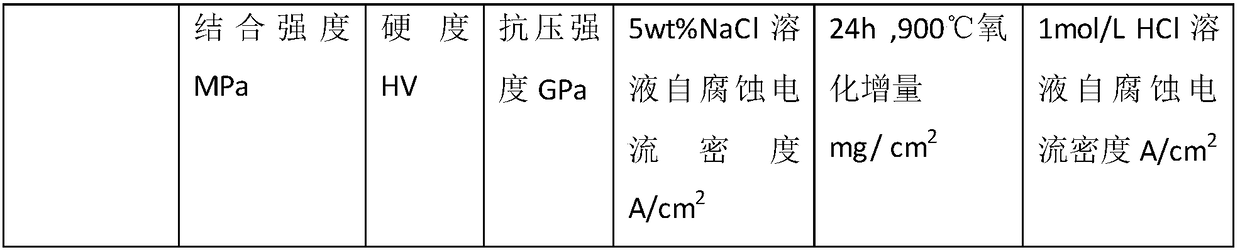

Patents

Literature

80results about How to "Good high temperature corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resistant stainless steel with high-lasting strength and manufacturing method thereof

ActiveCN101705437ASimple structureMeet the requirements of the use environmentTemperature control deviceFurnace typesPower stationSuperheater

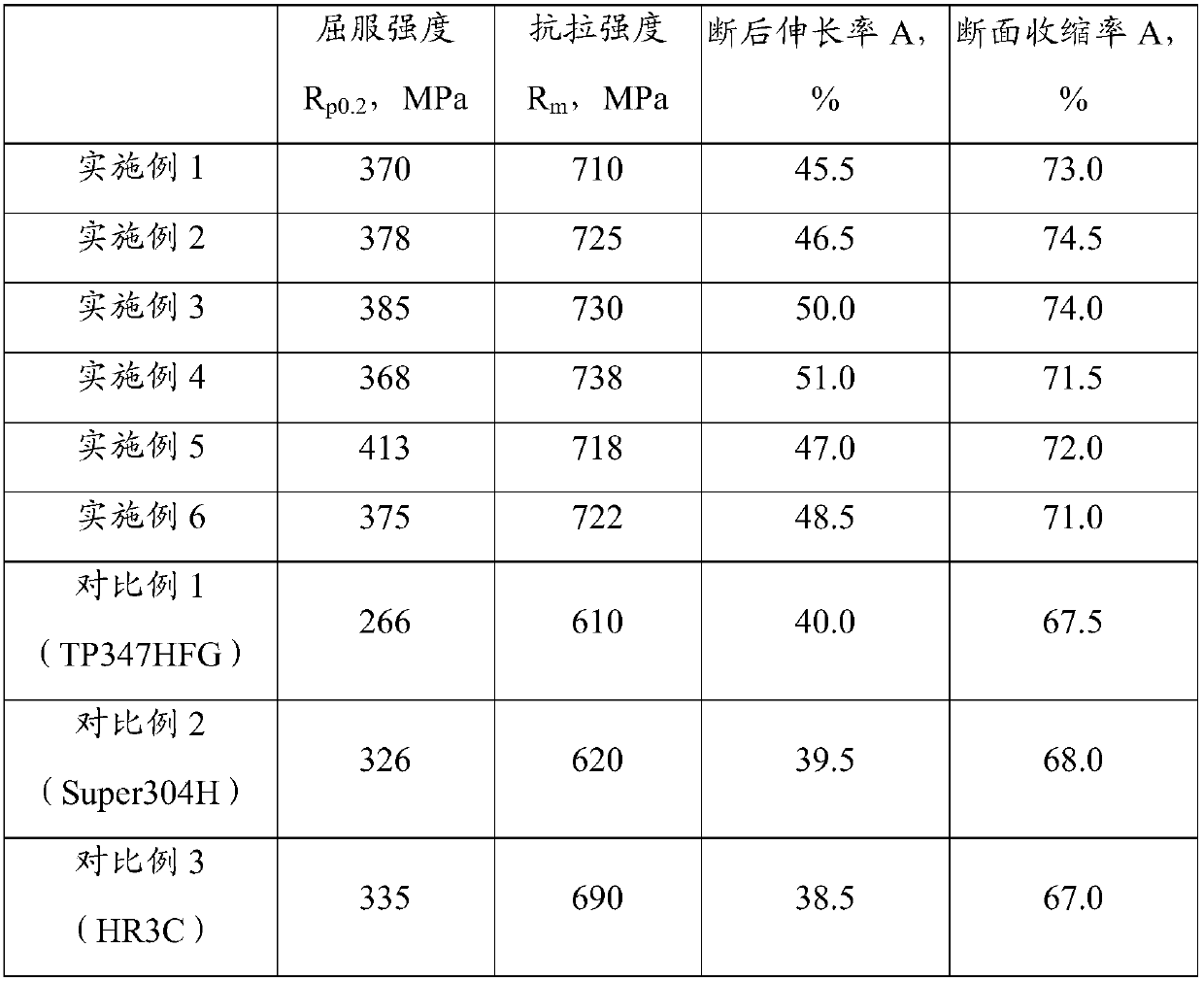

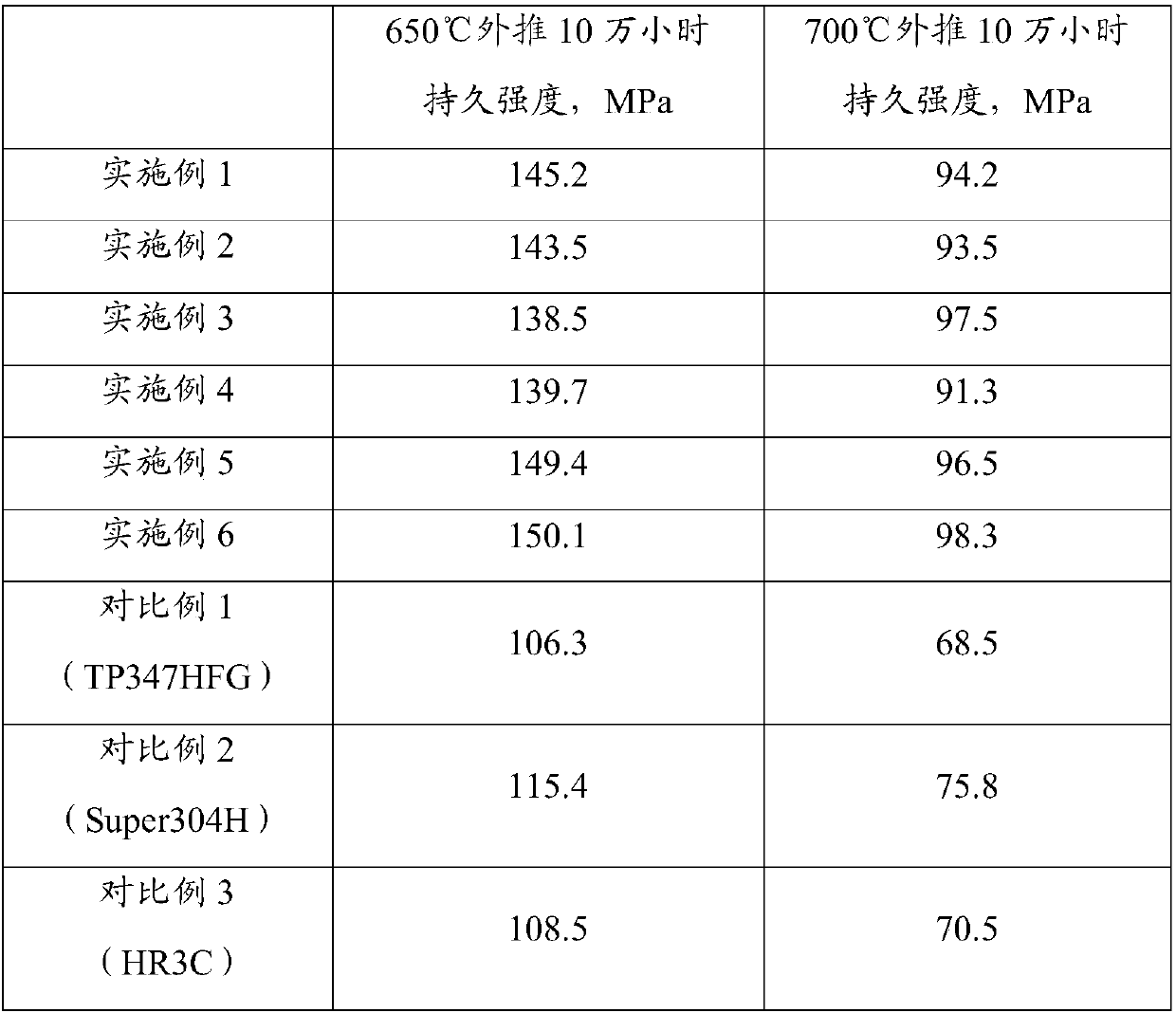

The invention discloses a heat-resistant stainless steel with high-lasting strength and a manufacturing method thereof. The heat-resistant stainless steel includes the following components by percentage: 24.00-26.00 of Cr, 17.00-23.00 of Ni, 0.05-0.75 of Si, 0.15-2.00 of Mn, less than or equal to 0.030 of P, less than or equal to 0.030 of S, 0.04-0.10 of C, 0.15-0.35 of N, 0.01-5.00 of RE, and 0.20-0.60 of M, wherein M is Nb and Ta. The manufacturing method comprises the following steps: 1. smelting: smelting molten steel in accordance with component requirements of the stainless steel; 2. pouring billet steel; 3. hot-rolling the billet steel: a. heating, the temperature of a uniform temperature section in a furnace is at the temperature of 1130 DEG C plus or minus 50 DEG C, and the soaking time is 80 minutes plus or minus 10 minutes; and b. rolling or forging, the initial rolling / initial forging temperature is at the temperature of 1100 DEG C plus or minus 50 DEG C, and the finishing rolling / finishing forging temperature is at the temperature of 860 DEG C plus or minus 50 DEG C; and 4. heat treatment, the solid solution temperature is at the temperature of 1175 DEG C plus or minus 75 DEG C, and water quenching after heat preservation. Through deduction by tests after sampling the stainless steel manufactured by the method, manufactured seamless tubes can satisfy the use requirements of superheaters and reheaters of ultra-supercritical power station boilers.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

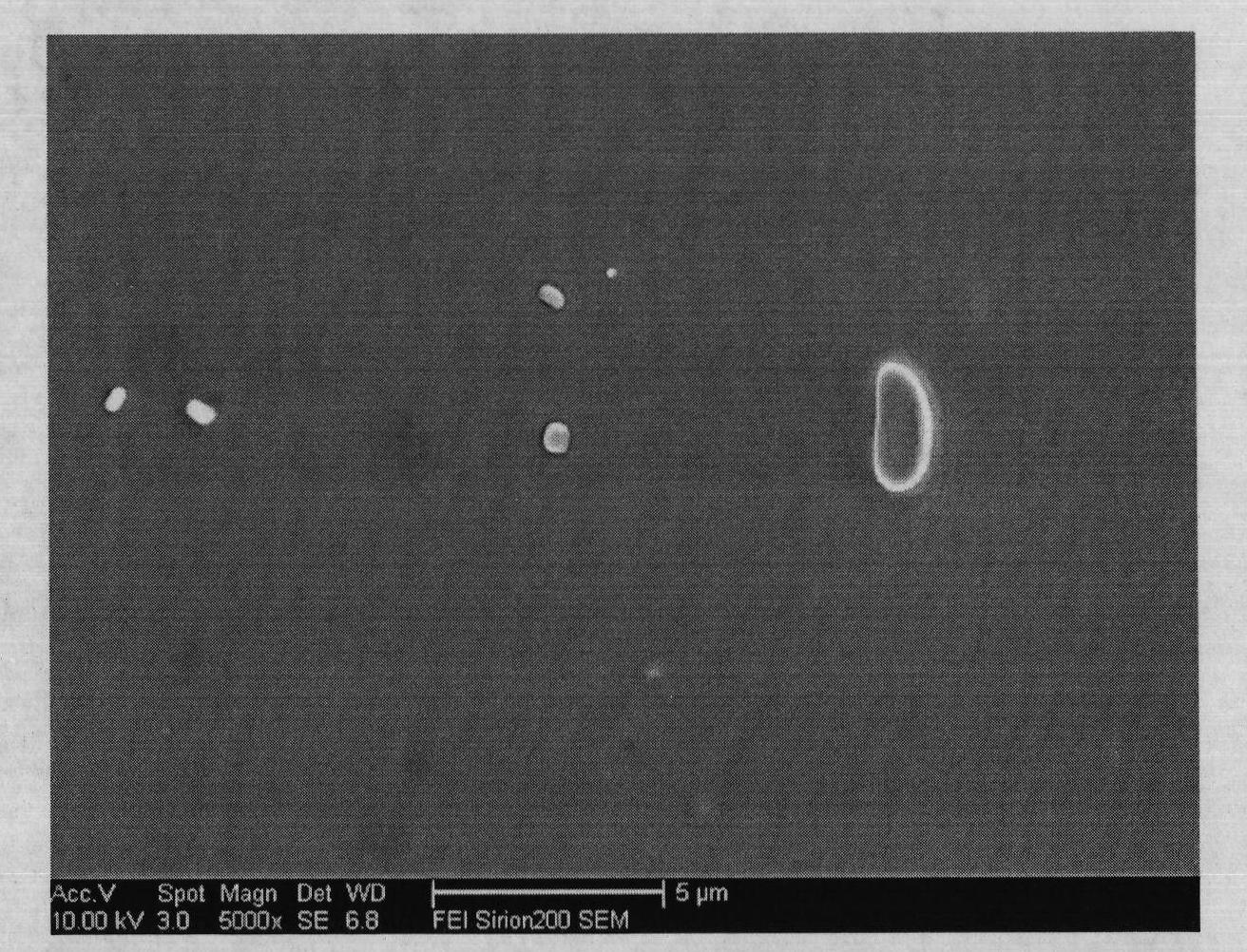

Nano ceramic particle reinforced nickel-based superalloy composite material and laser 3D printing forming method thereof

InactiveCN104745887AGood high temperature corrosion resistanceImprove wear resistanceAlloy compositeHigh energy laser

The invention discloses a nano ceramic particle reinforced nickel-based superalloy composite material and a laser 3D printing forming method thereof. A nickel-based superalloy with the particle size of 15-45mu m is taken as a matrix, CrC with the particle size of 40-100nm is taken as a reinforced phase, and the addition amount of CrC is 2.0-8.0% by weight of the composite material matrix; a nano CrC particle hybrid reinforced nickel-based superalloy composite material part has the advantages of good high-temperature anti-corrosion property, abrasion resistance, high temperature creep and the like and can meet special performance requirements of an aero-engine hot end component at high temperature; a high-energy laser forming method is applicable to preparation of a difficult-to-process material and forming of a complex part; and a forming die is not needed, so that a manufacturing cycle is shortened, and the cost is reduced.

