Patents

Literature

34results about How to "Good high temperature chemical stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous material matrix and composite phase-change heat storage material and preparation methods thereof

InactiveCN102061403AIncrease contentImprove heat storage capacityHeat-exchange elementsCeramicwareWater basedHeat conducting

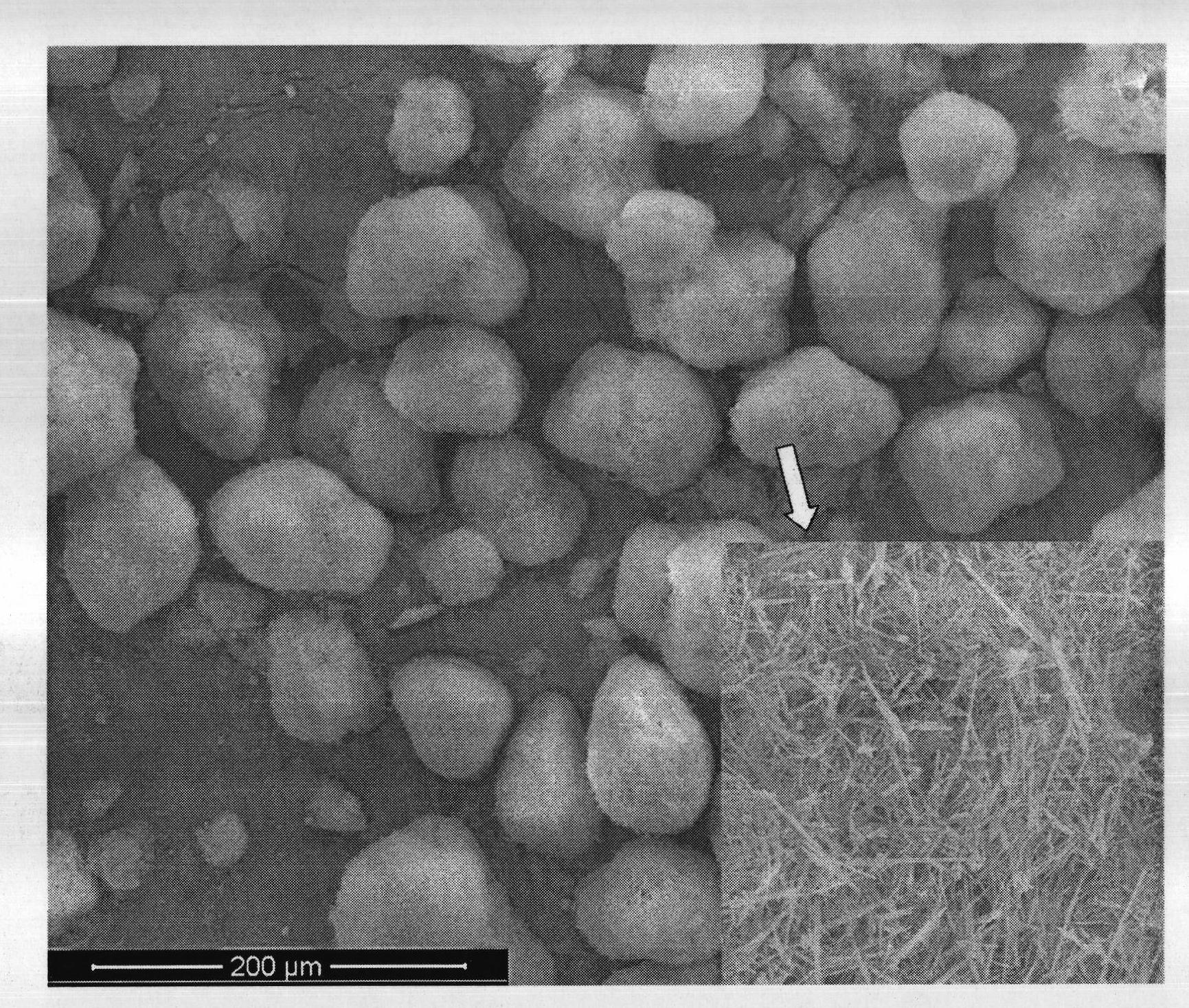

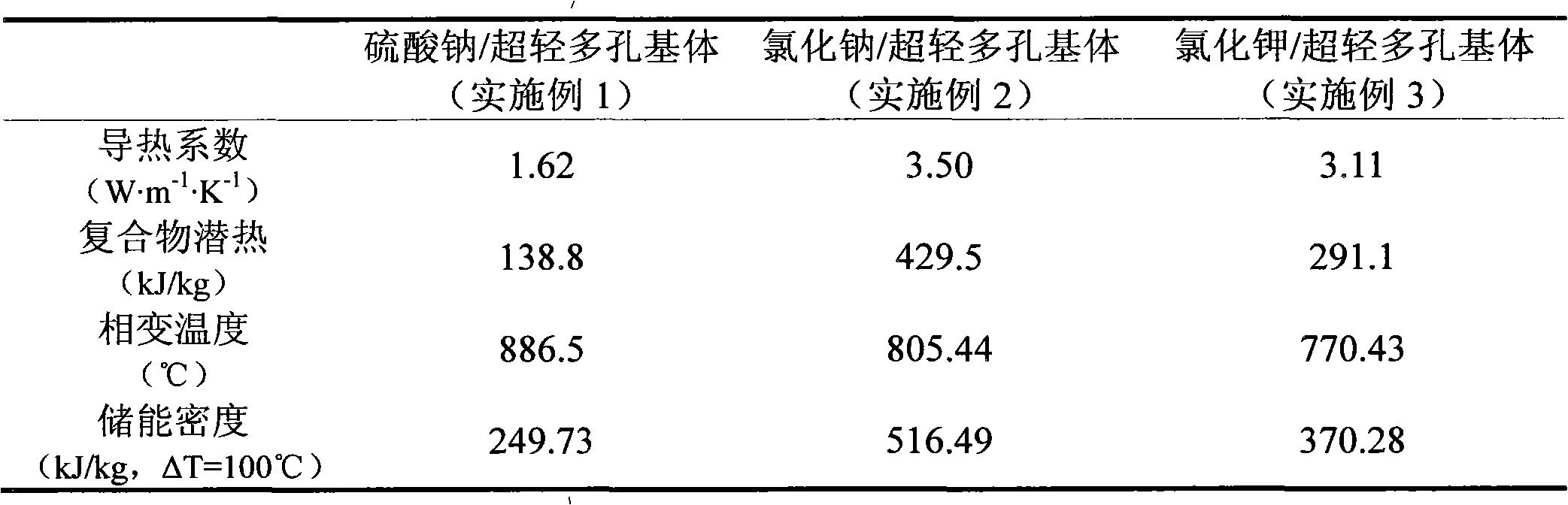

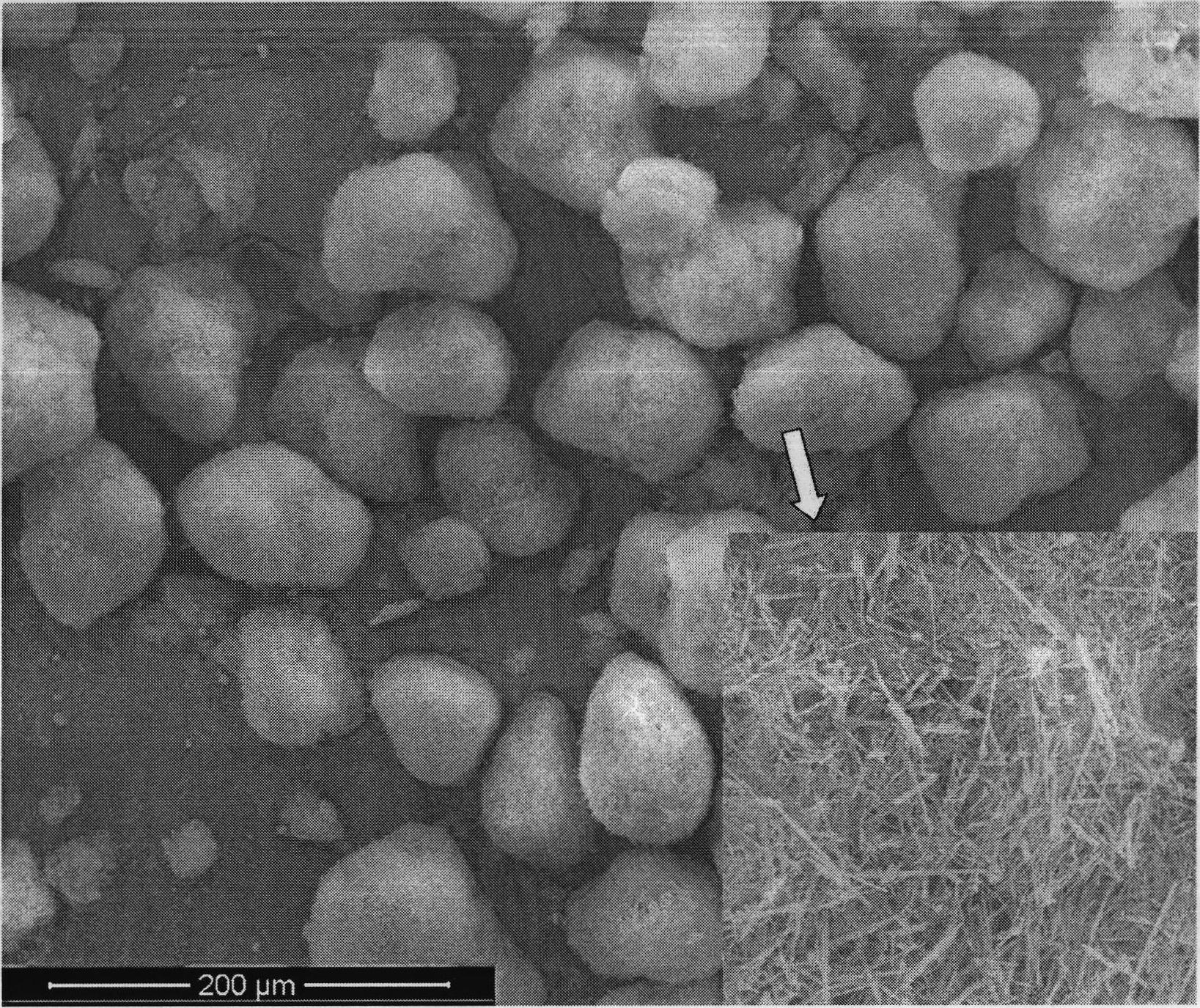

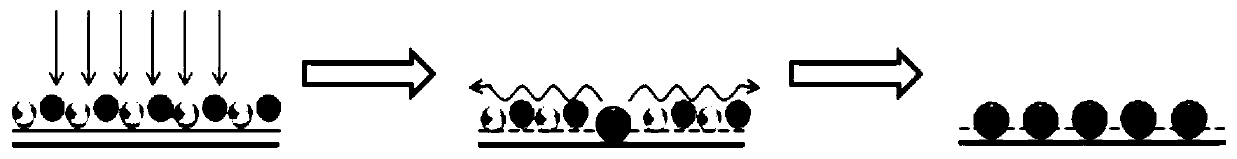

The invention provides a preparation method of a porous material matrix. The preparation method comprises the following steps: mixing a weighed calcium-containing raw material and a silicon-containing raw material at the mole ratio of Ca to Si of 1:(0.4-1), adding 20-40-times water based on the total weight of the raw materials, stirring and keeping the temperature of 180-320 DEG C for 4-12 hours, and obtaining porous material slurry; and adding 0%-5% of nano-metal powder after the slurry is cooled, drying and molding to obtain the porous material matrix. The preparation method of a composite phase-change heat storage material comprises the following steps: dipping the obtained porous material matrix into a fully fused inorganic salt phase-change material so that the phase-change material is completely infiltrated into a pore path of the porous material matrix; and blowing out for cooling, and then desalting the discharged sample to finally obtain the composite phase-change heat storage material. The obtained matrix material has the advantages of good infiltration property and excellent high-temperature chemical stability relative to inorganic salt; and the obtained composite phase-change heat storage material has the advantages of high heat storage density, good heat-conducting property and cheap raw material.

Owner:SOUTH CHINA UNIV OF TECH

Hard nanometer layered ZrO2/TiN coating

InactiveCN1888124AHigh hardnessImprove antioxidant capacityVacuum evaporation coatingSputtering coatingCeramic coatingArgon atmosphere

The present invention is one kind of multilayer hard nanometer ZrO2 / TiN coating and belongs to the field of ceramic coating technology. The multilayer hard nanometer ZrO2 / TiN coating includes alternately deposited ZrO2 layers of 2-8 nm thickness and TiN layers of 0.4-1.2 nm thickness on the substrate of hard alloy, ceramic or metal, and has total thickness of 2-5 microns. It is prepared through a double-target sputtering process in argon atmosphere. It has not only excellent high temperature oxidation resistance, but also hardness as high as 19.1-23 GPa. The multilayer hard nanometer ZrO2 / TiN coating of the present invention may be formed on high speed cutting tool and other high temperature wear and corrosion resistant workpieces.

