A laser-induced high-temperature solid-state reaction to generate a 2 b 2 o 7 Type Thermal Barrier Coating Material Method

A2B2O7, high-temperature solid-state reaction technology, applied in the direction of heating inorganic powder coating, etc., can solve the problems of limited thermal barrier coating materials, low safety performance, long high-temperature reaction time, etc., and achieve good high-temperature chemical stability and production The effect of high efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

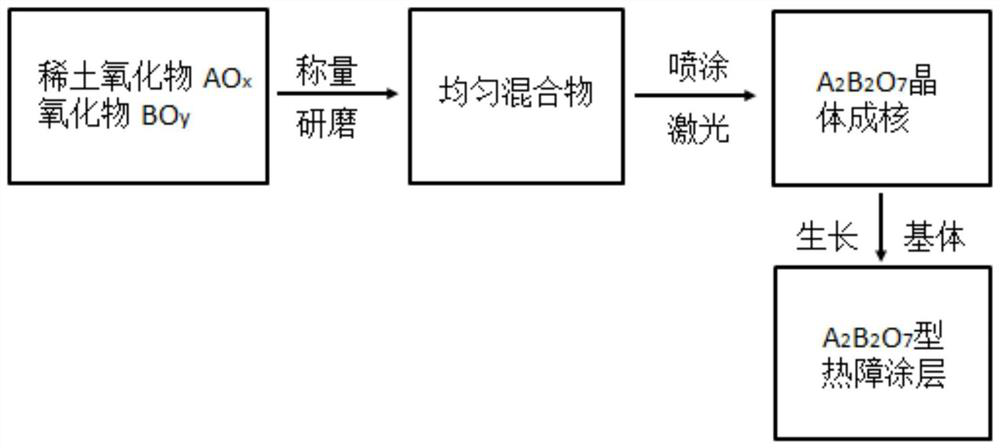

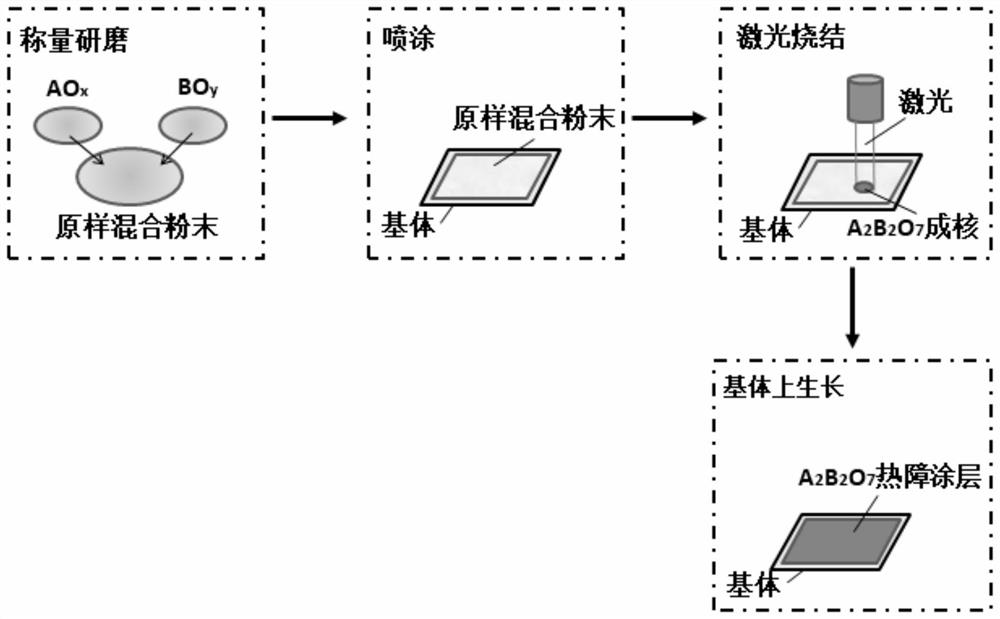

[0040] Such as Figure 1-3 As shown, a laser-induced high-temperature solid-state reaction to generate Yb 2 Zr 2 o 7 A method for a type thermal barrier coating material, comprising the steps of:

[0041] (1), get the Yb that purity is 99.9% 2 o 3 and ZrO with a purity of 99.9% 2 , whose molar ratio Yb 2 o 3 : ZrO 2 1:2, ball milled for 2 hours under the condition of ball-to-material ratio of 5:1 and rotating speed of 300r / s to obtain mixed powder;

[0042] (II), the mixed powder of step (I) is evenly distributed on the surface of the substrate, the substrate is a copper metal plate, the mixed powder is evenly distributed, the surface is smooth, and the thickness of the mixed powder is 0.5mm;

[0043] (III), irradiating the laser light on the surface of the substrate in step (II), under the action of continuous laser light with a wavelength of 980nm, the optical power density of the control laser light is 500W / cm 2 , the duration of the laser action is 5s, and the hi...

Embodiment 2

[0045] Such as Figure 1-3 As shown, a laser-induced high-temperature solid-state reaction to generate Yb 2 Zr 2 o 7 -Y 2 Zr 2 o 7A method for a type composite thermal barrier coating material, comprising the steps of:

[0046] (1), get the Yb that purity is 99.9% 2 o 3 , Y with a purity of 99.9% 2 o 3 and ZrO with a purity of 99.9% 2 , whose molar ratio Yb 2 o 3 : Y 2 o 3 : ZrO 2 0.5:0.5:2, ball milling for 2 hours at a ball-to-material ratio of 5:1 and a rotational speed of 300r / s to obtain a mixed powder;

[0047] (II), the mixed powder of step (I) is evenly distributed on the surface of the substrate, the substrate is a copper metal plate, the mixed powder is evenly distributed, the surface is smooth, and the thickness of the mixed powder is 0.5mm;

[0048] (III), irradiating the laser light on the surface of the substrate in step (II), under the action of continuous laser light with a wavelength of 980nm, the optical power density of the control laser ligh...

Embodiment 3

[0050] Such as Figure 1-3 As shown, a laser-induced high-temperature solid-state reaction to generate Gd 2 Zr 2 o 7 A method for a type thermal barrier coating material, comprising the steps of:

[0051] (1), get the Gd that purity is 99.9% 2 o 3 and ZrO with a purity of 99.9% 2 , whose molar ratio Gd 2 o 3 : ZrO 2 1:2, ball milling for 2 hours at a ball-to-material ratio of 5:1 and a rotational speed of 300r / s to obtain a mixed powder;

[0052] (II), the mixed powder of step (I) is evenly distributed on the surface of the substrate, the substrate is a copper metal plate, the mixed powder is evenly distributed, the surface is smooth, and the thickness of the mixed powder is 0.5mm;

[0053] (III), laser irradiation on the surface of the substrate of step (II), under the action of continuous laser light with a wavelength of 980nm, the optical power density of the control laser is 400W / cm 2 , the laser scans the surface of the matrix in a "bow" shape at a scanning spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com