Owner:JIANGSU SILAIMU INTELLIGENT TECH CO LTD

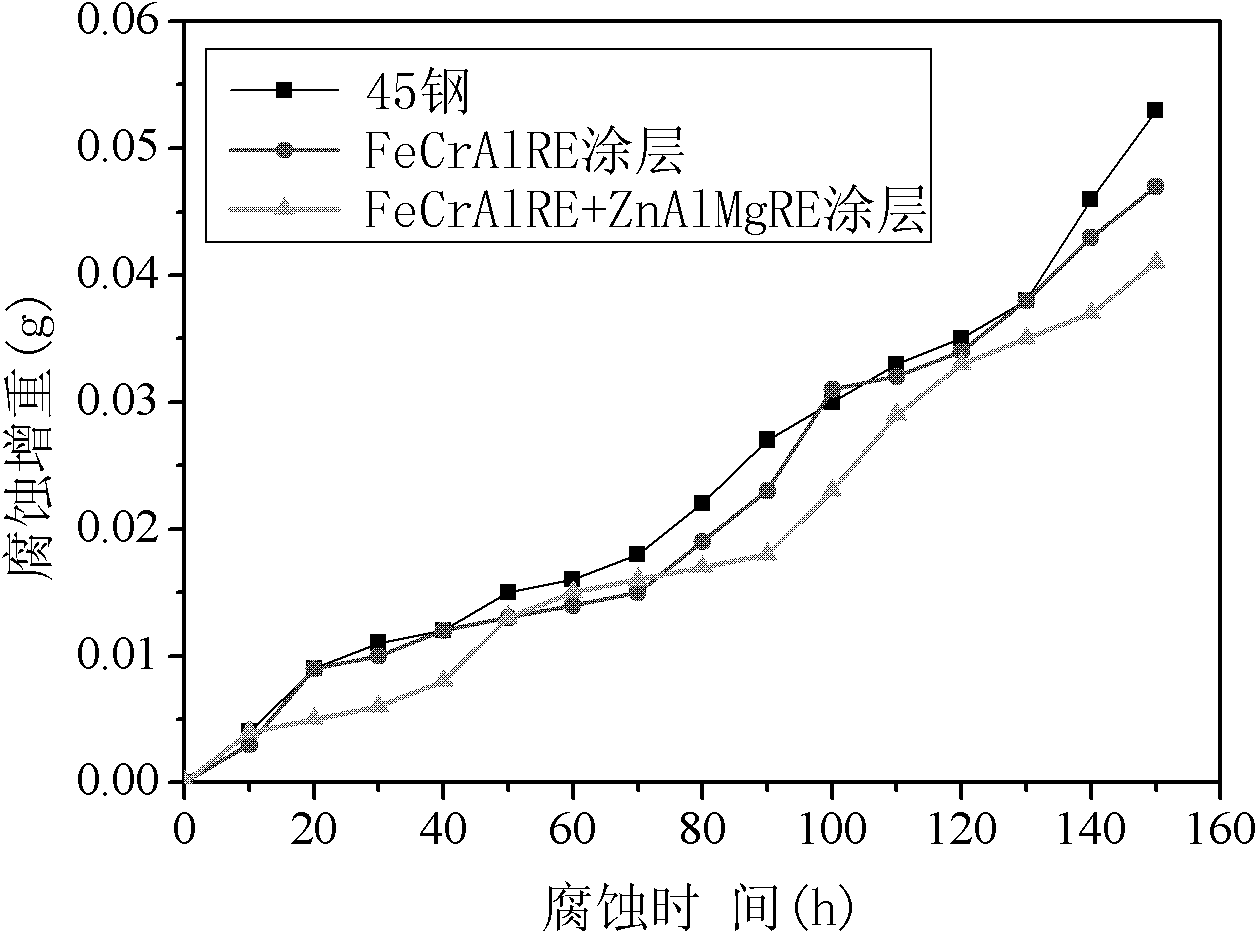

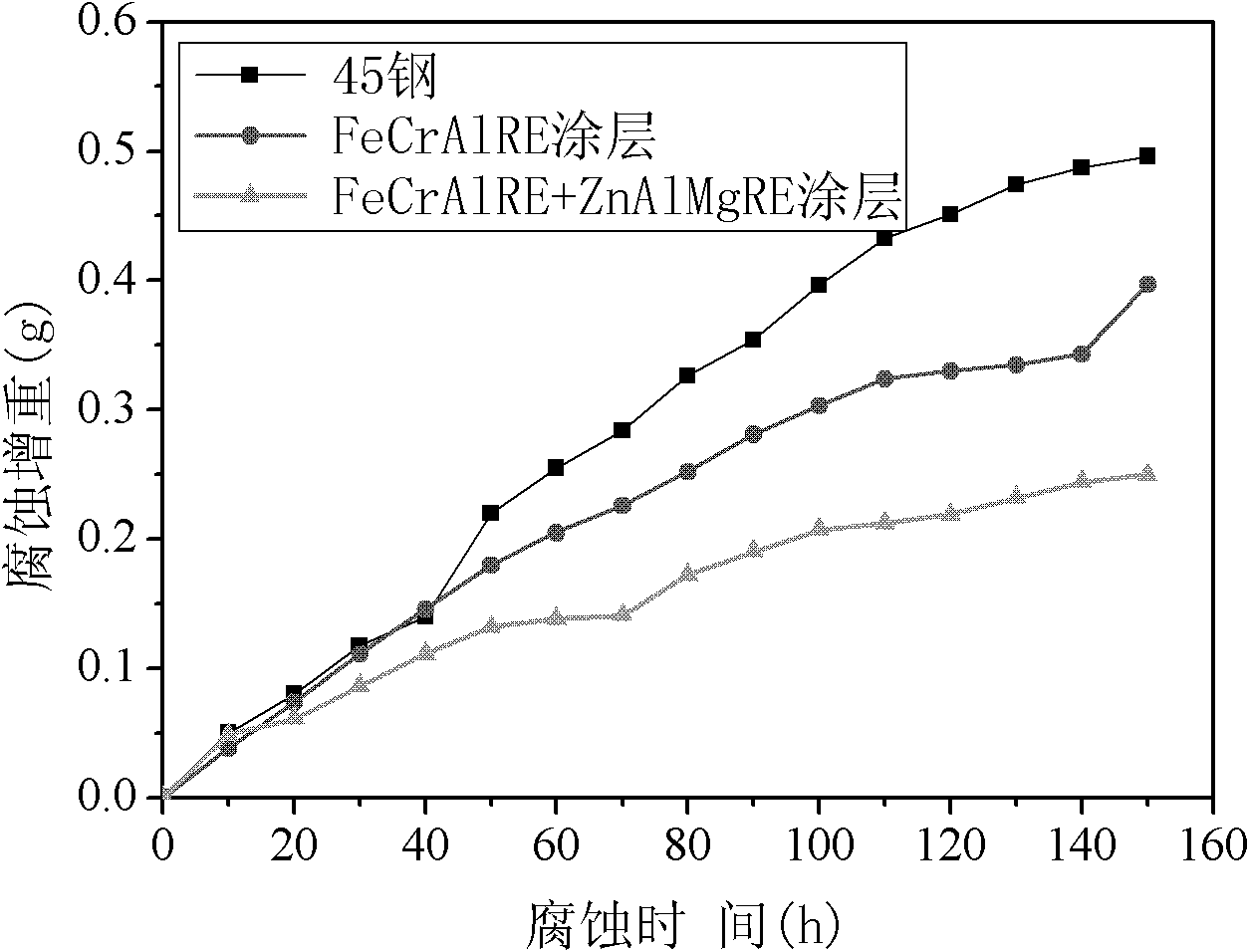

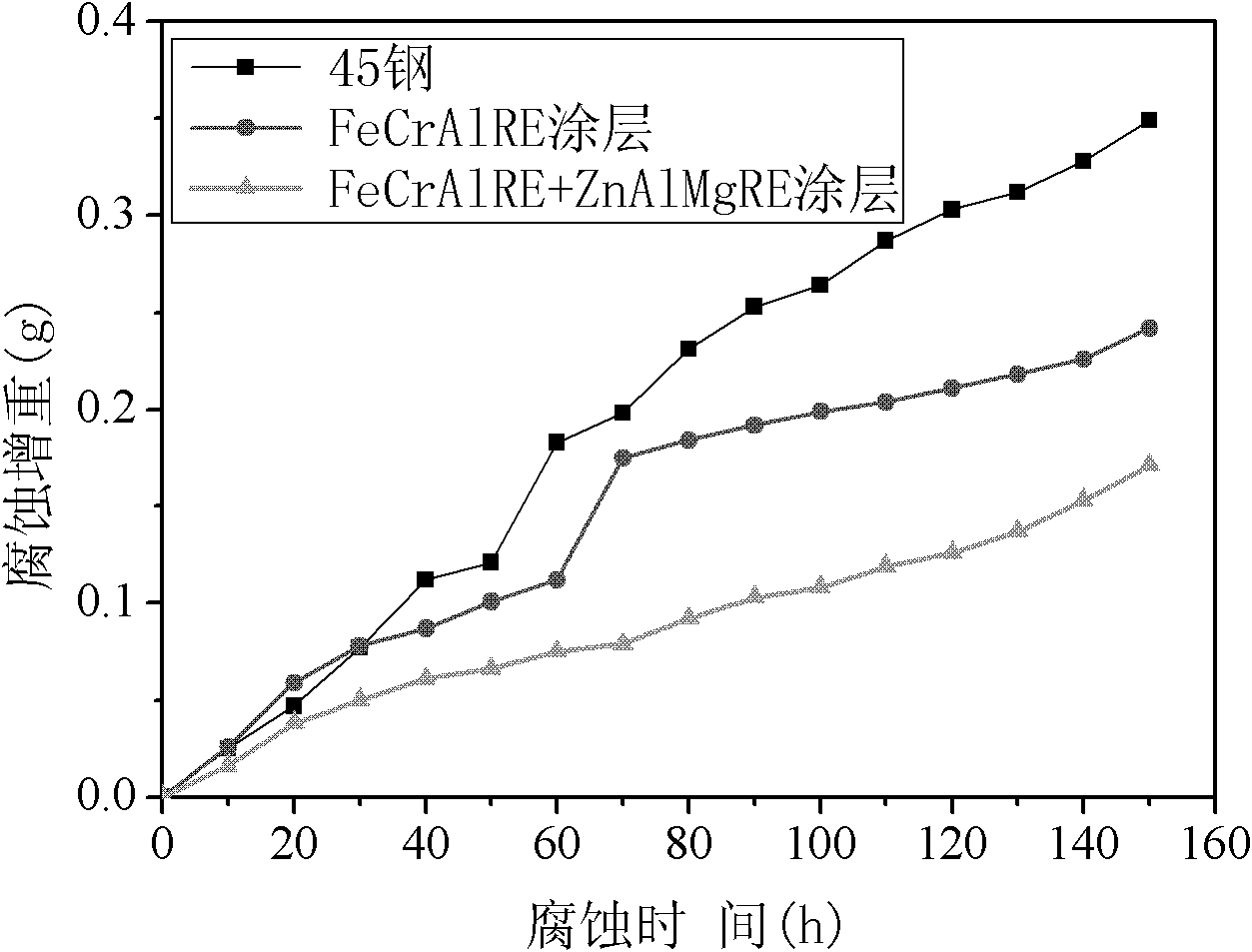

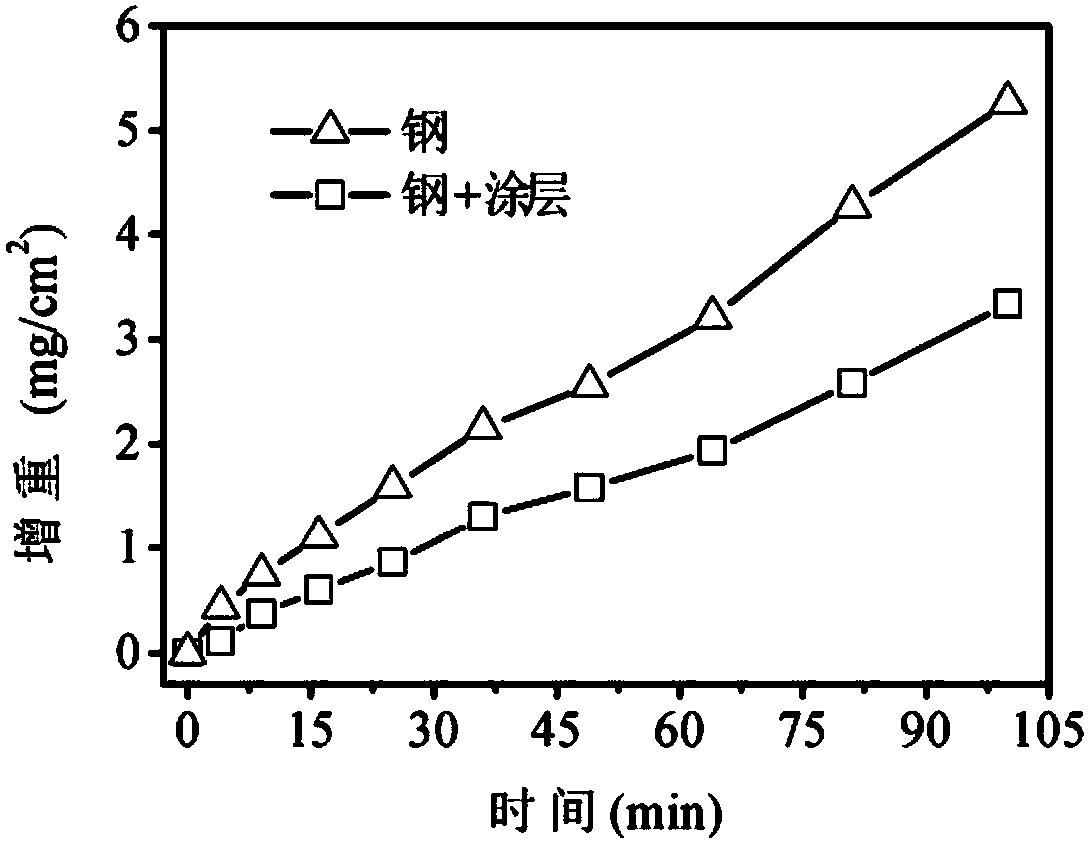

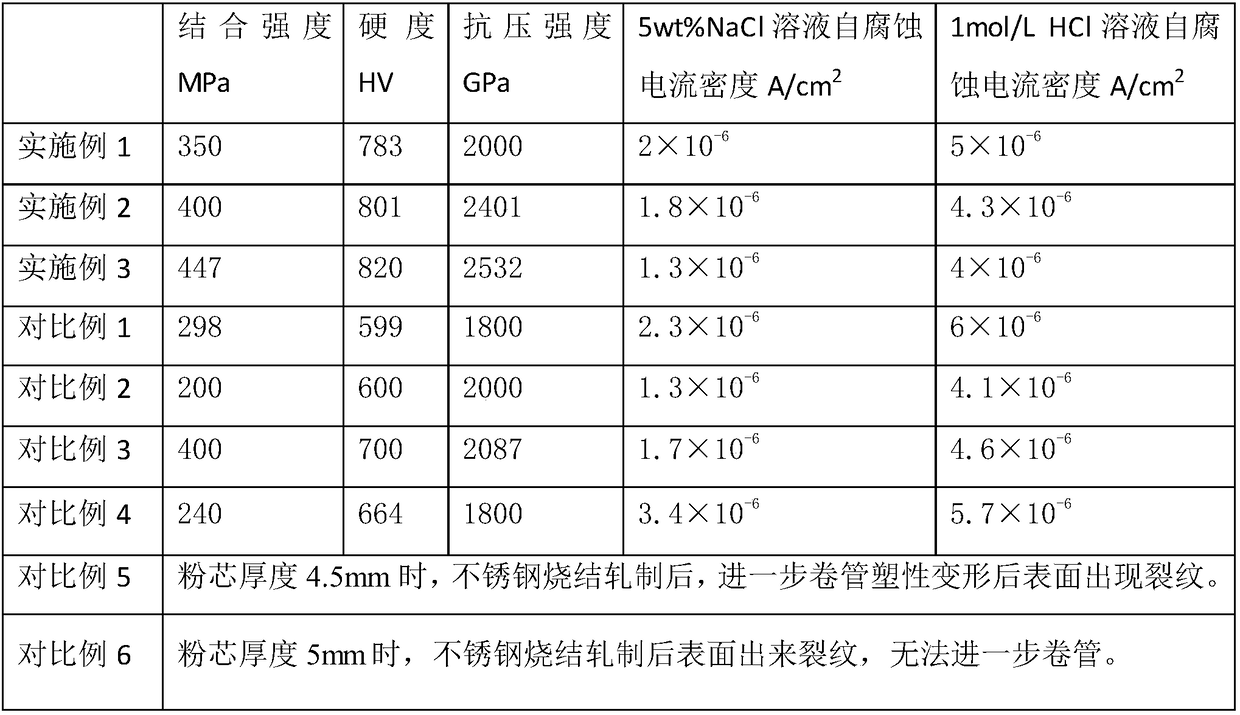

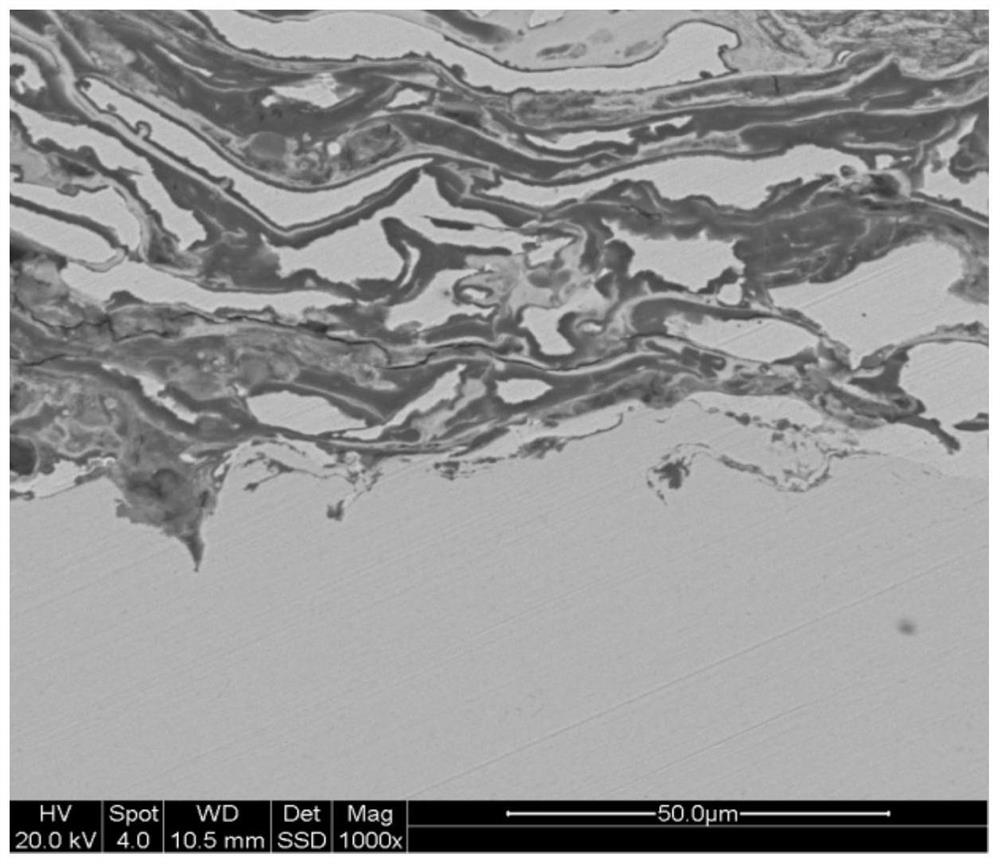

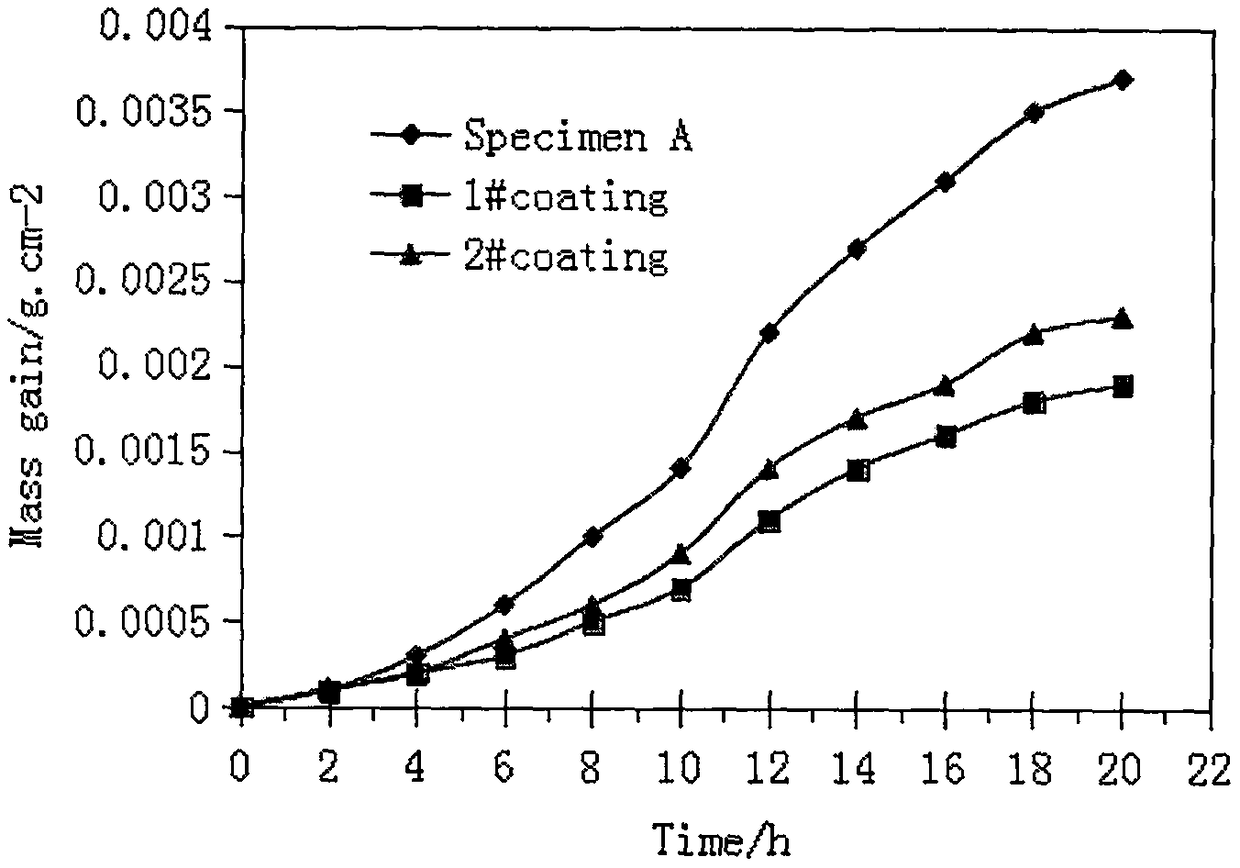

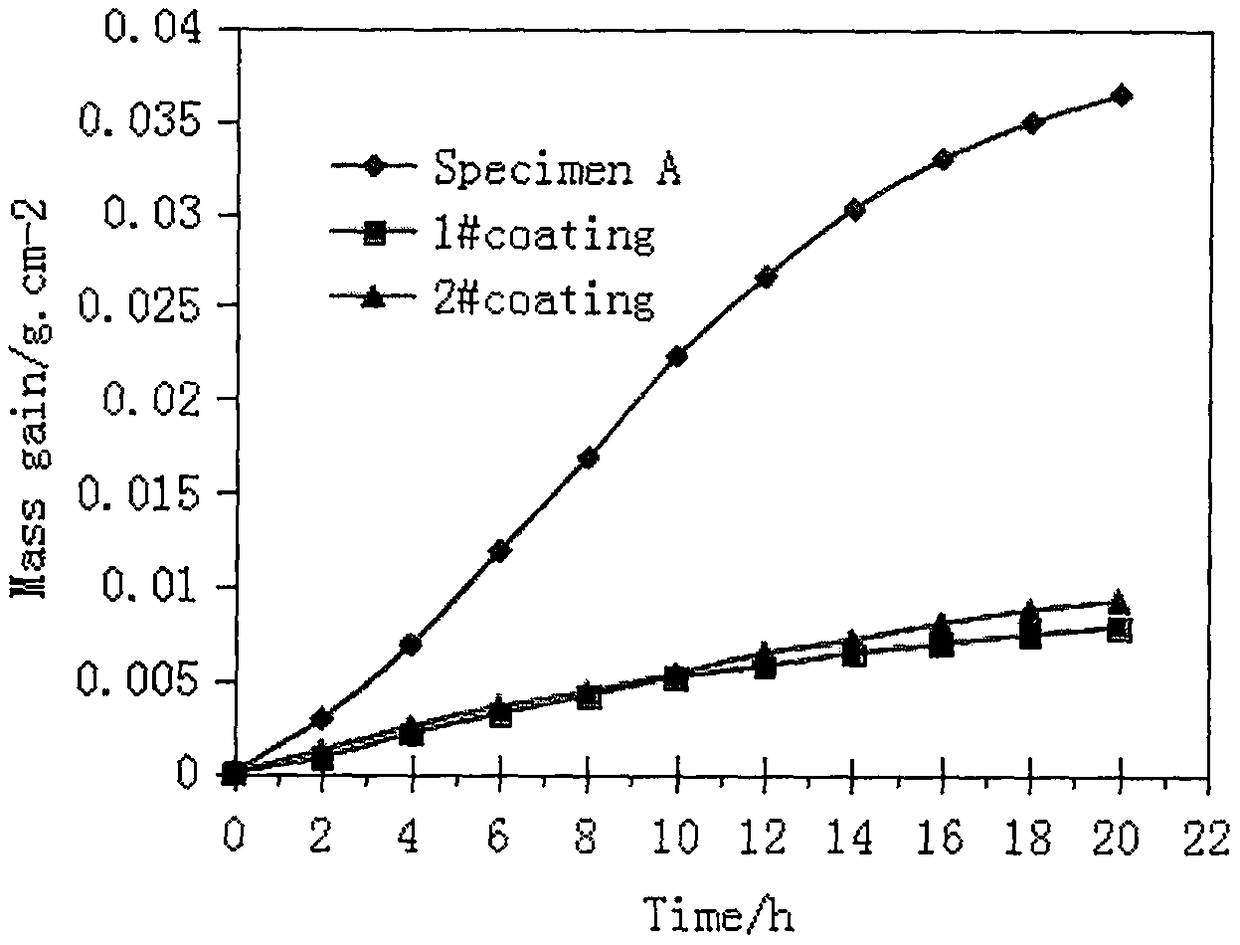

Marine-corrosion/hot-corrosion-resistant composite coating and preparation method thereof

ActiveCN102206797AGood high temperature corrosion resistanceGood self-sealingMolten spray coatingHigh humidityAlloy coating

The invention discloses a marine-corrosion / hot-corrosion-resistant composite coating and a preparation method thereof, belonging to the technical field of metal surface protection. A novel FeCrAlRe hot-corrosion-resistant powder core wire material is prepared by