Owner:SHANGHAI JIAO TONG UNIV

Glass sealing material as well as preparation and use methods thereof

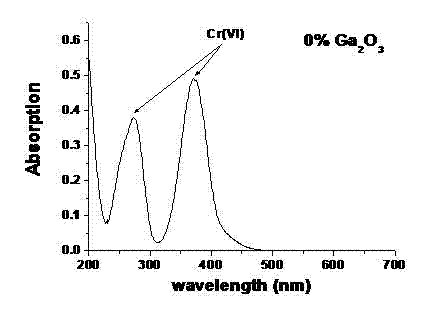

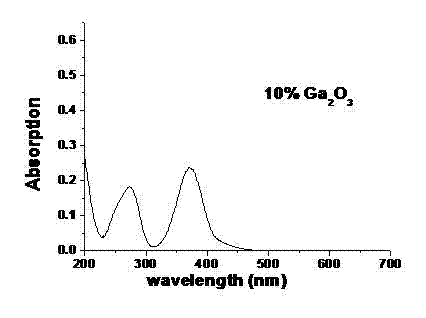

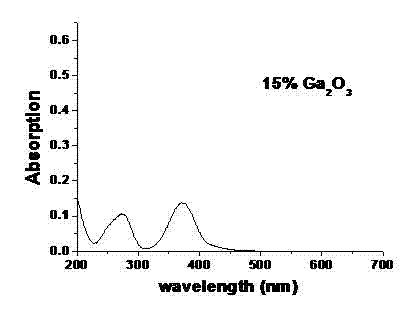

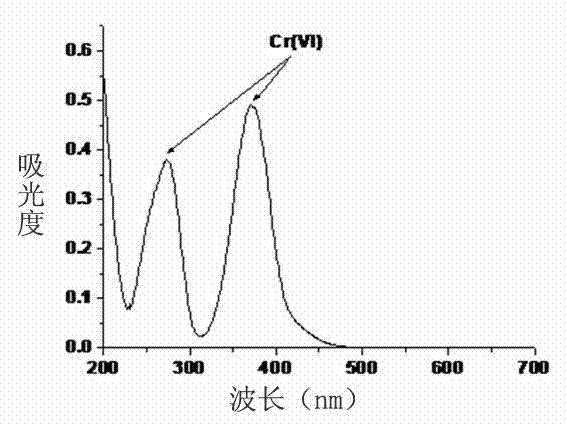

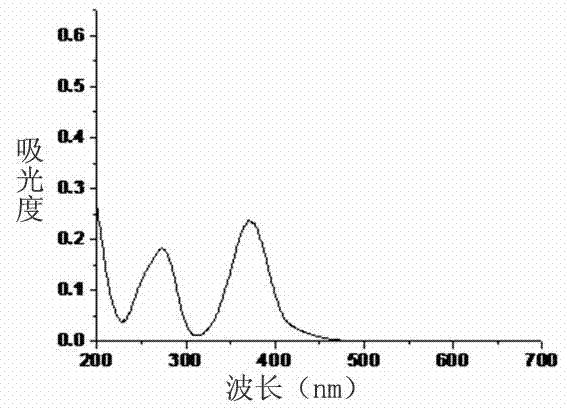

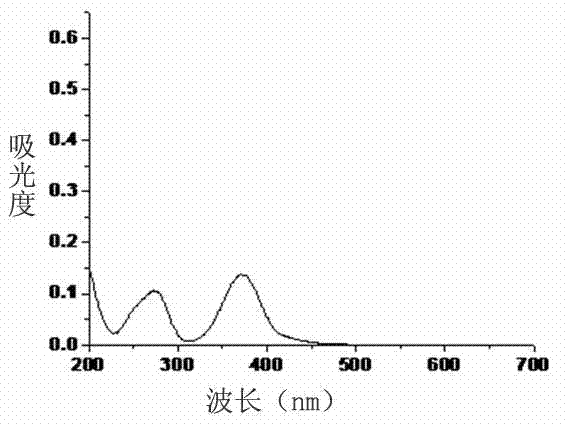

The invention relates to a glass sealing material as well as preparation and use methods thereof. The glass sealing material comprises the following raw material components at a molar ratio: 0-10 of B2O3, 0-5 of Al2O3, 25-60 of SiO2, 10-25 of CaO, 10-25 of SrO and 5-25 of Ca2O3. According to the invention, a Ga element is added in the glass sealing material so as to form a non-proliferation layer, thus effectively reducing the proliferation of Cr ions in a Cr-containing stainless steel alloy connection pole toward the sealing glass and significantly improving the high temperature chemical stability of sealing microcrystal glass; preparation raw materials are simple and available, and process is stable; and a reverse glass network structure in which SiO2 is used as a main body is obtained,cost is low, and process is simple and practicable, thereby achieving the conditions of practicality and industrialization.

Owner:FUZHOU UNIV

TiN enhanced ferrous matrix composite surface layer and processing method thereof

InactiveCN101798684AGood high temperature chemical stabilityGood thermal conductivityArc welding apparatusMetallic material coating processesDirect heatingHardness

The invention discloses a TiN enhanced ferrous matrix composite surface layer and a processing method thereof. The processing method is characterized by precoating a layer of pure titanium powder on the surface of a steel matrix, adopting nitrogen arc for direct heating after drying to locally smelt the pure titanium powder and the surface of the steel matrix, Ti in a weld pool and N from the arc atmosphere undergoing nitridation reaction (Ti+N->TiN) and the in-situ TiN serving as an enhanced phase to form the ferrous matrix composite with the steel matrix. By adopting the treatment methods of titanium powder precoating and nitrogen arc cladding, the TiN enhanced ferrous matrix composite surface layer with thickness of 1-2mm is prepared on the surface of the steel matrix. The TiN enhanced phase grows in situ, is metallurgically bonded with the steel matrix, dendritical and granular and uniformly distributed in the steel matrix and can obviously improve the surface hardness and the wear resistance of the steel matrix.

Owner:CHANGCHUN UNIV OF TECH

High temperature and high pressure direct synthesis method of cubic boron nitride in titanium nitride plated coating

InactiveCN103272527AHigh hardnessImprove wear resistanceUltra-high pressure processesAlkaline earth metalHexagonal boron nitride

The invention relates to a high temperature and high pressure direct synthesis method of cubic boron nitride in a titanium nitride plated coating, relating to a high temperature and high pressure synthesis method of an ultra-hard material. The method takes hexagonal boron nitride as a raw material, an alkali metal nitride or alkaline-earth metal nitride or boron nitride as a catalyst, and metallic titanium powder or a metallic titanium compound as an additive. The method comprises the following steps of: mixing the hexagonal boron nitride and the alkali metal nitride or the alkaline-earth metal nitride or the boron nitride according to a weight proportion of 1:(0.1-0.3), adding the metallic titanium powder or the metallic titanium compound accounting for 0.5wt%-10wt% of the total mixture, and synthesizing a cubic boron nitride product with the titanium nitride plated coating at a high temperature and a high pressure, wherein the synthesis temperature is 1000 to 1800 DEG C, the synthesis pressure is 4.0-6.0 GPa, and the temperature and the pressure last for 3-15 minutes. The cubic boron nitride provided by the invention has the characteristics of high hardness, good abrasion resistance, good high temperature resistance, good tenacity, thermal conduction and electrical conduction, and is particularly suitable for preparation of polycrystalline cubic boron nitride products and tools.

Owner:柳州市大荣非金属材料有限公司

Method for melting and casting alpha alumina product

The invention discloses a method for melting and casting an alpha alumina product, which comprises the following steps: calculating the weight of the raw materials according to the following chemical components, as a percentage by weight based on the oxides, 98-99 of Al2O3, 0.1-0.5 of SiO2, 0.9-1.2 of Na2O, preparing a mixture, then adding into an electric arc furnace for melting and refining, then casting into a mold, removing the mold to obtain the alpha alumina product. The alpha alumina product provided in the invention has the advantages of no cracks, tight structure, high refractoriness and high strength of temperature structure, good chemical stability at high temperature, wherein the refractoriness temperature is above 1900 DEG C, the compressive strength at normal temperature is more than 200 MPa, which can satisfy the use requirements of nonferrous metals furnaces and high temperature tunnel kilns, the service life is long and the production cost of users can be greatly reduced, so that the method of the invention can provide visible economic benefit to the users.

Owner:郑州振中电熔新材料有限公司

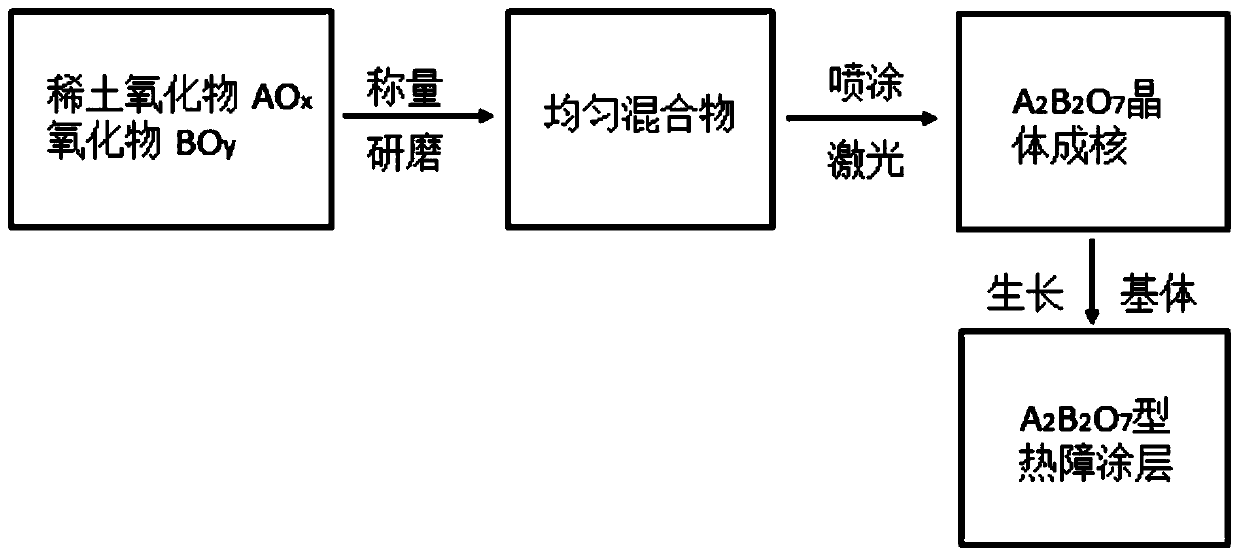

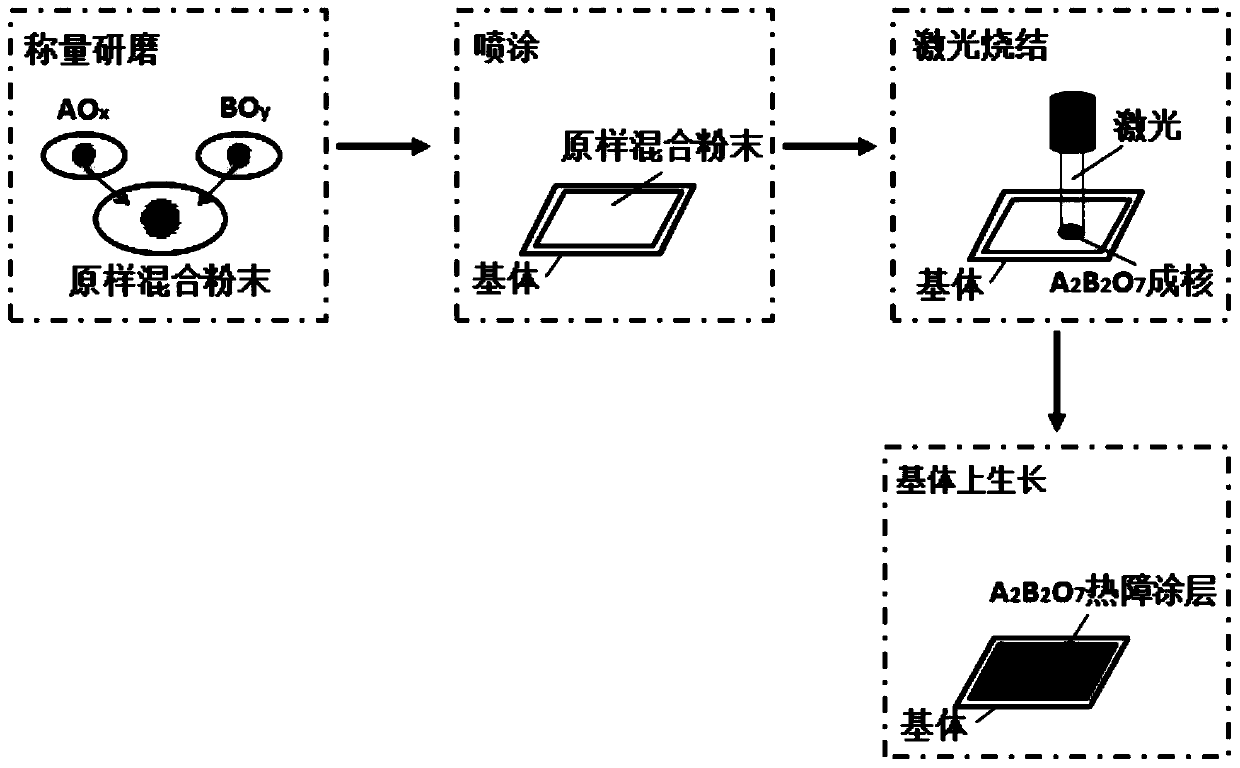

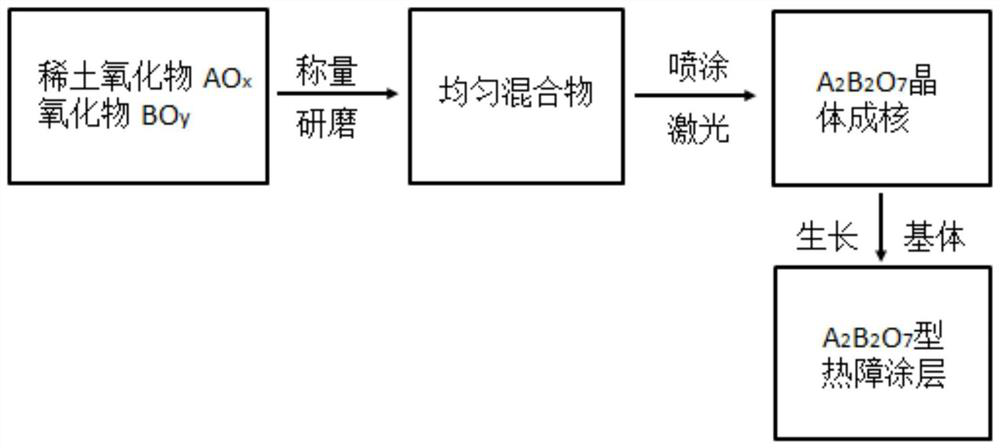

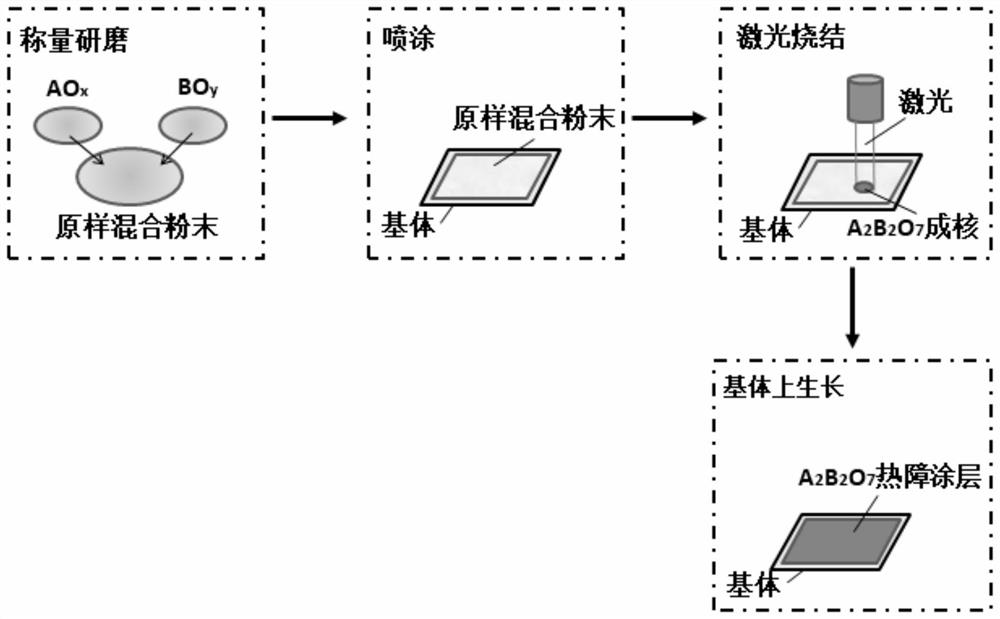

Method for generating A2B2O7 type thermal barrier coating material by laser-induced high-temperature solid-phase reaction

ActiveCN109851377AGood insulation performanceThe process steps are simpleHeat inorganic powder coatingRare-earth elementOxide

The invention relates to the technical field of thermal barrier coating materials, and particularly relates to a method for generating an A2B2O7 type thermal barrier coating material by a laser-induced high-temperature solid-phase reaction. The method comprises the following steps: (I) uniformly mixing an oxide AOx with an oxide BOy to obtain mixed powder; (II) uniformly distributing the mixed powder obtained in the step (I) to the surface of a substrate; and (III) irradiating the surface of the substrate obtained in the step (II) by laser, inducing the mixed powder to carry out a high-temperature solid-phase reaction under the action of the laser to obtain A2B2O7, and growing the A2B2O7 on the surface of the substrate to generate the A2B2O7 type thermal barrier coating material, wherein the element A is a rare earth element, the element B is at least one selected from Ti, Zr and Hf, x is greater than or equal to 0.5 and less than or equal to 2, and y is equal to 2. The preparation method is simple to operate and convenient to control, production efficiency is high, production cost is low, pollution is small, the production period is short, and the method can be used for large-scale production.

