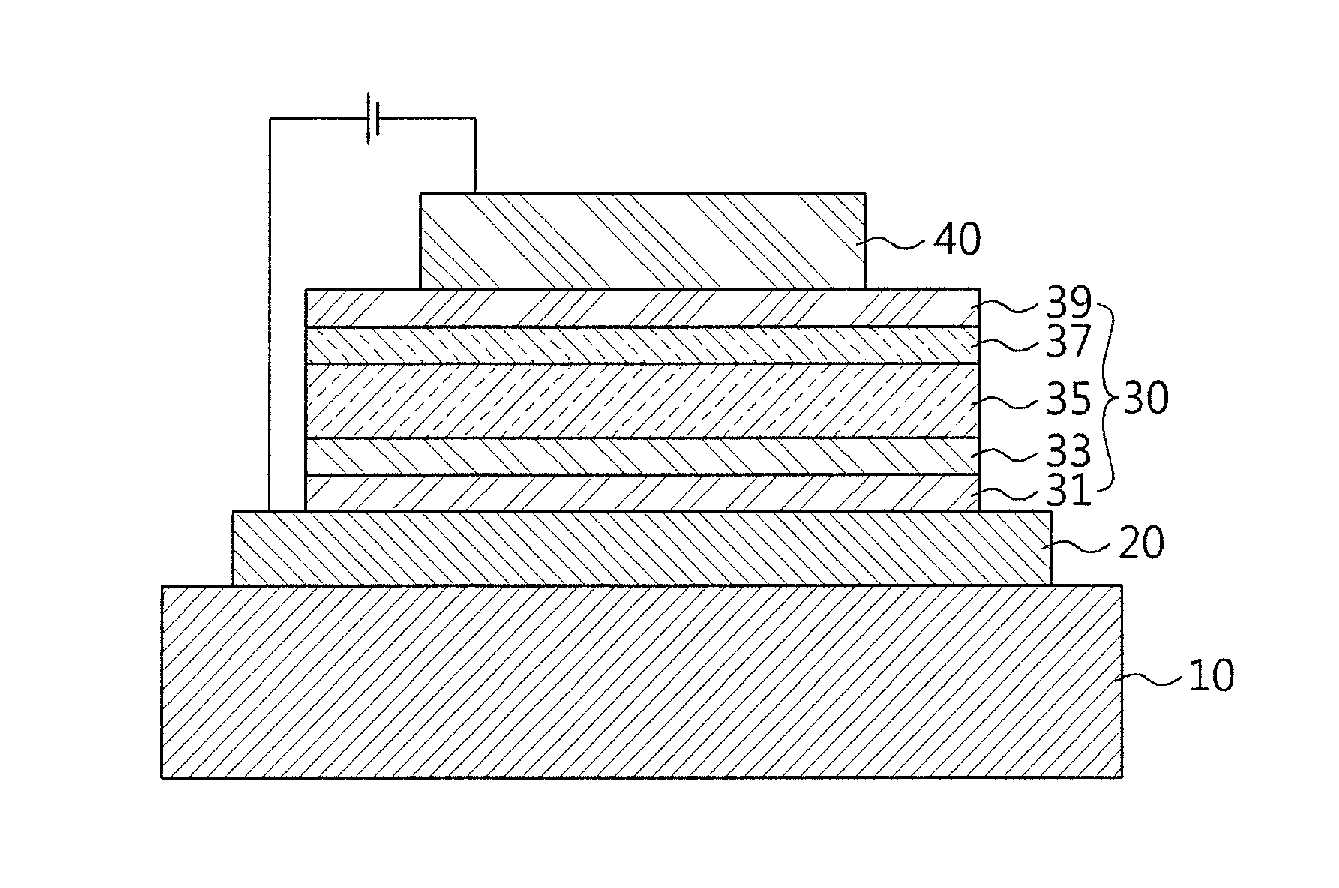

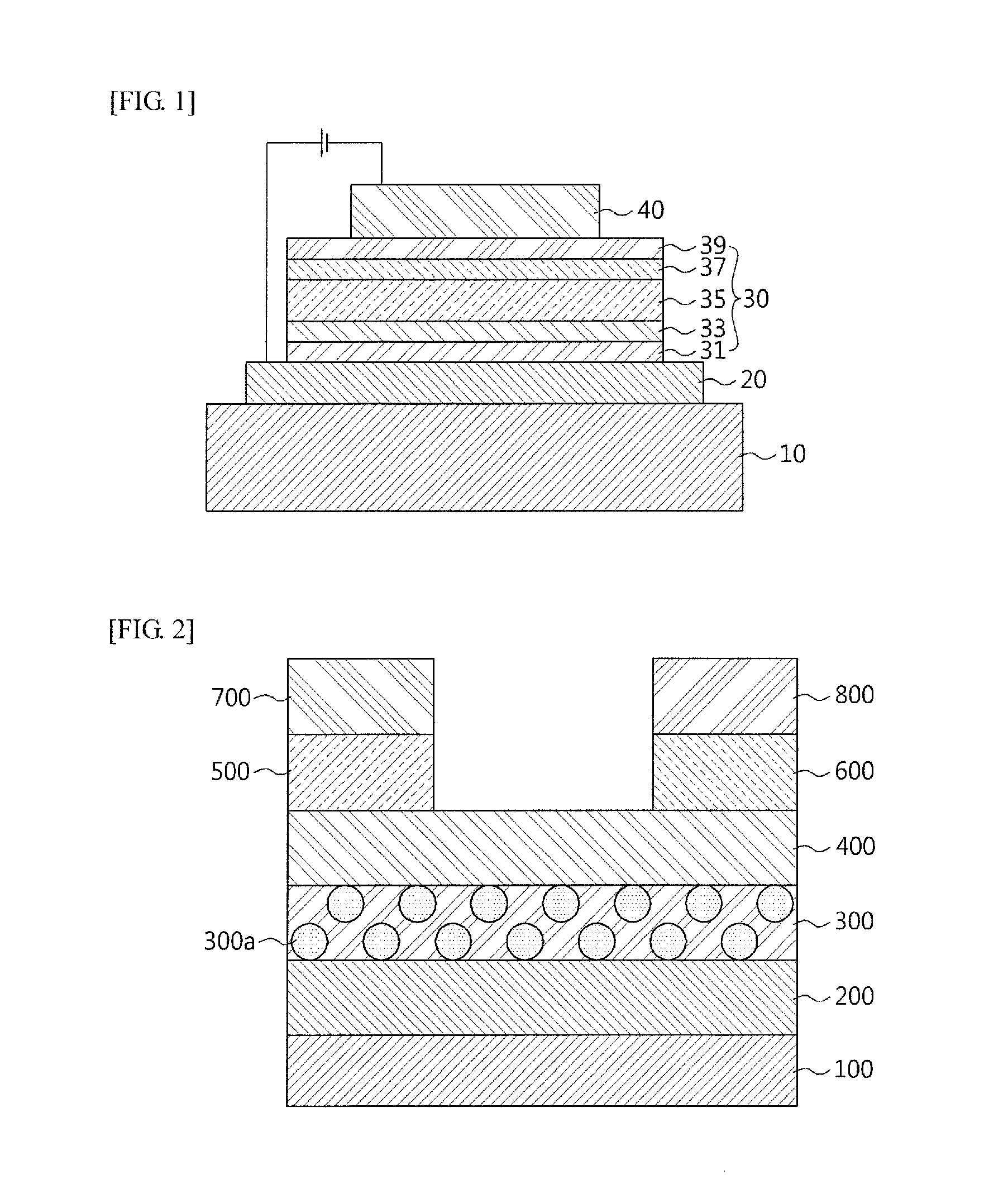

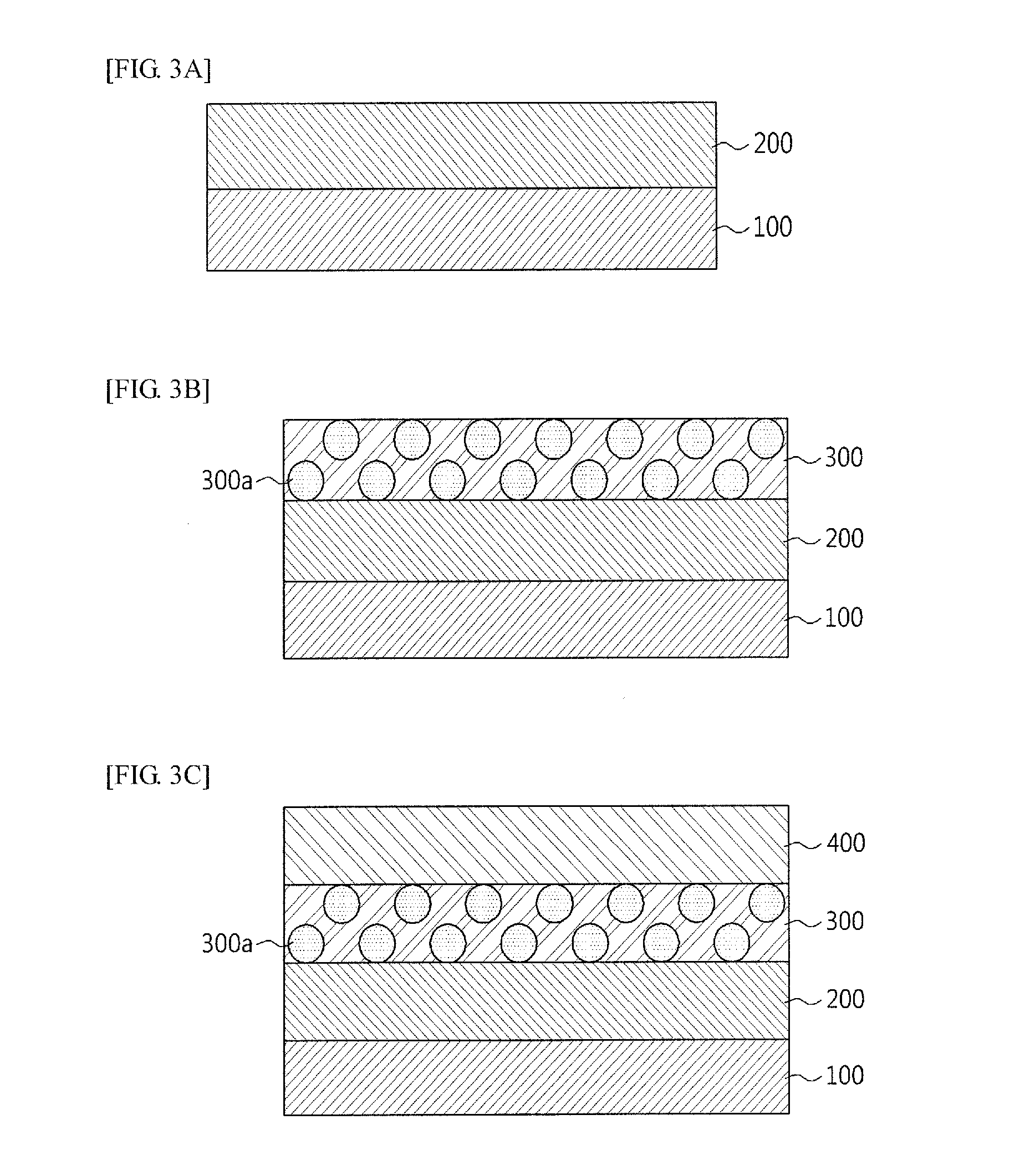

Organic light emitting device

InactiveUS20140231766A1Reduce in quantityIncrease the aperture ratioElectroluminescent light sourcesNanoinformaticsQuantum efficiencyElectron hole

Provided is an organic light emitting device including a nano composite layer. The organic light emitting device adopts a nano composite layer including an insulator and light emitting nano-particles within a device, thereby simultaneously insulating a control electrode and changing the color of light emitted from a light emitting layer, thereby improving external quantum efficiency. Further, the amount of electron holes and electrons injected into the light emitting layer may be adjusted through a voltage applied to the control electrode so as to secure a stable current when the device is operated. In addition, when compared to a conventional light emitting device, the surface area of positive and negative electrodes may be reduced so as to reduce reflectance with respect to external light.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV) +1

Microemulsion of hypocrellin, and its preparing method

InactiveCN101002757AImprove stabilityRaw materials are cheap and easy to getOrganic active ingredientsAntipyreticActive agentPhosphate

A microemulsion of hypocrelline for venous injection with high stability, target nature and biodegradability and strong photodynamic function is proportionally prepared from hypocrelline, natural oil, surfactant, water-soluble polyol, and water. Its preparing process is also disclosed.