coating mixed powder, containing Cr powder, Al powder and the like, on a carbon steel band. A ZnAlMgRe powder core wire material is prepared by coating mixed powder, containing Al, Mg, Zn and Re, on a Zn-base alloy band. The preparation method of the composite coating comprises the following steps: spraying the FeCrAlRe powder core wire material by using a high-speed arc spraying device to form an alloy coating on a pretreated steel base surface, and spraying a ZnAlMgRe coating to form a double-layer composite structure protective coating. The prepared coating can resist hot corrosion, and has excellent corrosion resistance in a marine high-humidity high-salt-mist environment.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

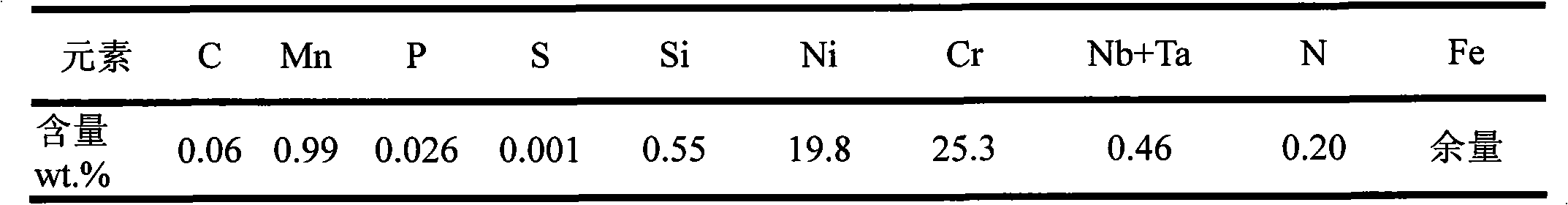

Seamless steel tube for ultra supercritical boiler and manufacturing method thereof