Owner:广东朗研科技有限公司 +2

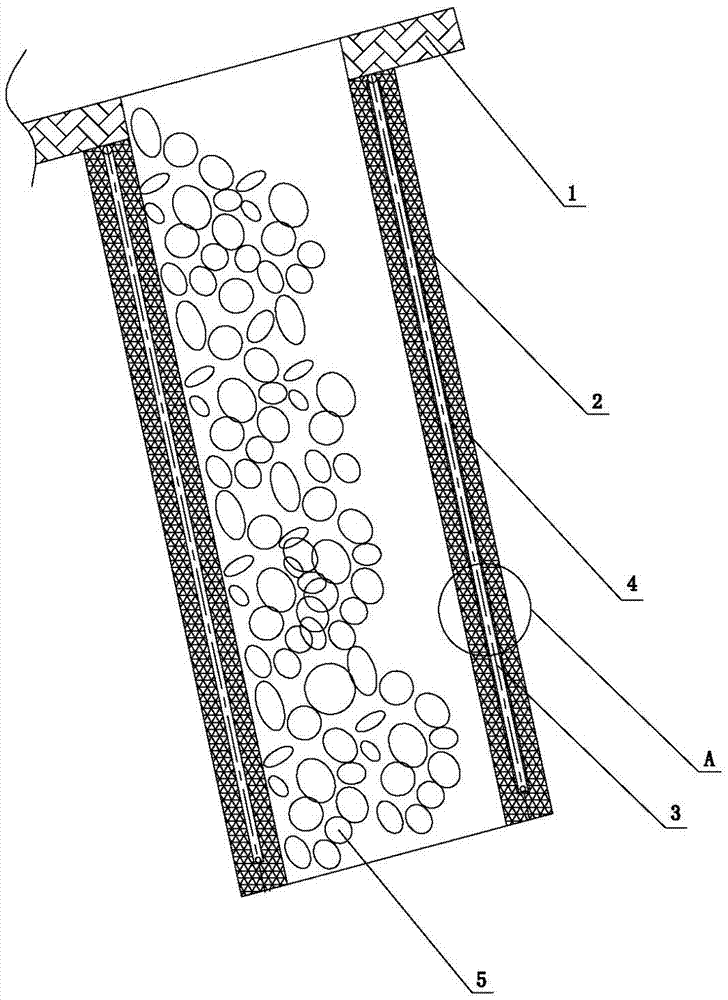

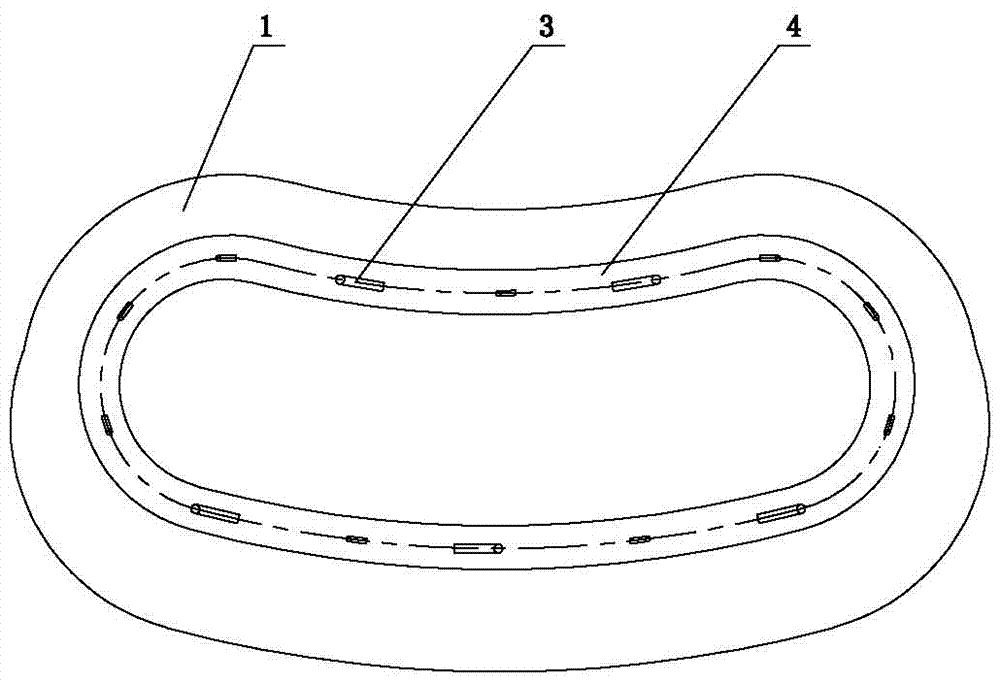

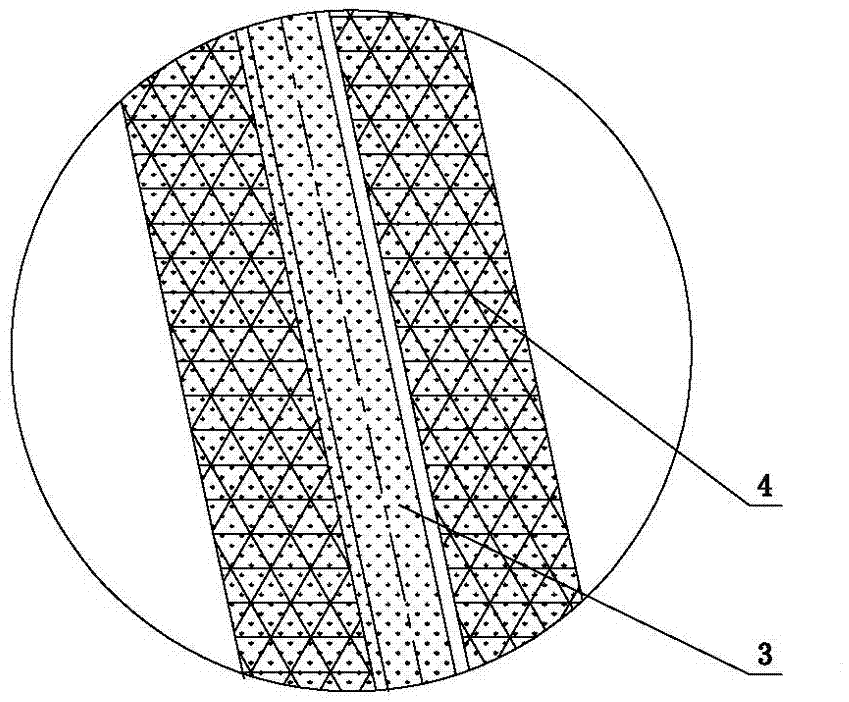

Preparation method of steam pipeline thermal insulation material

InactiveCN109880158AImprove thermal insulationHigh tensile strengthThermal insulationTemperature resistance

The invention relates to a preparation method of a steam pipeline thermal insulation material, and belongs to the technical field of thermal insulation materials. A basalt fiber honeycomb fabric prepared from sepiolite and expanded perlite as heat preservation fillers by a respiration pattern method is adopted as a reinforcing material to prepare polyurethane foam prepared by compounding with polyurethane resin by a medium-temperature foaming method, the prepared steam pipeline thermal insulation material has good thermal insulation performance, and the basalt fiber honeycomb fabric is added,so that the tensile strength of the steam pipeline thermal insulation material is improved; the sepiolite and the expanded perlite have the advantages of low heat conductivity coefficient, high temperature resistance, acid resistance, alkali resistance, salt resistance, oil resistance, and the like; the prepared steam pipeline thermal insulation material has the advantages of small density, high heat resistance, small heat conductivity coefficient, high compressive strength and small shrinkage rate, and the steam pipeline thermal insulation material has the advantages of excellent thermal insulation performance, ultralow density, flame retardancy, good light transmittance and the like.

Owner:常州鼎众冷暖设备工程有限公司

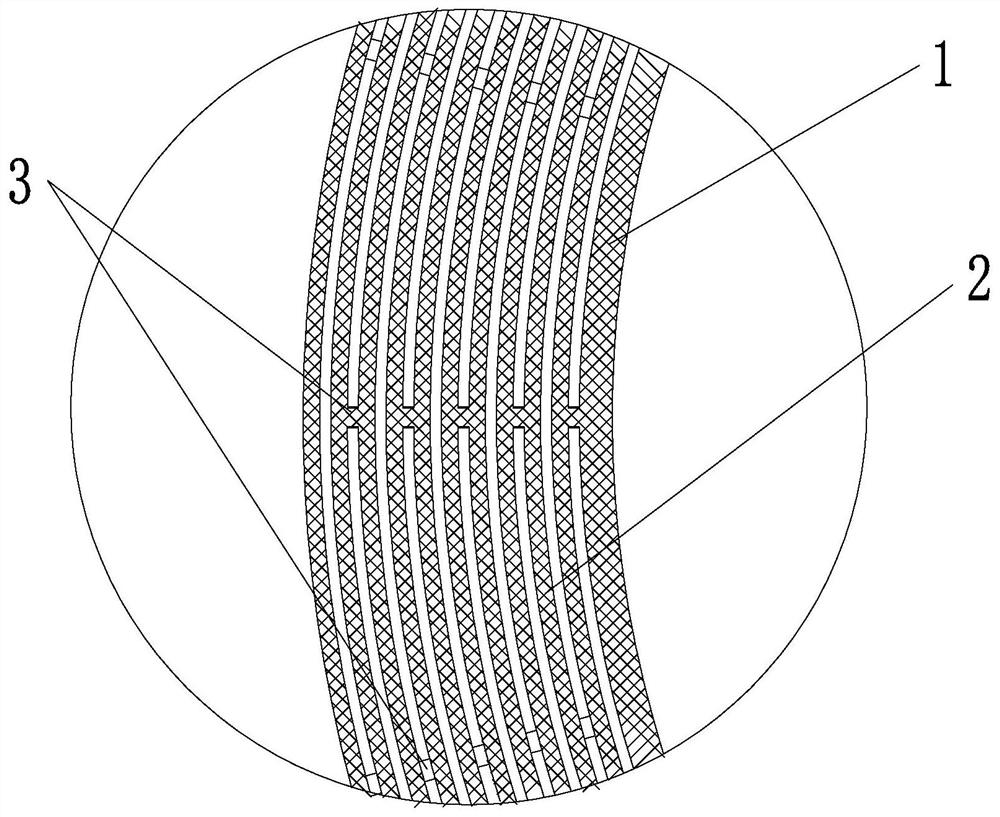

Castable, current stabilization slag ladle prepared from same as well as preparation methods thereof

ActiveCN106007753AGood high temperature chemical stabilityGood high temperature corrosion resistanceSlagGranularity

The invention discloses a castable, a current stabilization slag ladle prepared from the same as well as preparation methods thereof. The castable is prepared form the following raw material ingredients in percentage by weight: 15-30% of Al-Mg spinel with granularity of 5-8mm, 10-30% of forsterite with granularity of 3-5mm, 10-15% of kyanite with granularity of 1-3mm, 7-20% of fused corundum with granularity of 1-3mm, 5-20% of Si2ON2 with granularity less than or equal to 1mm, 5-15% of TiO2 with granularity less than or equal to 1mm, 1-5% of Fe2O3 with granularity of 180 meshes and 2-8% of silicon micropowder with granularity less than 0.088mm, as well as a water reducer which accounts for 0.1-0.3% of the total weight of the above raw material ingredients. The repairing material has the advantages of high strength, long service life, high temperature resistance, scouring resistance, erosion resistance, high peeling capability and the like.

Owner:SHANDONG IRON & STEEL CO LTD

Vacuum evaporation process of high-brightness transparent light reflecting film

InactiveCN109609913AWith high temperature and corrosion resistanceHigh hardnessVacuum evaporation coatingSputtering coatingEngineeringEvaporation chamber

The invention discloses a vacuum evaporation process of a high-brightness transparent light reflecting film. A plated plant base film is mounted in an evaporation chamber, then a cooling roller carries out low-temperature cooling, molybdenum boats where evaporation targets are arranged are put into an evaporation tank, it is guaranteed that the distance between each evaporation target and the bottom end of a center main drum is the same, after a cover plate is closed, the evaporation tank is fed into the evaporation chamber, and the evaporation chamber is vacuumized; the evaporation targets are heated to the melting point and are vaporized, the cover plate of the evaporation tank is opened, the plated plant base film is controlled to move in the evaporation chamber at a constant speed, andstep-by-step evaporation operation is carried out; and equipment is shut down after evaporation is completed. According to the vacuum evaporation process of the high-brightness transparent light reflecting film, the light reflecting brightness of the finally-obtained light reflecting film is far higher than that of a common transparent light reflecting film, a good light reflecting effect is achieved, the surface is light, thin and transparent, the vacuum evaporation process is suitable for later deep processing treatment, and meanwhile a metal film is firm and not prone to falling off.

Owner:合肥市辉耀真空材料有限责任公司

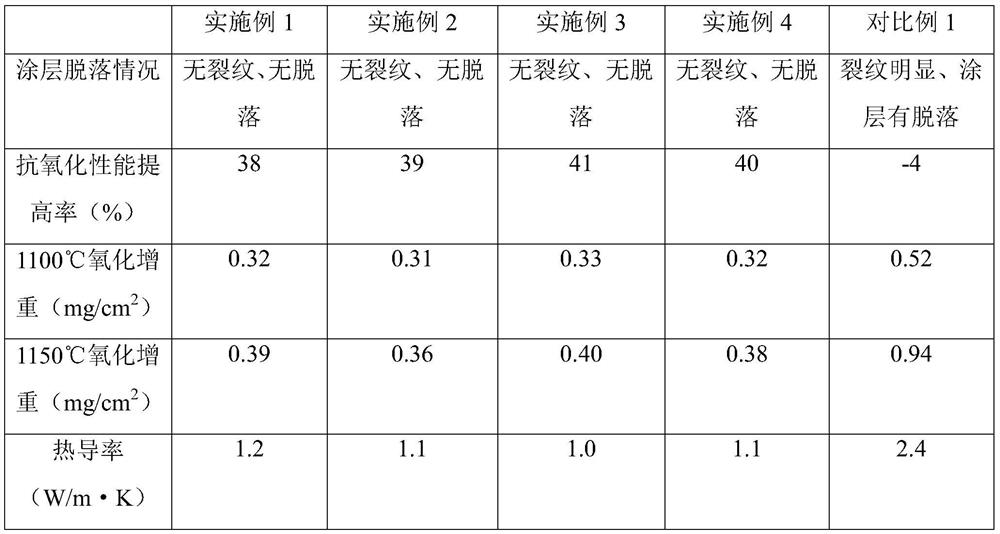

Closed-pore ceramic microsphere filled gradient ceramic coating and preparation method thereof

PendingCN114085092AImprove corrosion resistanceImprove wear resistanceCeramicwareResin microsphereCeramic coating

The invention discloses a preparation method of a closed-pore ceramic microsphere filled gradient ceramic coating. The method comprises the following steps: taking an organic resin microsphere as a core, attaching a ceramic precursor on the surface of the core to obtain a solid microsphere, performing calcining at high temperature to obtain a hollow ceramic microsphere, and mixing the hollow ceramic microsphere with a ceramic aggregate to form a ceramic coating on the surface of a matrix. According to the invention, the ceramic microspheres of the mullite (3Al2O3.2SiO2) crystalline phase are used for constructing closed pore channels in the coating, and in the spraying process, the gaps among the hollow microspheres are filled with the ceramic aggregate with small particle size, so that the compactness of the coating is effectively improved, the formation of communicated pore channels is avoided, and the ceramic coating can have lower heat conductivity and provide a better heat insulation effect.