Owner:INST OF CHEM CHINESE ACAD OF SCI

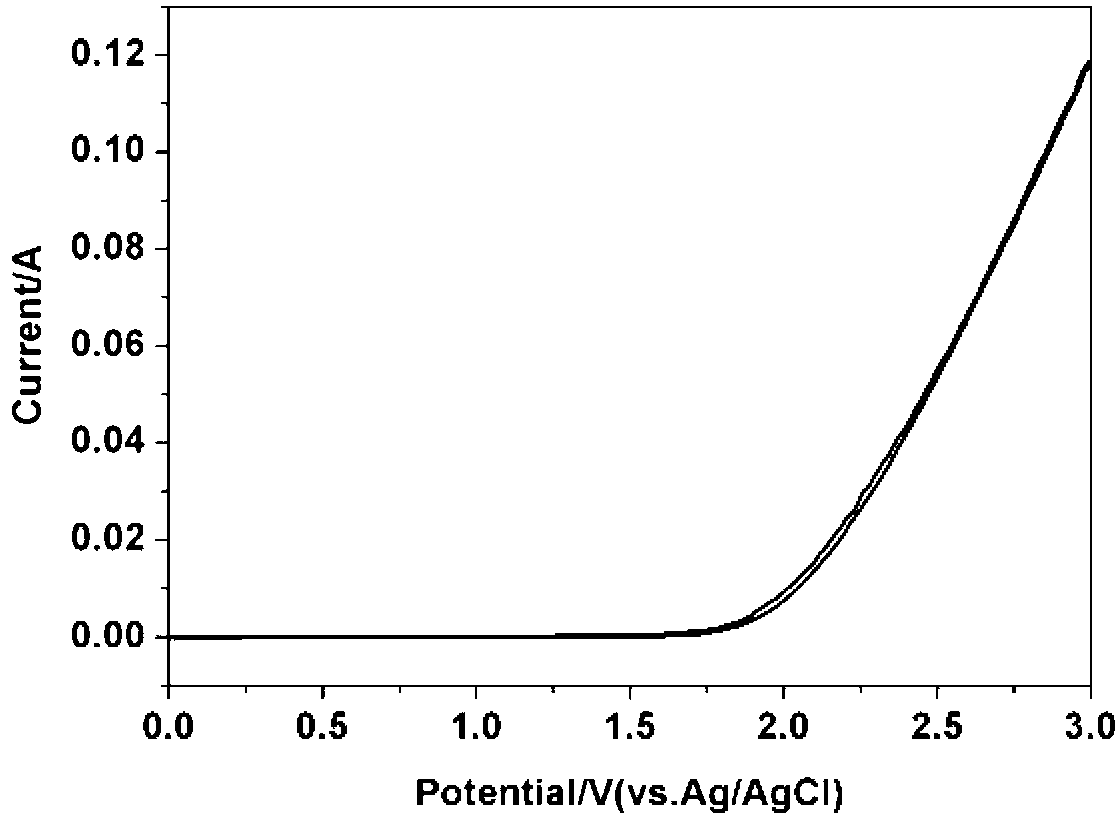

Fabrication method of long-life titanium base electrode

The invention discloses a fabrication method of a long-life titanium base electrode, which comprises the steps of fabricating a titanium oxide layer on a titanium substrate by a dipping-thermal decomposition method, reducing the titanium oxide layer in a reducing atmosphere, synchronously depositing a tin metal simple substance and an antimony metal simple substance in proportion on the surface of the titanium oxide layer by an electrodeposition method, and conducting thermal oxidation to allow an antimony doped tin oxide layer to be tightly combined with the titanium oxide layer connected with the titanium substrate to form a solid solution structure. The prepared titanium base tin dioxide electrode has the advantages of long service life, high oxygen evolution potential, high electrocatalytic activity, high generation efficiency of ozone from electrolyzed water, and the like. In addition, the cost of the fabrication process is low, the requirement of equipment is low, the operation is easy to control, and industrial mass production is facilitated.