ActiveCN101781743AImproved grain boundary structureGood high temperature corrosion resistanceFurnace typesHeat treatment furnacesSteel tubeSolution treatment

The invention relates to a seamless steel tube for an ultra supercritical boiler and a manufacturing method thereof. The seamless steel tube comprises components in percentage by weight: 24.00-26.00% of Cr, 17.00-23.00% of Ni, 0.05-0.75% of Si, 0.15-2.00% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 0.04-0.10% of C, 0.15-0.35% of N, 0.01-5.00% of RE, 0.20-0.60% of M, the balance of Fe and unavoidable impurities. The manufacturing method mainly comprises the following steps: smelting molten steel according to component requirements and poring the molten steel to form billet steel; then hot working the billet steel to form a solid-core tube blank, preparing the billet steel into a hollow tube blank and preparing the tube blanks into the seamless steel tube by hot extrusion; carrying out stretch rolling, shot blasting, discarding, and sawing, and finally carrying out solution treatment. The seamless steel tube of the invention can meet the service environment requirements of an ultra supercritical boiler superheater and an ultra supercritical boiler reheater.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

No-co ferrous alloy powder composition for sealing face of nuclear power valve

InactiveCN101797643AMeet the needs of the jobExtended service lifeMetallic material coating processesNuclear powerSulfur

The invention belongs to the field of alloy material, relating to no-co ferrous alloy, in particular to no-co ferrous alloy for enhancing material of the sealing face of a nuclear power valve. The no-co ferrous alloy powder composition contains the following ingredients by weight percent: 20.5%-21.5% of Cr, 3.0%-3.5% of Ni, 3.0%-3.5% of Mn, 2.0%-2.5% of Si, 0.9%-1.0% of C, 1.5%-2.0% of Mo, 0.7%-1.2% of W, 0.3%-0.5% of V, P is less than or equal to 0.02%, S is less than or equal to 0.02%, 0.5%-1.0% of Y and the balance of Fe. The no-co ferrous alloy powder composition contains no noble metal of Co, at the same time, since laser cladding technology is adopted to prepare the coating, the microhardness of the cladding layer is 1.6-1.8 times of that the stainless steel matrix. The no-co ferrous alloy powder composition has excellent high-temperature abrasion performance and high-temperature corrosion resistance, so the no-co ferrous alloy powder composition can prolong the service life of the valve.

Owner:SUZHOU UNIV

Preparation method for nickel-based superalloy for exhaust valve

InactiveCN102808111AImprove mechanical propertiesReduce chemical composition deviationExhaust valveRoom temperature

Owner:NANTONG WEALTH MASCH TECH CO LTD

Method for coating high-temperature corrosion and wear resistant coating layer on surface of steel material

InactiveCN104213067AImprove corrosion resistanceImprove wear resistanceMolten spray coatingCeramic compositeWear resistant

The invention relates to a method for coating a high-temperature corrosion and wear resistant coating layer on a surface of a steel material, and relates to the preparation of a metal-based ceramic composite material coating layer by a high-speed flame spraying method or a gas plasma spraying method. The preparation method of the coating layer comprises the steps of matrix surfaced cleaning, matrix surface sand blasting treatment and powder material spraying. The prepared coating layer has higher compactness, higher hardness, better toughness and excellent oxidation corrosion resistance under the condition of high temperature. The method has simple process steps; and the prepared protective coating layer can enable the steel material to be applied to the higher temperature environment, so that the problem of high-temperature corrosion resistance of the steel material is solved.

Owner:SHANGHAI JIAO TONG UNIV

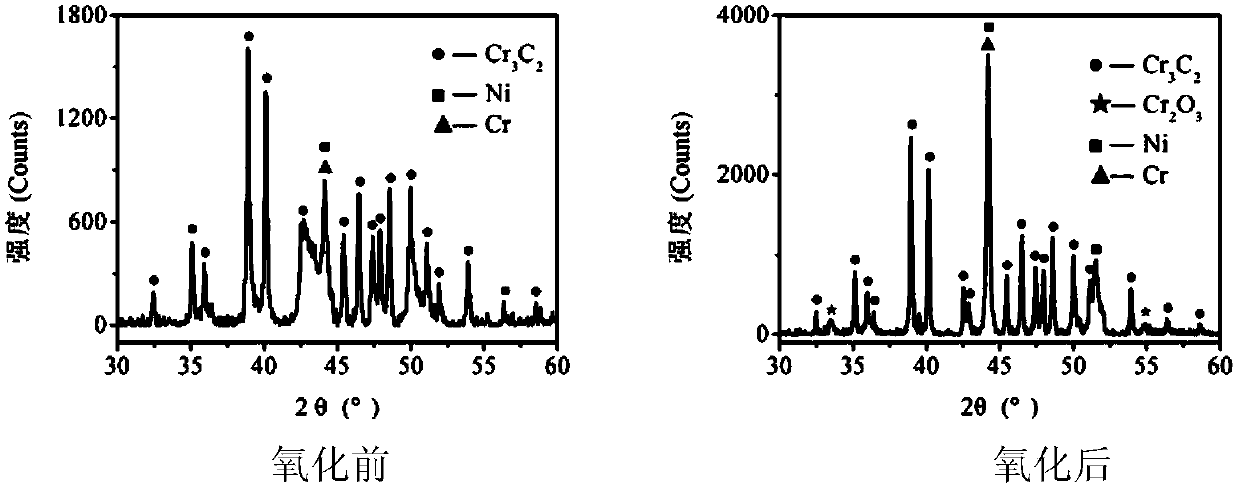

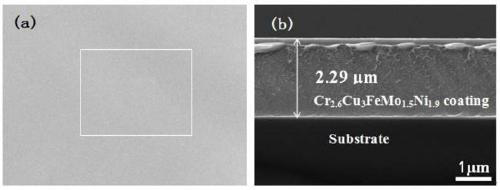

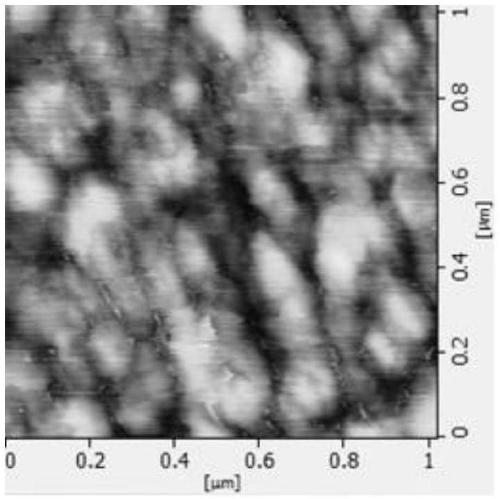

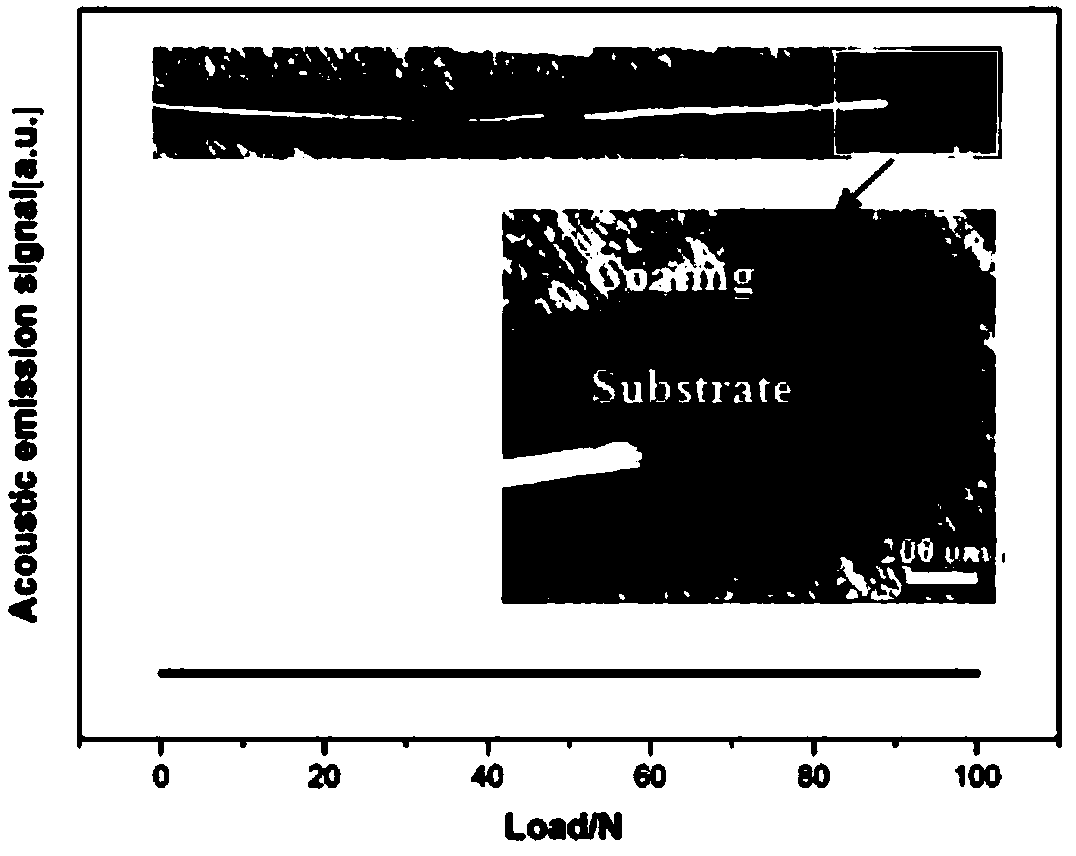

Nuclear zirconium alloy cladding surface high temperature and corrosion resisting high-entropy alloy coating and preparing method thereof

ActiveCN109666911AHigh hardnessImprove high temperature resistanceVacuum evaporation coatingSputtering coatingFault toleranceSputtering

The invention discloses a nuclear zirconium alloy cladding surface high temperature and corrosion resisting high-entropy alloy coating and a preparing method thereof. The high-entropy alloy coating deposited on the surface of a Zr alloy is a CrCuFeMoNi high-entropy alloy, and according to the atomic percents of Cr, Cu, Fe, Mo and Ni in the high-entropy alloy, Cr is 25%-35%, Cu is 20%-30%, Fe is 10%-14%, Mo is 15%-20%, and Ni is 15%-20%. The high-entropy alloy coating is deposited on the surface of the Zr alloy through the multi-target magnetron sputtering technology. According to the CrCuFeMoNi high-entropy alloy coating, the surface hardness of the Zr alloy is improved, corrosion resistance and radiation resistance are improved, good high-temperature resisting performance and corrosion resisting performance are shown, the actual engineering application can be achieved, and the CrCuFeMoNi high-entropy alloy coating is the potential alternative material for accident fault tolerance fuelcladding coatings. The adopted multi-target magnetron sputtering technology is mature, operation is simple, industrial production of the nuclear zirconium alloy cladding surface high temperature andcorrosion resisting high-entropy alloy coating to the engineering field can be achieved, and good development prospects are achieved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Cored wire for preparing nickel-based high-aluminum coating and coating preparation method of cored wire

ActiveCN105671471AHigh hardnessGood high temperature corrosion resistanceMolten spray coatingMaterials processingAluminum coating

The invention provides a cored wire for preparing a nickel-based high-aluminum coating and a coating preparation method of the cored wire, and belongs to the field of thermal spraying in material processing engineering. The cored wire comprises the following components in percentages by mass: 13-25% of Cr, 4-10% of Al, 3-6% of B, 3-6% of Si, and the balance Ni and inevitable impurities. A strip for the skin of the cored wire is a Ni80-Cr20 strip. When the nickel-based high-aluminum coating with good high-temperature corrosion resistance is prepared by electric arc spraying, conditions of a spraying process are as follows: current is 160-200 A, voltage is 28-34 V, pressure of compressed air is 0.4-0.6 MPa, and spraying distance is 190-210 mm. By the cored wire and the coating preparation method, the nickel-based high-aluminum coating with high hardness and good high-temperature corrosion resistance can be obtained.

Owner:BEIJING UNIV OF TECH

Preparation method of laminated composite material of titanium-aluminum/nickel-aluminum intermetallic compound

InactiveCN107053814ASimple production processLow equipment requirementsLamination ancillary operationsLaminationMaterials scienceMetallic Nickel

The invention belongs to the technical field of composite material preparation and particularly relates to a preparation method of a laminated composite material of a titanium-aluminum / nickel-aluminum intermetallic compound. The method comprises the following steps of (1) cutting a titanium foil, a nickel foil and an aluminum foil subjected to surface treatment into metal sheets with set shapes and sizes to form a sandwich laminated structure, wrapping the outermost side by using a pure titanium foil, putting a graphite mold into a vacuum hot press sintering device, applying pre-tightening pressure of 1-3MPa at a room temperature, keeping the pressure for 10-30min and controlling various foils in the sandwich laminated structure for mutual fit contact; (2) releasing the pressure applied to the sandwich laminated structure in the step (1); (3) heating the foils in the sandwich laminated structure to 900-1300 DEG C, simultaneously applying pressure of 10-30MPa and carrying out heat preservation for 0.1-2h; and (4) carrying out furnace cooling and demolding to obtain the laminated composite material of the titanium-aluminum / nickel-aluminum intermetallic compound.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Method for manufacturing abrasion-proof conveying roll with high-temperature erosion resistance

InactiveCN104384861AOvercome insatiable insufficiencyImprove performanceMolten spray coatingMetal rolling arrangementsSpray coatingAlloy

The invention provides a method for manufacturing an abrasion-proof conveying roll with high-temperature erosion resistance and belongs to a method for manufacturing a conveying roll for steel rolling and hot rolling. The abrasion-proof conveying roll with high-temperature erosion resistance is manufactured and molded from a medium steel roll body and metal ceramic roll working surfaces; the roll body is formed by welding a medium steel thick wall steel pipe and a mounting roll core, and properties of rotation, support, conveying and the like of the roll body are provided; the roll working surfaces are positioned at two ends of the conveying roll, NiCrMo-WC alloy of 2-6mm is adopted in the radial direction, and the roll working surfaces are formed by virtue of supersonic flame spray coating or supersonic plasma spray coating. The NiCrMo-WC alloy is composed of 4.0-5.5% of C, 10.5-15.5% of Ni, 1.5-15.0% of Cr, 1.0-2.0% of Mo, 0.5-1.5% of Fe and the balance of W and is a spherical particle powdered material formed by virtue of vacuum melting and gas atomization. The conveying roll has the advantages of high-temperature erosion resistance, abrasion-proof property and long service life.

