High-quality steel plate capable of resisting fatigue crack growth and manufacturing method thereof

一种裂纹扩展、制造方法的技术,应用在抗疲劳裂纹扩展优良钢板及其制造领域,能够解决未涉及等问题,达到缩短制造周期、低制造、优良抗疲劳裂纹扩展能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

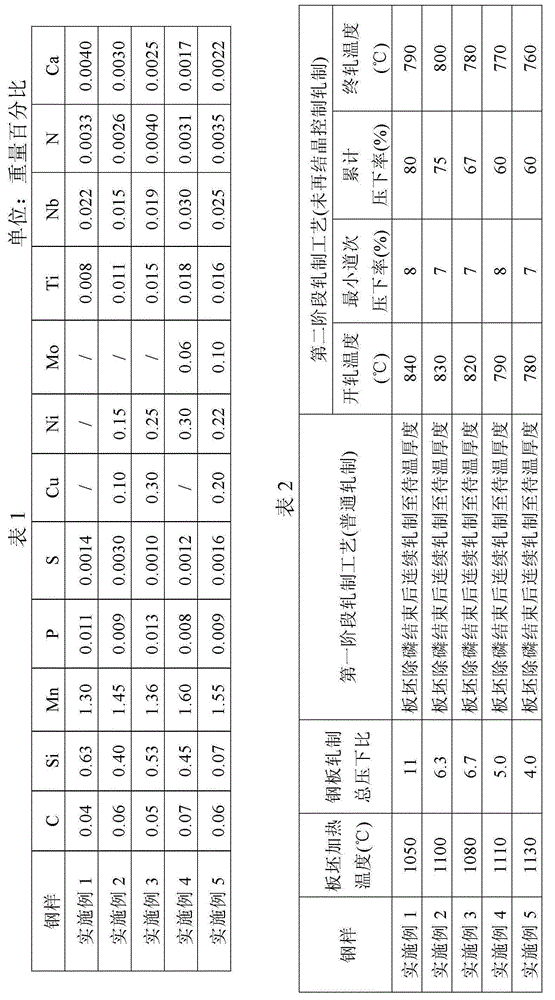

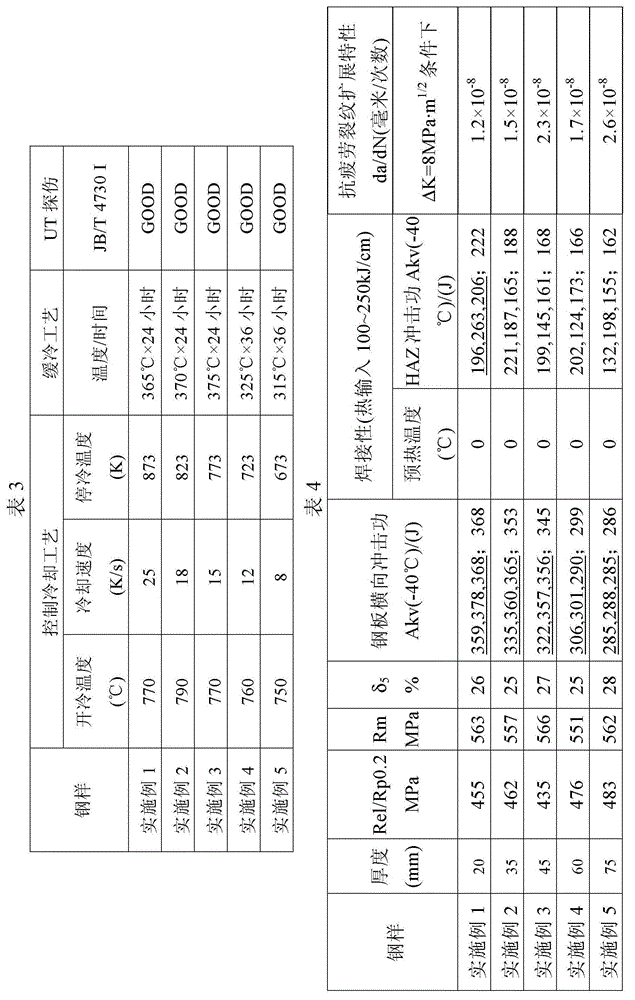

[0043] The composition of the steel embodiment of the present invention is shown in Table 1, and Table 2 and Table 3 show the manufacturing process of the steel embodiment of the present invention. Table 4 shows the performance of the steel plate of the present invention.

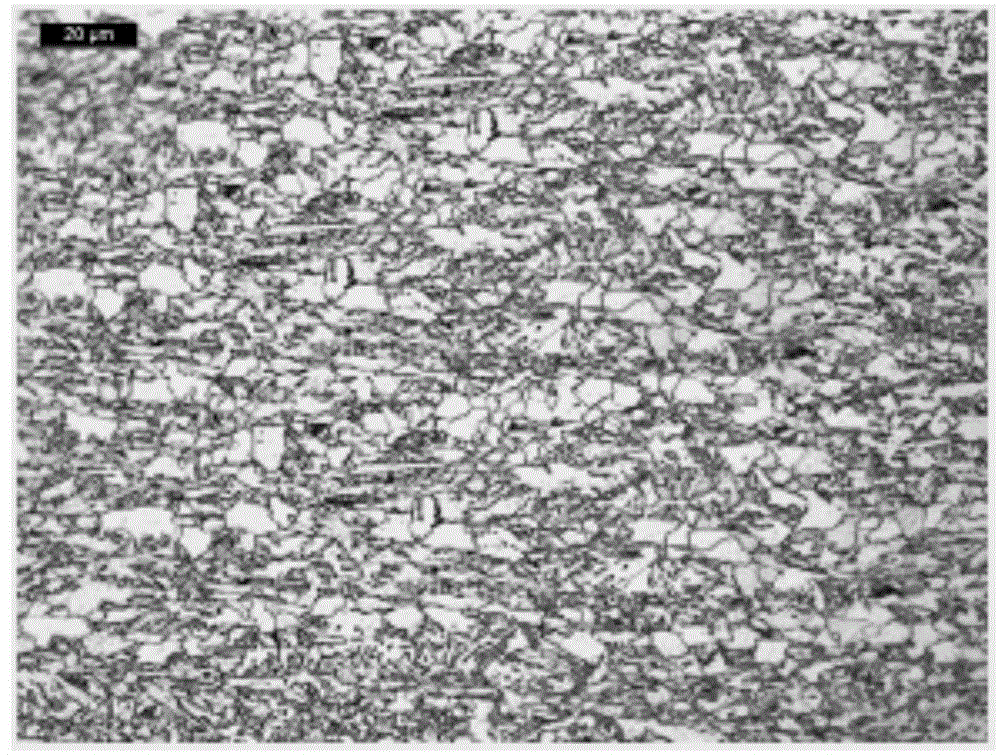

[0044] From Table 4 and attached figure 1 It can be seen that the steel plate of the present invention has a yield strength ≥ 385MPa, a tensile strength of 520-630MPa, a Charpy impact energy (single value) ≥ 80J at -40°C, and a fatigue crack growth-resistant steel plate with excellent weldability (at ΔK=8MPa·m 1 / 2 Under conditions, da / dN≤3.0×10 -8 ). The microstructure of the finished steel plate is a dual-phase structure of ferrite + uniformly dispersed bainite, and the average grain size of the microstructure is below 10 μm.

[0045] The steel plate of the present invention is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com