Owner:ZHAOSHAN TECH BEIJING CO LTD

Preparation and application methods of barium zirconate ceramic core

InactiveCN109574661AHigh strengthImprove high temperature stabilityFoundry mouldsFoundry coresDie castingRoom temperature

The invention relates to the technical field of ceramic cores, particularly to preparation and application methods of a barium zirconate ceramic core. The preparation method of the barium zirconate ceramic core comprises the following steps of mixing barium zirconate, beewax and paraffin to obtain a barium zirconate ceramic paraffin pulp; die-casting the barium zirconate ceramic paraffin pulp to obtain a barium zirconate ceramic core blank; sintering the barium zirconate ceramic core blank to obtain the barium zirconate ceramic core. The barium zirconate ceramic core prepared through the method is high in room temperature strength and high-temperature stability, maintains high size stability before and after being sintered, is applicable to at high temperature casting Nb-Si-based alloy turbine blades, avoids sharp reaction with chemical elements of Nb-Si-based alloy and ensures the quality of the inner cavity of Nb-Si alloy hollow blades.

Owner:沃尔曼科技张家港有限公司

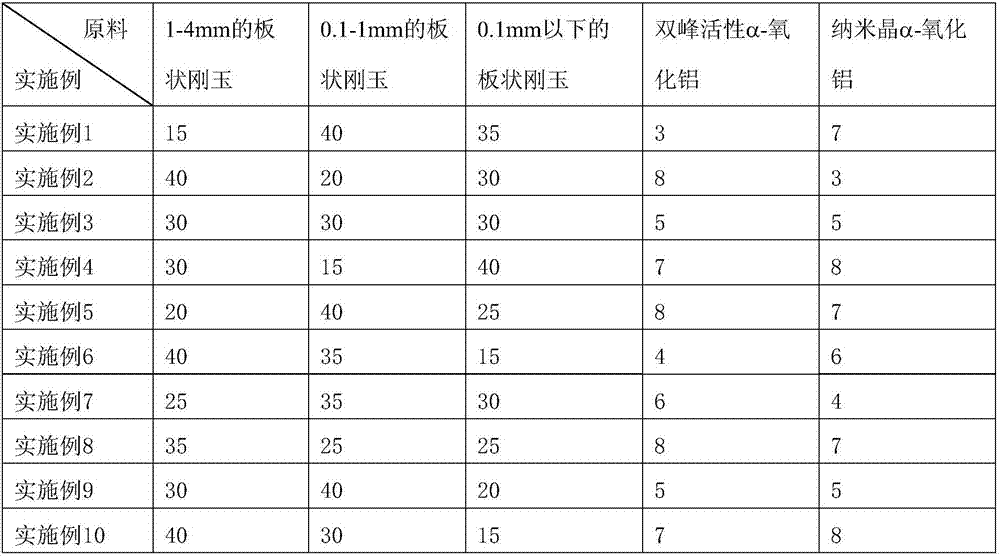

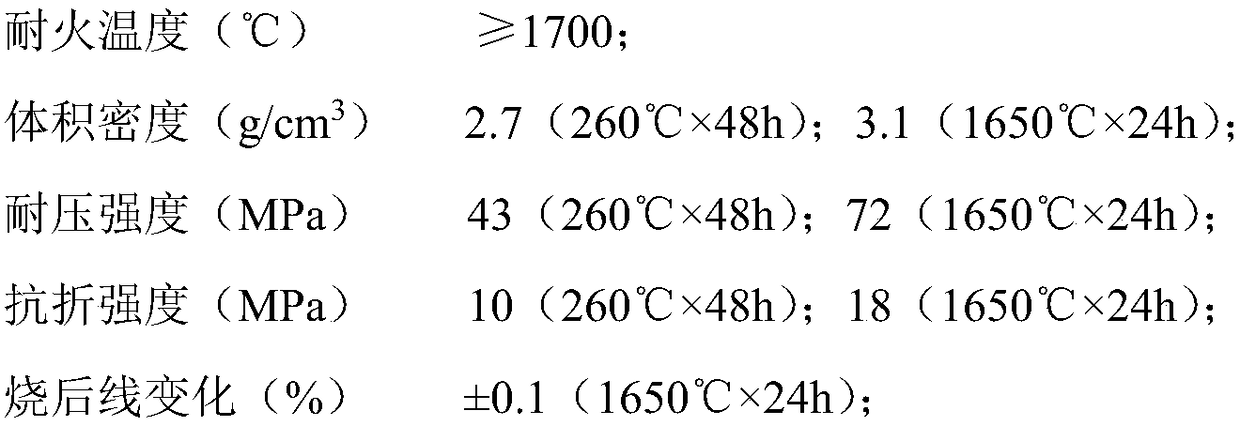

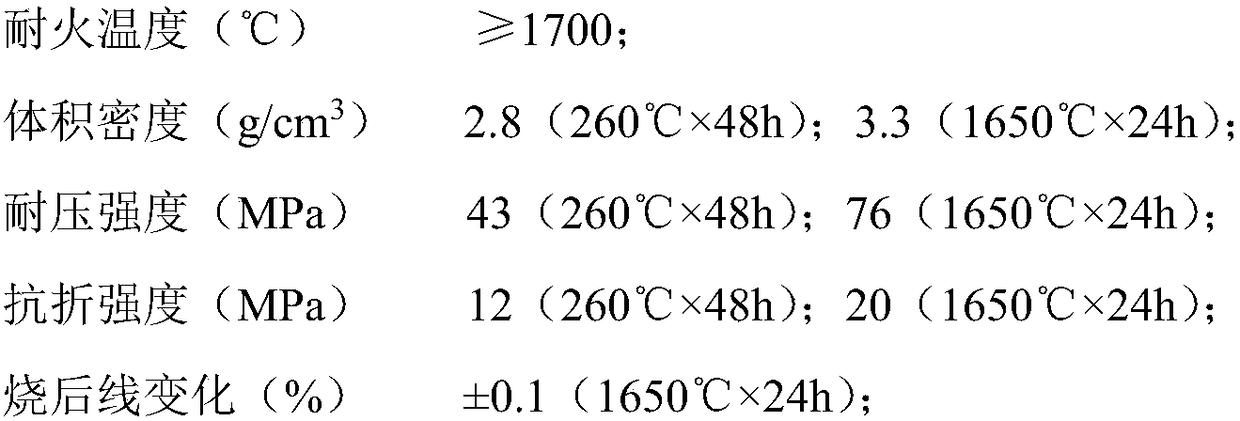

Refractory material for titanium-aluminum alloy smelting, and preparation method thereof

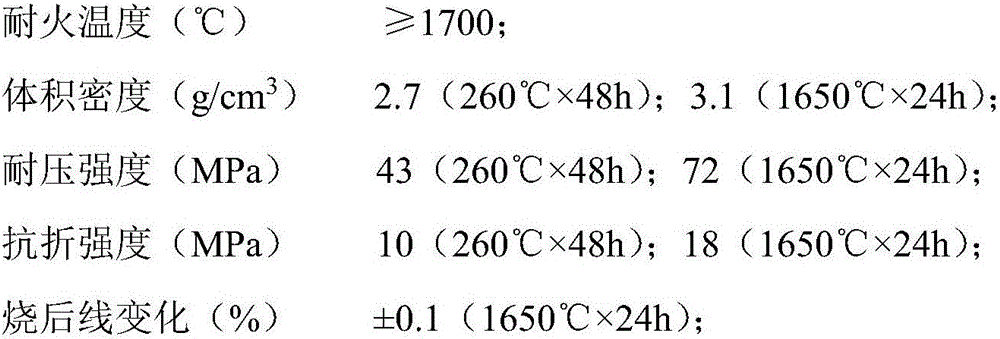

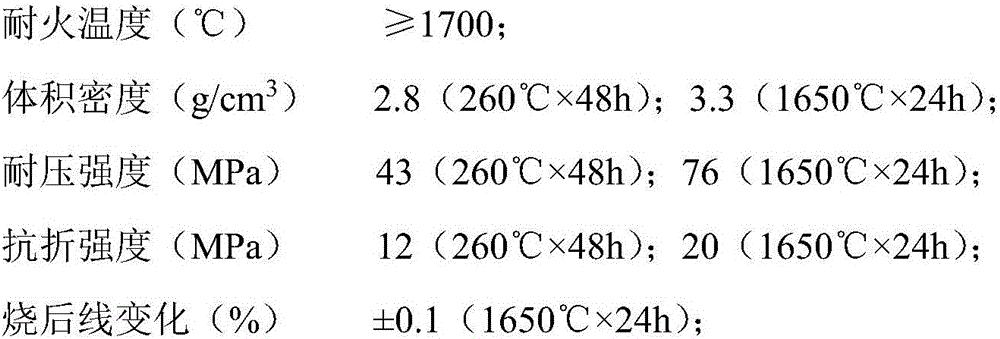

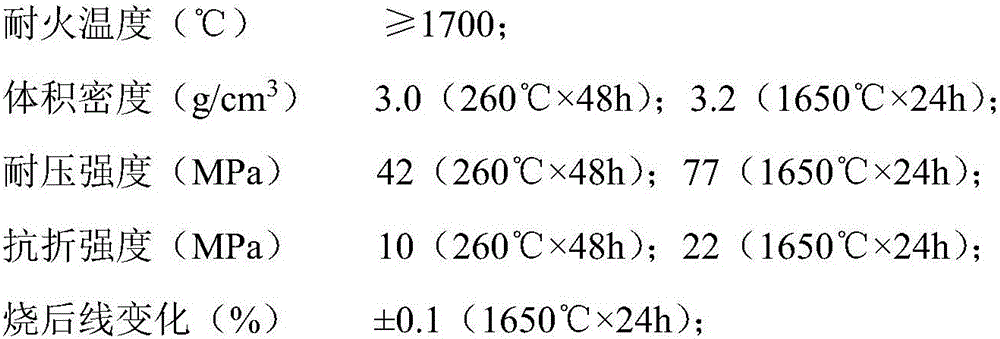

ActiveCN111362708AWide variety of sourcesSimple preparation processCompression moldingCalcium aluminates

The invention relates to a refractory material for titanium-aluminum alloy smelting, and a preparation method thereof. 60-75 wt% of titanium-containing calcium hexaluminate particles are used as aggregate, and 25-40 wt% of titanium-containing calcium hexaluminate fine powder is used as a matrix material. The preparation method comprises the following steps: adding the uniformly mixed matrix material into the aggregate, uniformly mixing, adding a binding agent accounting for 0.5-2 wt% of the sum of the aggregate and the matrix material, mixing and grinding, carrying out compression molding under 100-200 MPa, and drying at 110-200 DEG C to obtain the refractory material for titanium-aluminum alloy smelting. The particle size of the titanium-containing calcium hexaluminate particles ranges from 0.088 mm to 10 mm, and the particle size of the titanium-containing calcium hexaluminate fine powder is smaller than 0.088 mm; the Ca((Al0.84Ti0.16)2)6O19 phase content of the titanium-containing calcium hexaluminate particles and the titanium-containing calcium hexaluminate fine powder is greater than 90 wt%. The method is low in cost and simple in process, and the prepared product has the advantages of being good in high-temperature chemical stability, good in thermal shock resistance, high in titanium-aluminum alloy melt resistance and small in titanium-aluminum alloy pollution.

Owner:WUHAN UNIV OF SCI & TECH

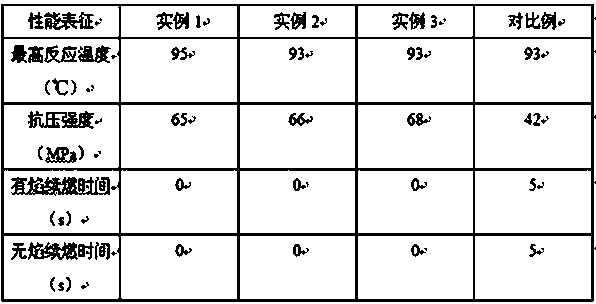

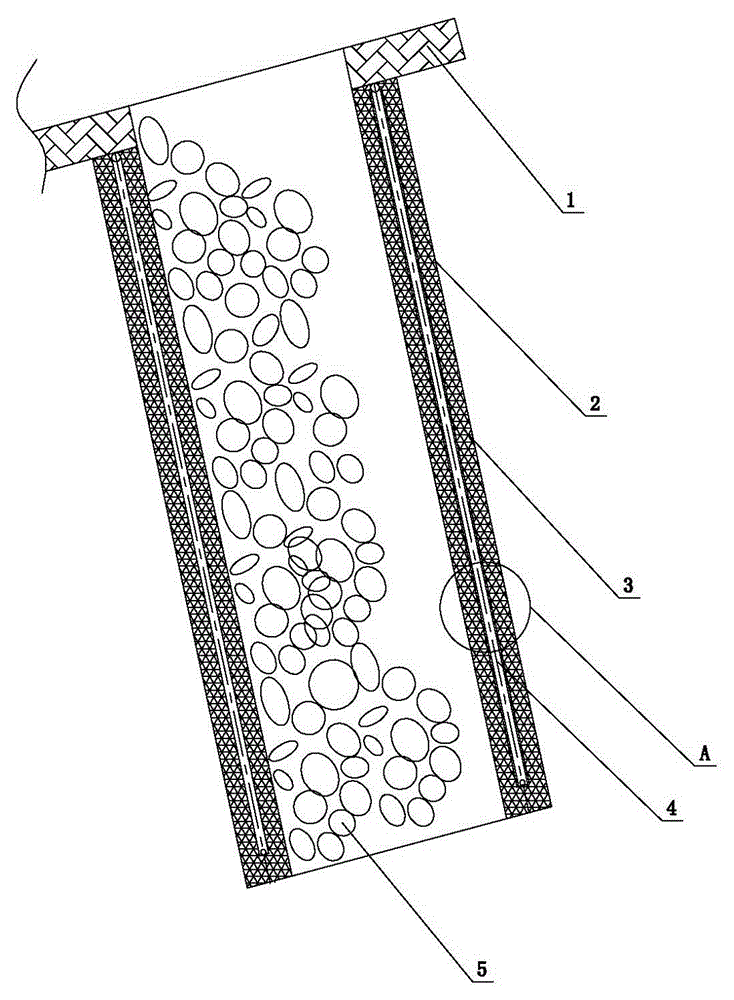

Preparation method of mining reinforcement material

InactiveCN109971159AExcellent flame retardantIncrease surface areaIn situ polymerizationLayered structure

The invention relates to a preparation method of a mining reinforcement material, and belongs to the technical field of mining materials. The preparation method of the mining reinforcement material ischaracterized in that based on the flame retardance characteristic of ammonium polyphosphate, with diatomite as a carrier, a double-component ammonium polyphosphate-diatomite inorganic composite flame-retardant filler is prepared by an in-situ polymerization method, and an ammonium polyphosphate-diatomite / synergist composite flame-retardant filler is designed on the basis of the double-componentcomposite flame-retardant filler with magnesium hydroxide the synergist; with good smoke absorbing effect of the diatomite with high specific surface area and based on the special layered structure and composition and also flame retarding, smoke suppressing and acid resisting functions of magnesium hydroxide, the prepared mining reinforcement material is allowed to have good flame retarding and smoke suppressing properties; cellular glass cloth is used as a reinforcing agent for the mining reinforcement material, so that the strength of the mining reinforcement material is effectively improved; and according to the invention, a synergistic effect between two flame-retardant elements silicon and phosphorus causes a decrease in the number of brittle amorphous carbon layers generated and an improvement in the flame retardance of the mining reinforcement material.