Owner:CHINA UNIV OF MINING & TECH

Heatproof stainless steel seamless tube and production method thereof

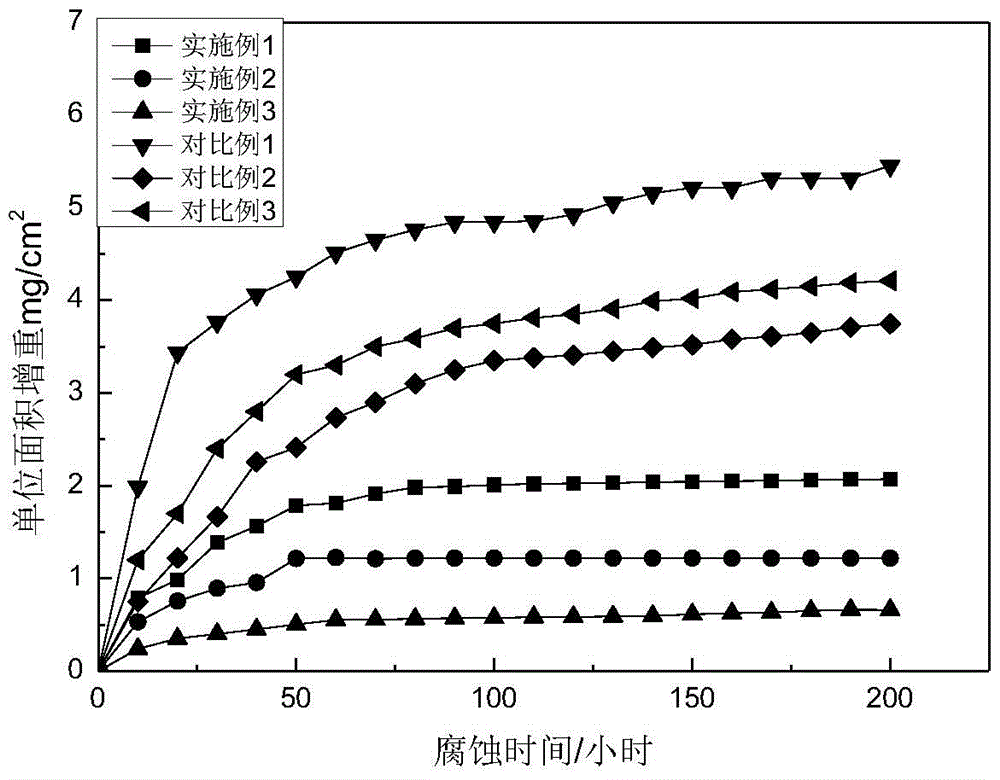

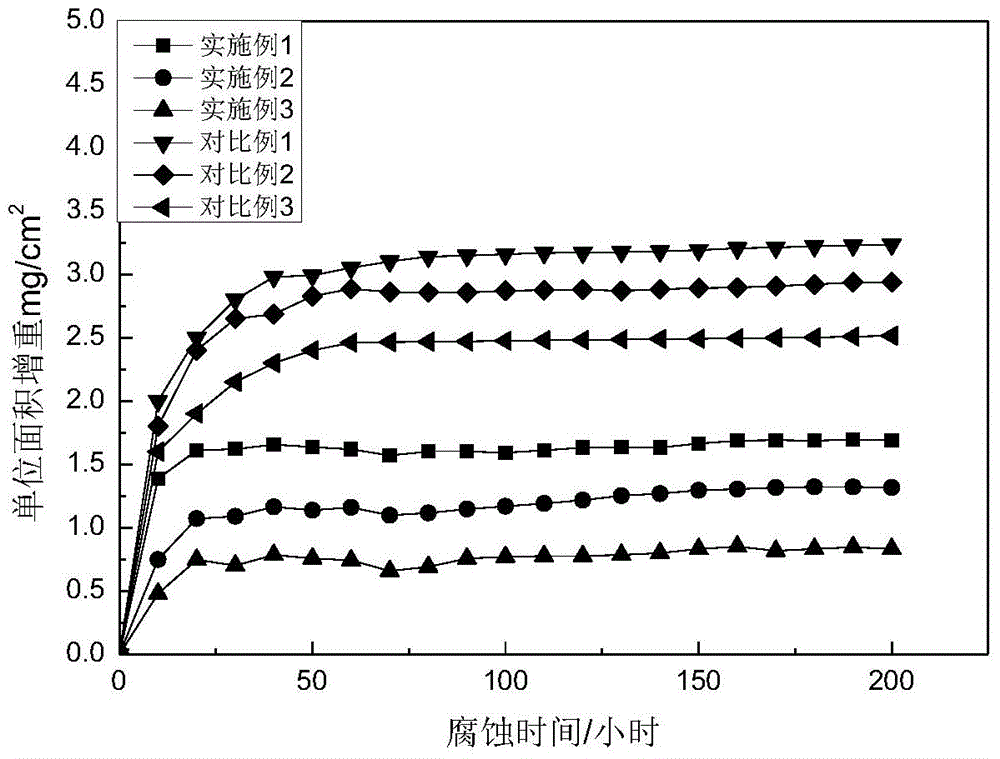

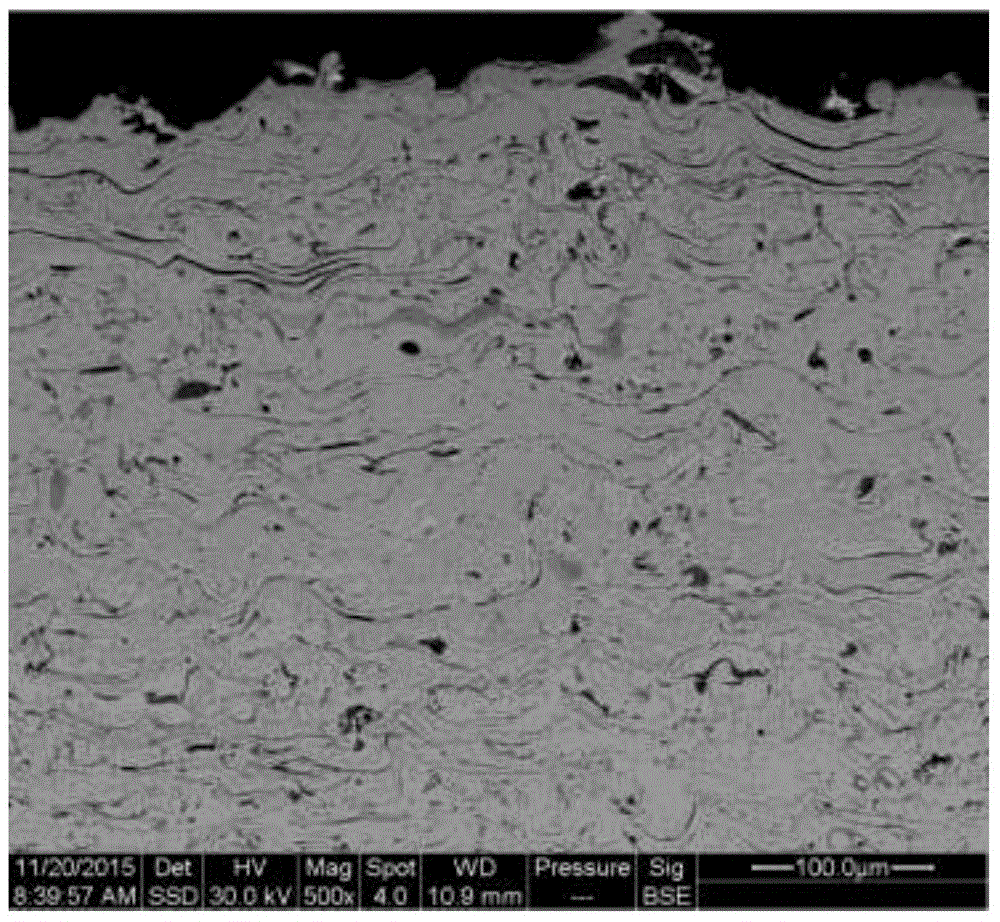

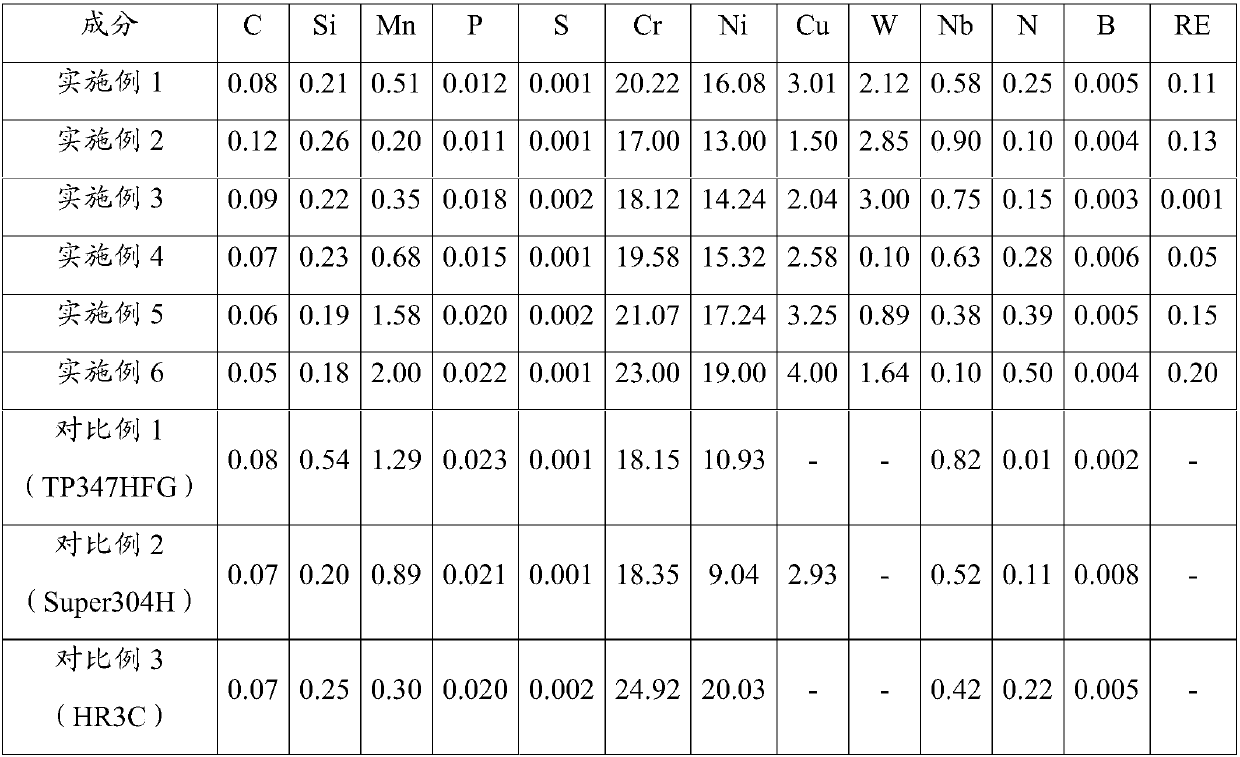

The invention provides a heatproof stainless steel seamless tube. The heatproof stainless steel seamless tube comprises, by weight, 0.05-0.12% of C, 0.3% or less of Si, 0.2-2% of Mn, 0.03% or less ofP, 0.02% or less of S, 17-23% of Cr, 13-19% of Ni, 1.5-4% of Cu, 0.1-3% of W, 0.1-0.9% of Nb, 0.1-0.5% of N, 0.003-0.006% of B, 0.001-0.2% of RE, and the balance of Fe and inevitable impurities. The invention also provides a production method of the heatproof stainless steel seamless tube. The method comprises the following steps: cogging cast ingots in an open die forging, radial forging or rolling manner to produce a tube blank; carrying out hot working on the tube blank through a hot extrusion technology or a hot piercing technology to produce a tubular billet; finishing the tubular billet,and carrying out cold working in a multi-pass cold rolling or cold drawing manner to obtain a pierced billet; and heating the pierced billet, and performing heat preservation.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Hot-corrosion-resistant enamel coating and preparation method thereof

The invention belongs to the technical field of enamel materials and particularly relates to a hot-corrosion-resistant enamel coating and a preparation method thereof. For solving the problems that anenamel coating in the prior art is liable to strip off and is poor in heat resistance at high temperature, the invention provides the hot-corrosion-resistant enamel coating and the preparation methodthereof, wherein the method includes steps of: firing the surface of a metal base body to form a enamel base glaze layer, then spray-coating the surface of the enamel base glaze layer with enamel surface glaze slurry; drying the coating at 130-150 DEG C and enameling the coating at 900-950 DEG C for 12-15 min to form the hot-corrosion-resistant enamel coating belonging to the series of inert oxides. The coating has good fullness and very low oxygen migration rate, excellent thermal stability and anti-oxidizing performance, and is good in anti-acid / alkali and anti-corrosion performances.