Owner:XI AN JIAOTONG UNIV

Heat insulation composite material with high temperature mechanical property and preparation method thereof

The invention discloses a heat insulation composite material with high temperature mechanical property and a preparation method thereof. The material comprises 33-39% of barium-phenolic resins, 5-7% of ethanol and 56-60% of high strength glass fiber cloth by mass. The method is characterized by firstly clipping the high strength glass fiber cloth, then mixing the barium-phenolic resins and the ethanol to form barium-phenolic resin adhesive solution, proportionally immersing the barium-phenolic resin adhesive solution into the high strength glass fiber cloth to form S-glass / phenolic aldehyde composite material prepreg and finally drying the aired S-glass / phenolic aldehyde composite material prepreg with an electrothermal blowing dry box. The invention solves the problem that the materials with heat insulation requirement in the aerospace products have poor mechanical properties at high temperature and simultaneously has the characteristics of low material price, simple production and low possibility of debris falling after the product is produced.

Owner:中国航天科工集团第二研究院二八三厂

Self-adhesive EVA (Ethylene-Vinyl Acetate) protective film and manufacturing process thereof

ActiveCN103640288AModerate adhesionEasy to pasteSynthetic resin layered productsForeign matterPolymer science

The invention relates to the technical field of protective films and particularly relates to a self-adhesive EVA (Ethylene-Vinyl Acetate) protective film and a manufacturing process thereof. The self-adhesive EVA protective film is formed by a film which is coextruded and adhered by a base film layer, a middle layer and a self-adhesive layer. Especially, due to the self-adhesive layer, adhesive force of the EVA self-adhesive protective film is moderate, so that the self-adhesive EVA protective film is easily stuck and torn; after the film is stuck, the change of the adhesive force along with the time is small, the self-adhesive EVA protective film can be stuck repeatedly without adhesive failure and residual foreign matters, and can be used in special and large-corner surfaces with a radian and without upwarping; since the specific material combination of the base film layer, the middle layer and the self-adhesive layer is adopted, the impact resistance is also greatly improved; the manufacturing process of the self-adhesive EVA protective film is low in cost and is simple.