Owner:张文中

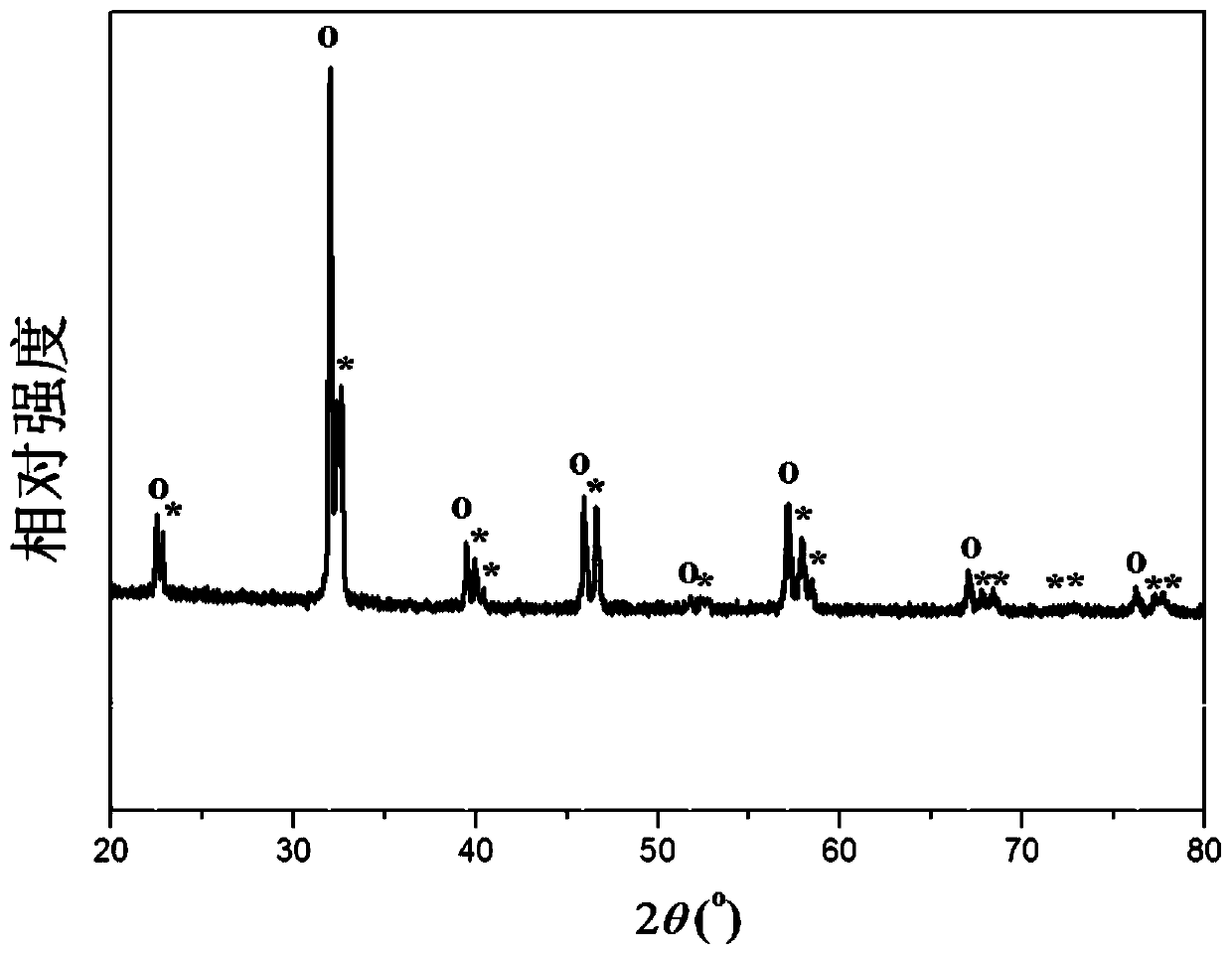

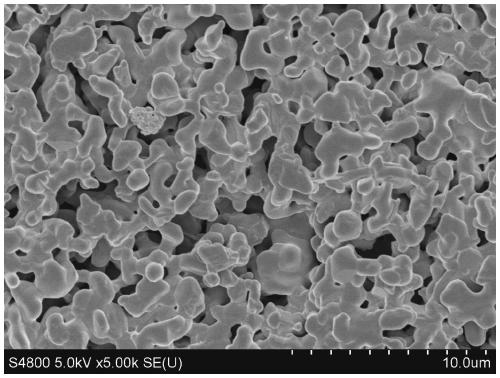

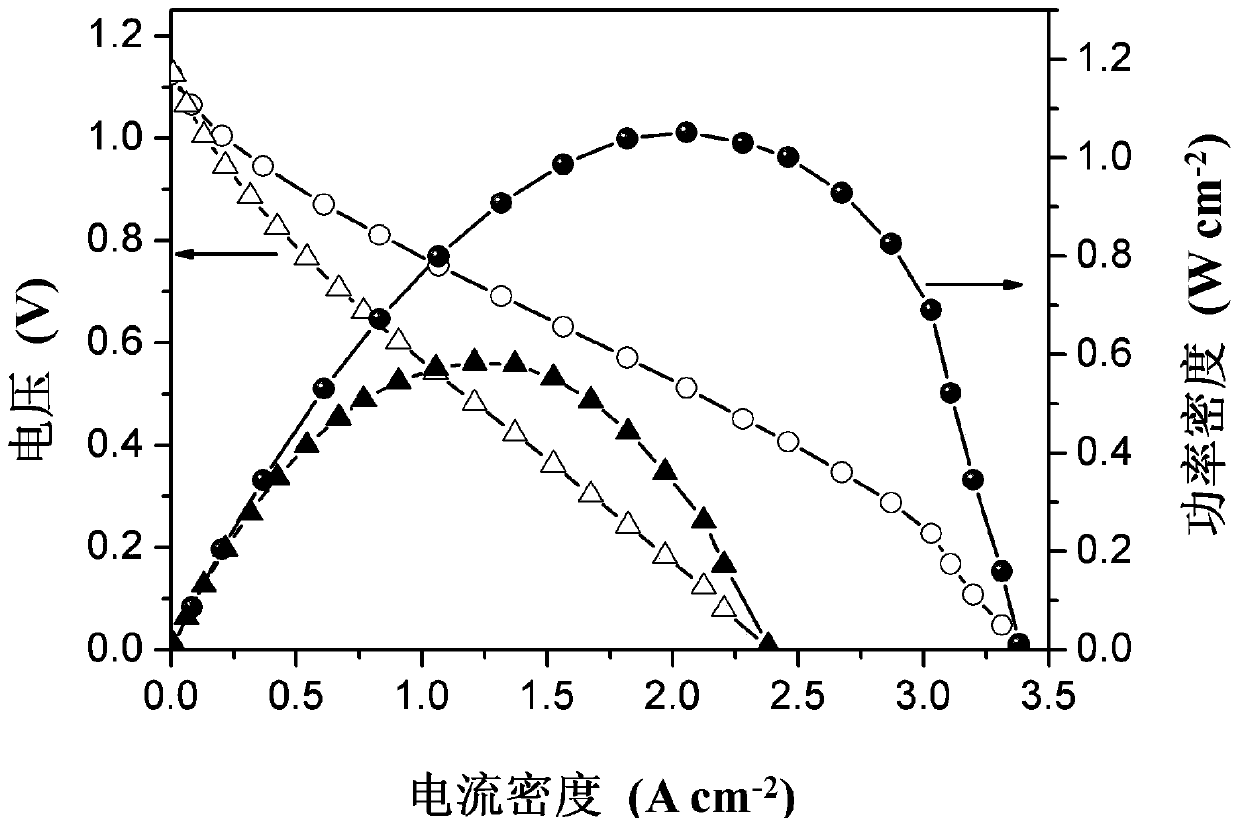

Low-temperature solid oxide fuel cell composite cathode material and preparation method of single fuel cell thereof

InactiveCN111403752AImprove electrocatalytic performanceImprove mixed conductivityCell electrodesSolid electrolyte fuel cellsComposite cathodeFuel cells

The invention discloses a low-temperature solid oxide fuel cell composite cathode material and a preparation method of a single fuel cell thereof, and belongs to the field of chemical power supply solid oxide fuel cell materials. The problems that an existing cathode material is low in electrocatalytic activity and poor in high-temperature chemical stability are solved. The material is composed ofa Bi<0. 5>Sr<0. 5>Fe<0. 9>Sb<0. 1>O<3-delta> cathode and an La<0. 8>Sr<0. 2>O<3-delta> electronic conductor. The method comprises the following steps: 1, mixing a cathode and an electronic conductor,and adding terpilenol to obtain mixed slurry; and 2, brushing the surface of the GDC buffer layer with the mixed slurry, drying, and sintering to obtain the single fuel cell of which the composite cathode is Bi<0. 5>Sr<0. 5>Fe<0. 9>Sb<0. 1>O<3-delta>-La<0. 8>Sr<0. 2>O<3-delta>. According to the invention, the output power of the single fuel cell is effectively increased, the electro-catalytic performance of the fuel cell is improved, and the high-temperature chemical stability is very good. The invention is suitable for the composite cathode material of the low-temperature solid oxide fuel cell.

Owner:HEILONGJIANG UNIV

Manufacturing method of corundum crucible for vacuum induction melting superalloy