Owner:PANZHIHUA UNIV

Electric-arc fusion-cladding powder core wire, and preparation method of high-entropy alloy coating

ActiveCN108998716AAvoid powder leakageLarge processing areaMolten spray coatingPower flowHigh entropy alloys

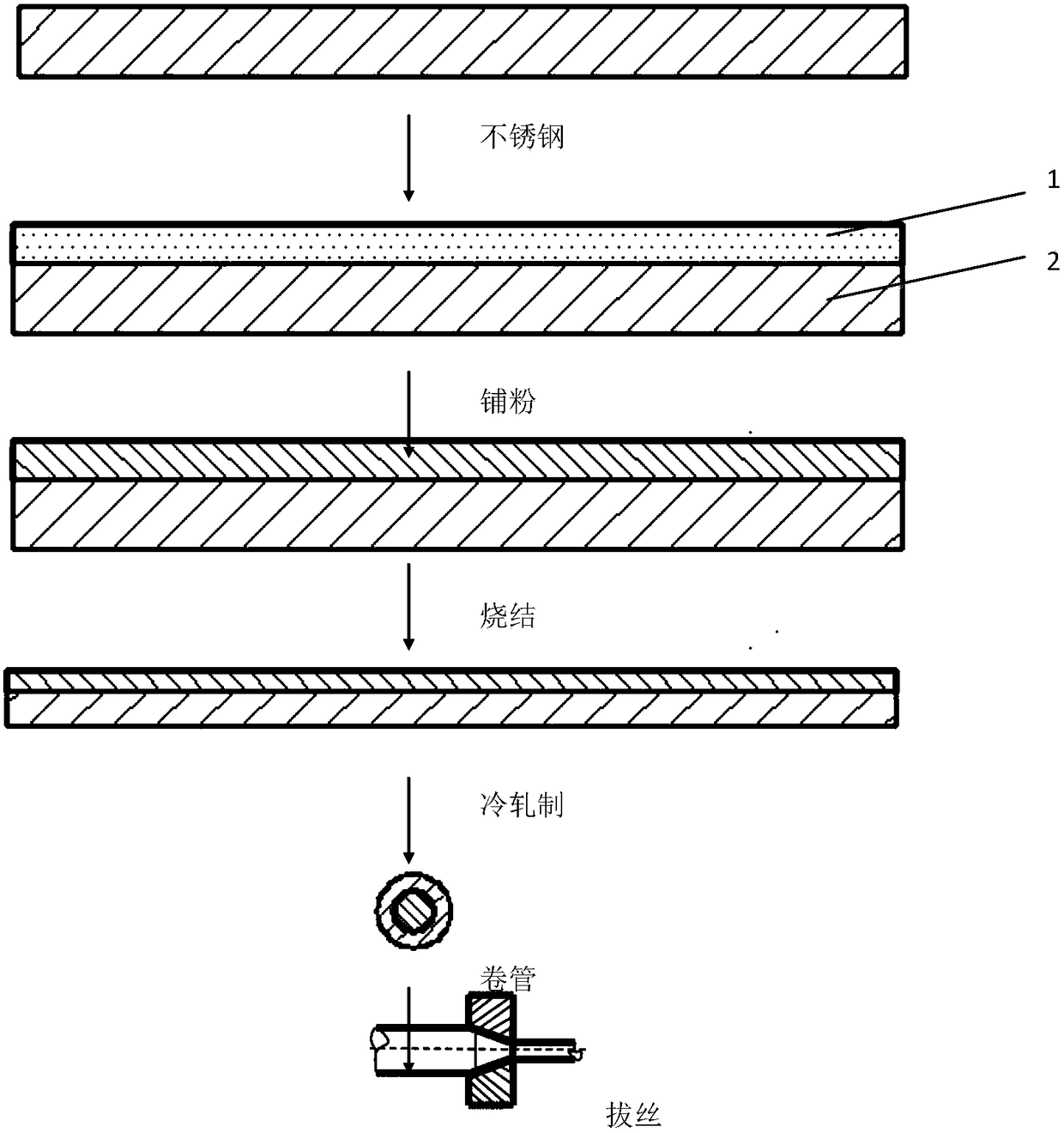

The invention provides an electric-arc fusion-cladding powder core wire, and a preparation method of a high-entropy alloy coating. The powder core wire is composed of a stainless steel strip and a powder core, wherein the thickness of the stainless steel strip is 0.8mm, and the powder core is powder of Mn, Cr, Fe, Ni, and Cu in a molar ratio of 2:2:2:2:1. A preparation method of the powder core wire comprises the following steps: (1) preparing the powder core; (2) paving powder and sintering; (3) performing cold rolling; and (4) coiling, drawing wires, reeling, installing coiled wires on a wire feeder, and spraying-deposing fused core wires on the surfaces of base materials by setting the electric-arc welding voltage to be 14 V, current to be 150A, and speed to be 8cm2 / min under the actionof 0.9MP high-pressure argon to form the high-entropy alloy coating.

Owner:JIANGSU UNIV OF TECH

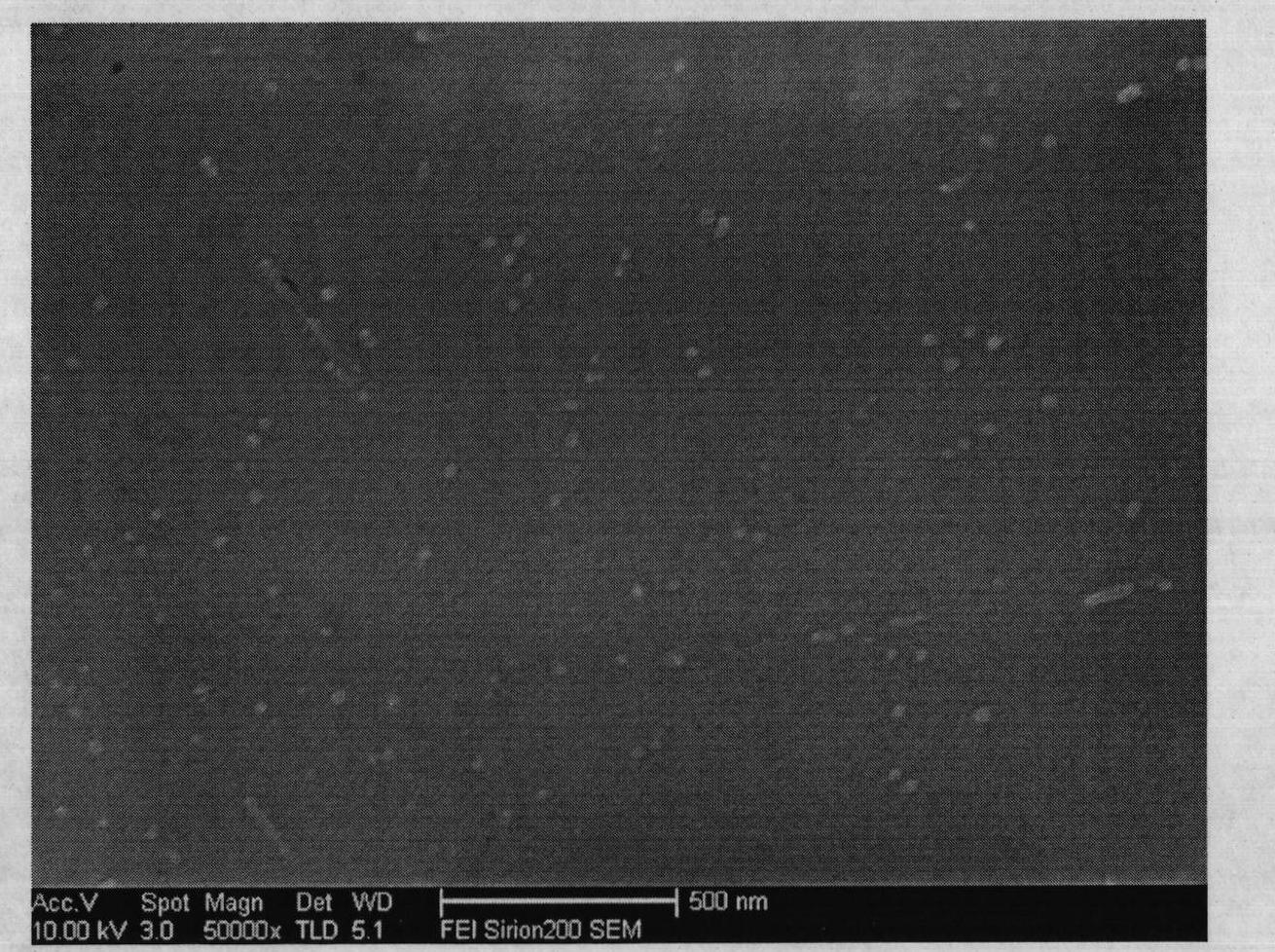

Thermal treatment method for obtaining nanometer strengthening phase by HR3C austenitic heat-resistance steel

InactiveCN101914662AImprove thermal stabilityGood high temperature corrosion resistanceSolution treatmentHigh density

The invention discloses a thermal treatment method for obtaining a nanometer strengthening phase by HR3C austenitic heat-resistance steel. The thermal treatment method comprises two steps as follows: firstly, solution treatment: heating a steel member to 1170-1250 DEG C for 30-60min, and then cooling water to the room temperature; and secondly, annealing treatment: heating the steel member after solution treatment to 800-950 DEG C for 30-240min, and then cooling air to the room temperature. In the HR3C austenitic heat-resistance steel treated by using the thermal treatment method, high-density NbCrN-type nanometer strengthening phases with the size ranging from 20 nm to 60 nm are evenly distributed in the austenite grain, wherein 5-30 strengthening phase grains are distributed in per square micro. The invention obviously improves the high-temperature duration intensity and ensures good high temperature corrosion resistance.

Owner:SHANDONG UNIV OF TECH

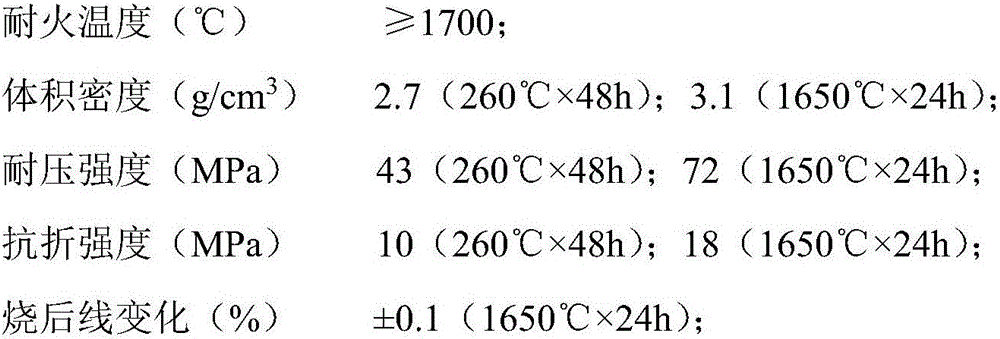

Fire-resisting lining body crack repairing material

The invention discloses a fire-resisting lining body crack repairing material, which is prepared from the following raw materials in parts by mass: 60 to 62 parts of brown aluminum oxide particles, 5 to 6 parts of active alpha-Al2O3, 25 to 30 parts of Al-80 special alumina homogenizing material fine powder, 3 to 5 parts of high-quality silicon dioxide micro powder, 5 to 6 parts of plasticizers and 1.5 to 2.5 parts of storing agents. 14.5 to 15.5 parts of bonding agents are added into the raw materials; first mechanical stirring mixing is performed; after the uniform mixing, the material ageing is performed for more than 24 hours; then, the secondary mechanical stirring is performed; finally, the crack repairing material is prepared after the extrusion treatment by an extrusion machine; the crack repairing material is in a paste shape with good plasticity; finally, a 5.0-10kg plastic bag is used for sealing and packaging. The fire-resisting lining body crack repairing material has the advantages that the intensity is high; the high-temperature etching resistance is high; the high-temperature wear-resistance is high; the construction is convenient; the adhesion performance is high; the fire-resisting lining body crack repairing material can be firmly combined with the original lining body; the safe period operation of a thermal kiln furnace is met; the fire-resisting lining body crack repairing material is particularly suitable for the CFB boiler lining body crack fast rush repair.

Owner:郑州耐都热陶瓷有限公司

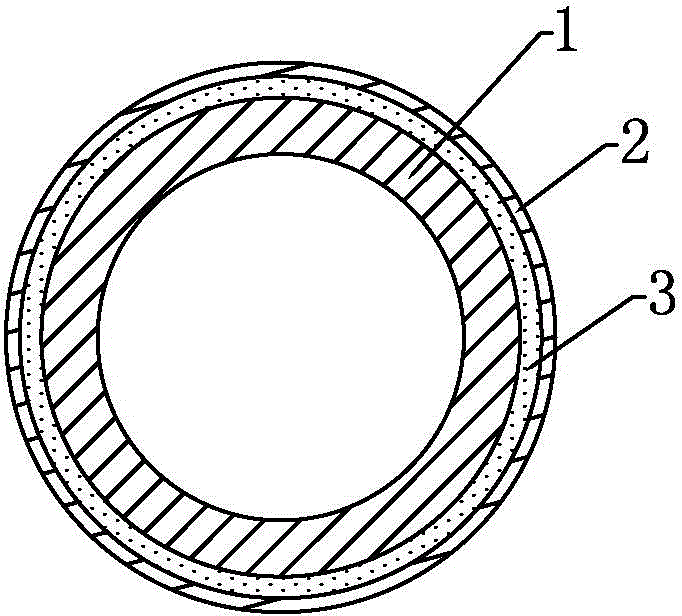

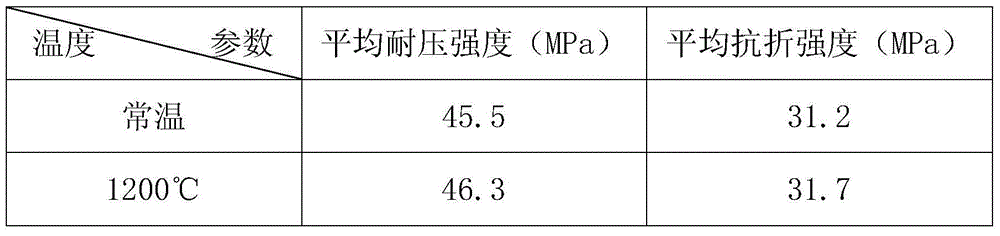

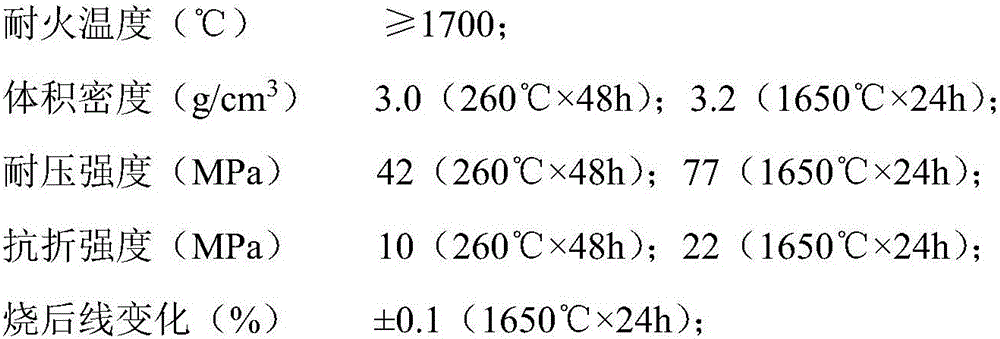

Thermal shock resistant ceramic tube mold and preparation method thereof

The invention belongs to the field of metallurgy casting and smelting, and particularly discloses a thermal shock resistant ceramic tube mold and a preparation method thereof. The thermal shock resistant ceramic tube mold comprises an inner ceramic tube mold, wherein an outer steel-made tube mold layer sleeves the outer side of the inner ceramic tube mold; a self-flowing thermal-resistant casting material is filled between the inner ceramic tube mold and the inner ceramic tube mold; the inner ceramic tube mold is made of the following raw materials in percentage by weight: 40-50% of carbon silicon micro powder, 20-25% of silicon powder, 20-25% of primary aluminum nitride powder, 2-5% of graphite micro powder, 2-3% of zirconium oxide micro powder, 0.5-1% of yttrium oxide micro powder, 0.2-0.5% of absolute ethyl alcohol and 3-4% of an adhesive. The thermal shock resistant ceramic tube mold is high in pressure resistance, good in breaking strength, good in high temperature corrosion resistance and long in service life; when nodular cast iron tubes are produced by using the thermal shock resistant ceramic tube mold, the production procedures can be reduced, the energy is saved, the equipment maintenance expense is reduced, and the production cost is lowered, so that the nodular cast iron pipe thermal shock resistant ceramic tube mold has great significance for the metallurgy tube industry and has wide application prospect and popularization values.