Owner:东莞市尼的科技股份有限公司

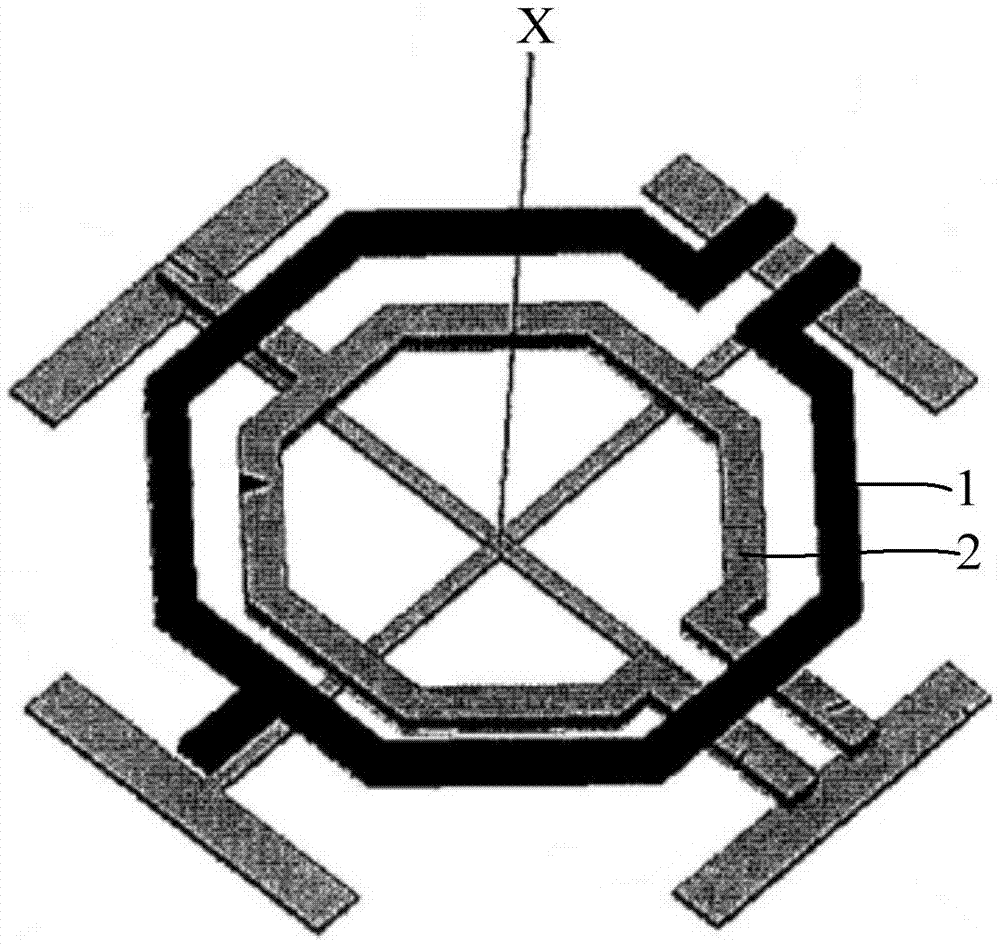

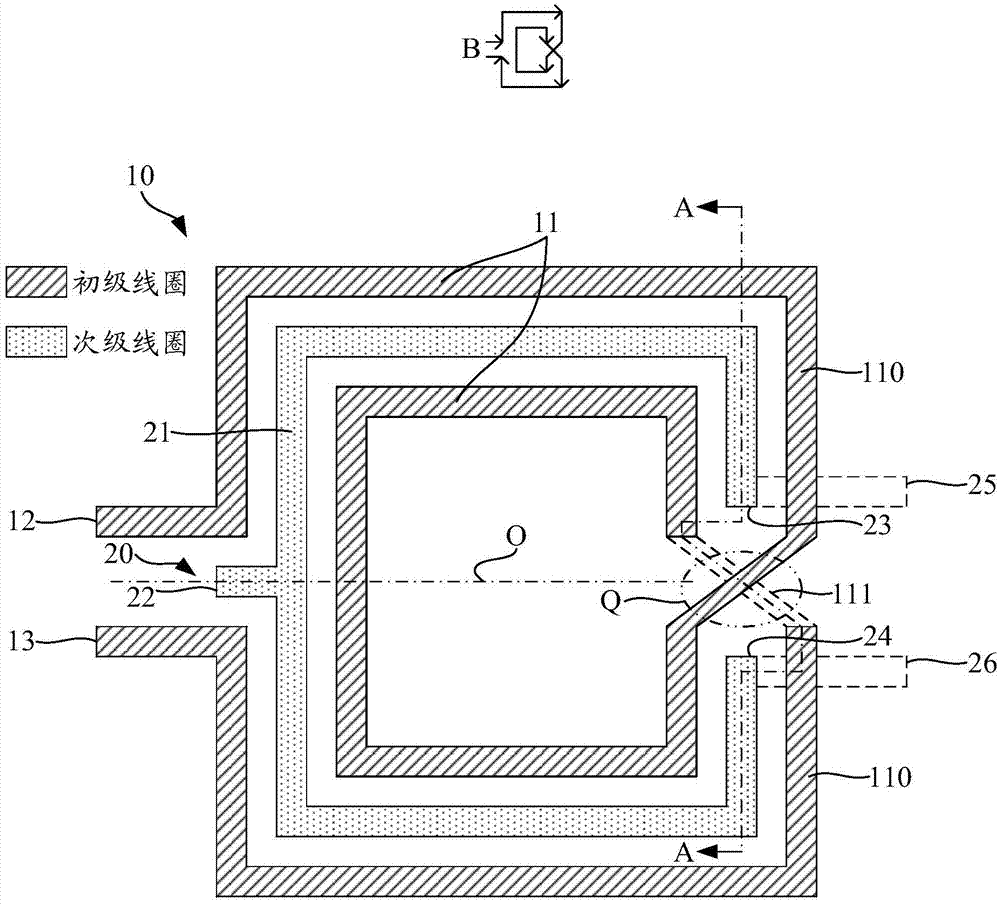

On-chip transformer Balun

ActiveCN107293393AImprove coupling coefficientReduce lossTransformers/inductances coils/windings/connectionsVariable inductancesElectricityTransformer

An on-chip transformer Balun comprises a primary coil and a secondary coil, wherein the turns of the primary coil is N, a first terminal and a second terminal of the primary coil are arranged on a winding at the outermost turns so that (N-1) lamination regions exist in the winding of the primary coil, the primary coil comprises a plurality of first metal lines and a plurality of connection bridges which are arranged in a staggered way along a winding direction, the first metal lines are arranged on the same plane, the connection bridges are arranged below the plane, the connection bridges are electrically connected with the first metal lines at the lamination regions, upper surfaces of the connection bridges are covered by a dielectric layer below the plane, N is more than or equal to 2, the secondary coil with M turns is arranged on the plane, and a winding of the secondary coil is arranged between two adjacent turns of windings of the primary coil. The on-chip transformer Balun disclosed by the scheme is relatively large in coupling coefficient and small in energy loss, the turn numbers of the primary coil and the secondary coil are relatively large, and the manufacturing process is low in cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Preparation method of porous tea residue biochar with high specific surface area