Owner:SHANDONG UNIV OF TECH

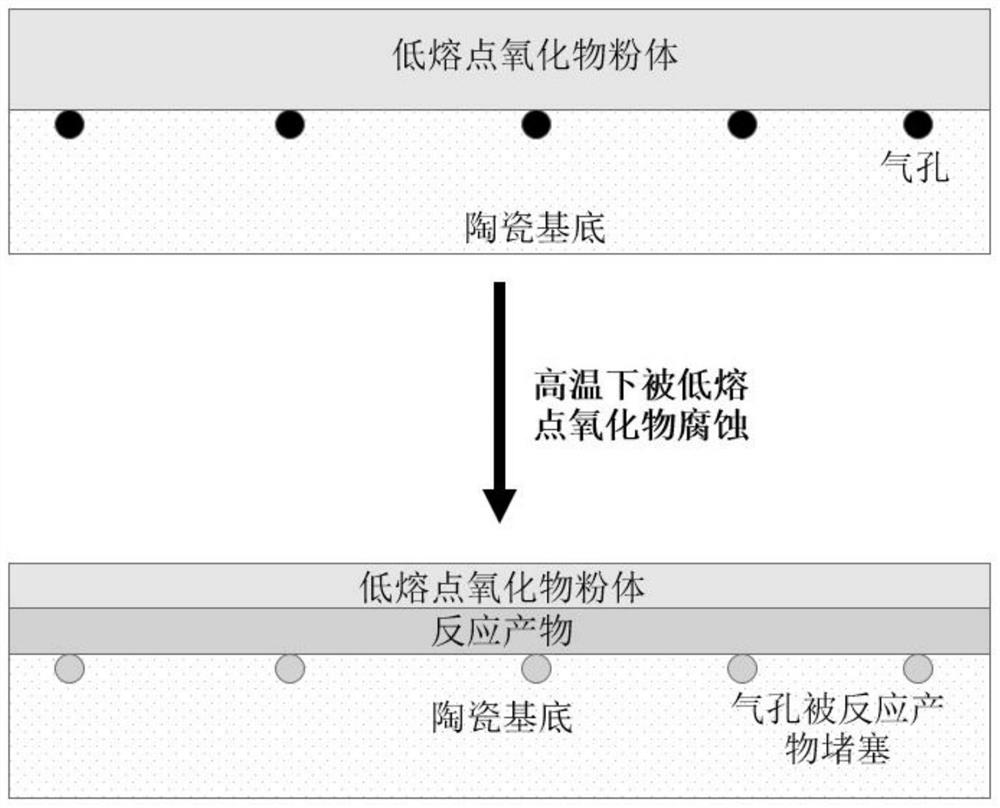

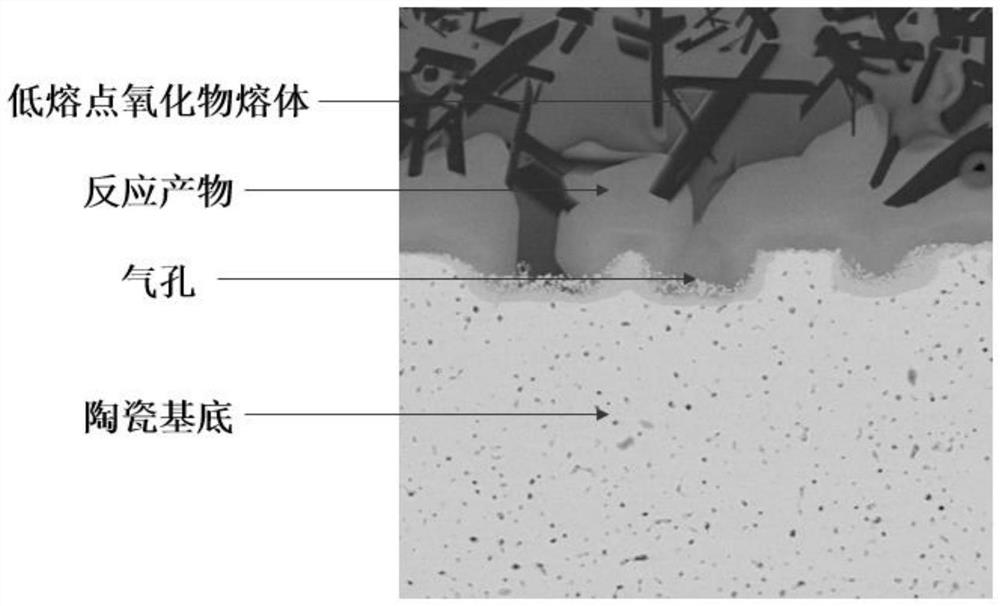

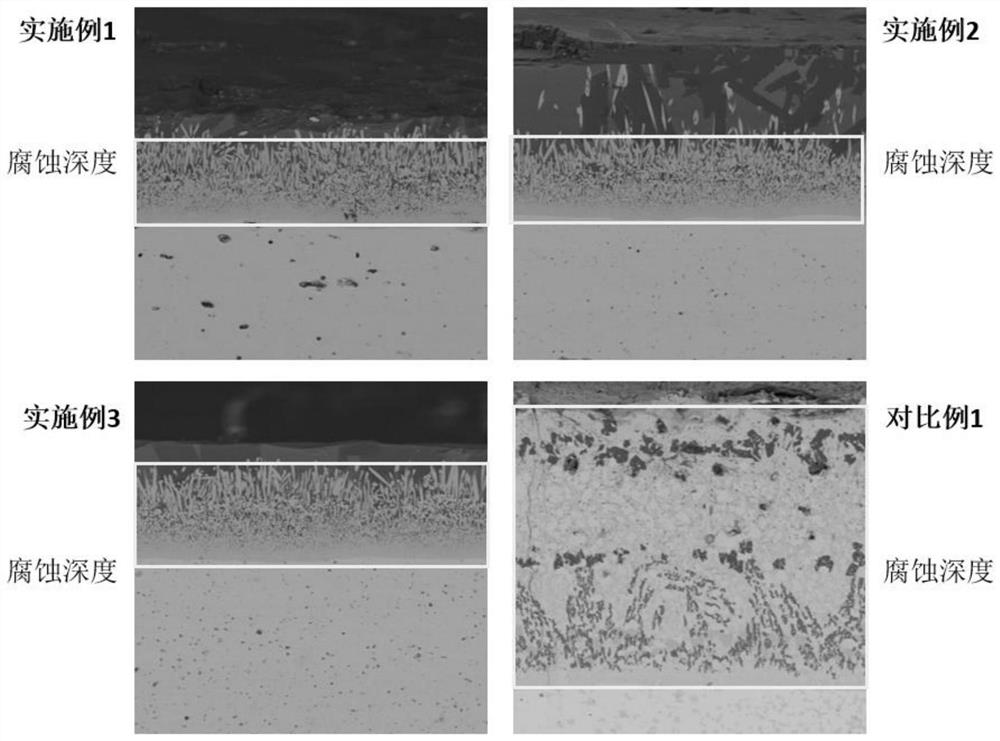

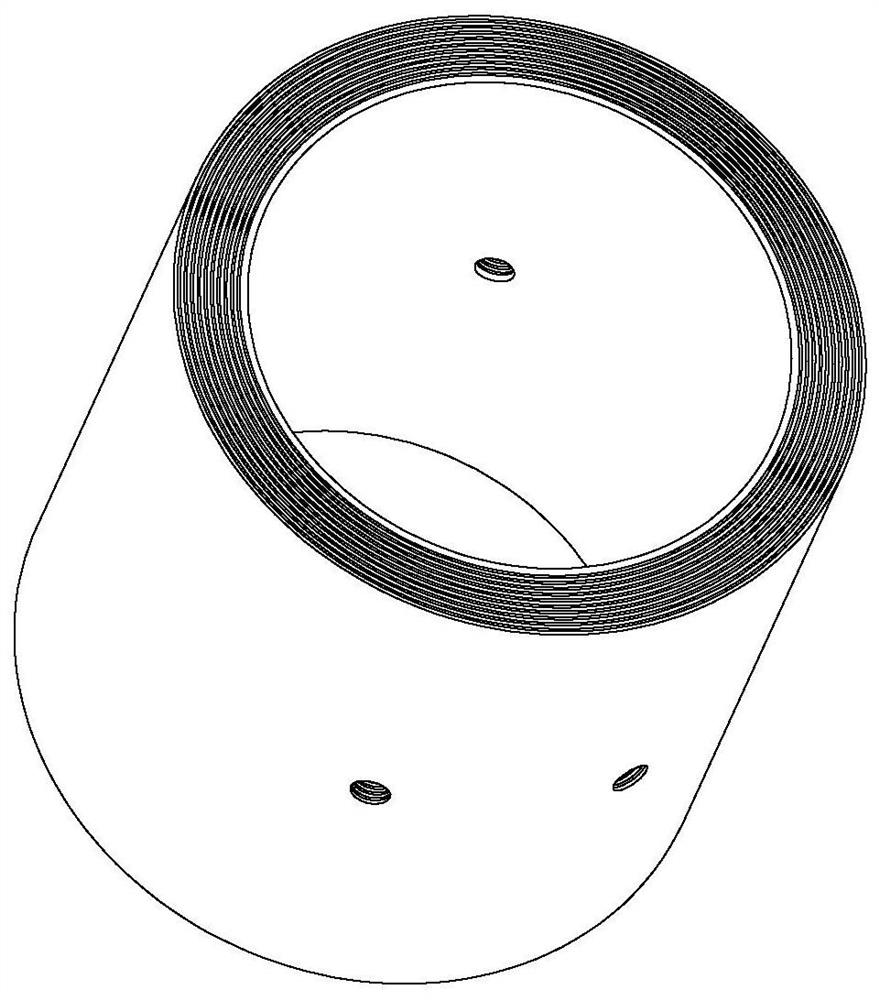

Preparation method of impermeable ceramic material capable of rapidly reacting with low-melting-point oxide

The invention relates to a preparation method of an anti-permeation ceramic material capable of rapidly reacting with low-melting-point oxides, which comprises the following steps: weighing La2O3, RE2O3 and Nb2O5 powder with the purity of more than 99%, uniformly mixing the powder through a ball mill, and using alcohol as a ball milling medium to obtain slurry; drying the slurry, presintering at high temperature, and cooling to obtain initial powder; and grinding and sieving the initial powder, tabletting and sintering to obtain the impermeable LaRE2NbO7 ceramic material which has the porosity of 5-15% and can quickly react with the low-melting-point oxide. The niobate ceramic with certain porosity is prepared by utilizing a high-temperature solid-phase method, the contact area of the niobate ceramic and the low-melting-point oxide is enlarged, so that the reaction is accelerated, and a product with large volume, small density and excellent chemical stability is formed through the rapid reaction of the material and the low-melting-point oxide; pores are quickly blocked, so that low-melting-point oxide melt is effectively prevented from permeating into the material, and the ceramic material which can be used for a long time at high temperature is obtained.

Owner:KUNMING UNIV OF SCI & TECH

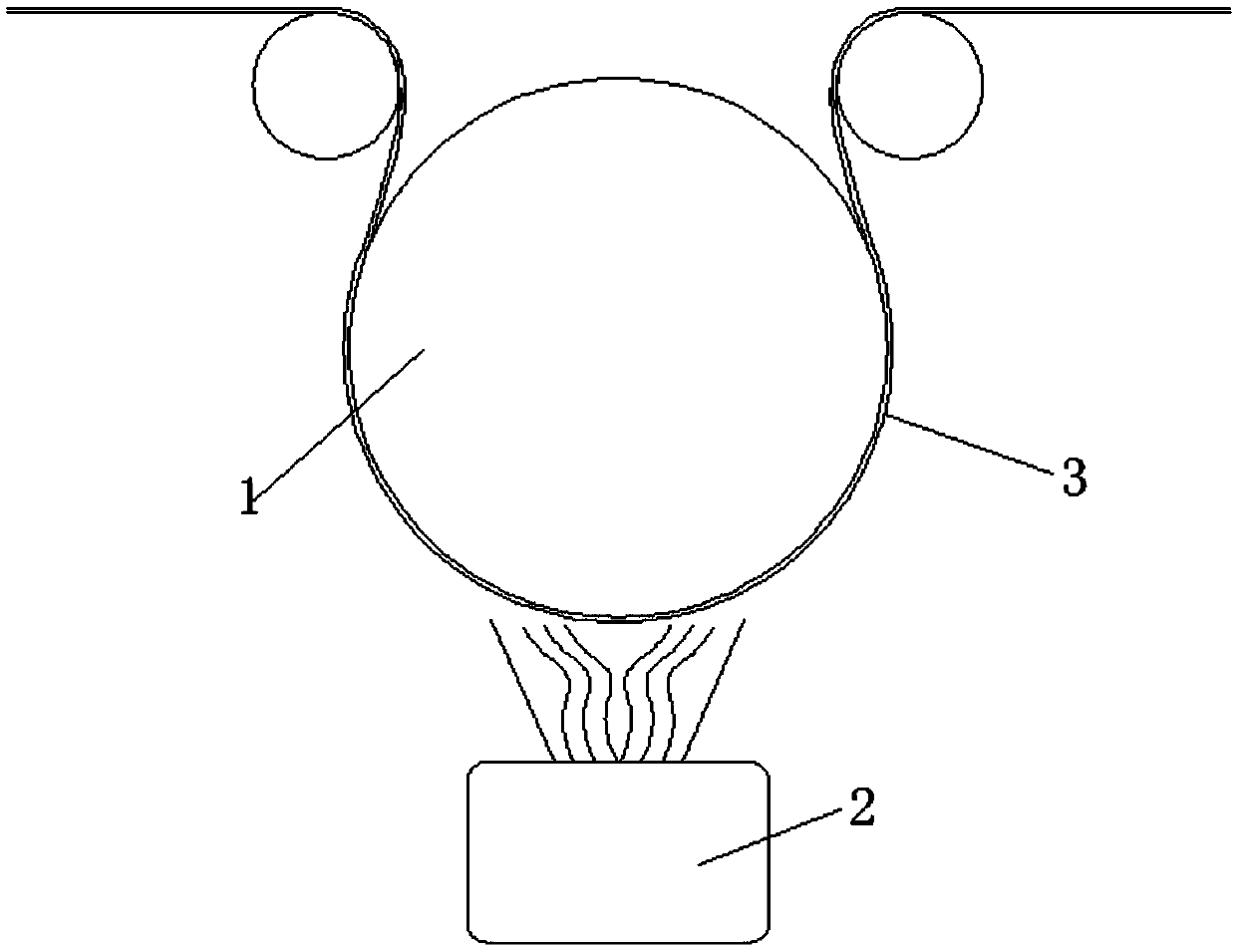

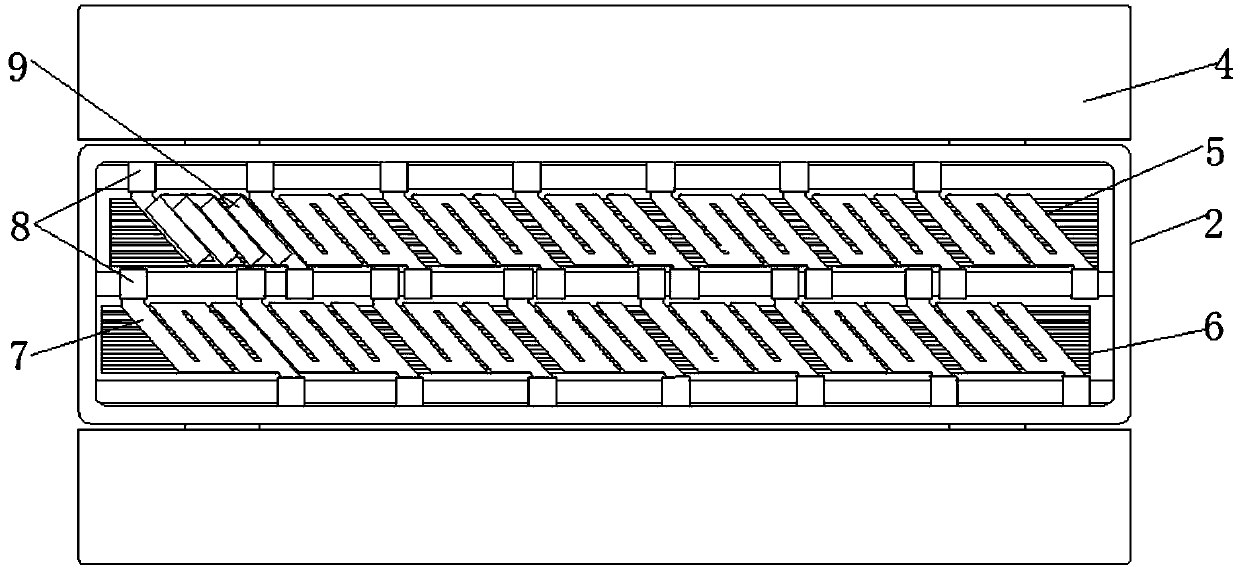

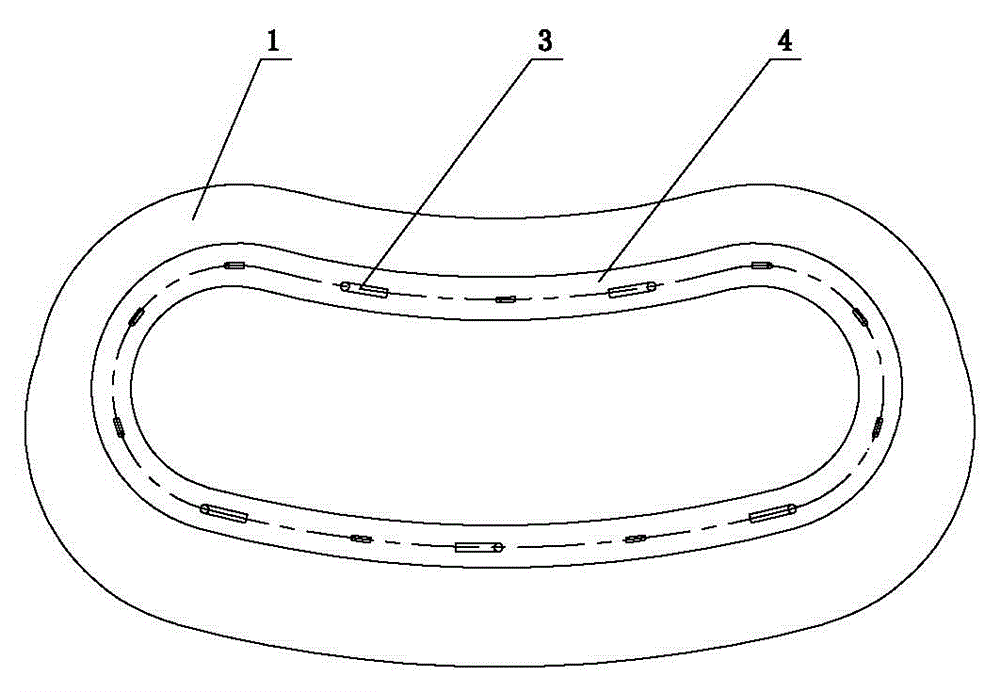

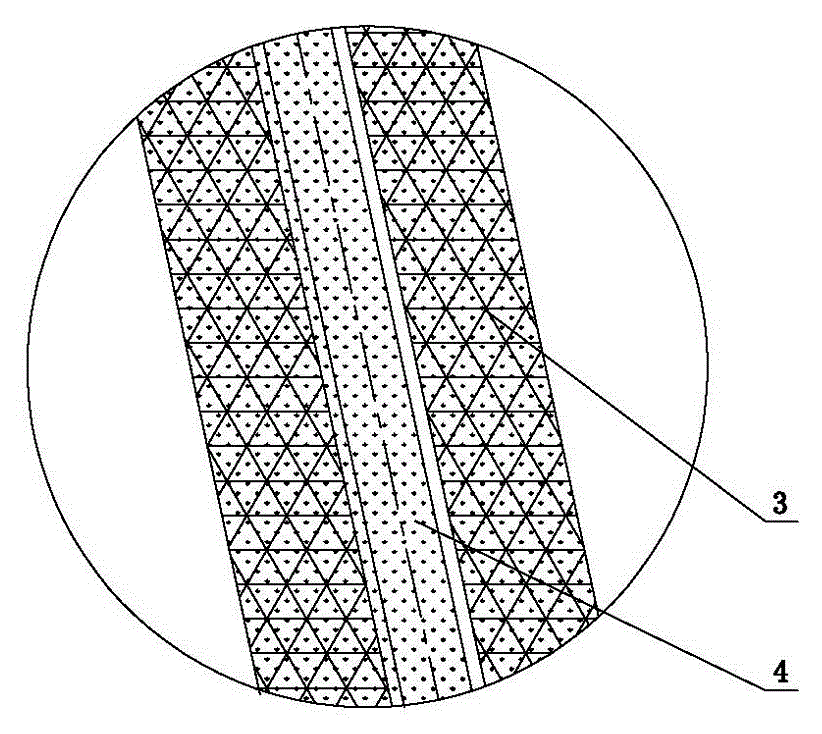

A kind of preparation method of 3D printing monolithic silicon carbide heat shield