Owner:山东坤能环保科技有限公司

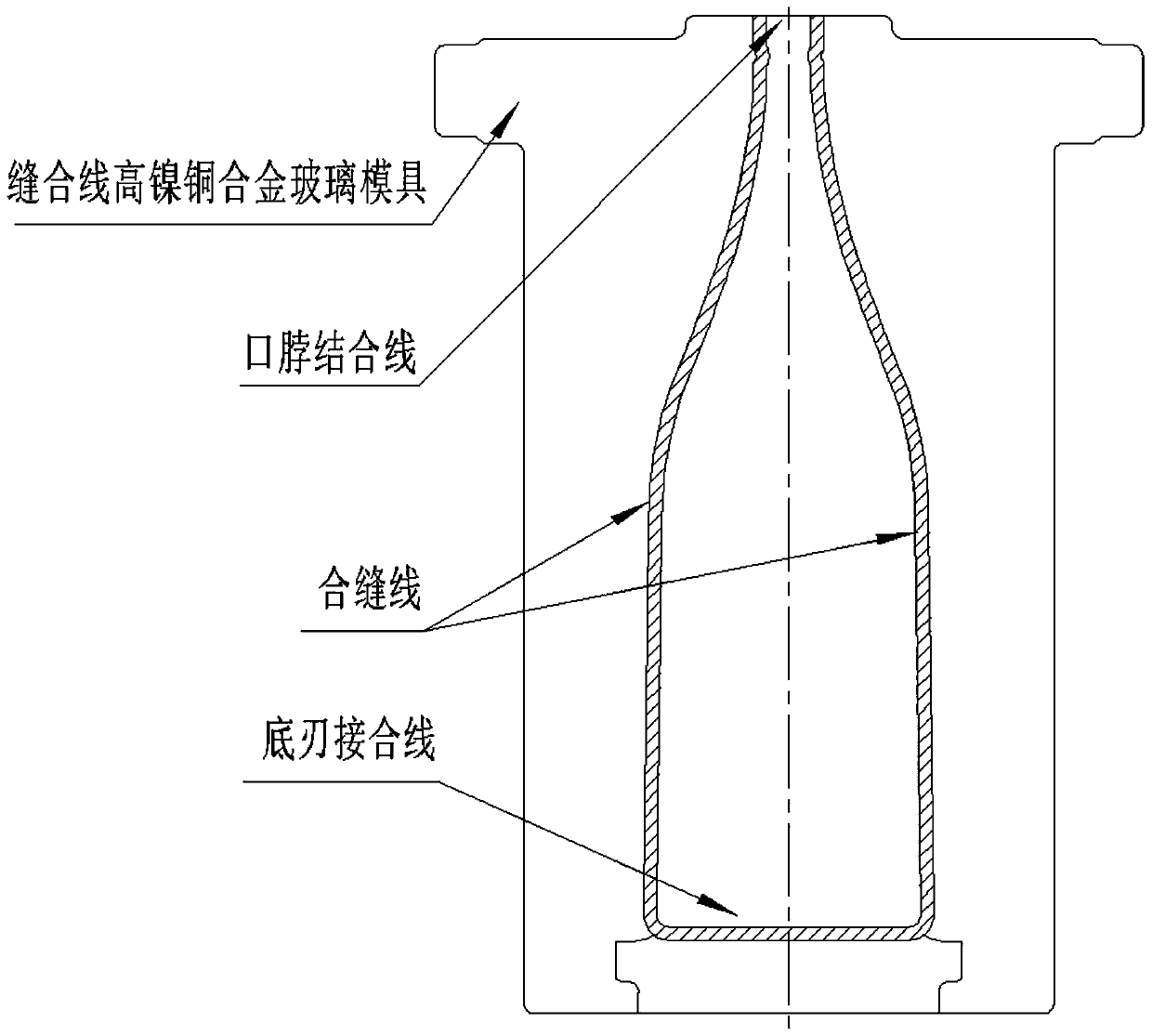

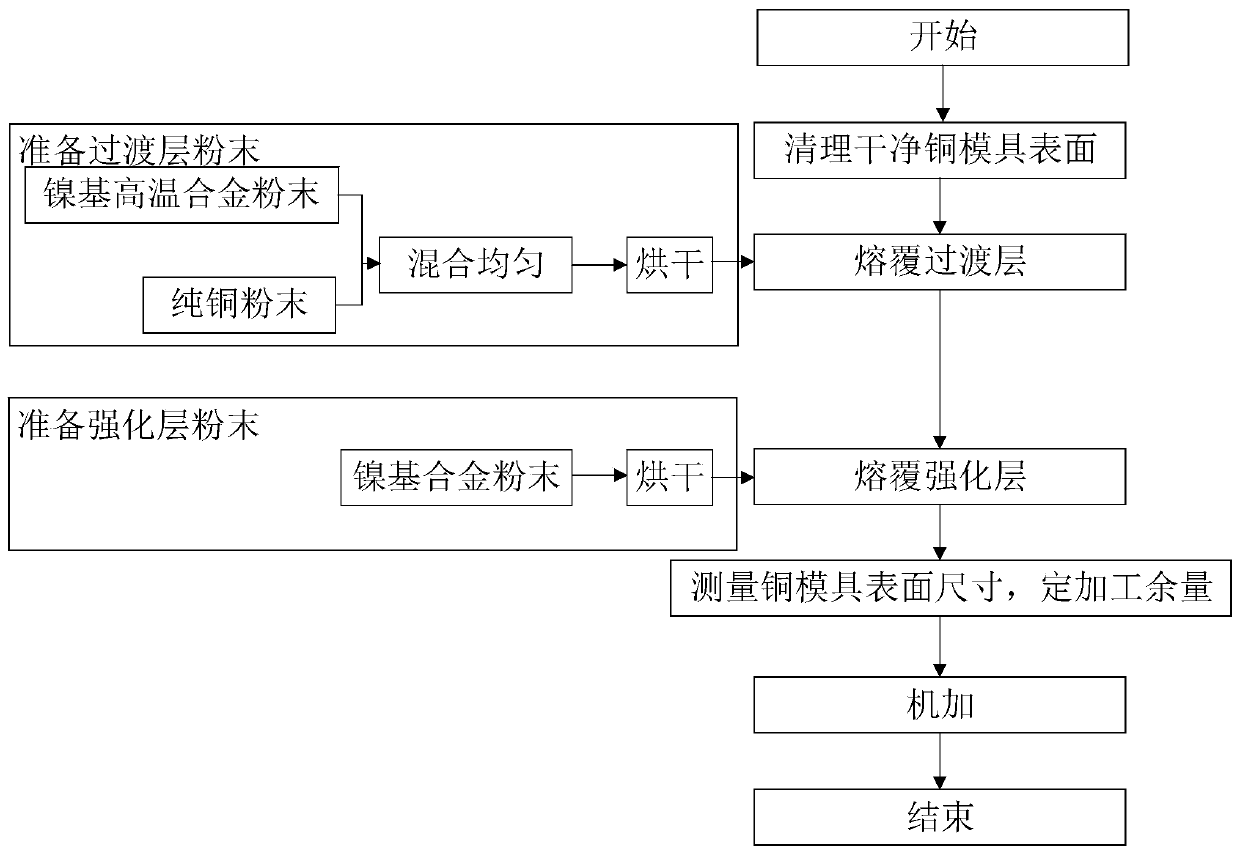

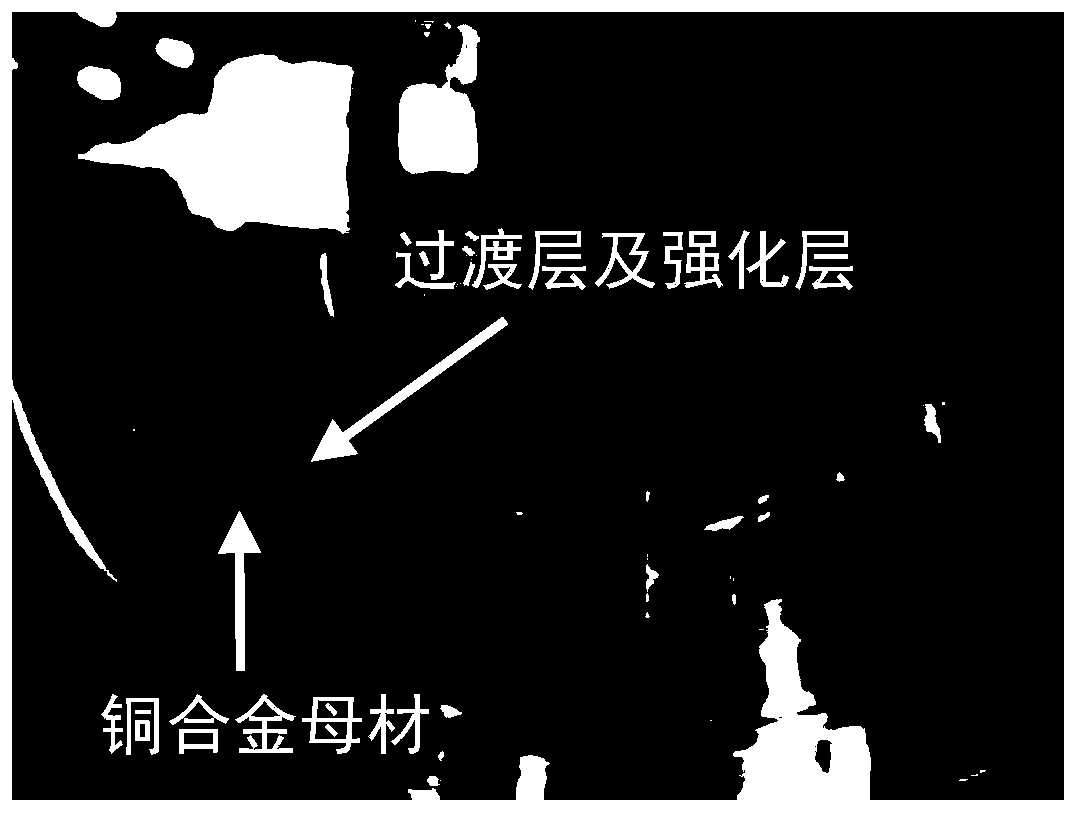

High-nickel copper alloy glass mold strengthening method

ActiveCN110699687AImprove high temperature performanceGood high temperature corrosion resistanceMetallic material coating processesSolderabilitySuperalloy

The invention discloses a high-nickel copper alloy glass mold strengthening method. The high-nickel copper alloy glass mold strengthening method includes the following steps that S1, oxide and dirt onthe surface of a copper mold are removed; S2, transition layer powder is prepared, wherein nickel-based superalloy powder is evenly mixed with pure copper powder with the weight ratio being 15%-30%,and drying is carried out to obtain the transition layer powder; and strengthening layer powder is prepared, wherein nickel-based alloy powder is adopted and dried to obtain the strengthening layer powder; S3, the transition layer powder covers the copper mold in a fusion manner, and a fusion covering layer formed by fusion covering is a transition layer; S4, the strengthening layer powder coversthe transition layer in a fusion manner, and a fusion covering layer formed by fusion covering is a strengthening layer; and S5, and the strengthening layer is modified by machining. The high-nickel copper alloy glass mold strengthening method effectively prevents occurrence of welding cracks and improves the strength of joints; meanwhile, copper alloy oxidizing at high temperature during preheatwelding is avoided, and the high quality of the welding interior on the mold is effectively ensured; and the transition layer improves the weldability and the bonding strength of the copper alloy glass mold and the strengthening layer.

Owner:成都青石激光科技有限公司

Surfacing welding strip with excellent heat fatigue resistance

InactiveCN108326467AExcellent resistance to cold and heat fatigueSolve the problem of resurgenceWelding/cutting media/materialsSoldering mediaMolybdenum carbideFerrochrome

The invention discloses a surfacing welding strip with excellent heat fatigue resistance. The surfacing welding strip is composed of a welding core and two layers of coatings, wherein the first layerof coating is fabricated by the following ingredients of , by weight, 18-26 parts of high carbon ferromanganese, 10-14 parts of carbon ferrochrome, 7-9 parts of magnet, 1-3 parts of hydroxyapatite, 2-5 parts of strontianite and 3-6 parts of aedelforsite, and the second layer of coating is fabricated by the following ingredients of , by weight, 15-20 parts of titanium oxide, 10-13 parts of ferrotitanium, 2-4 parts of silicon nitride, 5-7 parts of molybdenum carbide and 1-3 parts of tungsten disulfide nanotubes. By means of the surfacing welding strip with the excellent heat fatigue resistance,the fabricated welding strip can work in a high-temperature corrosion or high-temperature wear medium for a long time and can maintain excellent cold and heat fatigue resistance and good high-temperature performance of high-temperature oxidation resistance, high-temperature corrosion resistance, high-temperature tempering stability, red hardness and the like, in the working process, electric arc burns stably, arc breaking is not prone to appear, almost no slag is remained on the surface of weld metal, less dust and smoke are generated, and the surfacing welding strip with the excellent heat fatigue resistance has wide applicability.

Owner:安徽省明升机械科技有限公司

Castable, current stabilization slag ladle prepared from same as well as preparation methods thereof

ActiveCN106007753AGood high temperature chemical stabilityGood high temperature corrosion resistanceSlagGranularity

The invention discloses a castable, a current stabilization slag ladle prepared from the same as well as preparation methods thereof. The castable is prepared form the following raw material ingredients in percentage by weight: 15-30% of Al-Mg spinel with granularity of 5-8mm, 10-30% of forsterite with granularity of 3-5mm, 10-15% of kyanite with granularity of 1-3mm, 7-20% of fused corundum with granularity of 1-3mm, 5-20% of Si2ON2 with granularity less than or equal to 1mm, 5-15% of TiO2 with granularity less than or equal to 1mm, 1-5% of Fe2O3 with granularity of 180 meshes and 2-8% of silicon micropowder with granularity less than 0.088mm, as well as a water reducer which accounts for 0.1-0.3% of the total weight of the above raw material ingredients. The repairing material has the advantages of high strength, long service life, high temperature resistance, scouring resistance, erosion resistance, high peeling capability and the like.