InactiveCN111841495ASimple preparation processWide variety of sourcesOther chemical processesWater contaminantsEnvironmental engineeringThermal water

The invention discloses a preparation method of porous tea residue biochar with a high specific surface area, and belongs to the field of resource reutilization of product processing wastes. Potassiumbicarbonate is used as a modifier. The method comprises the steps: washing tea residues with hot water, drying and crushing; secondly, carrying out hydro-thermal treatment on the tea residues; dryinga tea residue hydrothermal carbon solid after hydrothermal treatment; then soaking and uniformly mixing the hydrothermal carbon and potassium bicarbonate; after drying, putting the mixture into a tubular muffle furnace for pyrolysis; and carrying out acid washing, water washing, drying and ball milling on the carbonized product after pyrolysis to obtain the tea residue biochar, wherein the prepared tea residue biochar has a developed pore structure and a large specific surface area, the specific surface area is 1278-1405 m<2> / g, and the pore volume is 0.6734-0.8067 cm<3> / g. The tea residue biochar has a good removal effect on tetracycline in a water body, and the adsorption capacity of the tea residue biochar on tetracycline in the water body can reach 429-478 mg / g.

Owner:ANHUI AGRICULTURAL UNIVERSITY

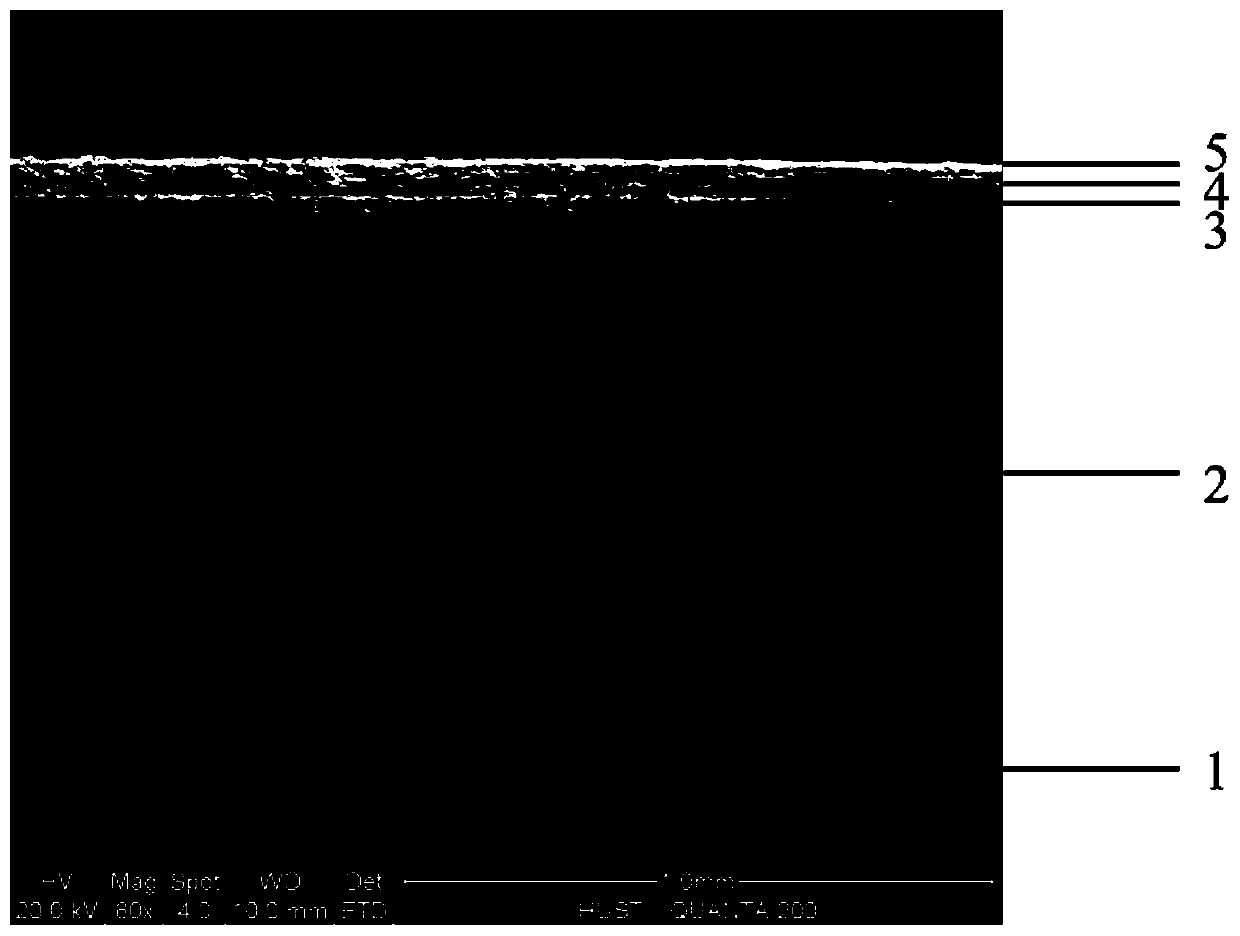

Anti-carbon metal-supported solid oxide fuel cell and preparation method thereof

ActiveCN109904497ALow cost of preparation processBroad application prospectsFinal product manufactureCell electrodesIonOxide

The invention belongs to the technical field of solid oxide fuel cells, and discloses an anti-carbon metal-supported solid oxide fuel cell and a preparation method thereof. The anti-carbon metal-supported solid oxide fuel cell comprises a porous catalytic reforming layer, a porous metal supporting layer, a porous anode functional layer, a dense electrolyte layer and a porous cathode layer which are sequentially and tightly combined; wherein the porous catalytic reforming layer comprises a Ni-M alloy and an oxygen storage-water absorbing oxide; the porous metal supporting layer comprises a Ni-Malloy and MgO; and the porous anode functional layer comprises a Ni-M alloy and a fluorite structural oxide or comprises a Ni-M alloy and a (ionic conductive) perovskite structural oxide. The invention further discloses the preparation method of the corresponding cell. When hydrocarbons are used as fuel, the anti-carbon metal-supported solid oxide fuel cell can operate steadily in a long term inthe hydrocarbon fuel, and the fuel cell has low preparation process cost, is suitable for large-area single cells and scale production and manufacturing, and has broad application prospects.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for manufacturing cellulose carbamate