ActiveCN111217609BLow thermal conductivityImprove thermal conductivityAdditive manufacturing apparatusFurnace components3d printComputer printing

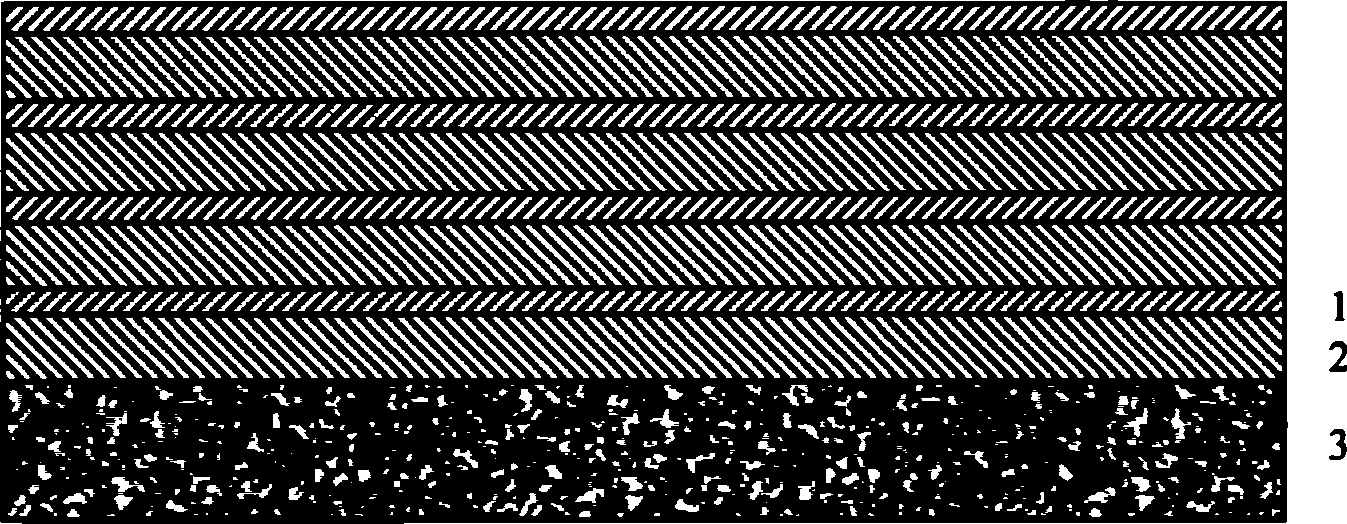

The invention discloses a method for preparing a 3D printing integrated silicon carbide heat shield. The prepared ceramic slurry is added to the barrel of a 3D printer, and the ceramic slurry is extruded into a filamentary unit body, which is piled up layer by layer and formed. Obtain an integral heat shield ceramic green body; the first layer is an inner layer, and the inner layer is an integral structural layer with a thickness of 5-15mm, and its inner wall is the main reflective surface; the second layer is initially an auxiliary reflective layer, and the auxiliary reflective layer The reflective layer and the thermal insulation layer have convective slots that create turbulent flow. The 3D printed integral silicon carbide heat shield prepared by this method; the heat shield that can be printed has a regular overall structure, the polished inner surface forms a reflective surface, and is subjected to high-temperature desiliconization treatment to remove high-temperature sintering pollution such as silicon vapor; The high temperature chemical stability is good, and the atmosphere in the furnace has a three-dimensional network outer layer with low thermal conductivity, the stability of the printing structure, the heat shield has a precise process installation position, and better controllability.

Owner:NINGBO VULCAN TECH CO LTD

Casting material, steady-flow slag-retaining bucket prepared with the same, and their preparation method

ActiveCN106007753BGood high temperature chemical stabilityGood high temperature corrosion resistanceSlagGranularity

The invention discloses a castable, a current stabilization slag ladle prepared from the same as well as preparation methods thereof. The castable is prepared form the following raw material ingredients in percentage by weight: 15-30% of Al-Mg spinel with granularity of 5-8mm, 10-30% of forsterite with granularity of 3-5mm, 10-15% of kyanite with granularity of 1-3mm, 7-20% of fused corundum with granularity of 1-3mm, 5-20% of Si2ON2 with granularity less than or equal to 1mm, 5-15% of TiO2 with granularity less than or equal to 1mm, 1-5% of Fe2O3 with granularity of 180 meshes and 2-8% of silicon micropowder with granularity less than 0.088mm, as well as a water reducer which accounts for 0.1-0.3% of the total weight of the above raw material ingredients. The repairing material has the advantages of high strength, long service life, high temperature resistance, scouring resistance, erosion resistance, high peeling capability and the like.

Owner:SHANDONG IRON & STEEL CO LTD

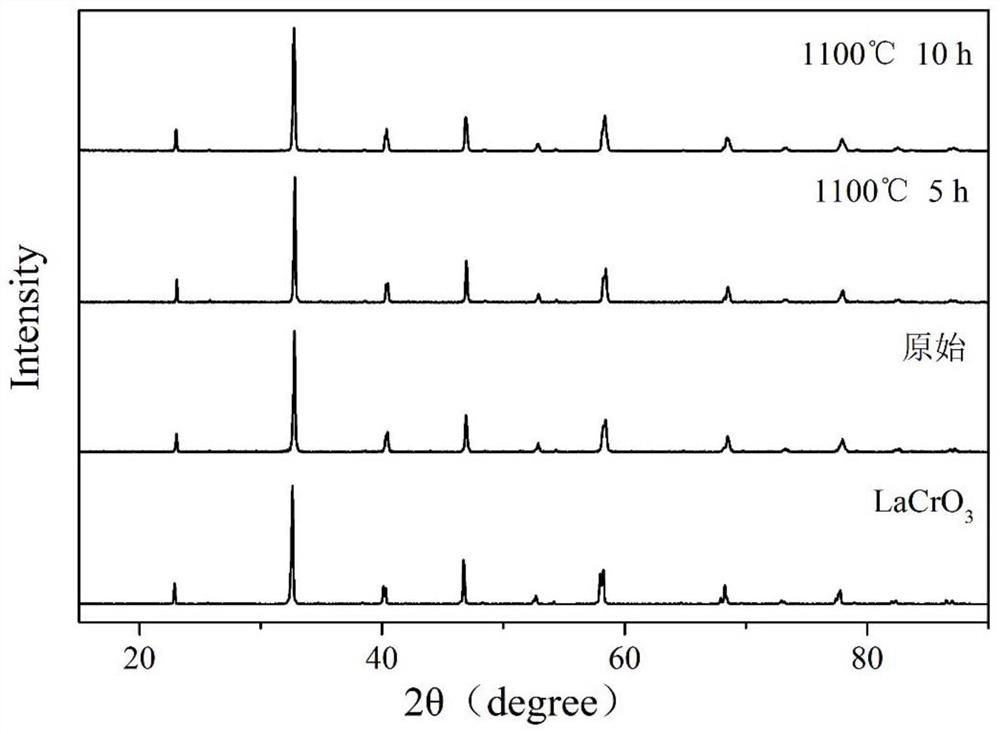

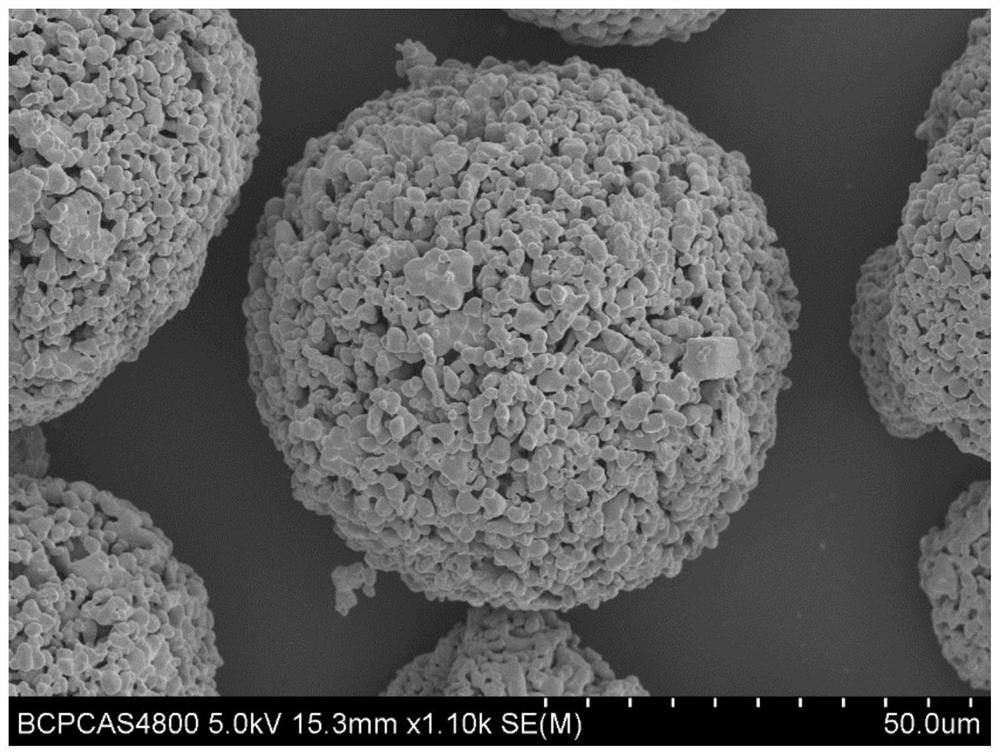

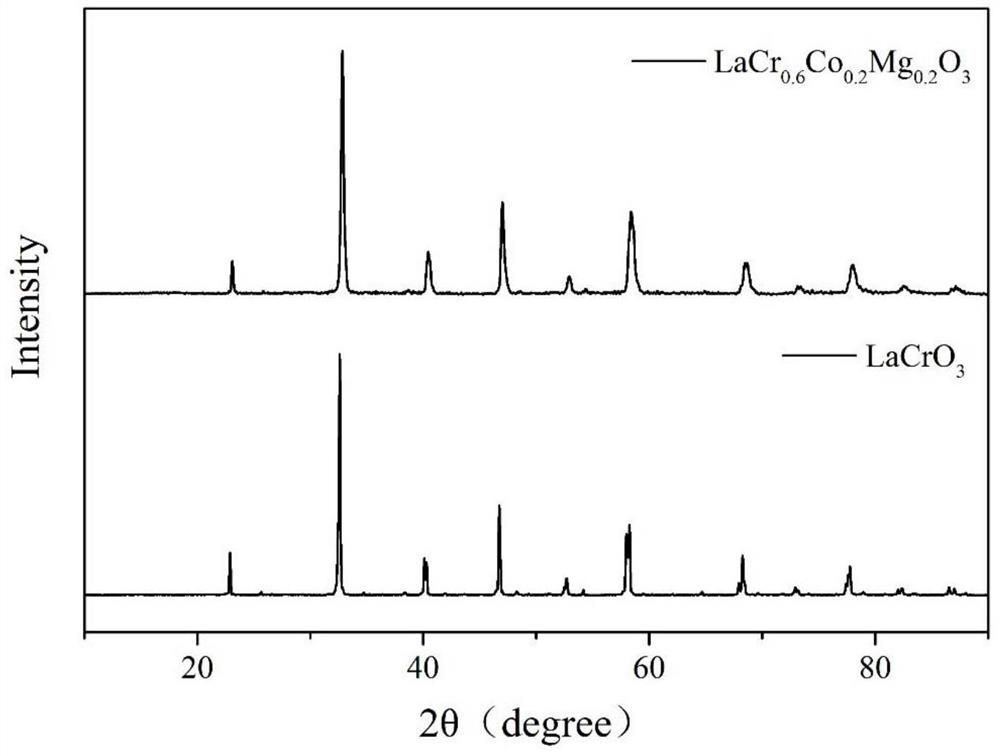

A kind of preparation method of perovskite type high emissivity spherical agglomerated powder

ActiveCN111634950BHigh emissivityWell mixedMolten spray coatingCobalt compoundsSpray GranulationSlurry