Owner:SHANDONG IRON & STEEL CO LTD

A martensite alloy steel material used for an air valve of an internal combustion engine and a preparation method of the alloy steel material

The invention discloses a martensite alloy steel material used for an air valve of an internal combustion engine. The alloy steel material comprises following elements by weight: 0.6-0.8% of carbon, 0.2-0.3% of silicon, 3.3-3.5% of manganese, 0.4-0.5% of chromium, 0.03-0.05% of molybdenum, 0.004-0.005% of vanadium, 0.06-0.08% of Ti, 2.3-2.5% of Ni, 0.01-0.03% of Sb, S not more than 0.030% and P not more than 0.030%, with the balance being iron. According to the alloy steel material and the method, by using composition of the antimony and other raw materials, and by reasonably arranging the ratio and the production technology and reasonably arranging the adding sequence, the alloy material formed has characteristics of high strength, high hardness, good wear resistance, good toughness, resistance to high-temperature corrosion, oxidation resistance, and the like. The alloy steel material is suitable for the air valve of the internal combustion engine so that the air valve has high air tightness. A portion of waste iron is used as a raw material to make the alloy quality stable and uniform. By addition of a refining agent, the porosity degree is reduced by 1-2 degrees.

Owner:WUHU HONGKUN AUTO PARTS

Heat-resistant stainless steel seamless pipe and preparation method thereof

The invention relates to the field of stainless steel, in particular to a heat-resistant stainless steel seamless pipe and a preparation method thereof. The heat-resistant stainless steel seamless pipe of the present invention, by weight percentage, includes: C 0.04-0.1%, Si≤0.4%, Mn≤0.5%, P≤0.03%, S≤0.02%, Cr 20-27%, Ni 23‑28%, Cu 2.0‑3.5%, W 2‑4%, Nb 0.2‑0.6%, N 0.1‑0.3%, Mo 0.05‑0.3%, B 0.002‑0.008%, the balance is Fe and other unavoidable impurity elements. The preparation method of the heat-resistant stainless steel seamless pipe of the present invention comprises the following steps: (1) smelting; (2) thermal processing of a tube blank; (3) thermal processing of a steel pipe; (4) cold processing of a steel pipe. The heat-resistant steel seamless pipe of the present invention has good mechanical properties, high-temperature durable strength, high-temperature oxidation resistance, high-temperature corrosion resistance and high-temperature structure stability, and can meet the use requirements of 630-650°C ultra-supercritical power plant boiler tubes .

Owner:TAIYUAN IRON & STEEL GROUP

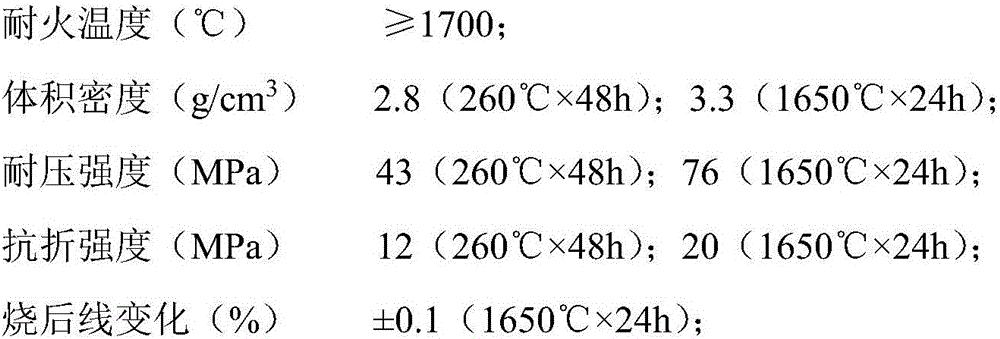

High-temperature lining surface repairing material

InactiveCN107010932AHigh strengthGood high temperature corrosion resistanceRepair materialPlasticizer

The invention discloses a high-temperature lining surface repairing material which is prepared from, by mass, 35-40 parts of coarse particle, alumina homogenizing material with Al2O3 content not lower than 80%, 20-25 parts of fine particle, brown alumina powder, 25-30 parts of fine powder, special-grade alumina homogenizing material with Al2O3 content not lower than 85%, 5-6 parts of active alpha-Al2O3, 3-5 parts of high-quality silicon dioxide micropowder, 5-7 parts of plasticizer, 1.0-2.0 parts of preservative and 0.05 part of anti-explosion fiber powder. A preparation method of the repairing material includes: adding a binding agent, stirring for the first time, mixing well, and discharging; aging for more than 24h, stirring for the second time, adding the binding agent of the same type, stirring, and extruding by an extruder to obtain the repairing material. The high-temperature lining surface repairing material is high in strength, quick in heat conduction, high in high-temperature corrosion resistance, high in high-temperature wear resistance, high in adhesive capacity, less prone to stripping, high in performance of combining with original walls and quick in construction, quick temperature-rise running can be realized after construction is finished, and safe periodic running of thermal equipment / high-temperature kiln is guaranteed.

Owner:郑州耐都热陶瓷有限公司

High-temperature gradient sealing coating for gas turbine and preparation method thereof

PendingCN112030097AAvoid erosionHigh bonding strengthMaterial nanotechnologyMolten spray coatingAl powderNiobium alloy

The invention relates to the technical field of coating preparation, in particular to a high-temperature gradient sealing coating for a gas turbine and a preparation method thereof. The high-temperature gradient sealing coating for the gas turbine comprises a bonding bottom layer, an oxygen barrier layer and a sealing surface layer, the spraying raw material of the bonding bottom layer is NiCrAl alloy agglomeration powder or NiCoCrAlY alloy agglomeration powder, the spraying raw material of the oxygen barrier layer is multi-component aluminum-coated zirconium-niobium alloy agglomeration powder, and the multi-component aluminum-coated zirconium-niobium alloy agglomeration powder comprises the components of 60-70wt% of zirconium-niobium alloy, 10-20wt% of nano alpha-Al2O3 and 20-30wt% of nano aluminum powder. The spraying raw material of the sealing surface layer is nano zirconium oxide based agglomerated powder, and the nano zirconium oxide based agglomerated powder comprises the components of 75-90wt% of nano ZrO2, 5-15wt% of nano Y2O3 and 5-20wt% of nano alpha-Al2O3. The prepared high-temperature gradient sealing coating for the gas turbine has the characteristic of long service life.

Owner:武汉钢铁有限公司

Cable sheath material resistant to seawater corrosion

InactiveCN108341999AReasonable ratio of ingredientsImprove anti-agingRubber insulatorsCross-linked polyethyleneChemical stability

The invention relates to the field of polymer materials, in particular to a cable sheath material resistant to seawater corrosion. The cable sheath material resistant to seawater corrosion is composedof the following raw materials: in parts by weight, 30-50 parts of modified polytetrafluoroethylene, 8-15 parts of aluminum bronze, 45-70 parts of nitrile rubber, 3-9 parts of ceramsite, 12-18 partsof glass fiber, 15-22 parts of phenolic resin, 5-11 parts of silica sol, 10-18 parts of crosslinked polyethylene, 2-6 parts of alumina ceramic powder, 0.3-1.7 parts of potassium titanate whisker, 11-17 parts of silicone, 1-6 parts of epoxidized soybean oil and 1-8 parts of a silane coupling agent. The cable sheath material resistant to seawater corrosion has reasonable component ratios, excellentchemical stability, excellent corrosion resistance, excellent anti-aging performance, high yield, high hardness, good wear resistance and long service life.

Owner:ANHUI DUJIANG CABLE GROUP

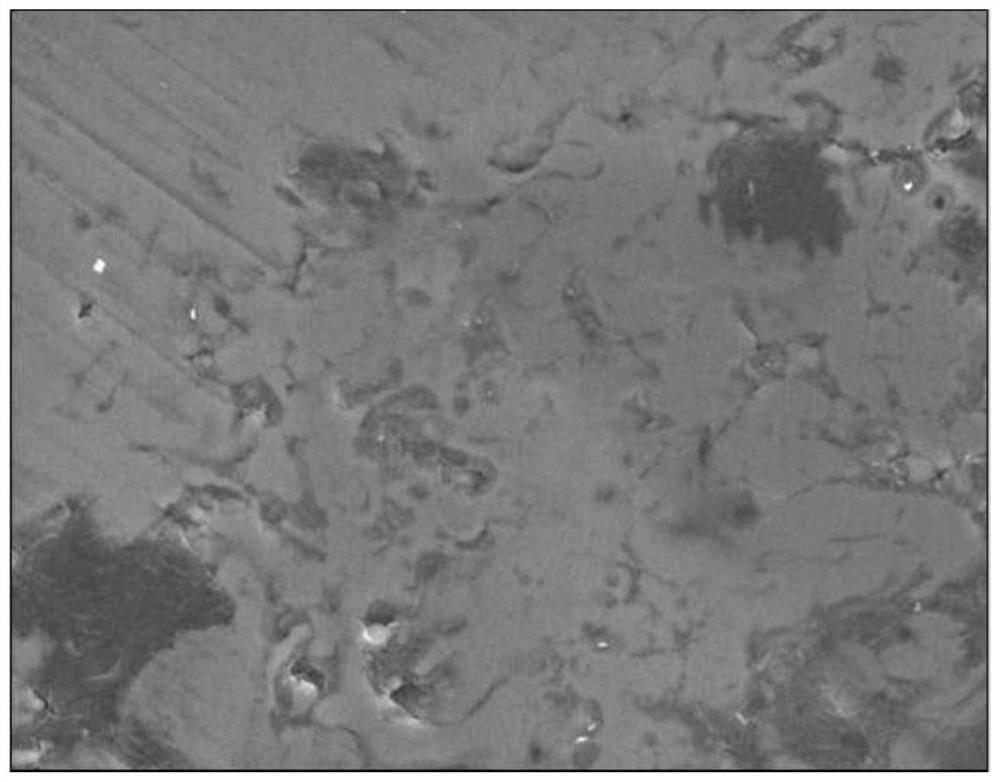

Preparation method of biomass boiler heating surface protection coating

The invention discloses a preparation method of a biomass boiler heating surface protection coating. The preparation method of the biomass boiler heating surface protection coating comprises the following operation steps of (1) placing powder core powder into a powder feeder of a wire rolling mill, firstly rolling a stainless steel band into a groove through a rolling machine, using the powder feeder for feeding the mixed powder core powder into the groove, using the rolling machine for gradually closing the steel band to form a circular wire material through a roller, placing the rolled wirematerial onto a wire drawing machine for drawing, gradually reducing the diameter, finally achieving the size phi 2.00mm required for electric arc spraying, and obtaining a powder core wire; (2) spraying a modification solution on the surface of a base material used for a biomass boiler heating surface, and then sand-blasting; and (3) adopting an electric arc spraying device for preparing the coating on the surface of the base material through a double-strand wire feeding manner. The preparation method of the biomass boiler heating surface protection coating provided by the invention is simpleto operate, low in cost, and remarkable in protection effect.

Owner:SHENYANG INST OF ENG

High-temperature-resistant hole sealing agent for hot-dip plating sink roll as well as preparation method and coating method of high-temperature-resistant hole sealing agent

InactiveCN113072826ACorrosion resistanceImprove adhesionFireproof paintsMolten spray coatingHexagonal boron nitrideCerium

The invention discloses a high-temperature-resistant hole sealing agent for a hot-dip plating sink roll as well as a preparation method and a coating method, and belongs to the field of sink roll surface treatment. The hole sealing agent is mainly prepared from the following components in parts by weight: 100 parts of silica sol, 60 to 100 parts of alumina sol, 100 to 240 parts of siloxane, 104 to 264 parts of hexagonal boron nitride dispersion liquid, 1.82 to 7.04 parts of cerous nitrate and a trace amount of hydrochloric acid solution. The obtained high-temperature-resistant hole sealing coating is an organic-inorganic hole sealing system, not only has high wear resistance and heat resistance of an inorganic coating, but also has corrosion resistance of an organic coating, and meanwhile, the adhesive force of the hole sealing coating is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Laser cladding treatment process for heating furnace hearth roll collar surface

InactiveCN106337178AGood high temperature wear resistanceExcellent high temperature oxidation resistanceMetallic material coating processesBroadbandAlloy

The invention relates to a laser cladding treatment process for a heating furnace hearth roll collar surface. The process comprises the steps of: cleaning a heating furnace hearth roll collar surface; conveying Co based alloy powder by a coaxial or paraxial powder feeding mode, selecting a carbon dioxide laser to rapidly scan the cleaned roll collar surface by means of narrowband or broadband scanning so as to realize alloying treatment of the heating furnace hearth roll collar surface, thus obtaining an alloying layer; and conducting crack and flaw detection and judging whether crack is produced. The process provided by the invention reinforces the hearth roll collar surface, improves the service life of the roll collar, basically solves the problem of nodulation on the roll collar surface, saves the roll changing time and maintenance time, improves the heating furnace work efficiency, and reduces the production cost.

Owner:WUHAN DIANJIN LASER TECH

Corrosion-resistant and high-temperature-resistant coating applicable to titanium aluminum alloy and preparation method thereof

InactiveCN102453870AGood high temperature corrosion resistanceReduce the temperatureVacuum evaporation coatingSputtering coatingAluminum substrateSilver coating

The invention relates to a corrosion-resistant and high-temperature-resistant coating applicable to a titanium aluminum alloy. The coating alloy has the nominal ingredients of 39 to 45 at percent of Ti, 47 to 49 at percent of Al, 7 to 9 at percent of Cr and 1 to 3 at percent of Ag. A magnetron sputter plating method is adopted for preparing the coating. The titanium aluminum based titanium aluminum chromium silver is adopted as coating materials of the titanium aluminum alloy, the performance that the coating and a substrate have the same expansion coefficient at high temperature and the like is utilized, and the effect of the chromium and the sliver for improving the anti-corrosion performance in the titanium aluminum is also considered. The magnetron sputter plating characteristic is used for preparing the titanium aluminum chromium silver coating with the firm combination on the titanium aluminum substrate, and the anti-corrosion performance of the titanium aluminum alloy is obviously improved at high temperature.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Laser surface alloying treatment process for heating furnace hearth roll collar

InactiveCN106337179AImprove hardness performanceStrong ability to maintain hardness at high temperatureMetallic material coating processesMelting tankLaser processing

The invention relates to a laser surface alloying treatment process for a heating furnace hearth roll collar. The process includes the steps of: adopting chromium nickel carbon alloy powder comprising the following components by weight percentage: 65%-80% of Cr, 17%-28% of Ni, and 3%-7% of C; selecting phi 3mm narrowband light spot or 10*1mm broadband light spot to scan the matrix; starting a CO2 laser, using a CNC laser processing machine as the work platform; employing a coaxial or paraxial powder feeding device to send the alloy powder automatically into a laser molten pool so as to form a uniform and compact alloying coating on the roll collar surface with a thickness of 0.3-0.5mm; and performing crack and flaw detection and judging whether crack is produced. The process provided by the invention reinforces the hearth roll collar surface, improves the service life of the roll collar, basically solves the problem of nodulation on the roll collar surface, saves the roll changing time and maintenance time, improves the heating furnace work efficiency, and reduces the production cost.

Owner:WUHAN DIANJIN LASER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com