InactiveUS7662953B2Reducing DP levelImprove efficiencySugar derivativesSugar derivatives preparationCelluloseOrganic solvent

The invention relates to a method for manufacturing cellulose carbamate. In the method, an auxiliary agent and urea in solution form and possibly in solid form are absorbed into cellulose, and a reaction between cellulose and urea is carried out in a mixture containing cellulose, a liquid, the auxiliary agent, and urea The absorption of the auxiliary agent and urea into cellulose, and the reaction between the cellulose and the auxiliary agent at least partly are carried out in a working device. According to the invention, it is possible to manufacture cellulose carbamate without ammonia, organic solvents or other auxiliary agents, by using only a small quantity of water as a medium.

Owner:INFINITED FIBER CO OY

High quality aluminum titanium boron refiner and preparation method thereof

The invention discloses a preparation method of a high quality aluminum titanium boron refiner. The prepared high quality aluminum titanium boron refiner comprises, by mass, 4.8-5.5% of Ti, 0.8-1.2% of B and the balance Al. The preparation method of the intermediate alloy comprises the steps that the quantities of potassium fluoborate and potassium fluotitanate required for two-time feeding are calculated according to a chemical reaction equation; the feeding method is two-time feeding; according to the matching ratio of villiaumite two times of feeding, the mass ratio of the potassium fluotitanate in the first feeding to the potassium fluotitanate in the second feeding is 1.09-1.52 and the mass ratio of the potassium fluoborate in the first feeding to the potassium fluoborate in the second feeding is 0-0.2; but it should be always guaranteed that the mass ratio of the potassium fluoborate to the potassium fluotitanate in the second feeding is 1.05:1; the potassium fluotitanate and the potassium fluoborate which are well proportioned are evenly mixed and dried, and added into a pure aluminum melt at a constant speed in two times; the mixture obtained in the previous step is stored for a period of time and then mixed for 3-5 minutes; and calcium fluoride is added into the mixture, water slag is removed 2-5 minutes later, and sticks are formed by pouring.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com