Owner:北京理工大学重庆创新中心 +1

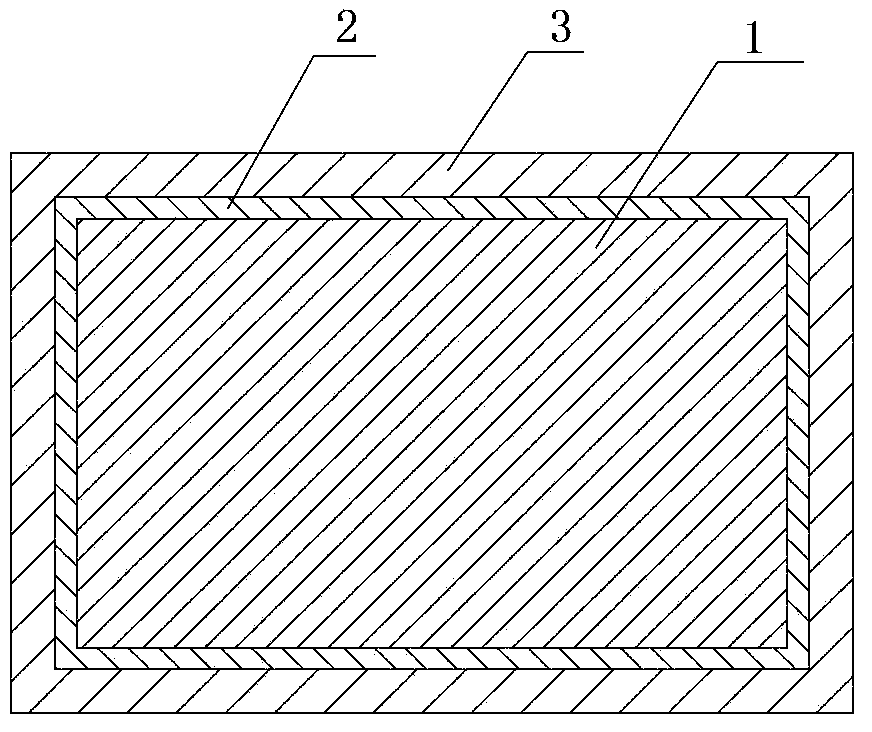

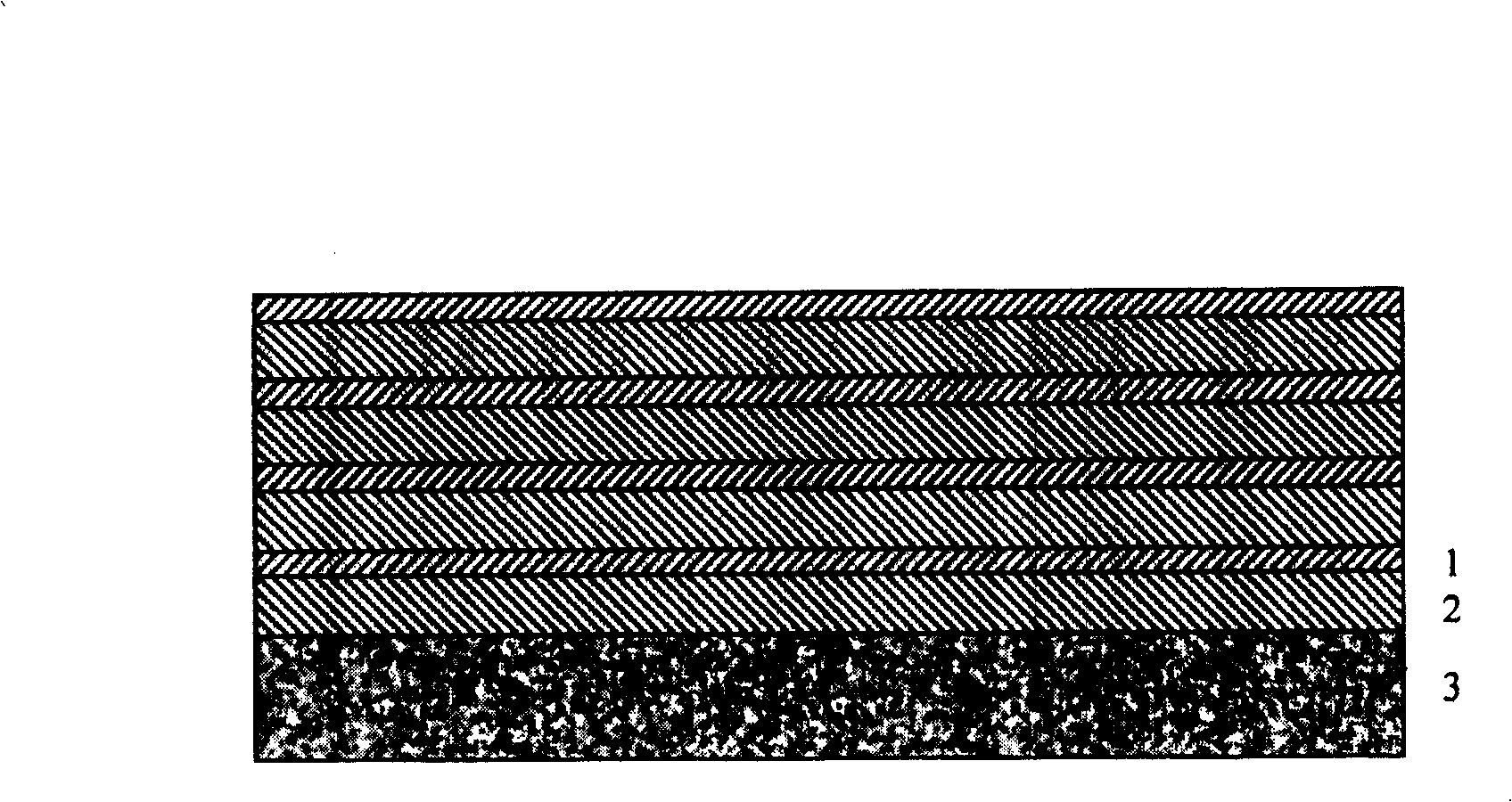

Boron nitride-boron carbide-graphite composite heating element used for high temperature electric heating

The invention discloses a boron nitride-boron carbide-graphite composite heating element used for high temperature electric heating, which is composed of a graphite matrix, a boron carbide intermediate layer coated on the outer surface of the graphite matrix and a boron nitride surface layer coated outside the boron carbide intermediate layer. The profile of the graphite matrix can be designed and treated according to the requirements of the electric heating equipments, the graphite matrix requires high temperature pretreatment; the boron carbide intermediate layer is coated on the surface of the graphite matrix, the thickness is 0.02-1mm, and the boron carbide intermediate layer can be prepared by chemical vapor deposition; the boron nitride surface layer is coated outside the boron carbide intermediate layer, and the thickness is 0.1-10mm, and the boron nitride surface layer is prepared by chemical vapor deposition. The boron nitride-boron carbide-graphite composite heating element can realize the electric heating requirements under the temperature of 2000-2800 DEG C, and has the advantages of stable electrical resistivity of the heating element, long usage life, accurate temperature control and less high temperature environmental pollution.

Owner:北京博宇半导体工艺器皿技术有限公司 +2

Hard nanometer layered ZrO2/TiN coating

InactiveCN100443625CHigh hardnessImprove antioxidant capacityVacuum evaporation coatingSputtering coatingCeramic coatingArgon atmosphere

The present invention is one kind of multilayer hard nanometer ZrO2 / TiN coating and belongs to the field of ceramic coating technology. The multilayer hard nanometer ZrO2 / TiN coating includes alternately deposited ZrO2 layers of 2-8 nm thickness and TiN layers of 0.4-1.2 nm thickness on the substrate of hard alloy, ceramic or metal, and has total thickness of 2-5 microns. It is prepared through a double-target sputtering process in argon atmosphere. It has not only excellent high temperature oxidation resistance, but also hardness as high as 19.1-23 GPa. The multilayer hard nanometer ZrO2 / TiN coating of the present invention may be formed on high speed cutting tool and other high temperature wear and corrosion resistant workpieces.

Owner:SHANGHAI JIAOTONG UNIV

Method for melting and casting alpha alumina product

Owner:郑州振中电熔新材料有限公司

Ceramic composite material and preparation method thereof

ActiveCN102515717BLow Photonic Thermal ConductivityStable chemical properties at high temperatureCeramic compositeRare earth

The invention relates to a ceramic composite material and a preparation method thereof. The material is an A2B2O7-C ceramic composite material, wherein A is Sc, Y, La, Nd, Eu, Gd, Dy, Er, Yb or Lu, B is Zr, Hf, Ce or Ti, C is SiO2, SiC, MoSi2 or PMMA, the volume fraction of C is greater than 0% and no more than 15% and the particle size of C is 1 to 35mu m; the material has low thermal conductivity of photons and stable chemical properties at high temperature. The method comprises the following steps: preparing A2B2O7 powder from ZrOCl2.8H2O with a purity of no less than 99% and rare earth oxide by using a chemical co-precipitation process; mixing C with a purity of no less than 99% with A2B2O7 powder so as to prepare A2B2O7-C composite powder; and sintering A2B2O7-C composite powder at a temperature of 1200 to 1600 DEG C in an inert gas atmosphere for 20 to 60 min so as to obtain the material. The method is simple and is suitable for industrial popularization.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

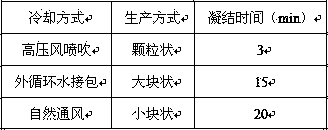

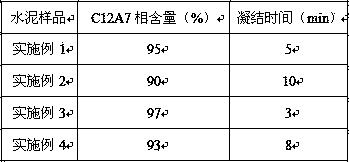

Fast setting cement and its preparation method and application

ActiveCN107986649BCongeal fastSolve the problem of difficult construction in winterElectric arc furnaceRaw material

The invention discloses rapid-condensation hard cement as well as a preparation method and application thereof. The rapid-condensation hard cement is prepared from the following raw materials in percentage by mass: 56 to 62 percent of Al2O3, 37 to 43 percent of CaO, 0.01 to 0.5 percent of SiO2 and 0.01 to 0.5 percent of Fe2O3. The preparation method of the rapid-condensation hard cement speciallycomprises the following steps: (1) stirring the raw materials in all proportions at high speed until the raw materials are evenly mixed to obtain a blank material; (2) slowly putting the blank material into an electric arc furnace, and heating to 1600 DEG C; (3) blowing high-pressure air and quickly cooling the heated blank material to obtain a ripe material; (4) pulverizing the ripe material; (5)performing separation to obtain fine powder to obtain a final product. The invention also discloses application of the rapid-condensation hard cement in building materials. The rapid-condensation hard cement disclosed by the invention is low in cost, has simple procedures, and is convenient and quick to operate; moreover, the cement can be rapidly condensed during natural ventilation, external circulation water connecting packaging, high-pressure air blowing and cooling, and the problem of difficult construction of the concrete in winter is solved.

Owner:河南和成无机新材料股份有限公司

Novel blanking column of hot charging type energy-saving airtight submerged arc furnace and manufacturing method thereof

InactiveCN104990414AAntioxidantAnti-oxidation and high temperature resistanceCeramic shaping apparatusCharge manipulationMetallic materialsOxidation resistant

Provided is a novel blanking column of a hot charging type energy-saving airtight submerged arc furnace. The novel blanking column is characterized by comprising a non-metallic blanking column body; the top of the non-metallic blanking column body is connected with a support connecting flange, and a heat-resisting metal reinforced grid is buried in the main body of the nonmetallic blanking column body. The novel blanking column has the characteristics of being resistant to oxidation and high temperature, long in service life, non-conducting, impermeable to magnetism and the like. The novel blanking column has the advantages of being small in thermal expansion coefficient, high in strength and hardness, resistant to erosion and oxidation, good in high-temperature chemical stability and the like, and meanwhile the non-metallic material is non-conducting, impermeable to magnetism, safe and reliable; certain difference exists between the linear expansion coefficient of the material of the heat-resisting metal reinforced grid and the linear expansion coefficient of the material of a cavity of the non-metallic blanking column body, and a high-temperature-resisting insulating coating separates the heat-resisting metal reinforced grid from the cavity of the non-metallic blanking column body so that heat stress generated by temperature variation can be reduced; meanwhile, the high-temperature-resisting insulating coating improves the insulating performance of the metal grid.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

A laser-induced high-temperature solid-state reaction to generate a 2 b 2 o 7 Type Thermal Barrier Coating Material Method

ActiveCN109851377BIncrease temperatureLow thermal conductivityHeat inorganic powder coatingRare-earth elementPhysical chemistry

The invention relates to the technical field of thermal barrier coating materials, in particular to a laser-induced high-temperature solid-phase reaction to generate A 2 B 2 o 7 The method for type thermal barrier coating material comprises the steps: (1), getting oxide AO x and oxide BO y Mix uniformly to obtain mixed powder; (II), uniformly distribute the mixed powder of step (I) on the surface of the matrix; (III), irradiate the laser on the surface of the matrix of step (II), and induce the described The mixed powder undergoes a high-temperature solid-state reaction to obtain A 2 B 2 o 7 and grow on the surface of the substrate to generate A 2 B 2 o 7 Type thermal barrier coating material; wherein, the element A is a rare earth element, and the element B is at least one of Ti, Zr and Hf; 0.5≤x≤2, y=2. The preparation method is simple in operation, convenient in control, high in production efficiency, low in production cost, less in pollution and short in production cycle, and can be used in large-scale production.

Owner:GUANGDONG ROI OPTOELECTRONICS TECH CO LTD +2

High-temperature-resistant anti-pricking composition and preparation method thereof

PendingCN114262542AImprove adaptabilityGood biocompatibilityStarch dervative coatingsRosin coatingsO-Phosphoric AcidStearic acid

The invention discloses a high-temperature-resistant anti-pricking composition and a preparation method thereof. The high-temperature-resistant anti-pricking composition is prepared from the following raw materials: rosin, starch, eucommia ulmoides, gum, stearic acid, pine tar, mica powder, sulfur, zinc oxide, alumina, kaolin, bentonite, potato residues, borax, flint, spinel, feldspar, rutile titanium dioxide, kyanite powder, andalusite powder, zirconium oxide, cobalt oxide, brown corundum sand, phosphoric acid and rare earth oxide. The high-temperature-resistant anti-pricking composition has the advantages of being safe, non-toxic, fireproof, antifouling, flame-retardant, water-resistant, weather-resistant, high-temperature-resistant, high-strength, blending and compounding, copolymerizing and grafting, cross-linking and interpenetrating, anti-radiation, anti-corrosion, natural, environment-friendly and the like, and has good adaptability and biocompatibility to biological tissues.

Owner:上海甘美珠宝有限公司 +1

A new type of blanking column for a heat-loading energy-saving sealed submerged arc furnace and its manufacturing method

InactiveCN104990414BAntioxidantAnti-oxidation and high temperature resistanceCeramic shaping apparatusCharge manipulationThermal energyEngineering

A new type of blanking column for a hot-loading energy-saving sealed submerged arc furnace is characterized in that the new type of blanking column includes a non-metallic blanking column, and the top of the non-metallic blanking column is connected to a connecting flange of a support seat, and the non-metallic blanking column A reinforced grid of heat-resistant metal is embedded in the column body of the feeding column. The invention has the characteristics of anti-oxidation and high temperature resistance, long service life, non-conduction, non-magnetic conduction and the like. The invention has the advantages of small thermal expansion coefficient, high strength, high hardness, erosion resistance, good high temperature chemical stability, anti-oxidation, etc., and at the same time, the non-metallic material is non-conductive, non-magnetic, safe and reliable; heat-resistant metal reinforced grid and non-metallic The linear expansion coefficients of the materials in the feeding column cavity have certain differences, and the high-temperature-resistant insulating coating separates them to reduce the thermal stress caused by temperature changes; at the same time, the high-temperature-resistant insulating coating improves the insulation performance of the metal grid.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

Glass sealing material as well as preparation and use methods thereof

The invention relates to a glass sealing material as well as preparation and use methods thereof. The glass sealing material comprises the following raw material components at a molar ratio: 0-10 of B2O3, 0-5 of Al2O3, 25-60 of SiO2, 10-25 of CaO, 10-25 of SrO and 5-25 of Ca2O3. According to the invention, a Ga element is added in the glass sealing material so as to form a non-proliferation layer, thus effectively reducing the proliferation of Cr ions in a Cr-containing stainless steel alloy connection pole toward the sealing glass and significantly improving the high temperature chemical stability of sealing microcrystal glass; preparation raw materials are simple and available, and process is stable; and a reverse glass network structure in which SiO2 is used as a main body is obtained,cost is low, and process is simple and practicable, thereby achieving the conditions of practicality and industrialization.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com